Patents

Literature

77results about How to "Realize the use function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

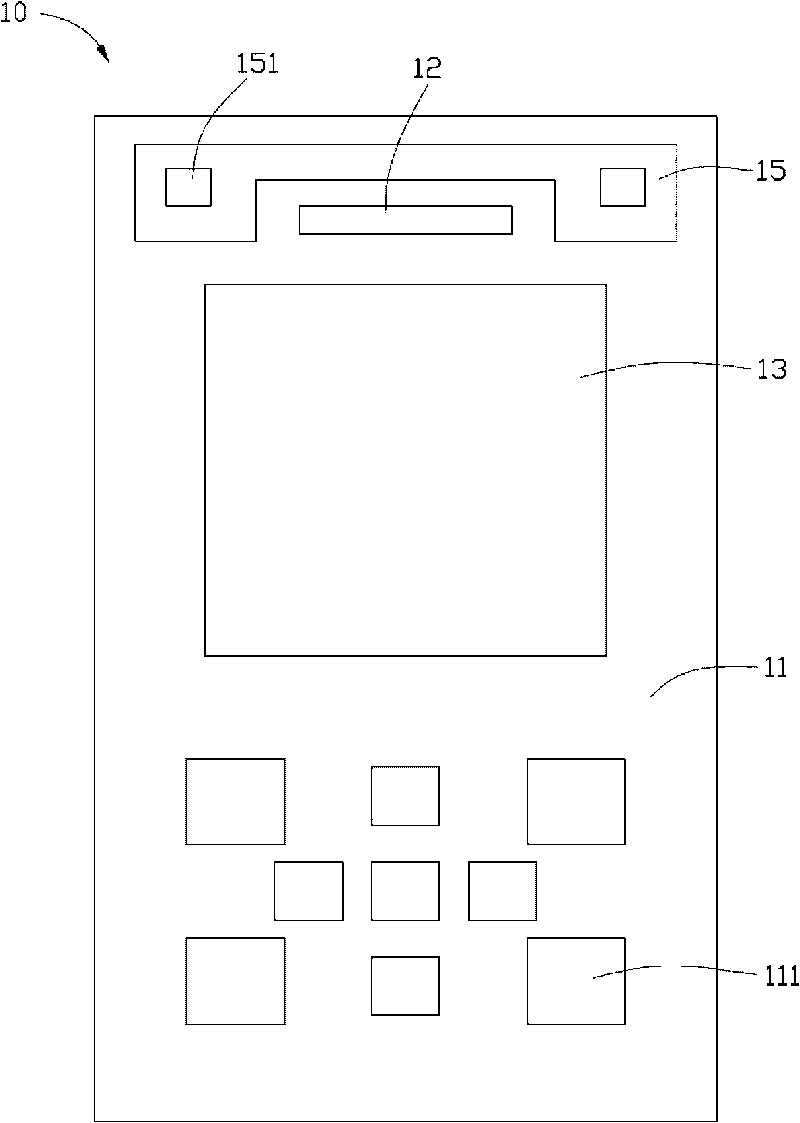

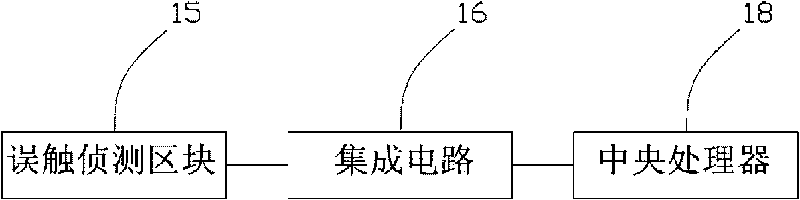

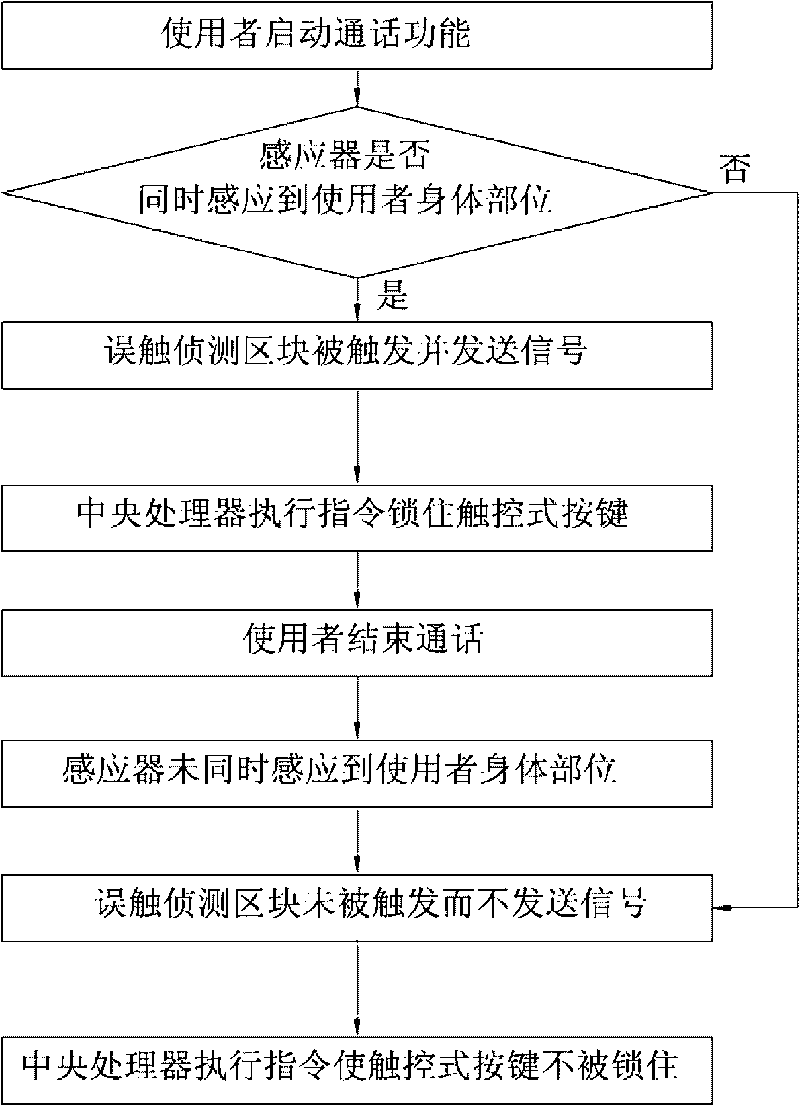

Method for preventing error touches during conversation and touch mobile phone using same

InactiveCN101715020ARealize the use functionAvoid misuseSubstation equipmentInput/output processes for data processingComputer scienceMobile phone

The invention relates to a method for preventing error touches during a conversation, which is used for preventing the error touches during the conversation by using a touch mobile phone. The touch mobile phone comprises touch keys. The method for preventing the error touches during the conversation comprises the following steps: setting an error touch detecting block which comprises a sensor capable of sensing an approaching object; when the sensor senses the approaching object, triggering the error touch detecting block and sending a triggering signal to a central processing unit, and locking the touch keys by executing an instruction corresponding to the triggering signal by the central processing unit; and when the object moves away from the sensor, sending no triggering signal to the central processing unit because the error touch detecting block is not triggered, and ensuring that the touch keys are not locked by executing an instruction by the central processing unit when the central processing unit cannot receive an error touch signal. The invention also relates to the touch mobile phone using the method for preventing the error touches during the conversation.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

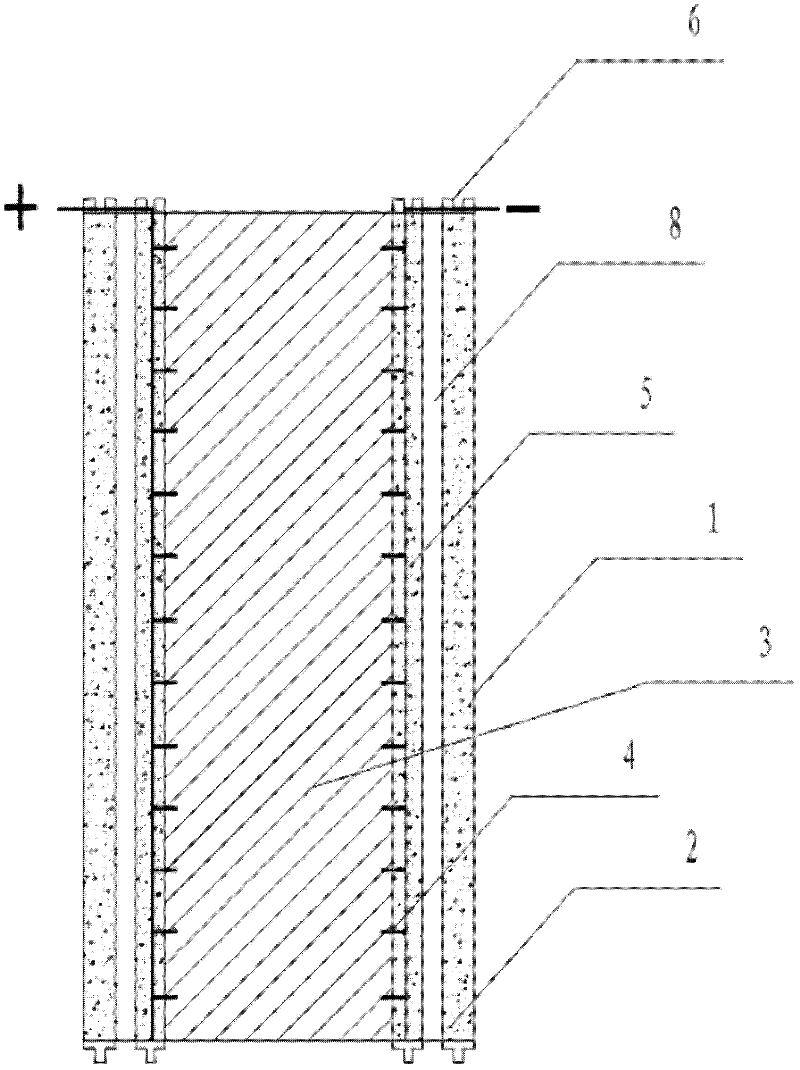

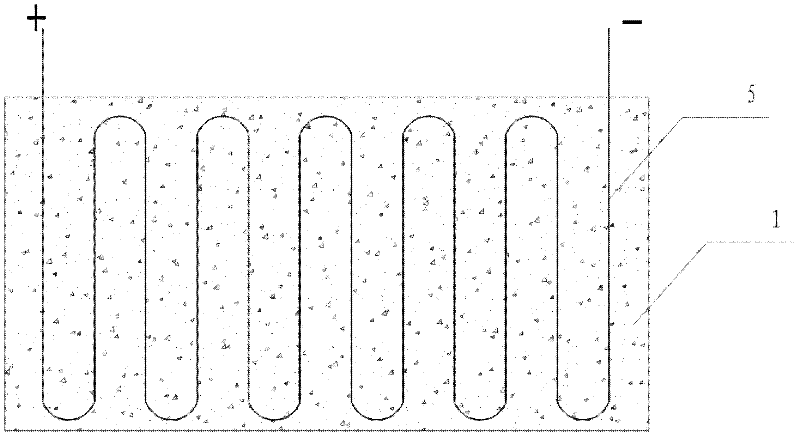

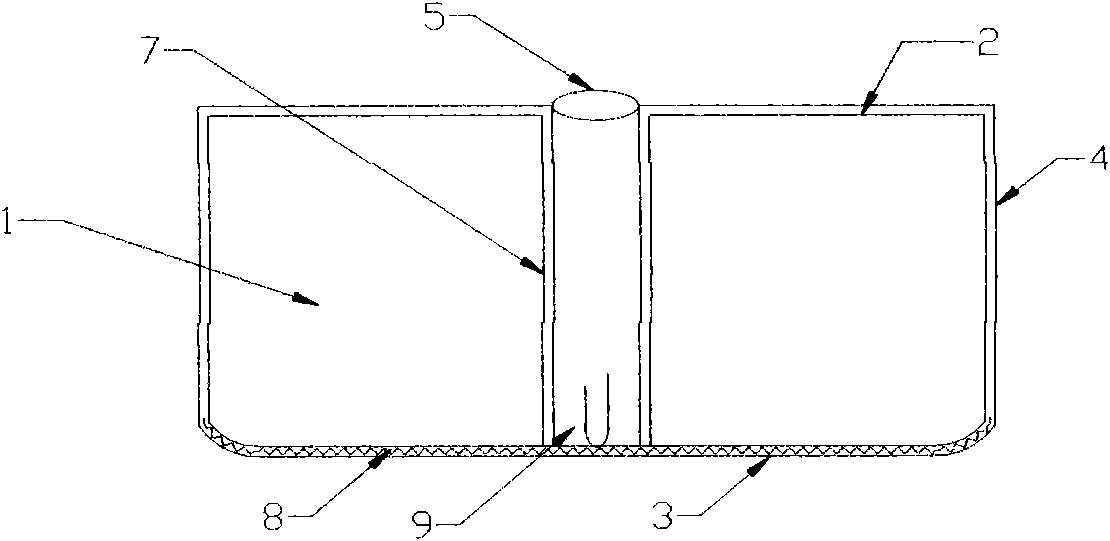

Novel precast concrete pipe die and construction method thereof

InactiveCN102373803ARealize the use functionReduce usageStrutsForms/shuttering/falseworksPre stressEngineering

The invention discloses a novel precast concrete pipe die, which is a precast concrete pipe pile of a hollow structure. The wall of the precast concrete pipe die is internally provided with annular and vertical reinforcing steel bars, the inner surface of the pipe die is provided with dowel bars connected with post-poured concrete into a whole and an electric heating wire for heating, the upper end and the lower end of the pipe die are provided with tooth-shaped connectors which are mutually matched, the wall of the pipe die is internally provided with preset pore canals for prestress reinforcing steel bars, and the pore canals are through longitudinally. A construction method of the novel precast concrete pipe die comprises the steps of: after positioning the precast concrete pipe die, switching on a power supply of the electric heating wire, and performing high-dropping self-compacting concrete pouring on the middle of the concrete pipe die; and after a first section of cylinder core of the pipe die is poured, performing hoisting positioning and concrete pouring on a second section of the concrete pipe die. The invention has the advantages that by precasting the concrete pipe die, the special requirement on the use functions of a concrete column surface and a column template can be met, and the heating functions of the novel precast pipe die can also ensure the smooth construction in winter; and the novel precast concrete pipe die and the construction method thereof have the advantages of simplicity and rapidness for construction, less required construction equipment, and capability of greatly reducing the construction cost and the comprehensive manufacturing cost.

Owner:TIANJIN UNIV

Energy-saving cast-in-place hollow floor

InactiveCN102003010AMaintain integrityMaintain aestheticsFloorsForms/shuttering/falseworksCrack resistanceEngineering

The invention relates to an energy-saving cast-in-place hollow floor, which comprises thin-wall box bodies, a rib beam between the box bodies and an upper flange plate, wherein the upper flange plate contains an electric heating tube, and an electric heater and heat retention liquid are arranged in the electric heating tube; the top surface of the thin-wall box body is provided with at least one groove, the lateral surface of the thin-wall box body is provided with a closed hole, the closed holes of the adjacent box bodies are connected through a junction pipe, the lower end of the hole wall is connected with the bottom surface and closed, and the upper end of the hole wall is communicated with the top surface to form a hole; and the inclined plane and the bottom surface of the box bodies form an included angle of 100 to 165 degrees, and the side length of the inclined plane is more than 20 millimeters. Sunken closed holes are reserved on the lateral surfaces of the box bodies, the closed holes are opened before casting and the junction pipe can pass through the open closed holes to form an interconnected through heat energy blowing passage, and grooves for laying heating pipes are reserved on the top surfaces of the thin-wall box bodies to form a floor energy supply system. The floor adopting the thin-wall box bodies has the advantages of light weight, high hardness, reasonable structure, energy conservation, environment friendliness, cracking resistance and seismic resistance, and also can solve the heating problem by using the box bodies to transfer the heat energy.

Owner:王本淼

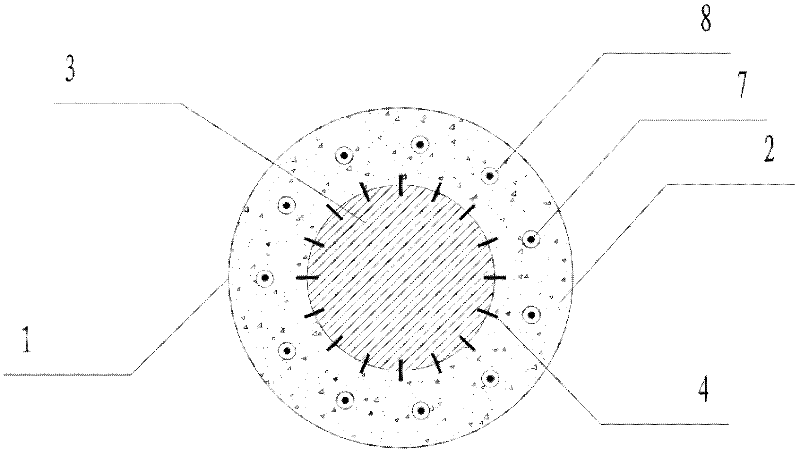

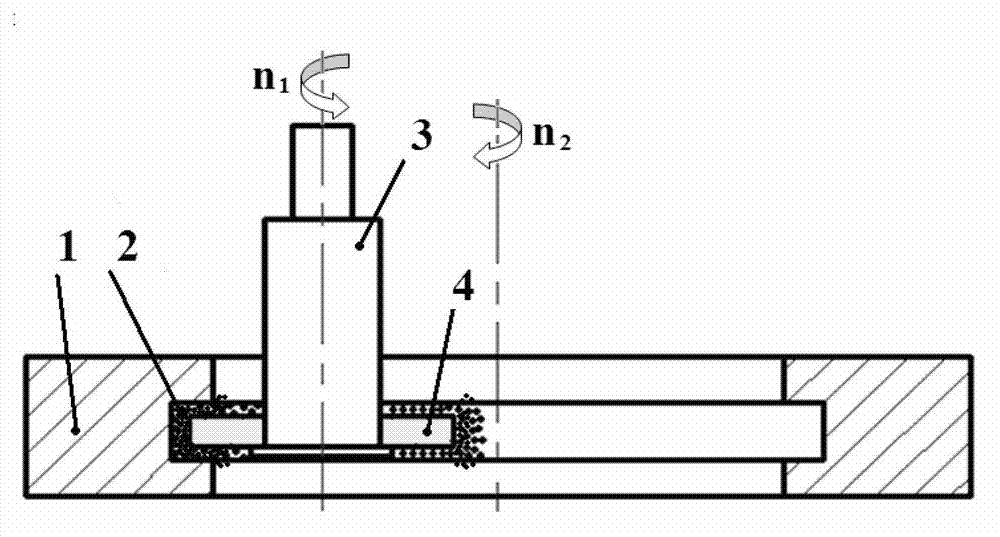

Method for finishing upper groove and narrow slit of workpiece

The invention discloses a method for finishing an upper groove and a narrow slit of a workpiece. The method for finishing the upper groove and the narrow slit of the workpiece can enable the surface quality of the upper groove and the narrow slit of the workpiece to be improved obviously. A set of mechanical equipment with a power rotation main shaft is adopted, so that an annular permanent magnet is fixedly arranged on the rotation main shaft through a clamp, and the workpiece is fixed by using a workpiece positioning frame. Magnetism abrasive particles are covered on the surface of a to-be-finished groove or a to-be-finished narrow slit of the workpiece, the annular permanent magnet is enabled to aim at the to-be-finished position for magnetic abrasive finishing, due to magnetic force, the magnetism abrasive particles are attached to the surface of the to-be-finished groove or the to-be-finished narrow slit of the workpiece in a pressing mode, the annular permanent magnet is driven to rotate by a main shaft motor, the magnetism abrasive particles conduct abrasion and squeezing to the groove or the narrow slit in the workpiece, and so that polishing and burring are achieved. The method for finishing the upper groove and the narrow slit of the workpiece is wide in range of application, concise in method, easy to operate, and capable of not only being used for die workpieces, but also being used for finishing of a circular groove in the inner surface of a hydraulic cylinder, the surface of a bearing inner race, the surface of a precise spline key groove and the threaded surfaces of a small bolt and a nut.

Owner:UNIV OF SCI & TECH LIAONING

Drum washing machine

ActiveCN111041761AAvoid retaining dirtImprove cleanlinessOther washing machinesWashing machine with receptaclesLaundry washing machineEngineering

The invention discloses a drum washing machine. The drum washing machine comprises a non-porous drum which is installed in a shell and does not include a dehydration hole; a clothes putting opening isarranged in the side wall of the non-porous drum, and a door body capable of opening and closing the clothes putting opening through turnover is arranged on the drum; an outer barrel is mounted outside the drum in a sleeving way; and an electromagnetic heating module is arranged on the outer barrel to heat the inside of the outer barrel and transfer heating heat to washing water contained in thedrum. According to the drum washing machine provided by the invention, the electromagnetic heating module is arranged on the outer barrel so as to utilize an electromagnetic field to carry out heatingtreatment on the drum inside the outer barrel and the washing water inside the drum, so that the use purpose of adjusting the washing water temperature in the drum of the washing machine is achieved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

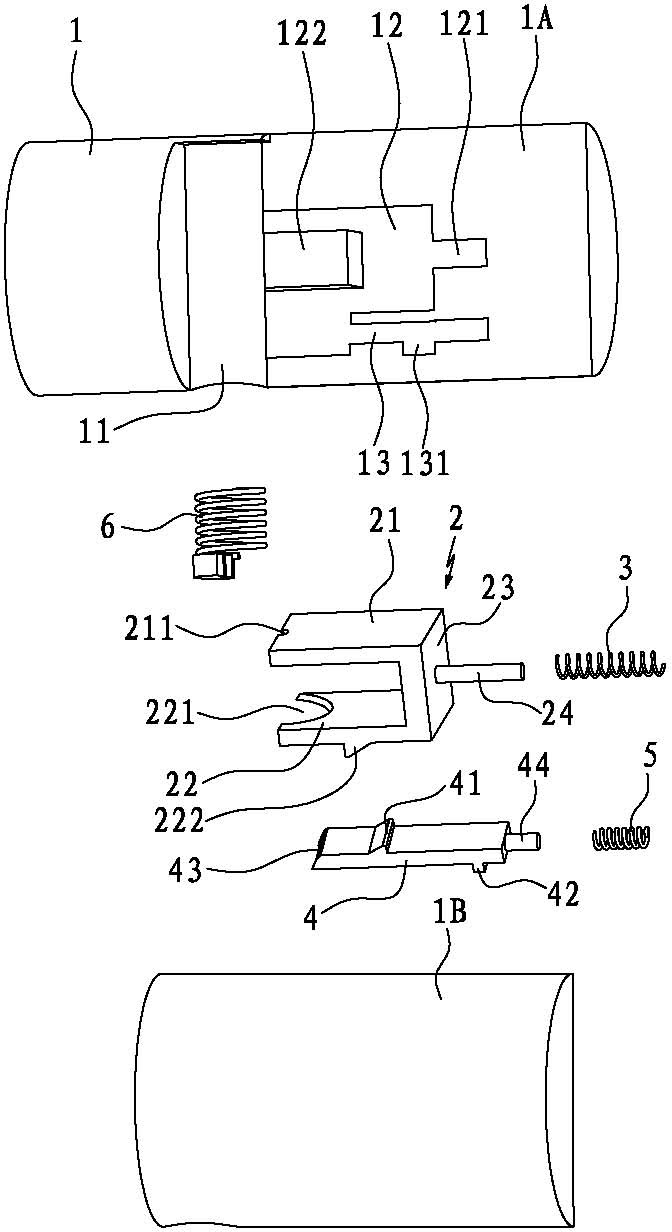

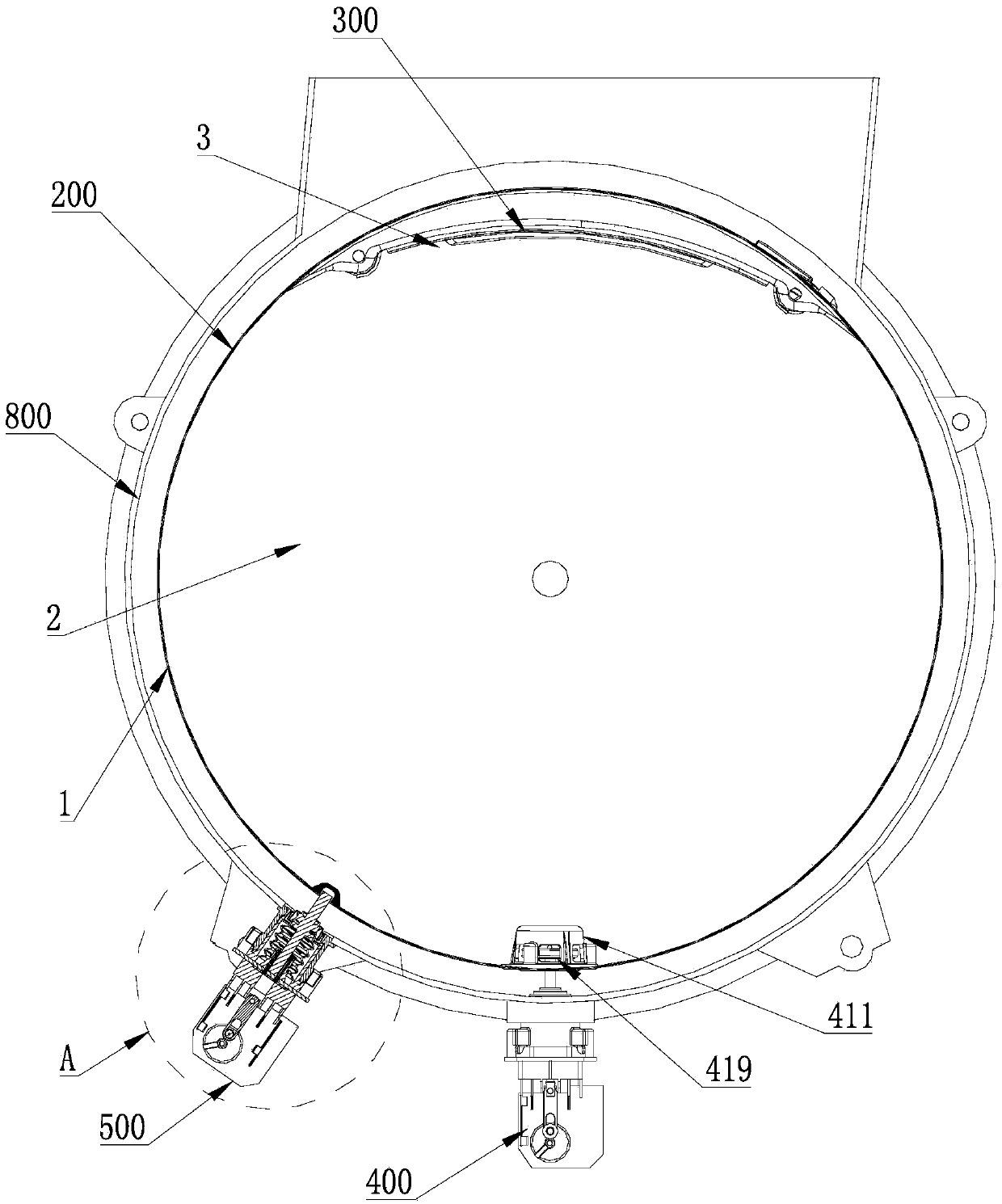

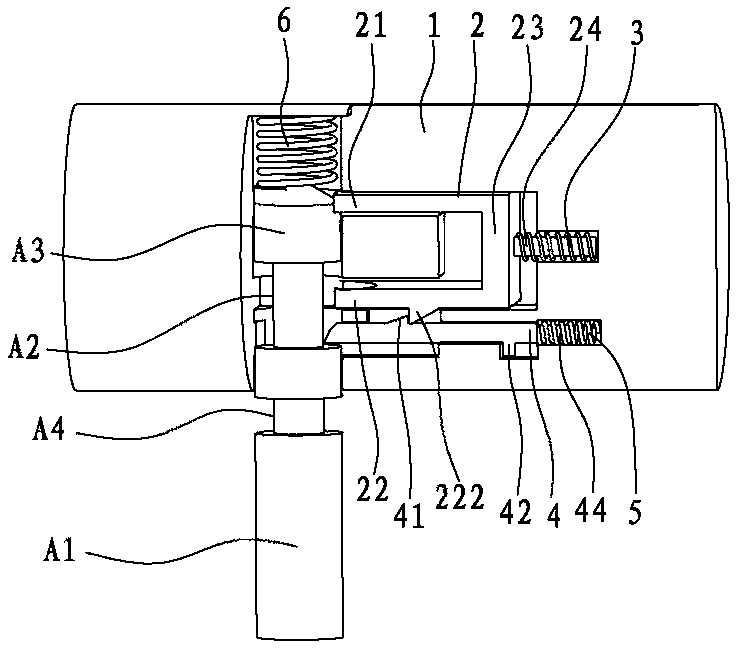

Fast automatic disassembling structure of toilet bowl cover plate assembly

ActiveCN102512114ARealize the installation functionRealize the use functionBathroom coversLocking plateEngineering

Disclosed is a fast automatic disassembling structure of a toilet bowl cover plate assembly, which is used by means of matching with two bases fixed on a toilet bowl. Each base is provided with a positioning rod with a reducing neck and a regular cone, a connecting shaft is pivotally connected with a cover plate and a seat ring via two automatic mechanisms, each automatic mechanism comprises a body, a positioning rod penetrates into the body, a slide part pushed by a slide part spring and a lock pushed by a lock plate spring are disposed in each body, arc-shaped notches are formed at front ends of an upper slide plate and a lower slide plate of each slide part, a one-way clamp table is formed on the lower surface of each lower slide plate, the distance between each upper slide plate and the corresponding lower slide plate is larger than the height of the regular cone on the upper portion of the positioning rod, a hook which is hung on the clamp table is formed on the upper surface of a lock plate, a ring slot is arranged on the lower side of the reducing neck of the positioning rod, a movable lock pin is disposed on a seat ring pivot sleeve or a cover plate pivot seat, and an inclined guide plane which pushes the movable lock pin is disposed on a side of the cover plate pivot seat or the seat ring pivot sleeve and corresponds to the lock pin, so that the movable lock pin movably extends into the ring slot of the positioning rod. The cover plate assembly can be quickly and automatically disassembled by means of integrally exerting force on the cover plate assembly.

