Patents

Literature

330results about How to "Improve spray uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

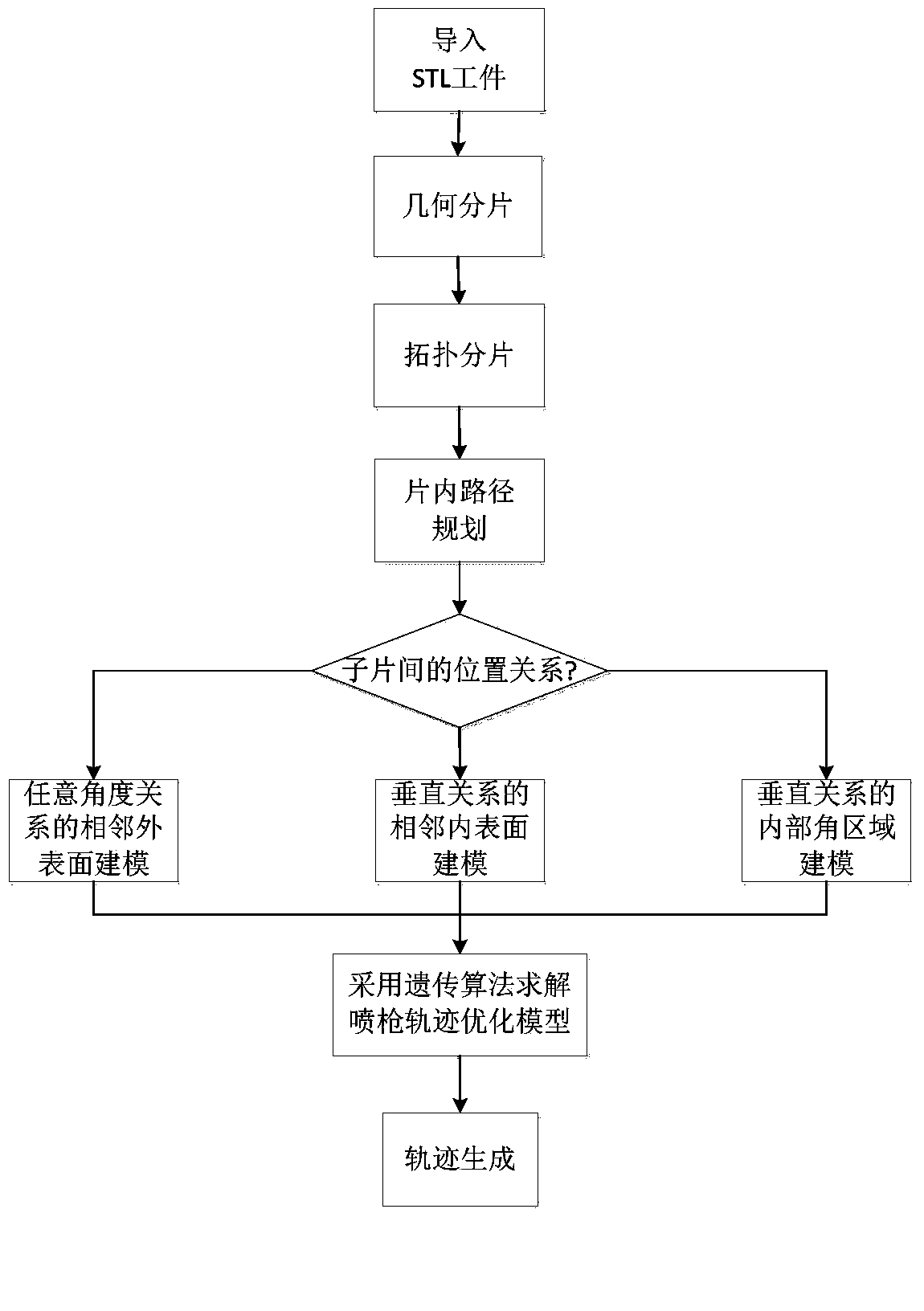

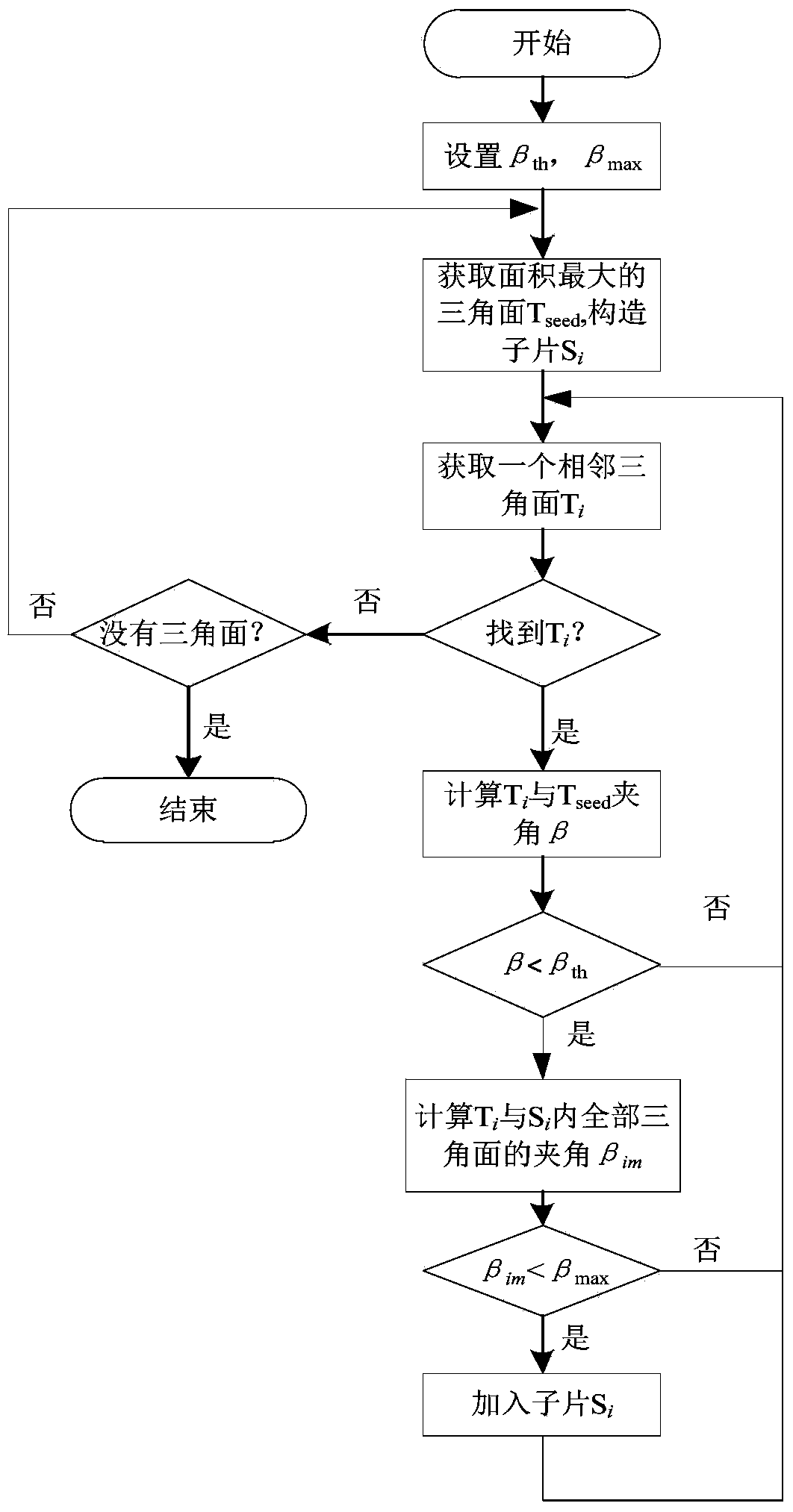

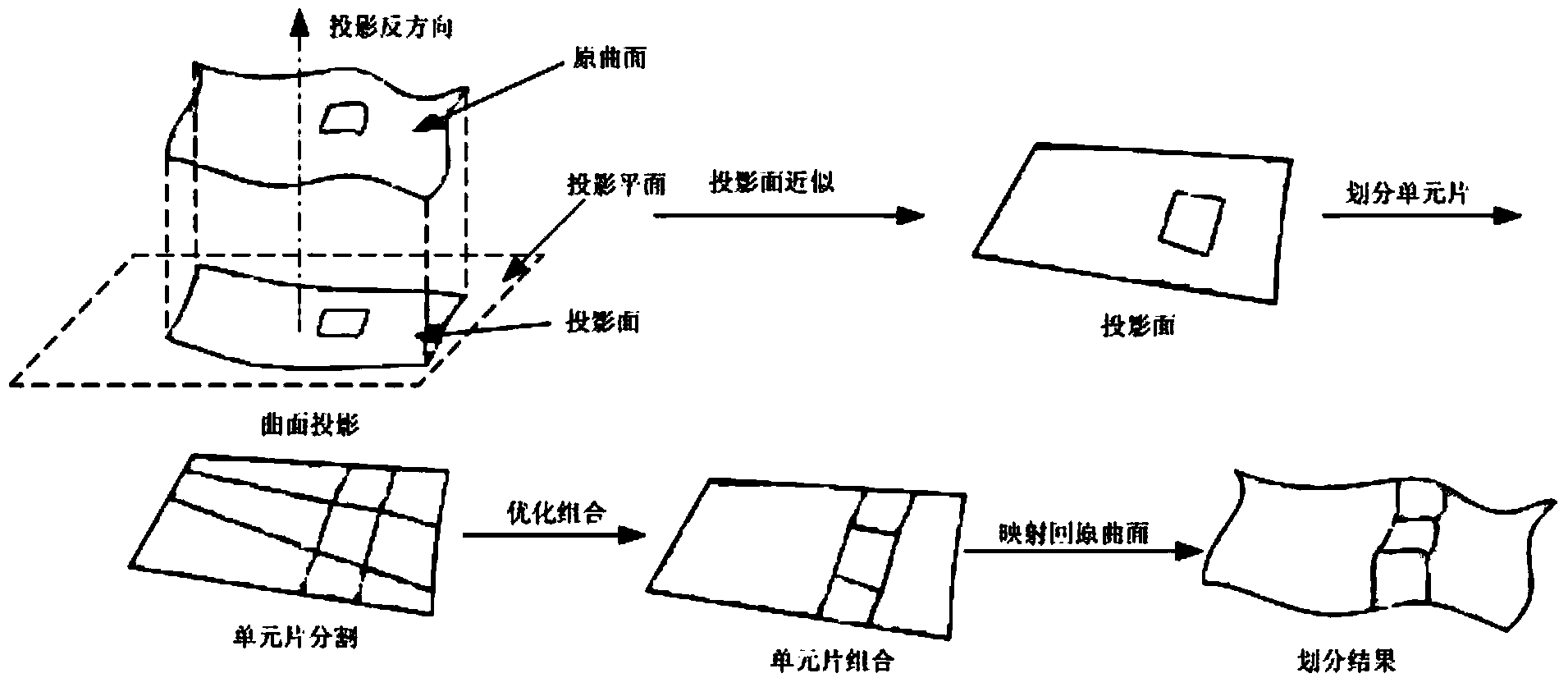

Inter-sheet dead area optimization process based uniform-spraying manufacturing method for complex curved surface

InactiveCN103394430AImprove spray uniformityImprove spray qualitySpraying apparatusNumerical modelsGenetic algorithm

The invention discloses an inter-sheet dead area optimization process based uniform-spraying manufacturing method for a complex curved surface. The inter-sheet dead area optimization process based uniform-spraying manufacturing method comprises the steps as follows: firstly, performing sheet division on an STL model via geometrical and topological characteristics of a workpiece, dividing the curved surface of the original workpiece into a plurality of simple sub-sheets approximate to planes and treating the sub-sheets respectively, then performing optimization solution on key spraying parameters such as the moving speed and the stroke pitch of a spray gun according to a spray forming model of the spray gun and corresponding process production indexes, so as to generate a spraying path inside each sub-sheet, extracting the position relation between edges of every two adjacent sub-sheets and the heading direction of the spray gun, and adopting a segmented sampling method to establish a numerical model for uniform spraying aiming at several common typical dead area conditions, and finally adopting a genetic algorithm to perform optimization solution on spraying paths in dead areas in an unified way. According to the invention, coating and manpower cost are saved, so that improvement on spraying production benefits is facilitated, and favorable application value and economic prospect are achieved.

