Patents

Literature

205 results about "Paint robot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial paint robots have been used for decades in automotive paint applications. Early paint robots were hydraulic versions - which are still in use today but are of inferior quality and safety - to the latest electronic offerings. The newest robots are accurate and deliver results with uniform film builds and exact thicknesses.

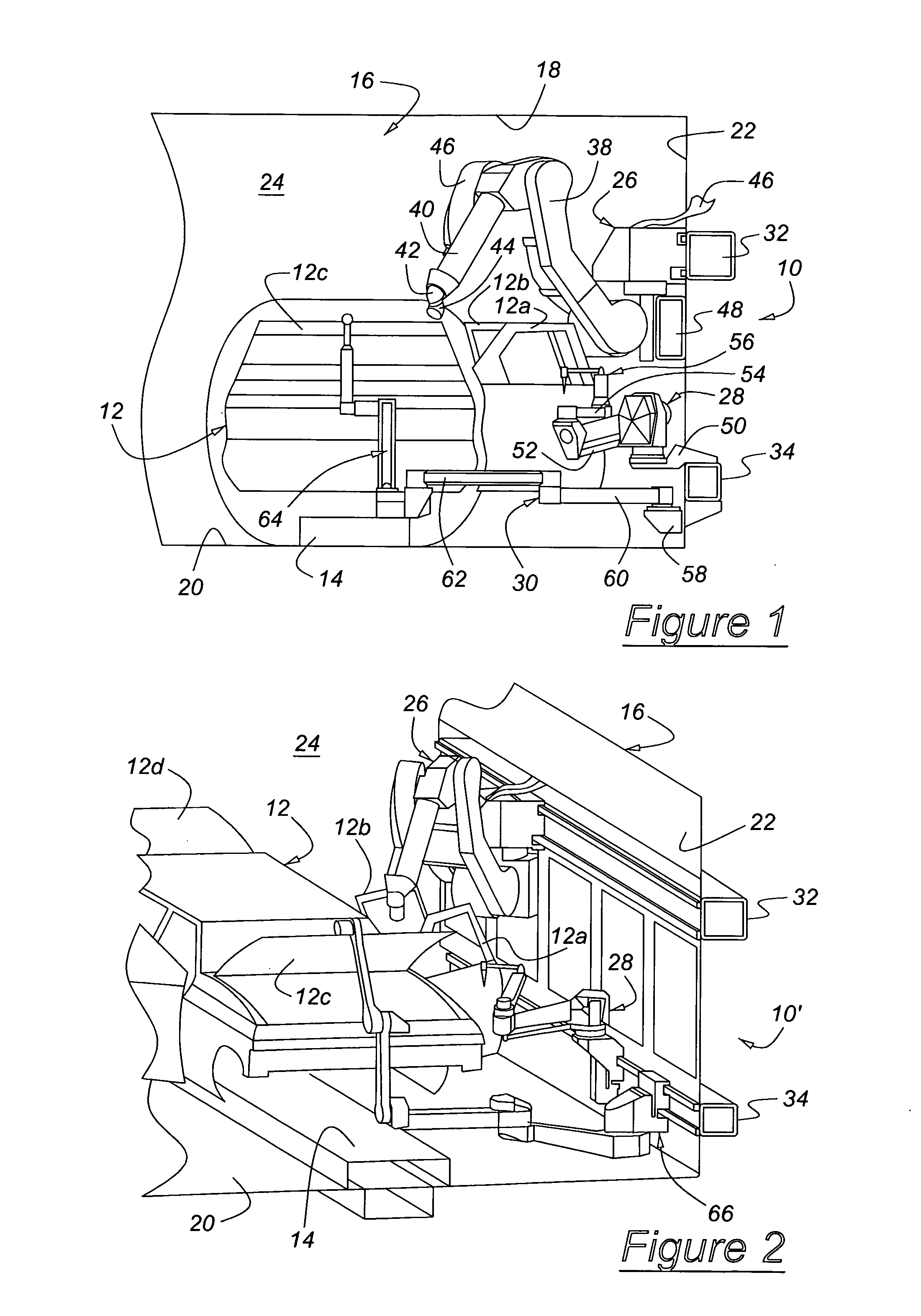

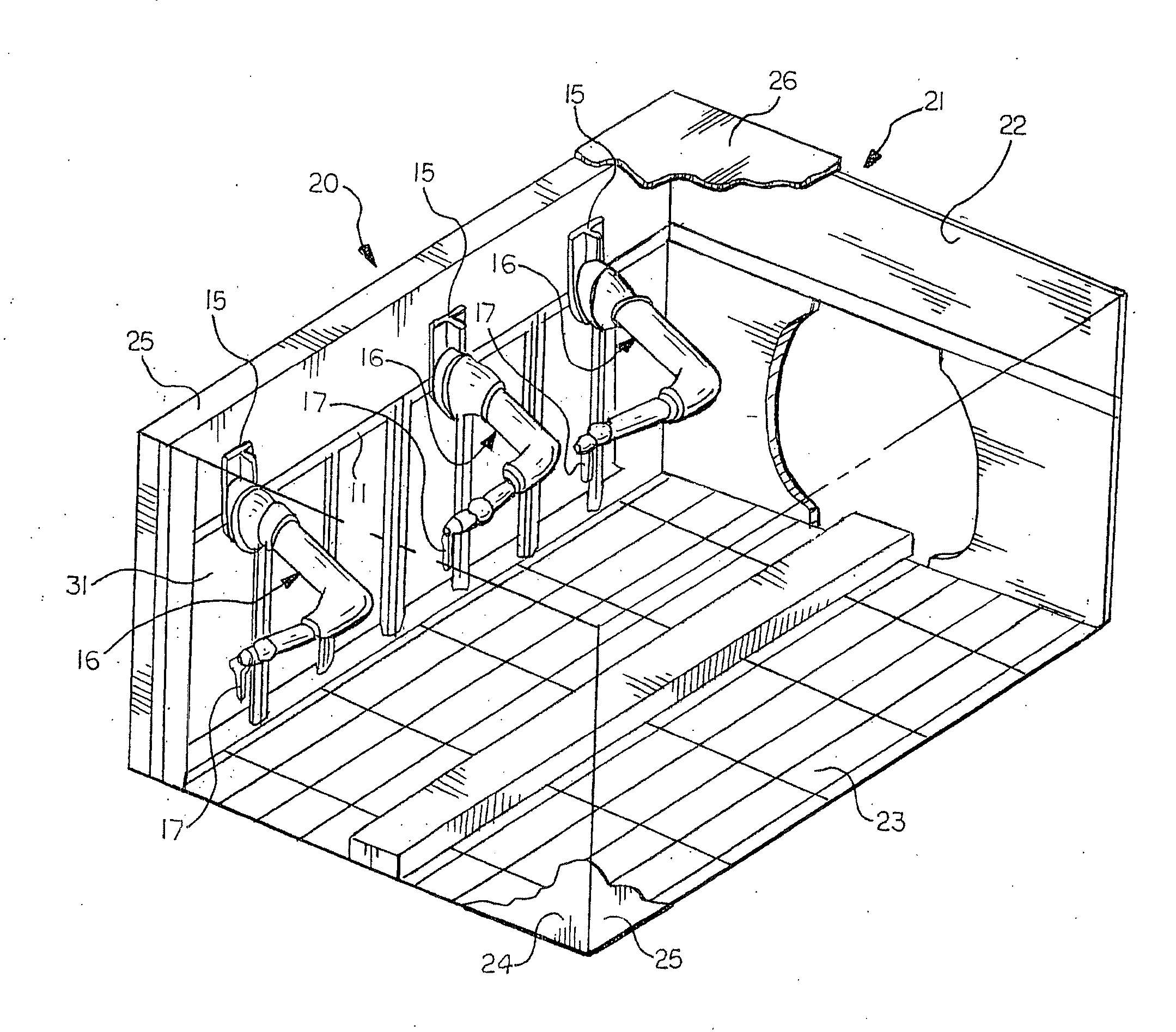

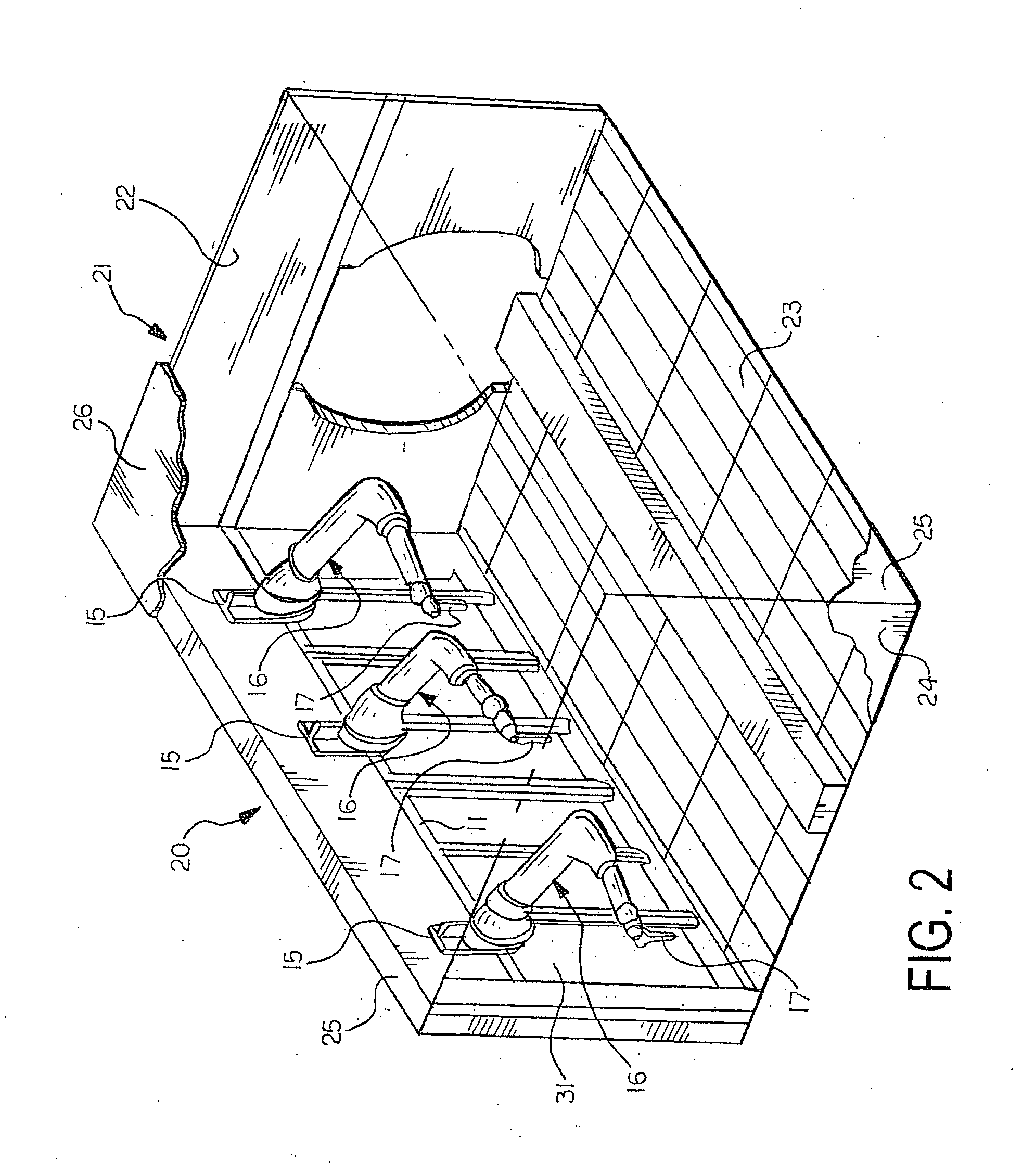

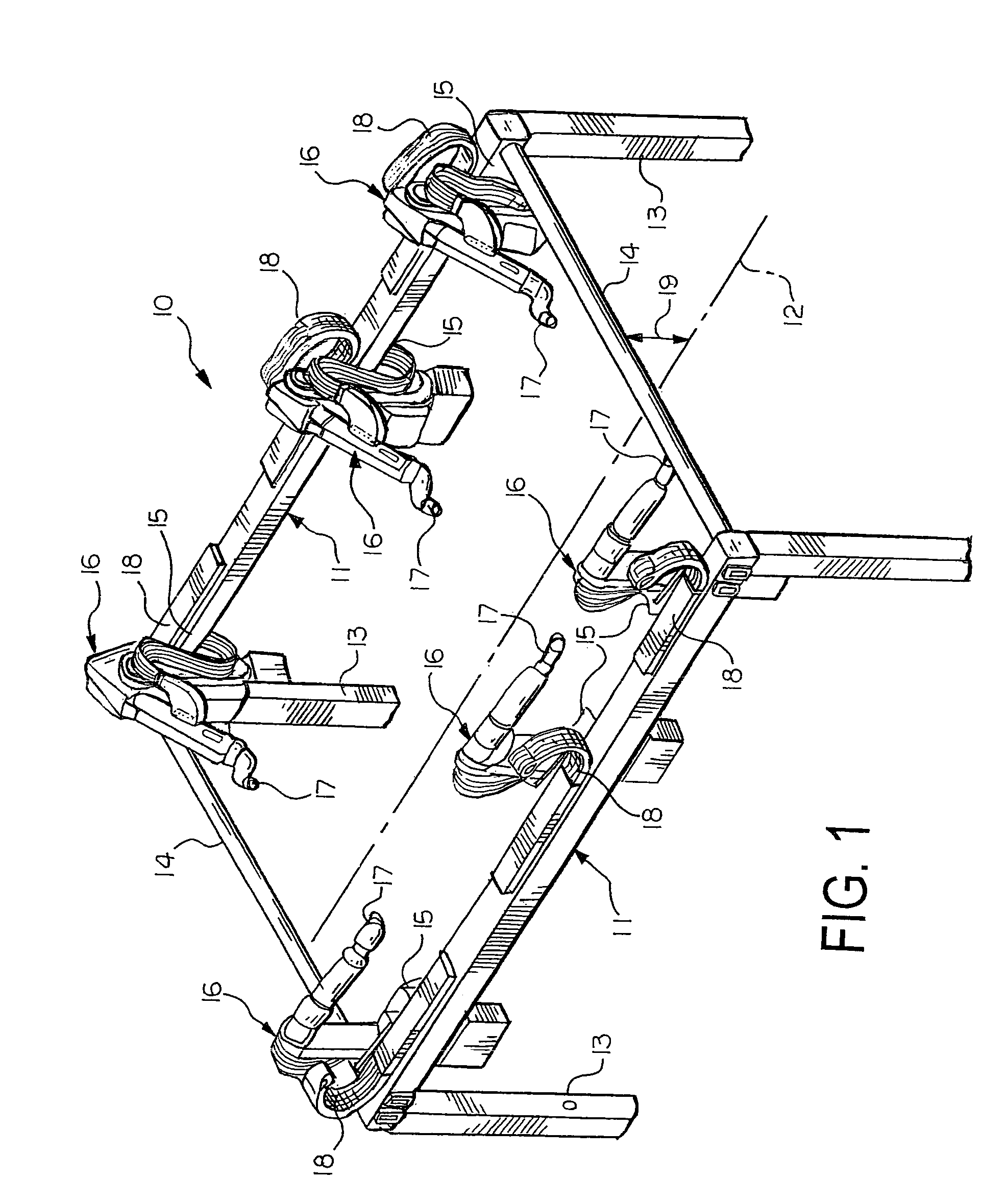

Compact robotic painting booth

ActiveUS20060292308A1Save spaceMinimize paint over-build-upProgramme controlProgramme-controlled manipulatorPaint robotEngineering

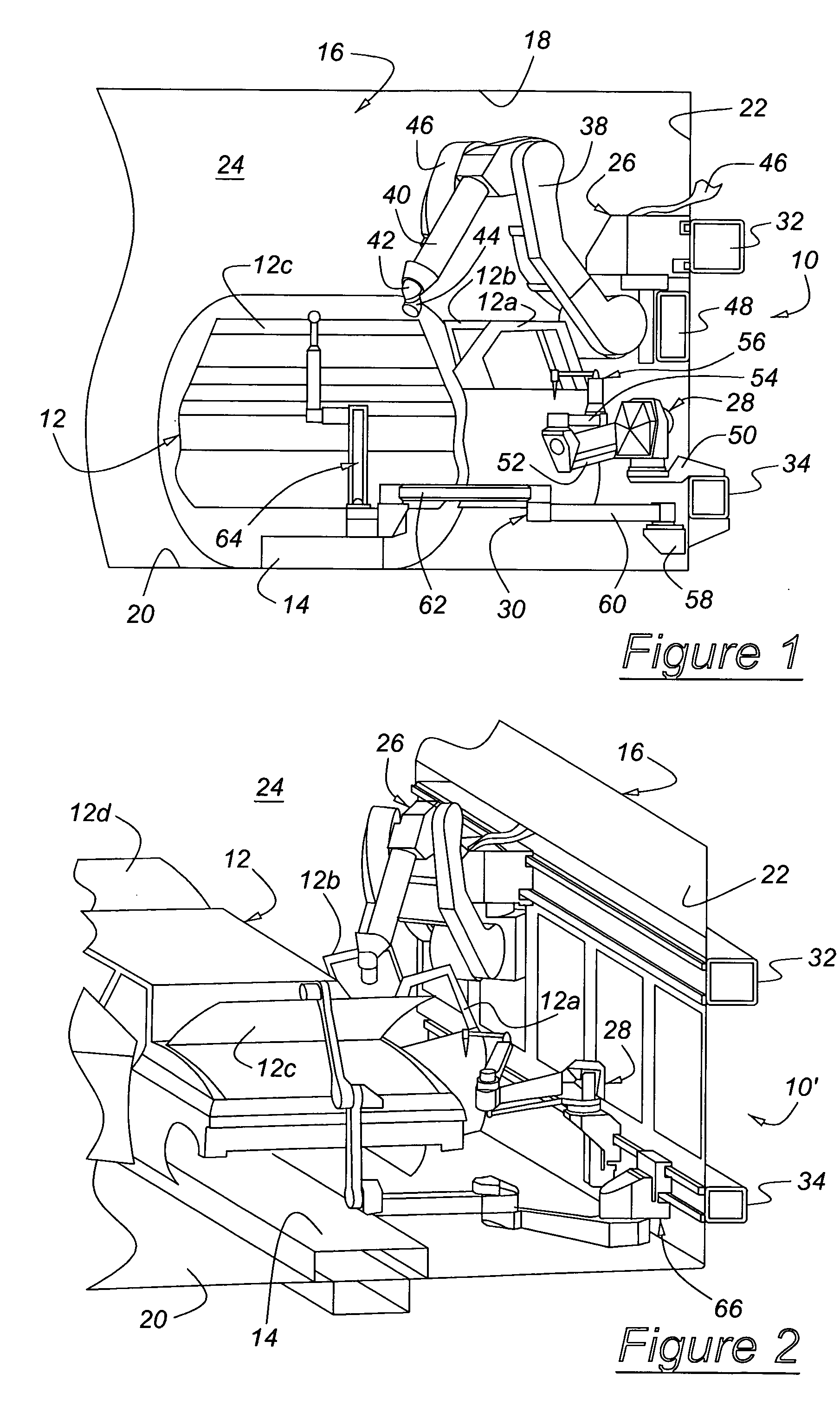

A system for painting an article, such as an automotive vehicle body, includes a painting booth, a conveyor for transporting articles through the painting booth, a first rail located beside and extending along the conveyor, a second rail located beside and extending along the conveyor at a lower elevation than an elevation of the first rail, a paint robot including an articulating arm mounted on the first rail for displacement along the first rail, a panel opener robot mounted on the second rail for displacement along the second rail such that the paint robot and the panel opener robot can move past each other on the rails without interference.

Owner:FANUC ROBOTICS NORTH AMERICA

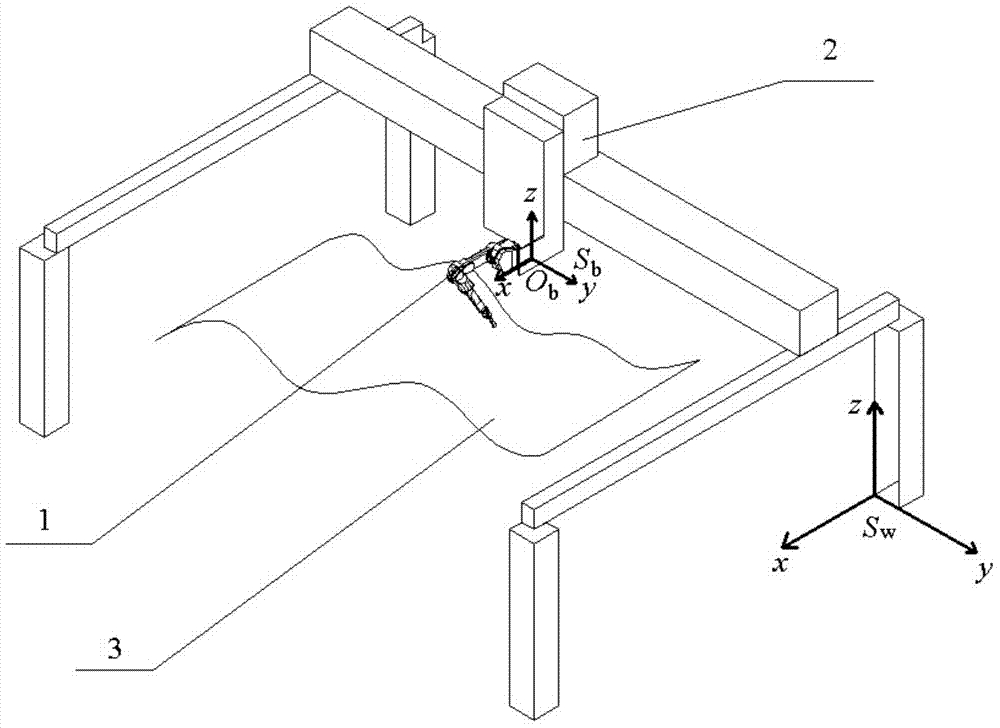

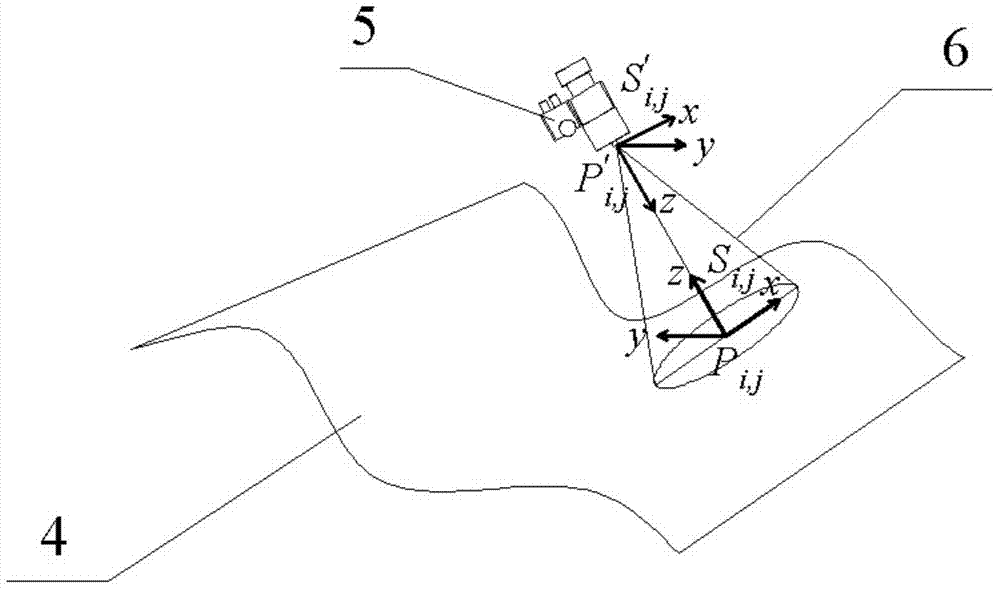

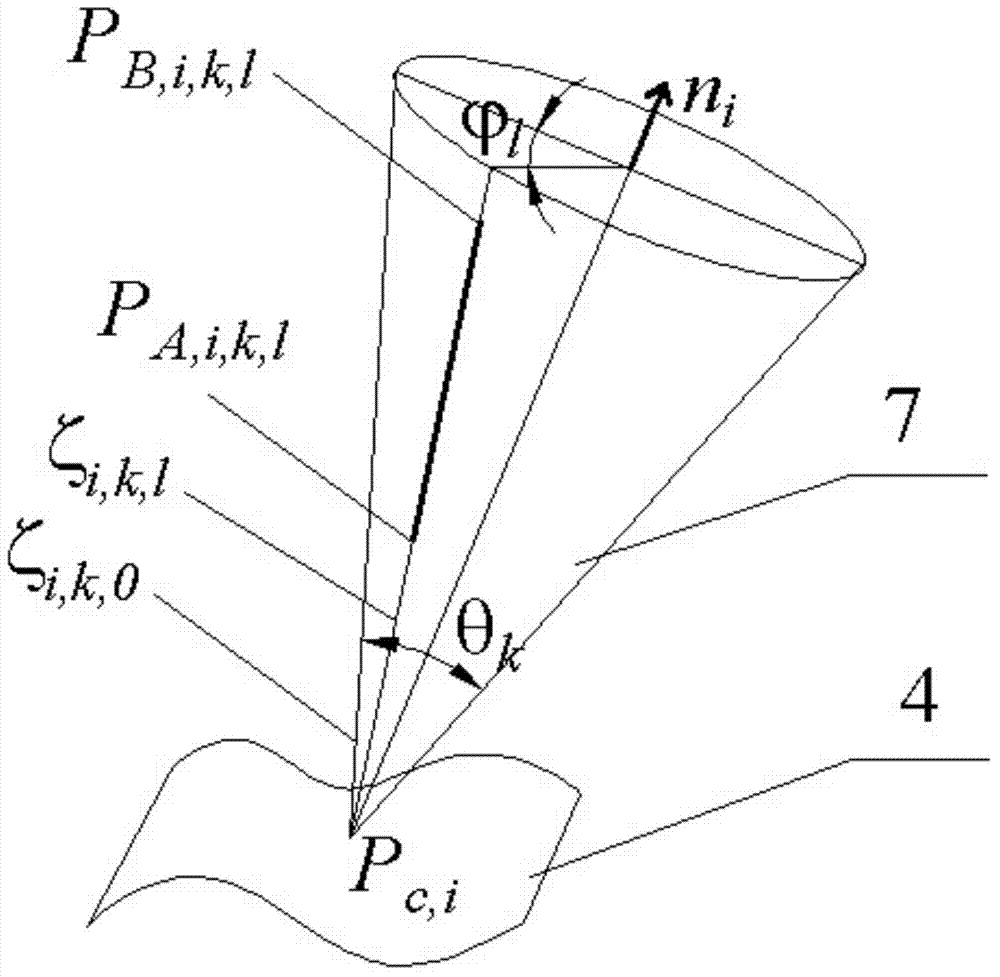

Painting robot position planning method for large-scale free-form surface

ActiveCN104331542AImprove efficiencyHigh degree of automationSpecial data processing applicationsFree formAngular velocity

The invention discloses a painting robot position planning method for a large-scale free-form surface and relates to the technical field of robot painting. According to the method, firstly, a spray gun track planning method is adopted to complete blocking of the large-scale free-form surface and planning of a spray gun track; then on a specified position search cone generatrix, a point in a working space of a painting robot and a three-dimensional moving platform is selected and a joint angle and a joint angular velocity in the painting motion are solved out by utilizing the robotics principle so as to carry out feasibility checking on the point; next, collision interference check is carried out by utilizing a motion simulation function of three-dimensional shaping software; finally, all feasible positions corresponding to free-form surface blocks are found. The painting robot position planning method for the large-scale free-form surface can implement batch position planning on a plurality of free-form surface blocks in the large-scale free-form surface and has a high calculating speed and a high automation degree.

Owner:清研同创机器人(天津)有限公司

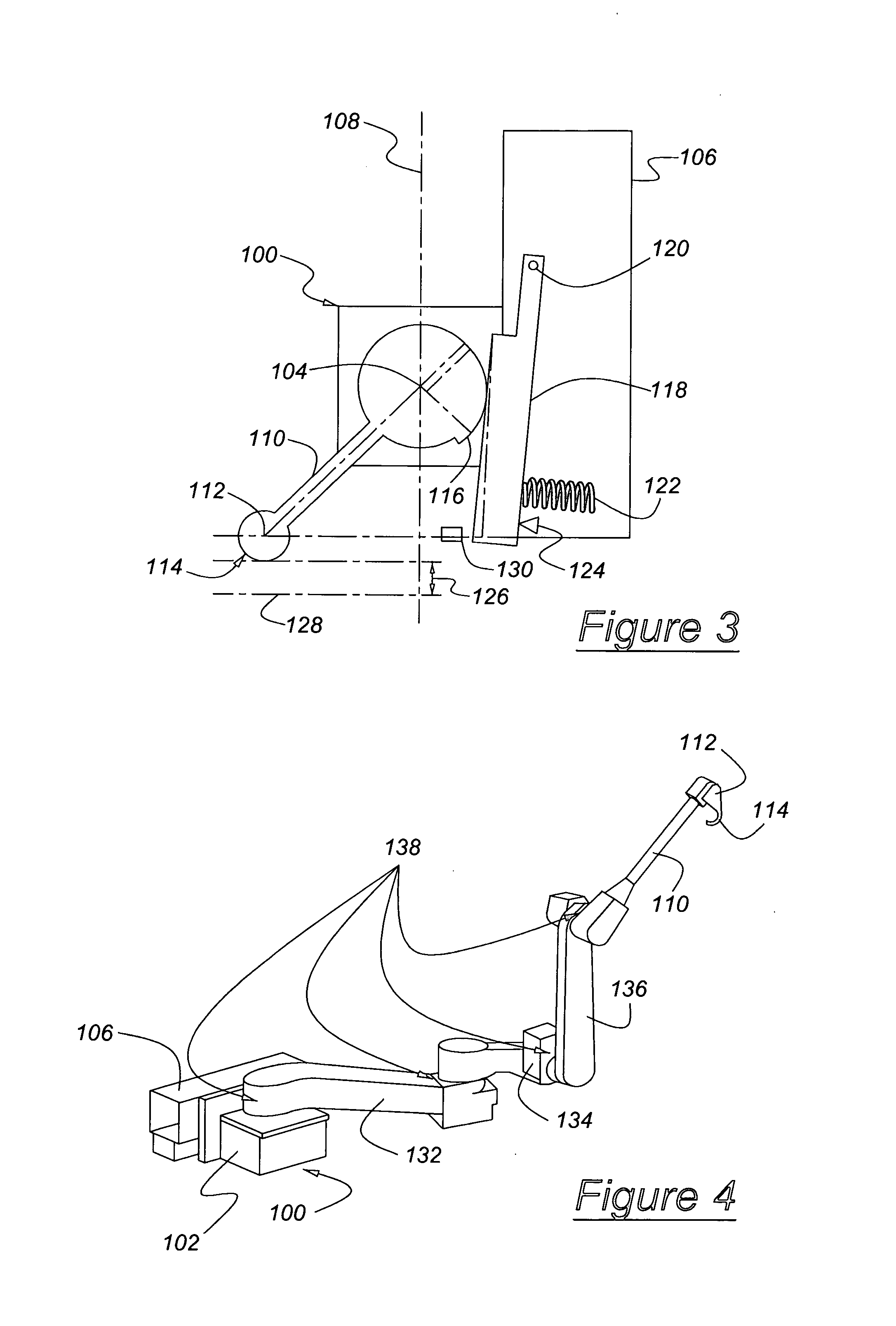

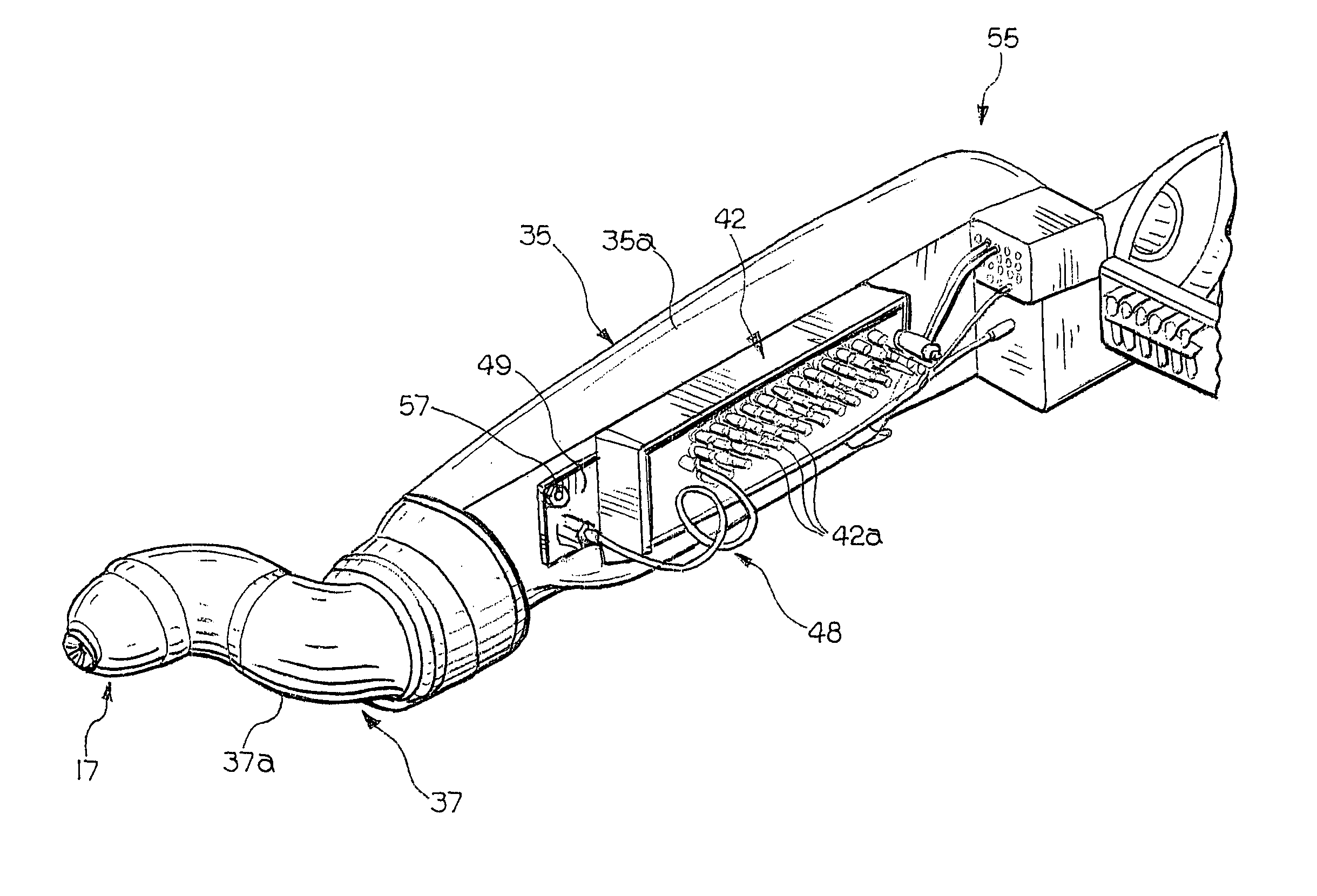

Robotic apparatus with non-conductive wrist for painting

ActiveUS20080083371A1Efficient use ofCost effectiveElectric shock equipmentsMovable spraying apparatusPaint robotDrive motor

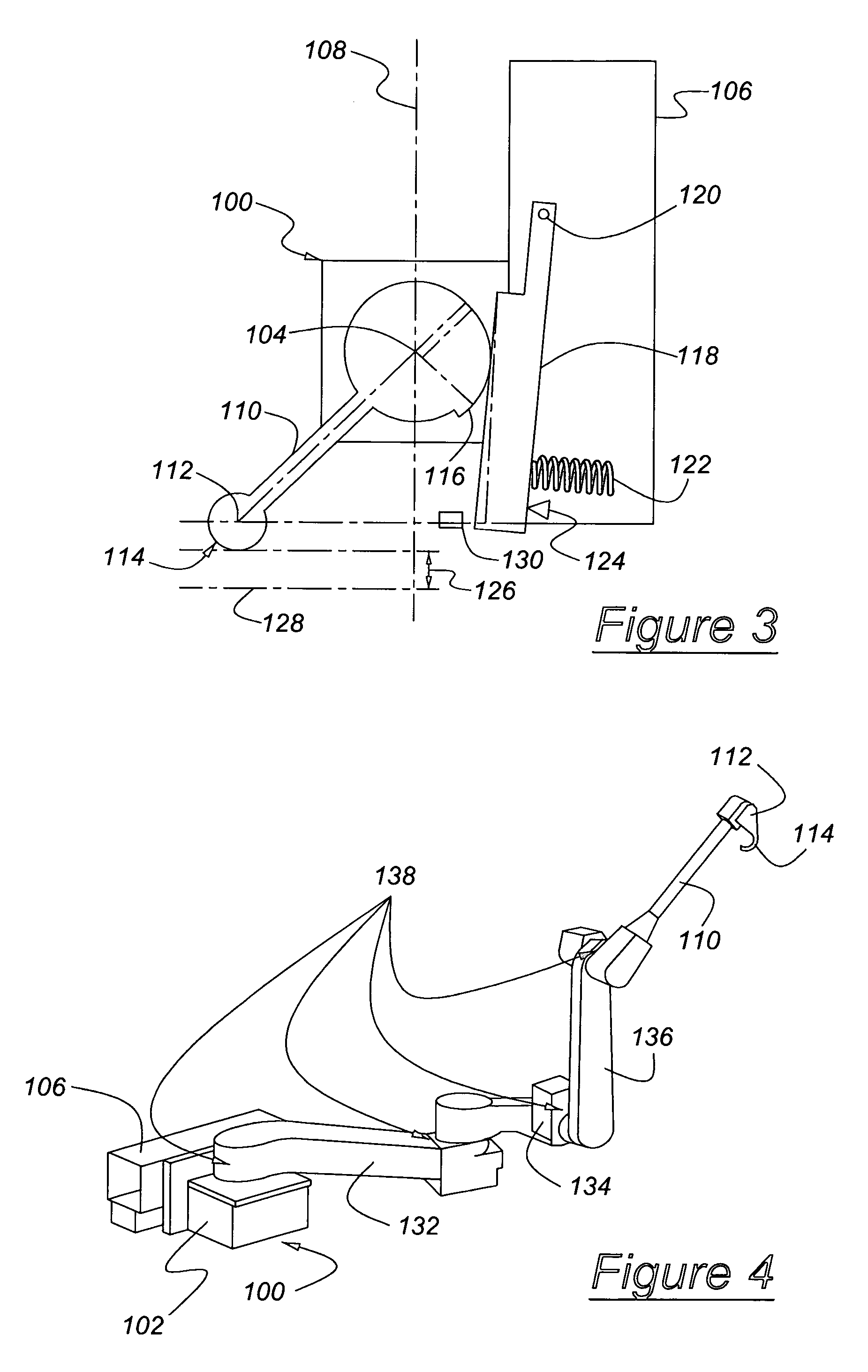

A painting robot outer arm includes a non-conductive housing mounting a color changer on the outside and a paint canister on the inside connected by an isolating paint transfer line. The paint canister is releasably attached to a piston ram and drive motor by a quick disconnect coupling. The paint supply is isolated from the applied high voltage by cleaning and drying the transfer line. The rate of filling of the canister can be controlled in response to sensed torque applied by a drive motor moving a piston in the paint canister.

