Novel precast concrete pipe die and construction method thereof

A prefabricated concrete and concrete pipe technology, which is applied to formwork/formwork/work frame, on-site preparation of building components, columns, etc., can solve the problems of high cost of erecting formwork and difficult quality assurance, so as to reduce construction costs. And the effect of comprehensive cost, less construction equipment and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

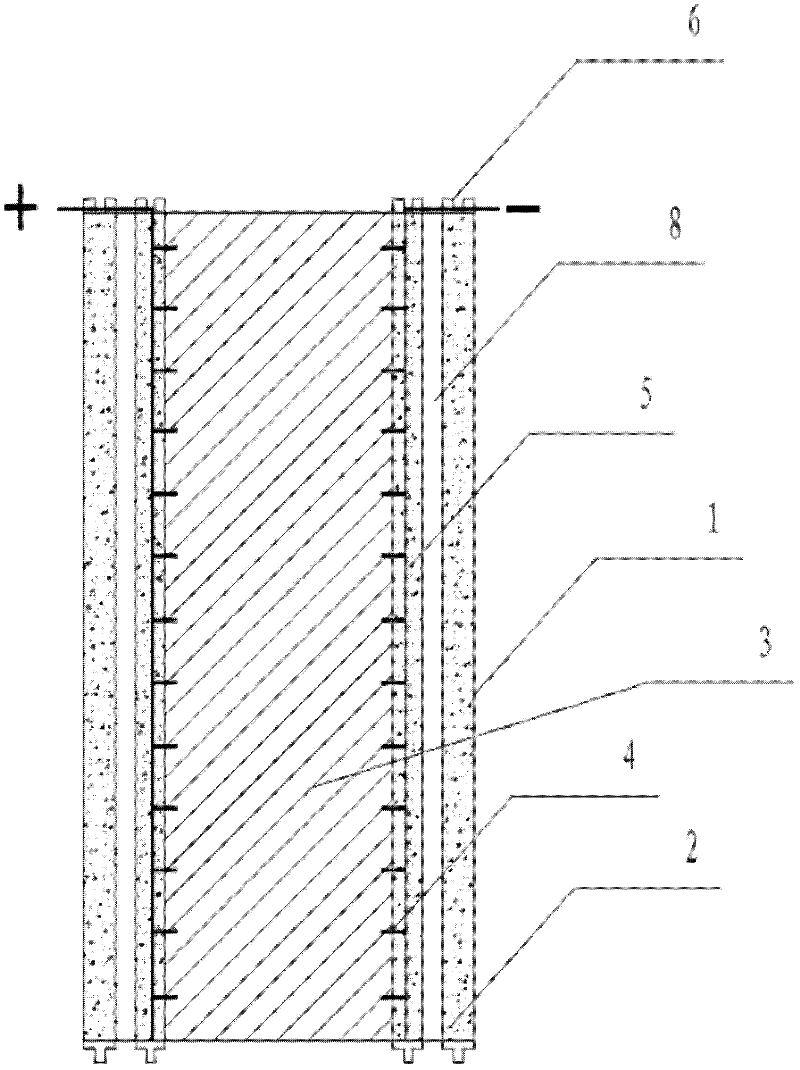

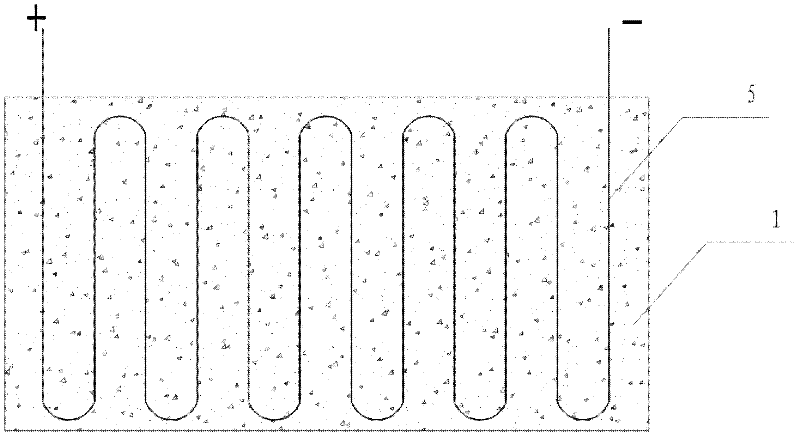

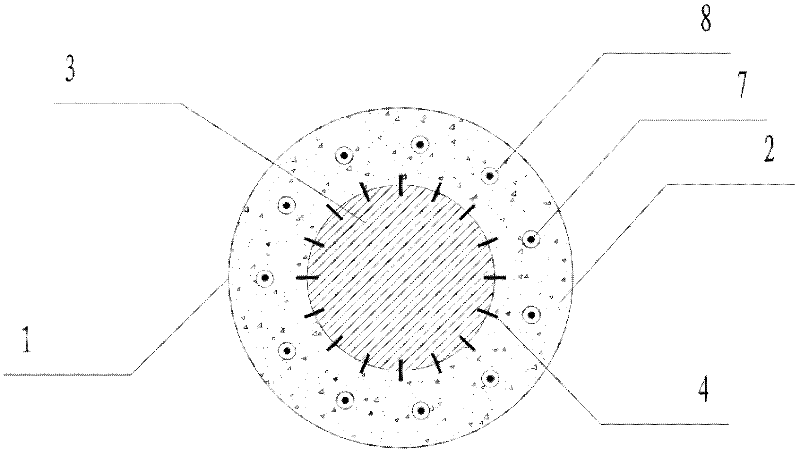

[0025] A new type of precast concrete pipe mold, such as figure 1 , figure 2 , image 3 As shown, it is a hollow structure of precast concrete pipe piles. The outer diameter of precast concrete pipe form 1 is 2m and the wall thickness is 0.2m. Precast concrete pipe form 1 is made of reinforced concrete 2. Waterproof, fireproof and anti-corrosion functions, the inner surface of the concrete pipe mold 1 is a rough surface, and the wall of the precast concrete pipe mold 1 is equipped with ring-shaped and vertical steel bars. The diameter of ordinary steel bars is 12mm, and the reinforcement ratio is 1%. The diameter of the prestressed steel bars is 15.2mm and is evenly arranged longitudinally along the concrete pipe mold wall with a spacing of 200mm. The circumferential prestressed steel bars are evenly arranged at a spacing of 500mm from top to bottom. The pouring concrete 3 is connected with the integrated rib 4 and the heating wire 5 for heating. The length of the rib 4 pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com