Three-jaw self-centering chuck clamping device

A self-centering chuck and clamping device technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor workpiece quality, low processing efficiency, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

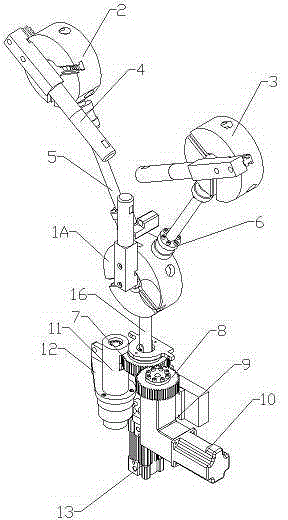

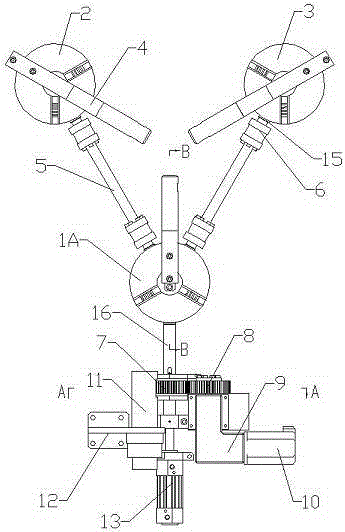

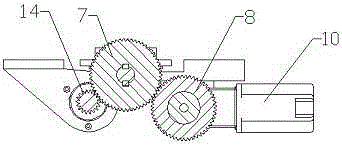

[0029] Examples such as figure 1 , figure 2 As shown, a three-jaw self-centering chuck clamping device is composed of three centering chucks arranged in a triangle, and the three centering chucks are driven by the same power and synchronously linked to realize self-centering Function.

[0030] The three centering chucks include a main chuck 1A, a sub-chuck 2 and a sub-chuck 3 that are uniformly distributed at 120 degrees on the same plane; each chuck is provided with a clamping rod 4 .

[0031] The clamping rod 4 and the claw 17 are connected by threads, and changing the clamping rod 4 of different lengths can realize the clamping of a wide range of pipe fittings with different diameters.

[0032] The main chuck 1A is connected with the auxiliary chuck 2 and the auxiliary chuck 3 respectively through connecting rods 5; both ends of the connecting rod 5 are respectively connected with connecting heads 15 through rigid couplings 6;

[0033] The connectors 15 close to the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com