Vehicle body paint spraying system and method

An automobile body and body technology, which is applied in the field of automobile body painting systems, can solve the problems of less paint sagging on the body paint surface, and achieve the effect of ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

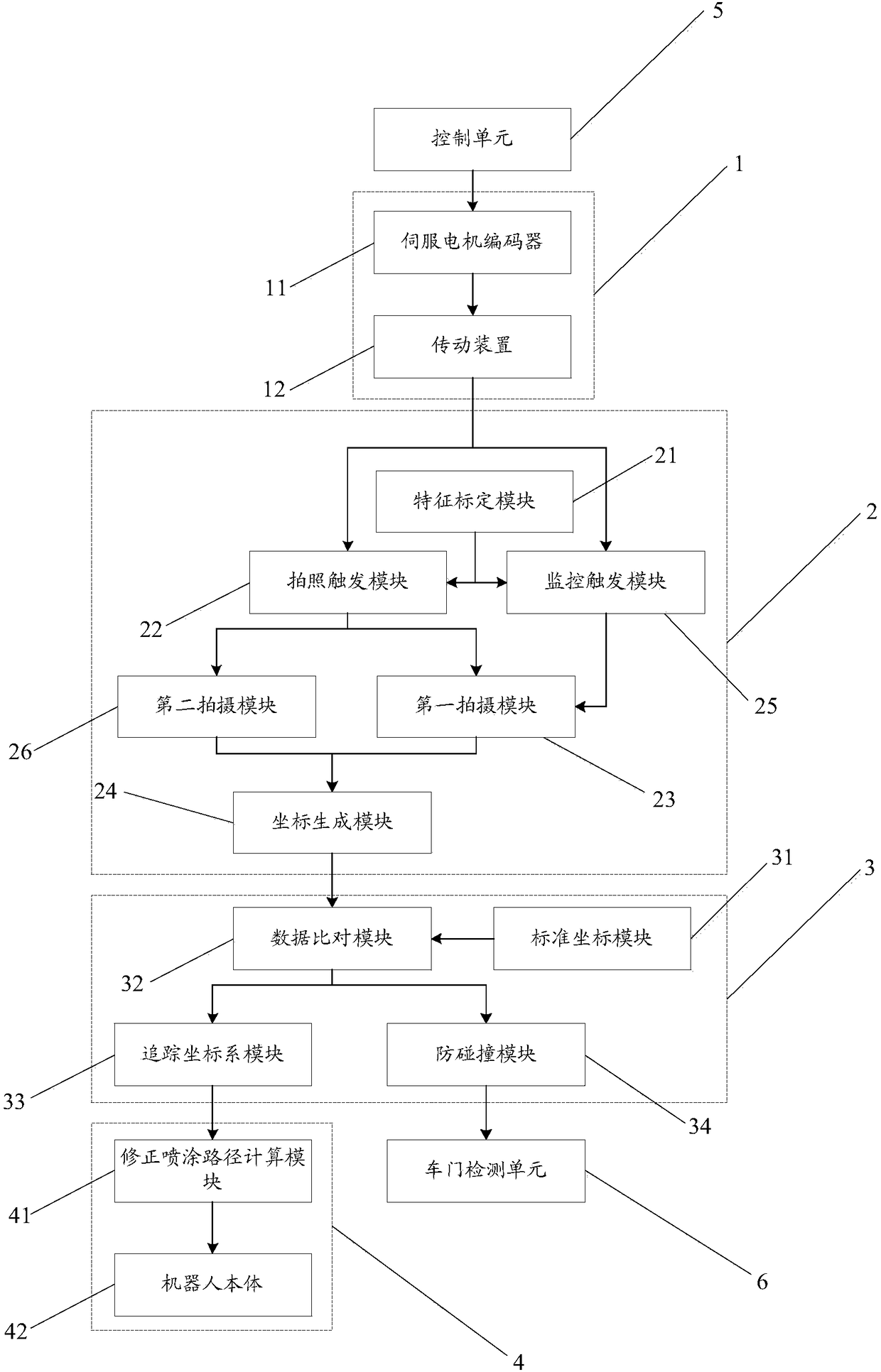

[0054] see figure 1 , the automobile body painting system provided in this embodiment is applied in the automobile painting booth. The automobile painting booth includes a coordinate generation area, a painting area and a detection area. 3 and the painting robot 4; the vehicle body transmission unit 1 is used to carry the vehicle body to be painted and move to the coordinate generation area, the painting area and the detection area in sequence according to the transmission signal; the visual sensing unit 2 is used to obtain the current position of the body to be painted in the coordinate generation area Position coordinates; the calculation unit 3 is used to generate a tracking coordinate system according to the current position coordinates, standard position coordinates and transmission signals; the painting robot 4 obtains a corrected spraying path based on the tracking coordinate system, and completes the painting of the vehicle body to be painted in the painting area.

