Omni-directional intelligent furniture paint spraying robot

A technology of intelligent furniture and robots, applied in the field of robots, can solve the problems of non-adjustable spray gun position, personal health injury, high cost of fixed spray paint machine, etc., achieve high application value and application prospect, increase anti-skid and stability, and adapt well to complex terrain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

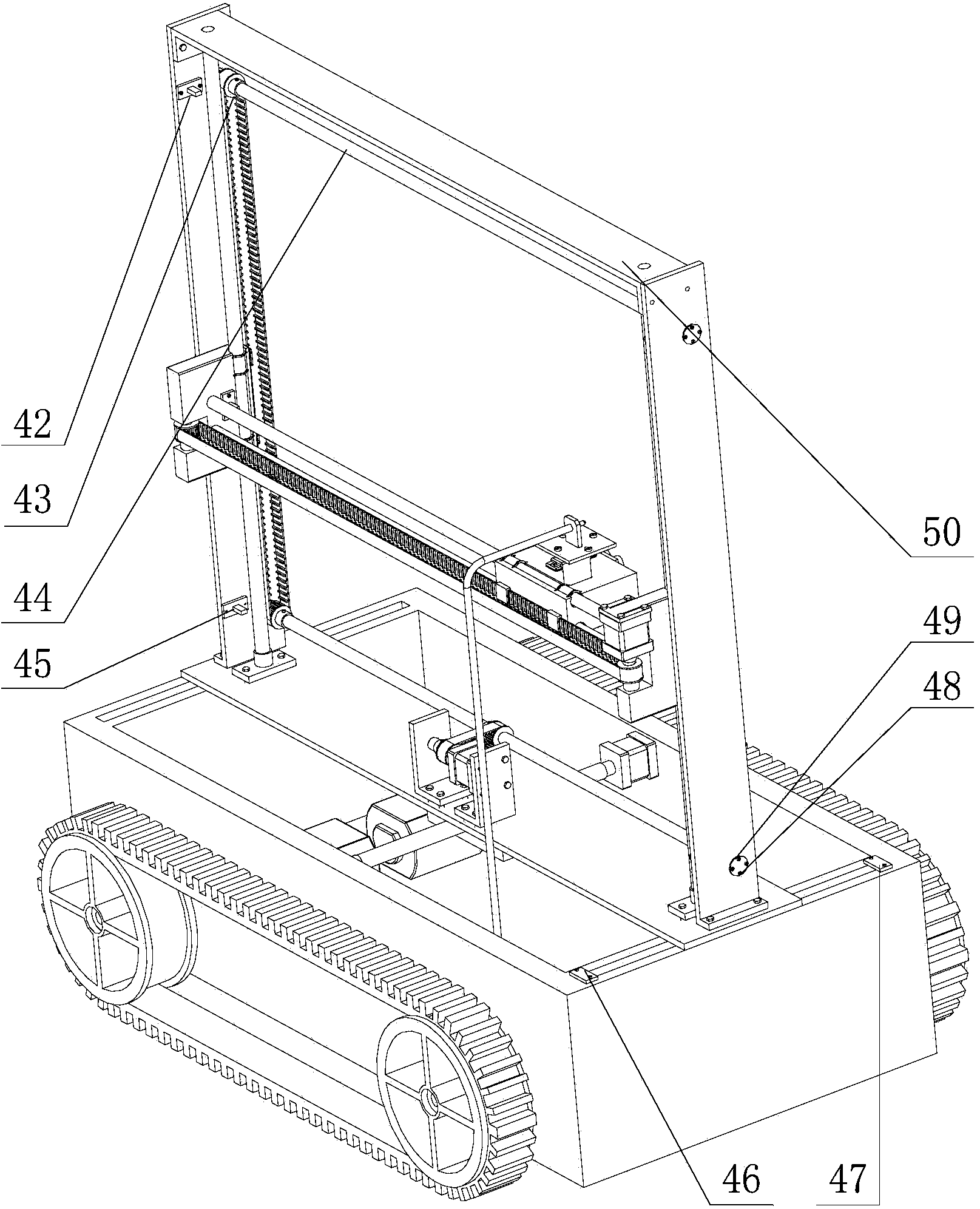