Owner:SOUTHEAST UNIV

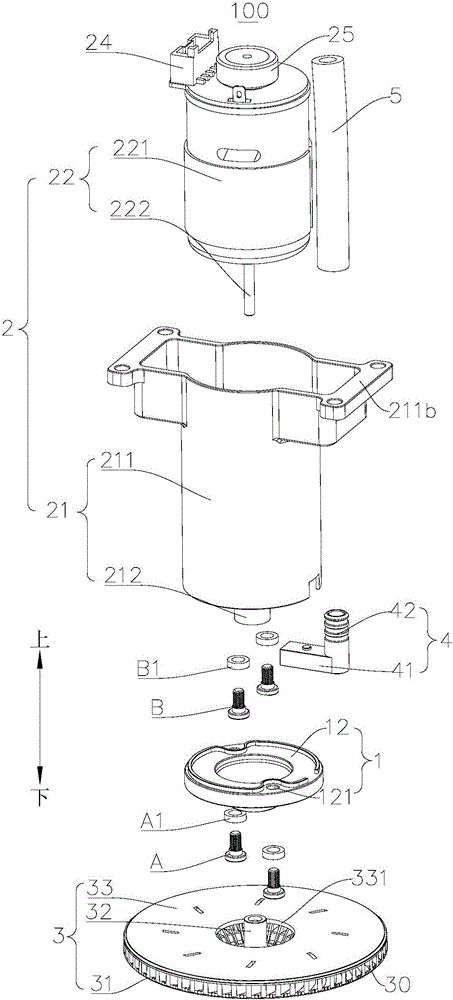

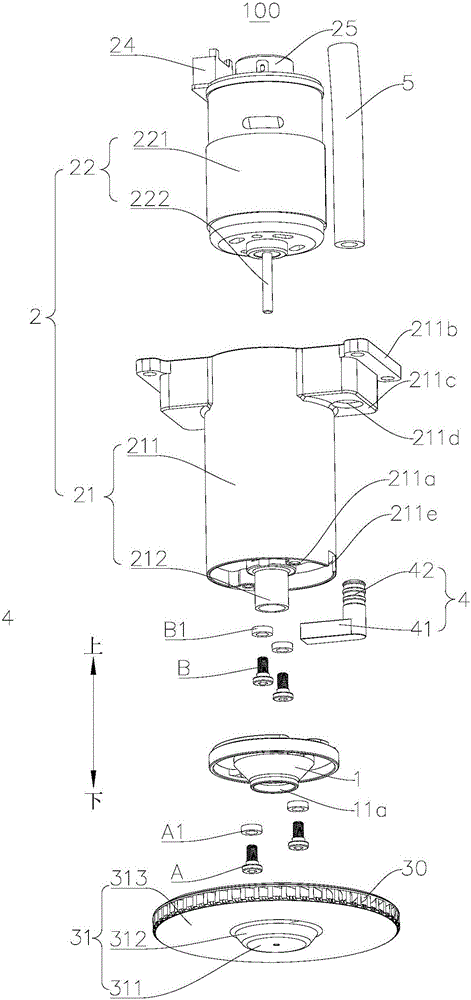

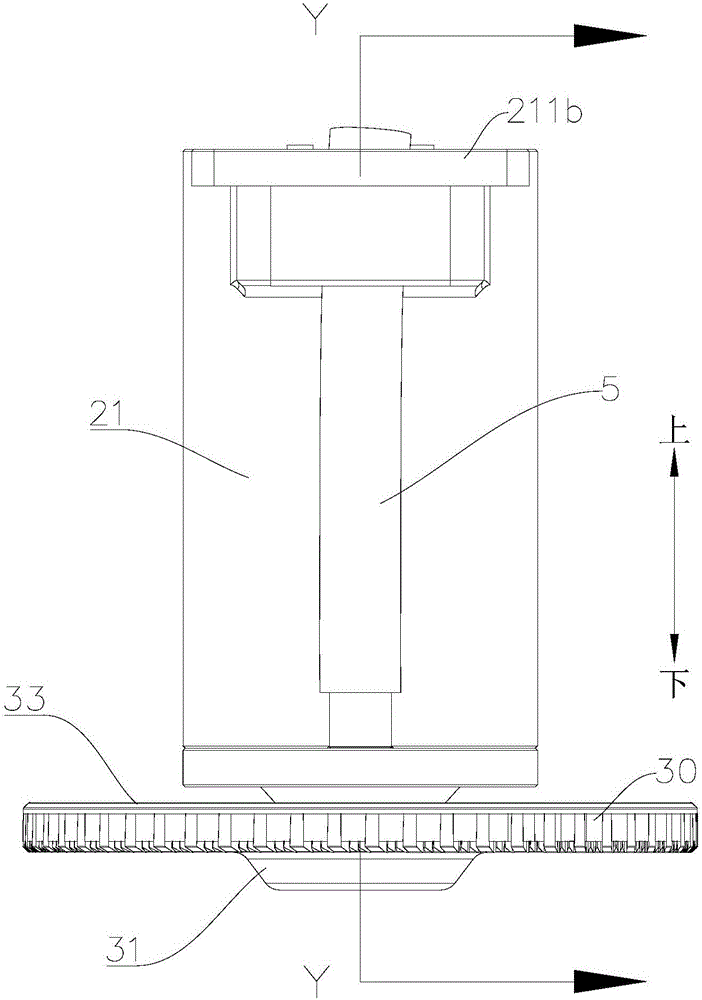

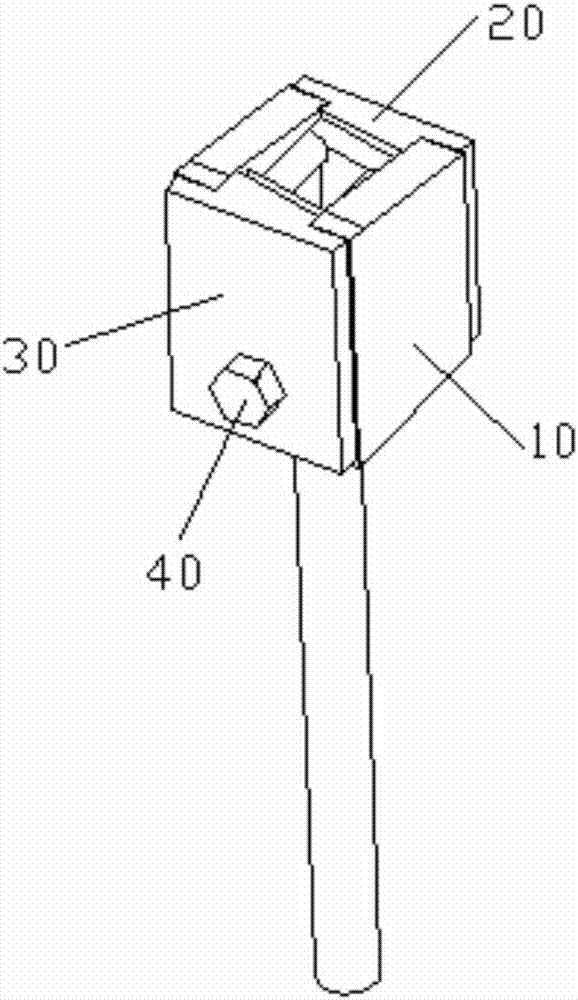

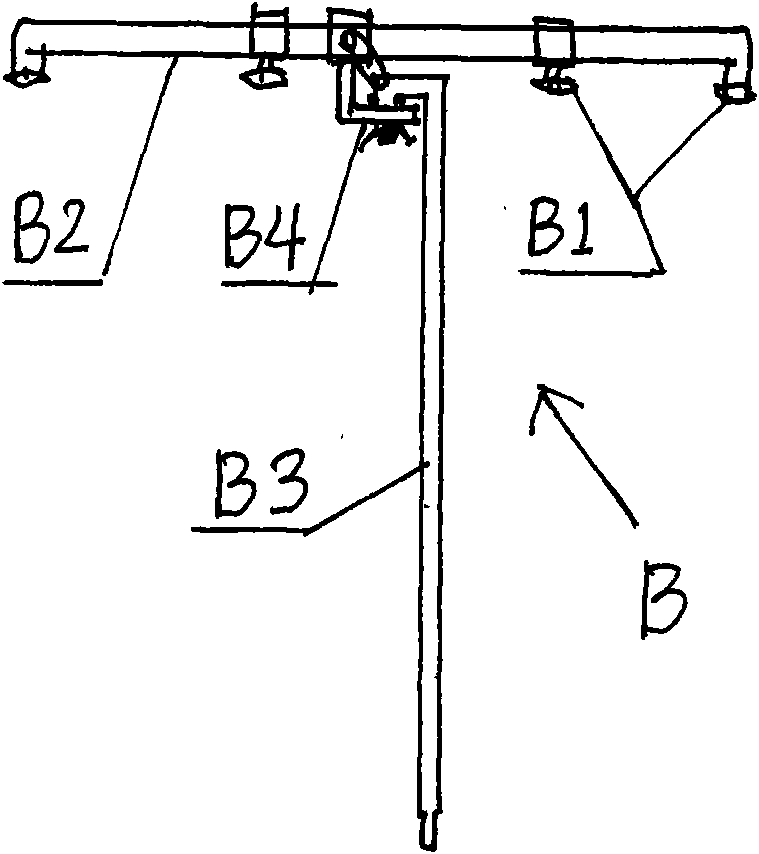

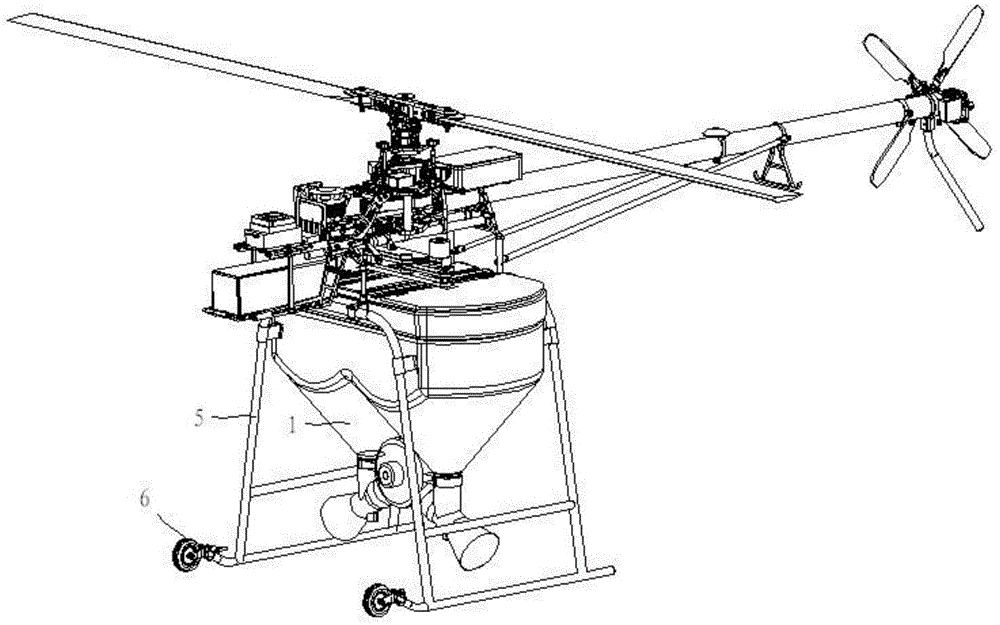

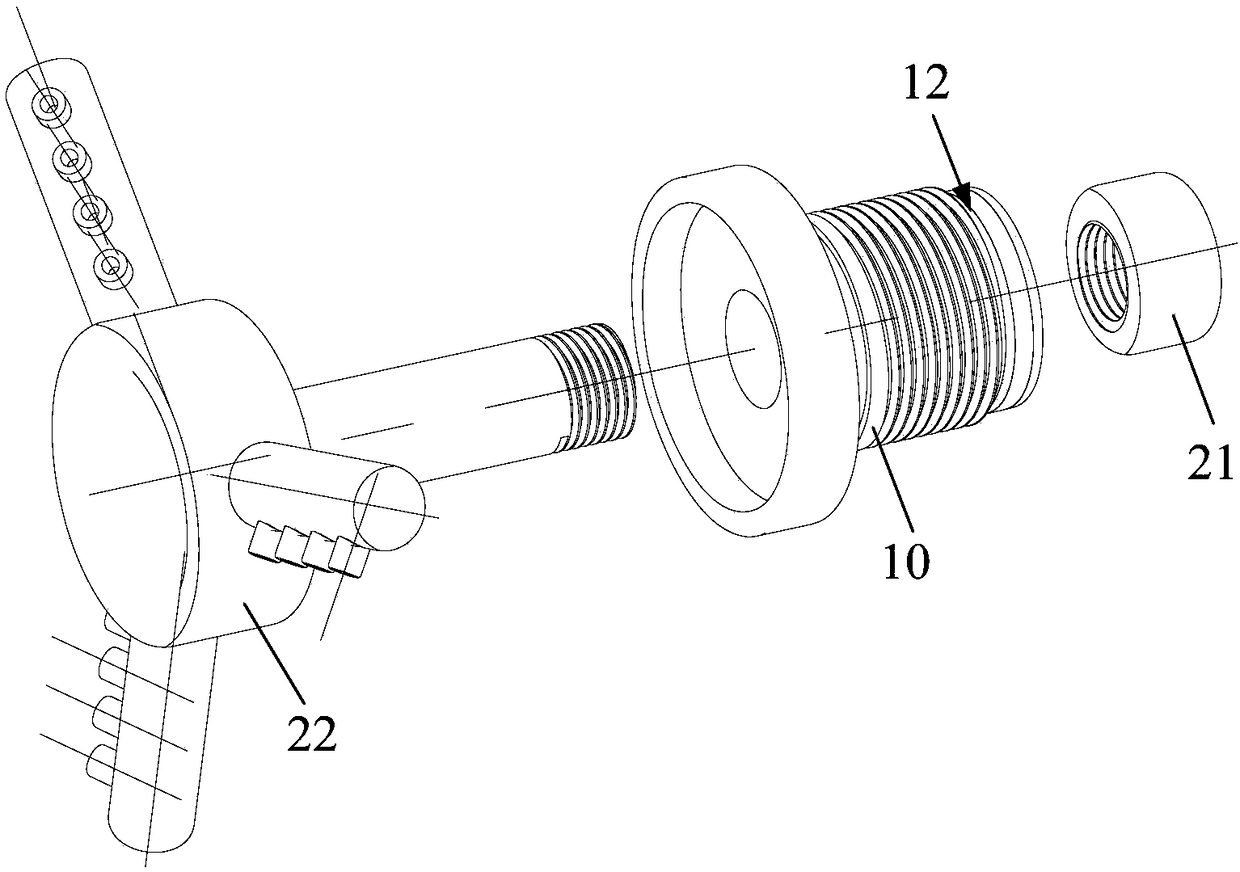

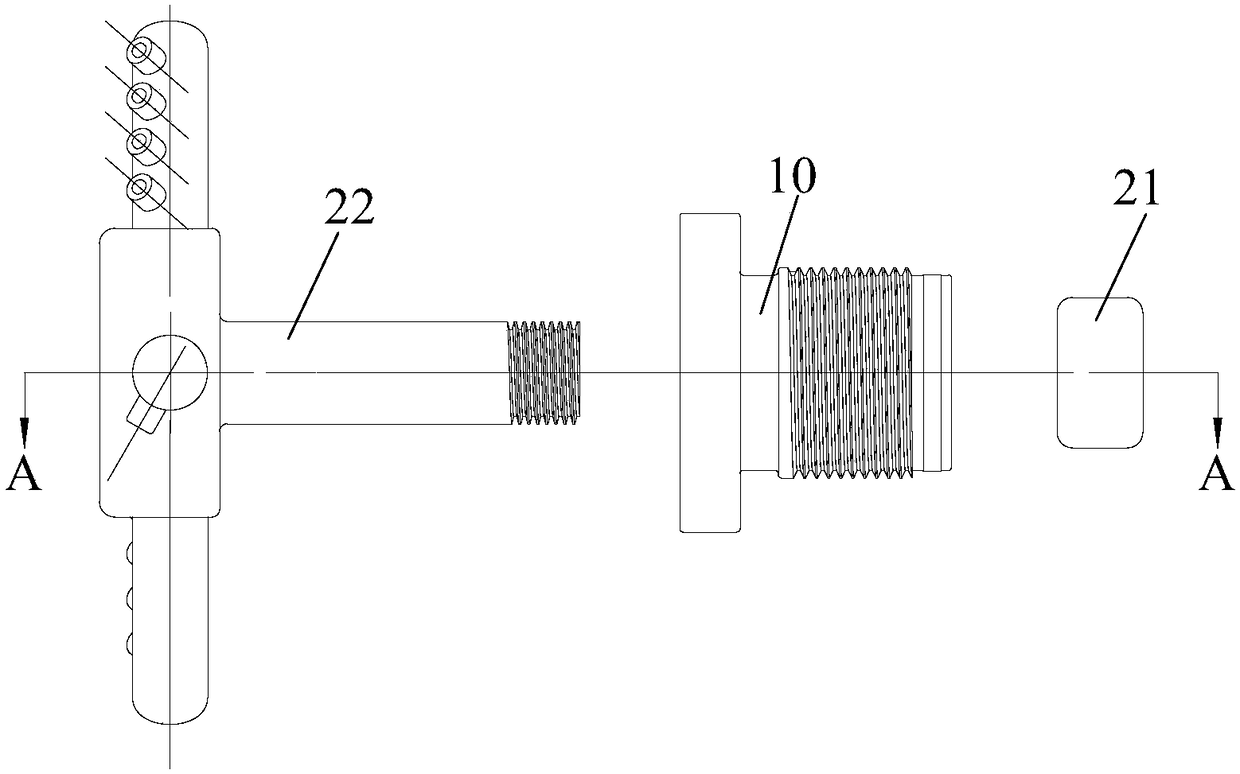

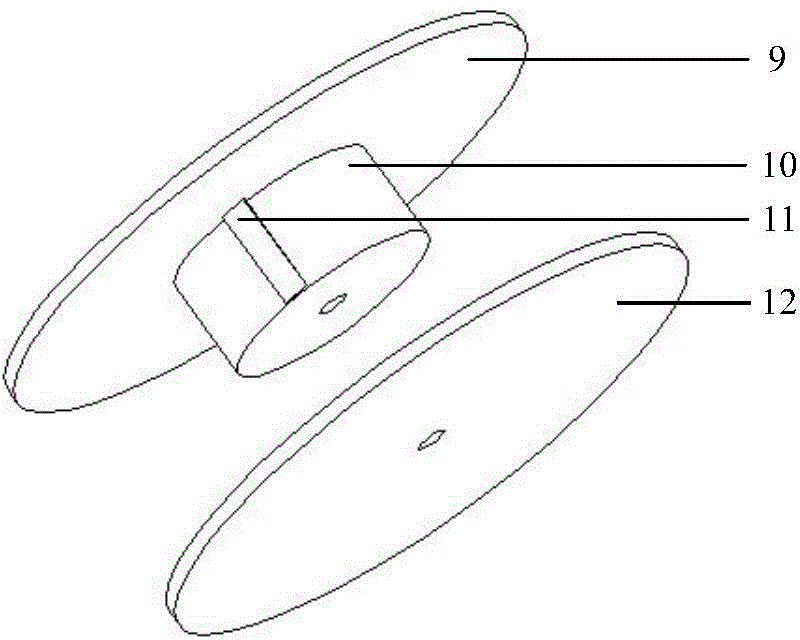

Sprinkler and unmanned aerial vehicle comprising same

ActiveCN105750107AExquisite structureImprove spray uniformityAircraft componentsMovable spraying apparatusEngineeringMechanical engineering

The invention discloses a sprinkler and an unmanned aerial vehicle comprising the same. The sprinkler comprises a liquid hopper, a motor and a centrifugal sprinkling disk, wherein a liquid drain outlet is formed in the bottom of the liquid hopper; the motor comprises a core and a shaft, the core is arranged above the liquid hopper, and the shaft is connected with the core and extends downwards into the liquid hopper from the top of the liquid hopper; the centrifugal sprinkling disk comprises a rotating disk and a rotating shaft, the rotating disk is positioned below the liquid hopper to receive liquid drained from the liquid drain outlet, and the rotating shaft is fixed in the center of the rotating disk and extends upwards into the liquid hopper from the liquid drain outlet to be connected with the shaft directly. The sprinkler has the advantages that since the liquid drain outlet sleeves the rotating shaft, the liquid hopper can pour liquid towards the center of the centrifugal sprinkling disk to increase sprinkling uniformity and improve droplet splashing effectively; since the liquid is poured to the centrifugal sprinkling disk by the liquid hopper, machining the shaft to be of a hollow structure is unneeded, and machining difficulty and production cost are lowered accordingly.

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

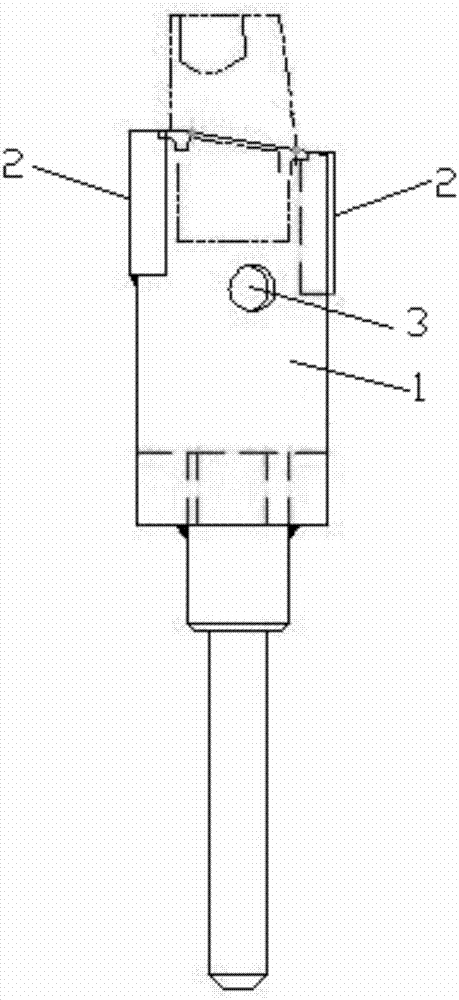

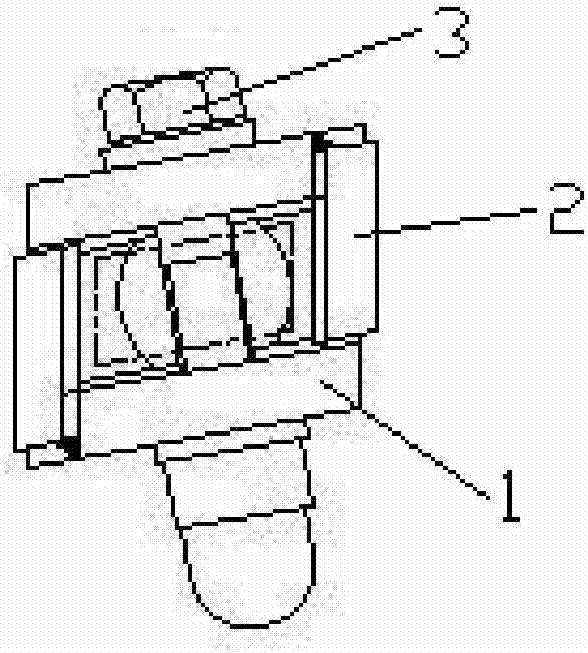

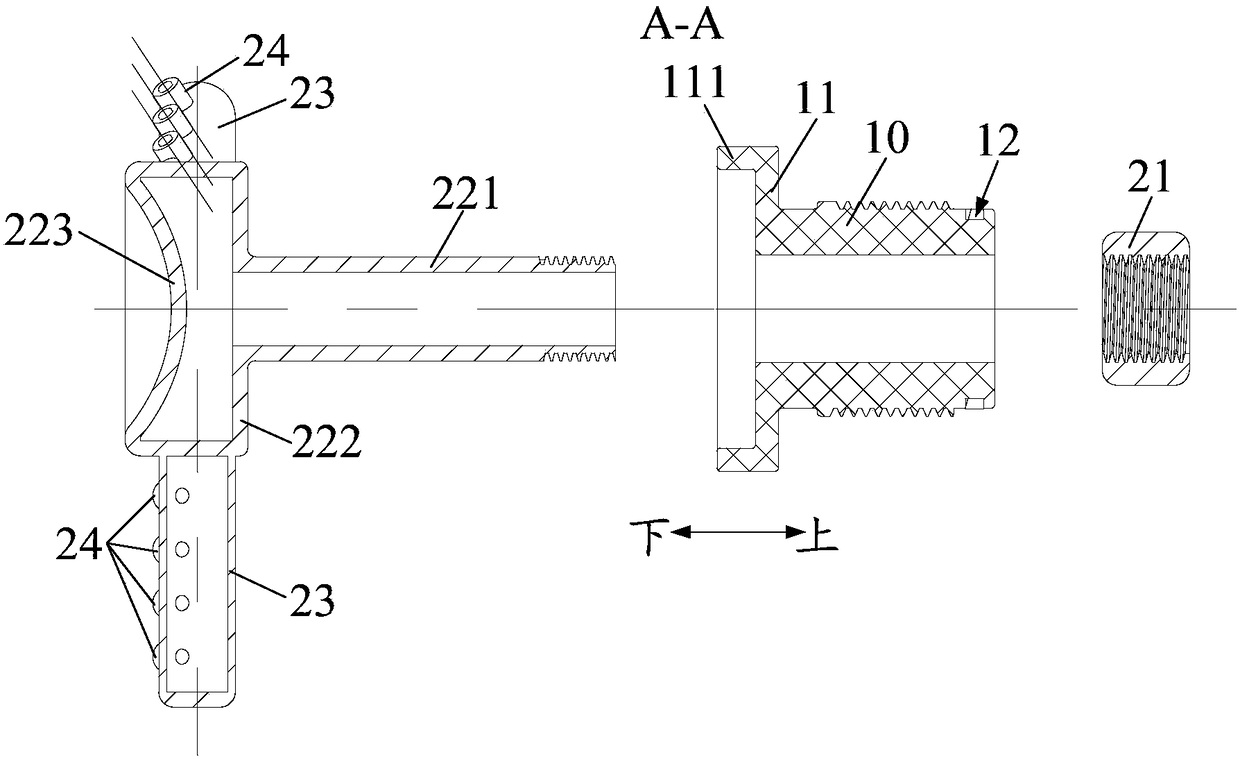

Blade spraying protective fixture

ActiveCN107138325AImprove spray uniformityNot prone to "collapse" phenomenonSpraying apparatusFlangeEngineering

Owner:CHINA HANGFA SOUTH IND CO LTD

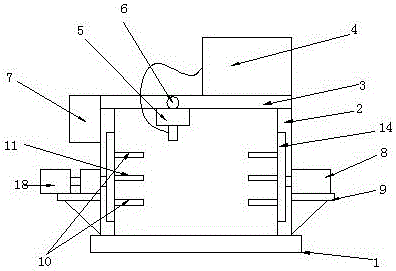

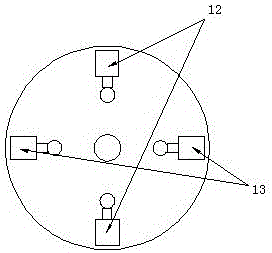

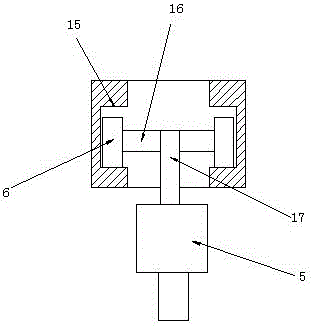

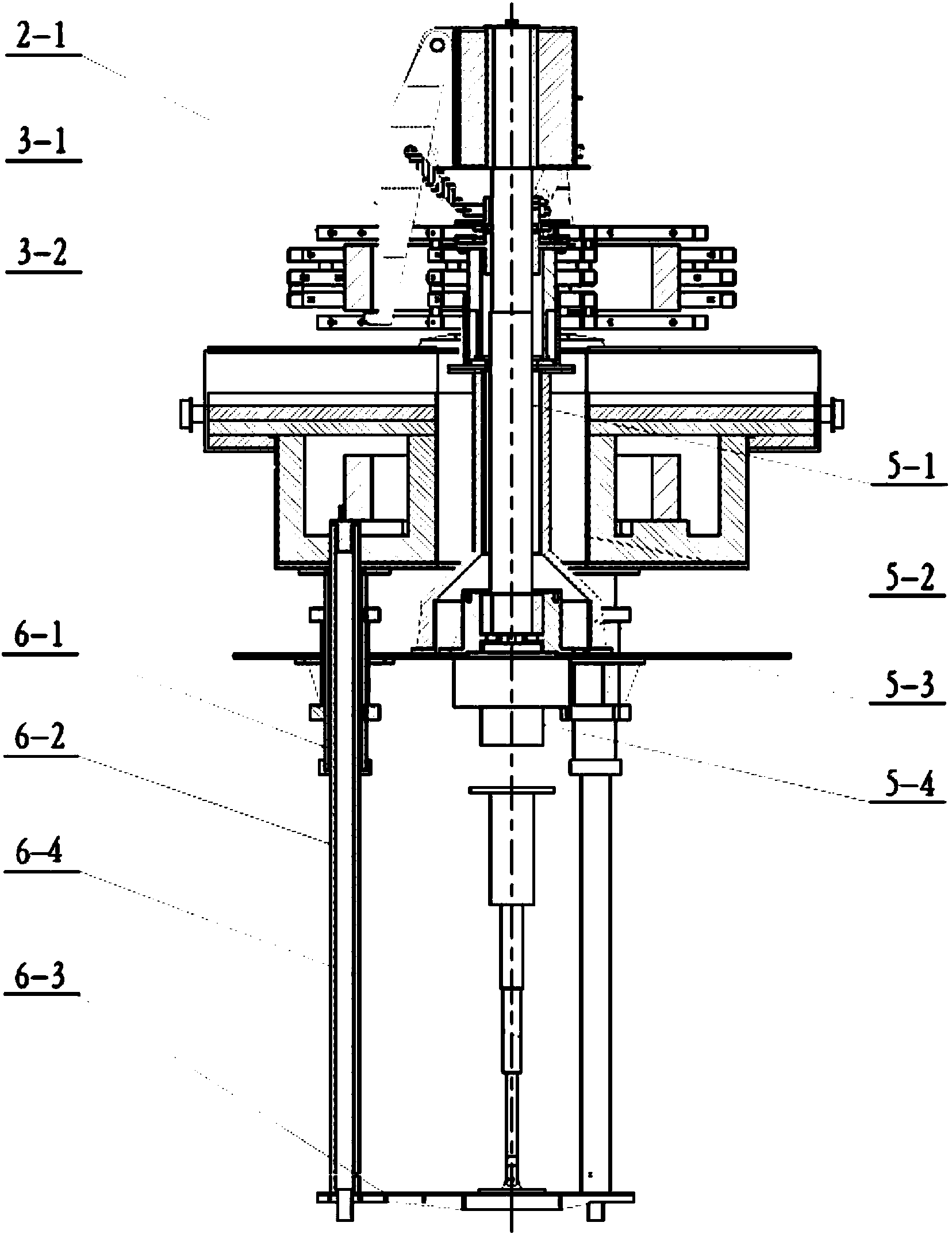

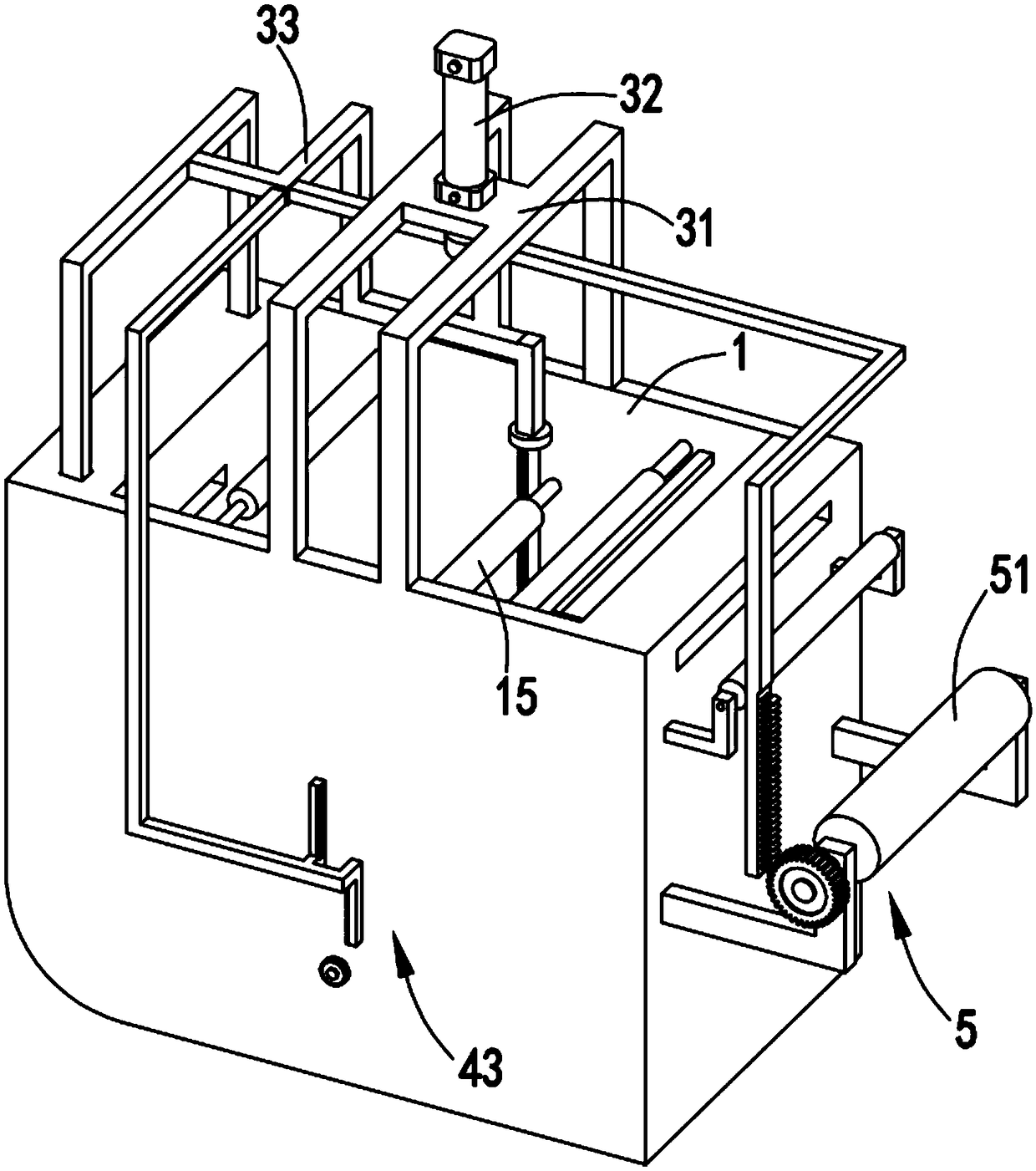

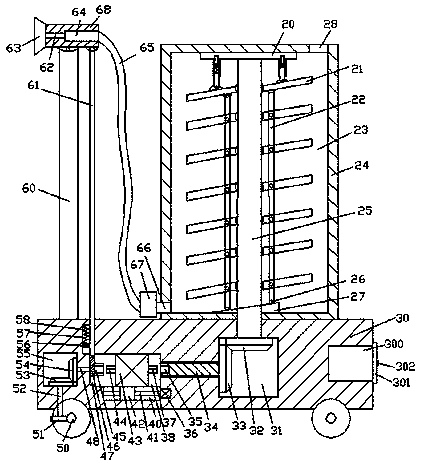

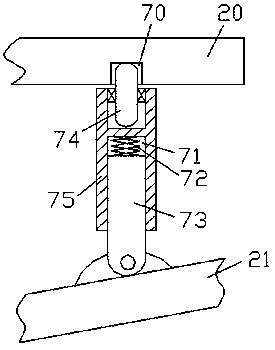

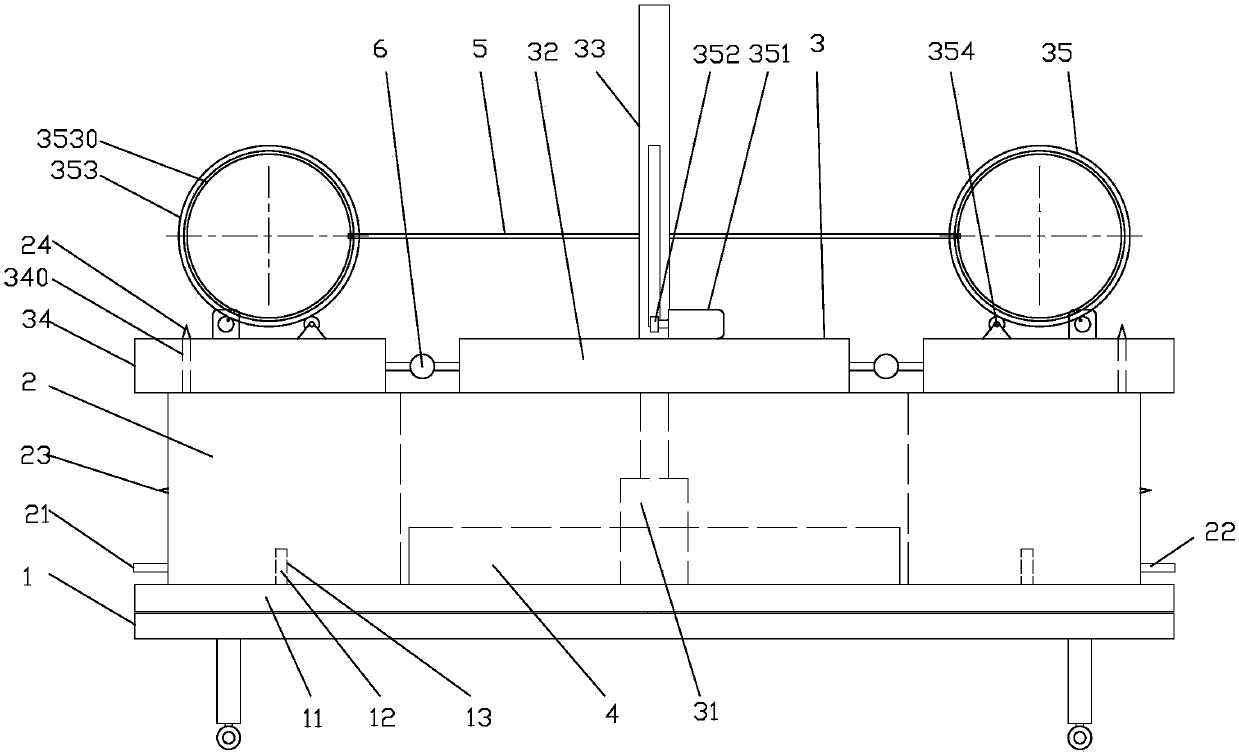

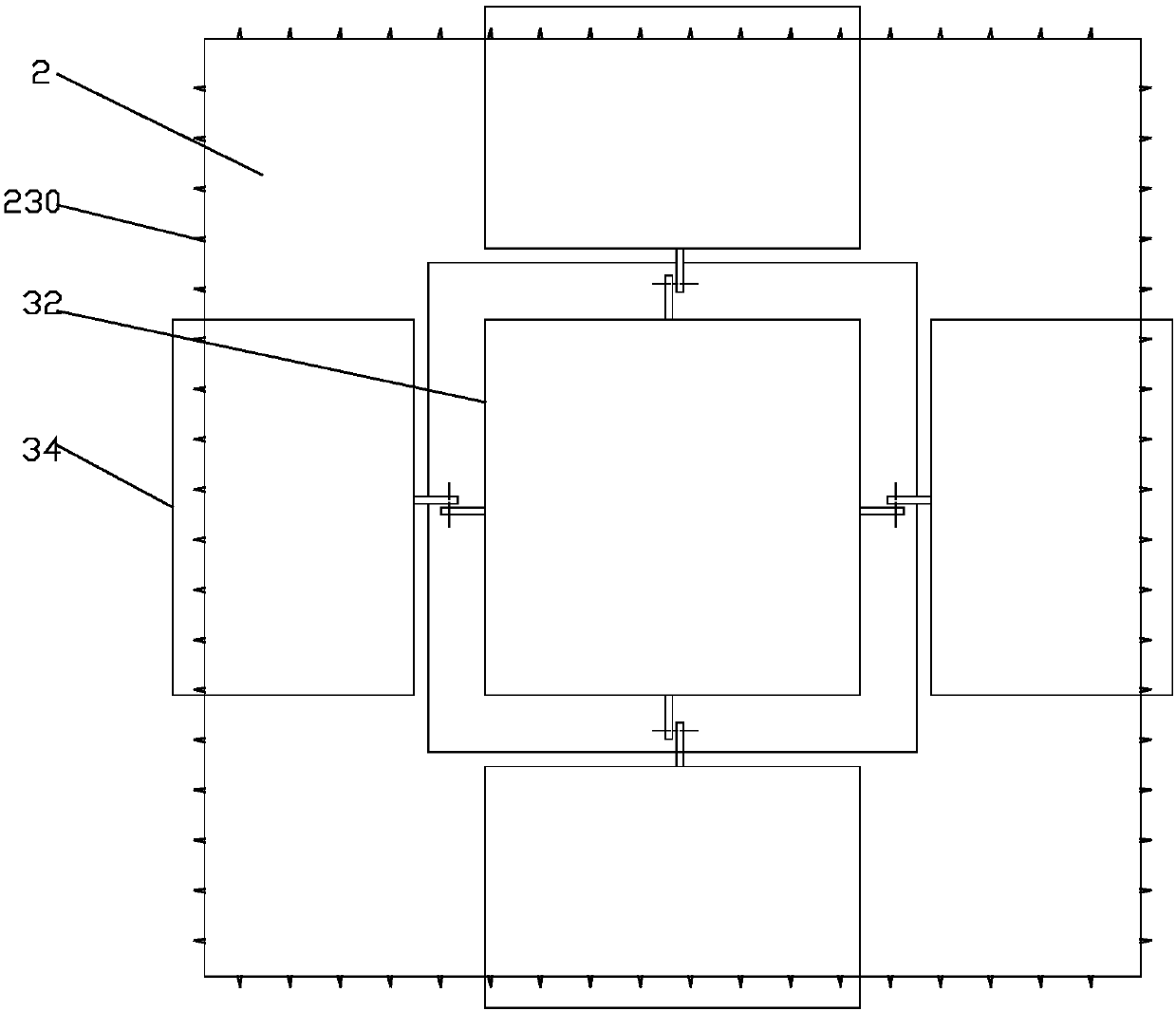

Full-automatic equipment suitable for pipeline spraying

ActiveCN106140532AImprove spray uniformityImprove spray qualityLiquid surface applicatorsCoatingsMechanical equipmentElectric control

The invention relates to full-automatic mechanical equipment, in particular to full-automatic equipment suitable for pipeline spraying. Vertical plates are arranged on the two sides of a base. A top plate is arranged at the tops of the vertical plates. A spraying liquid tank is arranged on the top plate. The spraying liquid tank is connected with a spraying gun through a pipeline. The spraying gun is movably arranged on the lower portion of the top plate through an electric hub. A rotary round plate is arranged on the inner side of each vertical plate, and each rotary round plate is fixed to an output shaft of a rotation motor. The rotation motors are fixed to the outer sides of the vertical plates. Two longitudinal distance adjusting motors are symmetrically arranged on each rotary round plate in the longitudinal direction. An output shaft of each longitudinal distance adjusting motor is connected with a longitudinal fixing rod. Two transverse distance adjusting motors are symmetrically arranged on each rotary round plate in the transverse direction. An output shaft of each transverse distance adjusting motor is connected with a transverse fixing rod. An electric control cabinet is connected to one side of one vertical plate. According to the full-automatic equipment, full-automatic spraying treatment can be conducted on the outer walls of pipeline type parts, the spraying uniformity is improved, the spraying quality is improved, and the practicability is higher.

