Patents

Literature

287results about How to "Reduce construction cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

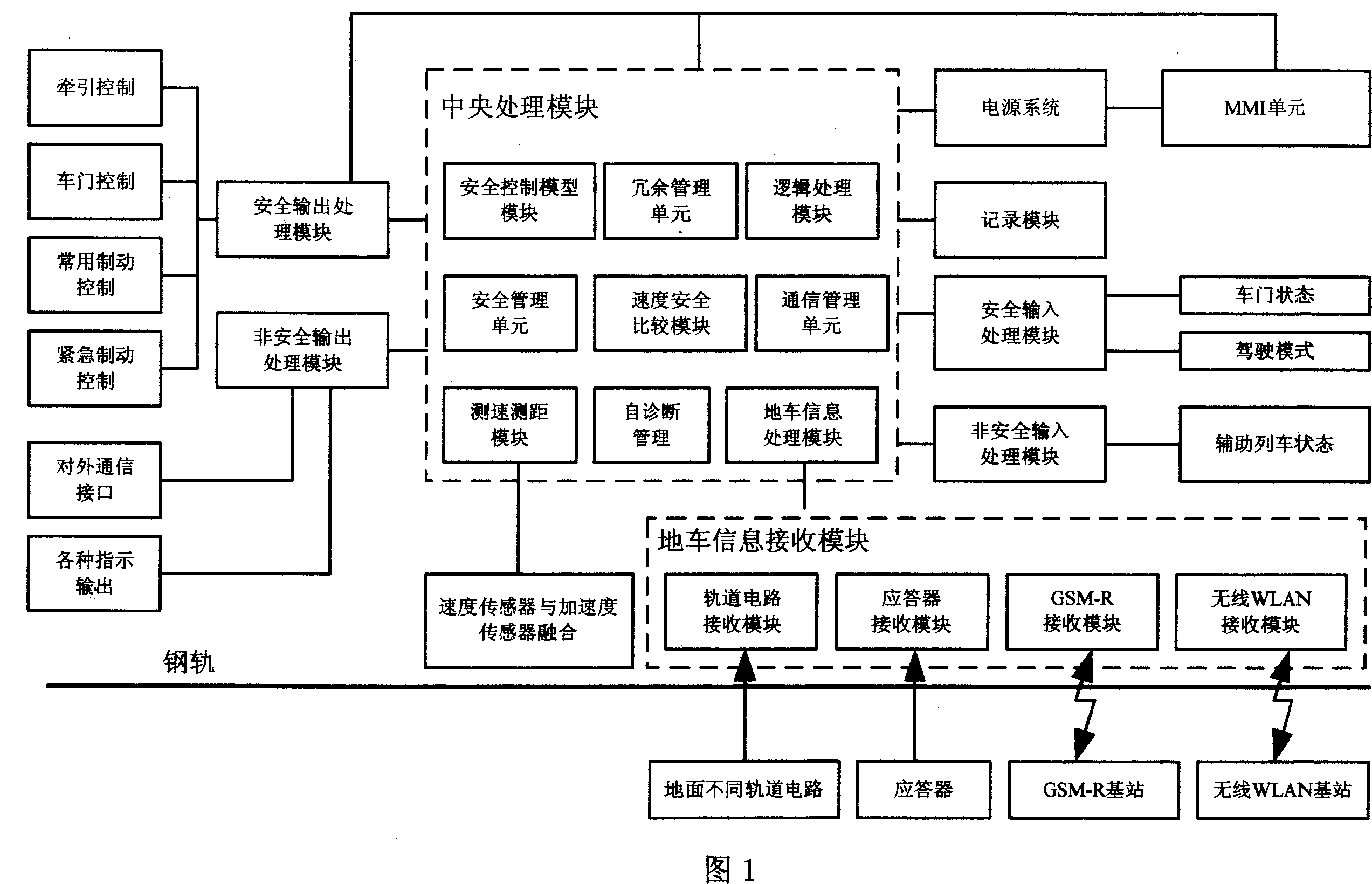

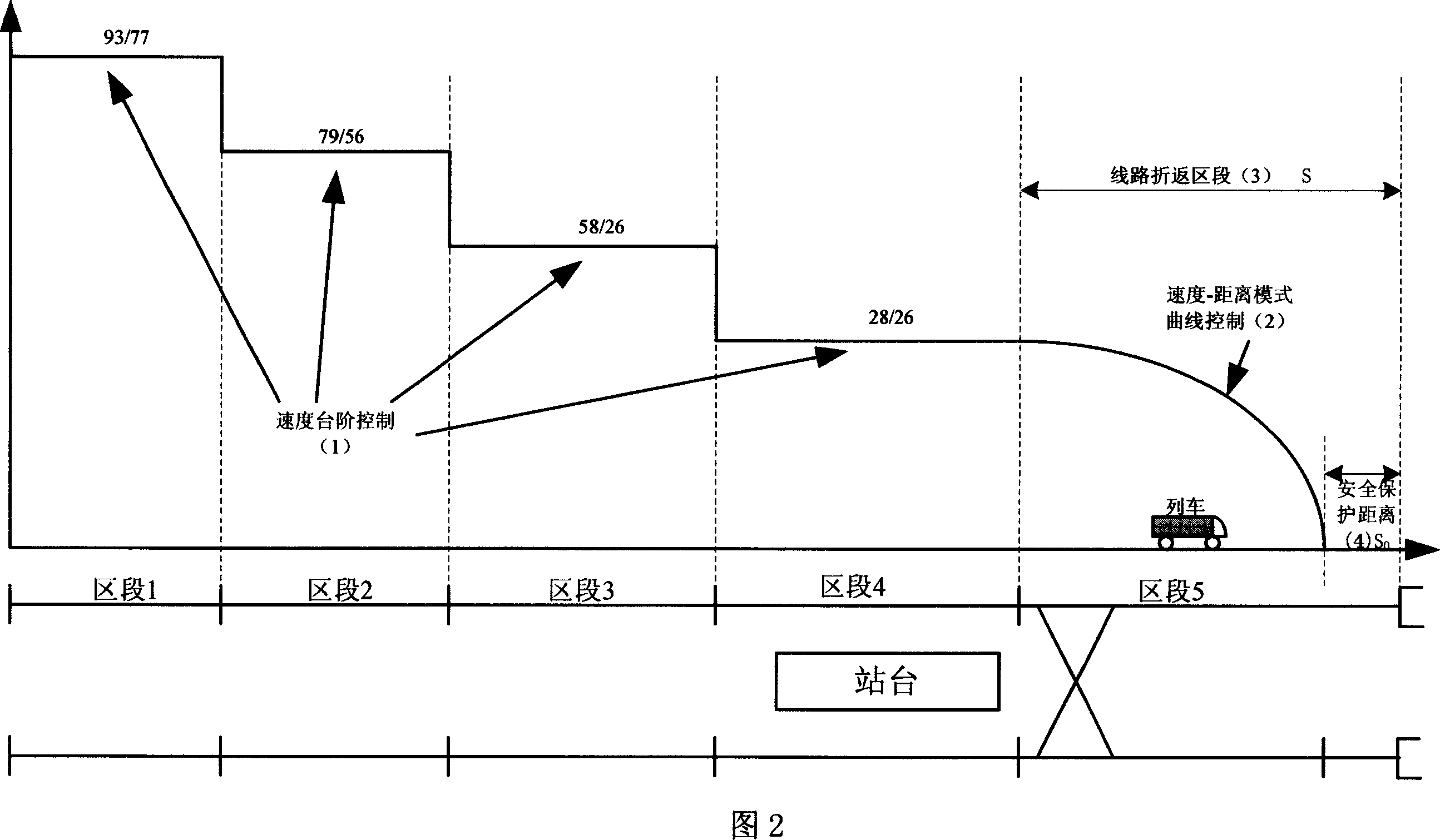

Universal automatic protection (ATP) vehicle-mounted system for train and its mode control method

InactiveCN101007537AReduce workloadIncrease flexibilityVehicle route interaction devicesDigital signal processingAutomatic control

A universal Automatic Train Protection ATP vehicle mounted system and mode control method. The invention mainly uses digital signal processing and safe redundant control technology, designs a safe Protection Automatic control system which can receive many varieties of ground vehicles information transmission modus, realize the combination of the train speed steps control and the first-order speed-distance model curve and realize the generalization of vehicle automatic protection system vehicle mounted equipments. And the ground vehicles information transmission modus consists of analog and digital track circuit, responder, GSM-R transmission, 2.4GHz wireless transmission, etc. the safe protect control is the safe braking model control using the combination of speed steps and first-order speed-distance model curve. The system mainly consists of power module, ground vehicles information transmission reception module, central processing module, recording module and man-machine interface MMI module, etc. The beneficial result is getting a solving program for users on the base of reducing construction costs and intercommunicating transport operation.

