Patents

Literature

37results about How to "Less construction equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

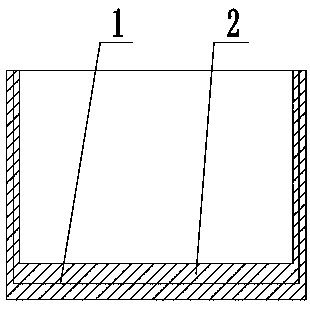

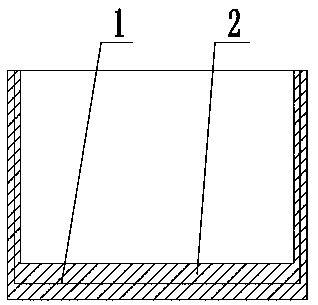

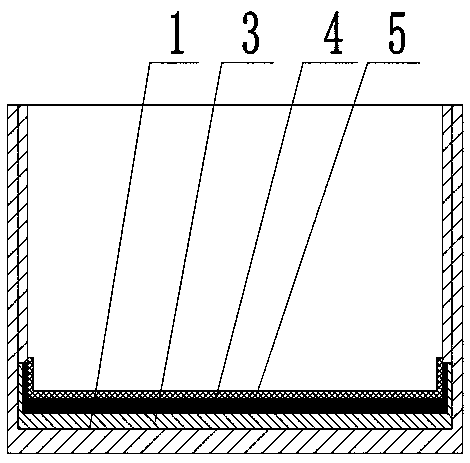

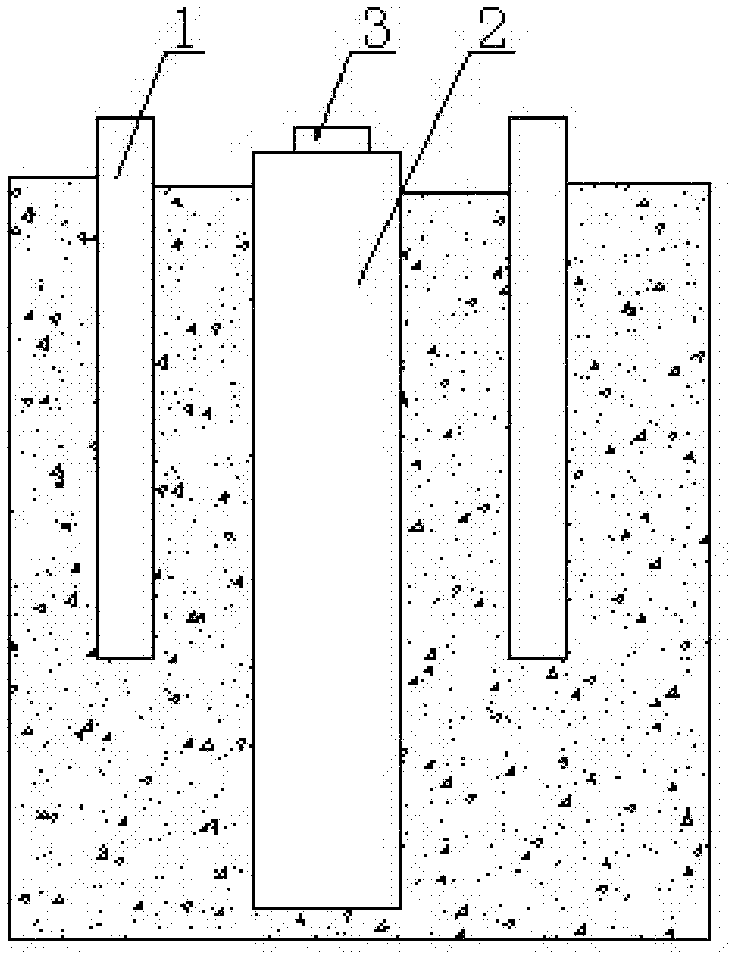

Novel precast concrete pipe die and construction method thereof

InactiveCN102373803ARealize the use functionReduce usageStrutsForms/shuttering/falseworksPre stressEngineering

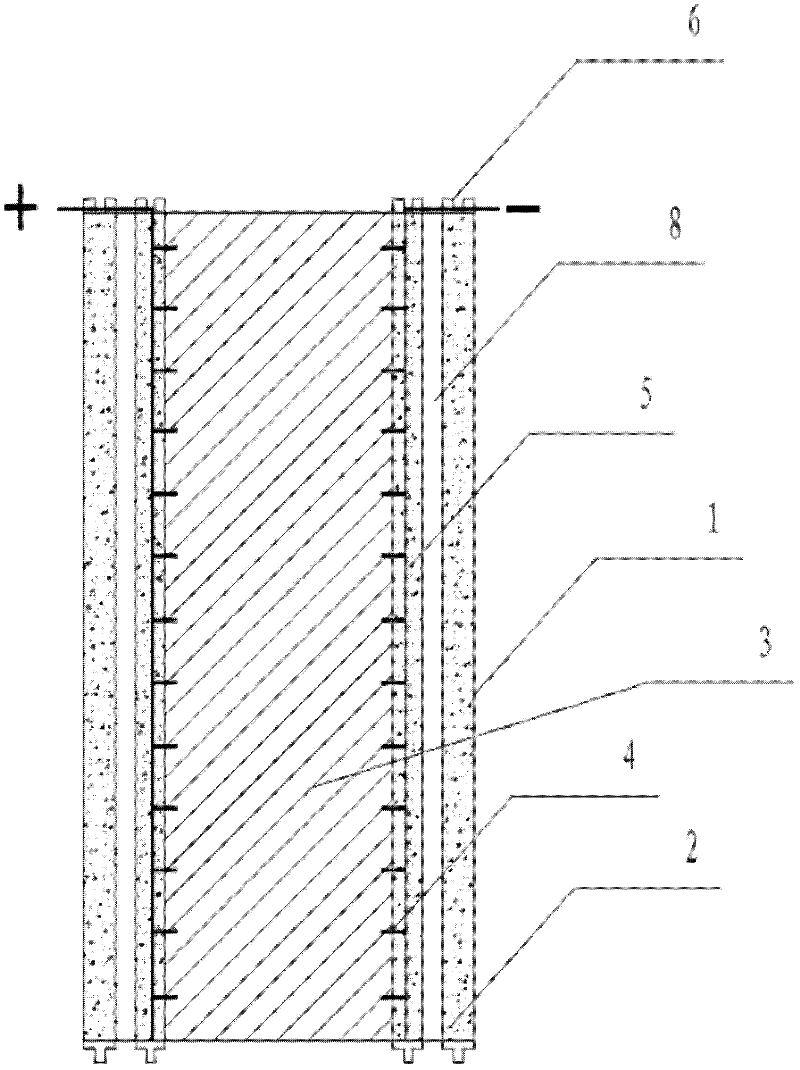

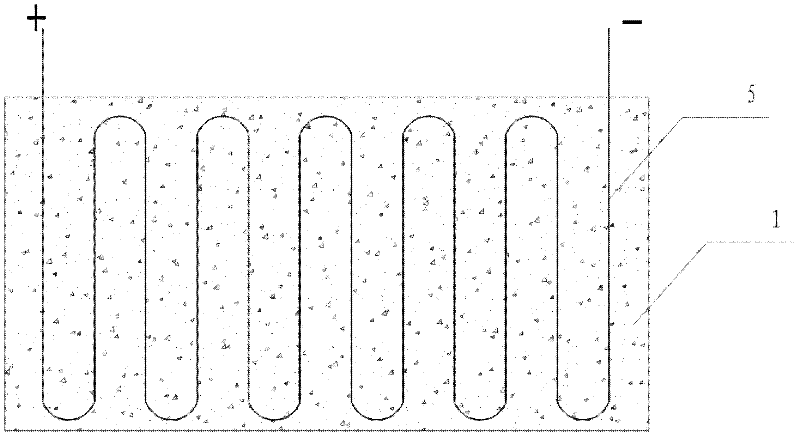

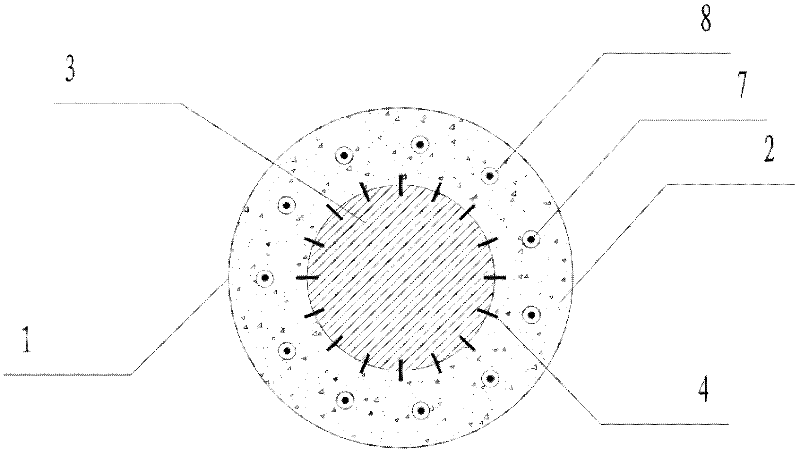

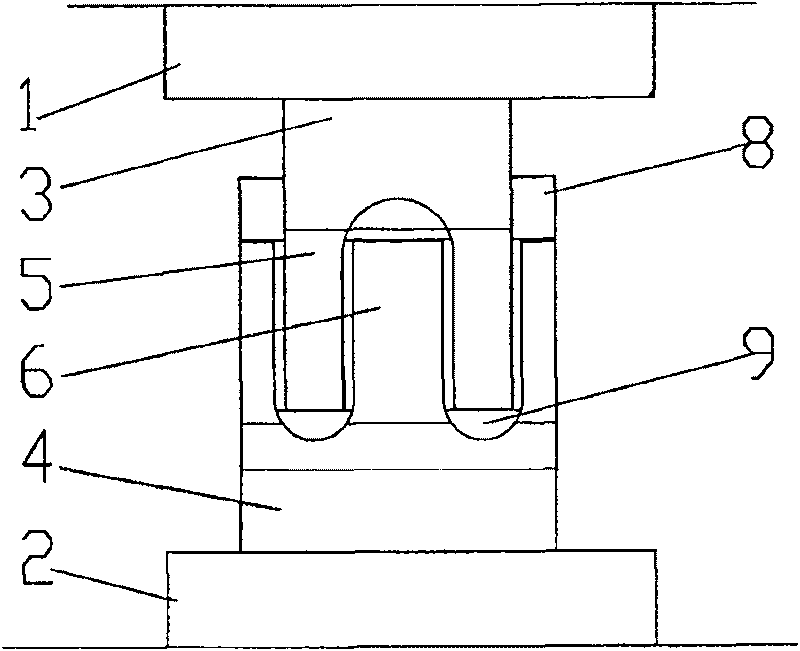

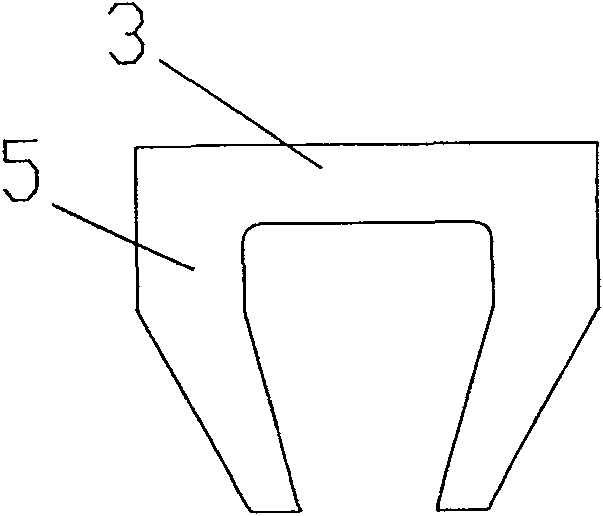

The invention discloses a novel precast concrete pipe die, which is a precast concrete pipe pile of a hollow structure. The wall of the precast concrete pipe die is internally provided with annular and vertical reinforcing steel bars, the inner surface of the pipe die is provided with dowel bars connected with post-poured concrete into a whole and an electric heating wire for heating, the upper end and the lower end of the pipe die are provided with tooth-shaped connectors which are mutually matched, the wall of the pipe die is internally provided with preset pore canals for prestress reinforcing steel bars, and the pore canals are through longitudinally. A construction method of the novel precast concrete pipe die comprises the steps of: after positioning the precast concrete pipe die, switching on a power supply of the electric heating wire, and performing high-dropping self-compacting concrete pouring on the middle of the concrete pipe die; and after a first section of cylinder core of the pipe die is poured, performing hoisting positioning and concrete pouring on a second section of the concrete pipe die. The invention has the advantages that by precasting the concrete pipe die, the special requirement on the use functions of a concrete column surface and a column template can be met, and the heating functions of the novel precast pipe die can also ensure the smooth construction in winter; and the novel precast concrete pipe die and the construction method thereof have the advantages of simplicity and rapidness for construction, less required construction equipment, and capability of greatly reducing the construction cost and the comprehensive manufacturing cost.

Owner:TIANJIN UNIV

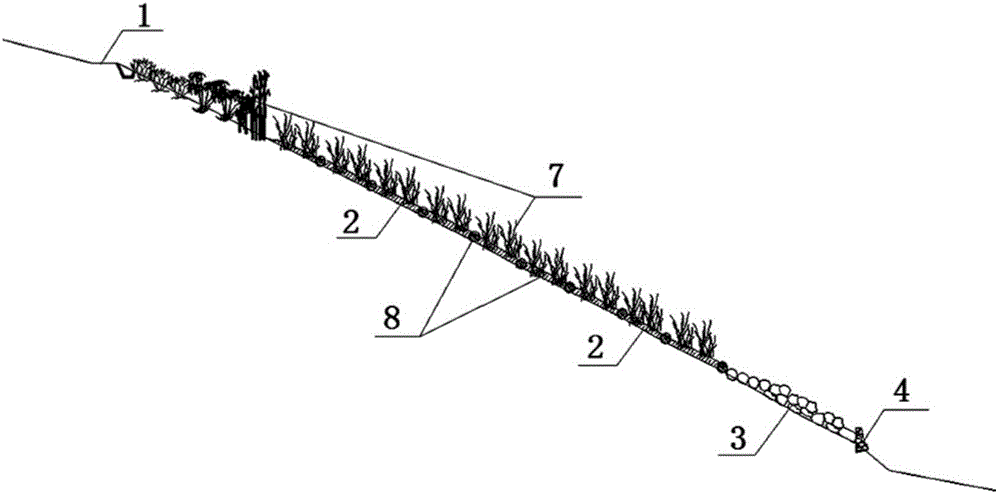

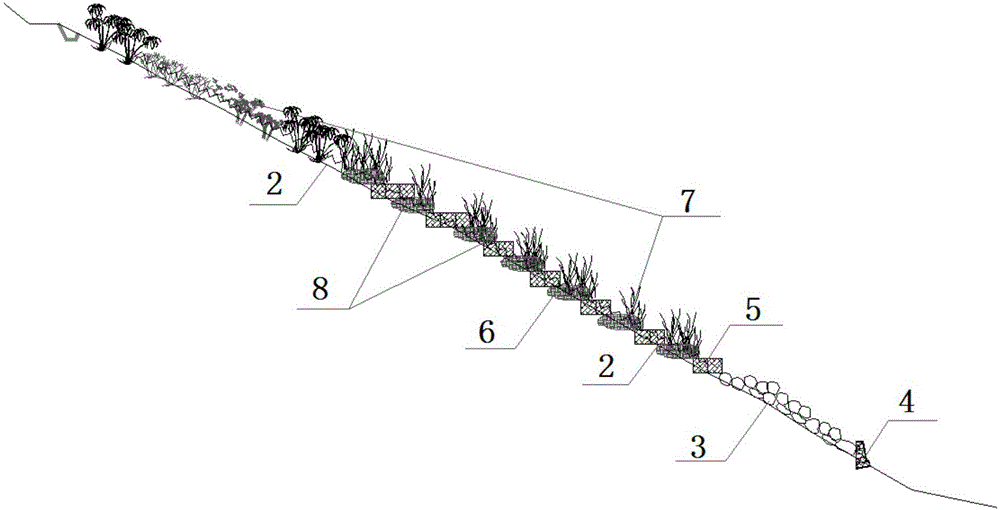

Ecological restoration structural system and restoration method for lakeside zone

ActiveCN106381837ALess construction equipmentFast constructionBreakwatersQuaysEngineeringRestoration method

The invention discloses an ecological restoration structural system and a restoration method for a lakeside zone. The ecological restoration structural system for a lakeside zone is provided with a planting plant zone and a physical substrate zone in sequence along a direction from a bank slope to a lakeside center, and a wave resistance device is arranged in an arranging region of the planting plant zone. According to the ecological restoration structural system and the restoration method for a lakeside zone, the ecological physical substrate is built in the lakeside zone, and the problem of harmonious coexistence of aquatic plants and the physical substrate is effectively solved.

