Patents

Literature

98results about How to "Save Spraying Time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

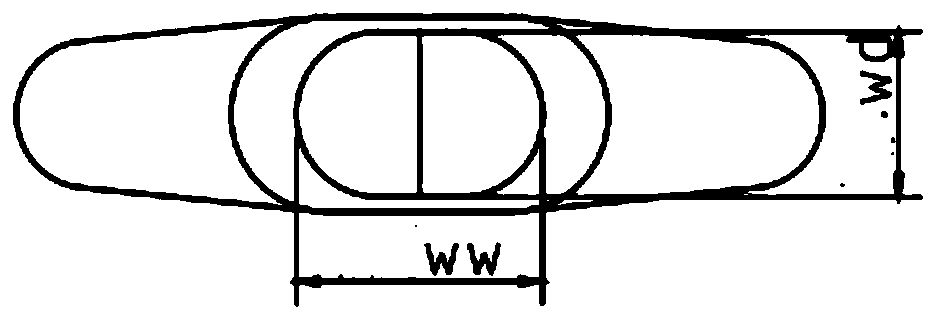

Racket automatic spraying system

ActiveCN106622771AAvoid mutual interferenceReduce movement distanceSpraying apparatusPretreated surfacesProduction lineControl signal

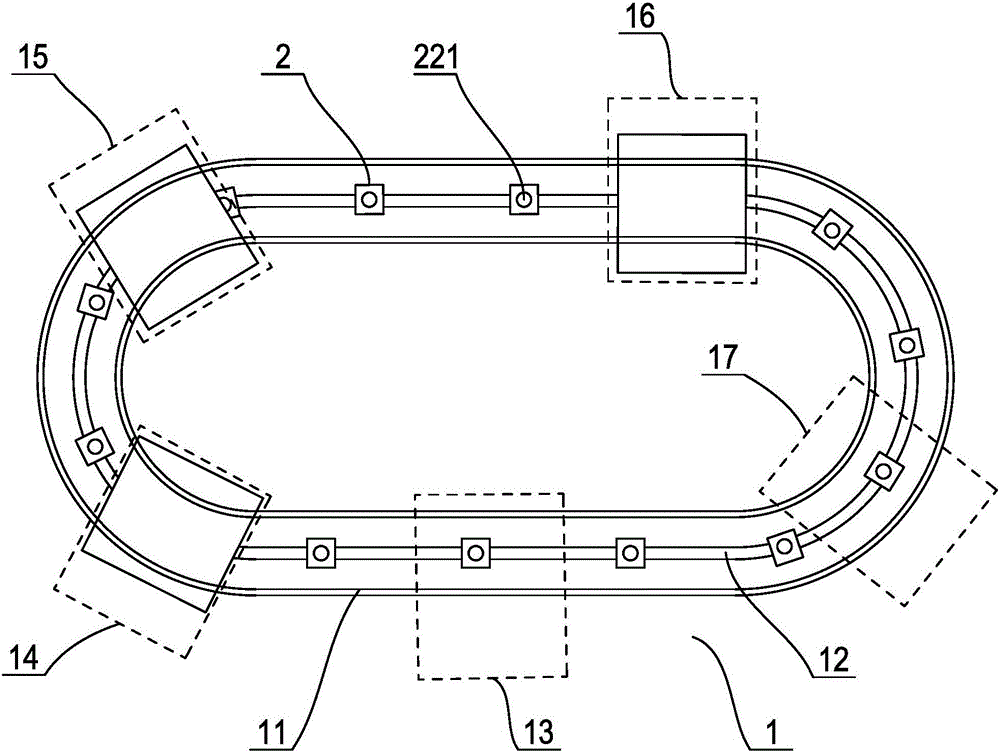

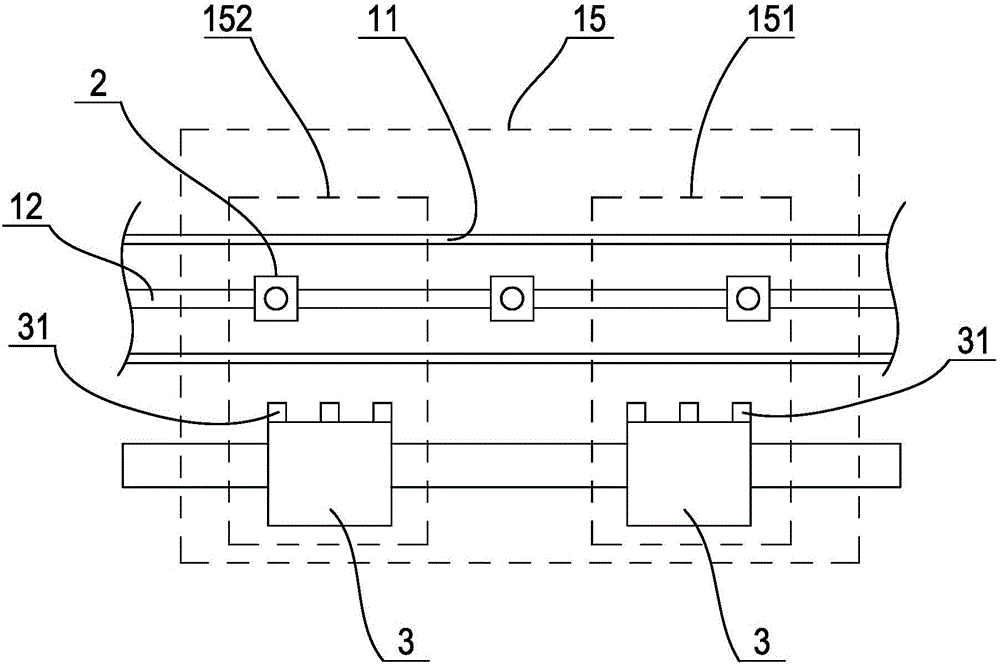

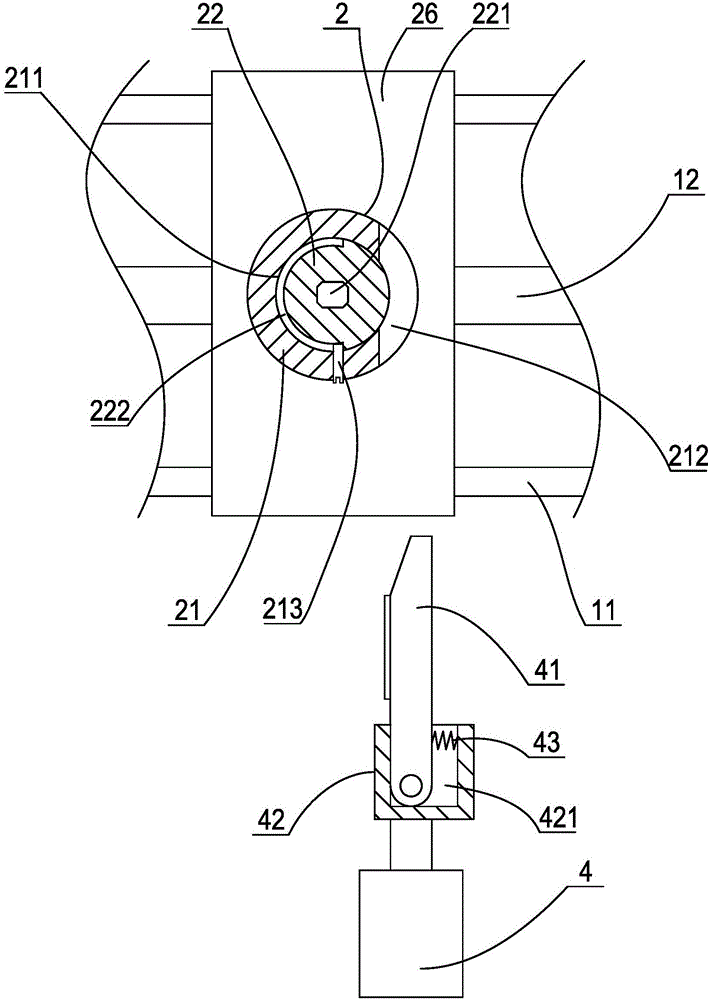

The invention discloses a racket automatic spraying system. The racket automatic spraying system comprises a loading station, a spraying station, a curing station and an unloading station arranged on a conveying production line in sequence; a driving chain of the conveying production line is provided with multiple racket fixed sleeves for inserting rackets; the spraying station is provided with a spraying manipulator; the spraying manipulator is provided with a combined spraying gun, a racket driving mechanism and a position detecting device; when the racket fixed sleeves move beside the spraying manipulator, the position detecting device sends a control signal; the spraying manipulator and the racket fixed sleeves keep synchronous movement; the combined spraying gun is controlled to automatically spray one surfaces of the rackets; after the combined spraying gun sprays one surfaces of the rackets, the racket driving mechanism acts to rotate the rackets on the racket fixed sleeves; and at this time, the combined spraying gun automatically sprays the other surfaces of the rackets by procedures. The racket automatic spraying system can realize full-automatic racket spraying to prominently improve the production efficiency, reduce the labor intensity of staff and effectively improve the spraying quality of the rackets.

Owner:杭州诚兴体育用品有限公司

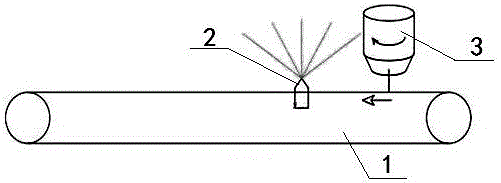

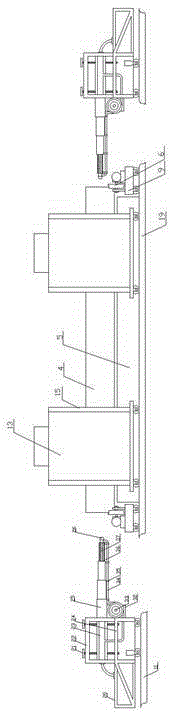

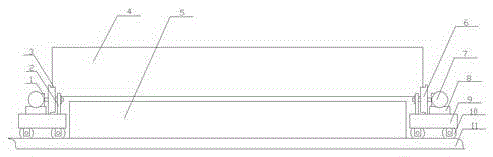

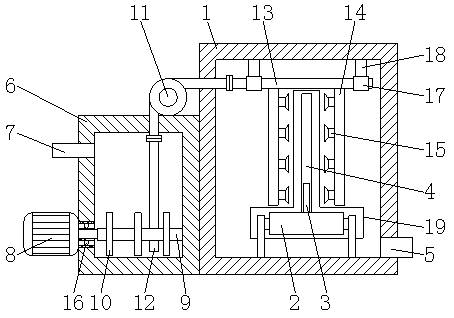

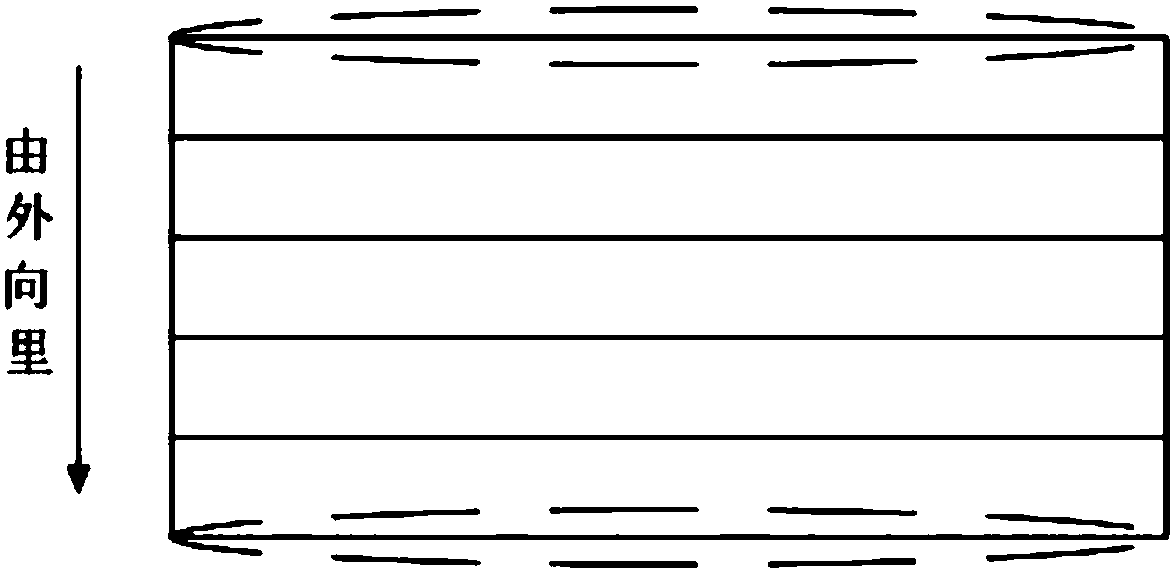

Synchronous spraying and curing processing method for pipelines arranged in parallel

ActiveCN105413978AIncrease profitAvoid vibrationSpraying apparatusPretreated surfacesMedium frequencyMaterials science

The invention discloses a synchronous spraying and curing processing method for pipelines arranged in parallel. The method includes the following steps that A, steel pipes are thrown into an acid pickling pond to be subjected to acid pickling for removing rust; B, the steel pipes subjected to acid pickling are cleanly flushed through clear water and then are dried for standby application; C, the steel pipes obtained in the step B are subjected to medium frequency heating; D, the interiors and the exteriors of the steel pipes are subjected to synchronous plastic coating through an electrostatic spraying method; E, heating and curing are carried out, and the pipelines are moved side by side before being cured; and F, natural cooling is conducted. In the step D, the plastic coating operation is carried out through an electrostatic spraying line, and the electrostatic spraying line comprises a steel pipe conveying device, an external spraying device, an internal spraying device, a powder recovery device and a pipeline side-by-side moving device. The method is simple, using is convenient, and production efficiency can be improved; a spray gun can be prevented from vibrating, powder is uniformly sprayed, and the powder utilization rate is high; the pipelines do not need to be lifted repeatedly and can be moved side by side.

Owner:青岛豪德博尔实业有限公司

Method for cultivating straw mushroom and culture material thereof

InactiveCN102649649ASolve the shortageStable outputRoof improvementClimate change adaptationThermal insulationMushroom mite

The invention relates to a method for cultivating straw mushroom by utilizing waste tea leaf in place of straw and a culture material thereof. The method comprises the following steps of: firstly erecting a mushroom room which is easy for thermal insulation and moisturizing and an anti-leakage plastic net bed; adjusting material ratio, acidity and alkalinity and water content of the culture material before the culture material is fed into the room; laying the culture material which is fed to the bed to be arched and then directly sealing the window and the door to perform pasteurization; subsequently opening the window to cool to 40 DEG C; spraying water to moisturize and then sowing after one hour; adjusting and controlling the material temperature to be 35 DEG C and air humidity to be 90 percent after sowing; and stably maintaining for five to seven years to spray out mushroom water. The method has the advantages of relieving the contradiction between supply and demand of the straw by using the cheap waste tea leaf resource, reducing the production cost, simplifying the production process, cultivating annularly, preventing mushroom pickup from being affected by mushroom mites, achieving an input-output ratio of 1:2.5 and being superior to the cultivation method with the straw as a main material.

