Spray painting robot arm component and spray painting robot

A technology for spraying robots and arm parts, applied in the directions of manipulators, spraying devices, mechanical equipment, etc., can solve problems such as reducing spraying yield, pollution, and difficulty in cleaning pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

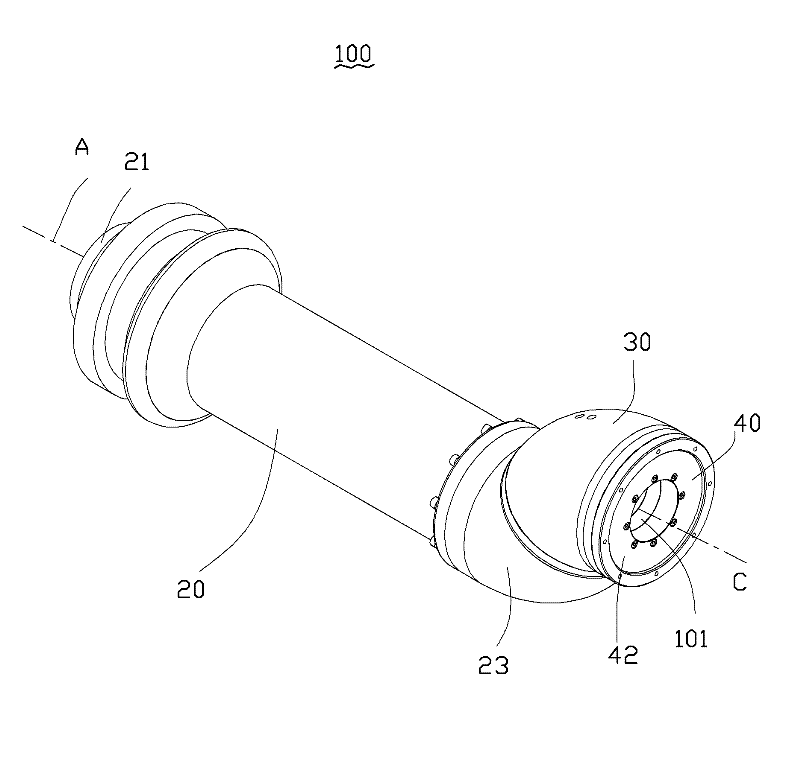

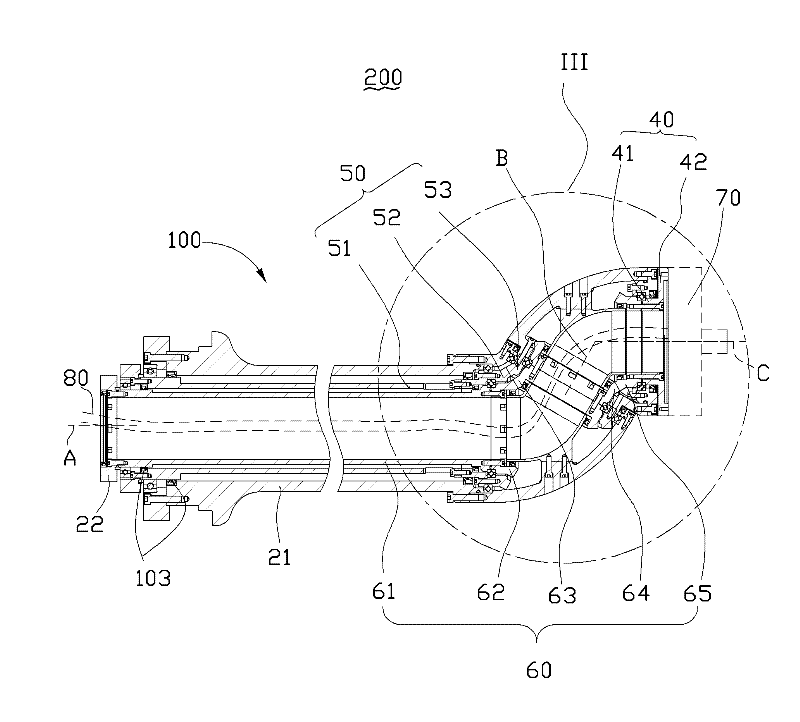

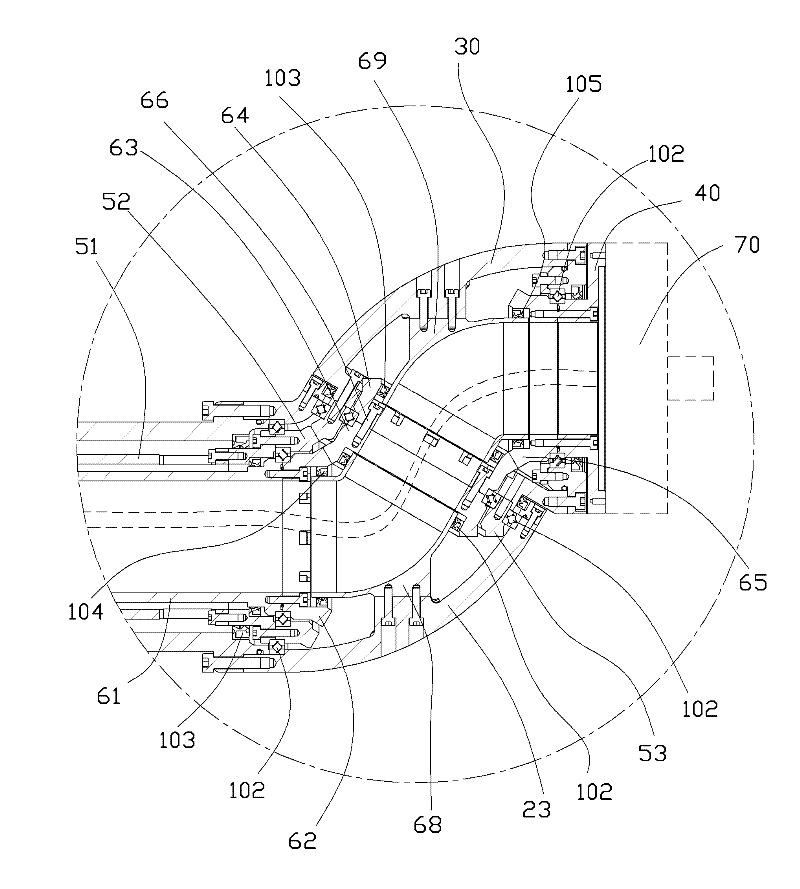

[0012] The spraying robot arm part and the spraying robot using the spraying robot arm part of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] See Figure 1 to Figure 3 , the painting robot arm part 100 according to the embodiment of the present invention can be applied to a six-axis painting robot 200 . The spraying robot arm part 100 includes a support arm 20, a wrist 30 that is rotatably connected with the support arm 20, a terminal arm 40 that is rotatably connected with the wrist 30, a first drive mechanism 50 that drives the wrist 30, and a first drive mechanism 50 that drives the terminal arm 40. Two driving mechanisms 60. The painting robot 200 includes a painting robot arm part 100, a painting mechanism 70, and a pipeline 80 connected to the painting mechanism. The spraying mechanism 70 is attached to the end arm 40 .

[0014] The support arm 20 rotates around the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com