Owner:POWERCHINA ZHONGNAN ENG

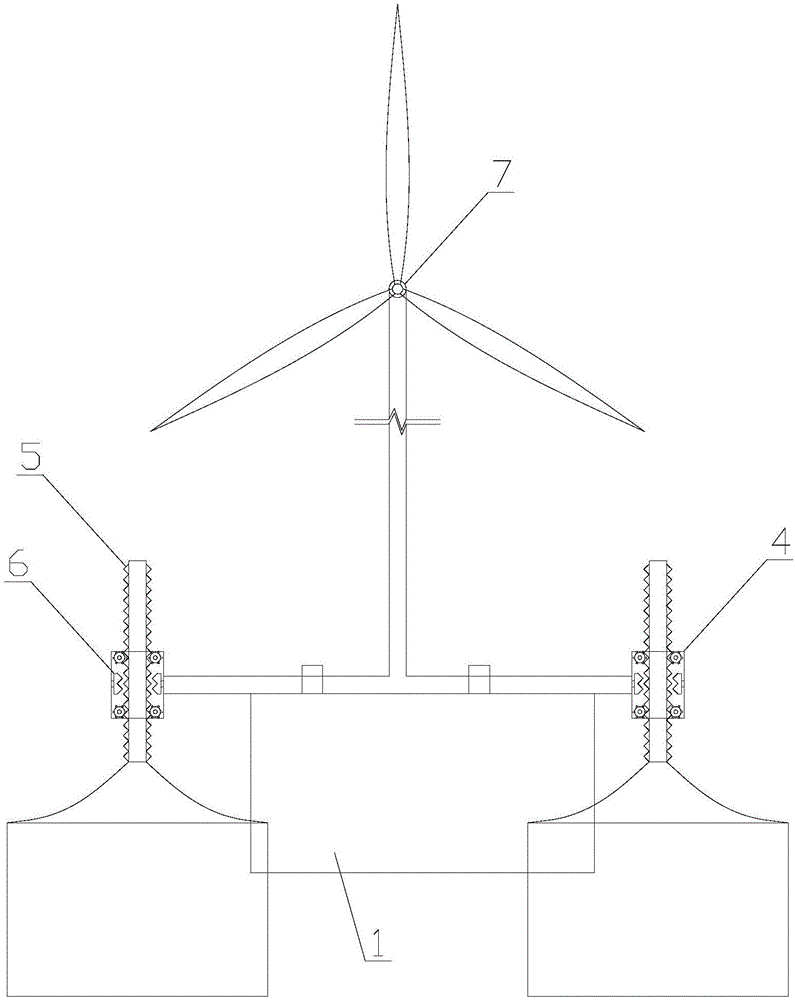

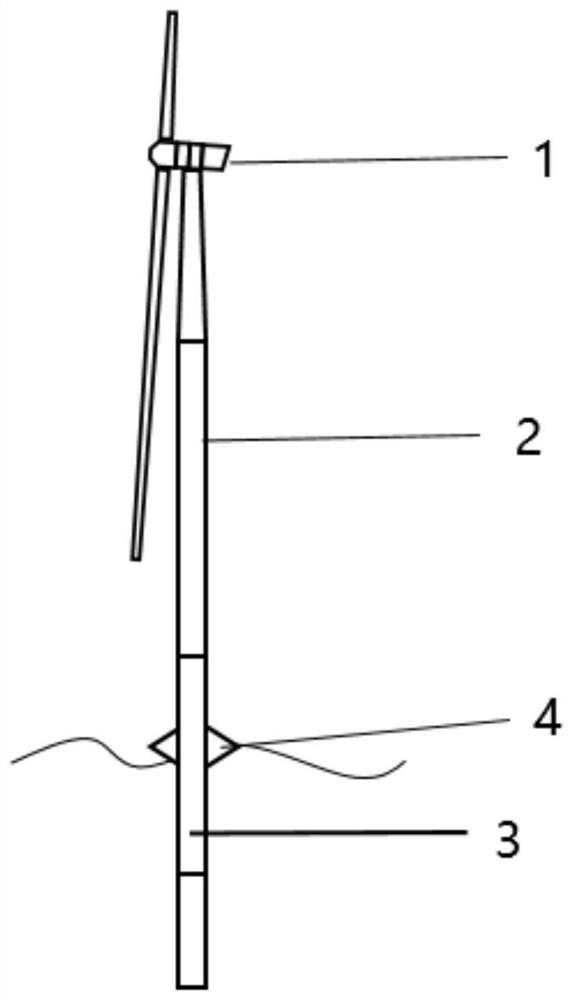

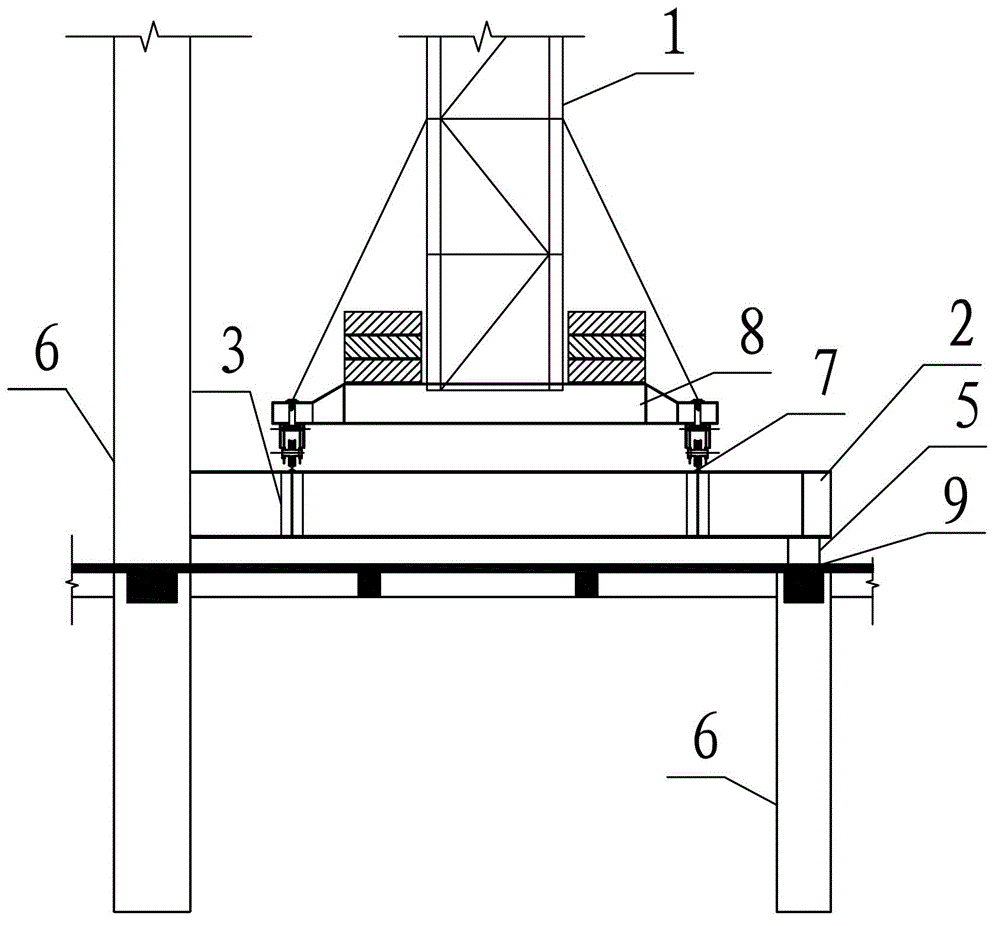

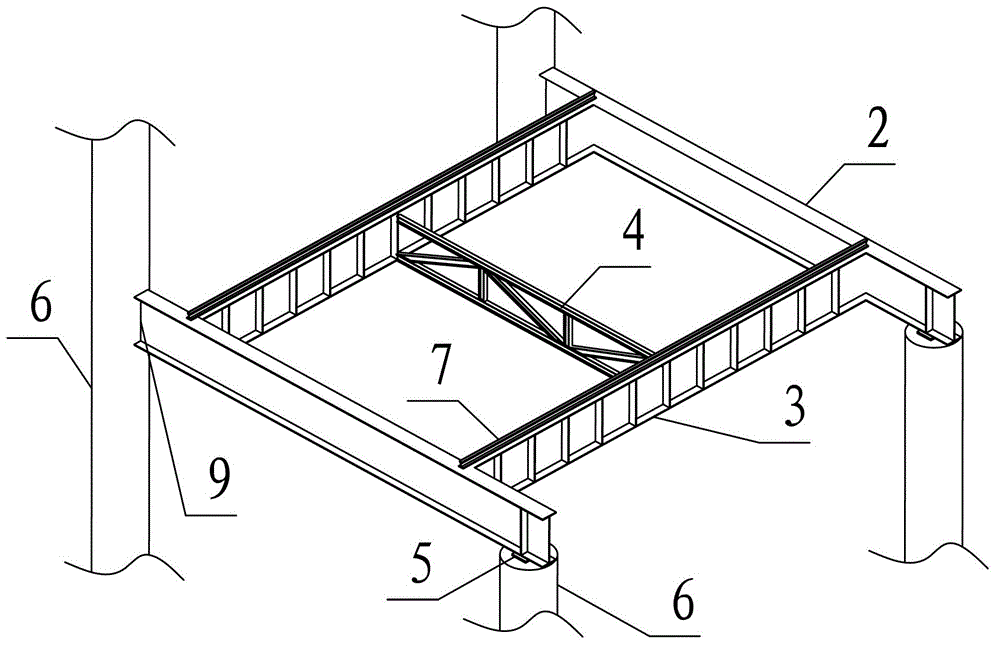

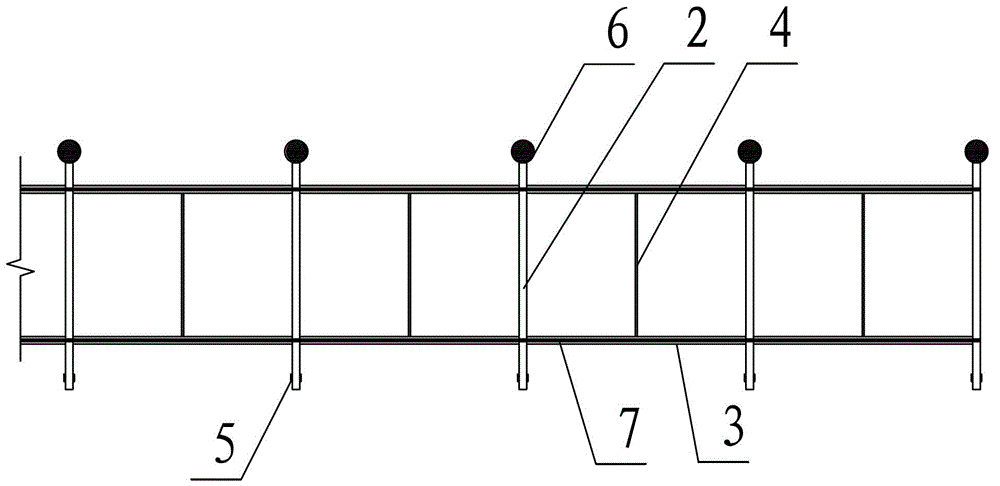

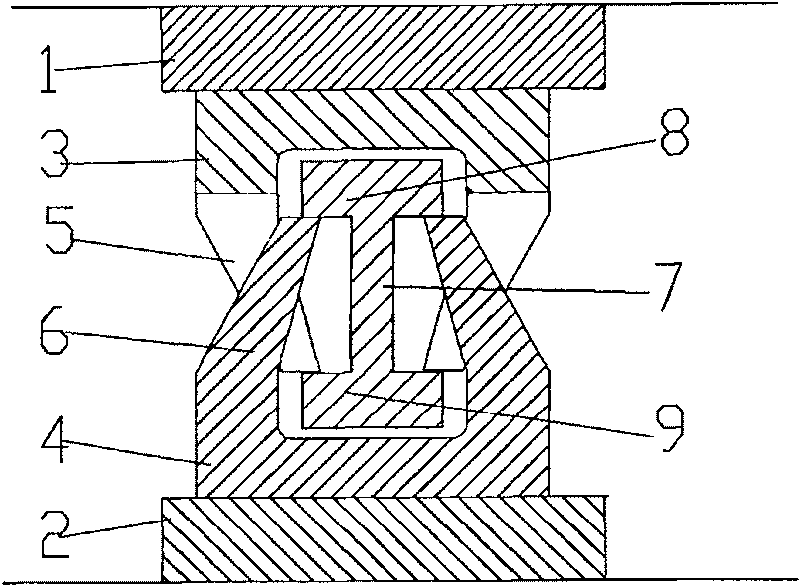

Three-barrel self-elevating gantry type wind power generator foundation structure and construction method thereof

ActiveCN106801431ASimplify the construction processLess construction equipmentFoundation engineeringElectricityEngineering

The invention belongs to the field of ocean wind power generator foundations, and discloses a three-barrel self-elevating gantry type wind power generator foundation structure and a construction method thereof. The three-barrel self-elevating gantry type wind power generator foundation structure comprises three barrel-shaped bases which are connected into an integral body through a gantry type tower frame; and the gantry type tower frame comprises three vertical tower frames and three transverse tower frames which are connected into a gate shape; the vertical tower frames and the transverse tower frames are connected through lifting mechanisms; the lifting mechanisms comprise racks mounted on the two sides of the vertical tower frames, gears mounted at the outer ends of the transverse tower frames, locking devices and lifting control systems; and during construction, on one hand, buoyancy of the barrel-shaped bases is effectively utilized during towing, and on the other hand, mechanical sinking is achieved through the lifting mechanisms, and mounting is achieved through a traditional sinking manner. The three-barrel self-elevating gantry type wind power generator foundation structure has the advantages of the barrel-shaped bases and a self-elevating gantry; and in the construction method, buoyancy of the barrel-shaped bases is effectively utilized during towing, the entire sinking process is simple and quick, few construction devices are required, a large on-water site construction device is not utilized, the construction speed is high, and comprehensive construction cost is low.

Owner:TIANJIN UNIV

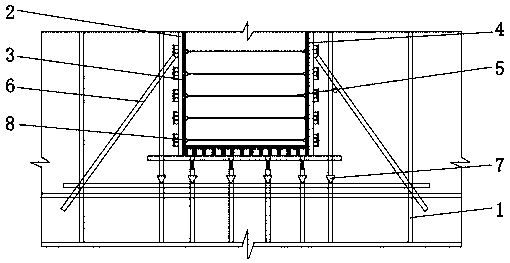

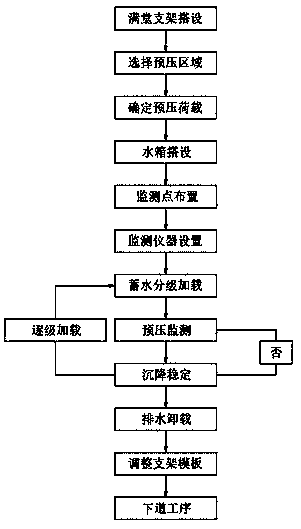

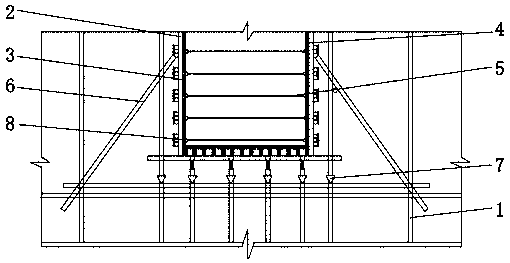

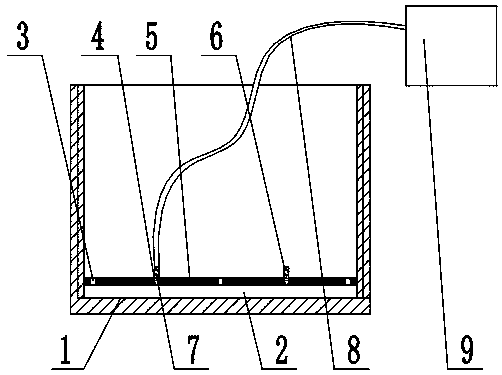

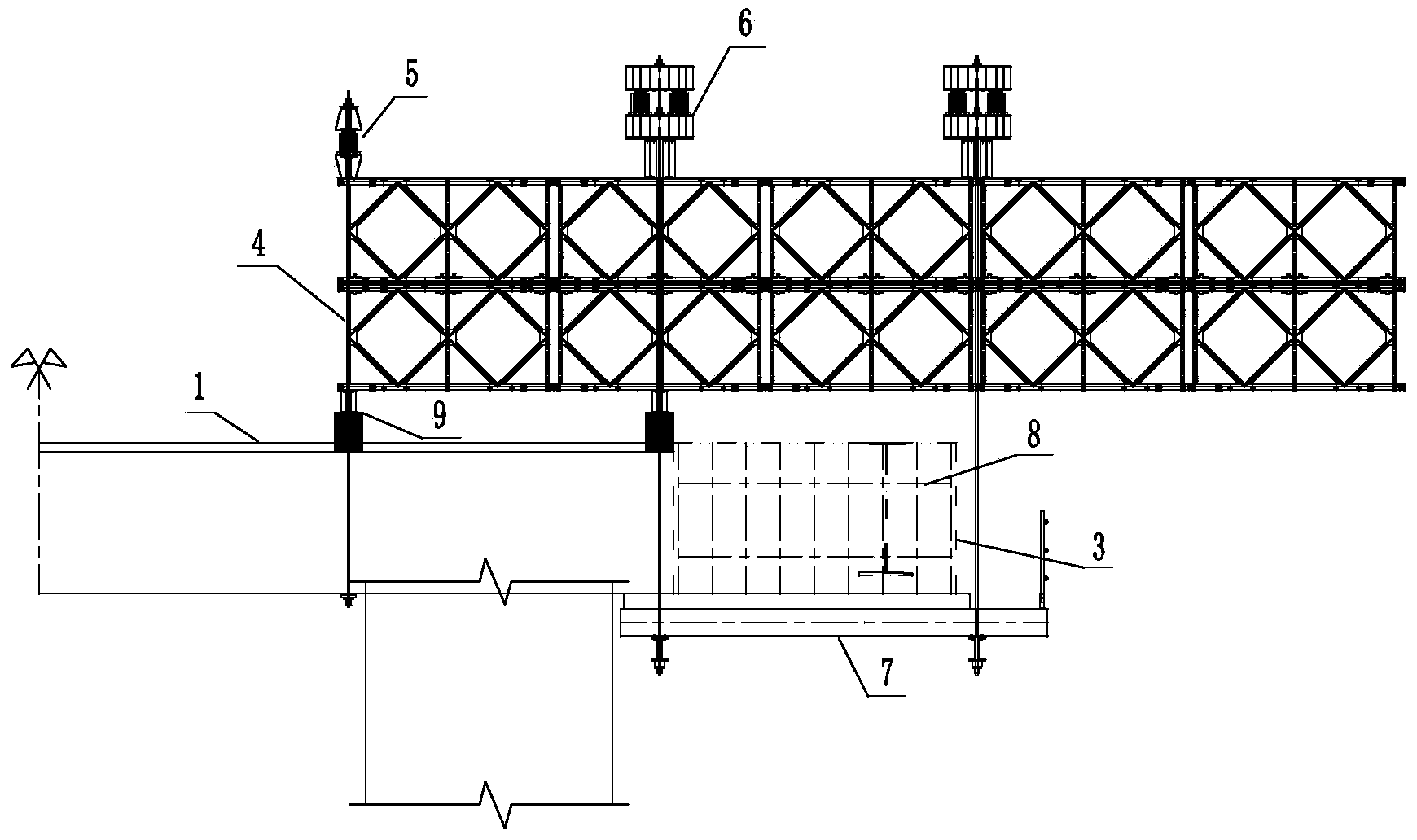

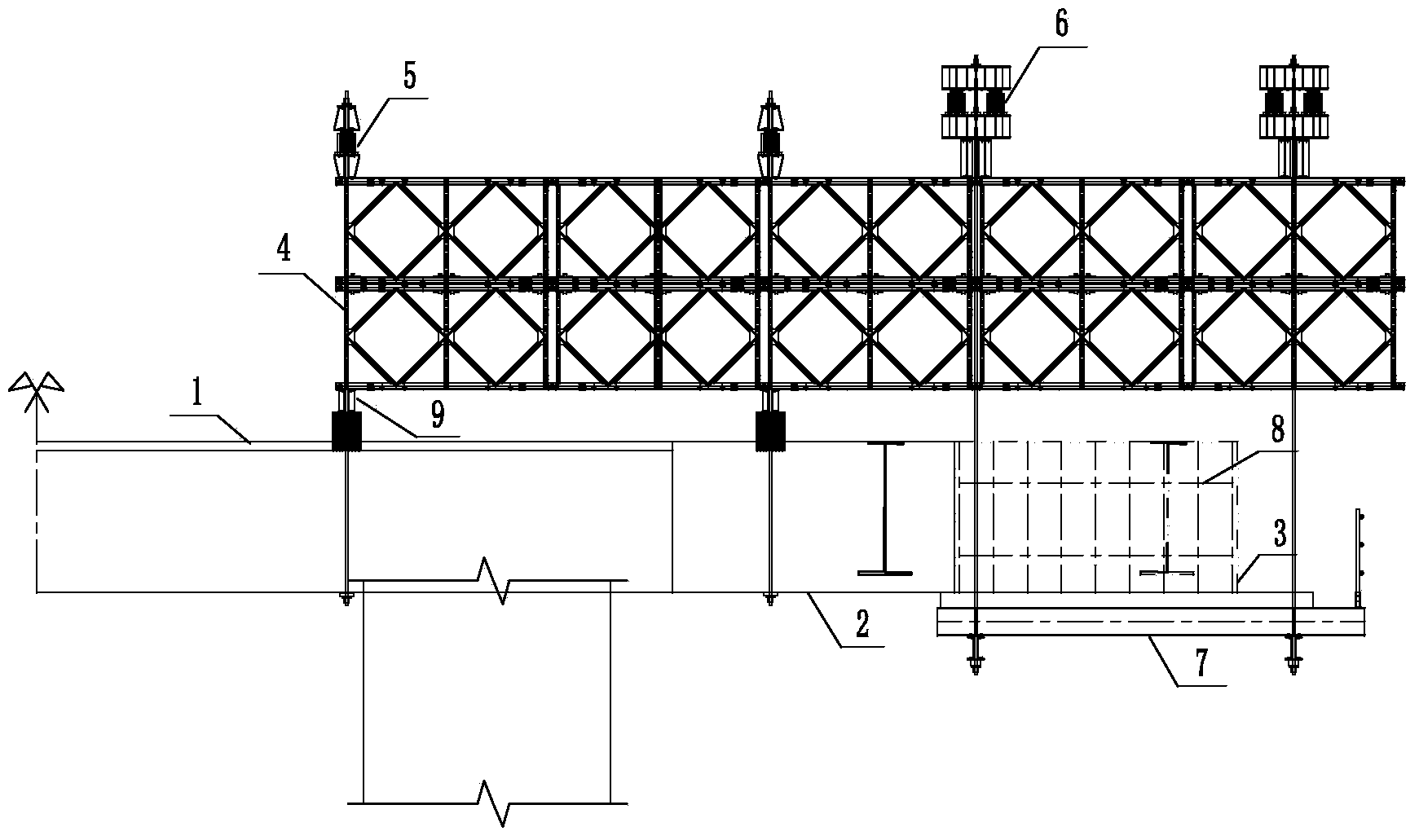

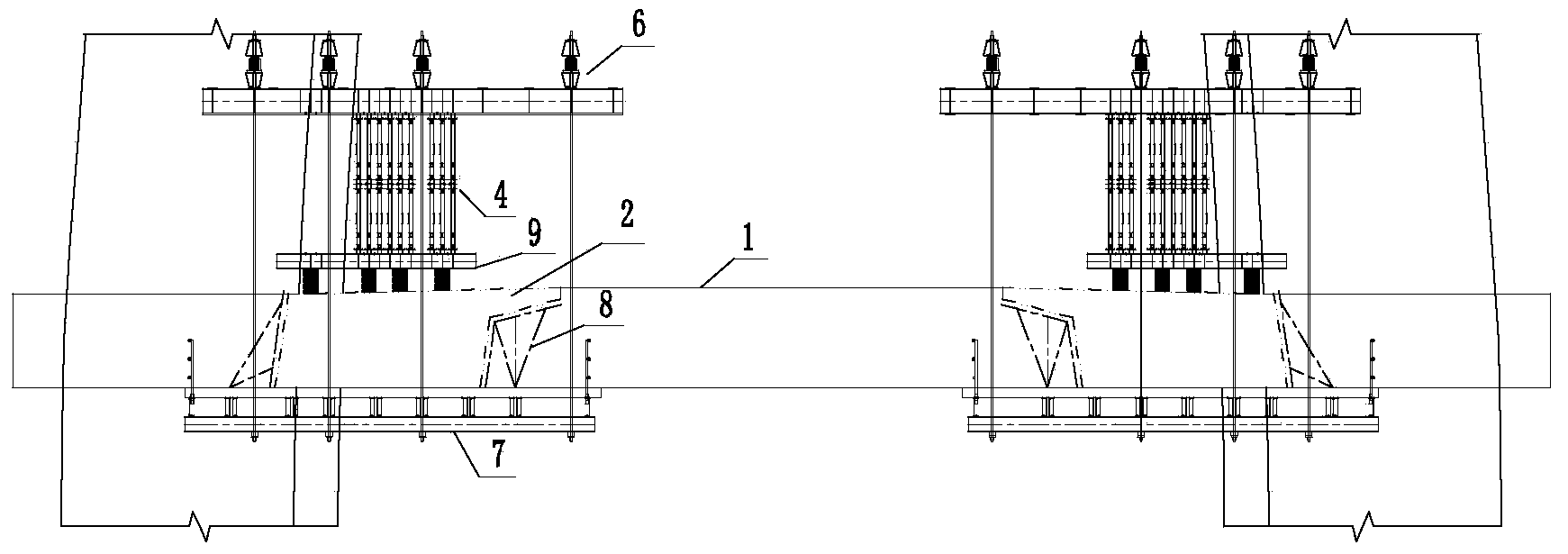

Preloading water tank and technology of huge open-frame girder steel tube full support

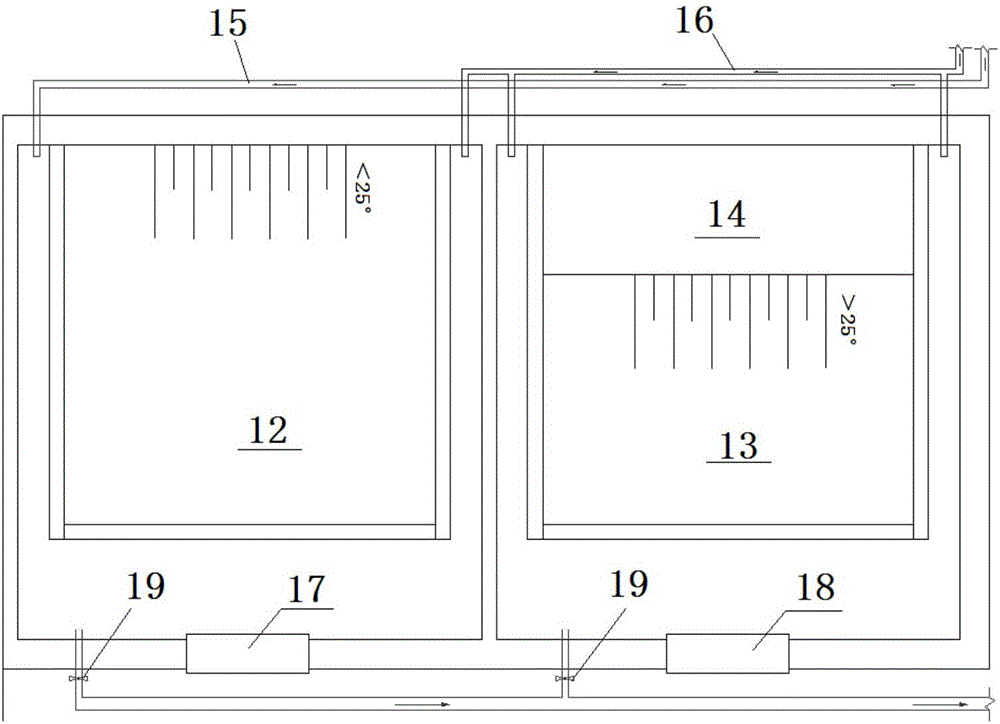

PendingCN110043029ASolve highSolve the problem of long and narrow pre-pressing surfaceMaterial strength using tensile/compressive forcesForms/shuttering/falseworksWater storageReinforced concrete

The invention relates to the technical field of building construction, and discloses a water tank preloading technology of a huge open-frame girder steel tube full support. The water tank preloading technology includes the following operation processes of full support erection, preloading area selection, preloading load determination, water tank erection, monitoring point arrangement, monitoring instrument setting, water storage gradation loading, preloading monitoring, settlement stabilization, drainage and unloading, support template adjustment and next procedure executing. By using simple equipment which is always available at the site and self-configuring a water tank, the flexibility, simpleness and convenience are achieved, the working efficiency is high, and compared with a traditional preloading method, the construction period can be shortened by 1 / 3 or above; and the processing cost is low, operation is easy and convenient, the cost is saved, compared with adopting a precast reinforced concrete block preloading method, the investment can be saved by 70-80%, compared with sandbag stacking preloading, the investment is saved by 30-40%, and compared with site reinforced material preloading, the investment can be saved by 20-30%, and the preloading method has the advantages of less construction equipment, high construction efficiency, local material using, easy manufacturing, environment-friendly construction, reasonable actual stress state in the simulated pouring process, and the like.