Owner:BAYEN (XIAMEN) SANITARY WARE CO LTD

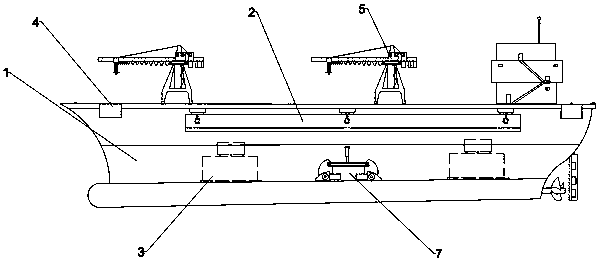

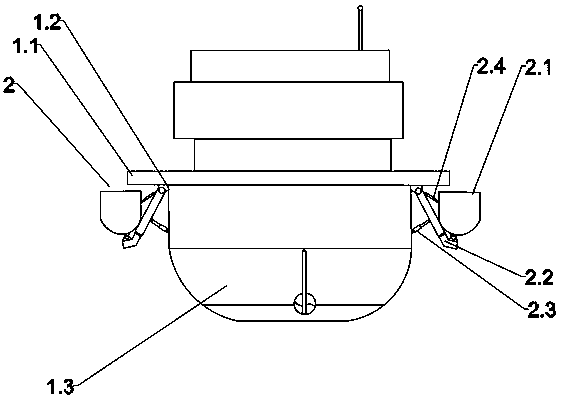

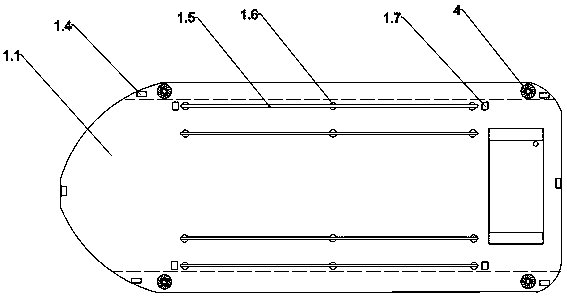

Multifunctional lifting ship balance system and working method thereof

InactiveCN109466717AAutomatically adjusts for tiltPrevent rolloverVessel safetyVessel movement reduction by jets/propellersBalance waterMultiple function

The invention provides a multifunctional lifting ship balance system and a working method thereof. The system comprises a ship body, balance water channels, a tuning balance water tank, lift fans, a self-balance crane, dual-water-spraying balance devices and a PLC system; the balance water channels are arranged at ship boards at the two sides of the ship body, the tuning balance water tank is arranged inside a ship compartment, the tuning balance water tank comprises a main water tank and an auxiliary water tank, the lift fans are arranged on decks at the periphery of the ship body, a fixing balancing weight and a variable balancing weight water tank device are arranged on a balance arm of the self-balance crane, and the dual-water-spraying balance devices are arranged at the bottoms of the two sides of the ship boards. By means of gravity and buoyancy of the balance water channels, the gravity of the tuning balance water tank, lifting force of the fans and thrust of a dual-water-spraying water pump, the balance torque of the ship body is supplied, the balance force of the crane can be automatically adjusted through the variable weighing water tank, the dual-water-spraying balancedevice can supply forward or backward thrust during ship navigation, when cargos are lifted, upwards thrust can be provided by turning by 90 degrees, and various operation functions can be achieved.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

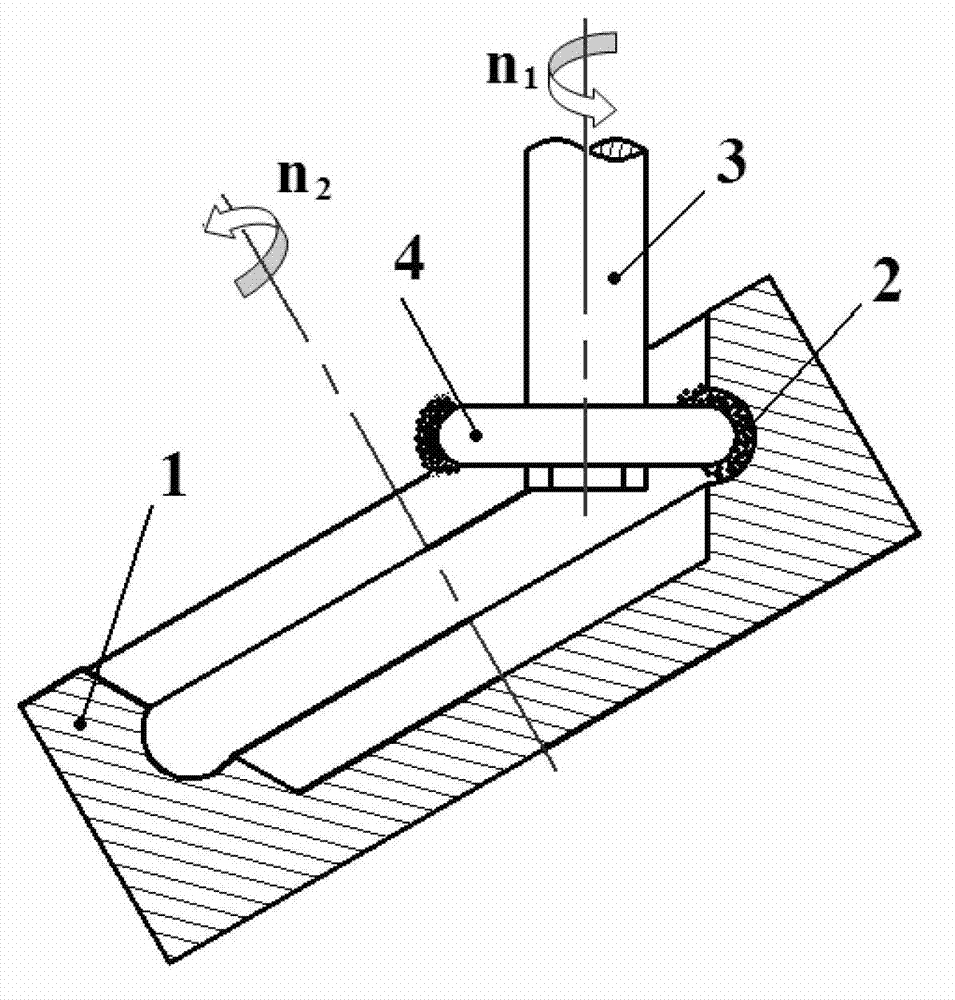

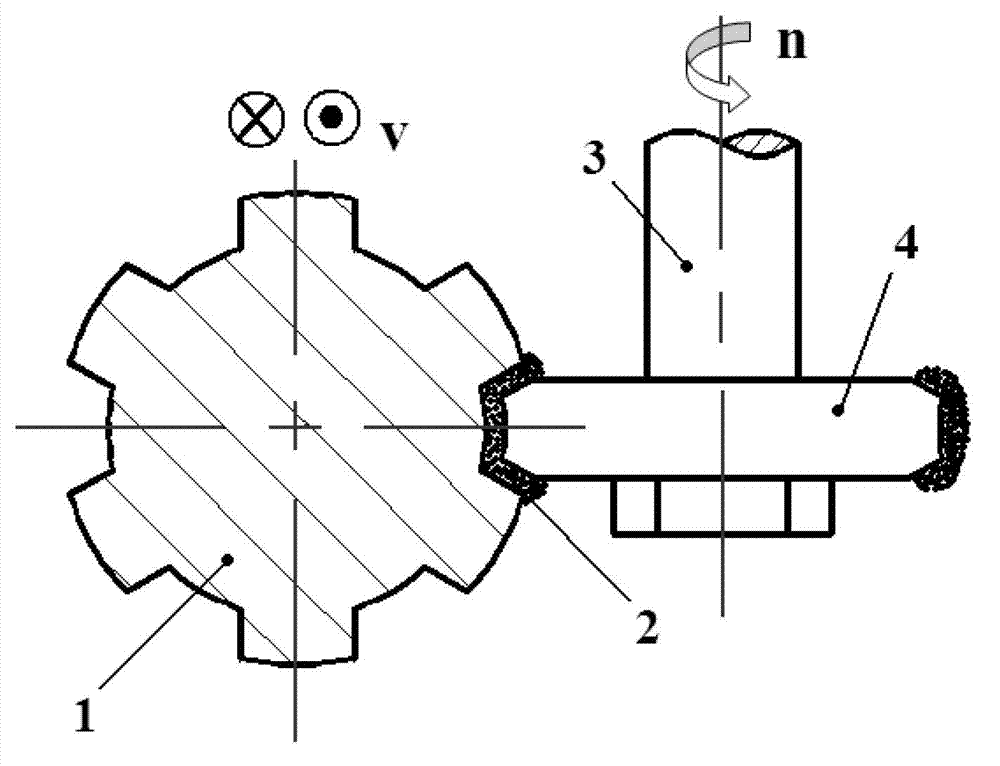

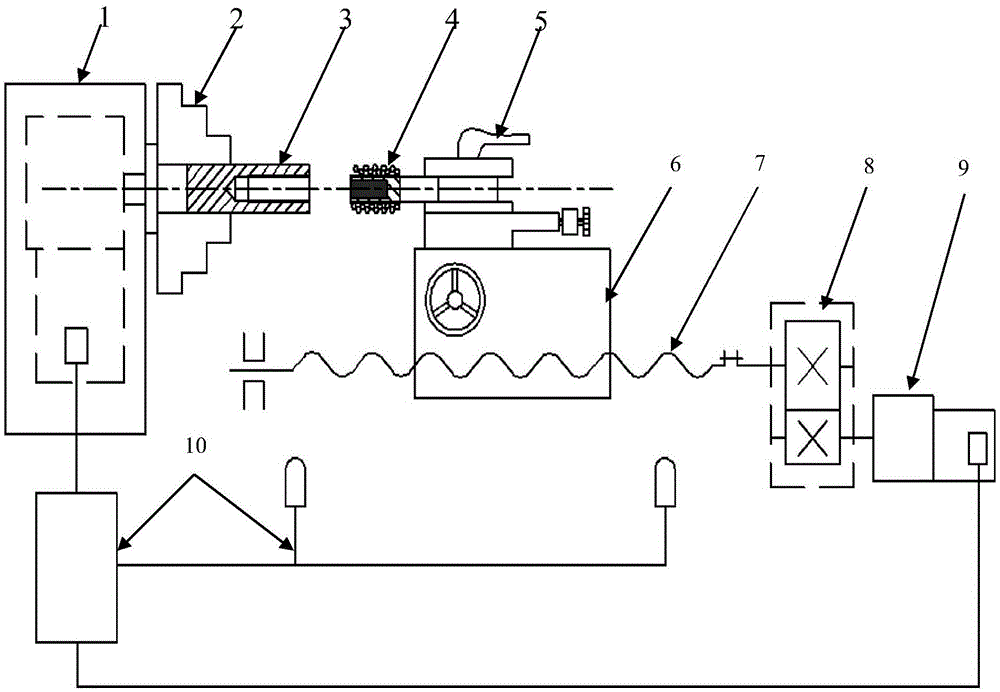

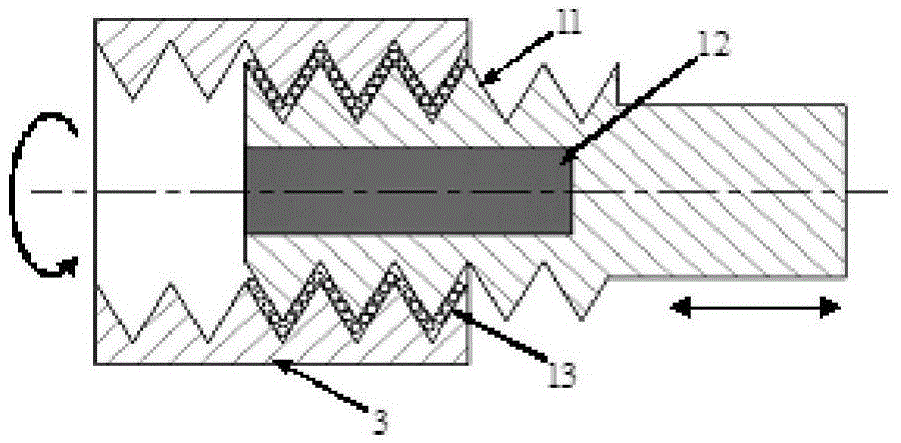

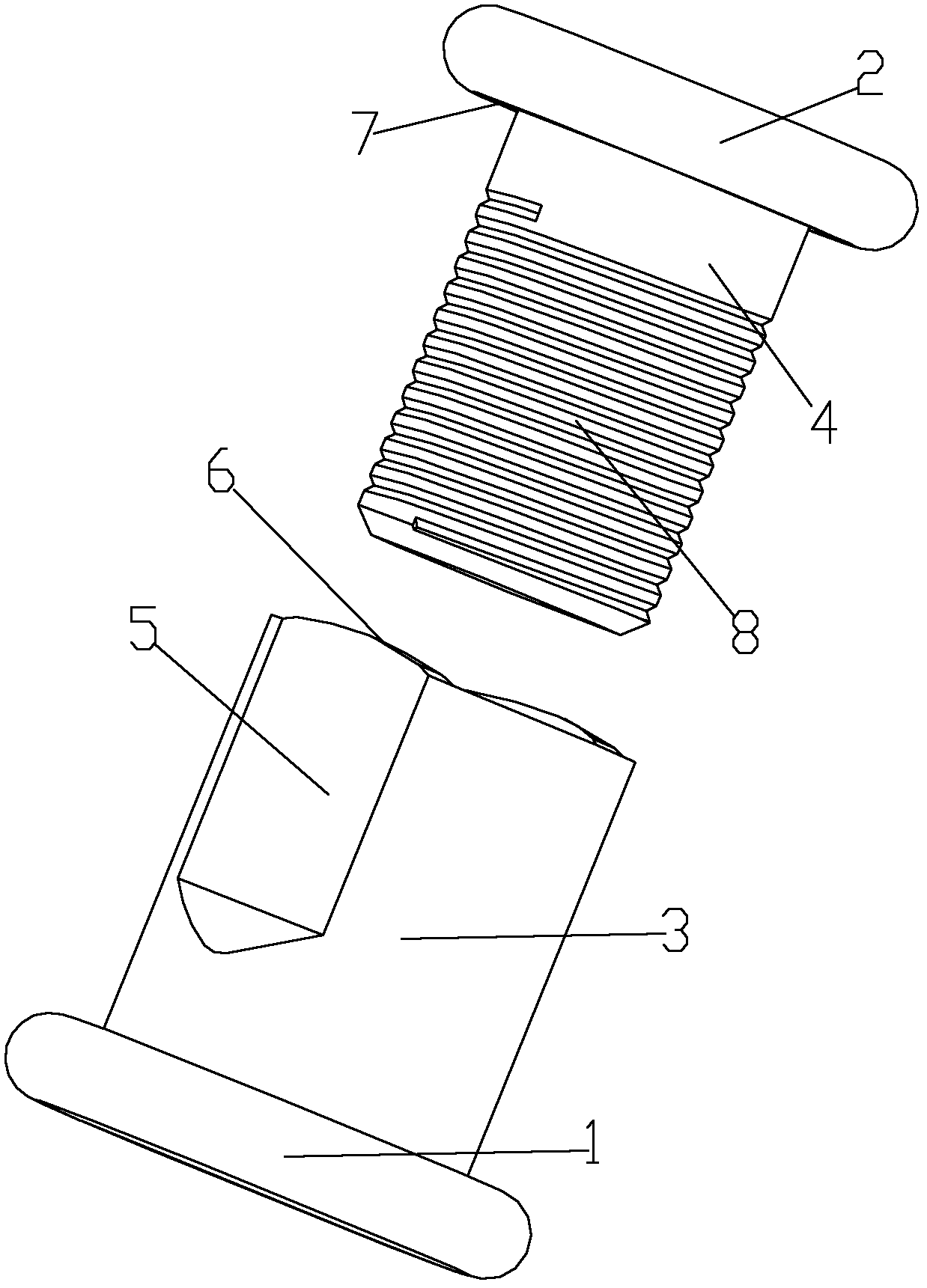

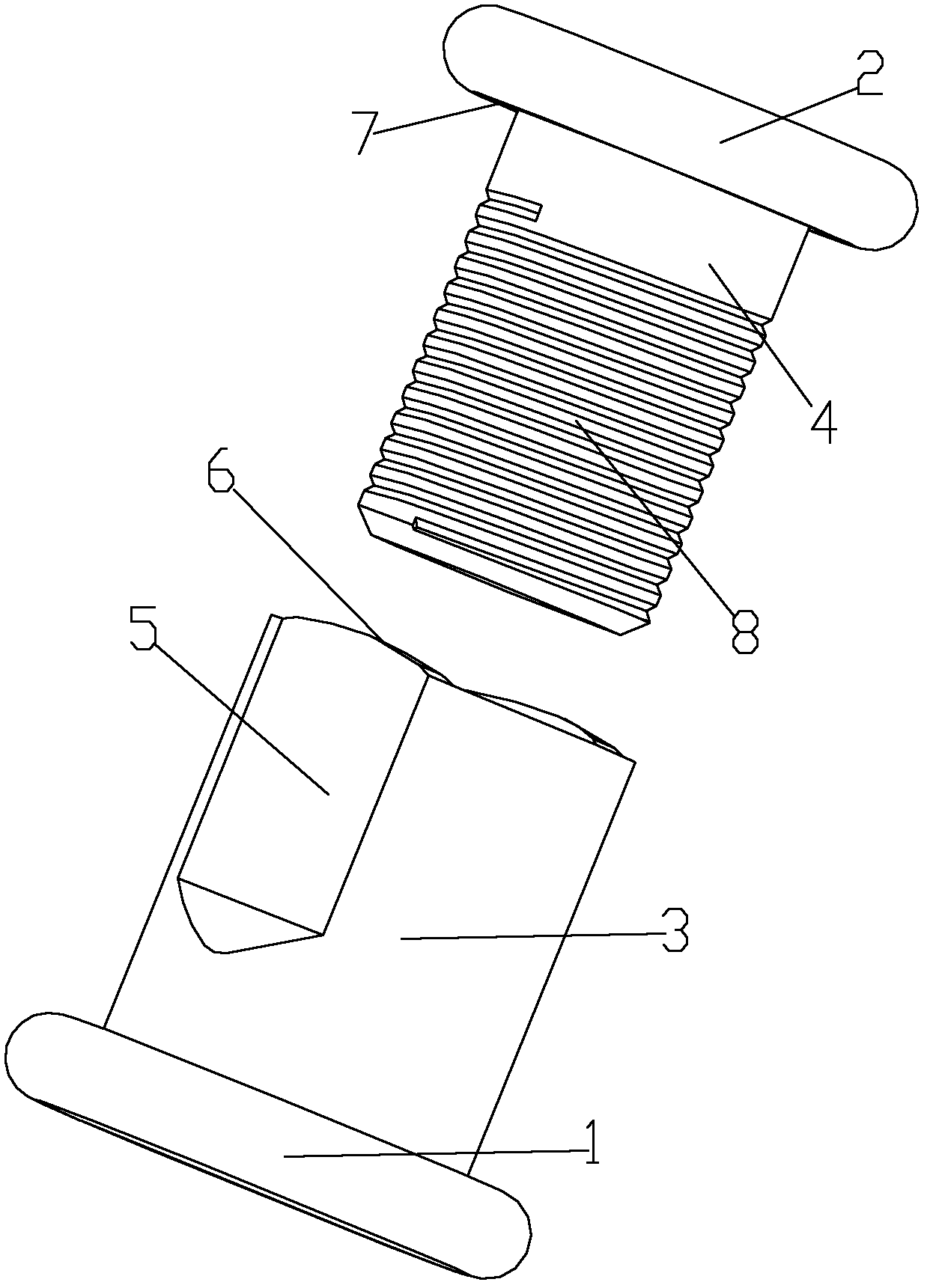

Magnetic grinding method and device for threaded part

The invention discloses a magnetic grinding method and device for a threaded part. The device comprises a main shaft drive motor, a sliding box, a magnetic pole cutter, a horizontal guide rail device and photoelectric switches. The threaded part is connected with the main shaft drive motor through a chuck. The magnetic pole cutter is fixed to the sliding box through an adjustable cutter rest, the sliding box walks on the horizontal guide rail device, the photoelectric switches are arranged at the two ends of the sliding box and connected with the main shaft drive motor and a driving motor of the horizontal guide rail device, and the magnetic pole cutter is coated with a magnetic grinding material. Compared with the prior art, the magnetic grinding method and device have the advantages that a polishing device for internal and external threads is reasonably designed out through the magnetic grinding technology; experimental results show that under the condition of ensuring thread shape and size precision, surface burrs and surface texture of the threads can be effectively removed, the surface smoothness is obviously improved, the using performance of the threaded part is greatly improved, and the service life of the threaded part is greatly prolonged.

Owner:UNIV OF SCI & TECH LIAONING

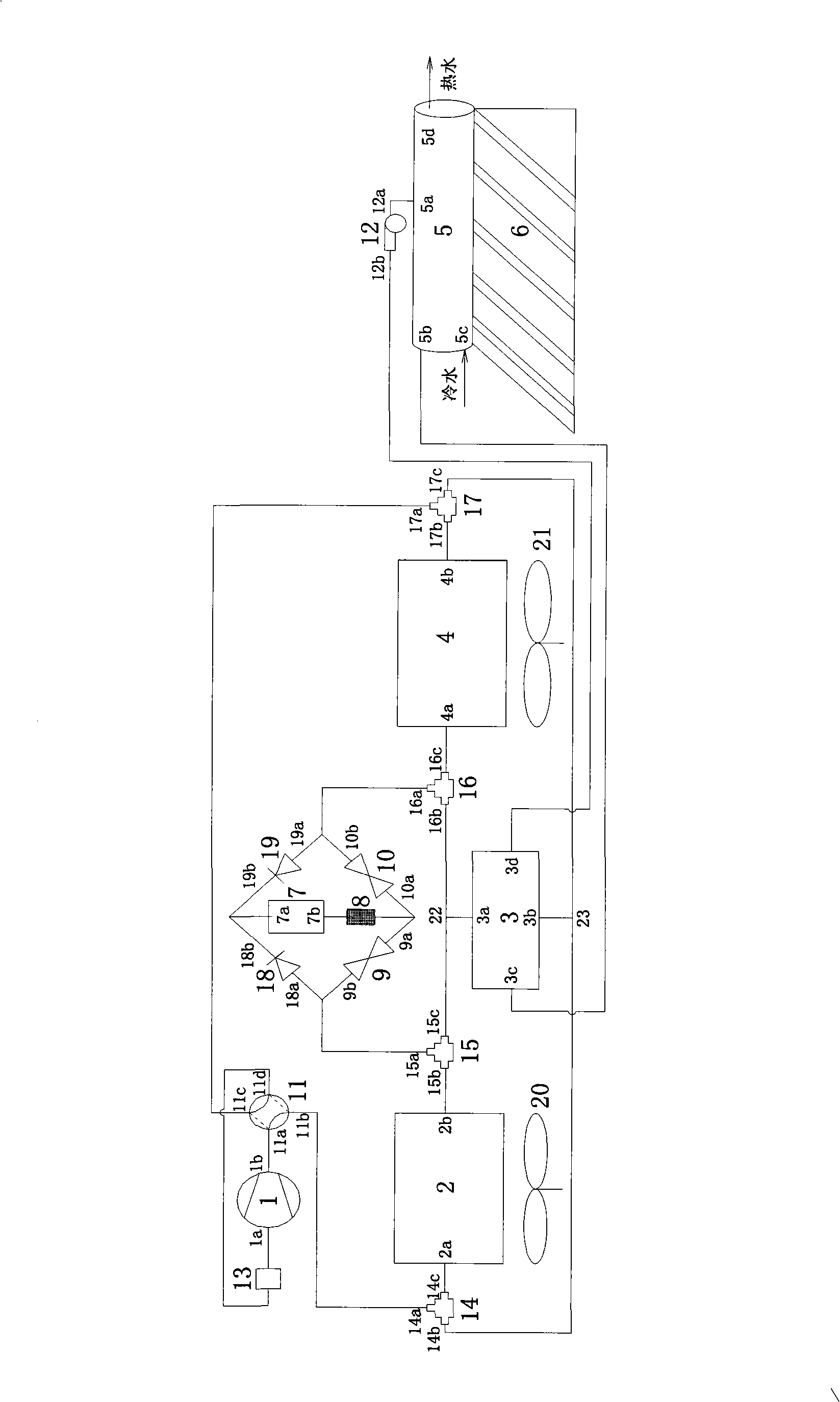

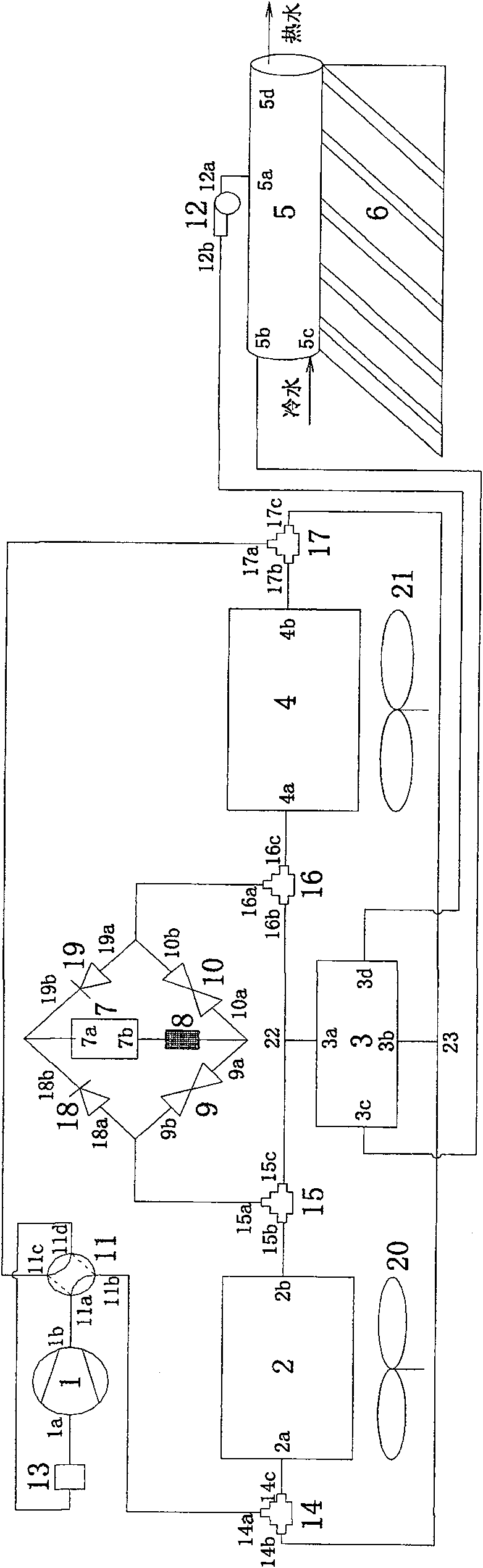

Multifunctional solar auxiliary air conditioning system

InactiveCN101344339AEfficient use ofMake up for the shortcoming of low COPFluid heatersHeat pumpsWater cyclingEngineering

The invention discloses a multifunctional solar-assisted air-conditioning system. The multifunctional solar-assisted air-conditioning system comprises two parts of a refrigerant circulating system and a water circulating system, wherein, the refrigerant circulating system comprises a compressor, an indoor heat exchanger, a refrigerant-water heat exchanger, an outdoor heat exchanger, a high pressure liquid storage barrel, a throttling device, a three-way valve, an one-way valve and a gas-liquid separator which are sequentially connected; and the water circulating system comprises a solar heat collection device, a water tank, a water pump and the refrigerant-water heat exchanger which are sequentially connected. The multifunctional solar-assisted air-conditioning system of the invention can high efficiently realize the functions of a cool-warm air conditioner and a water heater, thereby having very strong energy-saving property, practicality, economy and broad market prospect. The multifunctional solar-assisted air-conditioning system is particularly applicable to the occasions which are rich in solar energy resources and simultaneously need the cool-warm air conditioner and the supply of hot water.