Owner:XINGUANG NUMERICAL CONTROL TECH

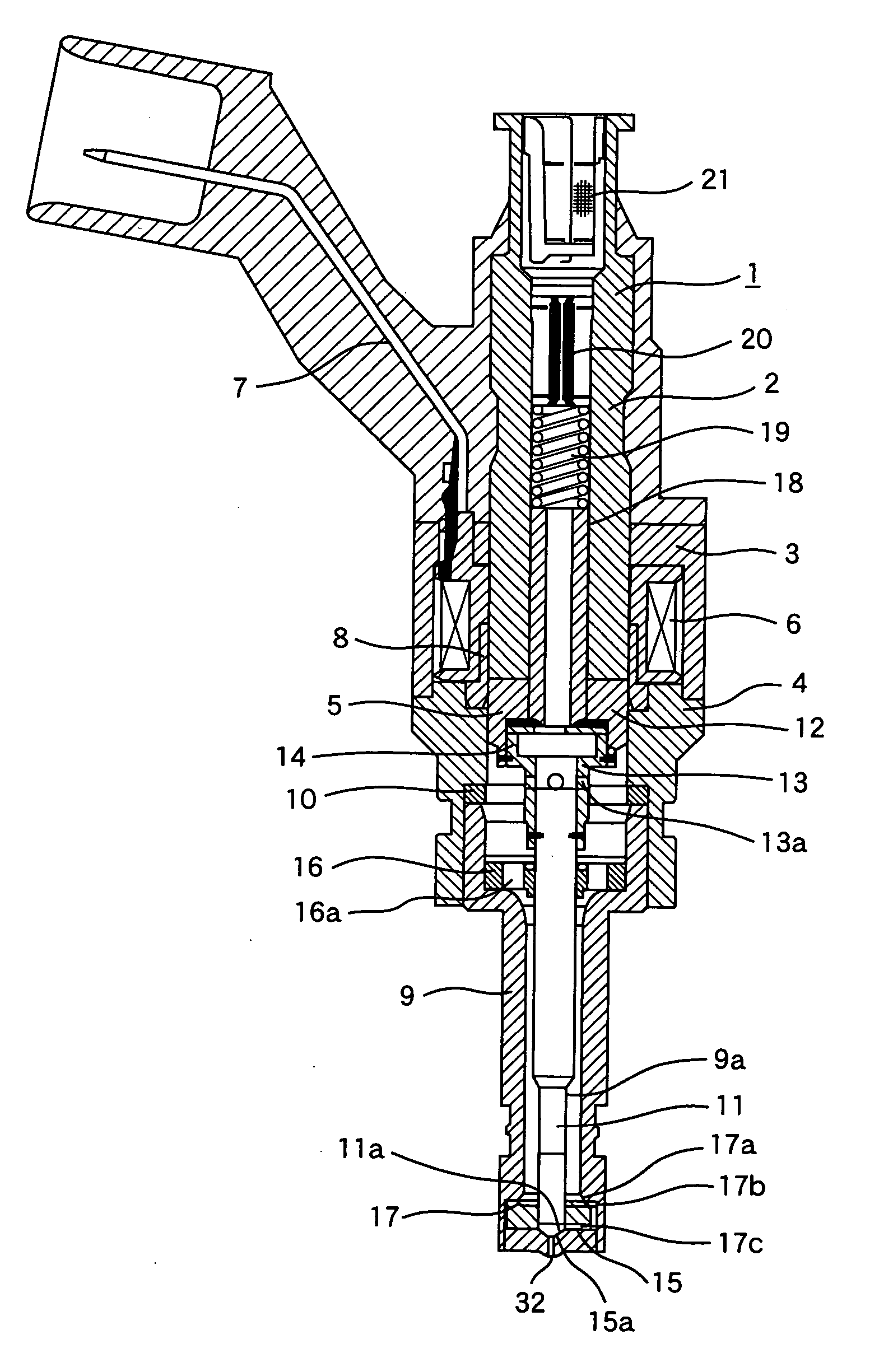

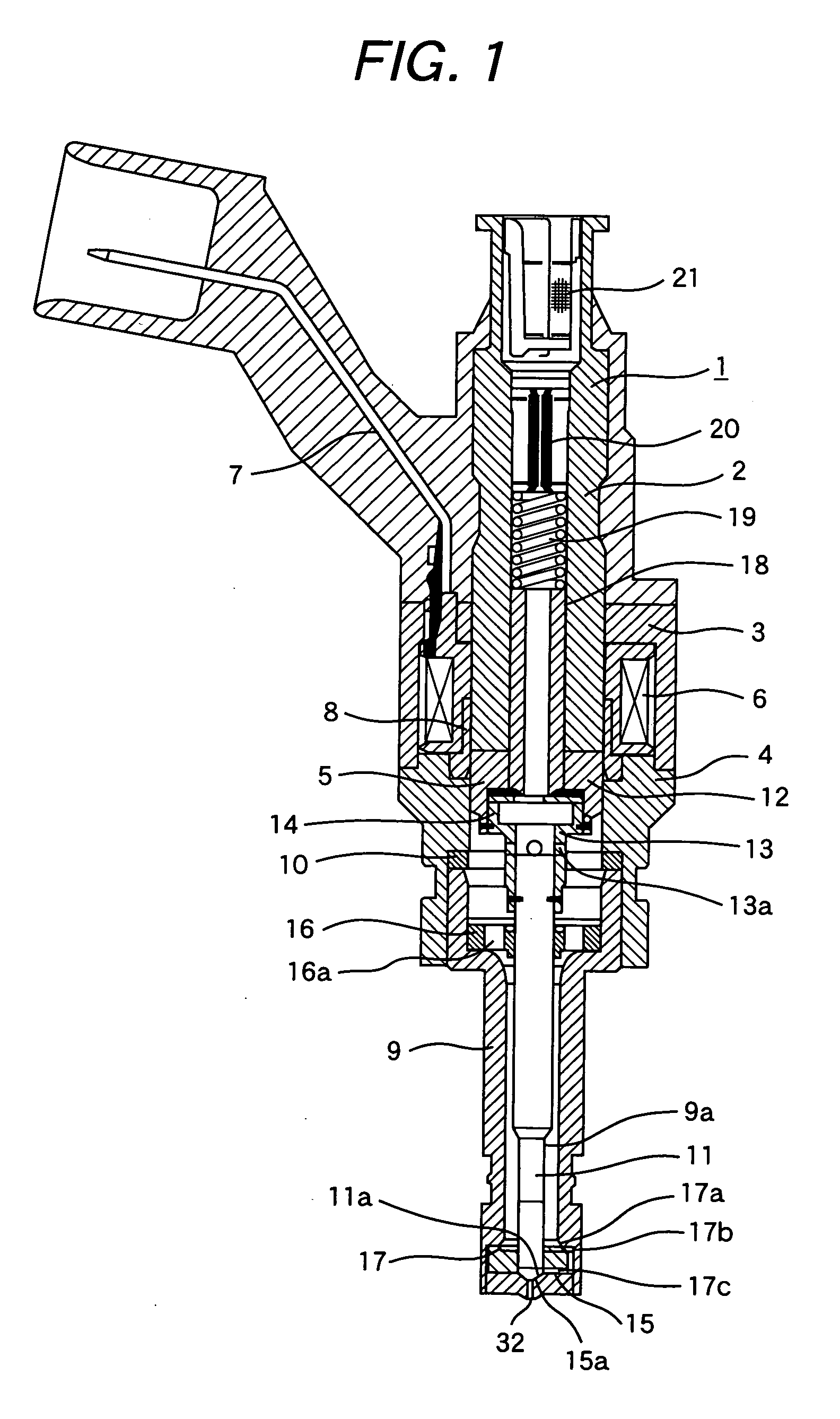

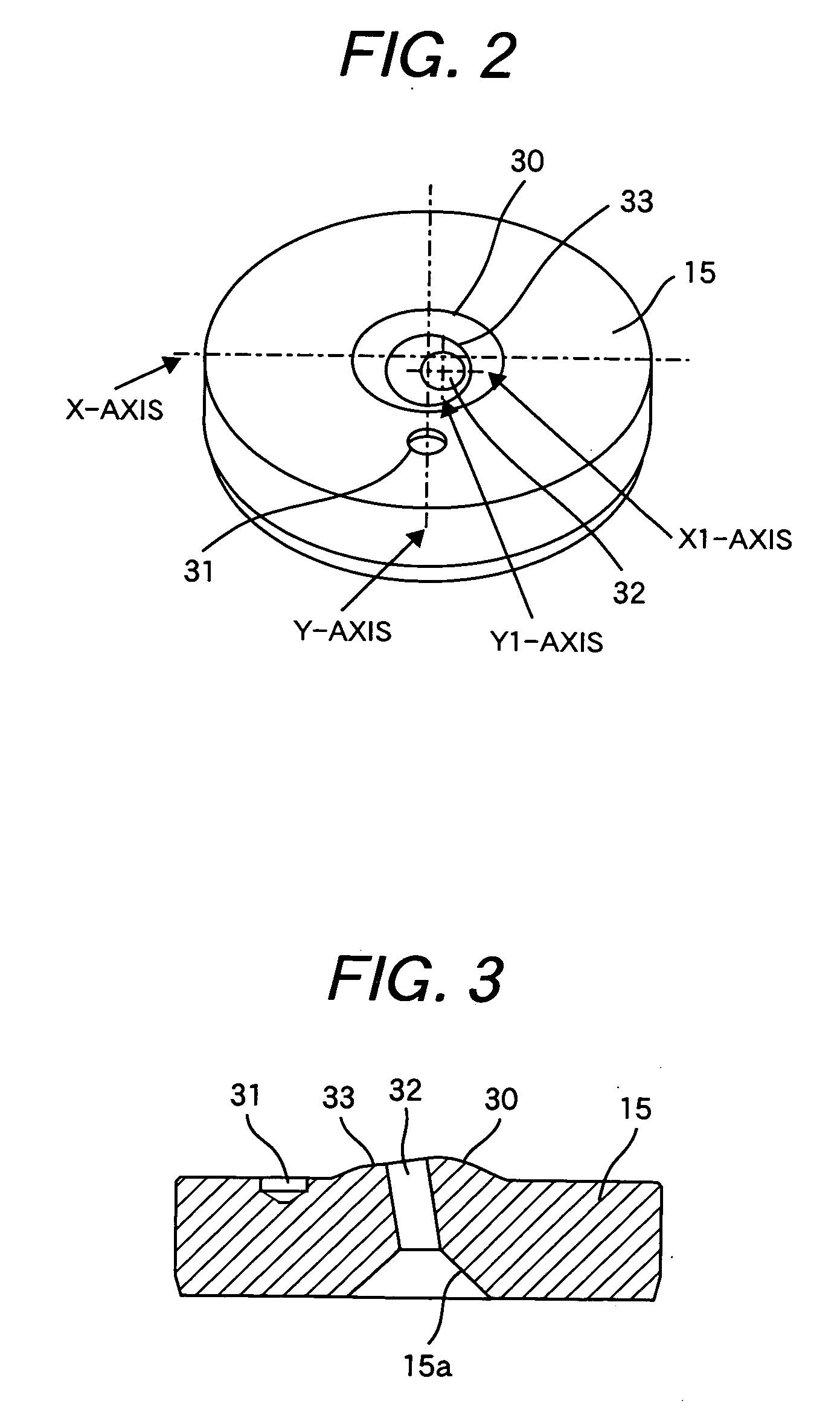

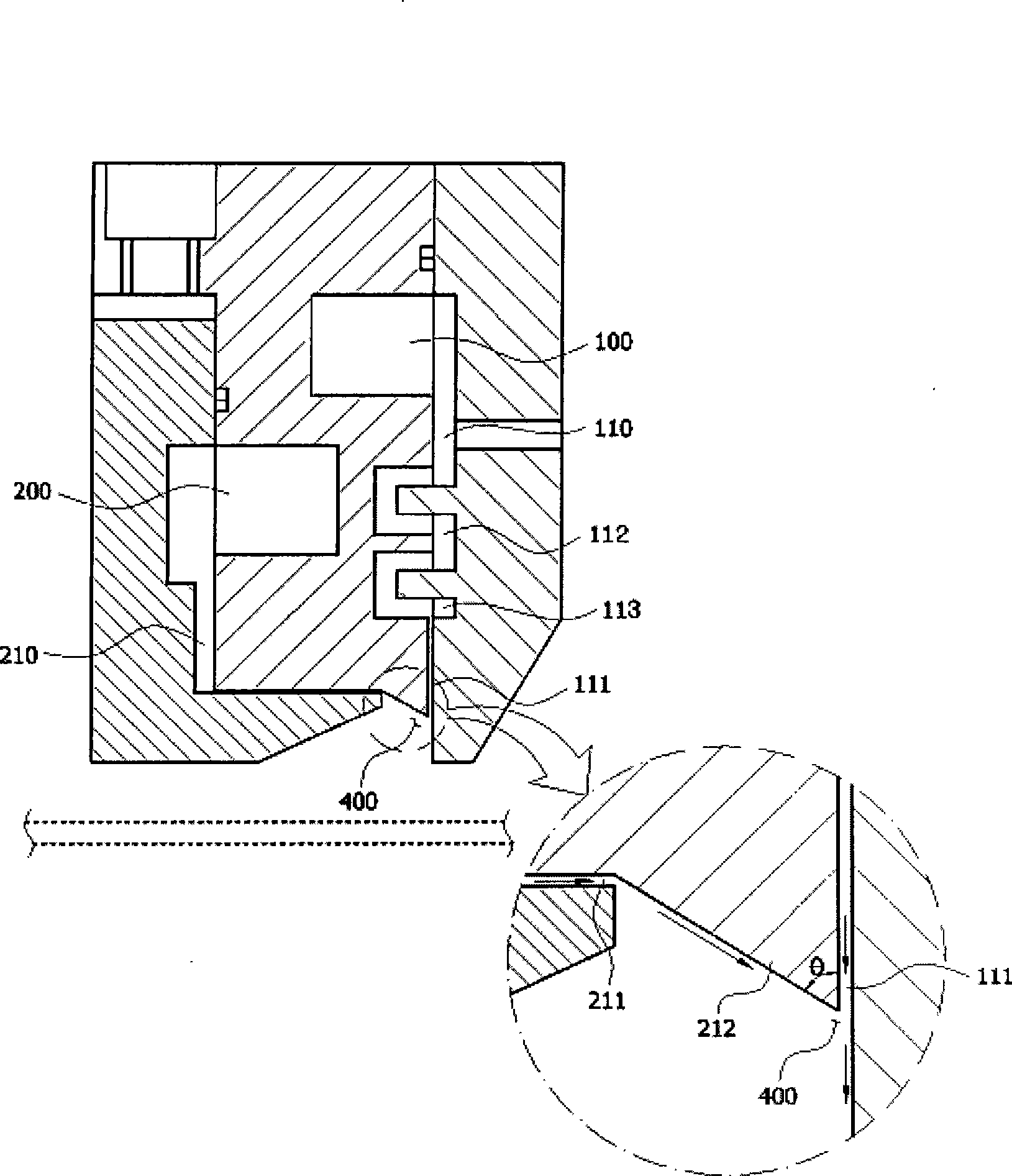

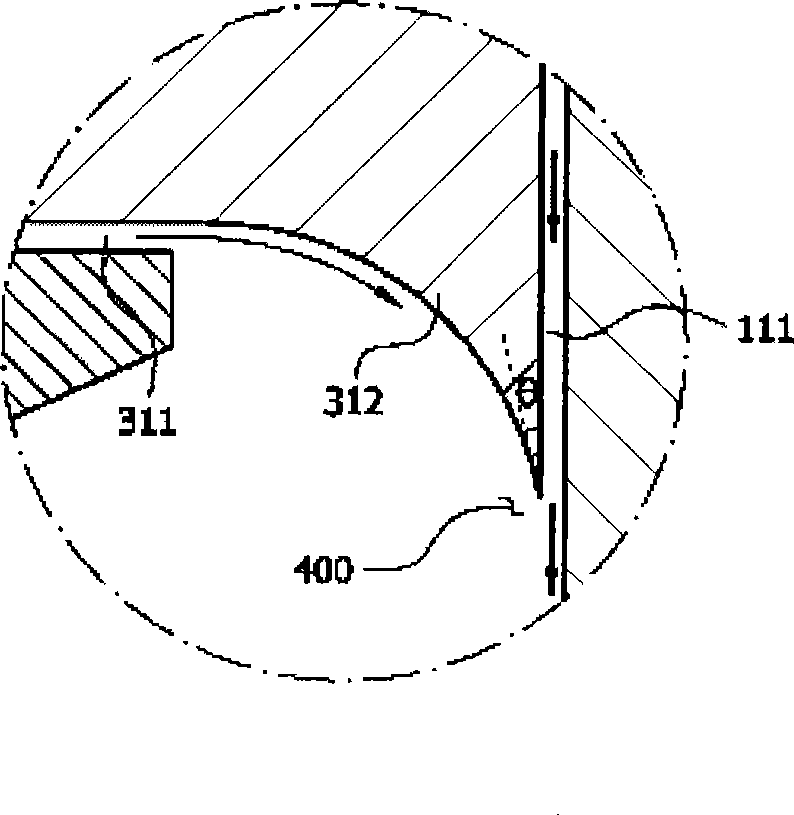

Injection valve and method of making orifice

InactiveUS20070057093A1Improve spray uniformityEasy to processValve arrangementsPiercing pressesOrifice plateEngineering

An injection valve has a nozzle body, a valve needle positioned in the nozzle body, an actuator for actuating the valve needle, and an orifice plate fixed at an end of the nozzle body. The orifice plate has a valve seat for cooperate with the valve needle and an orifice for injecting a fluid. The orifice plate is provided with a projection having a convex-curved surface on an orifice outlet side of the orifice plate. A flat surface portion is formed in the area of the convex-curved surface, and the outlet of the orifice is located in the flat surface portion.

Owner:HITACHI LTD

Aluminum alloy ring part spray-quenching equipment and using method thereof

ActiveCN104313274AEliminate Radial DistortionImprove performanceFurnace typesHeat treatment furnacesSupporting systemAutomatic control