Owner:贵州建工集团第二建筑工程有限责任公司

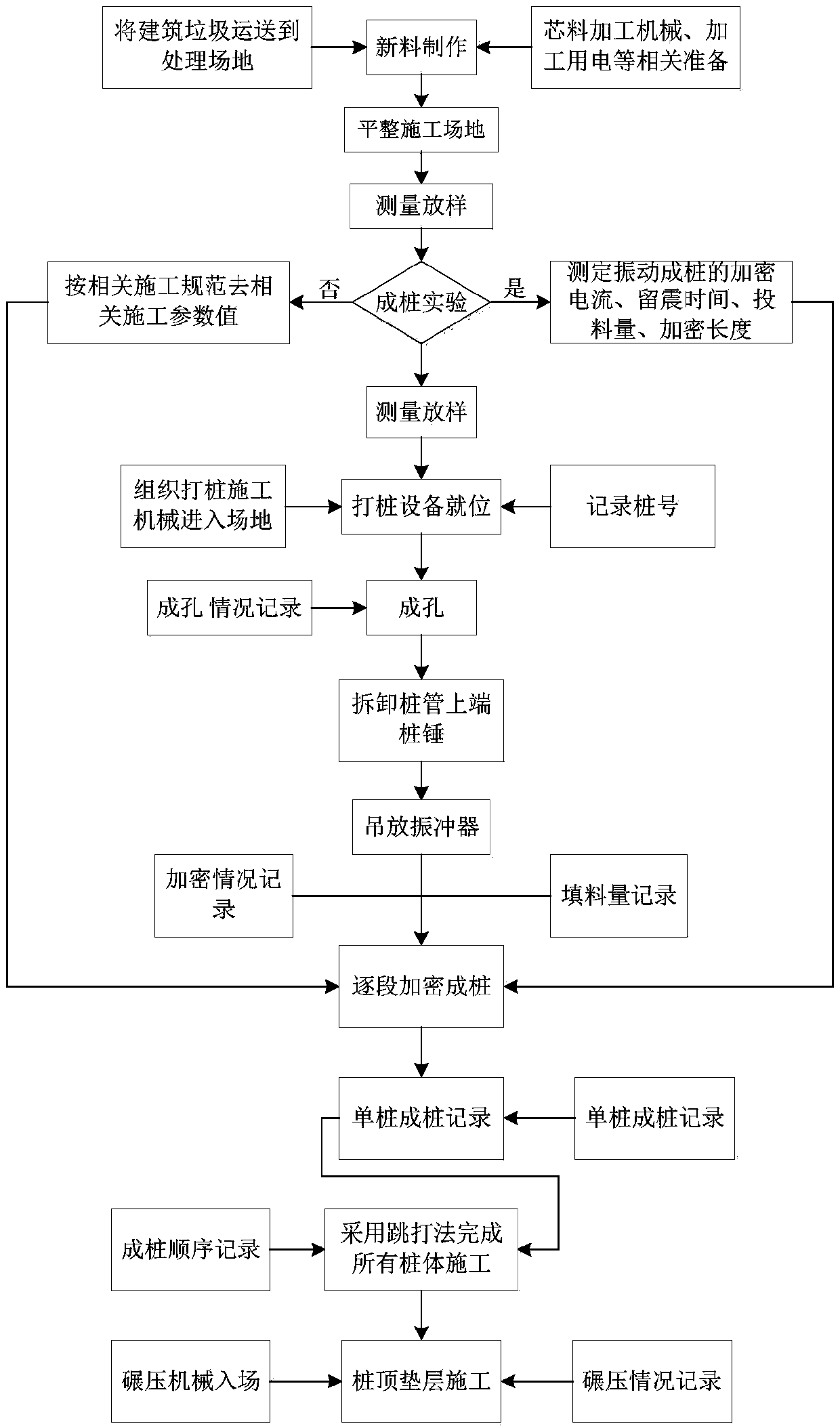

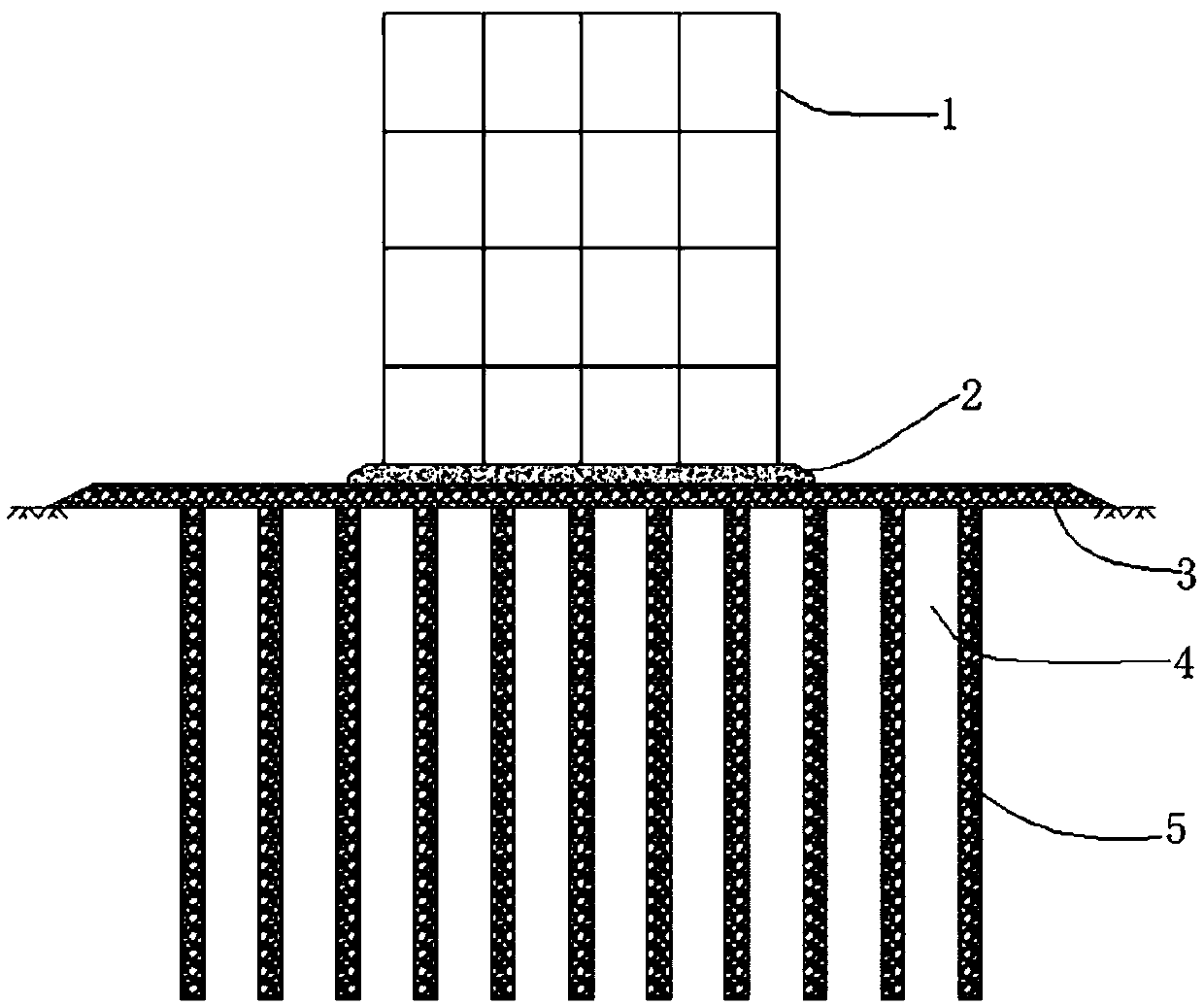

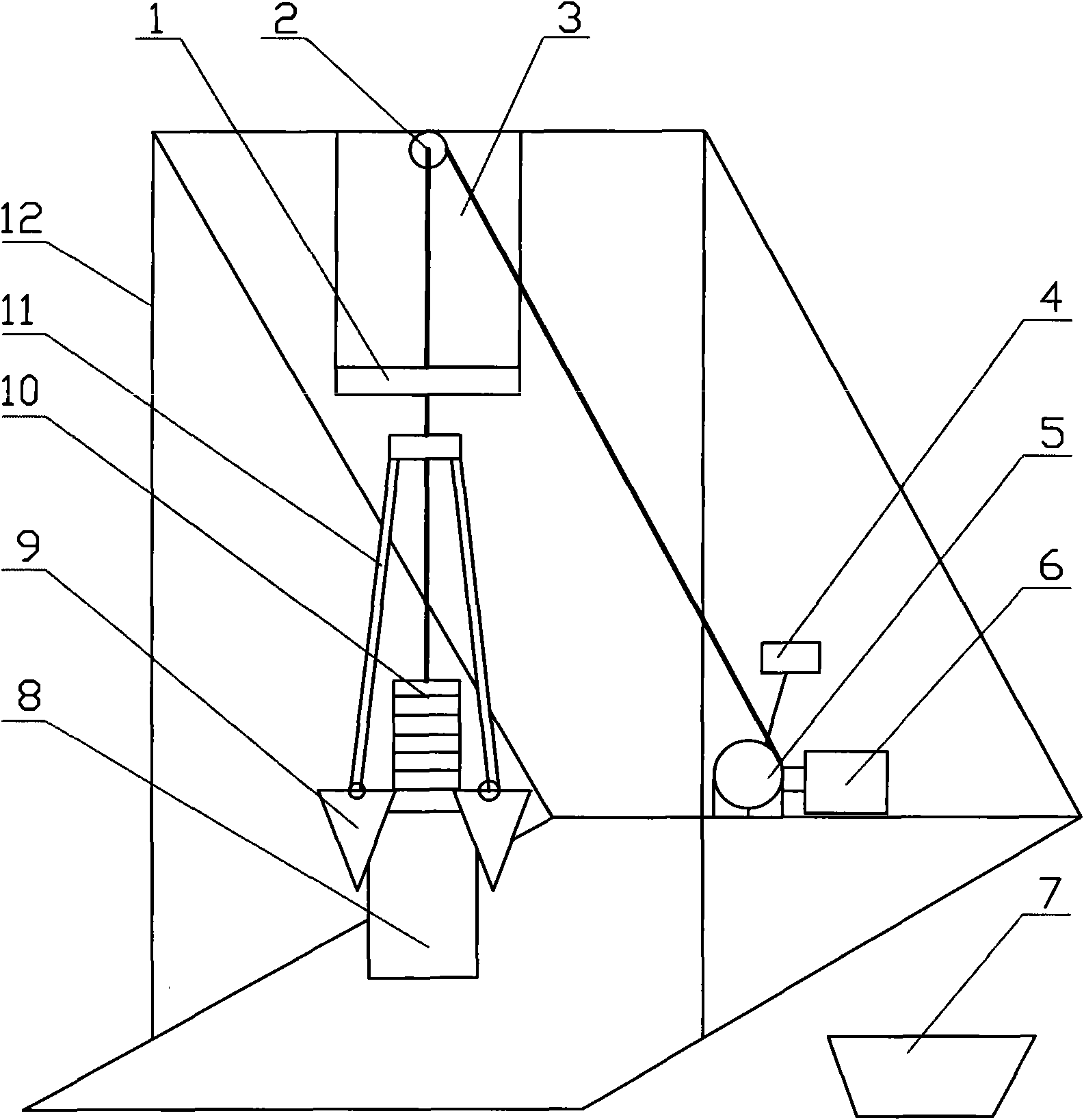

Liquefied foundation treatment method based on building garbage

InactiveCN109680671AEmission reductionImprove reinforcementFoundation testingBulkheads/pilesPile driverConstruction waste

The invention discloses a liquefied foundation treatment method based on building garbage. The liquefied foundation treatment method comprises the following steps of crushing the building garbage, andtransporting to a construction site; performing pile-forming test around a construction consolidated foundation site; measuring and lofting according to a pile diagram of building garbage piles; drilling pile driving holes by a steam pile driver and a guide pile driver; driving pile pipes to the preset depth of the treated foundation; feeding a core material with thickness of 80 to 100 cm into each pile hole, lifting each pile pipe until a contact coverage height of 20 cm is formed between the bottom of the pile pipe and the particle material, and placing a vibroflotation device to the bottompart of each pile hole via a sinking pipe; starting the vibroflotation device to maintain vibroflotation for 10 to 20 s, continuously feeding the material, and lifting the vibroflotation device and each pipe pile in a synchronous staged lifting way in the construction process of the pile body, wherein the lifting height is 30 cm in each stage, and the vibroflotation maintaining time of the vibroflotation device is 10 to 20 s until the construction of the pile body is completed; repeating the step S7, constructing by sections from bottom to top until the hole is reached, and recording the feeding quantity and vibroflotation maintaining time at the corresponding depth of each section; completing the construction of all pile bodies by a jump driving method; constructing a bedding layer of the pile top by a flat rolling method.

Owner:HAINAN UNIVERSITY

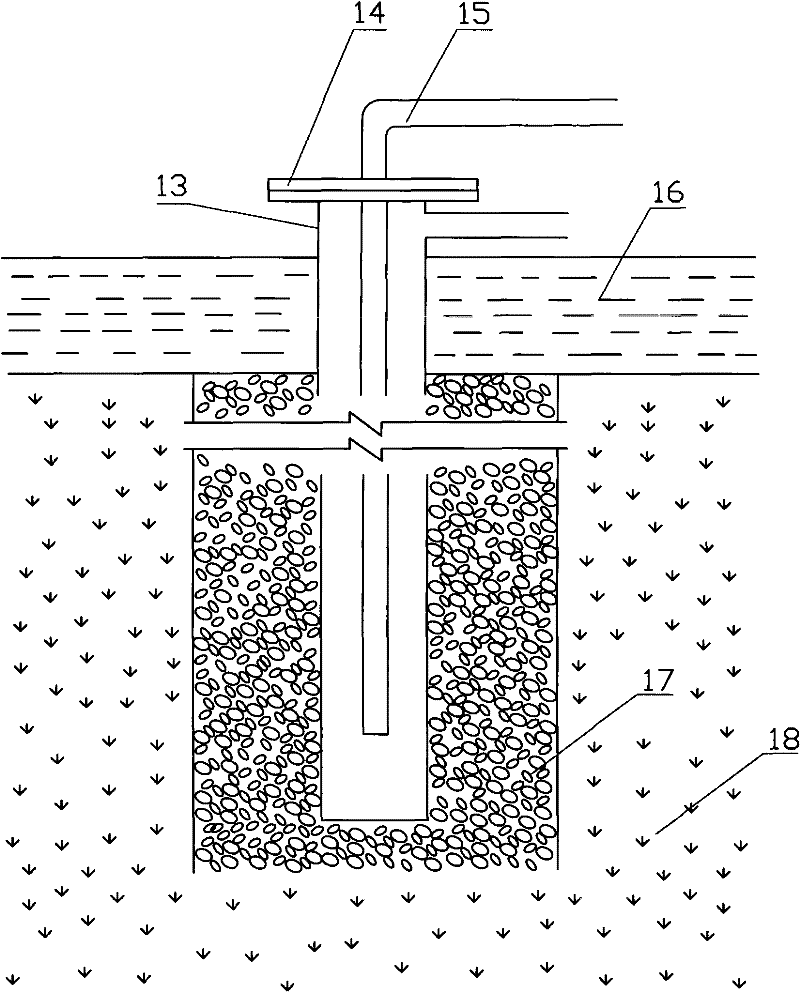

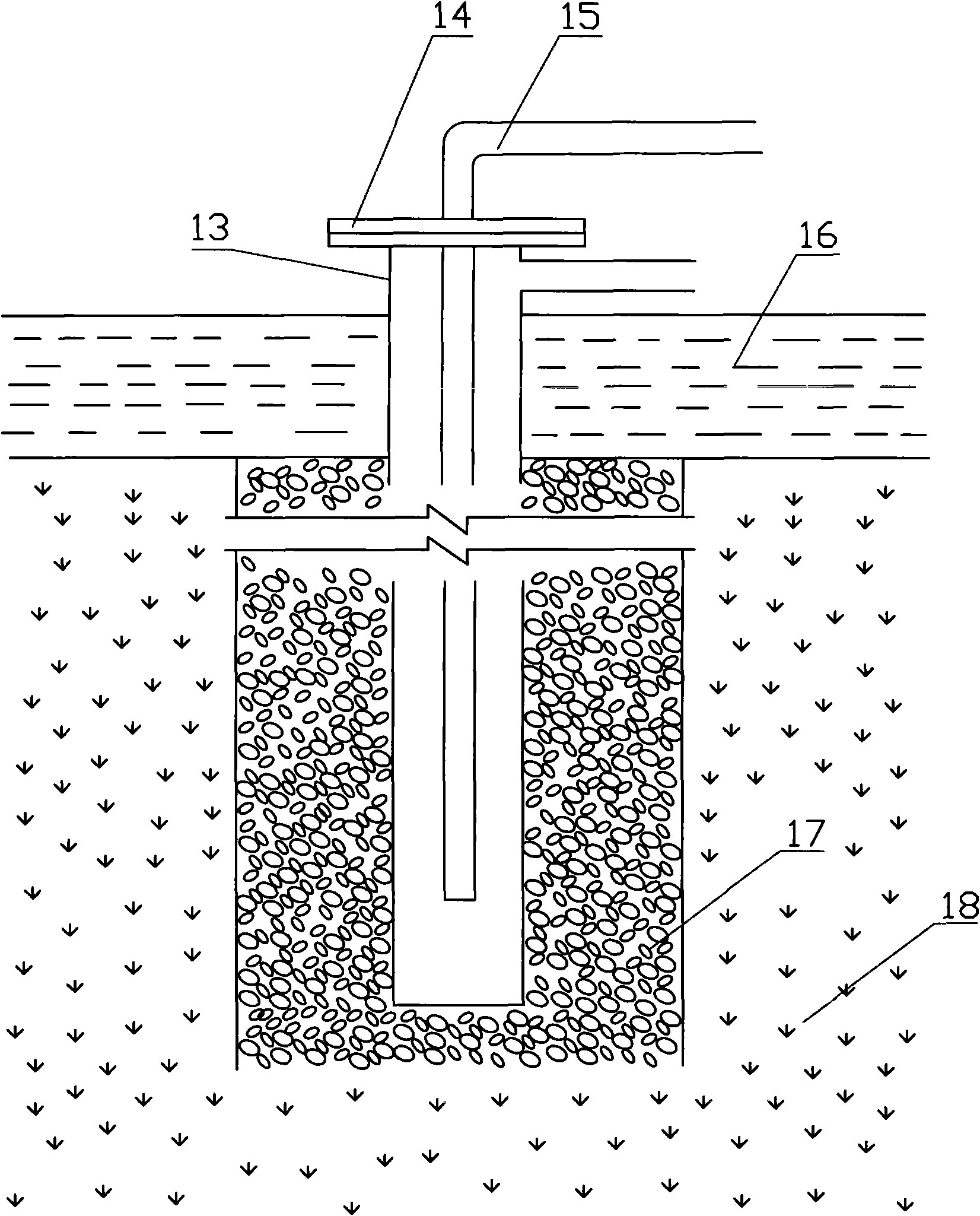

Landfill gas gas-collecting shaft construction method

ActiveCN101748751AImprove permeabilityImprove gas collection efficiencyArtificial islandsUnderwater structuresControl mannerPebble

The invention discloses a landfill gas gas-collecting shaft construction method, which adopts grabbing-bucket digging well method to dig the gas-collecting shaft, and the completed gas-collecting shaft has good permeability, and high gas-collecting efficiency. The grabbing-bucket is controlled through a steel rope, the length can be controlled; and the gas-collecting shaft with deep depth can be constructed according to needs, meanwhile, the control method can simplify the structure. Pebbles or gravels are poured into a gas-collecting vertical hole at the outside of a gas-collecting pipe to the top of the garbage layer, and the periphery of the gas-collecting shaft on the garbage layer is provided with bentonite, and the bentonite is tamped to form a sealing structure, accordingly, the efficiency can be further increased.

