Painting robot position planning method for large-scale free-form surface

A spraying robot, free technology, applied in the fields of instruments, computing, electrical and digital data processing, etc., can solve the problems of large demand for planning and low efficiency of offline spraying planning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

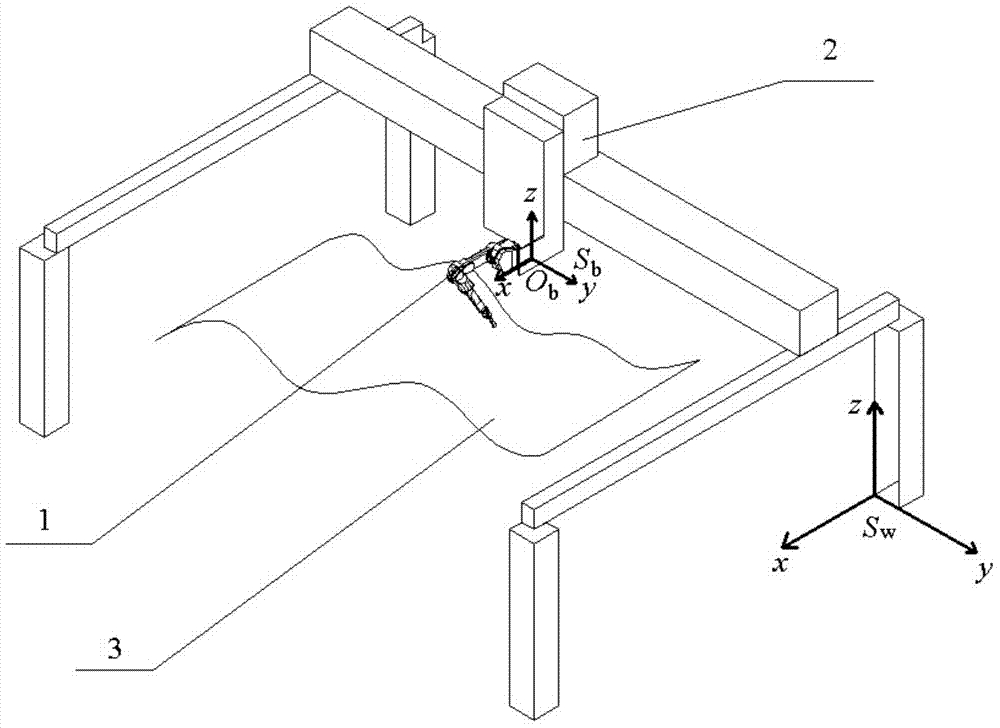

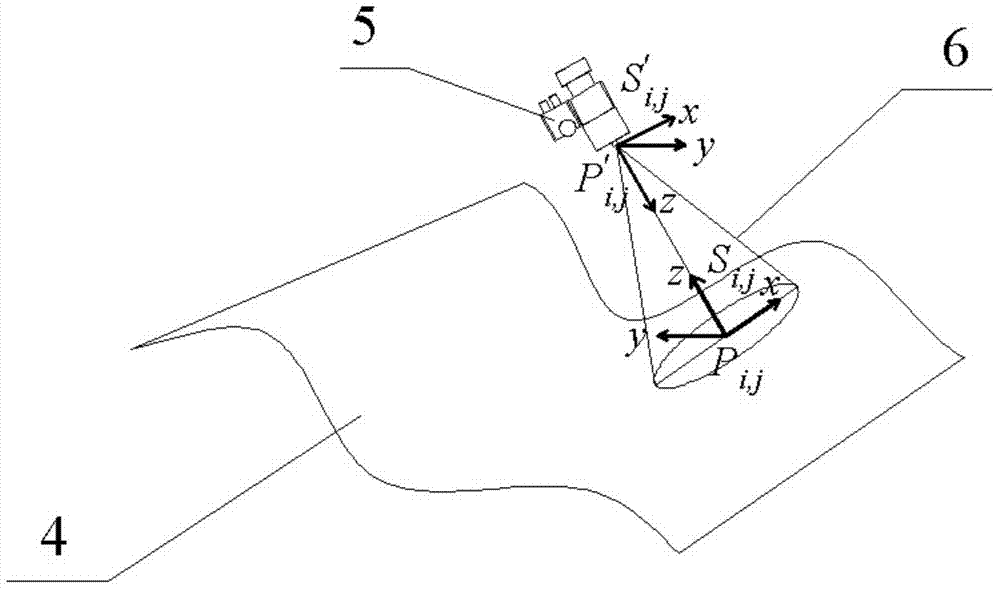

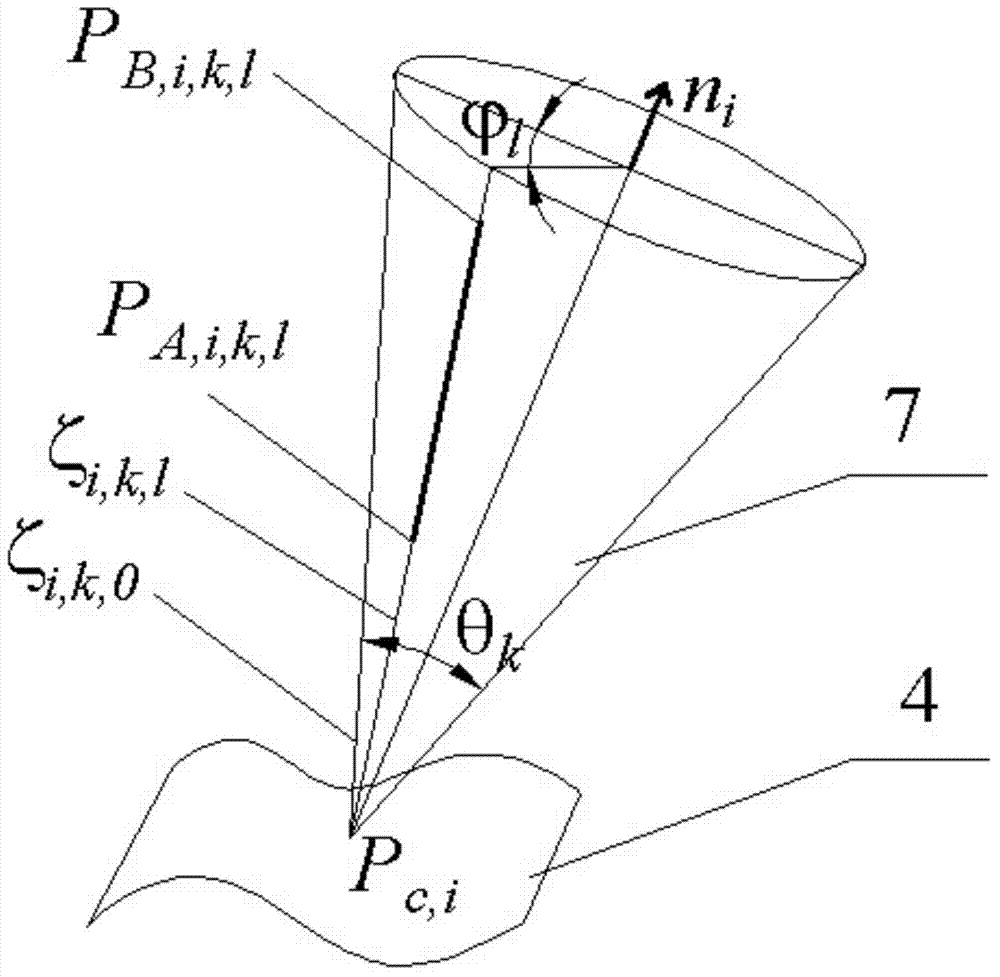

[0029] For large free-form surfaces, the workspace of common 6-DOF spraying robots can only cover a small area on it. In order to use as few spraying robots as possible to complete the spraying of large free-form surfaces, the spraying robot should be installed on a three-dimensional mobile platform with a large stroke. The three-dimensional mobile platform will transport the spraying robot to a suitable position and keep it still. Robots do the painting. When the spraying robot is spraying, the position where the origin of the base coordinate system is located is called the station. The station planning of the spraying robot on the large free-form surface is to find a suitable station for each free-form surface in the large free-form surface on the basis of completing the trajectory planning of the spray gun, so that the spraying robot can satisfy the requirements of the robot itself when moving according to the trajectory of the spray gun. Joint angle and angular velocity a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com