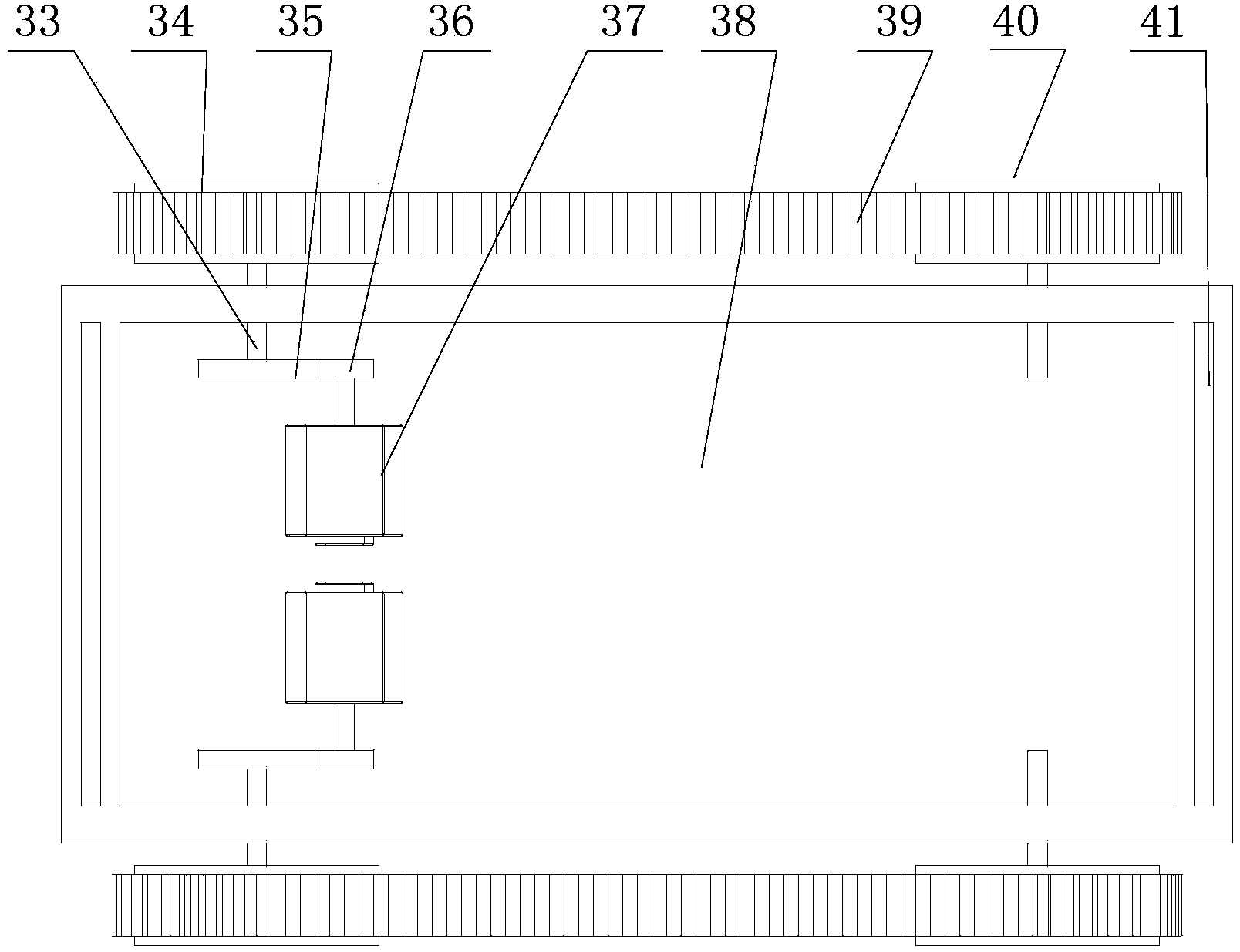

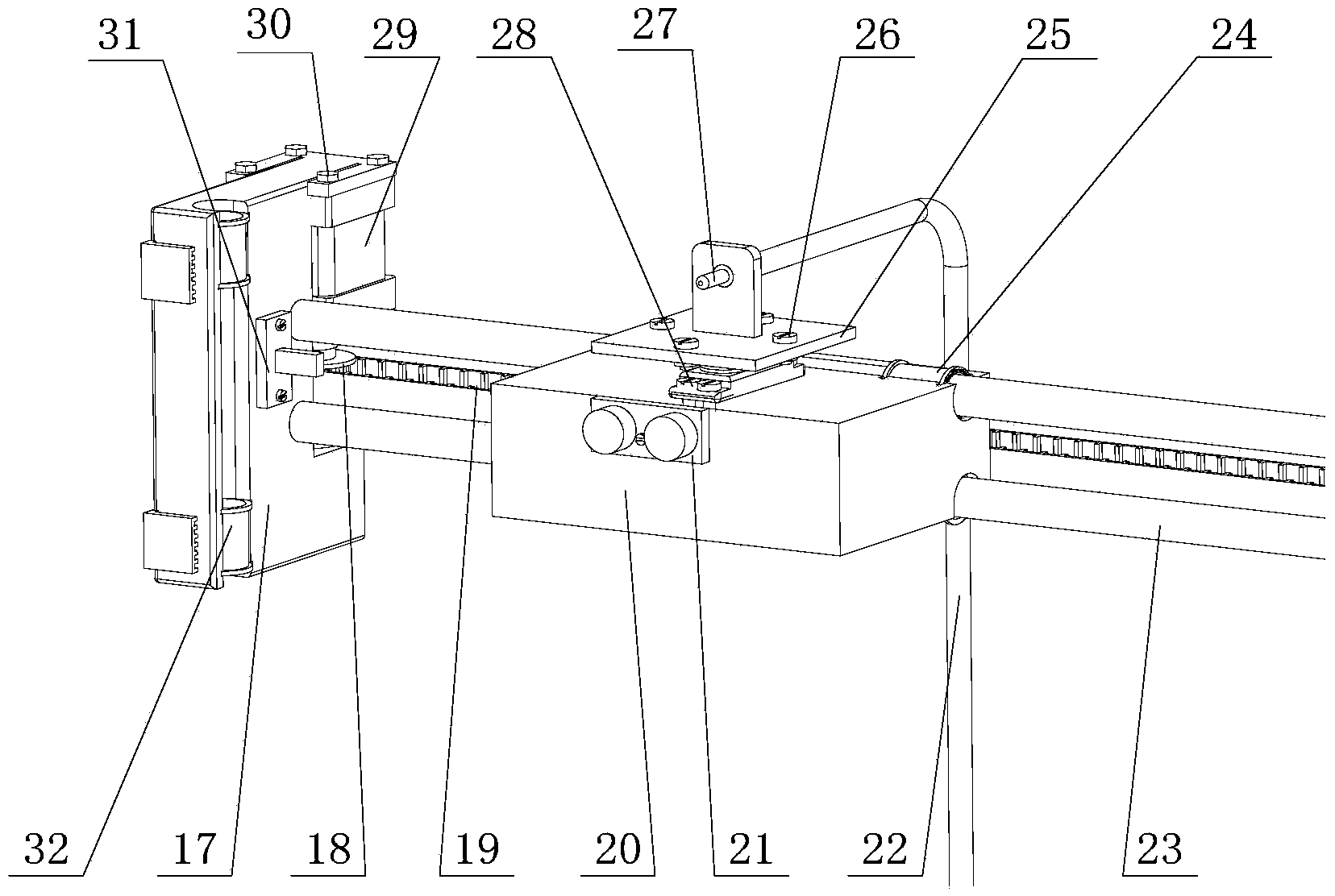

[0018] combine Figure 1~4 , the present invention is an all-round intelligent furniture painting robot, which can realize the translation along the XYZ axis and the rotation along the Y-axis, and complete the omnidirectional spraying operation on the furniture through the four-degree-of-freedom movement, mainly composed of a crawler robot body and a motor transmission mechanism , XYZ three-axis translation mechanism, Y-axis rotation mechanism, spray gun mechanism, support frame mechanism, CPU module, power supply module, input and output interface module, limit switch module, infrared distance measuring module. The motor is installed in the body to drive the wheels to rotate. The Z-axis moving mechanism is installed in the slideway of the body through the slider on the Z-axis mounting plate. The screw nut is used to drive the linear motion along the Z-axis. The Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com