Owner:山高十方环保能源集团有限公司

Non-water-stopping grouting repairing method for expansion joint of sewage treatment structure

ActiveCN109812042AReduce professional requirementsLess construction equipmentBuilding repairsSewage treatmentExpansion joint

The invention discloses a non-water-stopping grouting repairing method for an expansion joint of a sewage treatment structure. The non-water-stopping grouting repairing method for the expansion jointof the sewage treatment structure comprises the following steps: cleaning a caulking material above a waterstop of an expansion joint to be repaired in the length direction of the expansion joint to be repaired to form a caulking joint; taking a water-swellable water stopping strip, wherein a grouting through hole is vertically formed in the water-swellable water stopping strip, and two sides of the grouting through hole are provided with water outlets; embedding the water-swellable water stopping strip into the cleaned caulking joint so that a grouting cavity is formed in the caulking joint;and pouring a grouting material into the grouting cavity through the grouting through hole until the grouting cavity is filled with the grouting material. Compared with an existing repairing method, the non-water-stopping grouting repairing method for the expansion joint of the sewage treatment structure in the technical scheme disclosed by the invention has the characteristics of small construction engineering amount, less construction equipment, low requirements on professionality of constructors, low construction cost and the like, and is suitable for repairing the expansion joint of the sewage treatment structure without stopping water.

Owner:重庆中法环保研发中心有限公司 +1

High-pier cable-stayed bridge zero-number block non-bracket construction method and structure in construction process

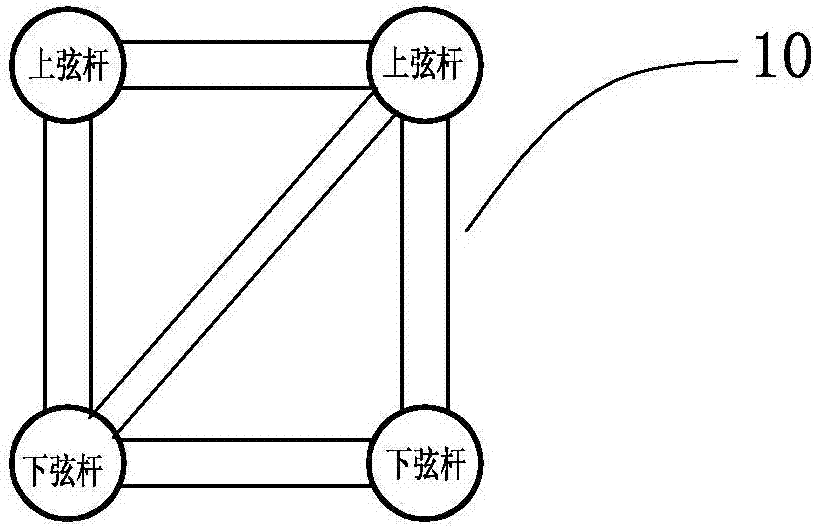

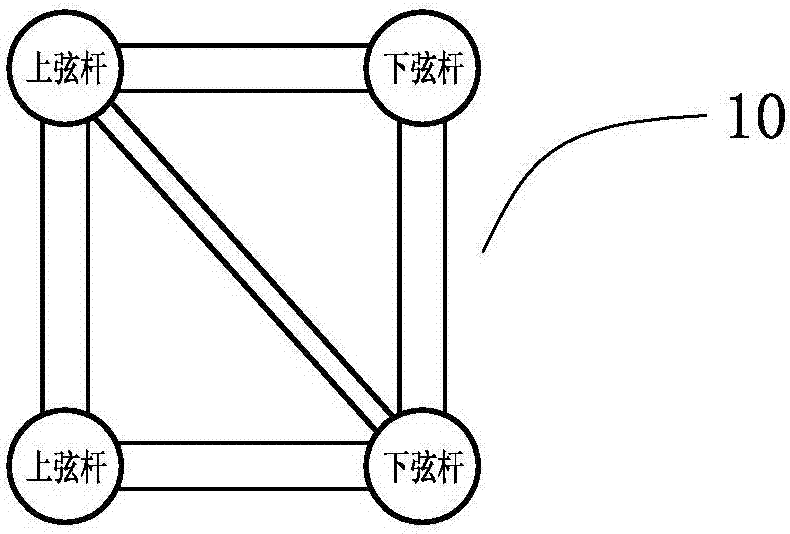

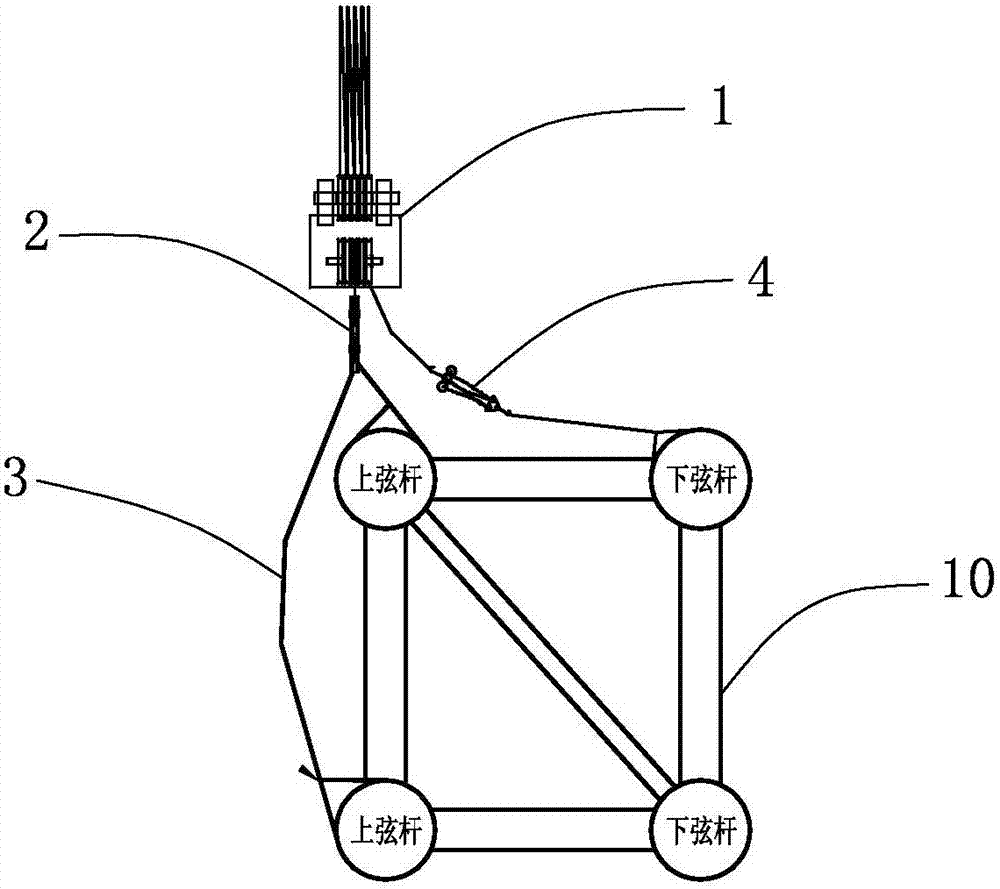

ActiveCN103835238AReduce weightLess construction equipmentBridge erection/assemblyArchitectural engineeringTower

The invention provides a high-pier cable-stayed bridge zero-number block non-bracket construction method and a structure in the construction process, and relates to the field of high-pier cable-stayed bridge construction. According to the construction method, a zero-number block is divided into a plurality of sections to be poured. First, two sleeper beams are laid on a main tower cross beam, and a spandrel girder is erected on each sleeper beam; then, the spandrel girders are anchored through a rear anchoring system. Each spandrel girder is provided with a suspension system to which a suspension bottom formwork system and a side formwork system are hung. Pouring of the zero-number block is realized section by section by moving the suspension systems and the sleeper beam close to the suspension systems till construction of the whole zero-number block is completed. By the adoption of the construction method, there is no need to use an ultrahigh extra-large steel tube stand column bracket or a steel corbel bracket, there is no need to utilize stay cables, as a result, construction cost and construction requirements are lowered, and the problem that a zero-number block which is high above the ground and has ultra-long sections is difficult to construct is solved.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

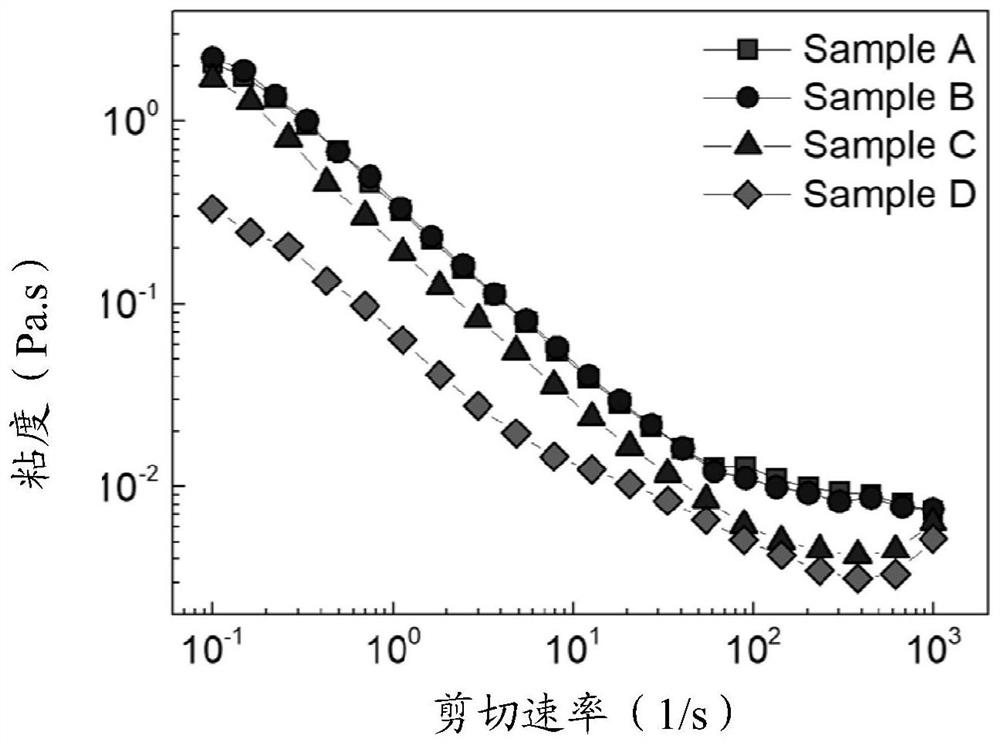

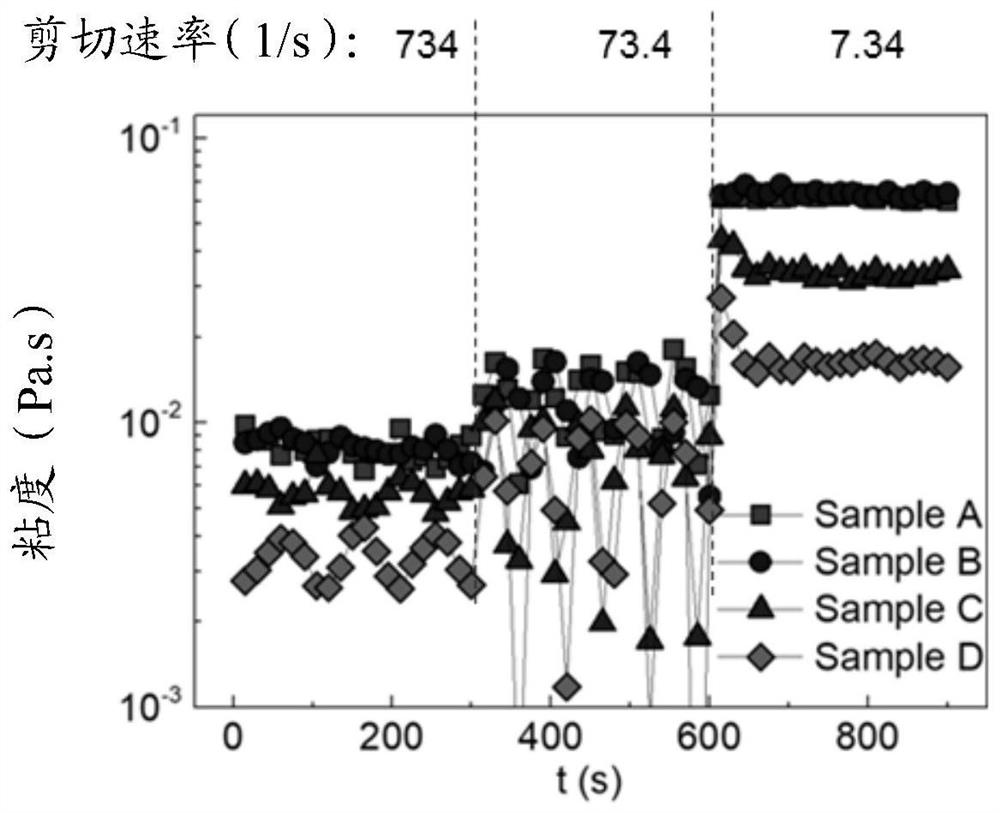

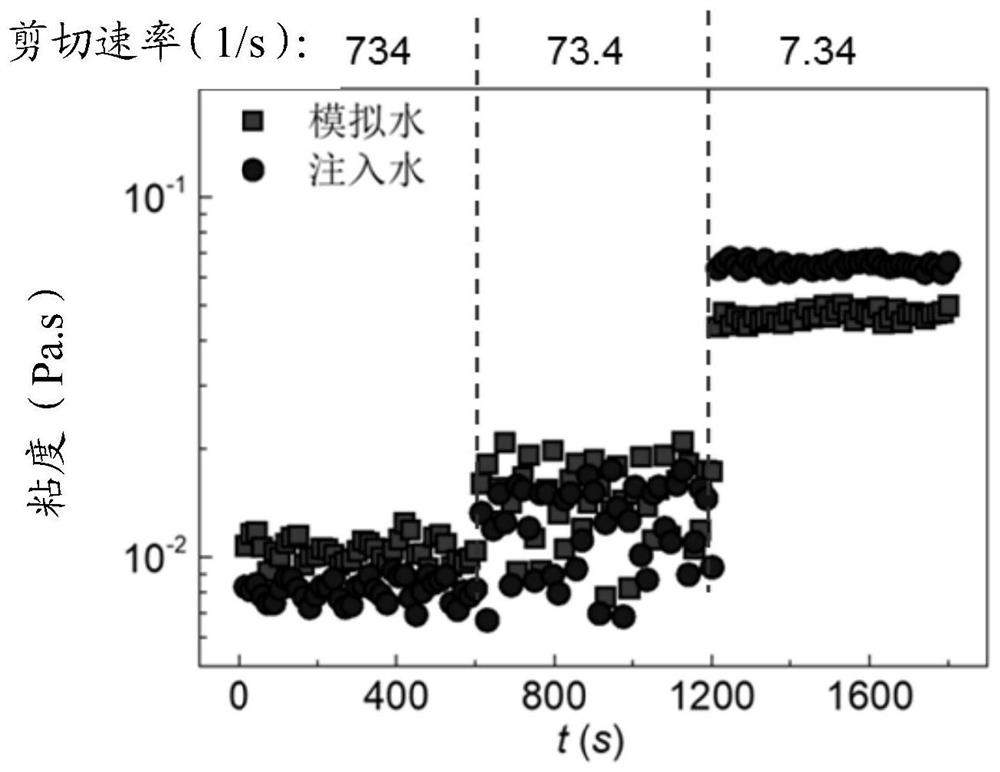

Nanocomposite viscoelastic oil displacement agent produced on line

The invention provides a nanocomposite oil displacement agent produced on line. The nanocomposite oil displacement agent comprises 0.05-0.8% of a surfactant, with the balance being water, wherein the surfactant comprises erucamide propyl hydroxy sulfobetaine or erucylamide propyl betaine, hexadecylamide propyl hydroxy propyl sulfobetaine and myristyl propyl sulfobetaine. The composite oil displacement agent disclosed by the invention may also comprises at least one selected from tetradecylamide propyl hydroxypropyl sulfobetaine and hexadecyl propyl sulfobetaine, and / or nanometer silicon dioxide with content of not more than 0.05%, and / or sodium dodecyl benzene sulfonate with content of not more than 0.03%, and / or 0.05 to 0.1% of polyether diamine and 0.05 to 0.1% of salicylic acid. For oil reservoirs with different mineralization degrees and permeability, the viscosity and interfacial tension of the nanocomposite viscoelastic oil displacement agent disclosed by the invention in an oil layer are controllable; and inorganic ions in stratum injection water are fully utilized under the condition of ensuring online injection.

Owner:CHINA OILFIELD SERVICES

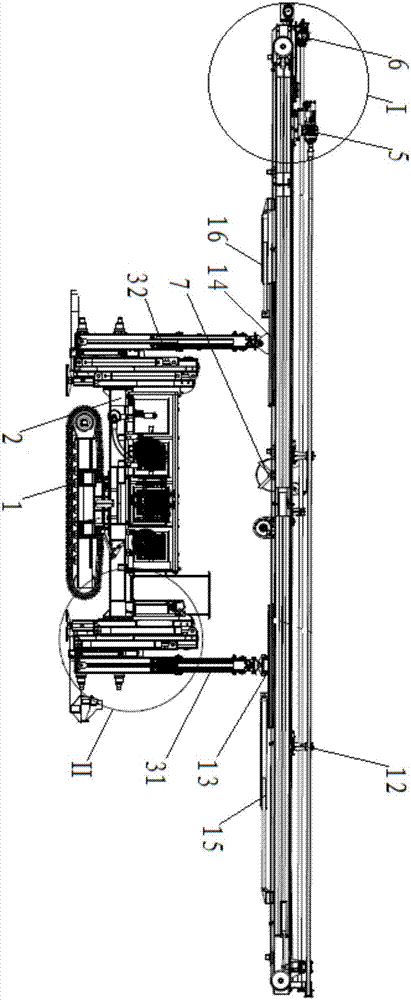

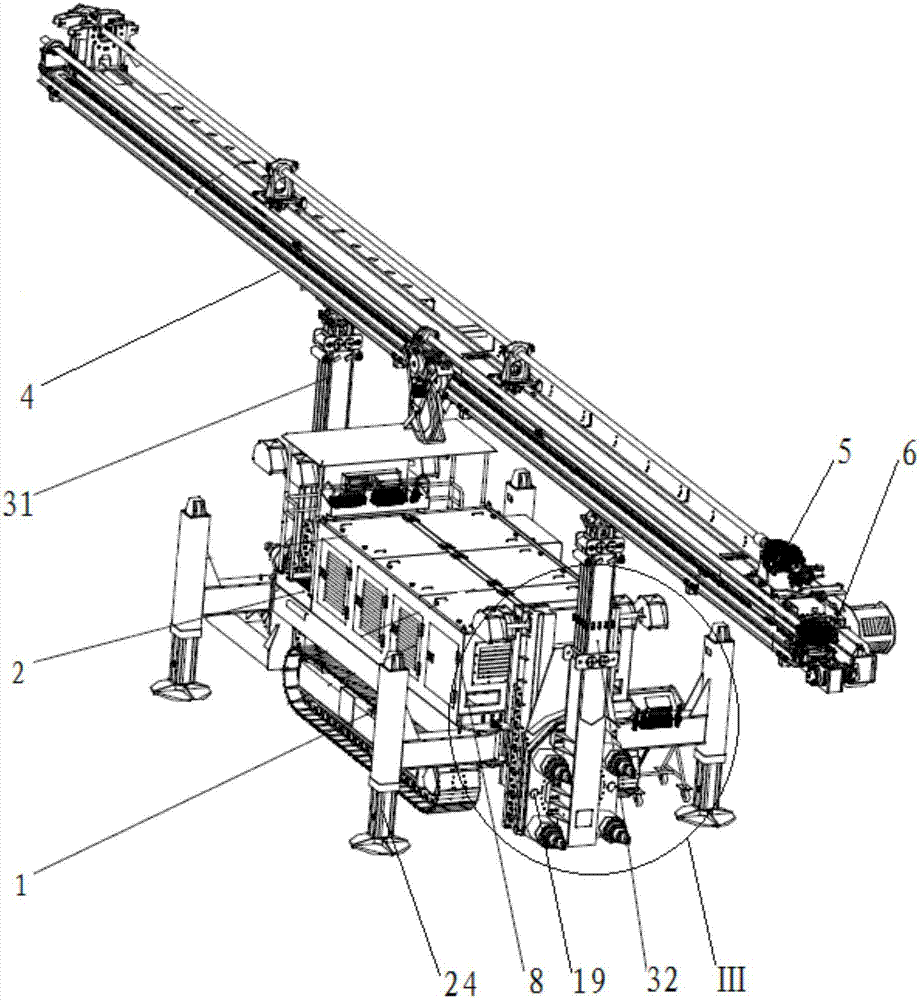

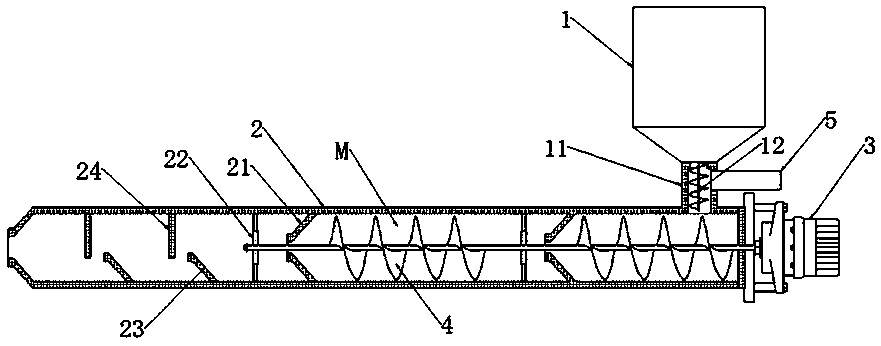

Horizontal jet grouting drilling machine

PendingCN107178382ALess construction equipmentImprove the efficiency of grouting reinforcementDerricks/mastsLiquid/gas jet drillingMachineCantilever

The invention discloses a horizontal jet grouting drilling machine which comprises a chassis, a drilling machine platform arranged on the chassis, a front lifting arm and a rear lifting arm respectively arranged at the front end and rear end of the drilling machine platform and a cantilever crane jointly supported by the front lifting arm and the rear lifting arm, wherein a head rig which is used for driving a drilling rod to operate and an anchor machine which is used for driving an anchor rod to operate are arranged on the cantilever crane. According to the horizontal jet grouting drilling machine provided by the invention, a drilling rod component is arranged on the head rig of the cantilever crane, and then an external high-pressure slime pump is used for drilling and jet-grouting into a pile, the anchor machine can be used for striking the anchor rod and a pipe shed and reinforcing a jet-grouting pile or a support surface, a multifunctional machine can be realized, the construction equipment can be reduced and the grouting reinforcing efficiency can be increased.

