Patents

Literature

70results about How to "Good spray effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

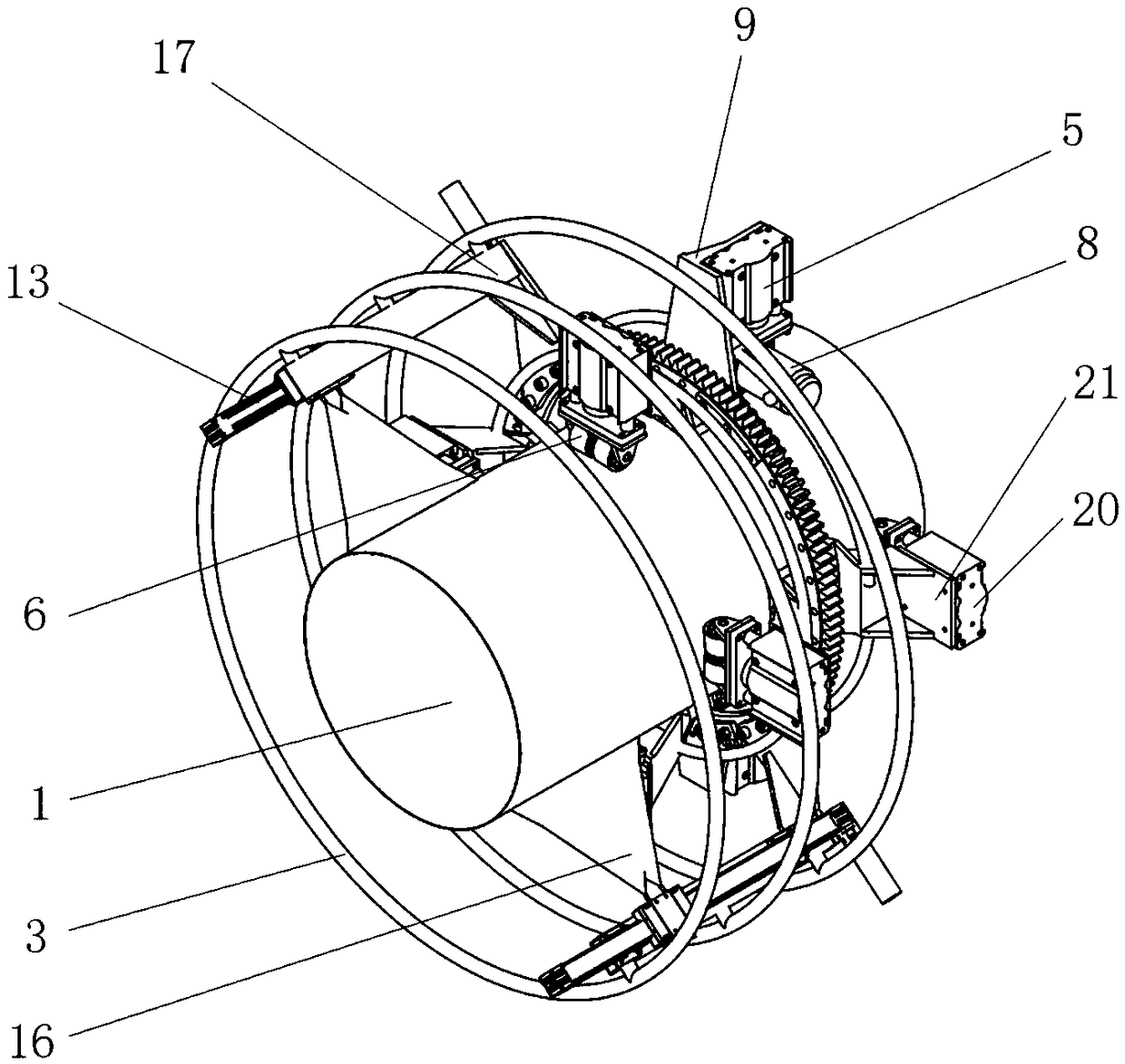

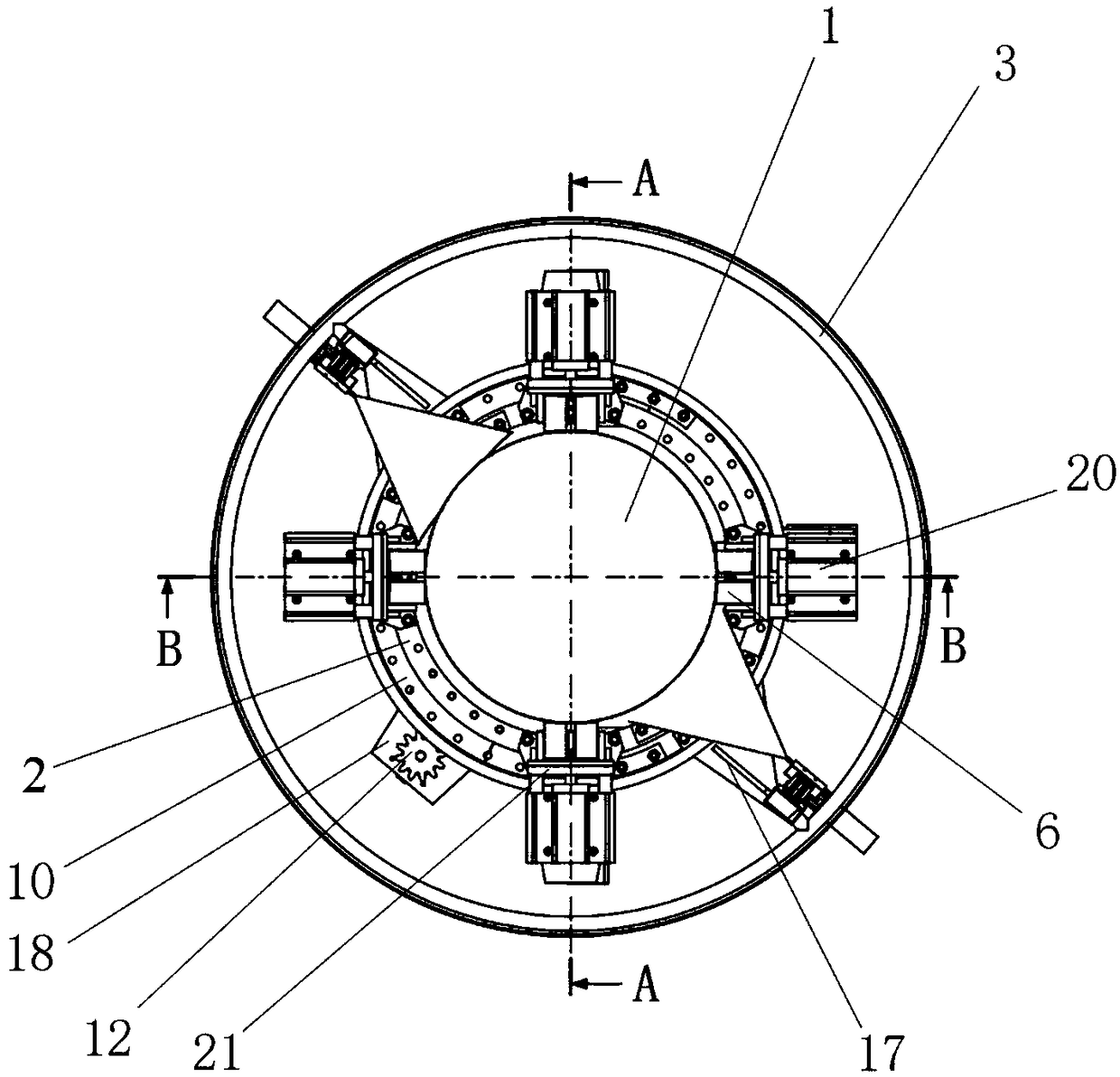

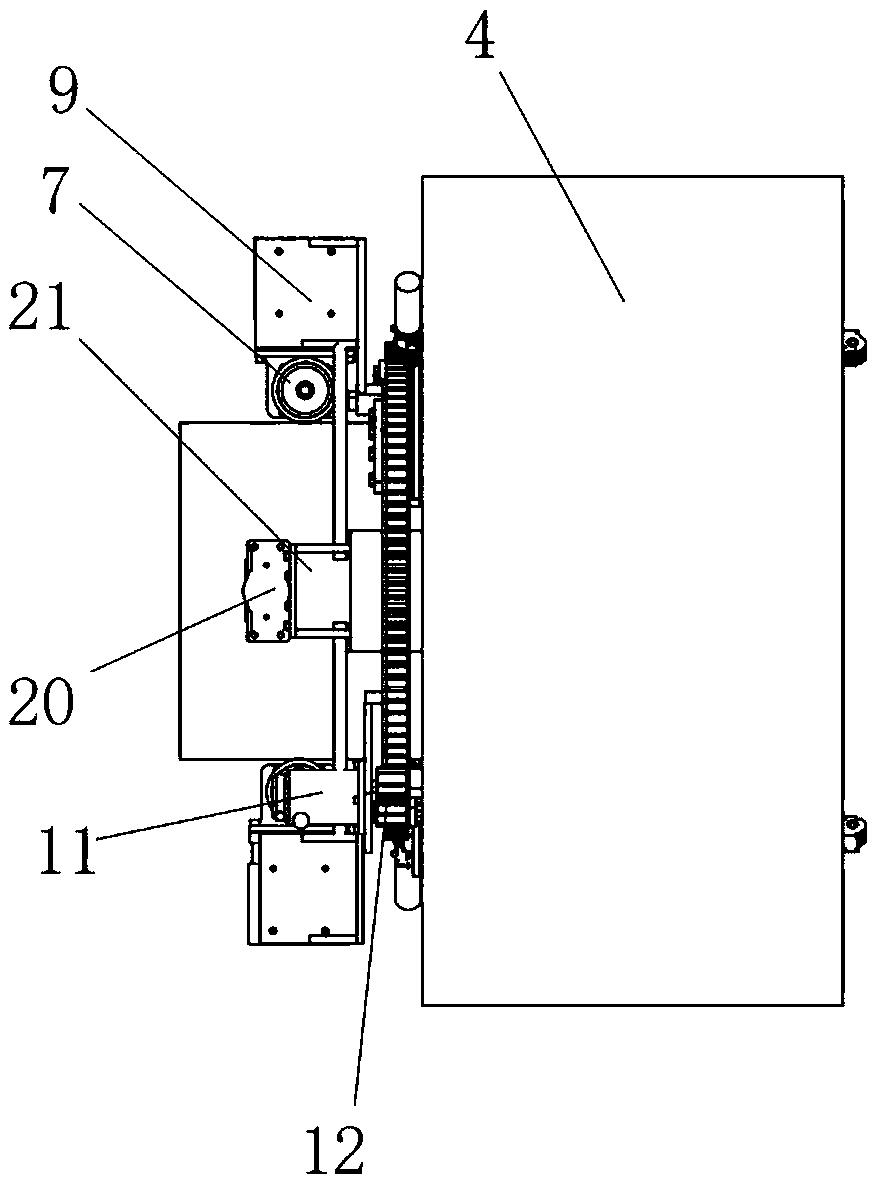

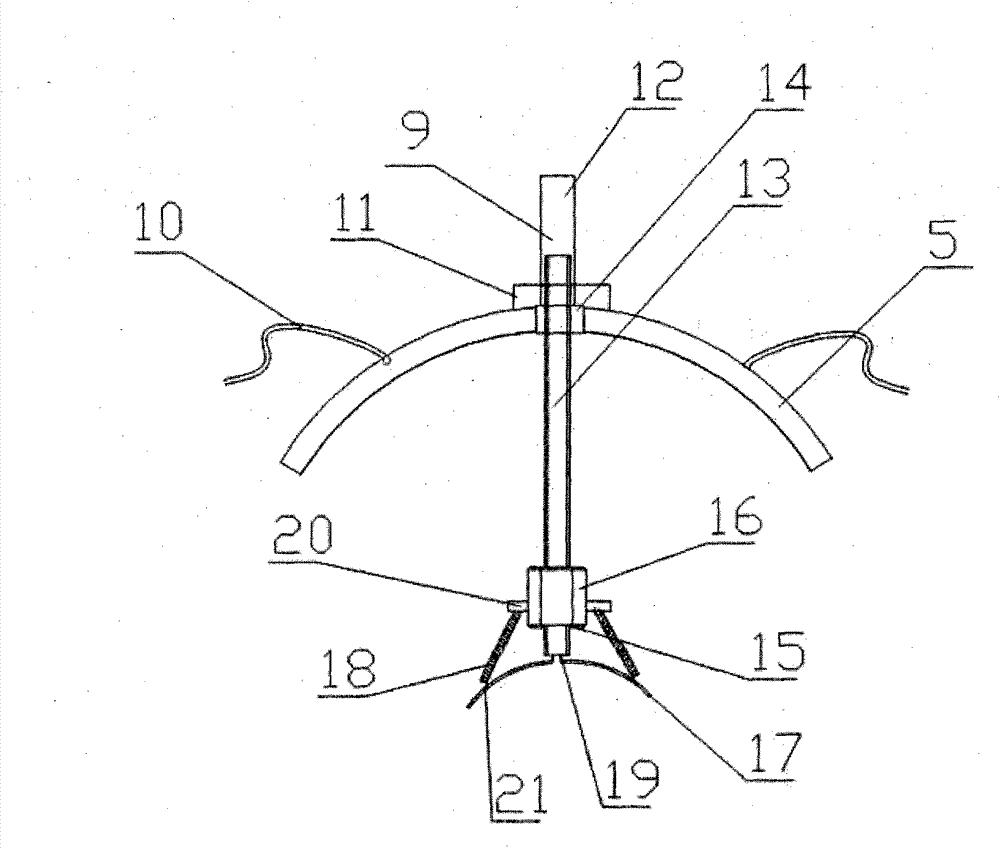

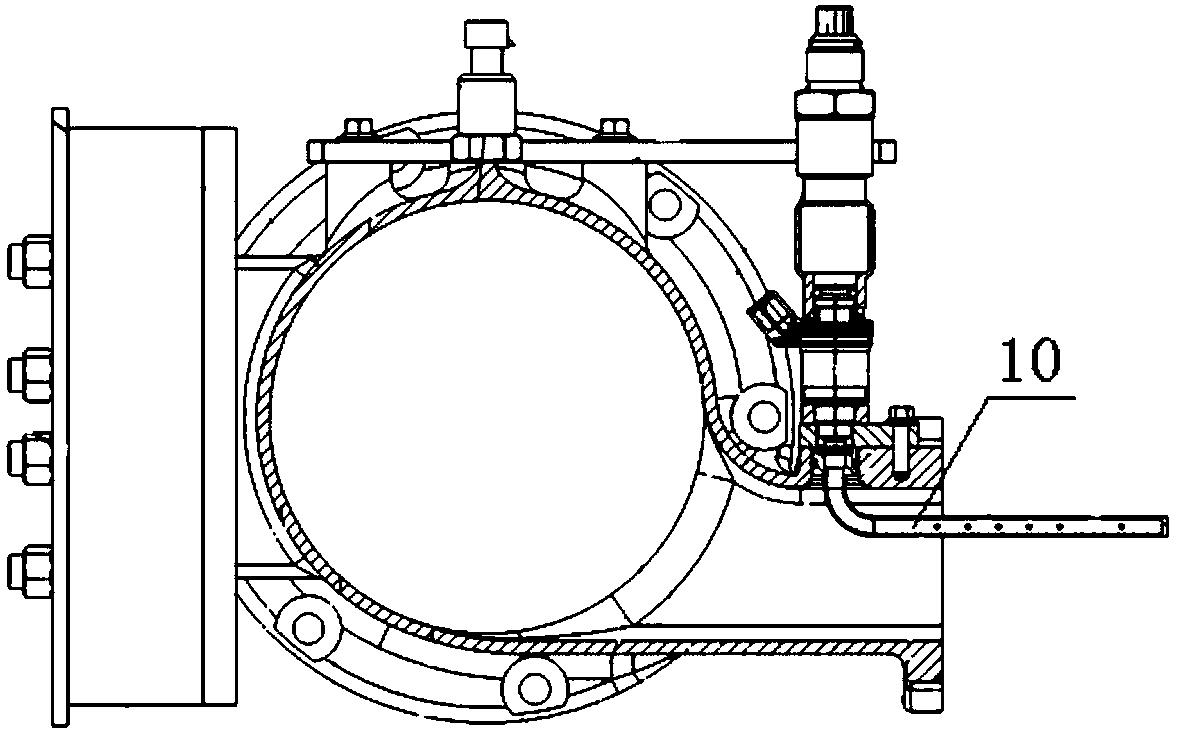

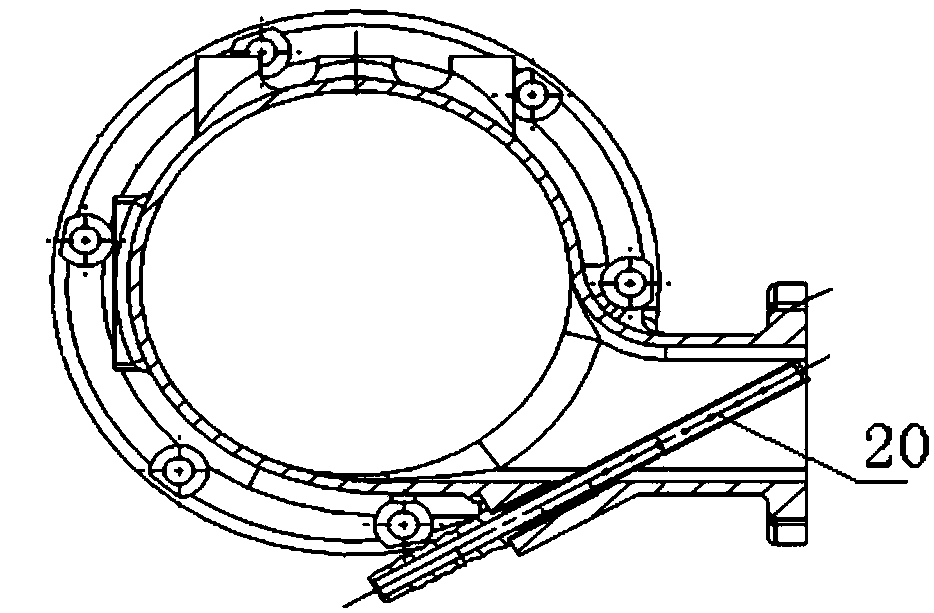

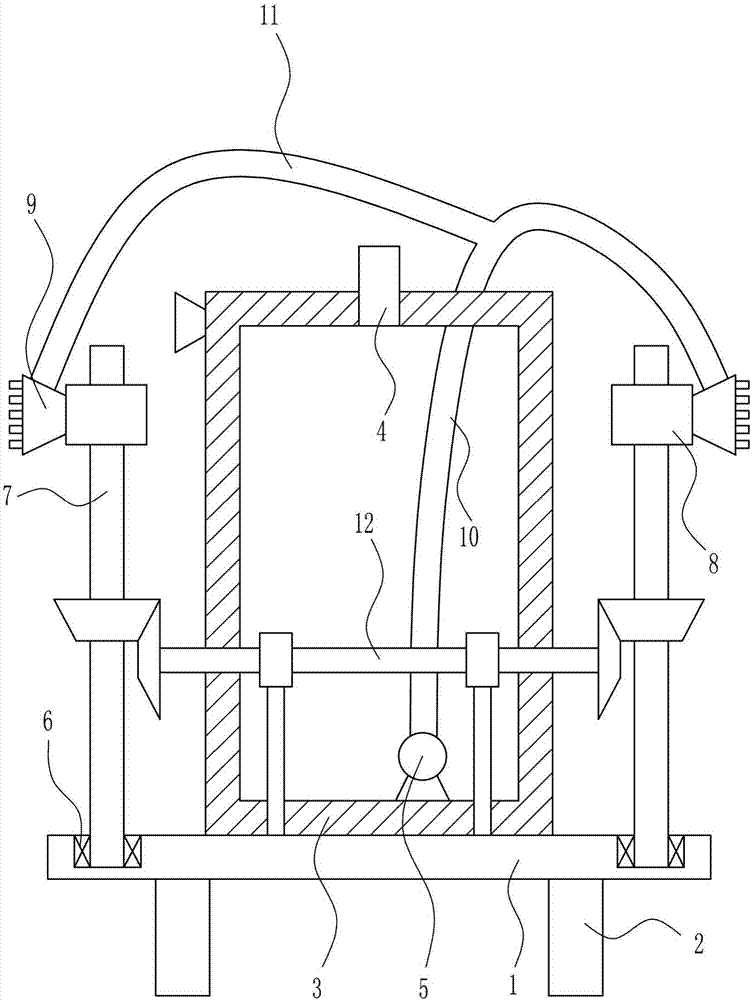

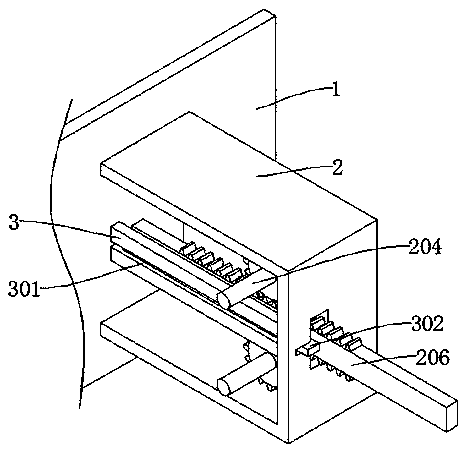

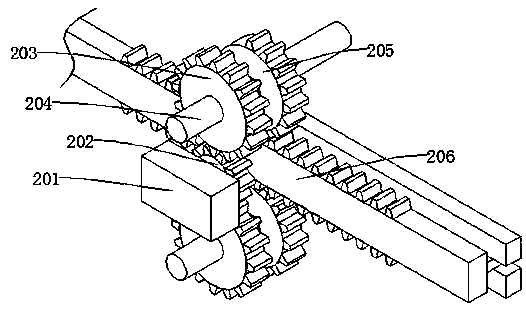

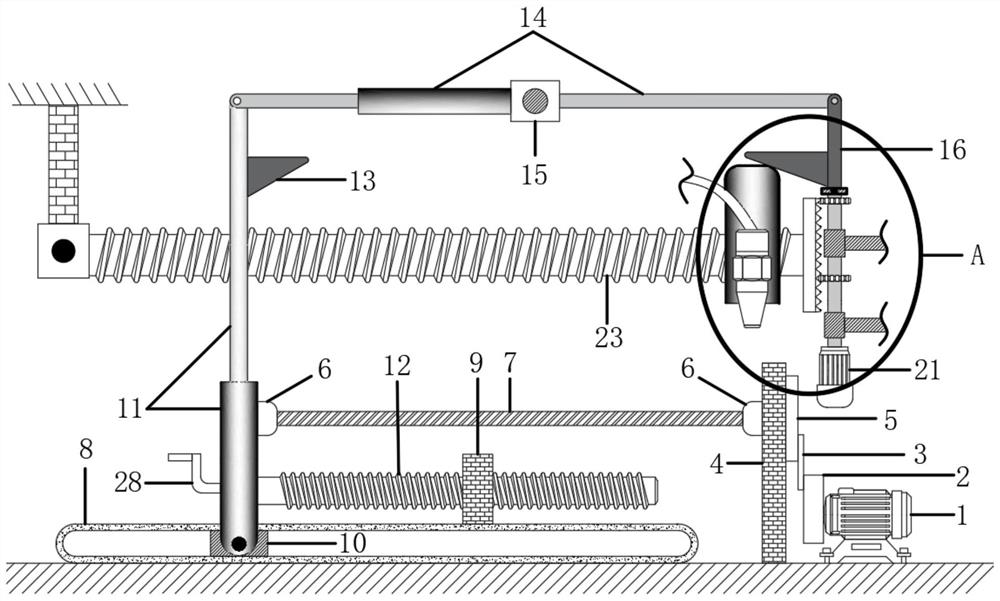

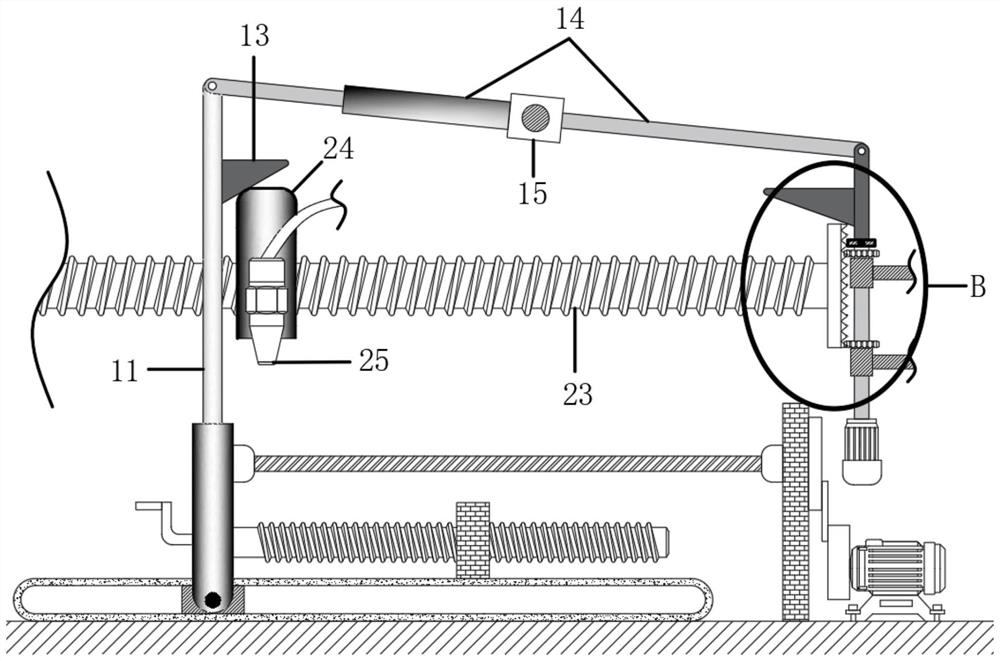

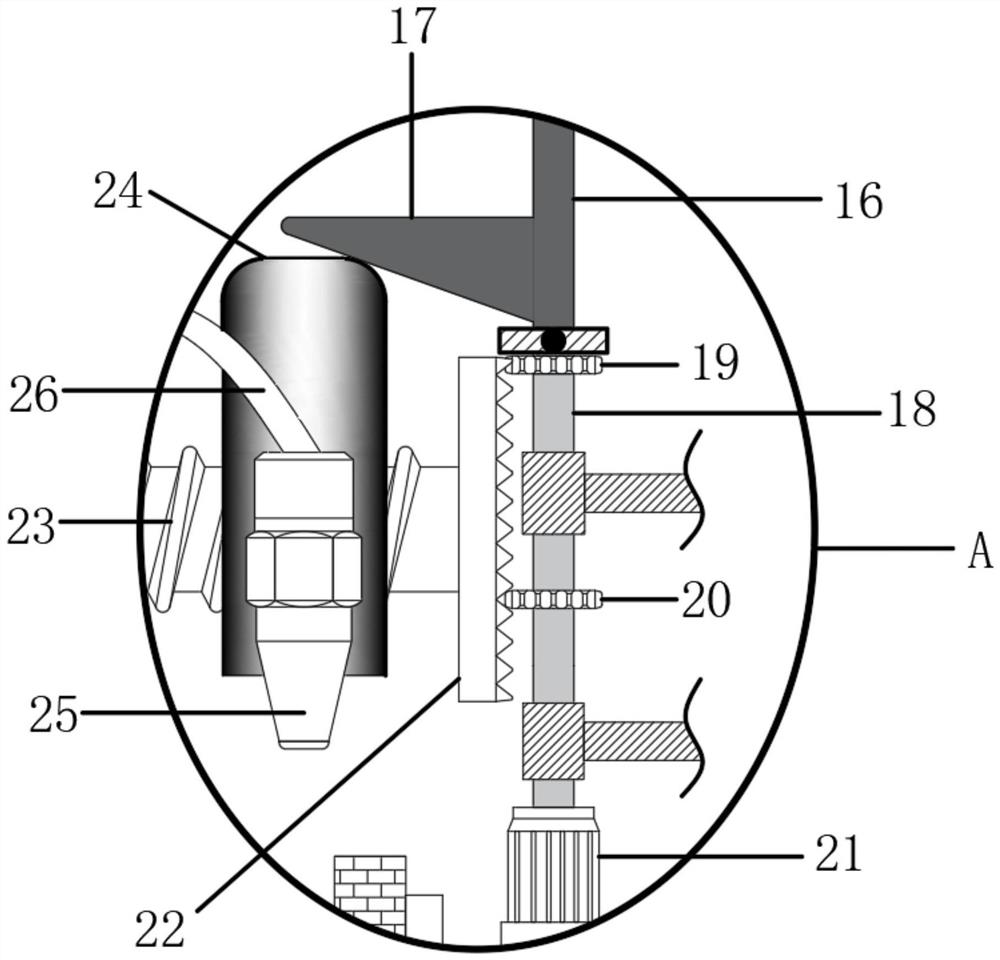

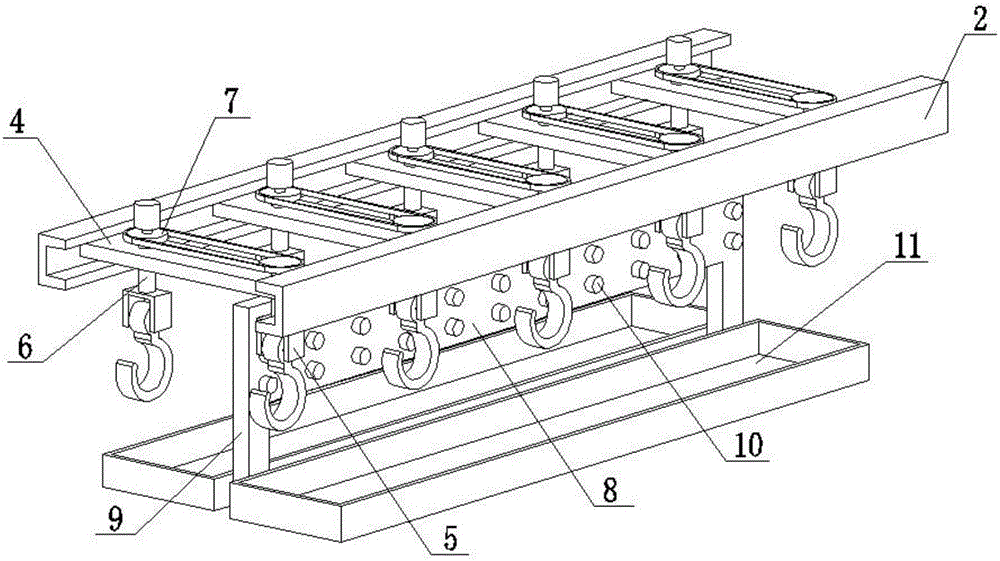

Cable rope coating spraying device and method

PendingCN109395942AImprove spraying efficiencyGood spray effectSpraying apparatusSpray nozzleElectric machinery

