Method for automatic color separation of ceramic tiles

A tile and automatic technology, applied in the field of tile manufacturing, can solve the problems of restricted response speed, difficulty in satisfying the response speed, and low sampling accuracy, and achieve the effect of improving system response speed, small distortion of intake information, and quick and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

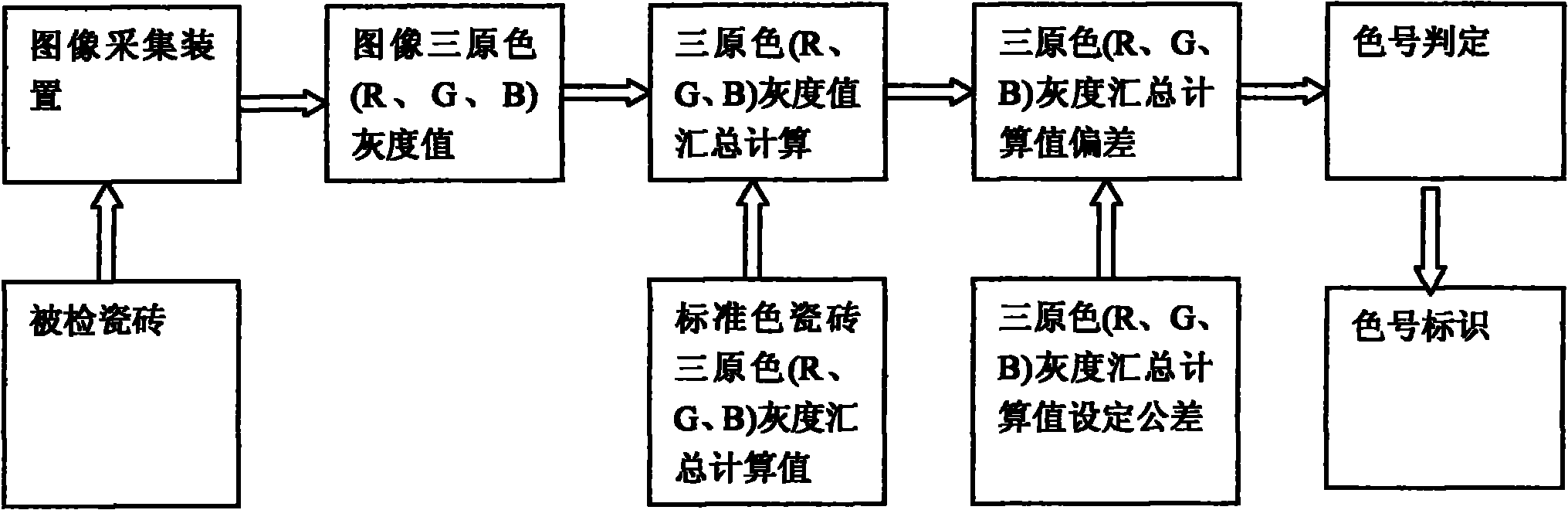

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

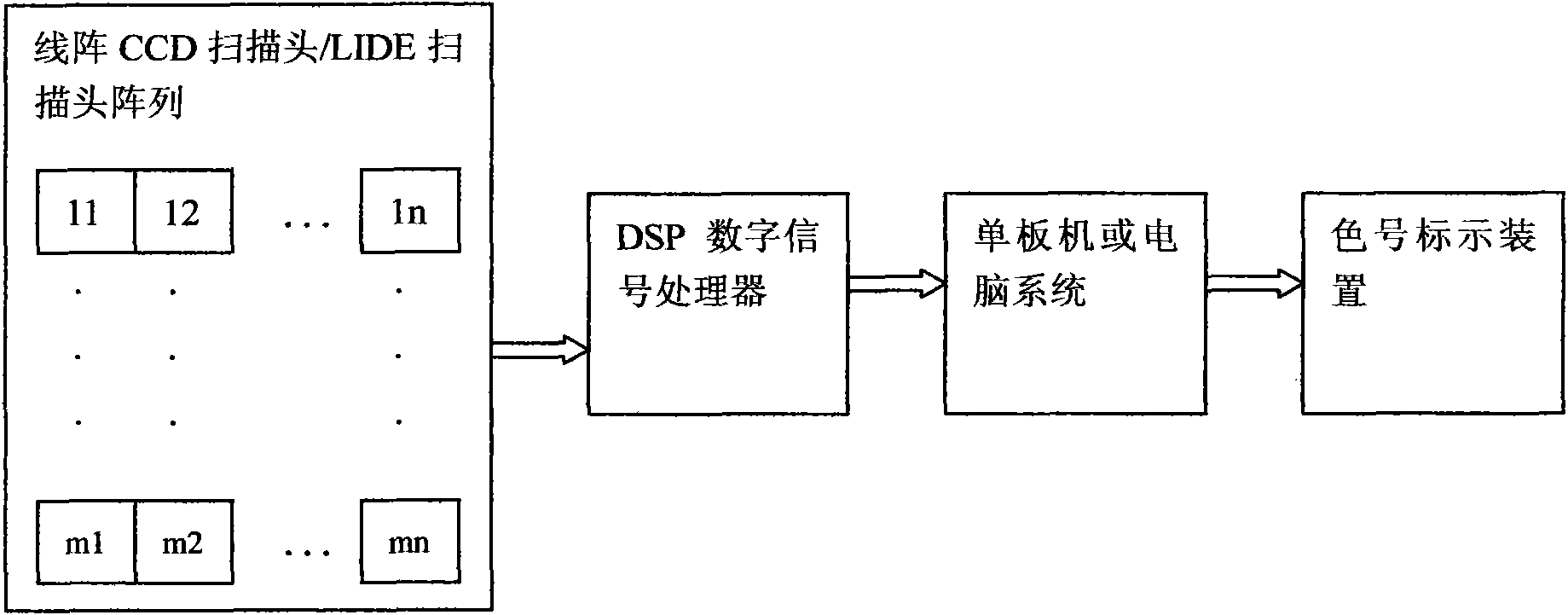

[0046] Such as figure 2As shown, the image acquisition device in this example adopts a scanner based on a linear CCD photoelectric sensor or a LIDE image sensor with N*M scanning heads forming an array of scanning heads with N columns and M rows. The number of columns N depends on the width of the detected tiles, the width of the scanning head is 200-210MM, and there is no gap between the scanning heads arranged in each row; the number of rows M depends on the speed of the pipeline, and the scanning speed multiplied by M should be greater than or equal to the speed of the pipeline. Column spacing is evenly spaced according to tile length.

[0047] Since the output of the scanning head is the analog signal of the three primary colors (R, G, B), several multi-channel DSP digital signal processing systems are used for A / D analog-to-digital conversion and summary calculation, and the calculation results are output to a computer or a single board computer for processing. Calculat...