Owner:BEIJING JIAOTONG UNIV

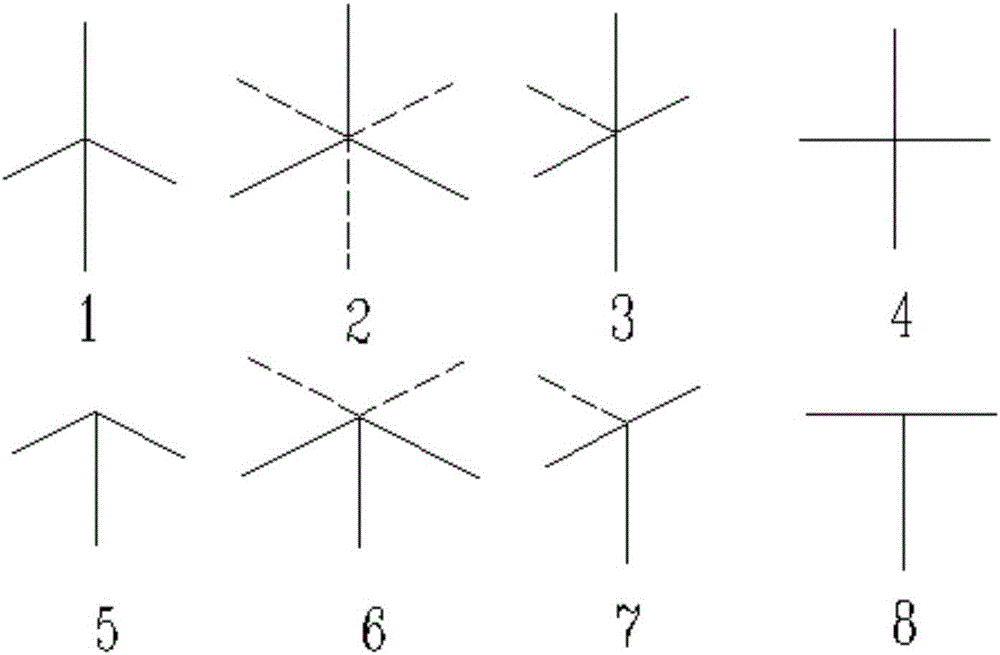

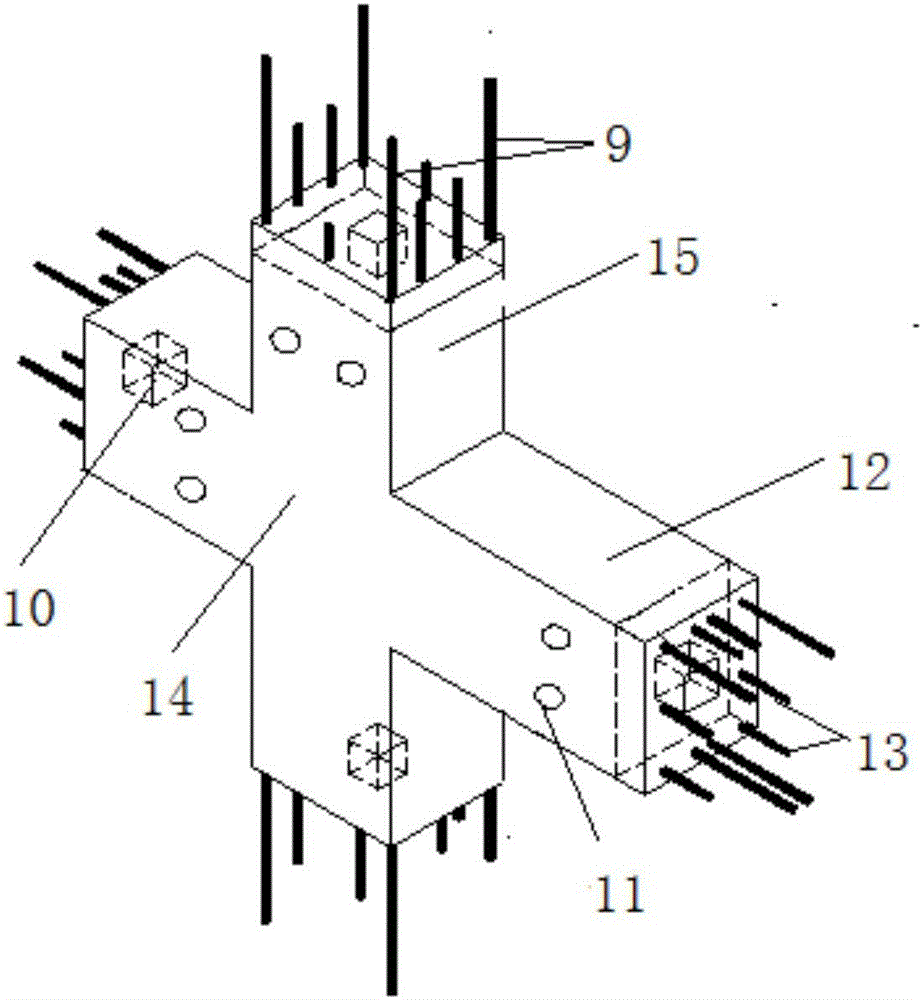

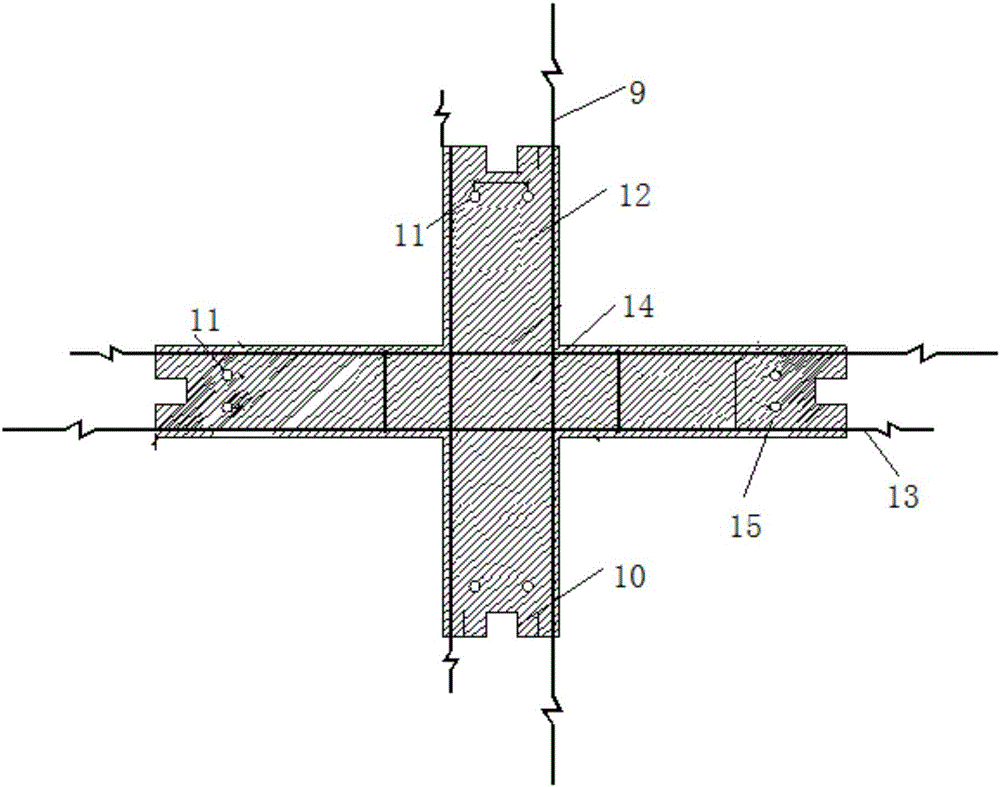

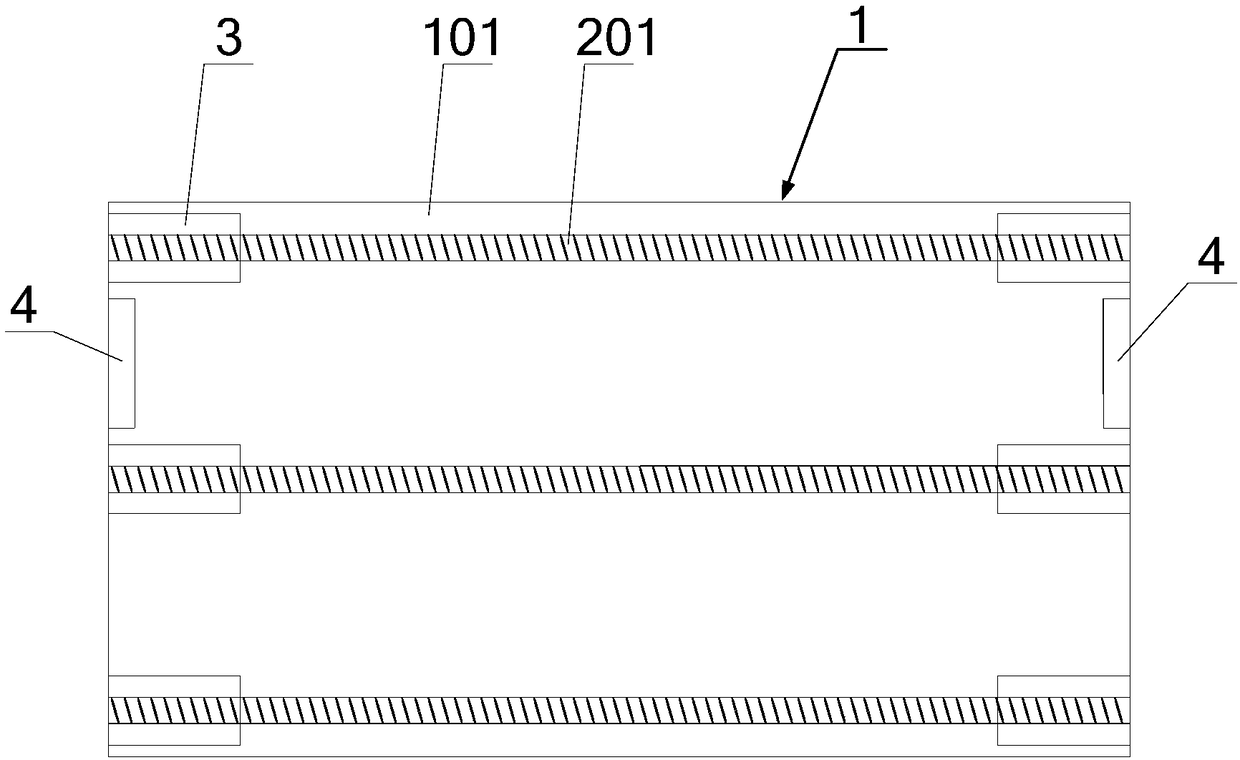

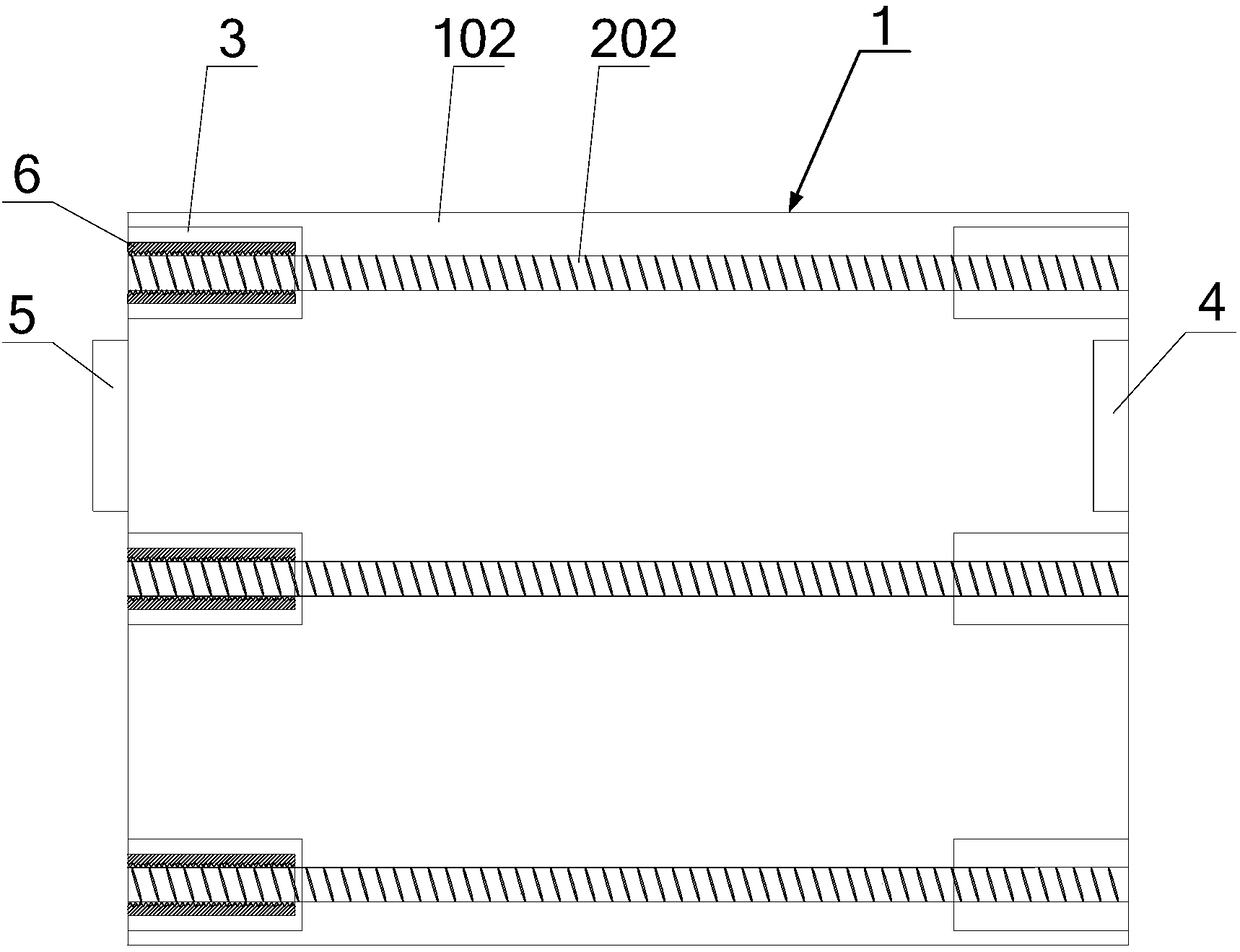

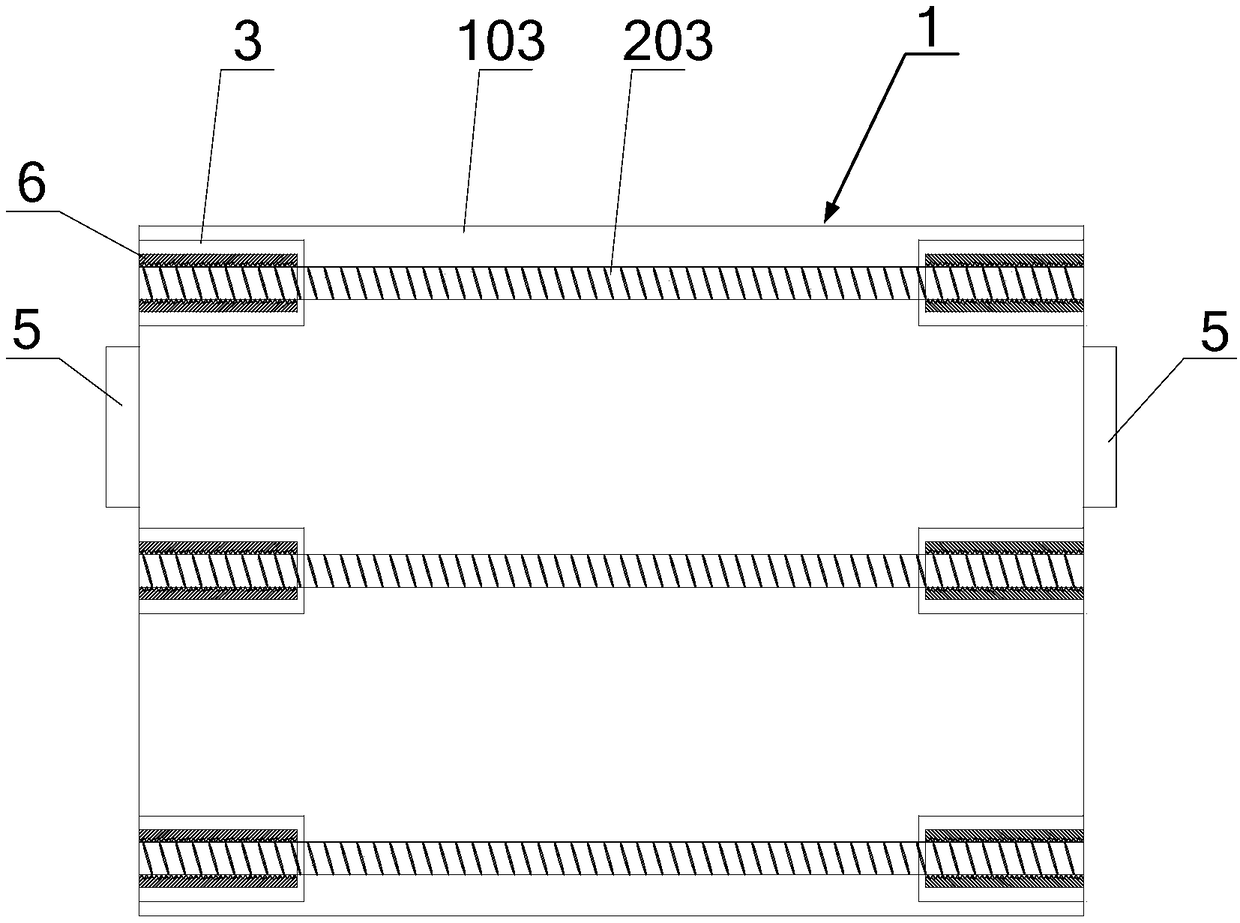

Prefabricated node and prefabricated frame structure and construction method thereof

ActiveCN106223463ARealize factory productionBuild fastBuilding constructionsReinforced concreteArchitectural engineering

The invention discloses a prefabricated node and a prefabricated frame structure and a construction method thereof. The prefabricated node can be subjected to workshop prefabrication according to the structure. The prefabricated frame structure is mainly characterized in that the prefabricated node with a node overhanging beam section and a node overhanging column section is prefabricated, prefabricated nodes of various kinds are designed according to a graph, the prefabricated nodes are accurately mounted, and the overall prefabricated assembled integral type structure is constructed by means of connecting beams or columns of the prefabricated nodes in site. The construction method includes the steps of 1), positioning, lifting and correcting the prefabricated nodes in site; 2), fixing and mounting the prefabricated nodes; 3), casting a beam connection portion and a column connection portion in site. A novel construction mode is innovatively put forward for the prefabricated frame structure, and the node prefabricated structure with the beams and the columns is put forward; unfavorable situation that durability and reliability of the nodes are pool due to conventional prefabricated beams and columns and in-site casting of reinforced concrete nodes is favorably improved, construction time is saved, and construction cost is reduced.