Owner:CENT SOUTH UNIV

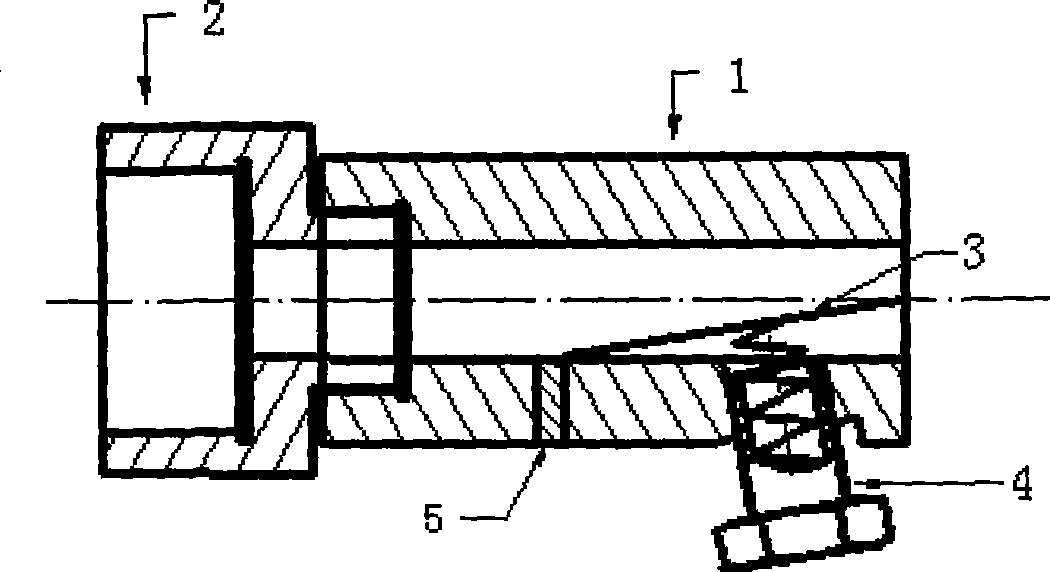

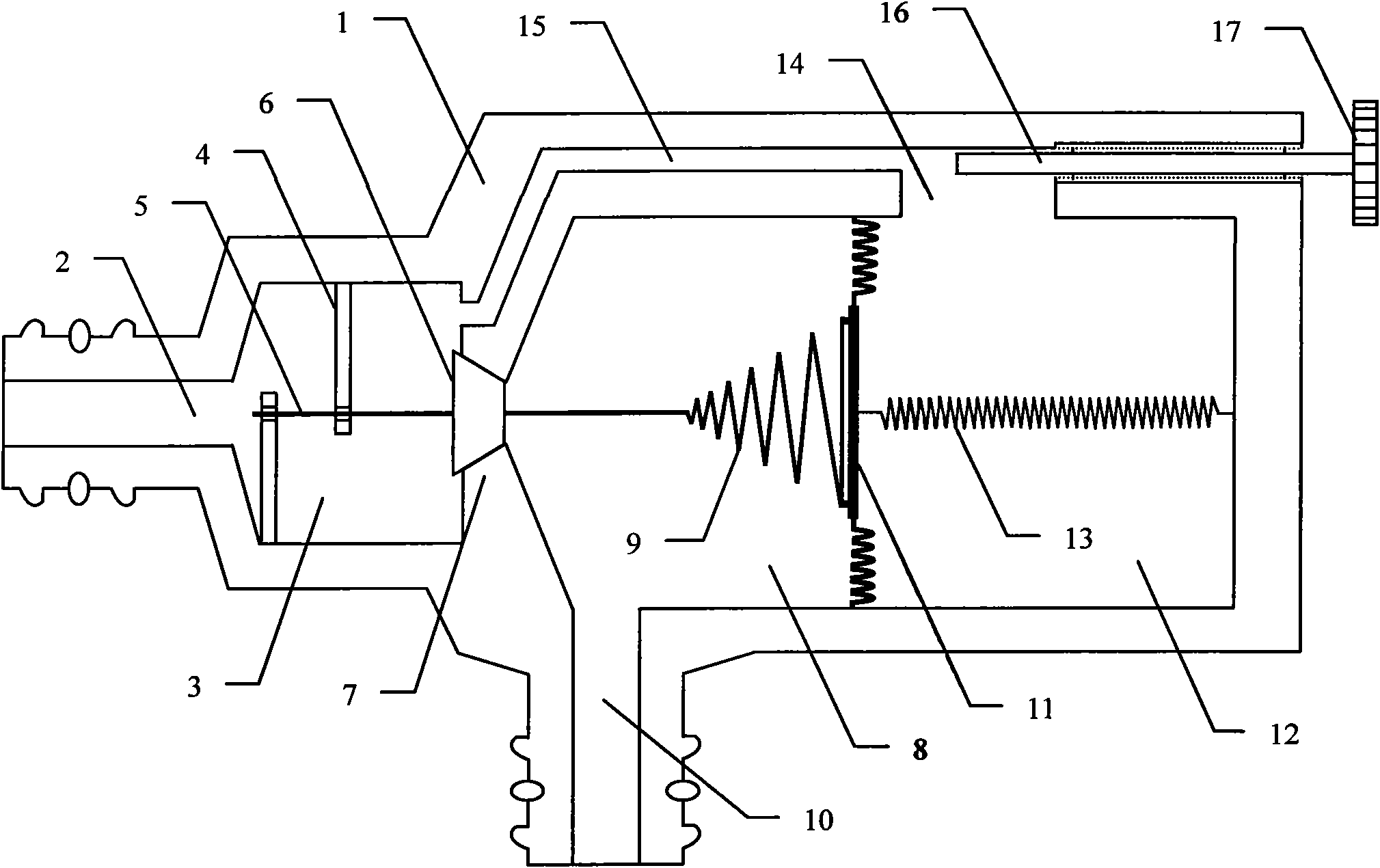

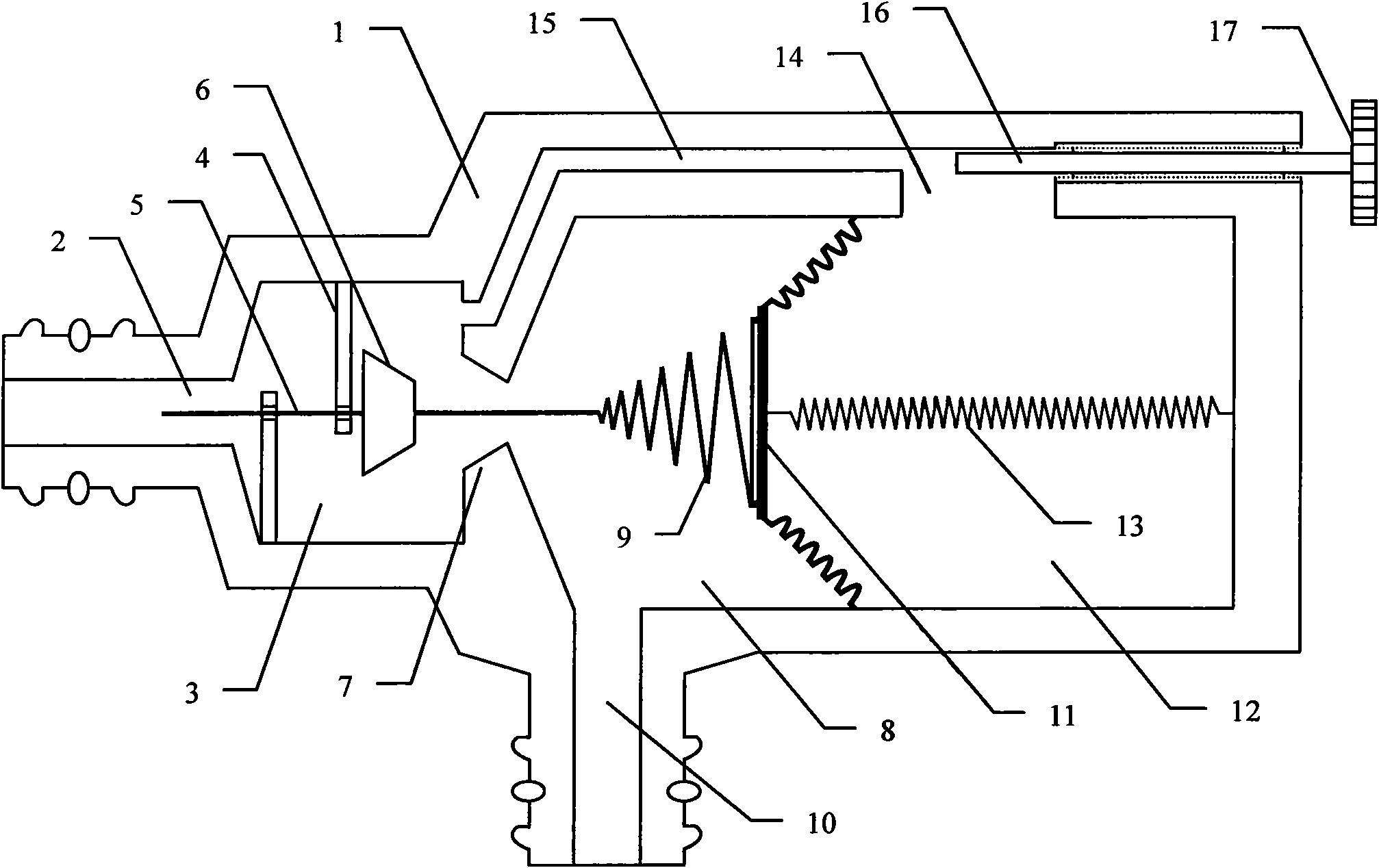

Automatic outlet pressure regulating device for variable sprayer

ActiveCN102513239AImprove spray uniformitySimple structureMovable spraying apparatusSpray nozzleInlet pressure

The invention relates to an automatic outlet pressure regulating device for a variable sprayer, which is capable of realizing variable spraying and comprises a spray pipe, springs, nozzles and an elastic runner, wherein the elastic runner is fixedly connected with the spray pipe, a sealing device is arranged at the joint of the elastic runner and the spray pipe, the elastic runner is internally arranged inside the nozzles and forms a certain contracting angle, and the internally arranged elastic rubber is connected with the inner wall surface of each nozzle through the springs so that the springs compressed by the elastic rubber are uniform in stress. The automatic outlet pressure regulating device is simple in structure, reliable in operation and high in operability, the nozzles of the sprayer are automatically adjustable in size, and the sectional area variation of each nozzle outlet is as same as that of an inlet pressure regulating device in proportion, so that spraying uniformity of the variable sprayer is improved.

Owner:JIANGSU UNIV

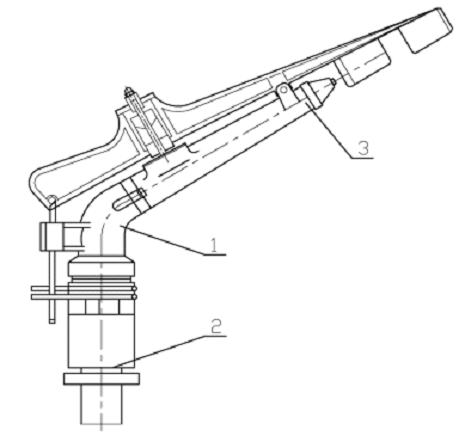

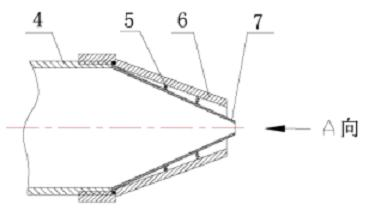

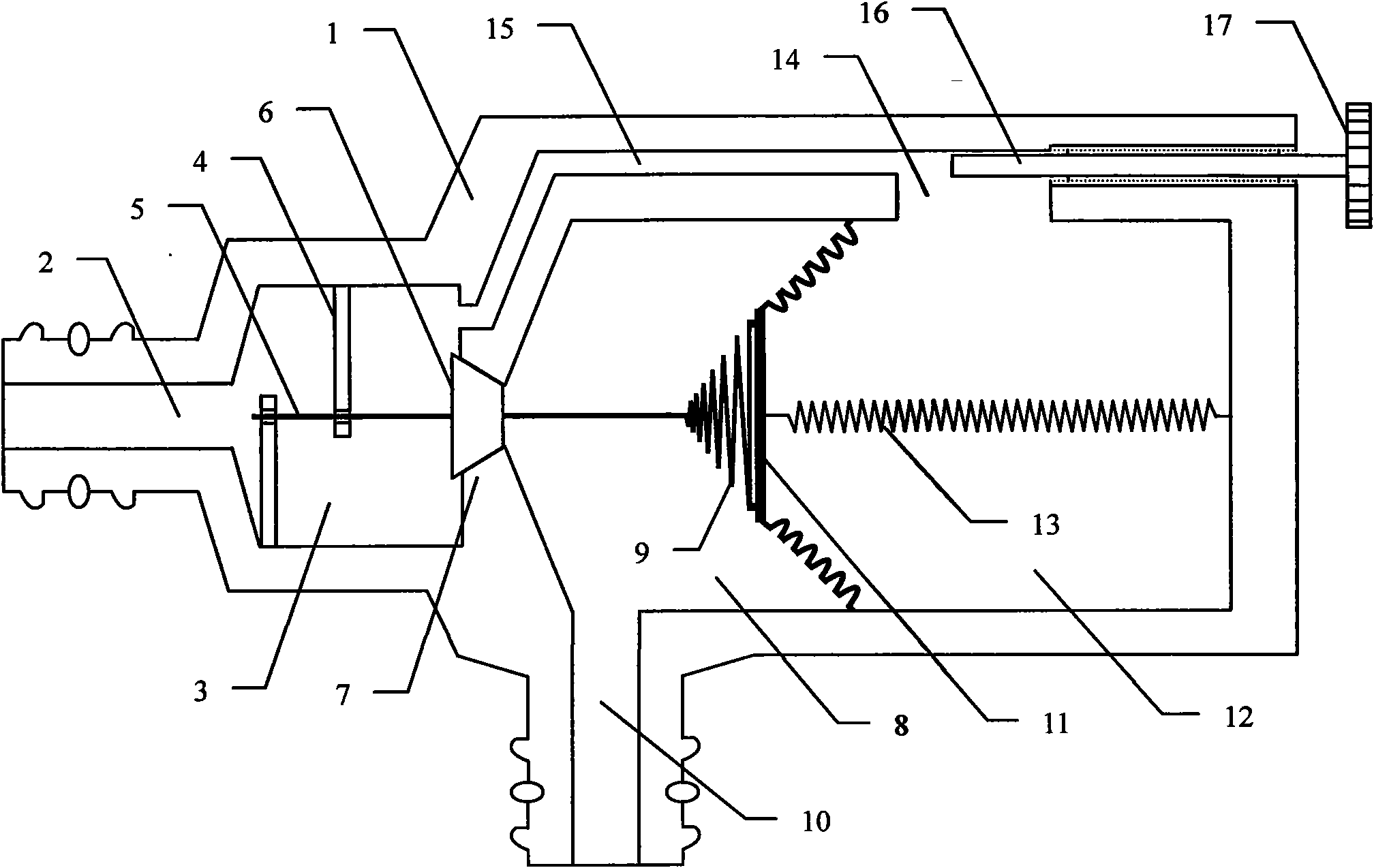

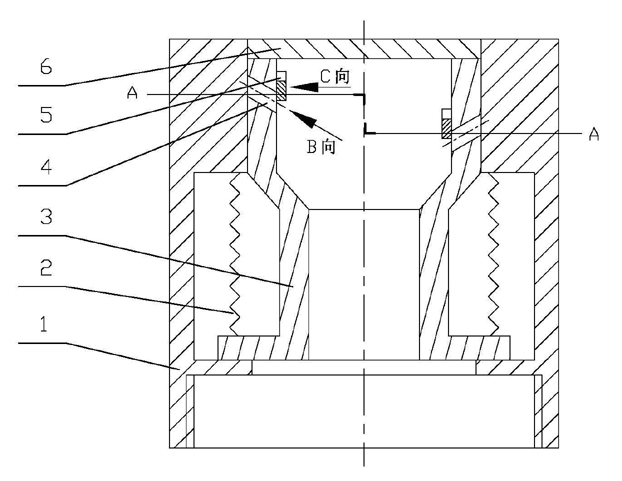

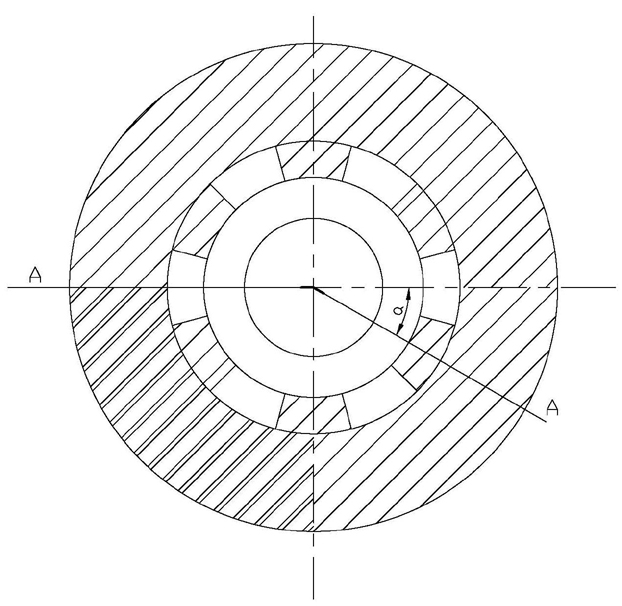

Pressure-compensation variable-cross-section special shaped spray head

The invention provides a pressure-compensation variable-cross-section special shaped spray head, which consists of four parts, namely a rotary sealing mechanism, a flow passage, a pressure compensation mechanism and a rocker-arm mechanism, wherein a key part is the pressure compensation mechanism; the pressure compensation mechanism is formed by sequentially combining and connecting a special shaped nozzle, a connecting piece, a sealing piece, a water baffle and a spring; and the water baffle is obliquely arranged at a certain angle in the flow passage so as to break down the impact force of water flow into downward component force and forward component force. When the pressure of the water flow increases and the downward component force surpasses the elastic force of the spring, the spring is compressed, the water baffle moves down, and the section of a nozzle exit enlarges. When the pressure of the water flow decreases and the elastic force of the spring surpasses the downward component force, the water baffle is reset upwards under the acting force of the spring, and the section of the nozzle exit reduces. The displacement amount of the water baffle is proportional to the change magnitude of incoming-flow pressure. Aiming at the problem of pressure fluctuation, the spray head realizes pressure compensation by a method of changing the exit section, improves spray uniformity, and has the advantages of simple structure, stabler performance, more uniform spray and the like.

Owner:JIANGSU UNIV

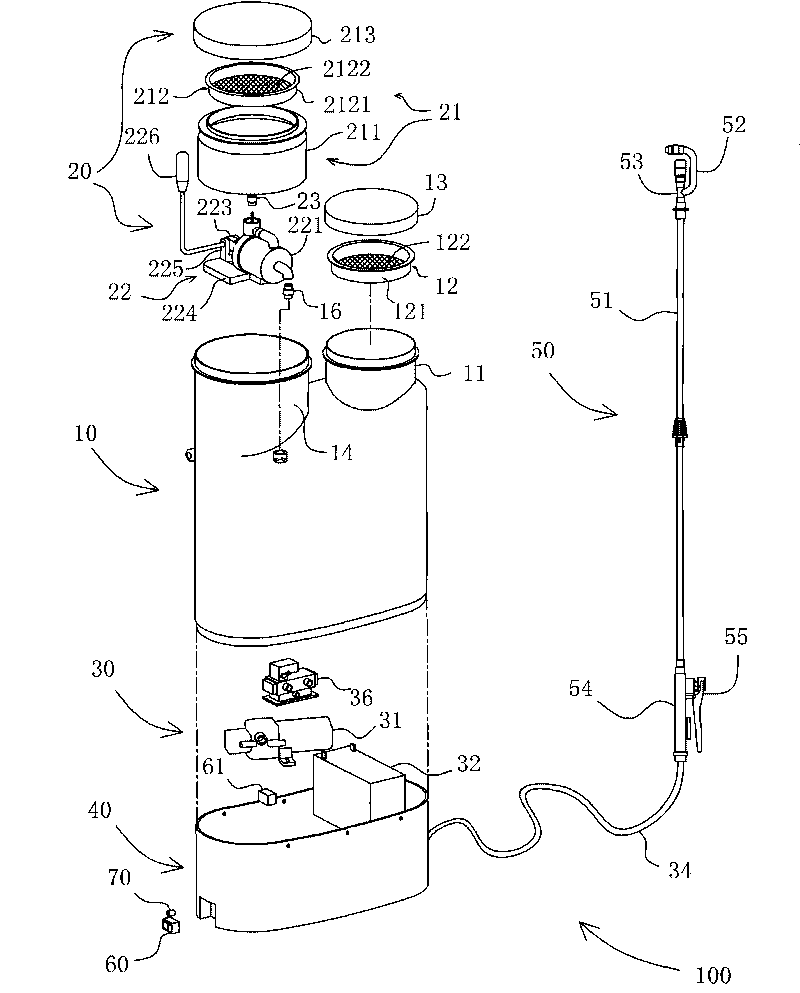

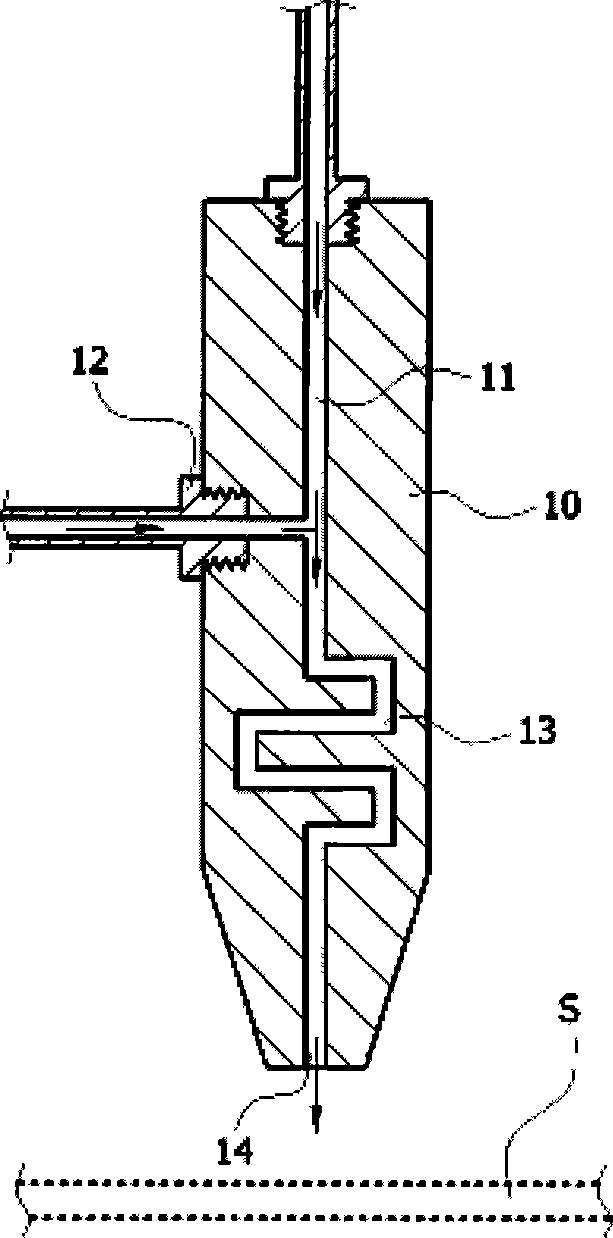

Sprayer with water adsorption function

InactiveCN101745483ASolve the problem of water fetchingSolve the water weightLiquid spraying apparatusSprayerAgricultural engineering

The invention relates to a sprayer with water adsorption function, comprising a water tank, a dosage device which is connected with the water tank, a water adsorption and spraying reversing device which is arranged in a bottom tank at the lower part of the water tank, a spraying device which is provided with a nozzle which can spray and adsorb water, and the spraying device is arranged outside the water tank and is connected with the water adsorption and spraying reversing device, and the nozzle can spray or adsorb water by the spraying and water adsorption functions of the water adsorption and spraying reversing device, and certain amount of pesticide stock solution is added in the water tank through the dosage device. The sprayer can directly adsorb water at places with water, and the drug liquid can be automatically prepared without dismounting the device, thereby greatly alleviating the labor intensity of operators and effectively improving the working efficiency.

Owner:魏华春

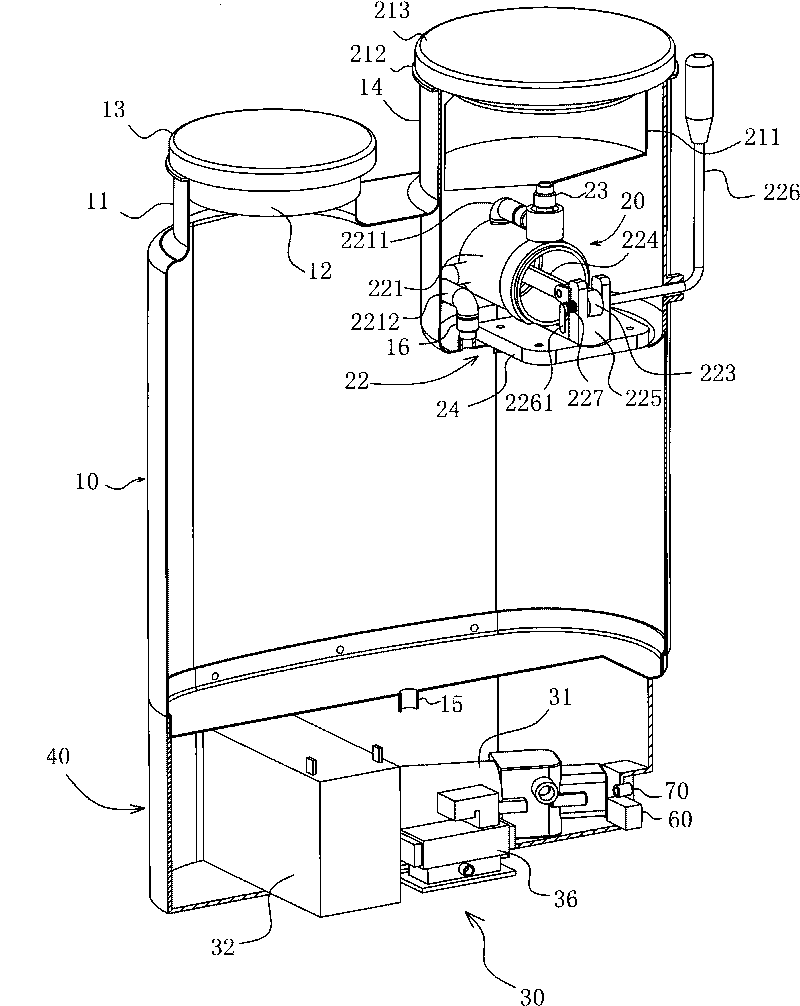

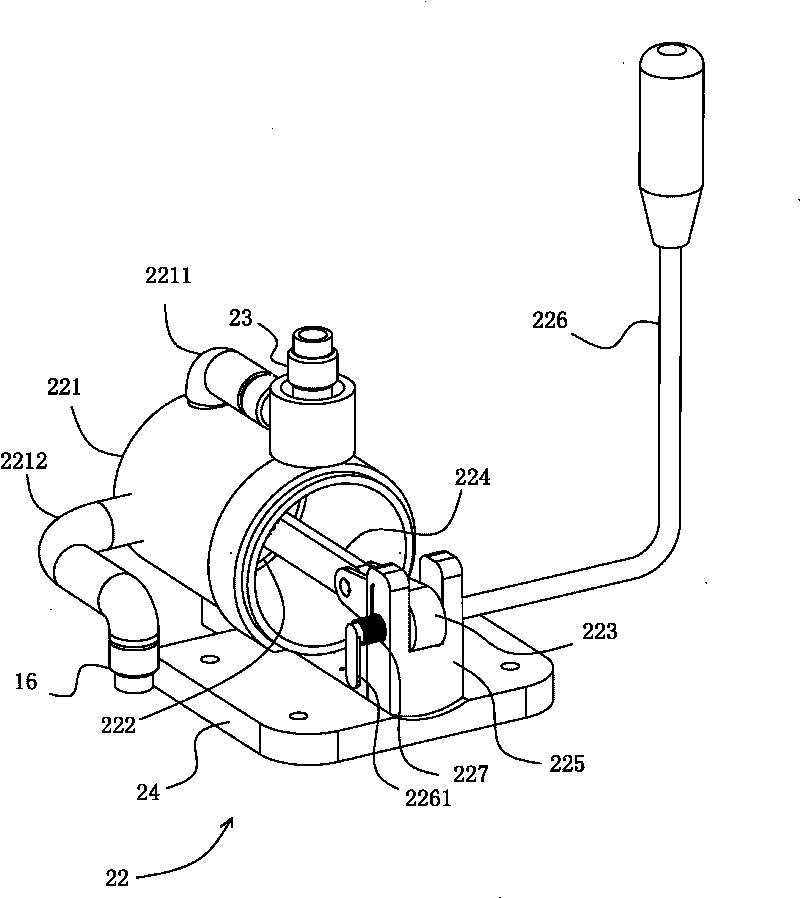

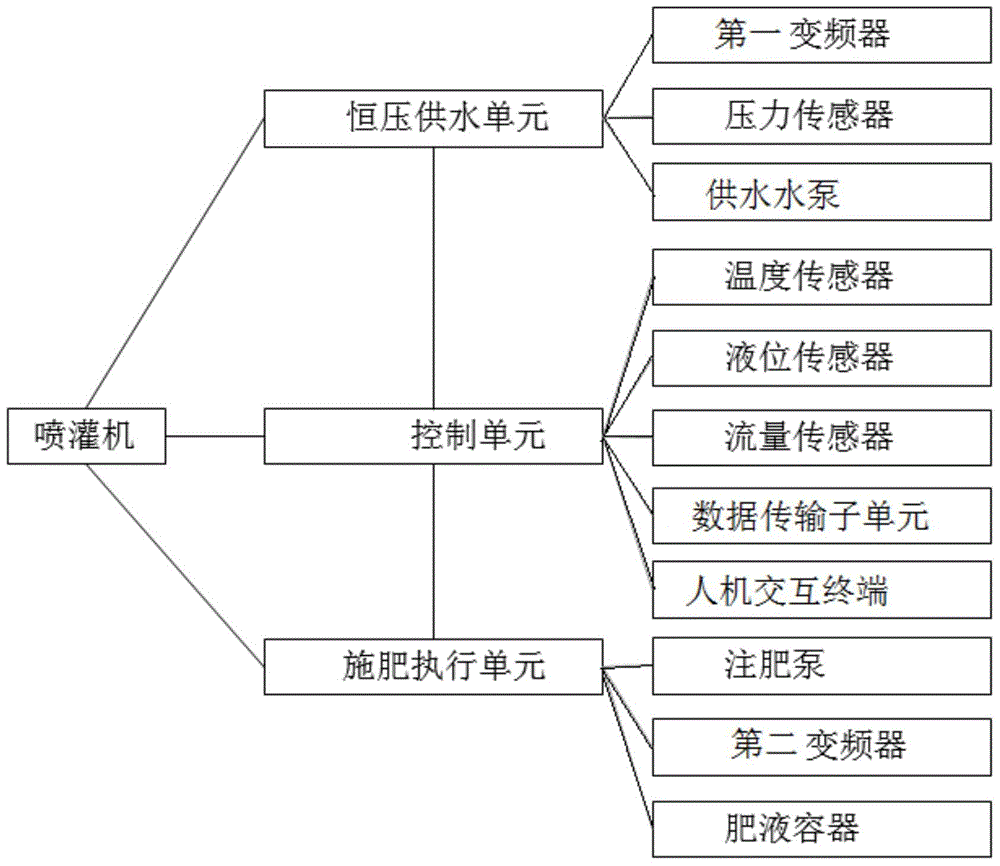

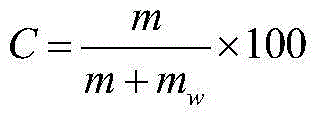

Fertilization control system for circular and translational motion type sprinkling irrigation machine

ActiveCN104938131AImprove operational reliabilityImprove spray uniformityPressurised distribution of liquid fertiliserAgriculture gas emission reductionControl systemSpray nozzle

The invention relates to a fertilization control system for a circular and translational motion type sprinkling irrigation machine. In the fertilization control system, a constant pressure water supply unit is equipped to solve the hydraulic pressure fluctuation caused by switching of spray nozzle and other reasons, so that the operational reliability and spraying uniformity of the fertilization control system are improved; a control unit is adopted to adjust the variation of the pumping flow of fertilization injection along with the water supply flow of the constant pressure water supply unit, so that the precise and constant fertilization concentration and fertilizing amount within the whole sprinkling irrigation range are guaranteed, and especially, the precise and constant fertilization concentration and fertilizing amount are guaranteed in the situation of large flow variation amplitude of a circular and translational motion type sprinkling irrigation machine provided with a tail gun within the opening and closing time period of the tail gun.