Owner:FANUC ROBOTICS NORTH AMERICA

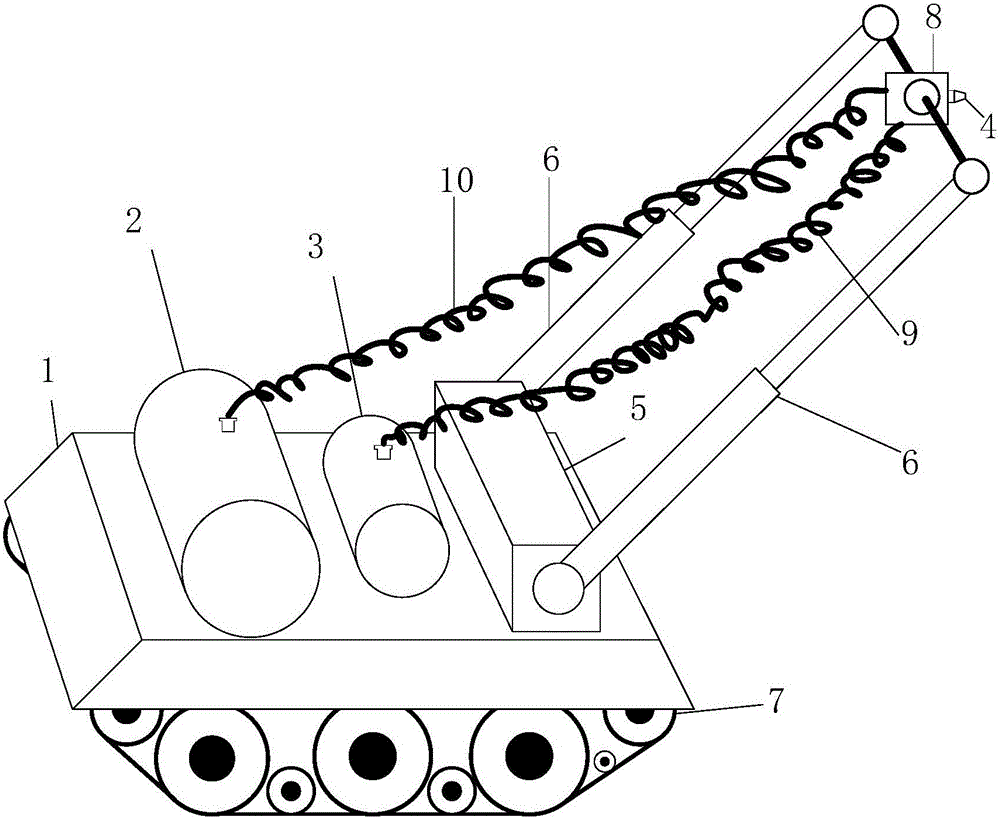

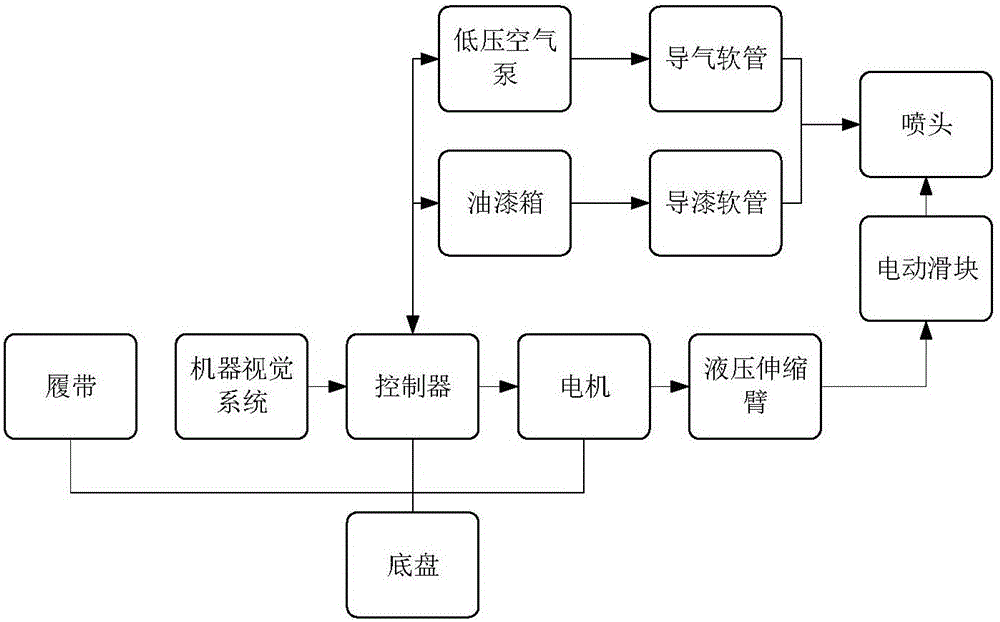

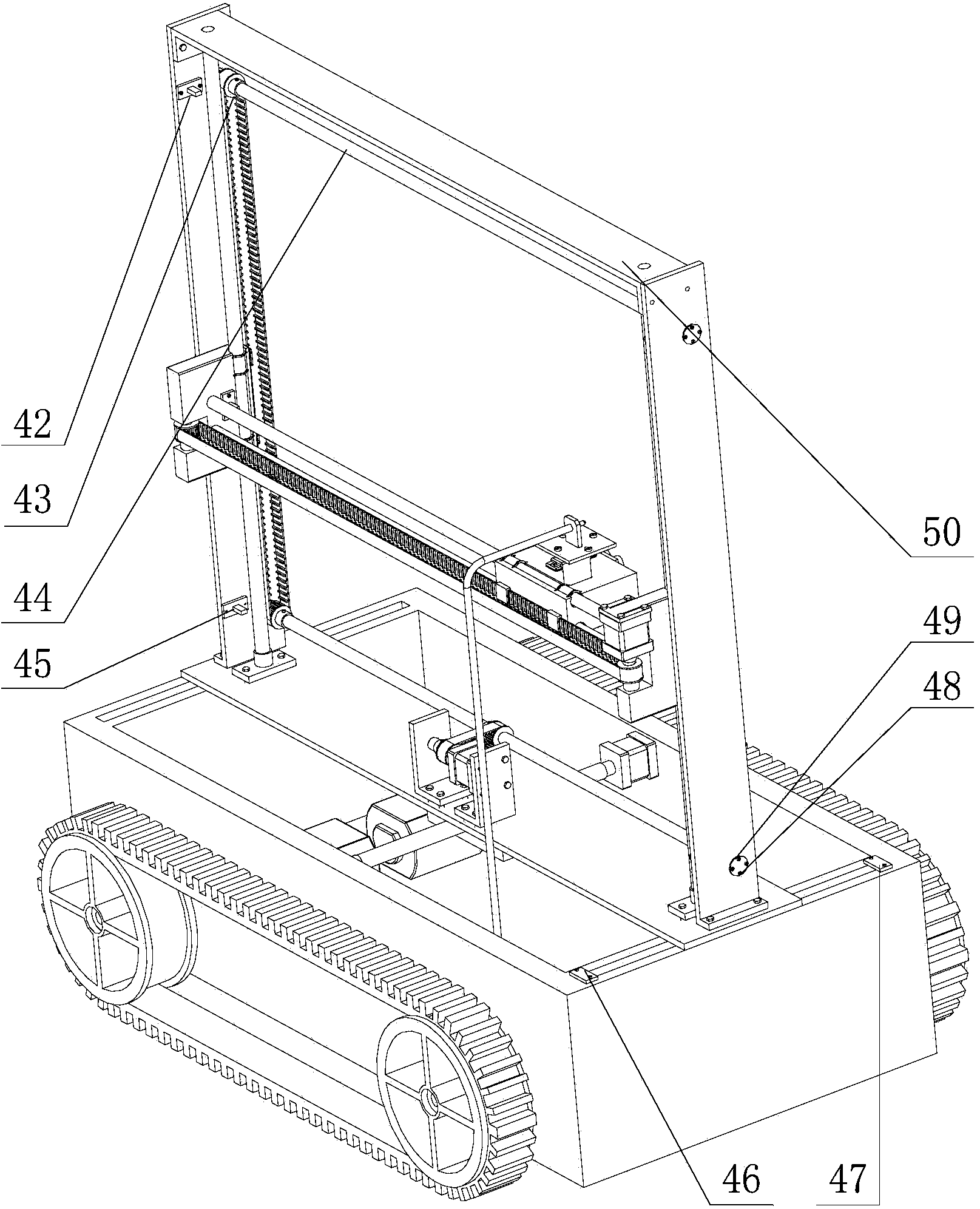

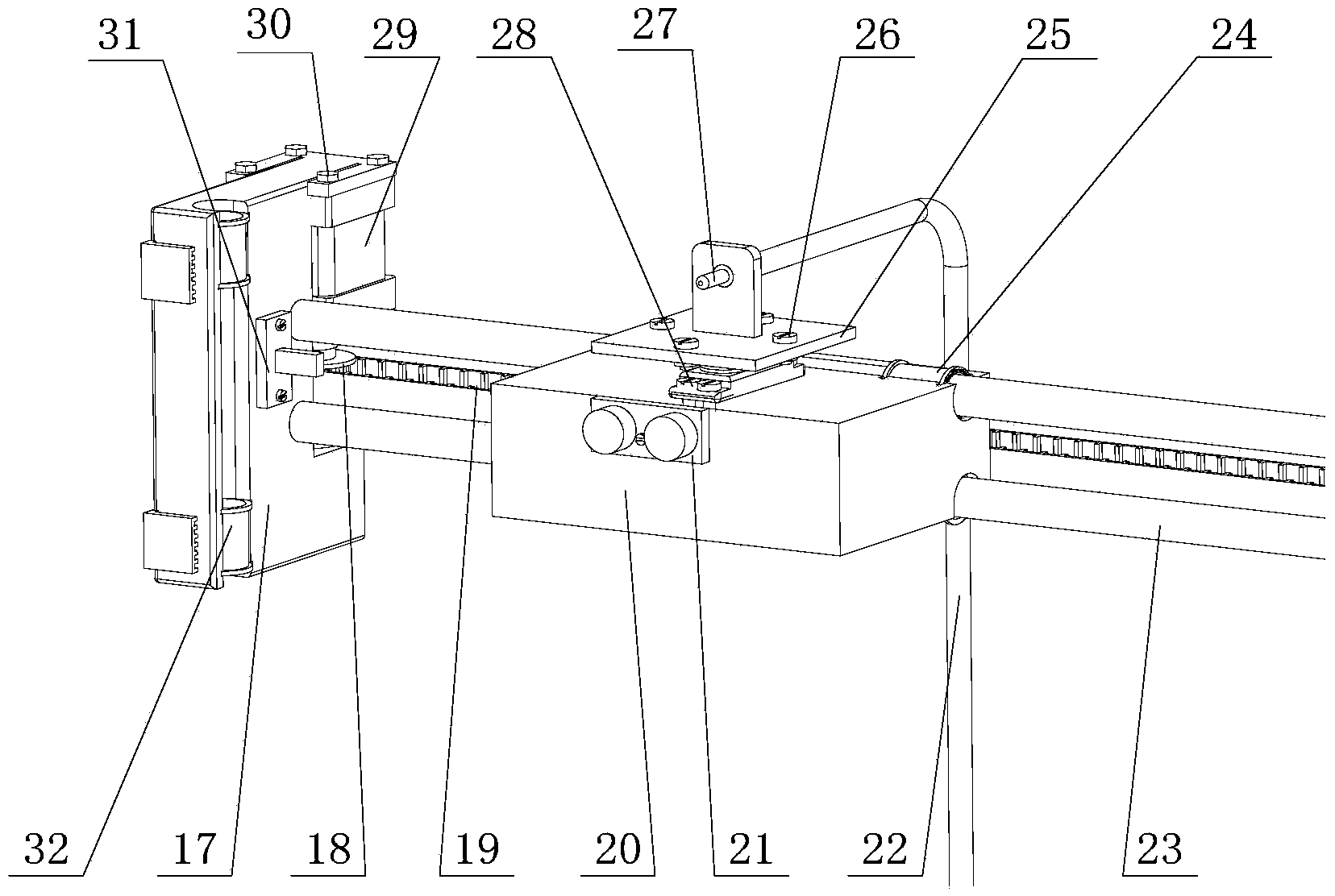

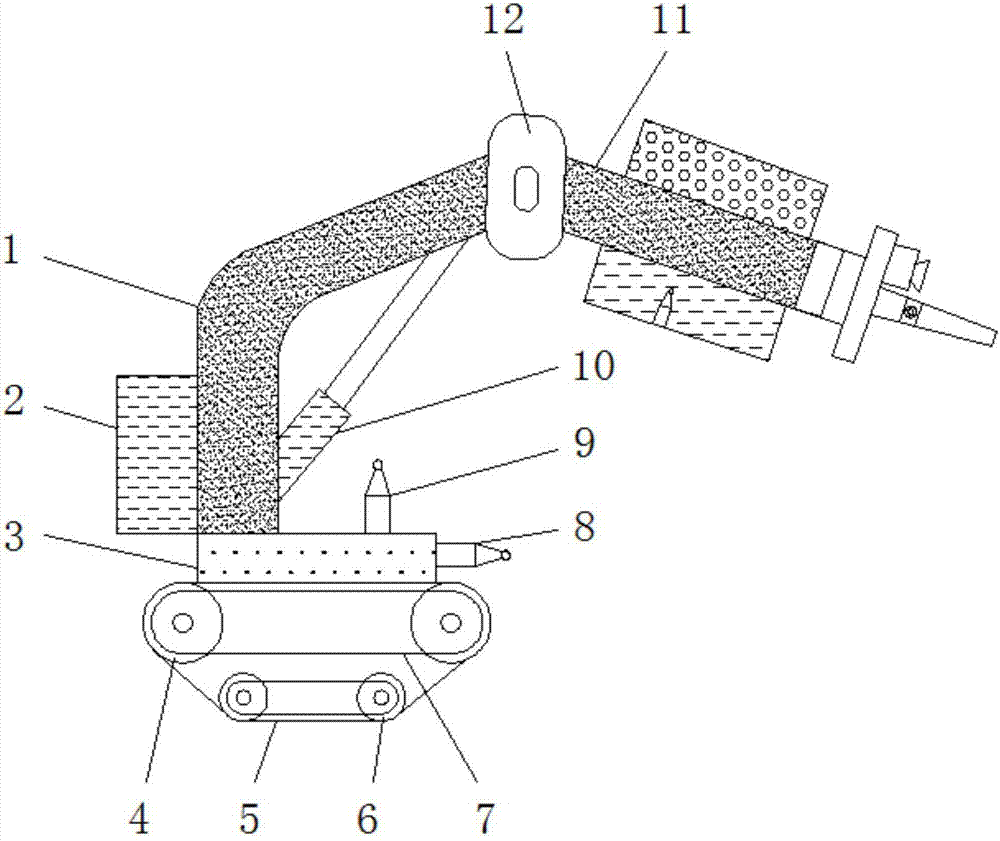

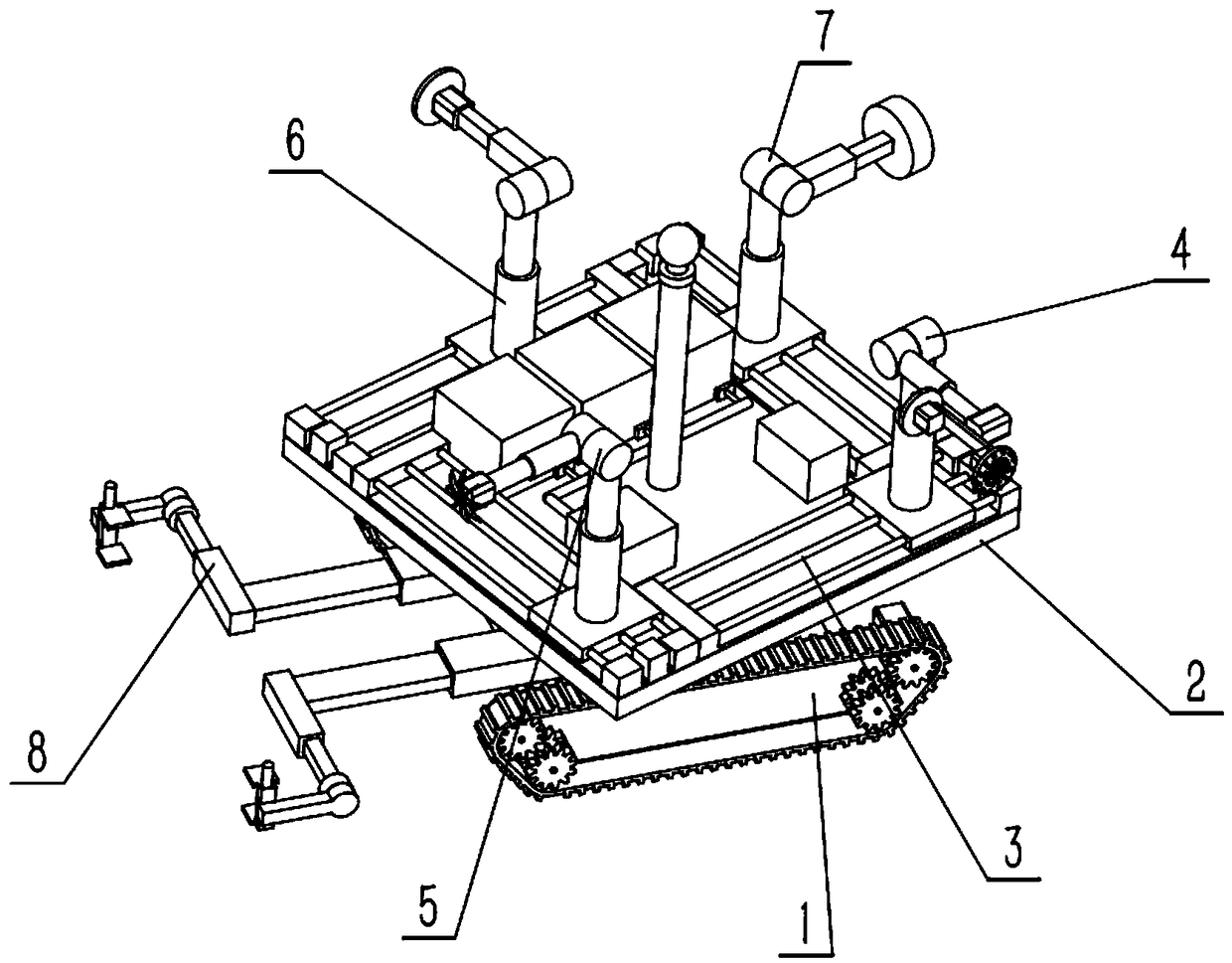

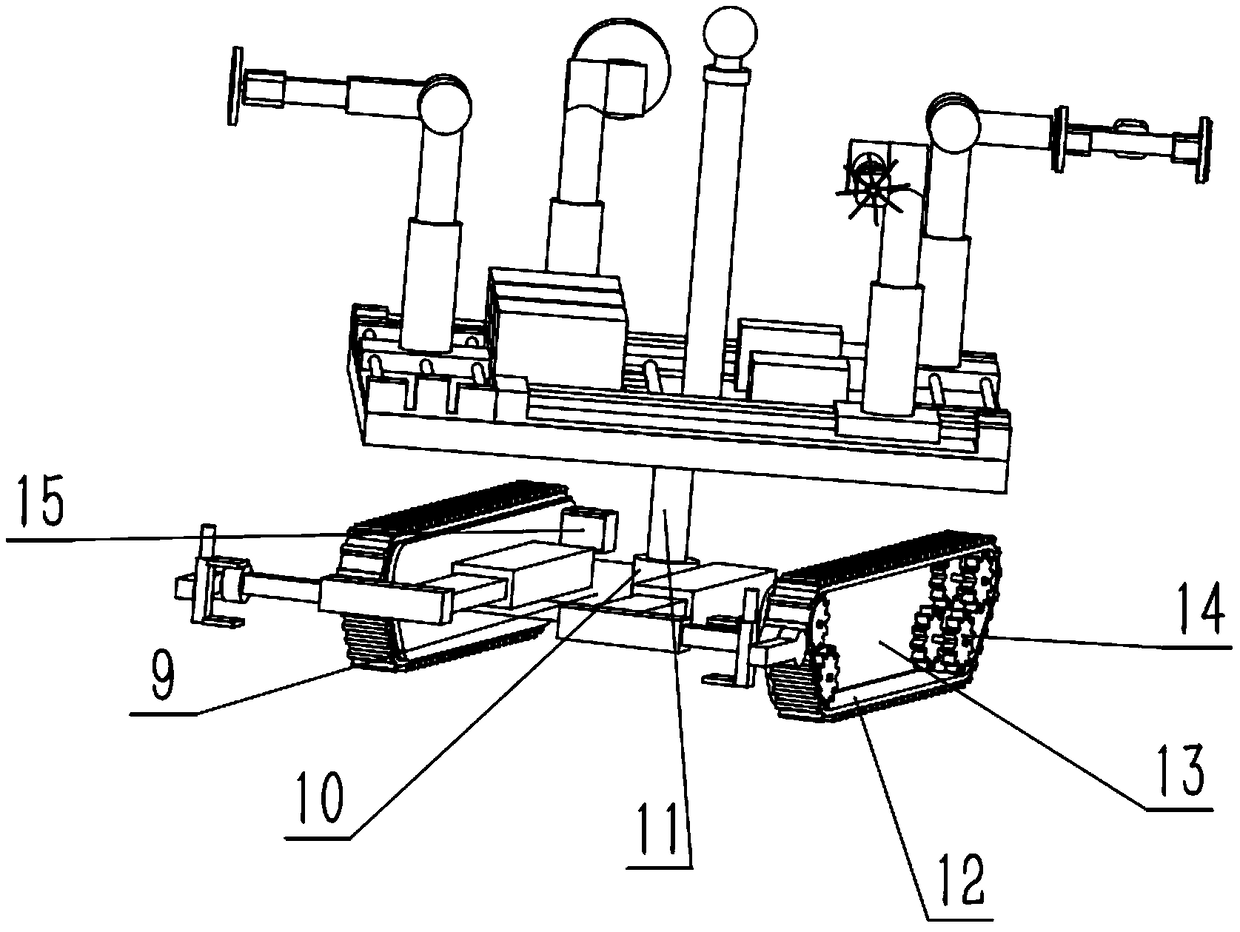

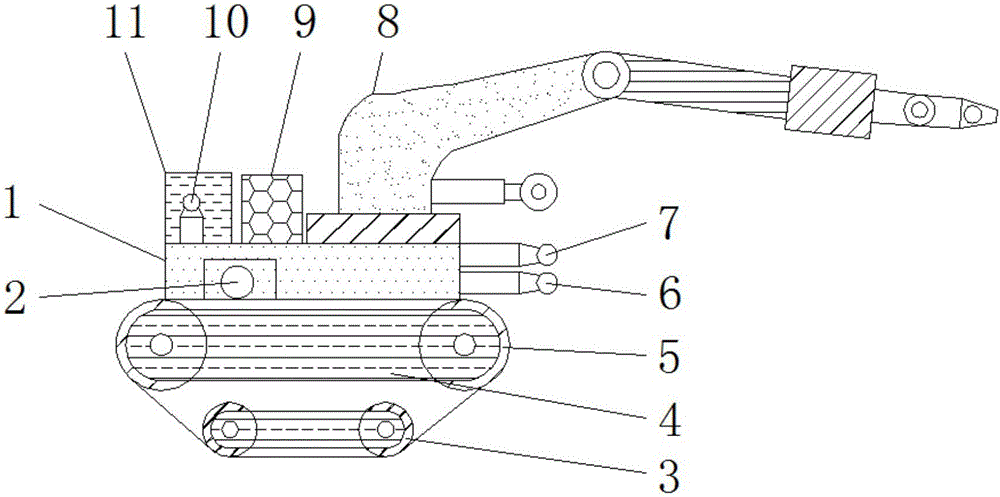

Automatic paint spray robot for building wall surfaces

ActiveCN106088544AAddress issues that impact healthSave human effortBuilding constructionsPaint robotControl theory

The invention provides an automatic paint spray robot for building wall surfaces. The automatic paint spray robot comprises a low-pressure air pump, a paint box, a spray head arranged on an electric slide block, a motor, a base plate, two hydraulic telescopic arms, a caterpillar track arranged under the base plate, a machine vision system and a controller connected with the low-pressure air pump, the paint box, the motor and the machine vision system. The low-pressure air pump, the paint box and the motor are all installed on the base plate. The spray head is connected with the low-pressure air pump and the paint box. The bottom ends of the two hydraulic telescopic arms are installed at the two ends of the motor correspondingly. A guide rail is supported between the top ends of the two hydraulic telescopic arms so that the electric slide block can horizontally slide on the guide rail under control of the controller. The machine vision system feeds back the gesture of the robot and judges the condition of the target wall surfaces. The controller controls the robot to spray paint according to the gesture of the robot and the condition of the target wall surfaces. The robot can complete uniform pain spray work of the wall surfaces, save manpower and meanwhile provide a better and more controllable paint spray effect.

Owner:TOPLUMEN LASER TECH BEIJING CO LTD

Robotic apparatus for painting

InactiveUS7399363B2Efficient use ofCost effectiveLiquid surface applicatorsMovable spraying apparatusPaint robotDrive motor

A painting robot outer arm includes a non-conductive housing mounting a color changer on the outside and a paint canister on the inside connected by an isolating paint transfer line. The paint canister is releasably attached to a piston ram and drive motor by a quick disconnect coupling. The paint supply is isolated from the applied high voltage by cleaning and drying the transfer line. The rate of filling of the canister can be controlled in response to sensed torque applied by a drive motor moving a piston in the paint canister.

Owner:FANUC ROBOTICS NORTH AMERICA

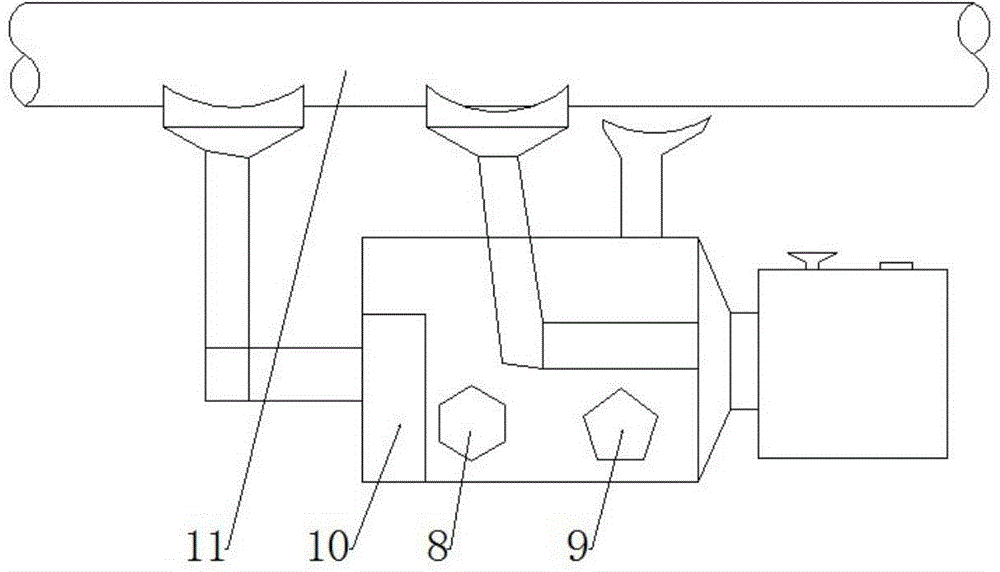

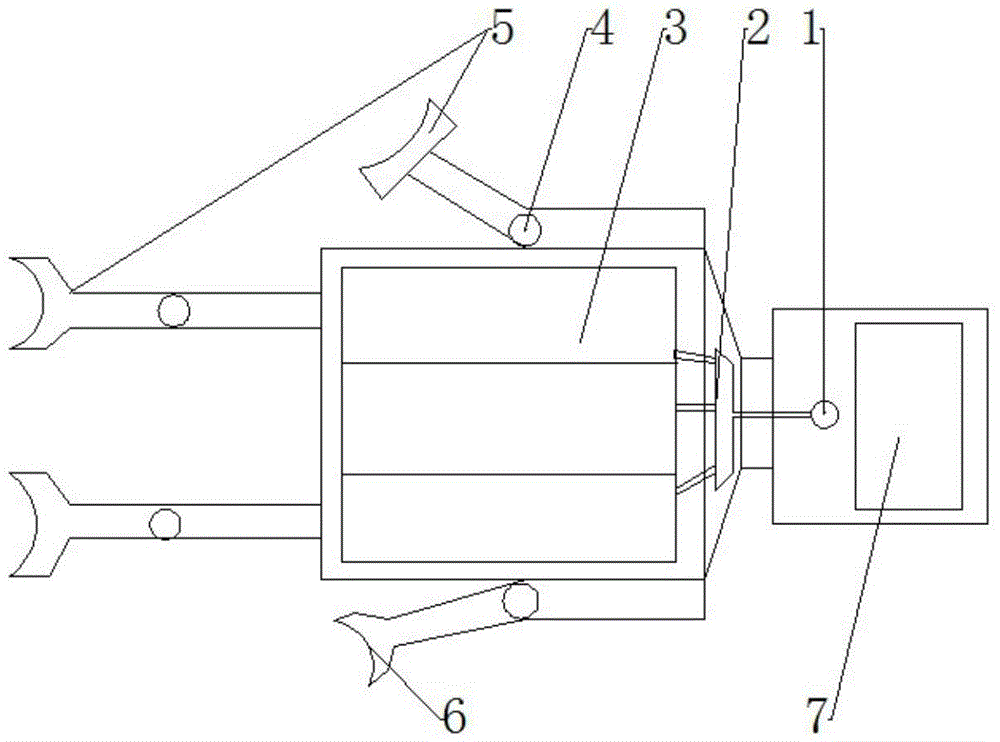

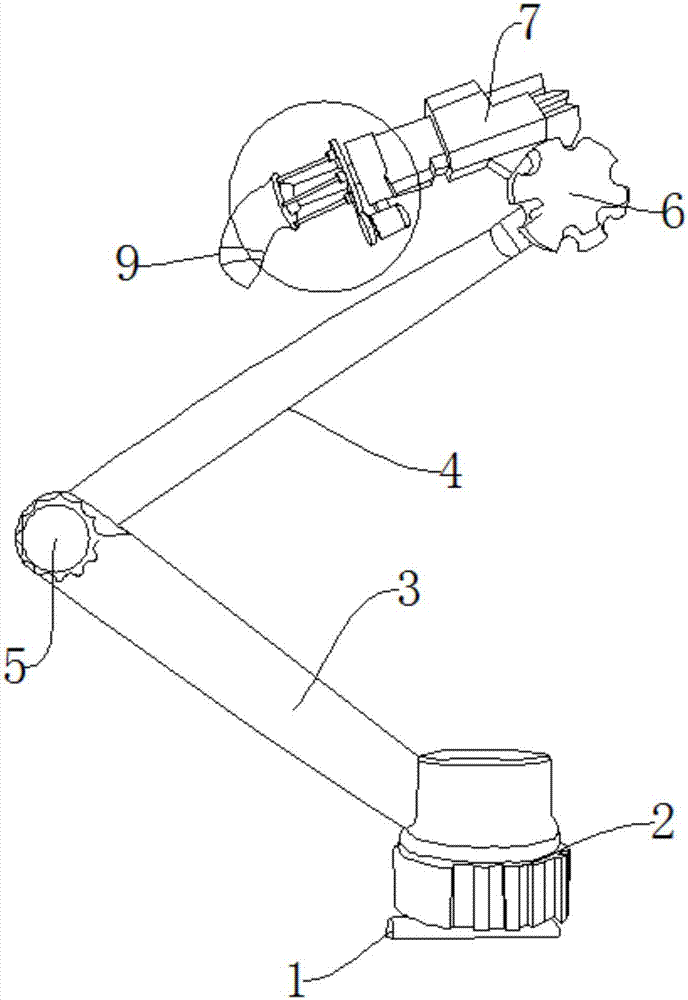

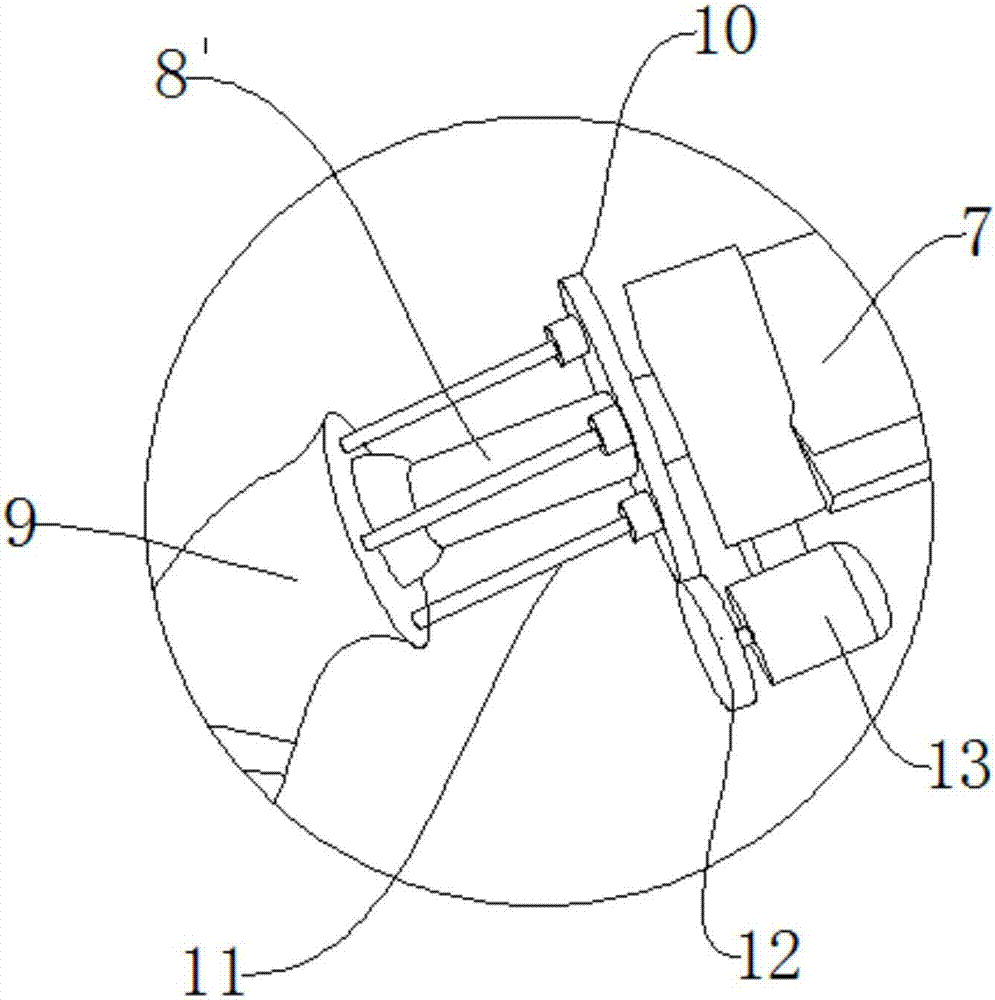

Spray painting robot for rust removal of large pipe

The invention discloses a spray painting robot for rust removal of a large pipe. The robot consists of the following parts: a nozzle (1), a paint mixing device (2), a spray material storage device (3), a linkage device (4), a controllable magnetic force absorber (5), a rust removing manipulator (6), an industrial controller (7), a power module (8), a data transmission module (9), an energy storer (10) and a pipe (11). The working principle of the robot is as follows: the robot can be remotely controlled by a person or intelligently operated by itself. The person sends an instruction to the industrial controller (7) of the robot; the industrial controller (7) starts to work; and a working instruction is sent according to a working task received by the industrial controller. The industrial controller performs the rust removal for a target through the robot data transmission module (9); the surface of the pipe (11) is polished through the rust removing manipulator (6); and paint colors required to be sprayed are transmitted by the industrial controller (7), and are mixed by the paint mixing device (3) for use.