Owner:XIAMEN NONGJIA SUNSHINE BIOTECH

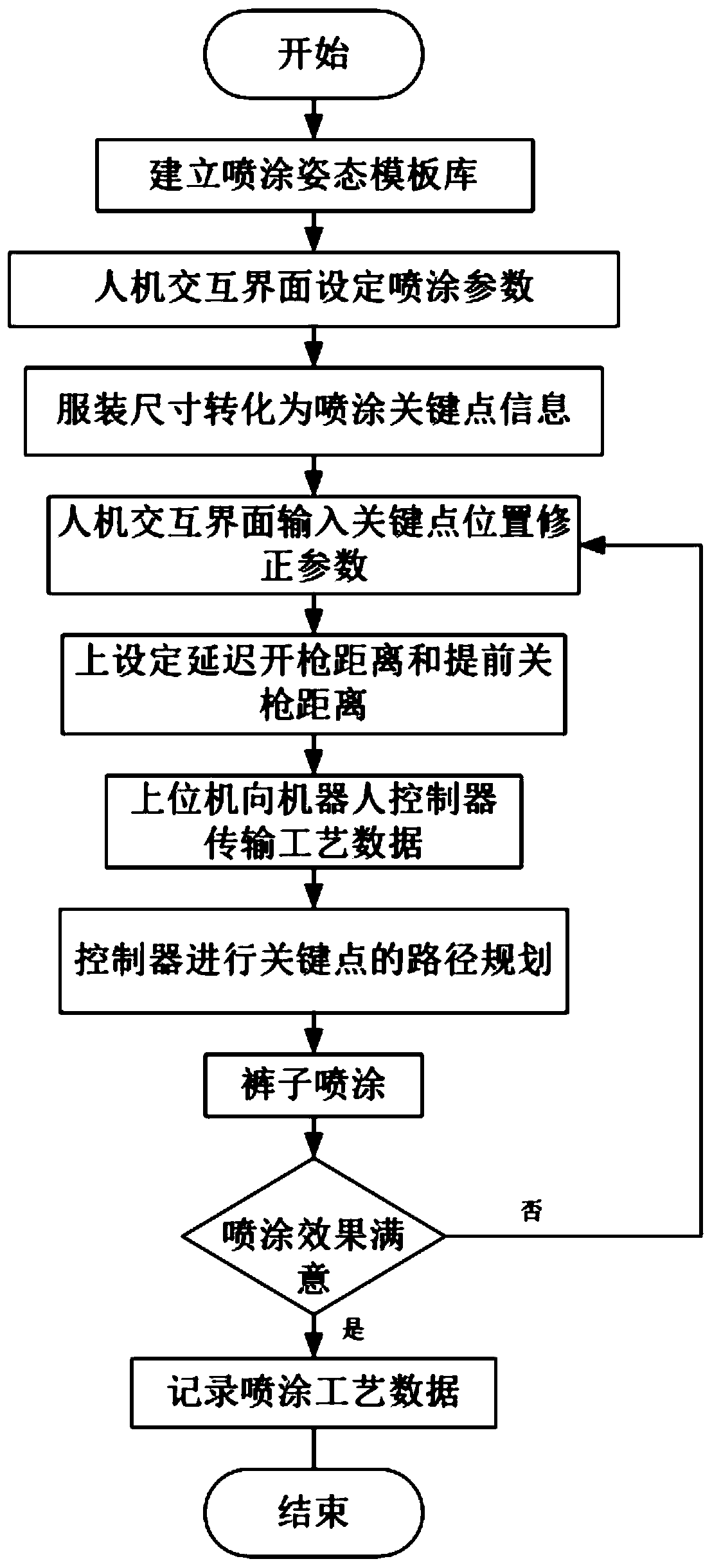

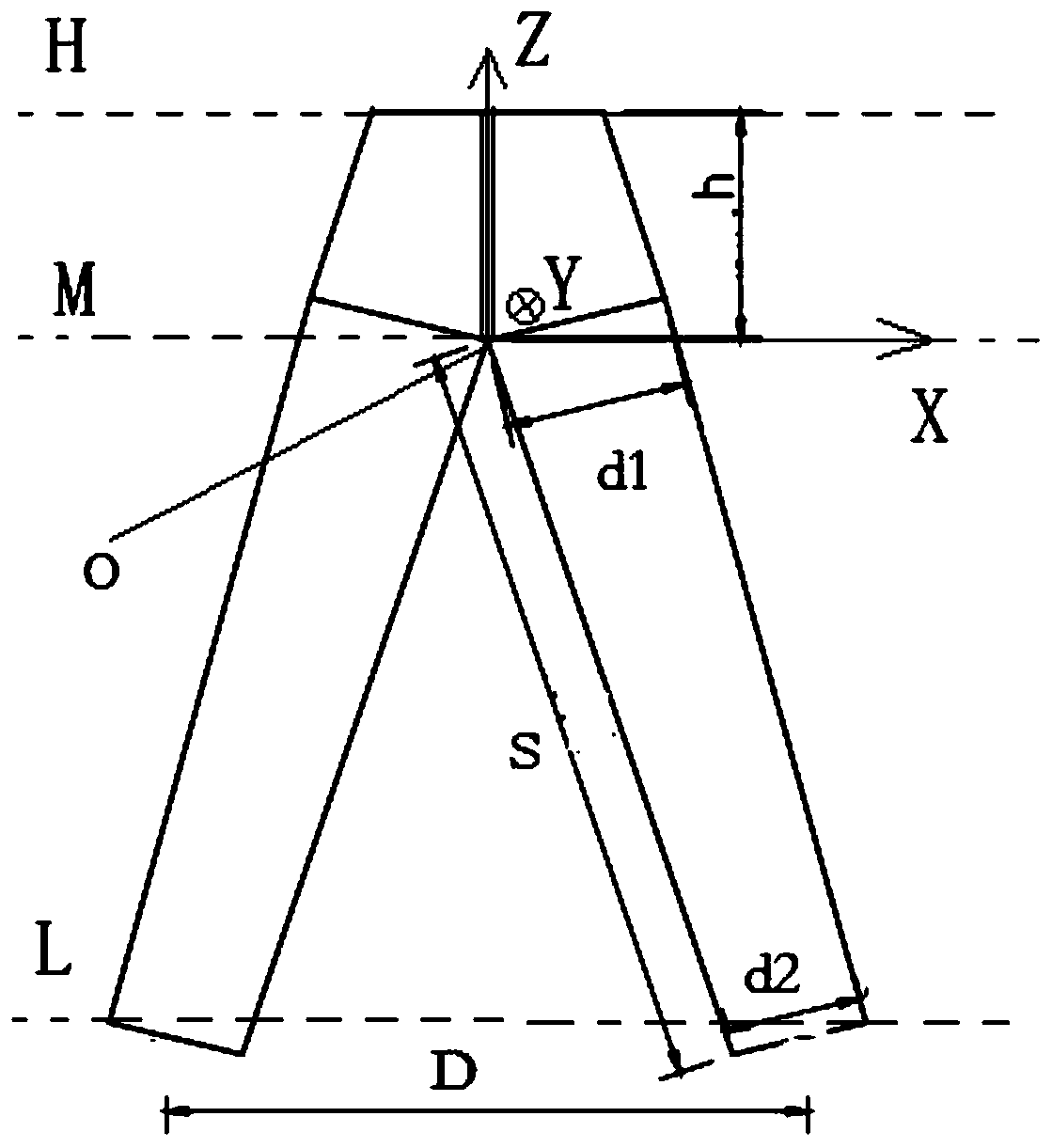

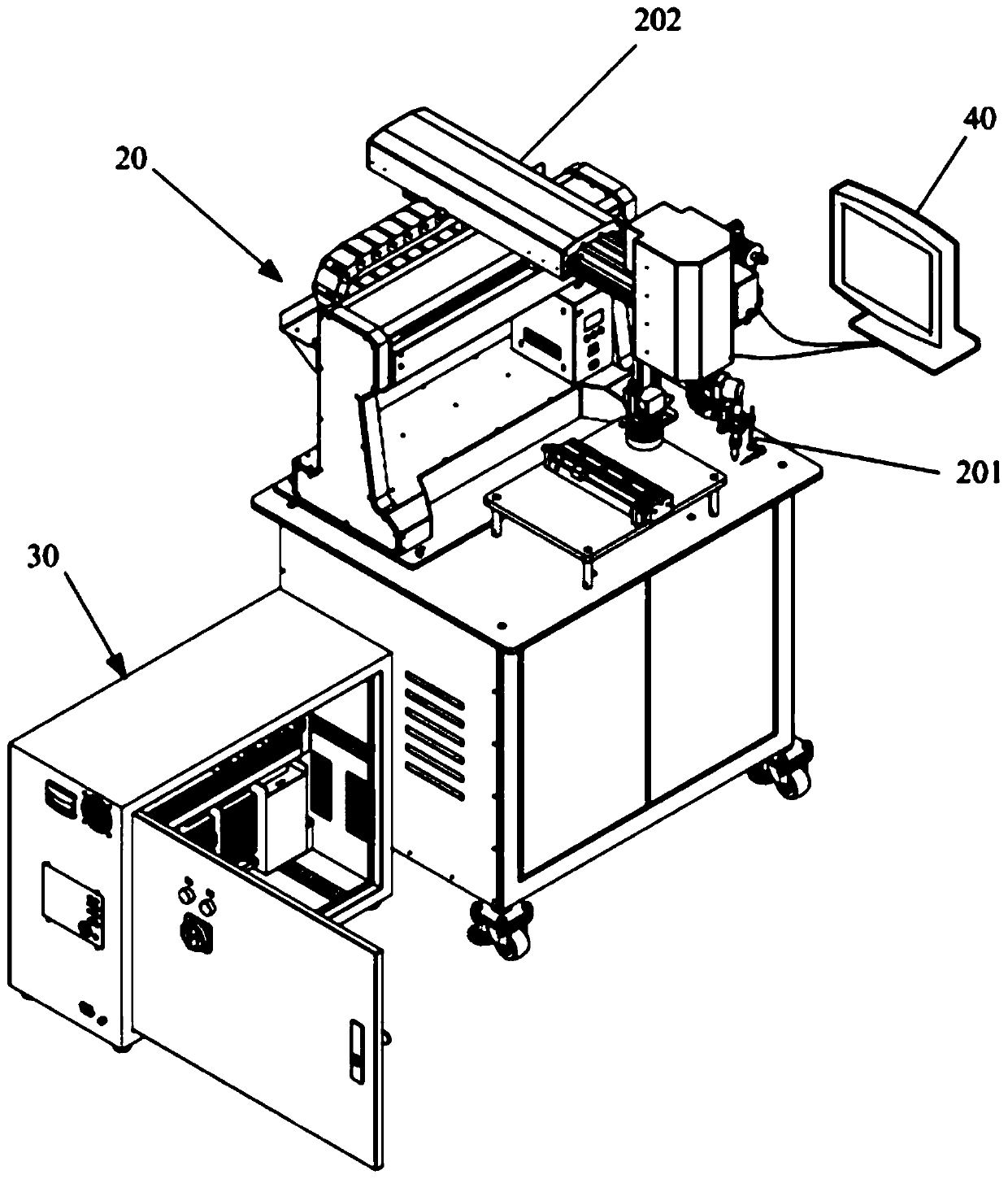

Method for carrying out garment spraying by using cooperation robot

ActiveCN110421561ARealize process parameterizationStable spraying effectProgramme-controlled manipulatorHuman–machine interfaceInteraction interface

The invention discloses a method for carrying out garment spraying by using a cooperation robot. The method comprises the following steps that a robot spraying gesture template library is established;spraying parameters are set through a human-computer interaction interface of an upper computer; the information of the key sizes of garments are converted into the position information of the spraying key points; position correction values of the key points are input a parameter box of the human-computer interaction interface of the upper computer; a delay gun starting distance and a gun pre-stopping distance are set in a parameter input box of the human-computer interaction interface of the upper computer; the upper computer transmits process data to a robot controller; the robot controllerperforms spraying path planning according to the positions of all the key points; a human-computer interaction interface operation button on the upper computer is clicked, and the robot controller controls a robot to perform spraying; and the position correction values of the key points in the step 4 are changed according to the spraying effect to improve the spraying effect. By adopting the method, the spraying effect is stable, and the spraying efficiency is improved.

Owner:TIANJIN UNIV

Spraying device and spraying method for bottle bodies

The invention discloses a spraying device and a spraying method for bottle bodies. The spraying device for the bottle bodies comprises a production line, wherein a plurality of rotary shafts are vertically arranged on the production line, tools are installed on the rotary shafts according to the bottle body requirements, the tools can horizontally rotate around the perpendicular bisectors of the tools, the bottle body is inversely inserted onto the tools, the bottle bodies are evenly distributed, and a spraying gun assembly is arranged on one side of the production line and is connected with an automatic controller. An original system is innovated, and a function of parallelly moving spray guns and the bottle bodies is added. When the bottle bodies pass through the positions of the spray guns, the spray guns perform automatic spraying and meanwhile perform synchronous and parallel movement with the bottle bodies so that the spray guns can be always aligned to the bottle bodies, spraying performed under the rotation of the bottle bodies is more uniform, and meanwhile coatings are also not wasted.

Owner:四川广安慧诚科艺玻璃有限公司

Automobile spraying method

The invention relates to an automobile spraying method. The automobile spraying method comprises the following steps: puttying: 1, cleaning and checking a puttied area; 2, preparing putty; 3, coating the putty; 4, drying the putty; 5, polishing the putty; and 6, removing polishing traces; polishing: a, degreasing and inspecting the surface, wherein inspection adopts a visual method or a hand touch method or a ruler measurement method; b, removing old paint, and polishing by using a high-speed polisher; c, polishing feather-like edges; d, cleaning and supplementing the putty; e, polishing the putty; f, finely grinding manually; g, removing grinding traces and cleaning; h, spraying a middle coating primer; i, grinding the middle coating primer by using a circular grinding machine; and j, cleaning by wiping with a scouring pad; and topcoating: I, preparing finish paint; II, spraying a color plate and checking the color; III, sticking dust; IV, spraying the finish paint; V, standing; VI, baking for drying; and VII, polishing and waxing. A standard automobile spraying method is worked, so as to help an automobile spraying worker to master the spraying method.

Owner:HANGZHOU CHEQISHI AUTOMOBILE MAINTENANCE

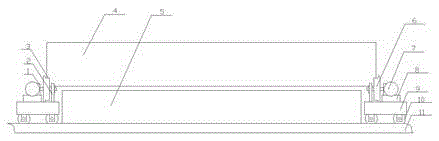

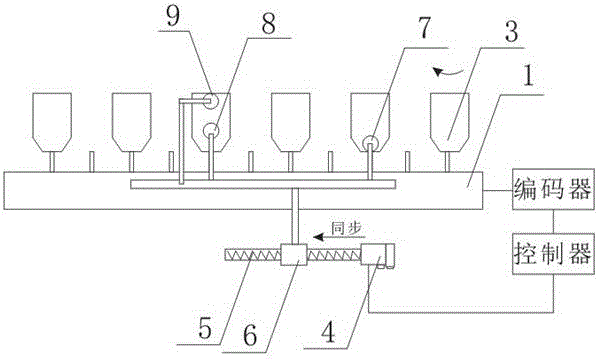

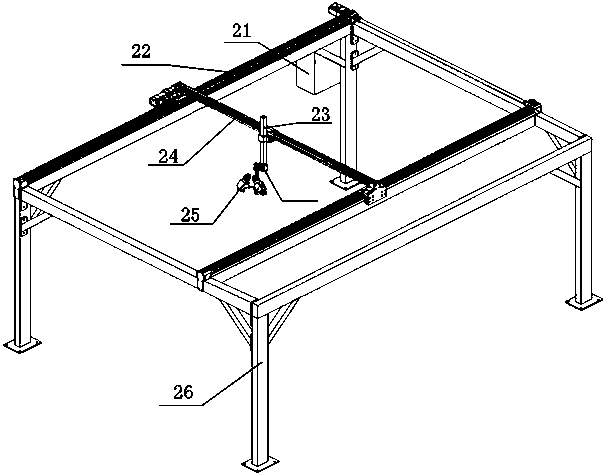

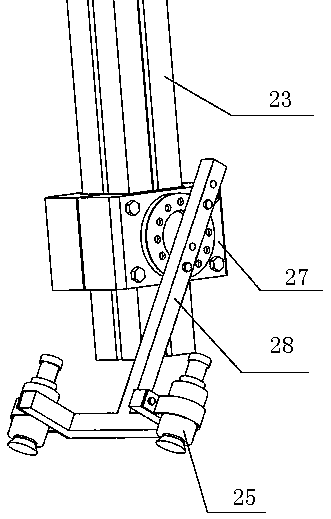

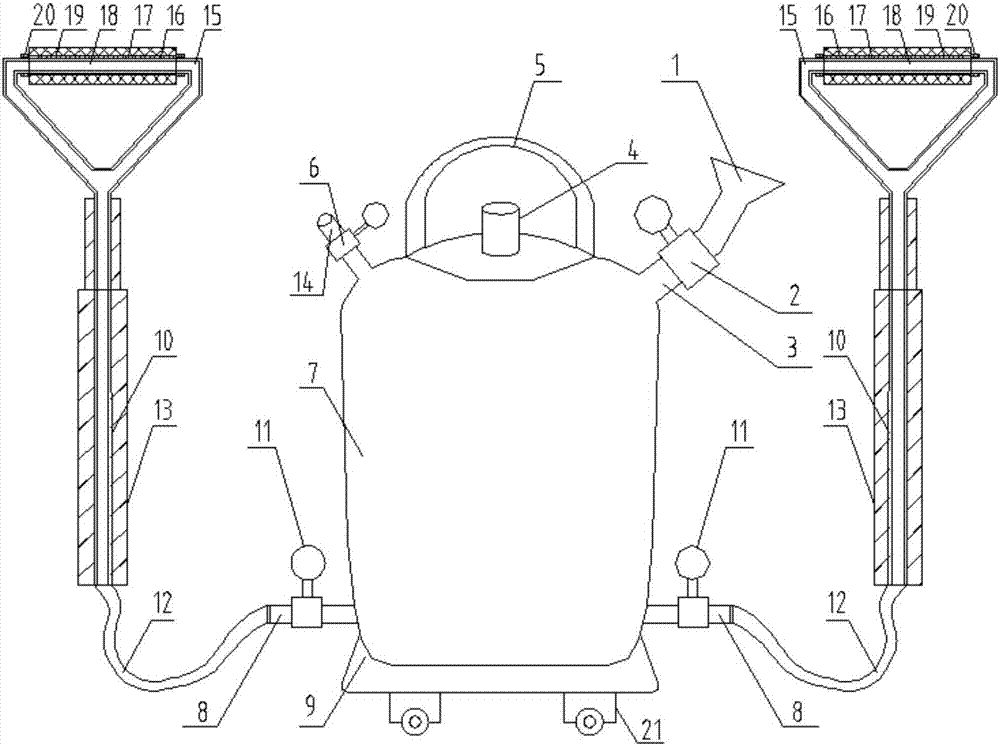

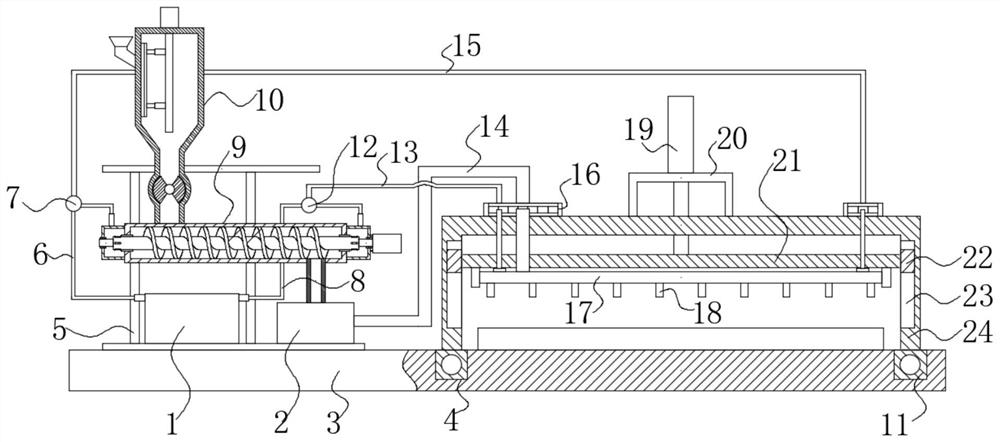

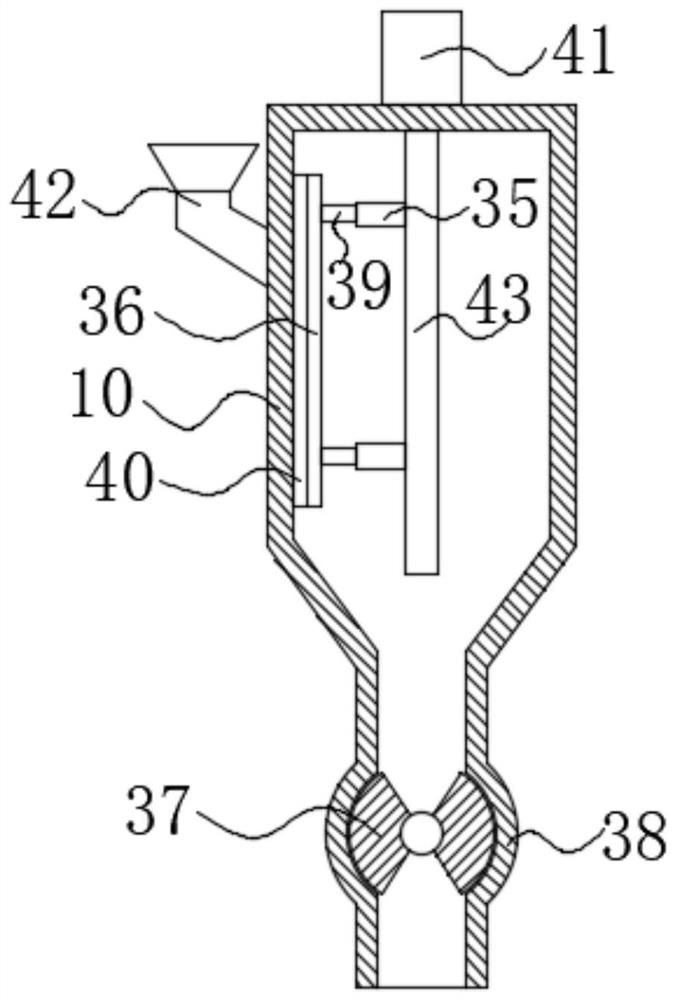

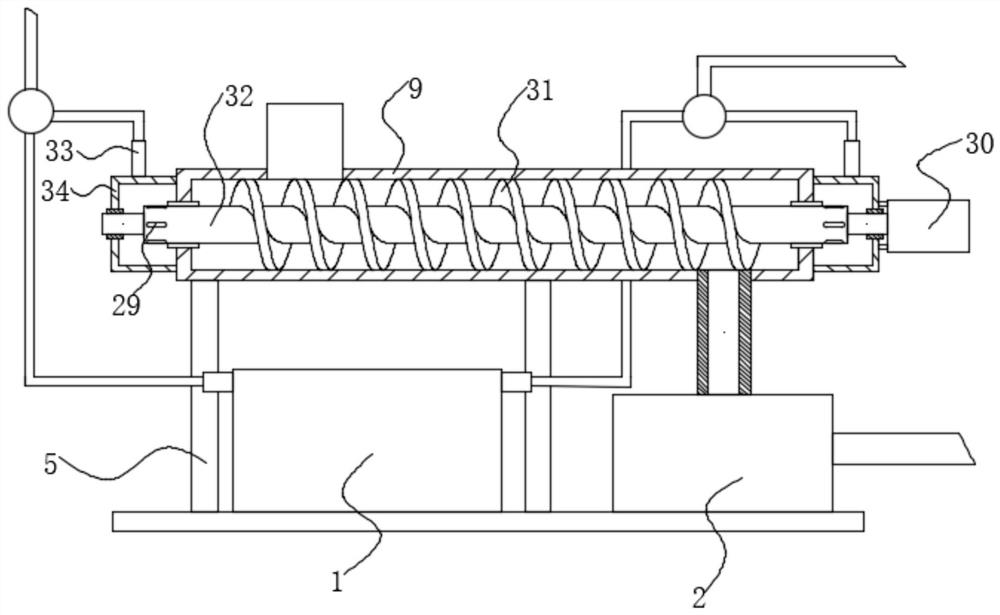

Double-block type automatic spray coating system of sleeper prefabricated de-molding agent

PendingCN108722710ASave Spraying TimeImprove spray uniformityLiquid spraying apparatusDiaphragm pumpProgrammable logic controller

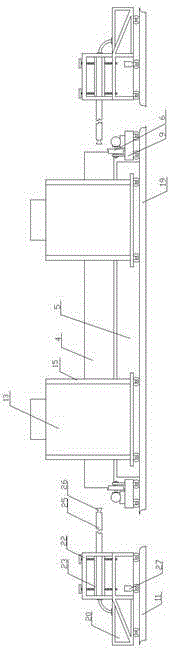

The invention provides a double-block type automatic spray coating system of a sleeper prefabricated de-molding agent and belongs to the technical field of production of railway engineering ballastless tracks. Aiming at solving the technical problems, the invention provides the double-block type automatic spray coating system of the sleeper prefabricated de-molding agent, which has the effects ofimproving the spray coating quality and shortening the spray coating time and has a good spray coating effect. The double-block type automatic spray coating system is characterized by comprising a pumping and discharging system, a spray coating system and an oil gas supplying system, wherein the pumping and discharging system comprises a sealed space composed of a sealing cover, a pumping and discharging pipeline, an exhaust fan set and an oil dirt filtering screen; the pumping and discharging system is used for pumping and discharging waste gas and waste materials, which are produced in a spray coating process of the de-molding agent, and filtering and discharging oil dirt out of a spray coating field; the spray coating system comprises a PLC (Programmable Logic Controller), a servo motorand a spraying gun; the spray coating system is used for spraying and coating the de-molding agent on a sleeper mold on a plane formed by two parallel longitudinal tracks along the movement of the servo motor; the oil gas supplying system comprises a gas pressure pump station, a storage tank and a diaphragm pump; the oil gas supplying system is used for providing the de-molding agent and air power to the spray coating system.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

Manufacturing method of epoxy resin pipeline

The invention discloses a manufacturing method of an epoxy resin pipeline. The manufacturing method of the epoxy resin pipeline comprises the following steps that A, a steel pipe is put into a pickling tank to be subjected to acid pickling and rust removal; B, the steel pipe subjected to acid pickling is washed through clear water and dried for later use; C, intermediate-frequency heating is conducted on the steel pipe obtained in the step B; D, epoxy resin powder is sprayed to the interior and the exterior of the steel pipe synchronously through an electrostatic spraying method; E, heating and curing are conducted; and F, natural cooling is conducted, plastic coating work is conducted through an electrostatic spraying line in the step D, the electrostatic spraying line comprises a steel pipe conveying device, an outer spraying, an inner spraying device and a powder recovery device, and an extension pipe which is arranged on the inner spraying device and used for being connected with an inner spraying gun is of a hydraulic-driven telescopic structure. The manufacturing method of the epoxy resin pipeline is simple; using is convenient, the occupied area of a production line can be reduced, production efficiency is improved, vibration of the spraying gun can be avoided, powder spraying is even, and the powder utilization rate is high.