Owner:CHINA AGRI UNIV +1

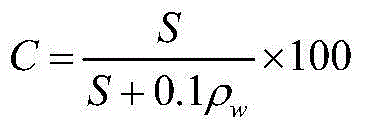

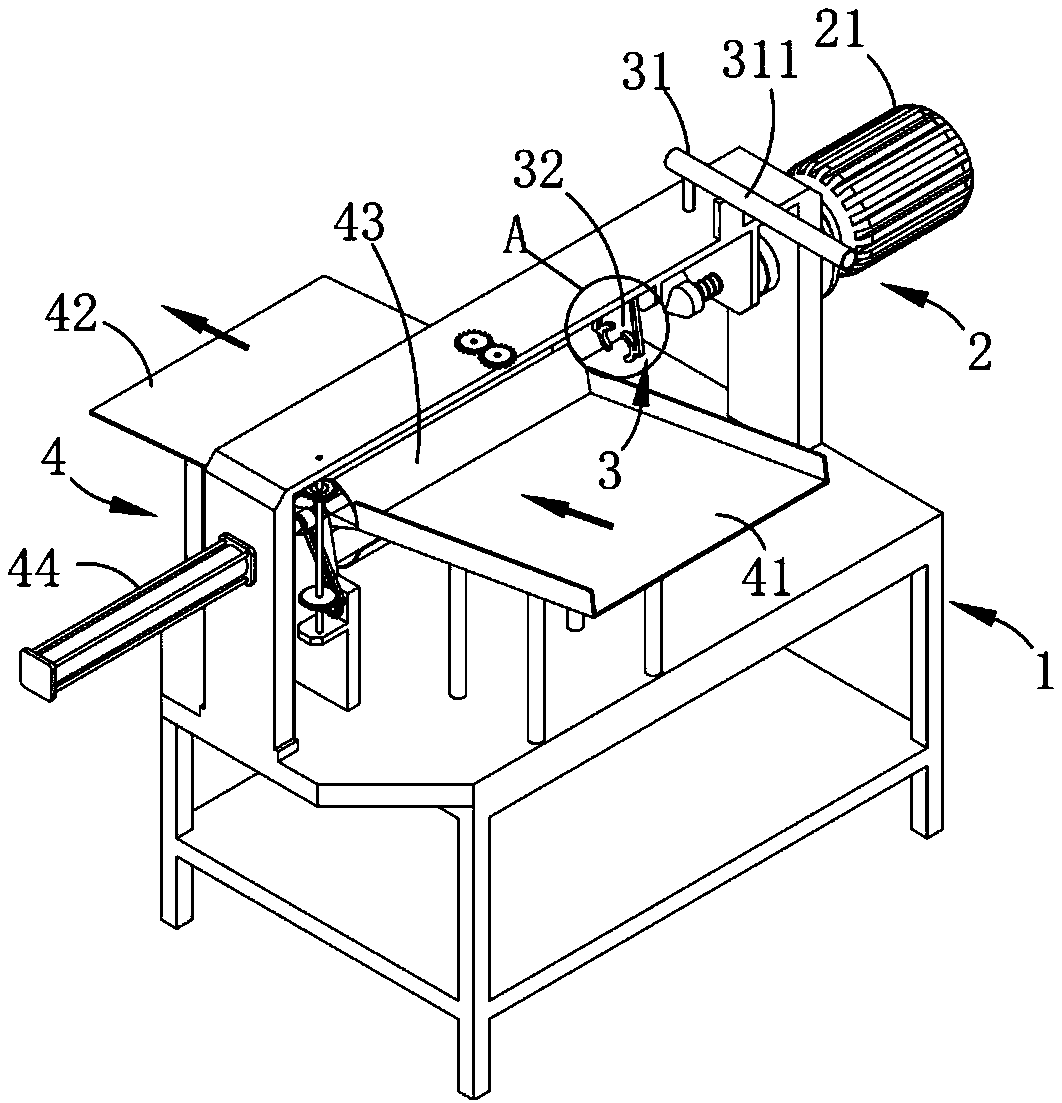

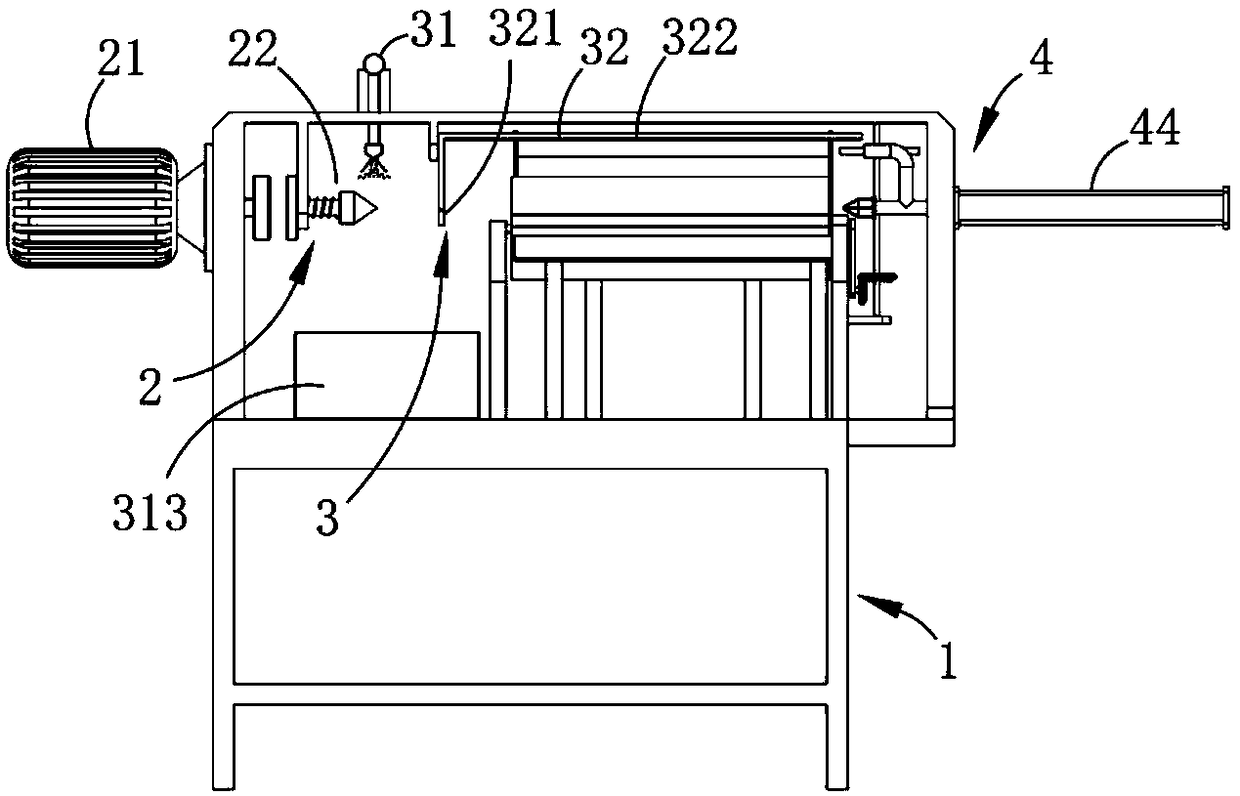

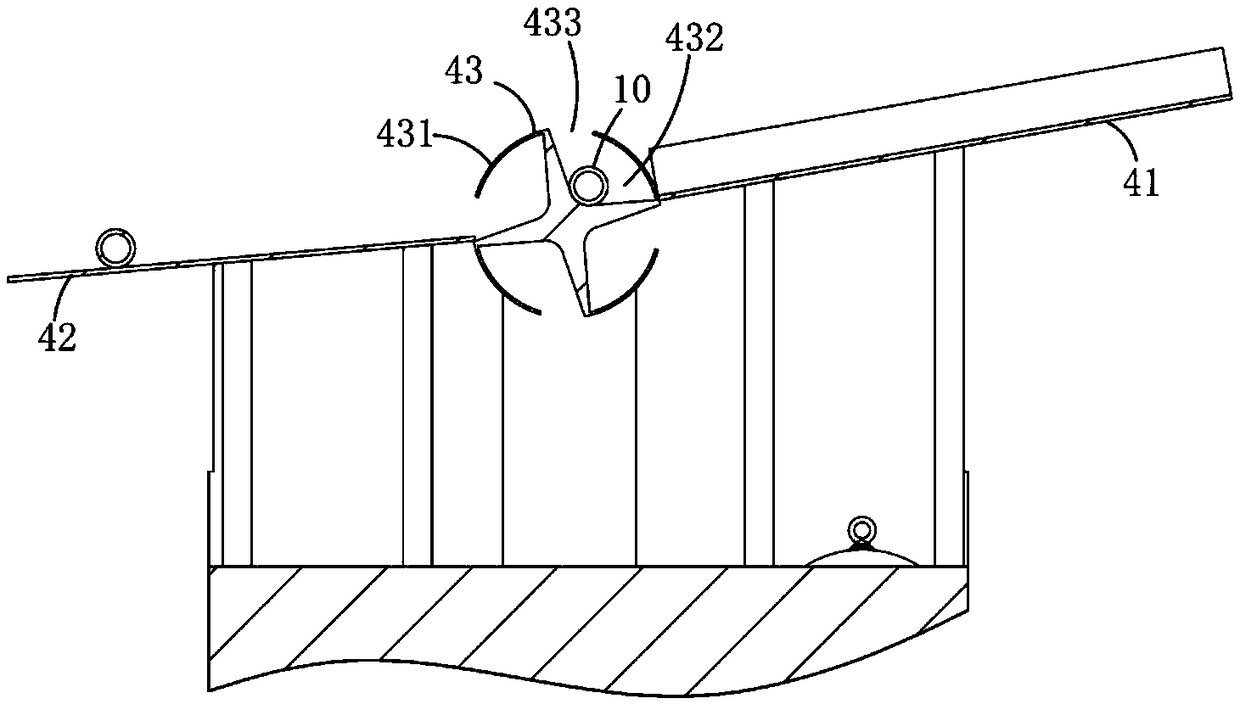

Automatic production device for carrying out rust-proof treatment on end part of steel pipe

InactiveCN108704787ARealize automatic outputUniform coating productionLiquid spraying apparatusReciprocating motionEngineering

The invention relates to the technical field of steel pipe processing and production, in particular to an automatic production device for carrying out rust-proof treatment on the end part of a steel pipe. The automatic production device for carrying out rust-proof treatment on the end part of the steel pipe comprises a rack, a positioning mechanism, an oil coating mechanism and a material transferring mechanism, wherein the oil coating mechanism comprises an oil spraying assembly and a coating assembly located at one end of the oil spraying assembly and is far away from the positioning mechanism; the material transferring mechanism comprises a loading assembly, a blanking assembly for outputting the steel pipe, a limiting assembly arranged between the loading assembly and the blanking assembly and intermittently communicating with the loading assembly and the blanking assembly, and a pushing assembly for transferring the steel pipe in the limiting assembly into the oil spraying mechanism; the limiting assembly is driven by the pushing assembly so as to directionally rotate; the coating assembly is driven by the pushing assembly so as to contact the steel pipe; and during the process that the pushing assembly sprays oil to the steel pipe and conveys the steel pipe through a reciprocating motion way, the steel pipe rotates and is coated with anti-rust oil and automatically outputted, so that the automatic oil coating production of the steel pipe is realized, and the technical problem of low production efficiency in the prior art is solved.

Owner:长兴新亚环保机械科技股份有限公司

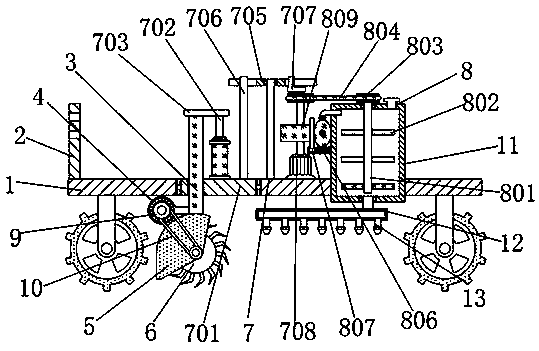

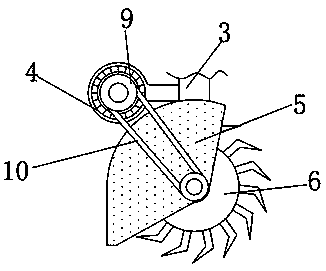

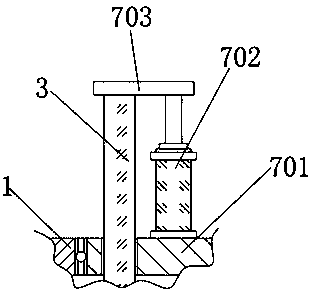

Environment-friendly soil remediation device

ActiveCN111389903APlay a mixing effectPrevent precipitationRotary stirring mixersTransportation and packagingSoil remediationLiquid storage tank

The device comprises an environment-friendly soil remediation device. The device includes a vehicle body, a connecting plate is fixedly connected to the left side of the top of the vehicle body, the bottom of a pesticide storage box is communicated with a diversion groove through a branch pipe, and a rotating assembly is arranged on the left side of the vehicle body. The invention discloses the environment-friendly soil remediation device, the vehicle body, the connecting plate, a first grooved wheel, a first belt and the rotating assembly are cooperated, in the rotating process of a hob, thehob can swing back and forth relative to the transmission of a fork-shaped sliding rail, then the soil breaking and turning capabilities and effects of the hob are further improved; through the cooperation of a second motor, a liquid storage tank, the diversion groove, spray heads and a turning assembly, a soil remediation liquid can be stirred by the device through the rotation of stirring rods,and then the soil remediation liquid can be uniformly mixed, the spraying effect is further guaranteed, a pressing plate can extrude an air bag in a reciprocating mode through extrusion of a cam on the pressing plate and springback of a compression spring, then the liquid storage tank is pressurized, and the spraying uniformity and the spraying continuity of the liquid medicine are greatly improved.

Owner:新昌县澄聚农业科技有限公司

Twin-fluid nozzle for cleaning substrate

InactiveCN101372001AImprove cleaning efficiencyImprove spray uniformitySemiconductor/solid-state device manufacturingLiquid spraying apparatusEngineeringElectrical and Electronics engineering

The invention discloses a double-fluid nozzle for substrate cleaning, the nozzle comprises: a first accommodation section and a second accommodation section for respectively accommodating mutually distinct fluids; a first channel for transferring a first fluid accommodated in the first accommodation section, a first jet orifice for jetting the first fluid is formed at one end thereof; a second channel for transferring second fluid accommodated in the second accommodation section, a second jet orifice for jetting the second fluid is formed at one end thereof; a double-fluid drainage section for draining the double-fluid which is generated by mixing the fluids jetted from the first and the second jet orifices; and a guide section formed at a front end of the second jet orifice and for guiding the jetting direction of the second fluid jetted from the second jet orifice to the first jet orifice. In accordance with the invention, the micronic and uniform double-fluid is generated by mixing the dry air with a washing liquid that is smashed to ultramicronic droplets, so as to prominently improve washing efficiency for the substrate.

Owner:K C TECH

Pulse micro-sprinkler irrigation system

InactiveCN102177833AGood anti-clogging performanceImprove spray uniformityClimate change adaptationWatering devicesEngineering

The invention relates to a pulse micro-sprinkler irrigation system. After passing pulse valves before all capillary pipes, pressurized water enters all the capillary pipes in a mode that pulse flow speeds up under rising pressure and slows down under lowering pressure, and the pressurized water is sprinkled out to irrigate crops through micro sprinkler heads arranged on all capillary pipes in a pulse mode. Quickly rising pressure can produce strong impact on blocking objects, and slowly lowering pressure cannot lead water in the capillary pipes behind the pulse valves to return, form negative pressure on water outlet holes of sprinklers and block the negative pressure sucking type water outlet holes. The pulse frequency can be adjusted in a large range, the pulse frequency can be slowed down under the same irrigation strength, and the sprinklers with large diameter water outlet holes are adopted to form the pulse micro-sprinkler irrigation system which does not require filters. The use of the pulse irrigation mode for micro-sprinkler irrigation overcomes the defects of concentrated annular water output of other micro-sprinkler irrigation equipment. The pulse micro-sprinkler irrigation system has the characteristics of blockage resistance, uniform sprinkling and low cost.

Owner:HENAN ZHONGPEN TIANRUN IND CO LTD

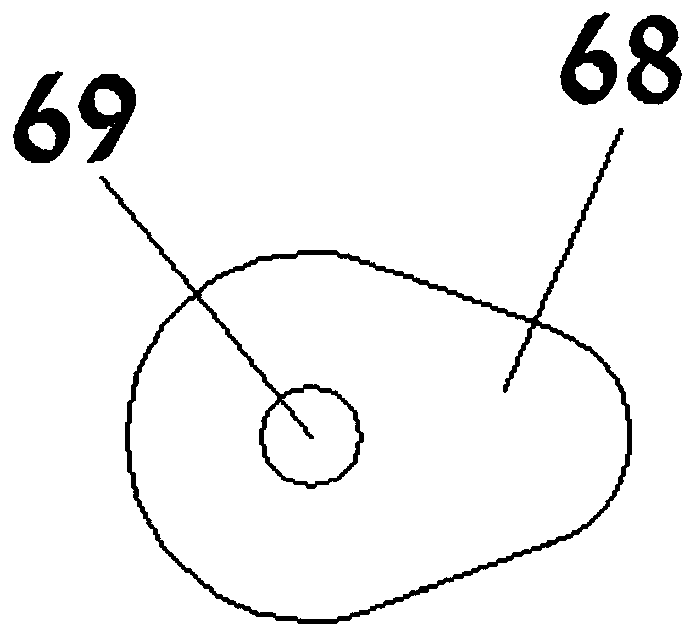

Cleaning and disinfecting vehicle

InactiveCN110124075AIngenious and reasonable structureEasy to useRotary stirring mixersTransportation and packagingMobile vehicleDisinfectant

The invention discloses a cleaning and disinfecting vehicle, comprising a moving vehicle body; the moving vehicle body is internally and rotatably provided with a disinfecting machine body; the disinfecting machine body is driven to rotate by means of a rotation driving assembly; the disinfecting machine body is internally provided with a liquid storage chamber; the top wall of the liquid storagechamber is provided with a liquid adding hole; a stirring shaft is rotatably installed in the liquid storage chamber; two groups of stirring blades for evenly stirring disinfectant are fixedly arranged at the periphery of the stirring shaft; the disinfecting machine body is internally provided with a transmission chamber; the stirring shaft extends into the transmission chamber, and a first bevelgear is fixedly arranged at the tail end of the bottom of the stirring shaft. The cleaning and disinfecting vehicle can effectively mix cleaning liquid evenly, thus greatly improving the spray uniformity, and having higher use and promotion values.