Owner:CHINA RAILWAY CONSTR HEAVY IND

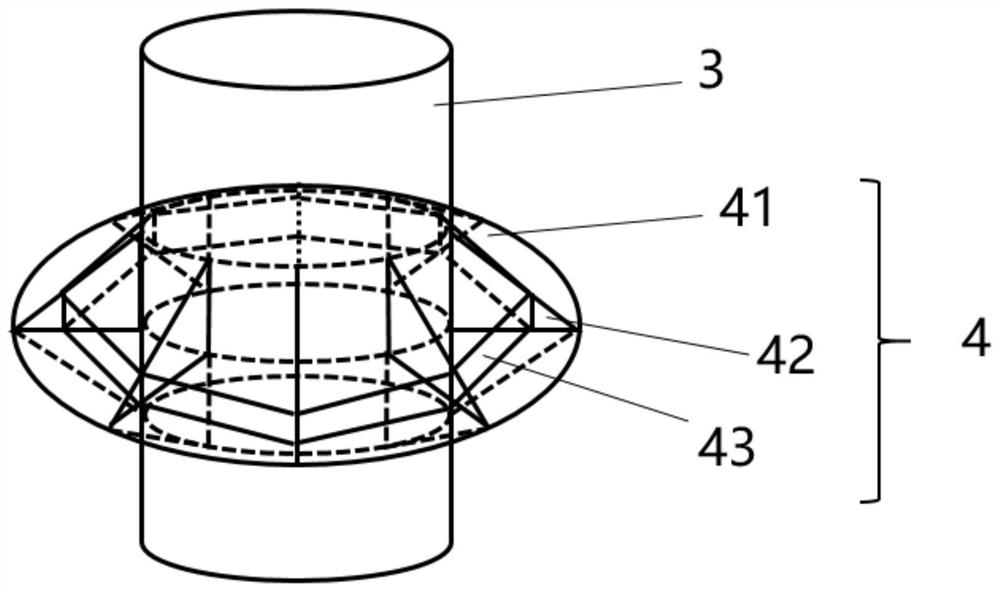

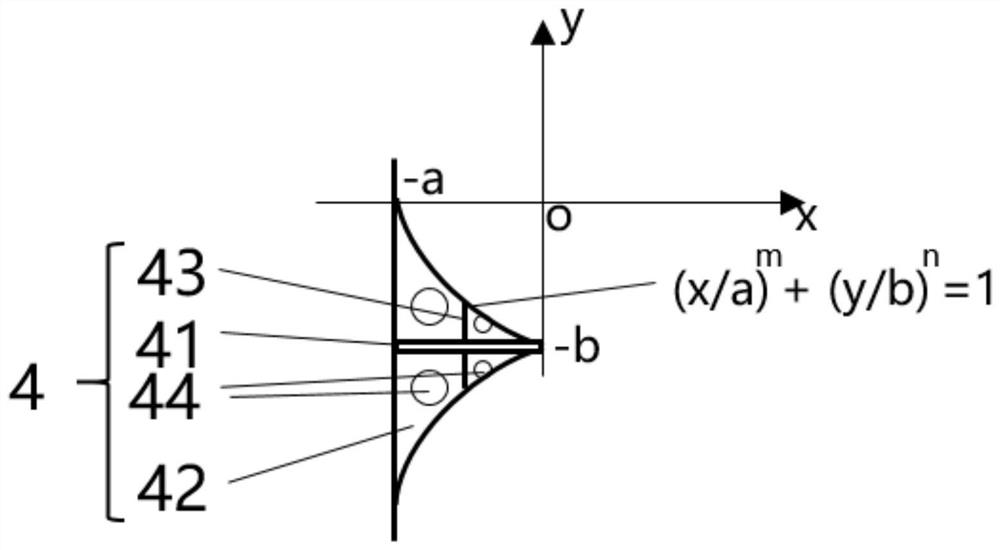

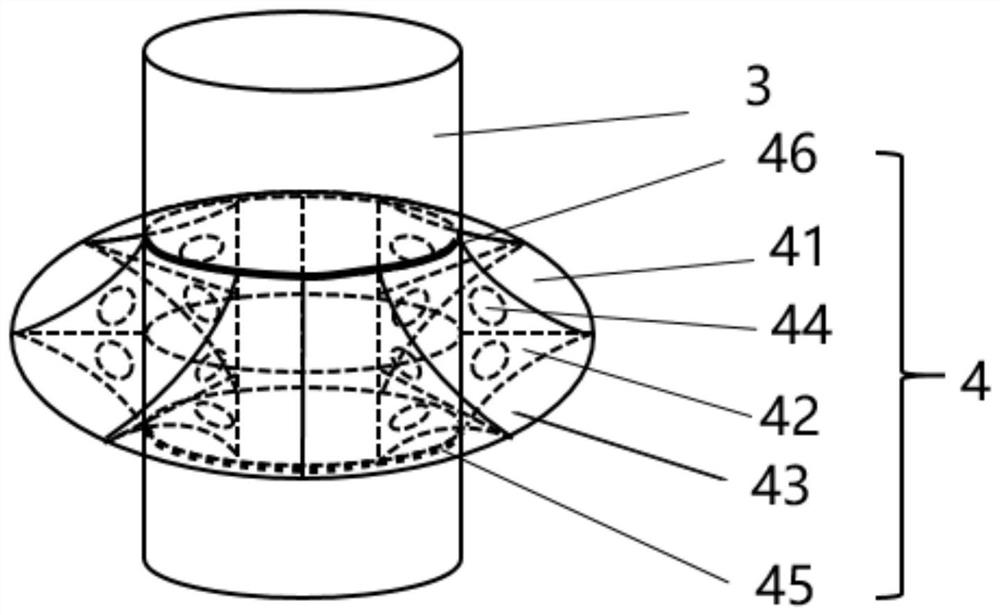

Offshore wind power cylindrical foundation, lattice type ice-resistant device and wind generating set

PendingCN112727700AReduce weightSmall water planeFinal product manufactureWind motor supports/mountsMarine engineeringOffshore wind power

The invention discloses an offshore wind power cylindrical foundation, a lattice type ice-resistant device and a wind generating set, and belongs to the technical field of offshore wind power tower ice resistance. The lattice type ice-resistant device comprises a transverse plate and longitudinal plates, the longitudinal plates are evenly arranged on the transverse plate in the circumferential direction, a stiffened plate is arranged between every two adjacent longitudinal plates, and the longitudinal plates and the stiffened plates are symmetrically arranged up and down with respect to the transverse plate. The impact force of floating ice can be decomposed into supporting force perpendicular to a shell plate more effectively, so that the damage mode of the floating ice is changed from compressive damage to bending damage; the arrangement is flexible, the wave load can be reduced through lightening holes in the longitudinal plates, and the number of the longitudinal plates required by the ice-resistant cone and the geometric dimension of an ice-resistant cone can be calculated and analyzed; the ice-resistant device is arranged along the periphery of a main body structure to achieve the optimal effect; and the ice-resistant device is simple in structural form, light in weight and low in manufacturing cost.

Owner:HUANENG CLEAN ENERGY RES INST +3

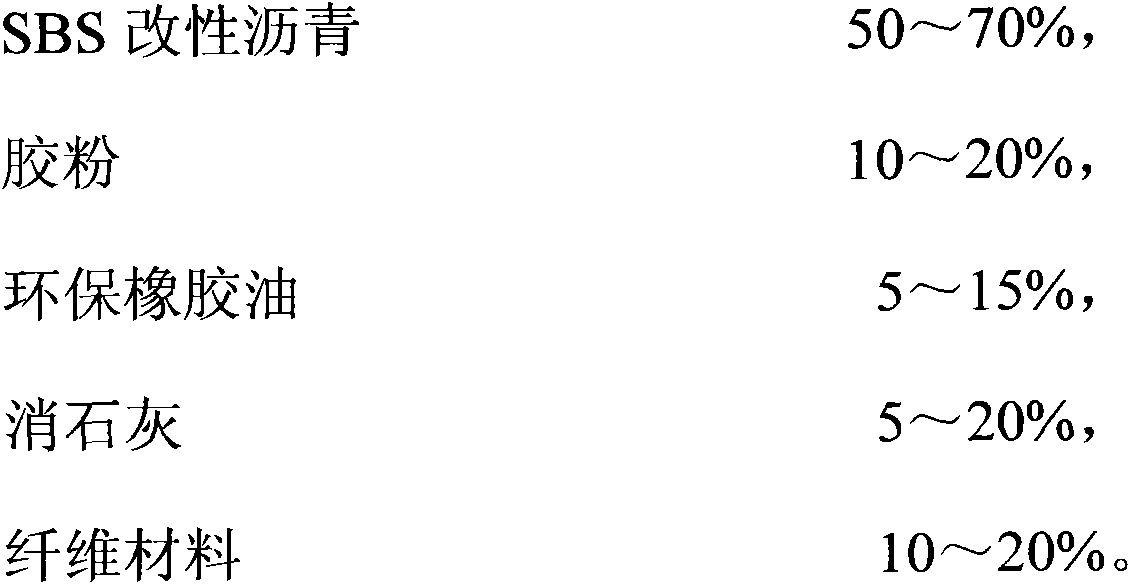

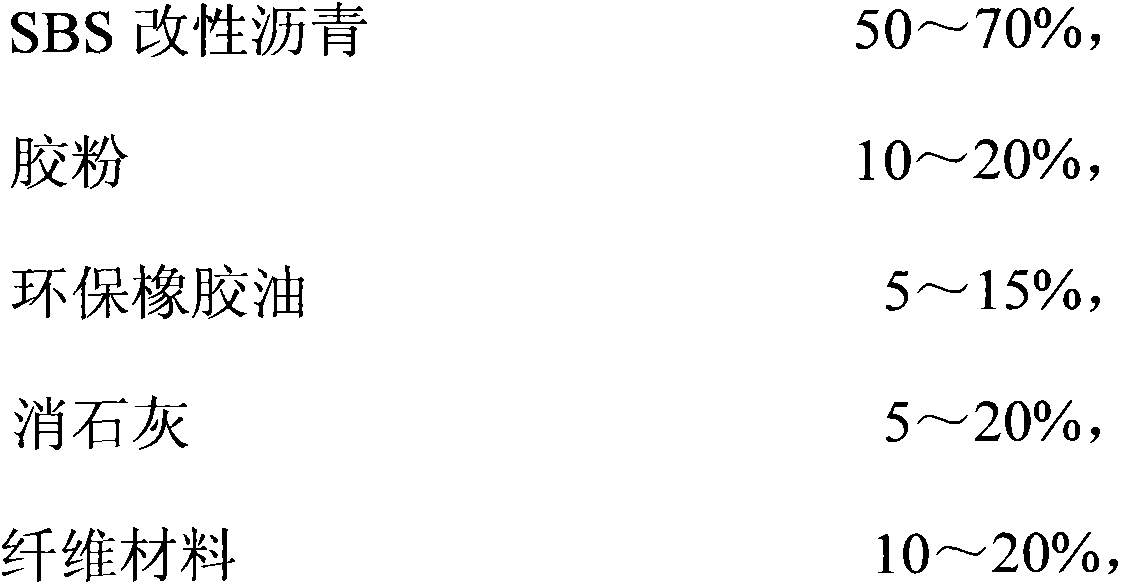

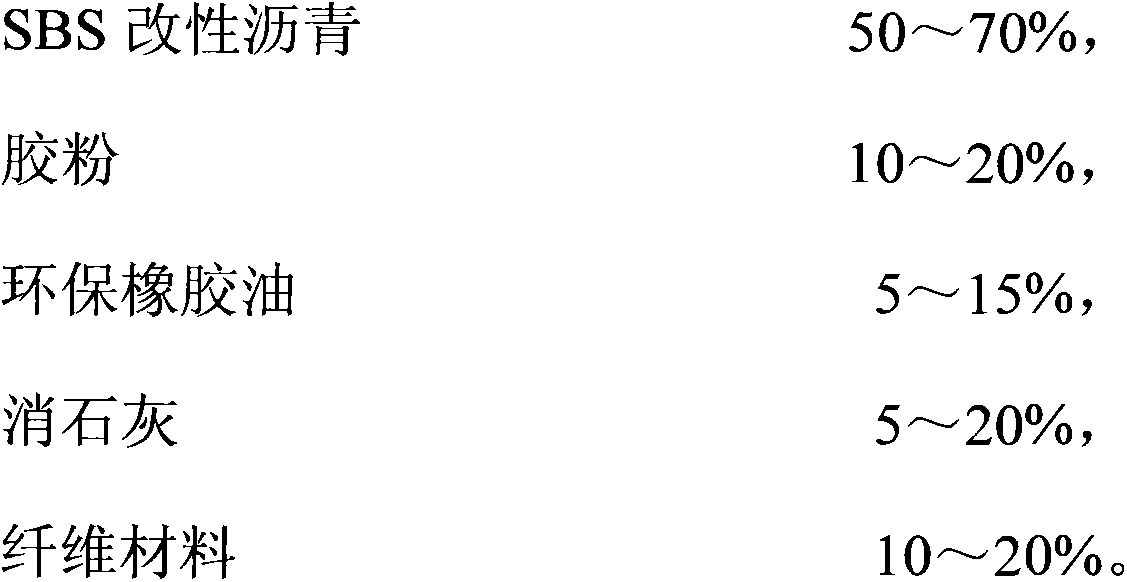

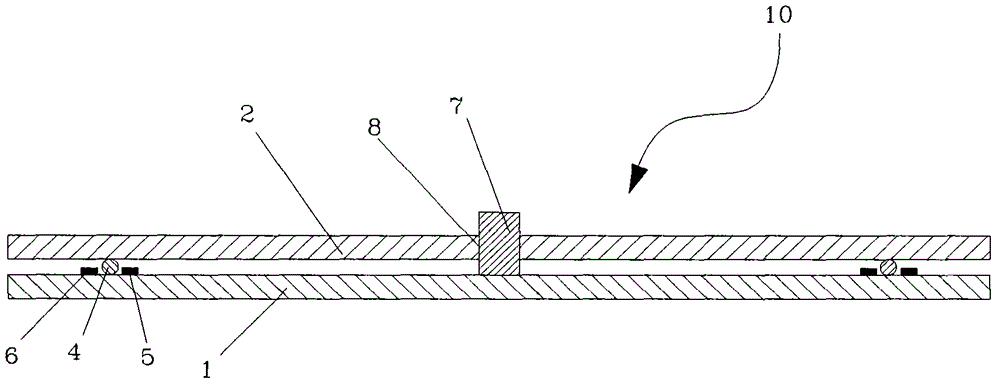

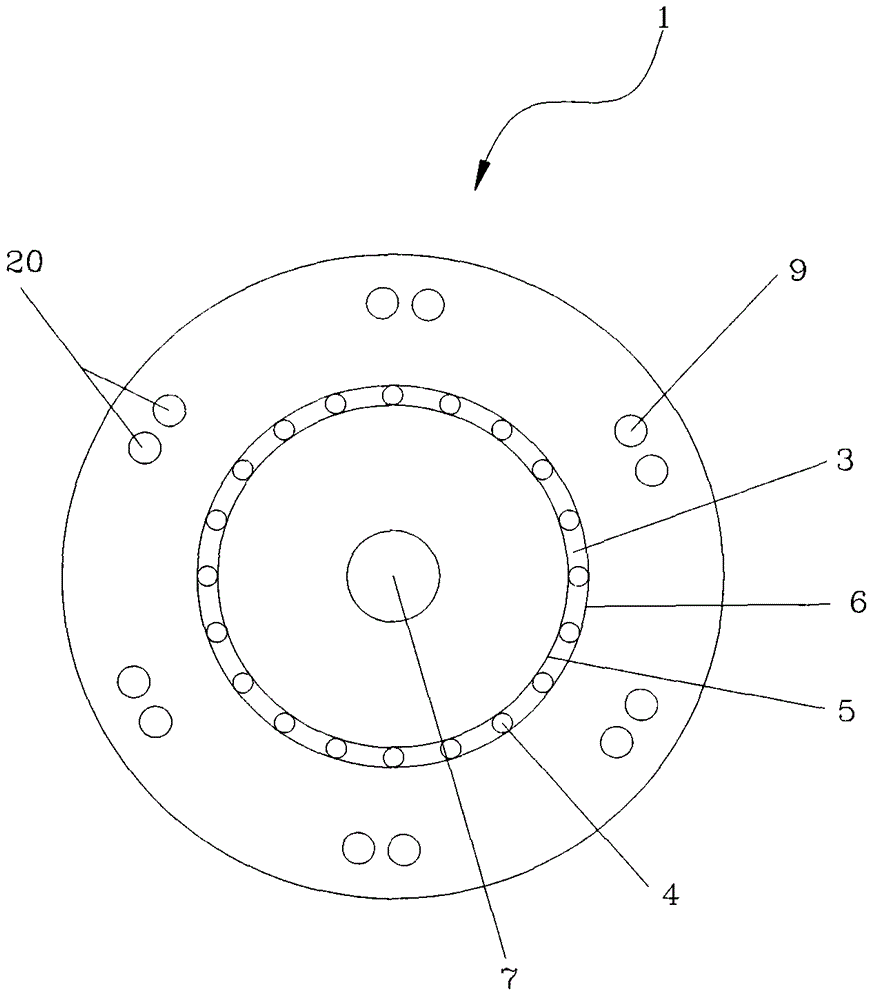

Carpet type quick paving belt, preparation method of carpet type quick paving belt and construction method applying carpet type quick paving belt

InactiveCN104343073AAvoid destructionAvoid damageIn situ pavingsNon-macromolecular adhesive additivesFiberCrack resistance

The invention discloses a carpet type quick paving belt. The carpet type quick paving belt is prepared from the following raw materials: styrene-butadiene-styrene (SBS) modified asphalt, rubber powder, environment-friendly rubber oil, slaked lime and fiber material. The invention also discloses a preparation method of the carpet type quick paving belt and a construction method adopting the carpet type quick paving belt. The carpet type quick paving belt is reasonable and scientific in formula and design, can be used for quickly repairing the fatigue cracking pavement, is high in bonding strength, rapid in strength molding, good in durability, good in repairing quality, good in low-temperature cracking resistance, attractive and durable, and is not friable at low temperature and not deformed at high temperature; the preparation method provided by the invention is simple in technology, easy to implement and high in production efficiency; the construction method provided by the invention is simple in construction technology, fewer in construction machines and tools needed by the field and low in noise; centralized prefabrication can be carried out before construction, so that waste gas can be better controlled in a centralized way, waste gas emission and damage to the environment and the constructors of the conventional paving operation are completely avoided, and construction is fast.