Owner:ZHEJIANG UNIV

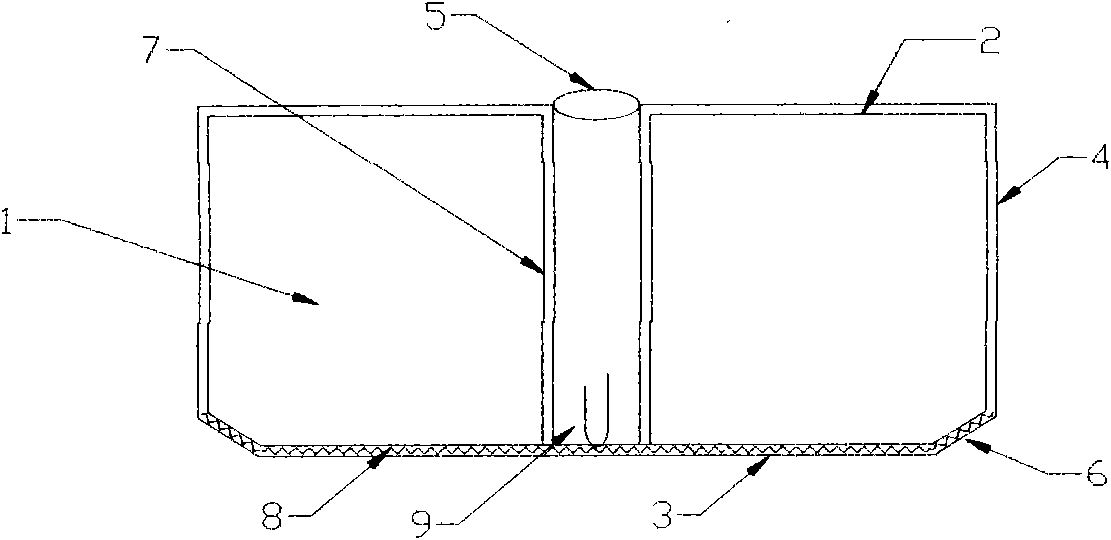

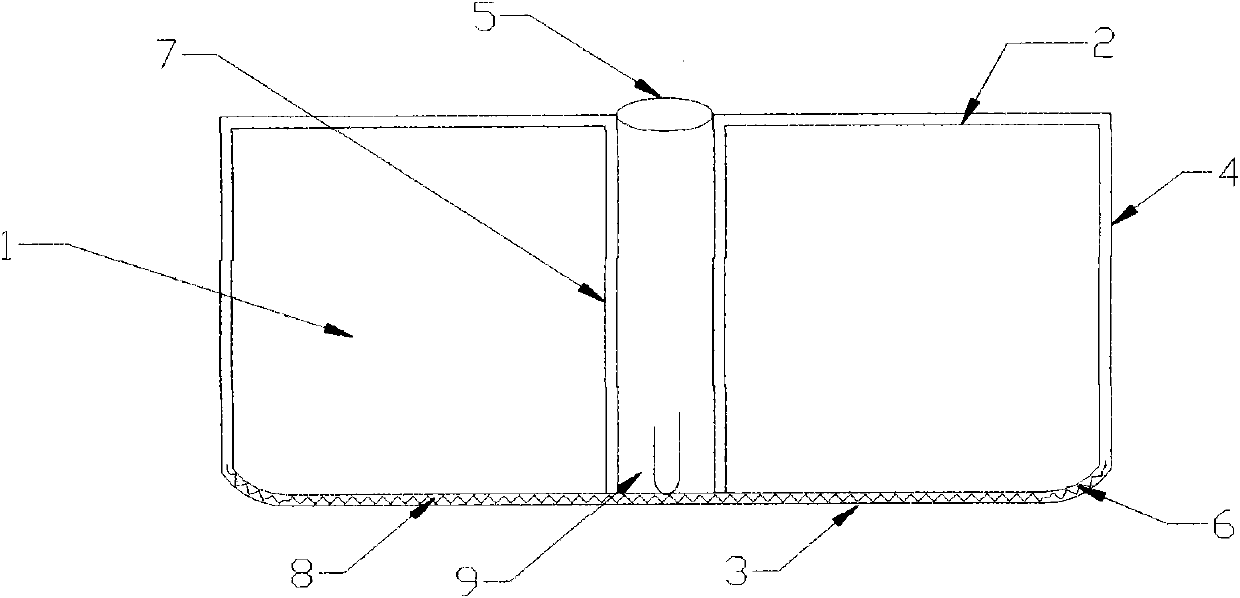

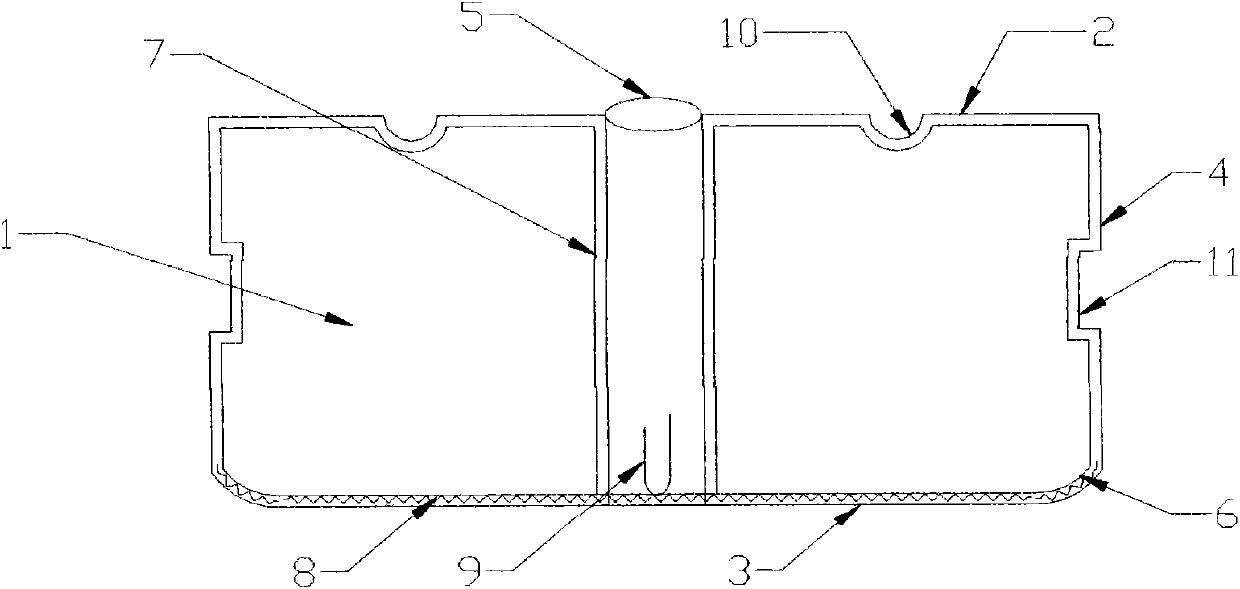

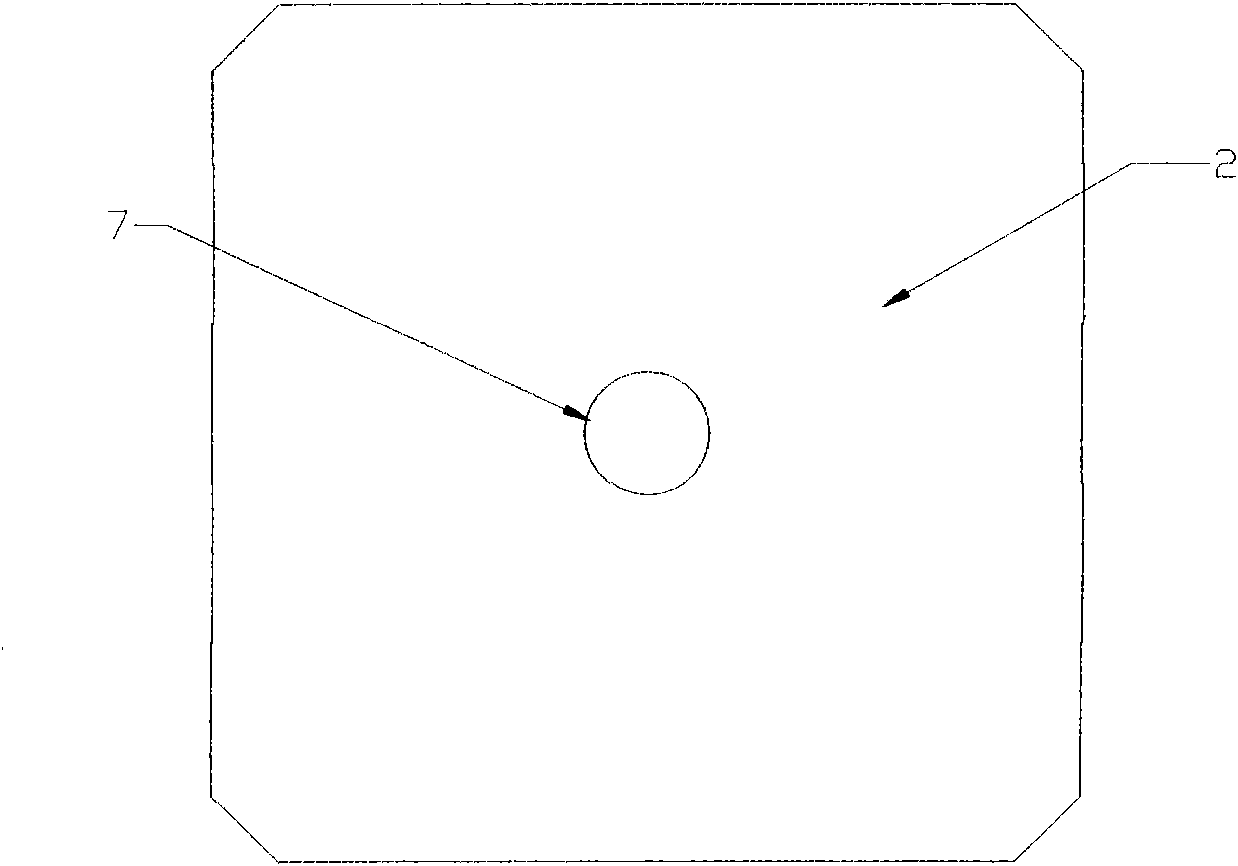

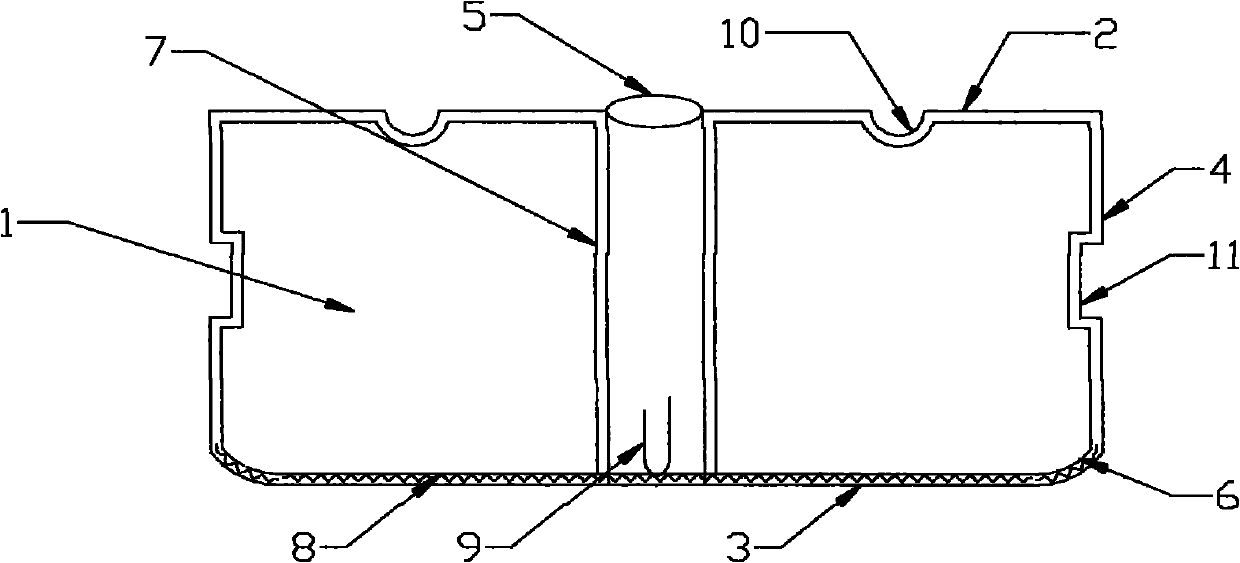

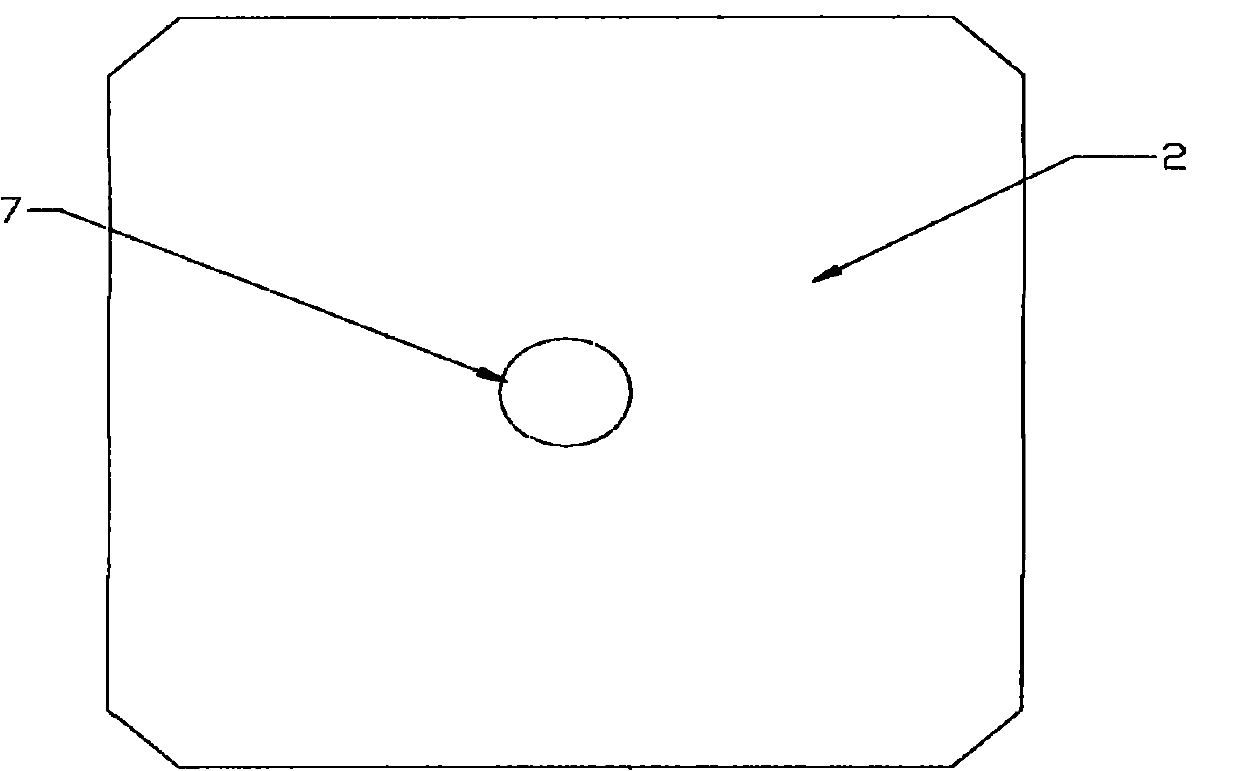

Combined hollow box body for cast-in-place energy-saving hollow floor

The invention relates to a combined hollow box body for a cast-in-place energy-saving hollow floor, which consists of a bottom surface, an arc-shaped surface, a hole wall, a side surface and a top surface, wherein inwards recessed closed holes are reserved on the side surface and can be penetrated before casting for passing a connecting short pipe to form mutually connected and penetrated heat energy air supply passages, grooves for paving heating pipes are reserved on the top surface, the side surface and the top surface form a floor energy supplying system, an arc-shaped surface is formed between the bottom surface and the side surface of the box body, the length of the arc shape of the arc-shaped surface is greater than 70mm, the length of the radius of the arc shape is greater than 45mm, the arc-shaped surface is used for preventing the cracking of the combined parts of the box body and rib beams and the falling of the box body under the conditions of earthquakes and the like, the upper end of the hole wall and the top surface form a casting hole, concrete is filled in the casting hole during cast-in-plate operation to be compounded with reserved iron wires of the bottom surface, an upper wing edge of the floor and the bottom surface of the box body can be tightly connected, and the floor stress structure is improved. The floor adopting the hollow box body has light weight, high hardness and reasonable structure, prevents the cracking, resists the shock and can simultaneously solve the heating problem by using the box body to transmit the heat energy.