Owner:ANHUI YINUOQINGCHUN IND DESIGN CO LTD

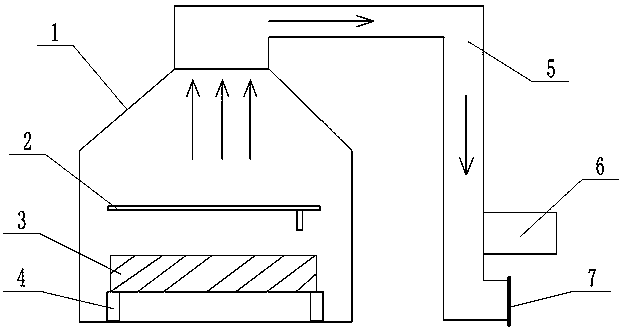

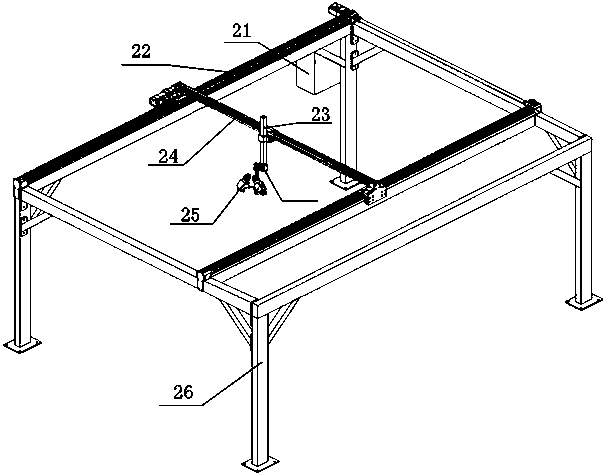

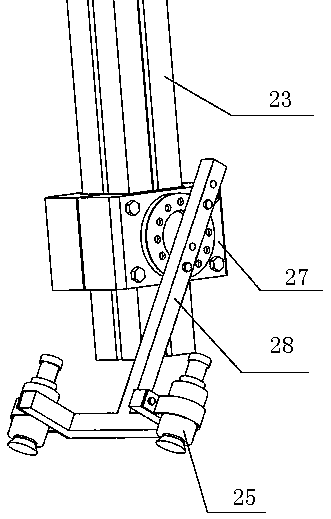

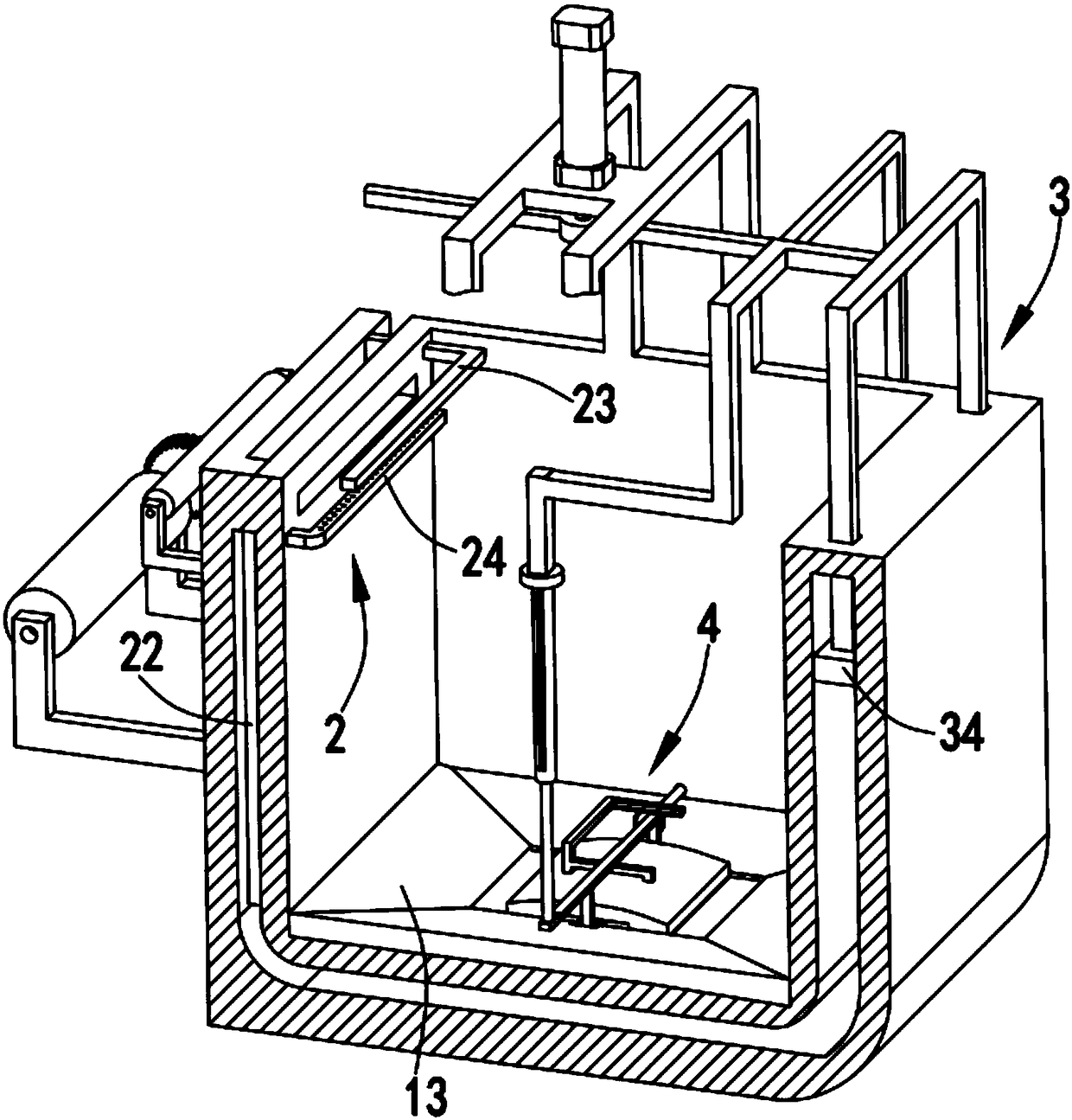

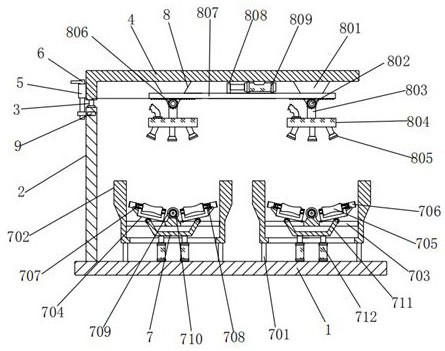

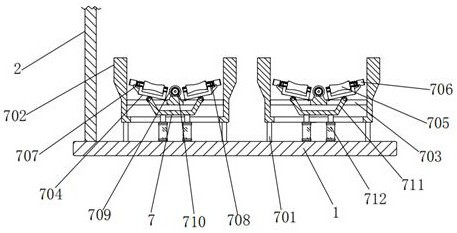

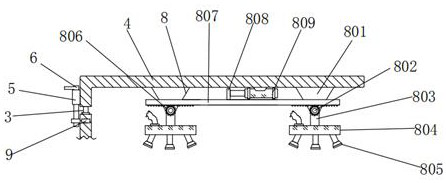

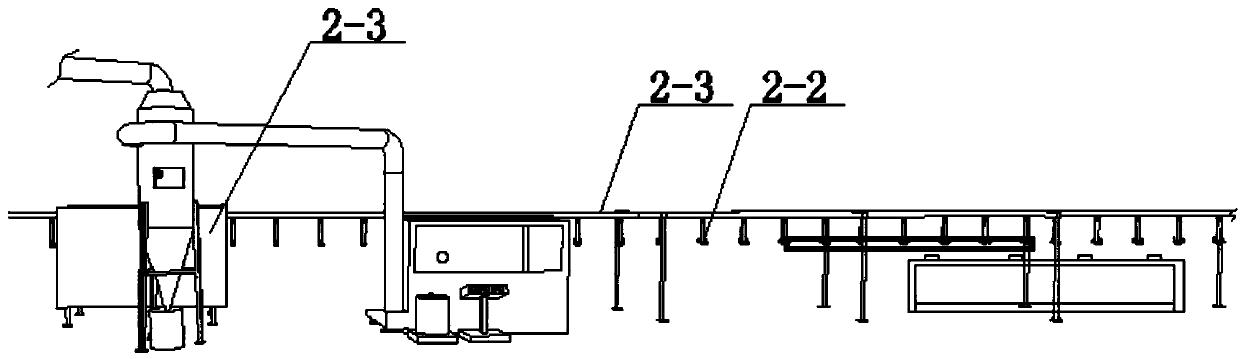

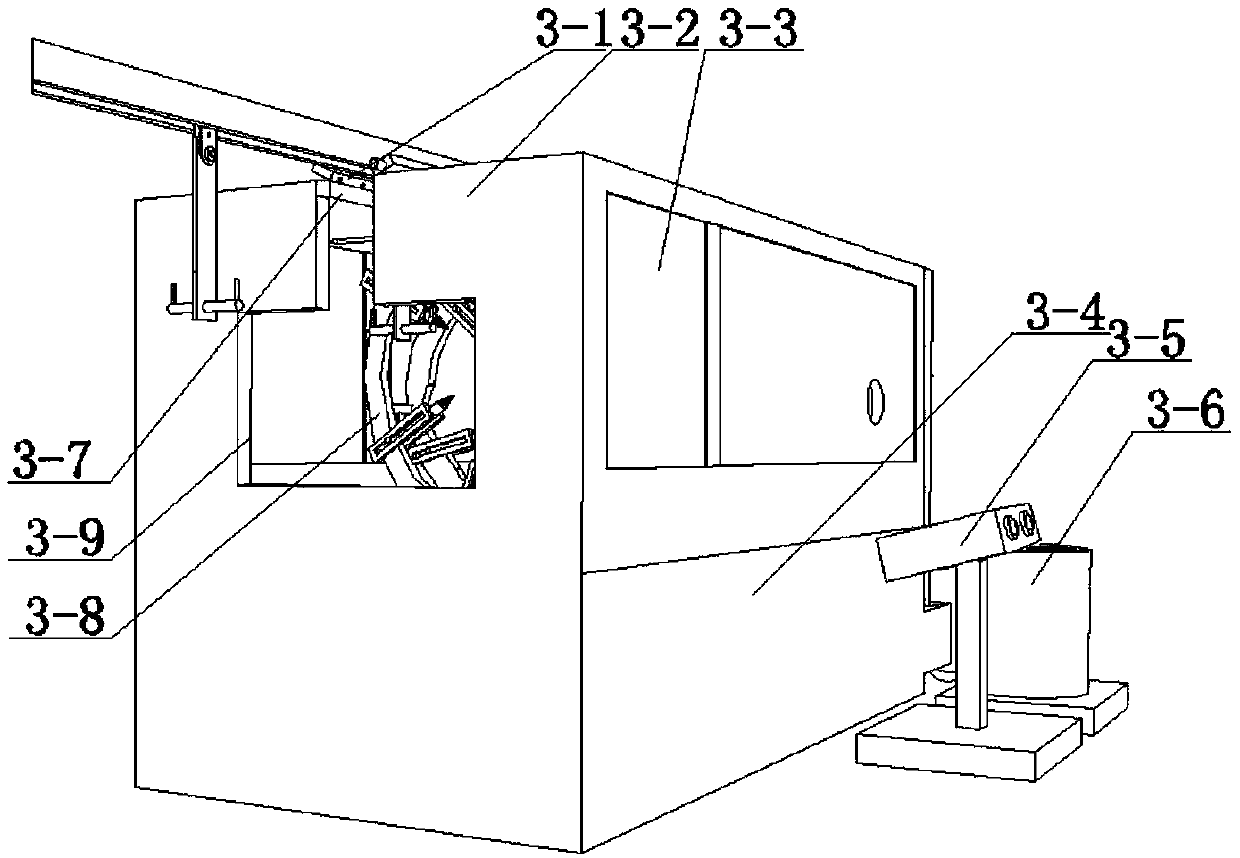

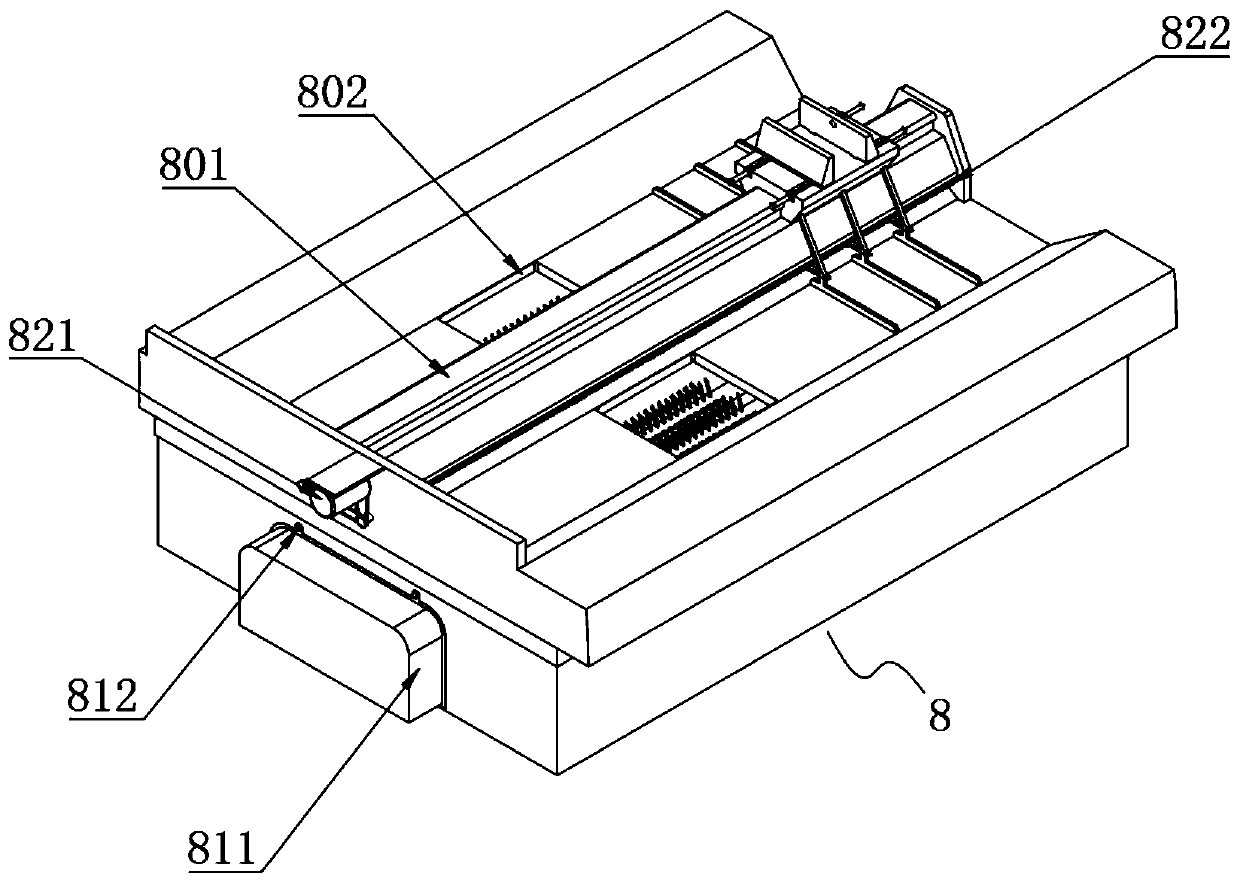

Double-block type automatic spray coating system of sleeper prefabricated de-molding agent

PendingCN108722710ASave Spraying TimeImprove spray uniformityLiquid spraying apparatusDiaphragm pumpProgrammable logic controller

The invention provides a double-block type automatic spray coating system of a sleeper prefabricated de-molding agent and belongs to the technical field of production of railway engineering ballastless tracks. Aiming at solving the technical problems, the invention provides the double-block type automatic spray coating system of the sleeper prefabricated de-molding agent, which has the effects ofimproving the spray coating quality and shortening the spray coating time and has a good spray coating effect. The double-block type automatic spray coating system is characterized by comprising a pumping and discharging system, a spray coating system and an oil gas supplying system, wherein the pumping and discharging system comprises a sealed space composed of a sealing cover, a pumping and discharging pipeline, an exhaust fan set and an oil dirt filtering screen; the pumping and discharging system is used for pumping and discharging waste gas and waste materials, which are produced in a spray coating process of the de-molding agent, and filtering and discharging oil dirt out of a spray coating field; the spray coating system comprises a PLC (Programmable Logic Controller), a servo motorand a spraying gun; the spray coating system is used for spraying and coating the de-molding agent on a sleeper mold on a plane formed by two parallel longitudinal tracks along the movement of the servo motor; the oil gas supplying system comprises a gas pressure pump station, a storage tank and a diaphragm pump; the oil gas supplying system is used for providing the de-molding agent and air power to the spray coating system.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

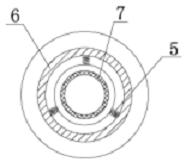

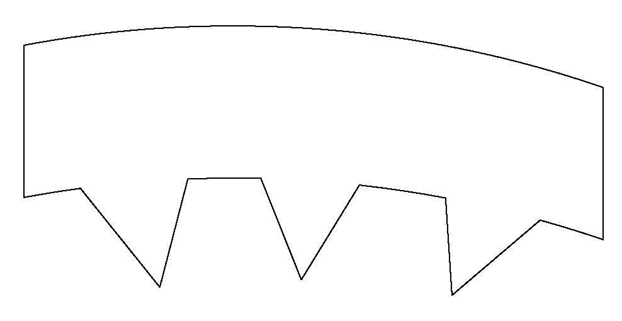

Non-rotating extensible variable sprayer

The invention belongs to a key device in a water-saving irrigation sprinkling system, particularly relates to a non-rotating extensible variable sprayer and aims to solving the key technical problems that the energy consumption is high, the operation is unstable, and a single spray head can not spray arbitrary shapes of variables. The non-rotating extensible variable sprayer comprises an outer shell connecting seat, a spring, a spray body, a nozzle, a limiting ring, a cover plate and a rubber ring. Before the non-rotating extensible variable sprayer works, the limiting ring 5 is regulated according to the shapes of application land blocks to lead each nozzle 4 to reach a range needed by the land blocks. When the non-rotating extensible variable sprayer works, the spray body is rushed by water current to overcome resistance generated by the spring and the rubber ring, and the spray body is moved upwards to lead the nozzle to expose the outer shell connecting seat, thereby realizing the variable domain spray of arbitrary shapes, including a sector. The invention has the advantages of simple structure, low energy consumption and reliable operation and can realize domain spray in arbitrary shapes.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH

High-quality printing and dyeing device for textile fabric

InactiveCN108866865AImprove color uniformityImprove uniformityTextile treatment machine arrangementsTextile treatment by spraying/projectingEngineeringImpurity

The invention relates to a high-quality printing and dyeing device for textile fabric. The device comprises a dyestuff box, the left side of the dyestuff box is provided with an extrusion cavity, thebottom side of the dyestuff box is provided with a flow guide channel communicated with the extrusion cavity, and the right side of the dyestuff box is provided with a spray-painting mechanism communicated with the flow guide channel; the extrusion cavity is provided with an extrusion mechanism, which is used for extruding dye liquor in the extrusion cavity to enable the dye liquor to be sprayed out through the spray-painting mechanism; a grinding mechanism is arranged at a position which is close to a bottom side in the dyestuff box, and comprises a lower grinding component as well as an upper grinding component and a driving component which are arranged above the lower grinding component, the extrusion mechanism downwards drives the upper grinding component to move downwards to the lowergrinding component, the driving component drives the upper grinding component to move left and right to grind coarse particle dyestuff on the lower grinding component; the right side of the dyestuffbox is further provided with a fabric rolling mechanism, and the extrusion mechanism drives the fabric rolling mechanism to roll the fabric; the high-quality printing and dyeing device is used for solving the problems that in the dyeing process, the dyestuff chroma homogeneity is poor, the dyestuff use ratio is not high, the dyeing effect is not good and impurities are easily adhered to the fabricsurface.

Owner:CHANGXING DEHONG MACHINERY CO LTD

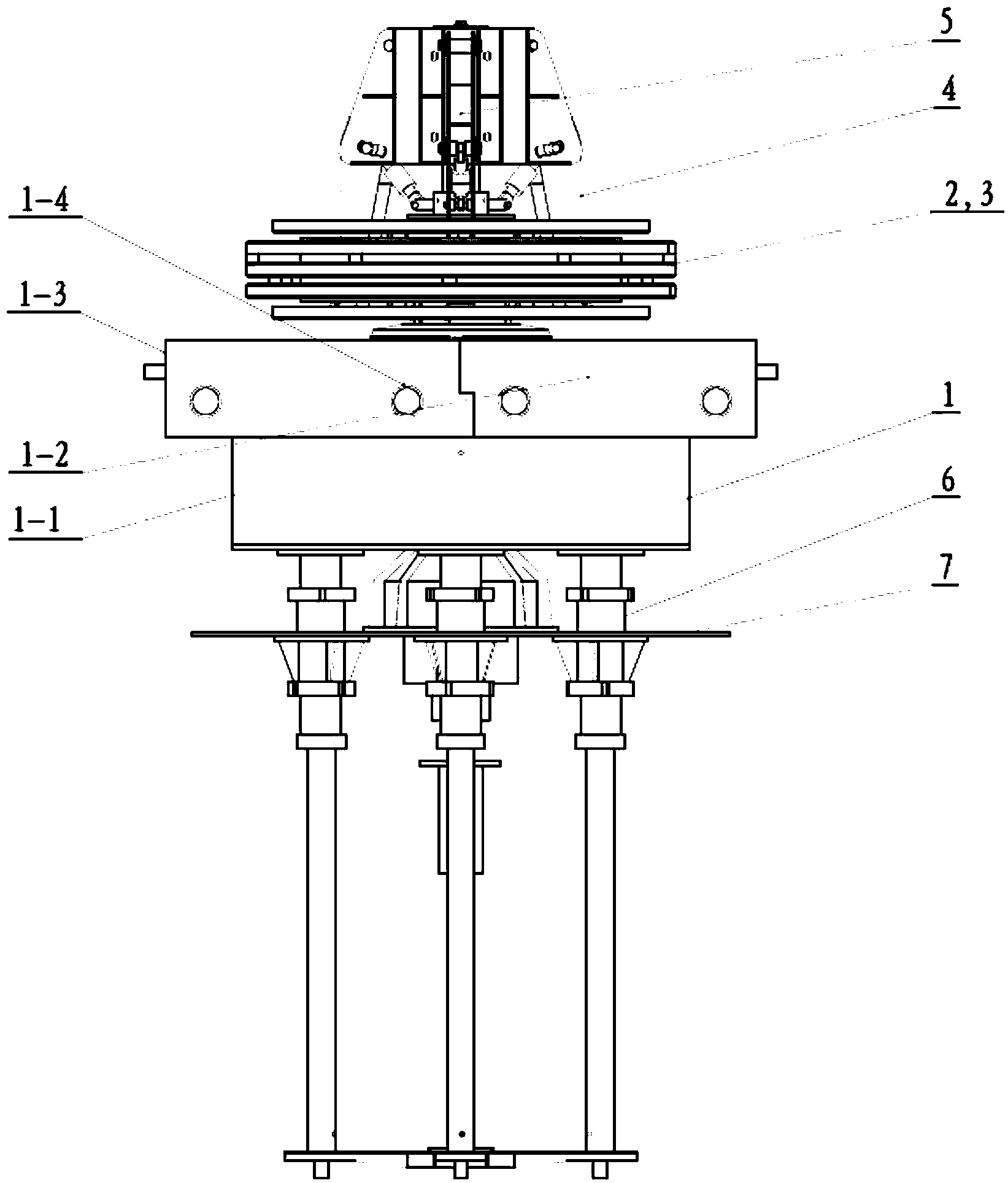

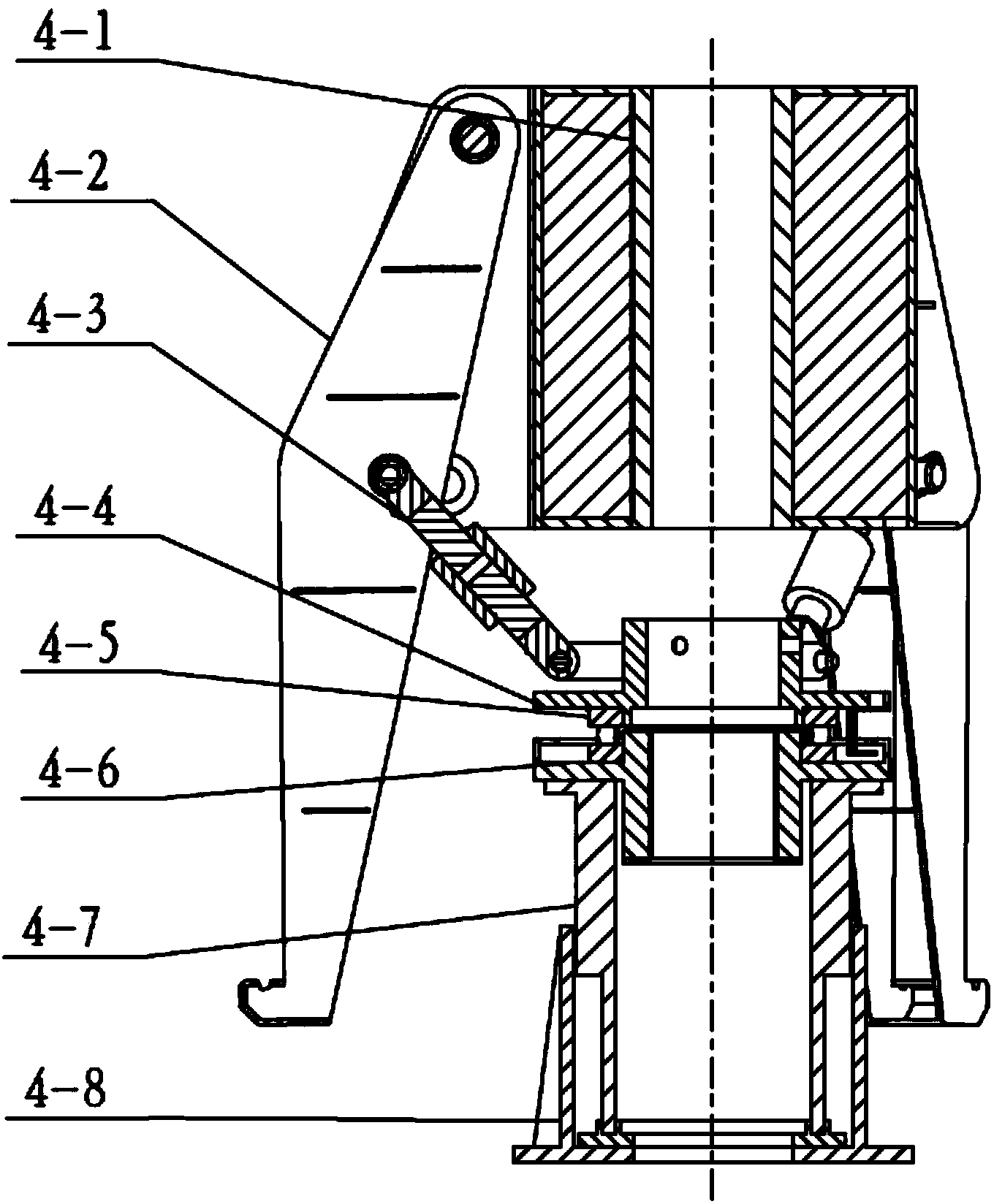

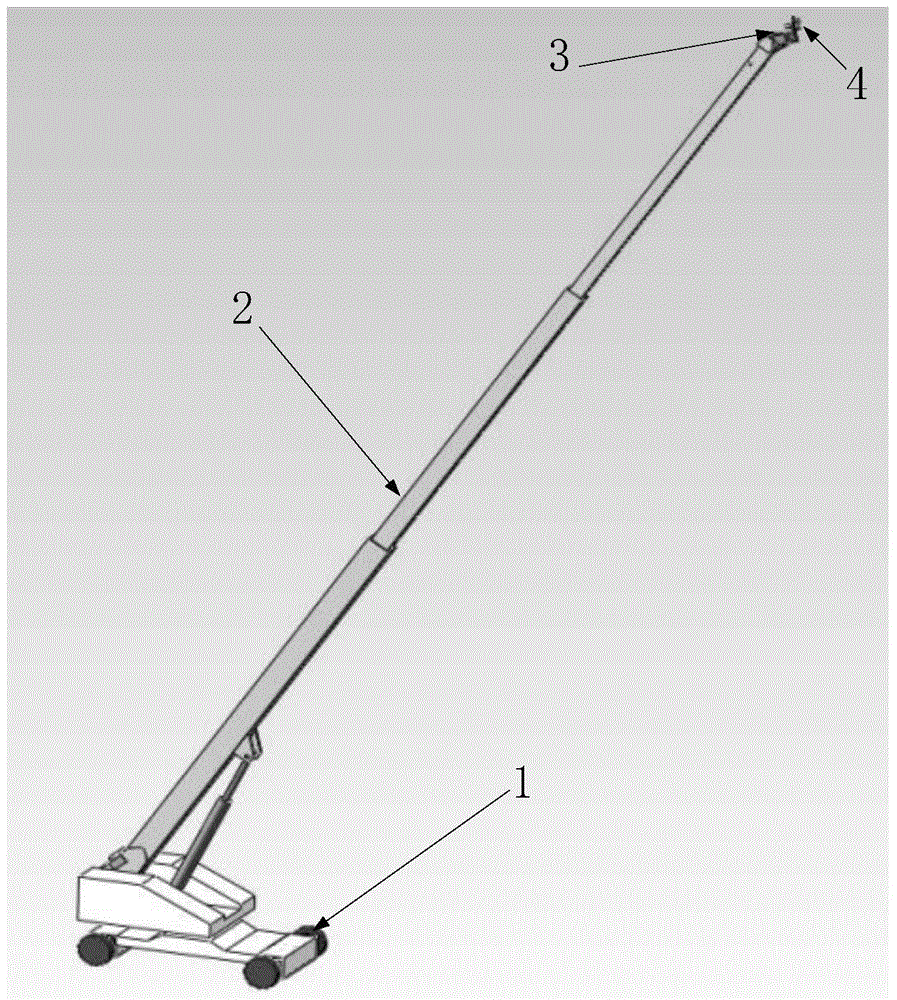

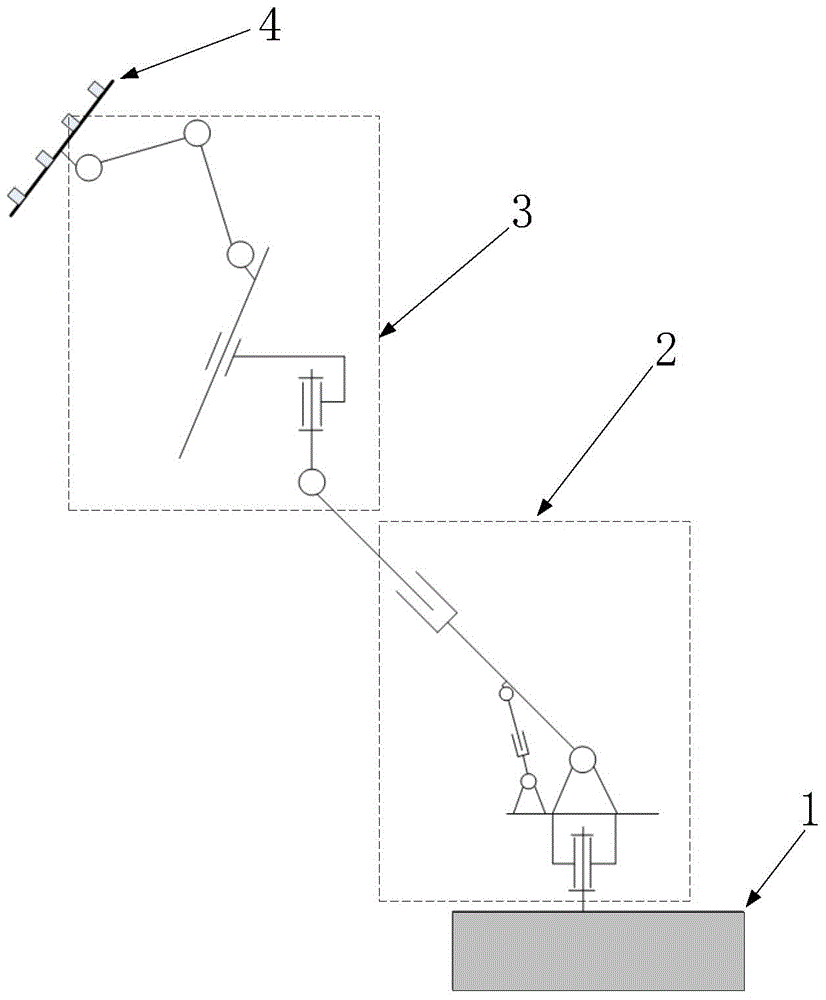

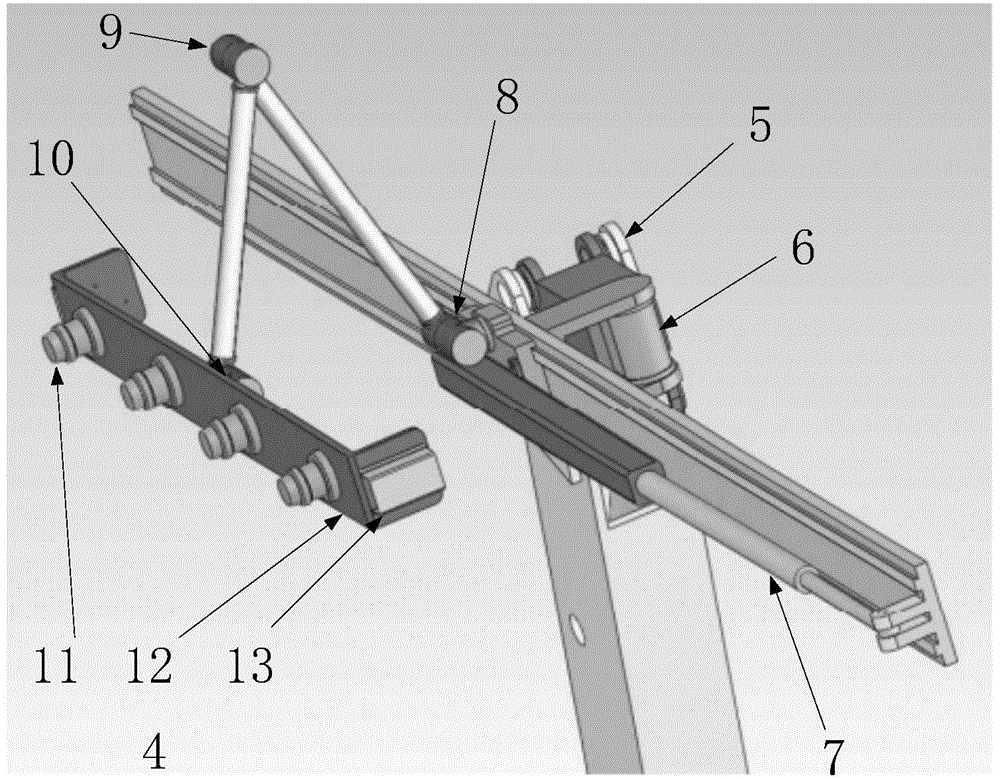

Spraying robot for surface of ship body

InactiveCN104624429AImprove spray uniformityHigh repeatabilitySpraying apparatusActuatorControl theory

