A kind of material automatic on-line device and its operation method

An automatic loading and material technology, applied to motor vehicles, conveyor objects, transportation and packaging, etc., can solve the problems of product quality and production efficiency that have not been greatly improved, manual operation, handling waste and high manpower consumption, etc. , to achieve the effect of facilitating automobile assembly materials, improving work efficiency, and reducing the cost of poor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings are only schematic diagrams rather than actual pictures, and should not be construed as limitations on this patent.

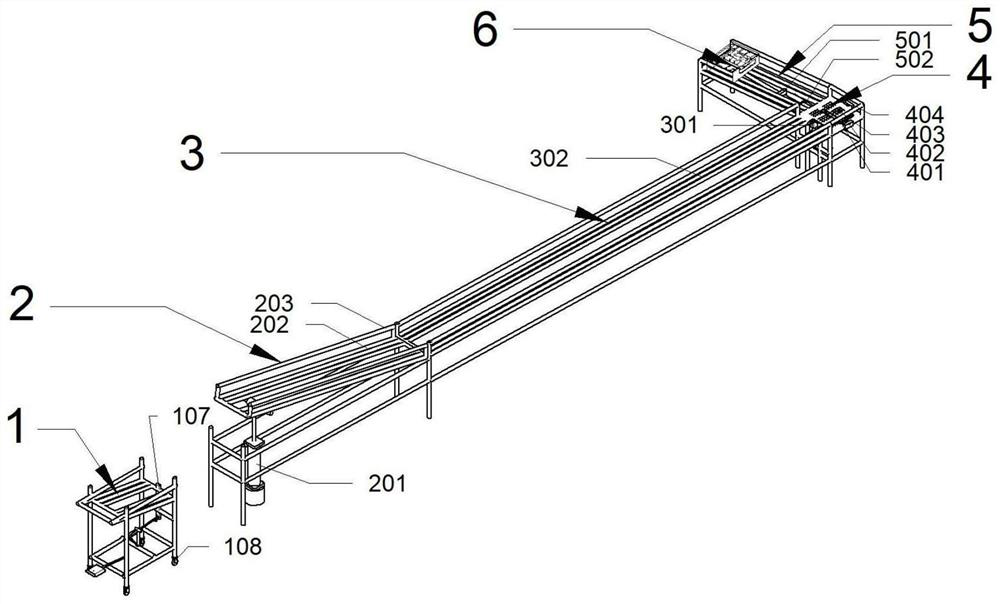

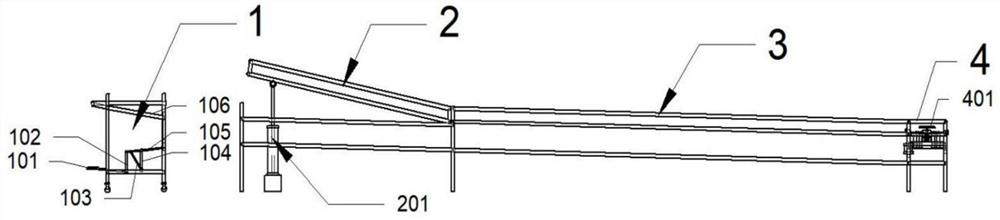

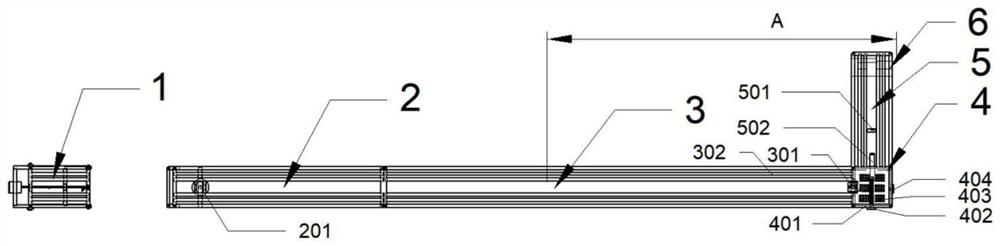

[0075] Such as Figure 1-6 As shown, a material automatic loading device includes a material turnover vehicle 1, a lifting guide mechanism 2, a conveying guide mechanism 3, a right-angle reversing mechanism 4, a material retrieving platform 5, and a material box 6. The material turnover vehicle 1 is used to turn over the on-line materials and discharge the on-line materials. The lifting guide mechanism 2 is used to raise the material and make the material slide to the rear section. One end of the conveying guide mechanism 3 is connected with the lift guide mechanism 2, and is used for transporting the materials sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com