Full-automatic coating stirring spray coater

A fully automatic, spraying machine technology, applied in the direction of construction, building construction, etc., can solve the problems of low work efficiency, high labor intensity of workers, high factory requirements, etc., to ensure the construction effect, shorten the construction period, and reduce construction equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

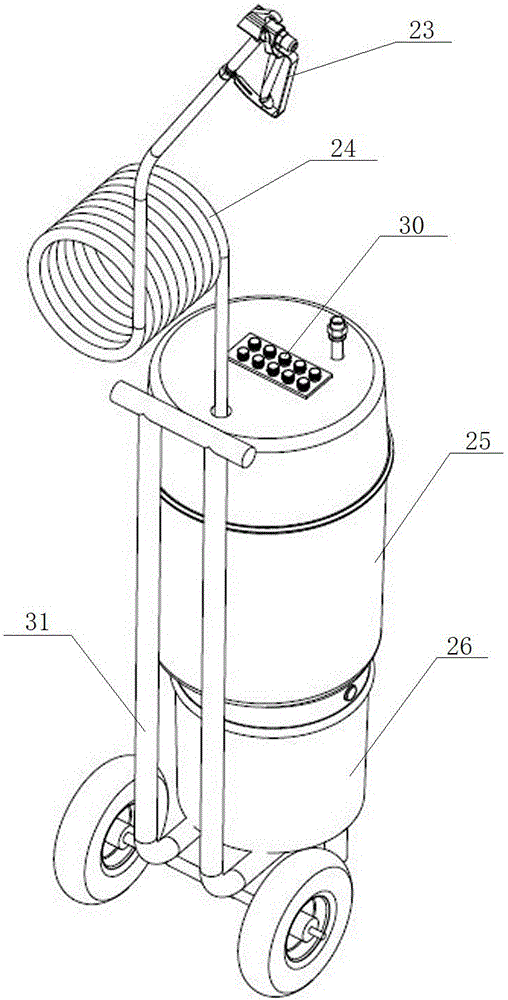

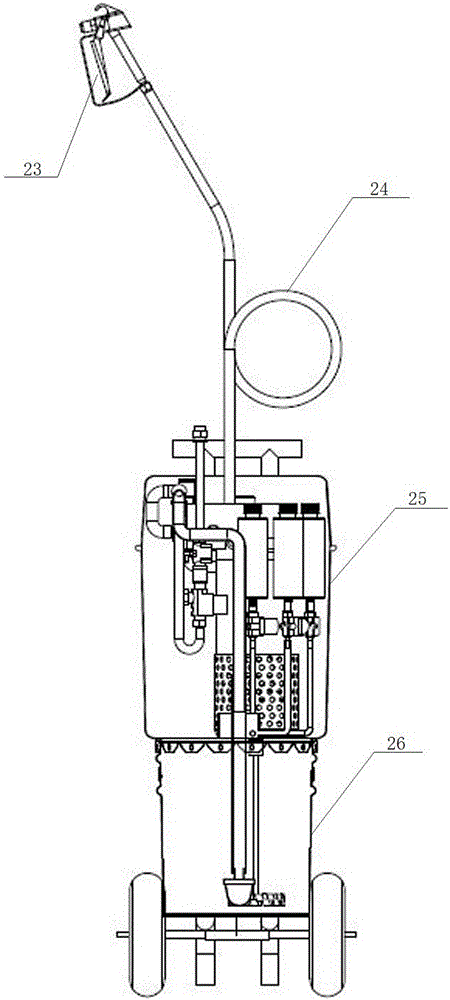

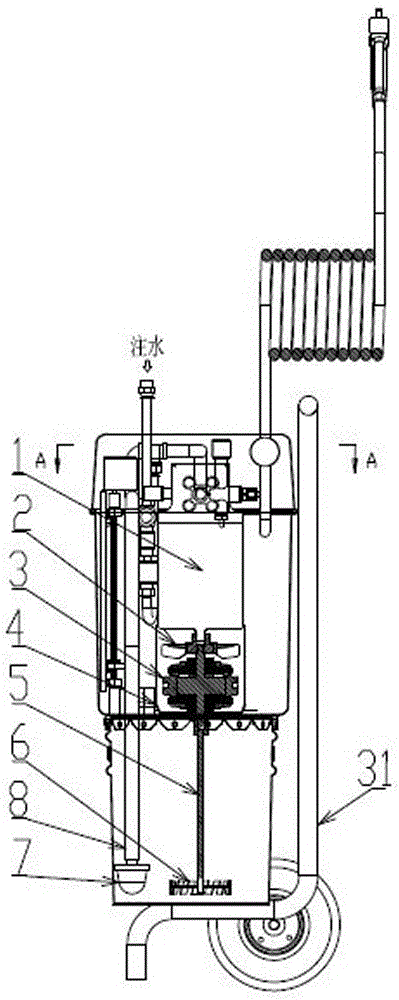

[0017] Such as Figure 1 to Figure 7 As shown, the paint automatic stirring spraying machine includes an electric high-pressure airless diaphragm pump 1, a cooling fan 2, a clutch 3, a protective cover 4, a stirring shaft 5, a dispersion disc 6, a suction pipe 8, a filter suction port 7, and a motor 17. Upper fixed bearing 15, lead screw 13, fixed rail 12, running block 11, lower fixed bearing 9, first solenoid valve 18, flow controller 19, tee 20, water inlet pipe 21, quick water outlet 22, spray gun 23 , discharge pipe 24, machine outer shell 25, raw material barrel 26, liquid raw material bottle 27, second solenoid valve 28, feed pipe 29, control panel 30 and mobile trolley 31, electric high-pressure airless diaphragm pump 1 lower part and cooling fan 2 connection, the lower part of the cooling fan 2 is connected with the input shaft of the upper end of the clutch 3, the upper end of the stirring shaft 5 is connected with the output shaft of the lower end of the clutch 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com