The invention discloses a spraying robot for a surface of a ship body. The spraying robot comprises a chassis, a large arm, a small arm and a tail end actuator. The tail end actuator comprises a spraying gun installation base, at least one spraying gun and at least one laser displacement sensor for controlling the pose of the tail end actuator. The spraying robot for the surface of the ship body is used for avoiding influence of harmful gas in spraying and repeating the same operation action tirelessly, and is suitable for replacing manpower to carry out the operation in high pollution and intensity work like ship body spraying. The intelligent spraying robot for the ship body is adopted to complete the spraying work so that the pollution in the spraying process can be reduced, energy can be saved, and the working efficiency can be improved.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

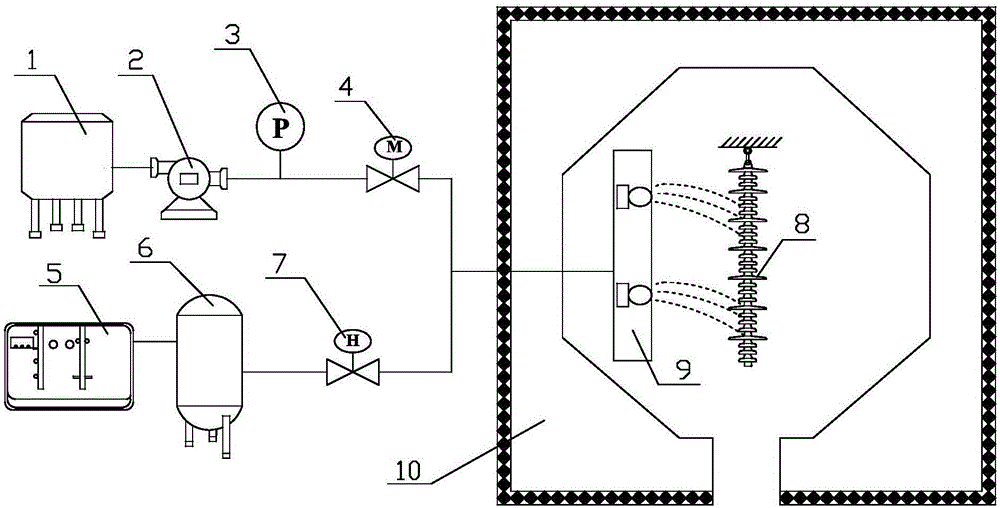

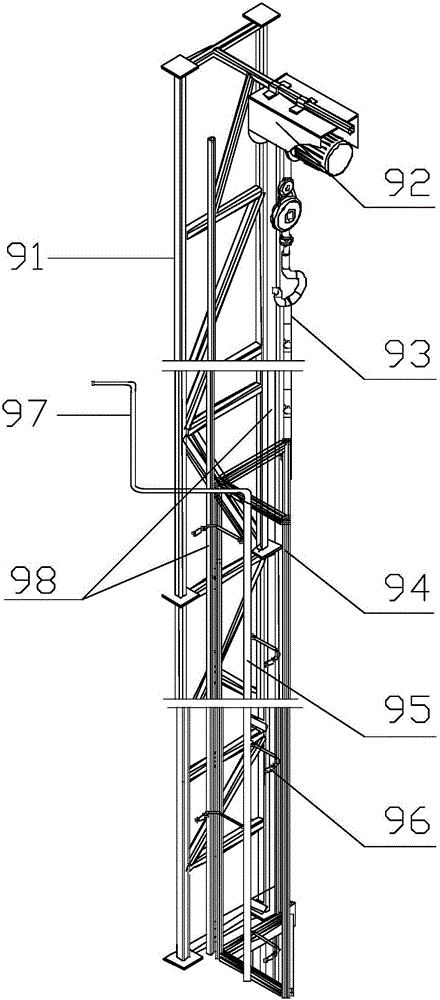

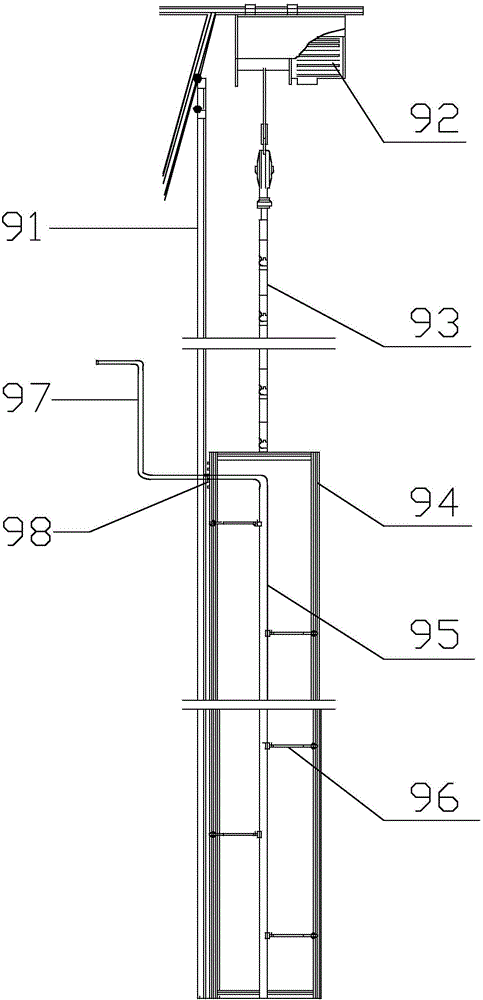

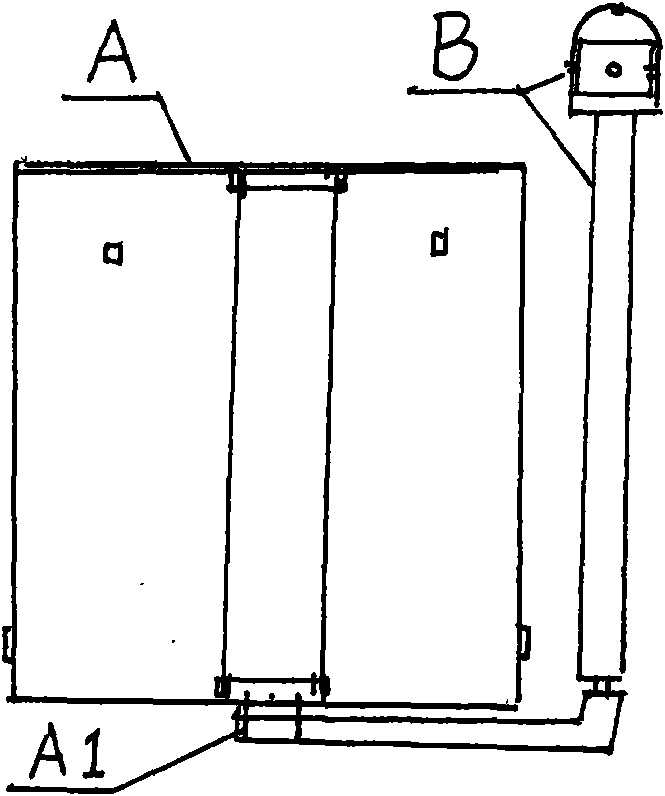

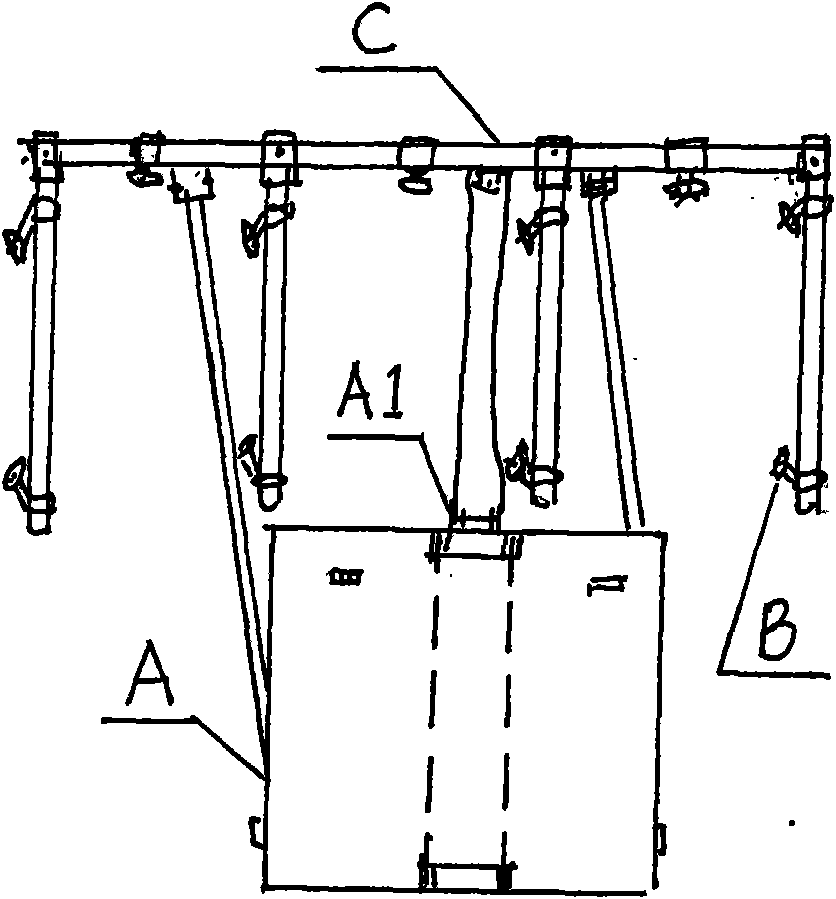

Spray control method used for insulator string rainfall test

InactiveCN105759154AAchieve uniformityImprove spray uniformityTesting dielectric strengthEnvironmental/reliability testsWater sourceEngineering

The invention discloses a spray control method used for an insulator string rainfall test. A rainfall apparatus is arranged in a manual simulation climate chamber (10). A water supply device is used to provide a water source for the rainfall apparatus. The rainfall apparatus is used for implementing simulation rainfall for an extra-high voltage insulator string to be tested in the manual simulation climate chamber. In the rainfall apparatus, a support is vertically installed. A nozzle group (96) arranged on the support is used for implementing water spray for the extra-high voltage insulator string. Heights of different nozzles relative to a support bottom are different. Sodium chloride is mixed into the water source of the water supply device so as to change a conductivity of spray water. The spray control method used for the insulator string rainfall test adopts a vertical-type spray apparatus so that a nature rainfall environment can be effectively simulated.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

Energy accumulation type sprayer and spraying frame

InactiveCN101856641ASmooth connectionReduce inhalationFlexible member pumpsSpray nozzlesProduction ratePipe fitting

The invention discloses an energy accumulation type sprayer and a spraying frame. The sprayer is characterized in that a flow inlet end head of a spraying head is connected with a flow inlet and outlet opening of an energy accumulation container through a soft water pipe fitting, or the sprayer is provided with the spraying frame arranged on the energy accumulation container, and the spraying head can be arranged on the spraying frame. The spraying frame is connected by a lateral transverse rod or / and vertical rod or through a connecting component, and can be arranged on a sprayer container body, the spraying head is arranged in the rod elements, or the spraying head is installed by a clamping element, and the soft water pipe fitting is connected with the flow inlet and outlet opening of the sprayer. The sprayer can also be provided with a lamination pump for pressurized flow supply to the energy accumulation container, and the sprayer is provided with a breathing apparatus arranged on the container body. The invention solves the problems such as heavy weight, high energy consumption, high cost, small spraying covering area, slow speed, low production rate, high work intensity, large pesticide suction amount and the like of the existing sprayer, and can adapt to different crops, plants and other wider purposes. When being used for plane or three-dimensional large-area spraying, the invention has higher efficiency.

Owner:陈广丰

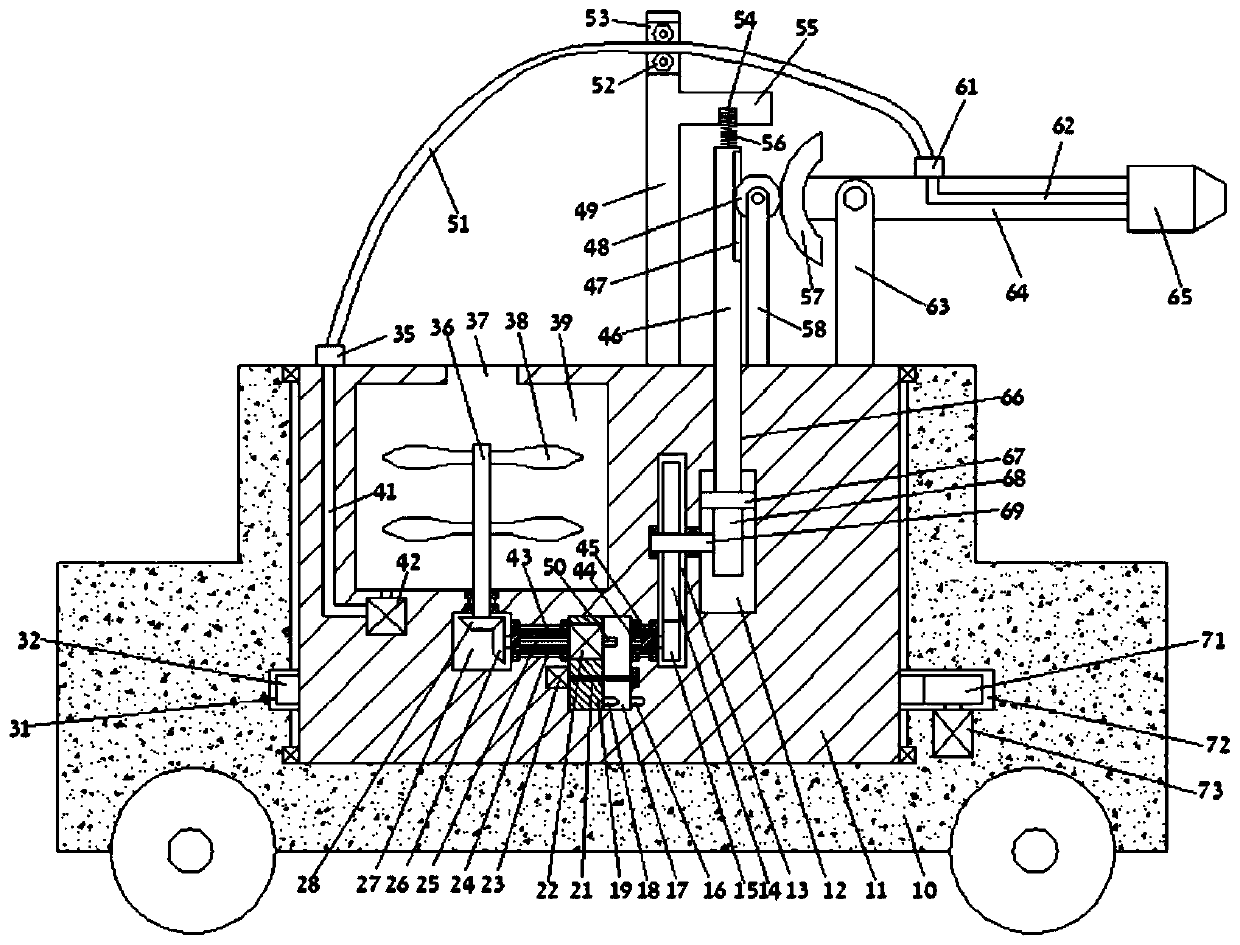

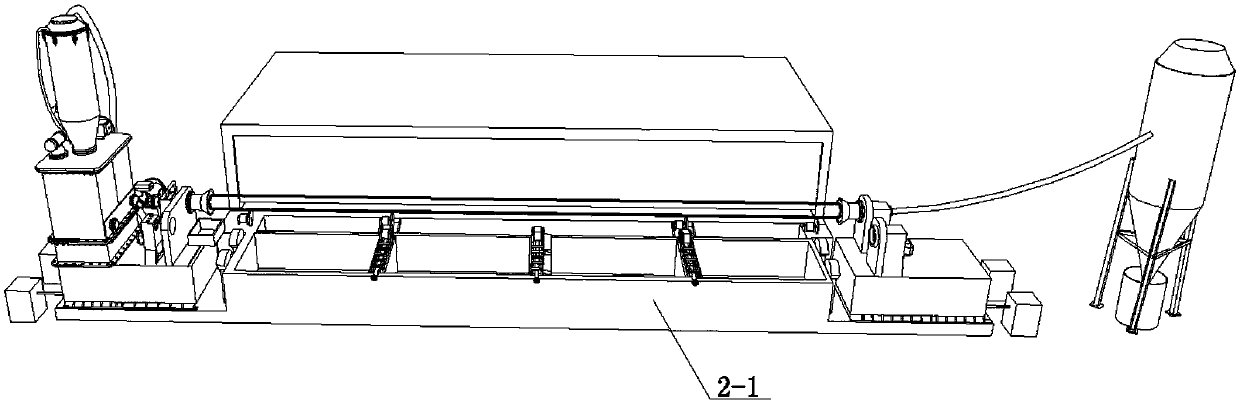

Automatic production line for concrete pipe pile

ActiveCN112277148APlay the effect of automatic transmissionEasy to integrate processingCeramic shaping plantsAuxillary shaping apparatusProduction lineAutomatic transmission

The invention discloses an automatic production line for a concrete pipe pile. The automatic production line comprises a bottom frame, a vertical rod is fixedly connected to the left side of the top of the bottom frame, and a transmission assembly is arranged at the top of the bottom frame. According to the automatic production line for the concrete pipe pile, a grooved wheel and a belt are connected in a rotating mode, a curved frame pushes a supporting groove to enable a first round roller to abut against a pipe pile mold, so that the automatic transmission effect on the pipe pile mold can be achieved, then integrated machining is facilitated, axial rotary adjustment can be carried out on the pipe pile mold, and then the use convenience and practicability are improved; and racks are connected in a meshing mode, a flow dividing box and a bracket are correspondingly arranged, so that the flow dividing box can drive a spray head to swing in the axial direction in a reciprocating mode, then release agent spraying or water washing can be carried out on the pipe pile mold according to use requirements during transmission of the pipe pile mold, in addition, the spraying uniformity is better, omission is avoided, then the cleanliness of the pipe pile mold is improved, the demolding effect is better, and then the pipe pile quality is improved.

Owner:嘉兴市通用水泥构件有限公司

Convenience steel pipe plastic coating system for once curing in inner and outer spraying

InactiveCN107899837AHigh outputSpeed up the gas flowLiquid spraying plantsSpray boothsCoating systemEngineering

The invention relates to a convenience steel pipe plastic coating system for once curing in inner and outer spraying. The system comprises a horizontal conveying frame, a steel pipe conveying frame, an inner spraying system, an outer spraying system and a high-temperature curing furnace; the horizontal conveying frame conveys steel pipes from a preheating furnace to the inner spraying system; theinner surfaces of the steel pipes are sprayed in the inner spraying system; the horizontal conveying frame conveys the steel pipes to a transporting frame; the transporting frame supports and hangs the steel pipes to the steel pipe conveying frame; and the steel pipes are transported to the outer spraying system for outer spraying. Spraying-uniform steel pipe outer plastic coating equipment is provided with an imaginary air blowing rod on the upper surface for preventing outward splashing of dust; and negative pressure is generated in a box on the lower bottom surface of the plastic coating equipment for negative-pressure absorption of the powder to further prevent leakage of the powder so as to maintain cleanness of operation space.