Owner:NANJING DAWU EDUCATION TECH

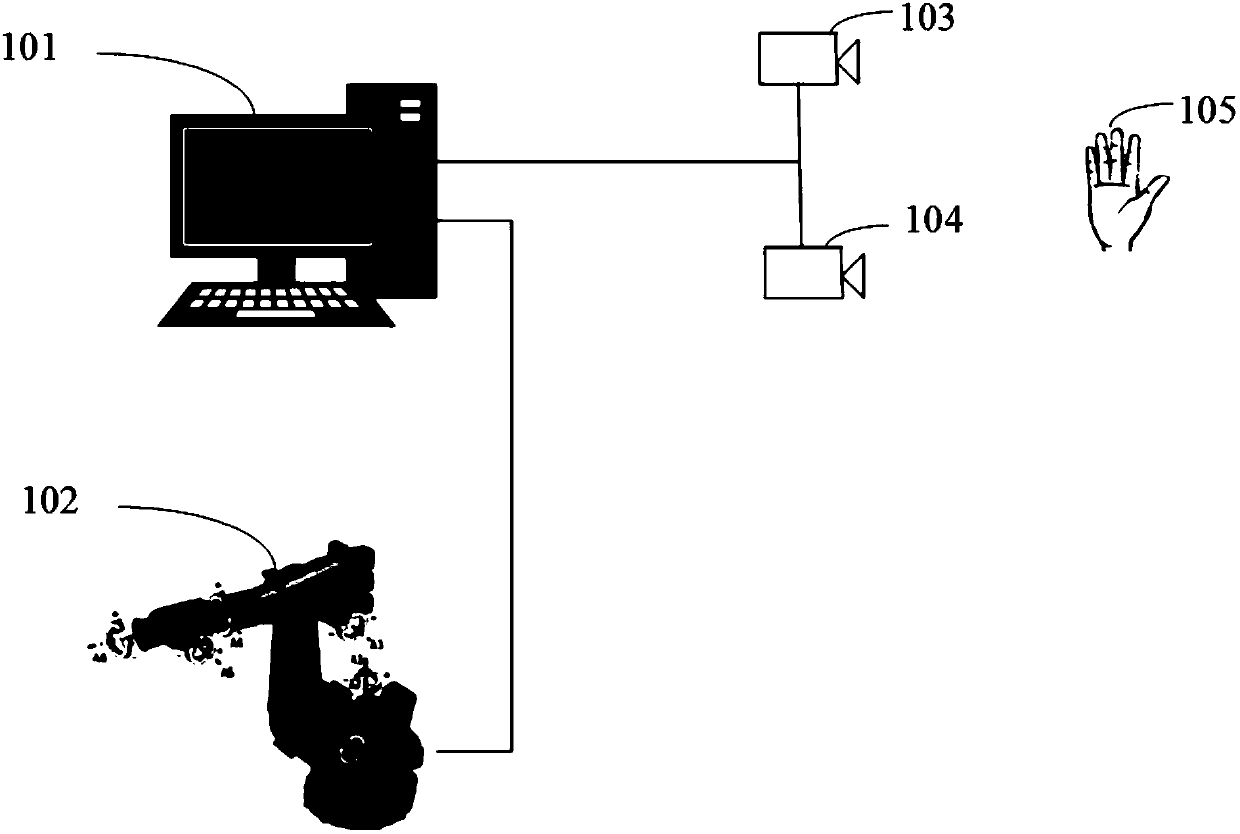

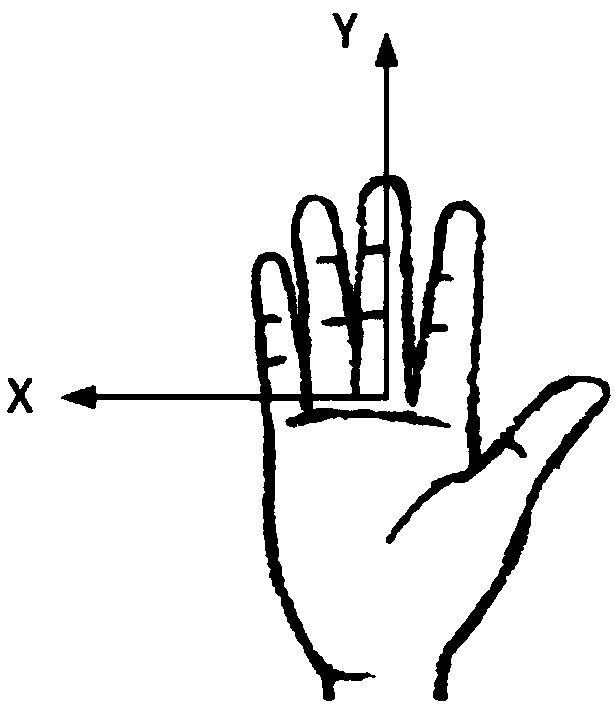

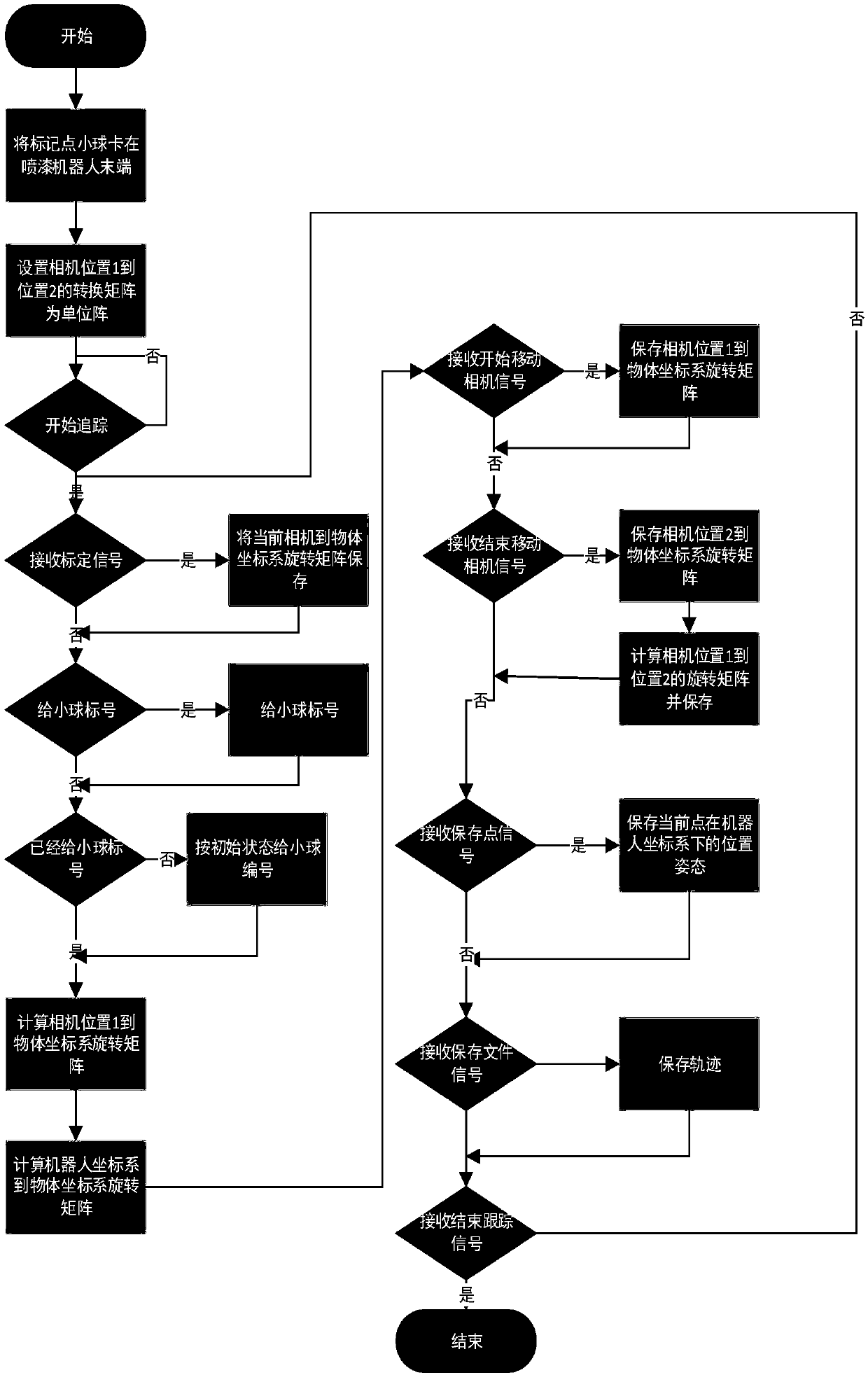

Multiple-gesture robot control method based on binocular vision

ActiveCN107813310ADefinitely not demandingWill not interfere with each otherProgramme-controlled manipulatorComputer graphics (images)Paint robot

The invention relates to the field of robot control methods, in particular to a multiple-gesture robot control method based on binocular vision. In order to overcome the defects that existing robot control methods based on vision are inconvenient to operate, hand identification is greatly affected by illumination and background colors, calculation workload of offline teaching methods is high, andthe precision requirements for robot model precision and coordinate determination are high, the multiple-gesture robot control method based on binocular vision is provided. The method comprises the steps that a binocular camera is arranged; a rectangular frame comprising gestures is manually selected; a classier is trained through a training sample set; a target is detected by the classier; then the target is tracked, and tracking results and detection results are fused; the deviation distance of the center point of the target from the initial point to the target point, a speed control instruction is output, and thus a robot translates; and characteristic points are extracted from the target frame, and rotary matrixes corresponding to the characteristic points are solved. The multiple-gesture robot control method is suitable for spraying robot control methods.

Owner:于兴虎

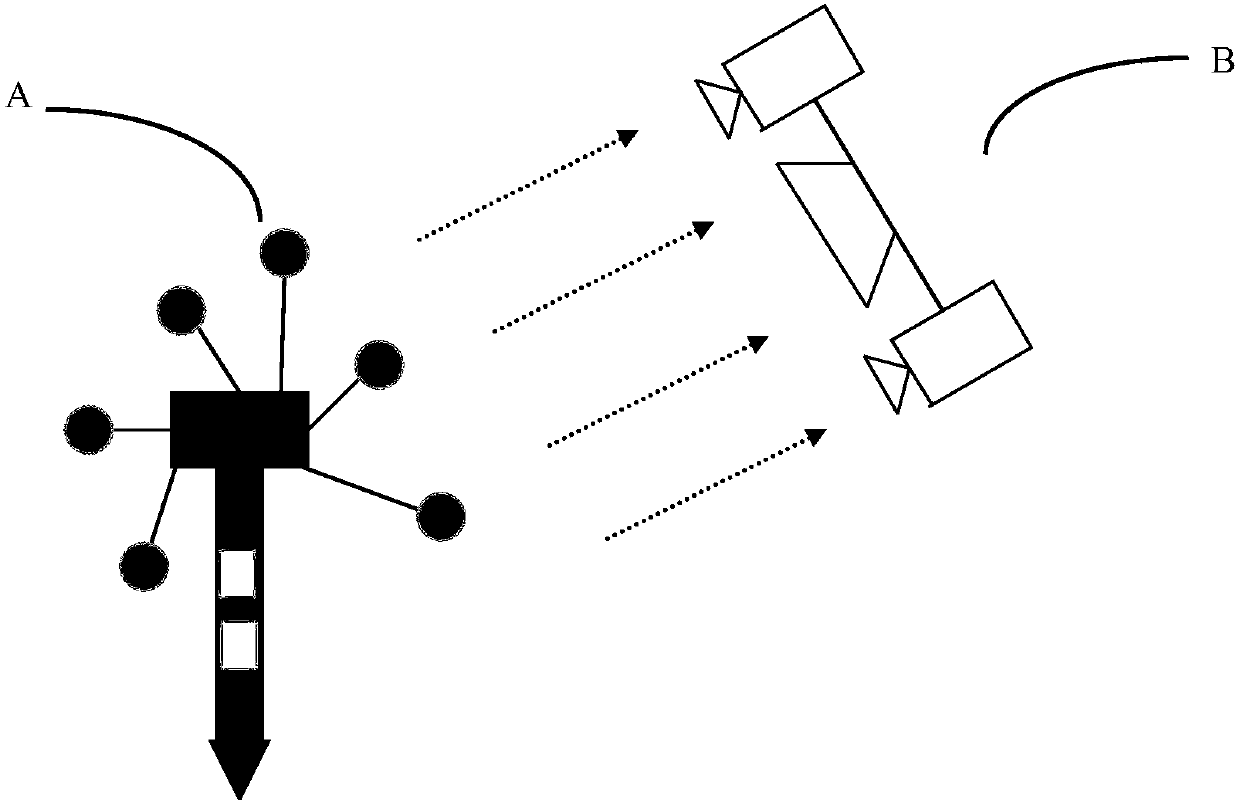

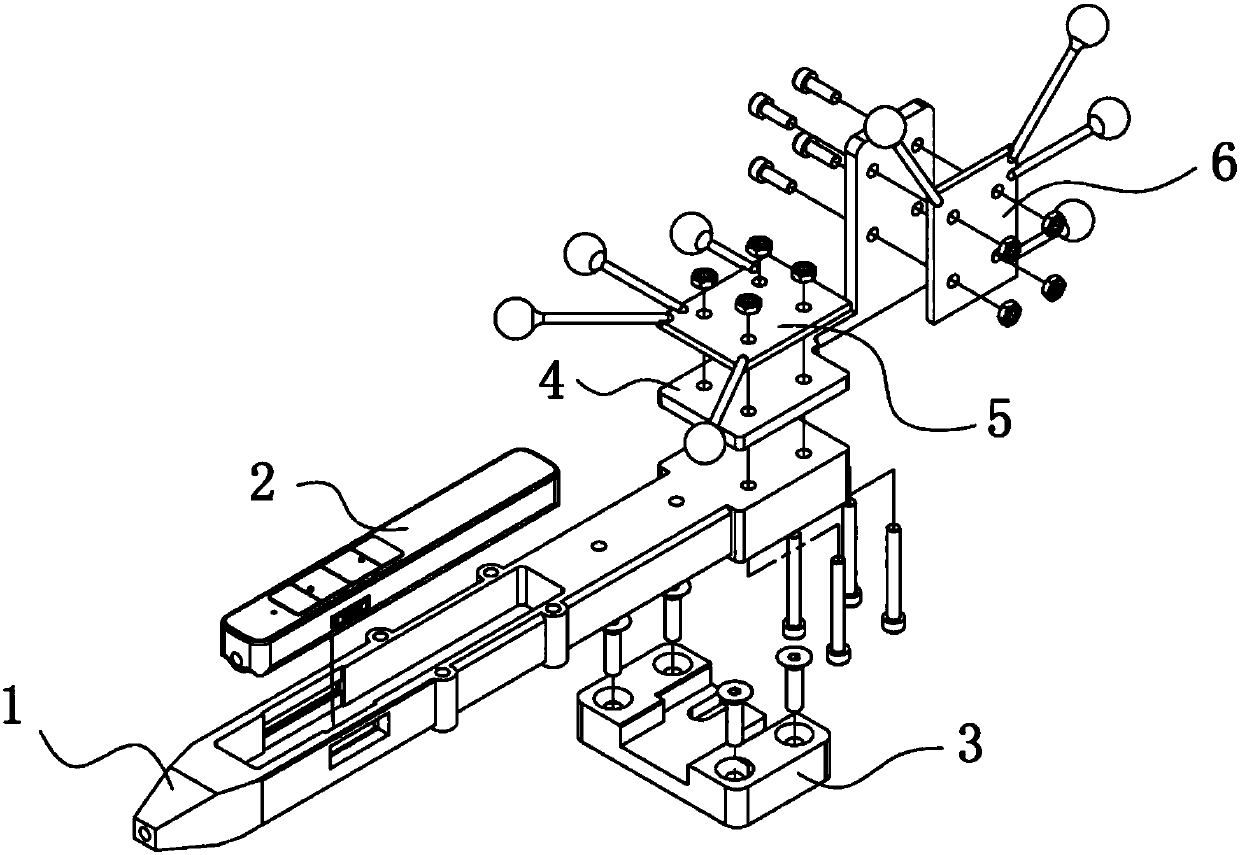

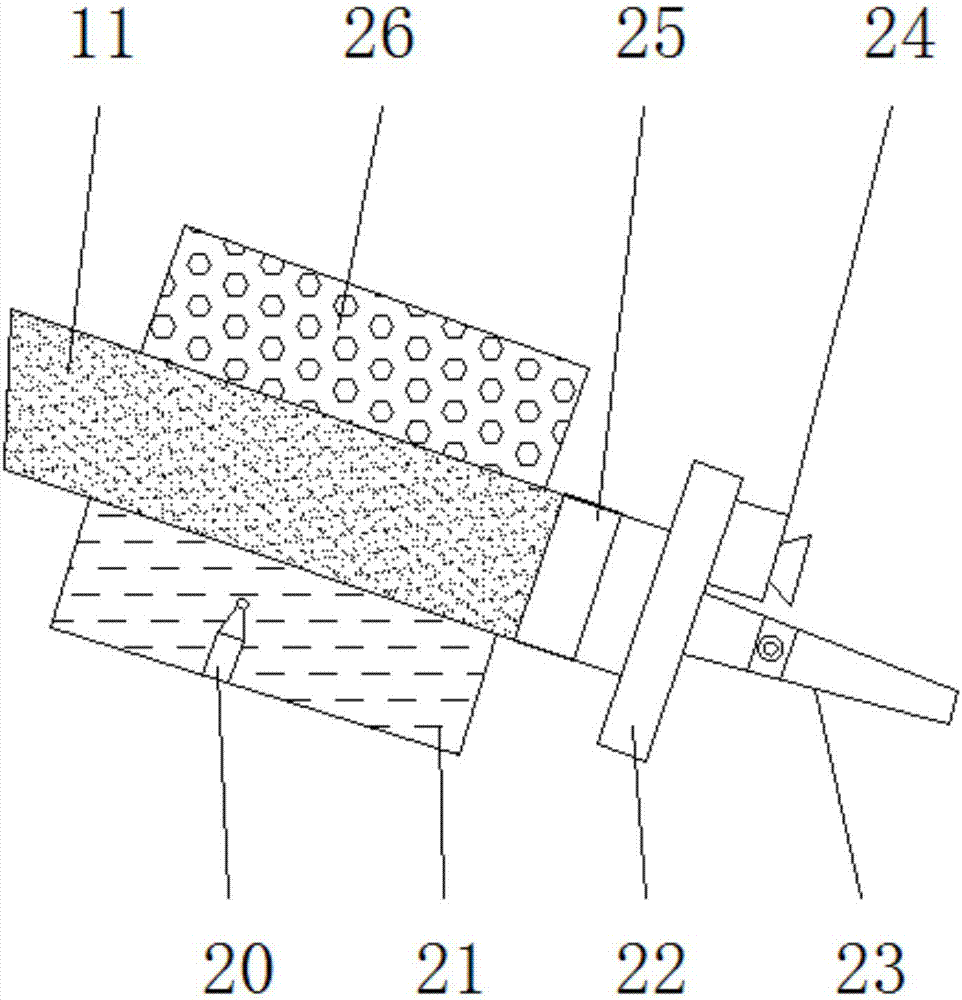

Robot track teaching device and method based on active infrared binocular vision

ActiveCN107756408ASimple structureEasy to installProgramme-controlled manipulatorPaint robotActive infrared

The invention relates to a robot track teaching device, system and method based on active infrared binocular vision. The problems that according to an existing robot teaching method, feature information is possibly shielded or confused and then needs to be processed manually, the cost is high, the occupied space is large, the calculated amount is large, and the requirement for coordinate system precision is too high are solved. The robot track teaching device based on active infrared binocular vision comprises a laser pen holder, a laser pen, a fixture, a fluorescent plate connection plate, afirst fluorescent plate and a second fluorescent plate; the first fluorescent plate and the second fluorescent plate are each provided with a preset number of balls coated with a fluorescent material;the fixture is fixed to the laser pen holder through screws; the fluorescent plate connection plate is fixed to the laser pen holder through bolts; the laser pen is provided with buttons used for preserving and deleting teaching points. The robot track teaching device, system and method based on active infrared binocular vision are suitable for manufacturing a paint spray robot teaching machine.

Owner:于兴虎

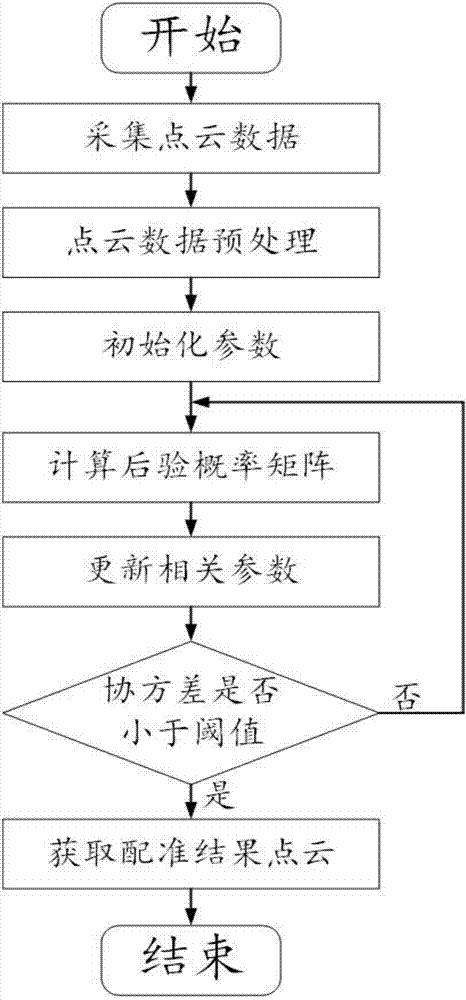

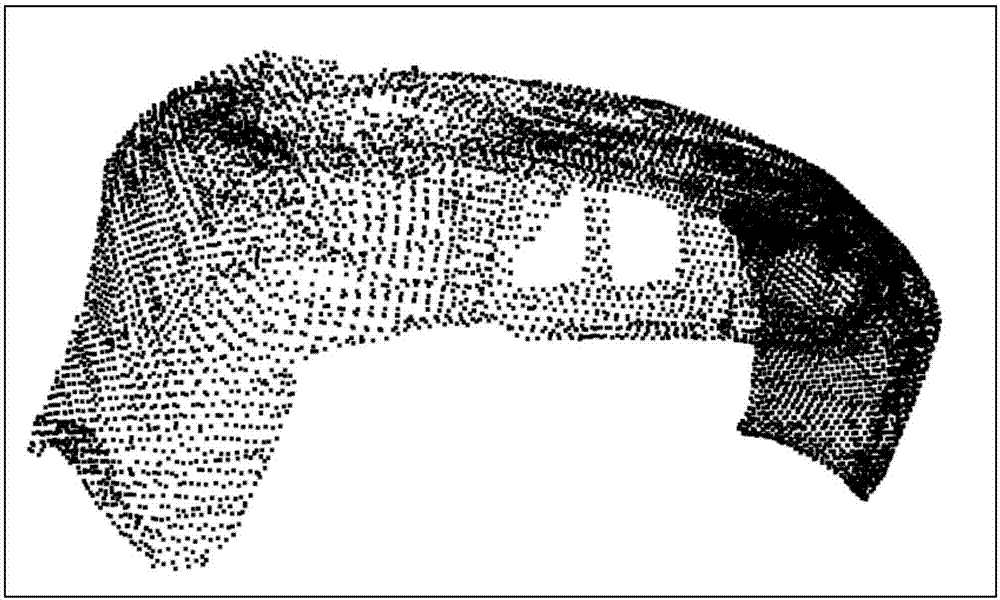

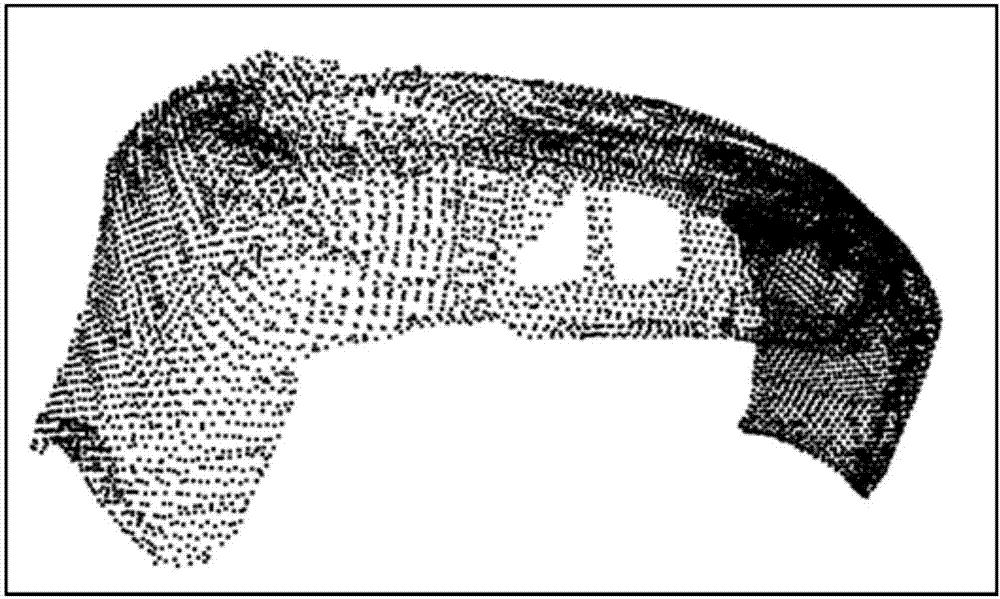

Three-dimensional point cloud registration method adopting CPD (coherent point drift) algorithm based on affine transformation model

ActiveCN107204009ASolve complexityResolution timeImage enhancementImage analysisCoherent point driftPoint cloud

The invention provides a three-dimensional point cloud registration method adopting a CPD (coherent point drift) algorithm based on an affine transformation model, relates to a spraying robot position registration method based on point cloud registration and aims to solve the problems of high complexity, long program running time, low registration accuracy and poor robustness of the conventional mainstream three-dimensional point cloud registration algorithm CPD. The specific process comprises the following steps: 1, obtaining a group of three-dimensional point cloud data to serve as to-be-registered point cloud; 2, taking the obtained point cloud data as a reference point set; 3, calculating a covariance and initiating B and t; 4, parallelly computing P by a GPU; 5, solving parameters B, t and sigma<2> when an objective function gets maximum; 6, iterating steps 4 and 5 repeatedly until the covariance is smaller than a set threshold, solving B and t as well as a finally registered result point set when the covariance is smaller than the set threshold, and performing spraying on a to-be-sprayed object according to the final registration result. The three-dimensional point cloud registration method applies to the field of spraying by spraying robots.

