Spray painting robot for rust removal of large pipe

A technology for spraying robots and pipes, applied in the field of robots, can solve problems such as danger and accidents, and achieve the effect of powerful functions and less space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

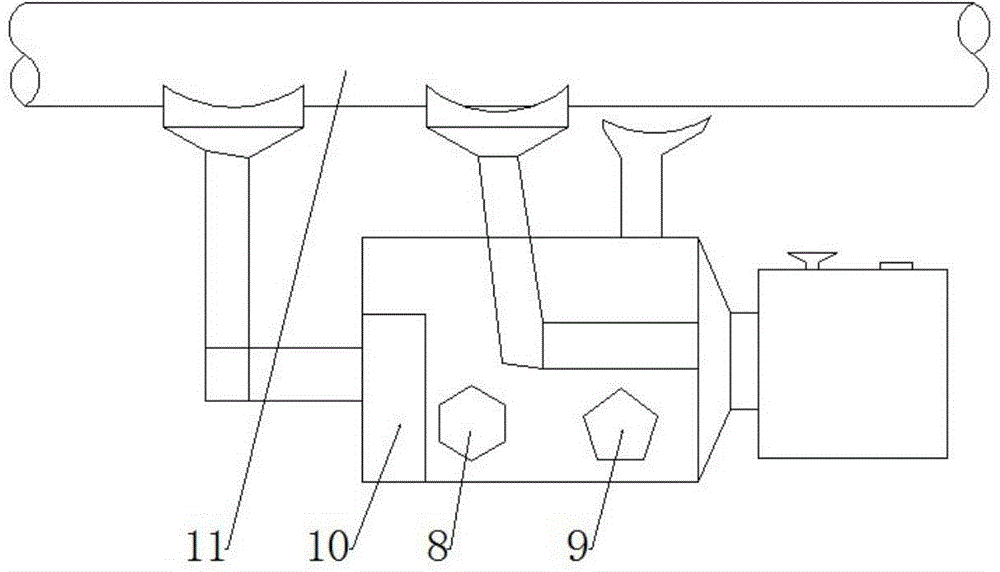

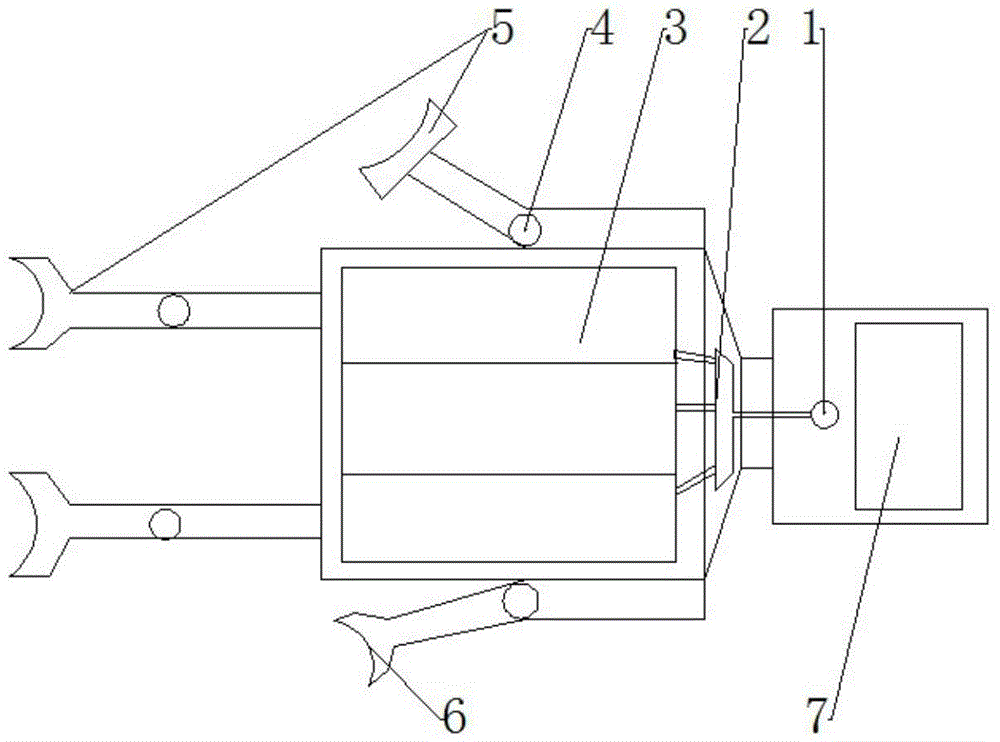

[0014] The large-scale pipeline derusting and spraying robot of the present invention is composed of the following parts: nozzle 1, material spraying mixing device 2, material spraying storage device 3, linkage device 4, controllable magnetic adsorber 5, derusting manipulator 6, industrial controller 7, power module 8. Data transmission module 9, accumulator 10, pipeline 11.

[0015] The working principle of the present invention is as follows: the robot can be remotely controlled by people or intelligently operated by itself. The human sends instructions to the industrial controller 7 of the robot, and the industrial controller 7 starts to work, and issues work instructions according to the work tasks received by the industrial controller. The industrial controller derusts the target through the robot data transmission module 9, and polishes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com