Owner:天津市源泉钢塑管有限公司

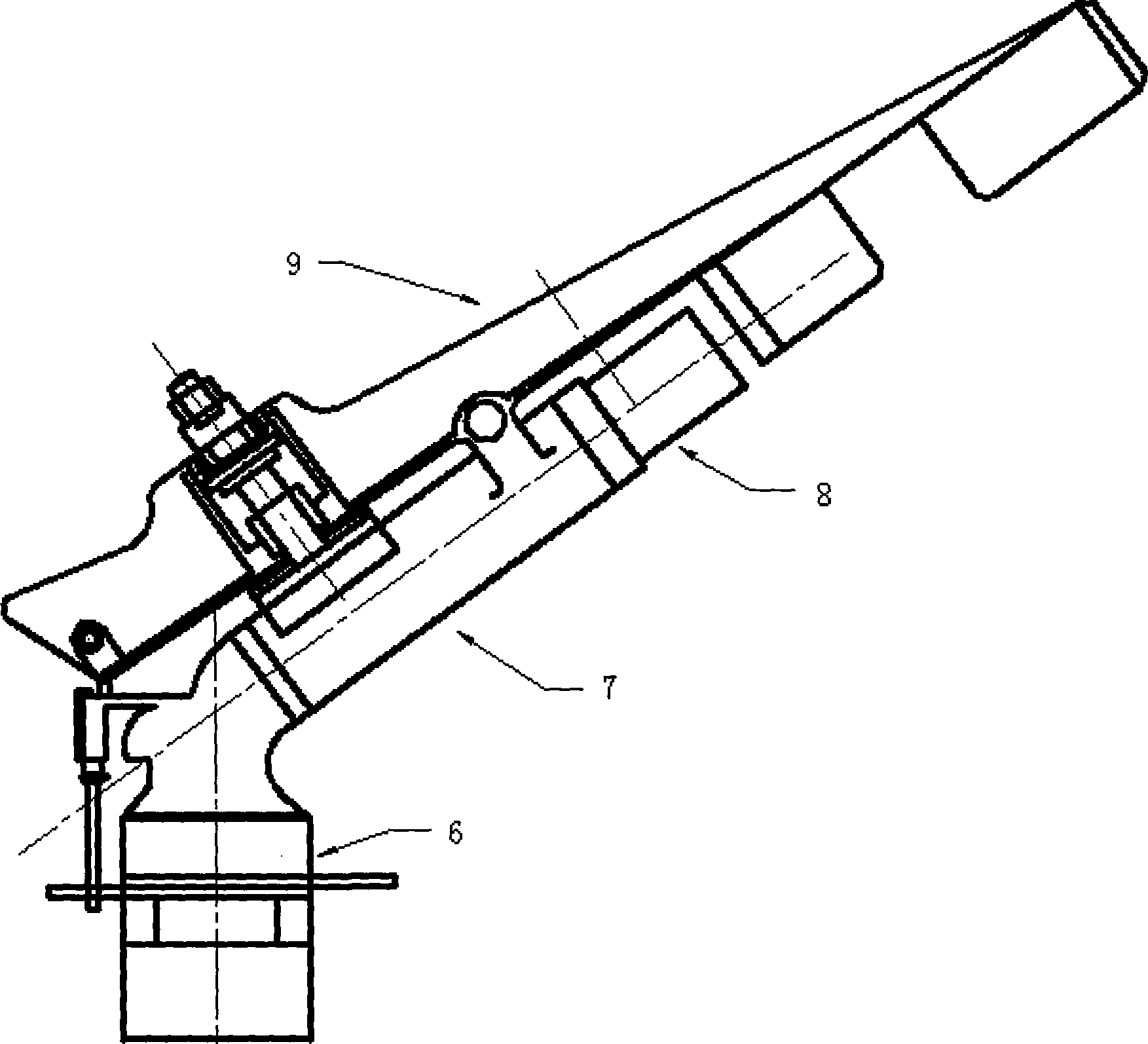

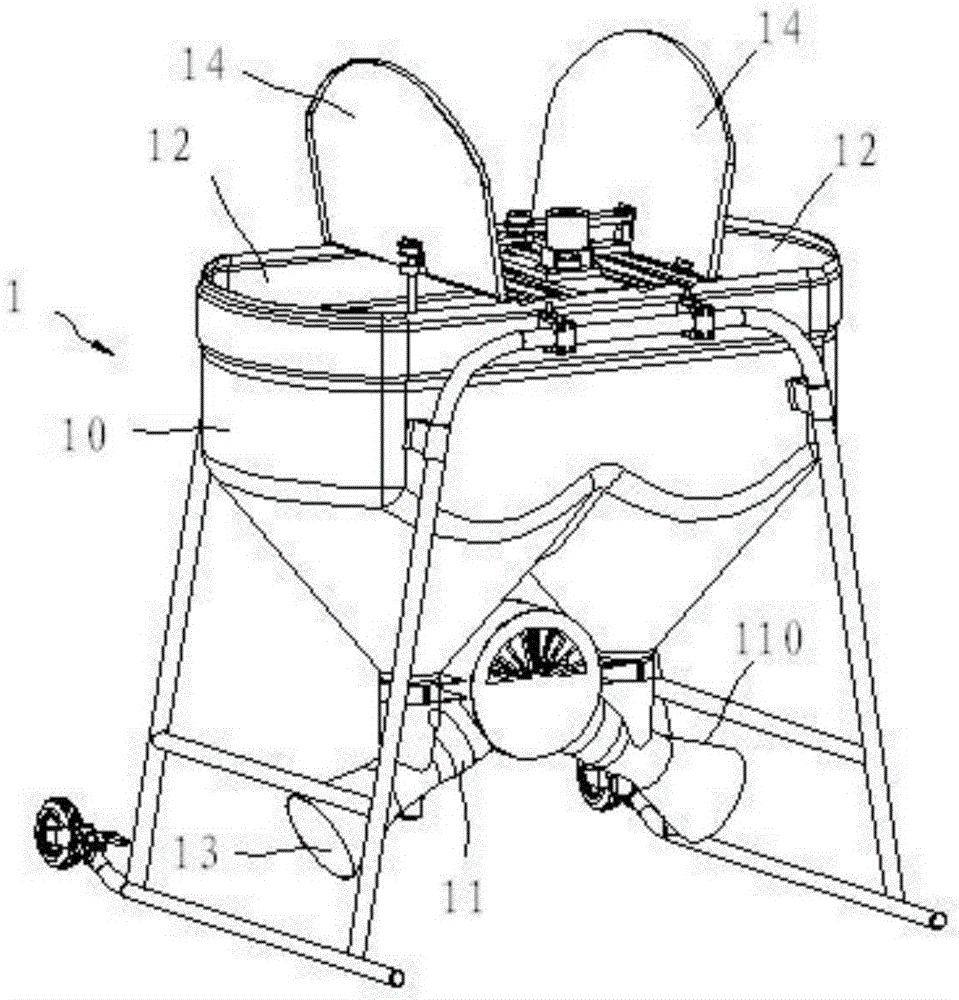

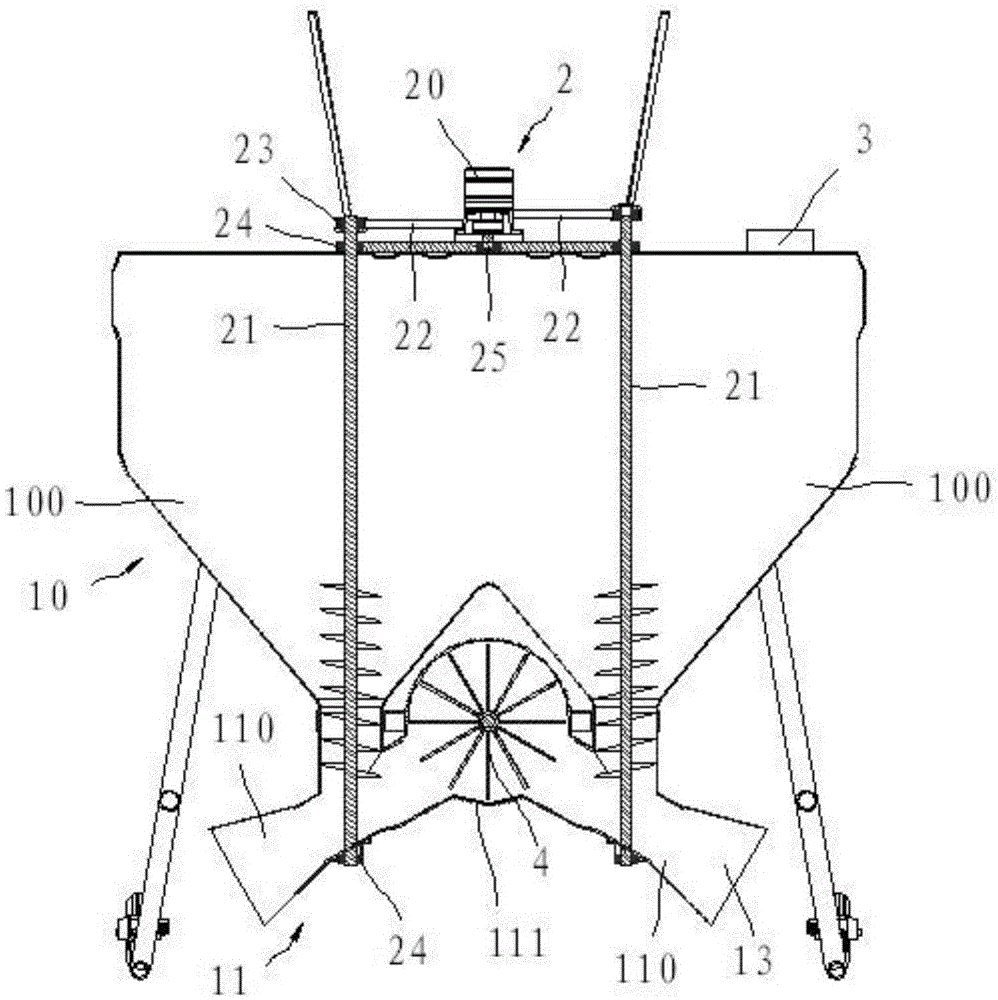

Dusting device and flying dusting device

PendingCN106628184AControl the feeding speedThe control unit controls the feeding speedAircraft componentsLaunching weaponsEngineeringMechanical engineering

The invention discloses a dusting device and a flying dusting device. The dusting device comprises a material cylinder, a material feeding mechanism and a control unit. The material cylinder comprises a primary material tank and a secondary material tank which communicate with each other. The material feeding mechanism comprises at least one screw shaft which is used for conveying the material in the primary material tank to the secondary material tank, and one motor which is coupled with the screw shaft. The control unit controls the material feeding speed of the screw shaft through the motor. At least one material discharge hole is formed in the secondary material tank. A fan is installed in the secondary material tank for blowing the material in the secondary material tank out of the material discharge hole. The dusting device has the advantages that the control unit is used for controlling the rotation speed of the rotation shaft, thus being capable of controlling the material feeding speed of the screw shaft, and attaining the predicted requirement, and the motor can drive two or more screw shafts to feed the material simultaneously, thus enhancing the dusting uniformity to attain the goal of uniform dusting.

Owner:SHENZHEN HI TECH NEW AGRI TECH CO LTD

Sprinkler and washing machine

ActiveCN108547113AExpand the spraying areaReduce flow rateMovable spraying apparatusWashing machine with receptaclesElectricityWater flow

The invention provides a sprinkler and a washing machine. The sprinkler comprises a spray head base provided with a connection portion connected with a drying tunnel and a rotary spray head rotatablymounted on the spray head base and provided with a spraying nozzle communicated with a water inlet; the axis of the spraying nozzle extends obliquely with respect to the radial direction of the rotaryspray head so that the rotary spray head can self-rotate with respect to the spray head base under the counter force of water flow. According to the sprinkler, the sprinkler is added at the water inlet of the drying tunnel of the washing machine, the sprinkler is used for automatically spraying water in the circumferential direction, condensed water can be dispersed and sprayed into the drying tunnel, a good shunting effect is achieved, the spray area of the condensed water is significantly enlarged, the flow speed of the condensed water is reduced, thereby increasing the residence time of the condensed water in the drying tunnel, the condensed water can fully exchange heat with hot and humid air, thereby improving the condensation efficiency, and the effects of saving water, time and electricity are achieved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

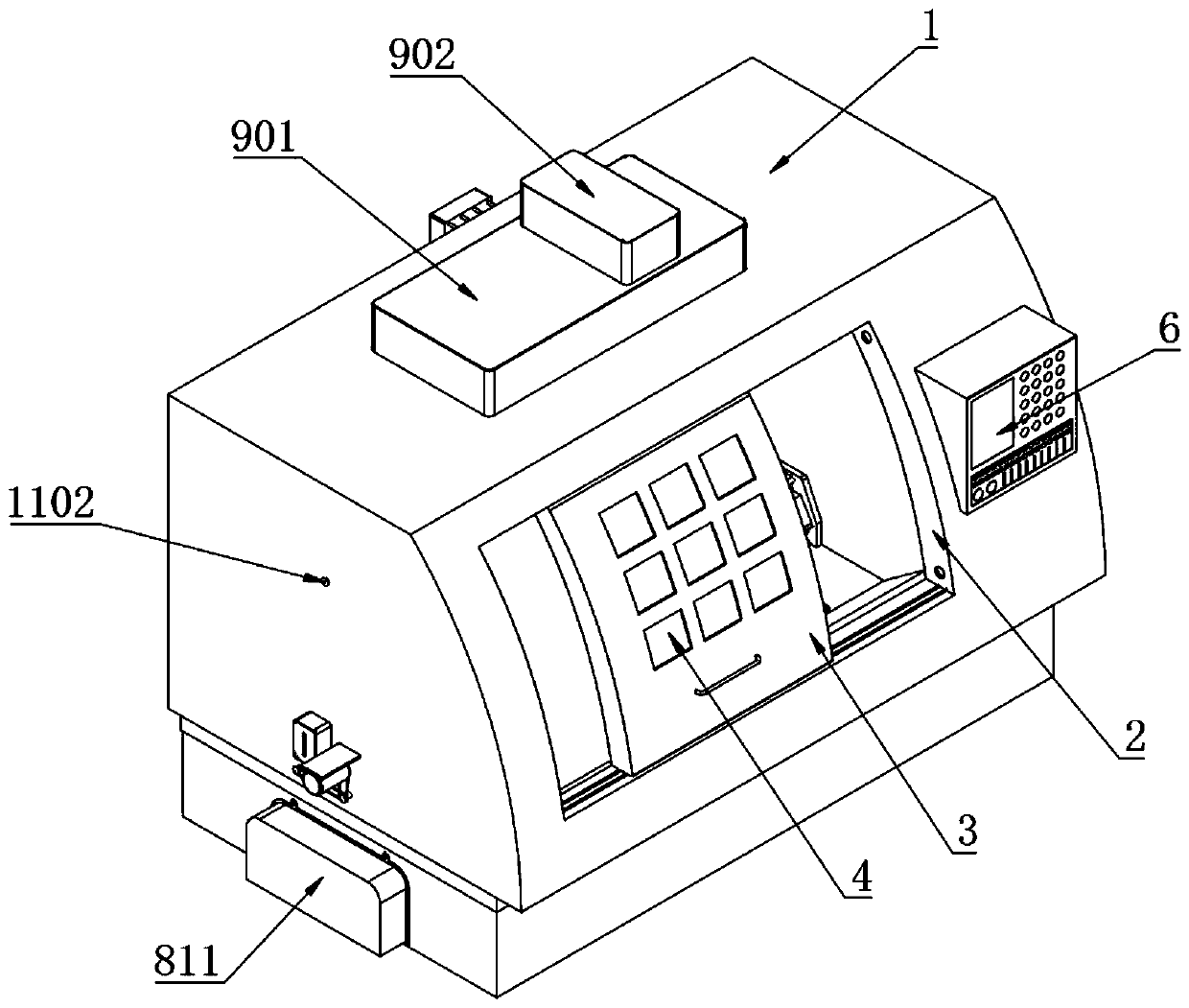

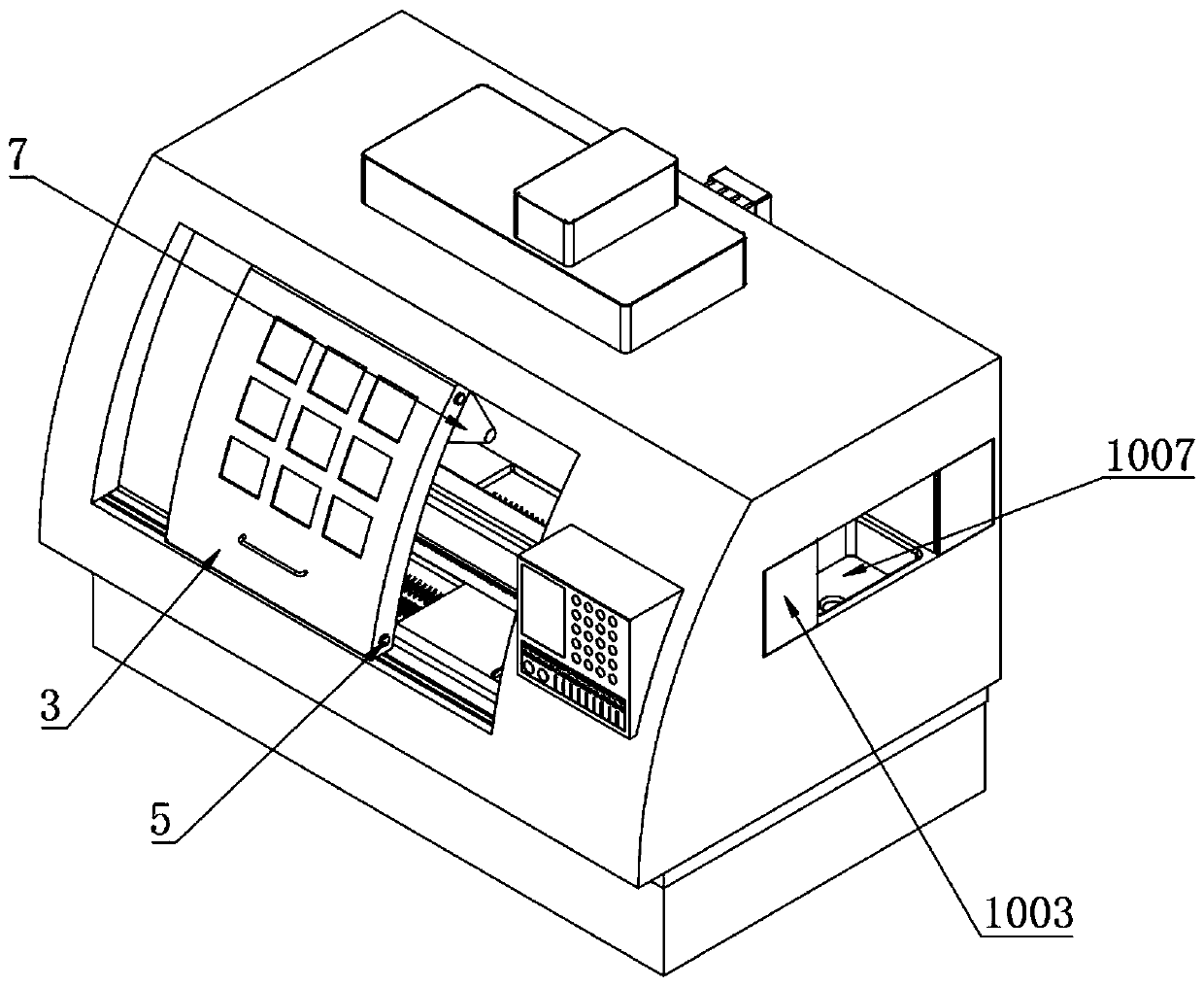

Safety protective production machine tool facilitating waste recovery and achieving environment friendliness

InactiveCN111589543AScientific and reasonable structureEasy to useCleaning using toolsCleaning using gasesElectric machineryEngineering

The invention discloses a safety protective production machine tool facilitating waste recovery and achieving environment friendliness. A placement groove is formed in one end of a machine tool bed, amachine tool cover is installed on the inner wall of the placement groove in a sliding manner, inspection windows are uniformly installed on the outer side of the machine tool cover in an embedded manner, and contact sensors are symmetrically installed at one end of the machine tool cover in an embedded manner. The safety protective production machine tool is scientific and reasonable in structure and safe and convenient to use. By arranging a drive motor, a drive screw, internal thread mounting bases, a sliding mounting plate and cleaning scraping plates, machining scraps can be crushed, collected and stored, the efficiency of scrap collection is improved, and the cleanness of the production machine tool in use is improved. By arranging air cylinders, clamping plates, pressure sensors and the contact sensors, the clamping fastness of workpieces can be monitored and observed, the fastness of workpiece clamping is improved, the safety in the use process of the production machine tool is improved, and the protection performance of staff is improved.

Owner:刘凯

Medical sterilizing device

ActiveCN107802861AImprove stirring efficiencyExpand the spraying rangeLavatory sanitoryChemicalsEngineeringOblique cutting

The invention relates to a medical sterilizing device. The medical sterilizing device comprises a sterilizing vehicle and a medicine box fixedly installed at the upper side of the sterilizing vehicle,wherein a first rotary cavity, a slide slot and a second rotary cavity are arranged in the inner wall of the sterilizing vehicle, a first conical oblique wheel is rotatably arranged at the inner topwall of the first rotary cavity, a rotary roller is fixedly installed at the top end surface of the first conical oblique wheel, the rotary roller and the sterilizing vehicle are in rotating matched connection and extend upward to enter a storage cavity of the medicine box, the top end surface of the rotary roller and an annular disk fixedly installed on the inner top wall of the storage cavity are in rotating matched connection, and an oblique cutting disk in rotating matched connection with the rotary roller is fixedly installed in the inner bottom wall of the storage cavity.

Owner:泰州国安医疗用品有限公司

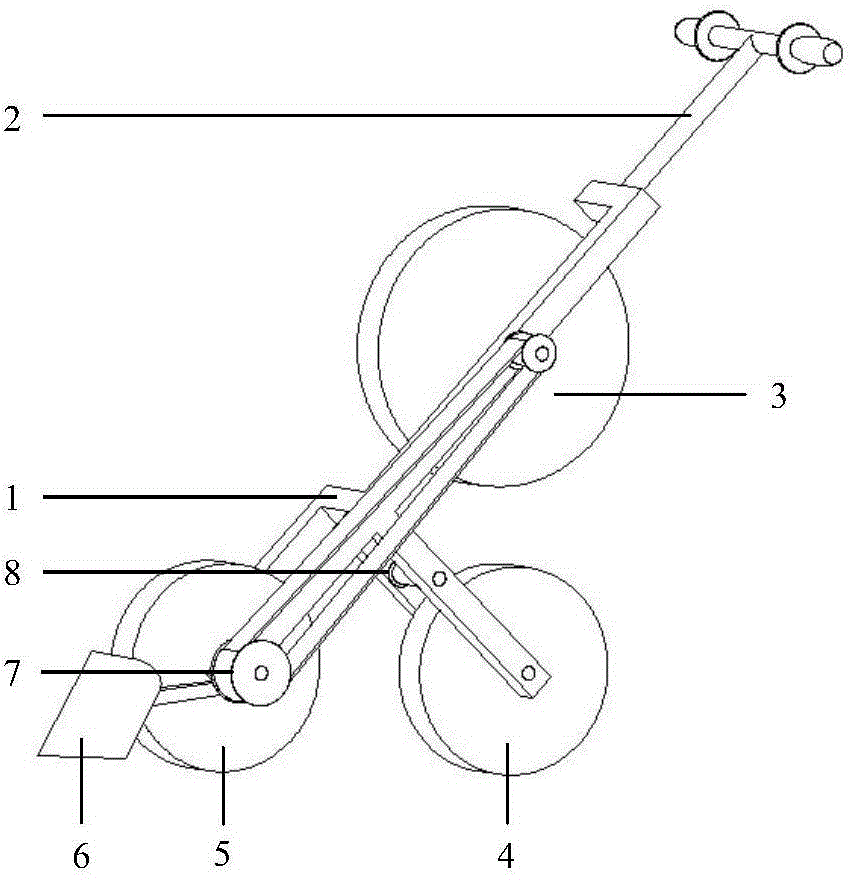

Micro-sprinkling belt spreading and rolling dual-purpose machine

The invention relates to a micro-sprinkling belt spreading and rolling dual-purpose machine. The micro-sprinkling belt spreading and rolling dual-purpose machine comprises a rack, a steering handle, a tape feed roller, a crawler wheel, a press wheel, a soil scraper, a transmission device and a guide wheel, wherein the rack consists of an upper beam, a long arm and two forked structures which are connected into an integer from top to bottom in sequence; the forked structures are respectively fixed at front and rear sides of the long arm through a lower beam vertical to the long arm; the two forked structures are respectively used for fixing the crawler wheel and the press wheel; the steering handle is T-shaped; the lower end of the steering handle is connected on the upper beam; the tape feed roller is fixed on the long arm between the lower beam and the upper beam through a wheel shaft; the crawler wheel and the press wheel are mounted on the rack through the wheel shaft; the soil scraper plate is movably connected to the front end of the press wheel through a connecting rod; the guide wheel is arranged behind the rack. The micro-sprinkling belt spreading and rolling dual-purpose machine can realize multiple purposes, is simple in structure, strong in function and good in stability, not only can be used for spreading micro-sprinkling belt, but also can be used for rolling the micro-sprinkling belt, so that the abrasion to the micro-sprinkling belt is reduced, and the service life of the micro-sprinkling belt is prolonged.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

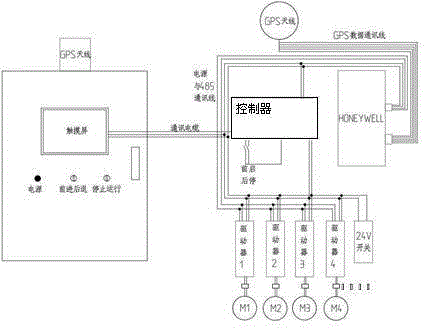

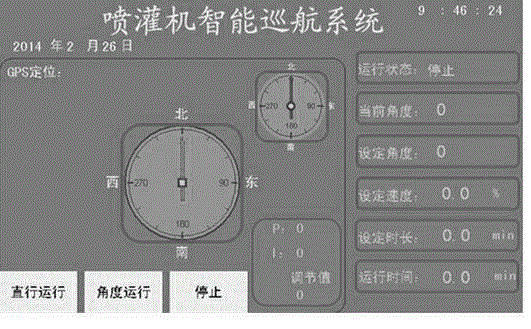

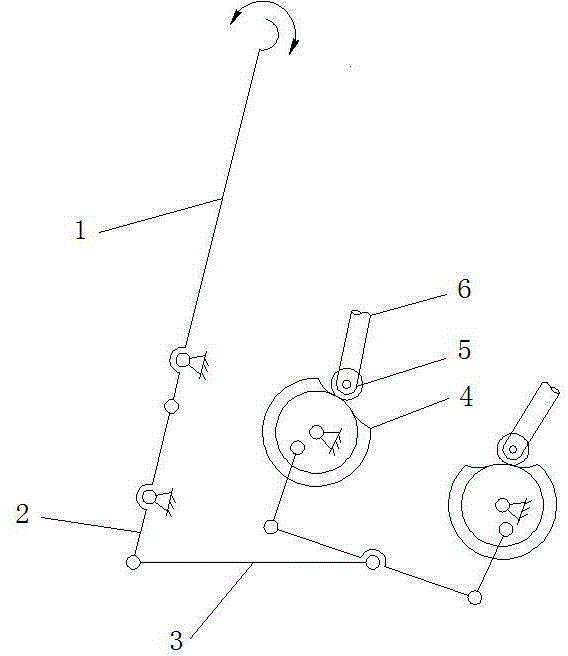

Joint navigation device for lateral-move sprinkling machine

InactiveCN104396701AEasy transferSensitivity flexible adjustmentWatering devicesCultivating equipmentsMotor speedControl system

The invention discloses a joint navigation device for a lateral-move sprinkling machine. The joint navigation device for the lateral-move sprinkling machine is composed of a GPS navigation system, a touch screen control system, a furrow navigation system and a motor speed regulation drive system; the GPS navigation system is composed of a GPS module, a GPS antenna and a GPS data communication line; the touch screen control system is composed of a touch screen, a communication line and a power supply; the motor speed regulation drive system is composed of a central controller, a motor driver and a motor. The joint navigation device for the lateral-move sprinkling machine uses the GPS and electric joint positioning and navigation mode, the problem of sprinkling route deviation in the sprinkling process is effectively solved, the navigation effect is good, the stability is strong, the operation is easy and convenient to perform, the working efficiency of the sprinkling machine is greatly improved, the labor investment is lowered, the sprinkling uniformity is improved, and the application is broad.

Owner:NORTHWEST A & F UNIV

Lawn sprinkler

InactiveCN107711445AAdjustable spraying distanceImprove spray uniformityWatering devicesCultivating equipmentsSprayerEngineering

A lawn sprinkler. It relates to a sprinkler, in particular to a lawn sprinkler for lawn and gardening. The utility model provides a lawn sprinkler which is simple in structure, convenient to operate and saves manpower. It includes a car body, a liquid bag and an adjustable mechanism. The center of the top surface of the car body is provided with a boss. A number of water outlets are evenly distributed on the ring surface of the liquid bag, and the boss is located in the central hole of the liquid bag. The invention is convenient to process and has low cost.

Owner:胡凡非

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com