Owner:HARBIN INST OF TECH

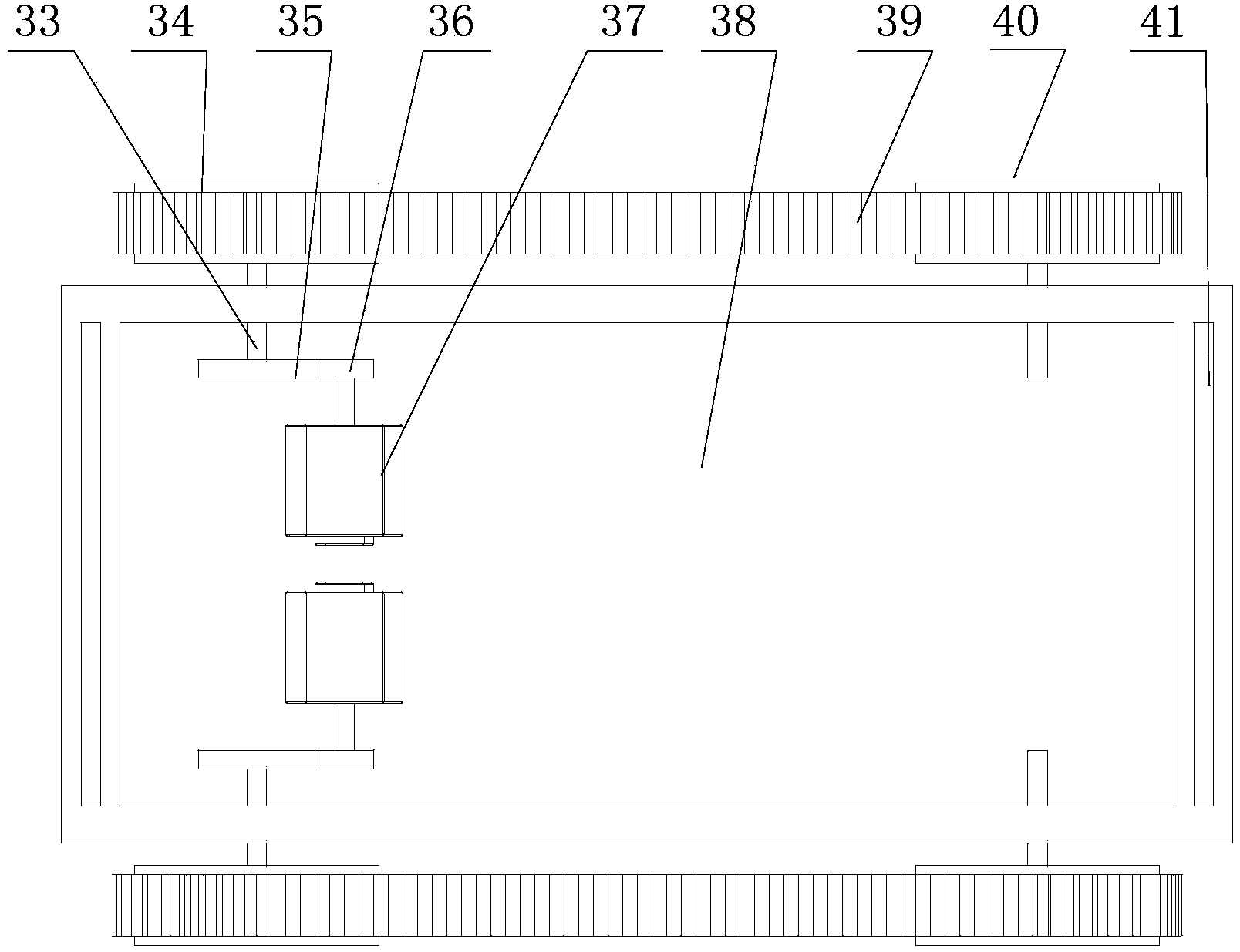

Omni-directional intelligent furniture paint spraying robot

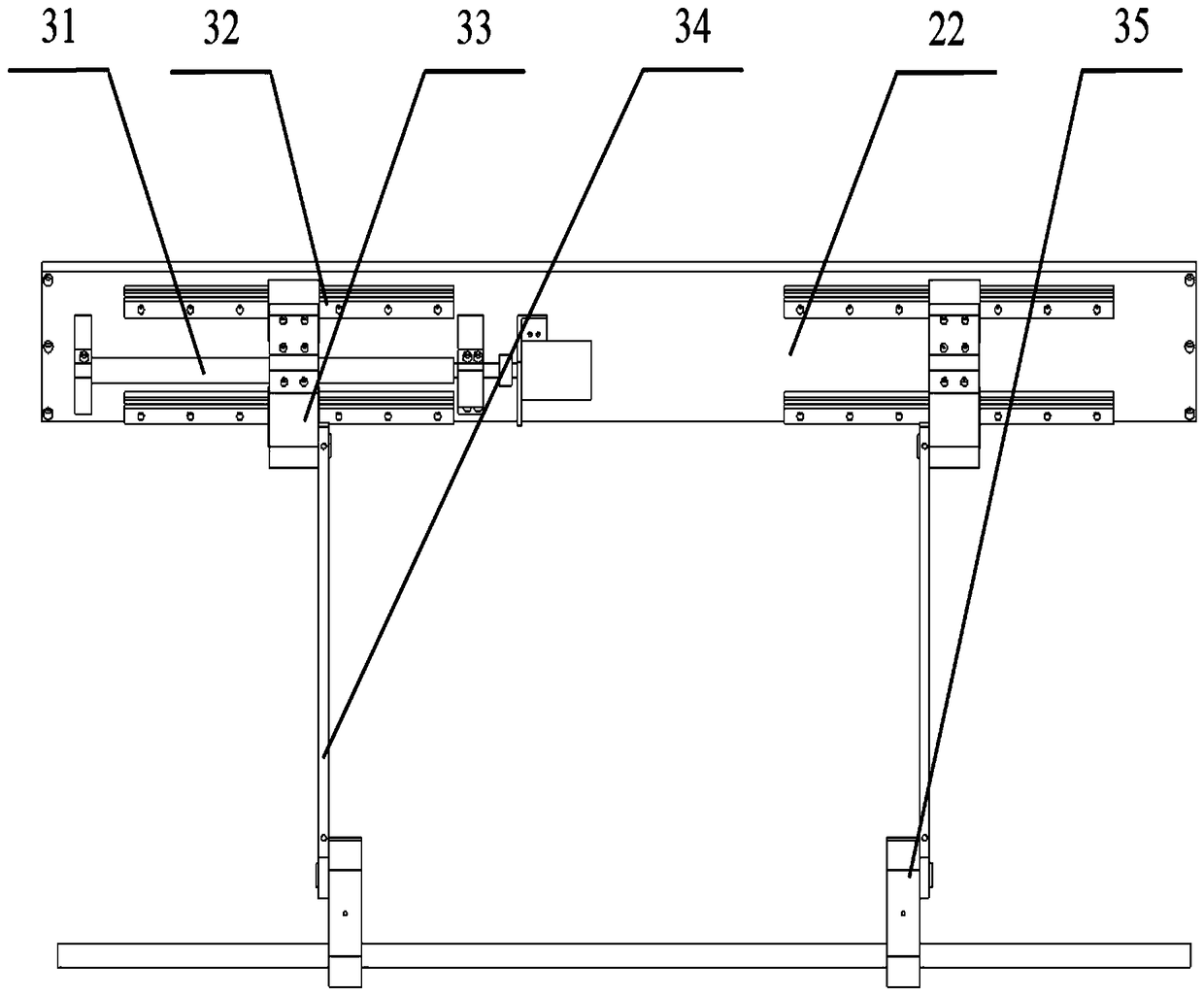

InactiveCN104260076ACompact structureStrong skid resistanceSpraying apparatusManipulatorLinear motionProduction line

The invention aims to provide an omni-directional intelligent furniture paint spraying robot. The omni-directional intelligent furniture paint spraying robot comprises an XYZ three-axis translational motion mechanism, a Y-axis rotating mechanism, a spraying gun, a supporting framework mechanism and the like; a Z-axis moving mechanism is mounted in a sliding way of a vehicle body through a sliding block on a Z-axis mounting plate, linear motion along a Z axis can be achieved through driving by screws and nuts, a Y-axis moving mechanism is mounted on the Z-axis mounting plate through a Y-axis mounting plate, linear motion along a Y axis can be achieved through driving by gears and racks, an X-axis moving mechanism is mounted on the Y-axis mounting plate through two polish rods, linear motion along an X axis can be achieved through driving by gears and racks, the Y-axis rotating mechanism is mounted on an X-axis sliding block through bolts, and rotating along the Y axis can be achieved through driving by a steering engine. By means of the omni-directional intelligent furniture paint spraying robot, space four-degrees-of-freedom movement of the spraying gun of the robot can be entirely achieved, omni-directional paint spraying can be performed on whole furniture, and defects that common paint spraying machines can only spray paint on panel plane furniture by fixed production lines, and the like can be overcome.

Owner:HARBIN ENG UNIV

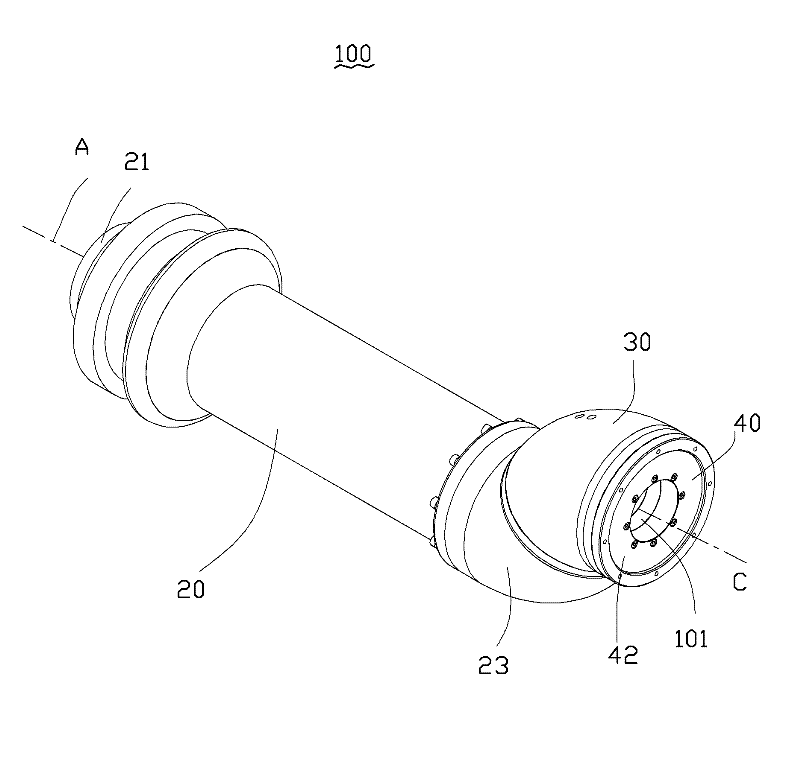

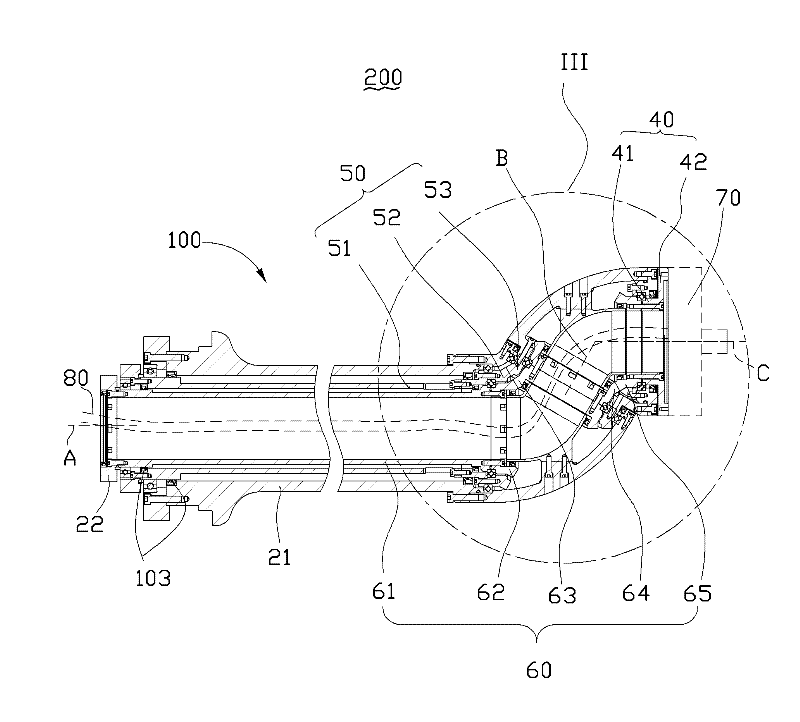

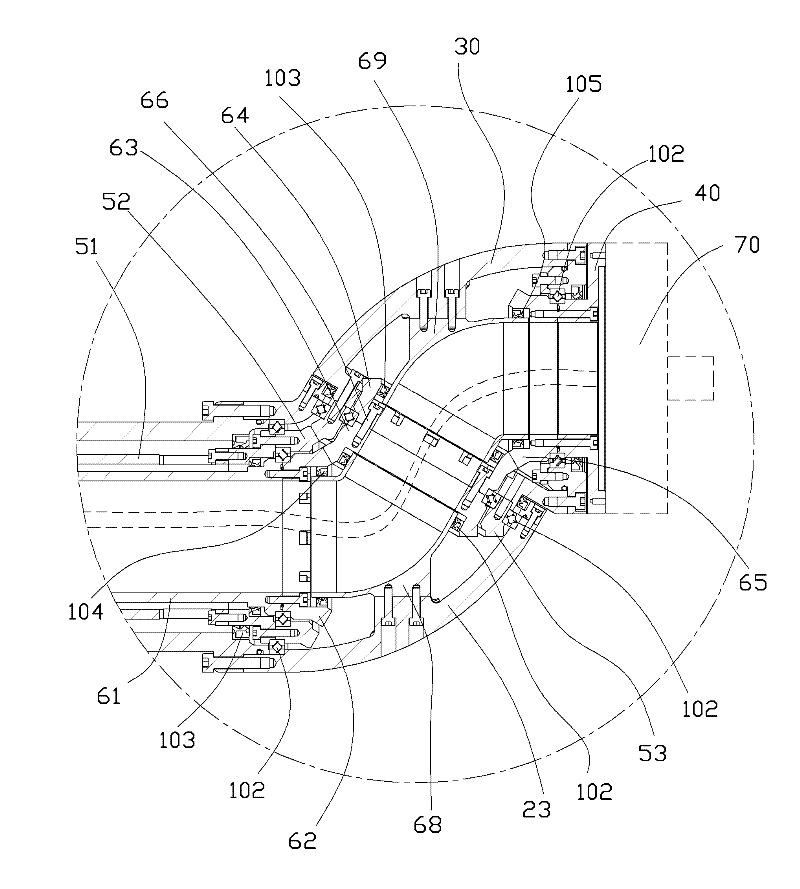

Spray painting robot arm component and spray painting robot

InactiveCN102527560AAvoid pollutionAvoid wear and tearMechanical apparatusJointsDrive shaftPaint robot

The invention discloses a spray painting robot arm component which comprises a supporting arm, a wrist, a tail end arm, a first driving mechanism and a second driving mechanism. The first driving mechanism comprises a first transmission shaft, a first bevel gear connected with the first driving mechanism through splines, and a second bevel gear meshed with the first bevel gear. The second driving mechanism comprises a second transmission shaft, a third bevel gear connected with the second driving mechanism through splines, a fourth bevel gear meshed with the third bevel gear, a fifth bevel gear coaxially and back to back arranged with the fourth bevel gear, and a sixth bevel gear meshed with the fifth bevel gear to drive the tail end arm. The first bevel gear and the third bevel gear are coaxially arranged, and the second bevel gear and the fourth bevel gear are coaxially arranged. The spray painting robot arm component is completely sealed, and a channel for a pipeline connected to a spraying mechanism to penetrate through is formed inside the spray painting robot arm component. The spray painting robot arm component can prevent the pipeline from being exposed to spraying environment and from being polluted. The invention also provides a spray painting robot using the arm component.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

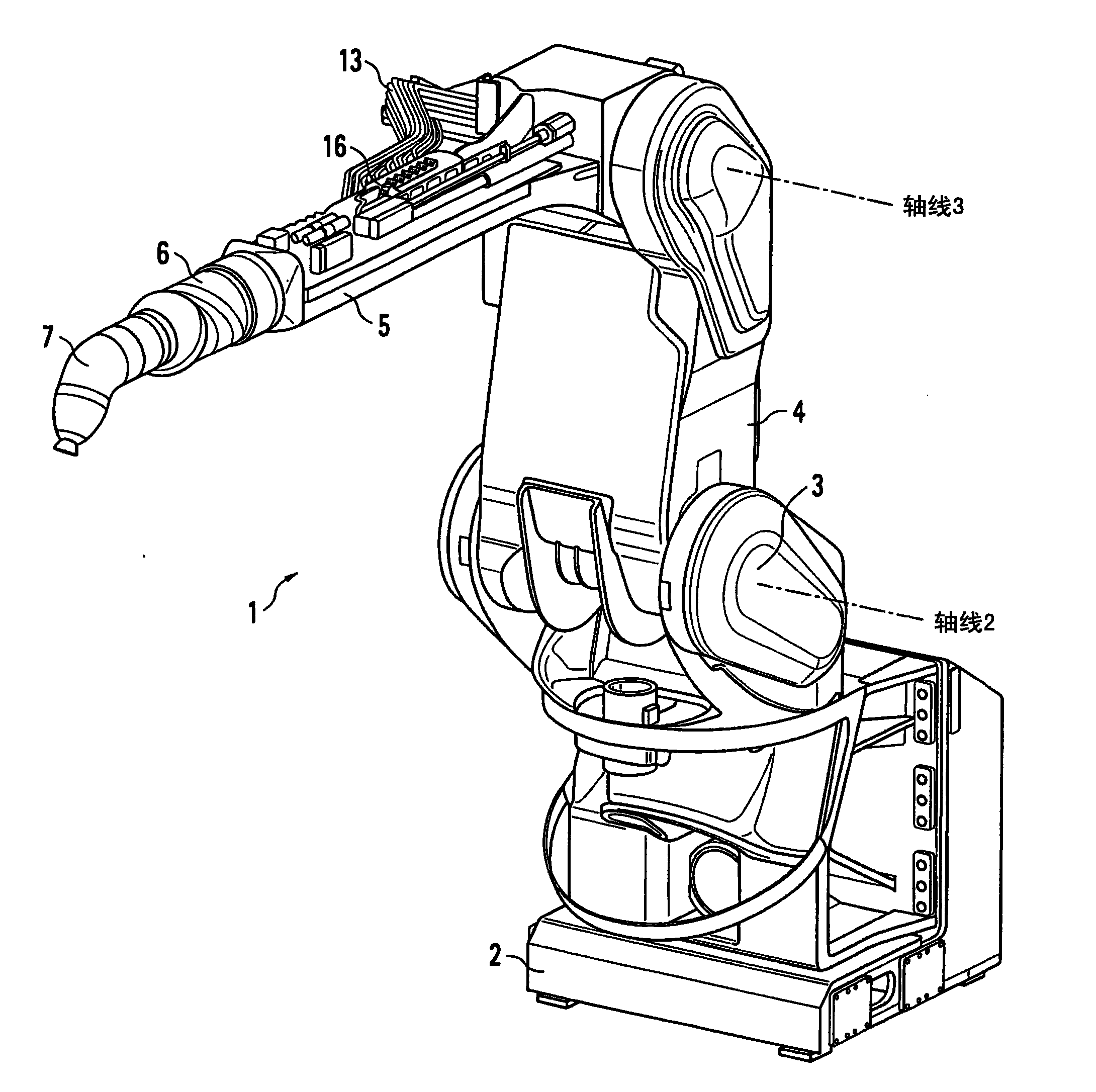

Painting robot and associated operating method

ActiveCN101977695AControl investment is smallReduce lossesLiquid supply arrangementsLiquid surface applicatorsPaint robotControl theory

The invention relates to a painting robot (1) for painting motor vehicle bodies having outer surfaces to be painted on the outside of the motor vehicle body and inner surfaces to be painted in the interior of the motor vehicle body by means of an atomizer (7) that is guided by the painting robot (7). According to the invention, the painting robot (1) is suitable for painting the outer surfaces and for painting the inner surfaces of the motor vehicle bodies. The invention further relates to a corresponding operating method.

Owner:DUERR SYST GMBH

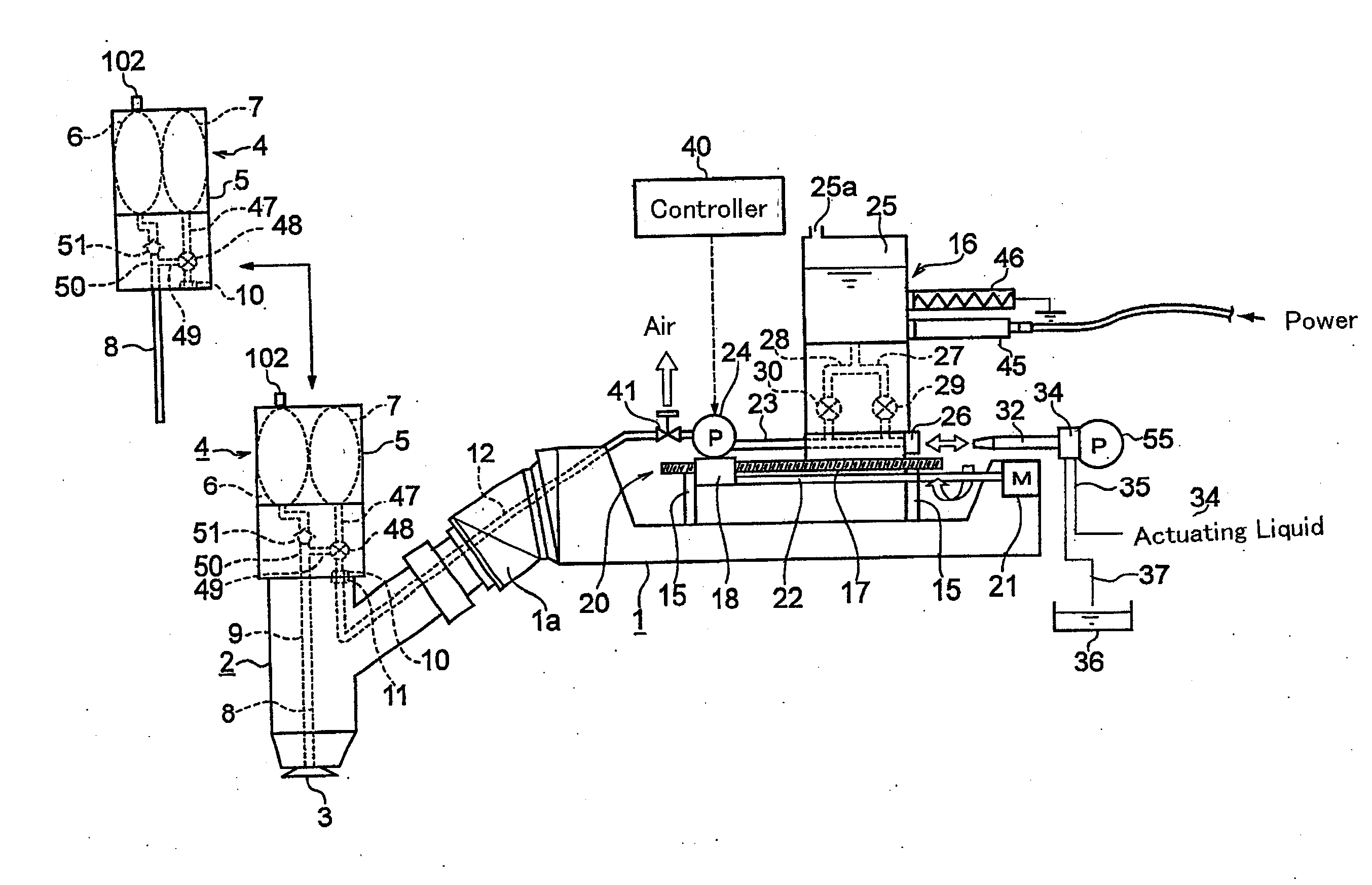

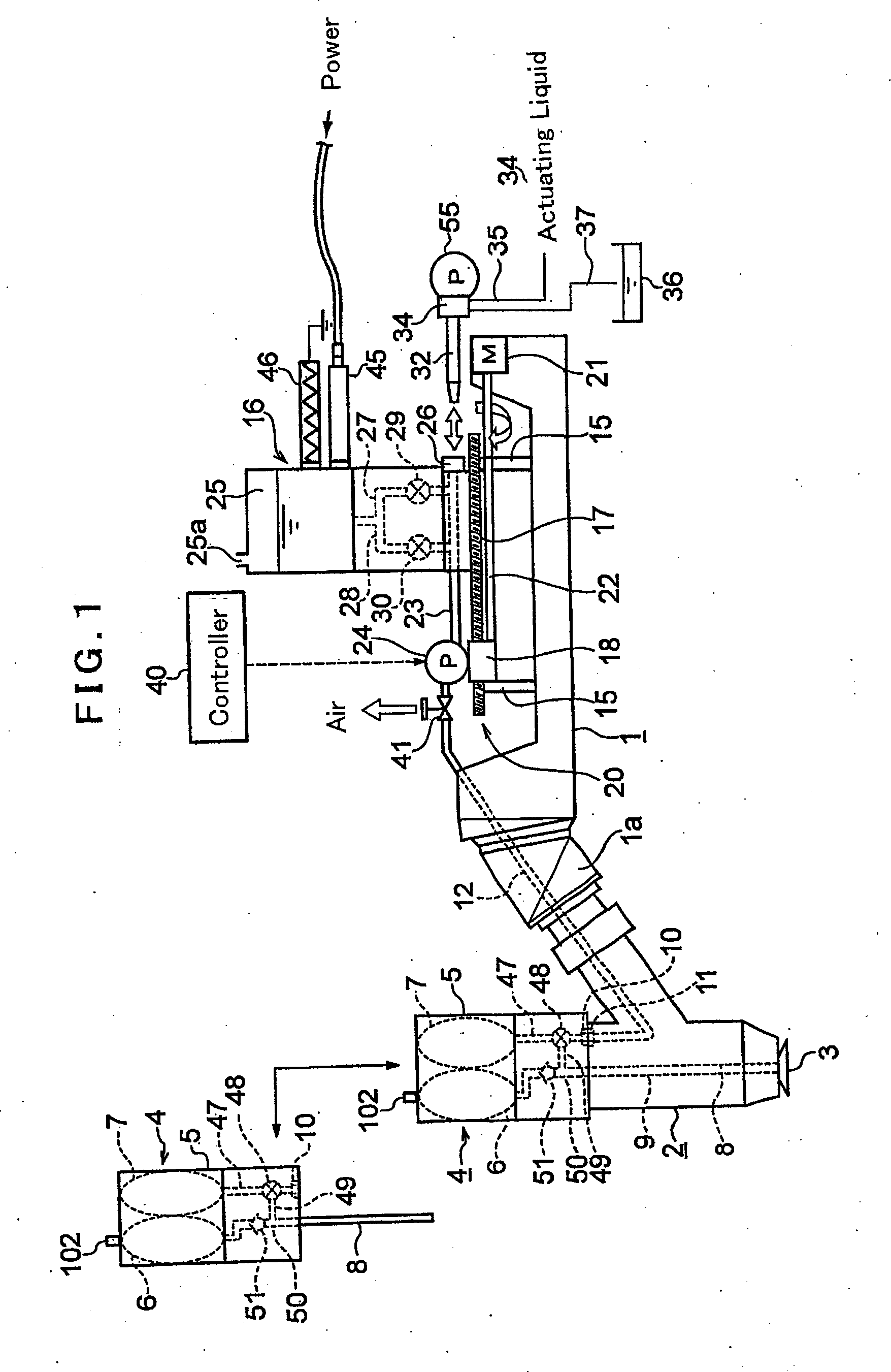

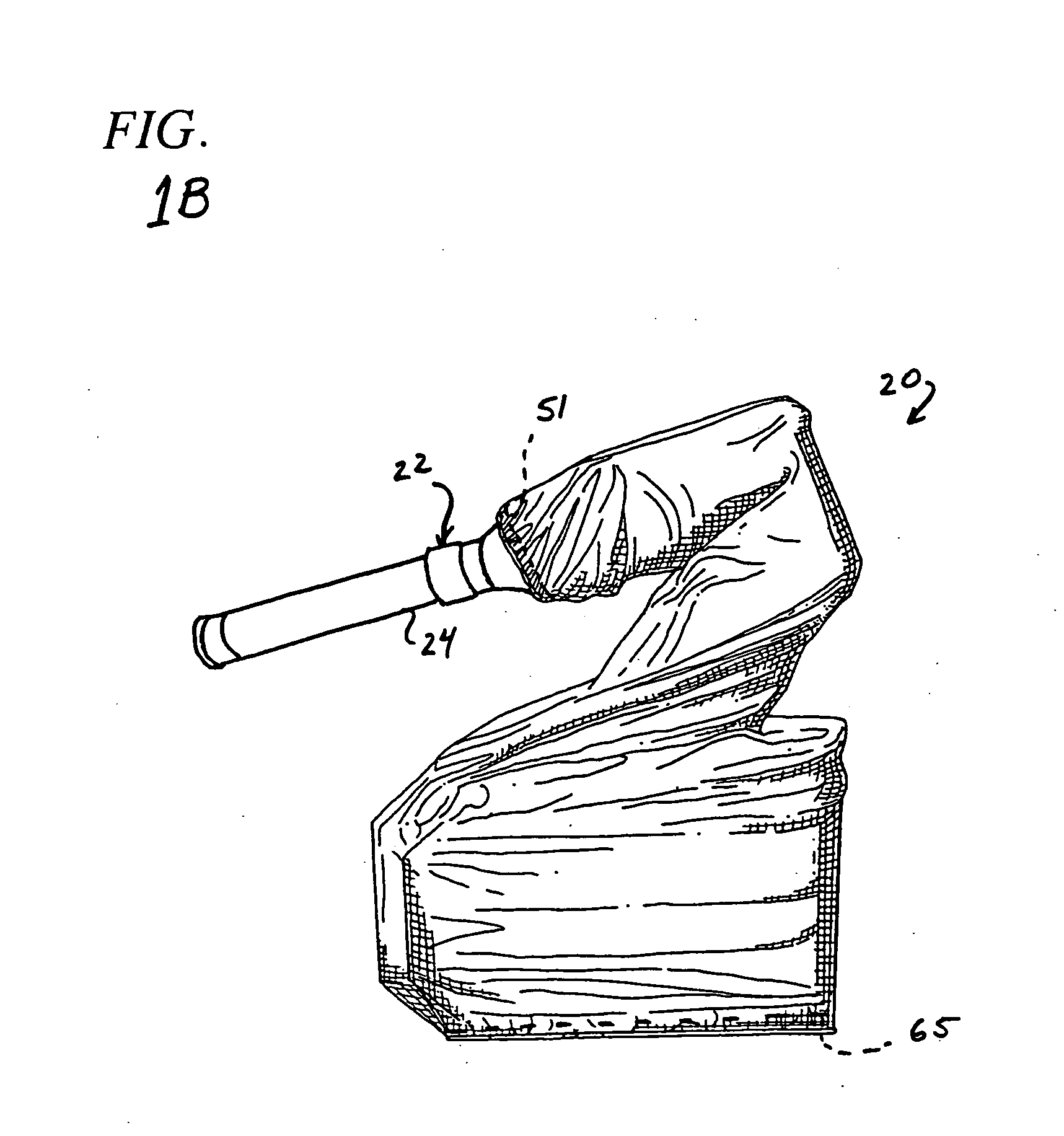

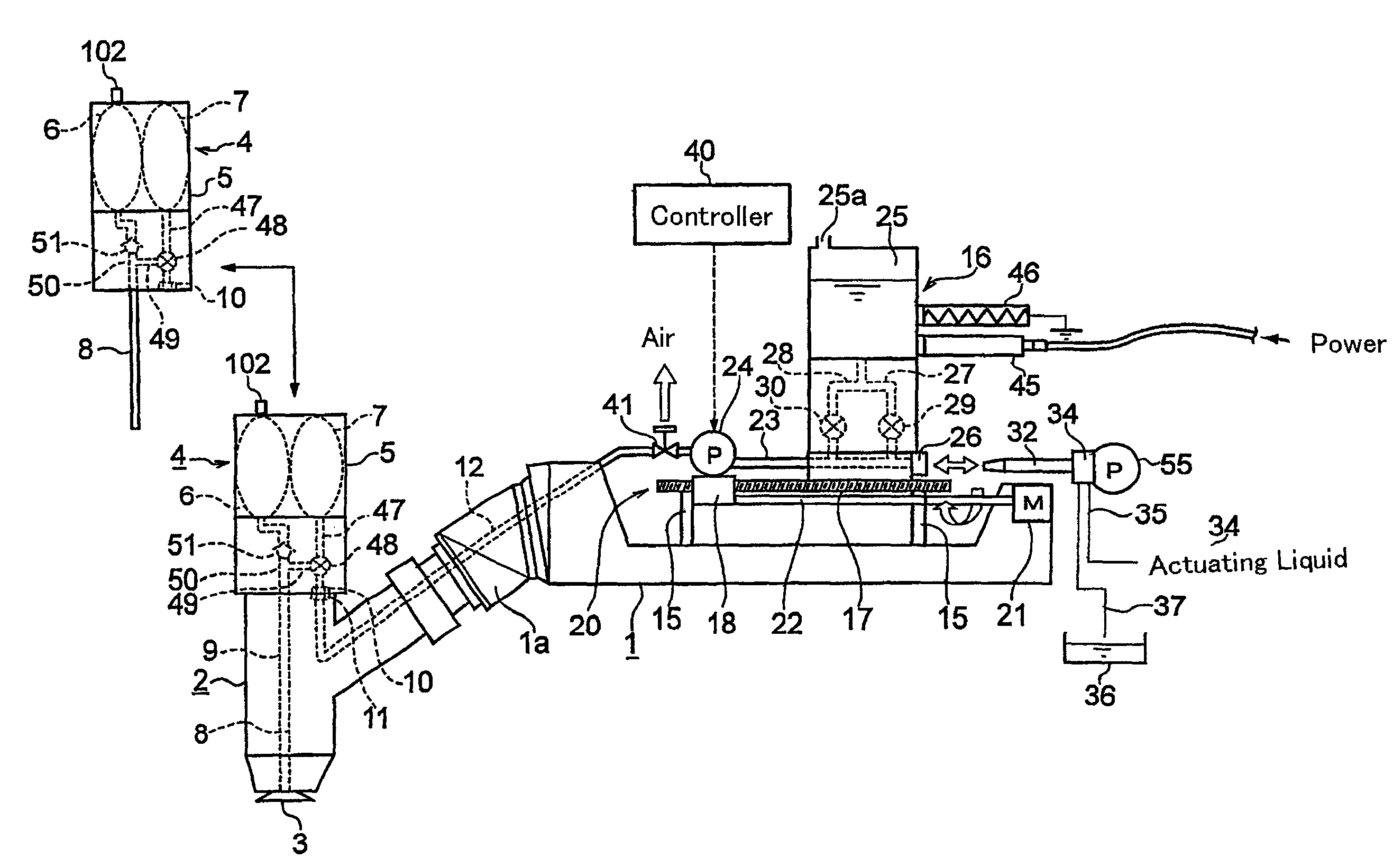

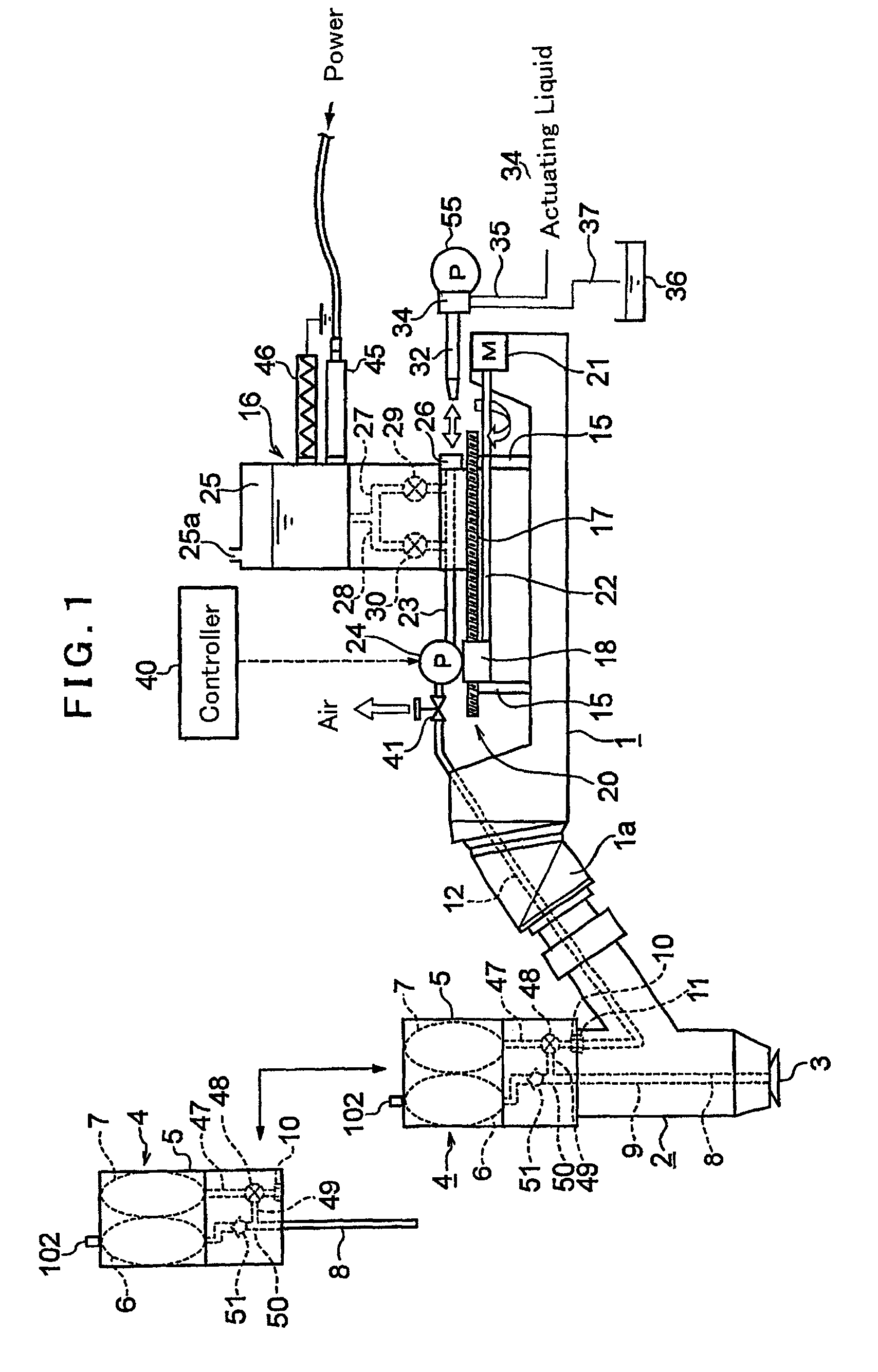

Paint robot and paint cartridge

An arm of a coating robot is used to prevent external leakage of a high voltage. A tank is installed on a robotic arm and contains water as an actuating liquid. The water is supplied to a paint cartridge by a pump controlled by a controller. The water sent from the pump under pressure is supplied to the paint cartridge by a conduit tube. A high voltage generator and a bleeder resistor are combined with the tank such that a high voltage generated by the high voltage generator is supplied to the electrostatic paint applicator via the water. For replenishment of water to the tank is attained by relatively connecting a nozzle in communication with a water source to a main pipe. While the high voltage generator generates a high voltage, the nozzle and the main pipe are kept disconnected to maintain electrical insulation between the nozzle and the main pipe.

