Production line error correction auxiliary system and method based on edge gateway

An edge gateway and auxiliary system technology, applied in the transmission system, closed-circuit television system, TV system components, etc., can solve problems such as low efficiency, inability to timely feedback and correct new employees, and long hours of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

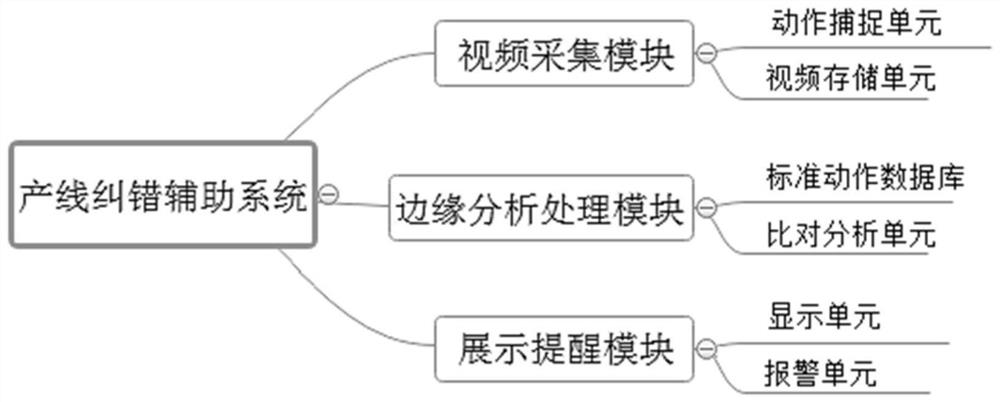

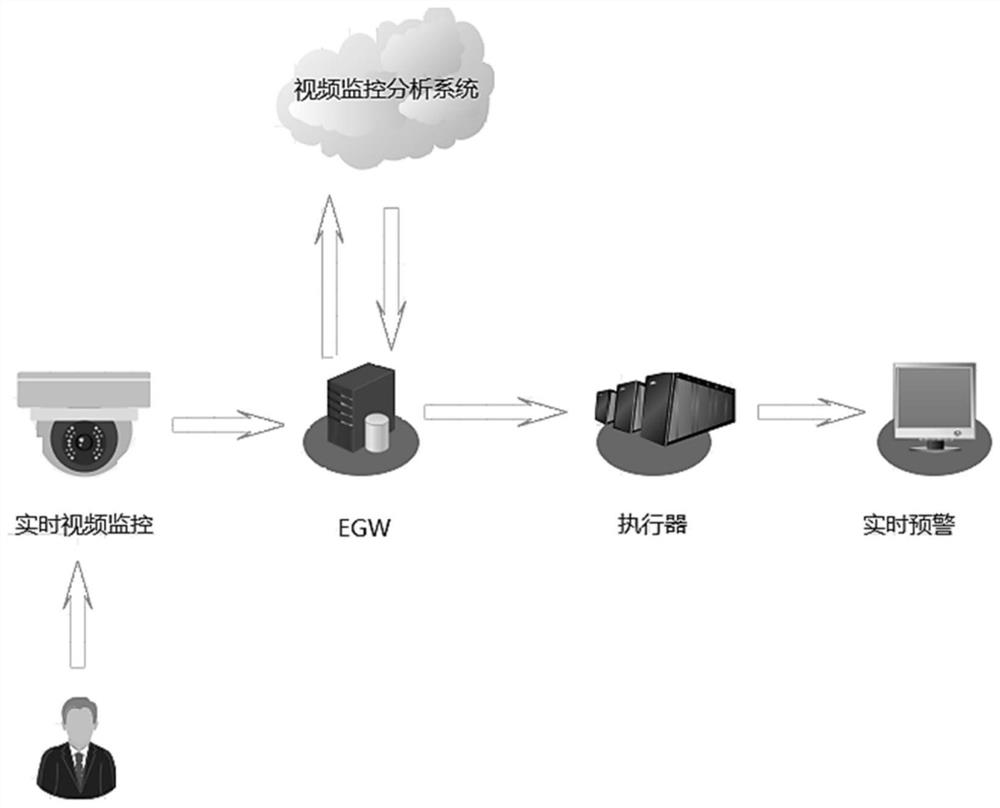

[0025] Such as figure 1 As shown, the present invention relates to an edge gateway-based production line error correction auxiliary system, the system includes:

[0026] The video acquisition module includes a motion capture unit and a video storage module, wherein the motion capture unit is used to collect the video image information of the actual automatic production operation of the production line operator and the start time of the product on the production line from the time it arrives at the production line operator By the time the workers leave the production line, the video storage unit is used to store the collected video image information and the elapsed time of the product on the production line.

[0027] The edge analysis processing module includes a standard database and a comparative analysis unit, wherein the standard database is used to pre-store standard action video image information that meets the operation requirements and store the average standard time-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com