Stable-temperature power self-optimization method and system, computer equipment and storage medium

A technology of self-optimization and power setting, applied in chemical instruments and methods, design optimization/simulation, self-melting liquid pulling method, etc., can solve the problem of low crystal pulling production efficiency, low setting accuracy, and unstable production and other issues to achieve the effect of increasing production, reducing waste of working hours, and reducing human intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

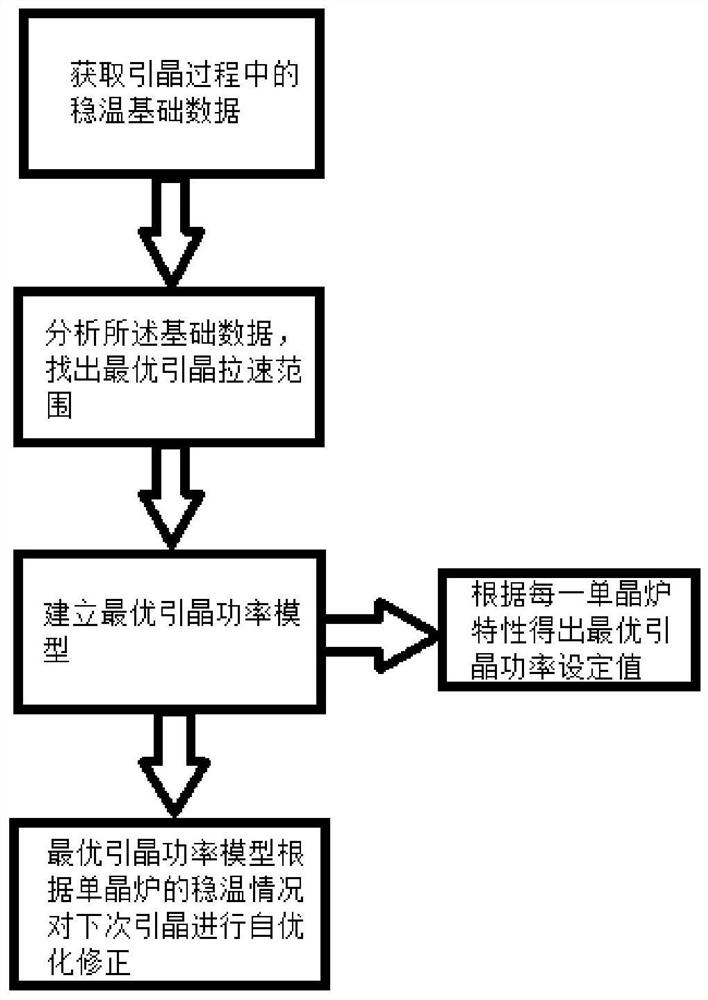

[0026] In one embodiment of the present invention, a method for self-optimization of temperature stabilization power is characterized in that, comprising:

[0027] S1: Obtain the basic temperature stabilization data during the seeding process. The basic data includes melt data, main heater power, bottom heater power, and historical crystal pulling data, because each single crystal furnace has different characteristics, even at the beginning The seeding temperature of each single crystal furnace set is the same, but in the reaction process, due to different positions, crystal raw materials and other influencing factors, the reaction process and the final data will be inconsistent, so it is necessary to collect each single crystal. Basic data of the furnace.

[0028] S2: Analyze the basic data to find the optimal seeding pulling speed range, and find the opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com