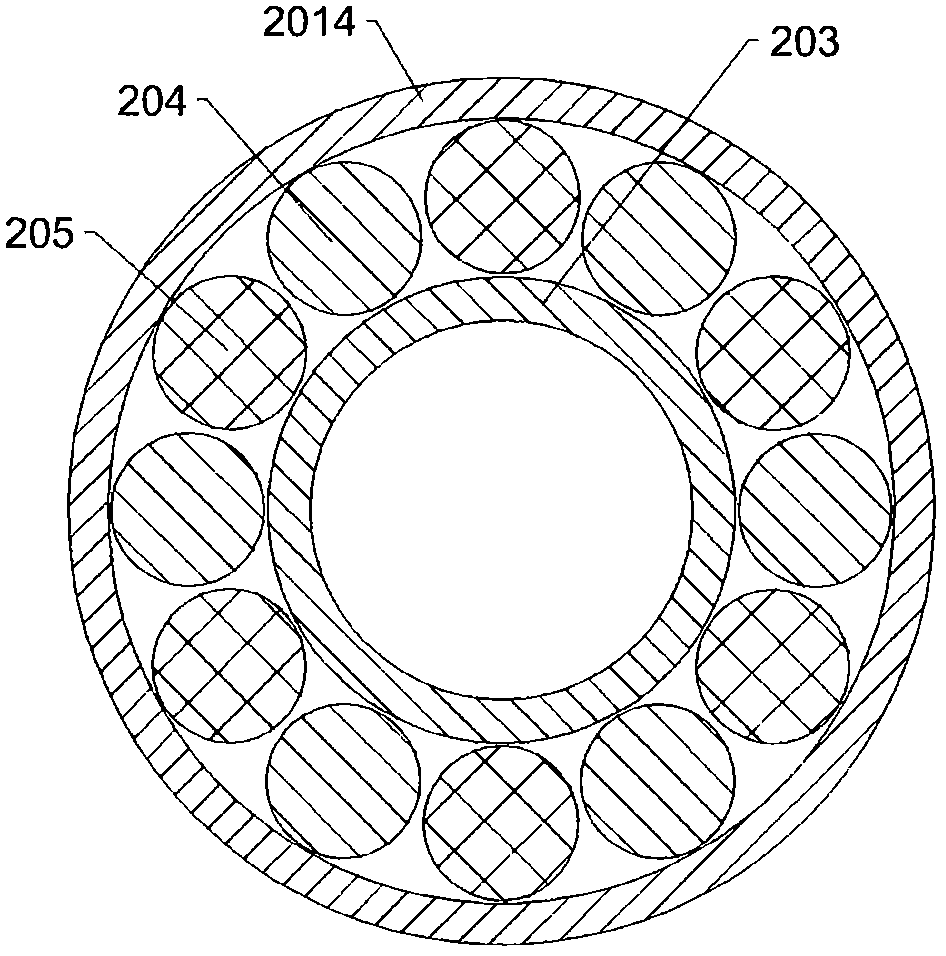

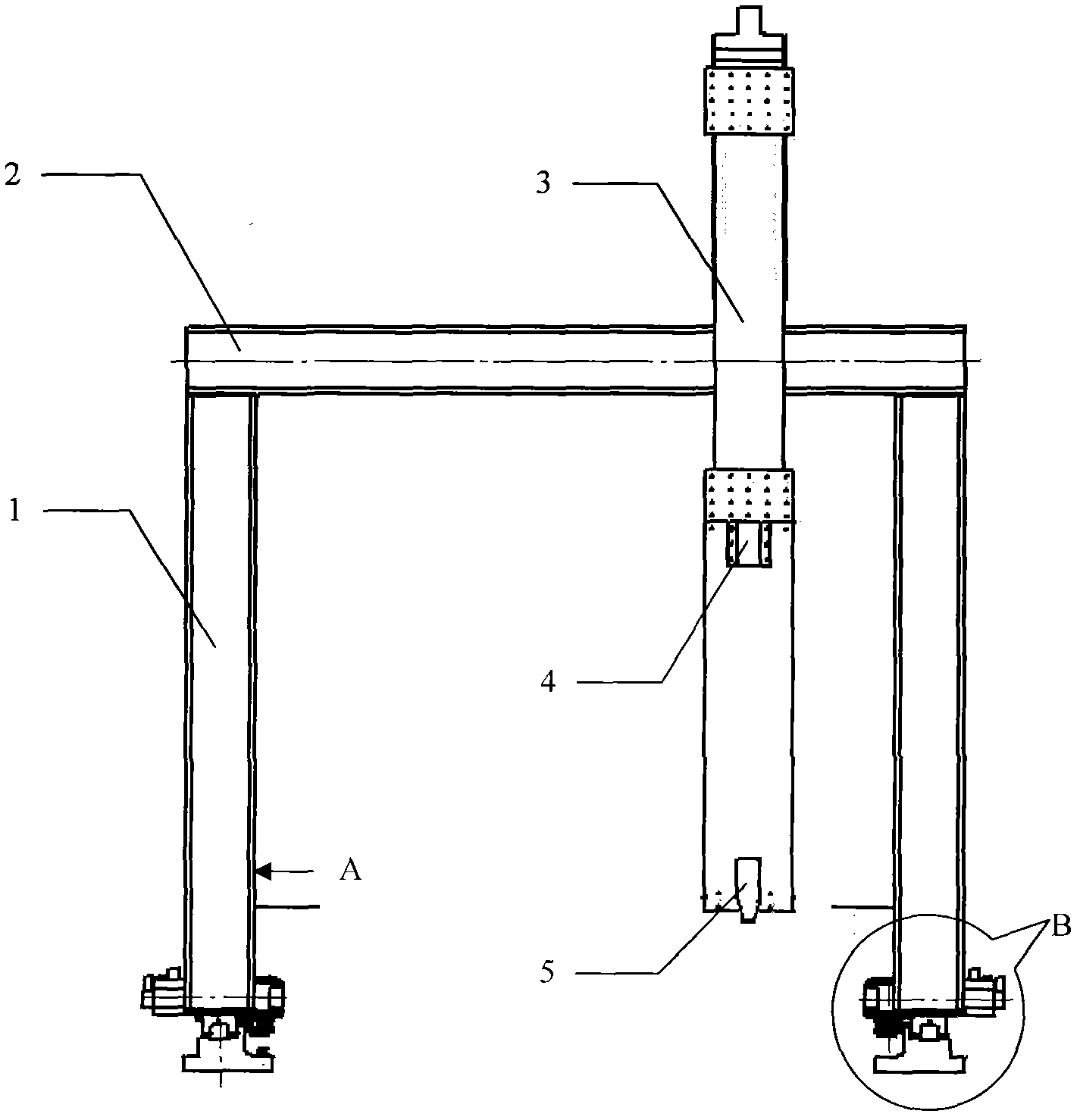

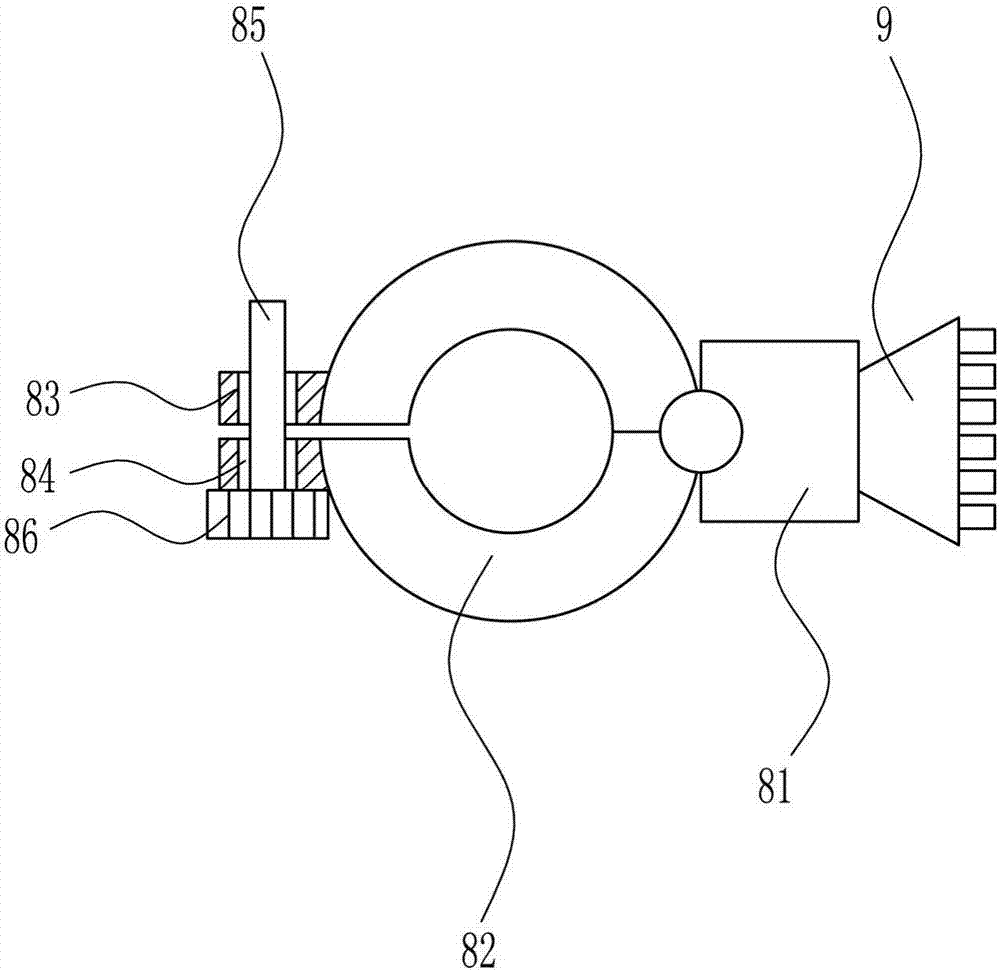

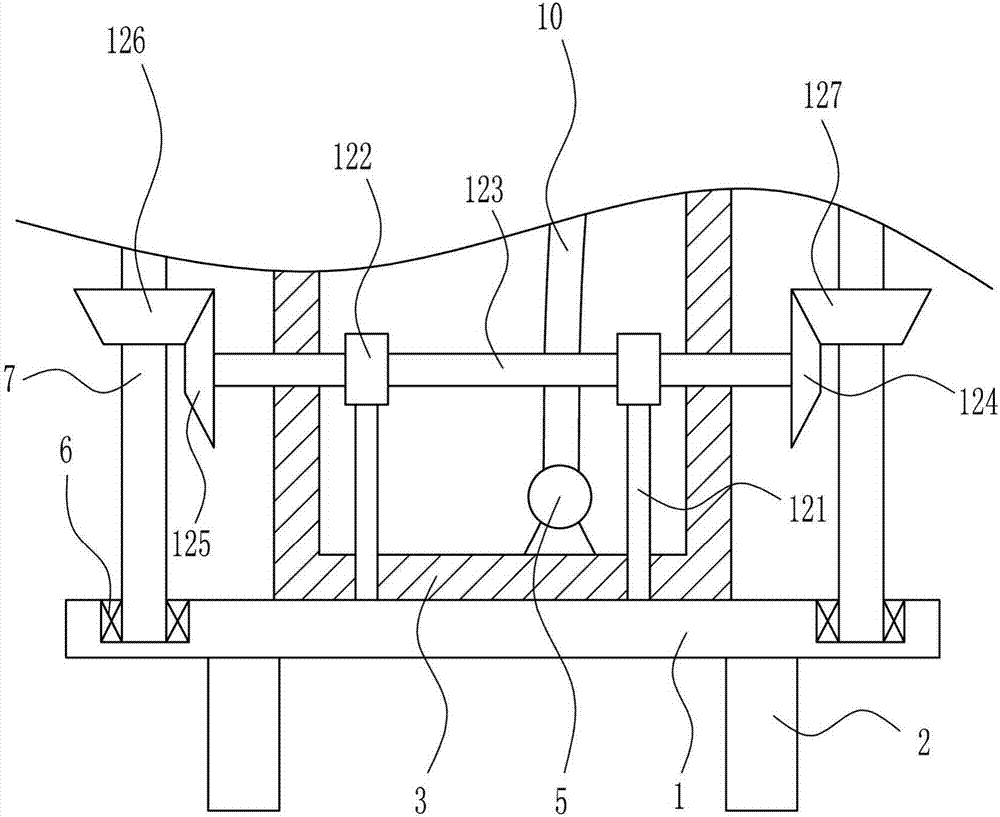

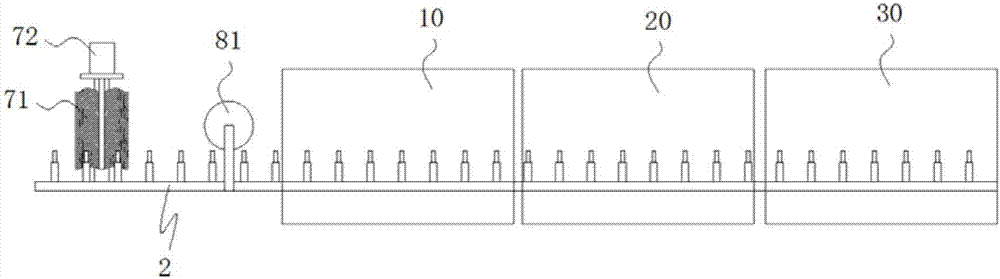

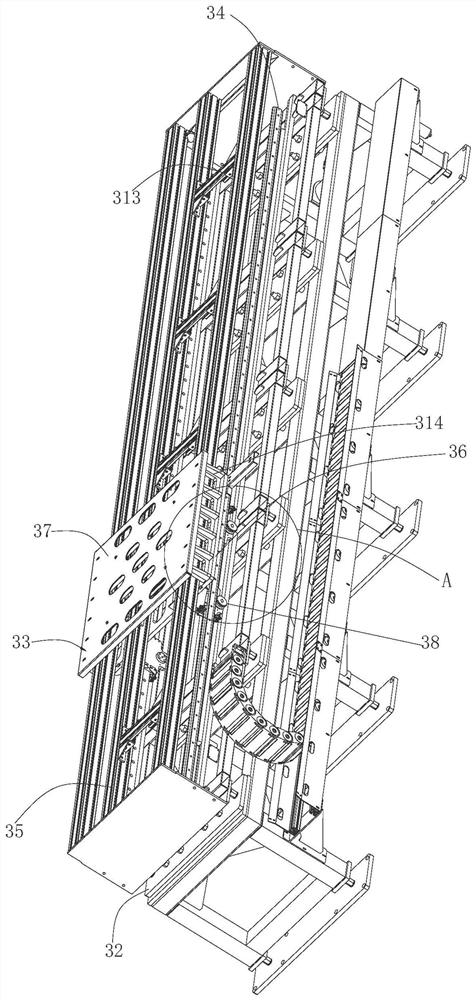

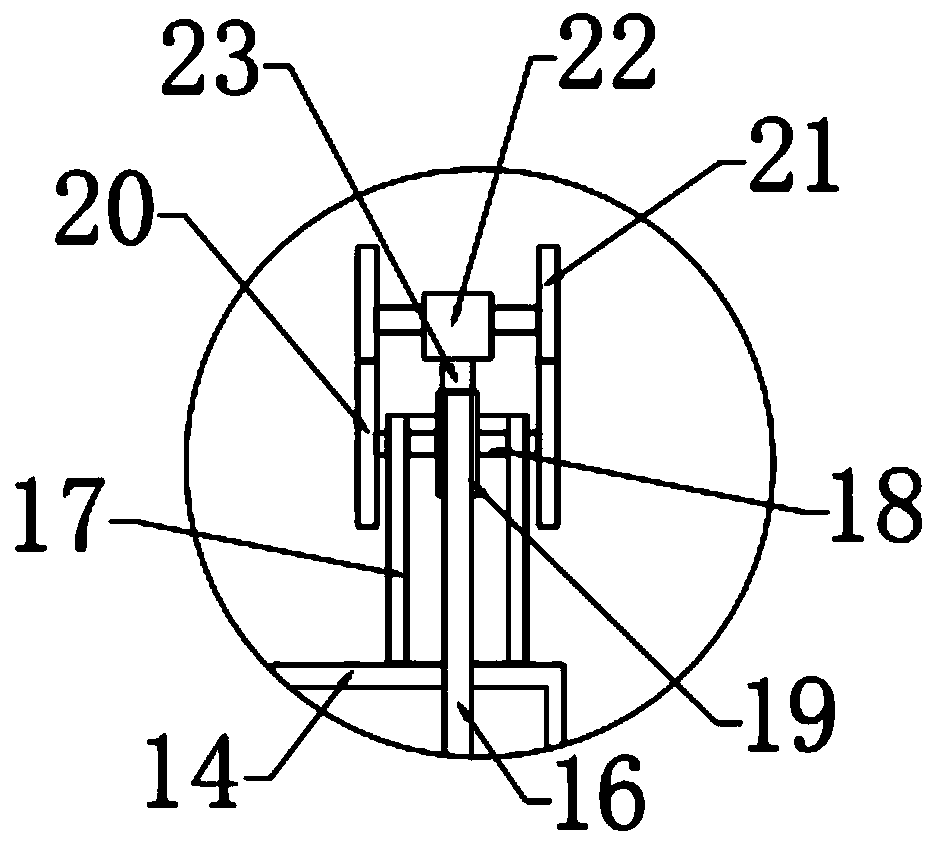

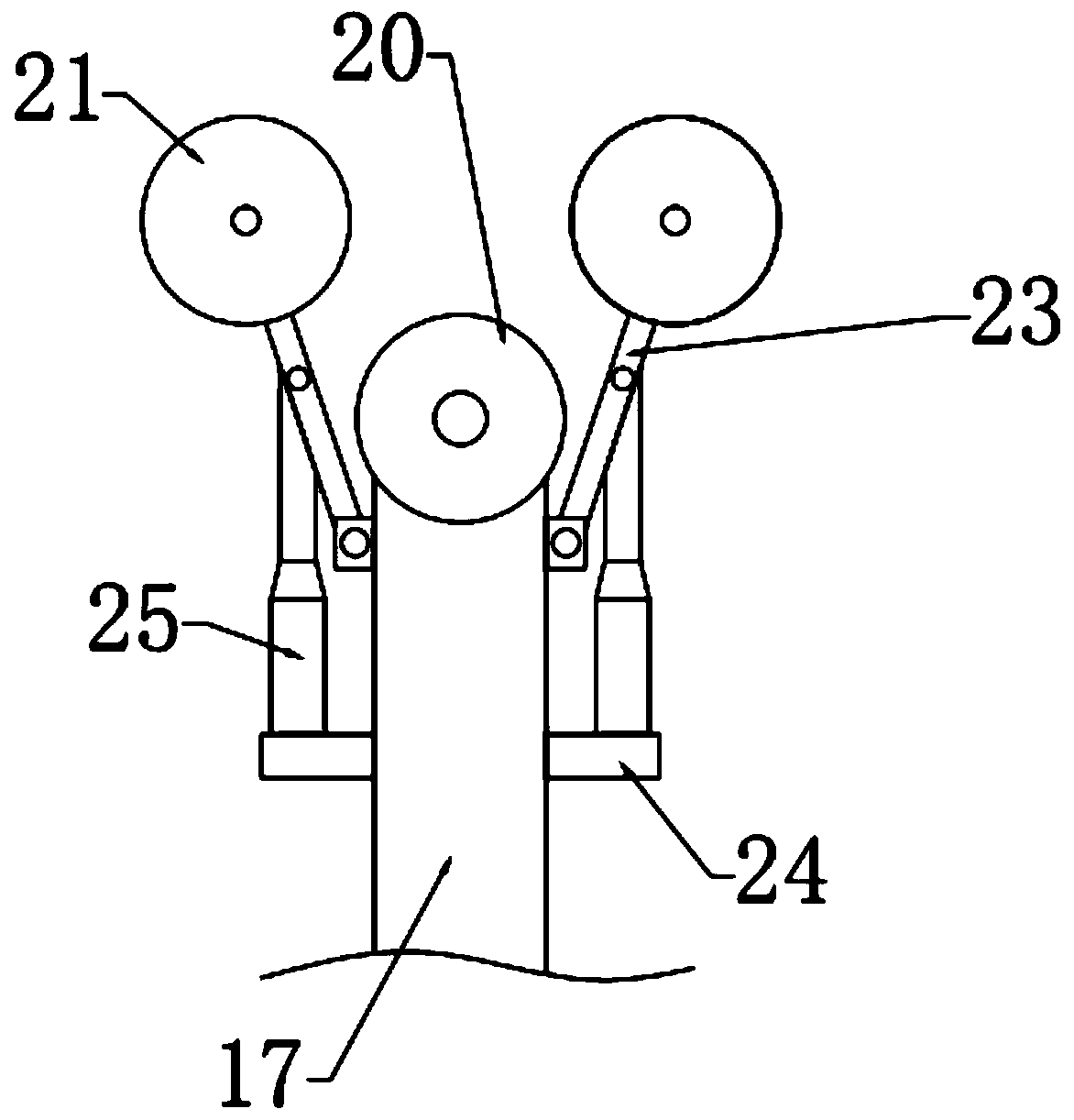

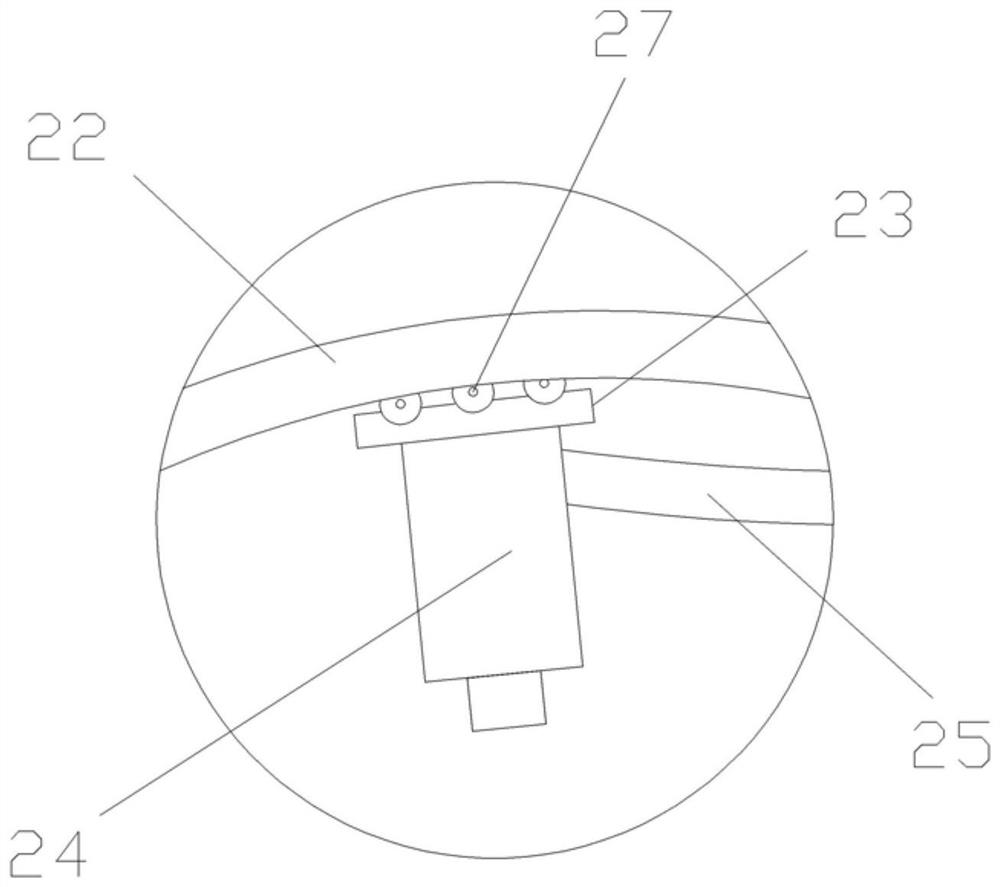

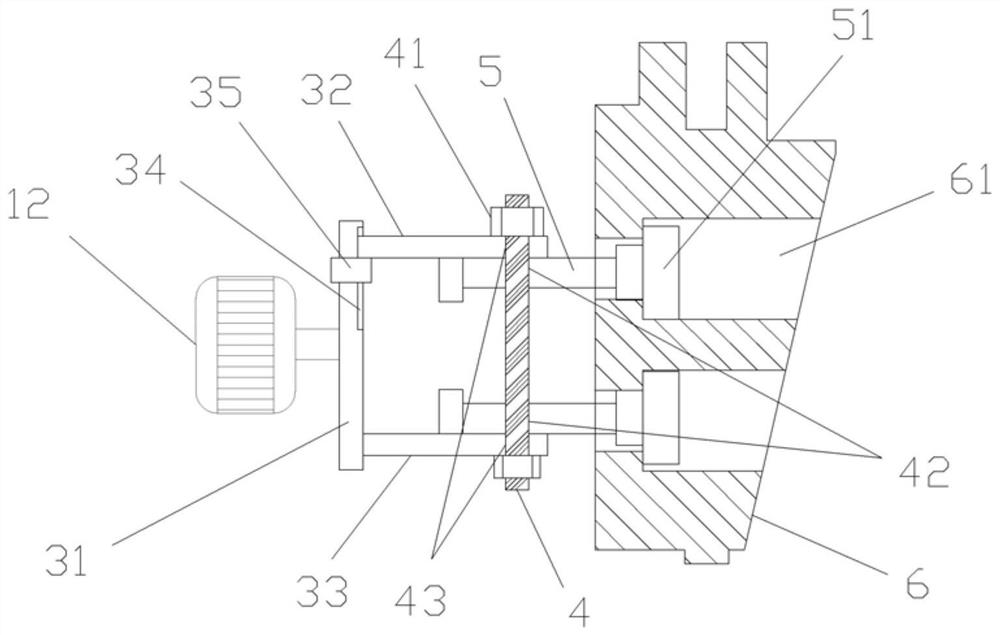

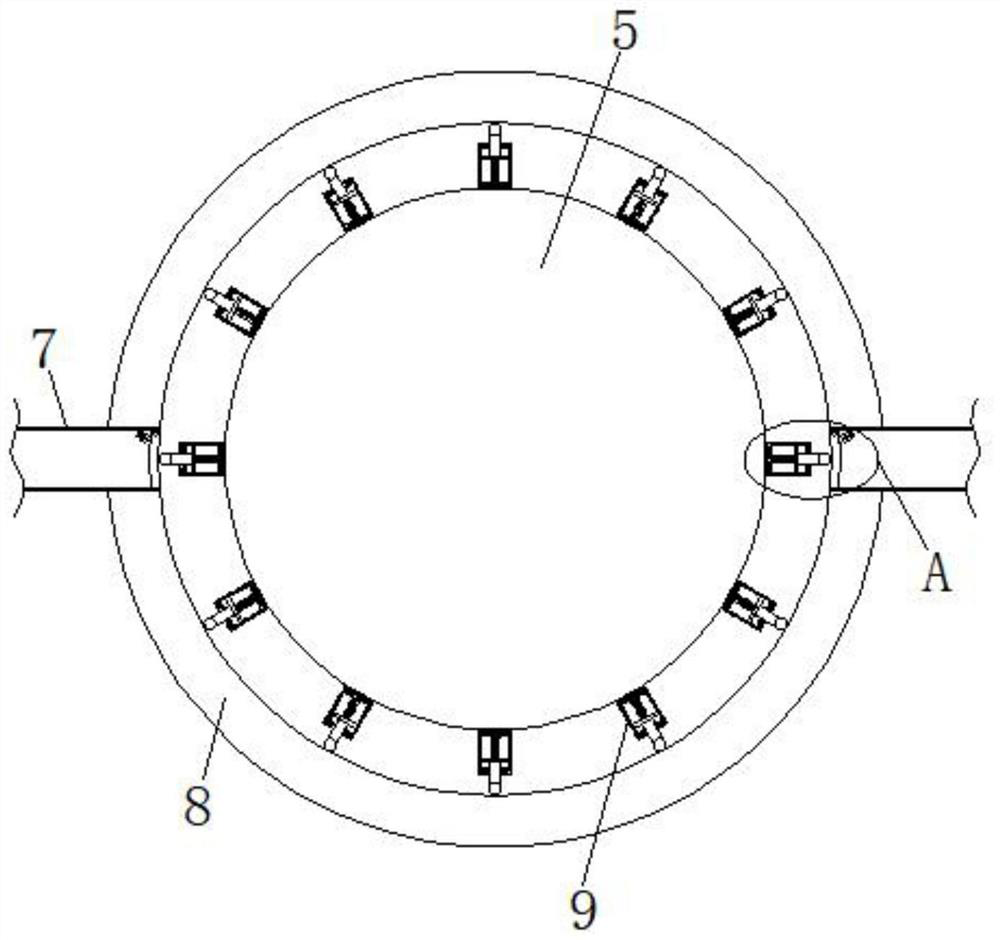

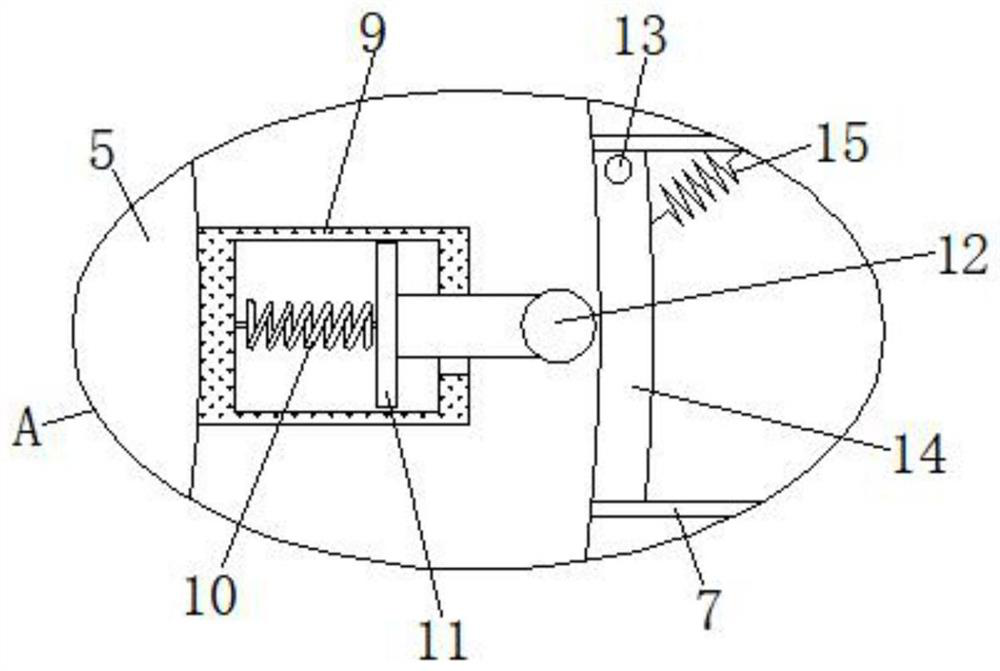

The invention provides a cable rope coating spraying device and method and relates to the technical field of coating spraying. A gas pump, a supporting and rotating mechanism, a spraying mechanism, atravelling mechanism and a wireless receiving controller are included. An inner ring formed by connecting semicircular rings in a lap joint manner is a supporting mechanism around a cable rope; an outer gear ring is combined with the outer diameter of the inner ring through a ball to form a rotating mechanism; the connection end of a track support is fixed to the outer gear ring through a bolt; the cantilever side face of the track support is provided with linear guide rails in clearance fit with a slider; the shaft end of a spraying motor is provided with a synchronous belt wheel, and a spraynozzle and the slider are fixed to form the spraying mechanism; according to the travelling mechanism, the 45 degree included angle position of the outer side of the inner ring and the track supportis uniformly provided with four cylinder supporting frames, the 45 degree included angle positions of the lower left of the inner ring and the cylinder supporting frames are provided with motor supports, and the end portion of an output shaft of a driving motor is provided with a power gear engaged with the outer gear ring; and the 45 degree included angle position of the inner side of the inner ring and the track support is uniformly provided with four cylinder supporting frames, and a travelling wheel is arranged below each cylinder.