Embodiment 2

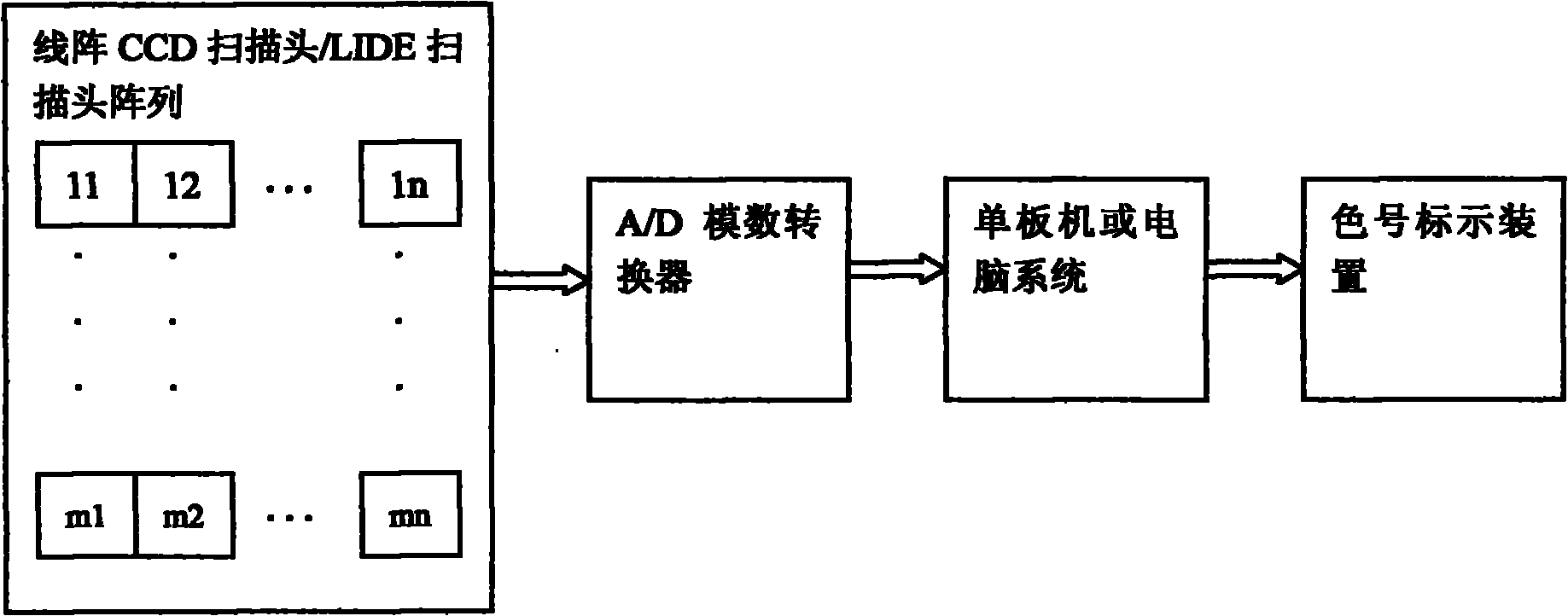

[0050] Such as image 3 As shown, the difference between this example and Example 1 is that the DSP digital signal processing system is replaced by an A / D analog-to-digital converter, and the data processing center is composed of an A / D analog-to-digital converter and a single-board computer or a computer.

Embodiment 3

[0052] Such as Figure 4 As shown, the image acquisition device in this example adopts a scanner based on a linear CCD photoelectric sensor or a LIDE image sensor with N*M scanning heads forming an array of scanning heads with N columns and M rows. The number of columns N depends on the width of the detected tiles, the width of the scanning head is 200-210MM, and there is no gap between the scanning heads arranged in each row; the number of rows M depends on the speed of the pipeline, and the scanning speed multiplied by M should be greater than or equal to the speed of the pipeline. Column spacing is evenly spaced according to tile length.

[0053] Since the scanning head outputs analog signals of the three primary colors (R, G, B), this example retains the main board of the scanner that matches the scanning head, and uses its A / D analog-to-digital conversion circuit to obtain the gray scale of the three primary colors (R, G, B) digital information. Since there are N*M outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com