Owner:RANSBURG IND FINISHING

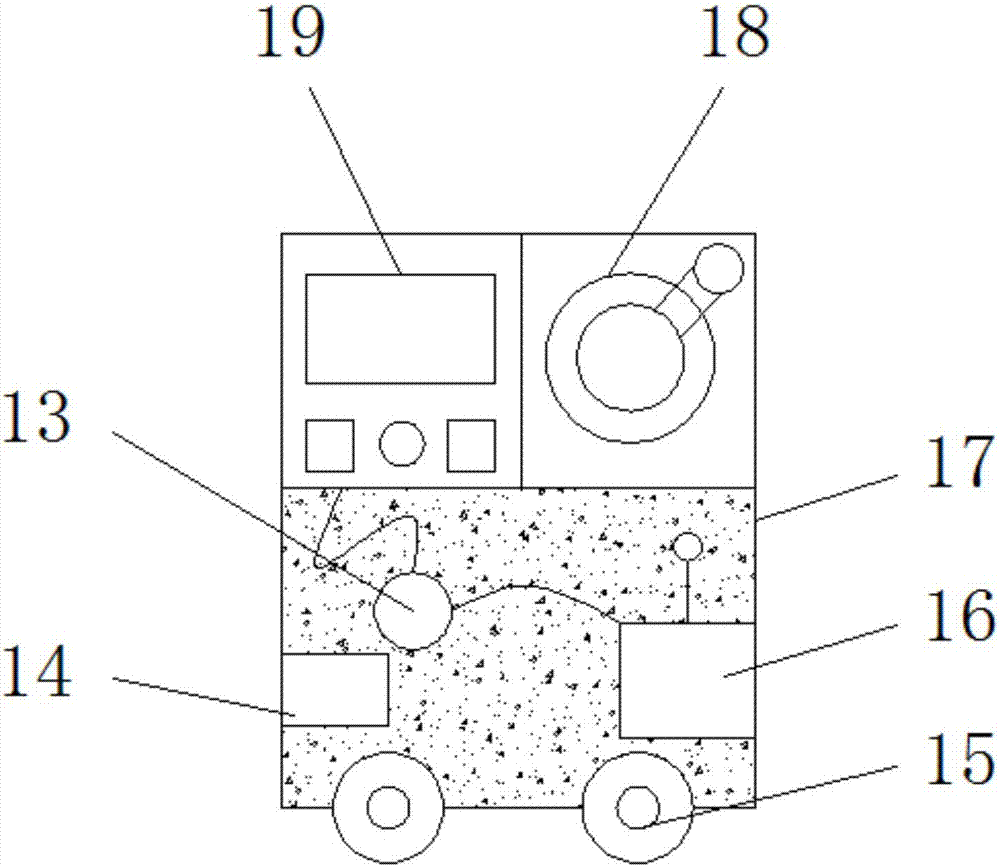

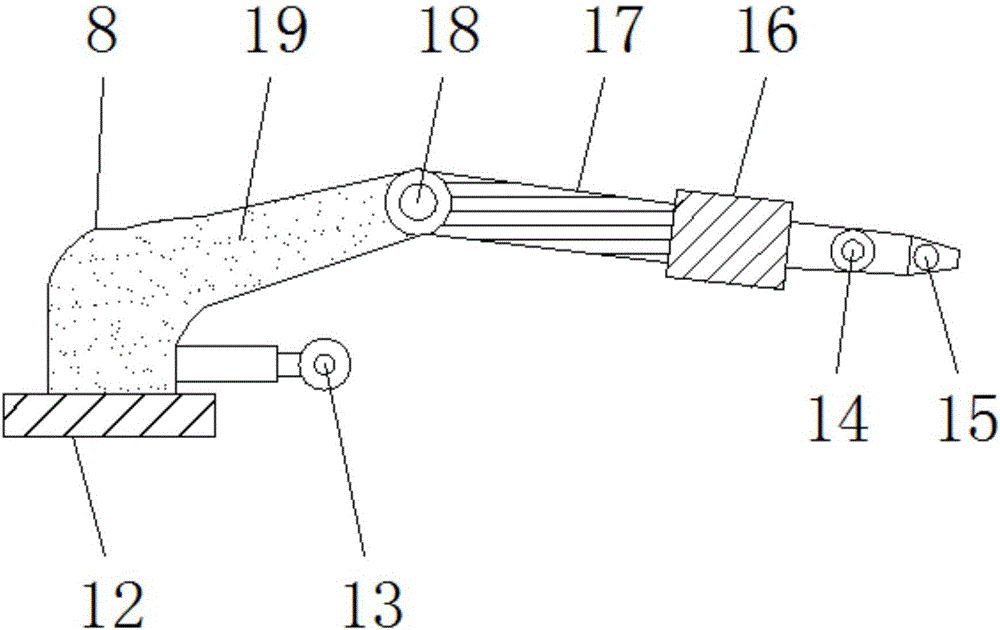

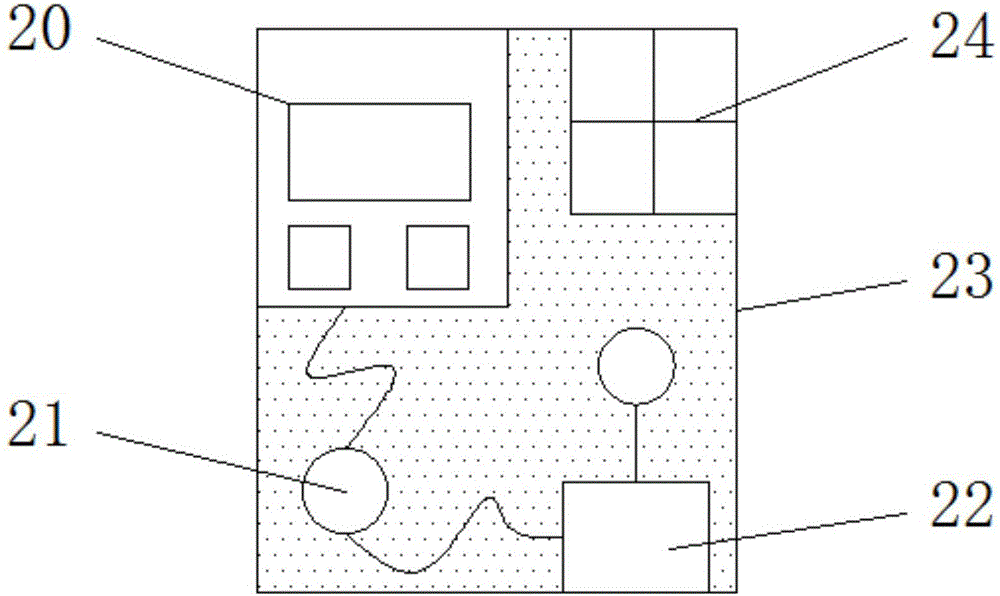

Intelligent paint spraying robot

InactiveCN107008599AGuaranteed to workAvoid route spray paintSpraying apparatusManipulatorPaint robotPressure sense

The invention discloses an intelligent painting robot, which comprises a walking chassis, a working arm and a control box. The main crawler wheel is installed inside the walking chassis, and a rotating base is installed on the upper end of the walking chassis, and a support is installed on the upper end of the rotating base. One end of the support arm is equipped with a rotating shaft, the upper end of the rotating base is equipped with an infrared detection head, one end of the rotating base is equipped with an infrared emitting lamp, one end of the rotating shaft is equipped with a working arm, and the upper end of the working arm is installed There is an air pump, a paint box is installed at the lower end of the working arm, a pressure sensing probe is installed inside the paint box, a pressure sensing head is installed on the lower side of the air pump, and a QC200 data processor is installed at one end of the pressure sensing head , one end of the QC200 data processor is installed with an adjustable mist nozzle, and a control display is installed inside the control box. The intelligent painting robot of the invention has the characteristics of stable and efficient work, and improves the painting efficiency.

Owner:吴俊

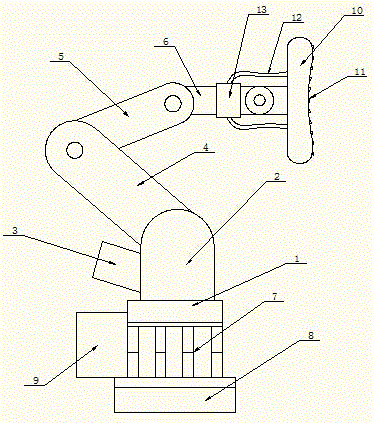

Paint spraying robot with angle of spray gun adjustable

ActiveCN107214025AReduce usageReduce manufacturing costSpraying apparatusManipulatorPaint robotSpray nozzle

The invention discloses a paint spraying robot with the angle of a spray gun adjustable. The paint spraying robot comprises a base; a rotating table is arranged at the upper end of the base; a supporting arm I is arranged on the side surface of the rotating table; a supporting arm II is arranged at the upper end of the supporting arm I; a stepping motor I is arranged on the side surface of the supporting arm I; a stepping motor II is arranged on the side surface of the supporting arm II; and the spray gun is arranged at the upper end of the supporting arm II. The paint spraying robot has the beneficial effects as follows: a gear ring and electric hydraulic push rods are additionally mounted on the spray gun of the paint spraying robot and can drive a nozzle to twist leftwards, rightwards, upwards and downwards and rotate around a spray pipe, so that the spray positon and the spray angle of the spray gun are greatly increased, the paint spraying operation for workpieces with the relatively complex surface shapes can be completed by 1-2 robots, the use amount of the paint spraying robots is greatly reduced, the production cost is remarkably reduced, and the robot is good in practicability.

Owner:WUHU CHAOYUANLI IND DESIGN CO LTD

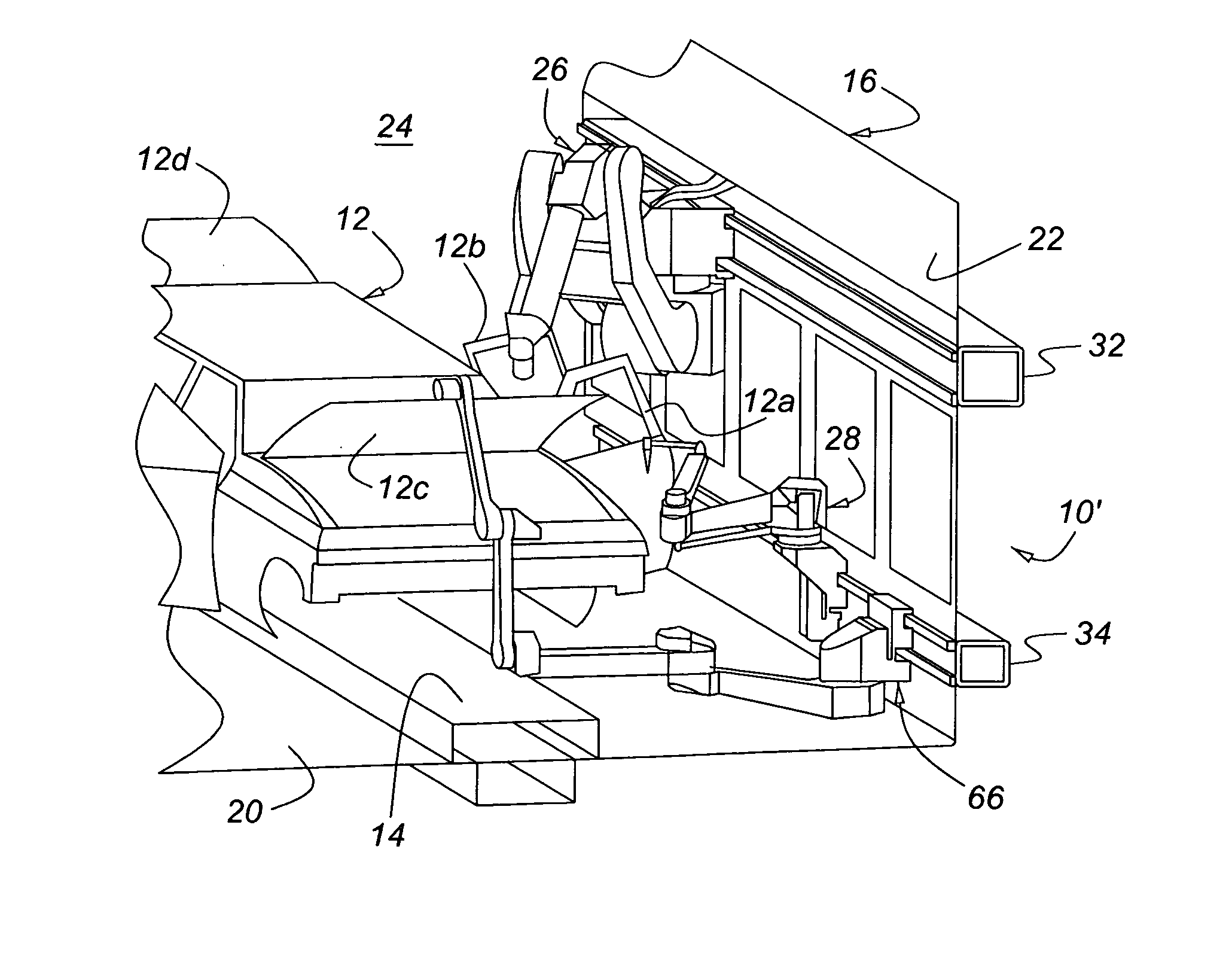

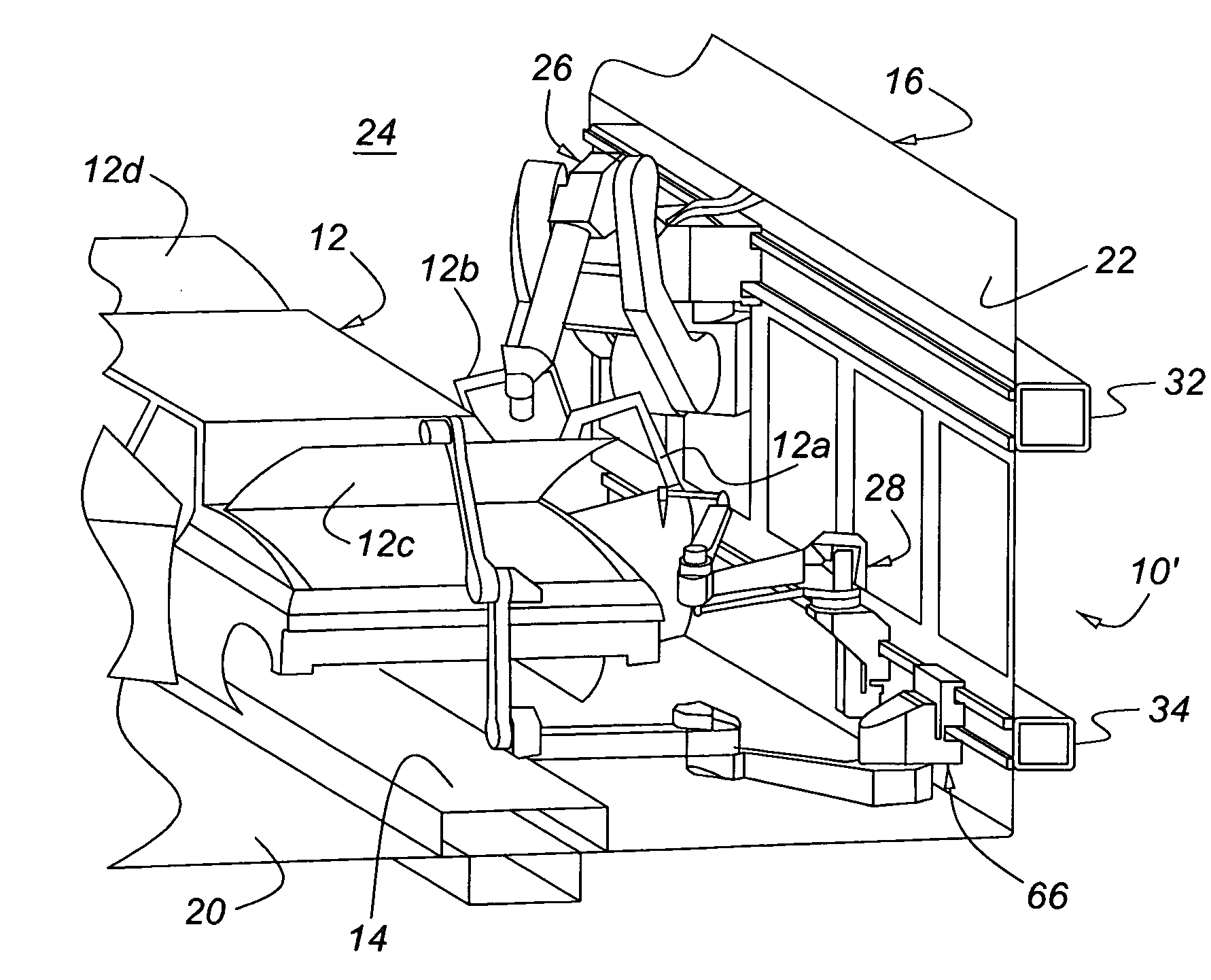

Compact robotic painting booth

ActiveUS7622158B2Minimize paint over-build-upShorten the lengthProgramme controlProgramme-controlled manipulatorPaint robotEngineering

A system for painting an article, such as an automotive vehicle body, includes a painting booth, a conveyor for transporting articles through the painting booth, a first rail located beside and extending along the conveyor, a second rail located beside and extending along the conveyor at a lower elevation than an elevation of the first rail, a paint robot including an articulating arm mounted on the first rail for displacement along the first rail, a panel opener robot mounted on the second rail for displacement along the second rail such that the paint robot and the panel opener robot can move past each other on the rails without interference.

Owner:FANUC ROBOTICS NORTH AMERICA

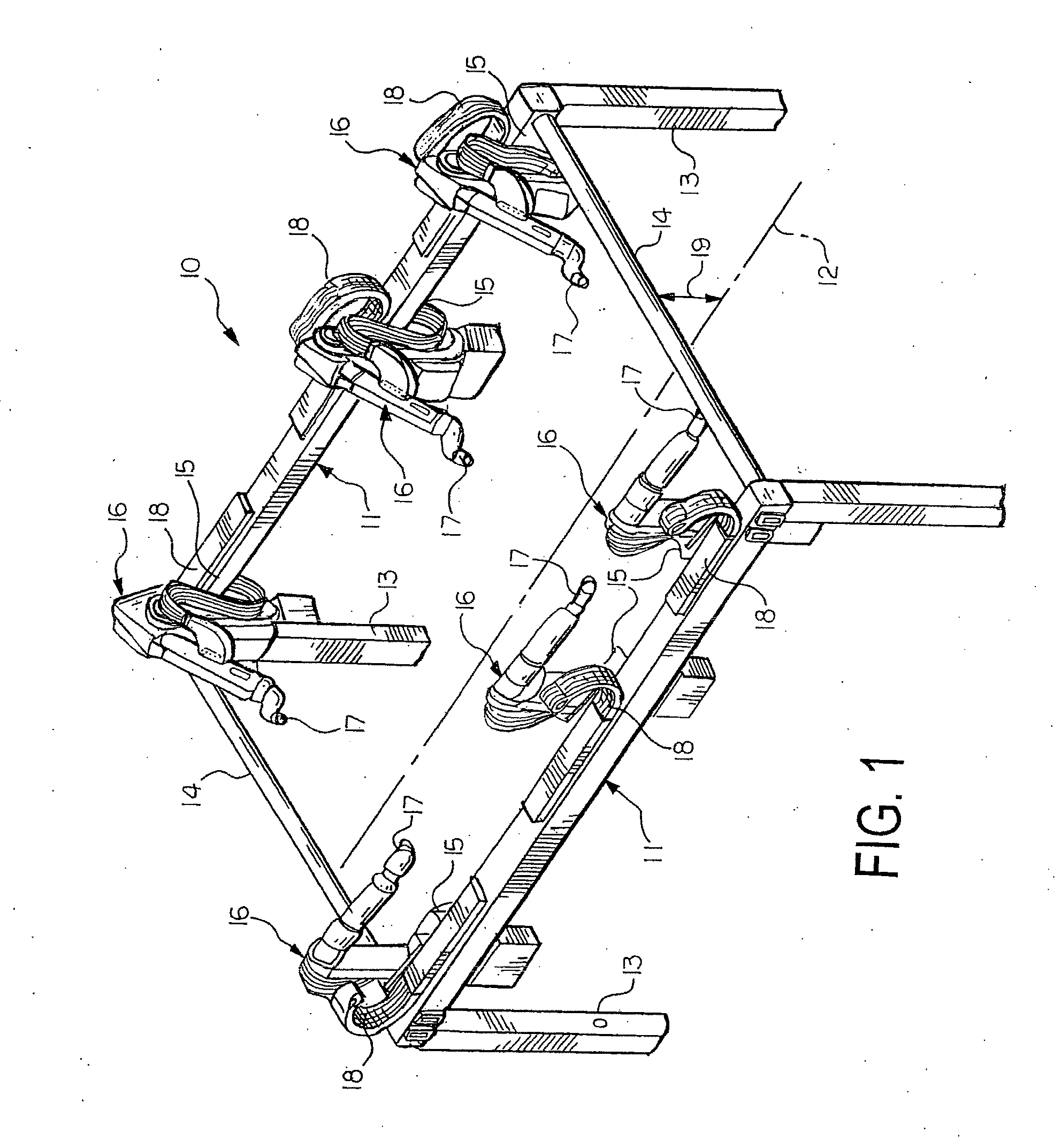

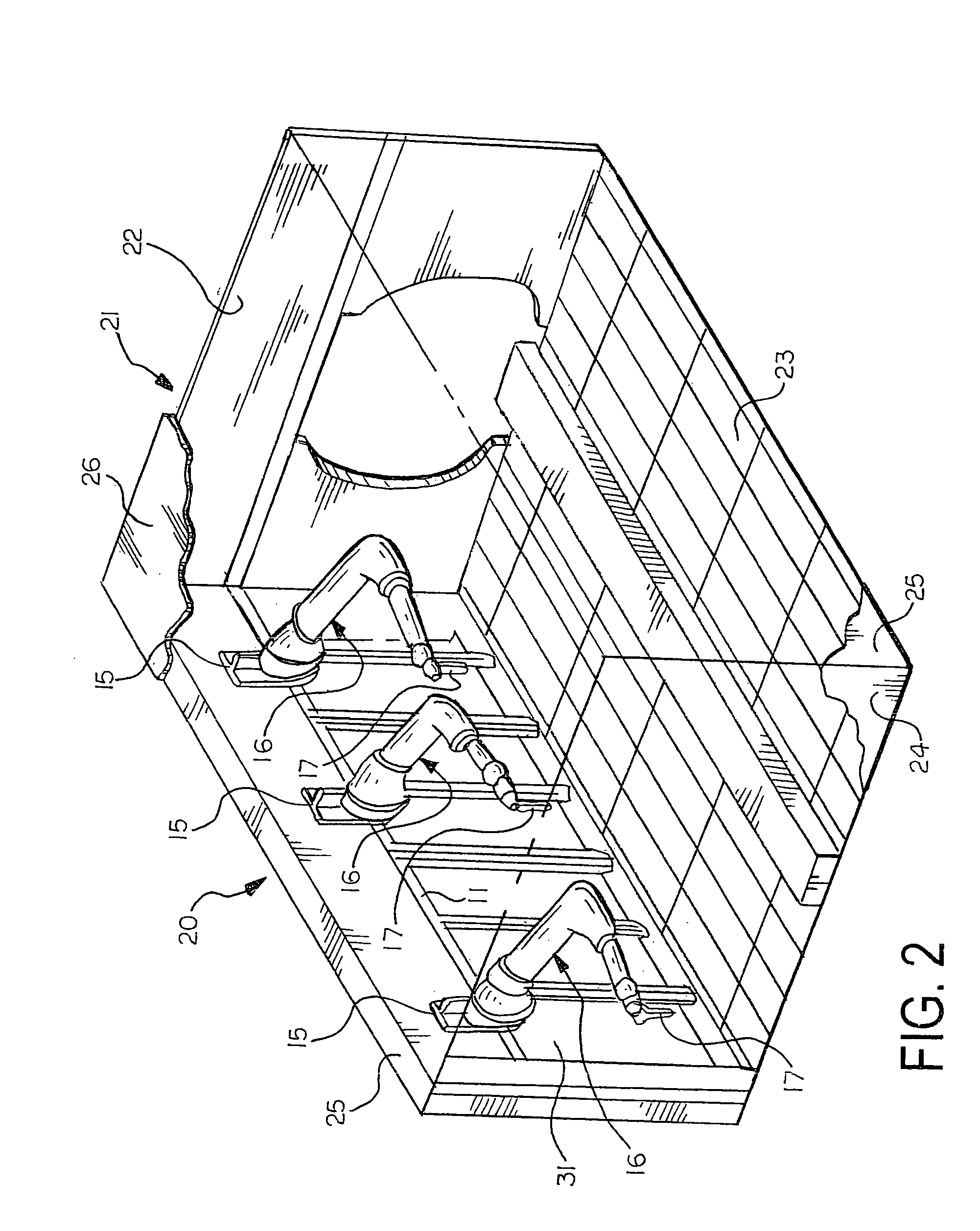

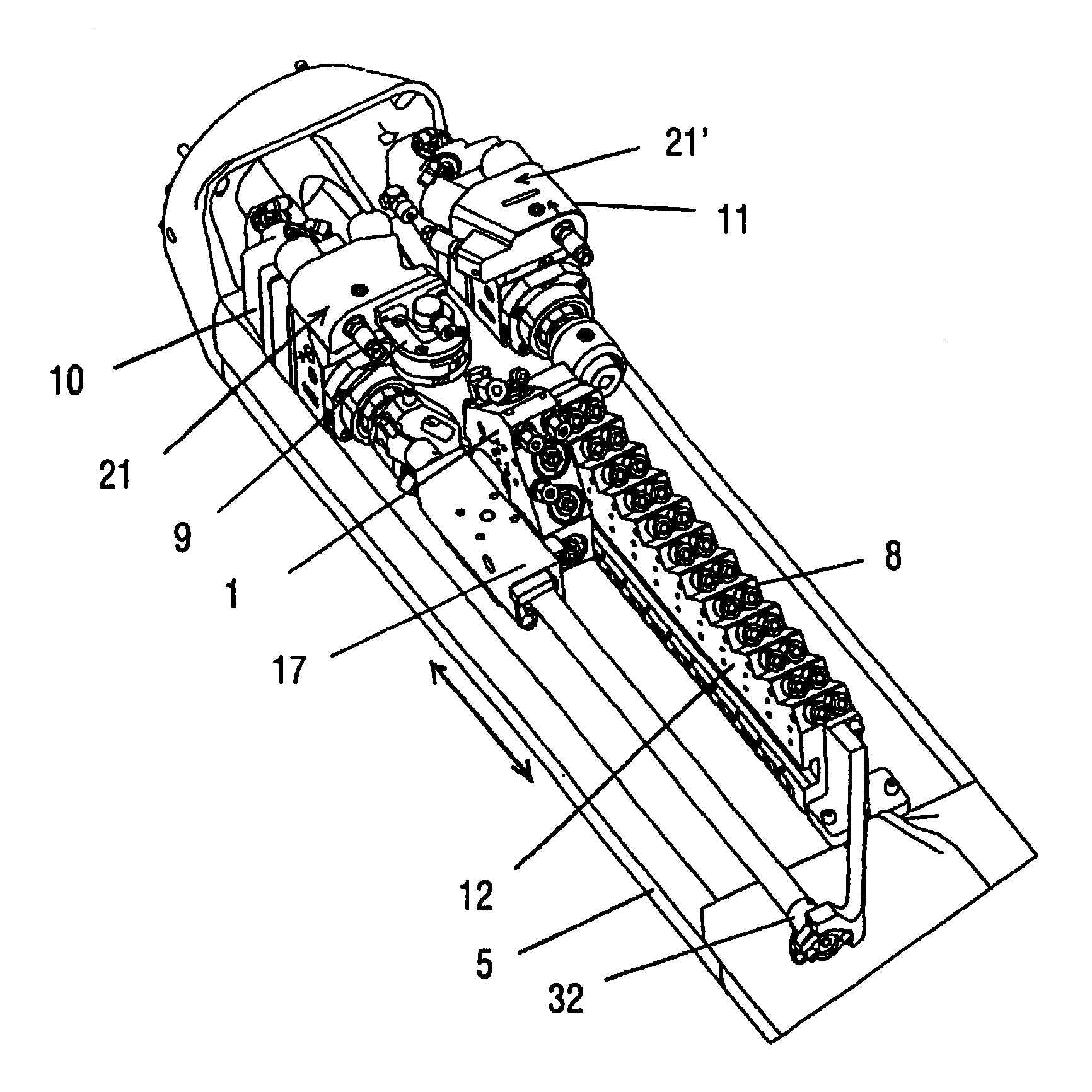

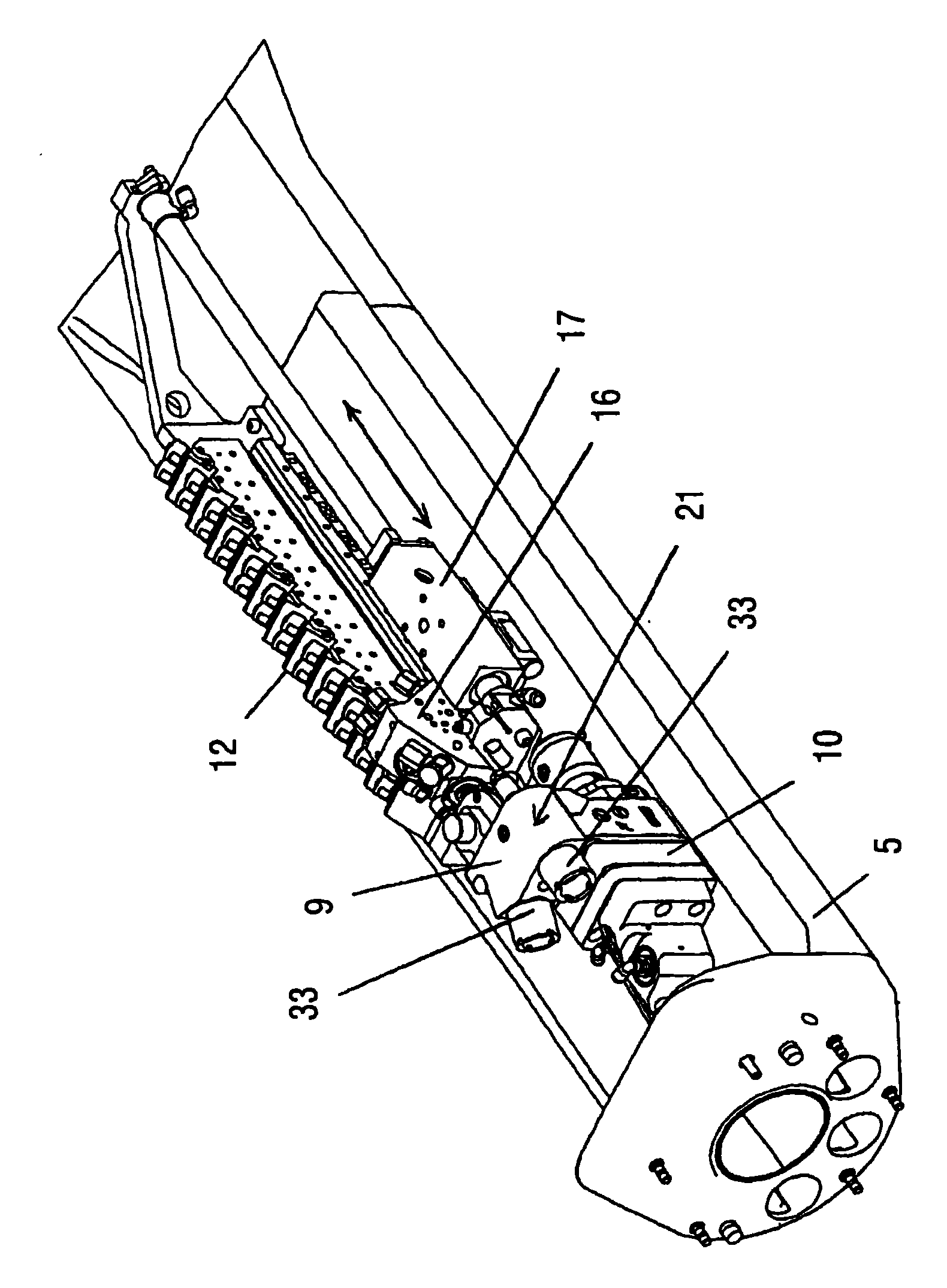

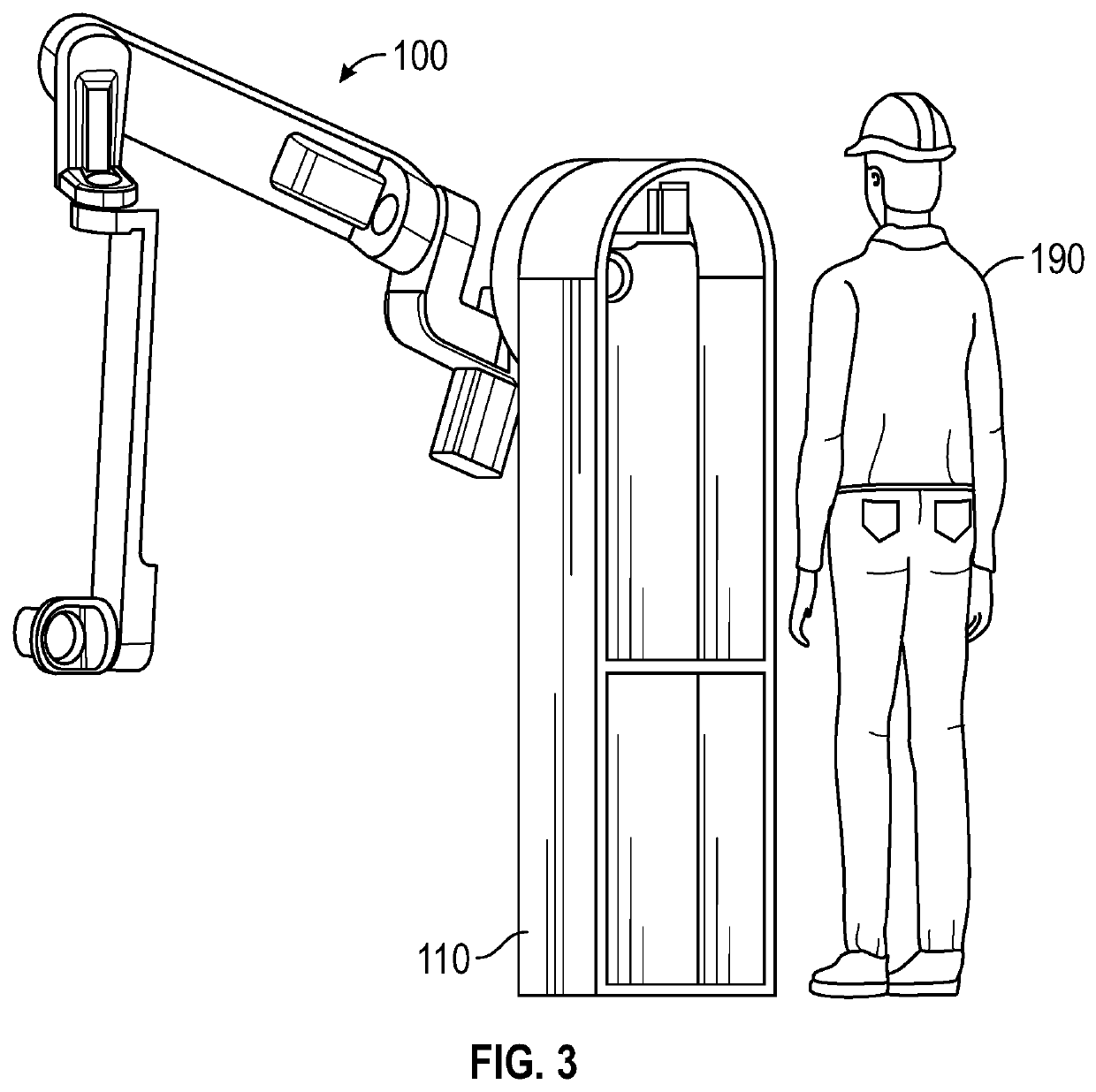

Robotic apparatus for a compact painting booth

ActiveUS20190337167A1Improved kinematicsMinimize paint wasteMovable spraying apparatusLiquid spraying apparatusRobot architectureElectrical conductor