Owner:SOUTHWEST JIAOTONG UNIV

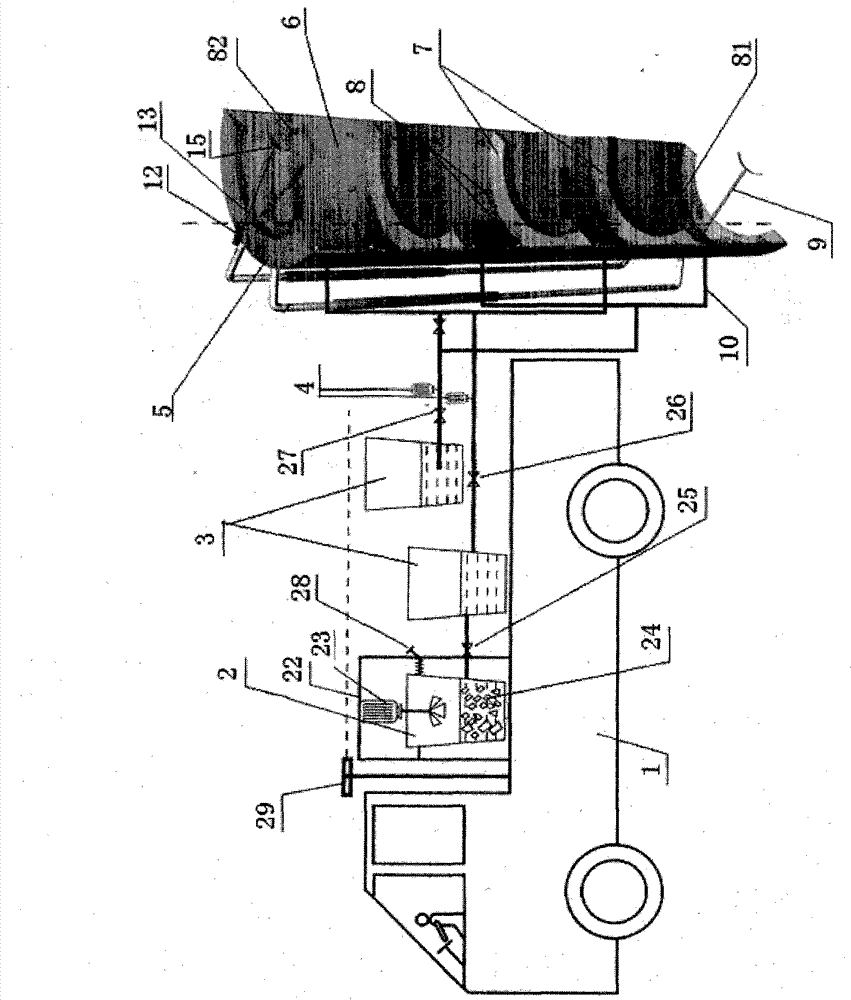

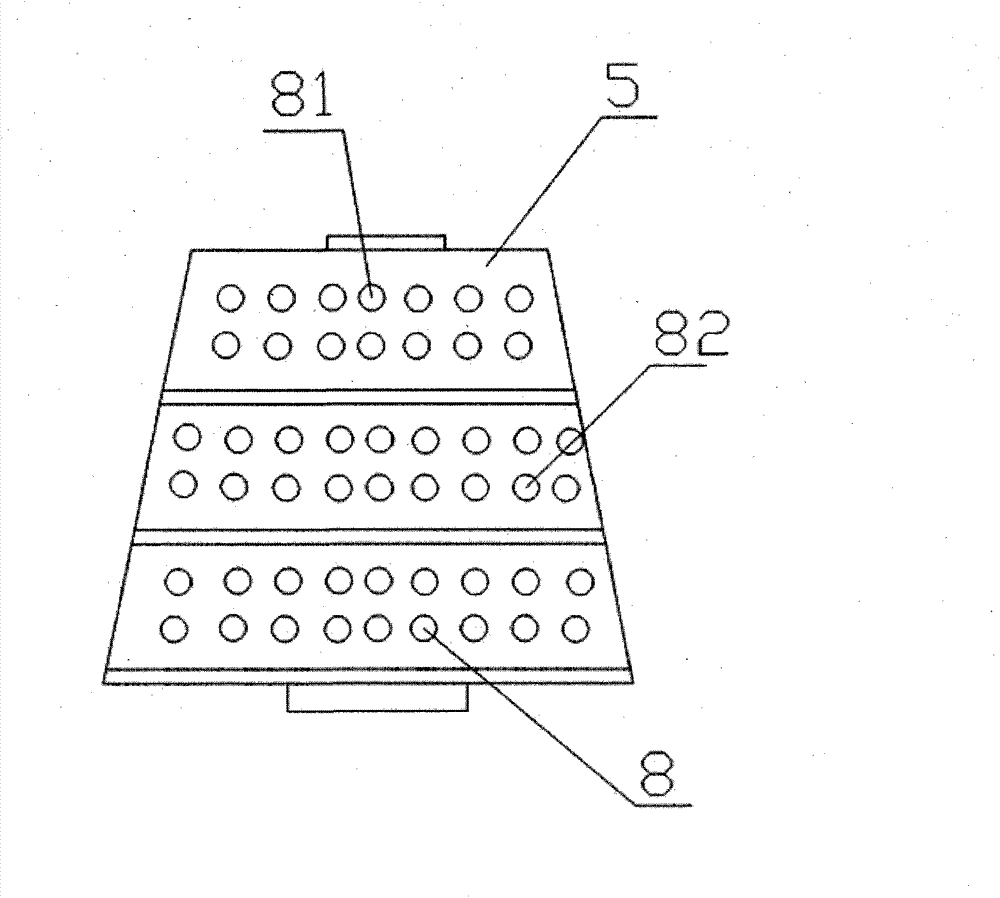

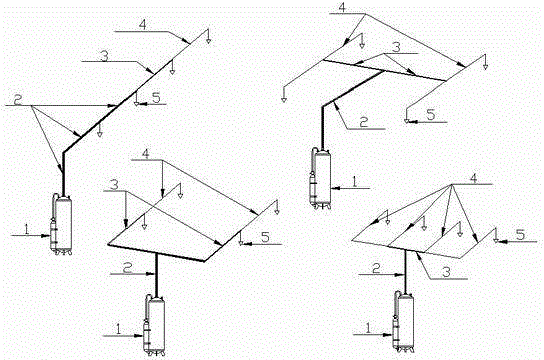

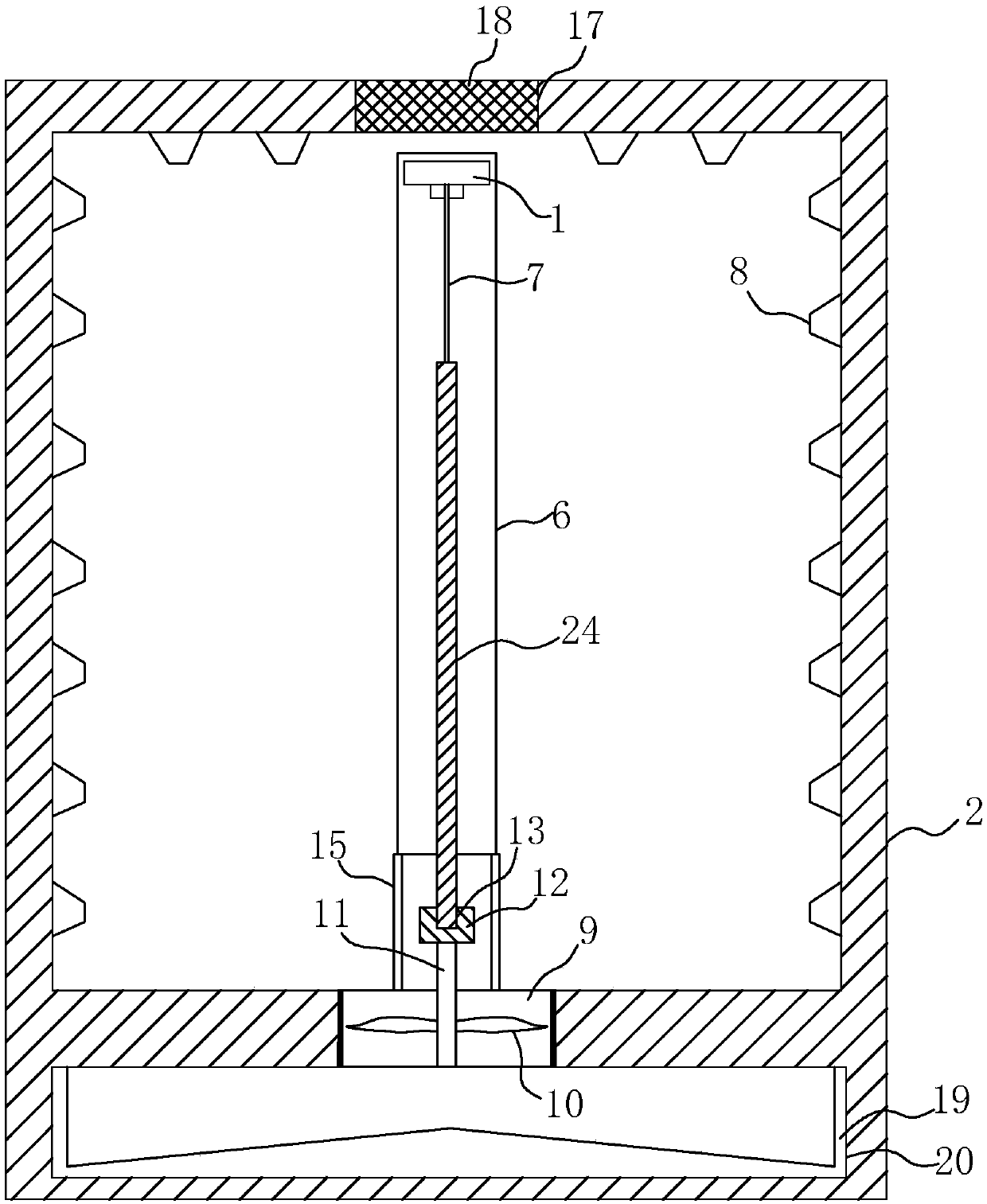

Tree pole/ telegraph pole whitewashing machine

ActiveCN103691592AGood spray effectAccelerateLiquid spraying apparatusUtility poleMechanical engineering

The invention discloses a tree pole / telegraph pole whitewashing machine which comprises a main locomotive; the whitewashing machine also comprises a stirrer, a liquid coating container, a pressure pump and a paint spraying device which are arranged on the main locomotive; the stirrer is connected with the liquid coating container; the liquid coating container is connected with the pressure pump; the pressure pump is connected with the paint spraying device; the paint spraying device is rotatably connected with the main locomotive; the paint spraying device is provided with a plurality of control cavities; a separating device is arranged between every two adjacent control cavities; the wall of each control cavity is provided with a plurality of spray heads; the paint spraying device is also provided with an adjustment device. After the tree pole / telegraph pole whitewashing machine is adopted, a tree pole or a telegraph pole can be sprayed by different color channels; the tree pole / telegraph pole whitewashing machine is good in spraying effect, rapid in speed and high in efficiency, and effectively solves the problems of high manual work load, high cost and the like of the original painting method.

Owner:铜陵汇泽科技信息咨询有限公司

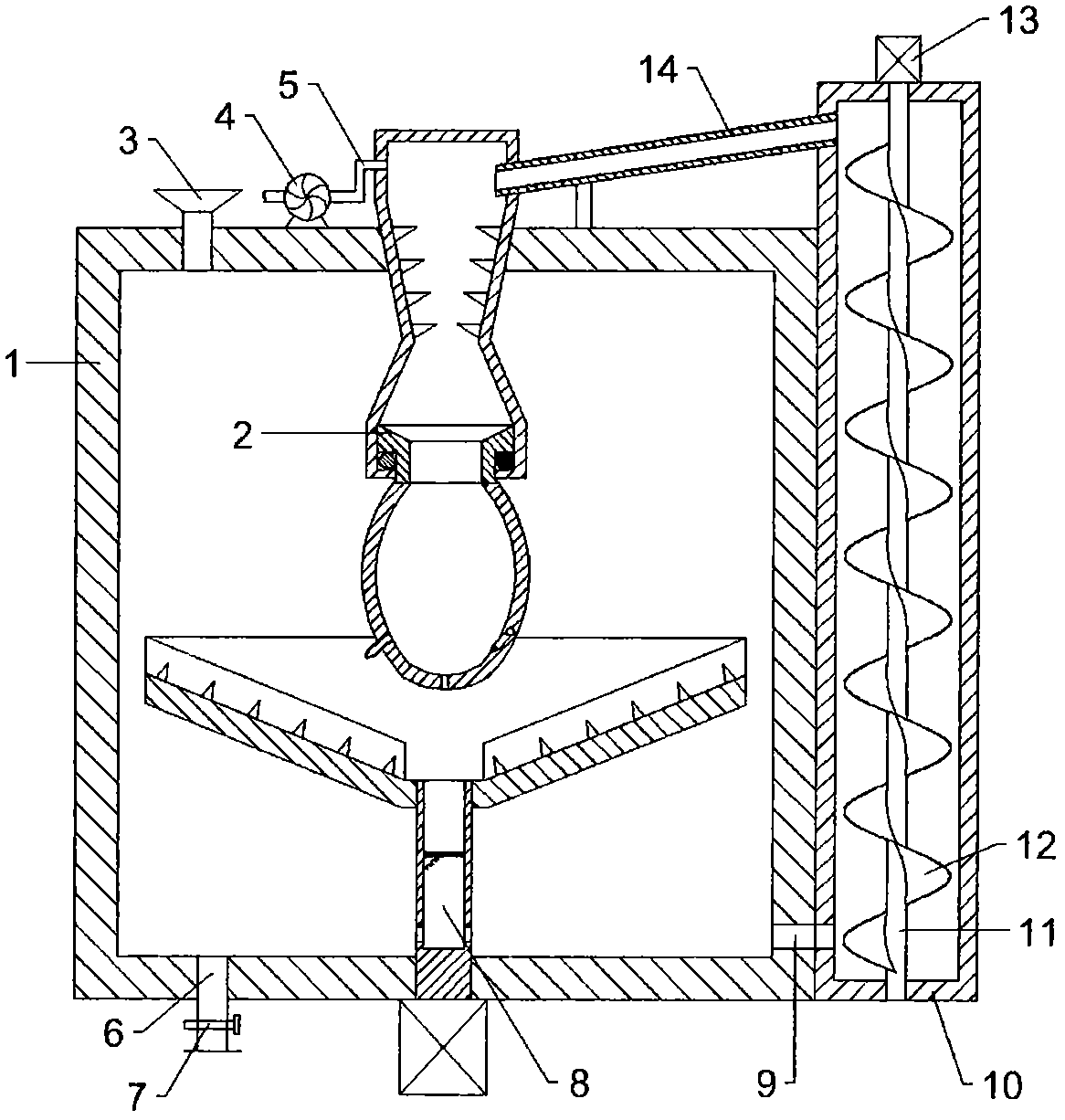

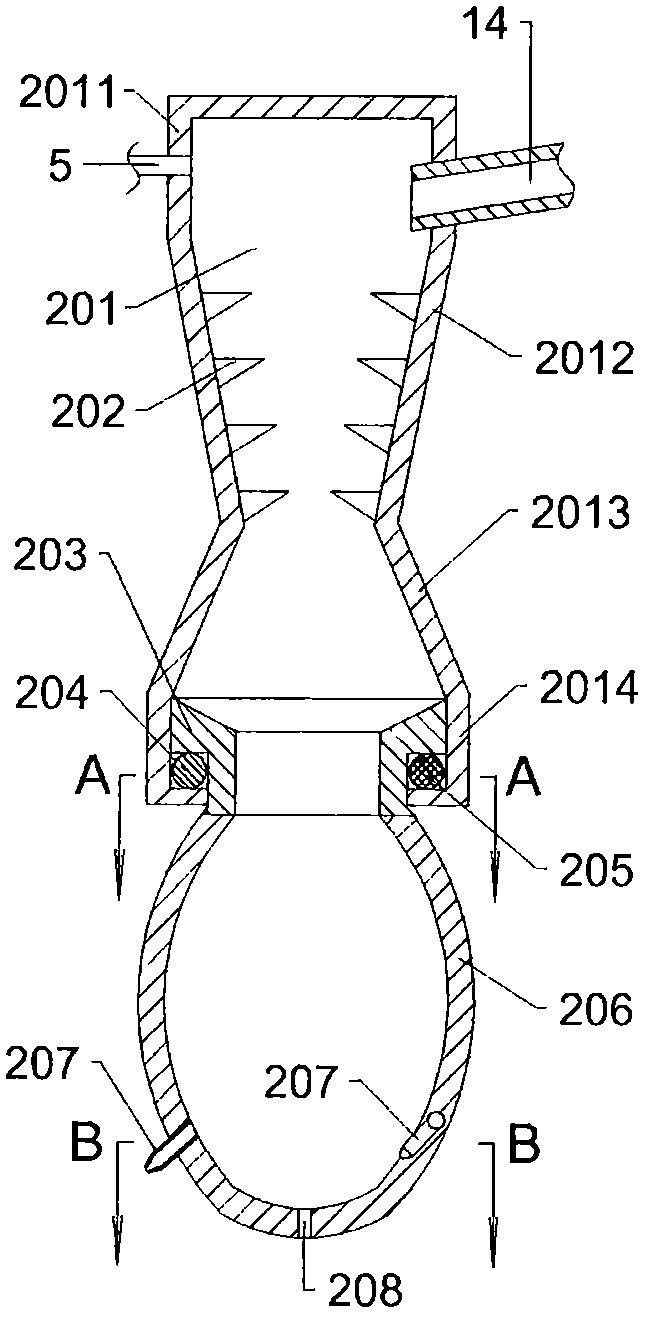

Quick beverage mixing equipment based on rotary jetting principle

InactiveCN108371893AReduce wear efficiencyExtended service lifeFlow mixersTransportation and packagingSteel ballEngineering

The invention provides quick beverage mixing equipment based on a rotary jetting principle. The quick beverage mixing equipment comprises a tank body, wherein a rotary jetting device is fixedly connected to the upper part of the tank body; the rotary jetting device comprises a jetting shell body; the jetting shell body sequentially comprises a first column section, a first circular truncated conesection, a second circular truncated cone section and a second column section from top to bottom; the first circular truncated cone section is in a shape with the big end up, and the second circular truncated cone section is in a shape with the small end up; the first column section, the first circular truncated cone section, the second circular truncated cone section and the second column sectionare sequentially and fixedly connected from top to bottom. The quick beverage mixing equipment disclosed by the invention has the following beneficial effects: firstly, in a process of flowing through the first circular truncated cone section, a flow speed of mixed liquid is accelerated as the diameter of the first circular truncated cone section reduces gradually, and a first turbulent flow protrusion can mix the mixed liquid; secondly, when the mixed liquid is sprayed out of a rotary ball, the rotary ball can rotate; the surface of a Teflon ball is smooth, so that the abrasion efficiency ofa steel ball is effectively reduced, and service life is prolonged.