Owner:王本淼

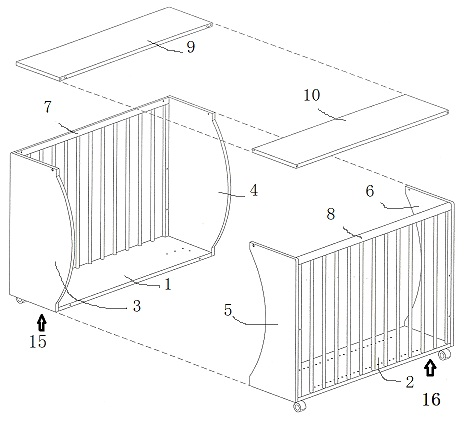

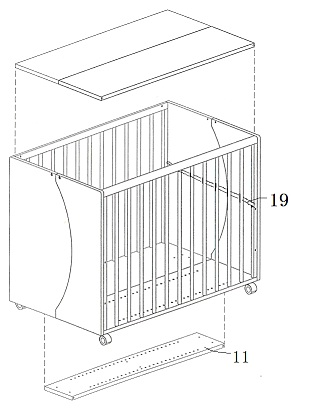

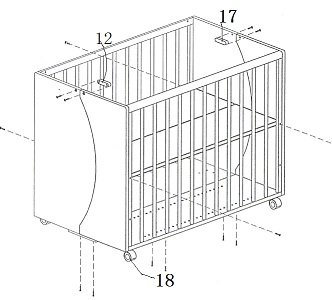

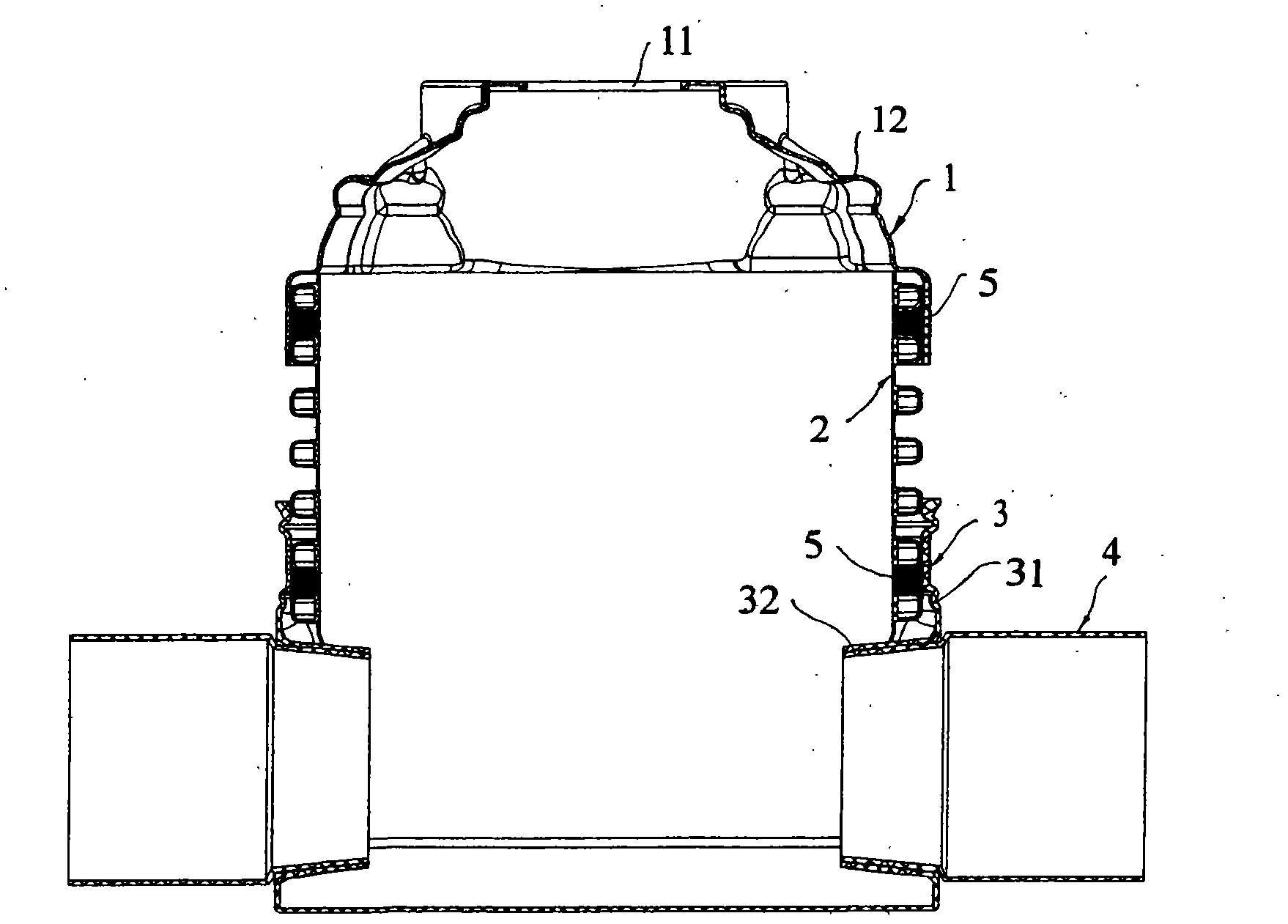

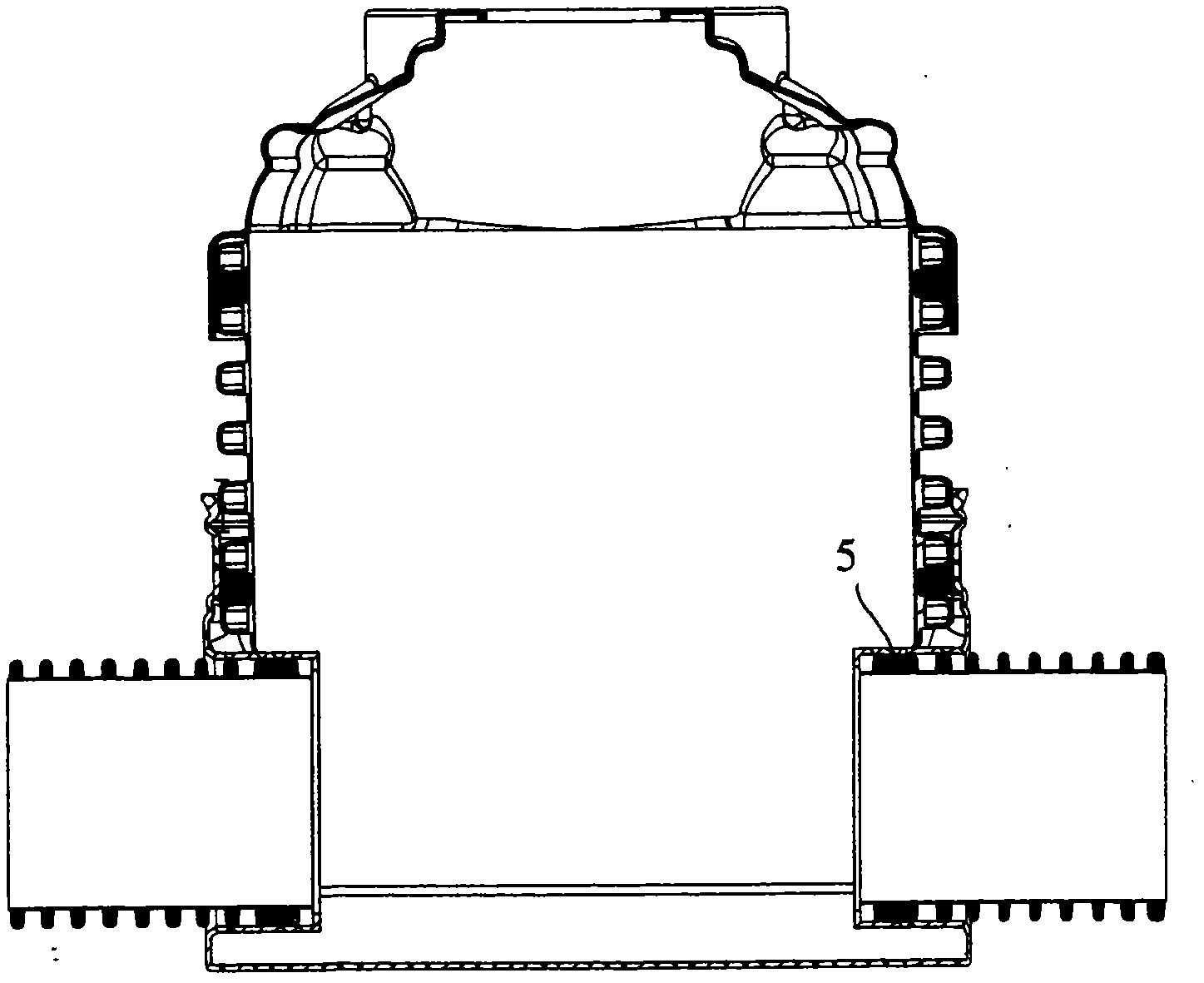

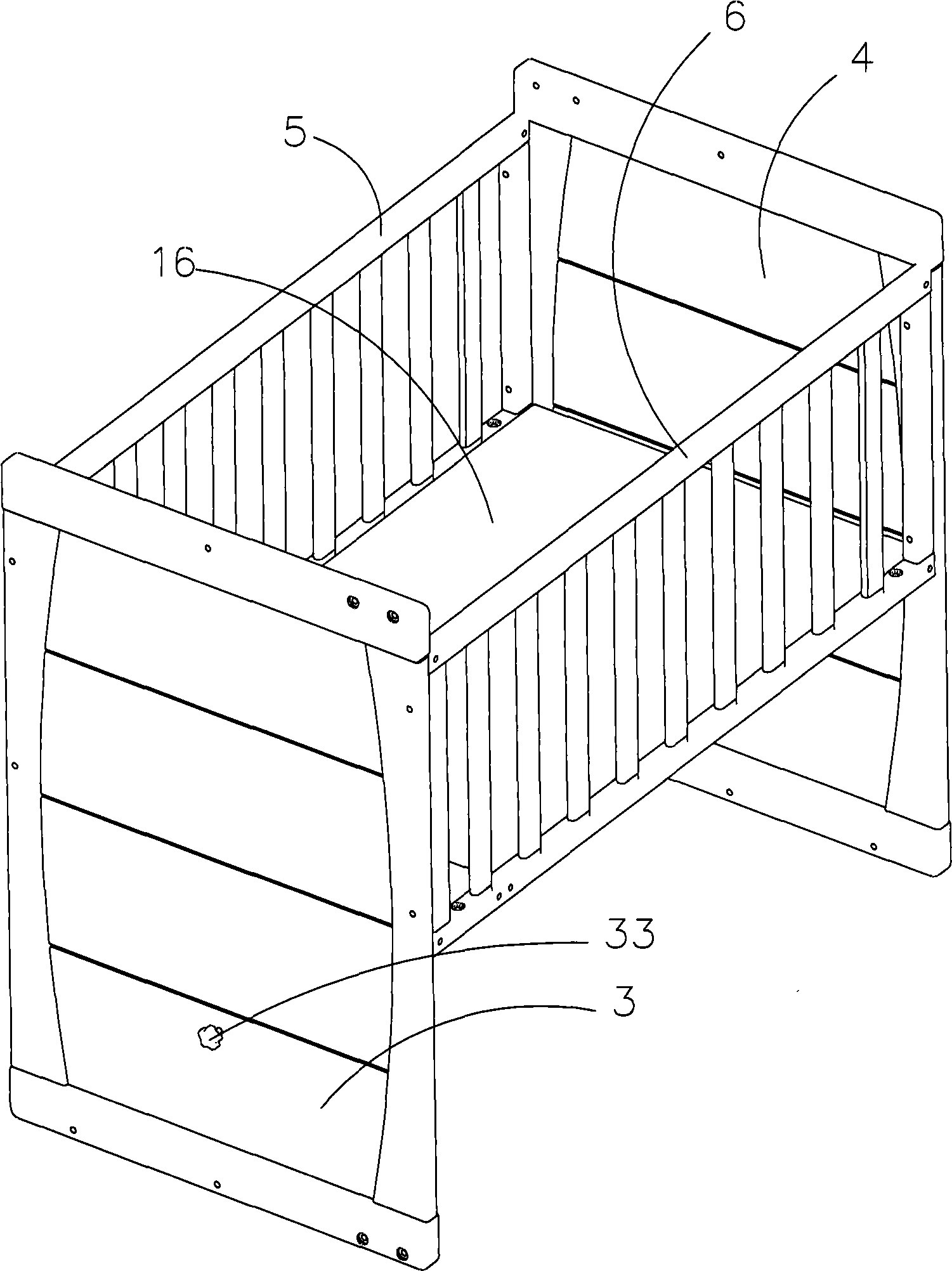

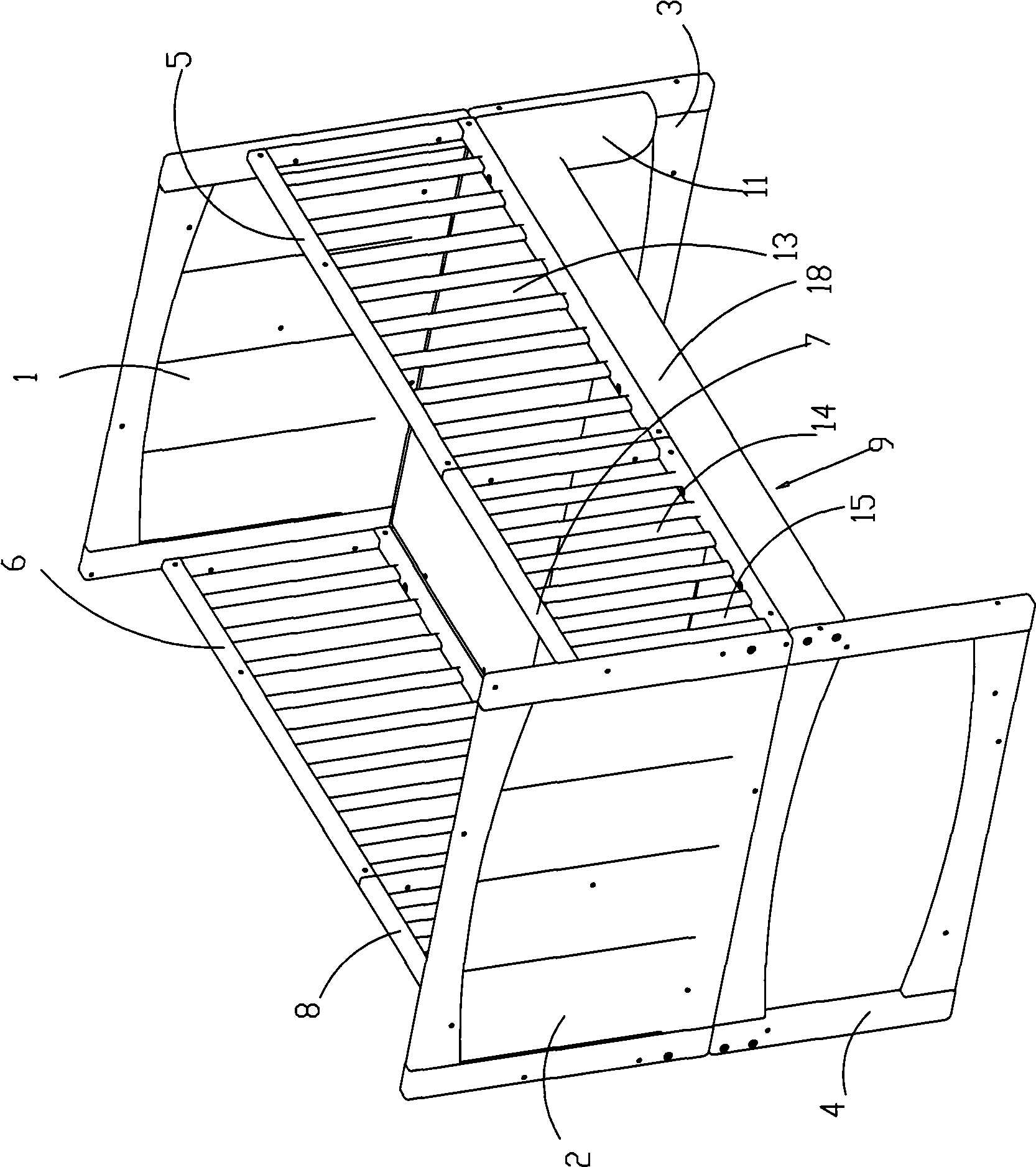

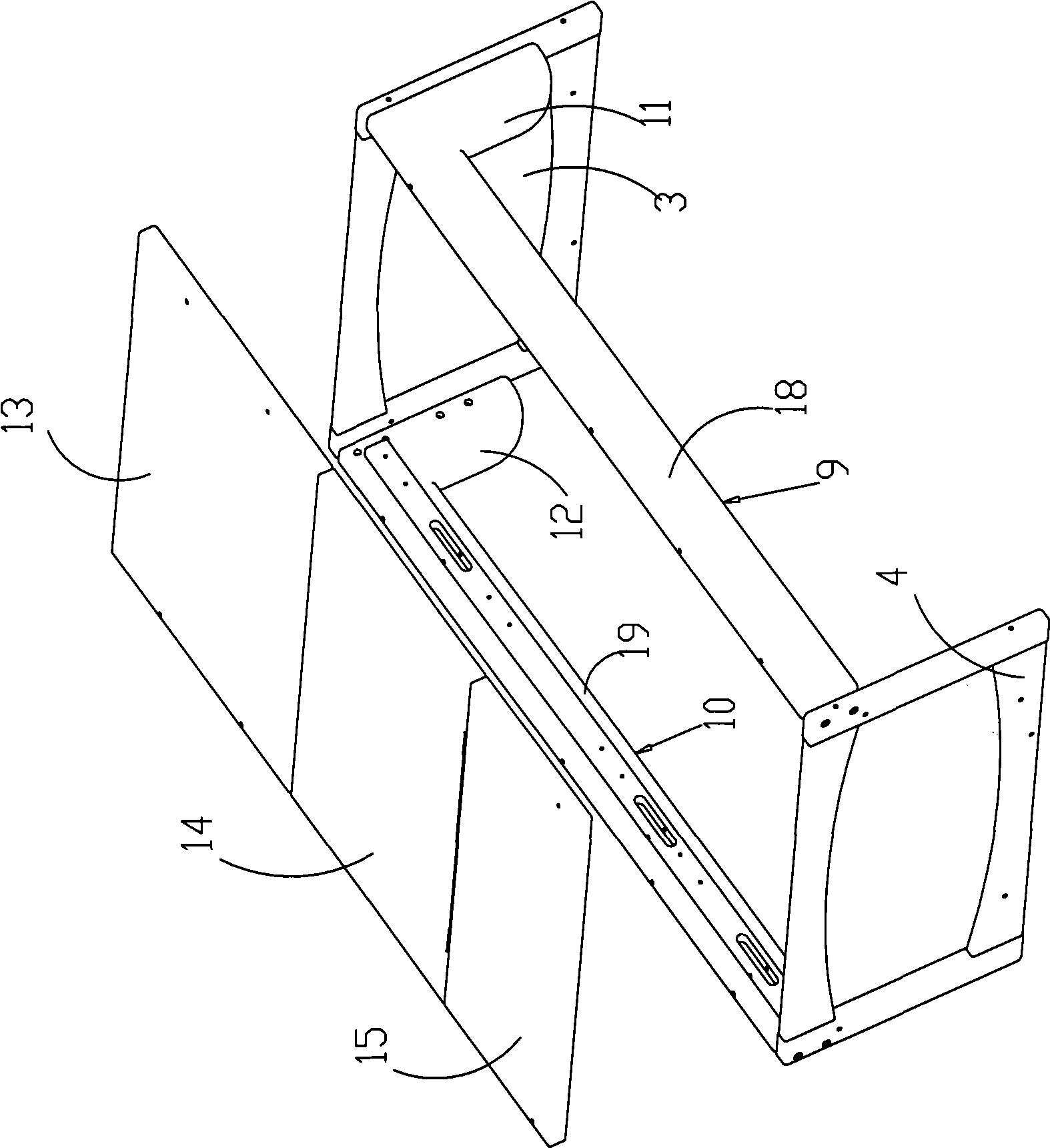

Baby crib

InactiveCN102188125ARealize the use functionExtended service lifeCradleKids convertible furnitureEngineeringMechanical engineering

The invention provides a baby crib. The baby crib comprises a first bottom plate (1), a second bottom plate (2), a first side plate (3), a second side plate (4), a third side plate (5), a fourth side plate (6), a first guardrail (7), a second guardrail (8), a first bed plate (9), a second bed plate (10), a first fixed plate (11), an object placement plate (13), a hanger shaft (14) and rollers (18). The baby crib has the advantages that the components of the baby crib can be disassembled and re-assembled into a clothes cabinet and an object placement rack, thus realizing multiple functions of the baby crib, prolonging service life of the baby crib and reducing household expense.

Owner:ASAKAI ARCHITECTURAL DESIGN FIRM

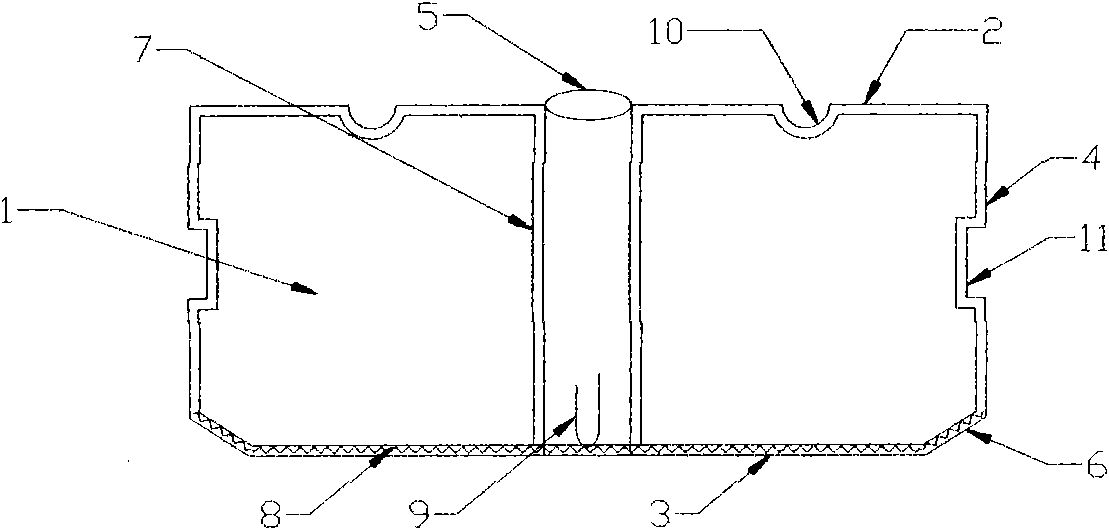

Combined hollow box body used for cast-in-place energy-saving hollow floor system

The invention relates to a combined hollow box body used for a cast-in-place energy-saving hollow floor system, which comprises a bottom surface, an arc surface, a hole wall, a side surface and a top surface, wherein a concave closed hole is remained in the side surface and got through before casting to enable a connecting short pipe to pass through to form a mutually connected through heat energy air supplying channel, a groove for laying a heating pipe is remained on the top surface, and the groove and the heat energy air supplying channel form a floor system energy supplying system; the bottom surface and the side surface of the box body form the arc surface, the arc length of the arc surface is more than 70mm, the length of the arc radius is more than 45mm, and the arc surface is used for preventing a jointing surface of the box body and a rib beam from cracking and the box body from dropping under the conditions of earthquake and the like; and the upper end of the hole wall and the top surface form a casting hole, concrete is poured in the casting hole to be compounded with an iron wire remained on the bottom surface during the cast-in-place, thus the upper wing edge of the floor system can be connected with the bottom surface of the box body, and the stress structure of the floor system is improved. The floor system adopting the hollow box body has the advantages of light weight, large hardness, reasonable structure, crack control and earthquake resistance; and the problem of heating can be solved by adopting a manner of transmitting the heat energy by the box body.

Owner:王本淼

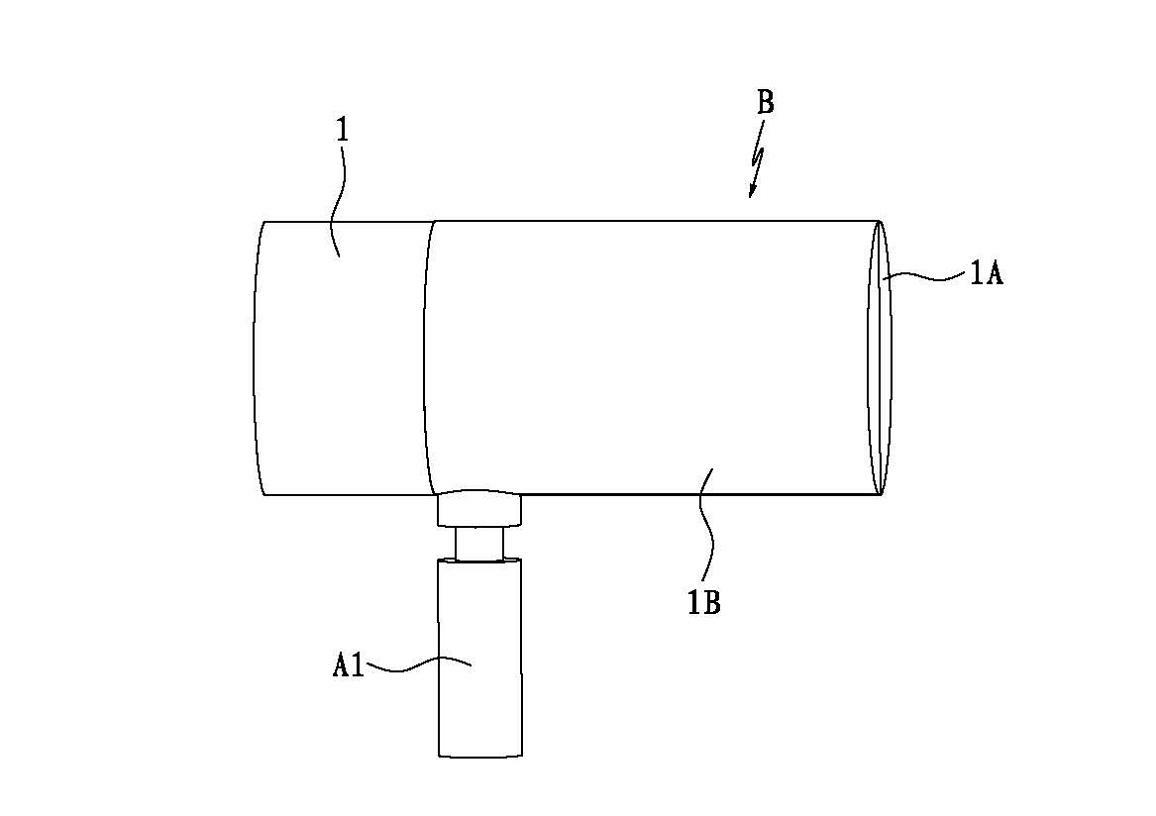

Inspection shaft

InactiveCN102102393AMore shopping opportunitiesRealize the use functionArtificial islandsSewerage structuresAgricultural engineeringSewage

The invention discloses an inspection shaft, which relates to an underground pipeline member for rainwater and sewage drainage and consists of a cover, a body, a base and an arm which are in sealing connection with each other in a manner of fusing or press-fit or the combination of fusing and press-fit. The splitting-type member is simple and convenient in manufacturing and is formed by assembled connection on the spot, adjustable installation connection can be realized based on the difference of onsite landform, the adjustment flexibility ensures the implementation of using functions, the splitting-type member is convenient for packaging, transportation, construction and installation, the standardized construction efficiency is high, and similarly, the inspection shaft can reach excellent anti-seepage performance, long service life and good safety since sealing connection is adopted totally.

Owner:CIXI DESHUN CONTAINER

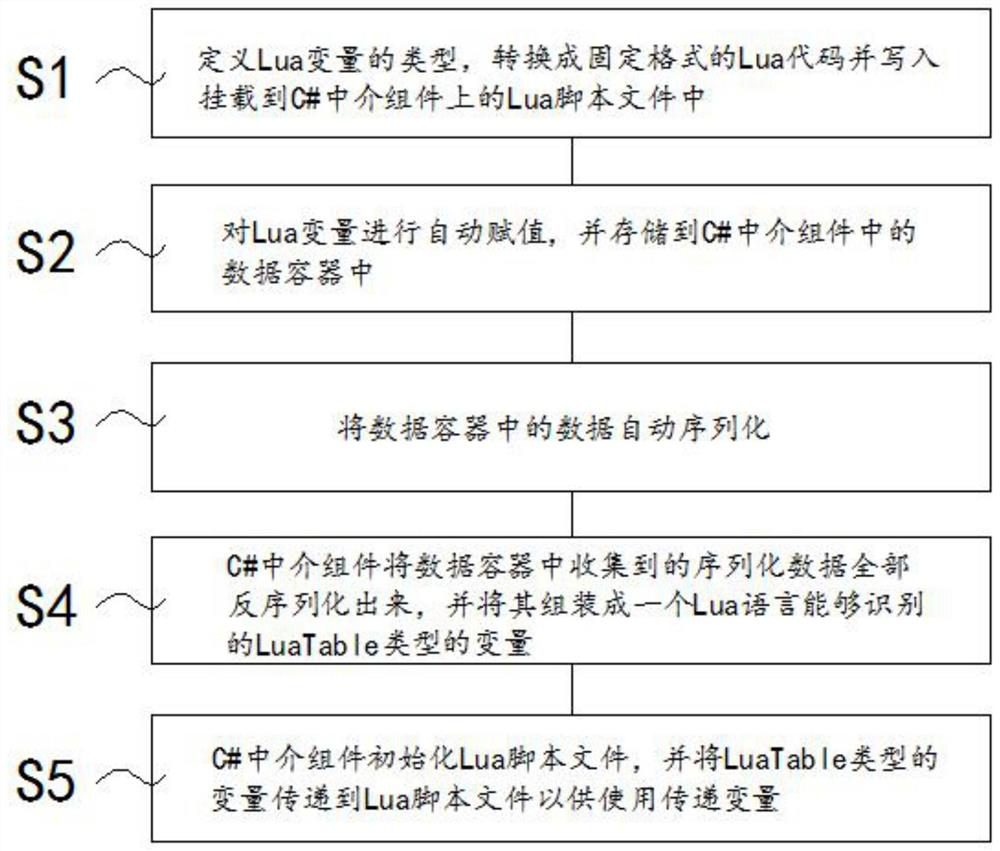

Data interaction method between Lua language and Unity

ActiveCN112579062ASimplify variable declaration and use processImprove game performanceProgramming languages/paradigmsVideo gamesSerializationTheoretical computer science

The invention discloses a data interaction method between Lua language and Unity, which comprises the following steps: S1, defining the type of a Lua variable, converting the Lua variable into a Lua code in a fixed format, and writing the Lua code into a Lua script file mounted on a C# intermediary component; S2, automatically assigning values to Lua variables, and storing the Lua variables into adata container in the C# intermediary component; S3, automatically serializing the data in the data container; S4, by the C# intermediary component, deserializing all the serialized data collected inthe data container and assembling the serialized data into a LuaTable type variable which can be recognized by a Lua language; and S5, by the C# intermediary component, initializing the Lua script file, and transmitting the LuaTable type variable to the Lua script file for use of the transmitted variable. According to the method, data interaction between Lua and Unity is realized through the C# intermediary component, variable declaration and use processes of the Lua language are greatly simplified, and meanwhile, the game performance of the Lua language when the Unity object is used is improved.

Owner:厦门极致互动网络技术股份有限公司

Drum washing machine

PendingCN111041762AImprove cleanlinessSimple structureOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

The invention discloses a drum washing machine. The drum washing machine comprises an imperforate drum which is arranged in a shell and does not have dewatering holes, a clothes input opening is formed in the side wall of the imperforate drum, and the drum is provided with a door body which can be turned over to open and close the clothes input opening; and two ends of the imperforate drum are sealed, the centers of the sealed ends are connected with the shell through rotating shafts in a relatively rotating way, the rotating shaft of at least one end is composed of a hollow sleeve, and the hollow part forms a flow channel and communicates with a water inlet pipe of the washing machine. A water inlet structure is arranged at the central rotating shaft of the drum, so that the use functionof the top-opening type washing machine for feeding water into the imperforate drum is realized, and water is enabled to flow into the imperforate drum smoothly.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

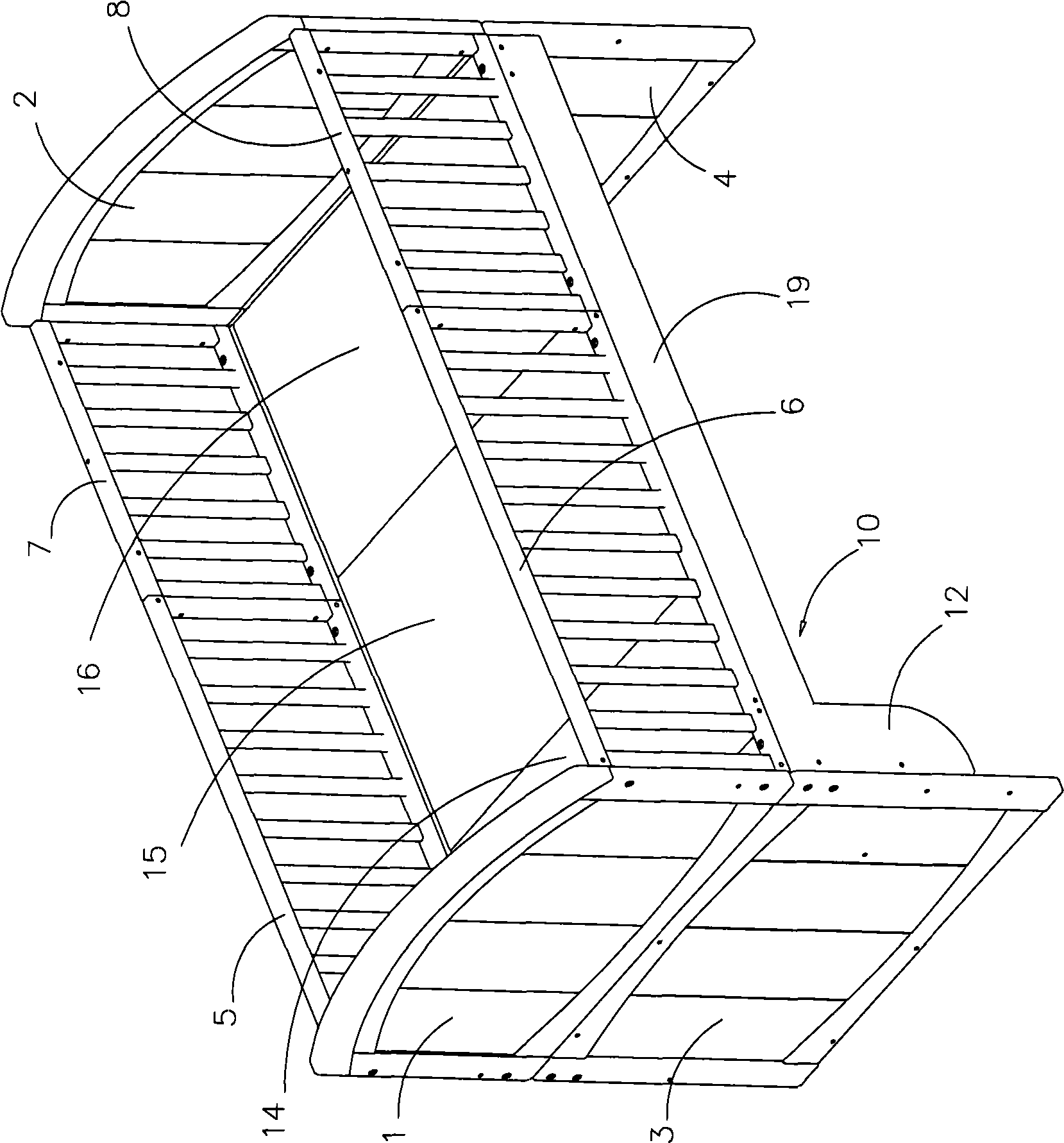

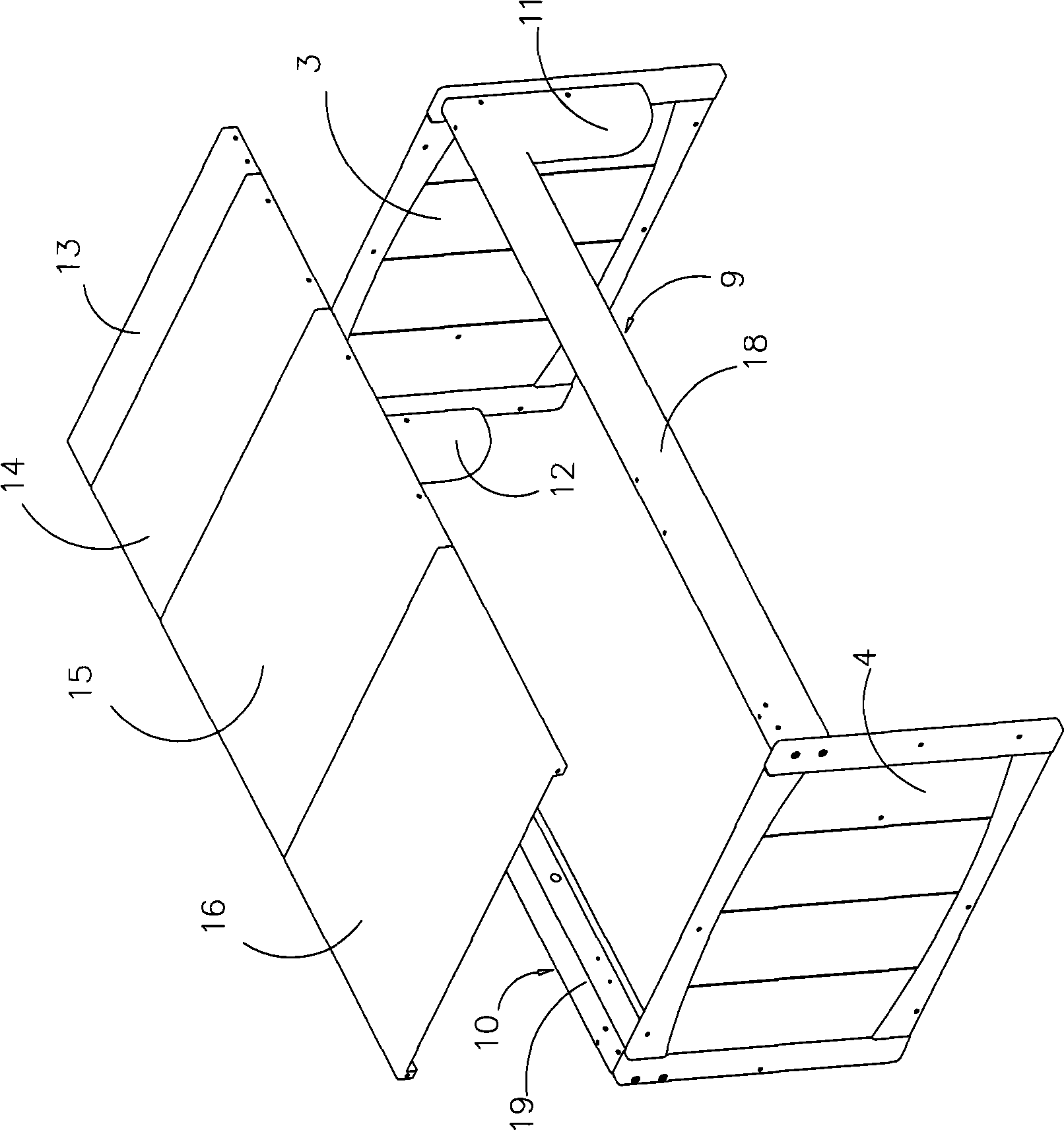

Multifunctional children's bed

ActiveCN101530273ARealize the use functionEasy to useKids bedsKids convertible furnitureEngineeringAssembly structure

Multifunctional children's bed comprises a headboard, a footboard, a head strut frame, a foot strut frame, a first long guard rail, a second long guard rail, a first short guard rail, a second short guard rail, a first bed beam, a second bed beam, a bed board assembly. The multifunctional children's bed can be assembled into baby's bed, cradle, youth's beds of at least two bed assembly structures by assembling the above parts. Namely the multifunctional children's bed can be assembled into baby's bed, or cradle, or youth's beds. The multifunctional children's bed has multi-use function and prolongs the service life, reduces the family expense and saves social resources.