Owner:赵挺生

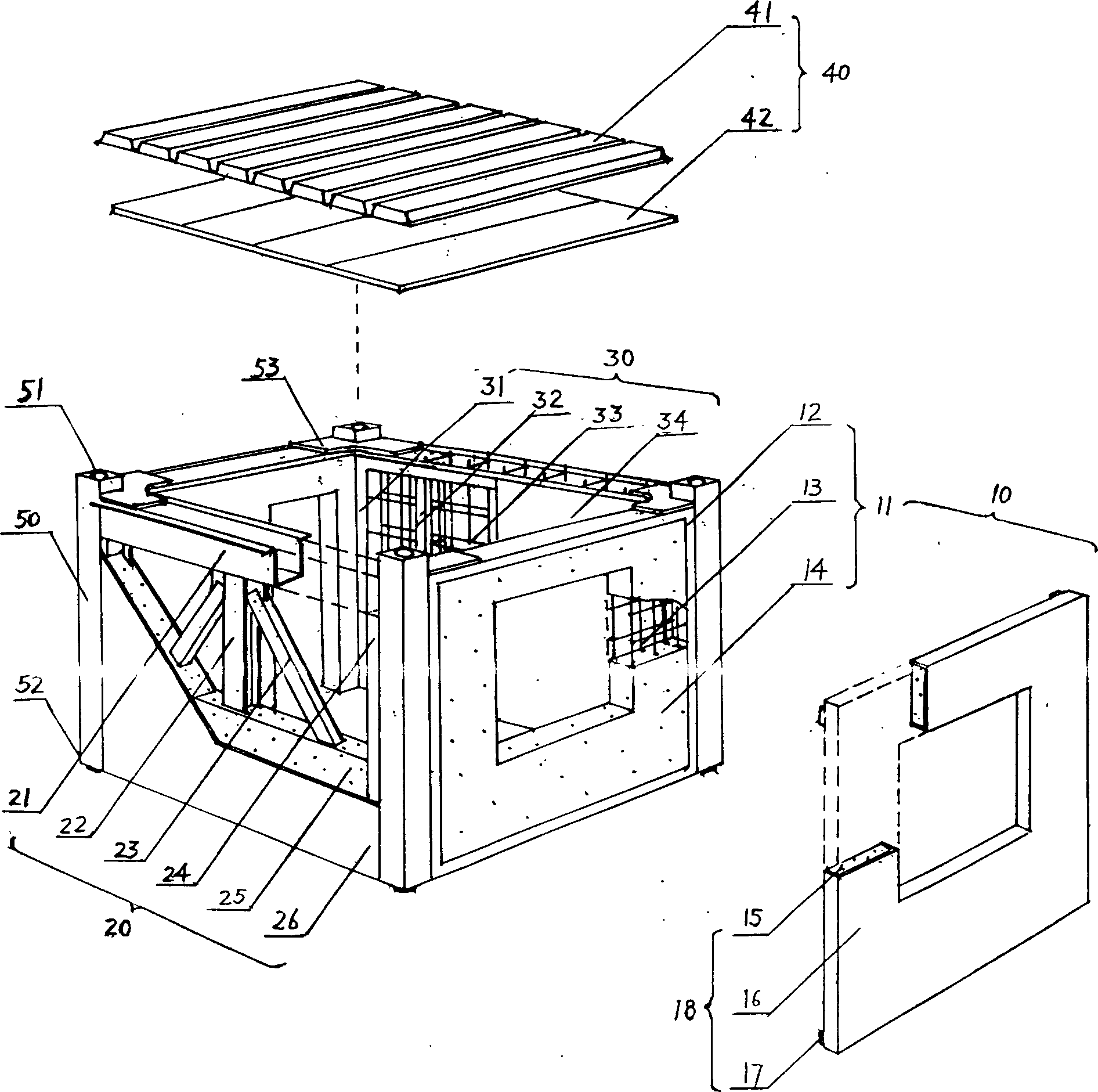

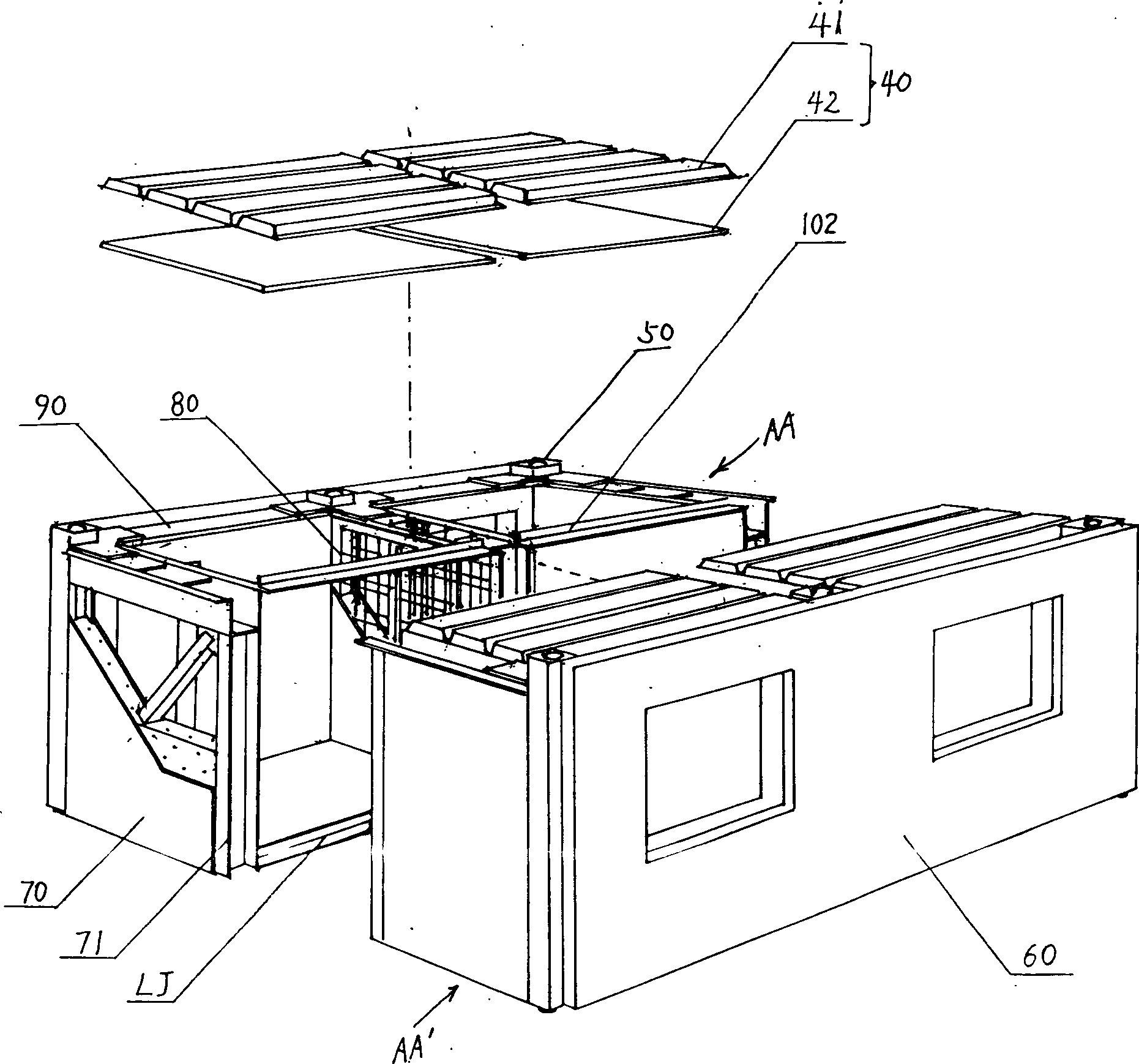

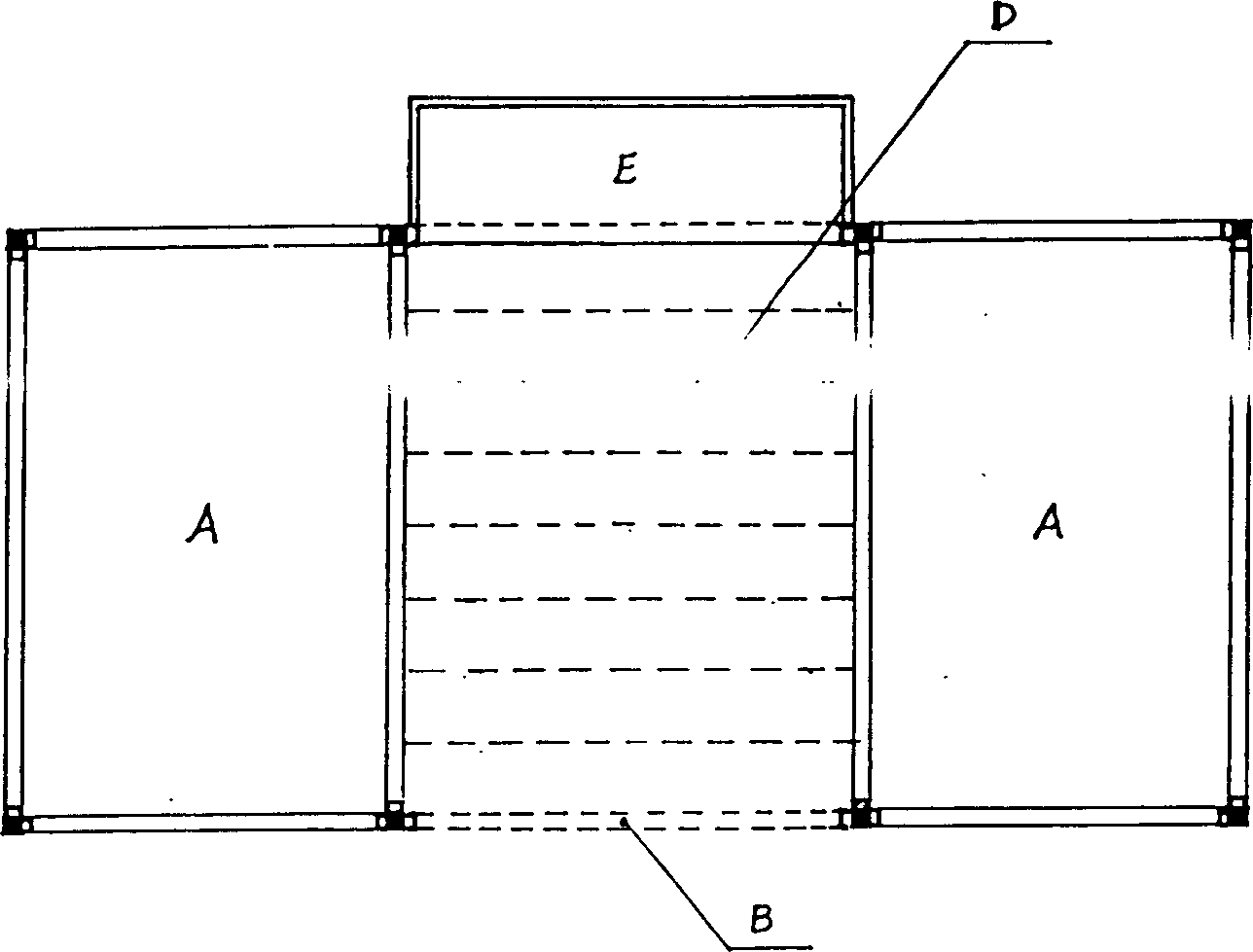

Box shaped house model of construction and fabricating method

A box type of house mould used on building consists of outer wall formed by steel frame, steel screen frame and aero ¿C concrete plate; inner wall formed by hollow wall plate and composite frame wall plate; top plate mould formed by pressed steel bearing plate and light thin plate and steel tube. It is featured as enclosing box type of house mould by one outer wall and three inner walls and furthermore forming stereo structure house mould with five surfaces by welding said box type of house mould with top plate mould.