Owner:何小平

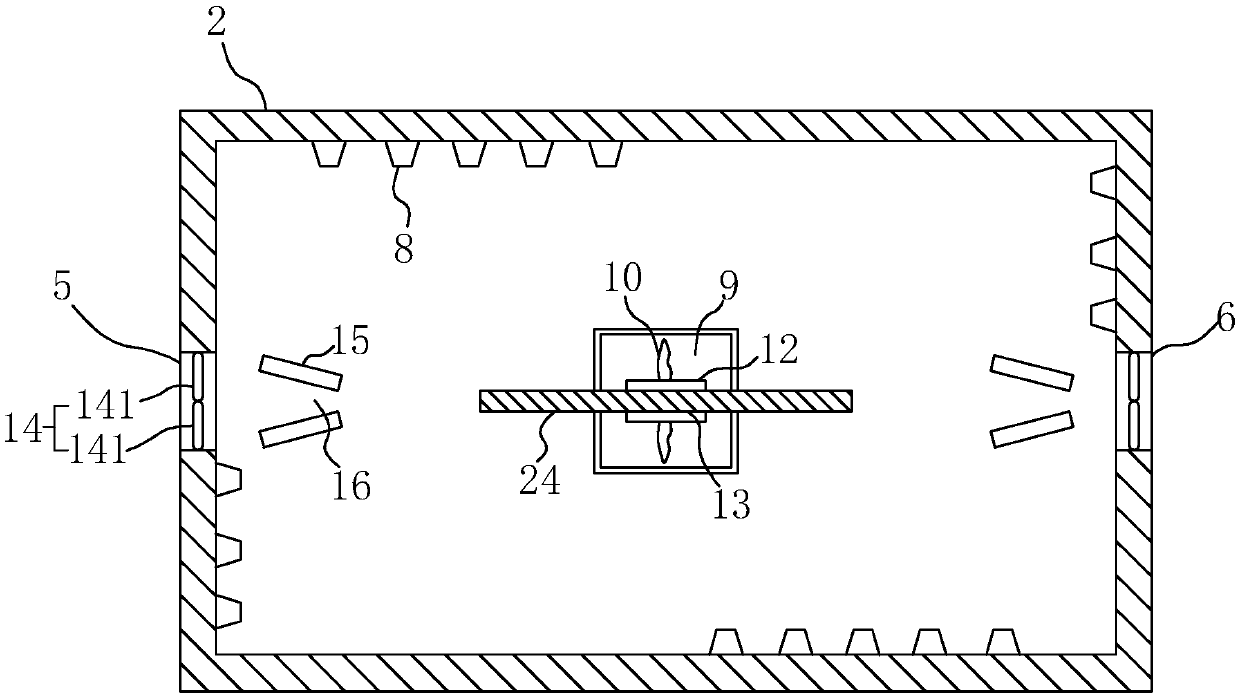

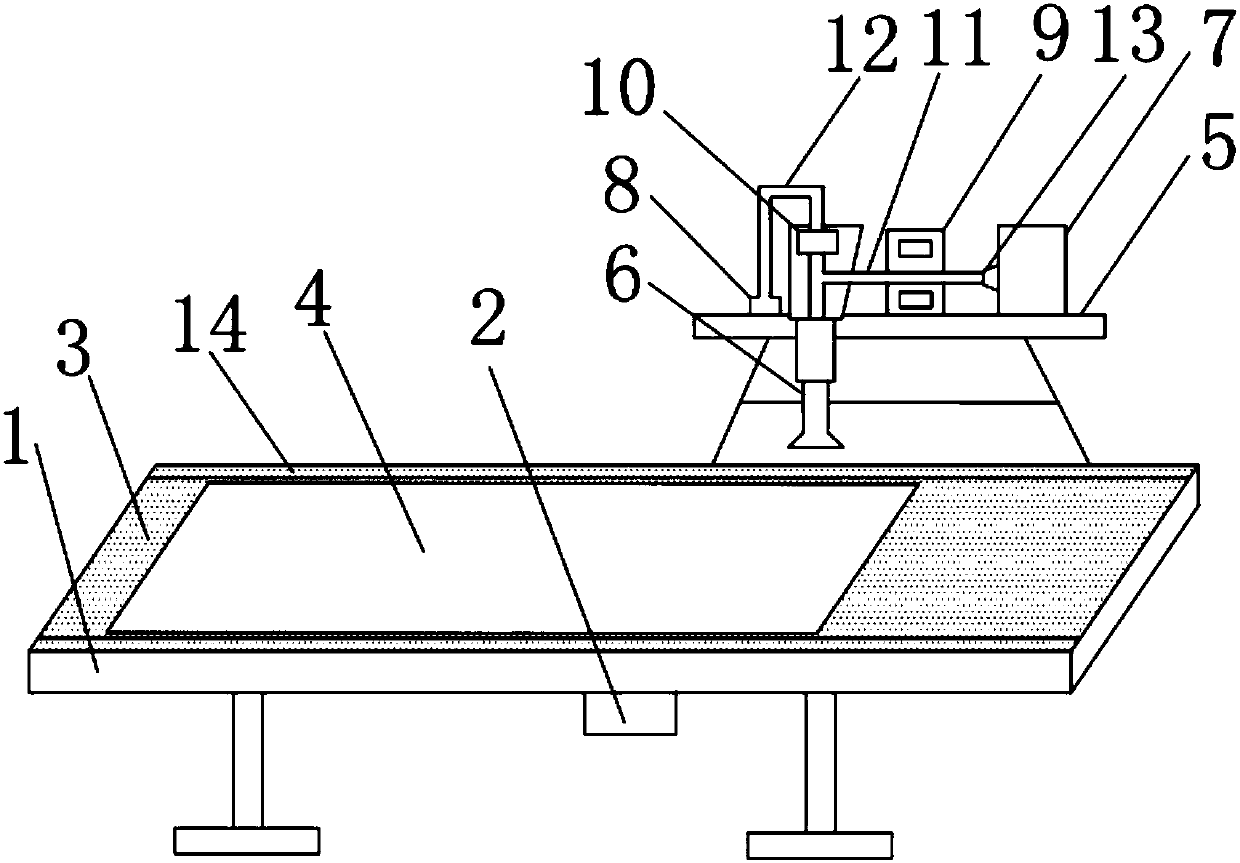

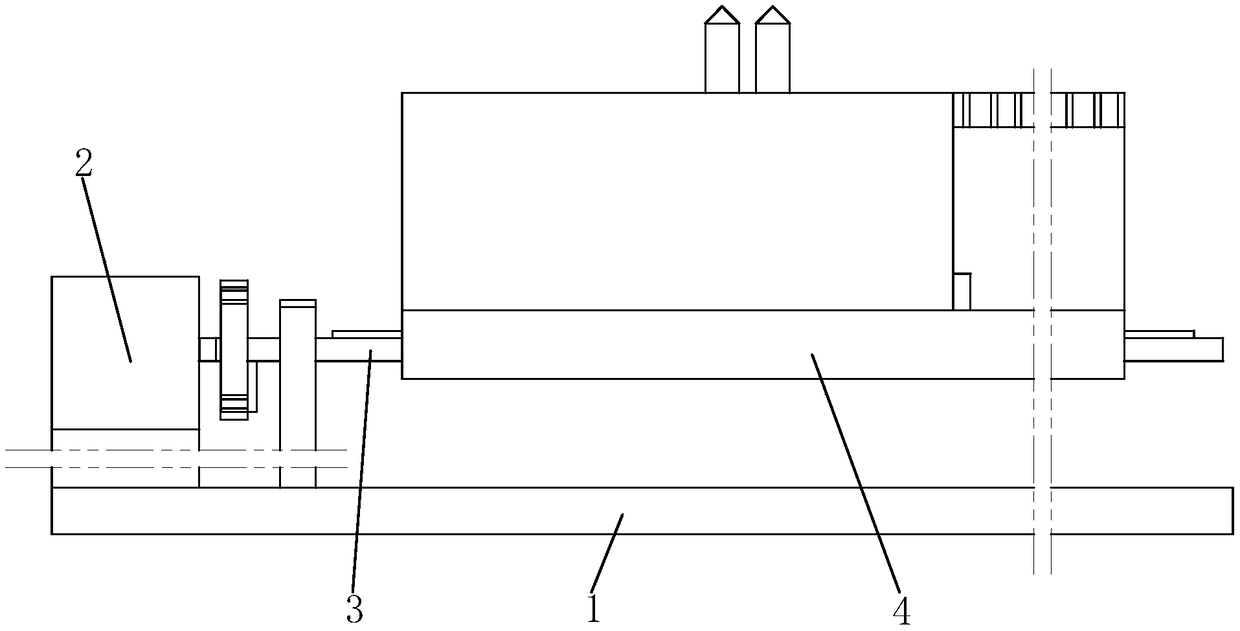

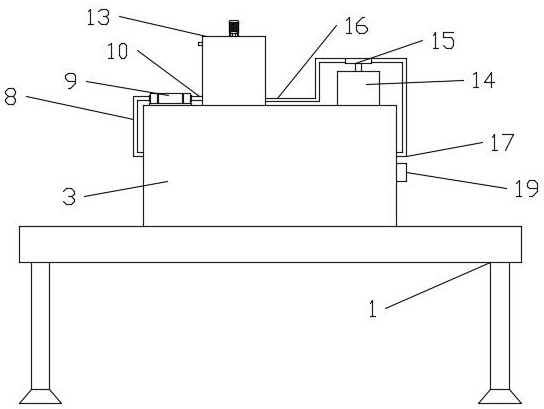

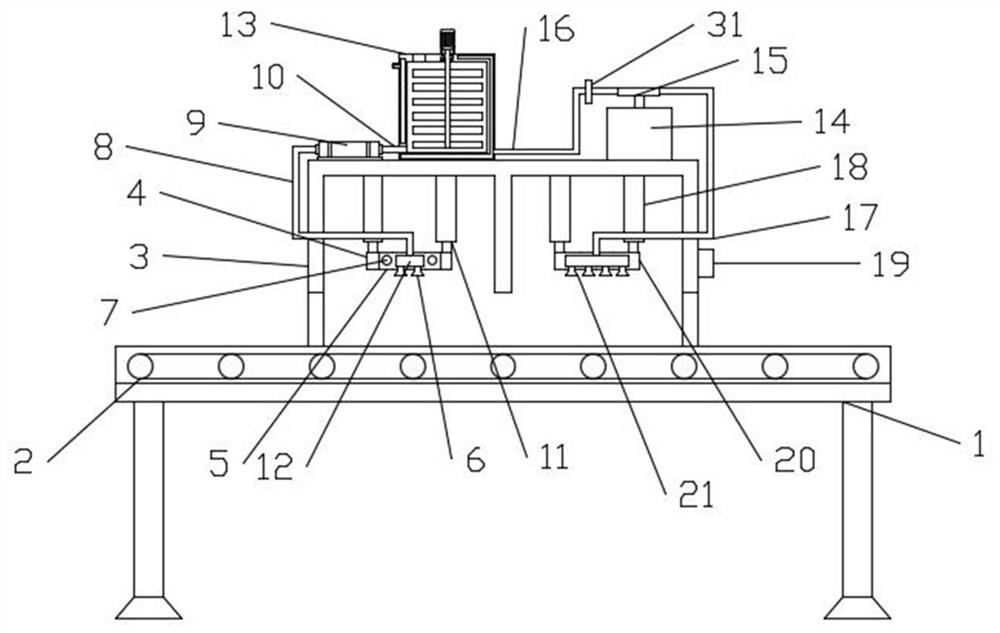

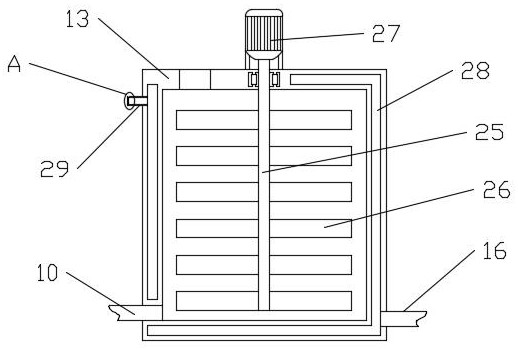

Device for automatically measuring and inkjet-marking steel tube

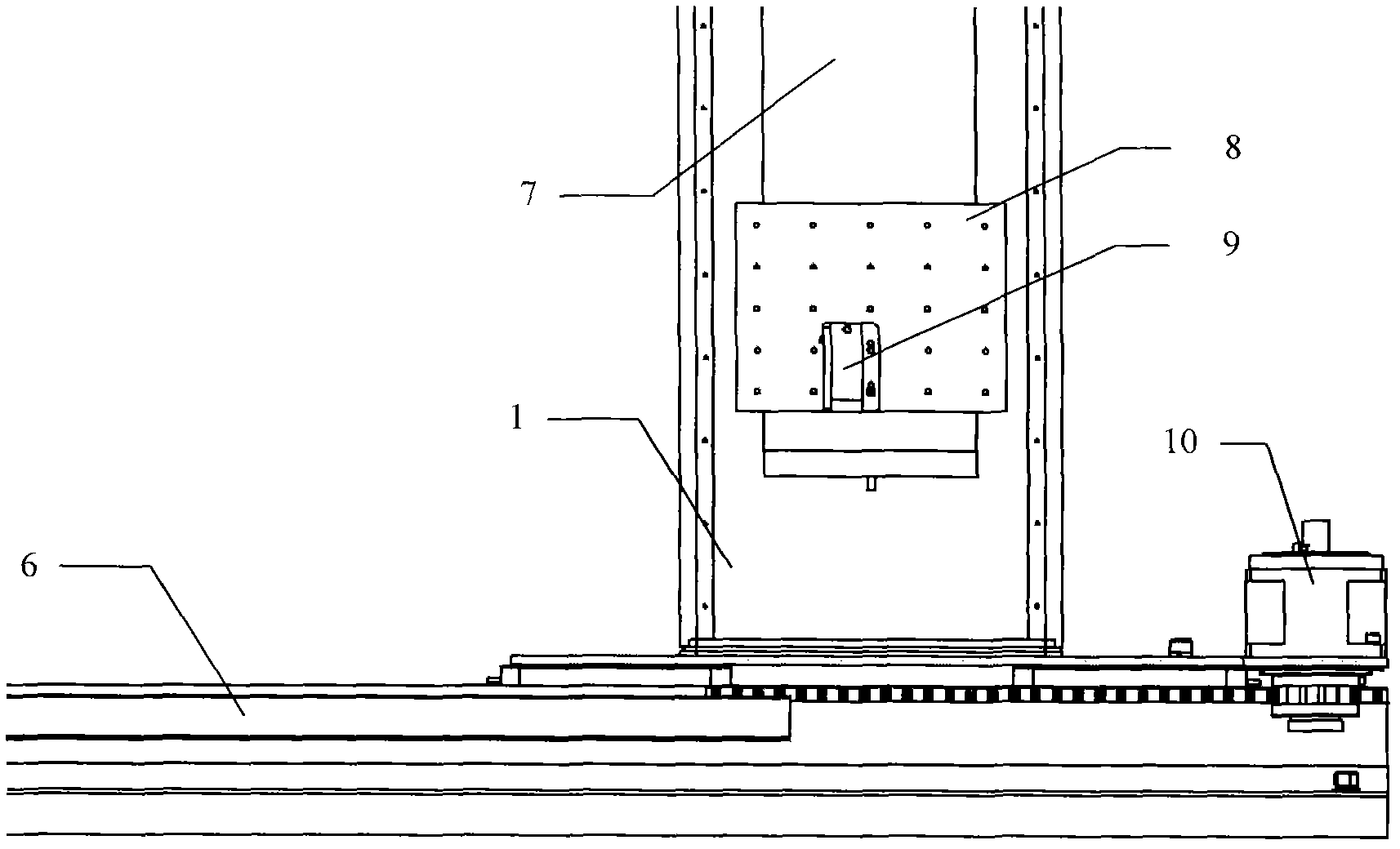

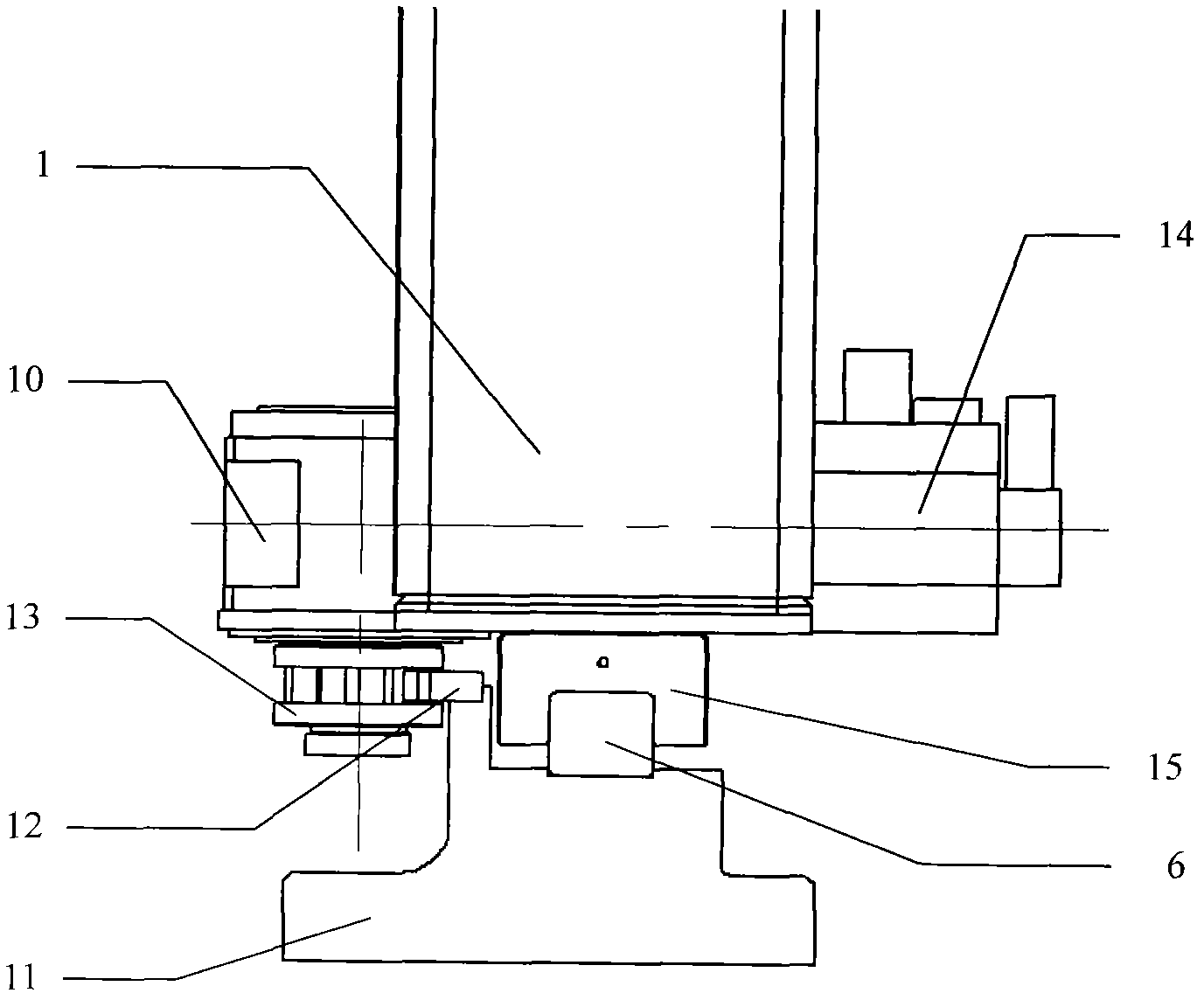

ActiveCN102489547AReduce labor intensityImprove reliabilityMetal working apparatusDrive motorReducer

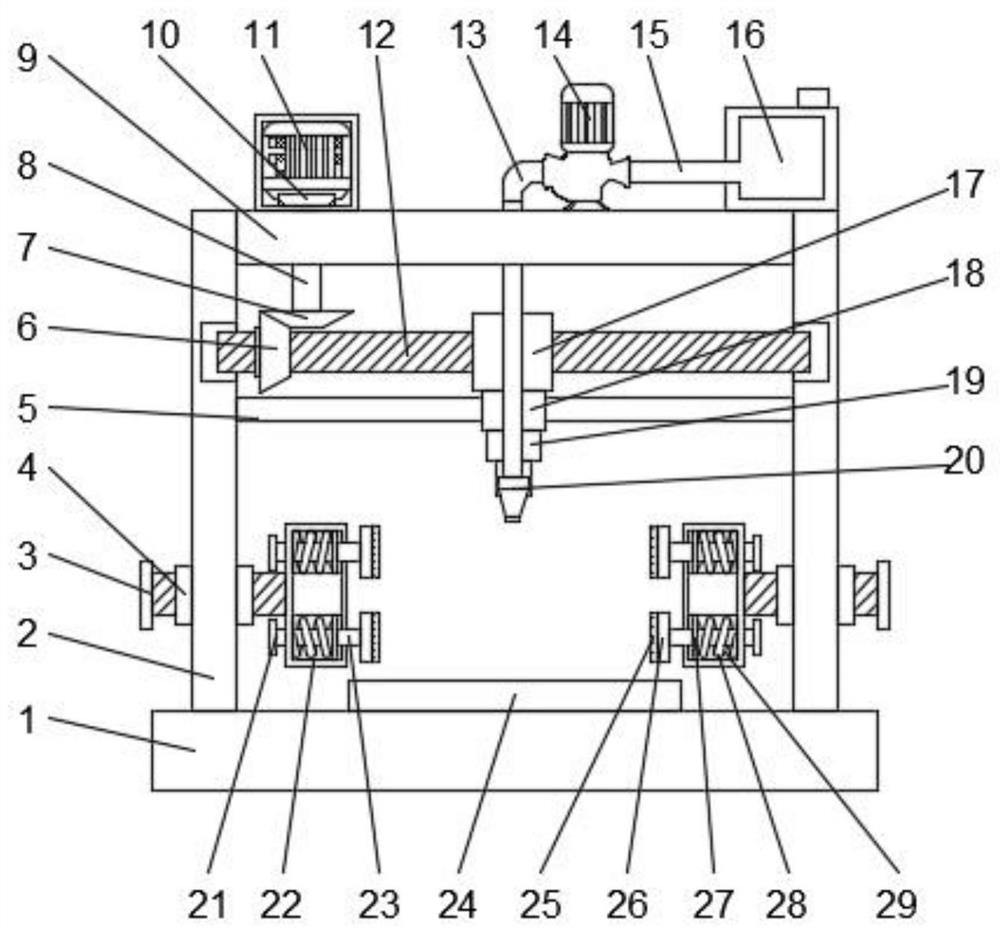

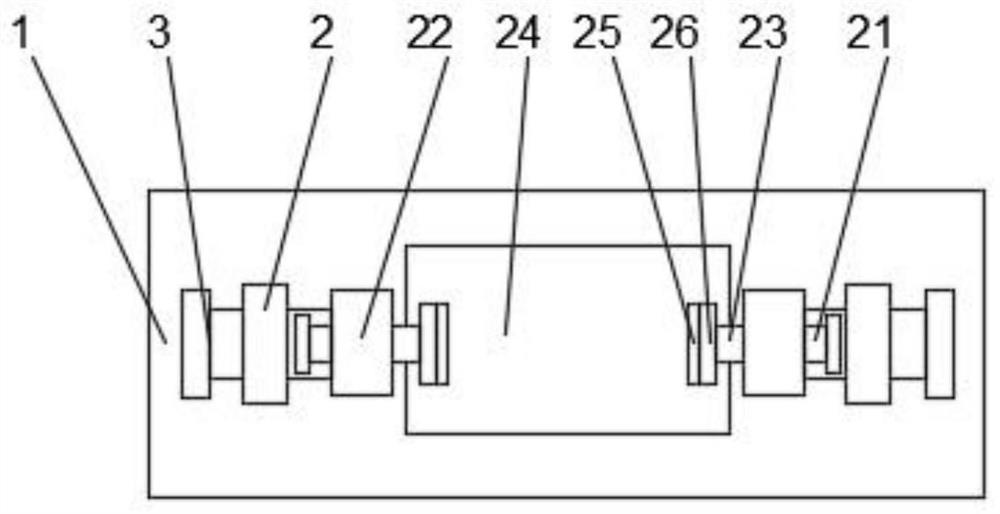

The invention relates to a device for automatically measuring and inkjet-marking a steel tube, belonging to detecting instruments. The device is characterized in that: guide rails are arranged in parallel on a base; a rack and a guide rail sliding block are arranged on the guide rails; a driving motor and a speed reducer are arranged on the guide rail sliding block; a gear engaged with the rack is arranged on a shaft of the speed reducer; vertical columns of a portal frame are provided with a first sliding block; a second sliding block is arranged on a cross beam; an inkjet-marking mobile table is vertically arranged on the second sliding block; an inkjet-marking head and an ink box are arranged on the inkjet-marking mobile table; the ink box is connected with the inkjet-marking head; a sensor mobile table is arranged on the portal frame; a sensor is arranged on the sensor mobile table; the driving motors are arranged on the inkjet-marking mobile table and the sensor mobile table; and the driving motors, the sensor and the inkjet-marking head are connected with an electric control system through cables. The device for automatically measuring and inkjet-marking the steel tube can be used for detecting the length, the diameter, the linearity and the roundness of the steel tube and inkjet-marking the steel tube, and has the advantages of high reliability, high detection precision, good inkjet-marking effect and reduced labor intensity.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

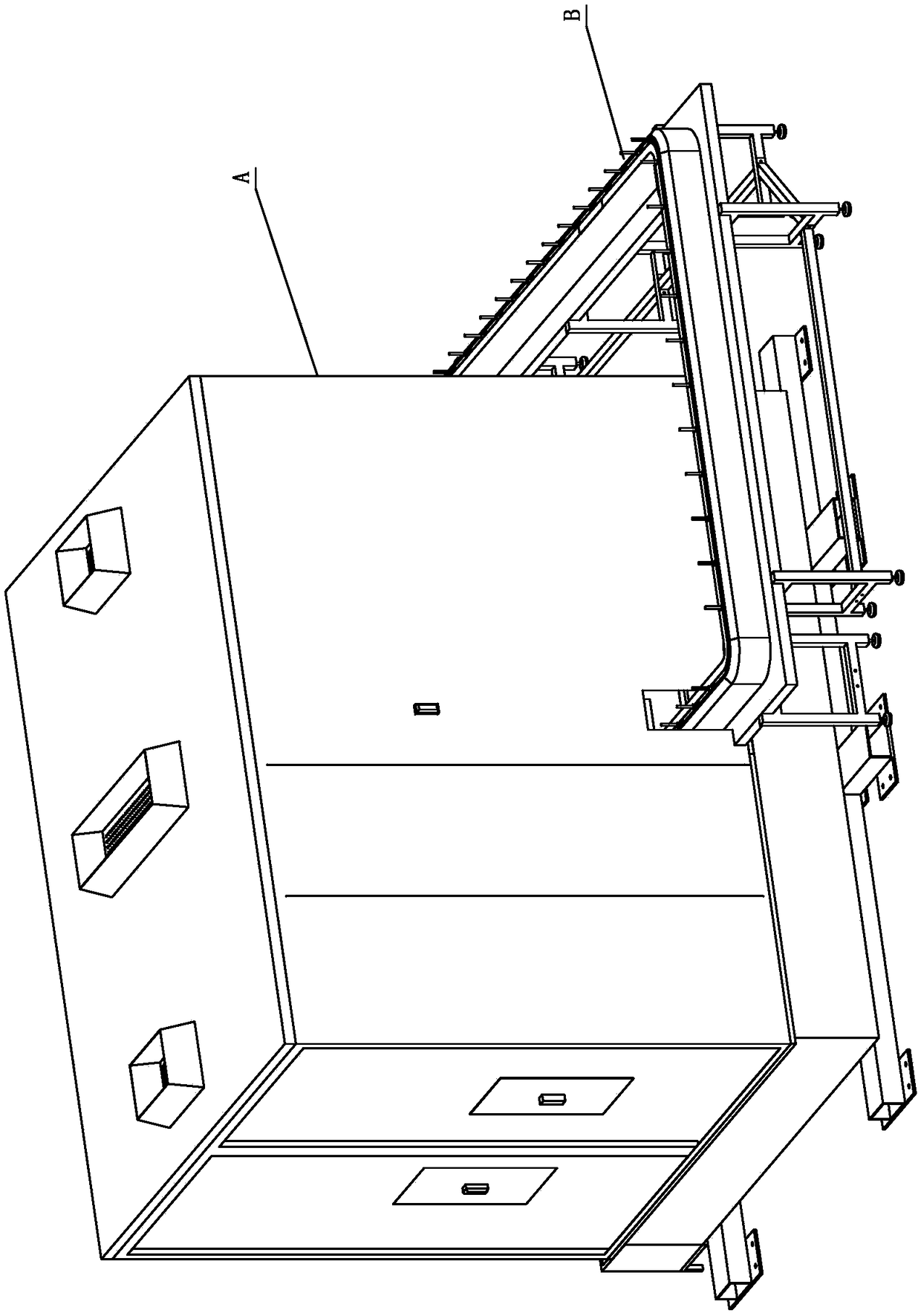

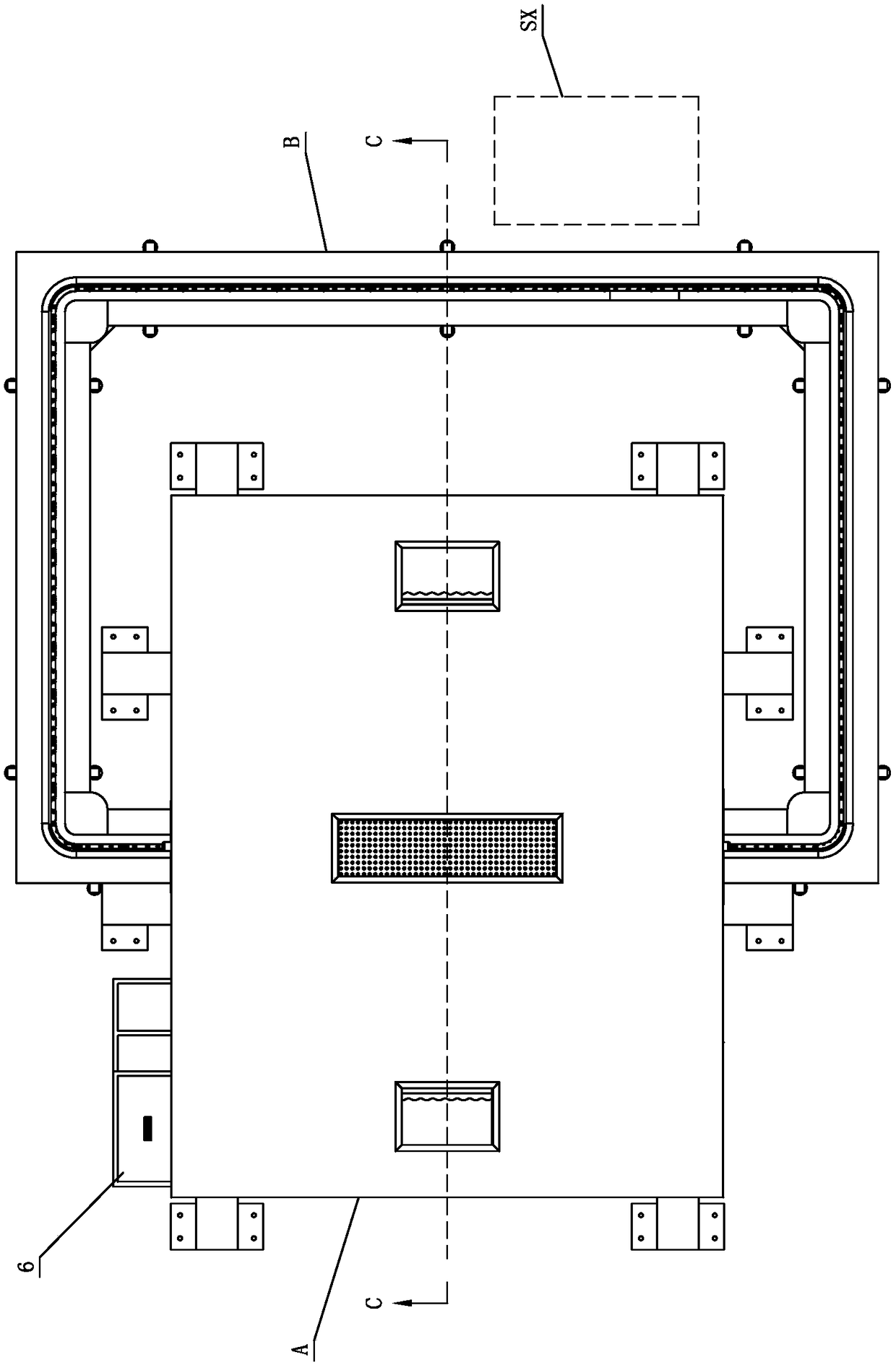

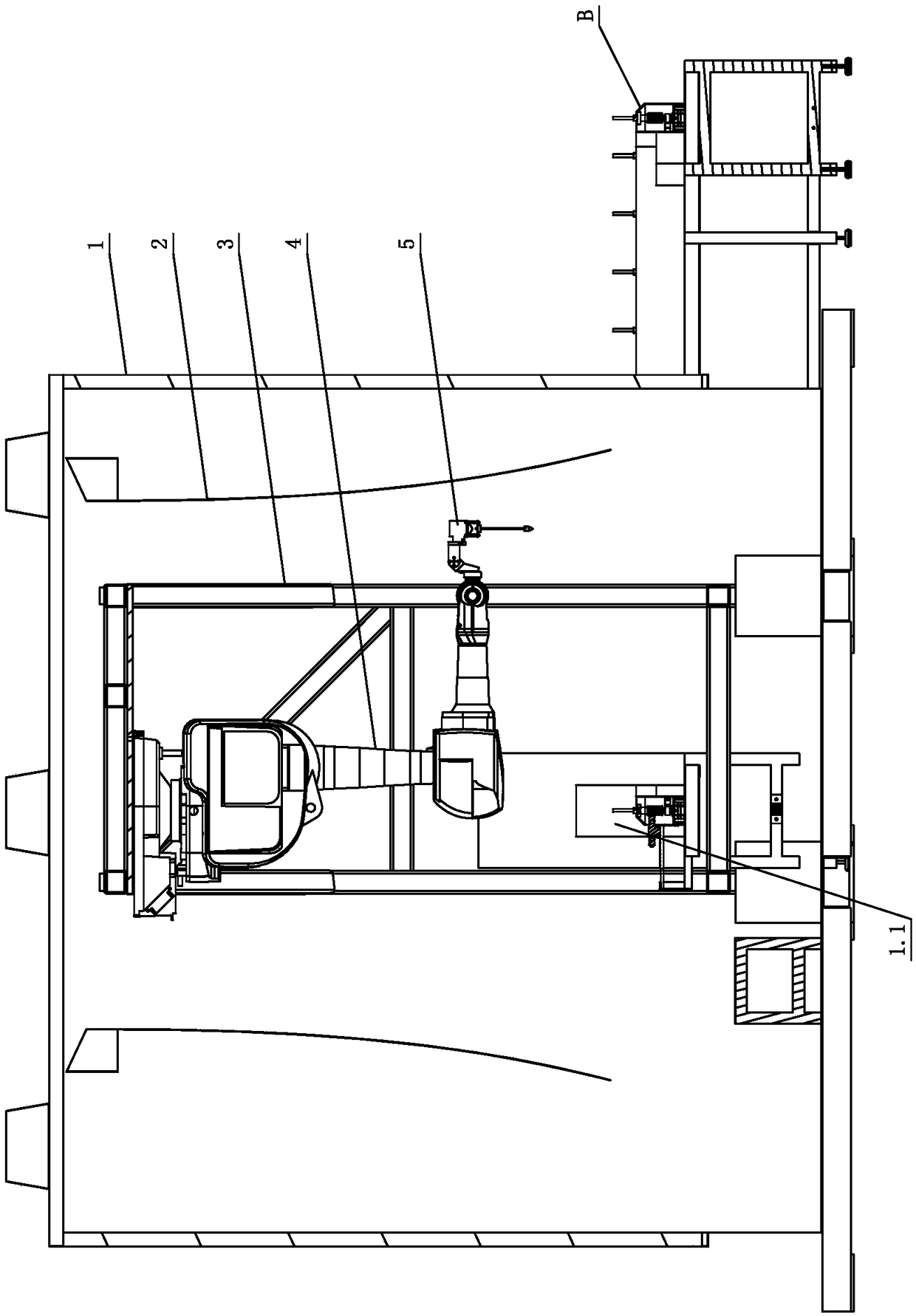

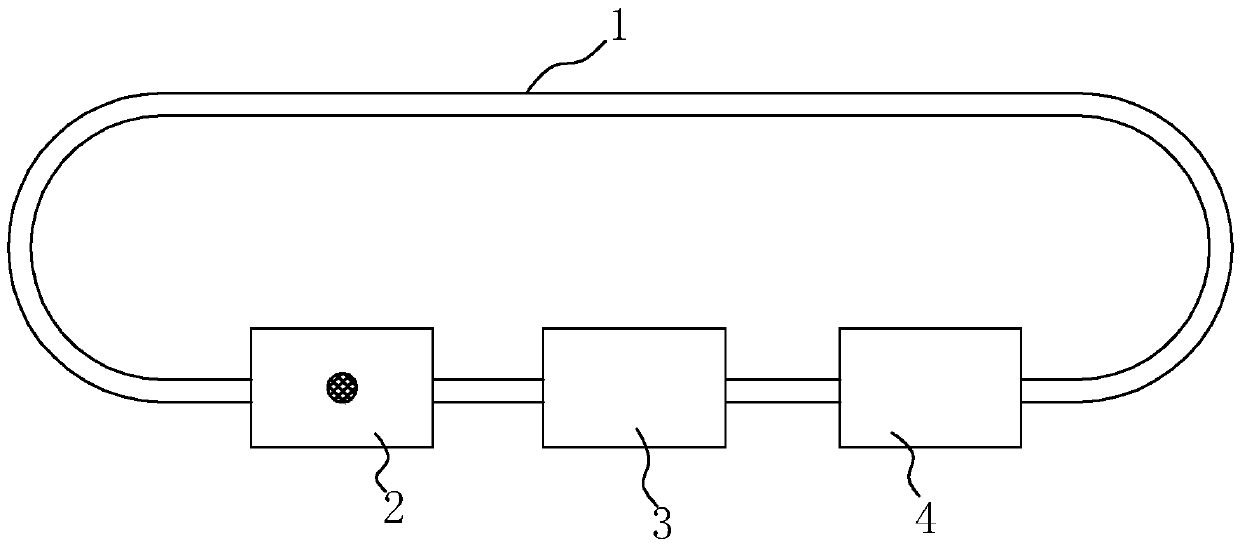

Automatic spraying line for golf club head

The invention relates to an automatic spraying line for a golf club head. The automatic spraying line comprises spraying equipment and conveying equipment, wherein at least one spraying equipment is arranged along the conveying equipment; the conveying equipment is annually arranged and penetrates through at least one spraying equipment; the spraying equipment comprises a water curtain cabinet, asupporting portal frame and a multi-shaft robot, the supporting portal frame and the multi-shaft robot are covered with the water curtain cabinet, the multi-shaft robot is arranged on the supporting portal frame in an upside down manner, and a spraying gun is arranged on the multi-shaft robot; and the conveying equipment comprises a conveying mechanism and a plurality of club head tool assemblies,the conveying mechanism comprises a conveying strip and a conveying driving assembly, the conveying belt is annularly arranged, the conveying driving assembly is used for driving the conveying stripto work, the conveying strip penetrates through the water curtain cabinet through a conveying opening in the water curtain cabinet, the multi-shaft robot is located above the conveying strip which penetrates through the inner side of the water curtain cabinet, and the club head tool assemblies are distributed on the conveying strip. The automatic spraying line is simple and reasonable in structure, high in degree of automation and spraying efficiency, good in spraying quality, high in finished rate and applicable to multiple spraying procedures, and the clean working environment is guaranteed.

