Labor-saving plug-pull connector

A technology of plug-in connector and plug-in mechanism, which is applied in the direction of connection, parts of connection device, device for engaging/disconnecting connection parts, etc., which can solve over-mating, inconvenient daily use, connector mating and separation Difficulties and other issues to achieve the effect of avoiding space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with above-mentioned embodiment accompanying drawing, the present invention is described in further detail:

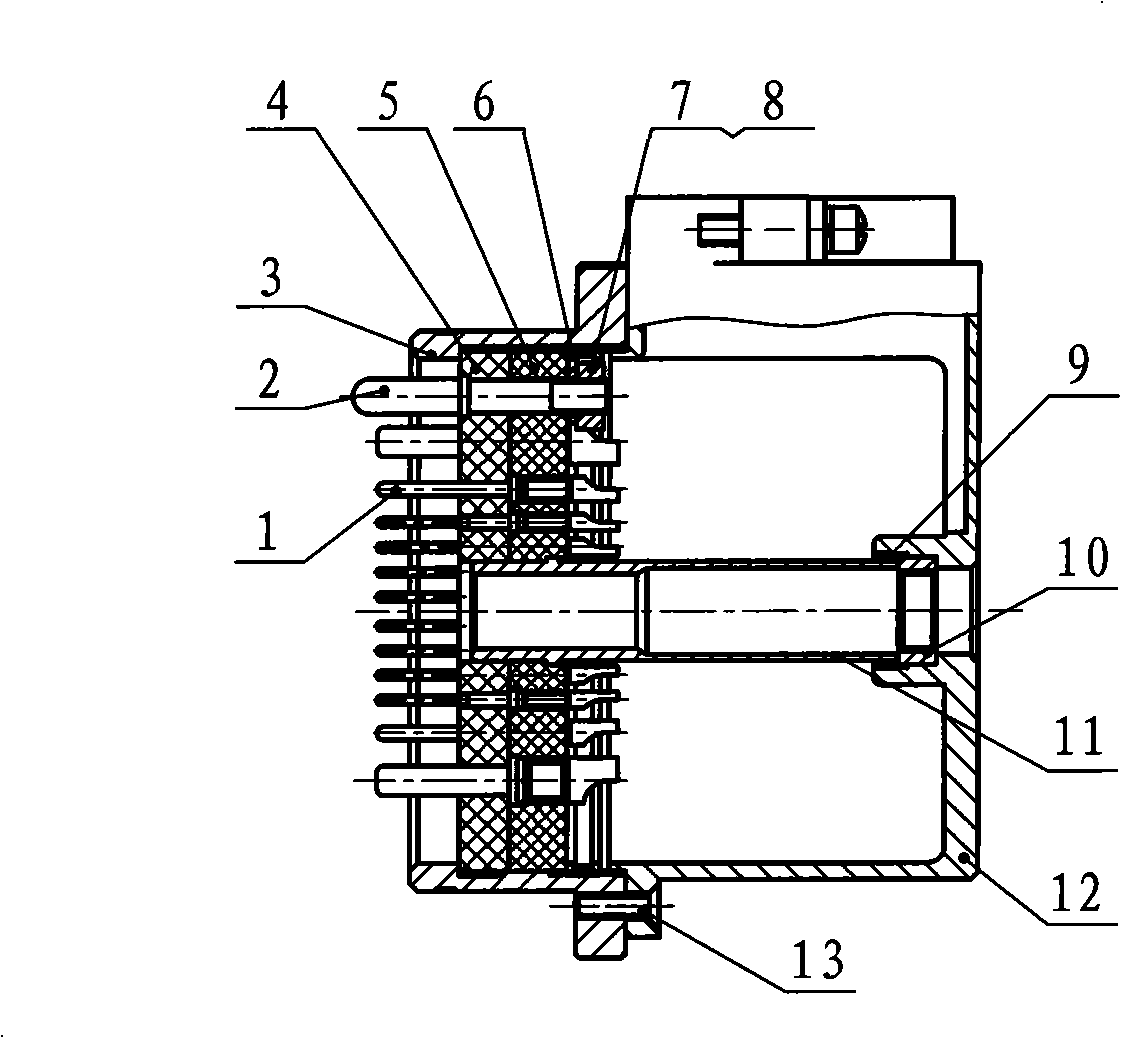

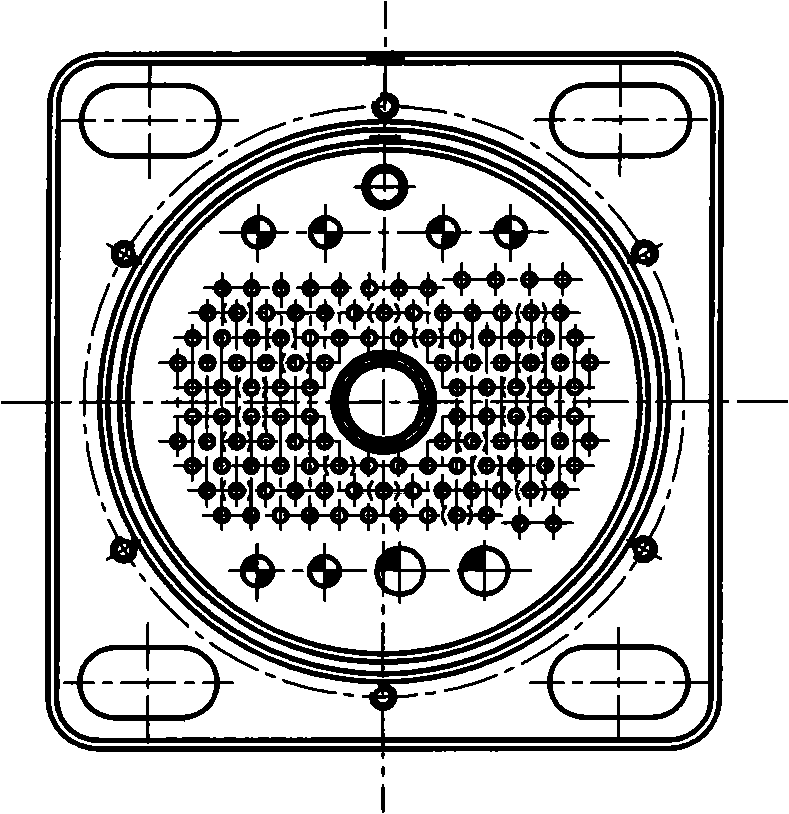

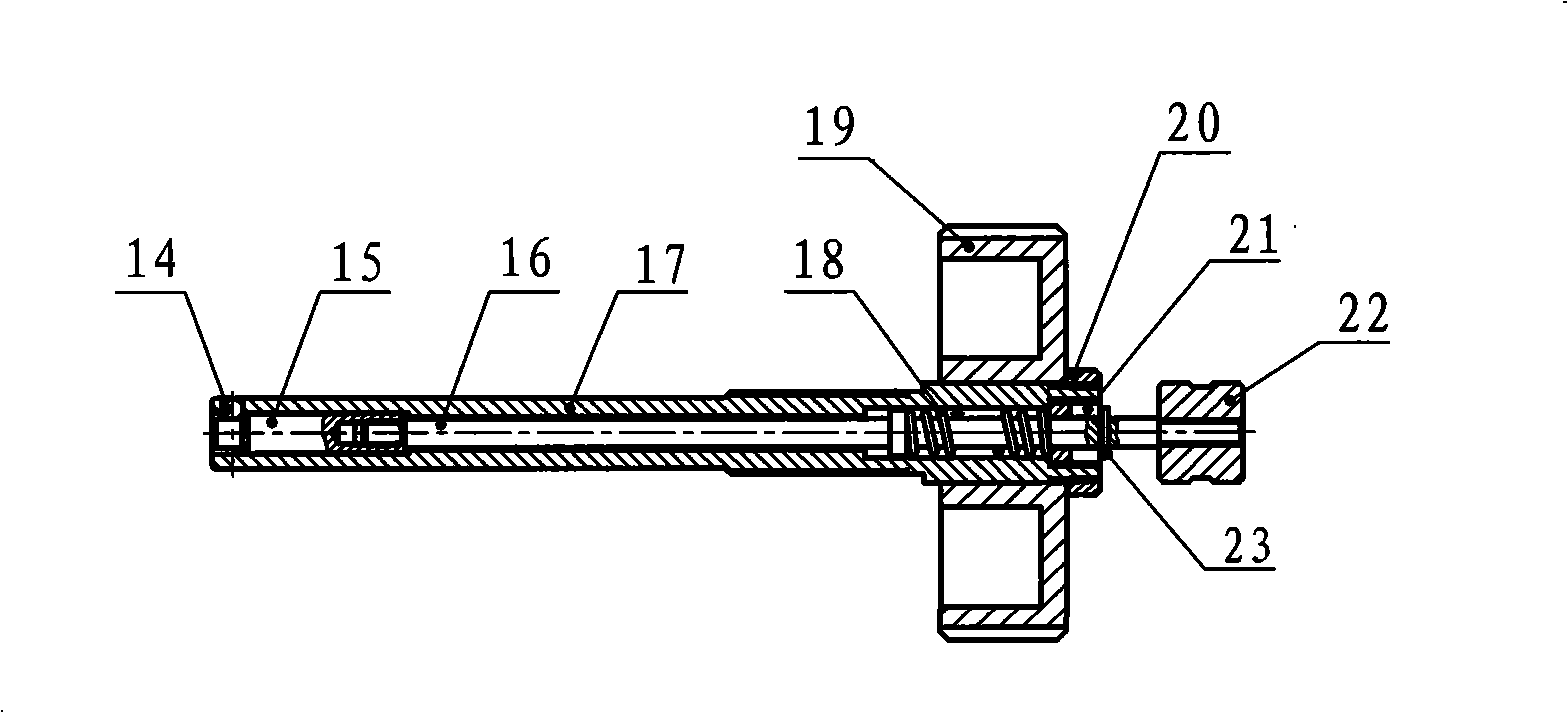

[0021] The labor-saving plug-in connector of the present invention comprises: a plug, a plug-in mechanism and a socket. Among them, the plug includes: pin 1, guide pin 2, shell 3, insulator 4, another insulator 5, pressure ring 6, spring washer 7, nut 8, pressure ring 9, screw sleeve 10, sleeve 11, tail cover 12 and screw 13. The plug-in mechanism includes: a steel ball 14, a push rod 15, a pull rod 16, a bush 17, a spring 18, a hand wheel 19, a nut 20, a positioning sleeve 21, a handle 22 and a bayonet pin 23. The socket includes: an O-ring 24 , a sealing ring 25 , a lock sleeve 26 , a nut 27 , a shell 28 , an insulator 29 , another insulator 30 , a pressure ring 31 , a jack 32 and another jack 33 .

[0022] Figure 1a , Figure 1b As shown in the figure, the plug pin 1 is kept in the correct position by the insulator 4 and another insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com