Owner:青岛豪德博尔实业有限公司

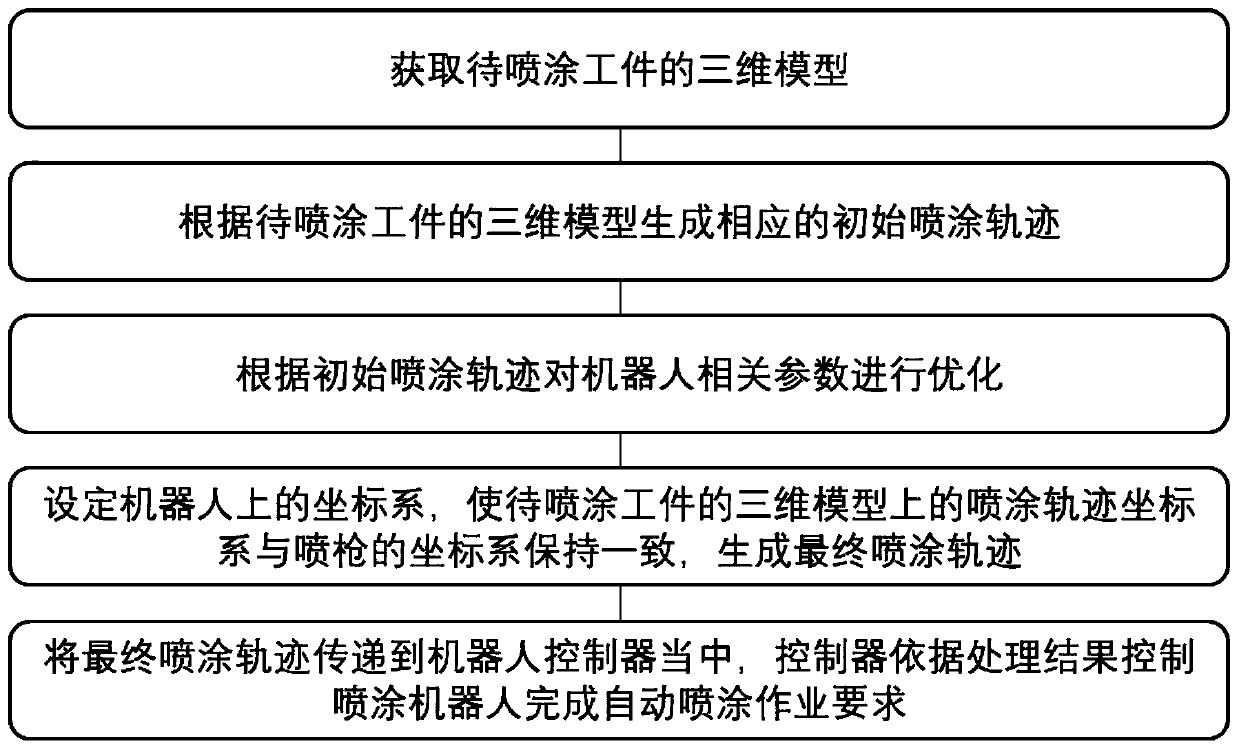

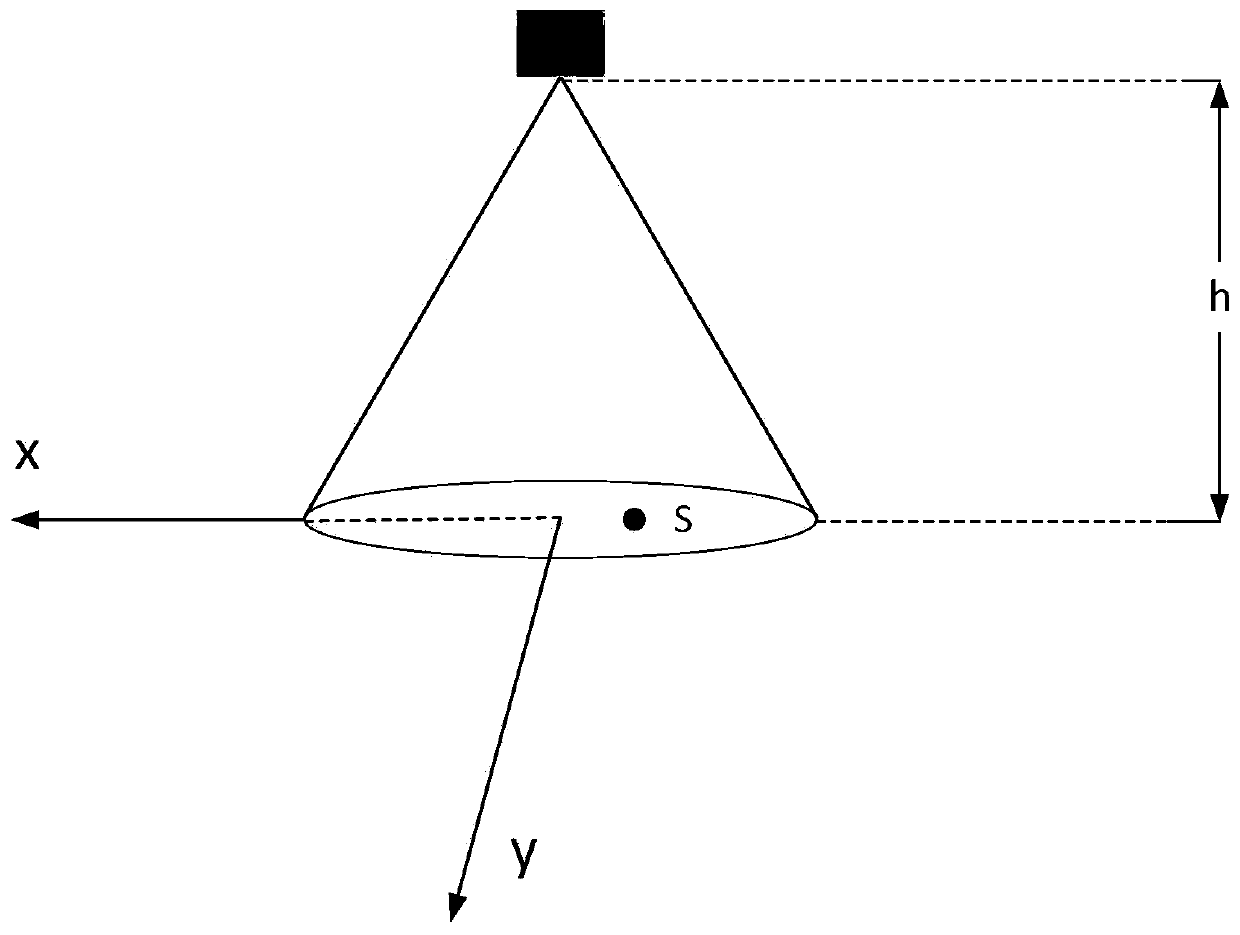

Intelligent robot spraying method based on spraying system

InactiveCN111530671AReduce dosageOptimize spray speedSpraying apparatusSpray coatingProcess engineering

The invention provides an intelligent robot spraying method based on a spraying system. A machine is adjusted through a spraying process library instead of a machine adjustment process library; for different workpieces to be sprayed, a spraying trajectory program can be automatically identified and generated; and an optimal spraying parameter and an optimal spraying trajectory are selected according to the built spraying process library. Compared with traditional spraying, after applying the method provided by the invention, the spraying quality and the spraying efficiency of workpieces are improved, meanwhile, the dosage of a spraying coating is relatively reduced, and for a determined spraying trajectory, trajectory optimization is carried out on relevant parameters such as the sprayingspeed and the spraying flow of a spraying robot by adopting the spraying uniformity as an optimal object, so that the spraying quality can achieve the best effect.