Owner:GOODBABY CHILD PROD CO LTD

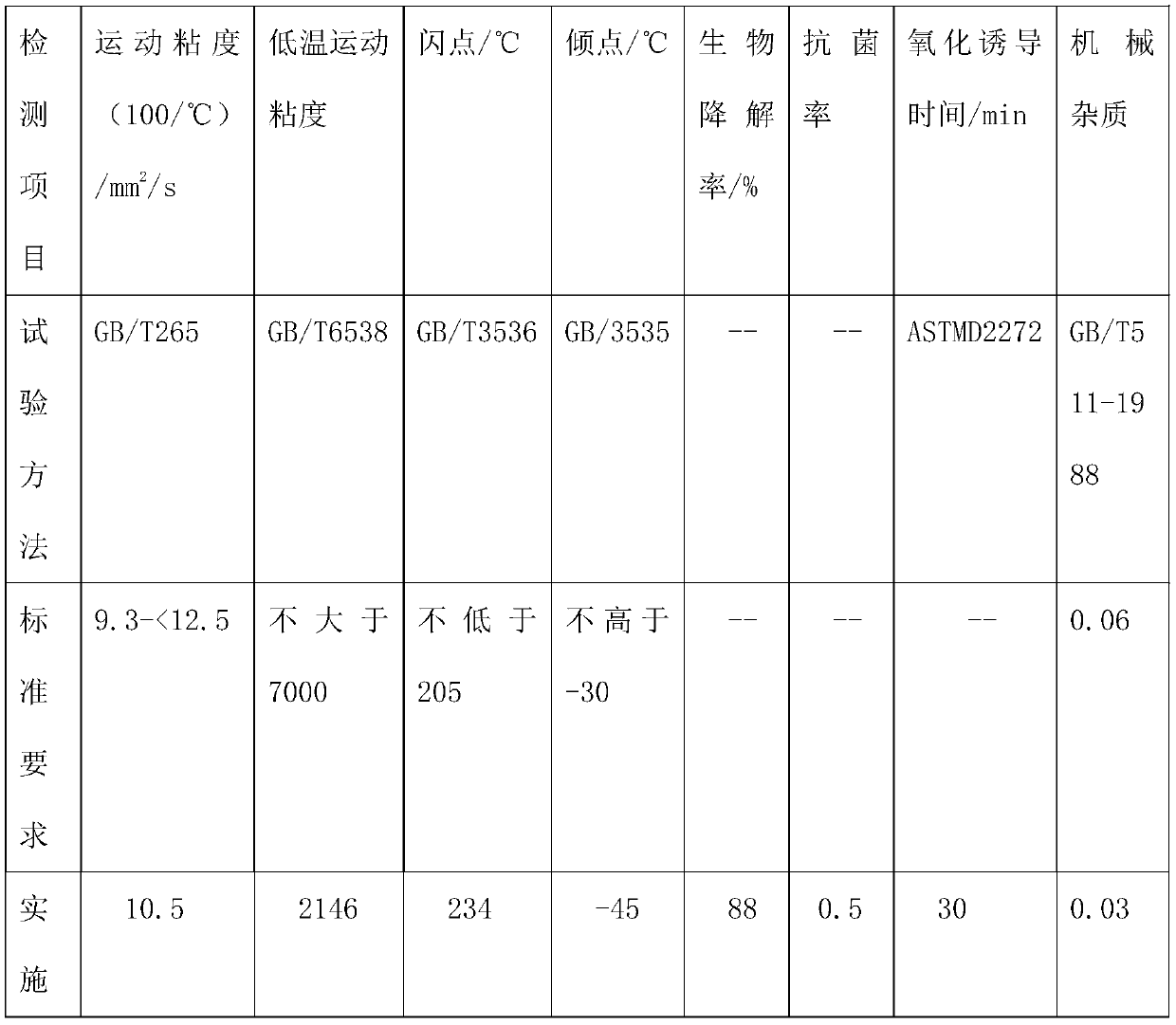

Lubricating oil for automobile chassis stamping parts

InactiveCN111378518ARealize the use functionImprove corrosion resistanceLubricant compositionSunflower seedChemistry

The invention relates to the related technical field of lubricating oil, and particularly discloses lubricating oil for automobile chassis stamping parts. The lubricating oil comprises biological baseoil and additives, wherein the mass ratio of the biological base oil to the additive is 7: 3, and the biological base oil comprises high oleic acid sunflower seed oil, castor oil, soybean oil and Chinese honeylocust fruit oil; the additives comprise an antioxidant, an organic amine preservative, a detergent dispersant, an anti-wear agent, an anti-foaming agent, a corrosion inhibitor, a flame retardant, a pour point depressant, a bacteriostatic agent, an extreme pressure agent, a viscosity index improver, a pour point reducer, a metal deactivator and an emulsifier. The invention aims to provide lubricating oil for an automobile chassis stamping part. The lubricating oil has the advantages of favorable wear resistance, favorable corrosion resistance, favorable biodegradability, flame retardancy, favorable moisture resistance, favorable dust resistance, favorable antibacterial property and high cleaning easiness, can better implement the use functions of the lubricating oil for automobile chassis stamping parts, and has favorable coordination effect due to the mutual cooperation of multiple additives, thereby improving the use properties of the product.

Owner:上海宝山大陆汽车配件有限公司

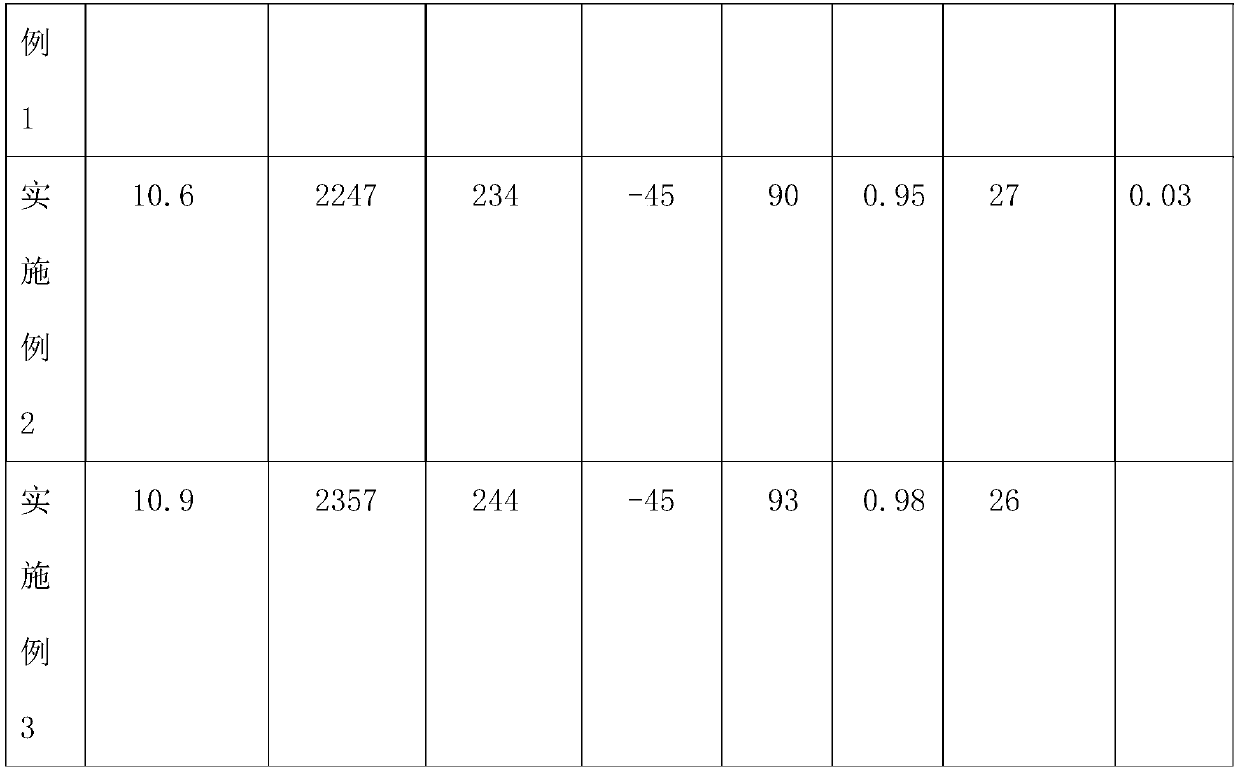

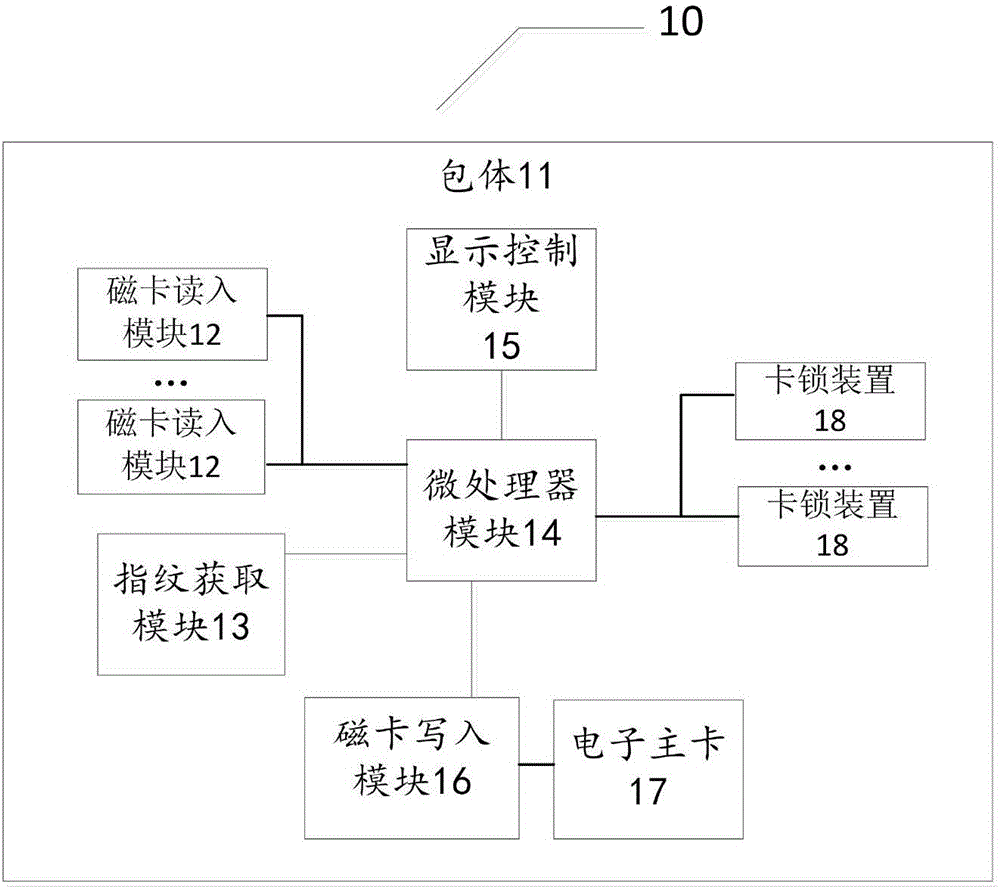

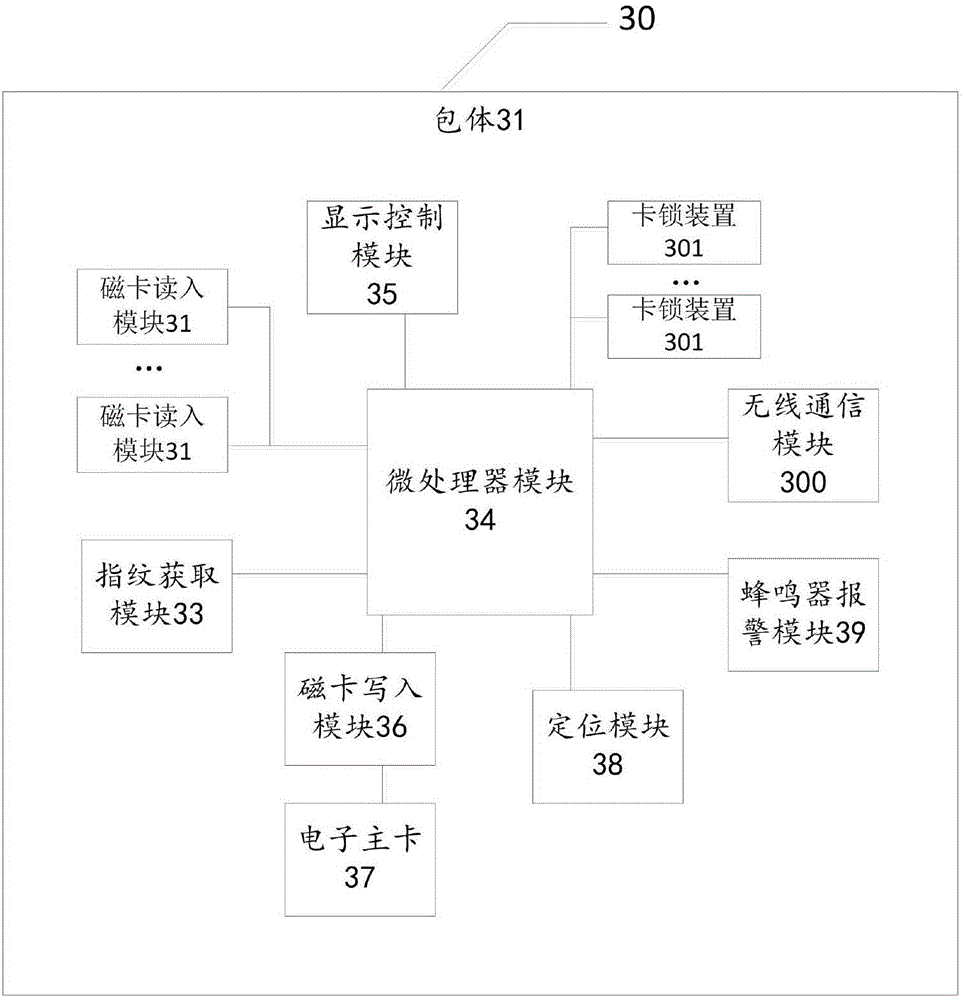

Multifunctional intelligent card bag and card loss prevention method

ActiveCN106723821AImprove securityImprove privacyOther accessoriesDigital data authenticationComputer moduleSmart card

The invention discloses a multifunctional intelligent card bag which comprises a bag body, wherein a plurality of card slots are formed in the bag body. The multifunctional intelligent card bag further comprises: each card lock device is arranged in the card slot and used for locking a magnetic card; each magnetic card reading module is arranged on the corresponding card slot and used for obtaining information of the magnetic card and sending the information to a microprocessor module to be stored; a fingerprint obtaining module can obtain current fingerprint information and send the fingerprint information to a processor module; the microprocessor module is used for comparing the current fingerprint information sent by the fingerprint obtaining module with preset fingerprint information and can generate a fingerprint unlocking instruction under the situation of comparison consistency; a display control module can display all magnetic card marks in a current card bag according to the fingerprint unlocking instruction, generate a corresponding magnetic card selection instruction according to the magnetic card mark selected by a user and send the magnetic card selection instruction to the microprocessor module; the corresponding magnetic card information can be written into an electronic main card through a magnetic card writing module. The invention further discloses a card loss preventing method based on the intelligent card bag.

Owner:GCI SCI & TECH

Multifunctional solar auxiliary air conditioning system

InactiveCN100561074CEfficient use ofMake up for the shortcoming of low COPFluid heatersHeat pumpsWater cyclingEngineering

The invention discloses a multifunctional solar energy auxiliary air conditioning system. The invention includes two parts: a refrigerant circulation system and a water circulation system. The refrigerant circulation system has a compressor, an indoor heat exchanger, a refrigerant-water heat exchanger, an outdoor heat exchanger, a high-pressure liquid storage tank, and a throttling device connected in sequence. , a three-way valve, a one-way valve and a gas-liquid separator, and the water circulation system has a solar heat collector, a water tank, a water pump and a refrigerant-water heat exchanger connected in sequence. The invention can efficiently realize the functions of heating and cooling air conditioners and water heaters, has strong energy saving performance, practicality and economy, and has broad market prospects. The invention is particularly suitable for occasions where solar energy resources are abundant and heating and cooling air conditioners and hot water supply are required at the same time.

Owner:ZHEJIANG UNIV

Steering wheel sleeve

The invention relates to a steering wheel sleeve which is manufactured by the following steps: adding resin in a curing agent to obtain a mixture, injecting the mixture into a model of a massage piece, and casting to obtain the massage piece; heating for melting a high-molecular polymer, injecting the melt high-molecular polymer into a sliding preventing layer mold, and filling the sliding preventing layer mold; keeping pressure integrally; cooling the sliding preventing layer mold after pressure keeping for the first time; demolding so as to obtain a sliding preventing layer; performing high-temperature heat treatment on elastic net-shaped cloth and the massage piece, pressurizing and bonding so as to obtain a first outer ring sleeve body; cooling the first outer ring sleeve body for the second time so as to obtain a second outer ring sleeve body; and cutting the second outer ring sleeve body to the size more than the size of the outer surface of the sliding preventing layer so as to obtain a third outer ring sleeve body. The steering wheel sleeve is simple in manufacturing process and is obtained easily, and the finished steering wheel sleeve is high in safety factor, attractive, and wide in application range.