Owner:GUANGDONG LXD ROBOTICS CO LTD

Dual-drive mixing fine water mist fire-extinguishing system

InactiveCN104906722AGood spray effectCause secondary damageFire rescueBoring toolsWater storage tankEngineering

The invention relates to a dual-drive mixing fine water mist fire-extinguishing system, which comprises an external steel cylinder, liquid-state carbon dioxide, a magnetic induction generator, an electric starter, a steel cylinder ejection switch, a gas pipeline, a water level probe, a fire extinguishing agent storage tank, a fire extinguishing agent, a built-in fire extinguishing agent ejection pipeline, a water storage tank spraying nozzle switch, a pressure limiting protection valve, a base bracket, a fastening snapping ring, an external fire extinguishing agent ejection pipeline and a fine water mist spraying nozzle. According to the dual-drive mixing fine water mist fire-extinguishing system of the present invention, the high temperature gas generated after liquid-state carbon dioxide gasification is adopted as the power source, the liquid fine water mist and the gas carbon dioxide are adopted as the fire extinguishing medias, and the two fire extinguishing ways such as the gas fire extinguishing and the fine water mist fire extinguishing are used during the fire extinguishing, such that the defects that the gas fire extinguishing requires the sealed space and the fine water mist fire extinguishing can not bypass the obstructions and directly contact the combustion zone is overcome to a certain extent, the advantages of the two fire extinguishing ways are completely provided, and the defects of the two fire extinguishing ways are overcome, wherein the most significant characteristic such as the complete advantage providing and the defect overcome of the system of the present invention is distinguished from the previous single fire extinguishing way.

Owner:马晖

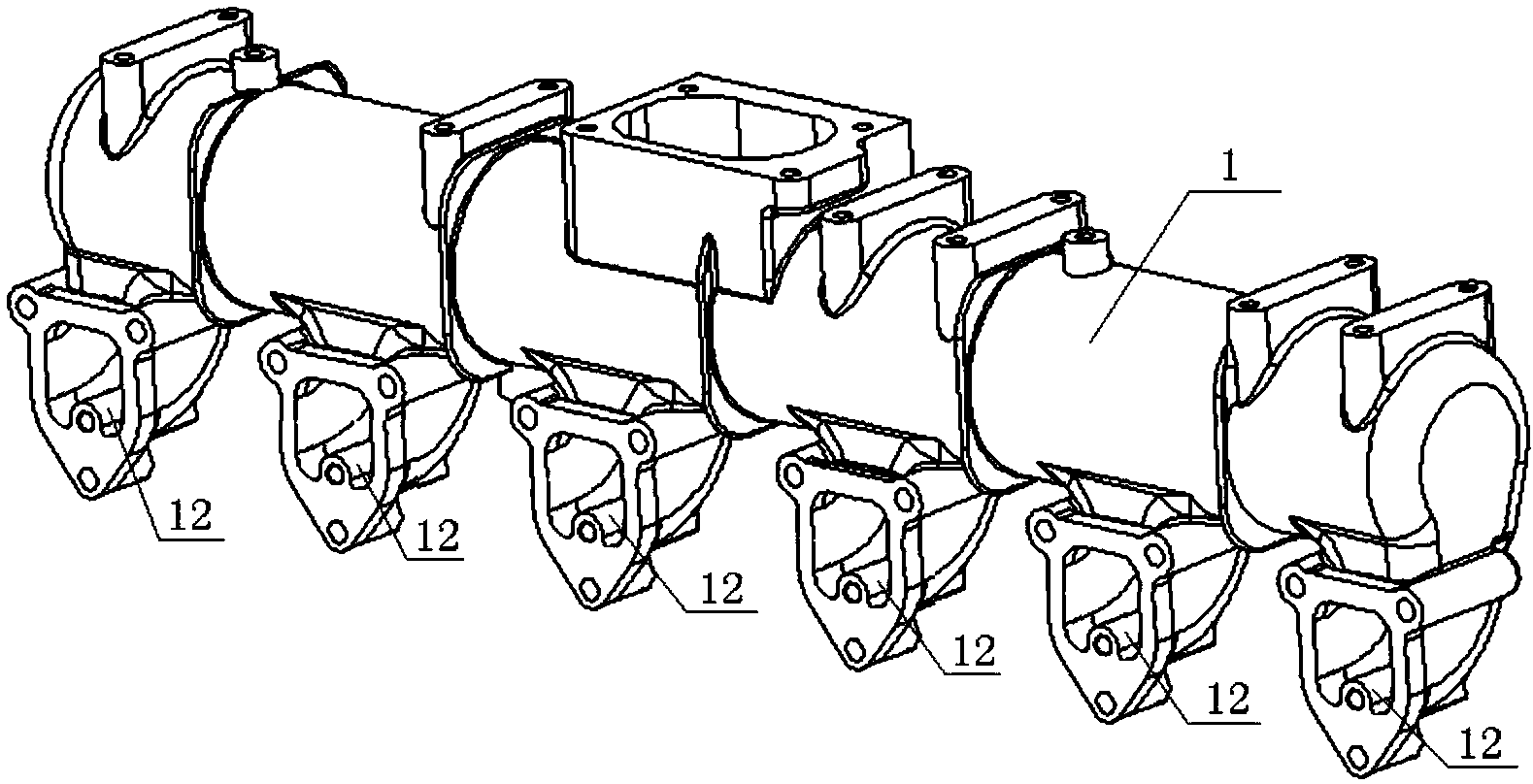

Multi-point injection intake pipe of gas engine

ActiveCN104295418AReduce the risk of fire and explosionInhibition retentionInternal combustion piston enginesFuel supply apparatusControl valvesInlet manifold

The invention discloses a multi-point injection intake pipe of a gas engine. The multi-point injection intake pipe of the gas engine comprises an intake pipe body and a fuel gas spraying pipe. The intake pipe body is provided with an intake manifold which can be communicated with an intake channel of a cylinder cover of the gas engine. A fuel gas channel is integrally cast on the inner side of the bottom pipe wall of the intake manifold. The outlet of the fuel gas channel is located in the intake manifold. The inlet of the fuel gas channel is used for being connected with a fuel gas control valve of the gas engine. One end of the fuel gas spraying pipe is connected with the outlet of the fuel gas channel, and the other end of the fuel gas spraying pipe is used for stretching into the intake channel of the cylinder cover of the gas engine. According to the multi-point injection intake pipe of the gas engine, fuel gas can be directly sprayed into the gas channels of all cylinders, the amount of residual fuel gas in an intake main pipe can be reduced to the maximum extent, generation of flame back and explosion is avoided, and the operation safety of the gas engine is improved greatly.

Owner:广西玉柴船电动力有限公司

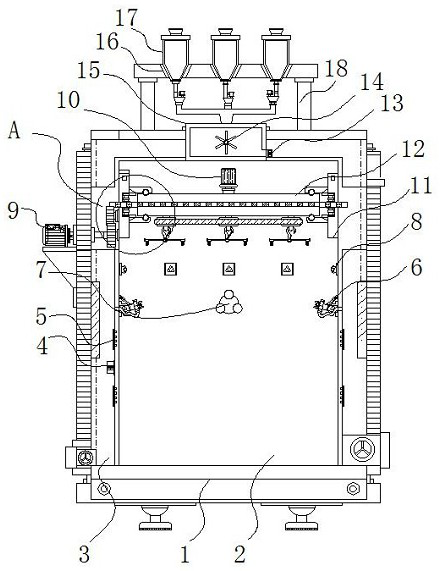

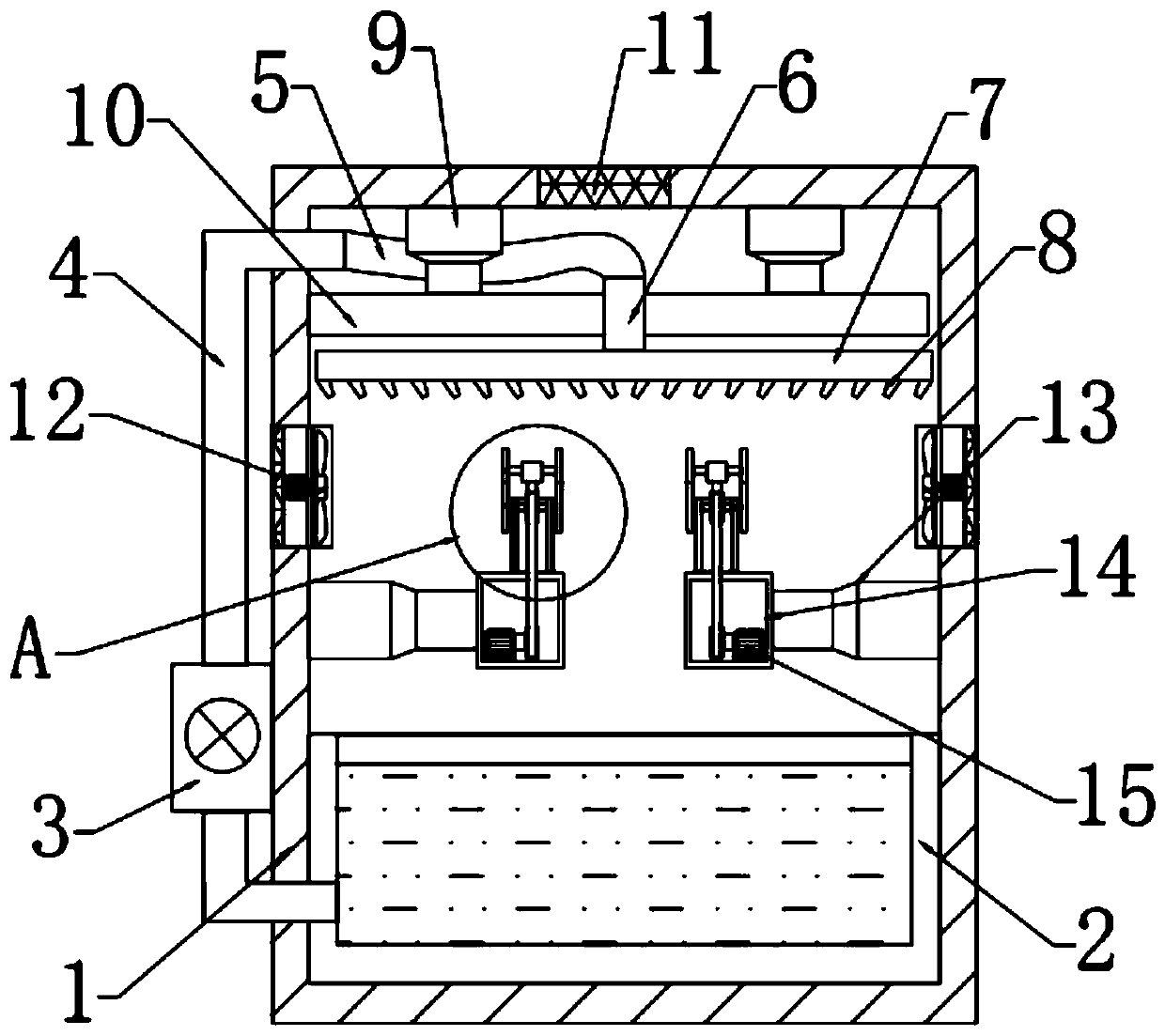

Regular disinfection and maintenance device for medical protective clothing

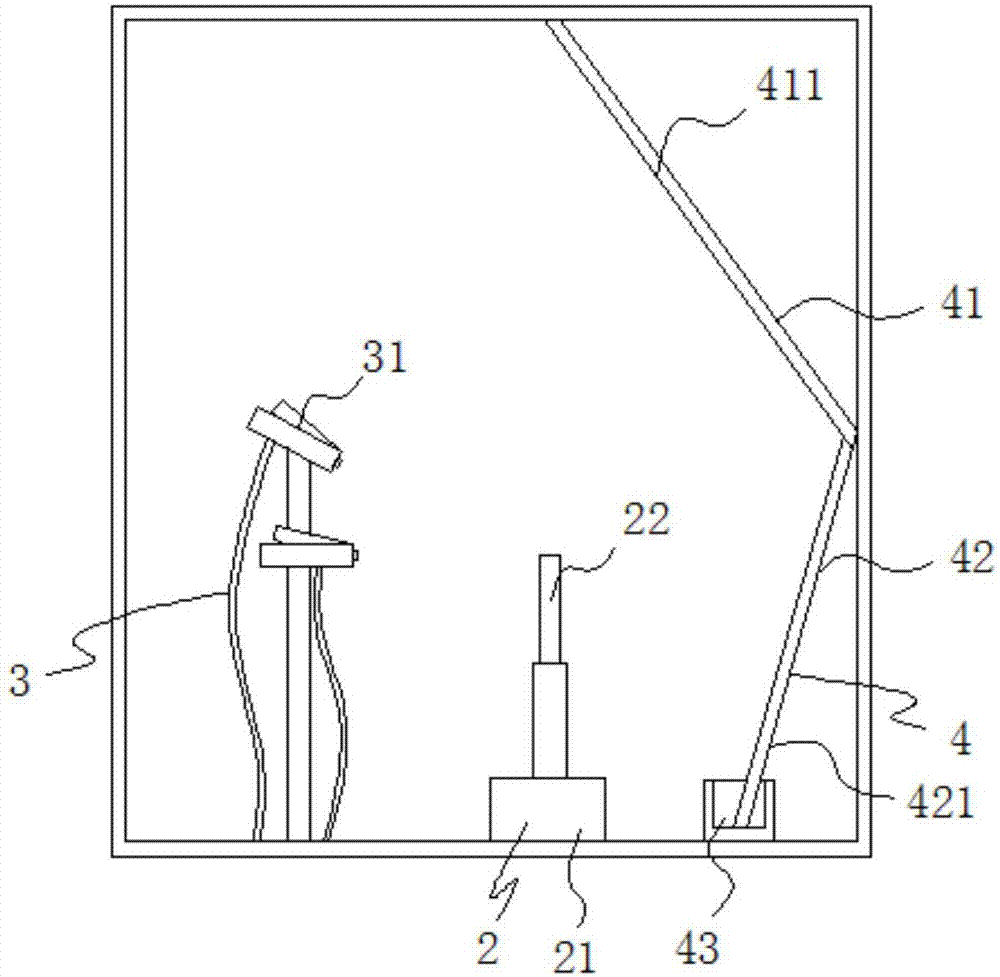

InactiveCN111729103AThorough cleaning and disinfectionGood cleaning and disinfection effectSpraying apparatusLavatory sanitoryDrive wheelEngineering

The invention discloses a regular disinfection and maintenance device for medical protective clothing. The regular disinfection and maintenance device specifically comprises a shell, a disinfection bin, a water cavity, a turntable and a driven wheel, wherein one end of the shell is hinged with a sealing door; a control panel is fixed on the shell above the sealing door; the disinfection bin is fixed inside the shell; the water cavity is formed between the disinfection bin and the shell; a temperature sensor is arranged on one side inside the water cavity; and heating wires are fixed on inner walls of the water cavity above and below the temperature sensor. According to the regular disinfection and maintenance device for medical protective clothing disclosed by the invention, due to the arrangement of a micro hydraulic telescopic rod, the micro hydraulic telescopic rod contracts to drive an atomizing nozzle to rotate upwards, and the micro hydraulic telescopic rod extends to drive the atomizing nozzle to rotate downwards, so that the spray-washing range of the atomizing nozzle can just cover one piece of protective clothing, the spray-washing effect is excellent, and waste of washing liquid is difficultly caused.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

Sprinkling equipment for built bridge

InactiveCN107100080AThe nozzle is conveniently locatedGood spray effectRoad cleaningBridge erection/assemblyEngineering

Owner:刘依桐

Spraying assembly line

ActiveCN107321527AImprove work efficiencyGood spray effectLiquid surface applicatorsCleaning using toolsLipstickAssembly line

The invention discloses a spraying assembly line which comprises a transferring device used for transferring materials, a clearing unit, a height adjusting unit, a dedusting unit, a spraying unit and a baking unit, wherein the clearing unit, the height adjusting unit, the dedusting unit, the spraying unit and the baking unit are sequentially distributed in the transferring direction of the transferring device. The transferring device comprises a conveyer belt moving forwards and a plurality of supporting pieces arranged on the conveyer belt at intervals and used for storing the materials. The dedusting unit comprises at least one a water-washing oil-removing part arranged on one side of the conveyer belt and used for spraying water mist to the materials and a dedusting part used for spraying gas to the materials. The spraying unit comprises at least two spraying heads arrange on one side of the conveyer belt and a recovering device used for recycling redundant coating. The recovering device is arranged on the opposite side of a spraying device in a corresponding mode. According to the spraying assembly line, full automation operation for spraying of lipstick tubes can be achieved, the working efficiency is high, the spraying effect is good, and after the materials are formed, the appearance aesthetic degree is high.

Owner:ZHEJIANG SHIHONG IND CO LTD

Roof paint spraying equipment

PendingCN110821105AAvoid depositionGood spray effectSpraying apparatusBuilding constructionsStructural engineeringSprayer

The invention discloses roof paint spraying equipment, and relates to the technical field of paint spraying. The roof paint spraying equipment comprises a vehicle body. A lifting device is arranged atthe top end of the vehicle body, a bottom plate is arranged at the top end of the lifting device, first sliding grooves are symmetrically formed in the portions, located on the two sides of a raw material barrel, of the bottom end of the bottom plate, the bottom plate is slidingly connected with sliding plates through the first sliding grooves, supports are arranged at the top ends of the slidingplates, a top plate is arranged at the top ends of the supports, a second sliding groove is formed in the top end of the top plate, supporting plates are arranged at the top end of the top plate, a threaded rod is arranged on the supporting plates in a penetrating manner, a sliding sprayer is in threaded connection to the threaded rod, a nozzle is arranged at the top end of the sliding sprayer, and a flexible blocking cover is arranged on the portion, located on the periphery of the nozzle, around the top end of the sliding sprayer. Spraying can be adjusted in different directions such as thefront-and-back direction, the left-and-right direction and the up-and-down direction, through the arrangement of the flexible blocking cover, falling paint can be intercepted and collected, the problems that as the paint falls, the body of an operator is endangered, and the ground is contaminated are solved, and higher health is achieved.