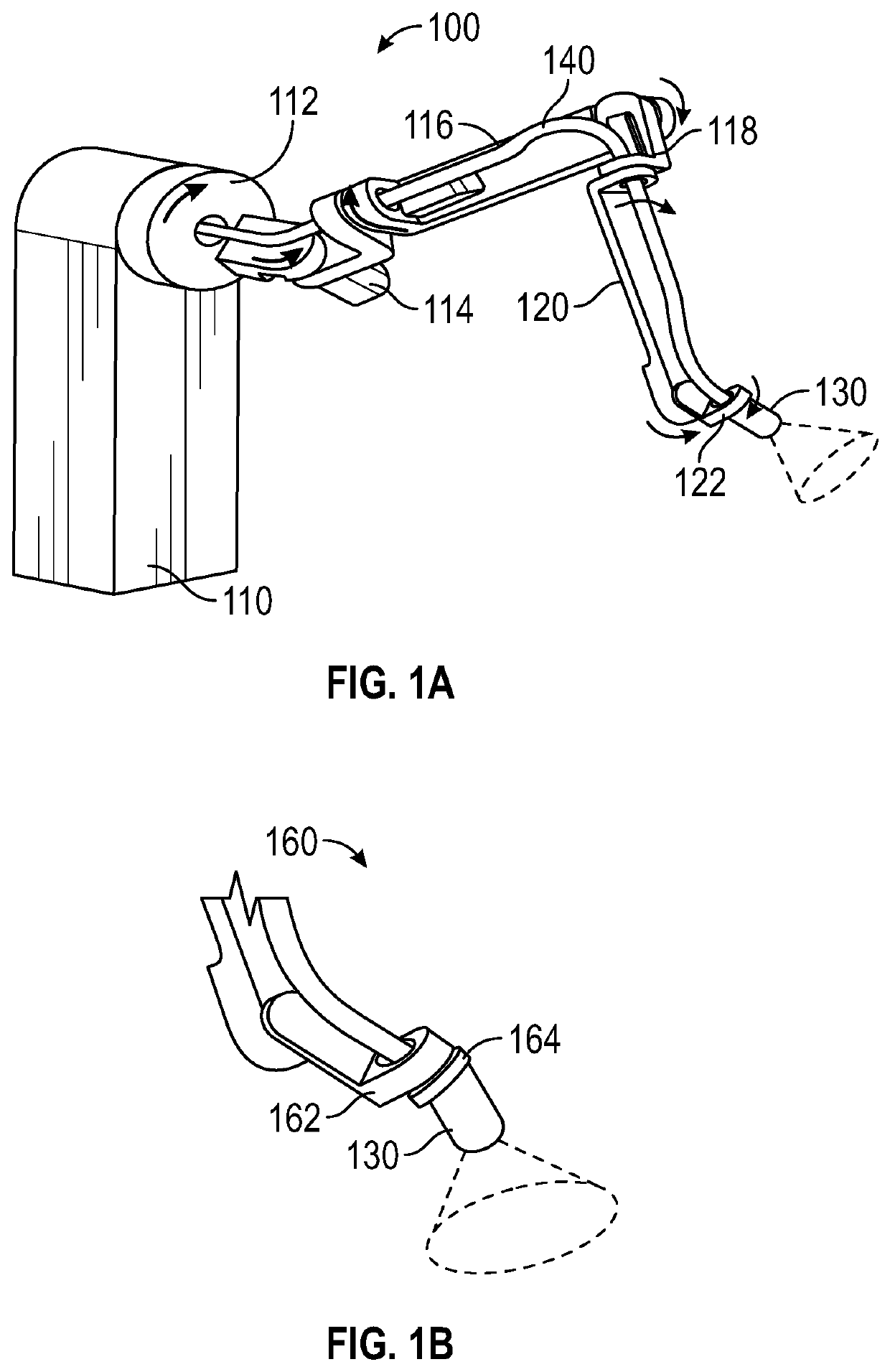

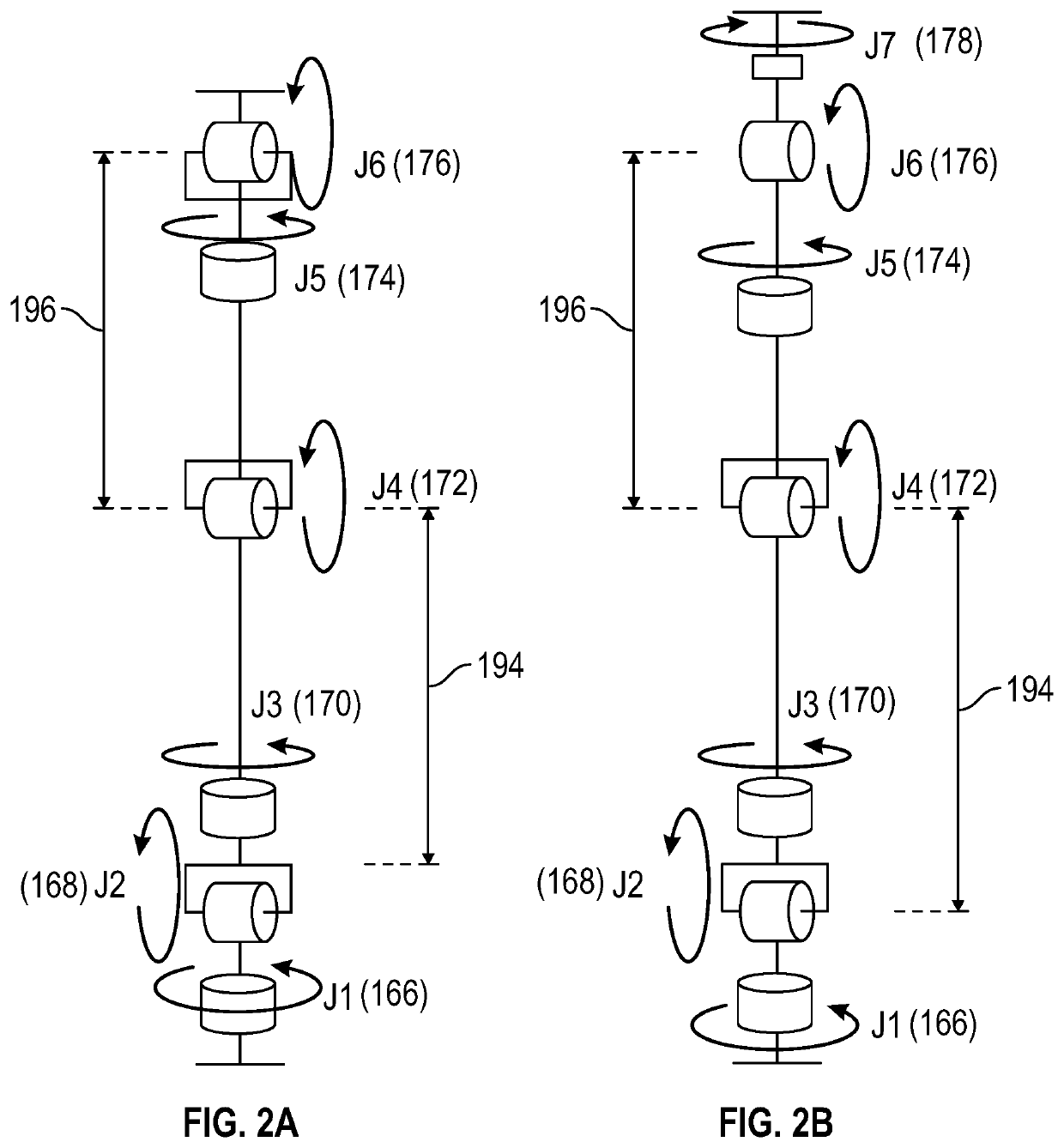

A next generation painting robot with advanced fluid delivery system, enhanced kinematics and a service airlock compartment. The painting robot includes a fluid delivery system which places color changing valves and pumping hardware on the back side of the robot's mounting pedestal, where it can be serviced without a technician having to enter the spray booth. The fluid delivery system also allows smaller and lighter robot arms, and is designed to minimize paint waste and wait time during color changes. The robot also features kinematics providing redundant inner arm rotation. The arm kinematics, along with the smaller arms, a paint supply line routed through the center of first and third arm joints, and optimized motor conductor routing, dramatically improve near reach flexibility. The improved near reach flexibility in turn allows a smaller spray booth than possible with previous robot architectures.

Owner:FANUC ROBOTICS NORTH AMERICA

Robot cover

InactiveUS20060141200A1Reduce material wasteEfficient layoutLayered productsSpraying apparatusPaint robotSpray nozzle

A cover for an automated paint robot having a paint nozzle includes a first side panel, a second side panel, and a front panel. The front panel has a first edge secured to the first side panel and a second edge secured to the second side panel. The front panel further includes a third edge that cooperates with the first and second side panels to define a generally cylindrical opening for accommodating the paint nozzle.

Owner:DANDRETA MARK

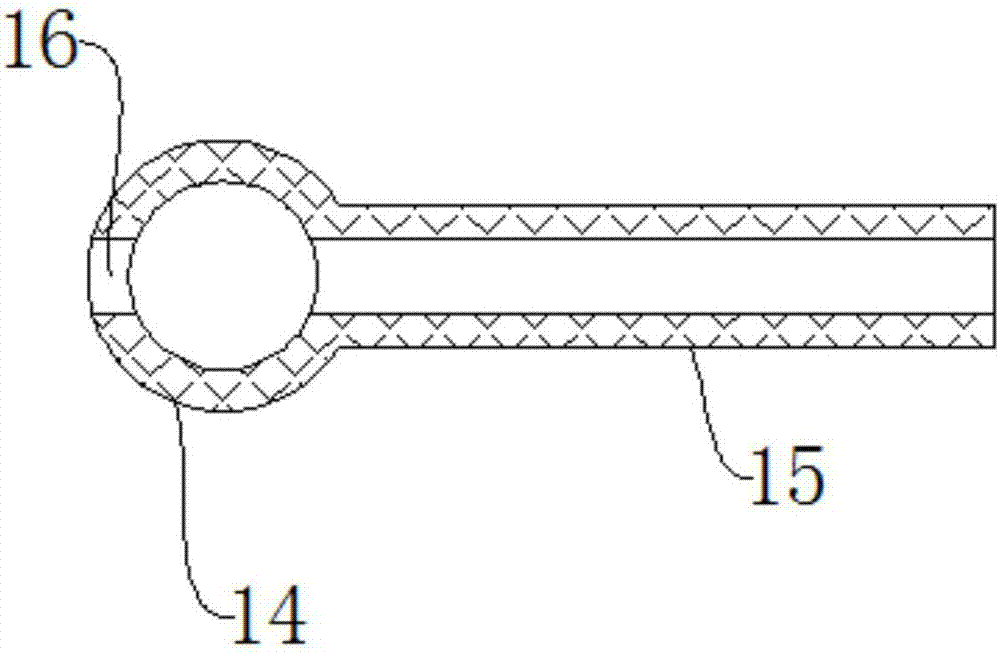

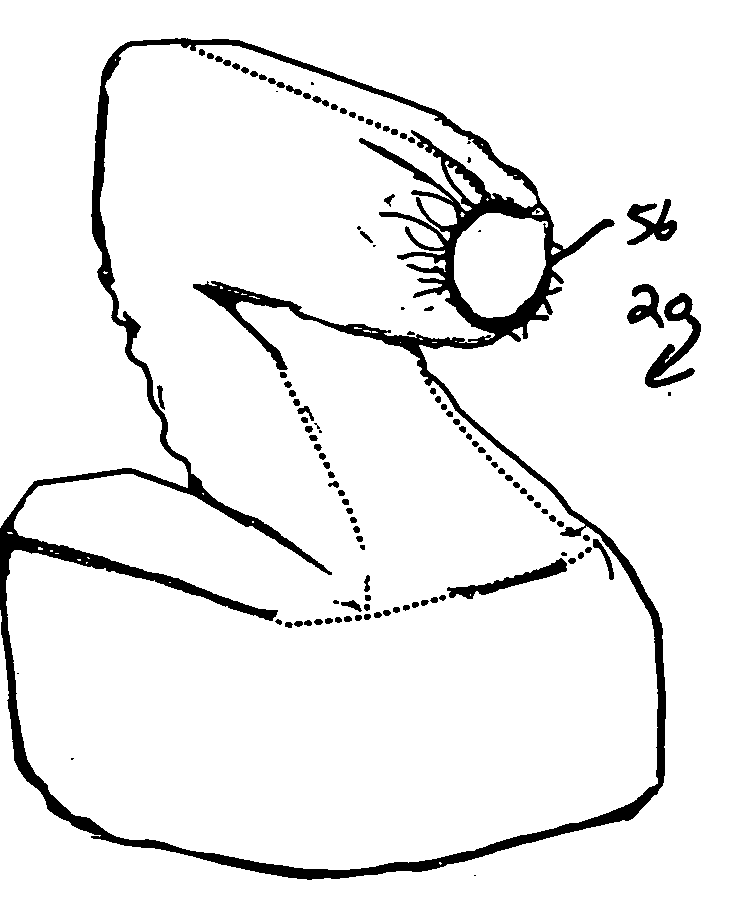

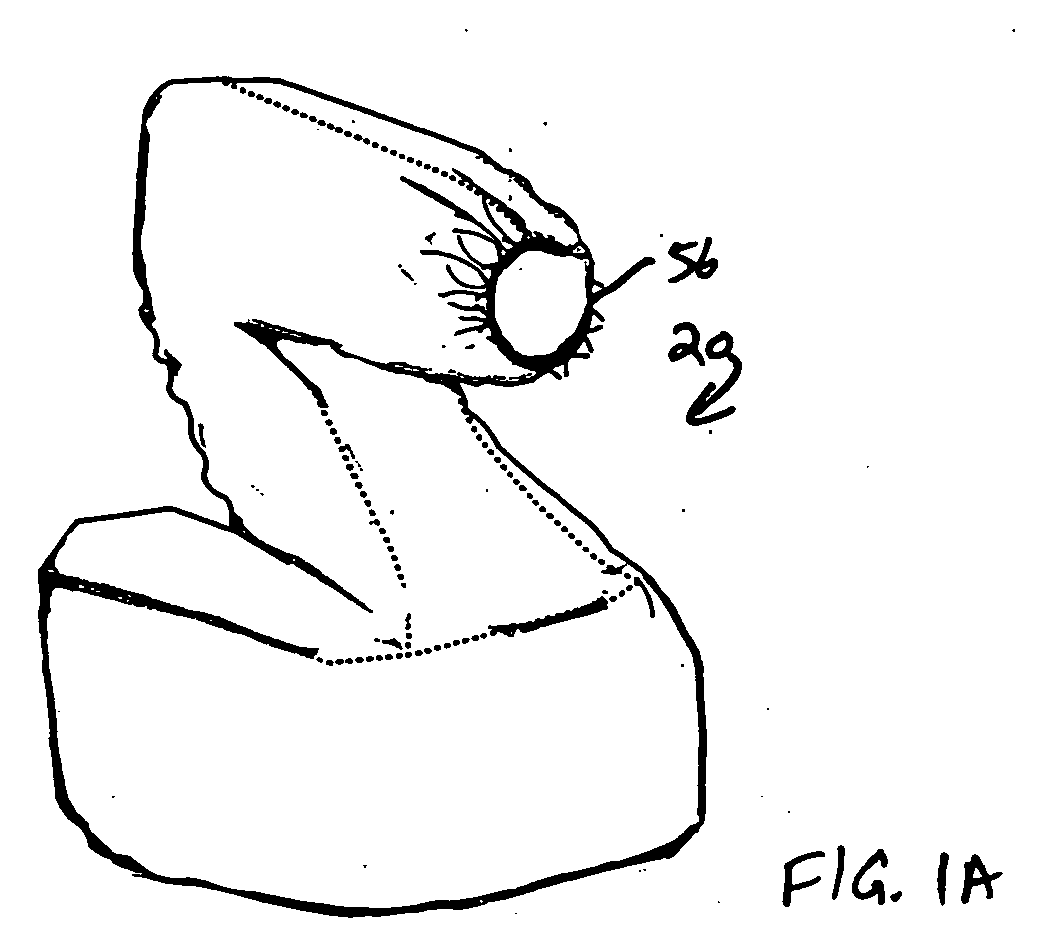

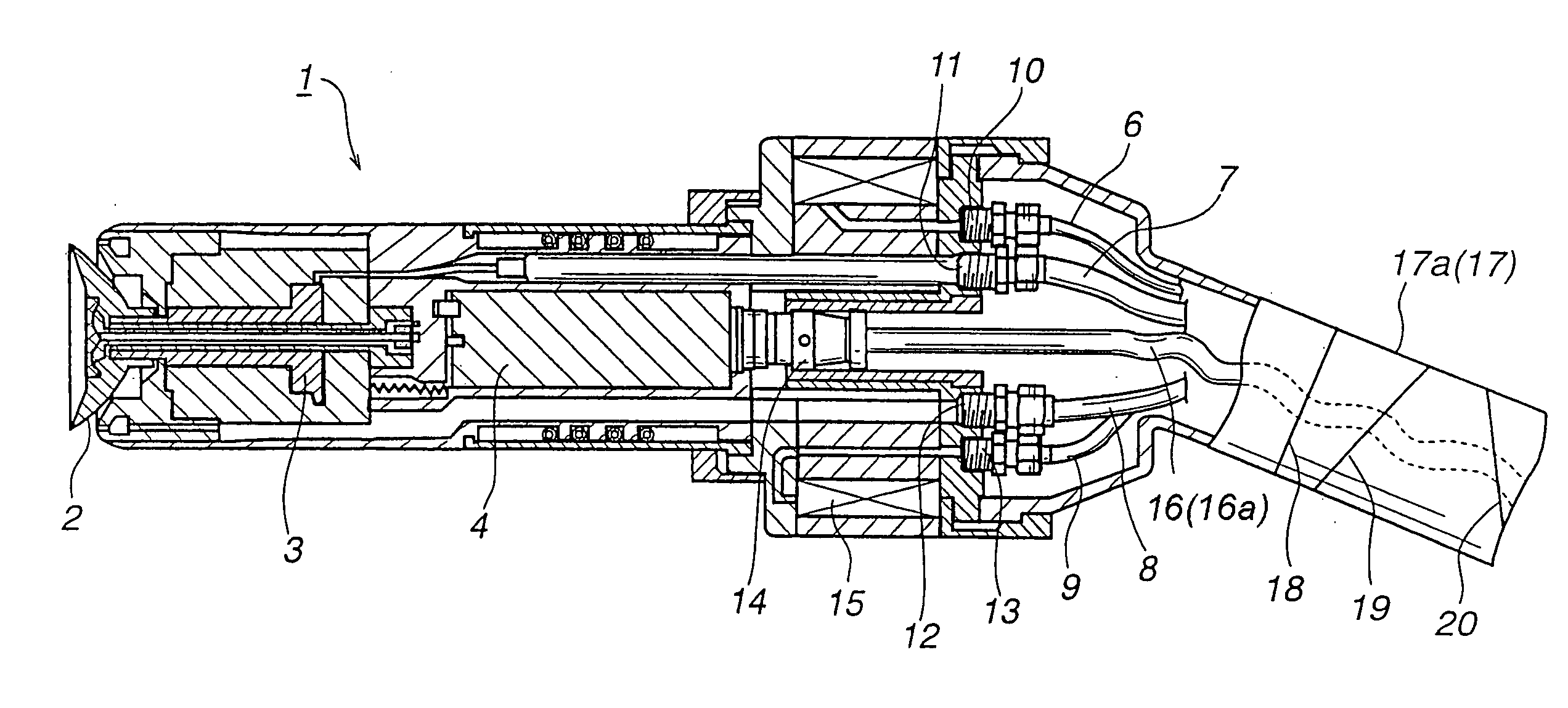

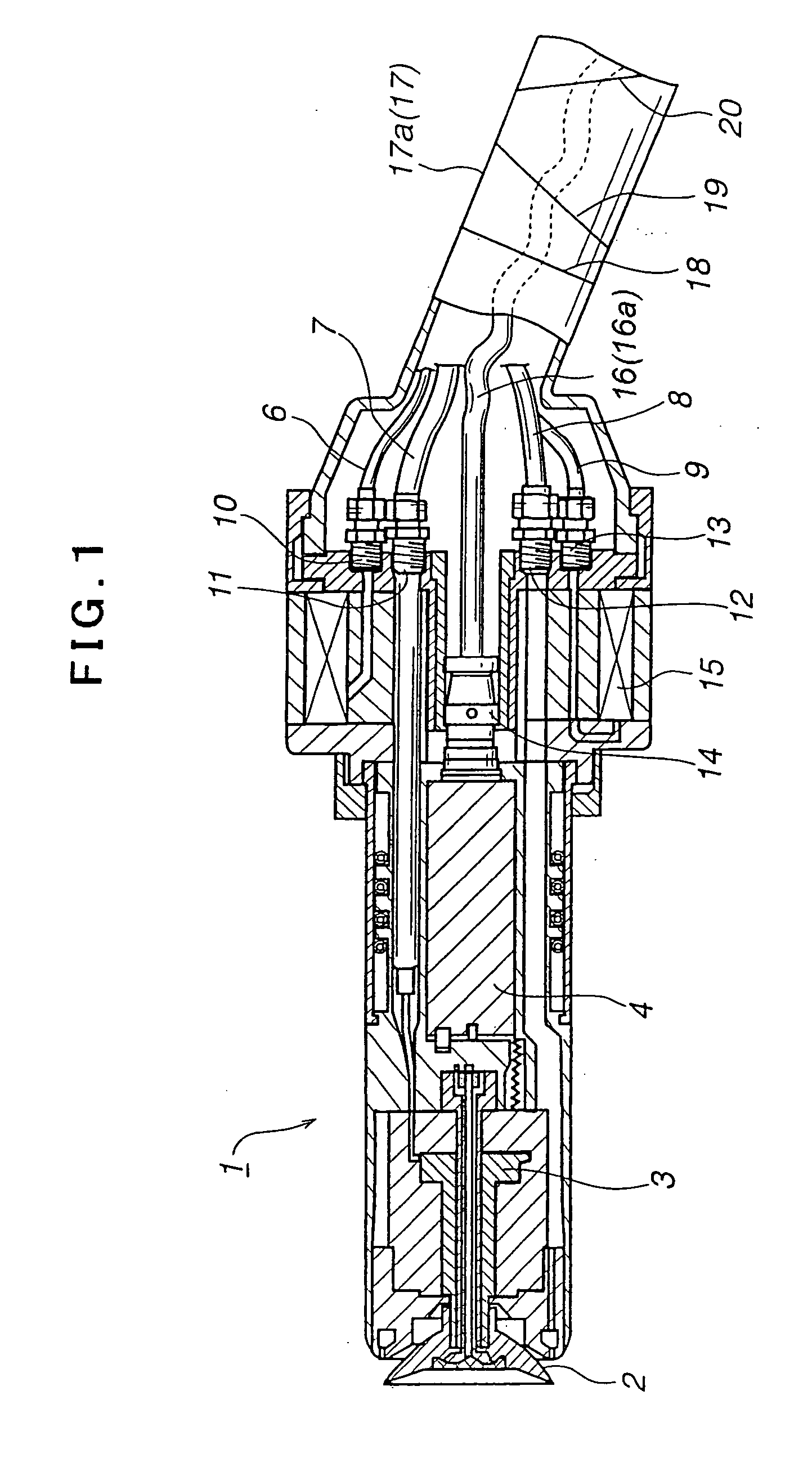

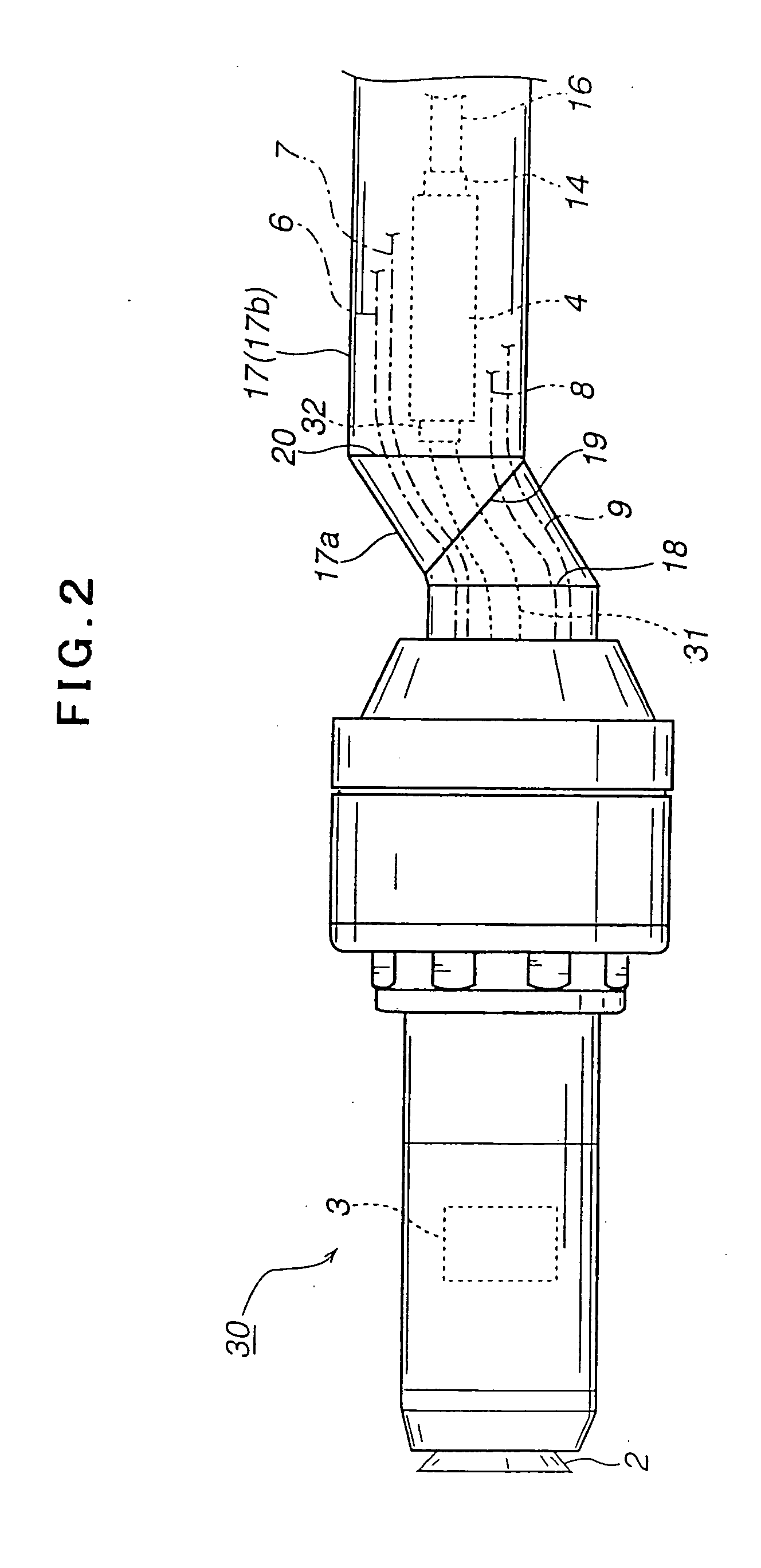

Electrostatic atomizer for a painting robot

InactiveUS20050194474A1Avoid breakingAvoid it happening againBurnersSpraying power supplyPaint robotLow voltage

An electrostatic atomizer (1) is attached to the distal end of an arm (17) of a painting robot to change the direction of paint sprayed from it, following to movements of a wrist portion (17a) of the arm (17). The electrostatic atomizer 1 includes a high voltage generator (4) that is supplied with electric power via a low voltage cable (16) extending through the arm (17). The low voltage cable (16) has an elastically shaped portion (16a) at least as a part thereof. The elastically shaped portion (16a) absorbs torsional or tensile force produced in the low voltage cable (16) under rotations of the wrist portion (17a) of the arm (17) and thereby prevents breakage of wires in the low voltage cable (16).