Owner:南陵县建设投资有限责任公司

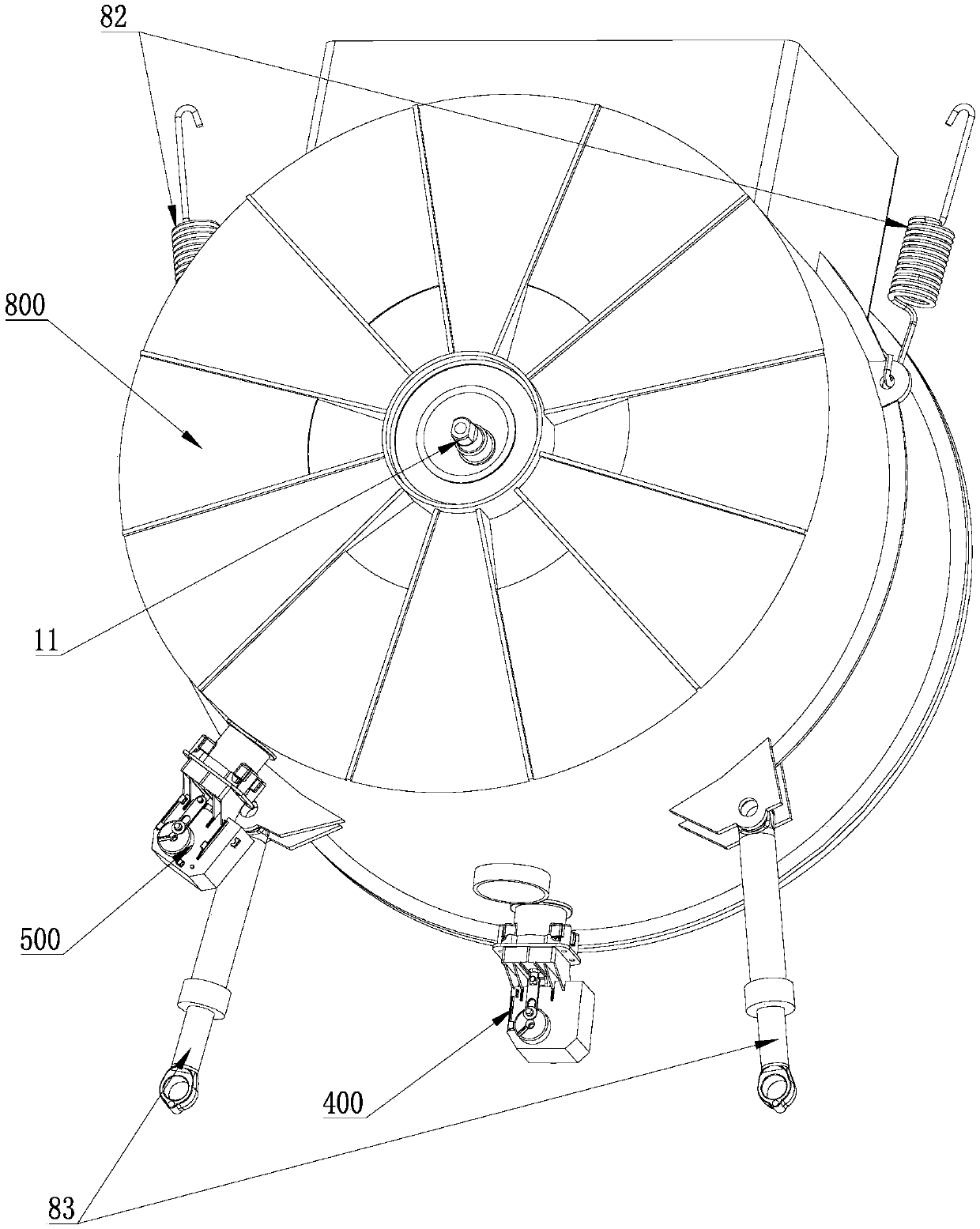

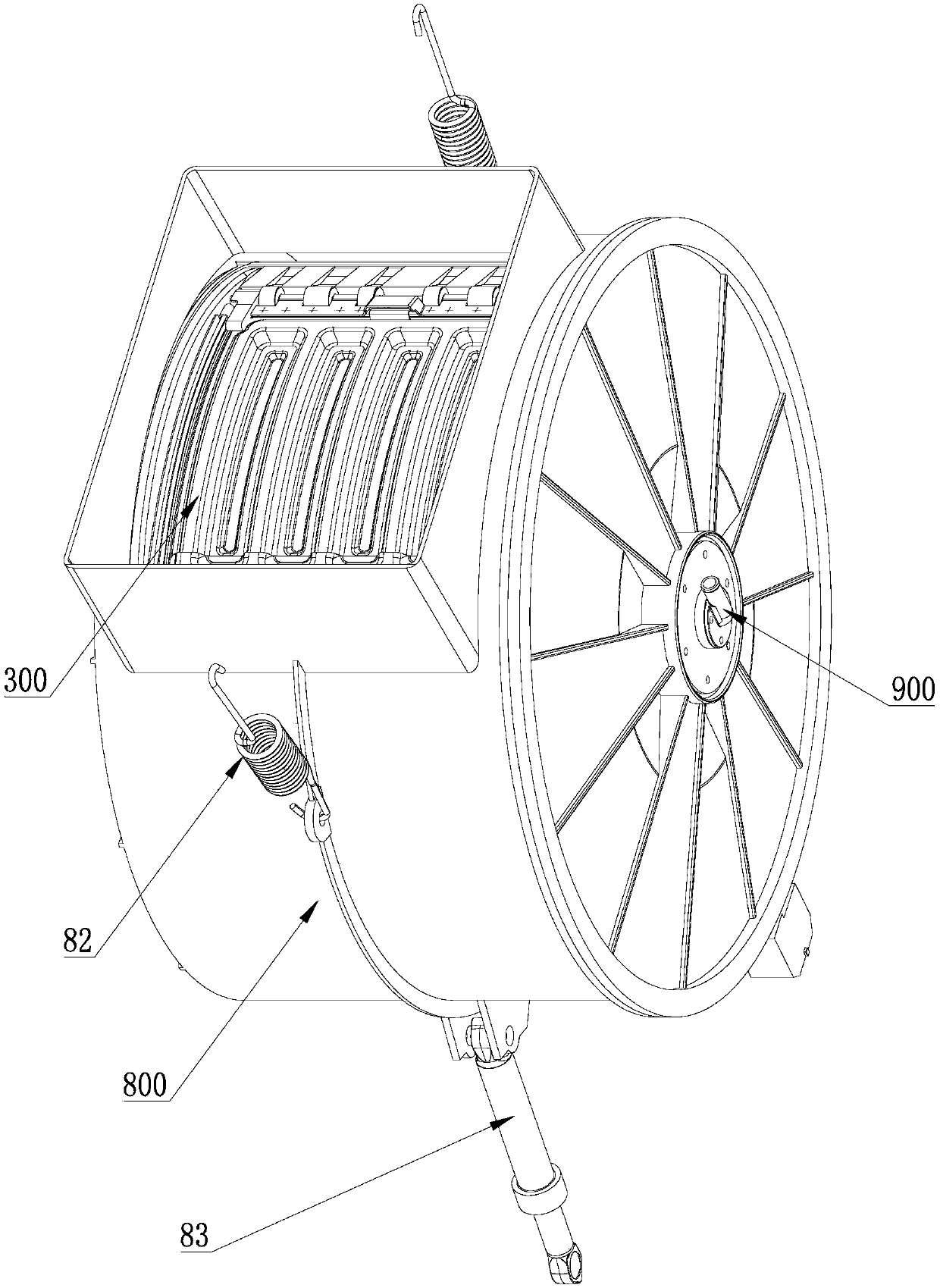

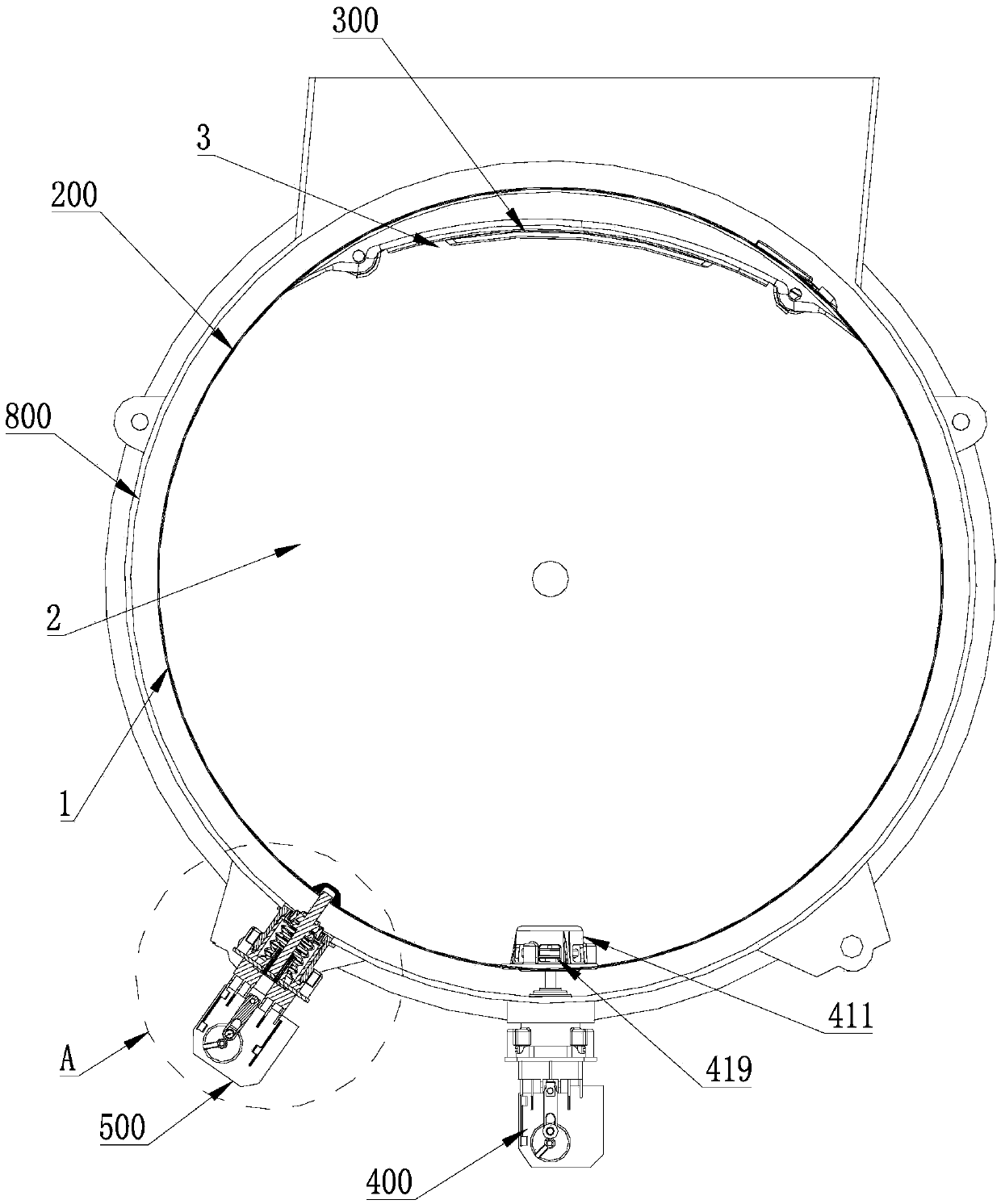

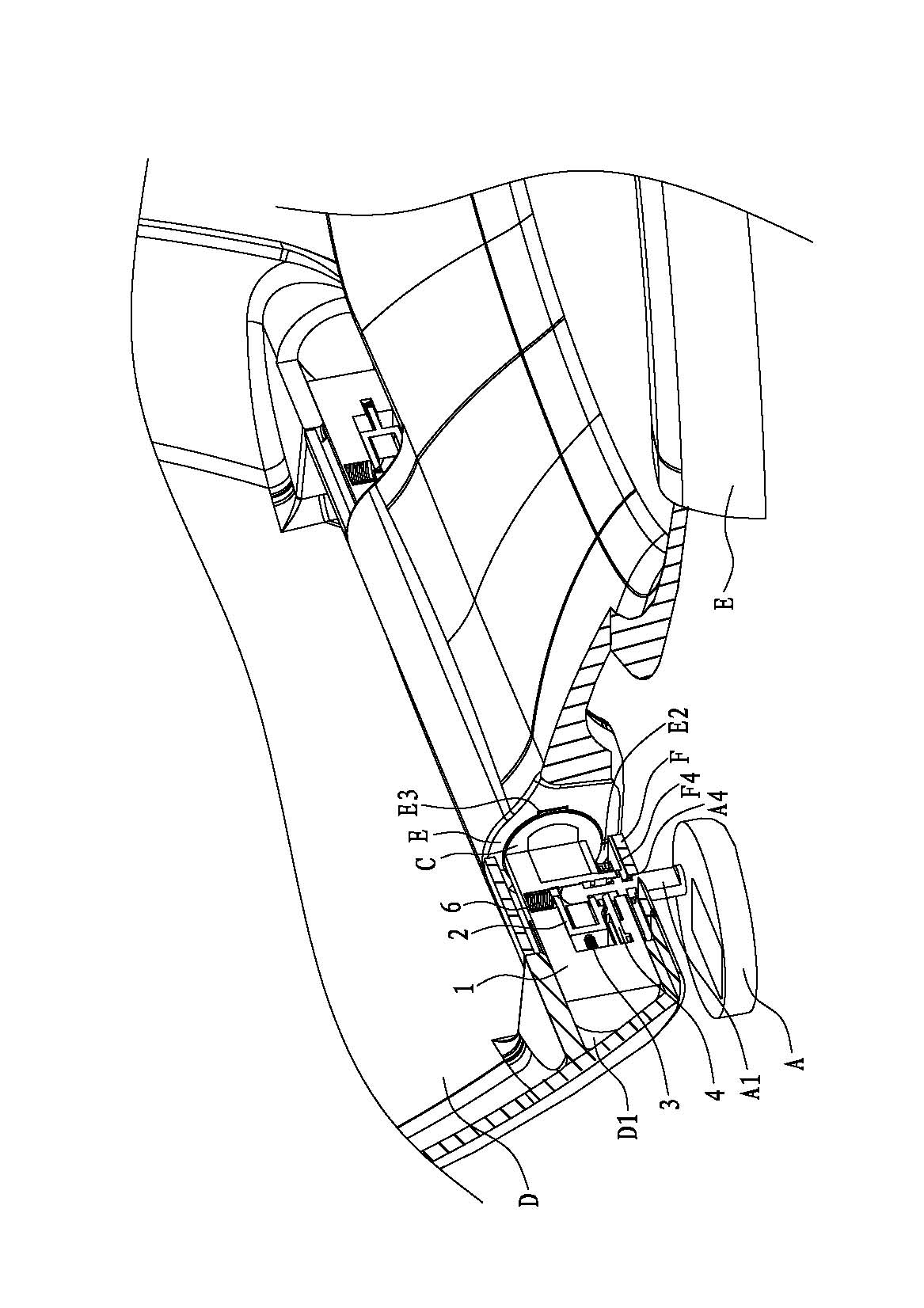

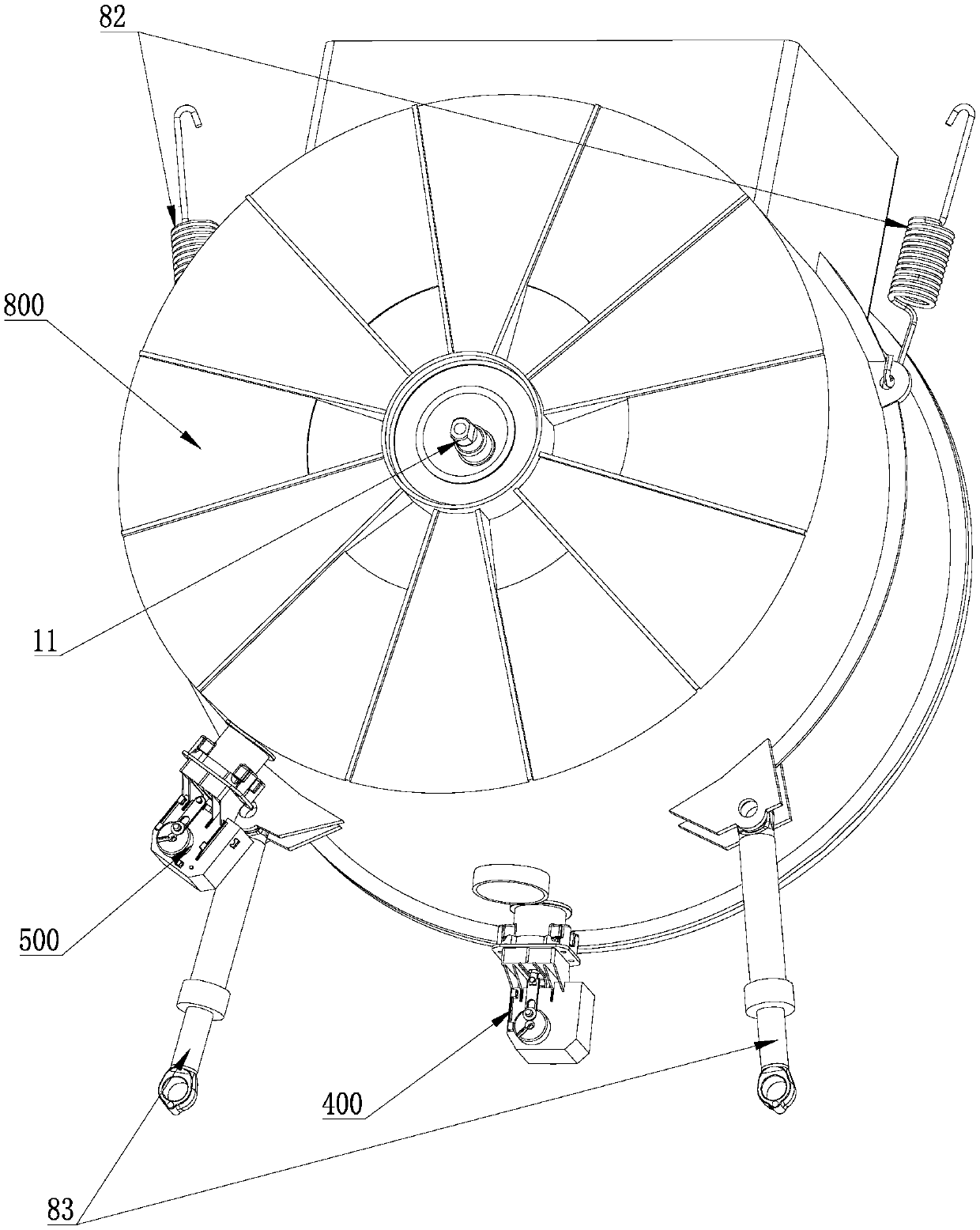

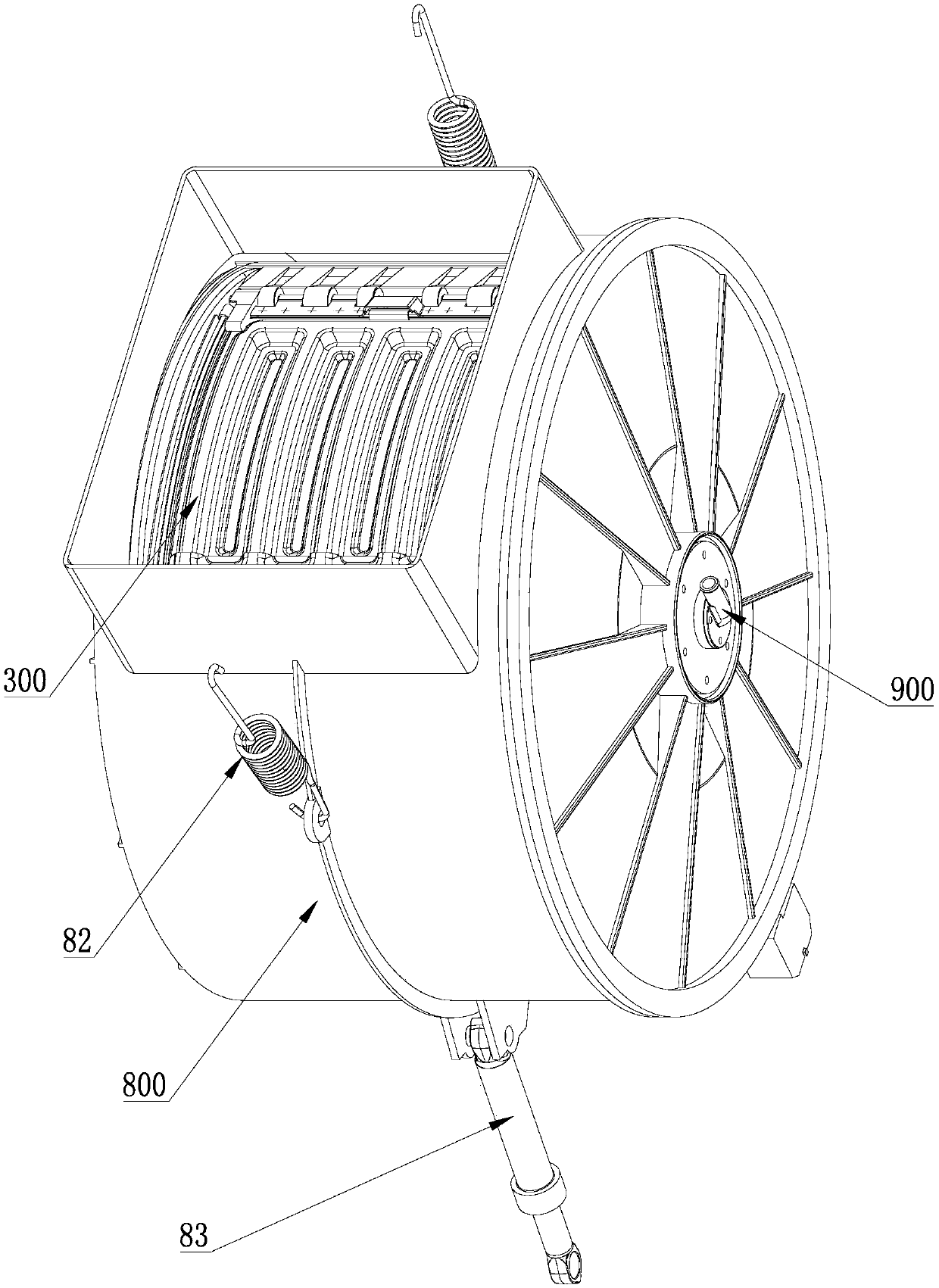

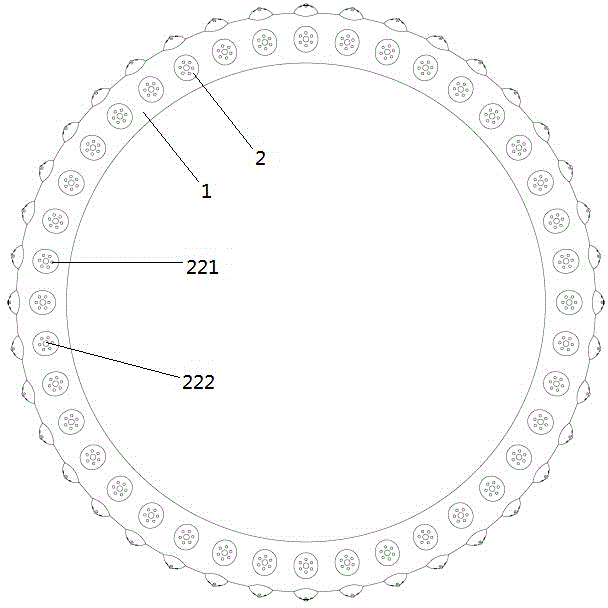

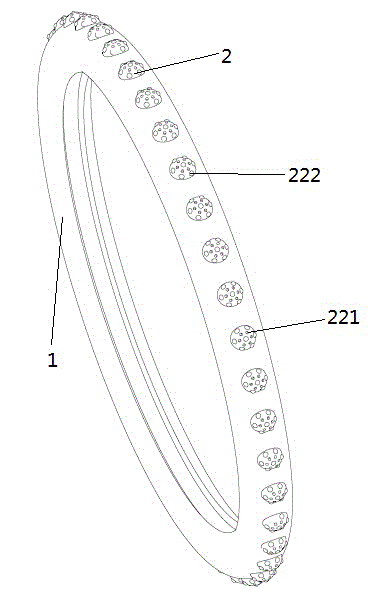

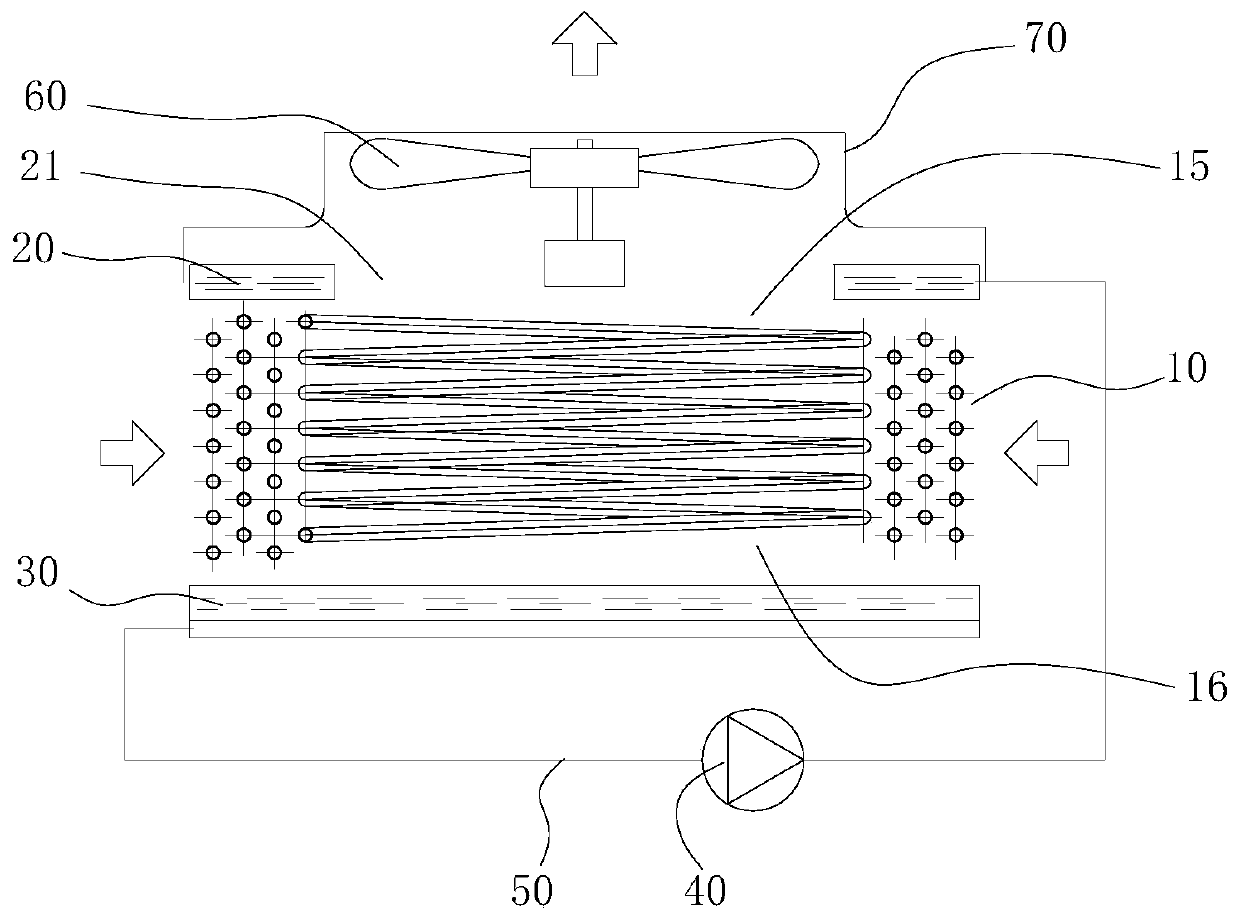

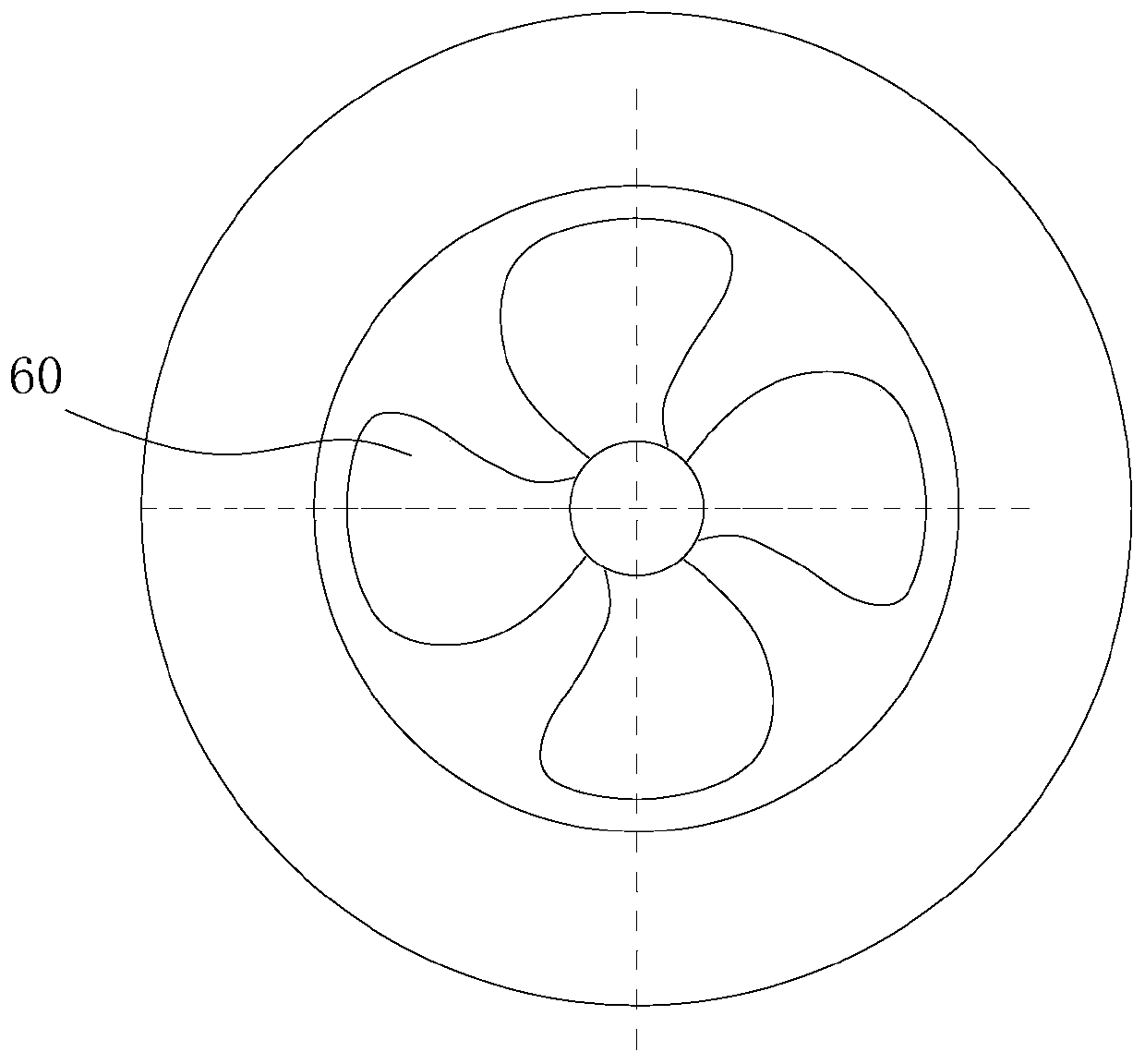

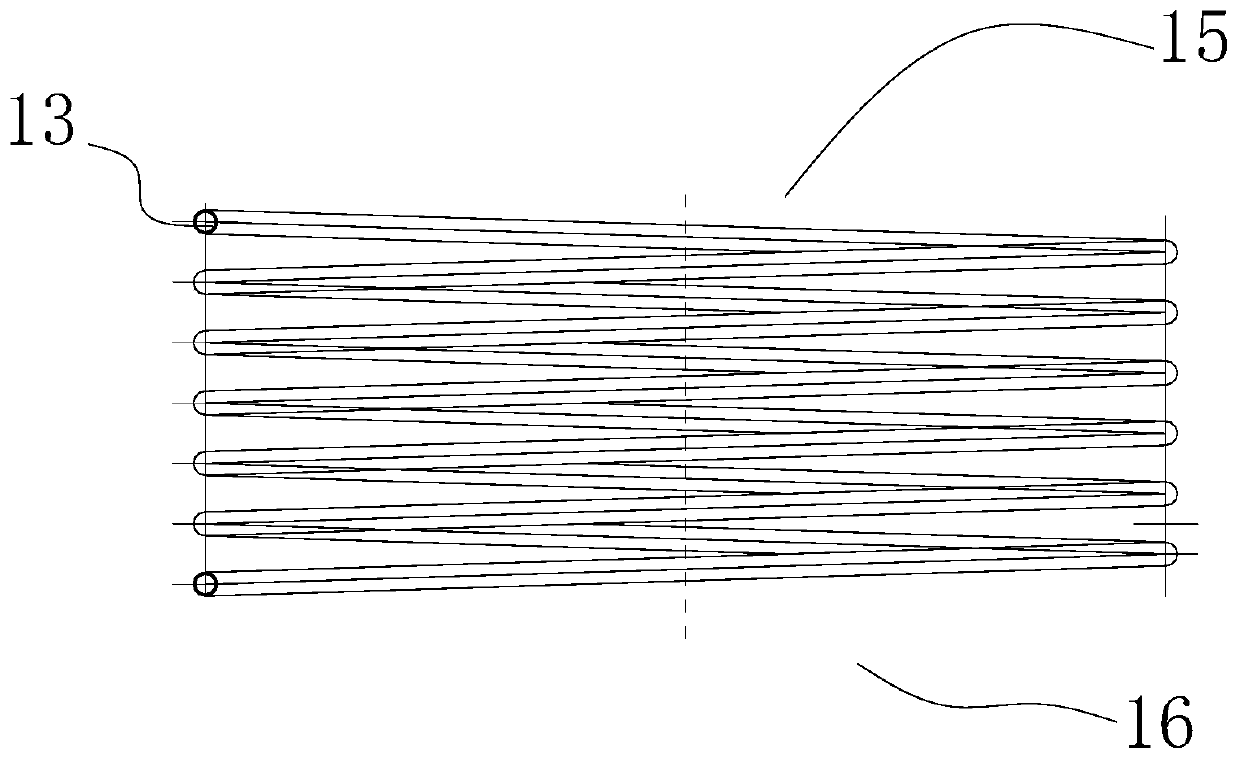

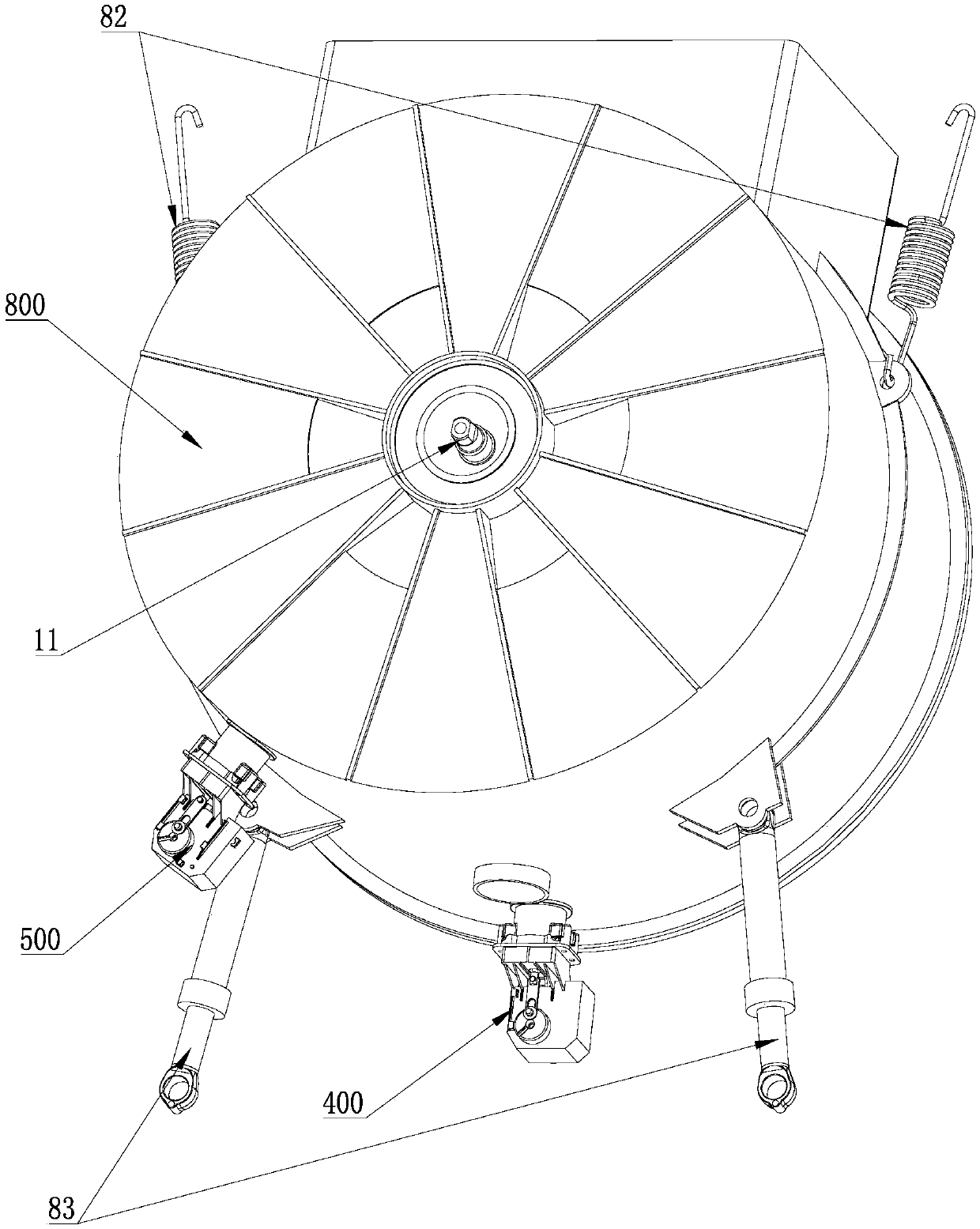

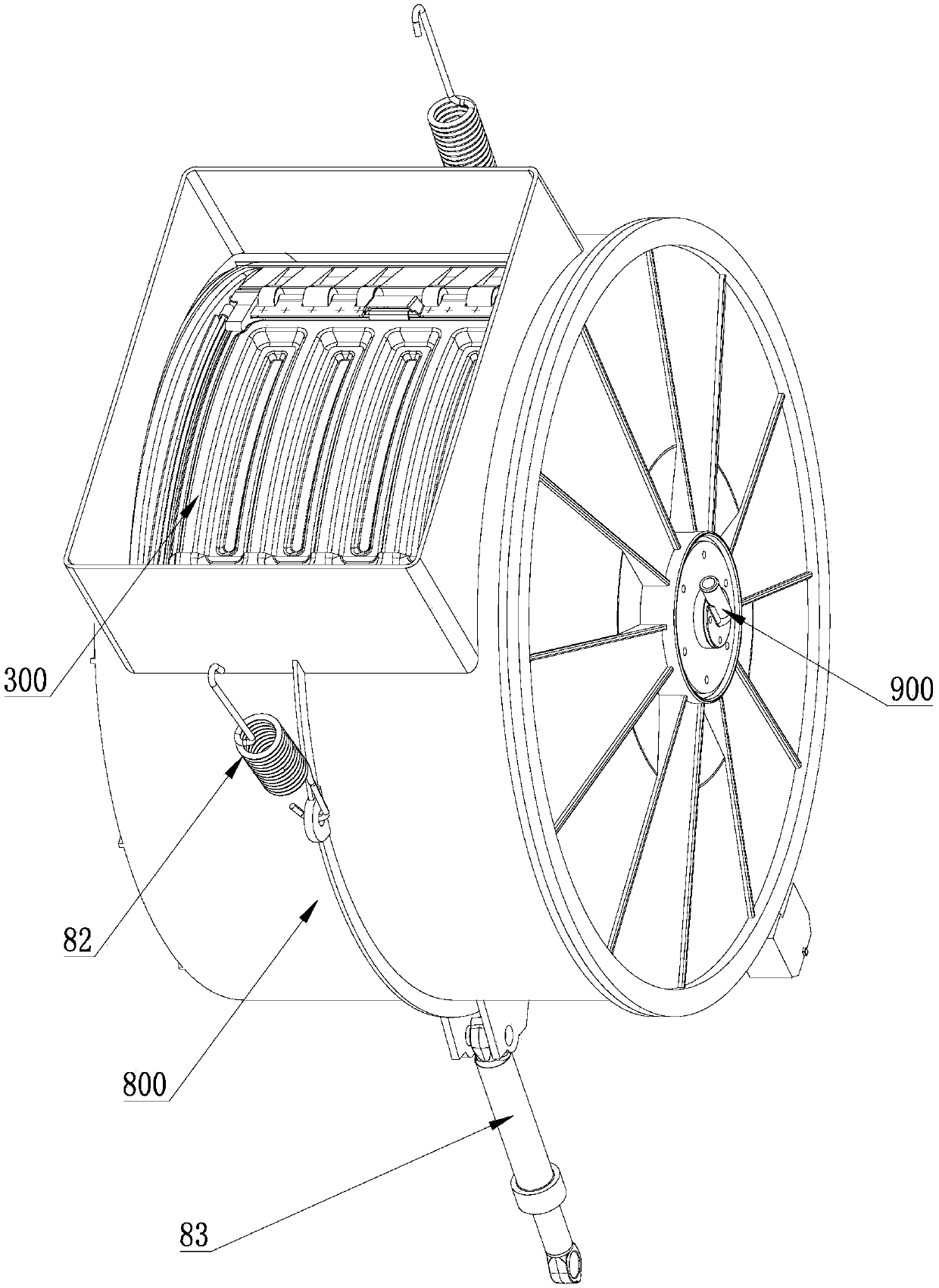

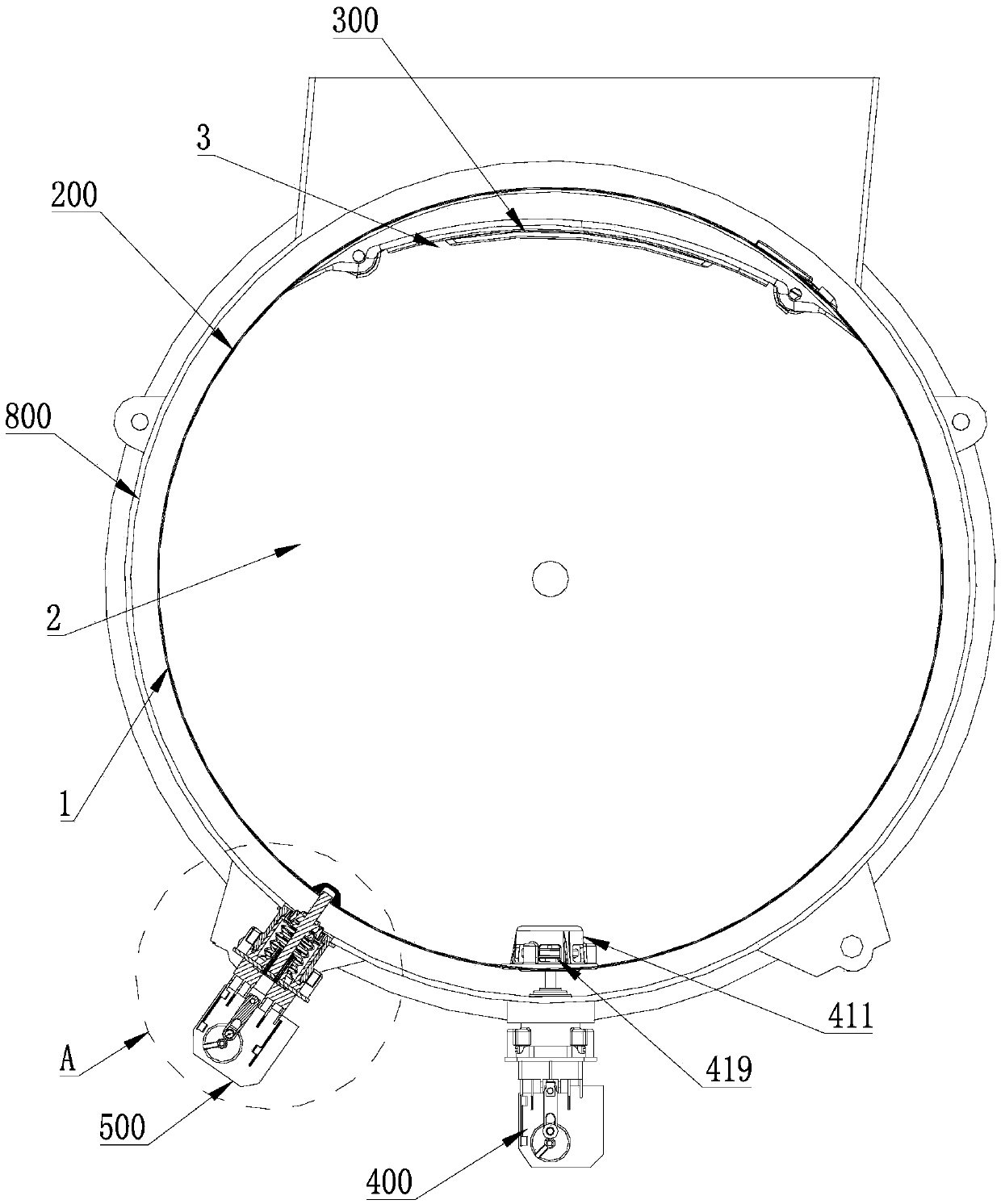

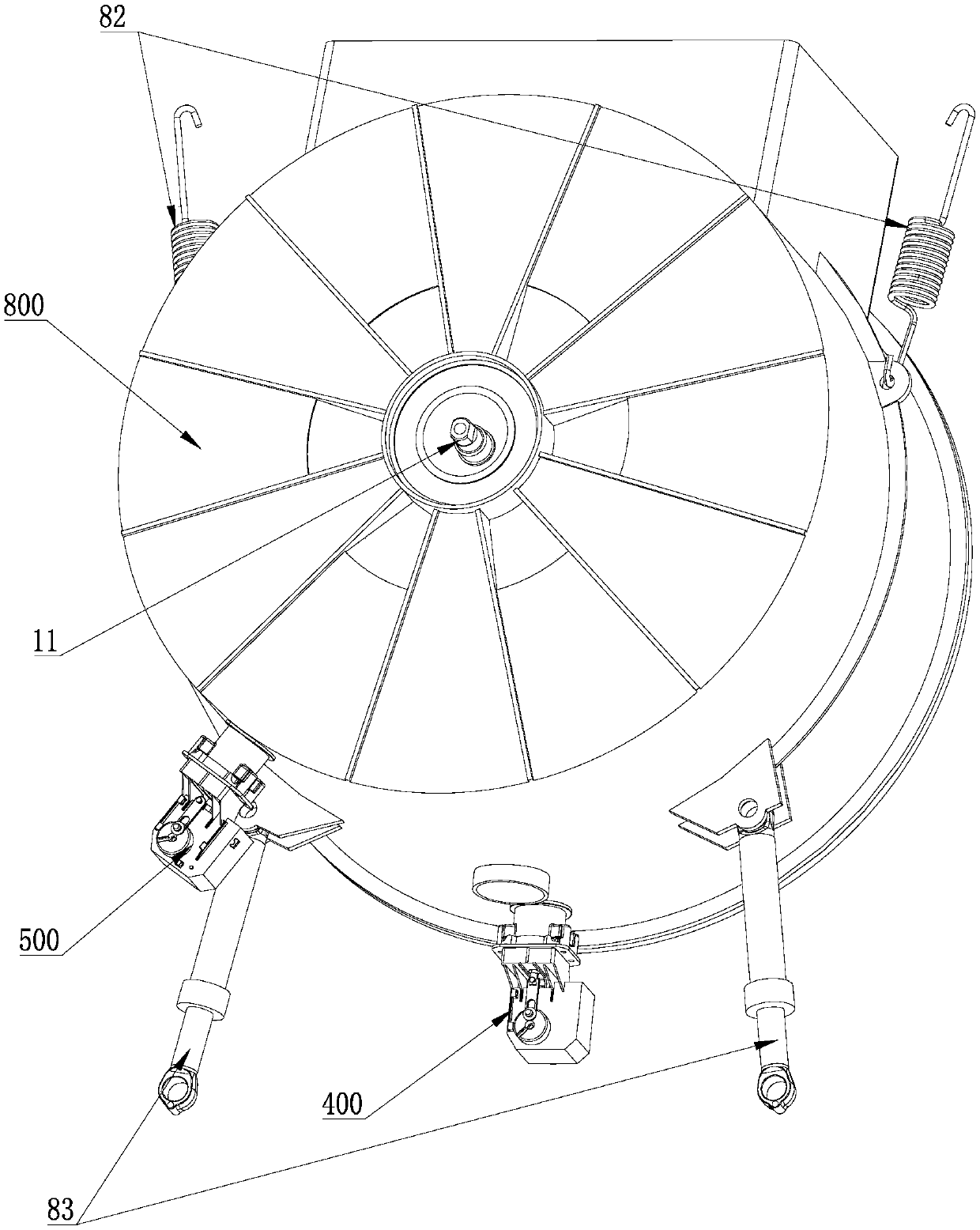

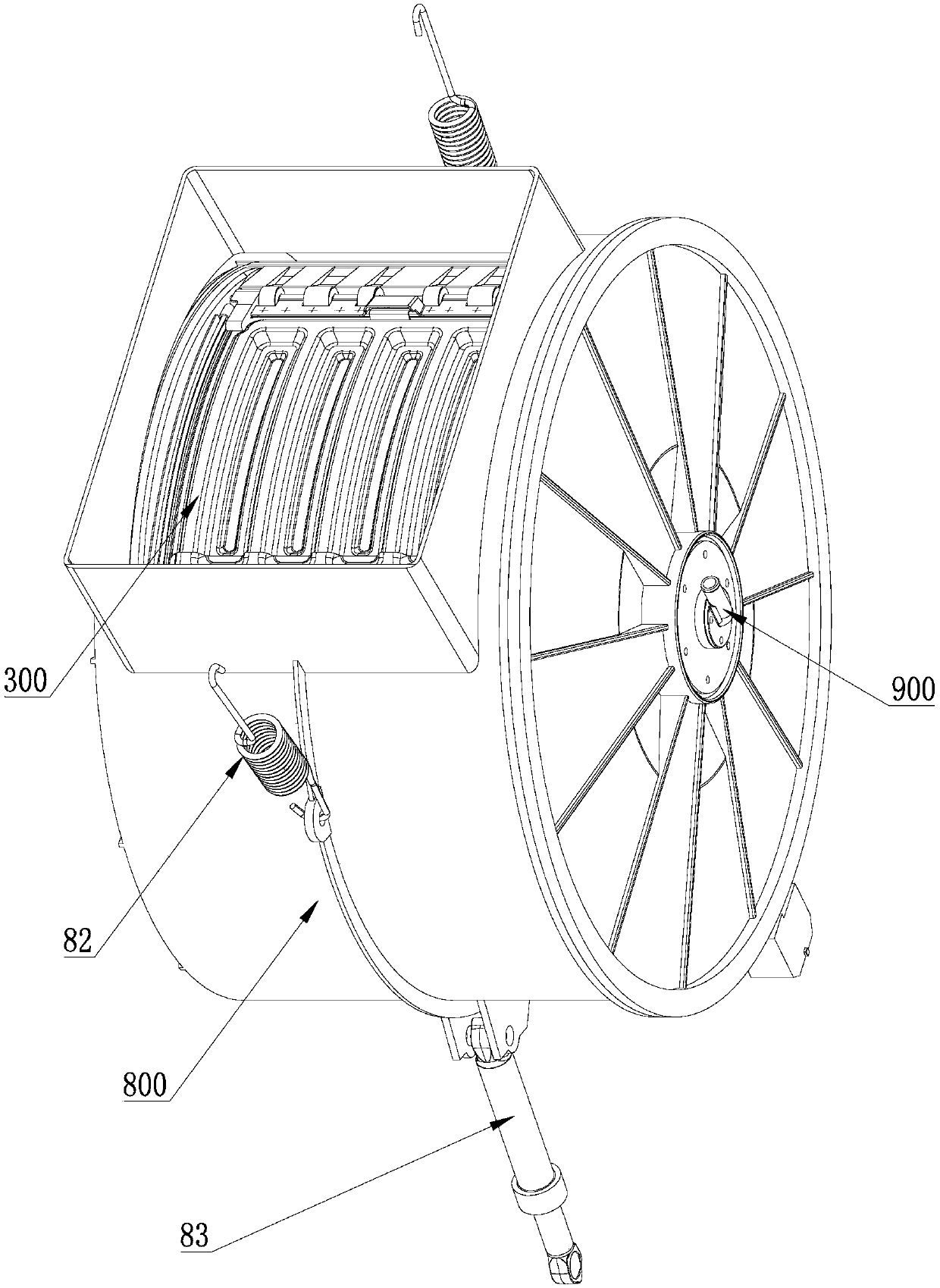

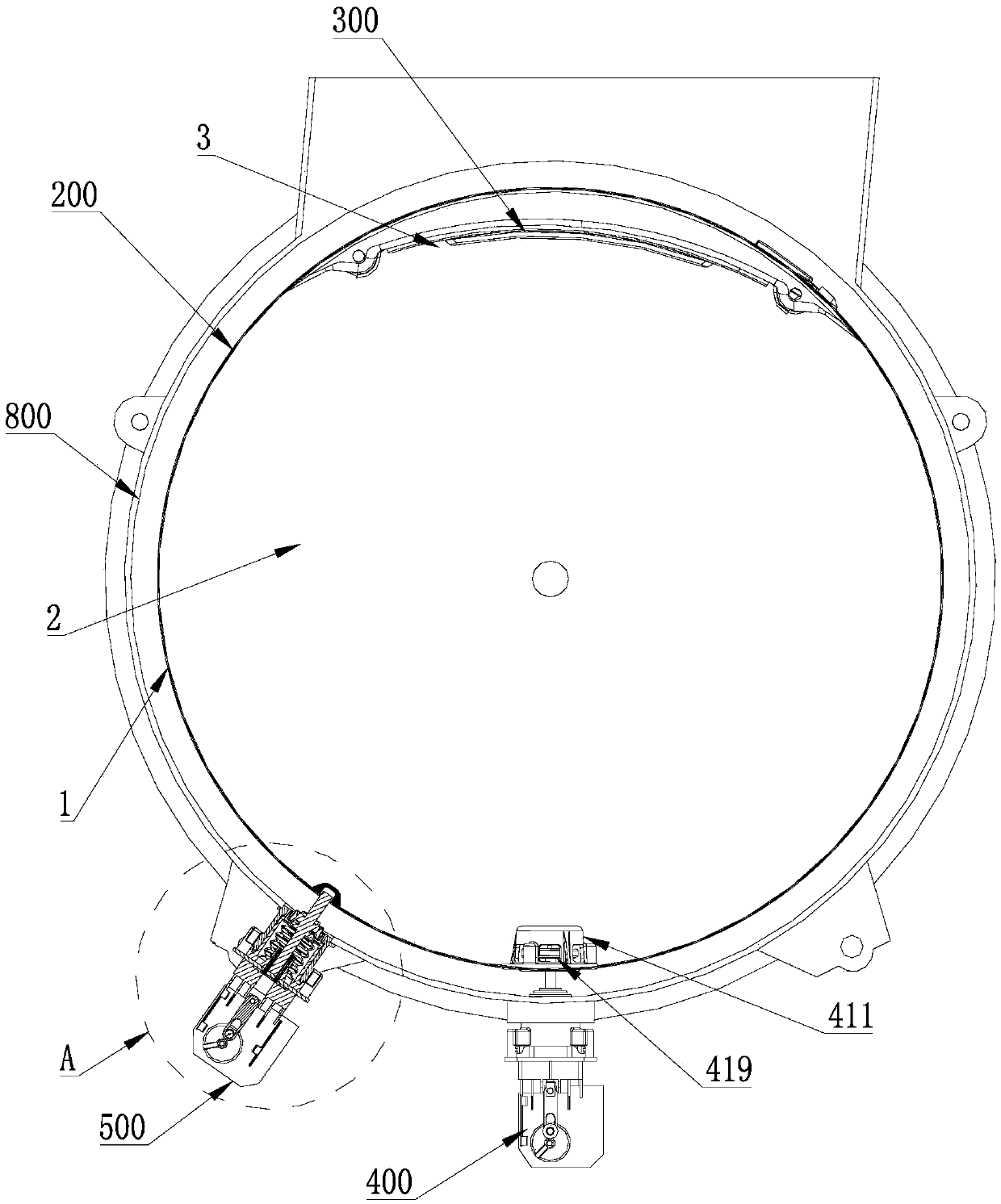

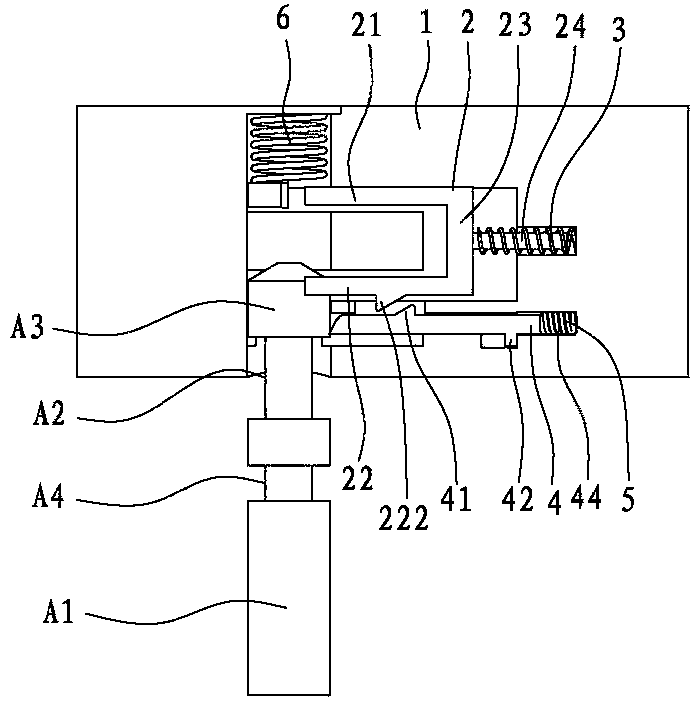

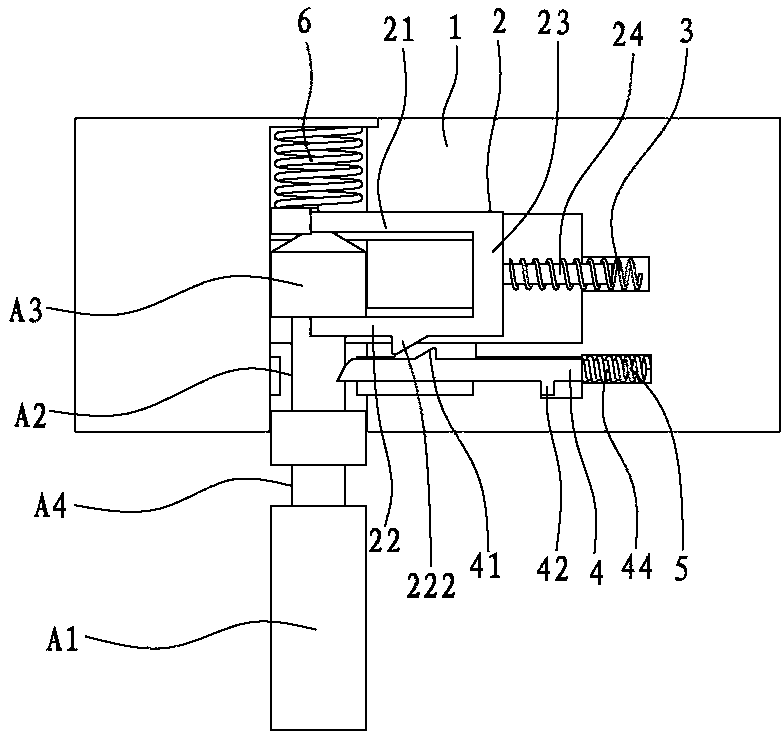

Annular sprinkling heat exchanging device and use method thereof

PendingCN109813148AImprove heat transfer efficiencyIncreased flow distanceStationary conduit assembliesHeat transfer modificationEngineeringElectrical and Electronics engineering

The invention discloses an annular sprinkling heat exchanging device. The annular sprinkling heat exchanging device comprises a heat exchanging coil pipe, a sprinkling disc, a receiving disc, a circulation pipeline and a rack, wherein the heat exchanging coil pipe, the sprinkling disc and the receiving disc are all installed on the rack, the heat exchanging coil pipe is of an annular structure inthe overlooking direction and is provided with a first port and a second port, the first port faces up, the second port faces down, the sprinkling disc is installed above the first port, the receivingdisc is installed below the second port, and the sprinkling disc communicates with the receiving disc through the circulation pipeline. According to the annular sprinkling heat exchanging device anda use method thereof, by means of heat exchanging of the sprinkling disc and the annular heat exchanging coil pipe, the heat exchanging efficiency is improved.