Owner:北京嘉格伟业筑路科技有限公司

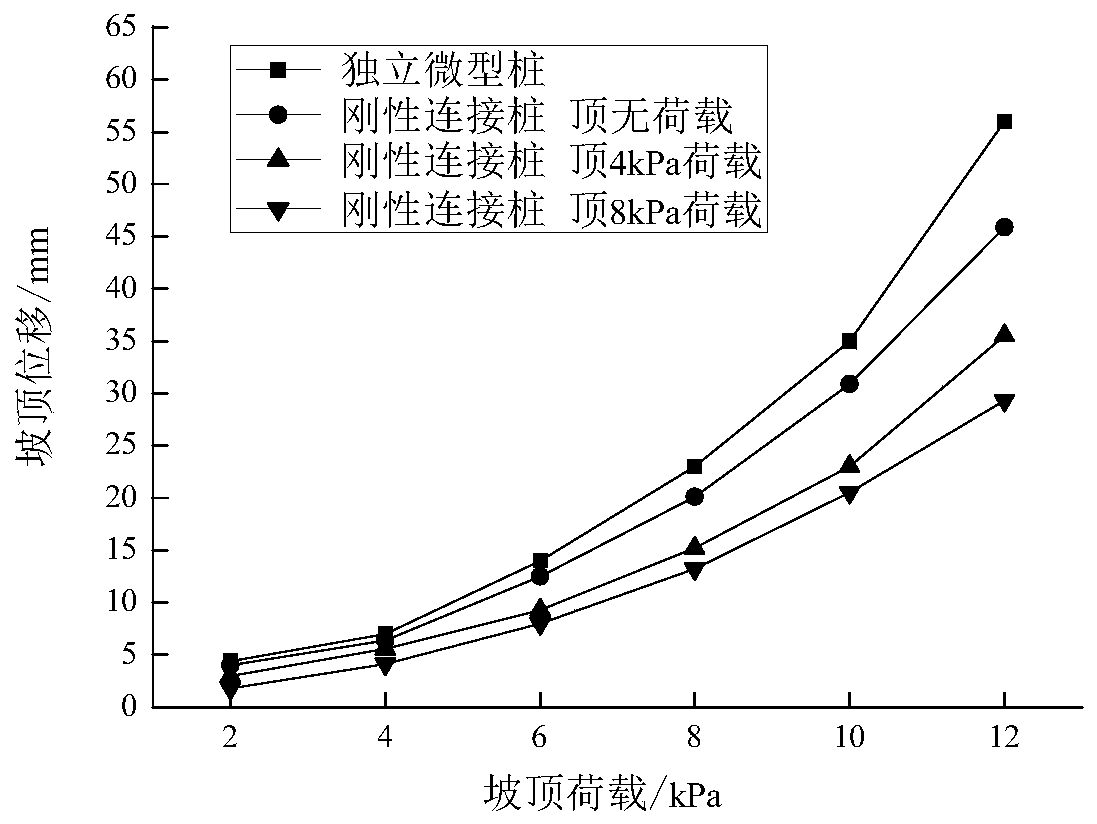

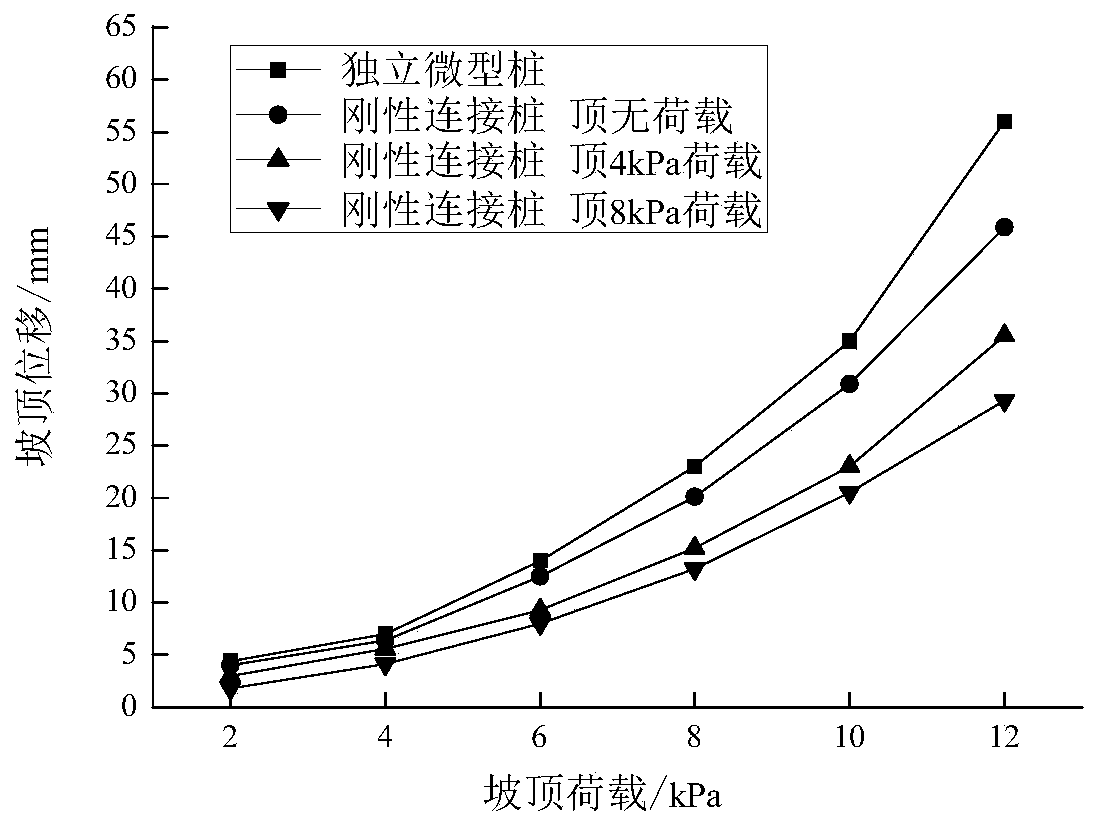

Evaluation method of anti-slide performance of rigid connection structure of simulated micropile

InactiveCN109870298AFast constructionIncrease the utilization areaMachine part testingStructure of the EarthPressure cell

The invention discloses an evaluation method of anti-slide performance of a rigid connection structure of a simulated micropile. The method comprises the steps of pasting a strain gauge on a pile bodyof each simulated micropile; setting a pressure cell on a soil-backing side and a soil-facing side of each simulated micropile; setting a displacement sensor in a slide bed soil mass; electrically connecting the strain gauge, the pressure cell and the displacement sensor to an external processor; simultaneously applying a vertical load step by step on a slope top of the slide bed and a top of therigid connection structure of the simulated micropile; acquiring a displacement of the pile top, a bending moment of the pipe body, the front and back soil pressures of the pipe body of the rigid connection structure of the simulated micropile by the processor; performing a numerical simulation calculation by finite difference software FLAC3D; and, acquiring an optimal top load of the rigid connection structure of the simulated micropile by the software analysis under the working condition the same with the physical simulation experiment. The optimal load of the top of the rigid connection structure is measured by the rigid connection structure of the simulated micropile.

Owner:XIAN TECHNOLOGICAL UNIV

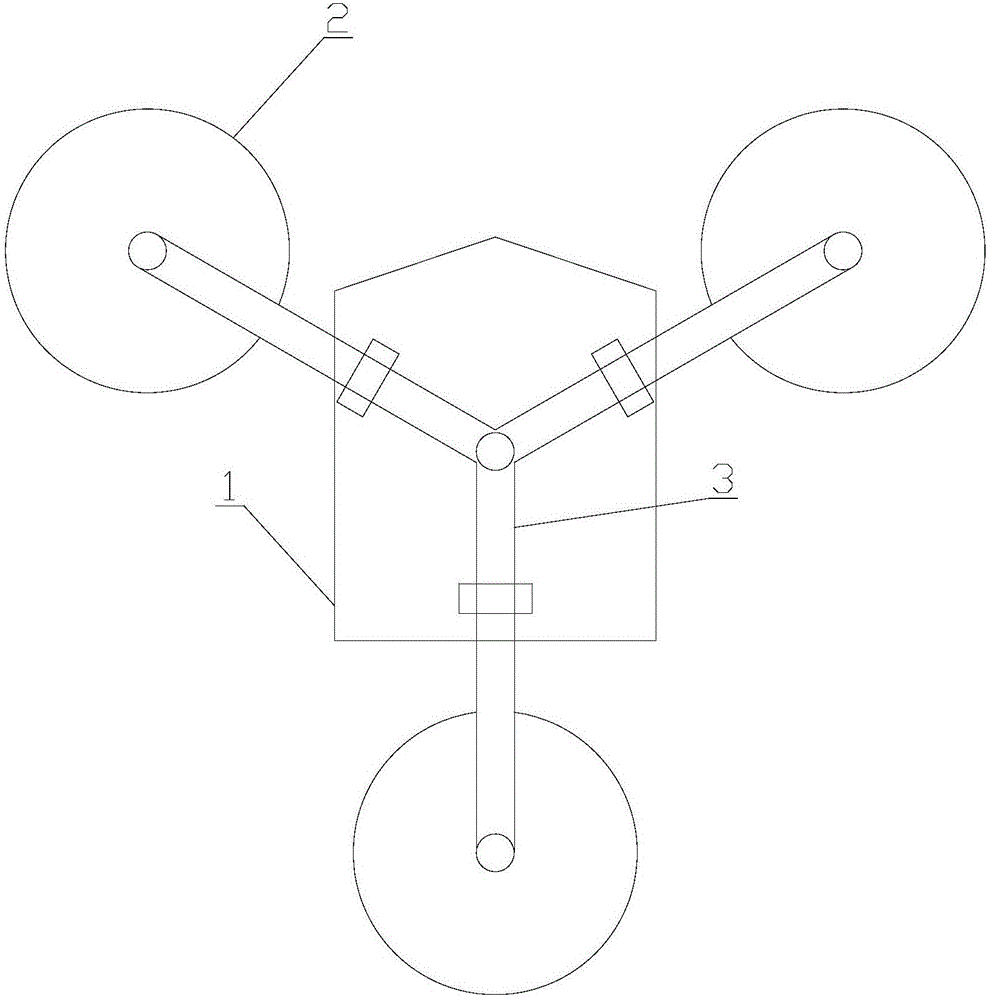

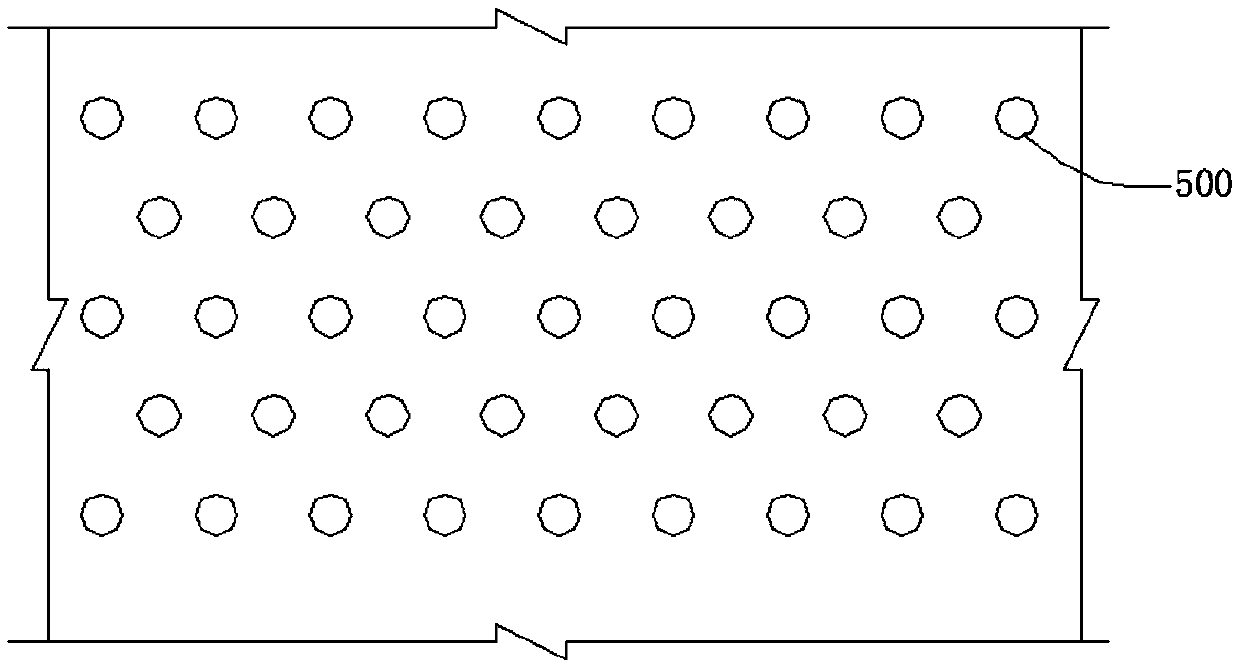

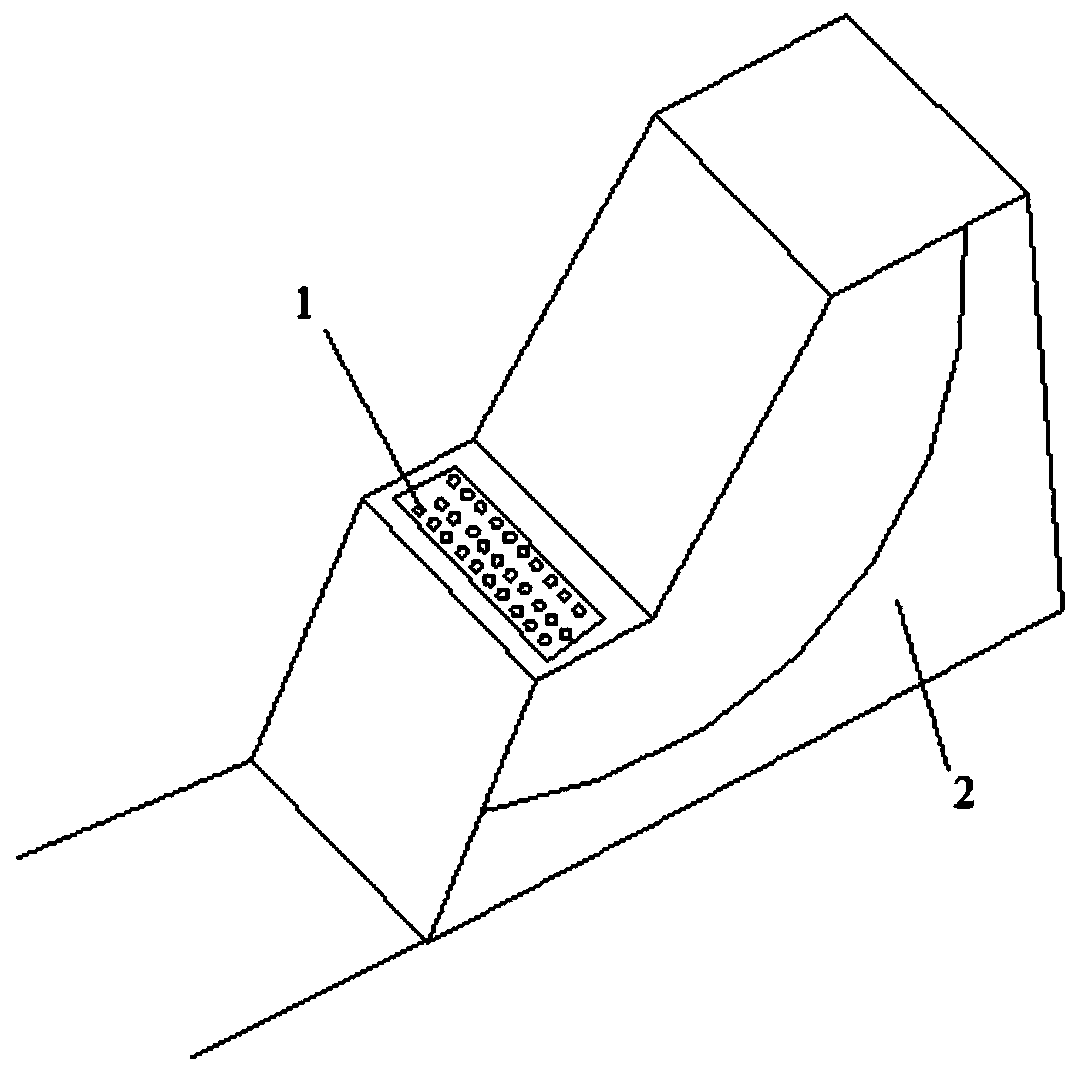

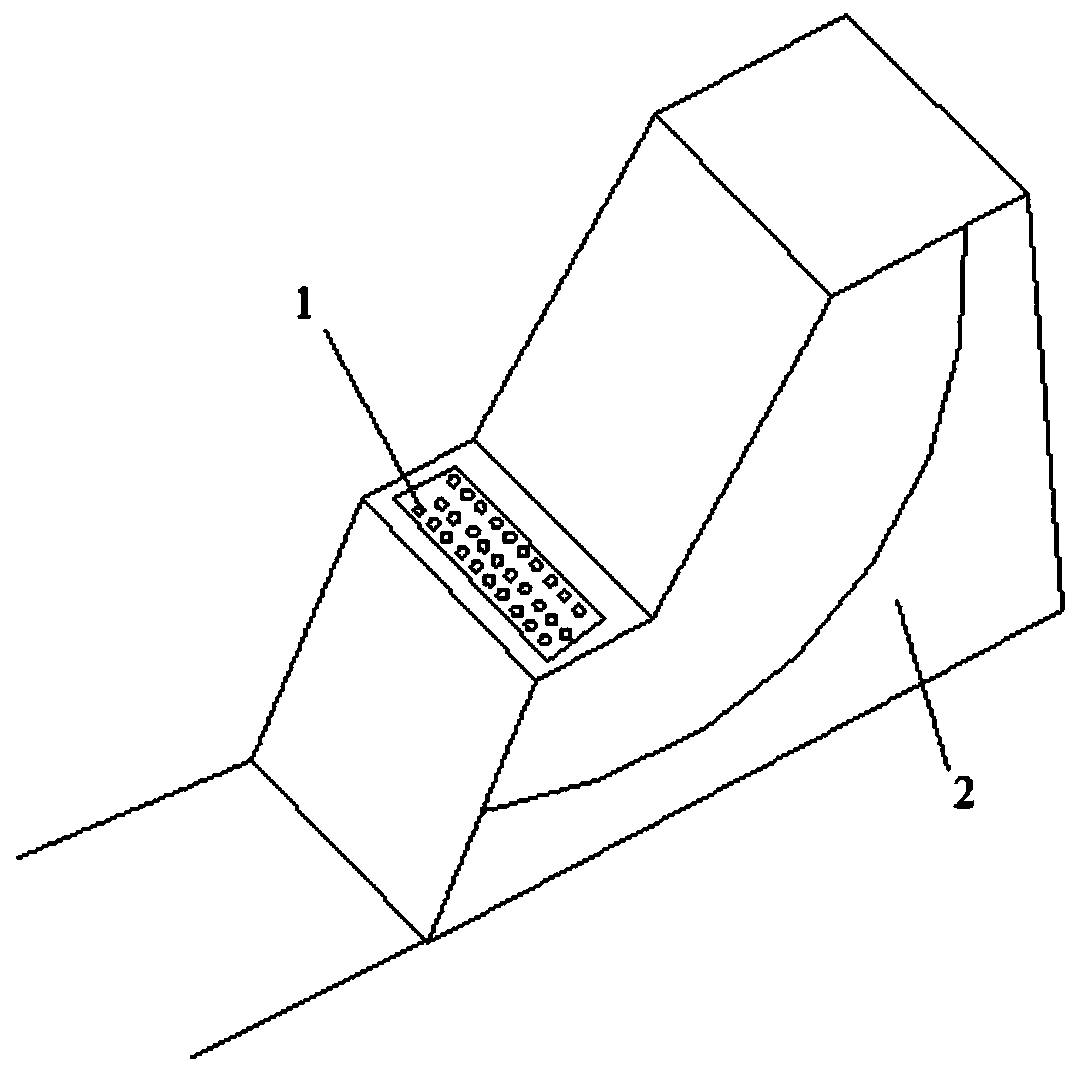

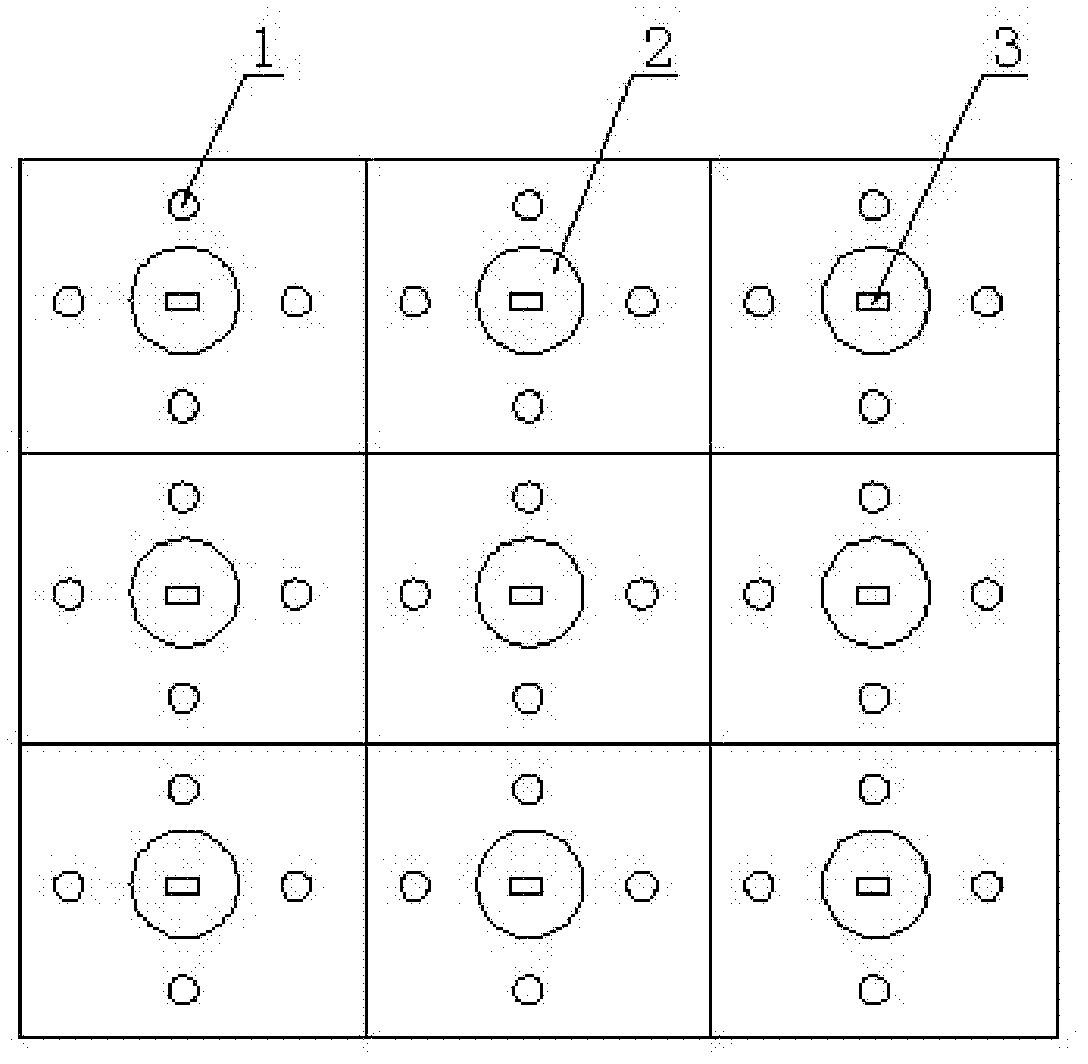

Micro pile rigid connection structure with landslide preventing and production road and construction method of micro pile rigid connection structure

PendingCN109853598AFast constructionLess construction equipmentRoadwaysExcavationsLandslideEngineering

The invention discloses a micro pile rigid connection structure with landslide preventing and a production road and a construction method of the micro pile rigid connection structure. The micro pile rigid connection structure is composed of a micro pile group and a concrete layer, wherein the micro pile group is used for preventing landslide phenomena and is composed of a plurality of micro pilesdistributed in plum blossom patterns, each micro pile is used for driving into the ground where slope treatment is needed, the lower end of each micro pile is located on the simulated sliding crack surface, the top end of each micro pile is beyond the ground, the micro piles are filled with concrete from the top end to the bottom, a concrete layer is formed between the micro piles, the thickness of the concrete layer is greater than the distance beyond the ground of the top ends of the micro piles, the concrete layer is used for filling gaps between the micro piles, making the top surface of the micro pile groups to form a flat road surface, and is further used for encrypting and fixing the micro piles, and the road surface is considered as the production road for people and trolleys to pass. According to the micro pile rigid connection structure with landslide preventing and the production road and the construction method of the micro pile rigid connection structure, the micro piles are used as roadbeds, through rigid connection at the top of the micro piles, the road surface of rigid connection at the top of the micro piles is used for people to pass, and the land utilization area is increased.