Owner:FOSHAN UNIVERSITY

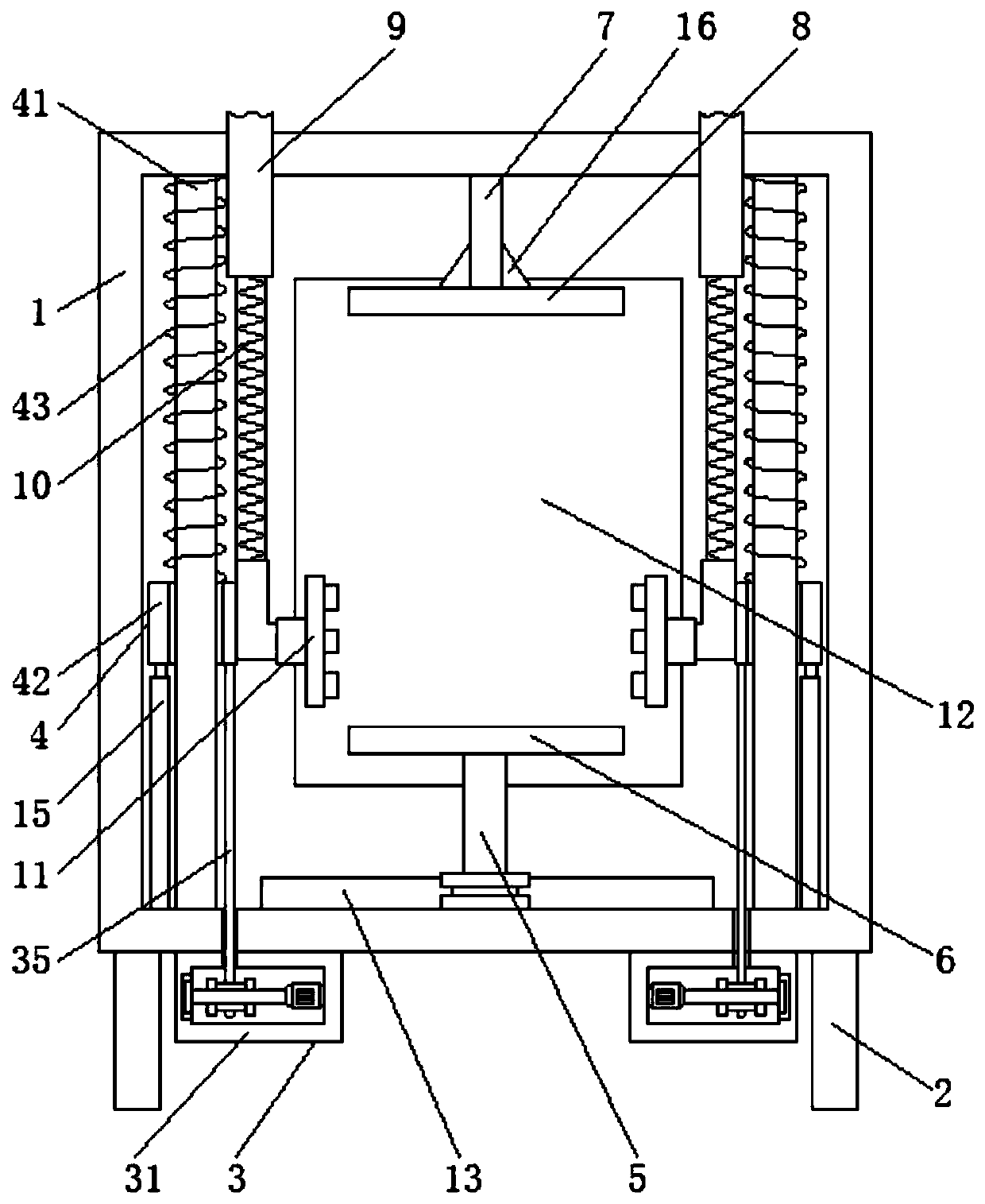

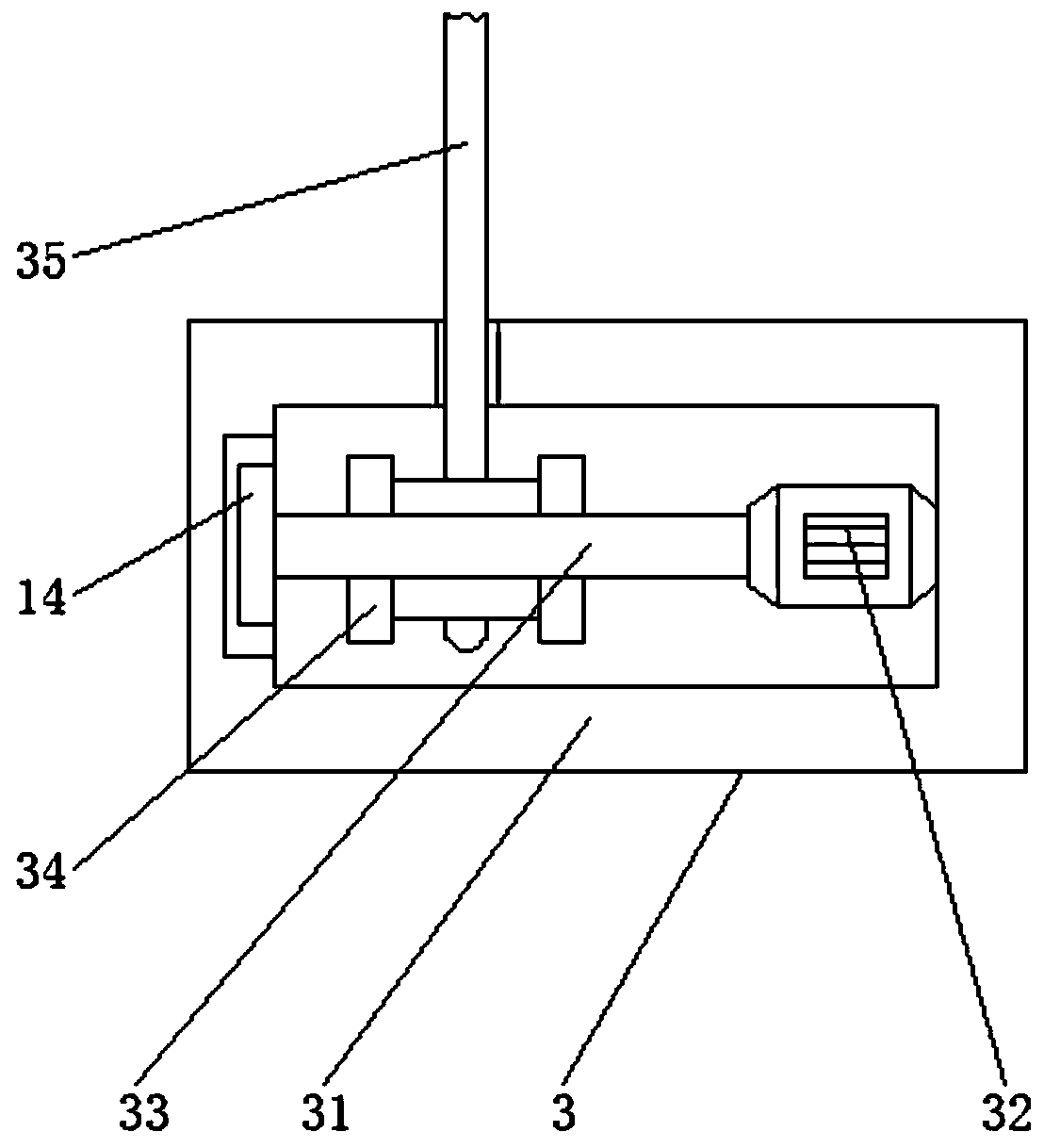

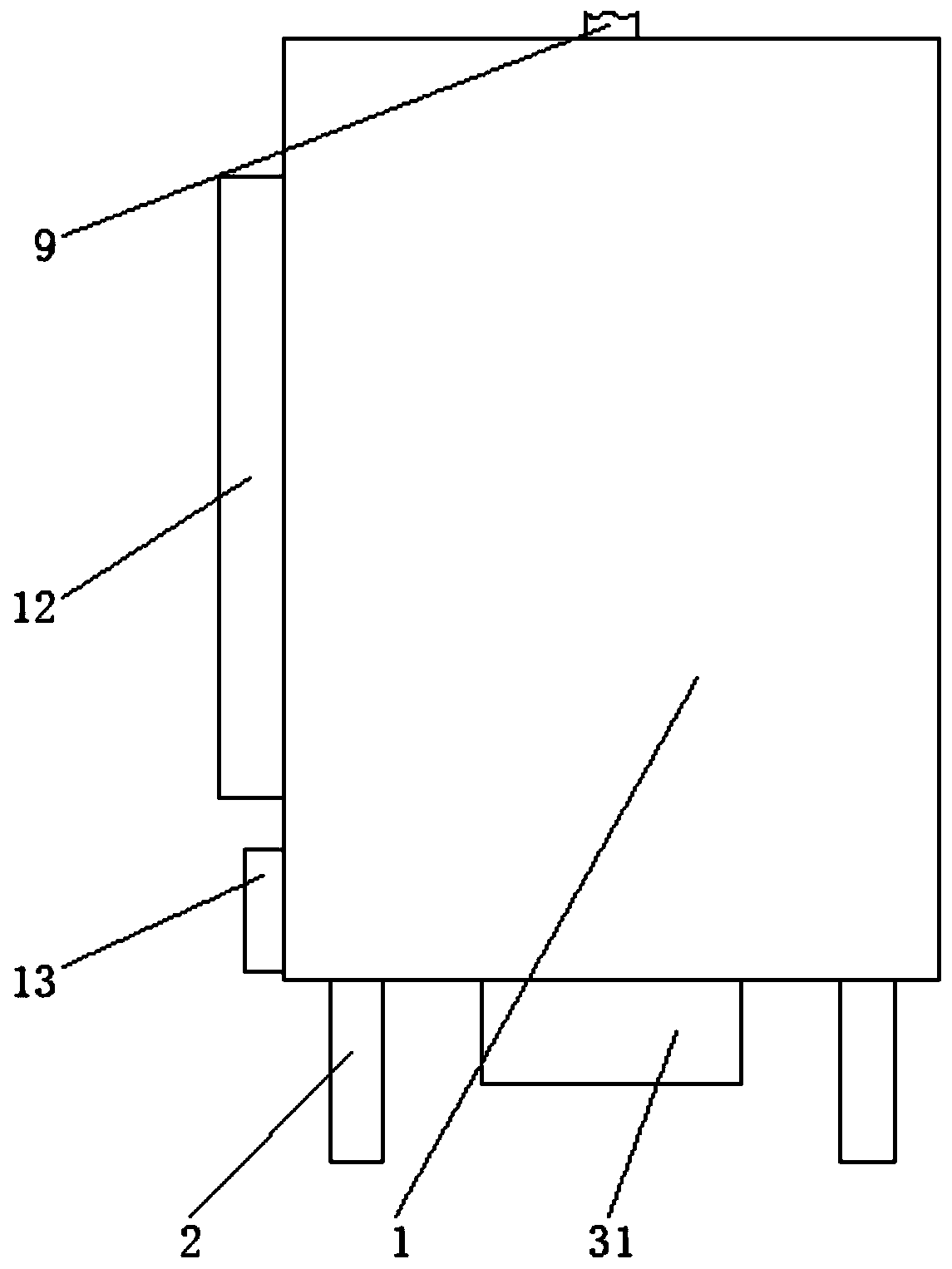

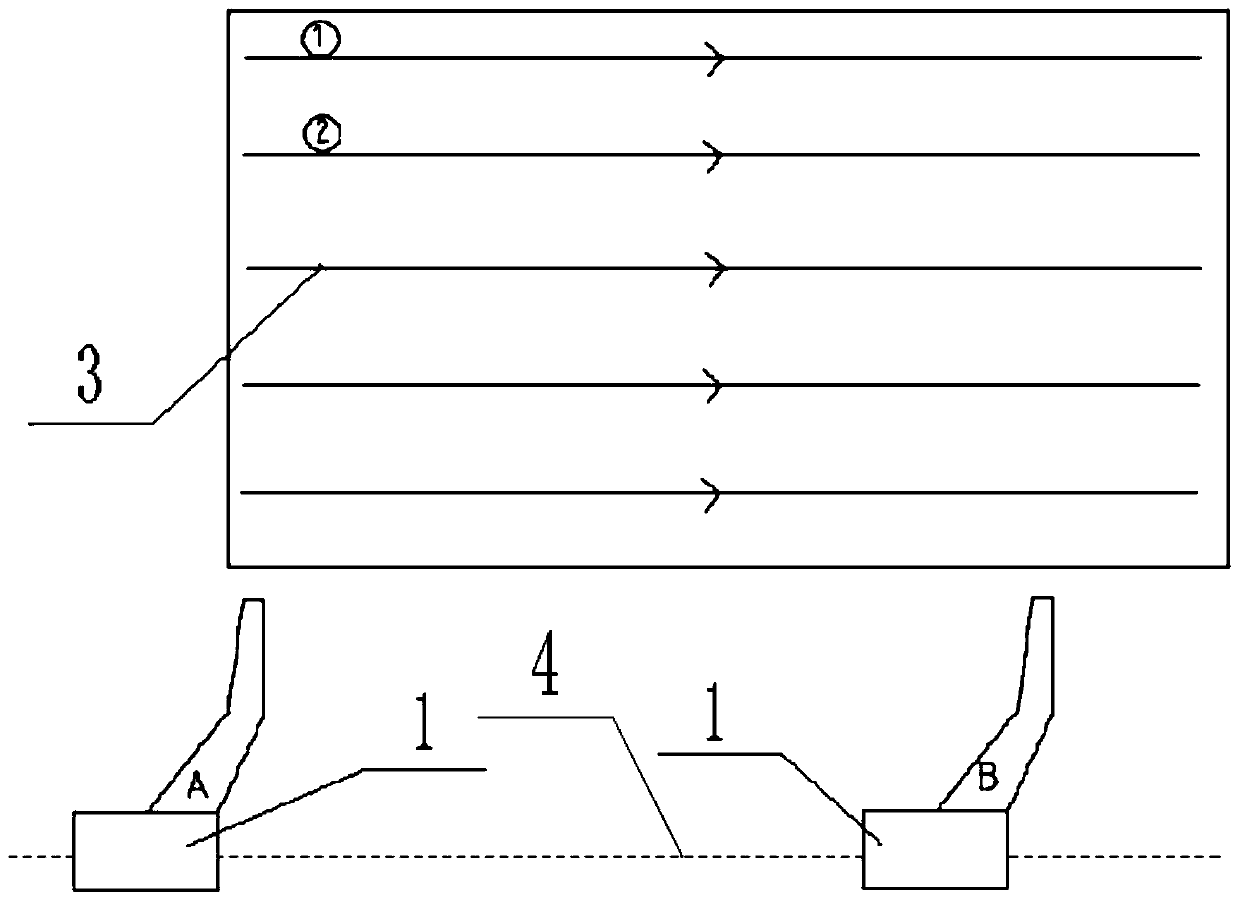

Spraying device used for automobile part machining

The invention discloses a spraying device used for automobile part machining. The spraying device used for automobile part machining comprises a fixed shell. Supporting plates are fixedly connected tothe four corners of the bottom of the fixed shell. Adjustment devices are fixedly connected to the left side and the right side of the bottom of the fixed shell. Movable devices are arranged on the left side and the right side of the inner wall of the fixed shell. A cylinder is fixedly connected to the midpoint of the bottom of the inner wall of the fixed shell. A fixed plate is fixedly connectedto the top end of the cylinder. According to the spraying device used for automobile part machining, through the cooperation of a rotary motor, a rotary shaft, a winding wheel, a fixing rope, slidingrods, sliding blocks, buffer springs, the cylinder, a connecting plate and a stabilizing plate, the effect of automatic spraying is achieved, the problem that most common spraying devices for automobile part machining adopt manual spraying is solved, the spraying time is shortened, the quality of sprayed products is improved, and the influence of long-term spraying on the bodies of workers is avoided; and the working efficiency is improved, labor consumption is reduced, and great convenience is brought to users.

Owner:惠州信邦精密部件有限公司

Novel anticorrosive material and preparation method thereof

InactiveCN106590372AWith self-cleaning functionImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGraphene

The invention discloses a novel anticorrosive material and a preparation method thereof. The anticorrosive material is prepared from the following raw materials in parts by weight: 80-200 parts of epoxy resin, 100-220 parts of alkyd resin, 20-30 parts of phenolic resin, 20-30 parts of silicone oil, 3-8 parts of graphene, 10-20 parts of a flatting agent, 3-8 parts of a curing agent and 30-80 parts of filler. The novel anticorrosive material has a self-cleaning function and strong corrosion resistance, is long-term effective in extreme environments, such as humid, acidic, alkaline environments and the like, has a long service life, can be stored for a long time and cannot be easily cured under a low-temperature condition, and can be easily cured when being used at a normal temperature, so that the spraying time can be reduced.

Owner:浩达船舶技术服务(天津)有限公司

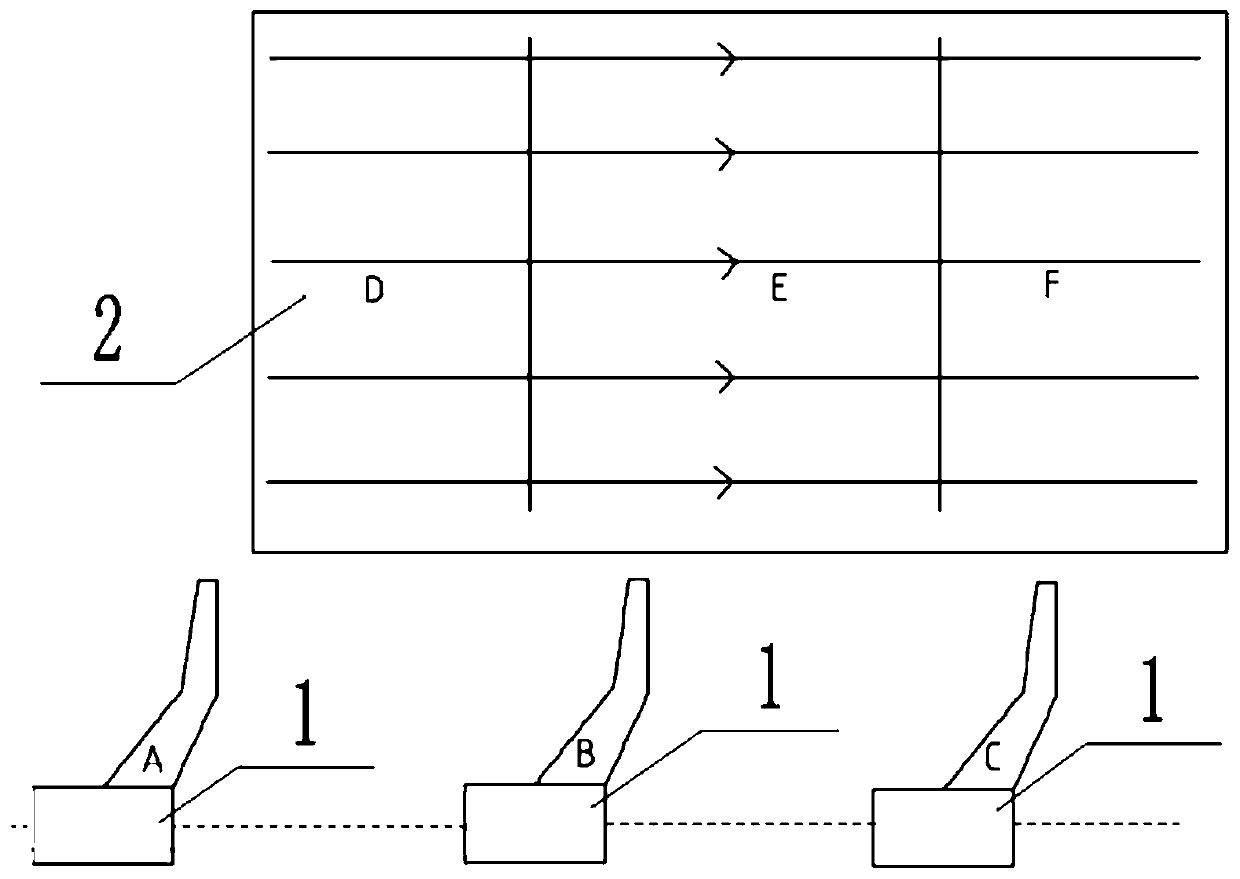

Camouflage spraying zoning operation method

InactiveCN110180760ASolve the empty run problemAvoid running back and forthSpraying apparatusCoatingsPath lengthOperation mode

The invention discloses a camouflage spraying zoning operation method. The method comprises the steps of determining the single-pass path length of a spraying robot according to the action range of the spraying robot and the length of an area to be sprayed, specifically, the single-pass path length is the length that a spray gun moves on the same spraying path when a seventh shaft of the sprayingrobot is fixed; and dividing the area to be sprayed according to the determined single-pass path length and the length of the area to be sprayed to obtain a plurality of unit spraying areas, and respectively spraying the plurality of unit spraying areas. According to the method, the large-area to-be-sprayed area is divided into the multiple unit spraying areas, the unit spraying areas are sprayedin sequence, the spraying of a whole workpiece can be completed through single-pass movement of the seventh shaft of the spraying robot, and the problem that the seventh shaft idles in a traditional operation mode is solved.

Owner:QINGDAO JINGUANGHONG INTELLIGENT MACHINERY ELECTRONICS CO LTD

Sprinkling equipment for built bridge

InactiveCN107100080AThe nozzle is conveniently locatedGood spray effectRoad cleaningBridge erection/assemblyEngineering

