Multi-purpose electro-hydraulic spraying device

A spraying device and multi-purpose technology, applied in the direction of construction, building structure, etc., can solve the problems that the safety of workers cannot be guaranteed, increase the outdoor wall, and the production efficiency is low, and achieve good spraying effect, simple main structure, easy to use Flexible and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

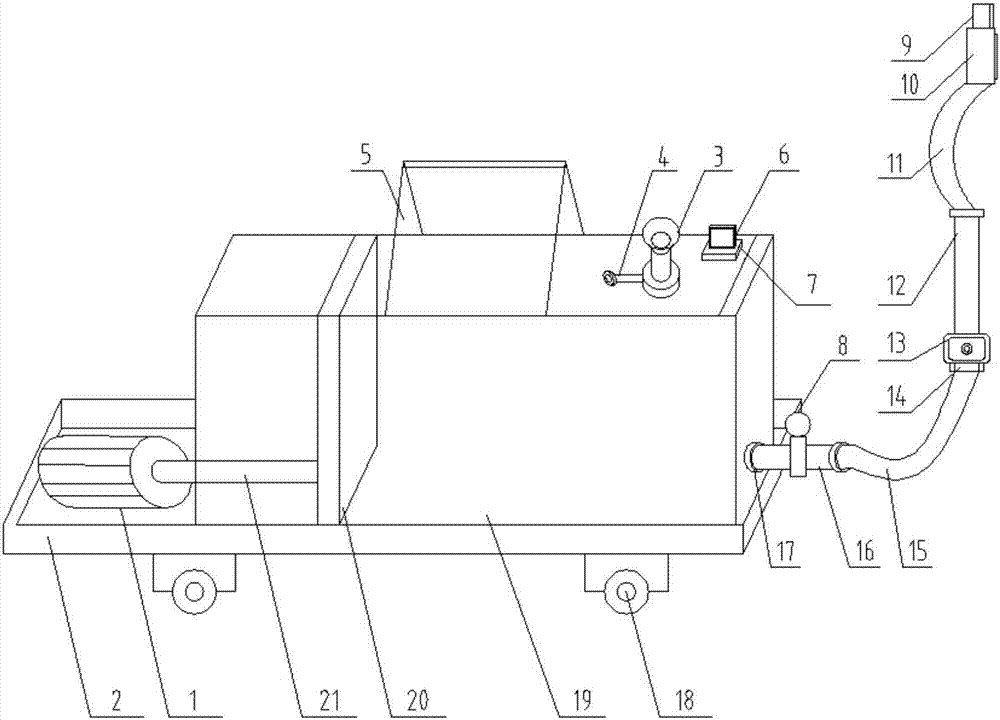

[0010] The main structure of the multi-purpose electro-hydraulic spraying device involved in this embodiment includes: the motor 1, the base 2, the injection port 3, the injection control valve 4, the handle 5, the video receiving device 6, the fixed support 7, and the feeding switch 8. Mini camera 9, spraying head 10, elbow 11, straight steel pipe 12, pressure regulating device 13, interface connector 14, conveying hose 15, conveying pipe 16, box interface 17, wheel 18, box 19 , Pressure regulating unit 20 and booster rod 21. The base 2 made of stainless steel has a rectangular structure. The four peripheries of the base 2 are provided with vertical plates to prevent the objects carried on the upper surface of the base 2 from sliding down. The upper side of the base 2 rests The right handle has a box 19 for storing paint. The metal box 19 has a rectangular parallelepiped structure. The upper middle of the box 19 is provided with a handle 5. The handle 5 includes a cross bar loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com