Owner:XIAN TECHNOLOGICAL UNIV

Online fracturing fluid and preparation method therefor

The invention relates to online fracturing fluid and a preparation method therefor. The online fracturing fluid contains the ingredients in parts by mass: 0.8-5 parts of agent A, 0.2-1 part of agent B and 94-99 parts of water; the agent A contains the ingredients in parts by mass: 10-20 parts of chitin, 10-20 parts of starch, 5-20 parts of acrylamide, 2-5 parts of bioactivator, 0.1-1 part of sugar, 0.1-0.5 part of sodium polyaspartate, 10-20 parts of environment-friendly solvent and 13.5-62.8 parts of water; and the agent B contains the ingredients in parts by mass: 5-20 parts of alkaline proteinase, 10-20 parts of bioactivator, 5-10 parts of EDTA-4Na, 0.1-0.2 part of sodium ethylenediamine disuccinate, 0.5-1 part of sodium polyaspartate, 0.2-1 part of sodium acetate, 0.5-1 part of sodium lactate, 0.5-1 part of potassium lactate, 0.5-1 part of sugar, 5-10 parts of ethanol and 34.8-72.7 parts of water. The online fracturing fluid has the characteristics that online continuous preparation is achieved, the operation is simple, the working concentration is low, the viscosifying speed is high, the sand carrying performance is good, the friction drag is low, the damage is low, the online fracturing fluid is heat-resistant and shear-resistant, the viscosity of flowback fluid is low, the applicable range is wide, the cost is low, the production increase effect is good, and the like.

Owner:SUNCOO PETROLEUM TECH

A kind of online fracturing fluid and preparation method thereof

Owner:DONGYING SHENGSHI PETROLEUM TECH CO LTD

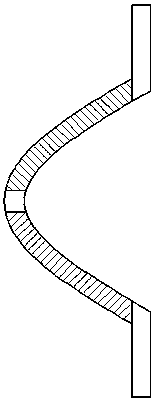

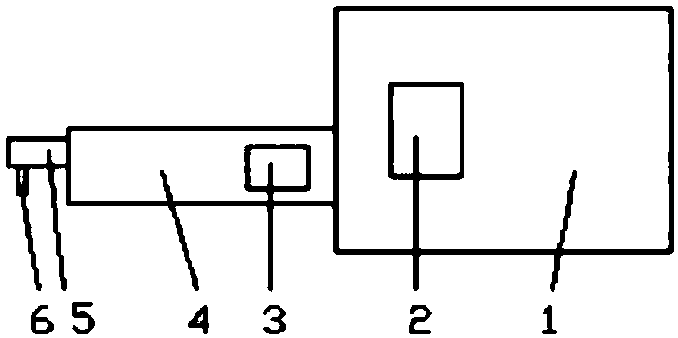

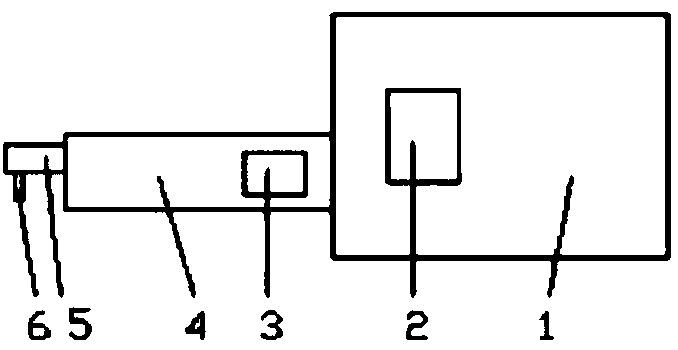

Single-slurry blending device for hole drilling and sealing

PendingCN111151187AAchieve ready-to-mix effectsAvoid engineering delaysFlow mixersRotary stirring mixersElectric machineSlurry

The invention relates to a single-slurry blending device for hole drilling and sealing. The device is composed of a feeding tank, a mixing pipe, a motor, a spiral pushing paddle and a water inlet pipe. The water inlet pipe is sequentially divided into a first mixing section and a second mixing section in the feeding direction, at least two single-slurry nozzles are arranged in the first mixing section in the axial direction, a mixing cavity is formed in the rear sides of the single-slurry nozzles, the spiral pushing paddle is installed in the mixing cavity, and the motor is used for driving the spiral pushing paddle. The mixing pipe is provided with a return plate in front of each single-slurry nozzle, and the return plates are used for rebounding the single slurry sprayed by the single-slurry nozzles to the outer walls of the single-slurry nozzles to form rotational flow. The second mixing section is sequentially provided with at least two groups of inclined plates and baffles, the inclined plates are arranged at the lower part, and the baffles are arranged at the upper part, so that single slurry impacts the baffles along the inclined plates, then flows down and is finally fed into a grouting device through a discharge hole of the mixing pipe, the direct mixing configuration in the feeding process is completed, and the construction flow is saved.