Owner:张东川

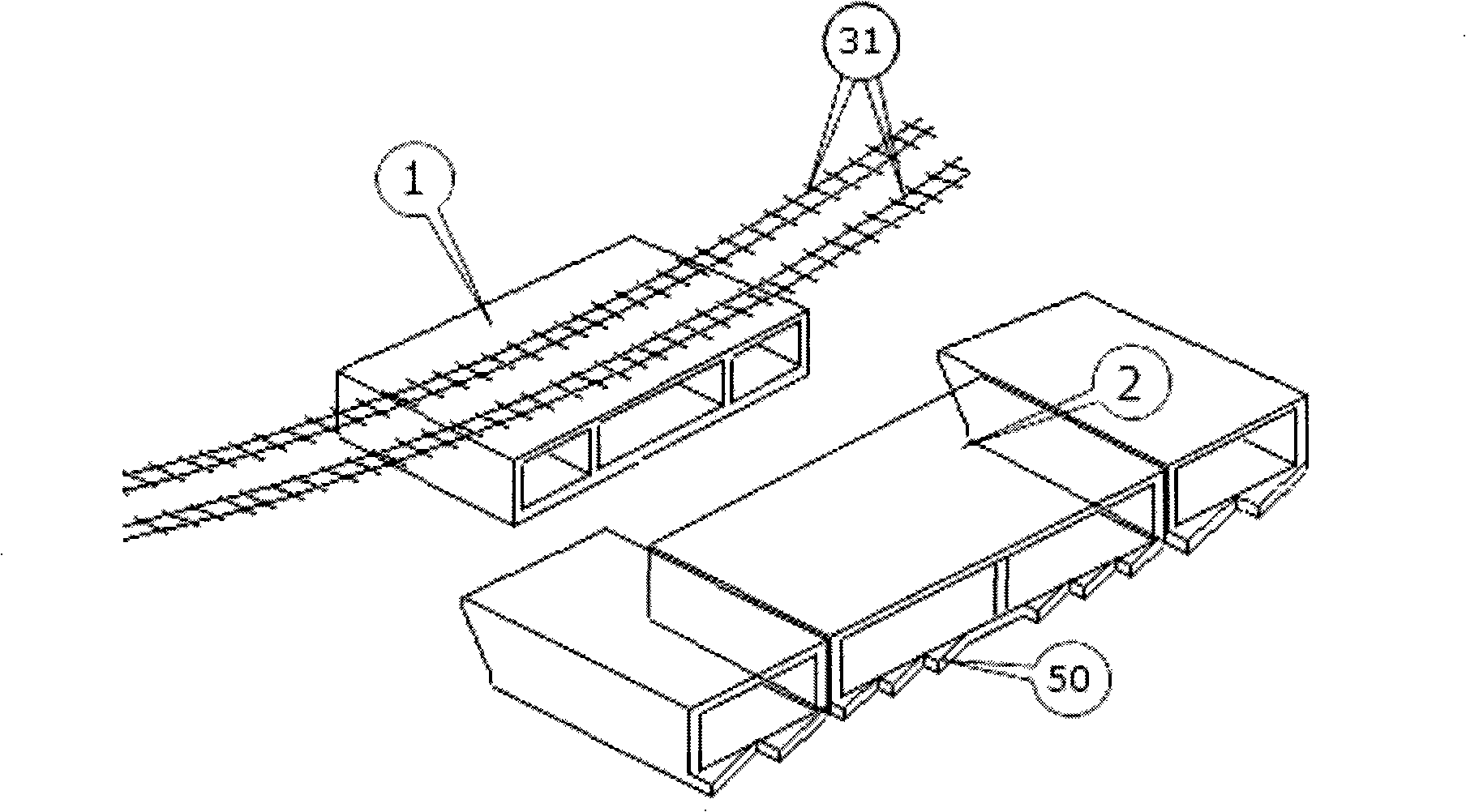

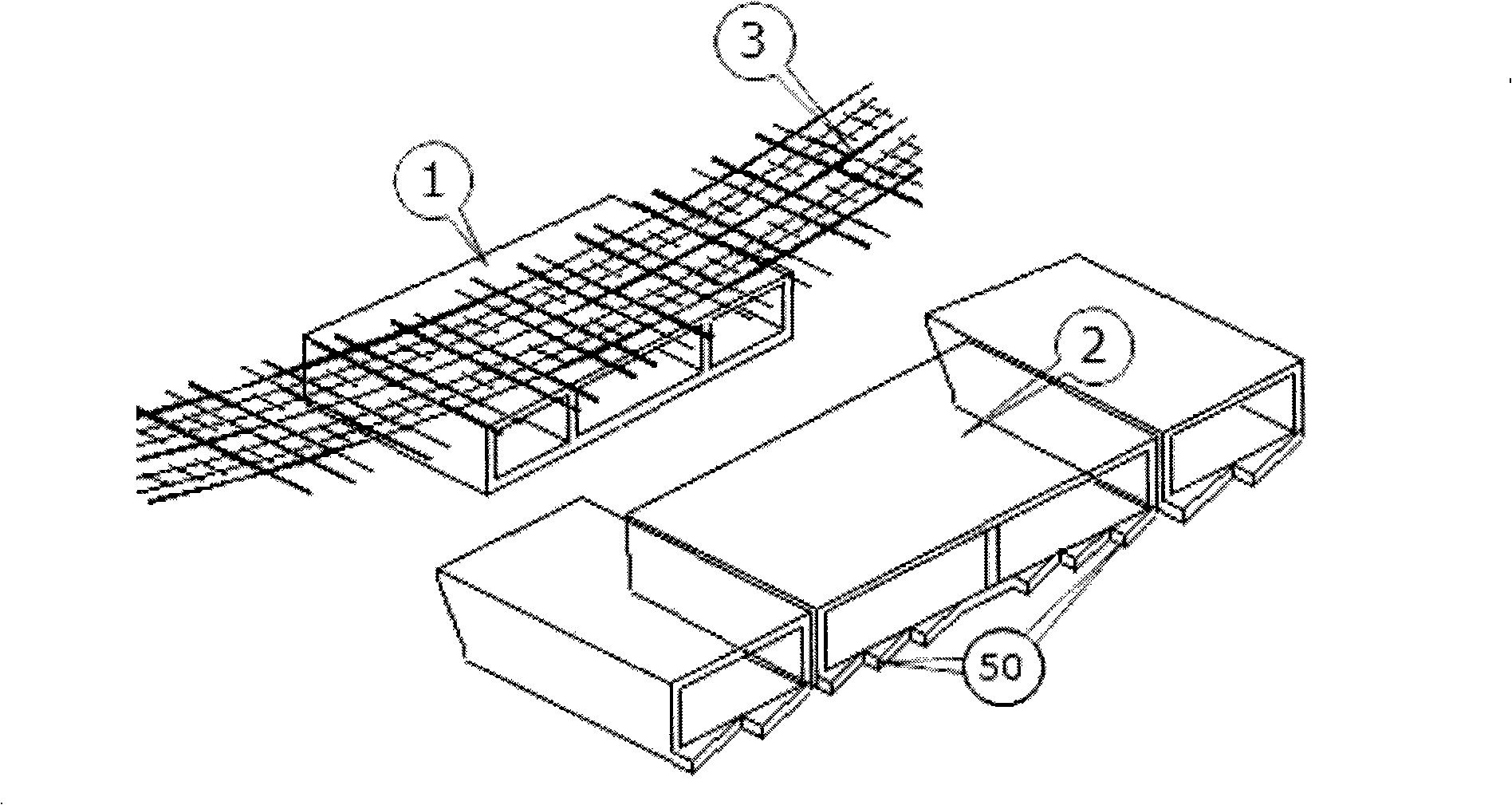

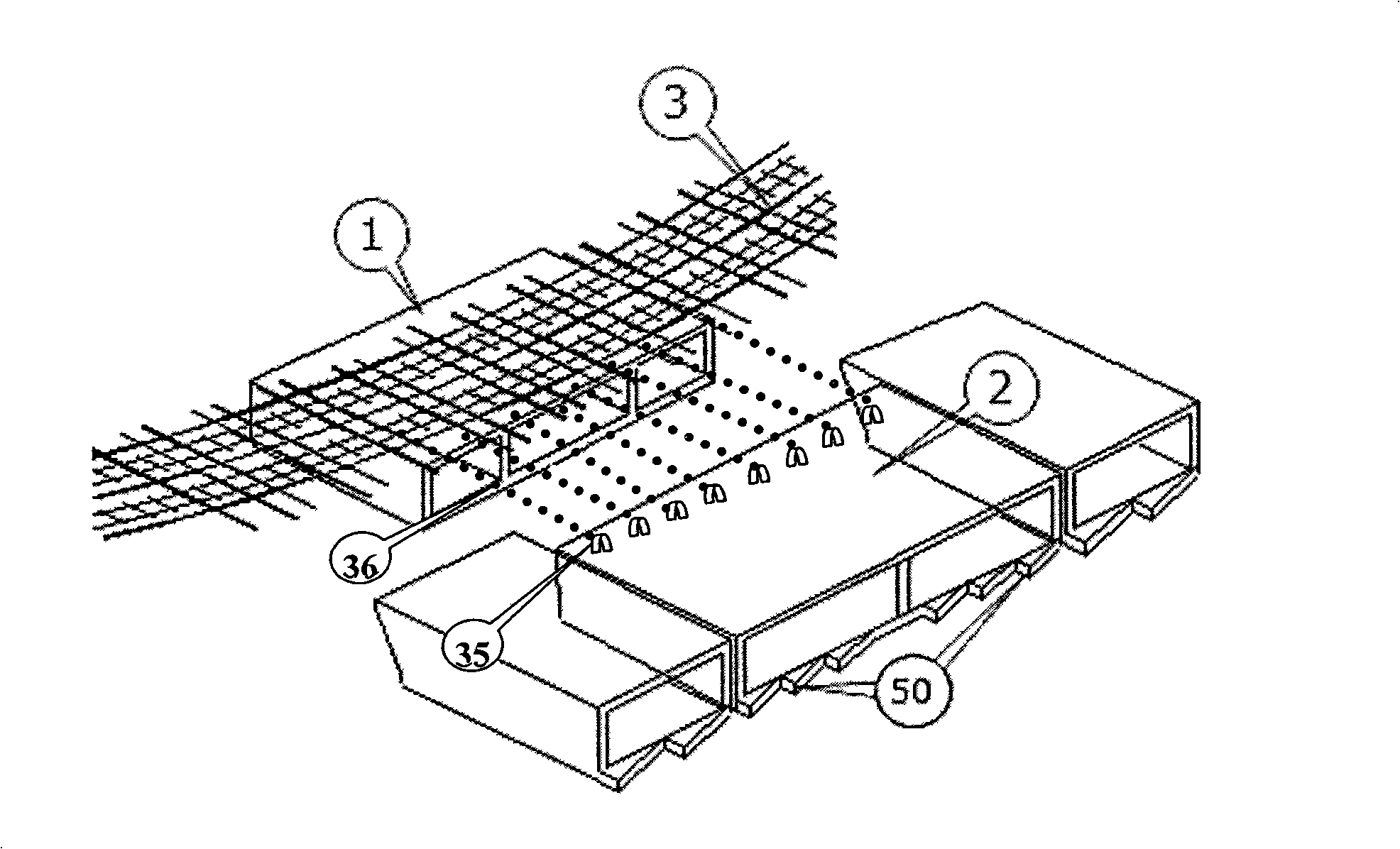

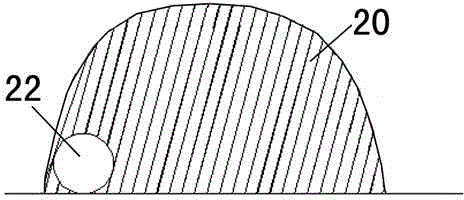

Construction method for replacing old frame bridge by new frame bridge in existing railway lines

InactiveCN101343861AEase of ejectionImprove securityBridge erection/assemblyBridge strengtheningEngineeringSlurry

The invention relates to a construction method for the new frame bridge to replace the old frame bridge on the prior railway. The construction method comprises the required jacking force of the old frame bridge according to the formula; the prior railway line is strengthened; the line strengthening system and the reinforcing steel drawing ring are tightened through a jack; the lately supplemented triangular blocks is arranged at the rear end of the bottom plate of the old frame bridge; a cantilever bracket is arranged; a new bridge back is arranged, and a jacking column and a jacking pickaxe are respectively arranged between the new frame bridge and the new bridge back and between the old frame bridge and the cantilever bracket; a plurality of thixotropic slurry holes are formed on the both sides of the old frame bridge and the bottom surface of the bottom plate, and thixotropic slurry is filled into the thixotropic slurry holes; the old frame bridge is jacked out; when the old frame bridge is jacked out, the new frame bridge is jacked in. Under the precondition that the railway operation is not interrupted, the construction method can rapidly jacked the old frame bridge out, the application scope is wide, and the construction method can not be limited by time and space. In addition, because the conventional reinforcement method of track lock plus the longitudinal and horizontal beam is adopted in the prior railway line, the construction method is suitable for various railway situations such as a straight line section and the curved line section, and the security is high.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

