Locking device for welding rotary jig of automobile body

A technology of locking devices and rotating fixtures, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as the head is easy to collide with the fixture, the labor intensity is high, and the working hours are affected, so as to eliminate potential safety hazards and reduce labor intensity. , The effect of reducing the waste of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

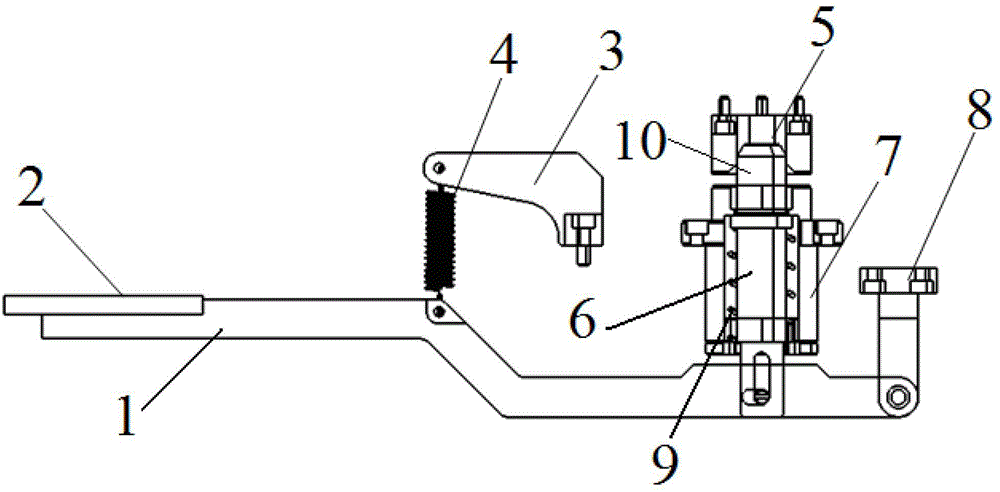

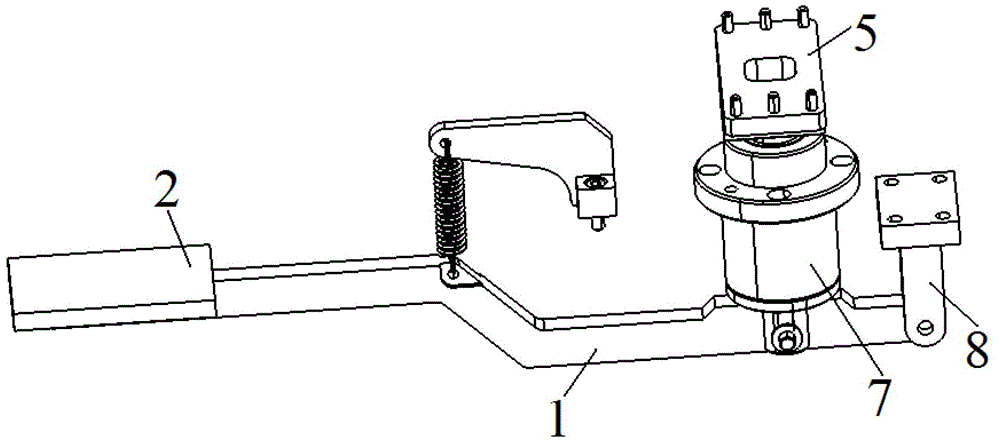

[0020] Such as figure 1 and figure 2 Shown is a locking device of an automobile body welding rotary jig according to the present invention, which is installed at the bottom of the jig. The locking device includes a pedal arm 1, a locking mechanism and a reset mechanism.

[0021] Pedal arm 1, one end of which is hingedly connected to the fixture BASE plate, and the other end is used for stepping on; the pedal arm 1 is a long rod connected to the fixture BASE plate, and can be rotated under the pedal of the operator. The locking mechanism, located above the pedal arm 1, is connected with the clamp BASE plate. The locking mechanism includes a locking rod 6 that can move up and down. The locking mechanism mainly realizes the locking and unlocking of the clamp through the locking rod 6. The upper end of the locking rod 6 can be inserted into the lock hole provided on the rotary table of the clamp. The lower end is connected with the pedal arm 1 at the position between the two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com