Owner:刘依桐

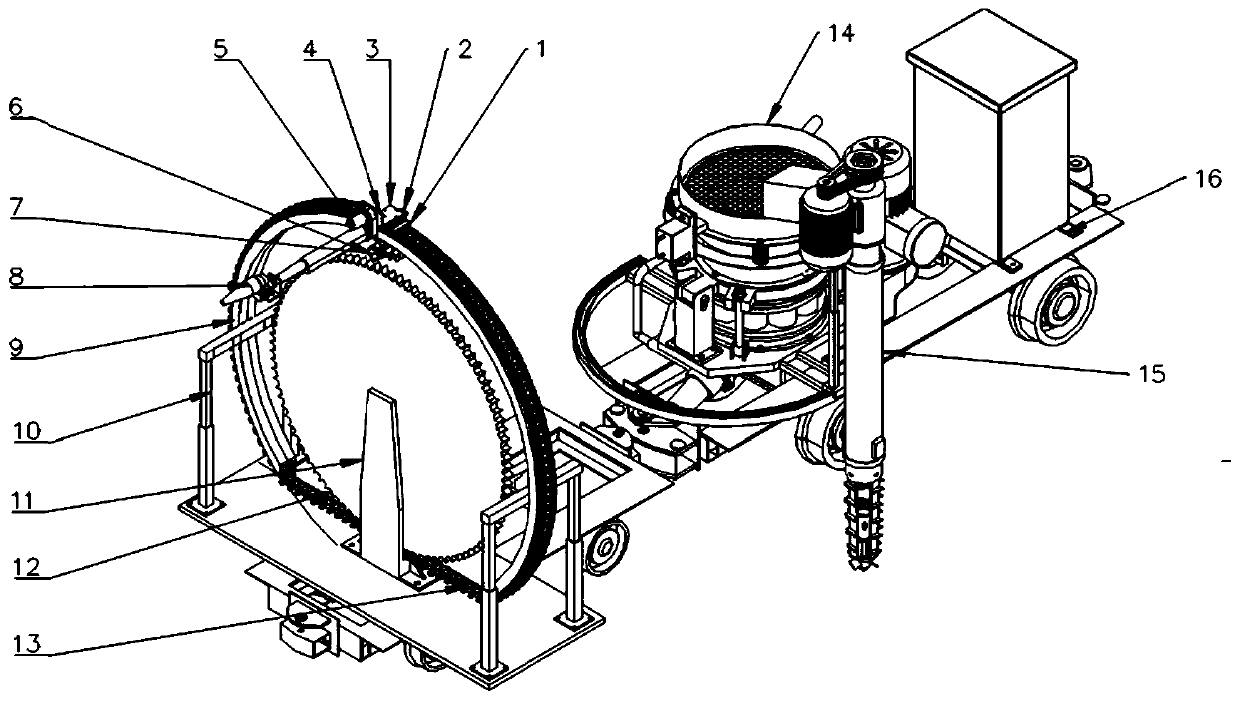

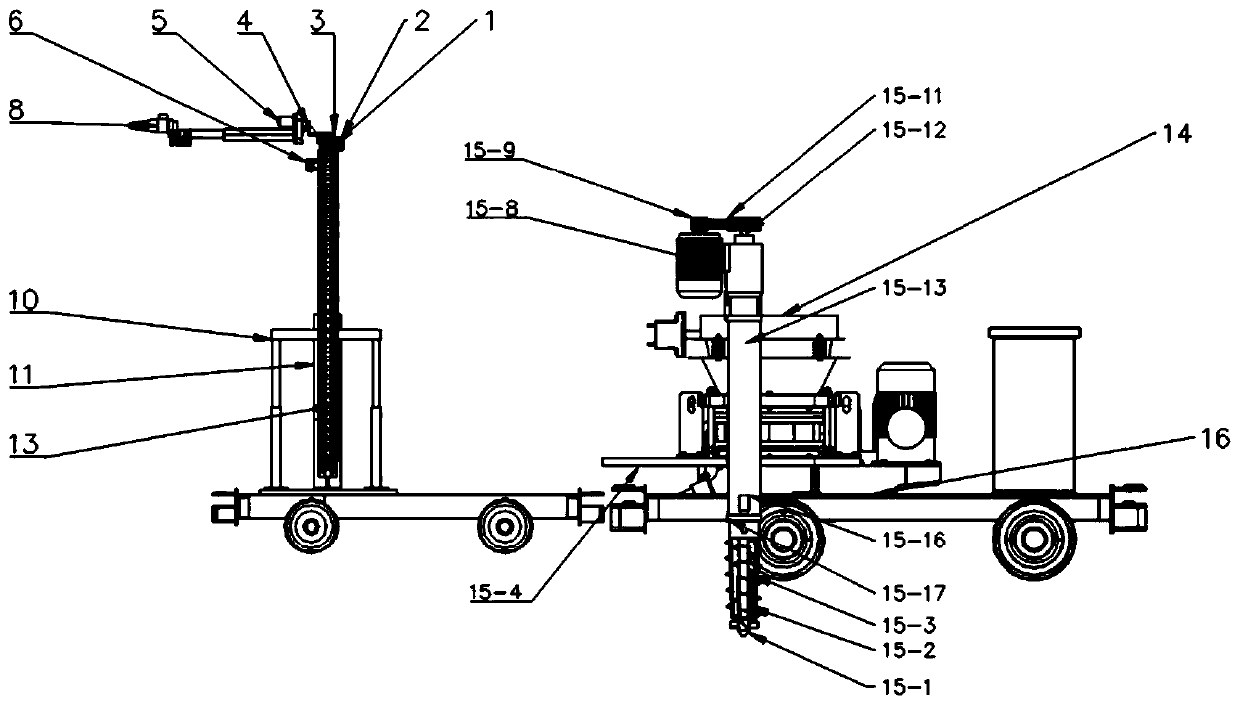

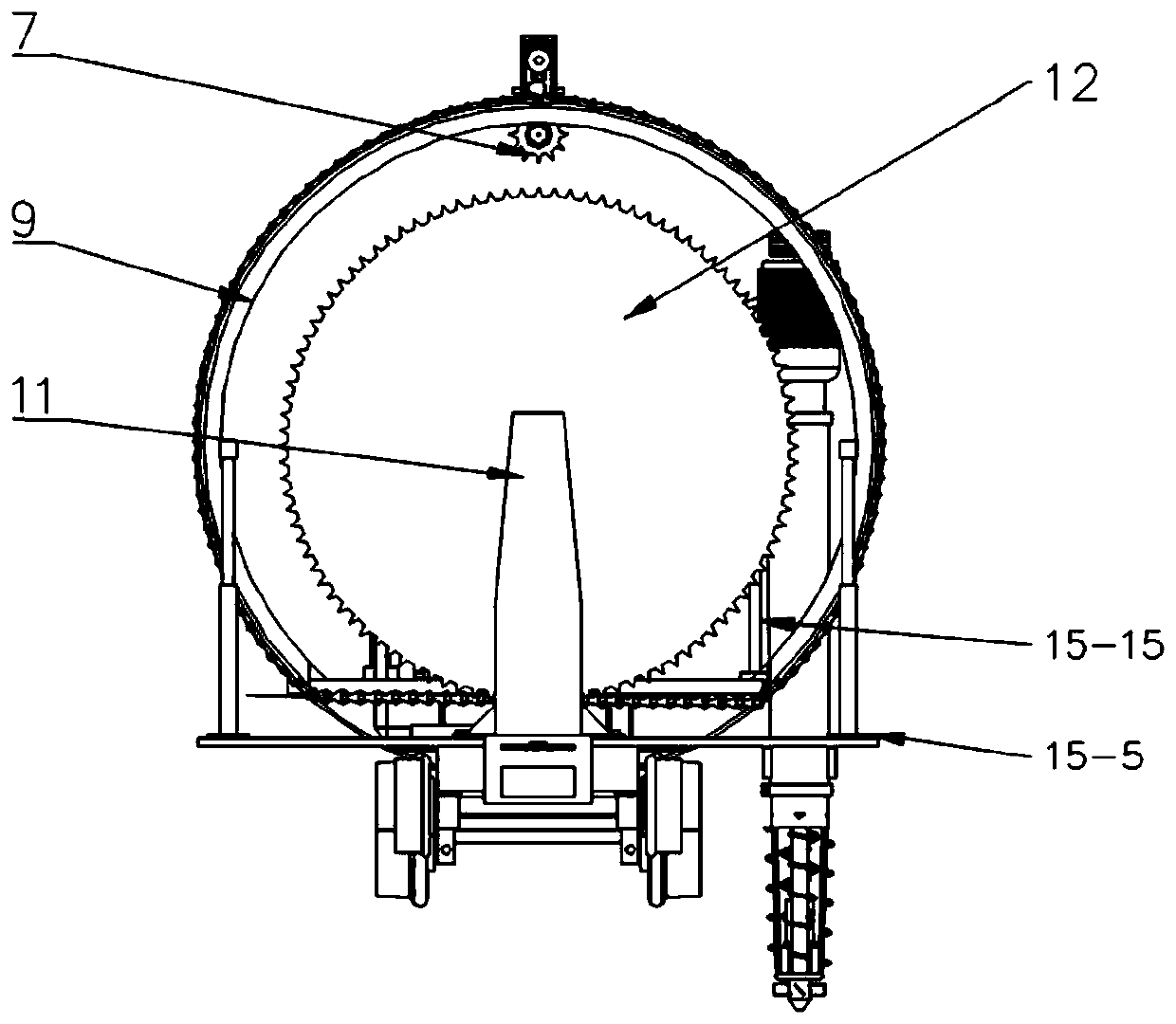

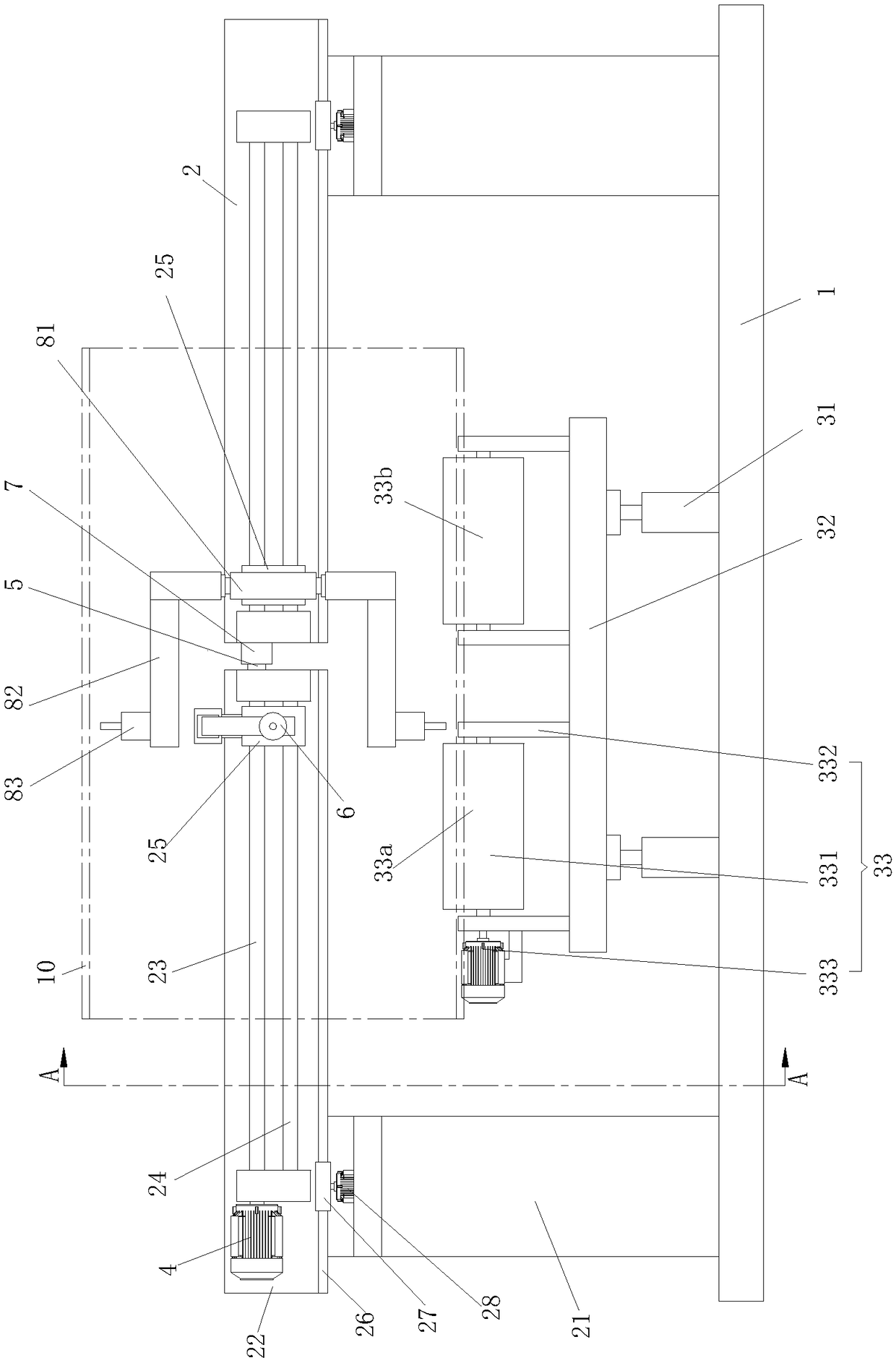

Automatic spraying wall concrete wet spraying machine based on chain transmission and work method thereof

PendingCN110878699AImprove practicalityLow costUnderground chambersTunnel liningLaser sensorSprocket

The invention relates to an automatic spraying wall concrete wet spraying machine based on chain transmission and a work method thereof. The wet spraying machine comprises a wet spraying machine hopper device, an annular transmission chain rail assembly, an automatic material taking device and an automatic spraying mechanism, wherein the annular transmission chain rail assembly is connected with awet spraying machine base through a liftable support frame. A whole spraying device assembly does arc-shaped movement on the annular transmission chain rail assembly through being driven by a first chain wheel; and the distance and the angle between a spray head and the surface of a laneway are regulated through a servo electric cylinder and a servo rotating platform according to signals such aslaneway surface distances and angles fed back by a laser sensor, so that automatic and uniform concrete spraying is realized.

Owner:XUZHOU ZHIRUN MINING EQUIP SCI & TECH CO LTD +1

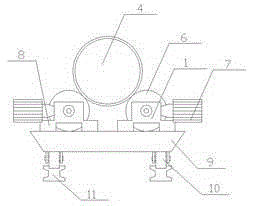

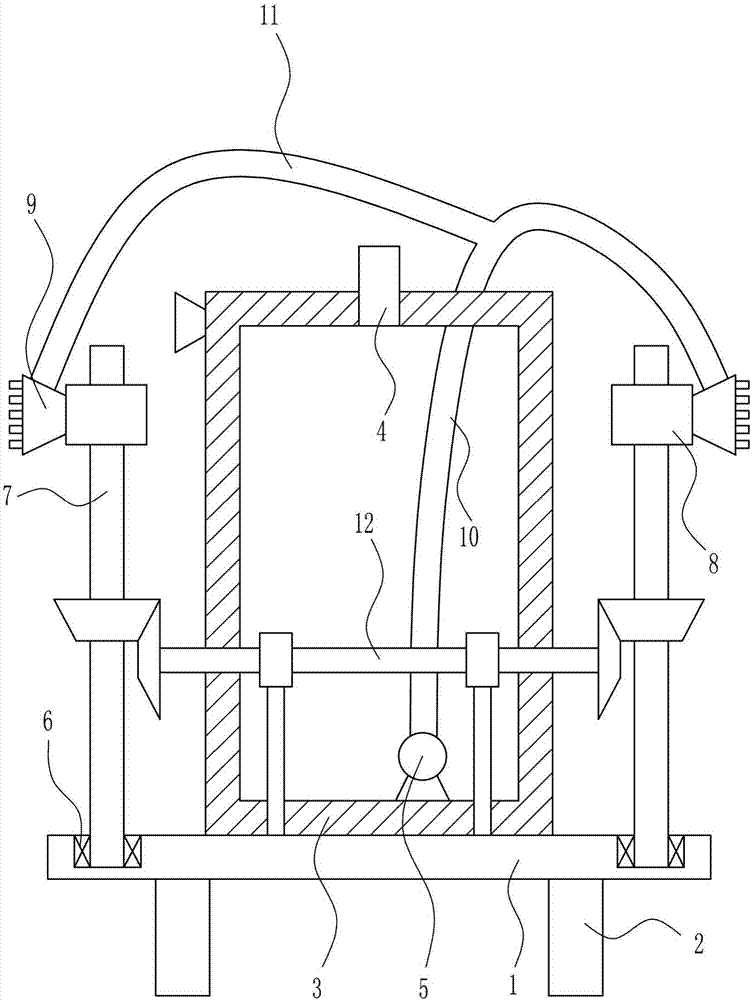

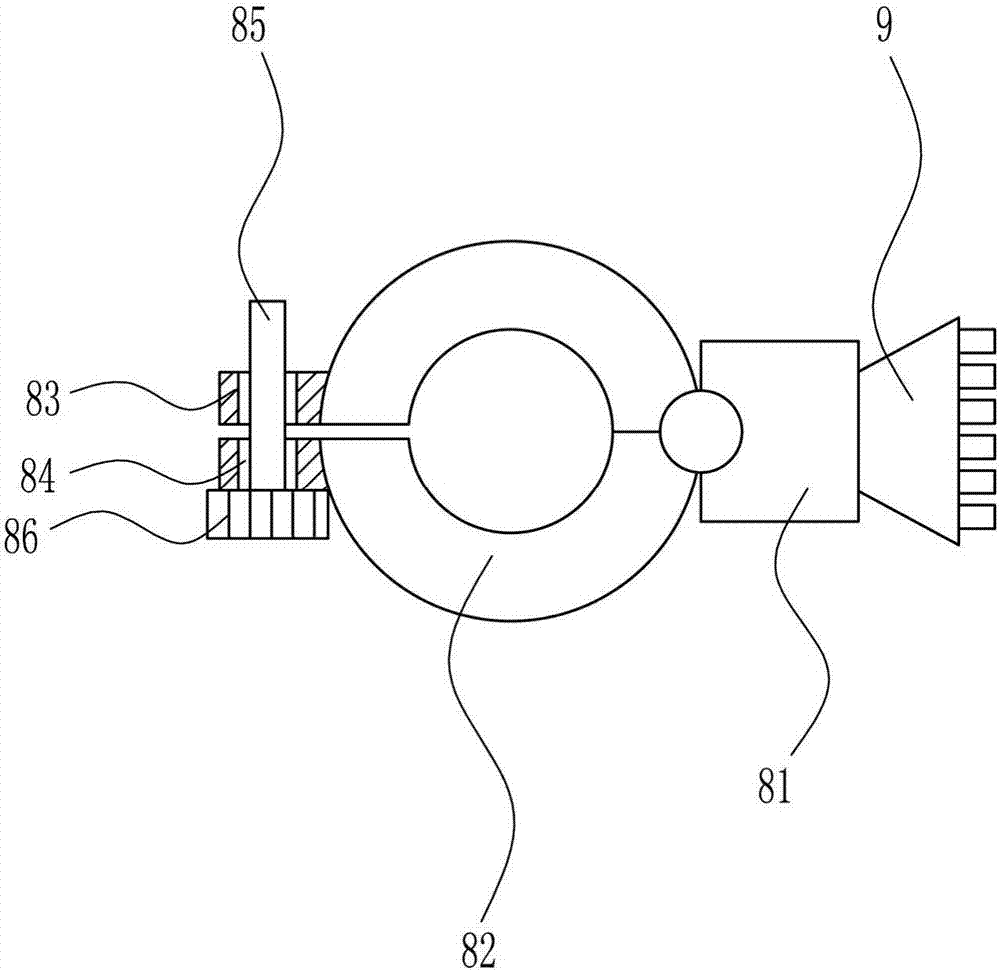

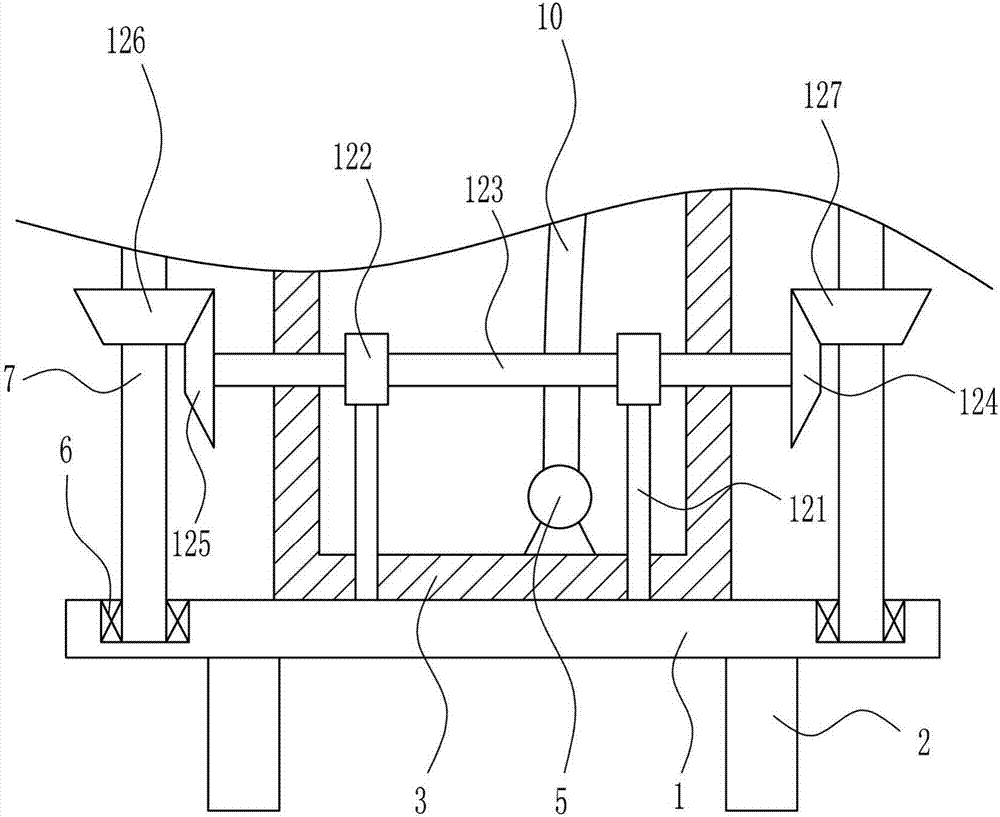

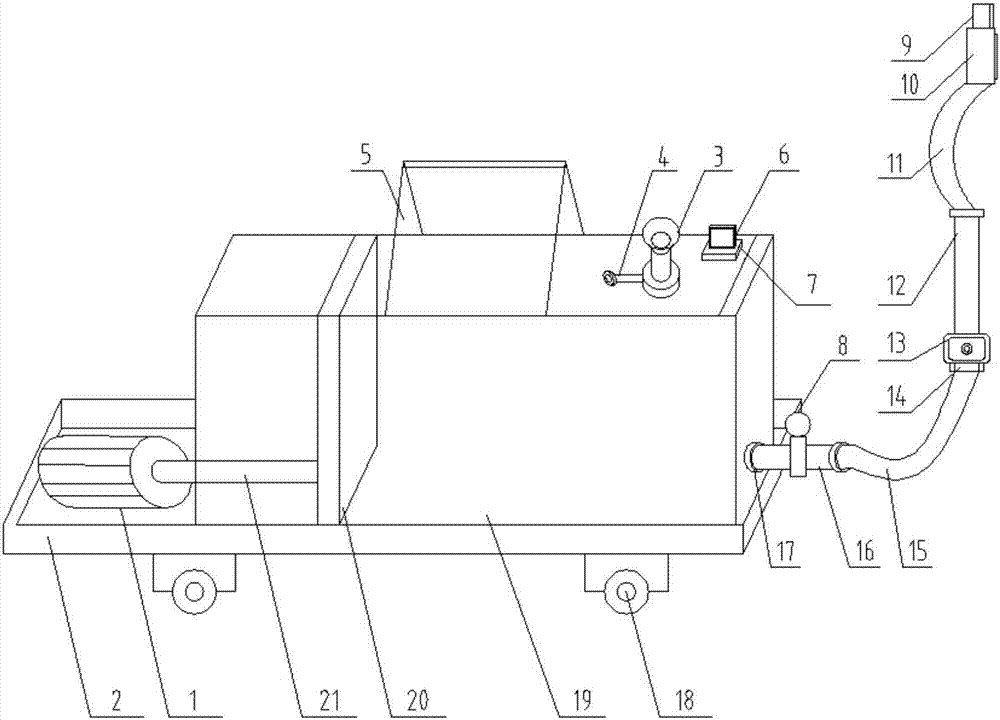

Spraying device suitable for inner walls of round pipes with different diameters

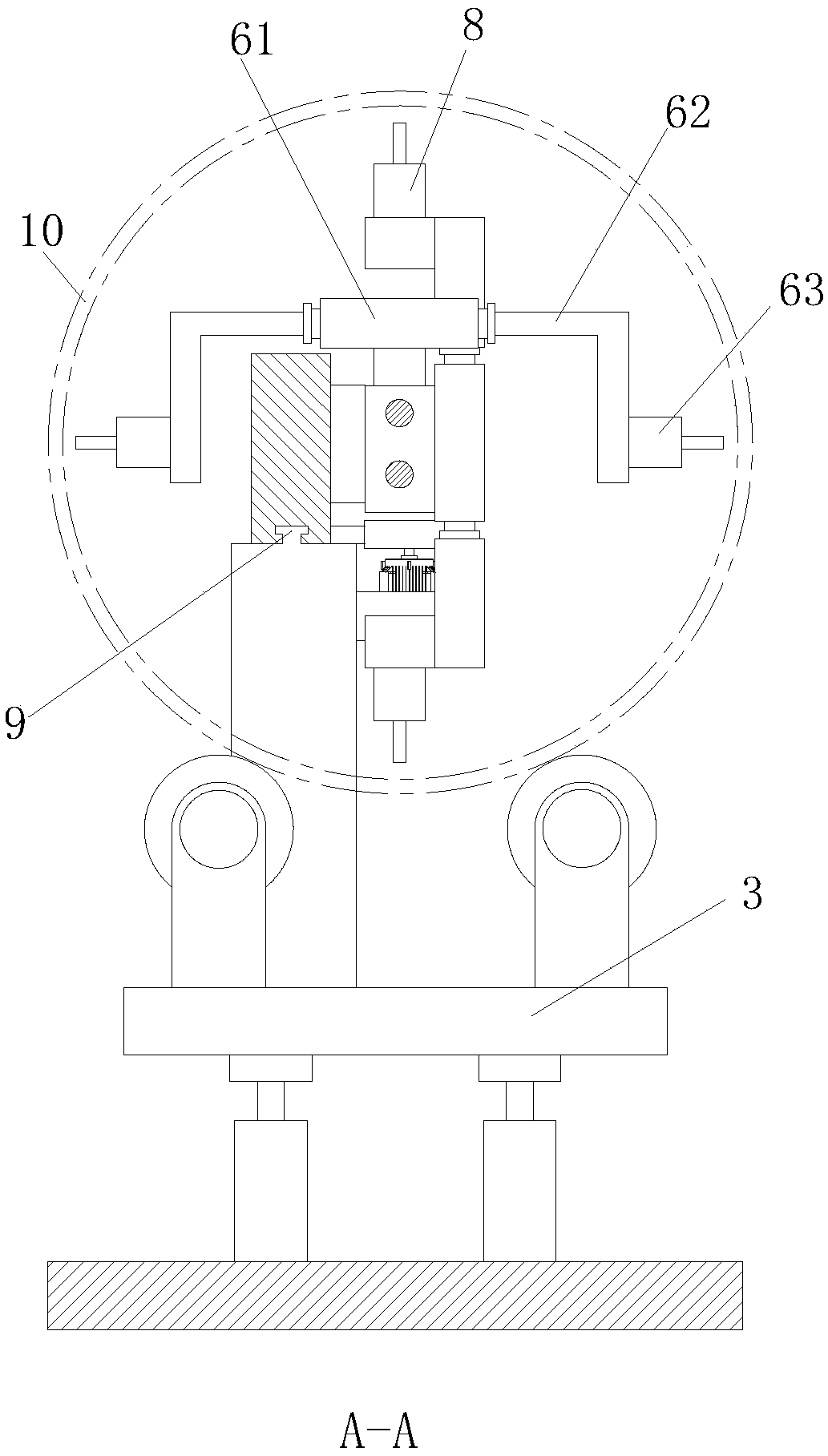

ActiveCN108993805AConvenient spray processingSave Spraying TimeSpraying apparatusHydraulic cylinderEngineering

The invention relates to a spraying device suitable for inner walls of round pipes with different diameters. The spraying device comprises a bottom plate, the left side and the right side of the bottom plate are correspondingly provided with moving mechanisms, the middle part of the bottom plate is provided with a lifting type rolling mechanism, the lifting type rolling mechanism comprises a hydraulic cylinder, a bearing plate and a rolling device, the moving mechanisms comprise supporting seats, cross beams, lead screws, guide rods, movable seats, long racks, gears and motors; in the moving mechanism on the left side, a servo motor is fixed on the corresponding cross beam, the lead screw is connected with a short spline shaft, a first spray gun device is installed on the corresponding movable base, and the first spray gun device comprises a first double-outlet-rod hydraulic cylinder, an l-shaped plate and a first spray gun; in the moving mechanism on the right side, the lead screw isconnected with a shaft sleeve, a second spray gun device is installed on the corresponding movable base, and the second spray gun device comprises a second double-outlet-rod hydraulic cylinder, a bentplate and a second spray gun. According to the spraying device, the two ends of the round pipes are subjected to spraying operation, the two spray guns are additionally arranged at each end part, thespraying time of the inner walls of the round pipes is greatly shortened, and the working efficiency is improved.