Owner:程晨

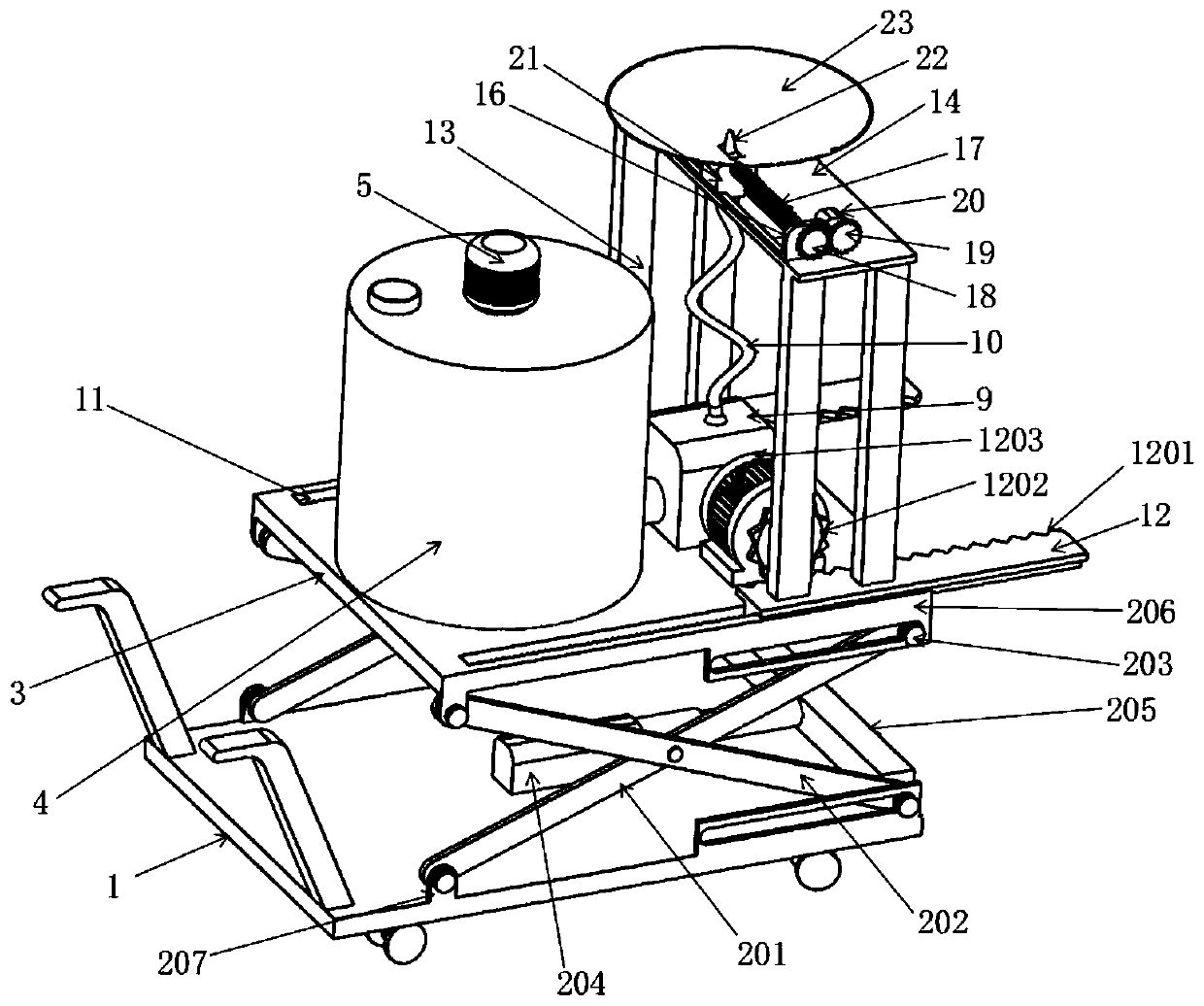

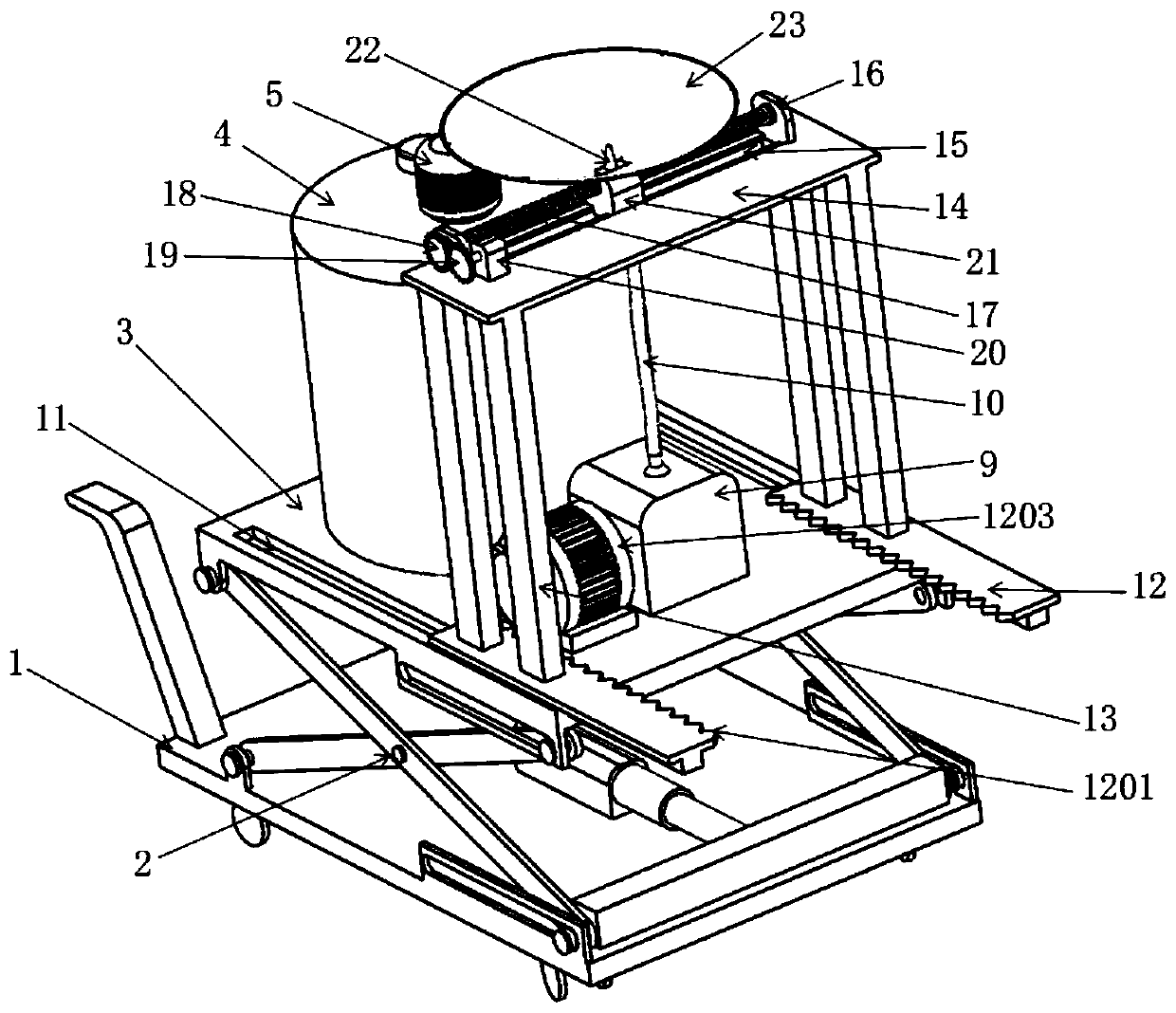

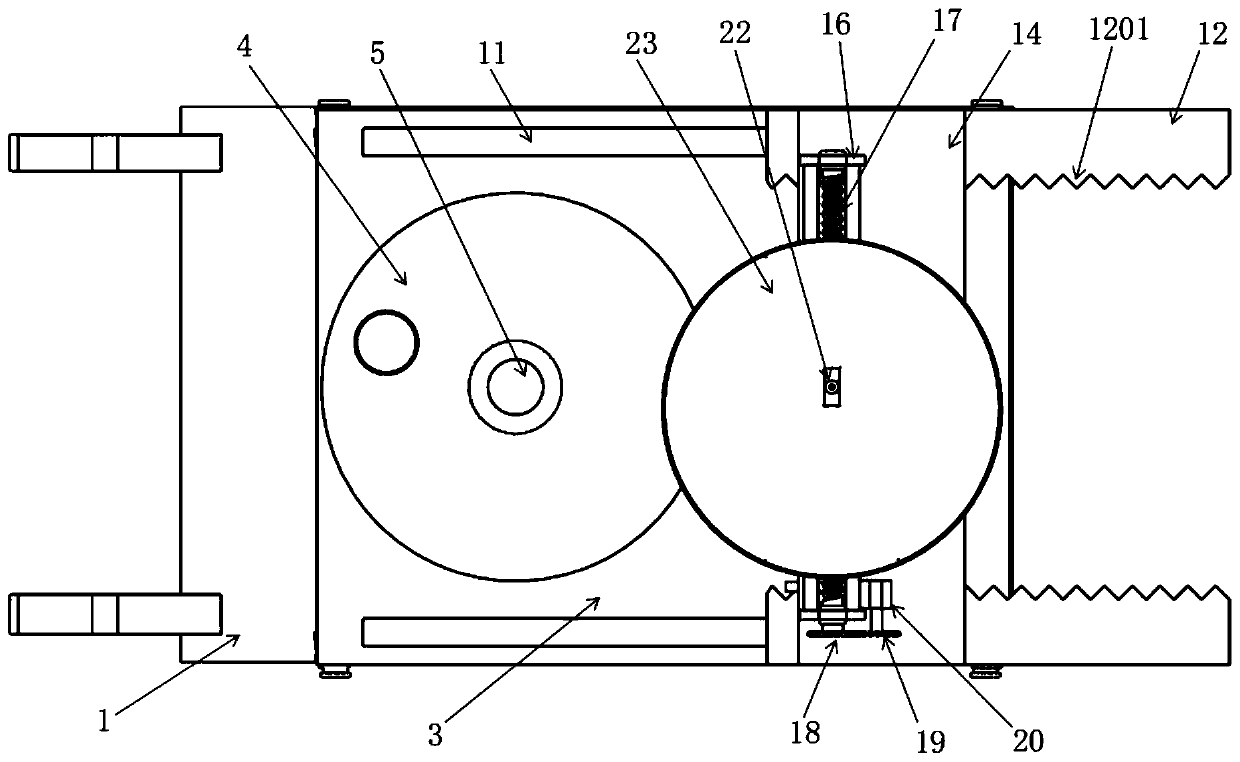

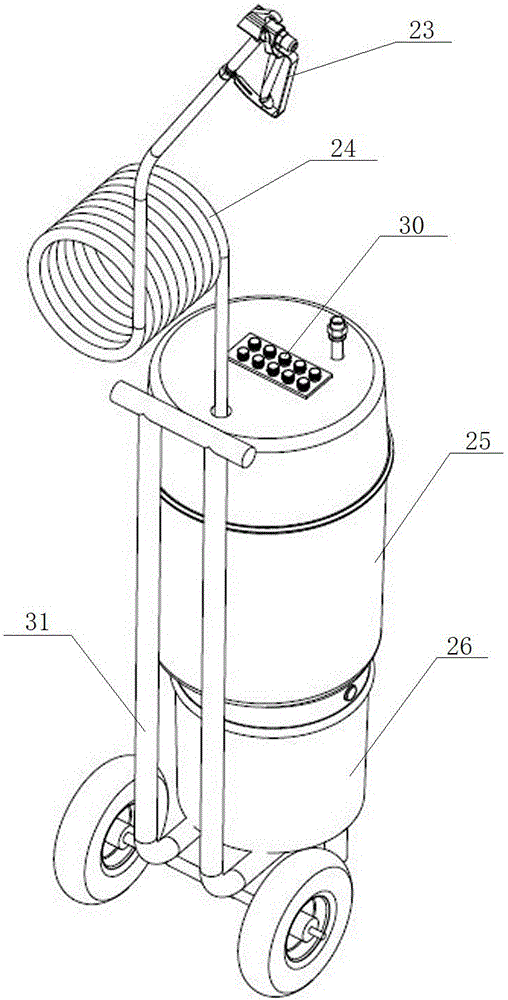

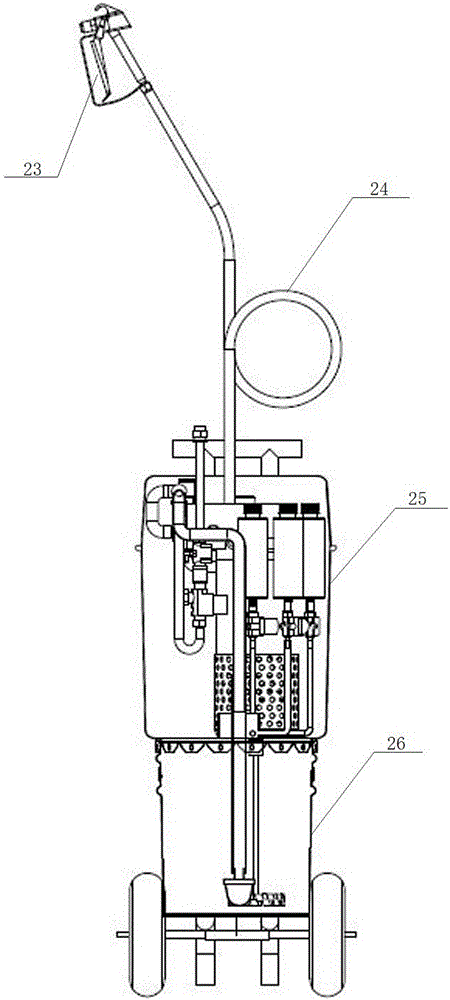

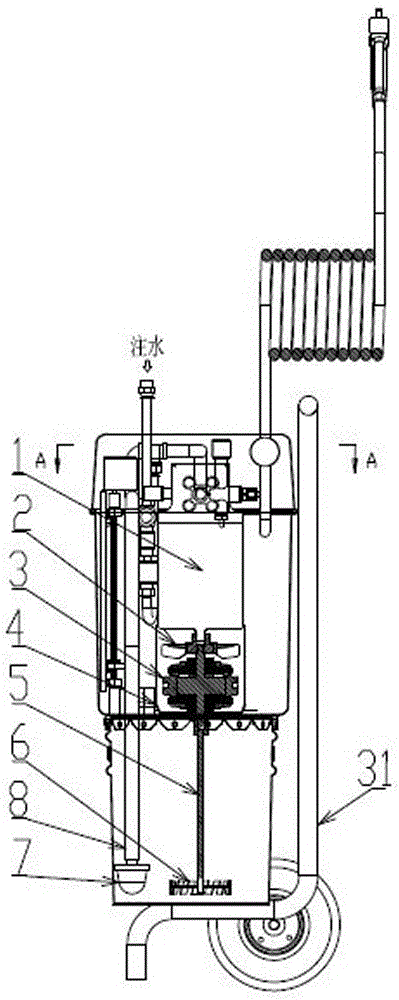

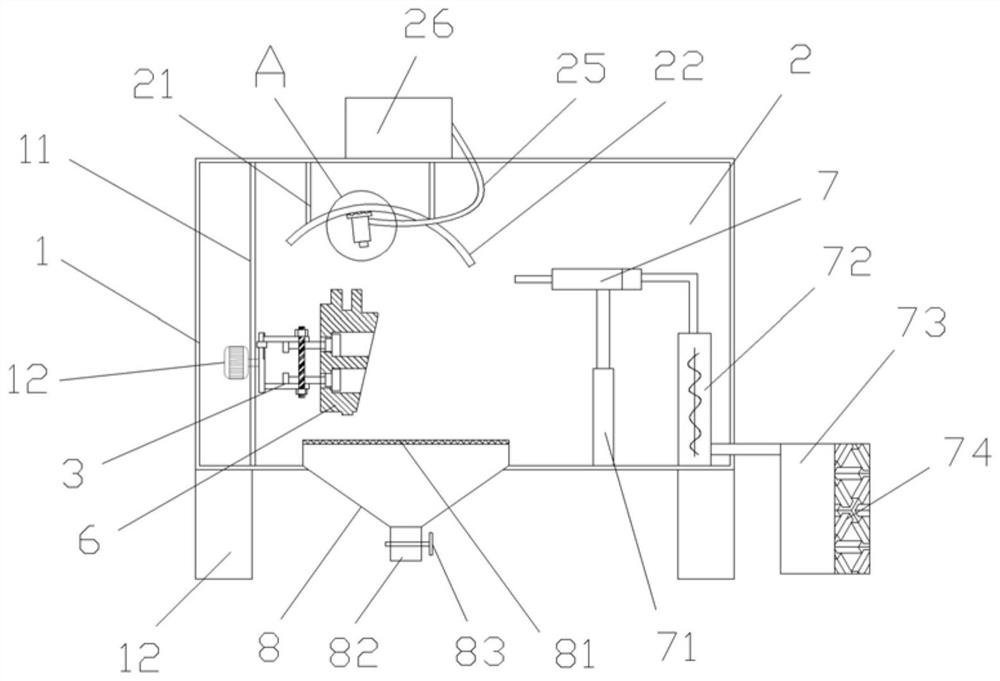

Full-automatic coating stirring spray coater

The invention discloses a full-automatic coating stirring spray coater comprising an electric high-pressure air free membrane pump, a cooling fan, a clutch, a stirring shaft, a dispersion disk, a material sucking pipe, a filtering material sucking opening, a motor, an upper end fixed bearing, a lead screw, a fixed track, an operating trolley, a lower end fixed bearing, a first solenoid valve, a flow controller, a tee branch, a water inlet pipe, a rapid water-containing opening, a spray gun, a discharging pipe, a machine shell body, a material barrel, liquid material bottles, second solenoid valves, material inlet pipes and a controlling panel. According to the full-automatic coating stirring spray coater, surplus preparation is not needed before construction spraying of the coating project; various power raw materials can be directly processed to be finished coating capable of being directly smeared on a wall, a middle link and various construction equipment of factory processing are not needed, and feed materials are intelligently and automatically metered; operation is easy, the spraying effect is good, and the construction effect of spraying operation is effectively guaranteed; the construction equipment can be decreased; labor is saved; the construction period is shortened; and energy saving and environmental friendliness are achieved.

Owner:王福民

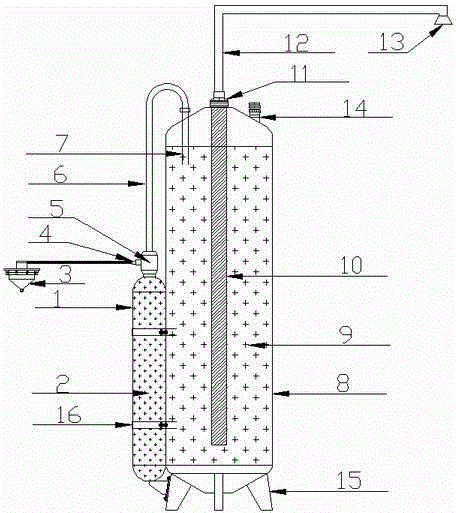

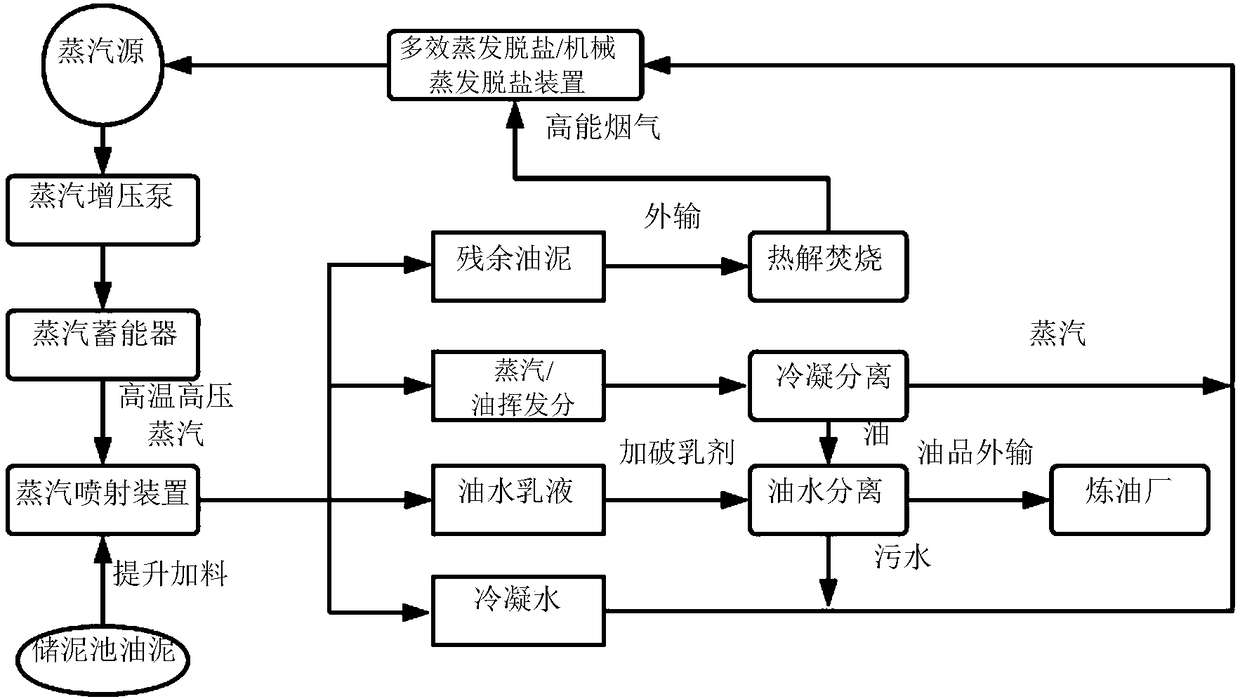

Synchronous recycling and purifying method for oil in oily sludge

PendingCN108624347ARapid viscosity reductionImprove liquidityLiquid hydrocarbon mixture productionHydrocarbon oils treatmentThermal energyCombustion system

The invention relates to a synchronous recycling and purifying method for oil in oily sludge. The synchronous recycling and purifying method specifically comprises a feeding system, a steam preparation system, a spraying system, an oil water separation system, a condensation separation system, a condensate water desalting and reinjecting system, and an oily sludge residue combustion system. The synchronous recycling and purifying method is characterized in that the high temperature and the strong-impact dispersion effect of the sprayed steam are used to recycle and purify the oil sludge, the recycled oil is dehydrated and conveyed to an oil refinery, the condensate water is desalted and reinjected to generate steam, and the oily sludge residue is combusted to recycle the heat energy. The various systems of the method are linked with one another and are efficient, fast, clean and environmentally friendly; a used steam spraying device is simple in structure and can run continuously.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

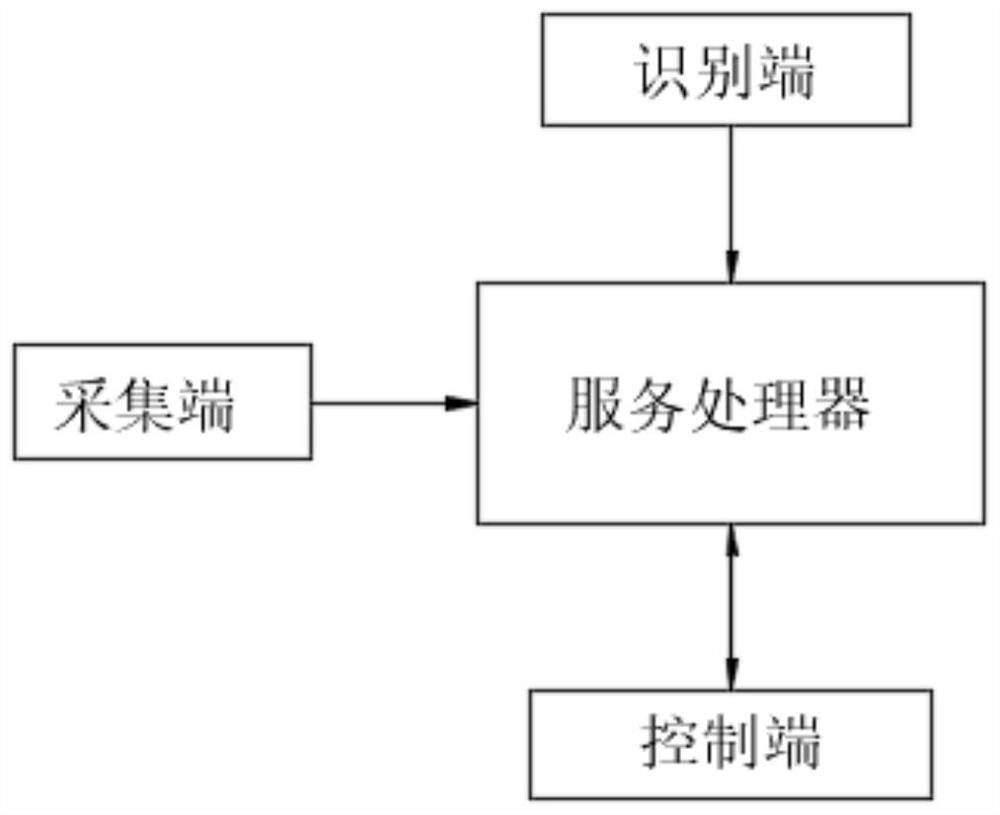

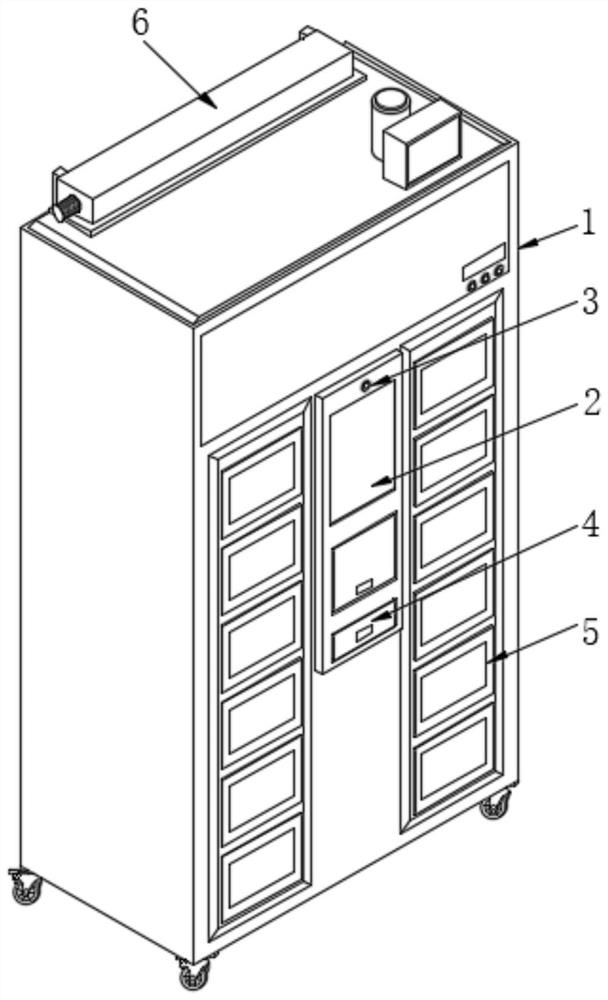

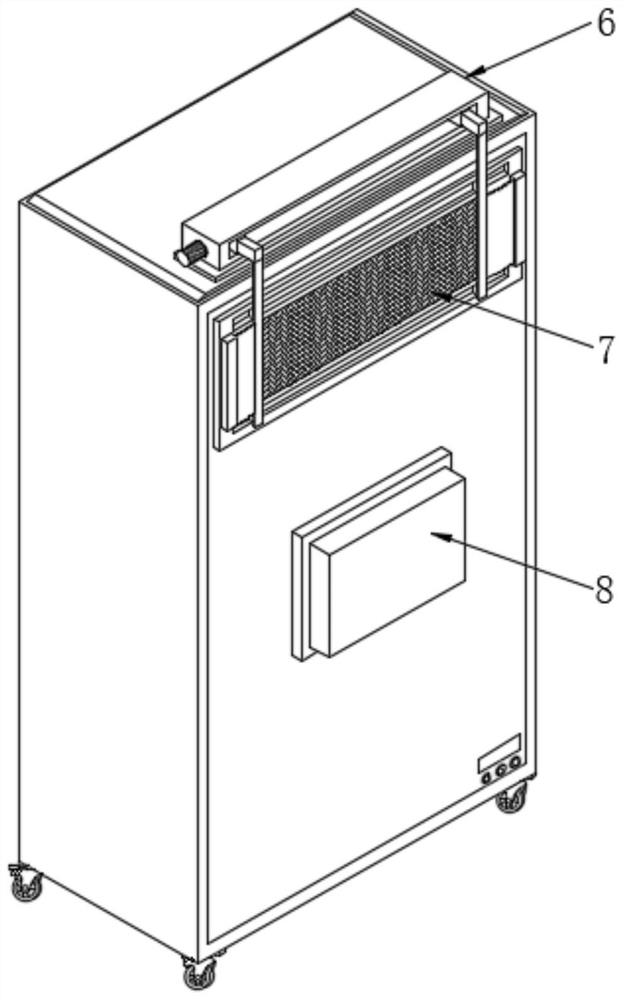

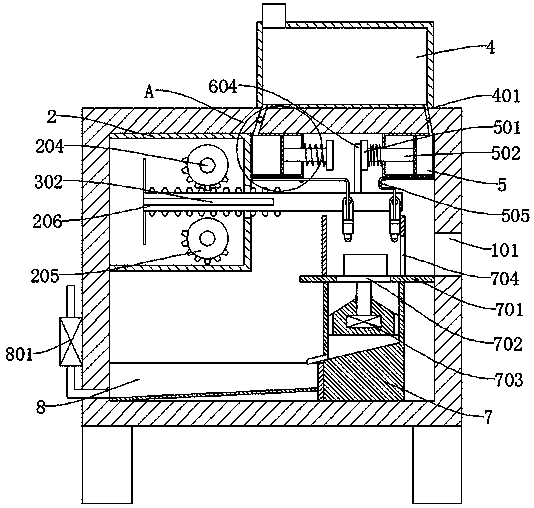

Intelligent food sample reserving cabinet

ActiveCN114440544AGood spray effectImprove refrigeration effectDomestic cooling apparatusLighting and heating apparatusProcess engineeringCool storage

The invention discloses an intelligent food sample reserving cabinet, relates to the technical field of food safety, and solves the technical problem that the cold storage effect is poor due to the fact that the surface areas of different sample reserving foods are different, but the spraying directions and the spraying speeds of internal cold air valve spraying openings are consistent. The method comprises the following steps: extracting a picture of a reserved sample, matching the picture with a Sudoku, checking the coincident area of the picture and the Sudoku, extracting edge center points of a coincident area region, processing multiple groups of center points to obtain corresponding cross points and coordinate values, and acquiring the weight of the reserved sample. Different cold air injection rates are adopted for reserved samples of different weights, the angle of the spray head is changed through the coordinate value and the control end, the reserved samples are completely covered with the injection angle of the spray head, and therefore the good injection effect is achieved, the surfaces of the reserved samples can be subjected to cold air injection, and the refrigeration effect of the reserved samples is improved.

Owner:浙江智飨科技有限公司

Anti-rust oil spraying device used for mechanical workpiece

InactiveCN110280417AGood spray effectReduce labor intensityLiquid spraying apparatusFuel tankEngineering

The invention discloses an anti-rust oil spraying device used for a mechanical workpiece and belongs to the technical field of spraying. The anti-rust oil spraying device used for the mechanical workpiece comprises a first box body, and the inner wall of the first box body is connected with a second box body and a sleeve; a rack plate is connected in the second box body in a sliding manner; the outer wall of the rack plate is rotationally connected with a spray head; the top of the first box body is connected with an oil storing box which communicates with the sleeve through a connection pipe; the outer wall of the sleeve is connected with a water spraying pipe; the end, away from the sleeve, of the water spraying pipe is connected with the spray head; a fixed table is further connected to the inner wall of the first box body; the top of the fixed table is connected with a top plate; a rotating disk is rotationally connected in the top plate; a part body is connected to the top of the rotating disk; and the outer wall of the rotating disk is provided with a concave hole. The anti-rust oil spraying device used for the mechanical workpiece is convenient to operate, manual operation is not needed, the labor intensity is lowered, the work efficiency is improved, and meanwhile the effect of spraying is better.

Owner:NANJING AOLINGKE INTERNET OF THINGS TECH CO LTD

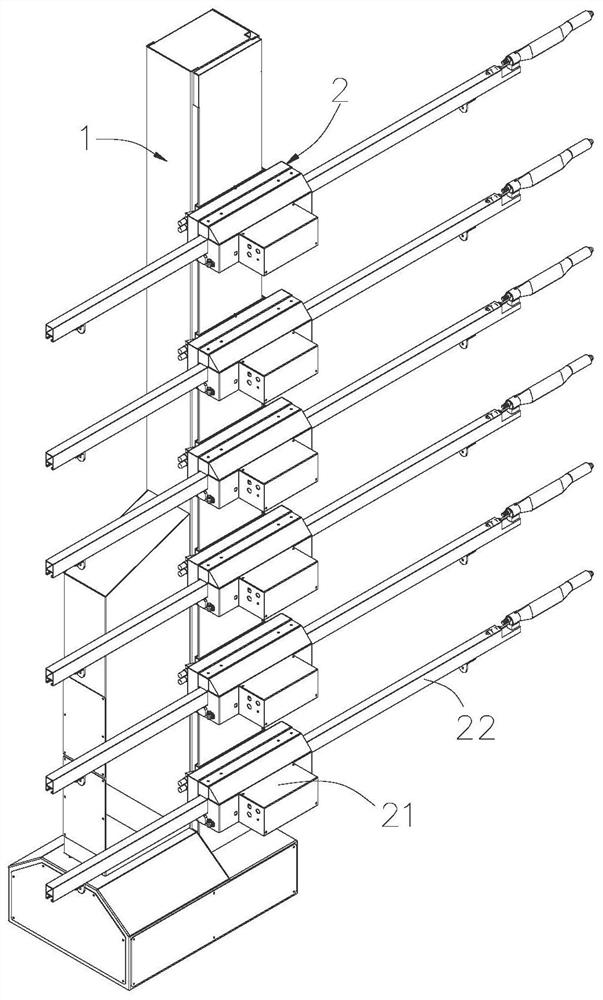

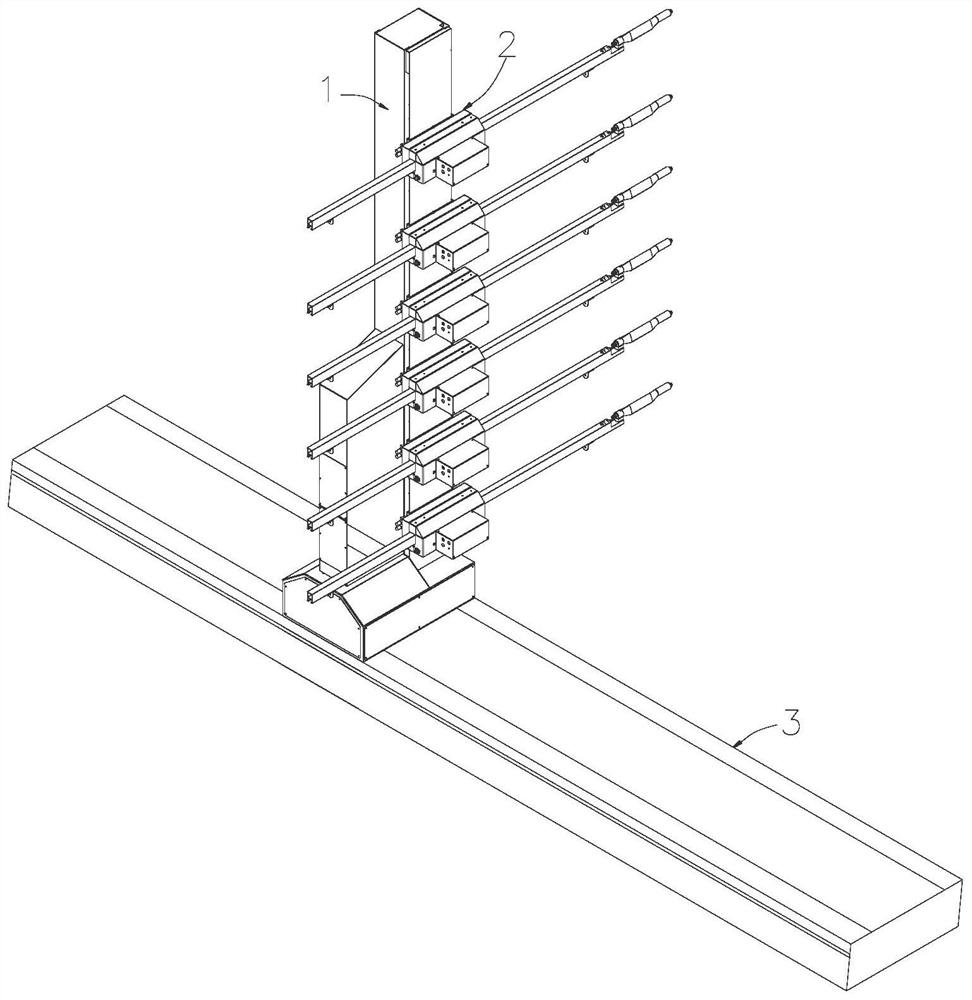

Spraying system and spraying method

ActiveCN112742615ASpray evenlyGood spray effectLiquid spraying plantsLiquid surface applicatorsPhysicsSpray method

The invention provides a spraying system and a spraying method. The spraying system comprises a spraying device, a control device and a scanning device, and the spraying device and the scanning device are both electrically connected with the control device; the scanning device is used for scanning a surface to be sprayed, and the control device is used for adjusting the positions of spraying guns according to data transmitted by the scanning device; the spraying device comprises a vertical track and a plurality of spraying guns, and the multiple spraying guns are arranged on the vertical track; each spraying gun comprises a spraying gun mechanism and a first power mechanism, and the first power mechanisms are slidably connected to the vertical track; each first power mechanism can be independently slide along the vertical track, and the spraying gun mechanisms are connected with the first power mechanisms; the spray gun mechanisms can be moved relative to the first power mechanisms, and each spray gun mechanism can be independently moved relative to the corresponding first power mechanism; and an included angle is formed between the sliding direction of the first power mechanisms and the moving direction of the spraying gun mechanisms. The spraying system and the spraying method are better in spraying effect.

