Painting robot and associated operating method

A technology of robots and robot arms, which is applied to robots, devices that apply liquid to surfaces, coatings, etc., can solve the problems of increased structure and logistics investment, and achieve the effect of small control investment and low loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

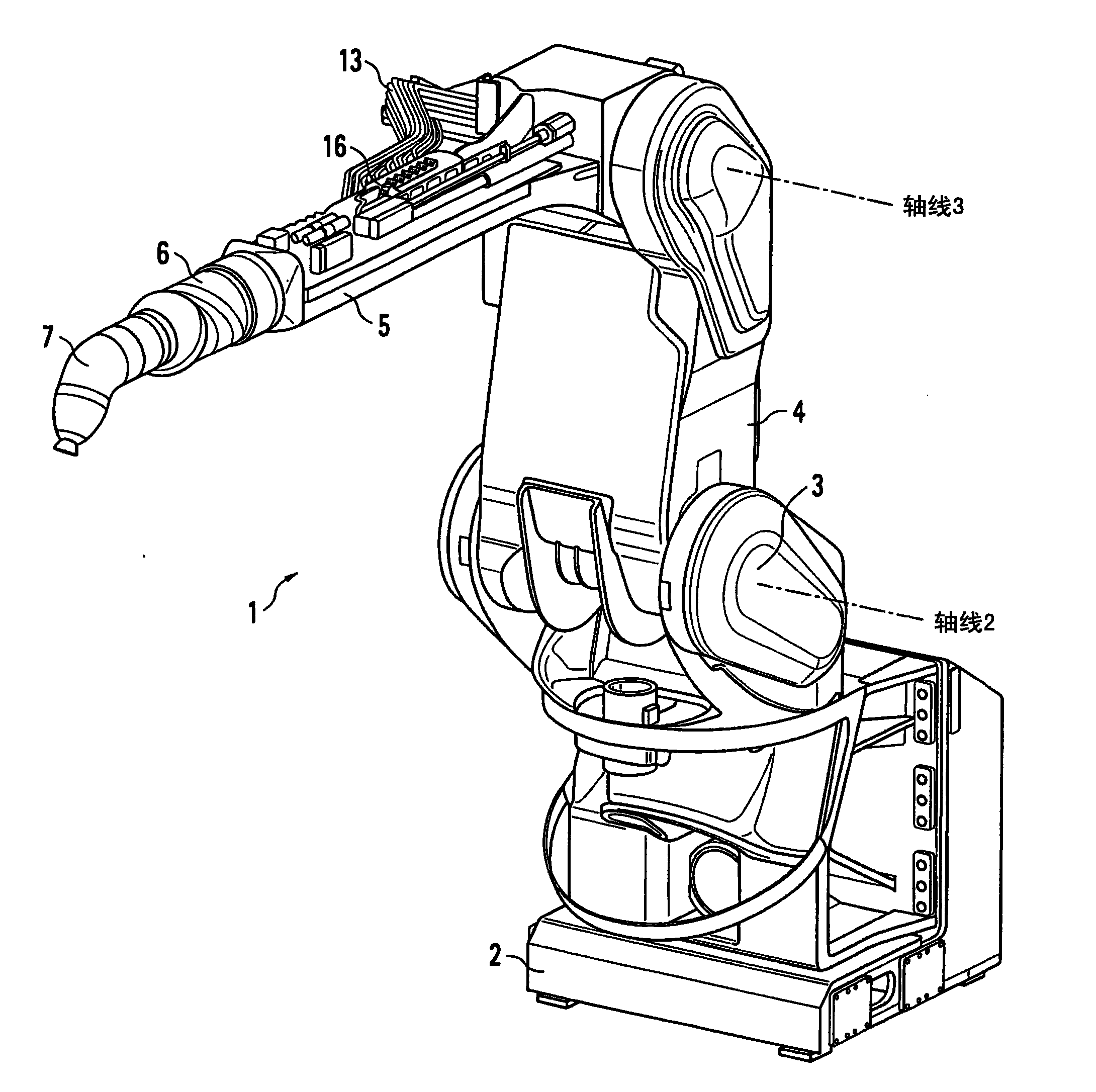

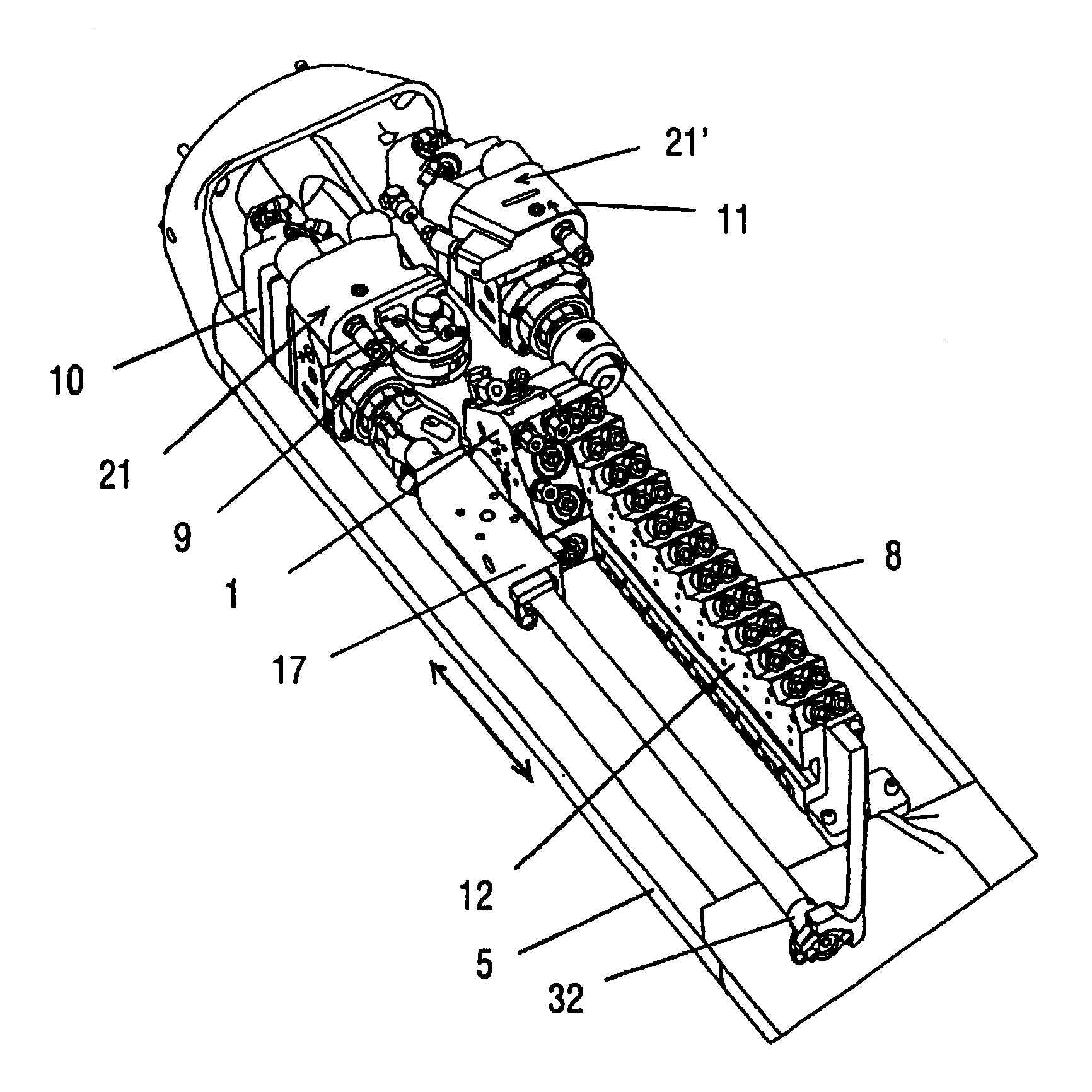

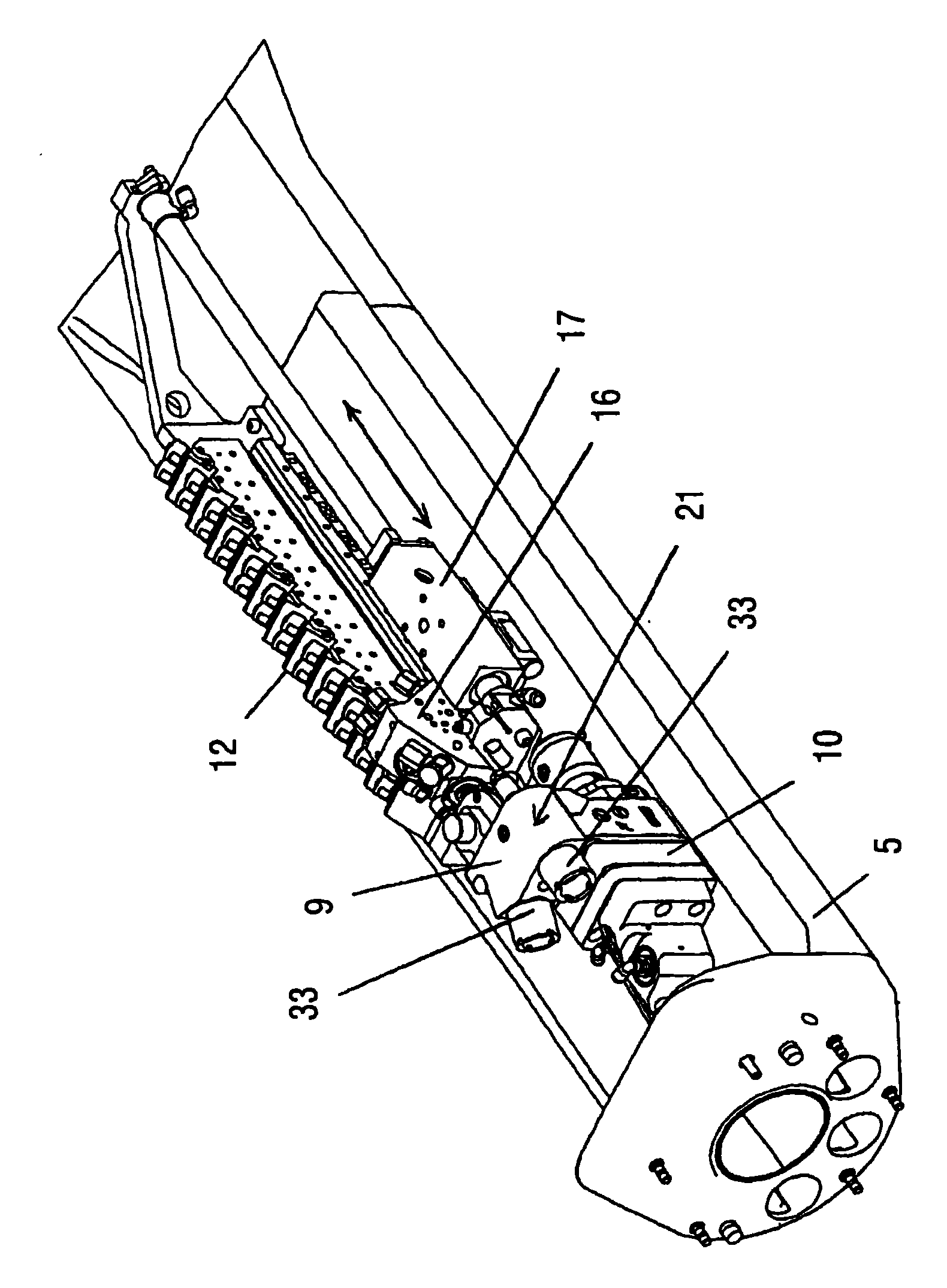

[0077] Figure 1 to Figure 8 Shows different views or parts of a painting robot 1 according to the invention which is used in a painting installation for painting motor vehicle bodies, wherein the painting robot 1 is not only suitable for painting motor vehicle bodies Exterior surfaces, but also suitable for painting the interior surfaces of motor vehicle bodies, as will be described in more detail.

[0078] The painting robot 1 is largely of conventional design and has a robot base 2 which, in the exemplary embodiment, can be fixedly mounted on the machine foundation. As an alternative, however, the robot base 2 can also be mounted on rails in a correspondingly modified manner so that the painting robot 1 can move in the painting booth relative to the position of the motor vehicle body to be painted. The conveying direction runs parallel. It is also expedient for the purposes described here that the rails are fitted in a manner known per se (EP 1 609 532 A1) at the level of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com