Owner:CHINA CONSTR FOURTH ENG DIV

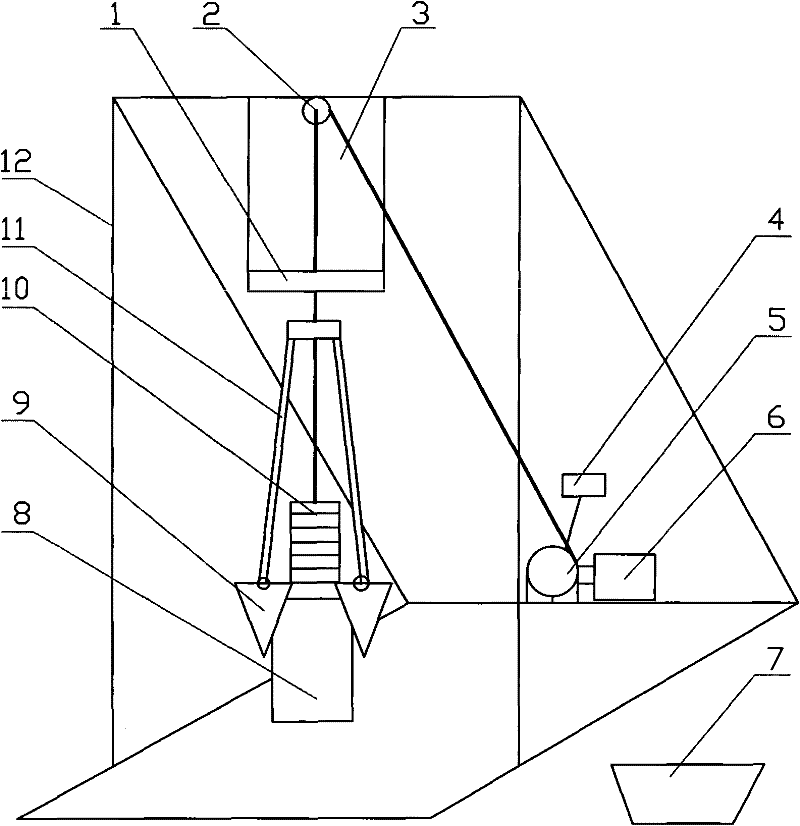

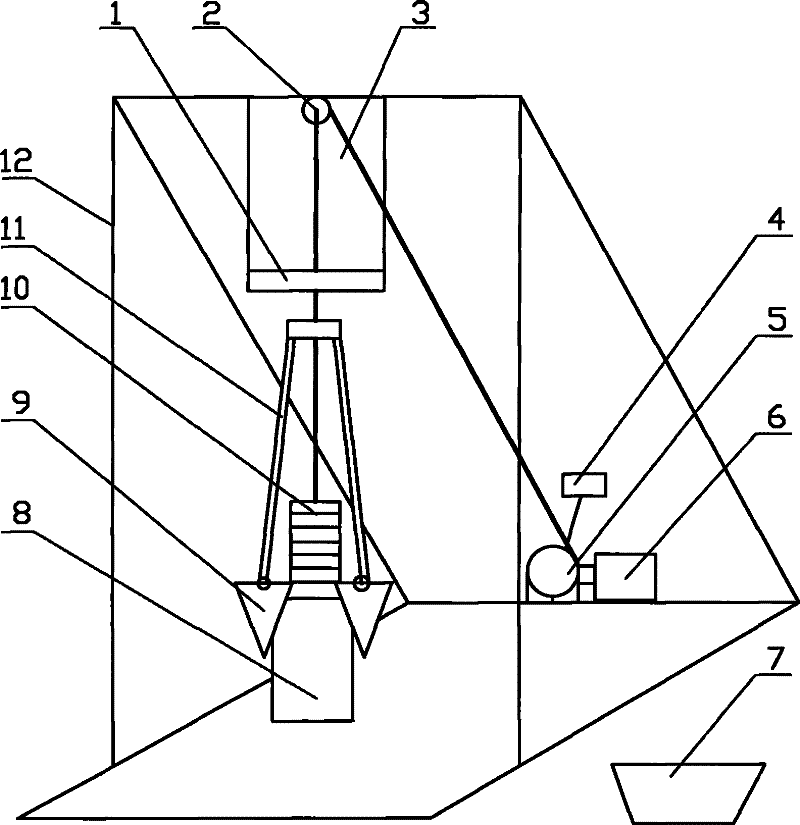

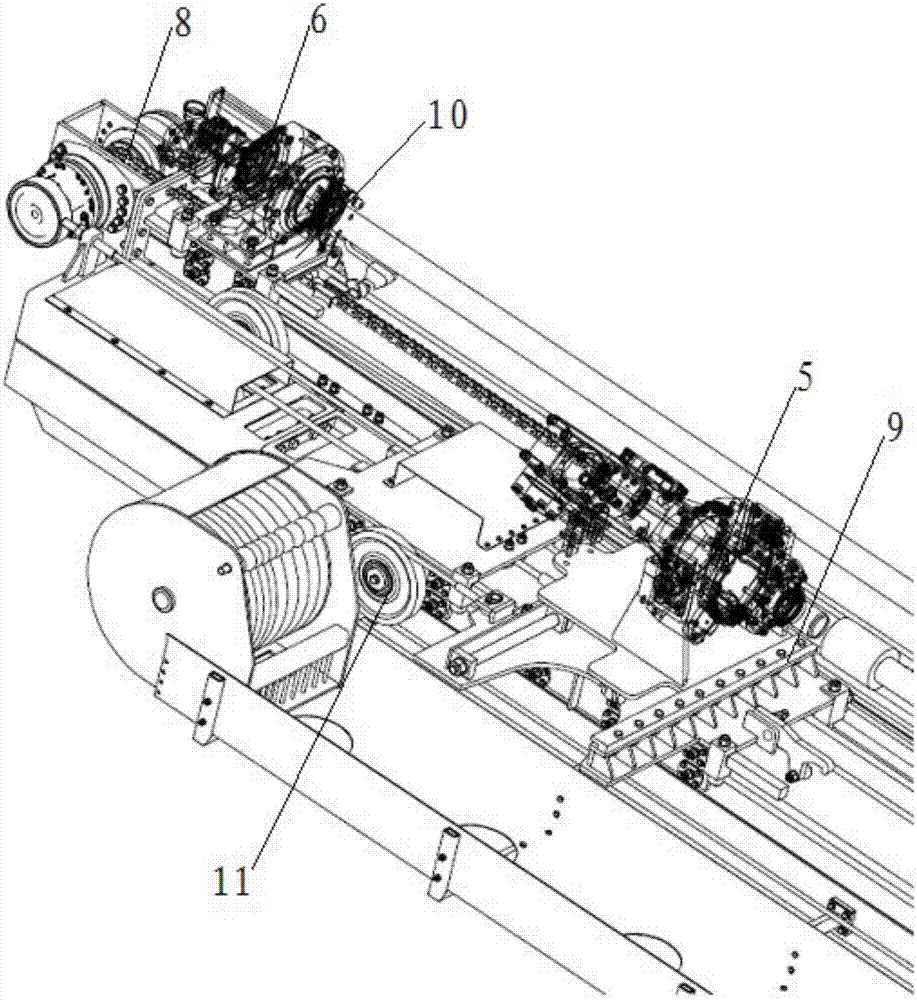

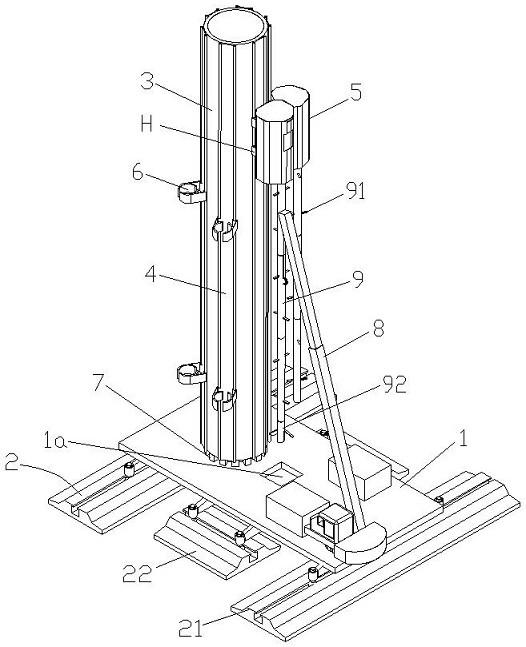

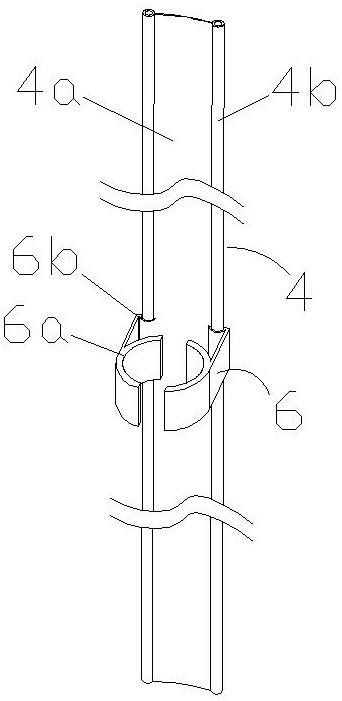

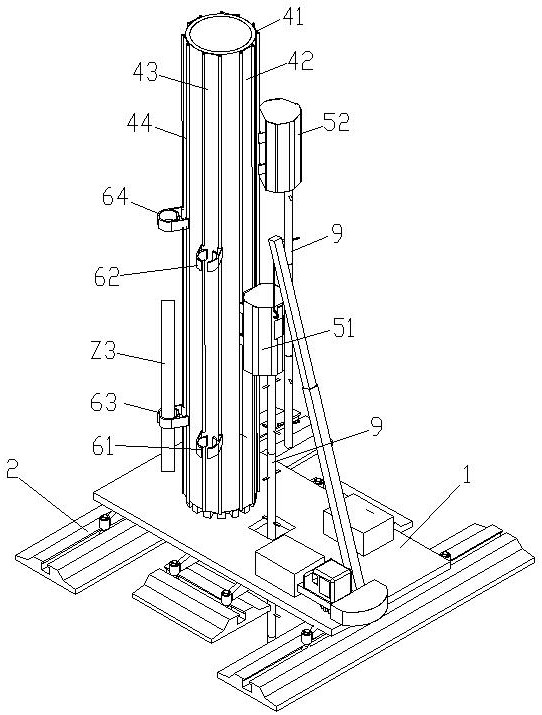

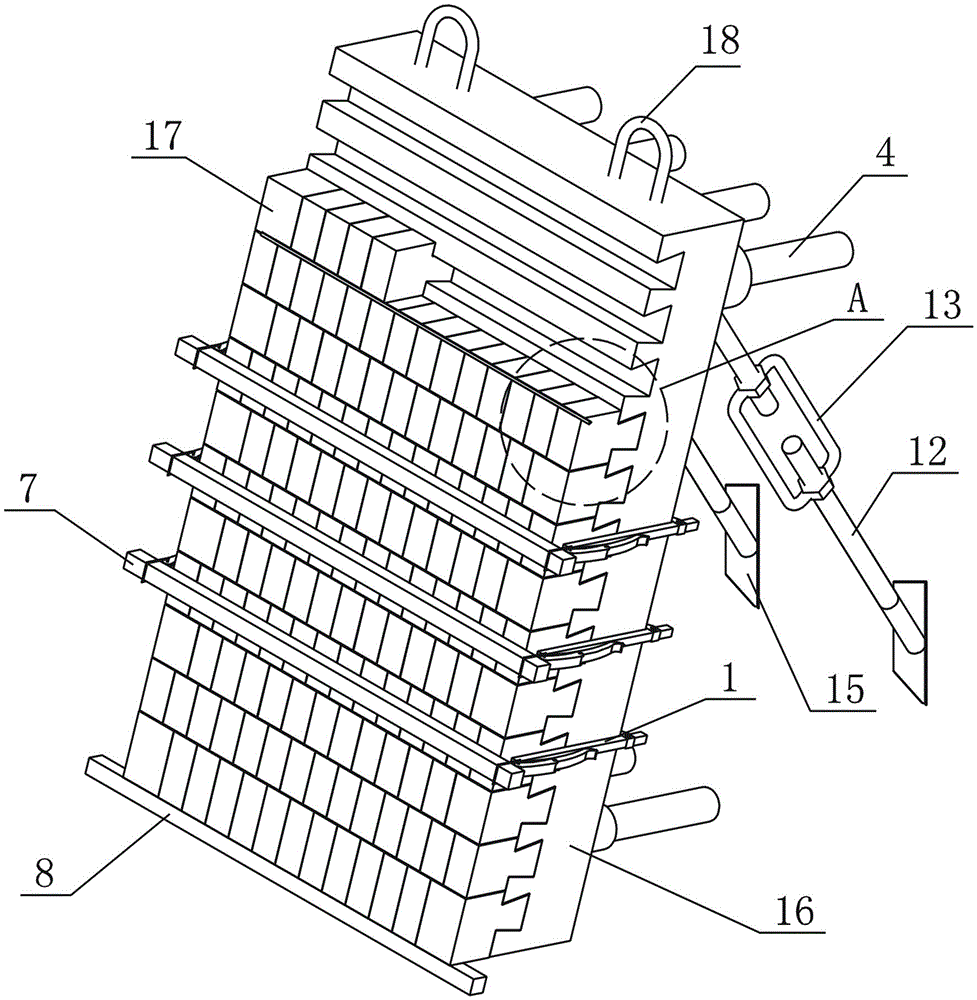

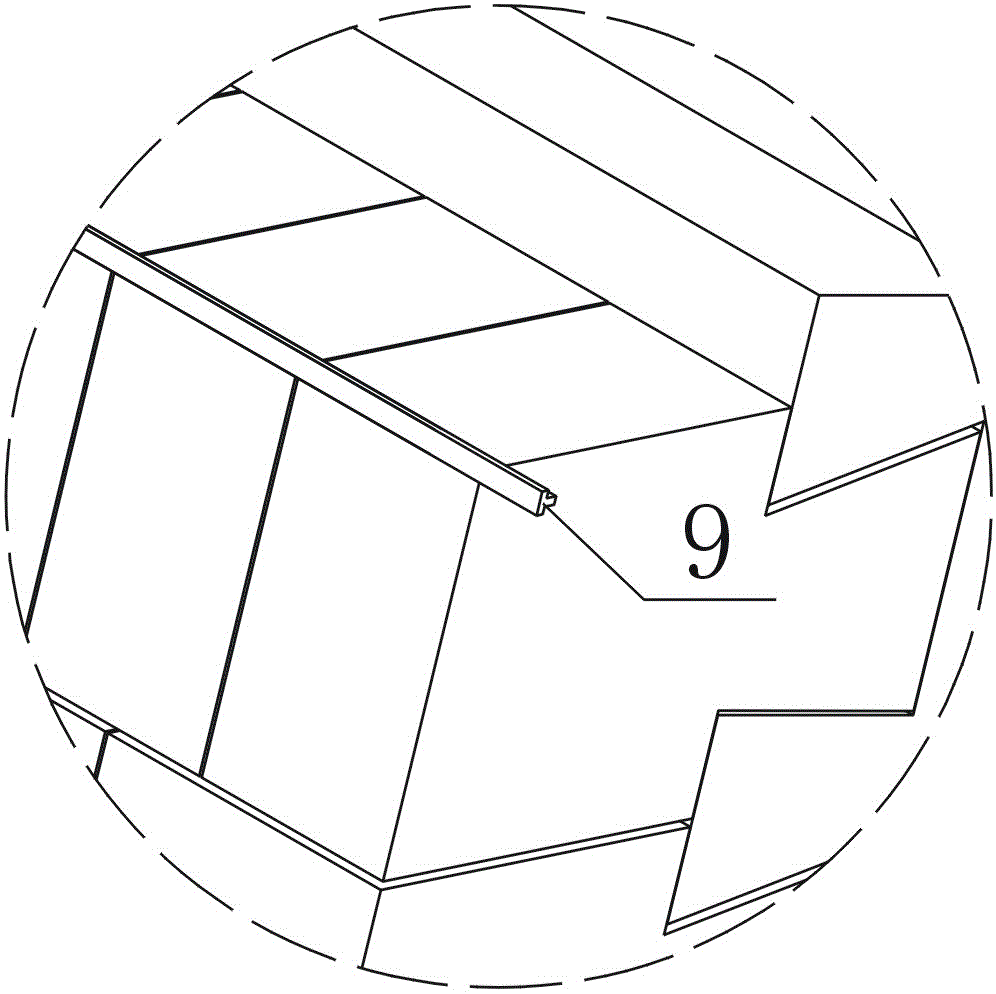

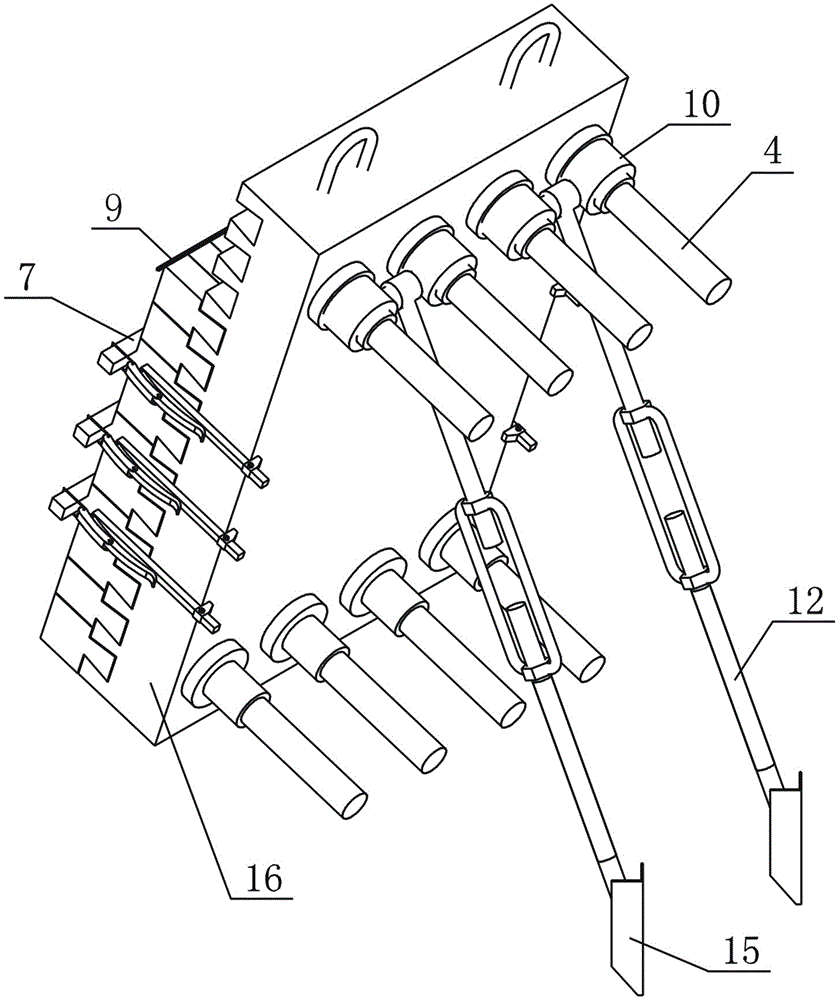

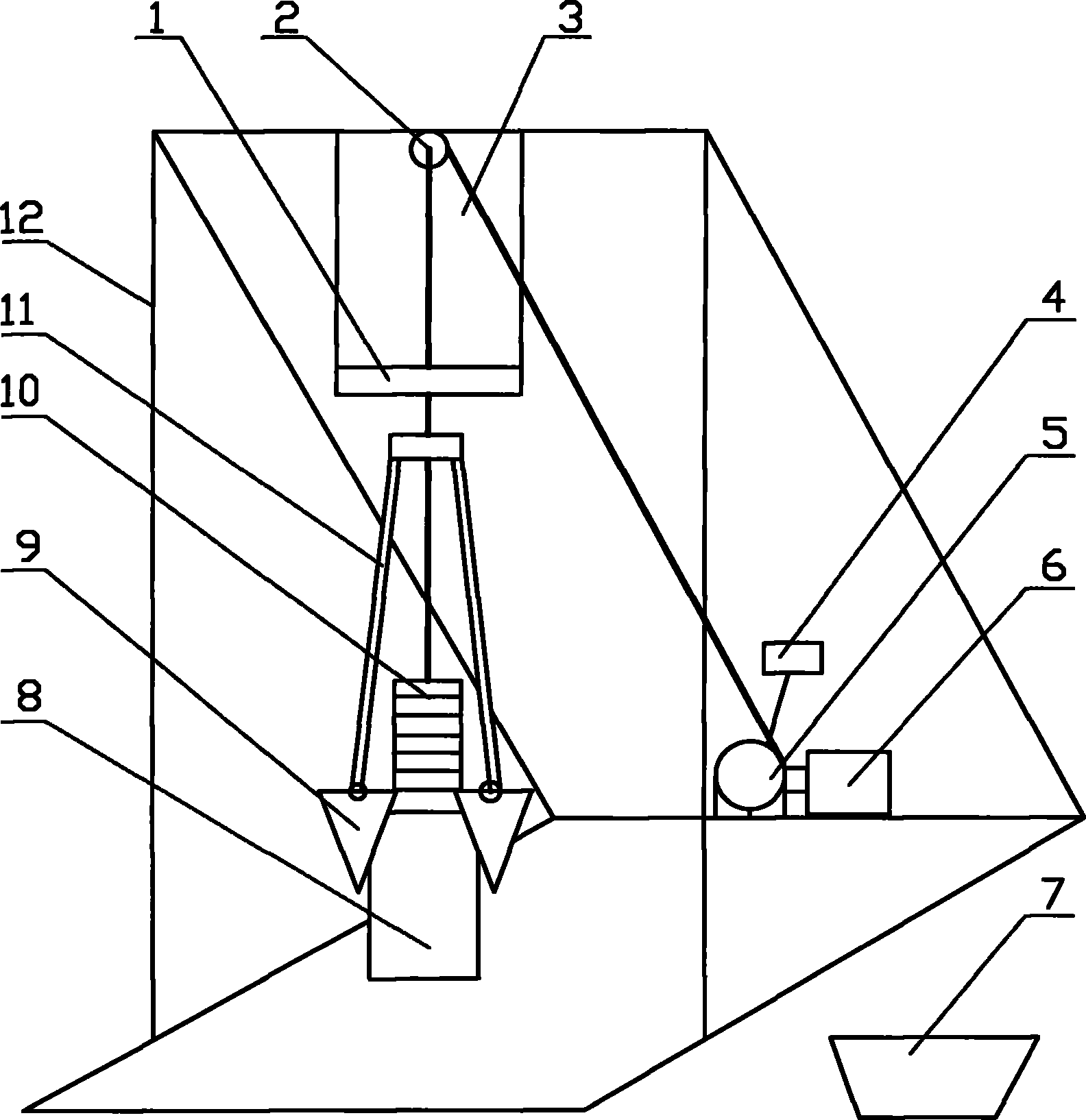

Construction equipment based on synchronous drilling and precast pile splicing and construction method thereof

PendingCN113250193AReduce construction costsLess construction equipmentDrilling rodsDrilling casingsDrill holeEngineering

The invention discloses construction equipment based on synchronous drilling and precast pile splicing and a construction method thereof. The equipment comprises an equipment main platform provided with drilling and pile planting holes, and a lifting device and a main mast are arranged on the equipment main platform; six track plates are arranged on the main mast, one drilling machine is arranged on each of the first track plate and the second track plate, and two pile clamping devices are arranged on each of the third track plate and the fourth track plate; the two pile clamping devices on the third track plate are the first pile clamping device and the second pile clamping device, and the two pile clamping devices on the fourth track plate are the third pile clamping device and the fourth pile clamping device; the third section of precast pile and the fourth section of precast pile are spliced on the fourth track plate while the drilling machine on the second track plate drives a drill rod to drill holes; and the first precast pile section and the second precast pile section are spliced on the third track plate while the drilling machine on the first track plate drives the drill rod to drill holes. The equipment construction method is simple and efficient, and the pile planting quality can be guaranteed.

Owner:宁波中淳高科股份有限公司

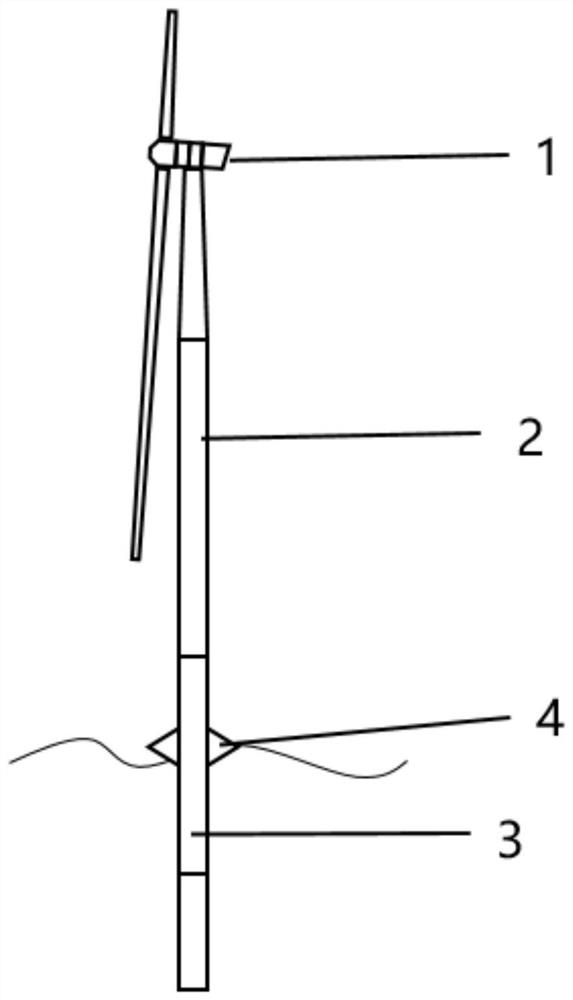

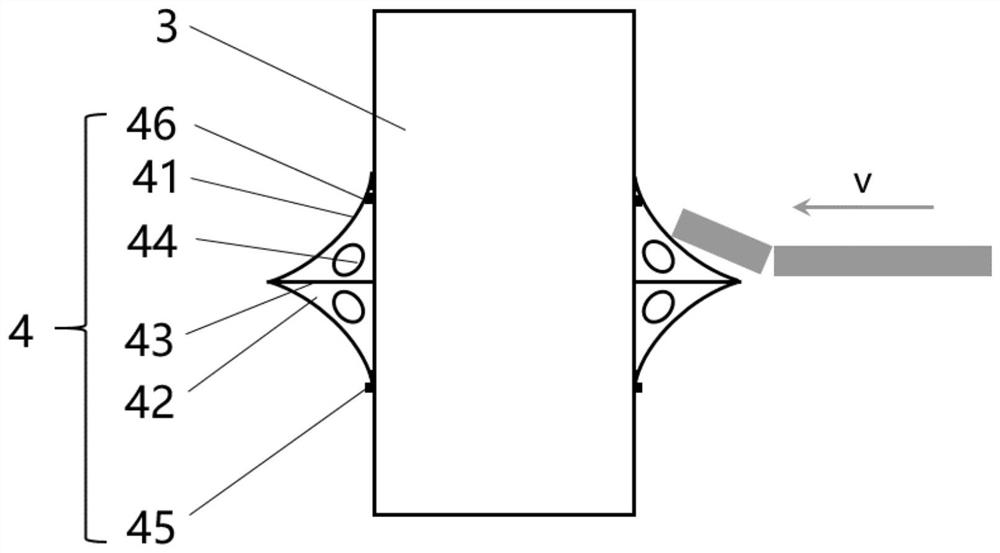

Offshore wind turbine foundation, construction method thereof, ice-resistant device and wind generating set

PendingCN112727699AReduce impactReduce intensityWind motor supports/mountsMachines/enginesCompressive failureMarine engineering

The invention discloses an offshore wind turbine foundation, a construction method thereof, an ice-resistant device and a wind generating set. The ice-resistant device comprises a shell plate, toggle plates, watertight partition plates, an upper ring beam and a lower ring beam; the upper ring beam and the lower ring beam are connected with the two ends of the toggle plates respectively; the toggle plates are evenly arranged in the circumferential directions of the upper ring beam and the lower ring beam; the watertight partition plates are arranged in the middles of the toggle plates; the width of the toggle plates gradually decreases from the center to the ends; the shell plate is symmetrical about the watertight partition plates up and down; and the shell plate is connected with the toggle plates, the upper ring beam and the lower ring beam, and the shell plate is curved. Compared with the prior art, the ice-resistant device of the invention has the advantages that the impact force of floating ice can be decomposed into supporting force perpendicular to the shell plate more effectively, and the failure mode of the floating ice changes from compressive failure to bending failure; the arrangement is flexible, the size and shape parameters of an ice-resistant cone can be analyzed according to calculation, arrangement is conducted along the periphery of a main structure, and an optimal effect is achieved; and the construction is simple and rapid, and cost is low.

Owner:HUANENG CLEAN ENERGY RES INST +3

Continuous-water-supply repairing method and repairing structure of sewage treatment structure expansion joints

InactiveCN109797982AReduce professional requirementsReduce construction costsBuilding repairsEngineeringSewage treatment

The invention discloses a continuous-water-supply repairing method of sewage treatment structure expansion joints. The method includes following steps: removing caulked joint materials on the surfacesof waterstops of to-be-repaired expansion joints of preset height sections at the lower ends of the undersurface and the side face of a structure to form caulked joints; filling each caulked joint with a sealant to form a sealant layer with the upper surface lower than the edge of the caulked joint; embedding a water-swelling waterstop strip in each caulked joint, wherein the lower surface of each the water-swelling waterstop strip is in close fit with the upper surface of the corresponding sealant layer; on each water-swelling waterstop strip, coating and filling a sealing agent at a position where each water-swelling waterstop strip and the corresponding caulked joint are connected and at the edge of each caulked joint. The invention further discloses a continuous-water-supply repairingstructure formed by adopting the method.

Owner:重庆中法环保研发中心有限公司 +1

Construction Method of Overturning the Arch Rib of the Arch Bridge Using the Cable Crane

ActiveCN105821775BAvoid damageLess construction equipmentBridge erection/assemblyStressed stateArch bridge

Owner:CCCC FOURTH HIGHWAY ENG +1

Device for realizing operation of mobile tower crane on structural floor and construction method

ActiveCN102815606BIncreased lifting capacityCost reduction needsRunwaysMechanical equipmentTower crane

Owner:CHANGJIANG & JINGGONG STEEL STRUCTURE GRP CO LTD

Construction method of tunnel thermal insulation in severe cold area

InactiveCN108798728AReduce pollutionSimplify the construction processUnderground chambersDust removalThermal insulationFreeze injury

The invention discloses a construction method of tunnel thermal insulation in a severe cold area. After the examinations of secondary lining clearance, surface evenness and water seepage situation arequalified, expansion anchor bolts are arranged to enable thermal insulation boards to be fixed to the surface of a secondary lining, and then fire prevention boards are laid and fire retardant coating is sprayed. The construction method of the tunnel thermal insulation in the severe cold area has the beneficial effects that the construction procedure is simple, the construction equipment is less,the construction period is effectively shortened, no special requirements for the operating environment is performed, tunnel environment pollution is small, and the construction cost is effectively reduced. Various freeze injuries caused by infiltration during the spring thawing period are effectively prevented, and the temperature of a structure and the traffic safety are guaranteed.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG

I-shaped structure pressure and pull conversion force application apparatus

The invention discloses a press and pull force converting device with an I-shaped structure, which comprises a pressure device, an upper press block and a lower press block, wherein, two jacking sections are formed by the step that the inner sides of the two sides of the grooved structures of the upper block and the lower block are bent towards the middle; the two jacking sections of the upper press block are respectively positioned at the two sides of an I-shaped web plate and are pressed downwards under a lower margin plate of the I-shaped structure, while the two jacking sections of the upper press block are respectively positioned at the two sides of the I-shaped web plate and are pressed downwards under an upper margin plate of the I-shaped structure; an upper load-bearing plate of the pressure device is arranged at the upper part of the upper press block, while a lower load-bearing plate thereof is arranged at the lower part of the lower press block; the device of the invention achieves pull resisting similar to the I-shaped structure by using a common pressure machine and arranges a ground anchor or assembles devices, such as a huge counter-force frame, and the like, in a preset filed, thereby greatly simplifies process, saving a large amount of rolled steel, avoiding the assembly of huge steel members, requiring no high measure costs for assembly, handling safety facilities, and the like, and improving working efficiency; during an anti-pull process, the integrity of the structure is increased remarkably and safety risk is greatly lowered, thus ensuring safety.

Owner:CHONGQING JIAOTONG UNIVERSITY

Construction Method of Vertical Laying and Bricking of Blast Furnace Cooling Wall

The invention relates to the technical field of brick-embedded staves in blast furnace construction, in particular to a construction method for vertically laying bricks inlaid with staves of a blast furnace. Step 1: Pressure test the water-cooled pipes of the stave and transport them to the construction site; Step 2: Turn the stave over on site and place it upright, and use the anti-tilt support frame to support and fix the stave; Step 3: Pop out the stave according to the actual width of the stave Lay the bottom row of inlaid bricks on the longitudinal center line of the stave; Step 4: Lay each remaining row of inlaid bricks in turn from bottom to top until all masonry is completed; Step 5: Hoist the stave after the masonry is completed. The construction process of this method is: pressure test of stave water-cooled pipe-transportation to site-site turning-over-masonry-hoisting. Compared with the traditional brick-embedded construction method, this method has simplified procedures, short construction preparation time, and low construction site requirements. , The scheme uses less material and less construction equipment, which improves the work efficiency and work quality.

Owner:CHINA FIRST METALLURGICAL GROUP

Real time monitoring strengthening method preventing pile foundation from descending

ActiveCN102493431BAvoid reinforcementImprove securityFoundation testingSoil preservationEngineeringDesign stage

The invention relates to a real time monitoring strengthening method preventing a pile foundation from descending, which comprises steps of 1 obtaining standard value of pressure stress in a pile foundation design stage; 2 embedding a pressure gage which is connected with a computer through a wire at the top of each pile foundation in advance; 3 embedding grout injection pipes on four faces of the lateral portion of each pile foundation; 4 starting the grout injection pipes embedded on the four faces of the lateral portion of the pile foundation occurring pressure value deviation when deviation occurs between a measured actual value and a standard value for slip casting, and 5 completing grout injection, leveling a pile body to be stressed in balance, and strengthening the pile foundation occurring the pressure value deviation. The real time monitoring strengthening method preventing the pile foundation from descending can timely monitor pile foundation states, strengthen the pile foundation at the first time, is simple and easy to conduct, effectively reduces strengthening time of the pile foundation, improves strengthening efficiency of the pile foundation, lowers construction cost, improves construction quality, and is safe and reliable.

Owner:MCC TIANGONG GROUP

Sludge suction truck for building construction

InactiveCN109837936AImprove construction efficiencyLess construction equipmentMechanical machines/dredgersSludgeHigh pressure

The invention relates to a sludge suction truck for building construction. The sludge suction truck comprises a truck and a motor, wherein the truck is provided with a motor and a high-pressure sludgesuction device; the motor is connected with a high-pressure sludge suction device; the high-pressure sludge suction device is connected with a sludge suction pipe, a spiral drill is arranged at the front end of the sludge suction pipe, the truck controls the spiral drill, and the truck controls the spiral drill to drill the sludge, the sludge is sucked into the truck from the sludge suction pipethrough the high-pressure sludge suction device, so that the sludge suction truck has the advantages that the construction efficiency is improved, the construction equipment is reduced and the cost isreduced.

Owner:安哲鹏

Rotating disc for turning whole bridge girder erection machine

The invention discloses a rotating disc for turning a whole bridge girder erection machine. The rotating disc comprises a chassis and a top rack which is movably mounted on the chassis in a buckled manner, wherein a first plane where the top rack exists is parallel to a second plane where the chassis exists; the top rack can rotate in the first plane relative to the chassis and does not deviate from the chassis. During construction, the rotating disc disclosed by the invention can be utilized to conveniently rotate the bridge girder erection machine.

Owner:蓝清

Landfill gas gas-collecting shaft construction method

ActiveCN101748751BImprove permeabilityImprove gas collection efficiencyArtificial islandsUnderwater structuresControl mannerEngineering

The invention discloses a landfill gas gas-collecting shaft construction method, which adopts grabbing-bucket digging well method to dig the gas-collecting shaft, and the completed gas-collecting shaft has good permeability, and high gas-collecting efficiency. The grabbing-bucket is controlled through a steel rope, the length can be controlled; and the gas-collecting shaft with deep depth can be constructed according to needs, meanwhile, the control method can simplify the structure. Pebbles or gravels are poured into a gas-collecting vertical hole at the outside of a gas-collecting pipe to the top of the garbage layer, and the periphery of the gas-collecting shaft on the garbage layer is provided with bentonite, and the bentonite is tamped to form a sealing structure, accordingly, the efficiency can be further increased.

Owner:山高十方环保能源集团有限公司

Sludge suction vehicle for building construction

InactiveCN109898584AImprove construction efficiencyLess construction equipmentMechanical machines/dredgersSludgeHigh pressure

The invention relates to a sludge suction vehicle for building construction. The sludge suction vehicle comprises a truck and a motor, wherein the truck is provided with the motor and a high-pressuresludge suction device, the motor is connected with the high-pressure sludge suction device, the high-pressure sludge suction device is connected with a sludge suction pipe, a spiral drill is arrangedat the front end of the sludge suction pipe, the truck controls the spiral drill, and the truck controls the spiral drill to drill and crush sludge. According to the sludge suction vehicle, the sludgeis sucked into the truck from the sludge suction pipe through the high-pressure sludge suction device, and the advantages that the construction efficiency is improved, construction equipment is reduced, and the cost is reduced are achieved.

Owner:宋贤露

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com