Owner:广州泽亨实业有限公司

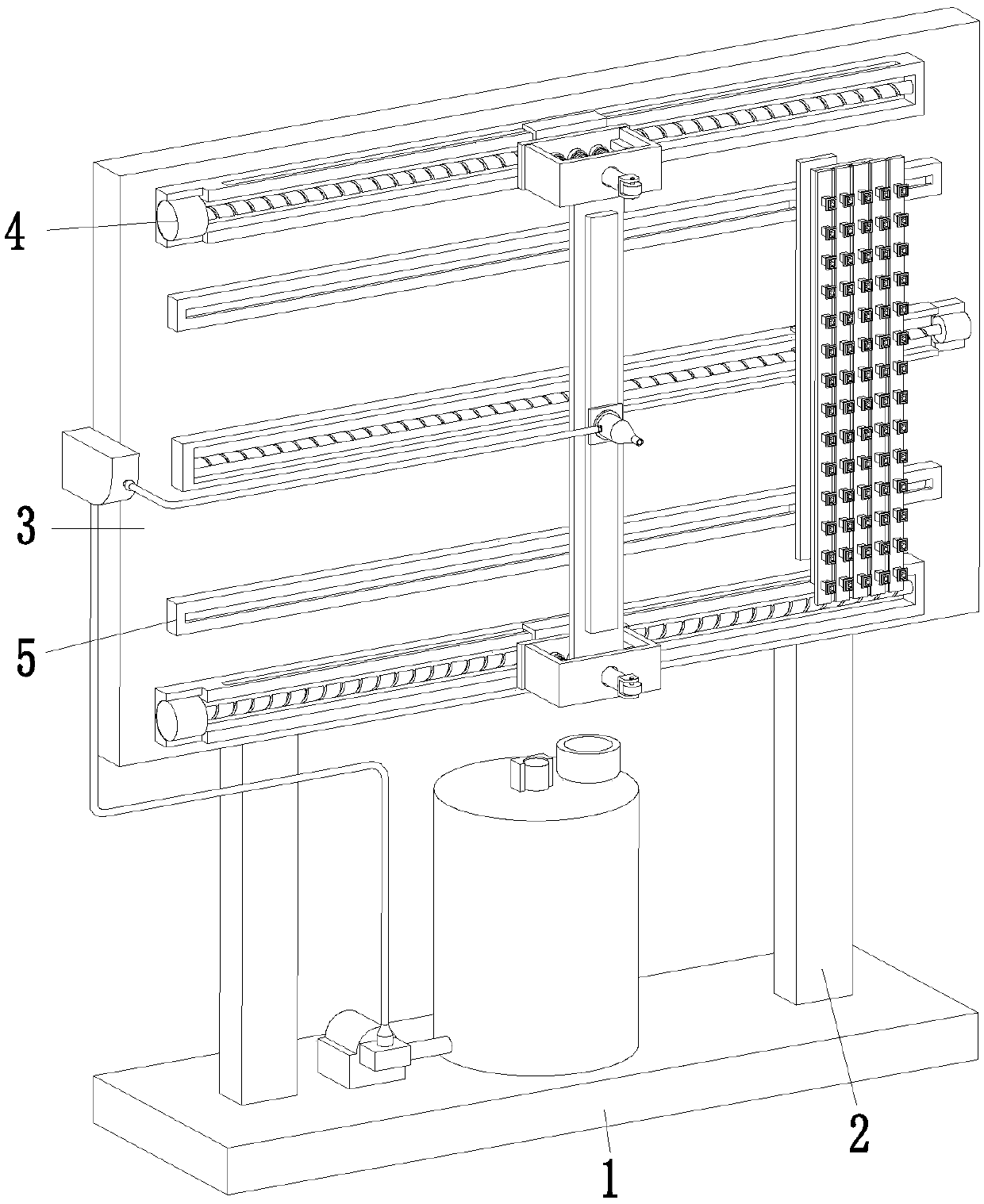

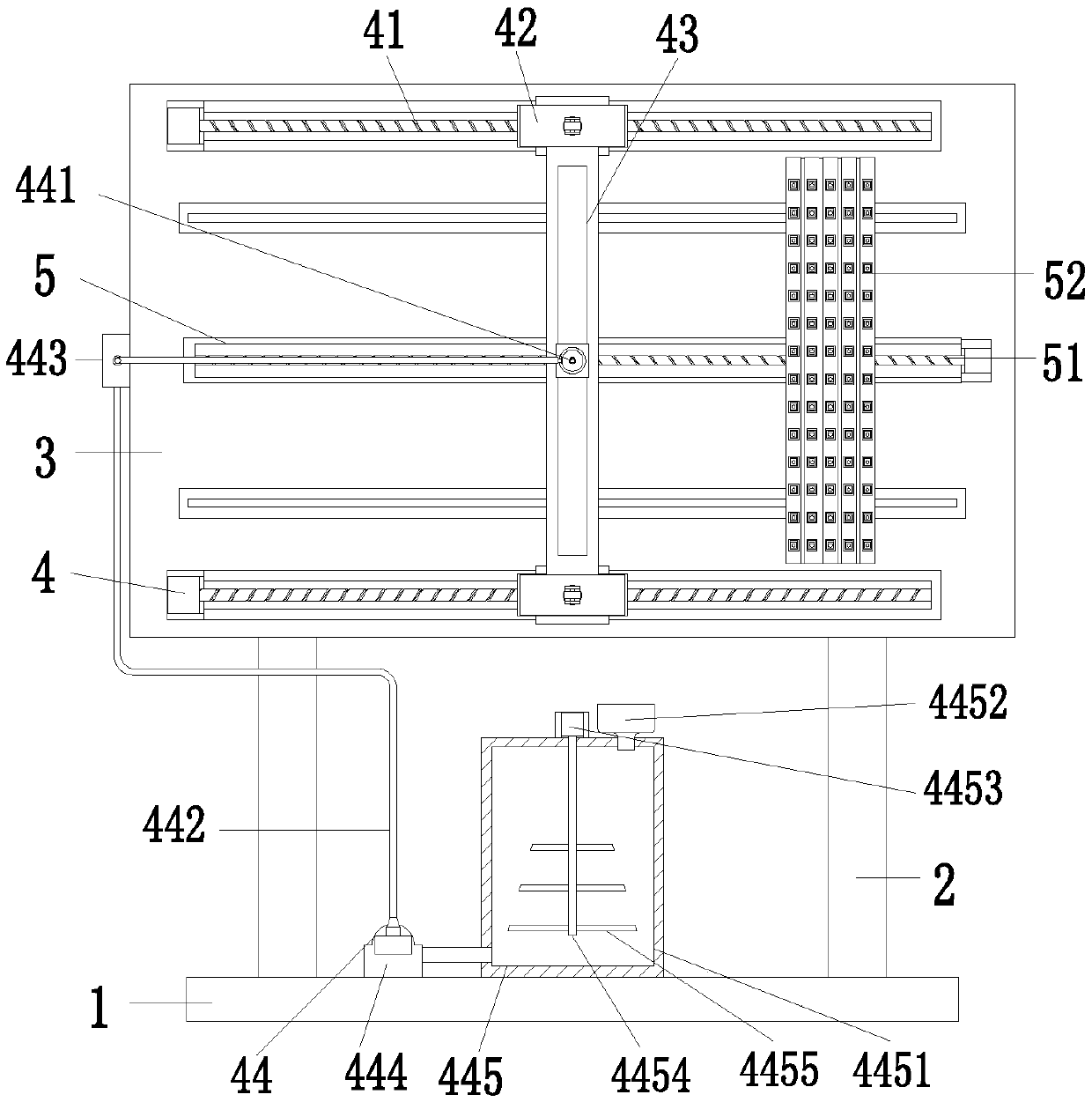

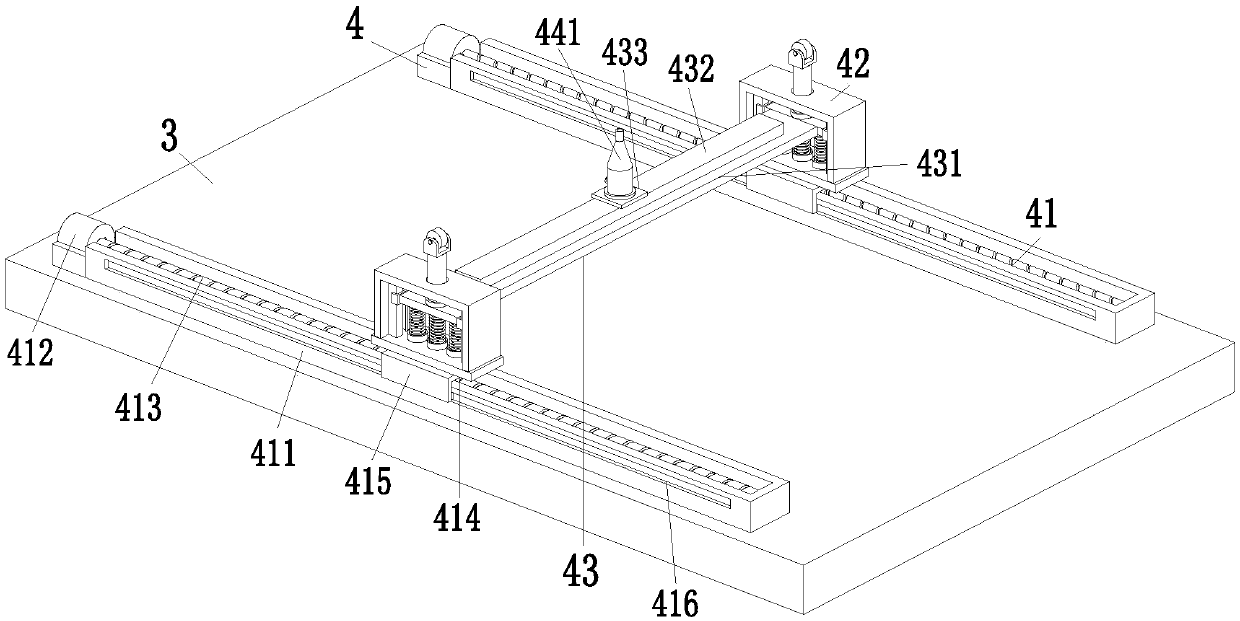

Spraying equipment for arc-shaped metal hard screen surface honeycomb coating

The invention relates to spraying equipment for an arc-shaped metal hard screen surface honeycomb coating. The spraying equipment for the arc-shaped metal hard screen surface honeycomb coating comprises a bottom plate, support frames, a fixed plate, a spraying device and a die device, wherein the support frames are symmetrically arranged at the upper end of the bottom plate; the fixed plate is arranged at the upper ends of the support frames; the spraying device is arranged in the middle of the front end of the fixed plate; and the die device is arranged on the fixed plate and is located on the right side of the spraying device. The spraying equipment for the arc-shaped metal hard screen surface honeycomb coating provided by the invention can solve the problems that when an existing arc-shaped metal hard screen is sprayed, the distance between a spray gun and the metal hard screen cannot be stably controlled, so that a spraying effect is poor, uneven spraying is caused, and the honeycomb coating cannot be formed after spraying; can realize a function on automatically honeycomb-spraying the surface of the arc-shaped metal hard screen surface; and has the advantages that the sprayingeffect is good, even spraying is realized, the distance between the spray gun and the metal hard screen can be controlled, and the honeycomb coating can be formed after spraying.

Owner:西安呱牛信息技术有限公司

Plastic part spraying machine capable of adjusting spraying distance and automatically turning over to-be-sprayed part

The invention relates to the technical field of plastic part spraying machines, and discloses a plastic part spraying machine capable of adjusting the spraying distance and automatically turning overa to-be-sprayed part. The plastic part spraying machine comprises a first motor, a driving plate is movably connected to the output end of the first motor, a driving rod is fixedly connected to the axis of the driving plate, a baffle is arranged on the left side of the first motor, a grooved wheel is movably connected to the right side of the baffle, clamping devices are arranged on the left sideof the baffle, a plastic part is clamped to the left side of the clamping device, a sliding rail is arranged below the plastic part, a screw hole fixing block is fixedly connected to the top of the sliding rail, and a first sliding block is connected to an inner rail of the sliding rail in a sliding mode. According to the plastic part spraying machine capable of adjusting the spraying distance andautomatically turning over the to-be-sprayed part, the distance between the clamping devices is adjusted through distance adjusting screws, the grooved wheel drives the plastic part to rotate intermittently, a sprayer is indirectly driven to reciprocate in cooperation with a first gear and a second gear, and therefore the effects that the spraying distance is adjustable, the plastic part is automatically turned over, and spraying is more uniform are achieved.

Owner:程长酉

Environment-friendly dumbbell spraying equipment

PendingCN110801977AGood spray effectIncrease the scope of applicationPretreated surfacesLiquid spraying apparatusManufacturing engineeringAir drying

The invention relates to the field of spraying equipment, in particular to environment-friendly dumbbell spraying equipment. The environment-friendly dumbbell spraying equipment comprises a shell, andthe bottom of the inner side of the shell is fixedly connected and provided with a paint box. The left side of the shell is in bolt connection with a paint pump, and the output end of the paint pumpis connected with a paint spraying mechanism. A supporting mechanism for fixing a dumbbell is arranged on the upper side of the paint box, and air drying mechanisms fixedly connected with the shell are arranged on the left side and the right side of the supporting mechanism. According to the environment-friendly dumbbell spraying equipment, by arranging the paint spraying mechanism, omnibearing paint spraying on the dumbbell can be achieved; by arranging oblique nozzles, spraying can be carried out aiming at the structure of the dumbbell, and the spraying effect is good; by arranging the supporting mechanism, a dumbbell rod can be fixed through second rotary wheels on the two sides; by means of rotation of first rotary wheels, the dumbbell can be rotated, and therefore spraying is more comprehensive; and by arranging the air drying mechanisms, air flowing in the shell can be promoted, the paint drying speed can be increased, and the production efficiency can be improved.

Owner:南通海清健身器材有限公司

Spraying device for metal surface treatment

InactiveCN112403711AGood spray effectHigh degree of automationLiquid spraying apparatusRotational axisManufacturing engineering

The invention discloses a spraying device for metal surface treatment. The spraying device for metal surface treatment comprises a base, two sets of stand columns are fixedly connected to the left side and the right side of the top end of the base, a transverse plate is fixedly connected between the upper ends of the outer surfaces of the two sets of stand columns, and a screw rod is installed between the outer surfaces of the two sets of stand columns and located on the lower side of the transverse plate; a three-phase asynchronous motor is fixedly connected to the left side of the top end ofthe transverse plate, a rotating shaft is fixedly connected to the bottom of the three-phase asynchronous motor, the power input end of the rotating shaft is electrically connected with the power output end of the three-phase asynchronous motor, and a rotating rod is fixedly connected to the bottom of the rotating shaft and penetrates through the top end of the transverse plate; and a bevel gearII is fixedly connected to the bottom of the rotating rod, the bevel gear II is in engaged connection with a bevel gear I, and the bevel gear I is rotatably connected with the screw rod. According tothe spraying device, a spray head can realize back-and-forth uniform spraying on the metal surface, meanwhile, the automation degree is improved, and the operation of people is reduced, so that the guarantee on the health of people is enhanced.

Owner:湖南菱瑞新材料科技有限公司

System for spraying stamping part

ActiveCN109513560AGood spray effectGood surface spraying effectSpray boothsEngineeringCentrifugal force

The invention discloses a system for spraying a stamping part. The system comprises a conveying chain, an air blowing chamber, a spraying chamber and a drying chamber, wherein the air blowing chamber,the spraying chamber and the drying chamber are sequentially arranged; a hanging part which is used for hanging the stamping part is arranged on the conveying chain; air blowing holes are formed in the all side walls of the air blowing chamber; the air blowing holes formed in the opposite side walls of the air blowing chamber separately correspond to the different sides of the stamping part; thehanging part is rotatably connected with the conveying chain; an air suction hole is formed in the bottom of the air blowing chamber; an air blower is arranged in an air suction hole; a rotating shaftof the air blower extends into the air blowing chamber and a fixed bar is fixed; the fixed bar is provided with a strip groove through which the bottom end of the stamping part passes; the stamping part is blown through the air blowing holes formed in the different sides of the side walls of the air blowing chamber so that the stamping part is continuously rotated, and dust formed in the stampingpart is removed more comprehensively and completely; and moreover, in a rotation process of the stamping part, certain centrifugal force is also produced, and the dust is helpful to be blown off fromthe surface of the stamping part, so that the effect of the surface of the stamping part is better after subsequent spraying.

Owner:深圳市友信鑫五金制品有限公司

Paint spraying device for cutter base body of shield tunneling machine

PendingCN113769929AUniform spraying effectGood spray effectLiquid spraying plantsPretreated surfacesStructural engineeringShield tunneling

The invention discloses a paint spraying device for a cutter base body of a shield tunneling machine. The paint spraying device comprises a box body, a paint spraying chamber is arranged in the box body, a partition plate is arranged on the left side of the paint spraying chamber, a fixing mechanism is arranged on the partition plate, the cutter base body is fixed to the fixing mechanism, a rotating motor is arranged on the left side of the partition plate, the output end of the rotating motor penetrates through the partition plate and is connected with the fixing mechanism, an arc-shaped first sliding rail is fixed to the top of the paint spraying chamber through a vertical rod, a sliding block is mounted on the first sliding rail in a sliding mode, and an electrostatic spraying head is fixed to the bottom of the sliding block. The cutter base body is fixed through the fixing mechanism, and then the cutter base body is driven to rotate through the rotating motor, so that the spraying effect is more uniform; the electrostatic spraying head is arranged on the arc-shaped first sliding rail in a sliding mode and slides back and forth for spraying of the surface of the cutter base body, it can be guaranteed that all the surfaces can be evenly painted, the spraying effect is good, and the probability of later supplementary spraying is reduced.

Owner:浙江福仑德重工有限公司

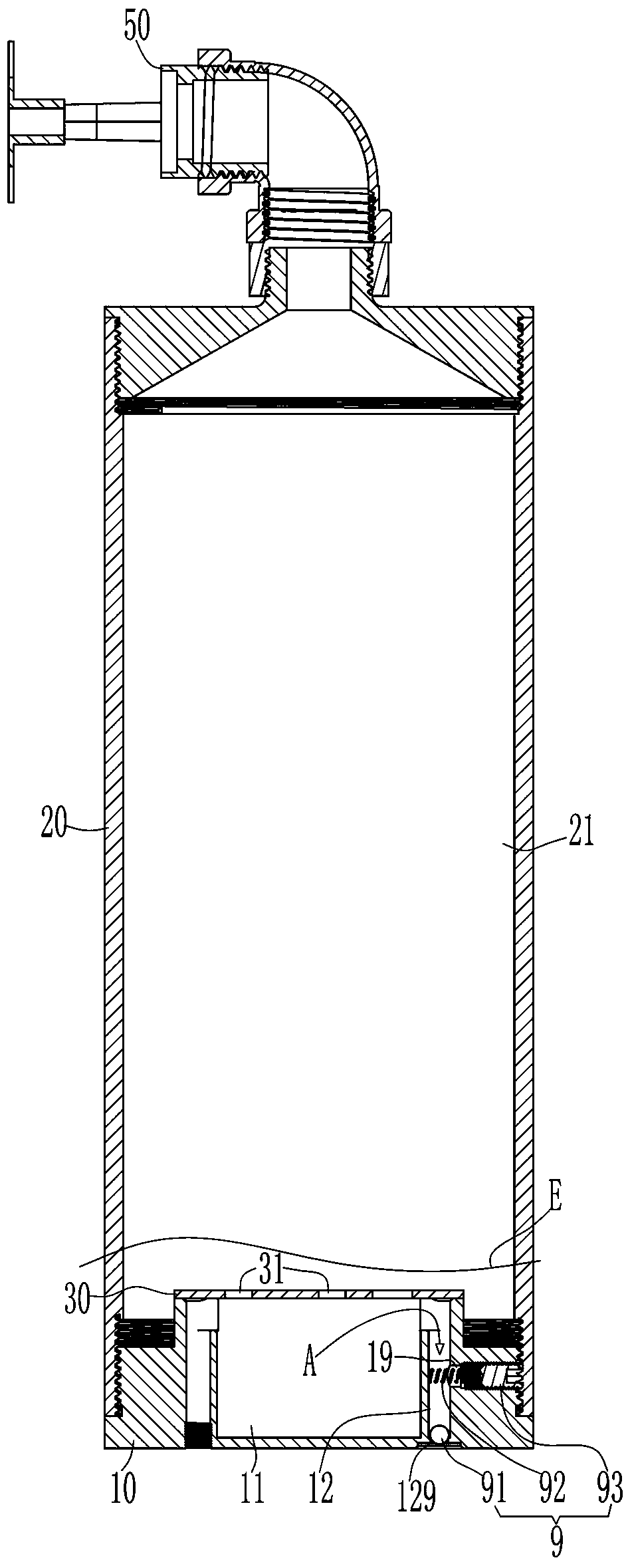

Automatic fire extinguishing device with leakage stopping structure

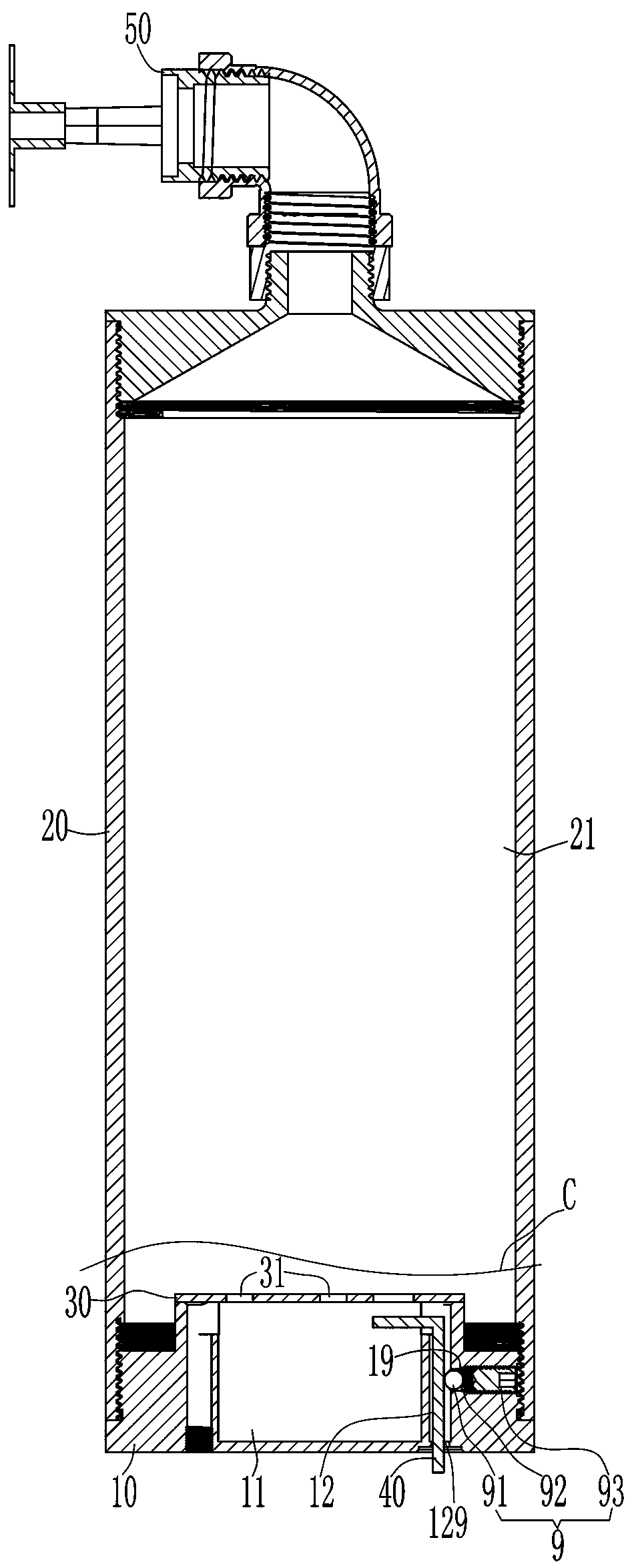

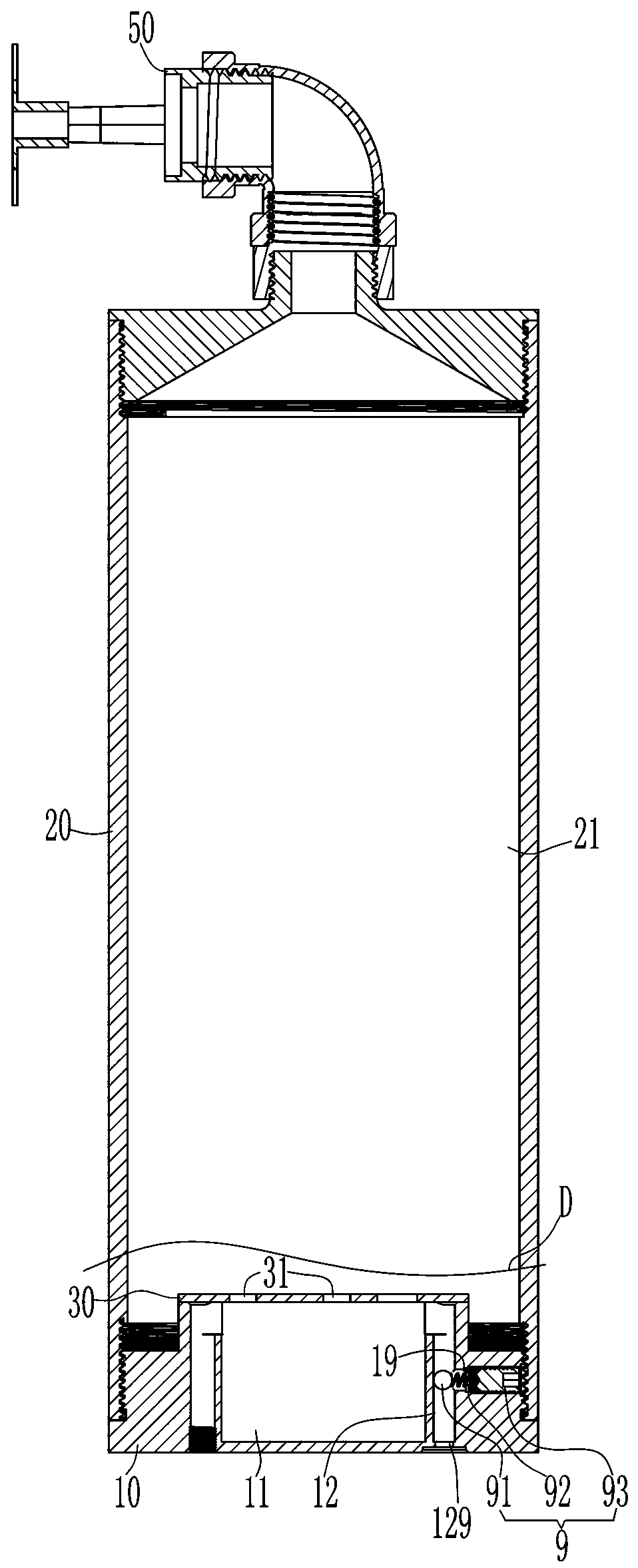

InactiveCN109395292AAir pressure does not leakEnough pressureFire rescueAutomatic fire suppressionAtmospheric pressure

The invention relates to an automatic fire extinguishing device with a leakage stopping structure. The automatic fire extinguishing device comprises a base, a bottle body with a second accommodating cavity, a gas dispersing cover with at least one second through hole, a thermal enable line and the leakage stopping structure, wherein a first accommodating cavity and a first through hole are formedin the base, the thermal enable line penetrates through the first through hole of the base, then, one end of the thermal enable line is located in the first accommodating cavity of the base, and the other end of the thermal enable line is located in an external space of the base; the second through holes of the gas dispersing cover are sealed up by a film, a gas generant is arranged in the first accommodating cavity of the base, and then, an opening of the first accommodating cavity is sealed up by the gas dispersing cover; the base is arranged at the lower end of the bottle body; when the thermal enable line is burnt, the leakage stopping structure can automatically block up the first through hole of the base, and thus, pneumatic pressure in the base and the bottle body cannot leak from the first through hole of the base. According to the automatic fire extinguishing device disclosed by the invention, no leakage of pneumatic pressure in the bottle body is guaranteed, the pressure in the bottle body can be sufficient, and the jet effect of a fire extinguishing agent in the bottle body can be optimal; the automatic fire extinguishing device has the advantages of simple and practicalstructure, simplicity and convenience in assembly, high safety, and the like.

Owner:沈奂

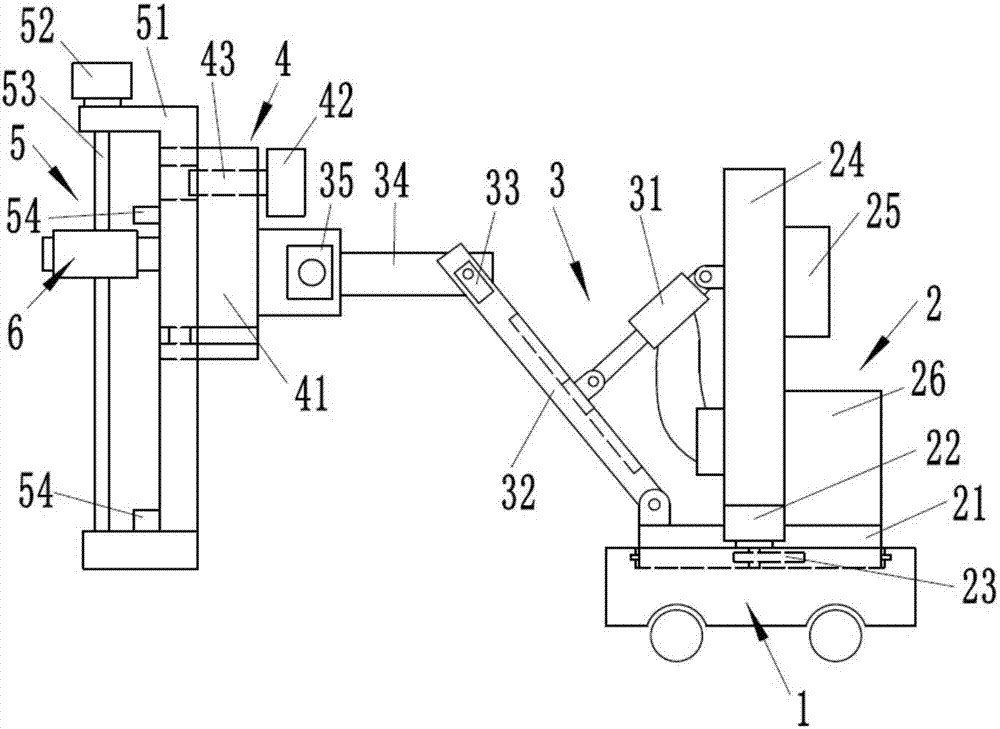

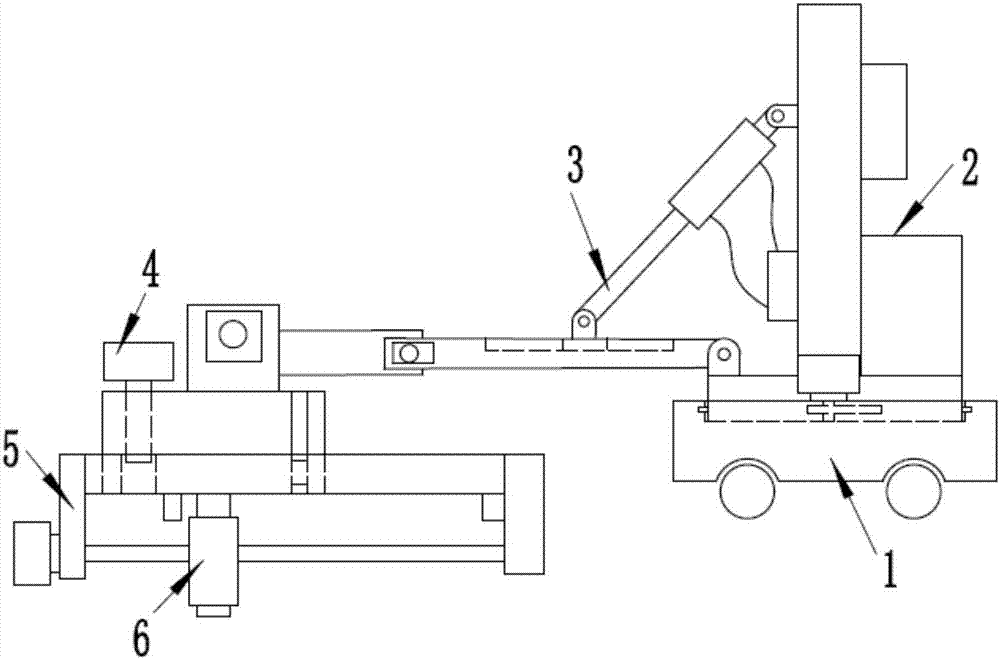

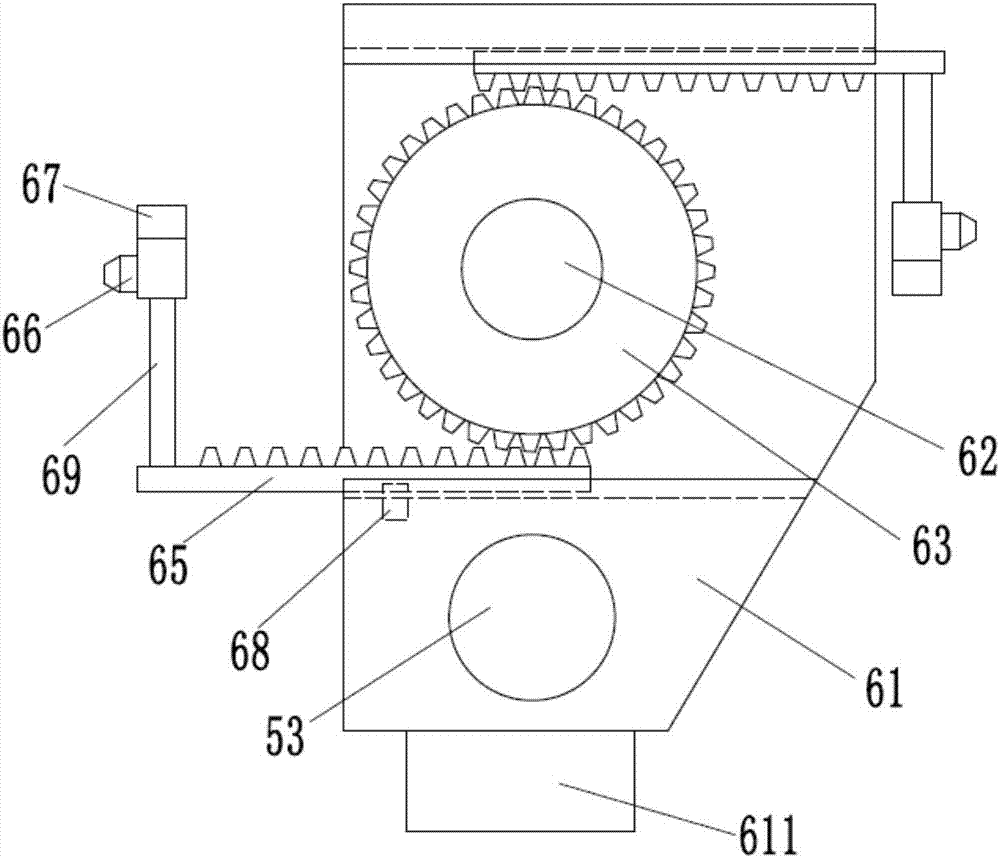

Special spray mechanical arm of robot

InactiveCN107156085AGood spray effectImprove spraying effectInsect catchers and killersElectric machineryRolling chassis

The invention discloses a special spray mechanical arm of a robot comprising a chassis, an adjusting mechanism which is movably installed on the chassis, a conversion device, a second lifting mechanism and a nozzle driving module; a moving disk of the adjusting mechanism can be dynamically positioned on a center line of two row of crops; a second leading screw of the second lifting mechanism is made vertical or parallel to the ground by the conversion device; the nozzle driving module comprises a moving seat, a fourth coding motor, a gear, a pair of racks and a pair of atomizer nozzles, wherein the moving seat is movably installed on the second leading screw; the fourth coding motor is fixedly installed on the moving seat; the gear is fixedly connected to an output shaft of the fourth coding motor; a pair of racks are slidably installed on the moving seat and are meshed with the gear; the moving directions of the pair of racks are opposite; a pair of atomizer nozzles are movably installed on a pair of racks. The special spray mechanical arm of a robot is suitable for drilling crops and has good spraying effect.