Owner:RANSBURG IND FINISHING

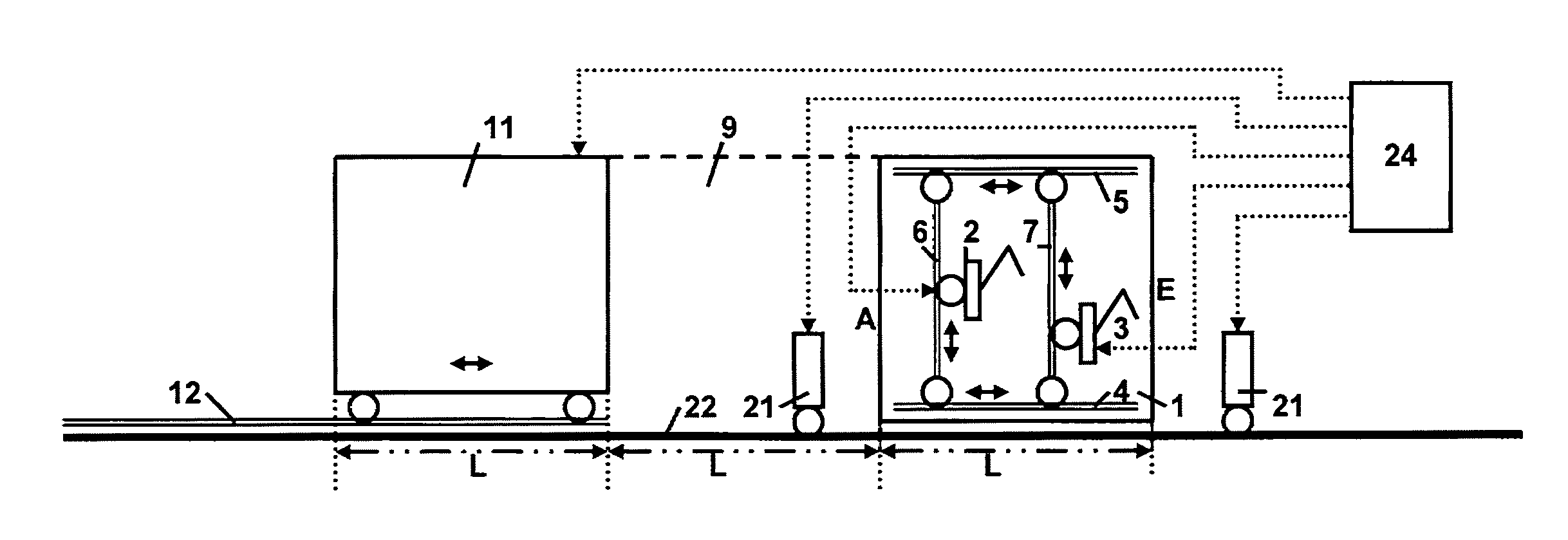

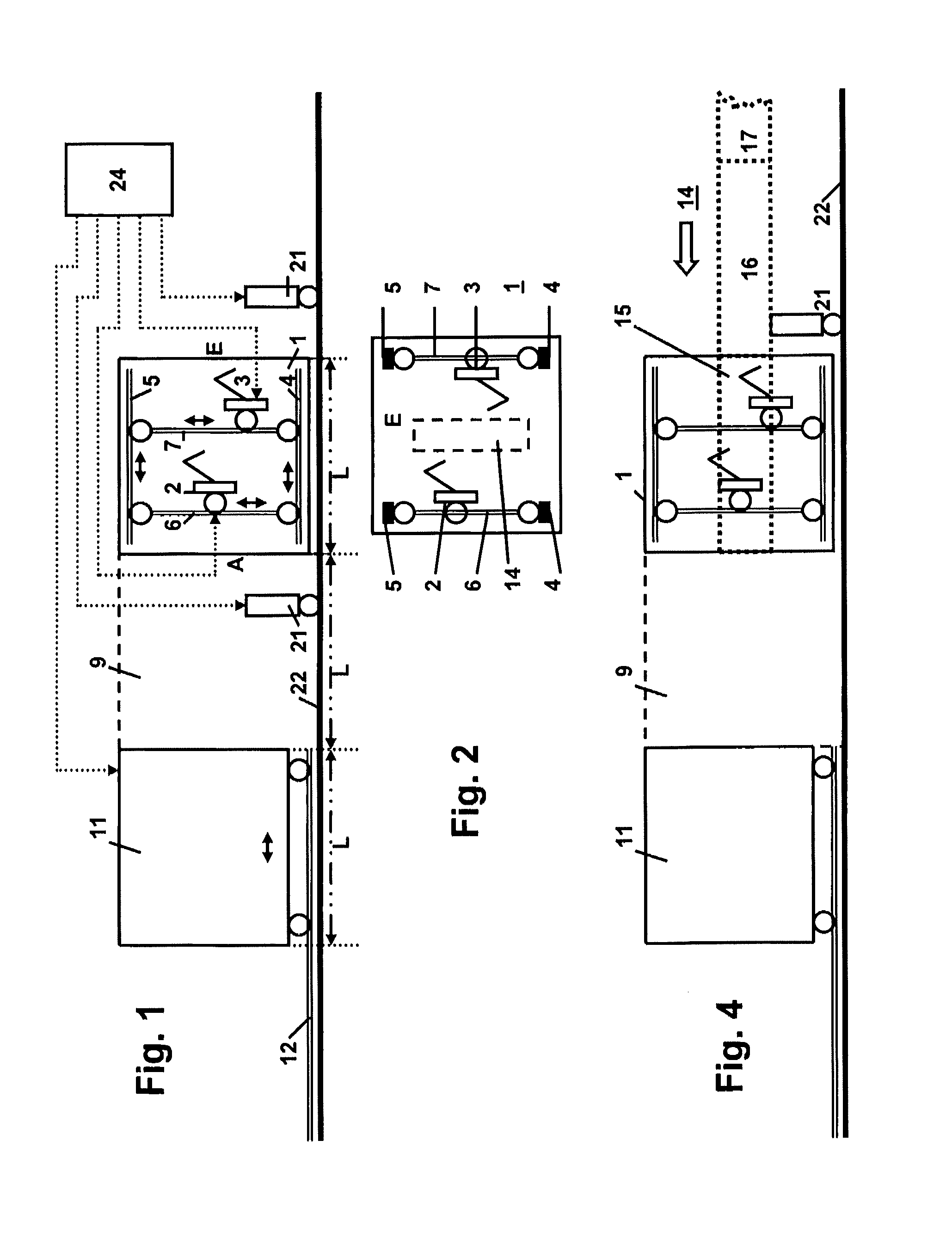

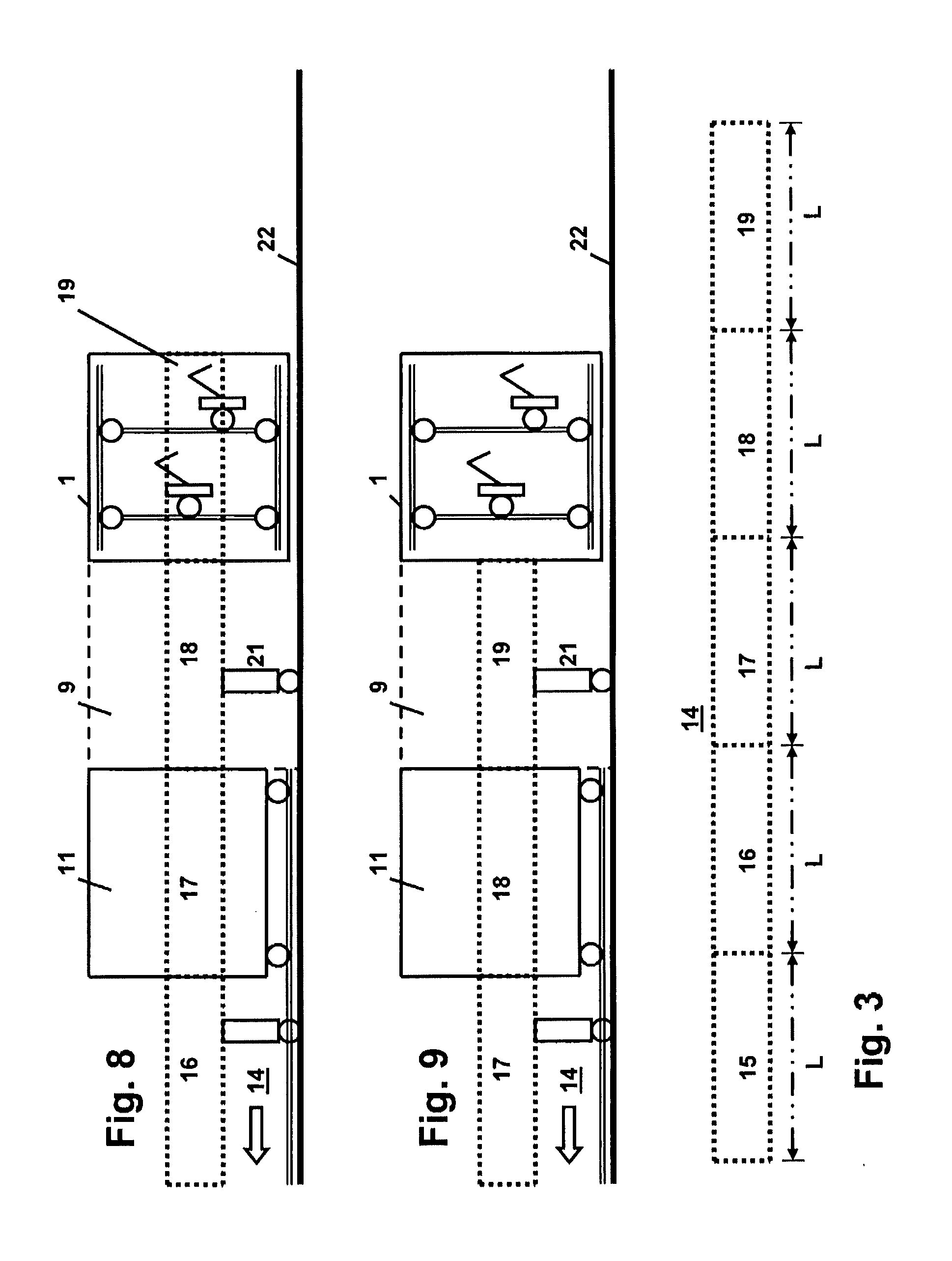

Painting installation for coating or painting an elongated workpiece

InactiveUS20130095248A1Drying solid materials with heatPretreated surfacesPaint robotMechanical engineering

A painting installation for coating (e.g., painting) a workpiece, such as an elongated workpiece is disclosed. The installation and / or workpiece can be subdivided into a number of segments of a predetermined length. The painting installation can have three zones arranged next to one another and demarcated from one another. A stationary painting cubicle which has at least one painting robot, an adjoining flashing-off zone and an adjoining dryer, each being at least of the length L. The installation can also include at least one holder for transporting the workpiece along a running rail such that the individual segments successively run step by step through the individual zones.

Owner:ABB (SCHWEIZ) AG

Automatic paint spraying robot

The invention discloses an automatic paint spraying robot which comprises walking mechanisms, a square plate, lead screw mechanisms, a grinding mechanism, a blowing mechanism, a paint spraying mechanism, a drying mechanism, a clamping mechanism, a bottom plate, a rotary disc and a first supporting column. The walking mechanisms are mounted on the two sides of the bottom plate. The lead screw mechanisms are fixedly mounted on the four sides of the upper end face of a square plate. The grinding mechanism, the blowing mechanism, the paint spraying mechanism and the drying mechanism are all mounted on the lead screw mechanisms. The clamping mechanism is mounted at the front end of the bottom plate. According to the automatic paint spraying robot, a metal plate can be polished through the grinding mechanism on the lead screw mechanisms, and air can be blown to the polished metal through the blowing mechanism on the lead screw mechanisms; paint can be sprayed to the metal through the paint spraying mechanism on the lead screw mechanisms; the paint can be dried through the drying mechanism on the lead screw mechanisms; a metal workpiece can be clamped through the clamping mechanisms; andmultiple paint boxes are arranged and can contain paint in different colors.

Owner:陕西亿青诚环保科技有限公司

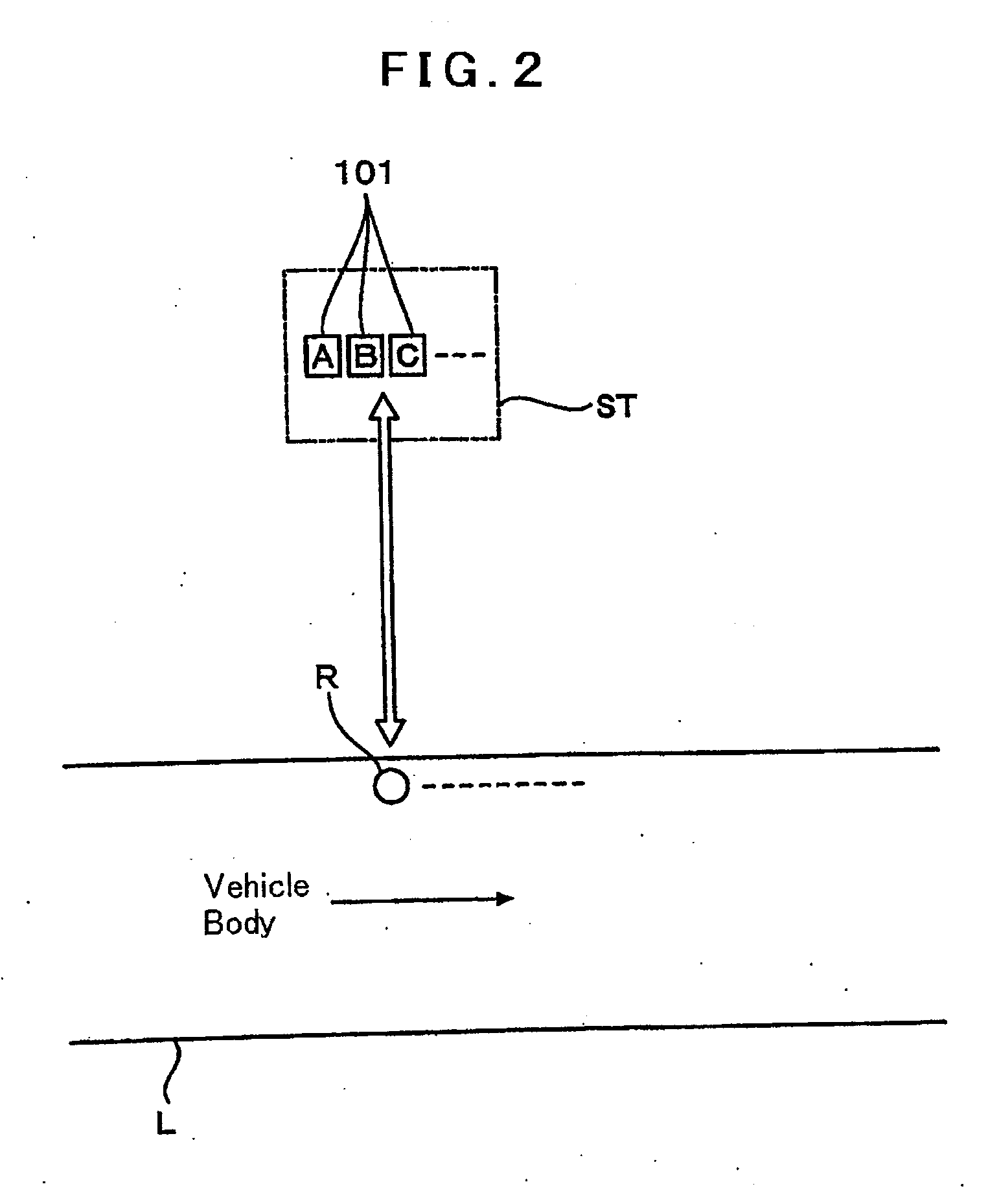

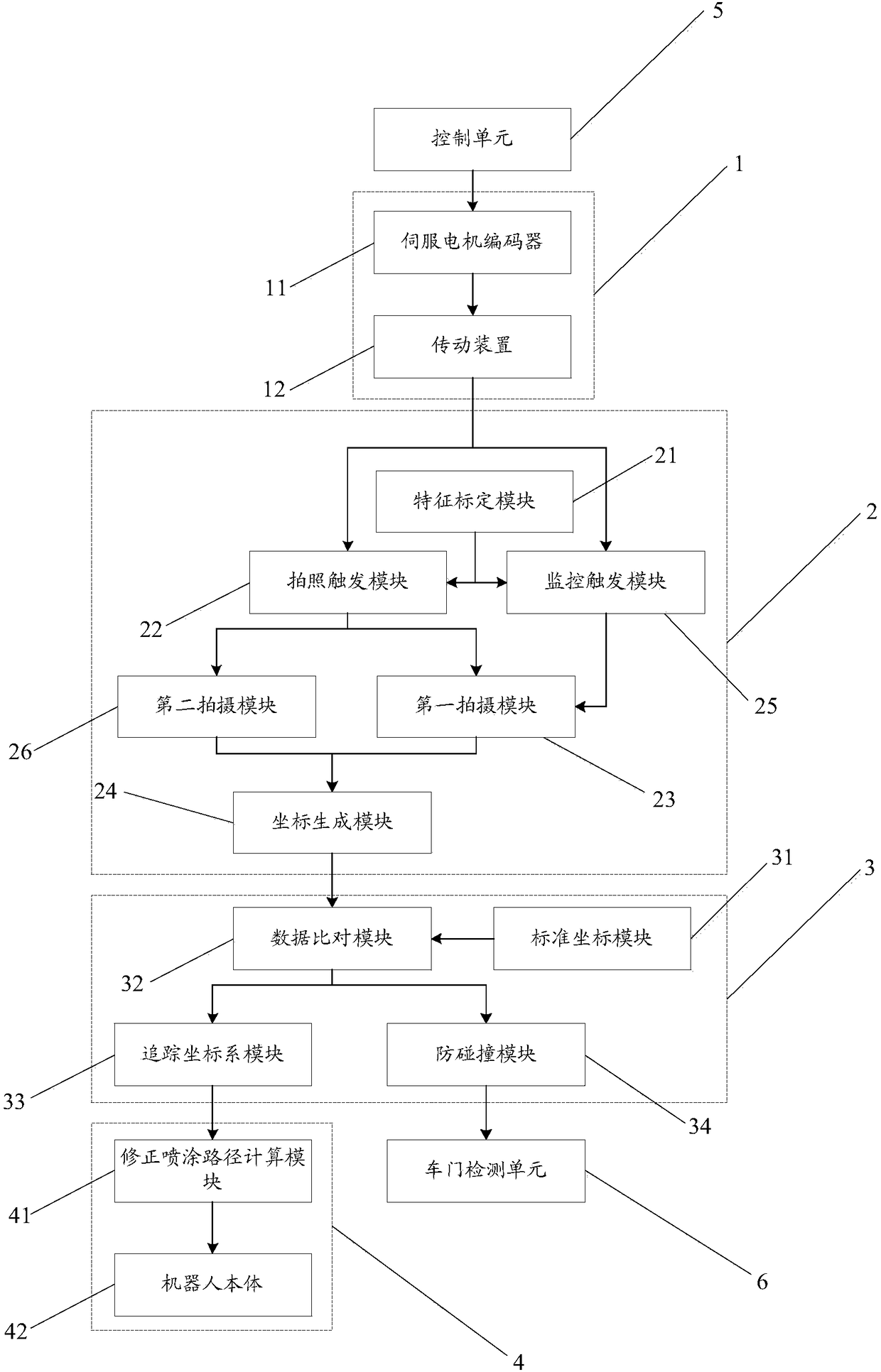

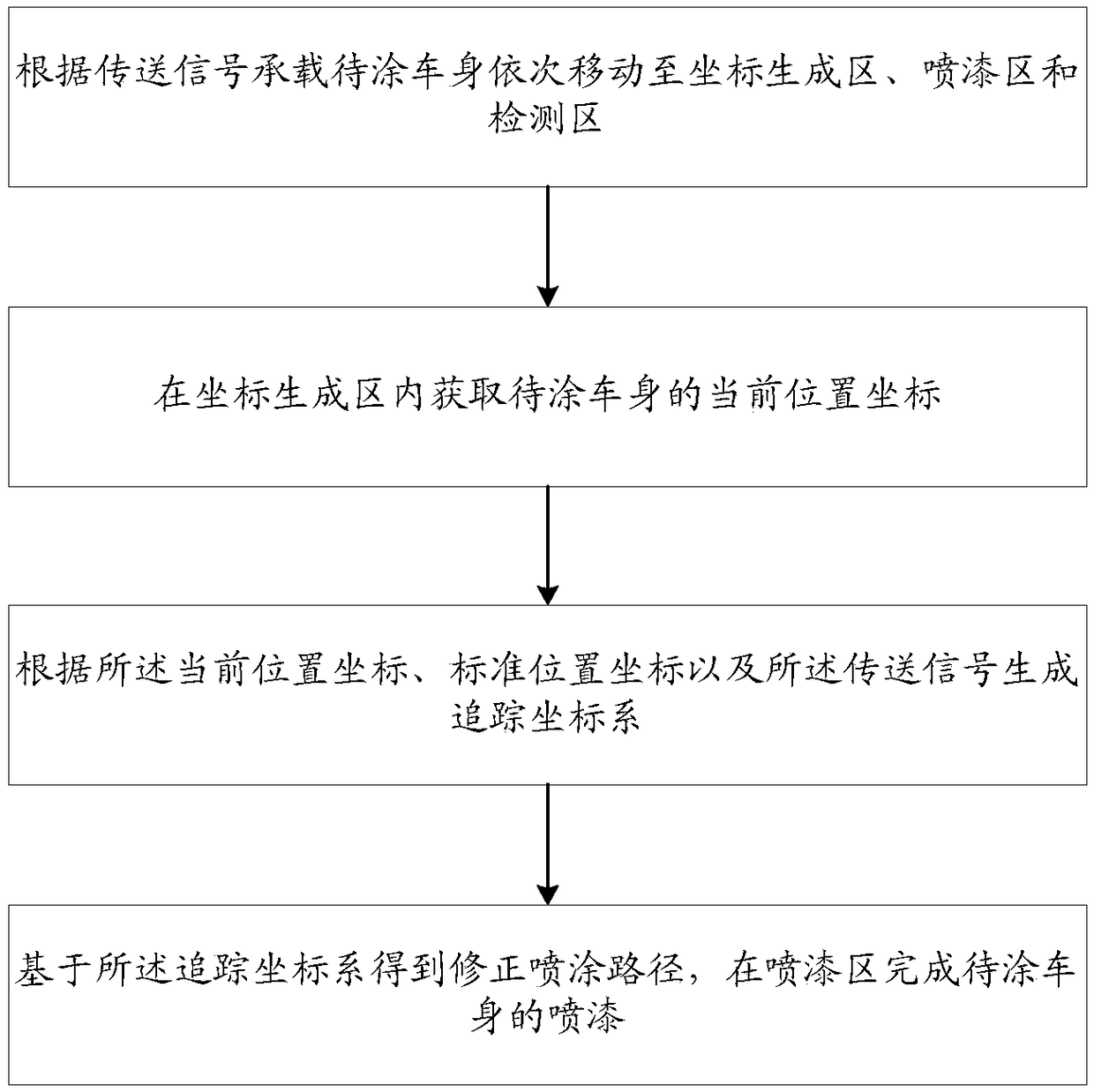

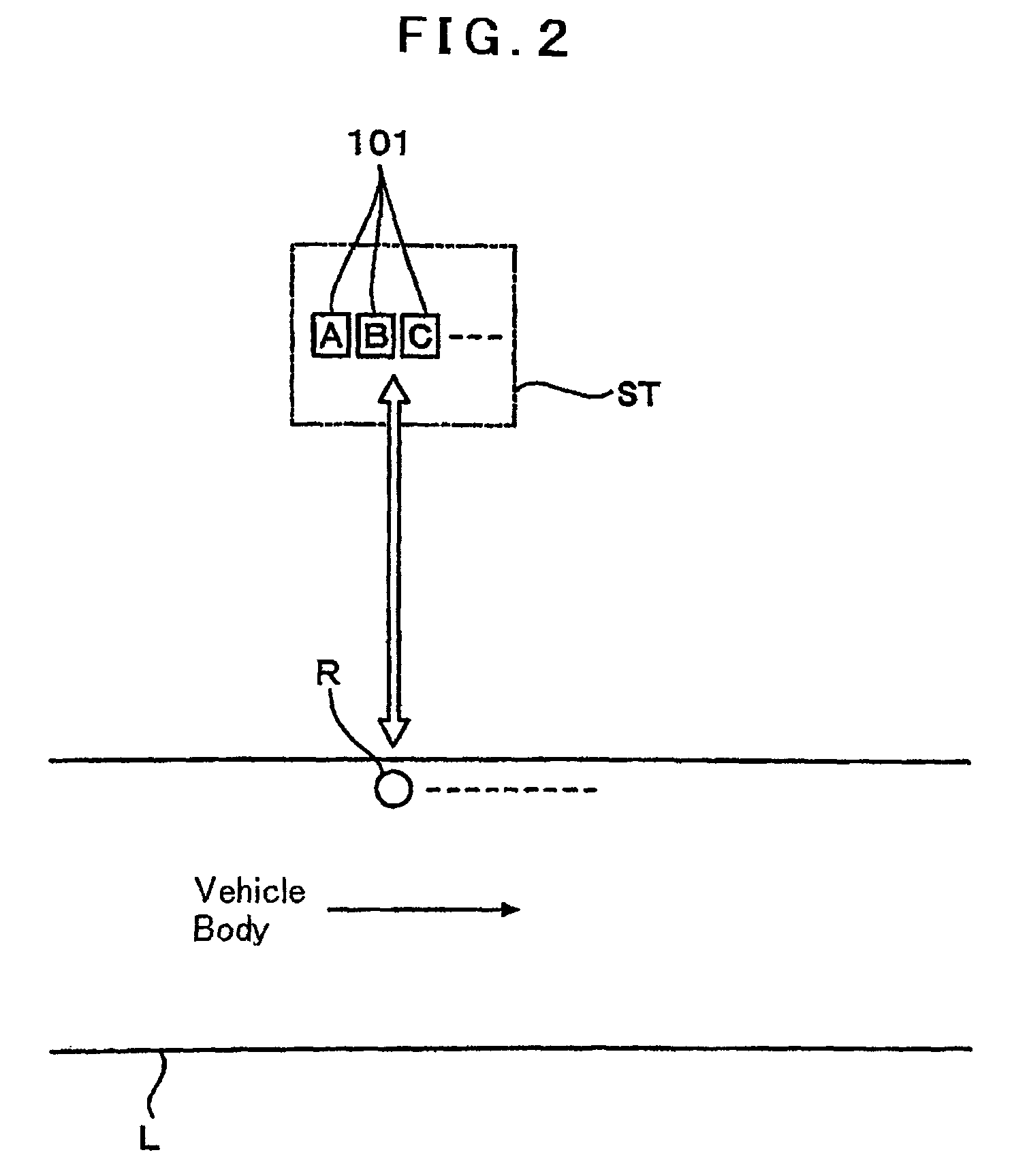

Vehicle body paint spraying system and method

PendingCN108297097AGuaranteed stabilityAvoid quality problems such as less paint saggingProgramme-controlled manipulatorManufacturing technologyPaint robot

The invention discloses a vehicle body paint spraying system and method, relates to the technical field of vehicle manufacturing and aims at solving the quality problem that less paint, sagging and the like on vehicle body paint finish caused by offset of the position of a vehicle body to be painted in the vehicle body paint spraying process in the prior art. The system comprises a vehicle body transferring unit, a vision sensing unit, a calculation unit and a paint spraying robot which are sequentially connected with one another; the vehicle body transferring unit is used for bearing the vehicle body to be painted to sequentially move to a coordinate generation region, a paint spraying region and a detection region according to a transferring signal; the vision sensing unit is used for acquiring a current position coordinate of the vehicle body to be painted in the coordinate generation region; the calculation unit is used for generating a track coordinate system according to the current position coordinate, a standard position coordinate and the transferring signal; and paint spraying robot obtains a corrected spraying path based on the track coordinate system and finishes paintspraying of the vehicle body to be painted in the paint spraying region. The vehicle body paint spraying system provided by the invention is used for a vehicle paint spraying booth.

Owner:FAW VOLKSWAGEN AUTOMOTIVE CO LTD

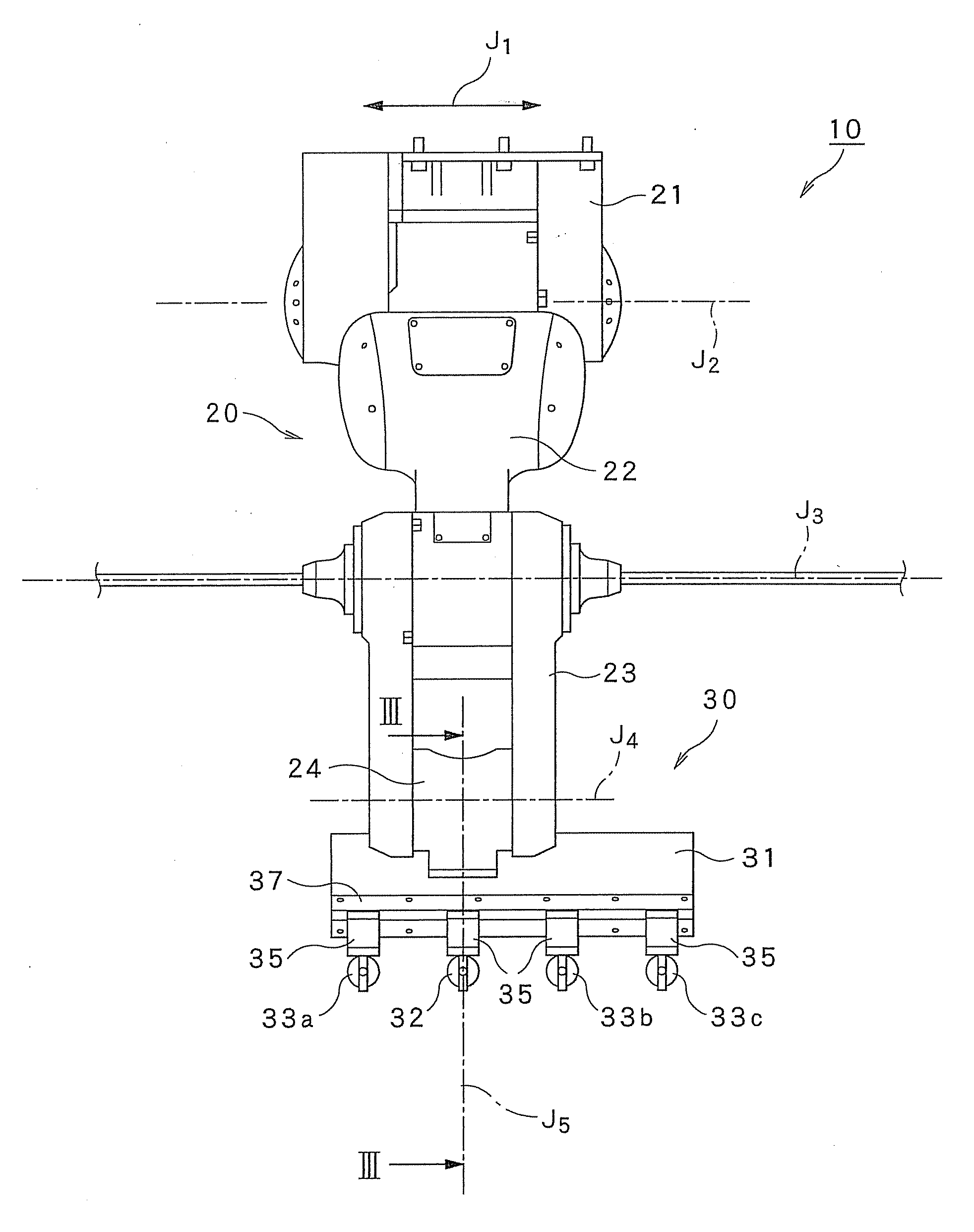

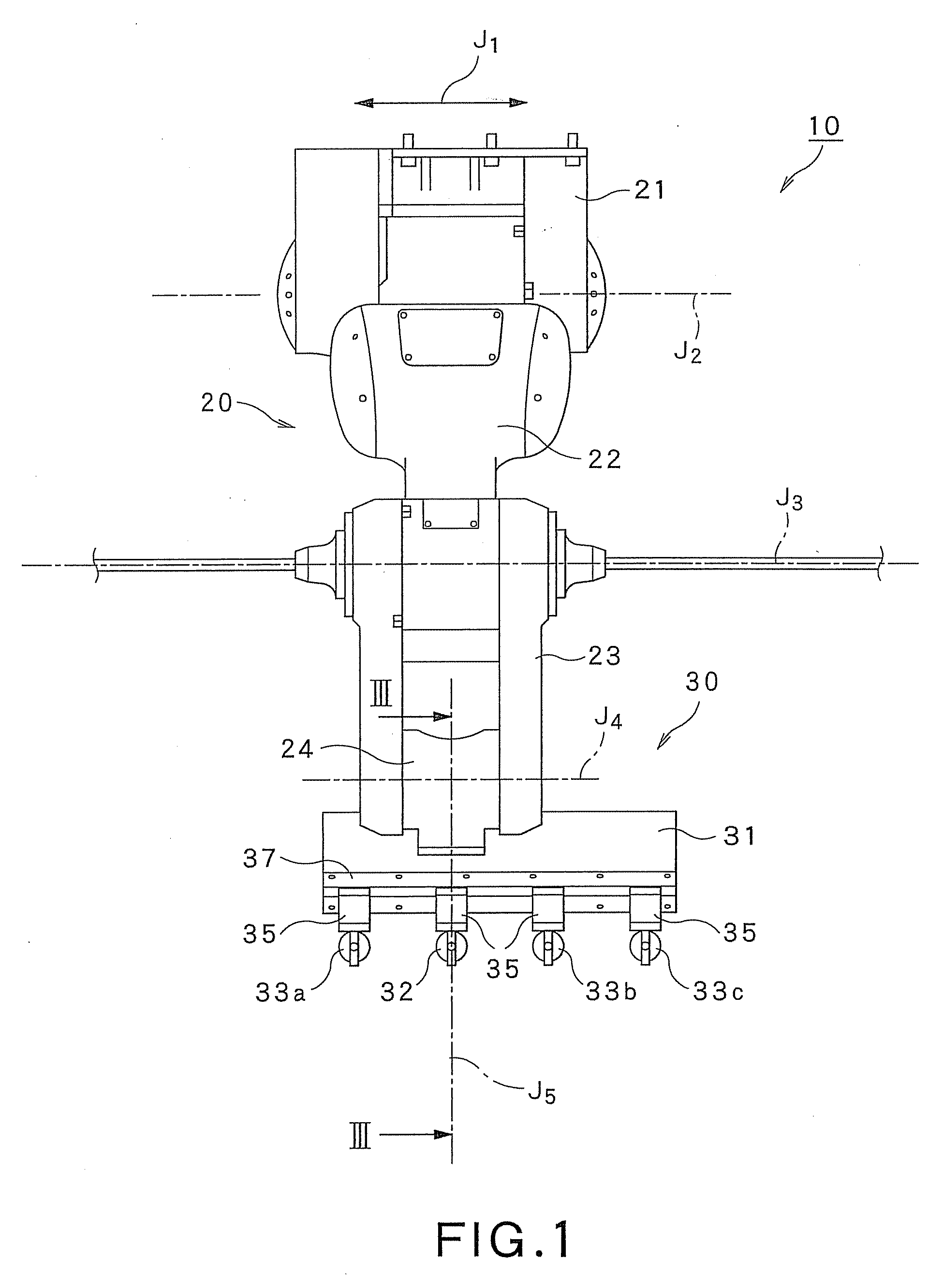

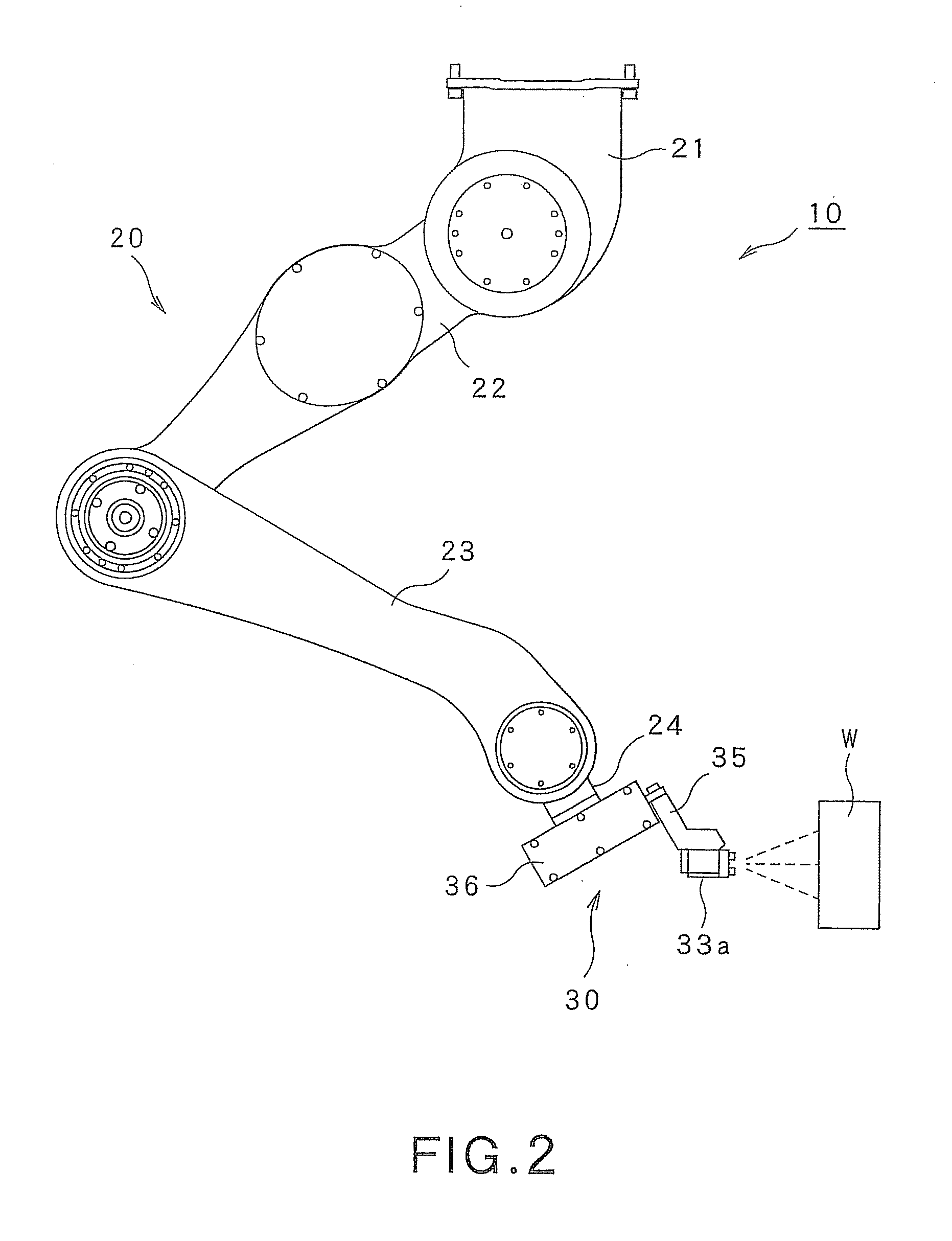

Painting robot system and spray gun unit

ActiveUS20130134236A1Cost involvedShorten the timeLiquid surface applicatorsGripping headsDrive shaftPaint robot

A painting robot system includes a robot and a spray gun unit. The robot includes a plurality of robot arms and a drive shaft member disposed on a distal end robot arm of the multiple robot arms, the drive shaft member being rotatable about a distal end drive axis. The spray gun unit is mounted on the robot arm. The spray gun unit includes a support member fixed to the distal end robot arm, guide members disposed on the support member, a plurality of spray guns disposed on the support member, and a linkage mechanism connecting between the movable spray guns and the drive shaft member. A spacing between at least one pair of adjacent spray guns can be varied via the linkage mechanism by rotating the drive shaft member of the robot.