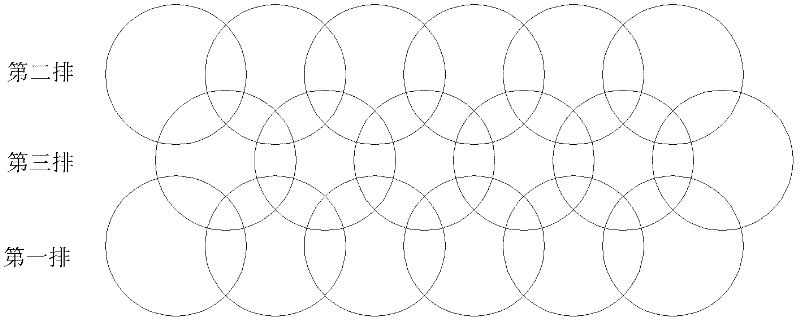

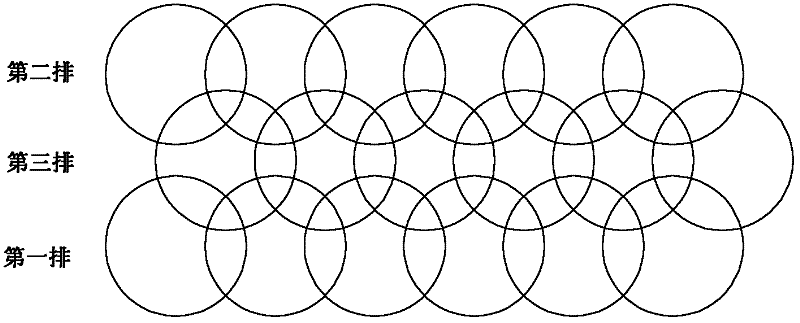

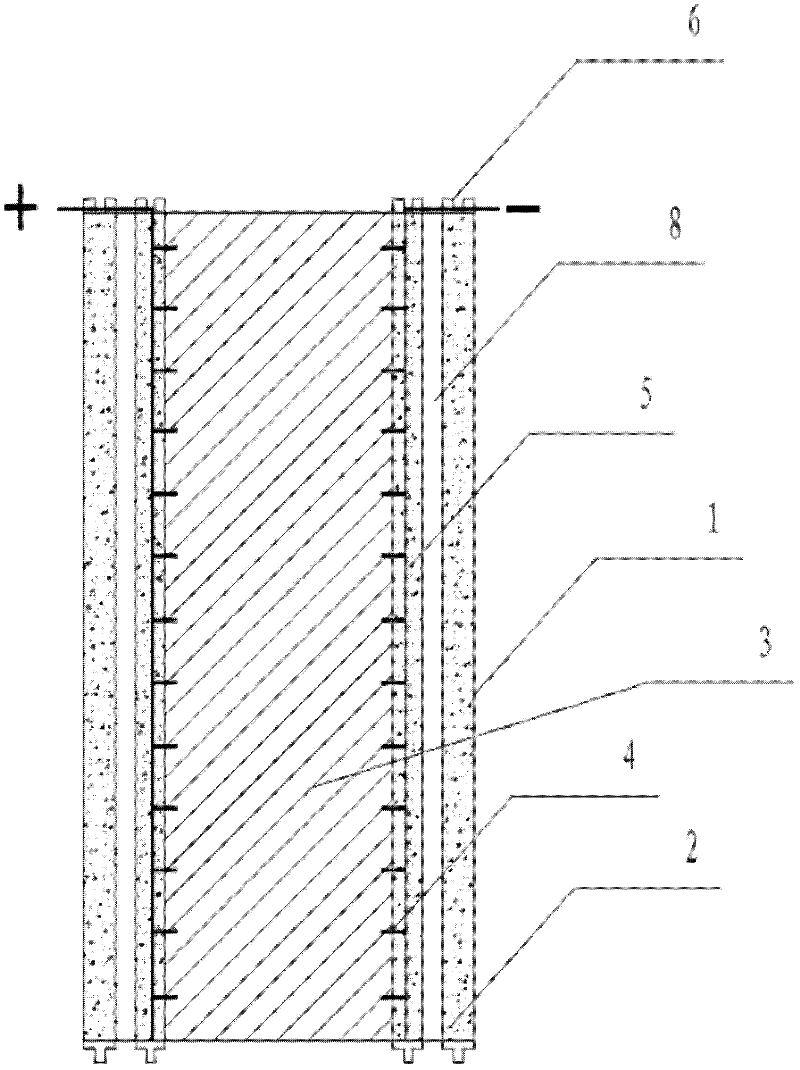

Construction method of water-stop curtain for double high-pressure rotary grouting piles

InactiveCN102286985AImprove water-stop reinforcement performanceHigh strengthExcavationsBulkheads/pilesSlurryHigh pressure water

The invention provides a method for constructing a water-stop curtain of a double-high-pressure rotary grouting pile, which is suitable for a water-stop curtain or foundation reinforcement of a deep foundation pit in a soil layer with a depth of 30 to 60 m. The method includes the following steps: construction of a water-stop curtain; Selection of design parameters; selection of dual high-pressure jet grouting piles and construction parameters. The effect of the invention is that the double-high-pressure rotary spraying method increases the slurry pressure on the basis of the traditional triple-tube rotary spraying method, and sprays and punches the soil body again to form a larger diameter and fill. It solves the technical problem that traditional techniques cannot form piles in 40-60m ultra-deep foundation treatment, and forms a vertical water-stop curtain through interlocking piles, which has been successfully applied in deep foundation pit anti-seepage, water-stop and foundation reinforcement. The performance of water stop reinforcement in ultra-deep foundation treatment is improved, the strength and impermeability of the pile body are improved, and the construction cost is reduced.

Owner:NO 4 ENG CO LTD OF CCCC FIRST HARBOR ENG CO LTD

Method for building subway station

InactiveCN102505706ASolve problems such as standardized temporary protectionEnsure stabilityArtificial islandsExcavationsCovering systemRoad surface

The invention discloses a method for building a subway station, and the method comprises the following construction steps of: sorting underground pipelines, and carrying out diversion on the pipelines needing diversion; modifying traffic guide; constructing a foundation pit enclosure structure; constructing a cover system, and taking part of a constructed cover plate as a half cover part; recovering a temporary pavement on the constructed cover plate; excavating a foundation pit, carrying out suspension treatment on the pipelines which are not moved away, and transporting the soil body excavated from the open cut part out from the foundation pit; constructing a main body structure of the station, and lifting material and constructors to pass in and out from the open cut part; and backfilling earthwork, dismounting the cover system and recovering a pavement.

Owner:BEIJING MUNICIPAL CONSTR

Heat insulating and preserving ceramic composite plate with decorative properties

ActiveCN102877614AReduce construction costWith thermal insulationCovering/liningsClaywaresCeramic compositeInsulation layer

The invention discloses a method for producing a heat insulating and preserving ceramic composite plate with decorative properties, comprising the following steps: preparing the powder of a decorative layer; preparing the powder of a heat insulating and preserving layer; loading the powder in a ceramic sagger in the secondary distribution way; sintering in a roller kiln in one time without drying and moulding by a ceramic pressing machine; demoulding, polishing and finishing the decorative surface, and determining the thickness and shape of the heat insulating and preserving surface by mechanical dry cutting. By the joint reaction of the ultrafine foaming agent, the dolomite, the diatomaceous earth and the polishing slag at high temperature, the heat insulating and preserving plate filled with tiny closed pores can be formed. The product has high strength, strong penetration resistance and lower thermal conductivity than the existing ceramic heat preserving material and has the characteristics of low production energy consumption, good decorative effect and prominent heat preservation, heat insulation and sound insulation effects.

Owner:FOSHAN RONGZHOU NO 2 BUILDING CERAMICS FACTORY

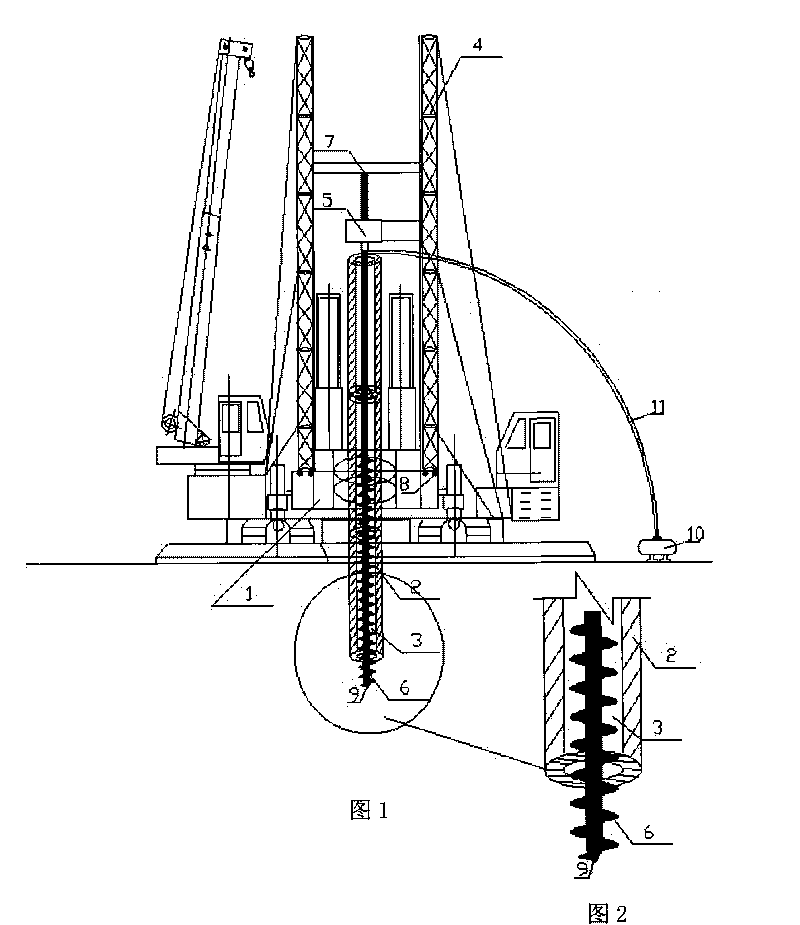

Static sunken pile construction technique for alternatively, sectionally and gradually spirally leading hole and statically sinking pile in pipe

InactiveCN101725146ADoes not affect bearing capacityDoes not cause tiltBulkheads/pilesMaximum pressureDrill pipe

The invention relates to an automatically leading hole and statically sinking pile method for alternatively, sectionally and gradually spirally leading hole and statically sinking pile in pipe, and further relates to a PHC pipe pile static pile sinking device. The automatically leading hole and statically sinking pile method for alternatively, sectionally and gradually spirally leading hole and statically sinking pile in pipe comprises: leading hole to a foundation 7 by a drilling rod 6 in a hollow hole 3 in the PHC pipe pile 2 when the PHC pipe pile 2 cannot be sunken at the maximum pressure by a static pile pressing machine 1; then statically sinking the PHC pipe pile 2; and repeatedly and alternatively operating until the PHC pipe pile 2 is sunken to part with level as designed. Making use of the method, the obvious problem that the geology hard layer cannot be penetrated in the way of static pressing PHC pipe pile can be solved, specifically the difficult problem that thick and deep grit layer cannot be penetrated; other subordinate contamination can be prevented in construction process of the method; excellent construction condition can be kept; the hole will not fall off when leading hole, and the leading hole failure phenomenon can be prevented.

Owner:江守慈

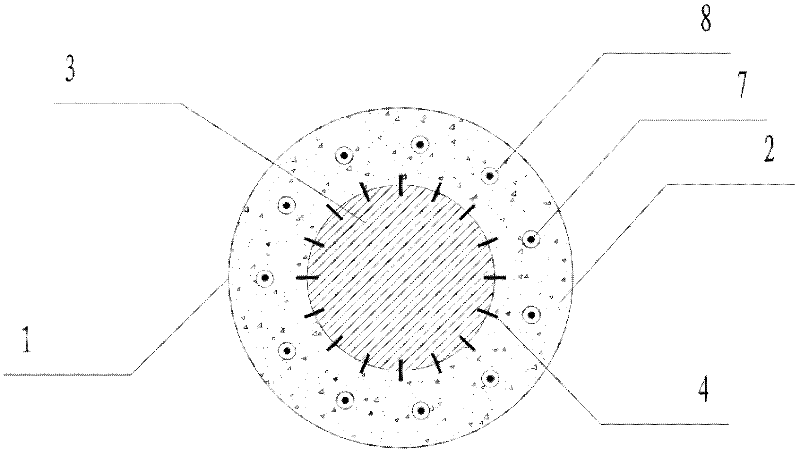

Novel precast concrete pipe die and construction method thereof

InactiveCN102373803ARealize the use functionReduce usageStrutsForms/shuttering/falseworksPre stressEngineering

The invention discloses a novel precast concrete pipe die, which is a precast concrete pipe pile of a hollow structure. The wall of the precast concrete pipe die is internally provided with annular and vertical reinforcing steel bars, the inner surface of the pipe die is provided with dowel bars connected with post-poured concrete into a whole and an electric heating wire for heating, the upper end and the lower end of the pipe die are provided with tooth-shaped connectors which are mutually matched, the wall of the pipe die is internally provided with preset pore canals for prestress reinforcing steel bars, and the pore canals are through longitudinally. A construction method of the novel precast concrete pipe die comprises the steps of: after positioning the precast concrete pipe die, switching on a power supply of the electric heating wire, and performing high-dropping self-compacting concrete pouring on the middle of the concrete pipe die; and after a first section of cylinder core of the pipe die is poured, performing hoisting positioning and concrete pouring on a second section of the concrete pipe die. The invention has the advantages that by precasting the concrete pipe die, the special requirement on the use functions of a concrete column surface and a column template can be met, and the heating functions of the novel precast pipe die can also ensure the smooth construction in winter; and the novel precast concrete pipe die and the construction method thereof have the advantages of simplicity and rapidness for construction, less required construction equipment, and capability of greatly reducing the construction cost and the comprehensive manufacturing cost.

Owner:TIANJIN UNIV

Rapid rescuing method for tunnel gateway collapse

The invention discloses a rapid rescuing method for tunnel gateway collapse. The rapid recuing method comprises the following steps: I, installing spiral excavation pipe-jacking pipe curtain construction equipment provided with a spiral excavation function and an oil cylinder jacking function, and capable of simultaneously performing spiral excavation operation and oil cylinder jacking operation at a safety area in an excavated tunnel hole; II, arranging at least one steel tube capable of passing through a person on the bottom of a gateway collapse area in an the excavated tunnel by virtue of the spiral excavation pipe-jacking pipe curtain construction equipment, introducing the steel through into a construction operation area of the excavated tunnel after passing through the gateway collapse area, and forming an escape channel by the steel tube; III, directing the staff in the construction operation area to escape to the safety area from the escape channel. The invention belongs to a novel-use invention of the known product, the spiral excavation pipe-jacking pipe curtain construction equipment is transferred and applied to a tunnel collapse manual rescuing direction from the tunnel forepoling construction direction, so that the complexity of the tunnel collapse rescue is greatly lowered, and the tunnel collapse rescue speed is increased.