Owner:甘肃金瑞园农业科技有限公司

Spraying equipment

InactiveCN108014937AGood spray effectAvoid oversprayLiquid spraying plantsSpray discharge apparatusSmooth surfaceThin sheet

The invention provides spraying equipment, which comprises a rack and a spraying device. A motor and a conveying crawler belt driven by the motor are arranged on the rack; a metal thin sheet is conveyed on the conveying crawler belt; a spraying device is arranged above the conveying crawler belt and is arranged on a fixed support; the fixed support is fixedly connected with one side of the rack; the spraying device comprises a high voltage static spray gun, a powder supply barrel, a high voltage static device and a controller; a high voltage generator is arranged in the high voltage static spray gun; a powder pipe and a gun pipe are connected onto the high voltage static spray gun; the powder pipe is connected with the powder supply barrel; the gun pipe is connected with the high voltage generator and the high voltage static device; and the high voltage generator is connected with the controller. The spraying equipment provided by the invention has the beneficial effects that the highvoltage static spray gun can be used for enabling powder to uniformly adsorb on a surface of the metal thin sheet during work so as to obtain a smooth surface, and a spraying effect is better throughthe arranged controller.

Owner:天津市德通制罐有限公司

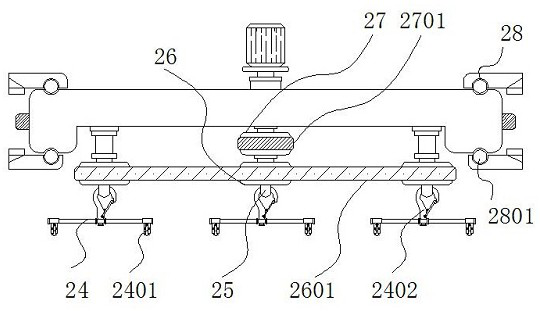

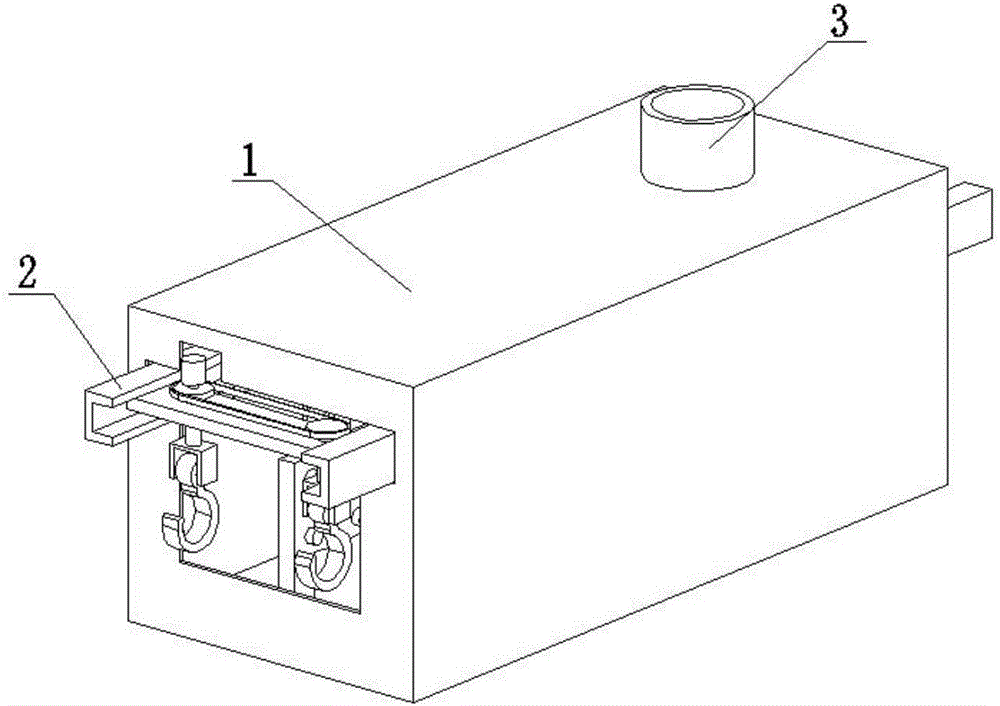

Film spraying mechanism for lifting hook parts

InactiveCN106670040AIncrease coverageFully automatedLiquid surface applicatorsCoatingsSpray nozzleEngineering

The invention discloses a film spraying mechanism for lifting hook parts. The film spraying mechanism comprises a film spraying box and rails penetrating the two ends of the film spraying box. The rails are provided with multiple moving plates driven through chains. Two connecting buckles are arranged below each moving plate, wherein the two connecting buckles are connected with two transmission wheels through drive rods, the drive rods penetrate the moving plates and are rotationally connected with the moving plates, the two transmission wheels are connected through a synchronous belt, and the transmission wheels are driven through a drive motor. A spraying opening is formed in the film spraying box and is located between the two rows of connecting buckles, and multiple nozzles are arranged on each of the two faces of the spraying nozzle. According to the film spraying mechanism for the lifting hook, the moving plates are arranged on the rails penetrating the film spraying box to drive lifting hooks hung on the connecting buckles below the moving plates to pass through the spraying opening, the drive motors are arranged above the moving plates to drive the lifting hooks to rotate, the spraying opening can be used for conducting 360-degree all-dimensional film spraying on the lifting hooks, automation of the film spraying work is achieved, the production efficiency is high, the film spraying covering rate is high, the film spraying effect is good, and the phenomenon that spraying is not even cannot happen.

Owner:ANHUI TAIFU HEAVY IND MFG CO LTD

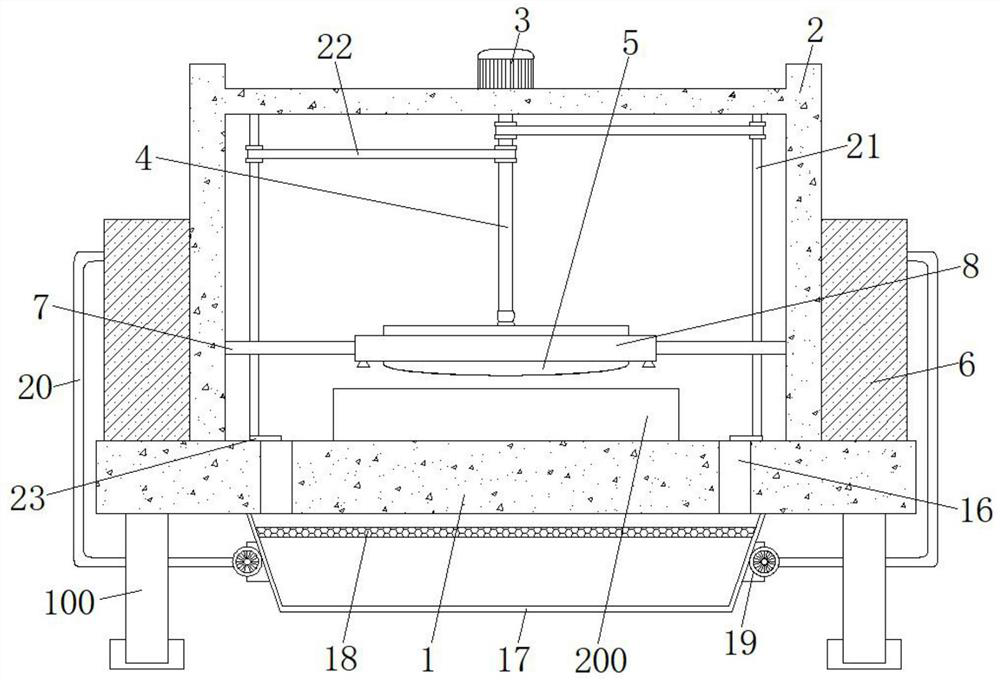

Temperature control type grinding machine with high polishing precision

ActiveCN112792692AFlow area controlAvoid wastingGrinding machinesCleaning using liquidsTemperature controlWater storage

The invention discloses a temperature control type grinding machine with high polishing precision. The temperature control type grinding machine comprises a grinding table, a positioning frame is fixedly mounted at the top of the grinding table, a driving motor is fixedly mounted at the center of the top of the positioning frame, the output end of the driving motor is fixedly connected with a polishing shaft, and the bottom end of the polishing shaft extends into a mounting frame and is fixedly connected with a grinding head. According to the temperature control type grinding machine with the high polishing precision, when external ball rods move to the position of a water storage pipe, the external ball rods abut against an automatic control valve, the automatic control valve is stressed to swing inwards around a spiral shaft, at the moment, a reset spring is compressed, and therefore the water storage pipe is in a semi-closed state, the automatic control valve effectively prevents the external ball rods from being clamped in the water storage pipe, the spraying effect is good, circumferential movement of the external ball rods is not affected, the twelve external ball rods abut against the automatic control valve successively, so that opening and closing of the automatic control valve are regular, the polishing and grinding progress is kept, and the working efficiency is improved.

Owner:CHENGDU YIGE MACHINERY CO LTD

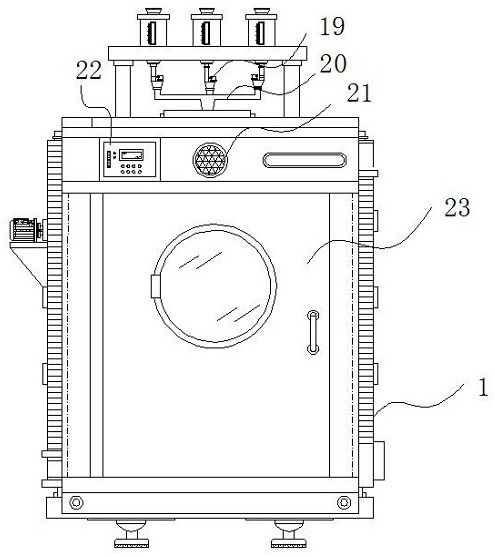

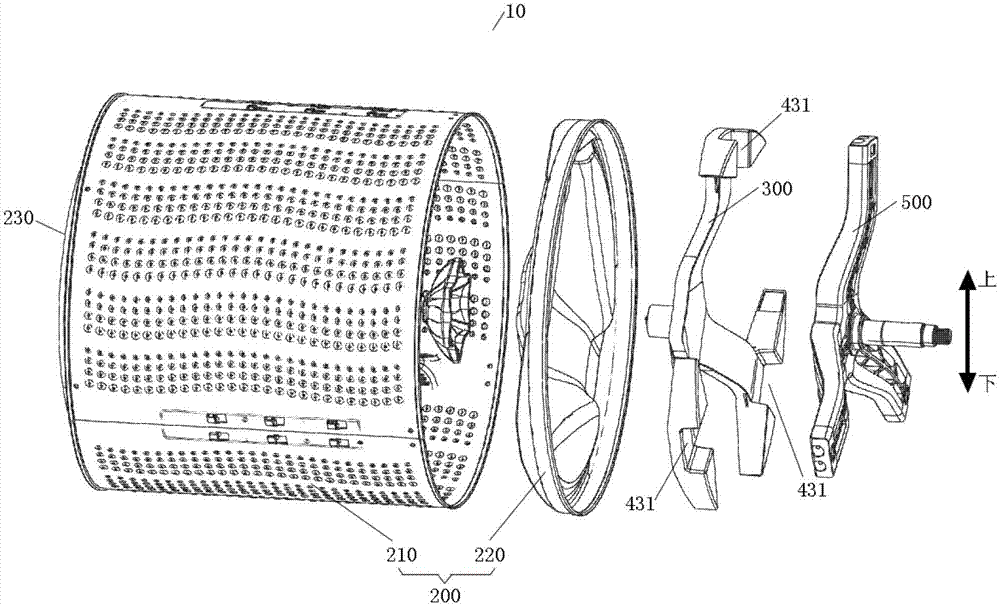

Drum washing machine and washing barrel assembly used in the same

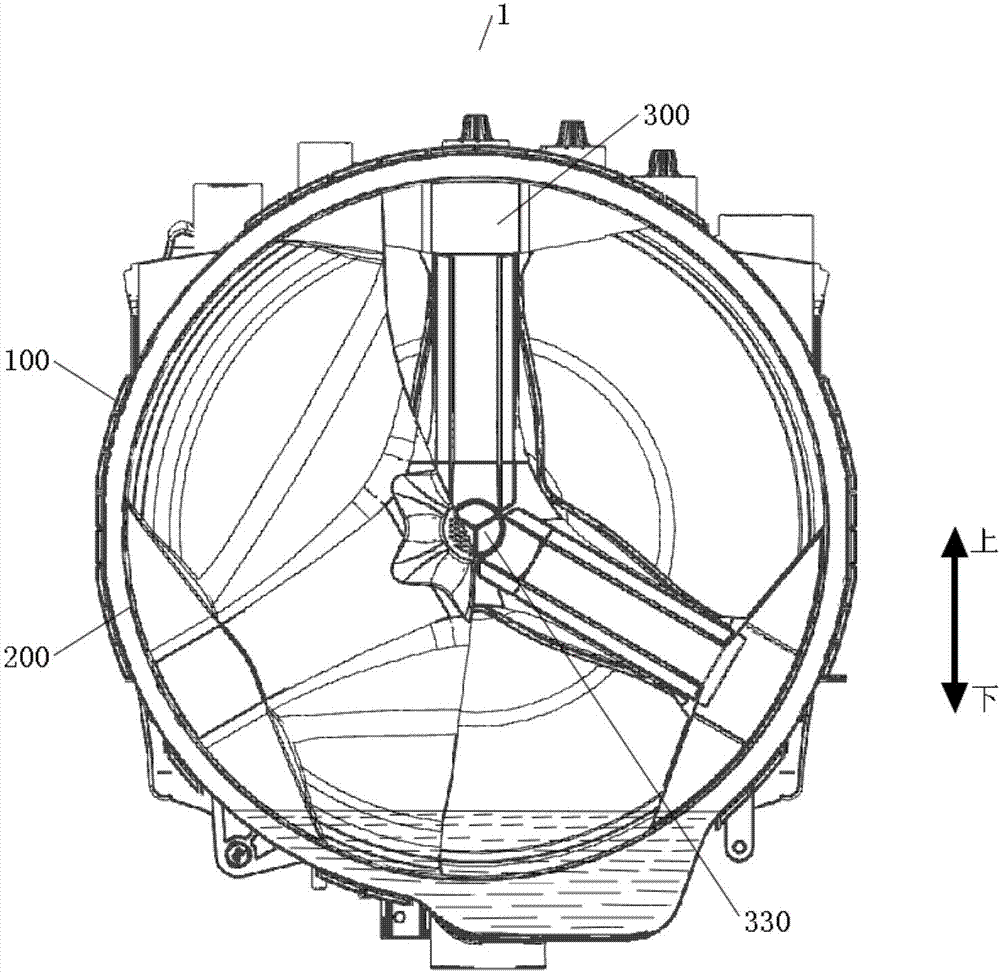

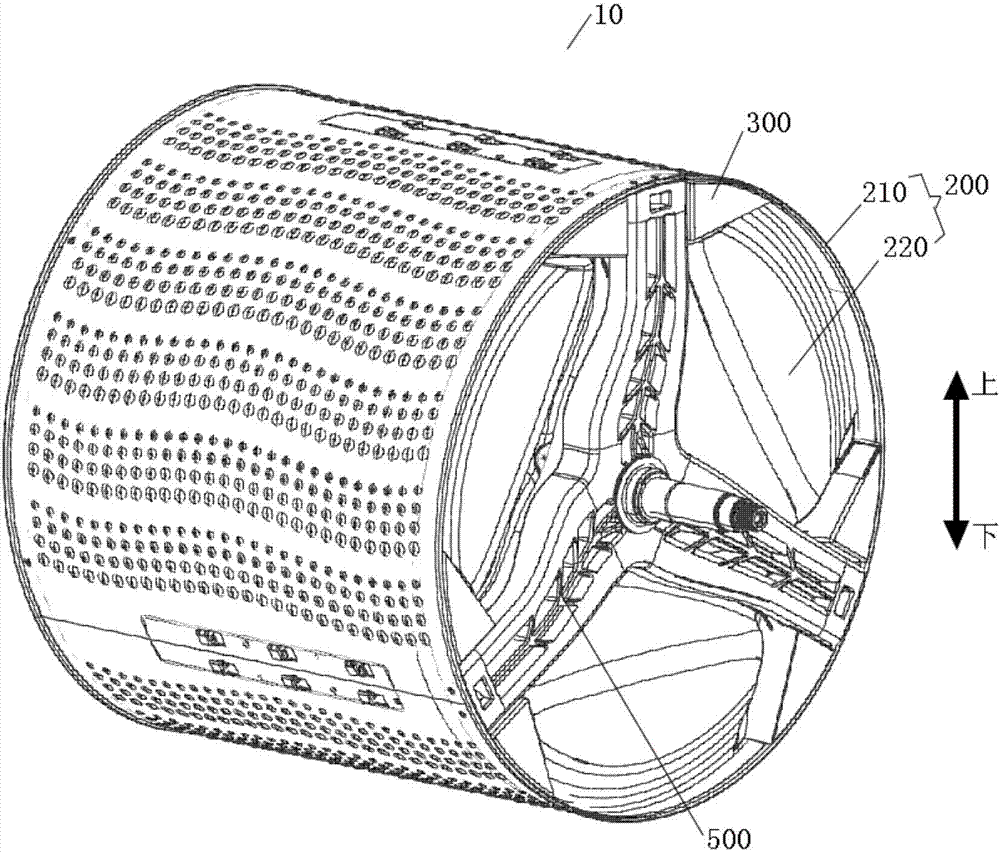

ActiveCN107503086AReduce electricity consumption costsGood spray effectOther washing machinesTextiles and paperMechanical engineeringPower consumption

The invention discloses a drum washing machine and a washing barrel assembly used in the same. The drum washing machine comprises a water barrel, a washing barrel, a water taking device and one-way connecting devices, wherein the washing barrel is rotationally arranged in the water barrel; the water taking device rotates along with the washing barrel and is provided with water taking openings, a flow channel and a spraying opening, the spraying opening is communicated with the inner space of the washing barrel, and the flow channel with the periphery closed is communicated with the water taking openings and the spraying opening; the one-way connecting devices are arranged on the water taking openings and achieve one-way connection from the outer sides of the water taking openings to the inner sides of the water taking openings; when the water taking device rotates along with the washing barrel, liquid in the water barrel is scooped by the water taking openings and flows into the washing barrel from the spraying opening along the flow channel under the action of gravity. The drum washing machine has the advantages of being low in power consumption cost, good in spraying effect, high in spraying efficiency and the like.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

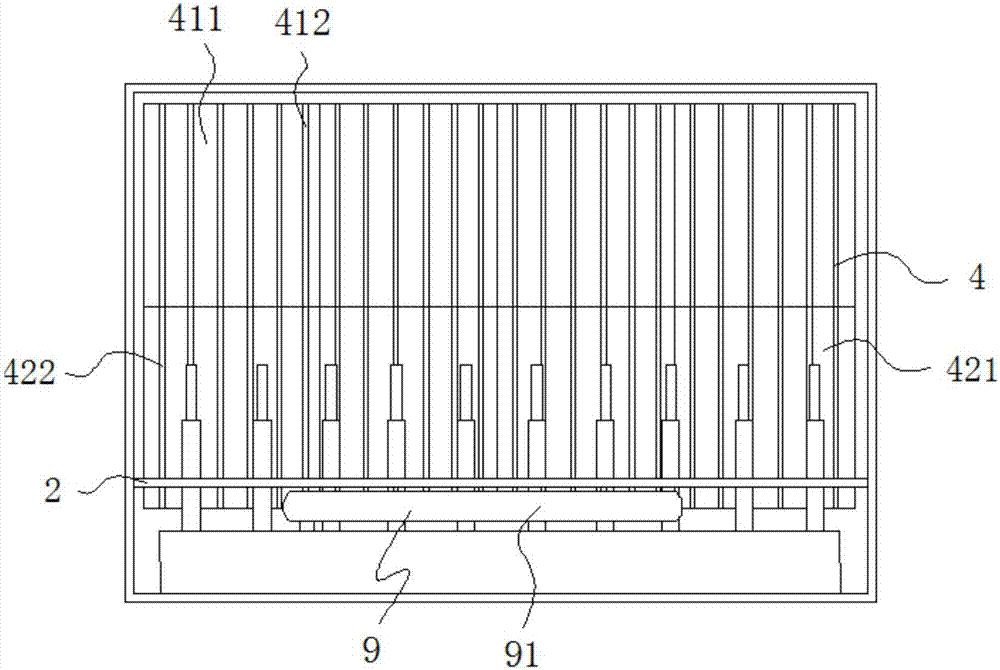

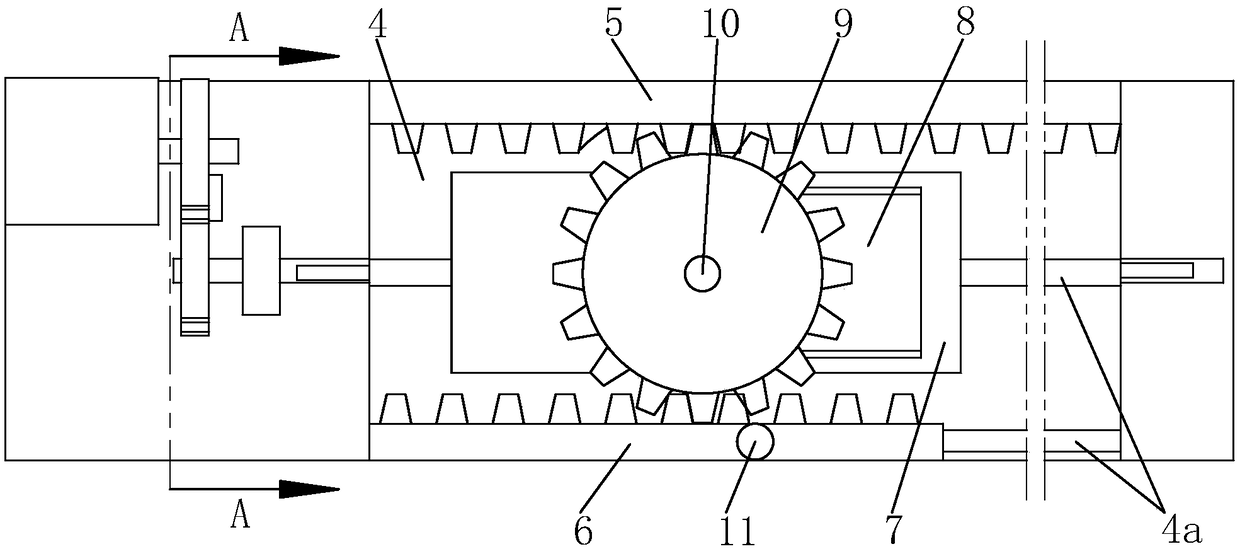

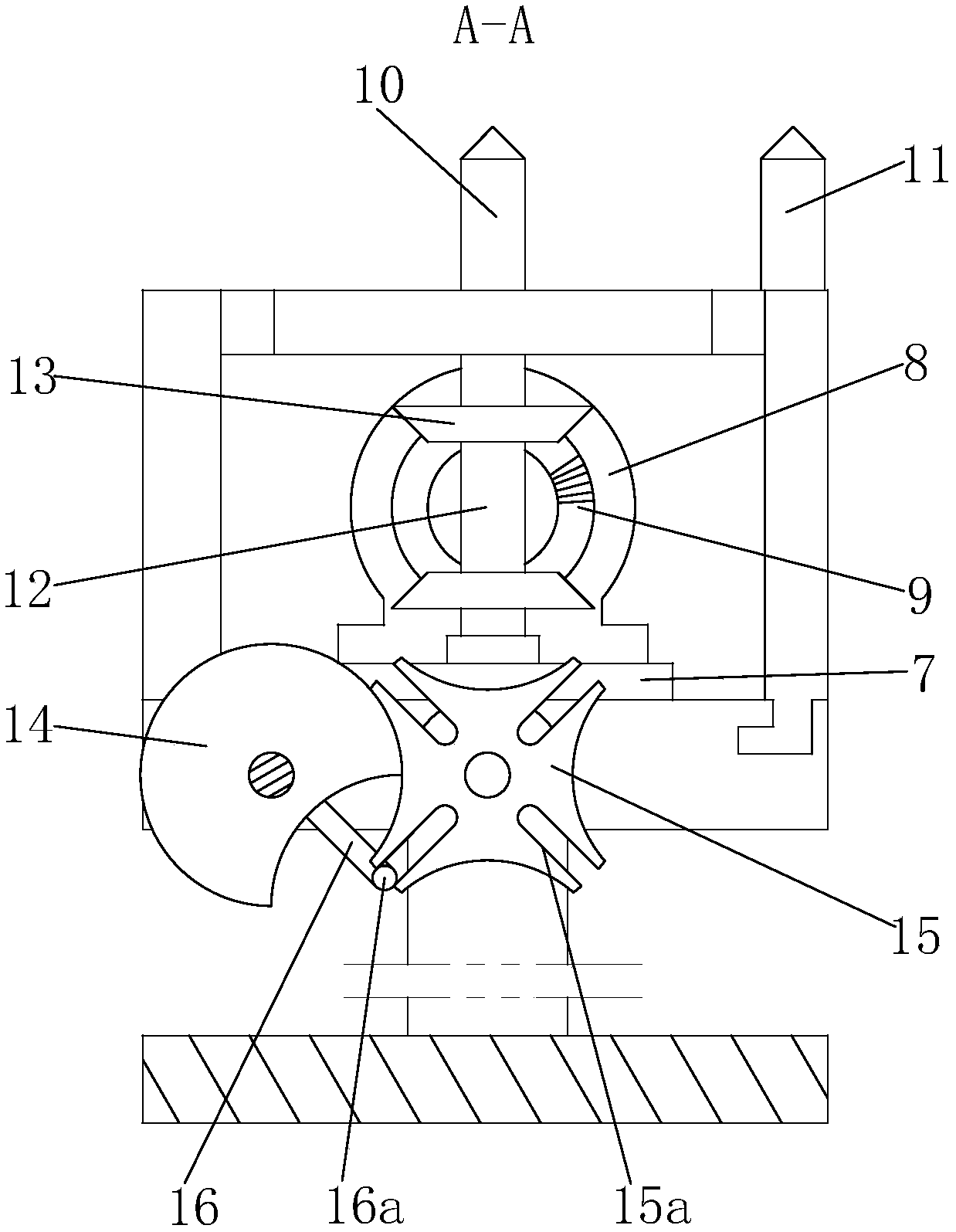

Large-scale pipe inner wall automatic pigment spraying device

The invention relates to a large-scale pipe inner wall automatic pigment spraying device. The device comprises a bottom plate. The bottom plate is respectively provided with a first motor and a spindle in a fixing mode and a bearing seat installation mode correspondingly. A Geneva mechanism for connecting the first motor and the spindle is arranged between the first motor and the spindle. A rotating frame is connected to the spindle by a key, and the rotating frame is fixedly provided with a first rack. Two sliding slots are formed in the rotating frame. One sliding slot is provided with a second rack in the sliding mode, and the other sliding slot is provided with a movable plate in the sliding mode. The device has high degree of automation, and can automatically achieve the spraying andrendering effects of two strips of different pigments alternatively arranged and different in length and color in the annular direction on the inner wall of a large pipe. The two spraying effects aregood, and the effect of improving the ornamental value and the enjoyment is achieved during playing of children.

Owner:WUHU TAINENG ELECTRIC APPLIANCES

Industrial robot and method for operating industrial robot

PendingCN114392863ASpray evenlyGood spray effectPretreated surfacesLiquid spraying apparatusProcess engineeringMechanical engineering

The invention relates to the technical field of industrial robots, in particular to an industrial robot and a method for operating the industrial robot, and adopts the technical scheme that the industrial robot comprises a mounting table, a conveying belt is arranged in the top end of the mounting table, a spraying box is fixedly mounted above the middle of the mounting table, and the industrial robot further comprises a spraying device and a controller; the spraying mechanism is fixedly installed in one side of the spraying box, the spraying mechanism is fixedly communicated with a feeding mechanism, an air injection assembly is fixedly installed in the side, away from the spraying mechanism, of the spraying box, the air injection assembly is fixedly communicated with a heating assembly, the controller is fixedly installed on one side of the spraying box, and the controller is electrically connected with the conveying belt. According to the paint spraying device, paint can be evenly sprayed to parts through the spray head, spraying is more uniform, the spraying effect is good, hot air is sprayed to the parts through the air spraying assembly, the paint on the parts is rapidly dried, and then the machining efficiency of the parts is improved.

Owner:NANTONG VOCATIONAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com