[0...

Embodiment 2

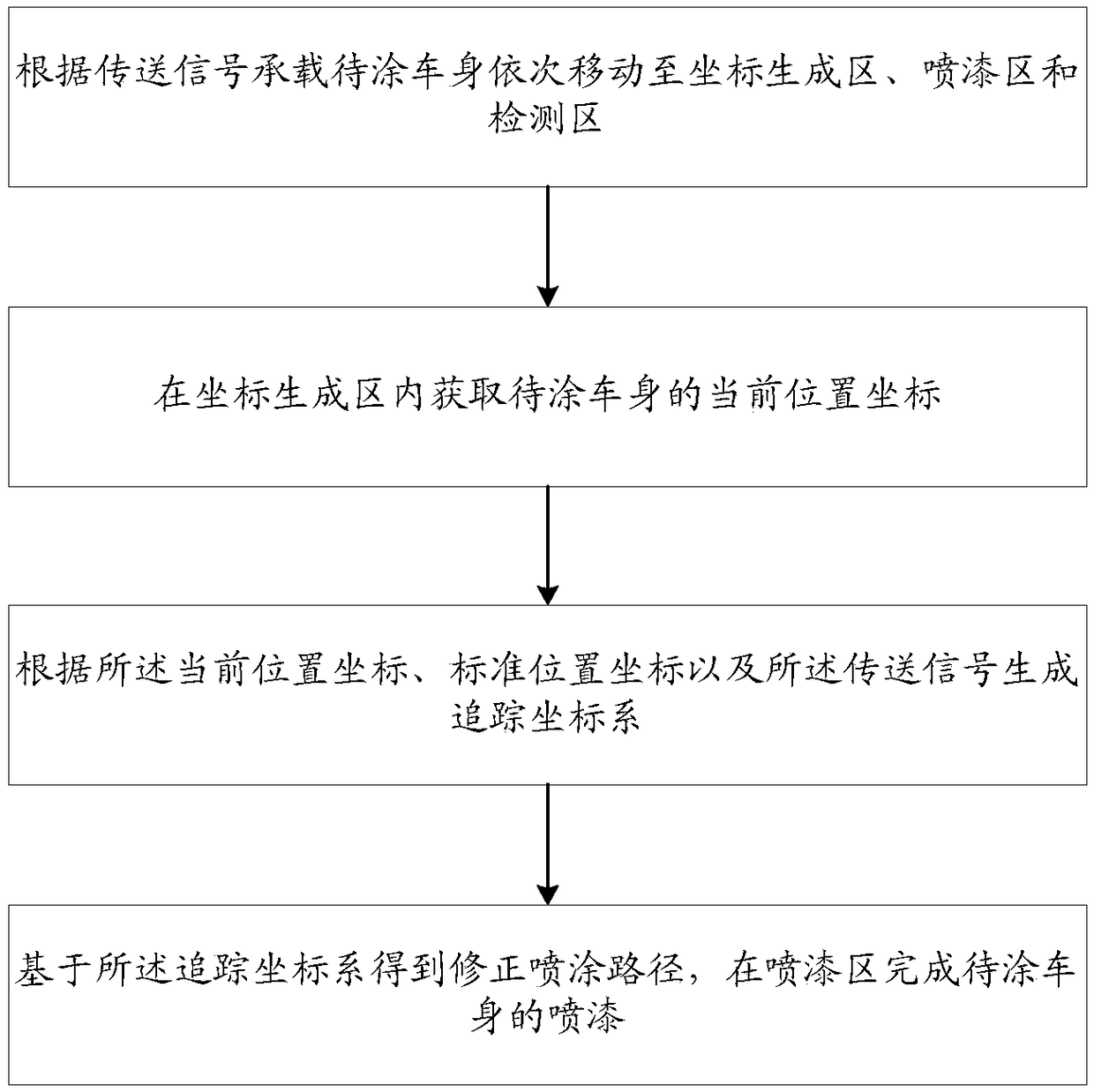

[0069] see figure 2 , another embodiment of the present invention provides a kind of painting method of automobile body, comprises:

[0070] According to the transmission signal, the car body to be painted is moved to the coordinate generation area, the painting area and the detection area in sequence;

[0071] Obtain the current position coordinates of the body to be painted in the coordinate generation area;

[0072] generating a tracking coordinate system according to the current position coordinates, the standard position coordinates and the transmission signal;

[0073] The corrected spraying path is obtained based on the tracking coordinate system, and the painting of the vehicle body to be painted is completed in the painting area.

[0074] Compared with the prior art, the beneficial effect of the automobile body painting method provided by the embodiment of the present invention is the same as that of the automobile body painting system provided in the first embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com