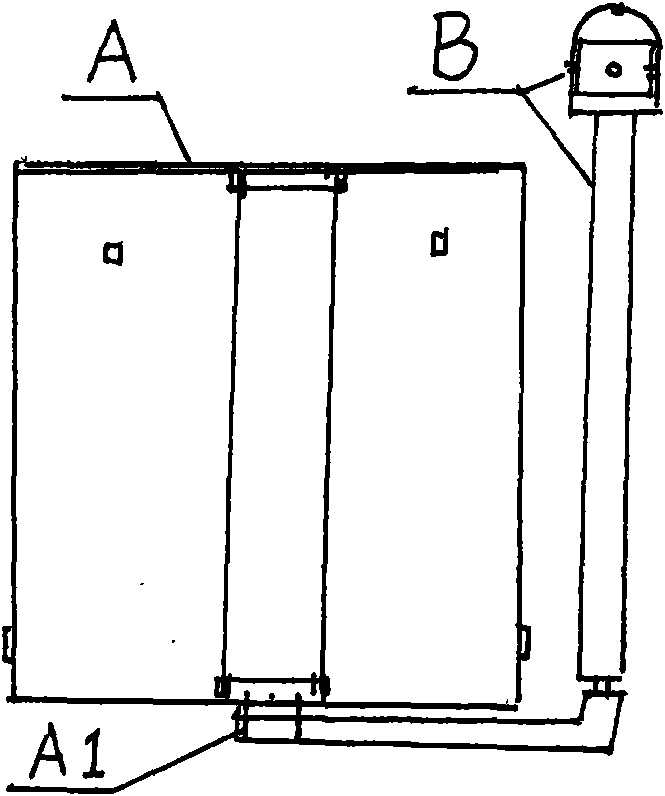

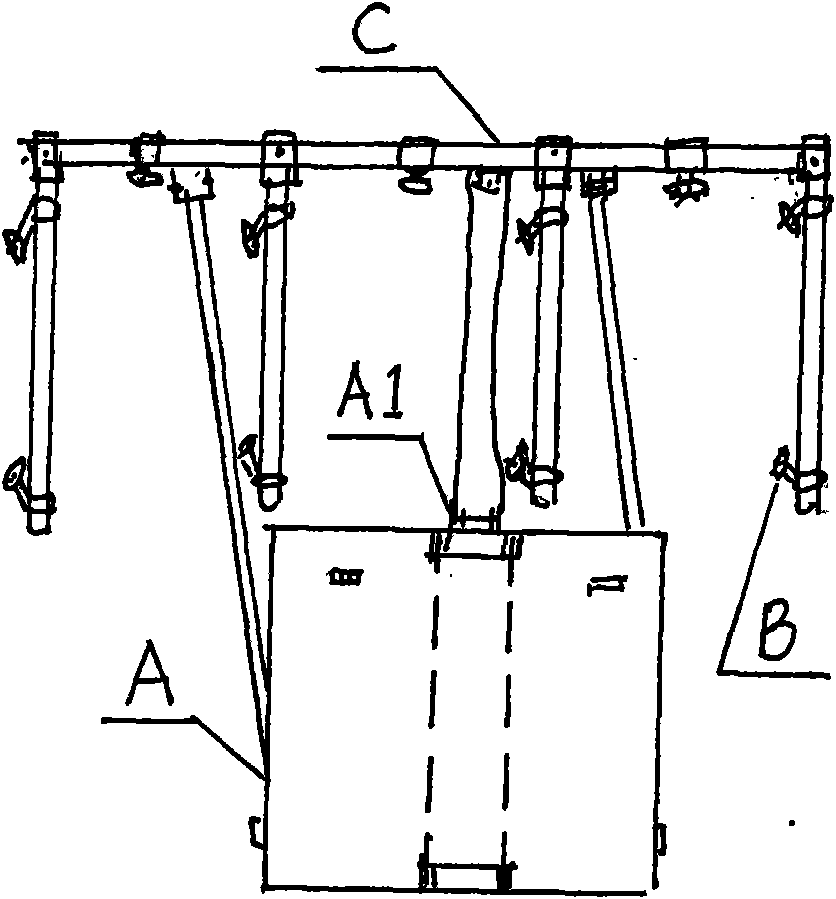

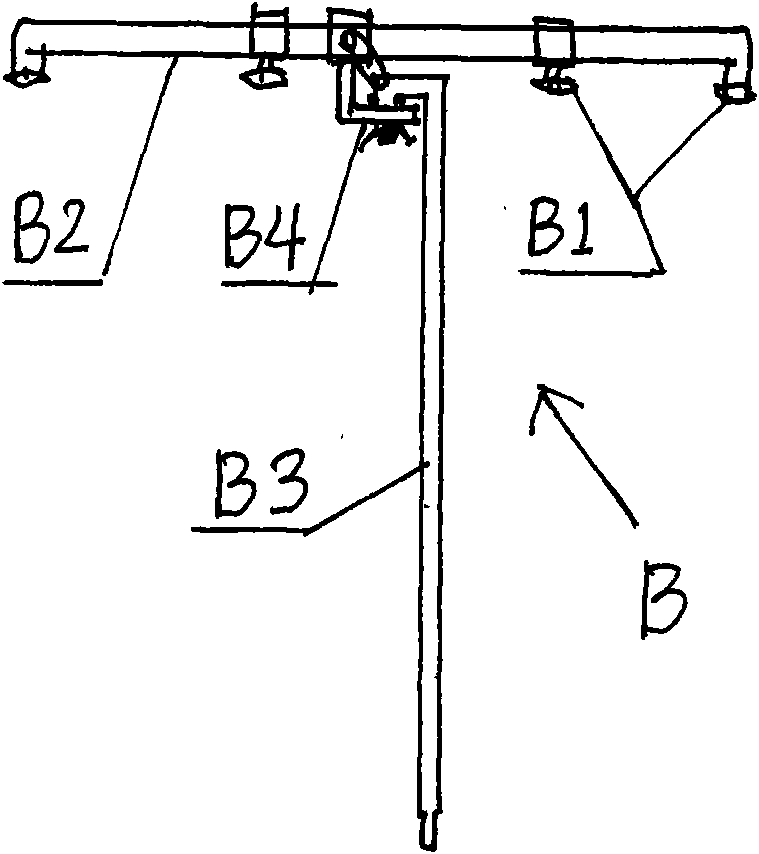

Energy accumulation type sprayer and spraying frame

A sprayer and container technology, which is applied in the fields of fluid pumps, air respirators, and sprayers. It can solve the problems of insufficient spray uniformity, poor effect, small spray coverage, and small fluid suction force, so as to achieve good spray uniformity and save the amount of spray liquid. , The effect of small inhalation volume of mist liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is a plurality of inventions under the general inventive concept. He solves many problems existing in various sprayers in the prior art, and points out the existing problems in the background technology part of the description, and proposes technical solutions and embodiments for solving the problems respectively. As described spray frame etc., it not only can be the organic component of this accumulator type sprayer, has common feature, and it also can cooperate with existing various sprayer independently, and it is universal, and can obtain comparative The significant beneficial effects of the prior art are listed as independent claims. According to the relevant provisions that a patent application under the general inventive concept may have more than two independent claims, the description is hereby provided. Below will provide respective preferred embodiment in conjunction with accompanying drawing:

[0029] 1. Implementation of energy stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com