Owner:TOSHIBA MASCH CO LTD

Three-dimensional non-rigid point cloud registration method based on consistent point shift algorithm

ActiveCN107133978AImprove registration accuracyGuaranteed strong robustnessImage enhancementImage analysisPoint cloudPaint robot

The invention discloses a three-dimensional non-rigid point cloud registration method based on a consistent point shift algorithm, which relates to a spray painting robot position registration method based on point cloud registration and aims at solving defects of low registration precision, poor robustness and long calculation time existing in the present three-dimensional point cloud non-rigid registration algorithm in conditions of large point cloud data amount, complex deformation, noise, outliers and missing point influences. The method particularly comprises steps: 1, an image acquisition device in the spray painting robot is used for scanning an object waiting for spray painting, and a group of three-dimensional point cloud data is obtained as a to-be-registered point cloud; 2, the obtained point cloud data serve as a reference point set; 3, the covariance sigma between the reference point set and the existing template point set is calculated, and related parameters of the consistent point shift algorithm are initialized; 4, a Gauss kernel matrix is constructed; 5, the final registered result point set is obtained, and according to the final registered result point set, spray painting work is carried out on the object waiting for spray painting. The method of the invention is used for spray painting robot position registration.

Owner:哈尔滨工业大学人工智能研究院有限公司

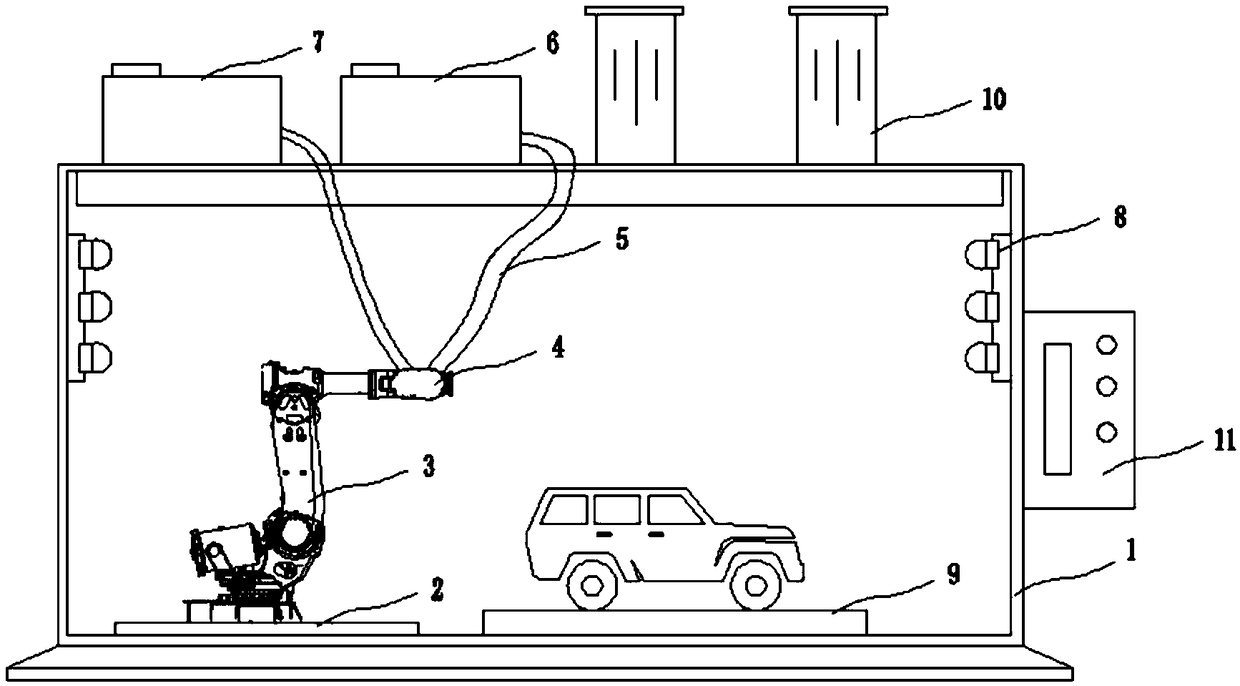

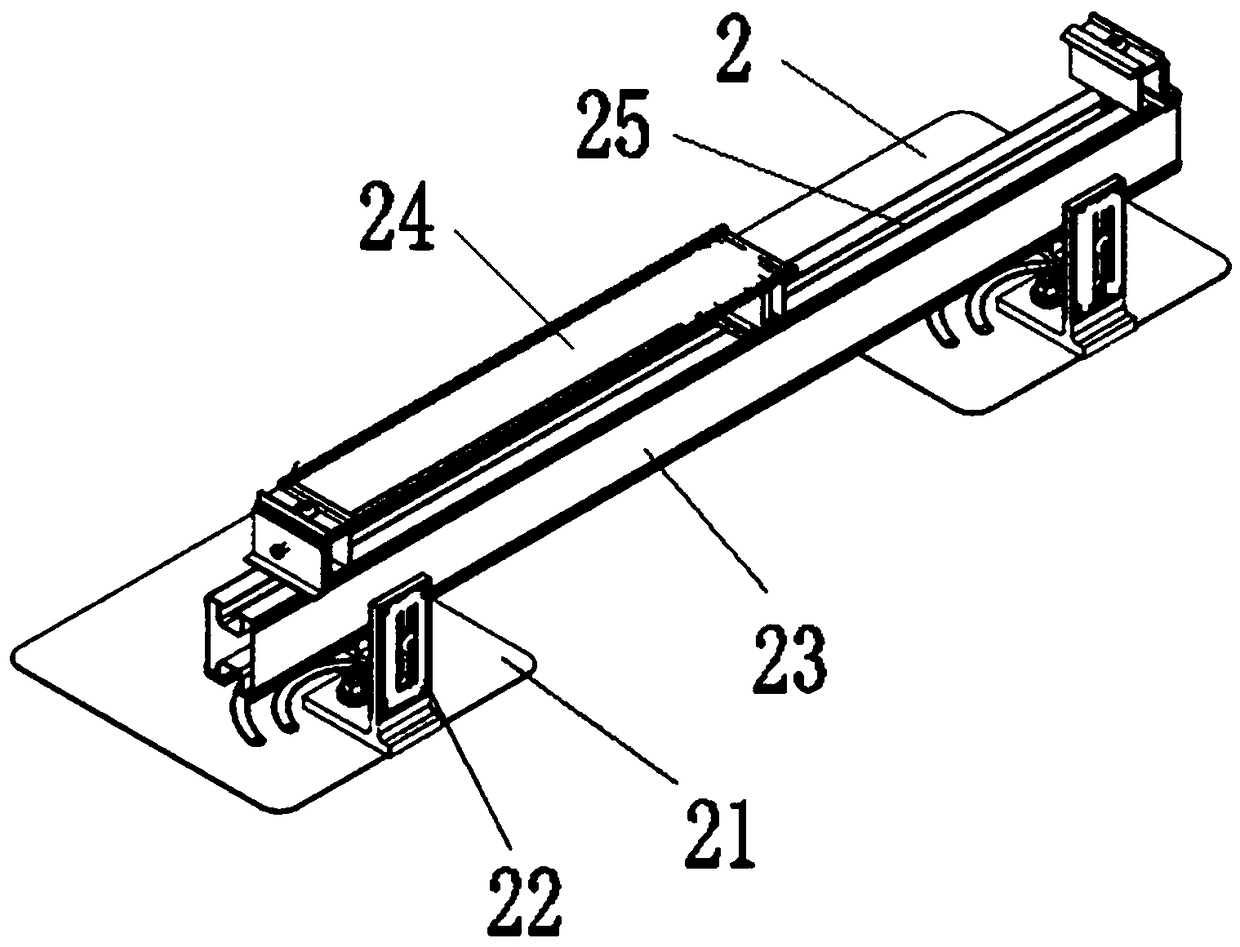

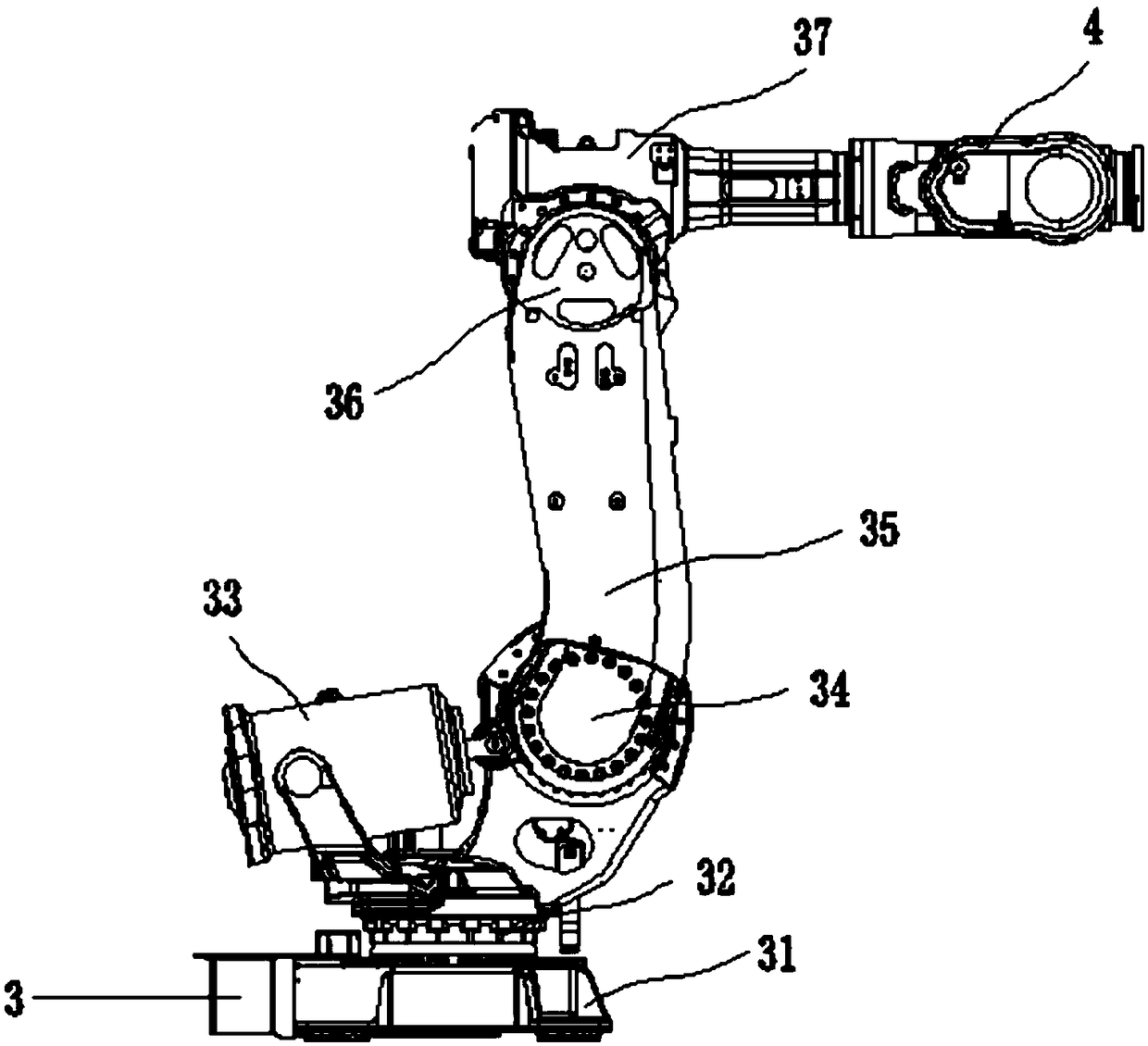

Car paint spraying robot assembly

PendingCN108940699AImprove uniformityImprove flexibilityPretreated surfacesCoatingsPaint robotEngineering

The invention discloses a car paint spraying robot assembly in the technical field of car paint spraying. The assembly comprises a paint spraying room, the top of a guide rail walking mechanism is fixedly provided with a robot arm assembly, a spraying head assembly is arranged at the right end of the robot arm assembly, the spraying head assembly is connected with a colored paint storage box and avarnish storage box through two sets of connection hoses, the right end of the guide rail walking mechanism is provided with a rotating disc mechanism, infrared heating assemblies are symmetrically arranged on the left side wall and the right side wall of an inner cavity of the paint spraying room, two draught fans are fixedly arranged on the top of the paint spraying room, and a control device is further arranged on the outer side wall of the paint spraying room. One robot is used for carrying out free point selection spraying on five faces and thirteen parting surfaces on the surface of a car, the spraying quality and the material use rate are improved, operation and maintaining are easy, the equipment use rate is high, the spraying track is precise, coating uniformity is improved, manual cost is saved, and the work efficiency can be improved.

Owner:葛岳良

Paint robot and paint cartridge

An arm of a coating robot is used to prevent external leakage of a high voltage. A tank is installed on a robotic arm and contains water as an actuating liquid. The water is supplied to a paint cartridge by a pump controlled by a controller. The water sent from the pump under pressure is supplied to the paint cartridge by a conduit tube. A high voltage generator and a bleeder resistor are combined with the tank such that a high voltage generated by the high voltage generator is supplied to the electrostatic paint applicator via the water. For replenishment of water to the tank is attained by relatively connecting a nozzle in communication with a water source to a main pipe. While the high voltage generator generates a high voltage, the nozzle and the main pipe are kept disconnected to maintain electrical insulation between the nozzle and the main pipe.

Owner:CARLISLE FLUID TECH RANSBURG JAPAN KK

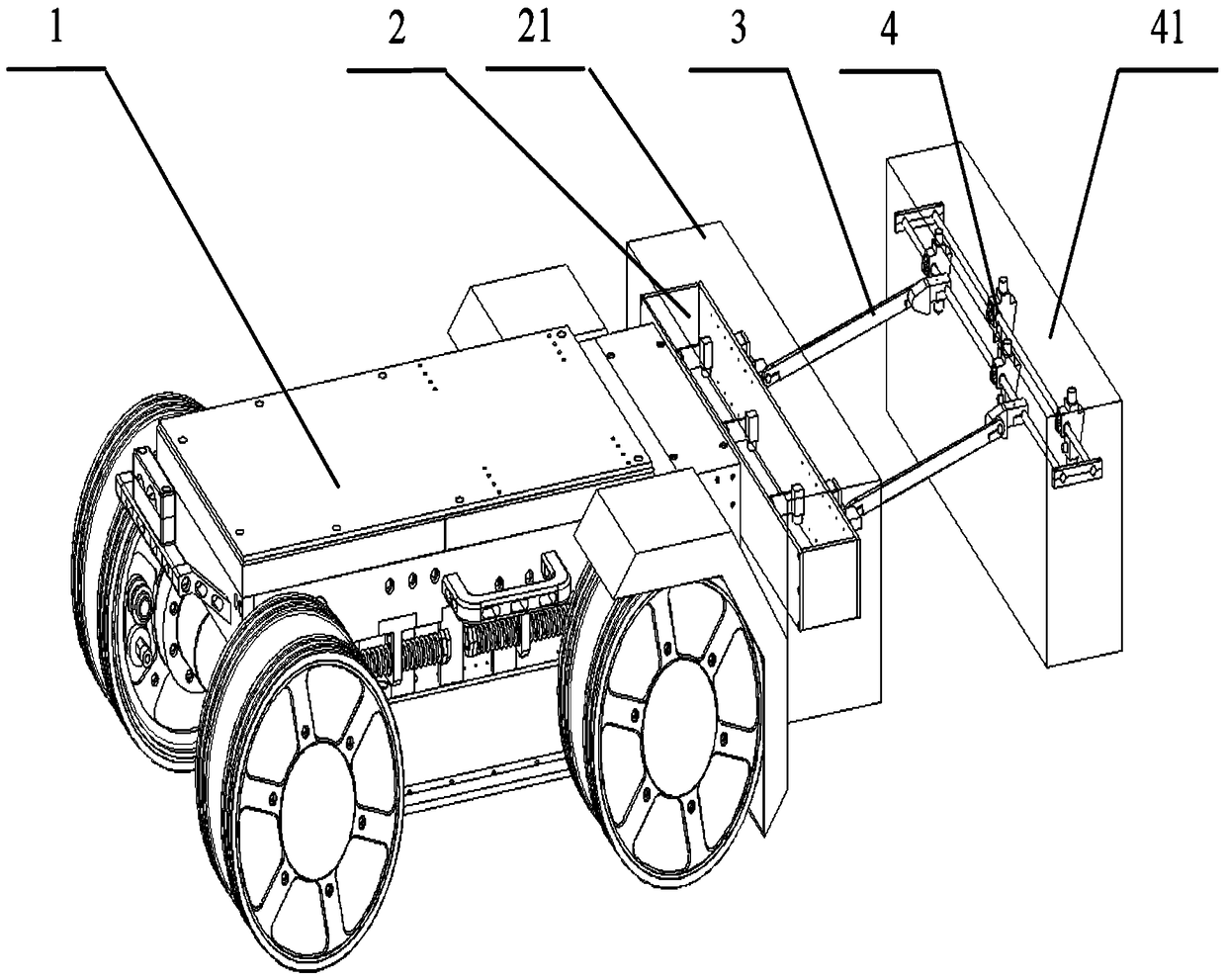

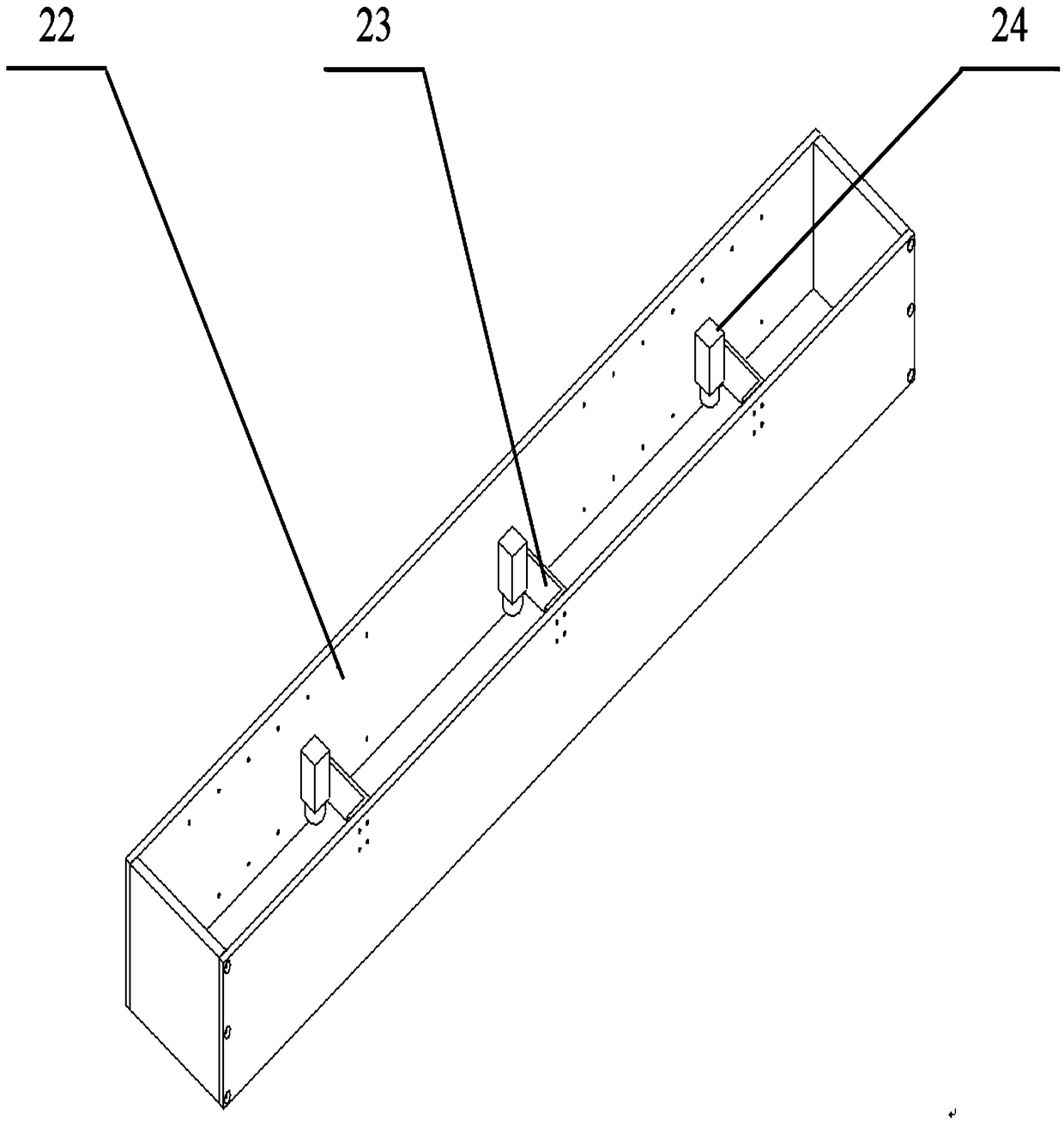

Multi-gun mixed control paint coating robot based on visual servo and spraying method of multi-gun mixed control paint coating robot

The invention discloses a multi-gun mixed control paint coating robot based on a visual servo and a spraying method of the multi-gun mixed control paint coating robot. A wall climbing car body, a visual servo mechanism, a connecting mechanism and a paint spraying mechanism are included, the wall climbing car body and the surface of to-be-operated equipment are attracted and fixed through permanentmagnet wheels, and the multi-gun mixed control paint coating robot has the multiple operation modes to adapt to the complicated operation working conditions; and in the robot paint spraying mechanism, all spraying guns are independently controlled, when large-area paint spraying operation is done, the spraying guns are all started to conduct efficient paint spraying operation, when local repairing point spraying operation is done, point spraying operating is carried out according to the surface position and shape obtained by the visual servo mechanism by adjusting the nearest spraying gun through a lead screw and nut module, and the effective fixed-point repairing and paint spraying operation is achieved.

Owner:LUOYANG SHENGRUI INTELLIGENT ROBOT

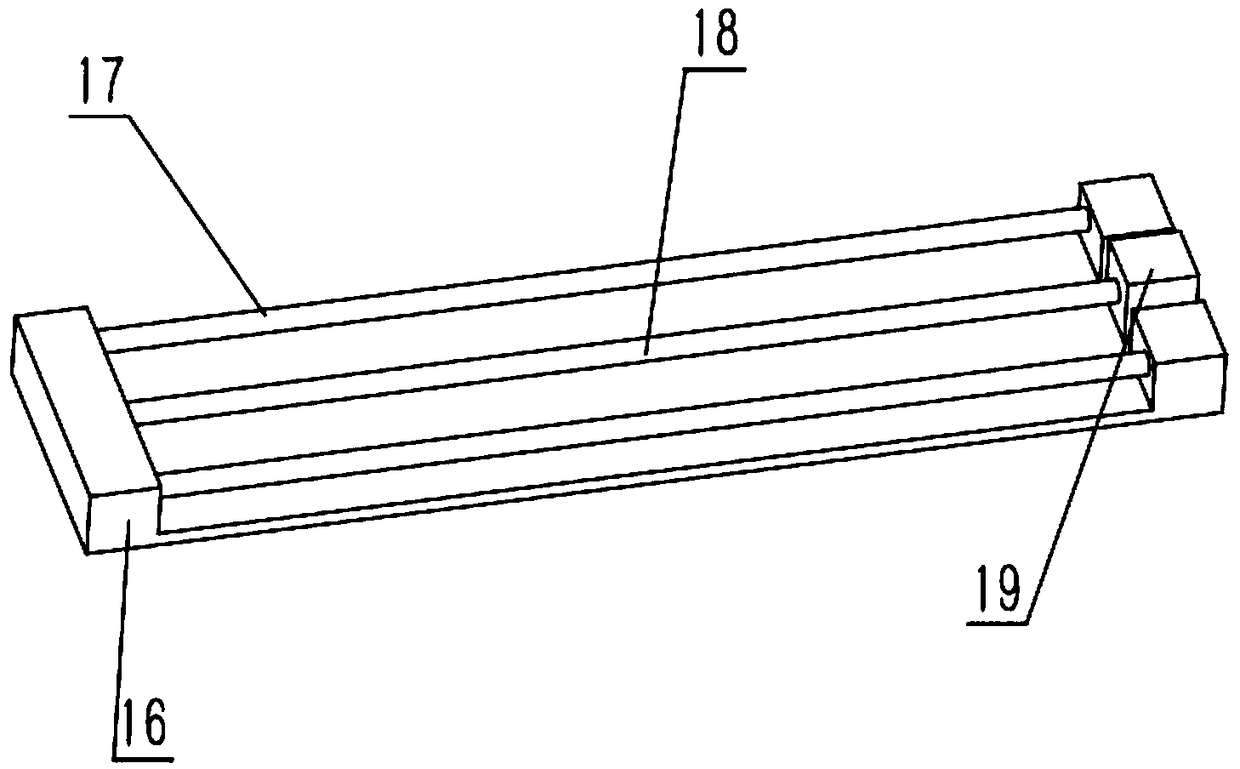

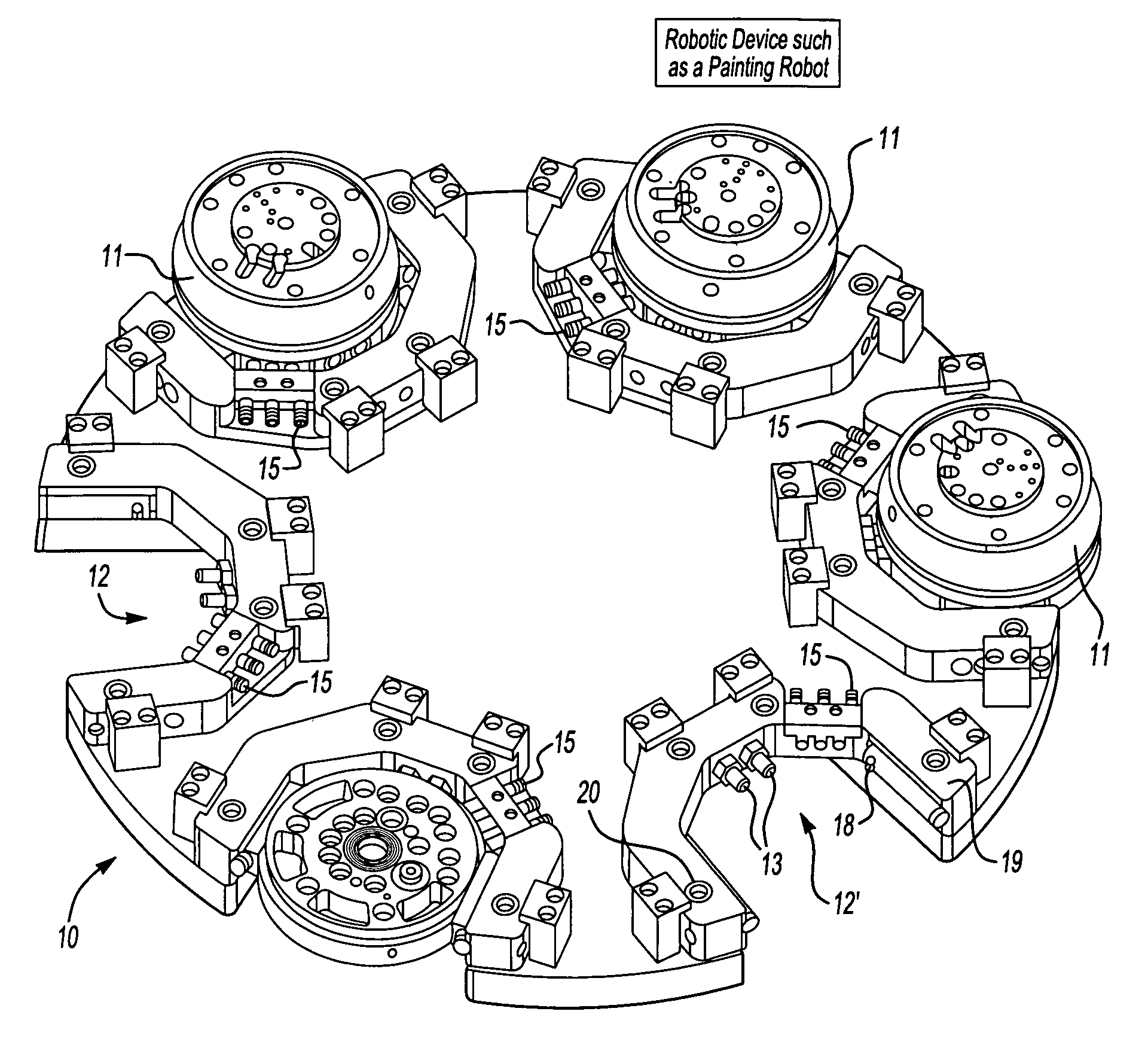

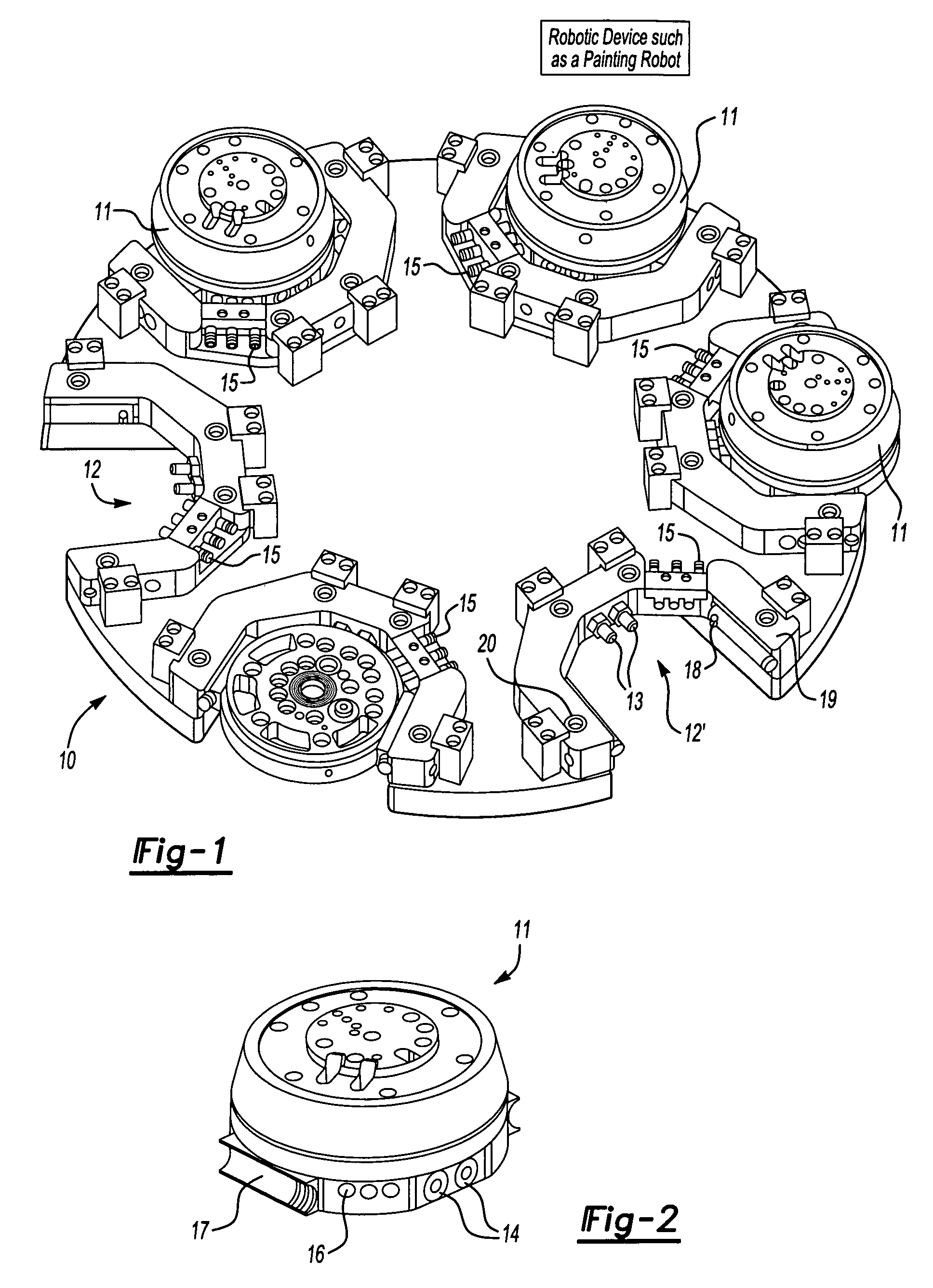

Tool change system for a machine

A plurality of atomizers or other tools are disposed in a mounting plate (10) in storage places (12), respectively. The mounting plate (10) is rotatable relative a paint robot of a coating installation and has a pneumatic lock or a tool holder (19) that can only be released automatically during storage of the atomizers by an external control device of the mounting plate.

Owner:DURR SYST INC

Large-area paint spraying robot for vehicle surface spraying

InactiveCN105107660AQuick and easy way to paint a large areaSimple structureSpraying apparatusPaint robotEngineering

The invention relates to the technical field of industrial robots, in particular to a large-area paint spraying robot for vehicle surface spraying. A mechanical arm fixing support is fixed to the upper end of a rotary chassis, a servo motor is connected to the left side of the mechanical arm fixing support, and a primary mechanical arm, a secondary mechanical arm and a ternary mechanical arm are sequentially connected to the upper end of the mechanical arm fixing support; a plurality of hydraulic lifting pillars are connected to the lower end of the rotary chassis, a hydraulic driving motor is connected to one side of the hydraulic lifting pillars, and the lower ends of the hydraulic lifting pillars are fixed to a fixed base. The robot is characterized in that the middle of the ternary mechanical arm is sleeved with an oil paint conveying box, the front end of the ternary mechanical arm is connected with a plate type paint spraying device through a rotary connecting part, a plurality of paint spraying holes are formed in the surface of the plate type paint spraying device, and the plate type paint spraying device is connected with the oil paint conveying box through a conveying pipe. The robot is simple in structure and novel in design. Through the cooperation of the plate type paint spraying device and the multiple paint spraying holes, large-area paint spraying of the surface of a vehicle body can be achieved quickly, paint spraying efficiency is improved, the number of devices is reduced, and production cost is reduced.

Owner:XINGUANG NUMERICAL CONTROL TECH

Intelligent movable portable spray painting robot

InactiveCN106179853AExpand the scope of workWork flexiblySpraying apparatusPaint robotIntelligent control

The invention discloses an intelligent movable portable spray painting robot. The intelligent movable portable spray painting robot comprises a machine case, a work main body and a controller, wherein an engine is installed inside the machine case; and a dip direction sensor is installed at one end of the machine case. An obstacle sensor is installed under the dip direction sensor. A paint containing box is installed at the upper left end of the machine case. A residual material sensor is installed inside the paint containing box. The work main body is installed at the upper right end of the machine case. A rotary base is installed at the bottom end of the work main body. A supporting arm is installed at the upper end of the rotary base. A camera is installed at the lower right end of the supporting arm. The supporting arm is connected with a work arm through a rotary shaft. A paint sprayer is installed at one end of the work arm. An intelligent spraying amplitude mist regulator is installed at one end of the paint sprayer. An operation display screen is installed in the controller. The intelligent movable portable spray painting robot has the characteristics of stable work and intelligent control, and greatly improves work efficiency.

Owner:成都元始信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com