Owner:苏宇贵

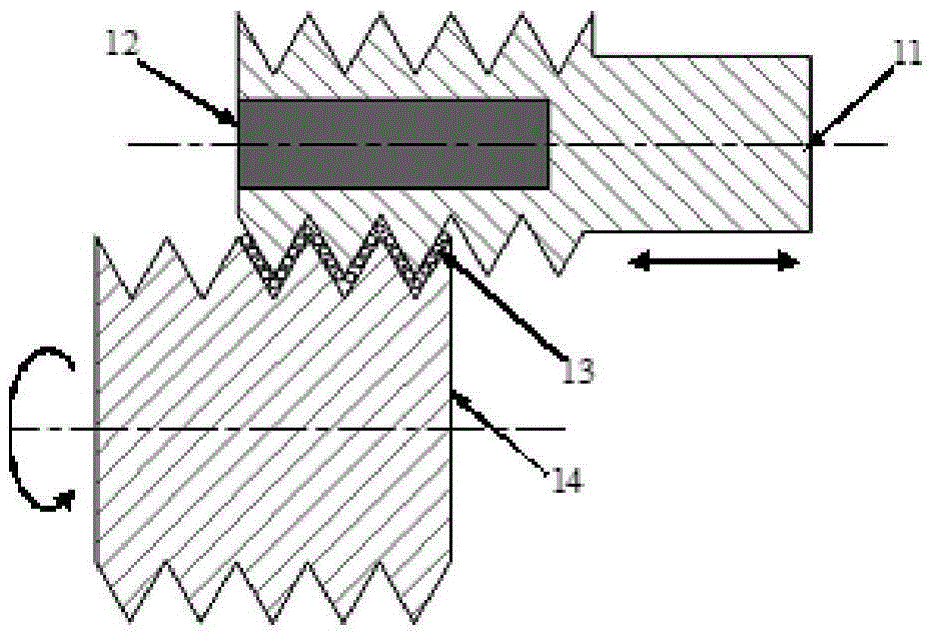

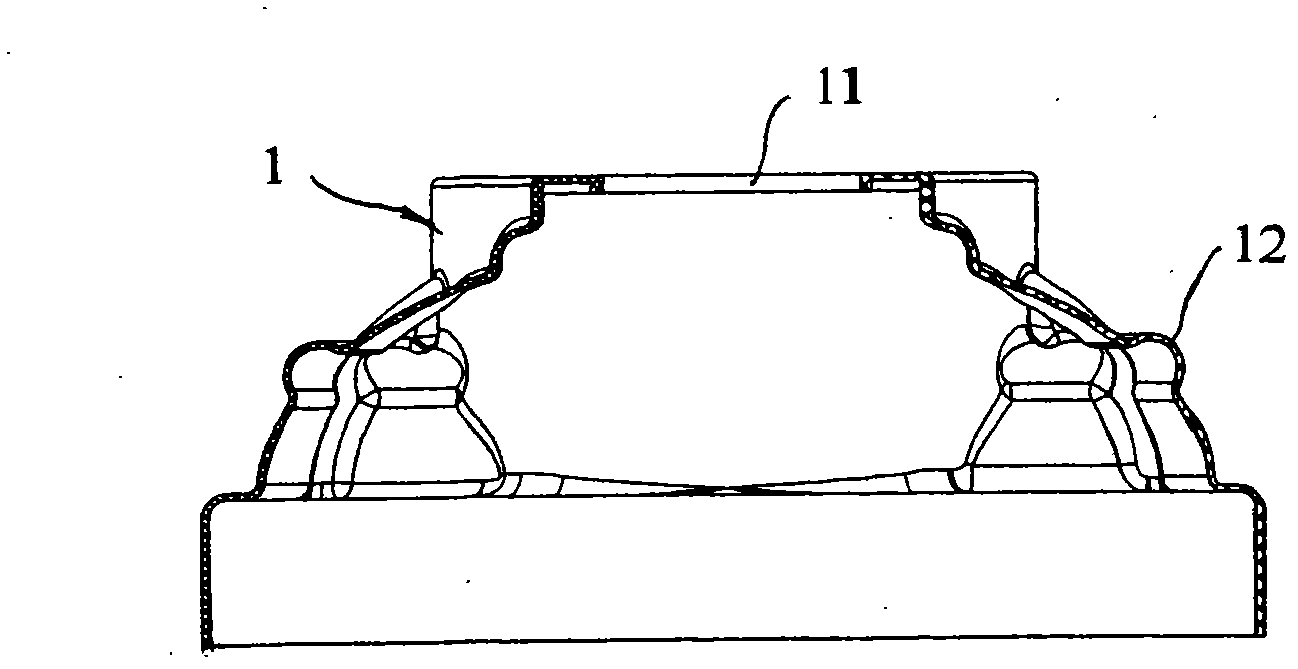

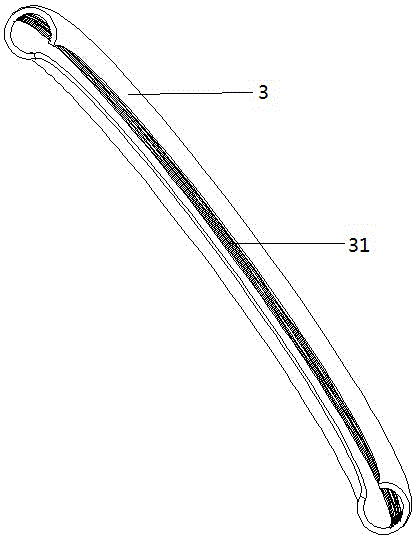

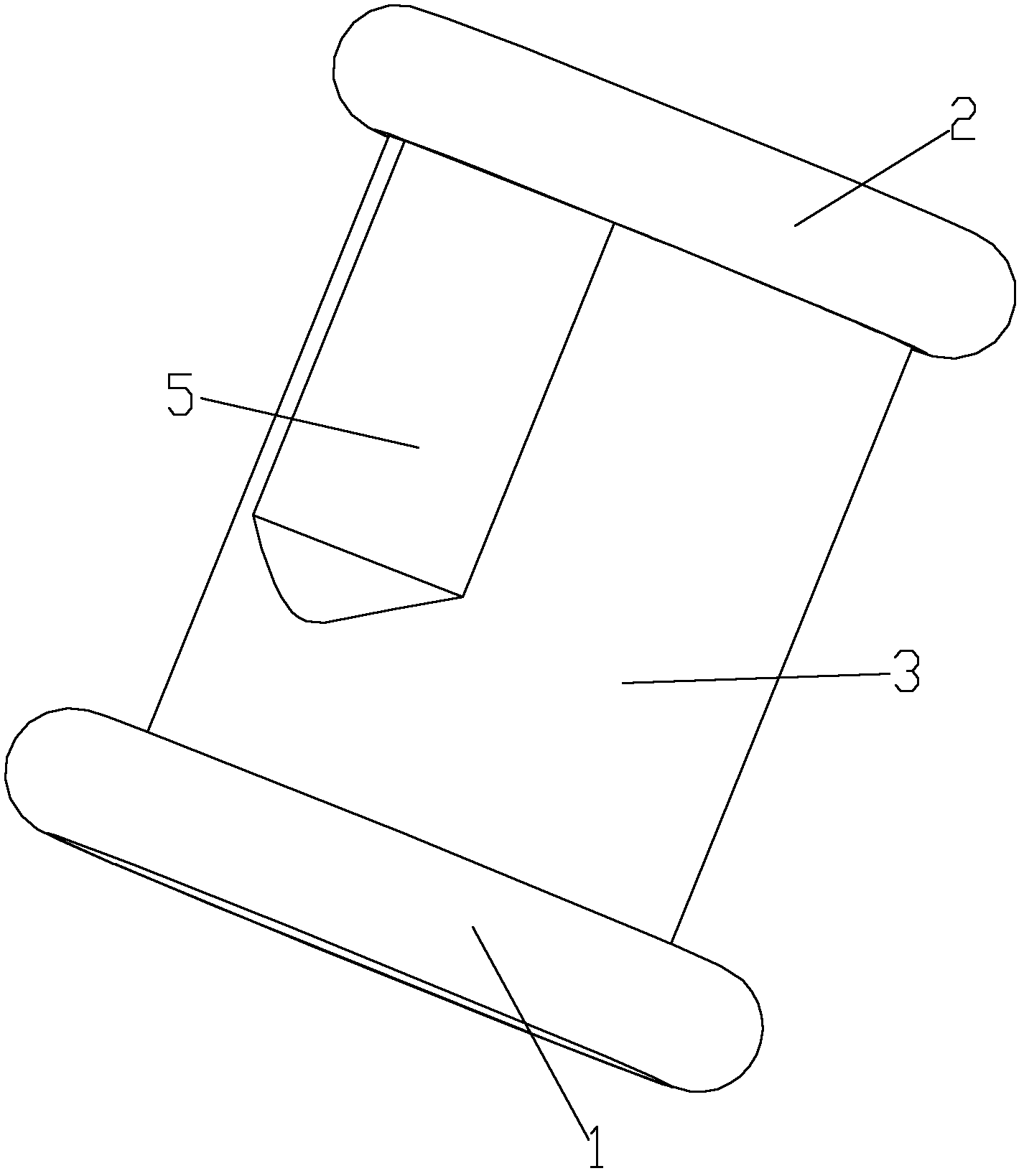

Coupling screw for shear bodies

InactiveCN102601808AAchieve interconnectionRealize the use functionPivotal connectionsMetal working apparatusCouplingEngineering

The invention discloses a coupling screw for shear bodies. The coupling screw comprises a main screw and an auxiliary screw connected in the main screw; the main screw consists of a head and a connecting part; the connecting part of the main screw is in a cylinder shape, inner threads are arranged on the inner wall of the cylinder, and two straight face ends are symmetrically arranged on the outer wall of the cylinder; an embossment is arranged on the end face of the connecting part; the auxiliary screw consists of a head and a connecting part; the connecting part of the auxiliary part is of a column shape, and outer threads matching with the inner threads of the main screw are arranged on the upper end of the column; a groove matching with the embossment is arranged on the end face of the head of the auxiliary screw; and the outer walls of the heads of the main screw and the auxiliary screw are respectively of an arc shape. According to the scheme disclosed by the invention, the coupling screw for the shear bodies adopts a structural design of combining the main screw and the auxiliary screw, so as to realize the mutual connection between the shear bodies and achieve the using function of a pair of shears; and the coupling screw has a simple structure and is very convenient to use.

Owner:苏州新凌高强度紧固件有限公司

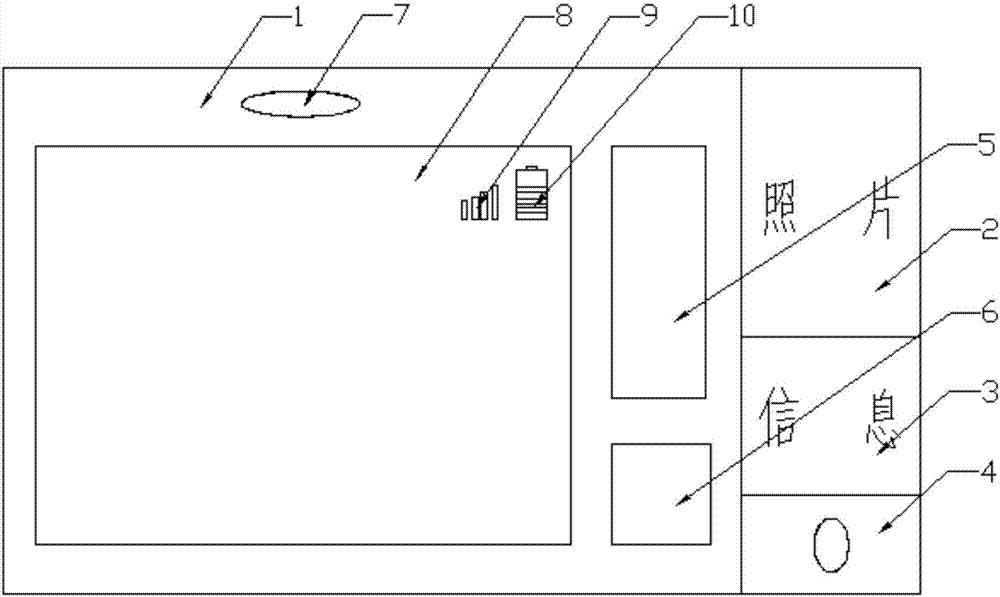

Multi-functional electronic student ID card based on digitized campus

InactiveCN107330504ARealize the charging functionImplement the unlock functionRecord carriers used with machinesTelephone cardDigitization

The present invention discloses a multi-functional electronic student ID card based on a digitized campus, which comprises a student ID card body, a fingerprint unlocking device and a touch screen type control panel. The outer surface of the student ID card is provided with a photo area, the lower side of the photo area is provided with an information area, the fingerprint unlocking device is arranged on the lower side of the information area, a discount magnetic stripe is arranged on one side of the photo area, a bank card magnetic stripe is arranged on the lower side of the discount magnetic stripe, and the touch screen type control panel is provided on the side of the discount magnetic stripe away from the photo area. The fingerprint unlocking device is arranged to achieve the unlock function of the touch-screen control panel, which can verify the identity of students before they can use the various functions of the student ID card. By setting the phone card insert slot, the phone card insert function is achieved to facilitate communication among students on campus to save money. By setting the charging interface, the charging function of the student ID card body is achieved in order to facilitate the timely use of the student ID card. The multi-functional electronic student ID card is reasonable in design and suitable for promotion.

Owner:CHUZHOU ZHUANGYUANLANG ELECTRONICS TECH

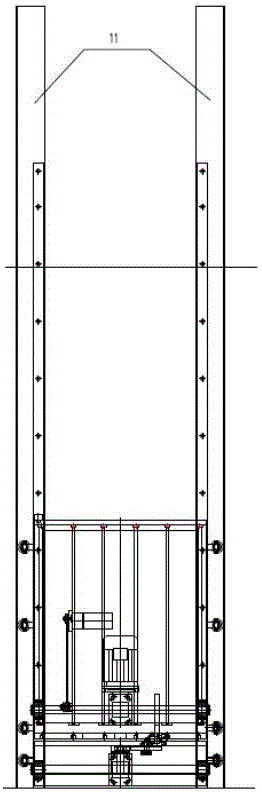

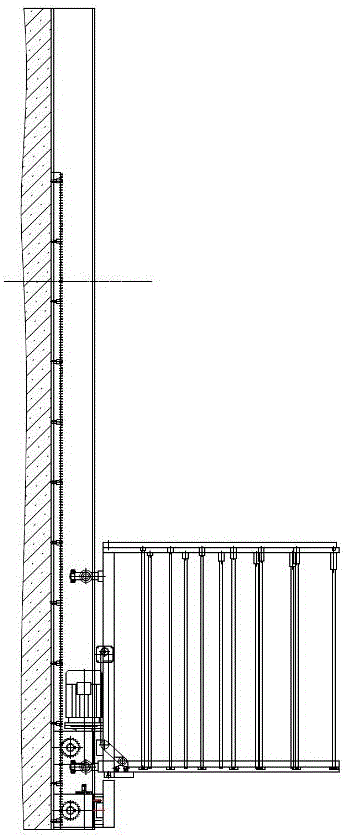

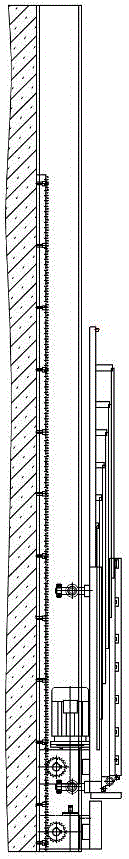

Folding small-sized elevator

The invention relates to lifting equipment, in particular to a folding small-sized elevator which comprises a main rack which is vertically arranged, a passenger compartment which is vertically positioned on the main rack in a sliding manner through a plurality of guide wheel groups, and a lifting mechanism used for driving the passenger compartment to ascend and descend, wherein the passenger compartment comprises a bottom plate, a backing plate and a guardrail which are arranged on the bottom plate; the folding small-sized elevator is characterized in that the passenger compartment adopts a folding structure; the bottom plate and the guardrail can rotate around the respective rotating axes by a certain angle under the driving of a folding power mechanism to realize folding or reverse unfolding toward in plane where the backing plate is located. The folding small-sized elevator provided by the invention has a folding function, and can effectively save space, improve the space utilization ratio, enable the passenger compartment to perform up-down movement through the lifting mechanism, and realize using functions like going upstairs and downstairs; besides, a protection mechanism which is additionally equipped can eliminate accident potentials, therefore the elevator is safe and reliable, and can further ensure personnel security.

Owner:HANGZHOU XINGHE TRANSMISSION MACHINERY RES INST CO LTD

Water inlet end cover applied to holeless drum and drum washing machine

ActiveCN111041759AAvoid retaining dirtImprove cleanlinessOther washing machinesWashing machine with receptaclesLaundry washing machineWater flow

The invention discloses a water inlet end cover applied to a holeless drum. The water inlet end cover is mounted in a bowl-shaped upside-down mode on the inner wall of the drum; a water inlet cavity is surrounded by the water inlet end cover and the drum wall together; and the water inlet end cover is provided with at least one hollow-out part so as to communicate the water inlet cavity with the inside of the drum. The invention further discloses a drum washing machine, wherein a drum comprises a cylindrical side wall; both ends of the cylindrical side wall are respectively sealed so as to form a cylindrical sealed container; and the water inlet end cover is arranged at the center of a sealed end of the drum, so that the water inlet cavity is surrounded by the water inlet end cover and theinner wall of the drum together. By arranging the water inlet end cover at the center of the sealed end of the holeless drum, inlet water flow is blocked by the water inlet end cover to generate divergent spurting so as to increase a covering area of the inlet water flow and promote an immersion wetting effect on clothes. Meanwhile, the water inlet cavity surrounded by the water inlet end cover and the inner wall of the drum together is formed inside the drum so as to take a buffer effect on the inlet water flow and promote water inlet smoothness.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

Roller washing machine

ActiveCN111041786AAvoid eccentric rotation situationsAvoid retaining dirtOther washing machinesTextiles and paperLaundry washing machineStructural engineering

The invention discloses a roller washing machine, which comprises a nonporous roller which is arranged in a shell and does not have dewatering holes, wherein a clothes input opening is arranged on a side wall of the roller, and a door cover which can controllably open and close the clothes input opening is arranged on the roller; one side of the door cover is hinged with a rotary shaft of the roller, and a rotatable spring bolt is arranged at the other end of the door cover so that the spring bolt rotating around the shaft can be locked with or broken away from the roller. Through the arrangement, a user can realize the purpose of controllably opening and closing the door cover arranged at the clothes input opening of the roller only by rotating the spring bolt, so that the complexity of opening and closing the door cover is greatly reduced; meanwhile, the locking degree of the closed door cover is ensured, and the condition that the roller is opened by mistake in the rotating processis effectively avoided.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

Fast automatic disassembling structure of toilet bowl cover plate assembly

ActiveCN102512114BRealize the installation functionRealize the use functionBathroom coversSlide plateEngineering

Disclosed is a fast automatic disassembling structure of a toilet bowl cover plate assembly, which is used by means of matching with two bases fixed on a toilet bowl. Each base is provided with a positioning rod with a reducing neck and a regular cone, a connecting shaft is pivotally connected with a cover plate and a seat ring via two automatic mechanisms, each automatic mechanism comprises a body, a positioning rod penetrates into the body, a slide part pushed by a slide part spring and a lock pushed by a lock plate spring are disposed in each body, arc-shaped notches are formed at front ends of an upper slide plate and a lower slide plate of each slide part, a one-way clamp table is formed on the lower surface of each lower slide plate, the distance between each upper slide plate and the corresponding lower slide plate is larger than the height of the regular cone on the upper portion of the positioning rod, a hook which is hung on the clamp table is formed on the upper surface of a lock plate, a ring slot is arranged on the lower side of the reducing neck of the positioning rod, a movable lock pin is disposed on a seat ring pivot sleeve or a cover plate pivot seat, and an inclined guide plane which pushes the movable lock pin is disposed on a side of the cover plate pivot seat or the seat ring pivot sleeve and corresponds to the lock pin, so that the movable lock pin movably extends into the ring slot of the positioning rod. The cover plate assembly can be quickly and automatically disassembled by means of integrally exerting force on the cover plate assembly.

Owner:BAYEN (XIAMEN) SANITARY WARE CO LTD

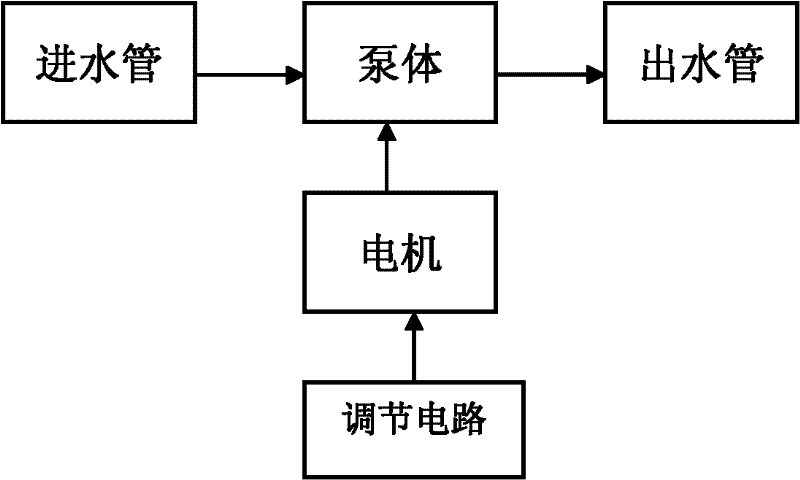

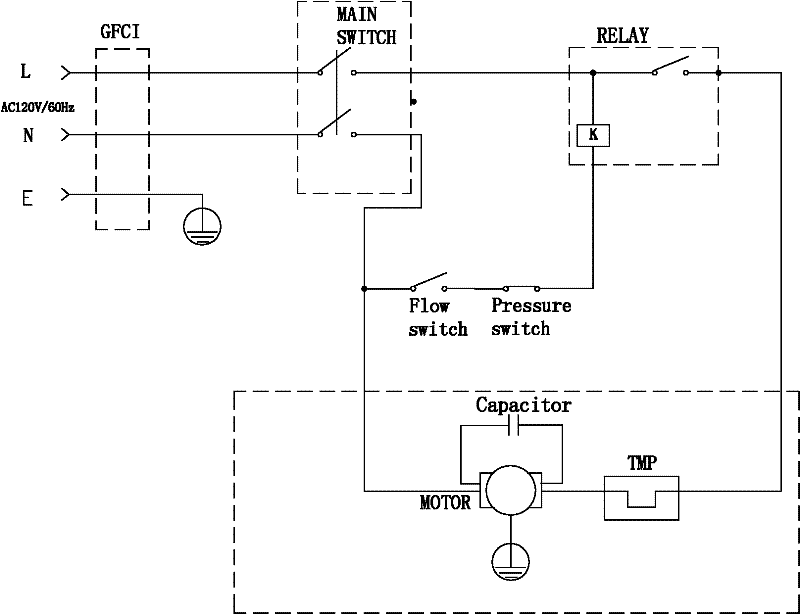

Garden cleaning machine

InactiveCN102205325AIncrease pressureHigh trafficWatering devicesCultivating equipmentsWater savingElectricity

The invention discloses a garden cleaning machine, which comprises a motor, a pump, a water outlet and inlet pipe and an adjusting circuit, wherein the pump is driven by the motor; the pump is connected to the water outlet and inlet pipe; the adjusting circuit can control the running of the motor according to water flow and water pressure; and the adjusting circuit is connected to the motor. By using the machine, the motor and the pump can be automatically started, the water pressure and the water flow can be increased, the function of cleaning courtyards, cars, outer walls, and the like is achieved, and the function of using the machine as a water pump is also achieved. Besides, in the machine, water enters and exits from a common garden pipe and the use is convenient. The method can be used for realizing multifunction, is water-saving and electricity-saving, is energy-saving and environmentally-friendly, and is suitable for being used in wide country and urban villas.

Owner:SUZHOU KINGCLEAN PRECISION MACHINERY

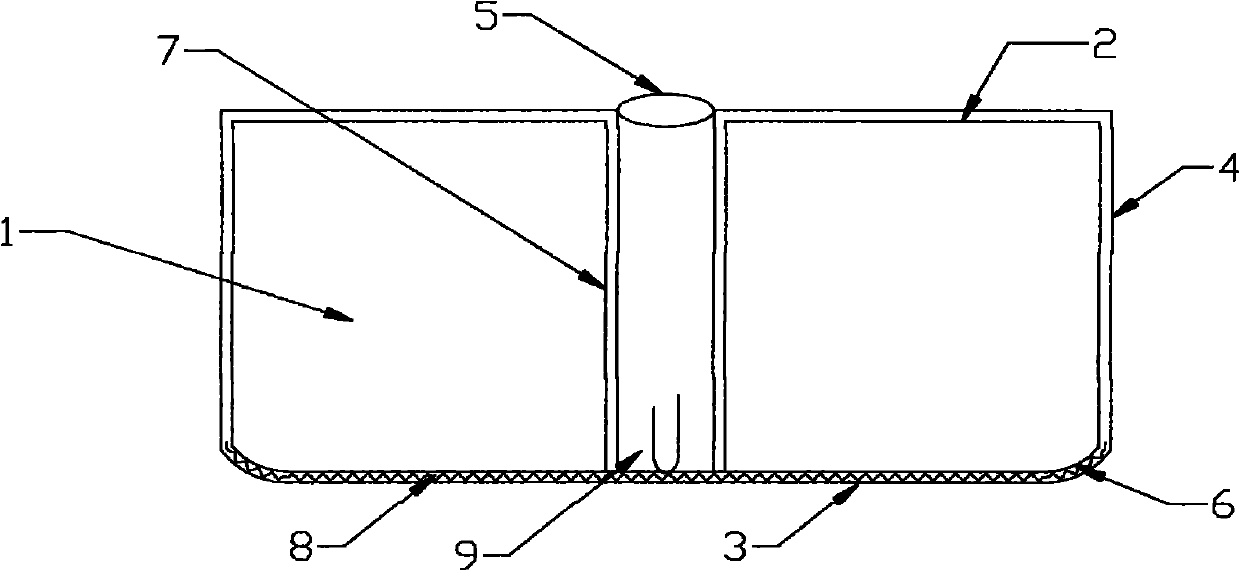

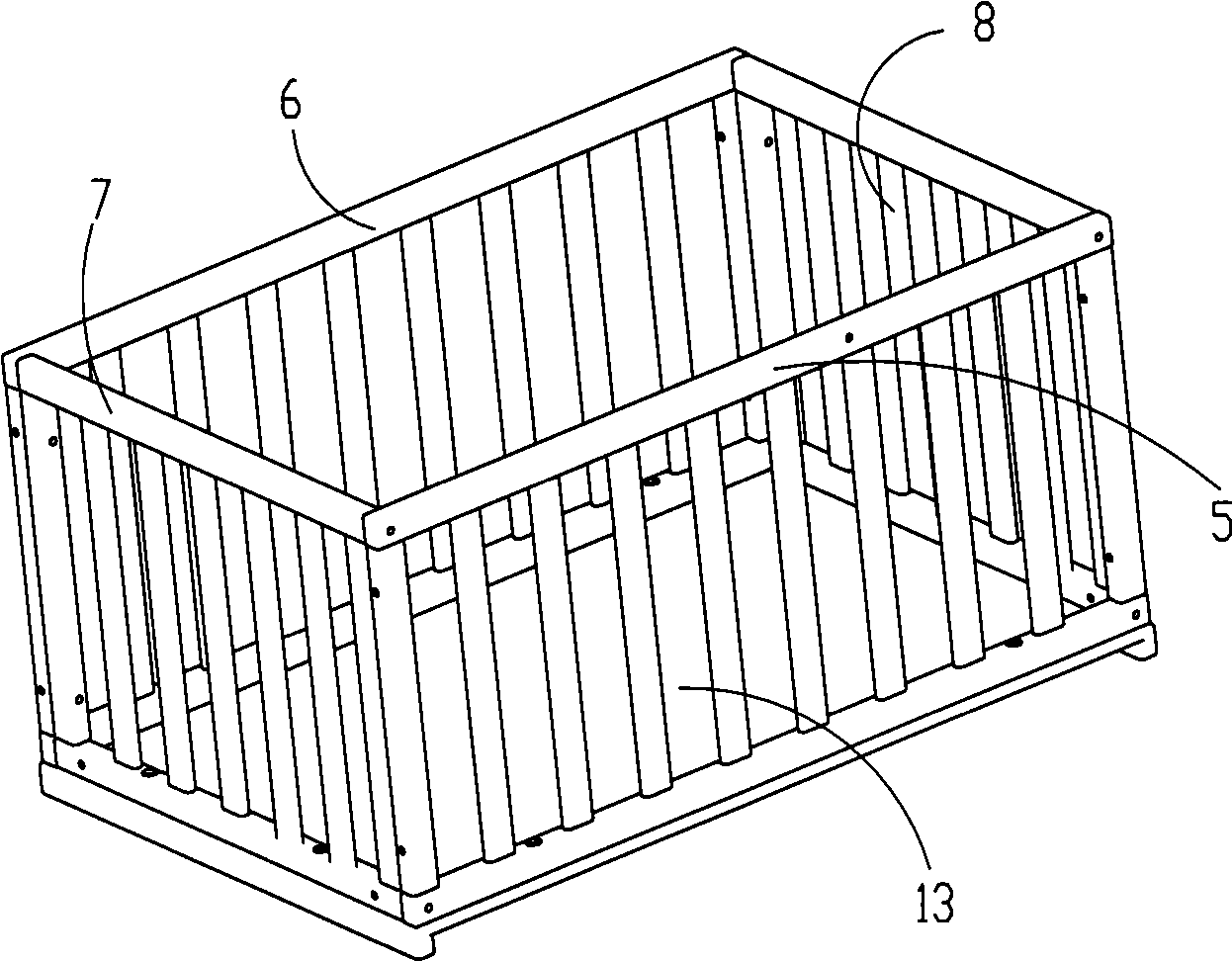

Multifunctional crib

InactiveCN102224990ARealize the use functionExtended service lifeKids bedsKids convertible furnitureEngineeringMultiple function

The invention discloses a multifunctional crib which comprises a bottom plate (1), a first side plate (2), a second side plate (3), a first baffle (4), a second baffle (5) and a headboard (6), wherein a roller (17) is arranged on the bottom plate (1); and through different assemblies of the components, the multifunctional crib can be assembled into a crib or a juvenile bed. Through the invention, multiple functions of the crib are realized, the service life of the crib is prolonged, and the household expenses are reduced.

Owner:ASAKAI ARCHITECTURAL DESIGN FIRM

Multifunctional children's bed

Multifunctional children's bed comprises a headboard, a footboard, a head strut frame, a foot strut frame, a first long guard rail, a second long guard rail, a first short guard rail, a second short guard rail, a first bed beam, a second bed beam, a bed board assembly. The multifunctional children's bed can be assembled into baby's bed, cradle, youth's beds of at least two bed assembly structures by assembling the above parts. Namely the multifunctional children's bed can be assembled into baby's bed, or cradle, or youth's beds. The multifunctional children's bed has multi-use function and prolongs the service life, reduces the family expense and saves social resources.

Owner:GOODBABY CHILD PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com