Owner:安徽鼎恒再制造产业技术研究院有限公司

Wind power tower drum surface treatment method

InactiveCN109848863AImprove spraying effectGuaranteed anti-corrosion performancePretreated surfacesSpecial surfacesElectricityAging resistance

The invention relates to a wind power surface treatment method, in particular to a wind power tower drum surface treatment method. The wind power tower drum surface treatment method comprises the following steps that the surface of a tower drum is cleaned; the surface of the tower drum is subjected to shot blasting; primer is sprayed to the tower drum; intermediate paint is sprayed to the tower drum; and finish paint is sprayed to the tower drum. The wind power tower drum surface treatment method can effectively ensure anti-corrosion performance, ultraviolet aging resistance and wind sand corrosion resistance, meets the long-term anti-corrosion requirement, improves the working efficiency by shortening the spraying time through drying, is high in air-free spraying effect, and is smooth insurface.

Owner:苏州华达环保设备股份有限公司

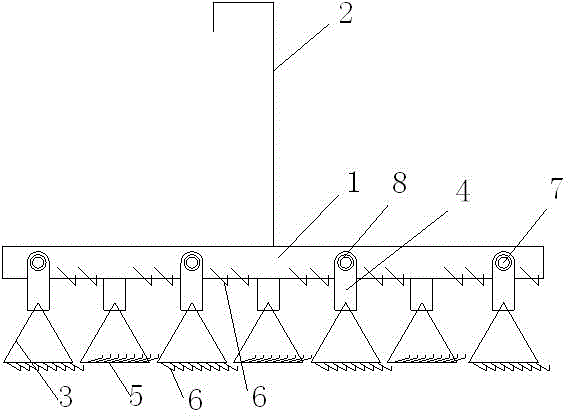

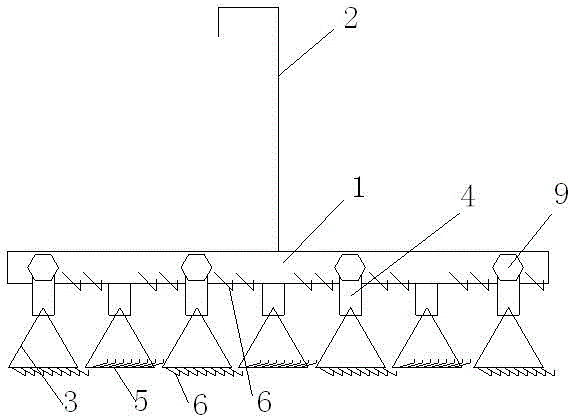

Spraying hanger

InactiveCN104148223ANot easy to shakeSpray evenlySpraying apparatusClassical mechanicsStructural engineering

The invention relates to a hanger, in particular to a spraying hanger. According to the technical scheme, the spraying hanger comprises a body, a fixing support is fixed to the upper end of the body, a plurality of detachable hanging units are evenly installed on the two sides of the body in a staggered mode, and the hanging units are respectively of a triangular structure, the top ends of the hanging units are detachably connected with the body through connecting rods, the bottoms of the hanging units are fixing cross rods, the cross rods are provided with hooks, and hooks which are respectively of a structure in the shape of a horizontally placed L are further arranged between first installation holes and second installation holes in the two sides of the body. The spraying hanger has the advantages that due to the fact that the hanging units are fixedly connected with the body and the hooks are fixedly connected with the hanging units, sheet metal parts are not prone to waggling in the machining process, spraying is made to be even, and spraying time is saved; the hooks are further arranged between the first installation holes and the second installation holes of the body, therefore, more sheet metal parts can be hung on the hanger, and the spraying efficiency is improved.

Owner:周元忠

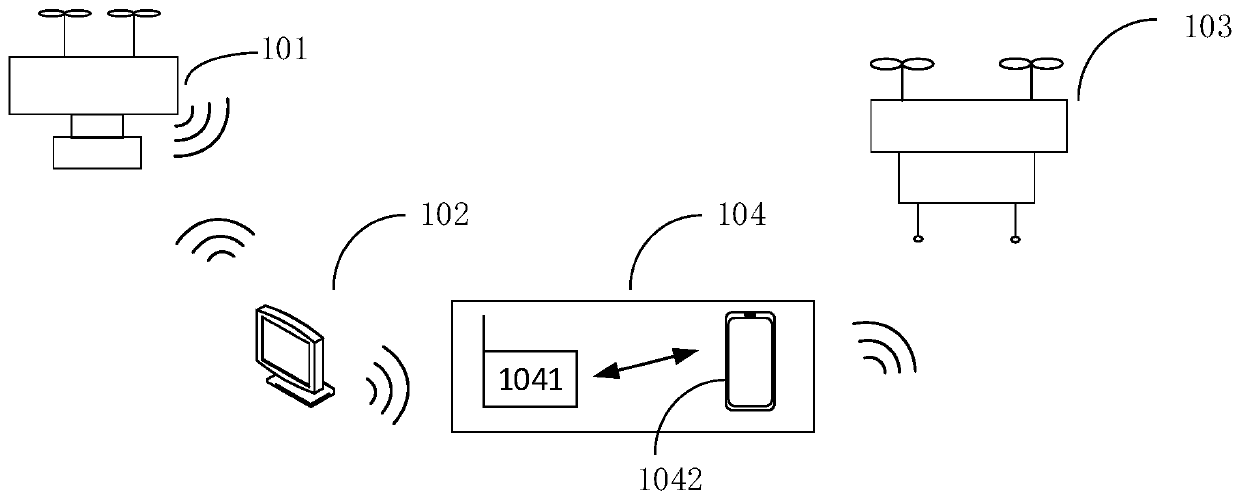

Control method and device, surveying and mapping unmanned aerial vehicle and spraying unmanned aerial vehicle

ActiveCN110832425ASave Spraying TimeImprove completenessAircraft componentsCharacter and pattern recognitionEngineeringCrop

The embodiment of the invention provides a control method and device, a surveying and mapping unmanned aerial vehicle and a spraying unmanned aerial vehicle, and the method comprises the steps of: obtaining an image outputted by a photographing device in a flight process of the surveying and mapping unmanned aerial vehicle in a target crop region, and obtaining the three-dimensional space information of the target crop region according to the image. The spraying control information determining equipment acquires three-dimensional space information and determines spraying control information according to the three-dimensional space information, and the spraying control information comprises a spraying mode when the spraying unmanned aerial vehicle sprays each target crop planted in the target crop area, and the spray mode includes a flight mode. The spraying unmanned aerial vehicle obtains spraying control information, and the spraying unmanned aerial vehicle is controlled to spray thecorresponding target crops according to the spraying mode of each target crop. The spraying time of the spraying unmanned aerial vehicle is shortened, the time cost is guaranteed, the spraying efficiency is improved, it is guaranteed that a good spraying effect is achieved for different target crops, and the intelligent degree and convenience of spraying operation of the spraying unmanned aerial vehicle are improved.

Owner:SZ DJI TECH CO LTD

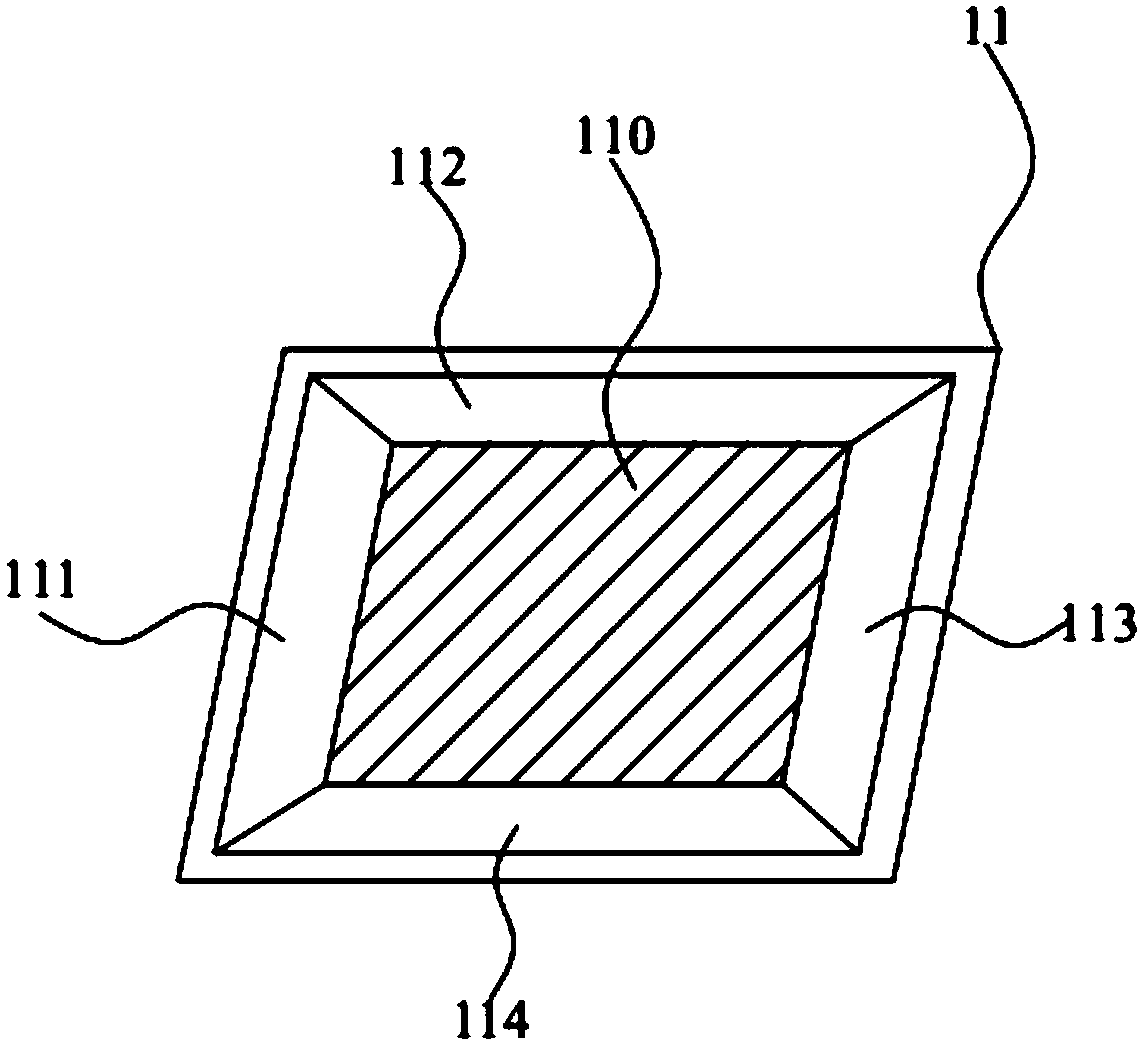

Method for preparing crucible coating for polycrystalline silicon ingot casting and crucible

InactiveCN106283186AImprove stabilityGuaranteed release integrityFireproof paintsPolycrystalline material growthHexagonal boron nitrideIngot casting

The invention discloses a method for preparing a crucible coating for polycrystalline silicon ingot casting. The method includes the following steps that hexagonal boron nitride is weighed and slowly added into a mixed solution of silica sol and high-purity water to be evenly stirred, and needed slurry is prepared, wherein the slurry is prepared from, by weight, 20-23% of hexagonal boron nitride, 53-55% of high-purity water and 23-25% of silica sol; before spraying, the slurry is continuously stirred and kept at the room temperature of 24-28 DEG C, the temperature of a crucible to be sprayed is kept at 60-80 DEG C, the slurry is sprayed on the bottom face of the crucible, and silicon nitride is sprayed on the side face of the crucible; the sprayed crucible is roasted, and the crucible coating for polycrystalline silicon ingot casting is formed on the bottom face of the crucible after roasting. The process is simple, operation is convenient, impurity elements are not introduced, and high compactness of the crucible coating is effectively guaranteed, so that the prepared crucible coating is high in purity, accordingly crucible pollution caused by impurities is effectively inhibited, the coating at the bottom of the roasted crucible is good in stability and high in bonding strength, and the service life of a spoon at the bottom is prolonged.

Owner:CHINA UNITED NORTHWEST INST FOR ENG DESIGN & RES

Portable double-brush-head wall surface brushing device

The invention belongs to the technical field of brushing equipment manufacturing and relates to a portable double-brush-head wall surface brushing device. The portable double-brush-head wall surface brushing device mainly structurally comprises a feeding hopper, a feeding valve, a feeding pipe, an inflation valve, a handle, a deflation valve, a tank, discharge pipes, a base, telescopic rod cavities, discharge valves, material conveying soft pipes, telescopic rods, a deflation pipe, connecting rods, interlayers, discharge holes, brush head inner cavities, brush heads, fixing bolts and wheels, wherein two ends of the upper side of each connecting rod are connected with the left and right ends of the corresponding brush head, one fixing bolt is arranged at the connection of each brush head and the corresponding connecting rod, each brush head is of a cylindrical hollow structure, brushing bristles are arranged on the outer surface of each brush head, one interlayer of a hollow cylindrical structure is arranged in the inner cavity of each brush head, and the outer surface of each interlayer tightly attaches to the inner surface of the corresponding brush head so as to support the brush head. The portable double-brush-head wall surface brushing device is simple in main structure, ingenious in design concept, flexible and convenient to use, good in brushing effect, high in efficiency, high in practicality, good in application environment and promising in market prospect.

Owner:QINGDAO HECHENG INTPROP CO LTD

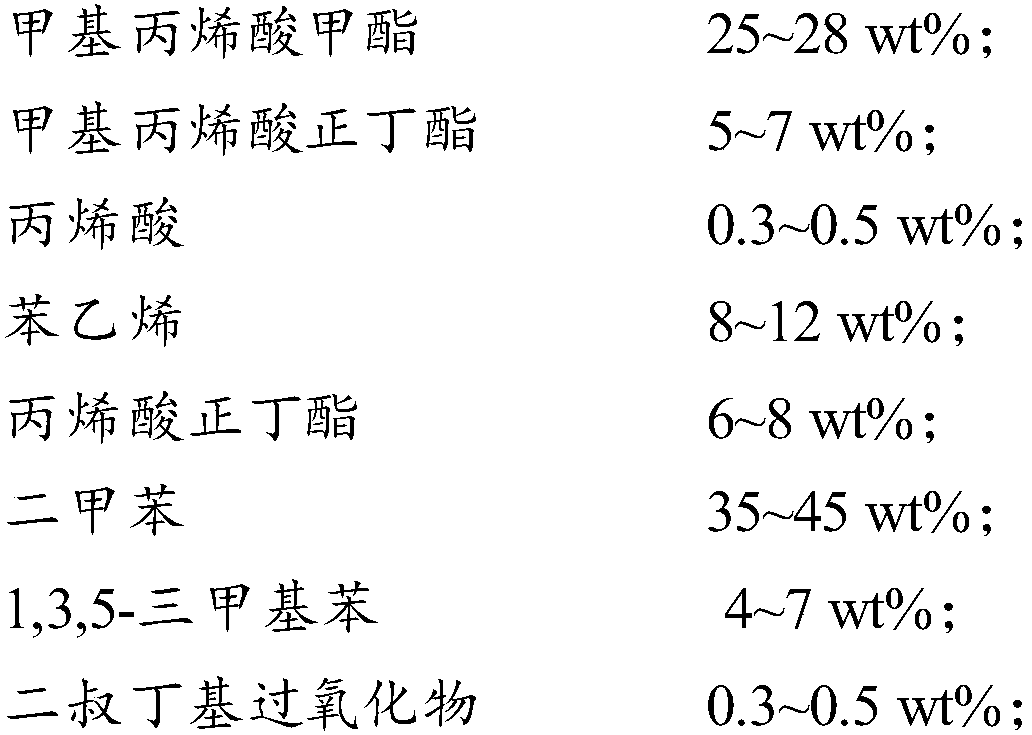

Paint for zipper puller, paint spraying method and paint-sprayed puller

InactiveCN108864877AReduce wasteThere will be no paint peeling phenomenonEpoxy resin coatingsEpoxyAcrylic resin

The invention provides a paint for a zipper puller. The paint is prepared from the following components of 60 to 80wt% of acrylic resin, 5 to 20wt% of color powder, 5 to 10wt% of leveling agent, 1 to20wt% of durene, 1 to 2wt% of epoxy resin, and 1 to 5wt% of amino resin, wherein the sum of usage amounts of the components is 100%. The paint has the advantages that under the cooperation function ofthe acrylic resin, the epoxy resin, the amino resin and other components according to a certain ratio, the paint for the zipper puller is obtained; the paint is sprayed to the zipper puller, so thatthe falling of whole paint piece is avoided in the water washing process of clothes; when the puller is matched with the zipper, the seizure of the puller is avoided; the spraying of the thicker paintis not required, so that the good paint spraying effect can be obtained, and the spraying time is effectively shortened; the waste amount of paint is small, and the resource is effectively saved.

Owner:ZHEJIANG WEIXING IND DEV

Multi-purpose electro-hydraulic spraying device

InactiveCN107217820APrecise pressure regulationImprove thermal insulation performanceBuilding constructionsManufacturing technologyMotor drive

The invention belongs to the technical field of manufacturing of whitewashing equipment and relates to a multi-purpose electro-hydraulic spraying device. A main structure comprises a motor, a base, a filling port, a filling control valve, a lifting handle, video receiving equipment, a fixed support, a conveying switch, a micro-camera, a spraying head, a bend, a straight steel pipe, a pressure regulating device, a connector connecting part, a conveying hose, a conveying pipe, a box body connector, wheels, a box body, a pressure regulating unit and a boosting rod. The motor is in drive connection with the pressure regulating unit through the cylindrical boosting rod, the motor drives the boosting rod to move left and right to drive the pressure regulating unit to move, the camera is fixedly arranged above the spraying head to record the position and spraying information of the spraying head, and the video receiving equipment is used for checking real-time position information, transmitted by the micro-camera, of the spraying head. The multi-purpose electro-hydraulic spraying device is simple in main structure, ingenious in design concept, flexible and convenient to use, good in spraying effect, high in efficiency, high in practicality, good in application environment and wide in market prospect.

Owner:QINGDAO HECHENG INTPROP CO LTD

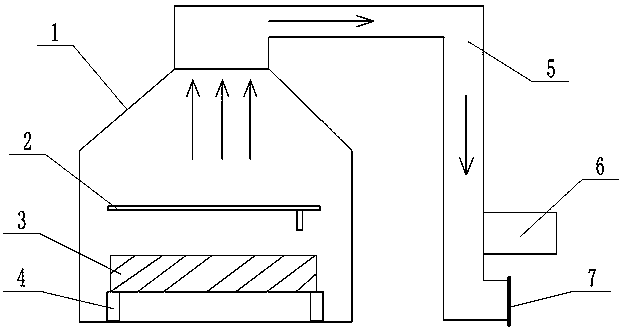

Spraying device for processing integrated cooker

InactiveCN109834005AAvoid condensationImprove spraying efficiencyLiquid spraying apparatusSpray boothsEngineeringCooker

The invention discloses a spraying device for processing an integrated cooker. The spraying device for processing the integrated cooker comprises a box body, a conveying device is fixedly connected tothe bottom of an inner cavity of the box body, clamping blocks are fixedly connected to the top of the conveying device, an integrated cooker accessory is arranged between the two clamping blocks, the bottom of the integrated cooker accessory is in contact with the top of the conveying device, and the bottom of the right side of the box body is communicated with a discharging pipe. Through the cooperation among a coating box, a feeding pipe, a motor, a rotating shaft, stirring blades, a fan, a first material guide pipe, a second material guide pipe, a third material guide pipe and spraying heads, the spraying device for processing the integrated cooker solves the problems that only one side of the accessory can be sprayed when the existing spraying device for processing the integrated cooker is used for coating the integrated cooker accessory, and the agglomeration phenomenon can occur when the coating is not used in time. The spraying device for processing the integrated cooker has the advantages of being high in spraying efficiency and capable of preventing coating from being agglomerated, shorting the spraying time of the integrated cooker accessory, and improving the sprayingefficiency of the integrated cooker accessory.

