Combined hollow box body for cast-in-place energy-saving hollow floor

An empty floor and box technology, which is applied to floors, building components, buildings, etc., can solve the problems of high construction cost, unreachable, unbalanced force transmission in the vertical and horizontal directions of the floor, etc., to reduce construction costs, Reasonable structure and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

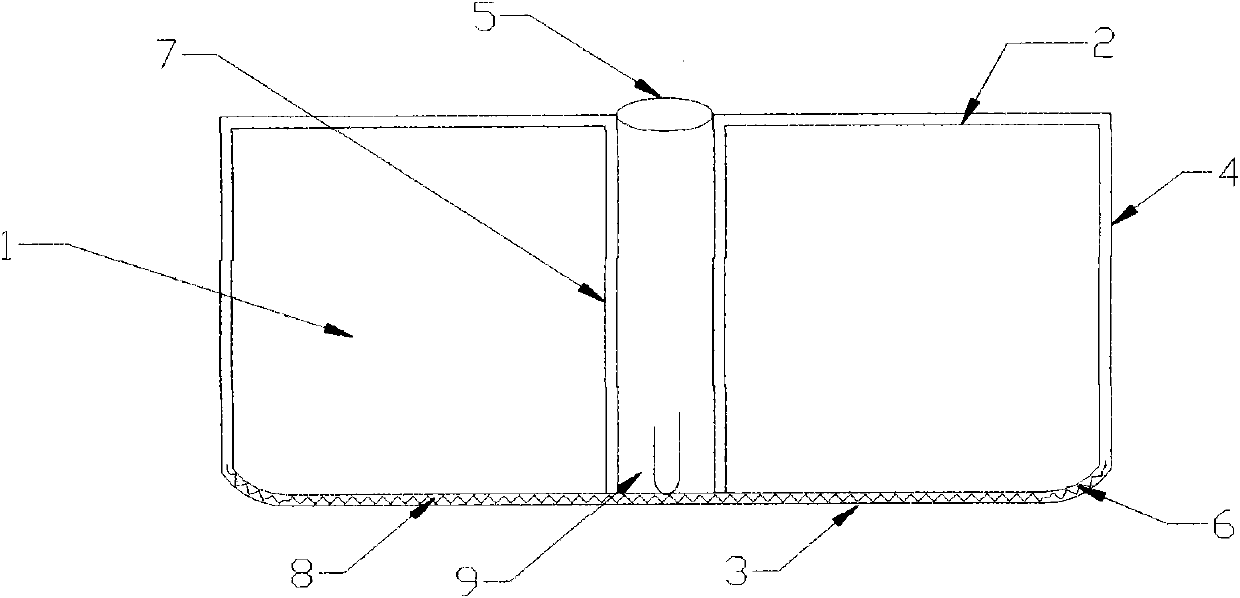

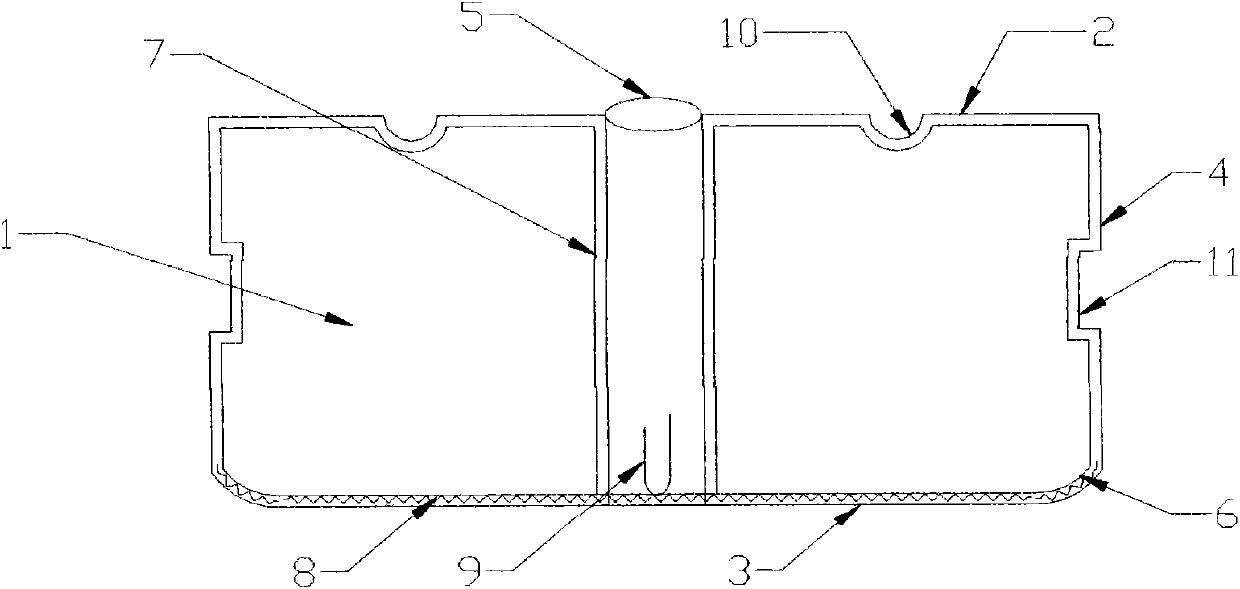

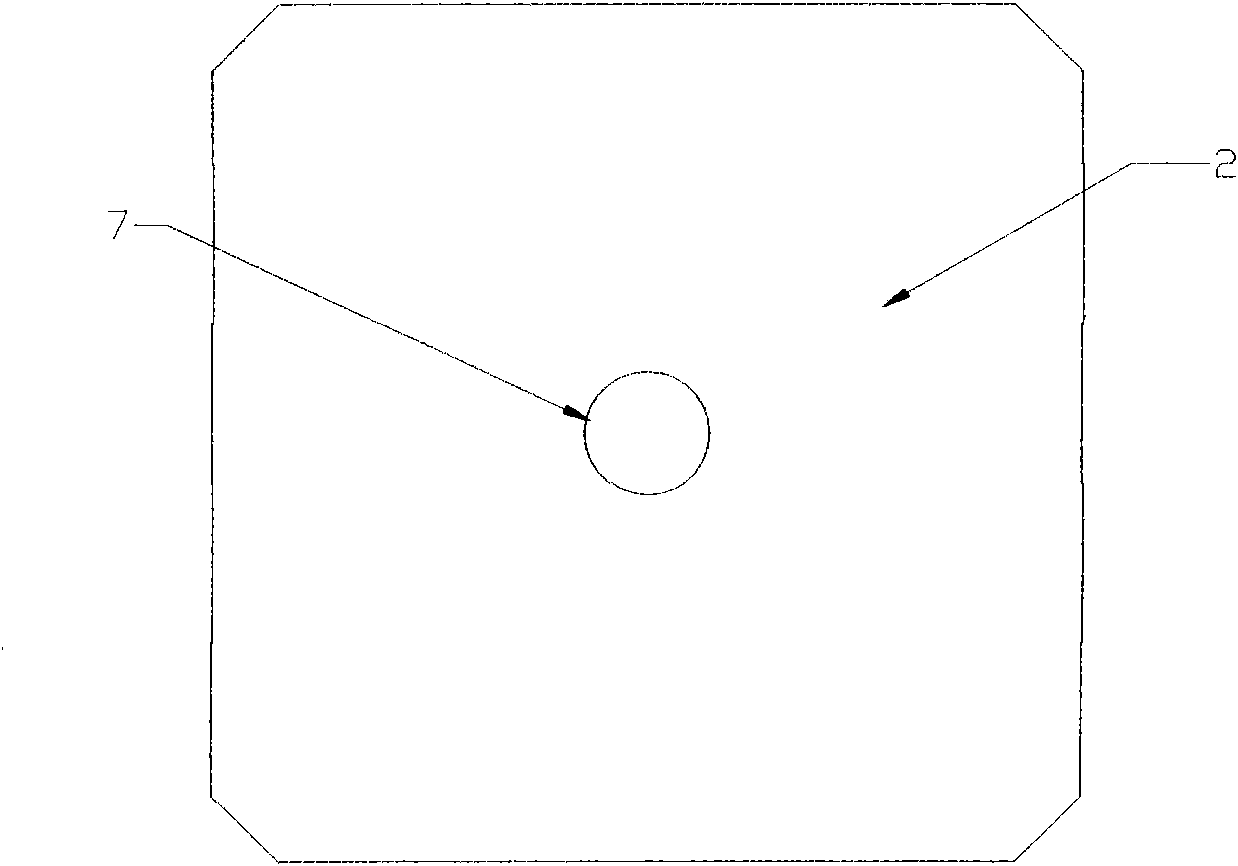

[0030] The present invention will now be further described with reference to the drawings, such as Figure 1a As shown, the hollow box body 1 in this scheme is composed of a bottom surface 3, a side surface 4, a top surface 2, an arc surface 6 and a hole wall 7, and a one-time forming mold formed by a combination of a bottom surface mold, a side surface mold and an arc surface mold , Smear cement mortar on the inner wall of the mold to form the bottom surface 3, the side surface 4 and the arc surface 6 of the hollow box body 1. In order to enhance the strength of the hollow box, reinforcement materials can be added to the cement mortar. The reinforcement materials can be steel wire mesh, glass fiber cloth, short fiber wire, short iron wire, etc. Preferably, the bottom surface 3 and the curved surface 6 of the hollow box body are made of steel mesh 8 as the reinforcing material, and the iron wire 9 is used to string into the steel mesh 8 in the central part of the bottom surface 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com