Owner:BEIJING SHOUER ENG TECH

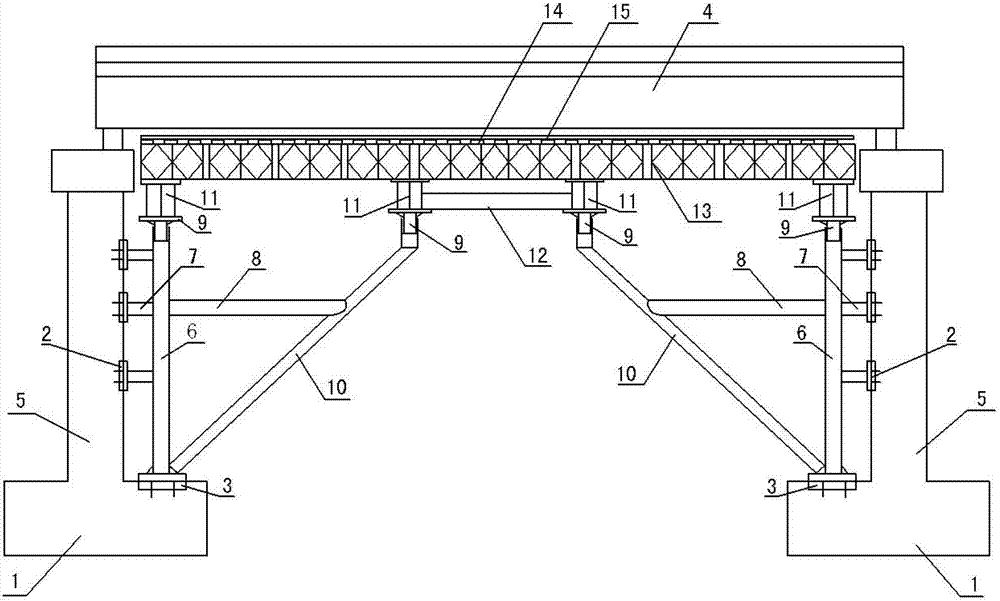

Large-span non-floor type cast-in-place beam falsework and construction method thereof

ActiveCN103243652AFlexible structureEasy to assemble and disassembleBridge erection/assemblyFalseworkContinuous beam

The invention discloses a large-span non-floor type cast-in-place beam falsework and a construction method thereof. The large-span non-floor type cast-in-place beam falsework is characterized in that two side supports are symmetrically arranged on two side bearing platforms and piers used for bearing a cast-in-place beam, embedded bearing platform steel plates are arranged at the top of the concrete bearing platforms via foundation bolts, embedded pier steel plates are respectively arranged at different height on side portions of the concrete piers via foundation bolts, vertical steel tube columns and bracket side stays are respectively arranged on the embedded bearing platform steel plates, and vertical pier column connecting steel tubes are arranged at different height between the embedded pier steel plates and the vertical steel tube columns, and horizontal bracket supports are arranged between the vertical steel tube columns and the bracket side stays, sand cylinder disassembling top caps are respectively arranged at the top of the vertical steel tube columns and the bracket side stays, double-spliced H-shaped steel is arranged on the sand cylinder disassembling top caps, and Bailey beams are arranged on the double-spliced H-shaped steel. The large-span non-floor type cast-in-place beam falsework is used in construction of cast-in-place continuous beams and continuous steel structures, foundation treatment can be omitted, and construction cost and safety risks in construction are reduced.

Owner:中铁二十四局集团安徽工程有限公司 +1

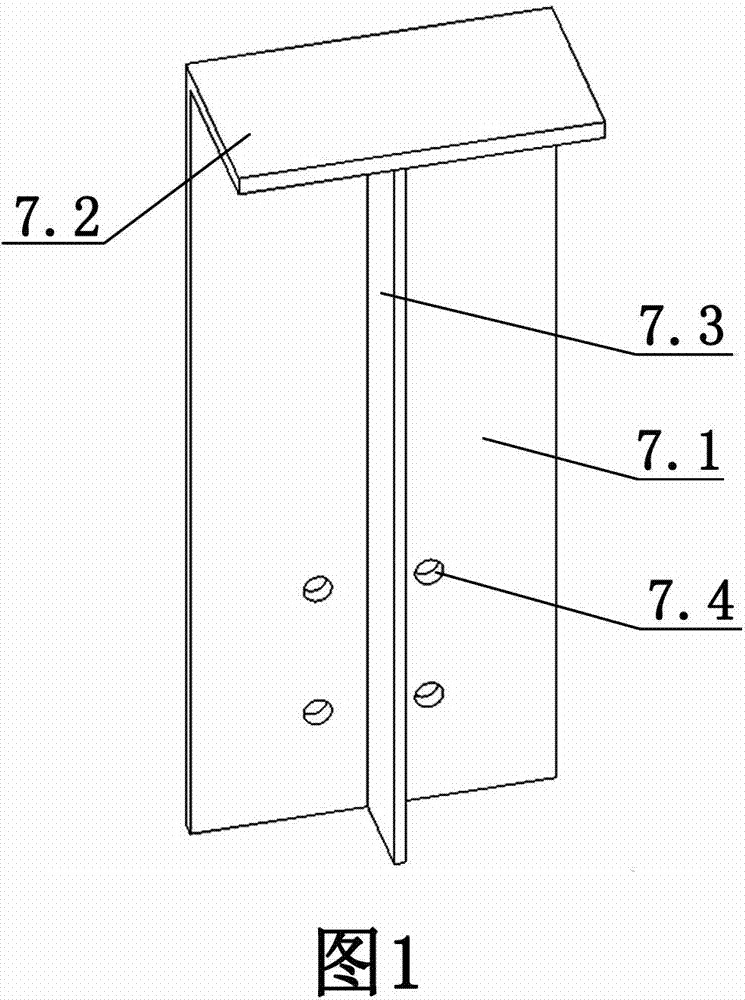

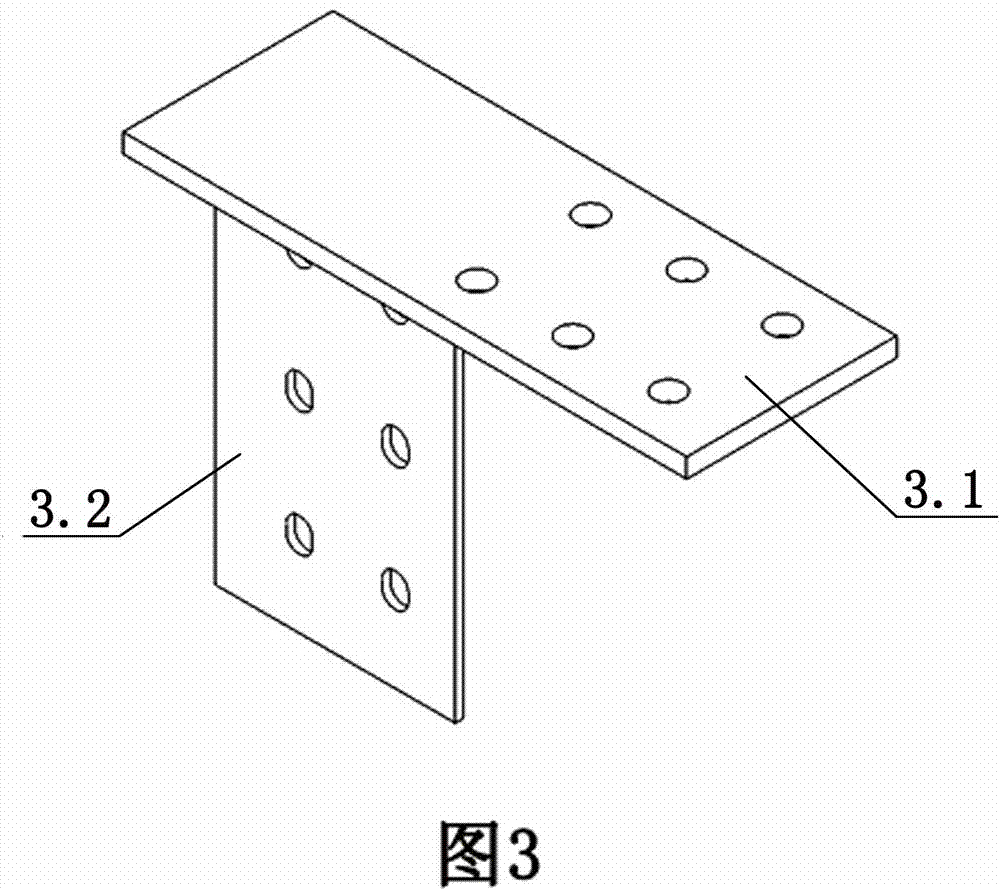

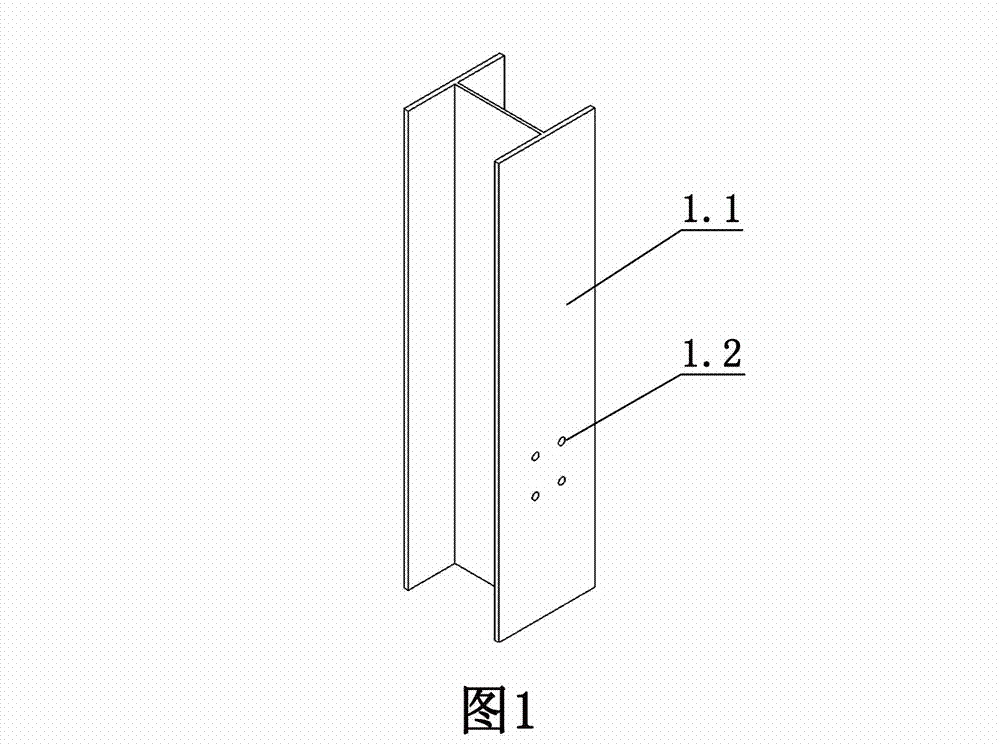

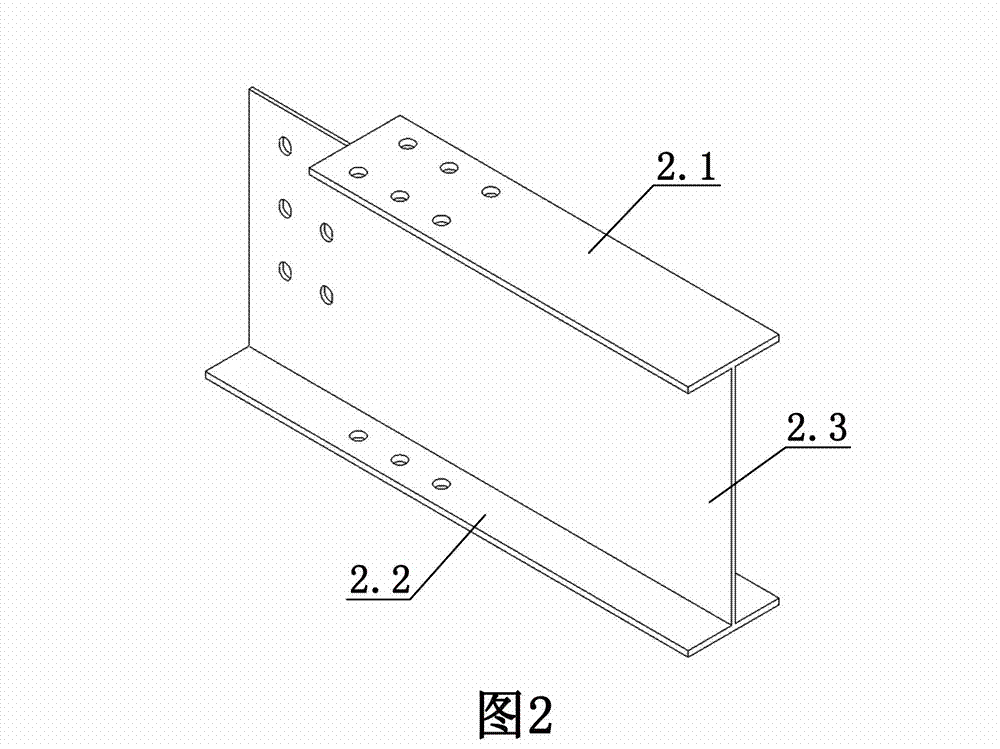

H-shaped steel beam and H-shaped steel column minor axis variable beam height fabricated node and construction method thereof

InactiveCN102733492AMeet the requirements of prefabricated constructionHigh node stiffnessBuilding material handlingSteel columnsMinor axis