Owner:陈小英

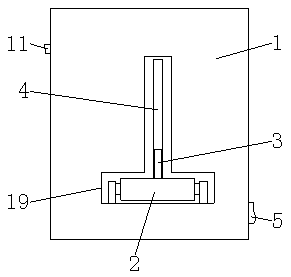

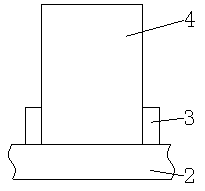

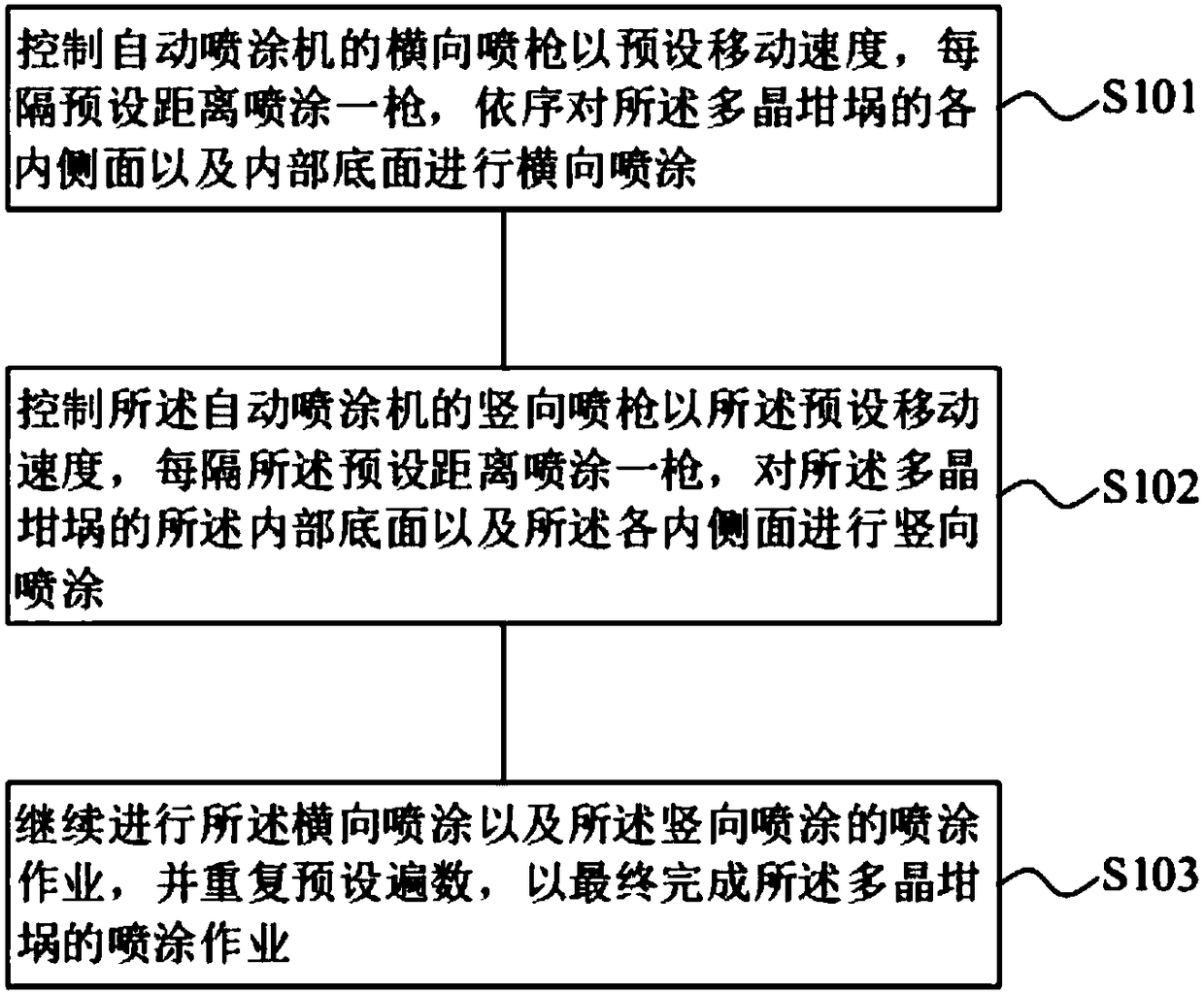

Polycrystalline crucible automatic spraying method

The invention relates to a polycrystalline crucible automatic spraying method. A polycrystalline crucible adopted in the polycrystalline crucible automatic spraying method is a regular container provided with an opening. The polycrystalline crucible automatic spraying method comprises following steps: a transverse spray gun of an automatic spraying machine is controlled to move at a preset speed,and one time of spraying is carried out at preset intervals so as to complete transverse spraying of the internal side surfaces and the internal bottom surface of a polycrystalline crucible sequentially; a vertical spray gun of the automatic spraying machine is controlled to move at a preset speed, and one time of spraying is carried out at preset intervals so as to complete vertical spraying of the internal bottom surface and the internal side surfaces of the polycrystalline crucible sequentially; the transverse spraying operation and the vertical spraying operation are carried out continuously for preset repeat times so as to complete the spraying operation of the polycrystalline crucible. The polycrystalline crucible automatic spraying method is simple in operation, spraying time is shortened, and production power is increased.

Owner:JINKO SOLAR CO LTD +1

Thermoplastic plastic powder spray fusing device

InactiveCN111889261AReasonable structureInnovative designLiquid spraying apparatusEngineeringPowder Spray

The invention provides a thermoplastic plastic powder spray fusing device. The device comprises a feeding tank, a hot melting drum, a steam furnace, an extruding machine, a rack, a bottom plate and amaterial spraying pipe; the rack is fixedly installed on the bottom plate; the feeding tank, the hot melting drum, the steam furnace and the extruding machine are arranged on the rack; a portal frameis arranged on the bottom plate in a back-and-forth sliding mode; the material spraying pipe is arranged on the portal frame in a vertically sliding mode; an air cylinder is arranged on the portal frame and is used for driving the material spraying pipe to slide vertically; a feeding hopper is arranged on the side wall of the feeding tank; a discharging pipe at the bottom of the feeding tank is connected with a feeding port of the hot melting drum; a quantified discharging device is arranged on the discharging pipe at the bottom of the feeding drum; a shaft sleeve is rotatably installed insidethe hot melting drum in a coaxial sealing mode; a discharging end of the hot melting drum is connected with the extruding machine; hollow spiral plates are distributed on the shaft sleeve along the axial direction; sealing shades are installed at two ends of the hot melting drum in a sealing mode; and the end parts of the shaft sleeve extend into the sealing shades.

Owner:蒙城县虹升塑粉有限公司

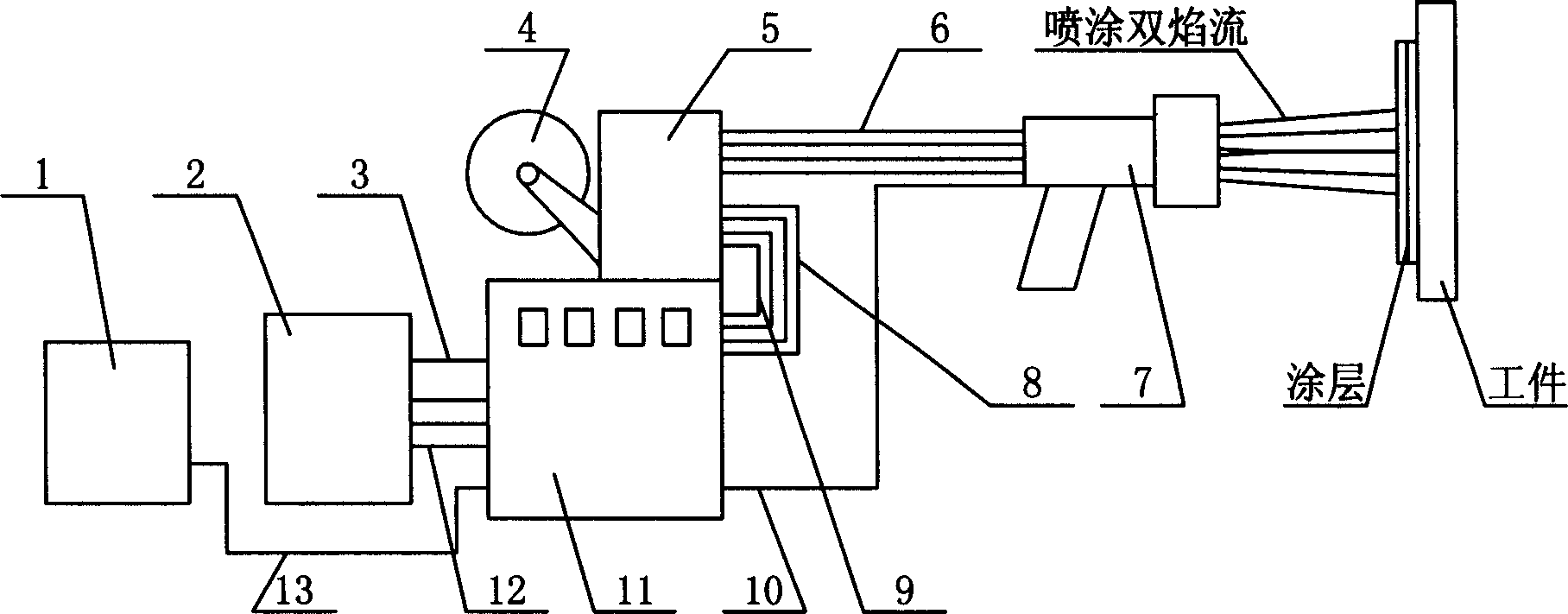

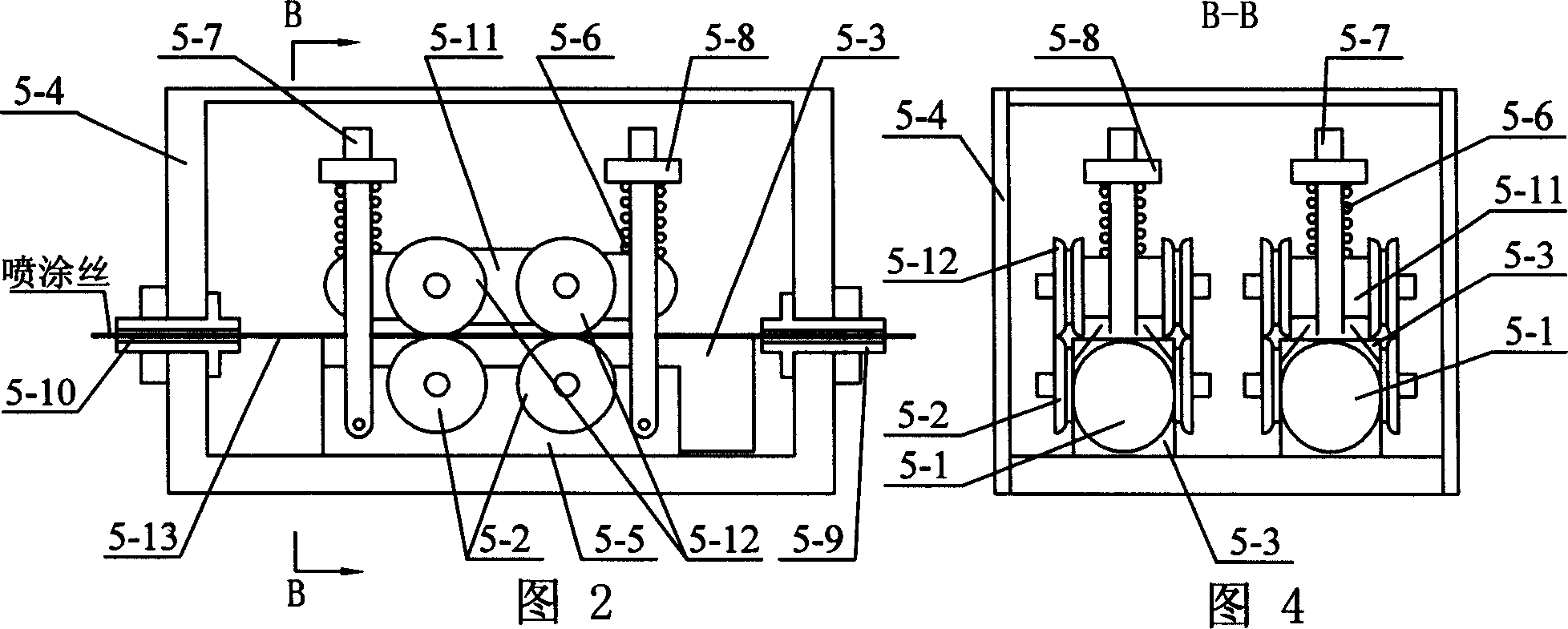

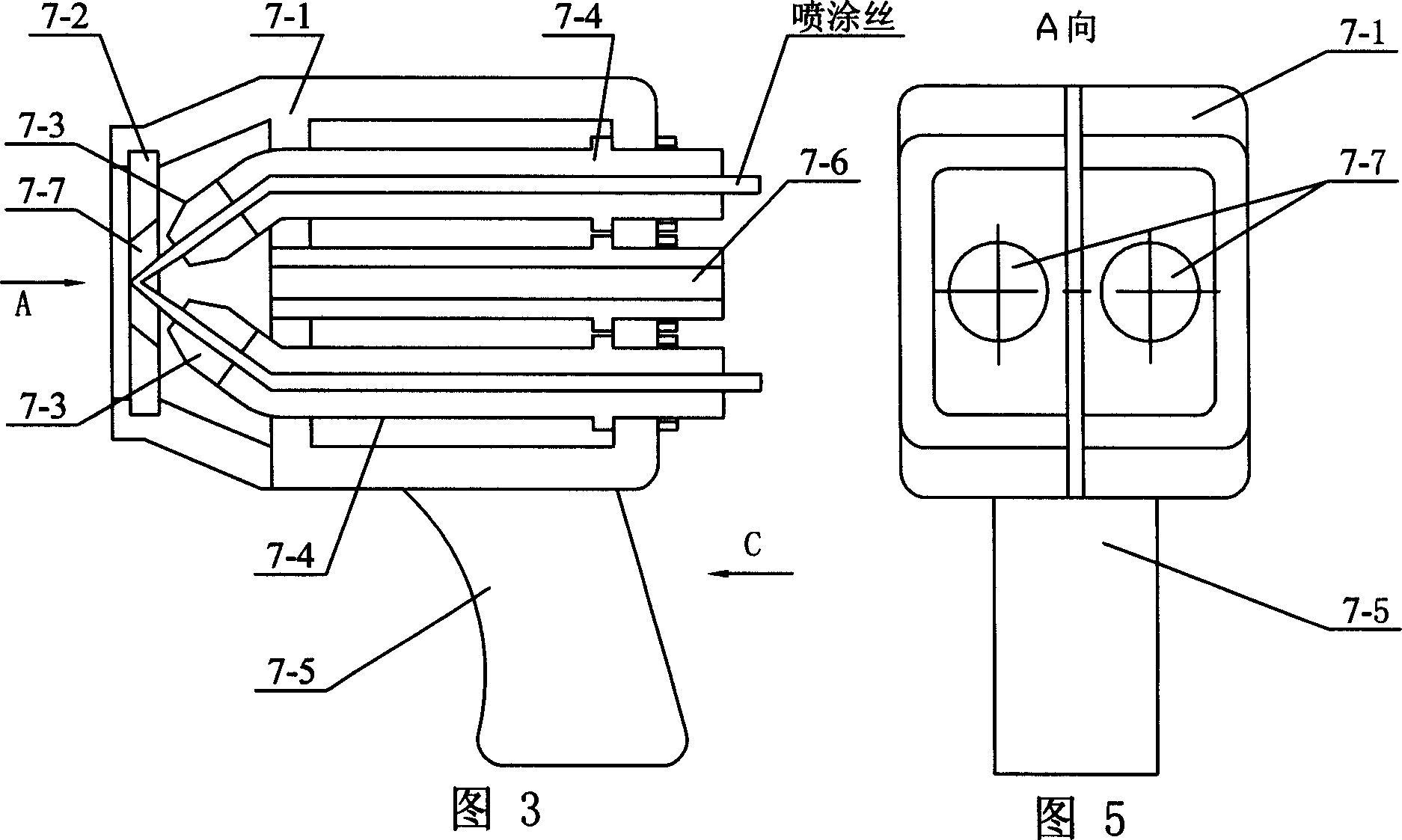

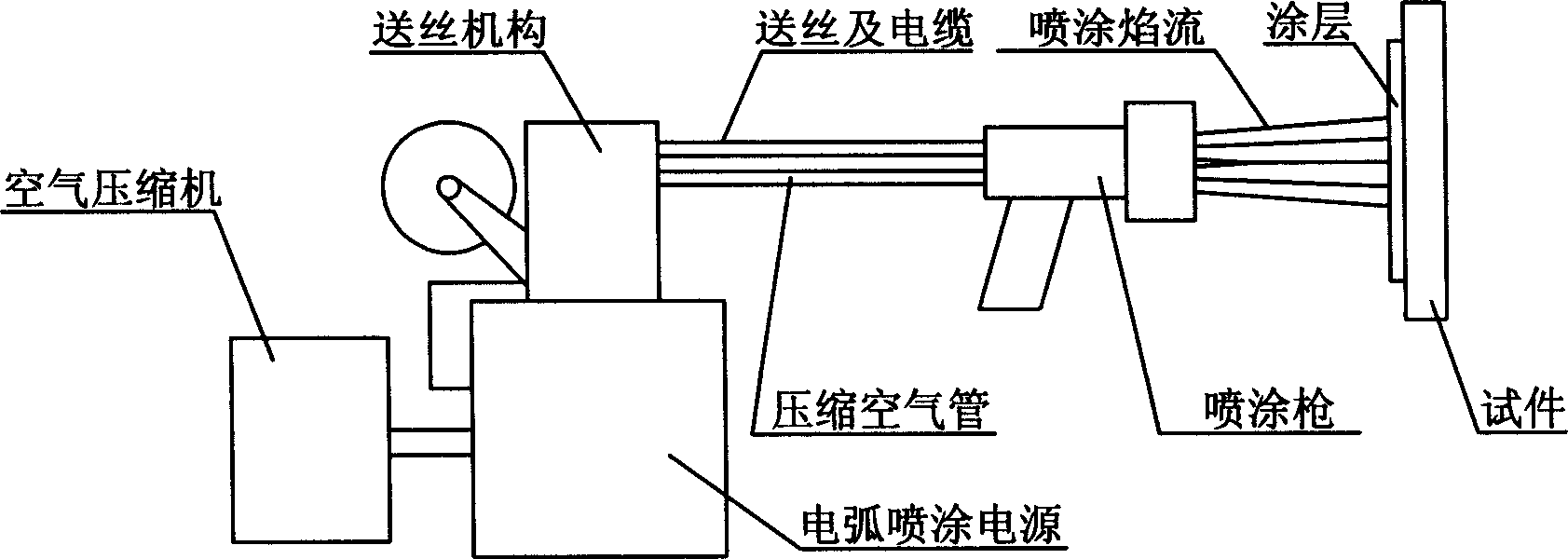

Integrated double end electric arc spraying equipment and spraying method

InactiveCN1593782AMeet one spray formingImprove spraying efficiencyPretreated surfacesLiquid spraying apparatusAir compressionControl line

The invention relates to a kind of arc spray device and spraying technology. A carrying wire plate is on the wire feeder of the device. Electric source for spraying connects to controlling box through size 1 controlling line and size 1 electric output cable. The controlling box connects to the double-spout spray gun through size 2 air-compressed tube. The wire feeder connects to the double-spout spray gun through electric cables and wire duct. Pressure of compressed air for spraying is 0.6Mpa to 0.8Mpa. The eclectic voltage for spraying is 20V to 35V .The electric current for spraying is 50A to 300A. The invention eliminates steps such as renewing painting material, adjusting technical parameter and so on .So it can save spraying time and raise working efficiency .The invention can be used to make mosaic laminating layers of different material and different performance, for example, thick base Ni3Al layer with thin mosaic WC layer .The invention has prominent advantages such as simple spray procedure, high spray efficiency, saving energy and resource and so on. The spraying method of this invention can be operated easily.