The invention discloses an H-shaped steel beam and H-shaped steel column minor axis variable beam height fabricated node and a construction method thereof. The node comprises an H-shaped steel column, an H-shaped steel beam, a column sealing piece, a T-shaped connection piece, an L-shaped connection piece and bolts. The column sealing piece consists of a column sealing plate, a beam upper flange stiffening rib and a column sealing plate stiffening rib; the T-shaped connection piece consists of an upper flange plate connection plate which is arranged horizontally and a web connection plate which is perpendicular to the bottom surface of the upper flange plate connection plate; the L-shaped connection piece consists of a lower flange plate connection plate which is arranged horizontally and a column connection plate which is perpendicular to the lower flange plate connection plate downward. All accessories required by the node are prefabricated in a factory, the requirement of equal-strength connection in the process of changing the section of the H-shaped steel beam in a certain range can be met, high-strength bolts are adopted by a construction field node so as to realize the fabricated connection, and the node is high in rigidity and high in connection speed, and can meet the requirement of the fabricated construction of a steel structure.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

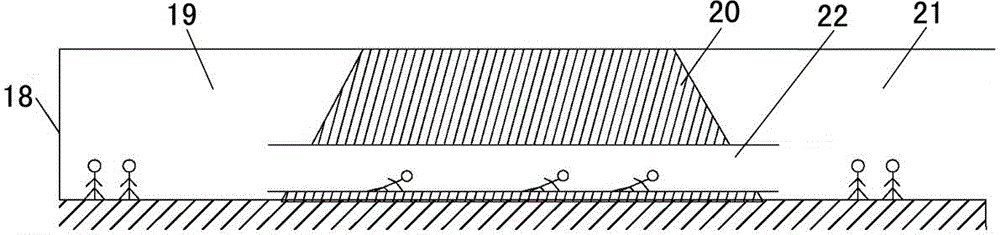

Geocell reinforced rubber particles-sand mixture compound shock insulation layer and strip

The invention discloses a geocell reinforced rubber particles-sand mixture compound shock insulation layer and strip, which belongs to the technical field of structure shock absorbing and shock insulation, and is mainly used for solving the problem of serious destructions of a general multi-story building in an earthquake. According to the invention, the compound shock insulation layer and strip are manufactured by the filling and layered punning of rubber particles-sand mixture mixed by an optimal mix proportion in geocell inner layers; the shock insulation layer is arranged at the bottom of a base; shock insulation strips are arranged on two sides of the base; the geocell is a geotechnique material which can be bought easily and is low in cost; the rubber particles are rubber fragments with certain particle diameters, and are obtained by the mechanical fragmentation of junked tires; the sands are ordinary river sands used for construction. The shock insulation layer and strip have good shock insulation effect, low cost, environmental protection, simple structure, and convenience in construction, and is generally suitable for the compound shock insulation technology of the multi-story building; the technical scheme can effectively solve the problems of bad shock resistance and serious destructions of a low story dwelling in a town, and has a wide application prospect.

Owner:刘方成 +2

Prefabricated assembly type cover beam and construction method thereof

PendingCN108560402AEasy constructionReduce construction costBridge structural detailsBridge erection/assemblyPre stressPre stressing

The invention discloses a prefabricated assembly type cover beam and a construction method thereof. The prefabricated assembly type cover beam comprises a plurality of cover beam sections and threadedsteel rib connectors, wherein a plurality of threaded steel ribs are pre-buried in each cover beam section, the cover beam sections are spliced and assembled, and an operation slot hole is formed inthe spliced part, corresponding to the threaded steel rib, between each two adjacent cover beam sections; and the threaded steel ribs of each two adjacent cover beam sections are spliced through one threaded steel rib connectors, and the threaded steel rib connector is accommodated in each operation slot hole. Compared with an existing cover beam formed by connecting three sections of structures through pre-stressed steel ribs and slip casting into a whole, the prefabricated assembly type cover beam has the advantages that the threaded steel ribs and the threaded steel rib connectors are standard products and do not need to be customized and machined by virtue of special equipment, so that the construction is simplified, and the construction cost is lowered; and by utilizing a mechanical connection manner, the subsequent construction can be carried out on the cover beam without waiting, so that the construction period is shortened.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

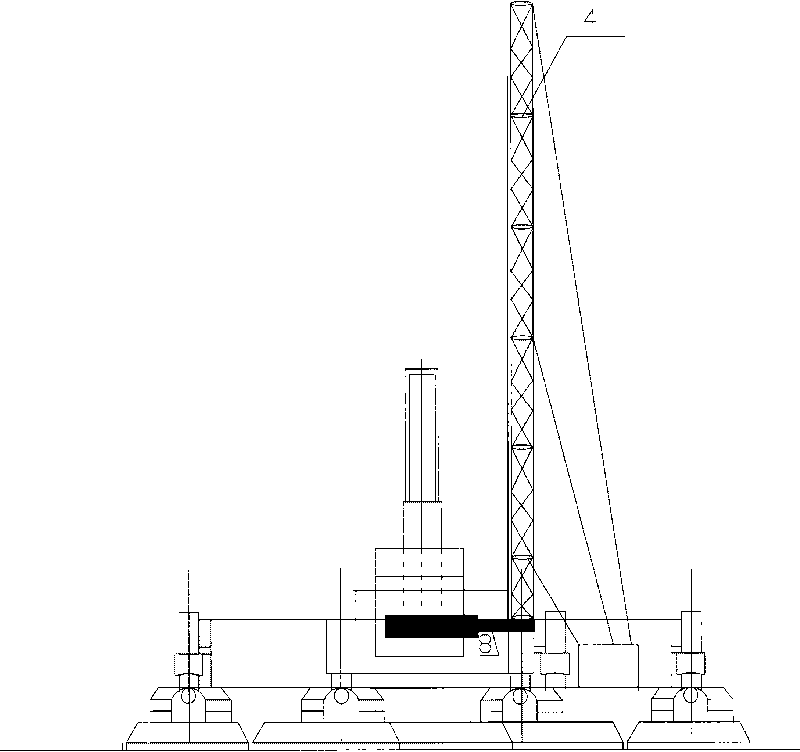

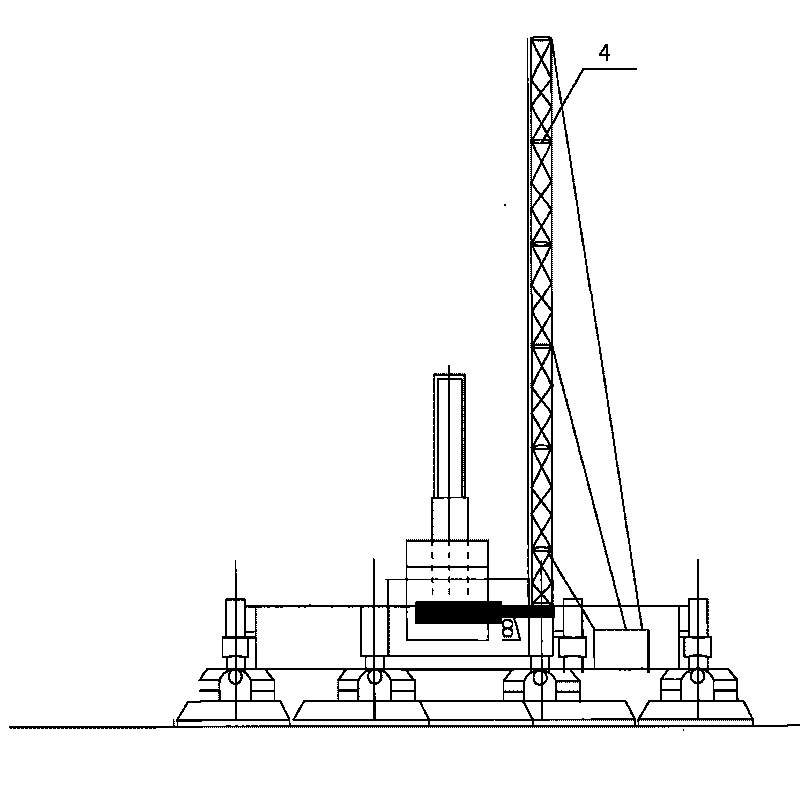

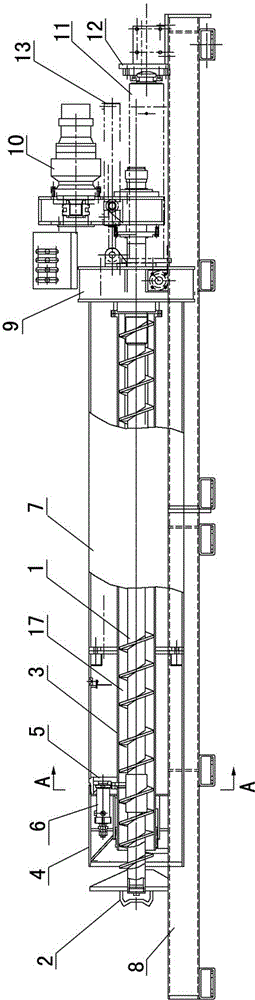

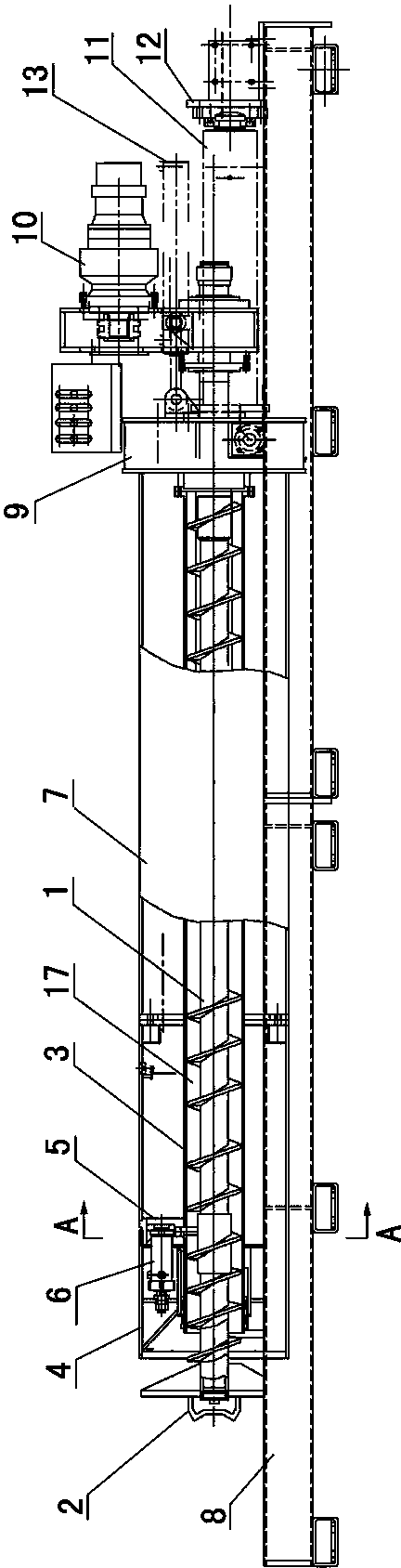

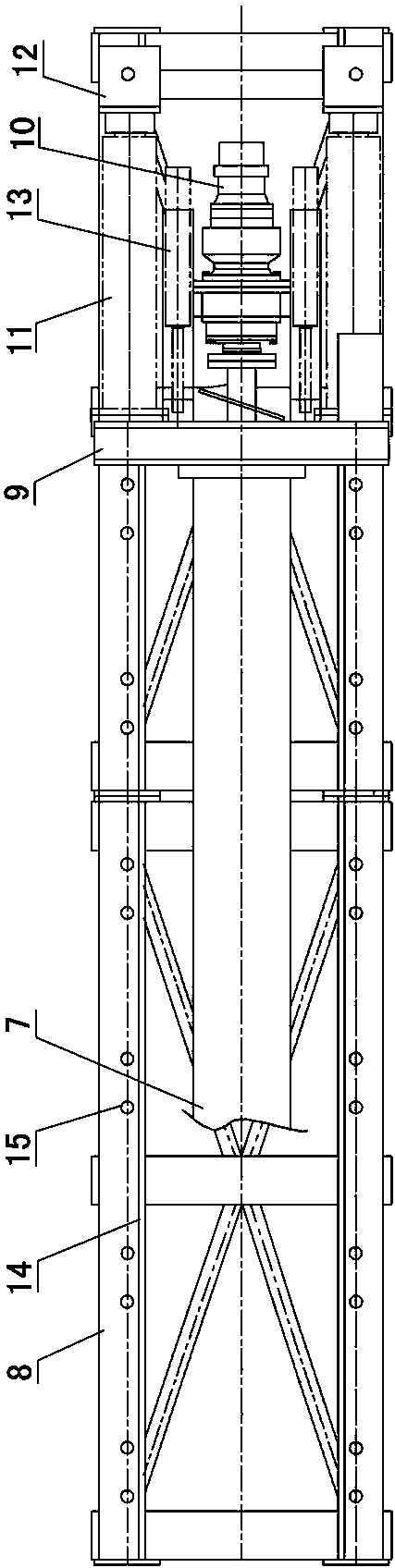

Spiral-unearthing pipe-jacking pipe curtain construction method and device

ActiveCN103590833AReduce disturbanceImprove construction accuracyDrilling rodsTunnelsArchitectural engineeringSteel tube

Provided are a spiral-unearthing pipe-jacking pipe curtain construction method and device. The method comprises the steps that the step 1, foundation pits and a site are prepared; the step 2, the spiral-unearthing pipe-jacking pipe curtain construction device and an electric welding machine are installed and debugged; the step 3, a common drill, a guide head, a stub, deviation correction oil cylinders, an initial-section spiral drill pipe, an initial-section outer sleeve and an initial-section pipe curtain steel pipe are installed on the spiral-unearthing pipe-jacking pipe curtain construction device; the step 4, a hole-entering angle is regulated; the step 5, drilling and jacking are conducted; the step 6, lengthening is conducted; the step 7, drilling, jacking and lengthening are circulated; the step 8, the common drill, the guide head, the stub and the deviation correction oil cylinders are dismounted at the position of the receiving foundation pit; the step 9, disassembly is circulated; the step 10, the spiral-unearthing pipe-jacking pipe curtain construction device is moved to a second hole, and the steps 3-10 are repeated; the step 11, in this way, construction of pipe curtain steel pipes of all other holes is finished. The method for combining spiral unearthing and oil cylinder jacking is adopted, disturbance in stratums is small, and construction accuracy is high.