Owner:HARBIN INST OF TECH

Pulsation reciprocating self-control range lawn nozzle

InactiveCN105499000ASmall modificationImprove spray uniformityMovable spraying apparatusEngineeringLawn

The invention discloses a pulsation reciprocating self-control range lawn nozzle. The nozzle comprises a rocking arm (1), a pressing plate (2), a connecting rod (3), an eccentric shaft (4) and an end cover (5); the pressing plate (2) is fixed at one end of the end cover (5); the bottom of the end cover (5) is fixed in the middle position of the rocking arm (1) through the eccentric shaft (4); and one end of the end cover (5) is fixed on the rocking arm (1) through the connecting rod (3).

Owner:BEIJING UNIV OF TECH

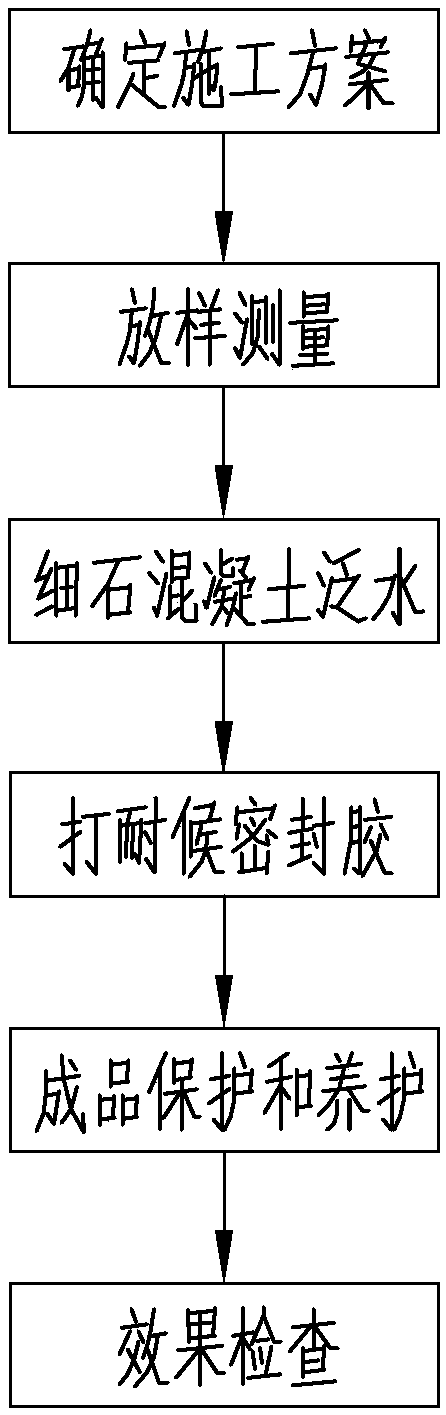

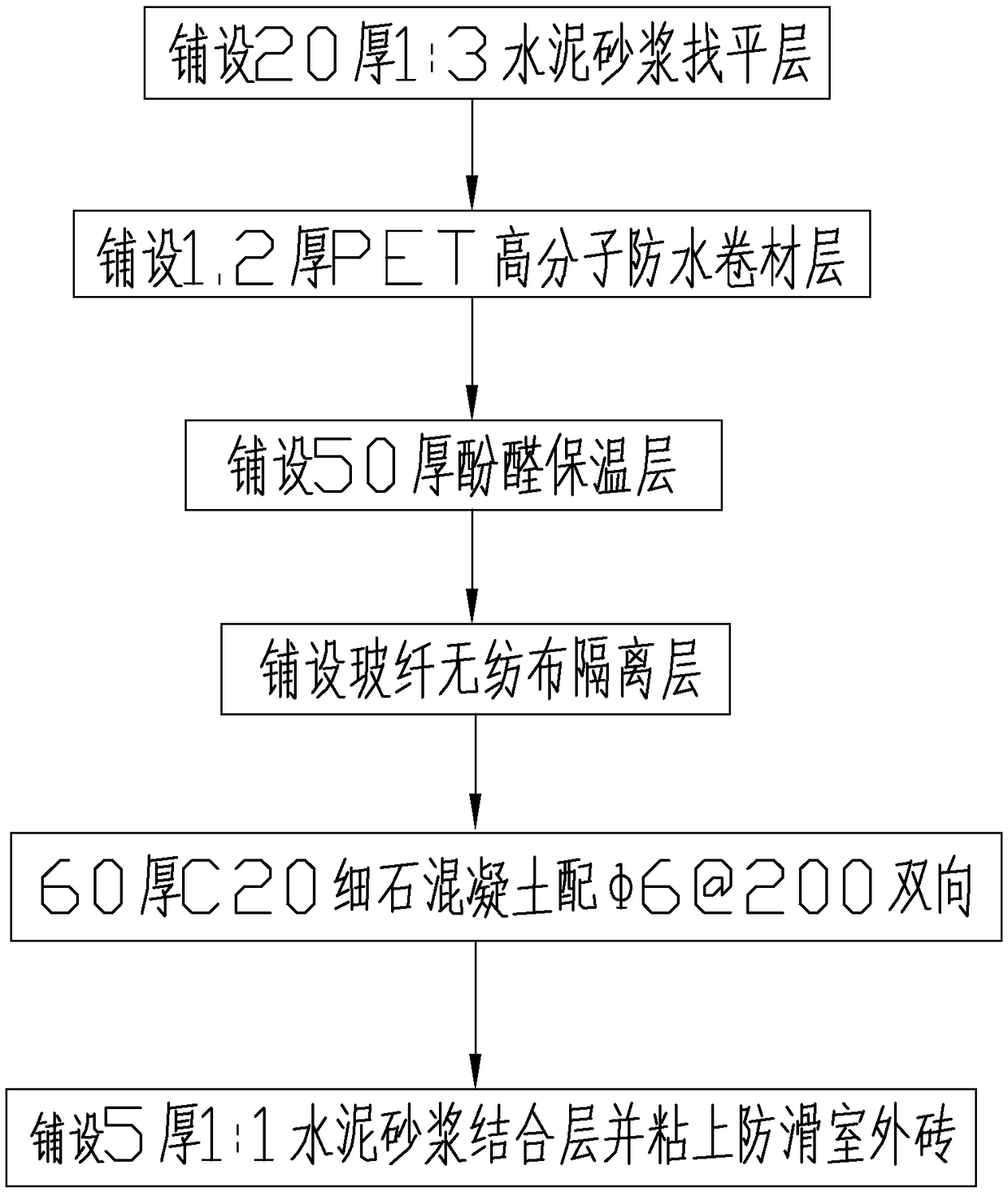

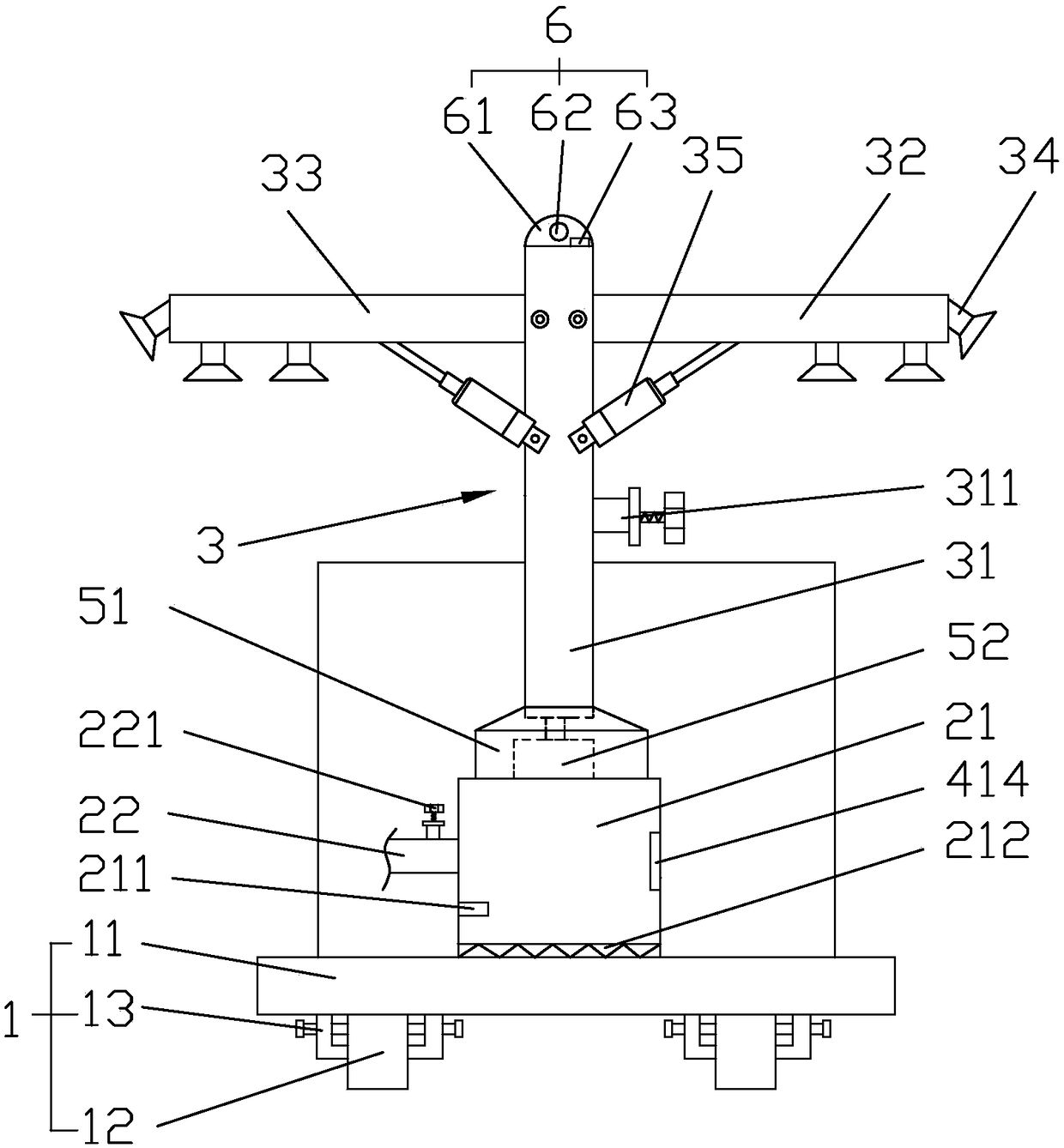

Integrated-mold fine-aggregate-concrete flashing construction method and waterproof maintenance device thereof

InactiveCN109162411AInvoluntary movementExpand the spraying areaRoof covering using sealantsBuild-up roofsWireless controlWater storage tank

The invention mainly discloses an integrated-mold fine-aggregate-concrete flashing construction method and a waterproof maintenance device thereof. The method comprises the following steps: step one,determining a construction plan; step two, carrying out molding measurement; step three, carrying out foundation course processing; step four, carrying out fine-aggregate-concrete flashing; step five,carrying out weather-proof sealant gluing; step six, carrying out finished product protection and maintenance; and step seven, carrying out effect checking. In addition, the waterproof maintenance device comprises a mobile device, a water storage device, a spraying device and a wireless control device. The water storage device includes a water storage tank and a water supply pipe. The spray device includes a main water pipe, a first water distribution pipe, a second water distribution pipe and a water spray head; a rotating device is arranged between the main water pipe and the water storagetank; and a second electromagnetic valve is arranged on the main water pipe. The wireless control device includes a temperature control device and a time control device. According to the invention, the construction becomes convenient; the method and the device are easy to implement; the construction cost is low; the quality is god; and the waterproof effect is good. With the waterproof maintenancedevice, watering and maintenance can be carried out on the concrete comprehensively and automatically; the time and manpower are saved; and the maintenance effect is good.

Owner:浙江广辉建设有限公司

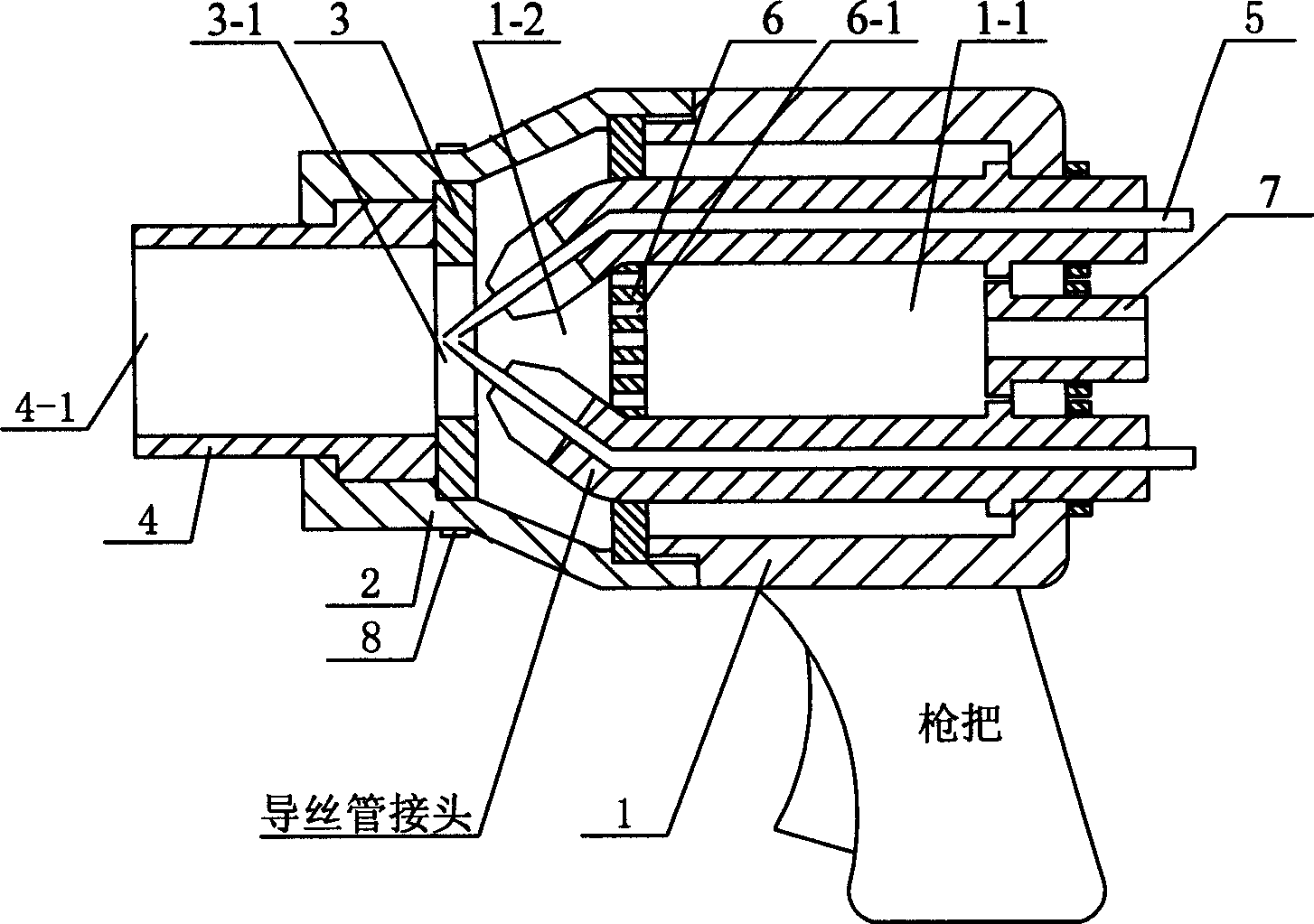

Narrow gap electric arc spraying gun

InactiveCN1593780AReduce shadowing processSave Spraying TimeSpray nozzlesLiquid spraying apparatusEngineeringArc spray

This invention relates to a kind of arc spray gun with a spout of new structure. When using the common arc spray gun to spray a narrow shape, we have to cover the place that need not to be coated, so it is inconvenient and inefficient. The invention consists of gun body and spray wire in it. In the front end of the gun body, there is a device to fix the gun spout. And a rectangular air cover is inside the device, in the middle of which is a bore, where is the end of the spray wire. Because its special spout is suited to spraying over the space of such shape as narrow strip, narrow path, narrow annular slot, and little space and so on, the invention can eliminate the step of covering, so that it can save both the time for spraying and lots of painting material, cutting the cost and raising working efficiency.

Owner:HARBIN INST OF TECH

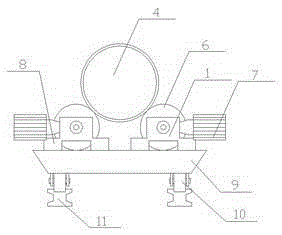

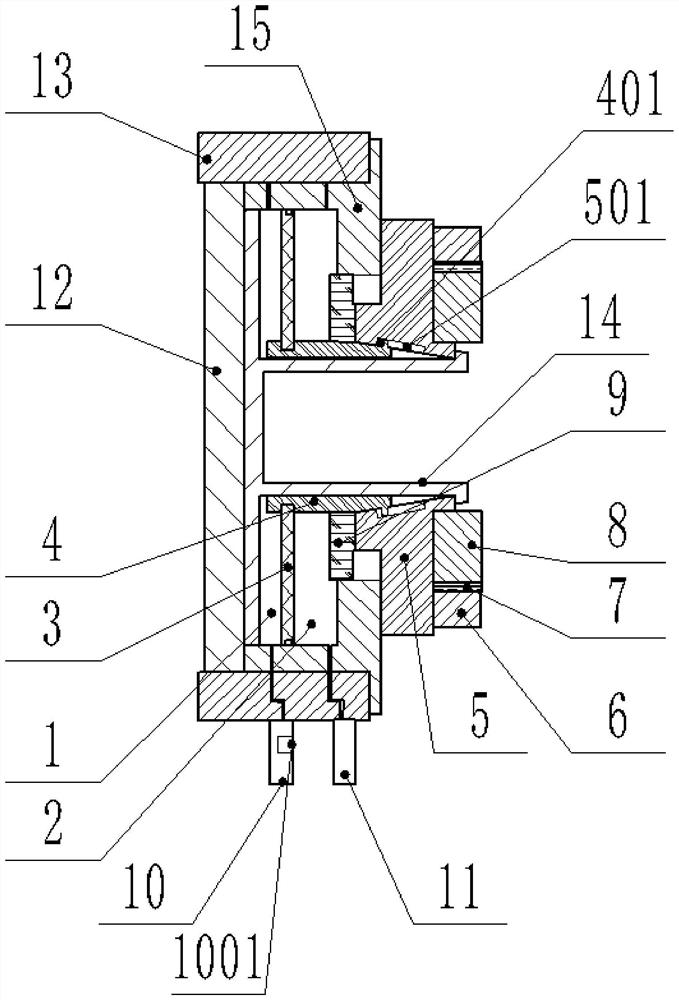

Hydraulic chuck device for spraying polyurethane thermal insulation pipe

The invention relates to a hydraulic chuck device for spraying a polyurethane thermal insulation pipe. The hydraulic chuck device comprises a first oil cylinder, a second oil cylinder, a piston, a horizontal pull block, a vertical pull block, an outer supporting clamping jaw, a strain gauge, an inner clamping clamping jaw, a sealing block, a first chuck body, a second chuck body, a third chuck body, a fourth chuck body, a first oil valve, a second oil valve and a central control module. The theoretical oil inlet amount of the first oil cylinder is calculated through the central control module, and the oiling speed is determined by the theoretical oil inlet amount of the first oil cylinder; and when the central control module starts the first oil valve to add oil to the first oil cylinder, the strain gauge detects the pressure borne by the strain gauge in real time, a flow detector records the oil injection amount of the first oil cylinder in real time, and the central control module adjusts the oil adding speed of the first oil cylinder according to the pressure borne by the strain gauge and the oil injection amount of the first oil cylinder. By intelligently adjusting the oiling speed of the oil cylinders, the situation that a to-be-sprayed pipeline is damaged due to the too high oiling speed and the too large supporting force of the outer supporting clamping jaw is prevented.

Owner:内蒙古伟之杰节能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com