Owner:BEIJING SHOUER ENG TECH

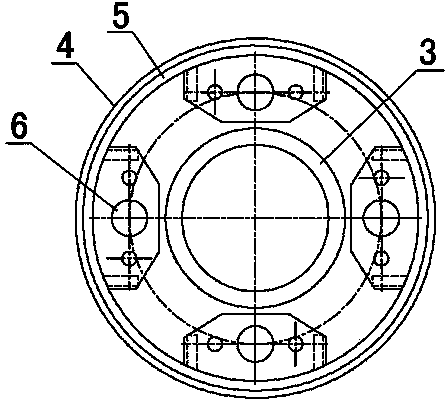

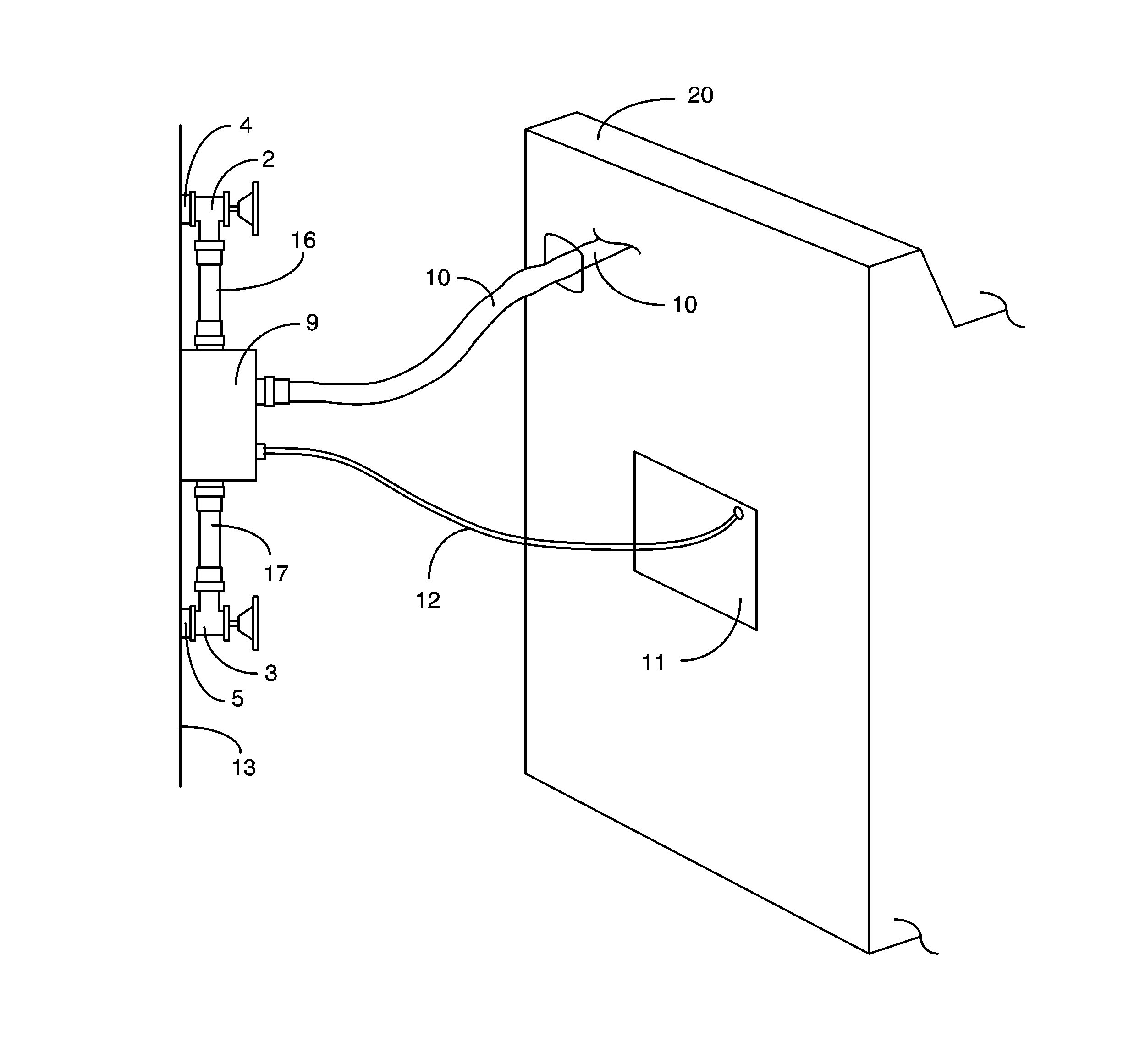

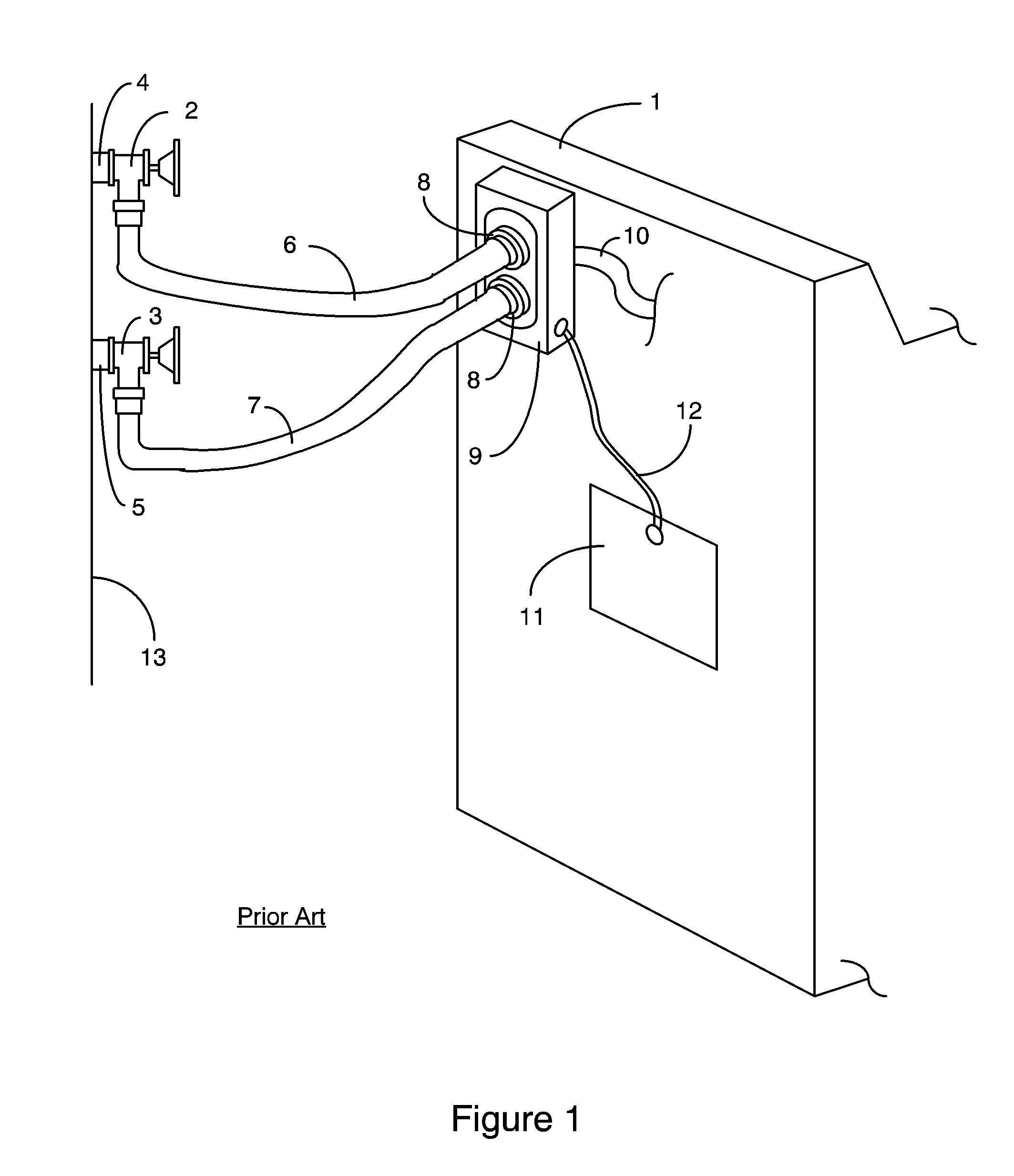

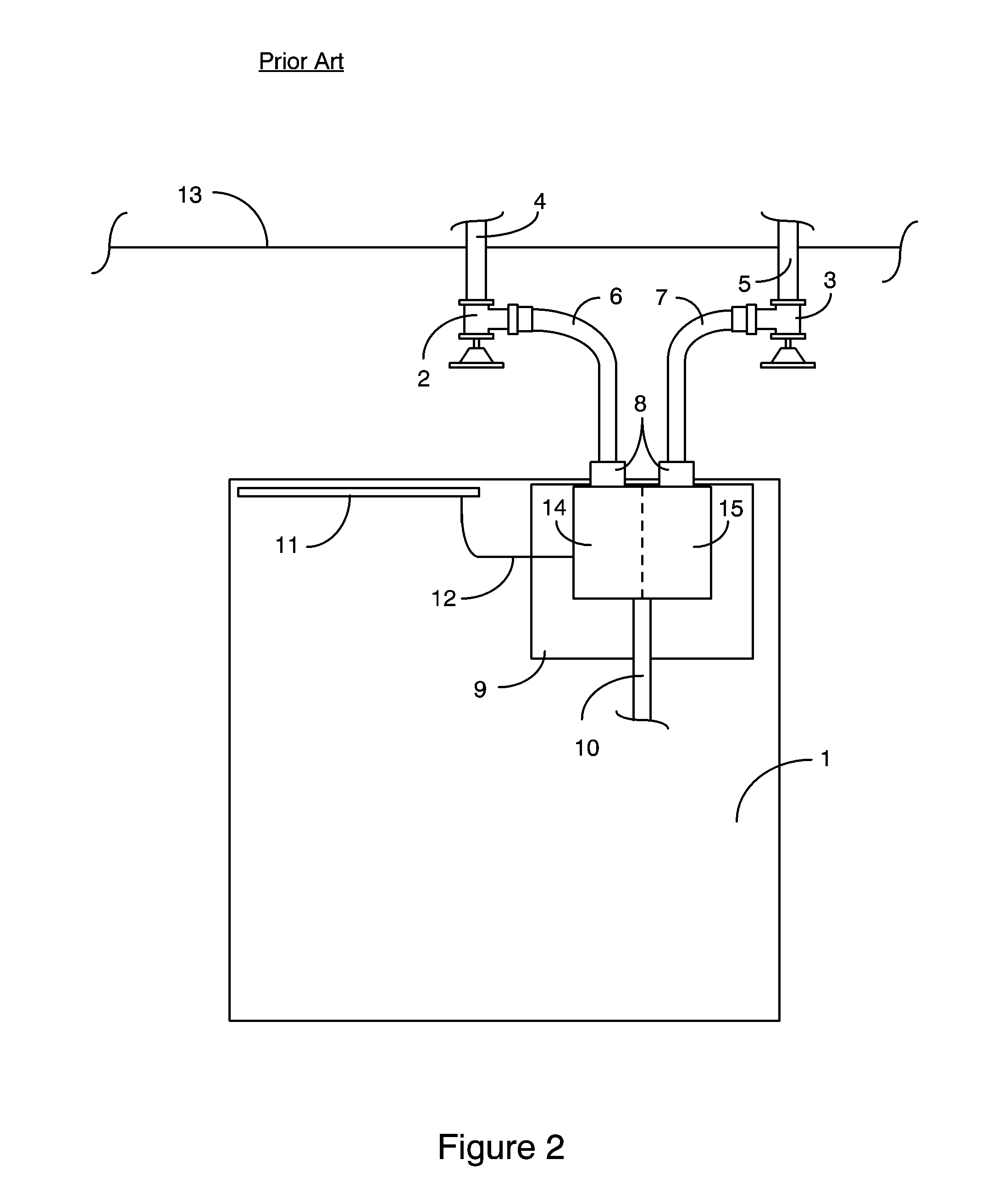

Apparatus And Method For Supplying Hot, Cold Or Mixed Water To A Washing Machine Using A Single Water Supply Hose

InactiveUS20110041561A1Reduce construction costReduce operating costTemperature control without auxillary powerValve arrangementsEngineeringBackflow

A washing machine with a single input hose for both hot and cold water. The solenoid-operated water mixing valve assembly has a direct attachment to the hot and cold water supply valves. A flexible hose connects the washing machine to the solenoid-operated water mixing valve assembly. When the washing machine fill cycle begins, the solenoid-operated water mixing valve assembly is turned on and the water is output to the flexible hose. When the washing machine fill cycle ends, the water supply is turned off. The hot and cold water are mixed prior to input to the flexible hose, and as a result, only one flexible hose is required to supply water to the washing machine. The flexible hose is attached to the output of the solenoid-operated water mixing valve assembly and therefore is not under water pressure unless the washing machine is in a fill cycle. A vacuum breaker can be attached to the output of the solenoid-operated water mixing valve assembly to prevent backflow into the building water supply from the hose connection.

Owner:APEL ADAM

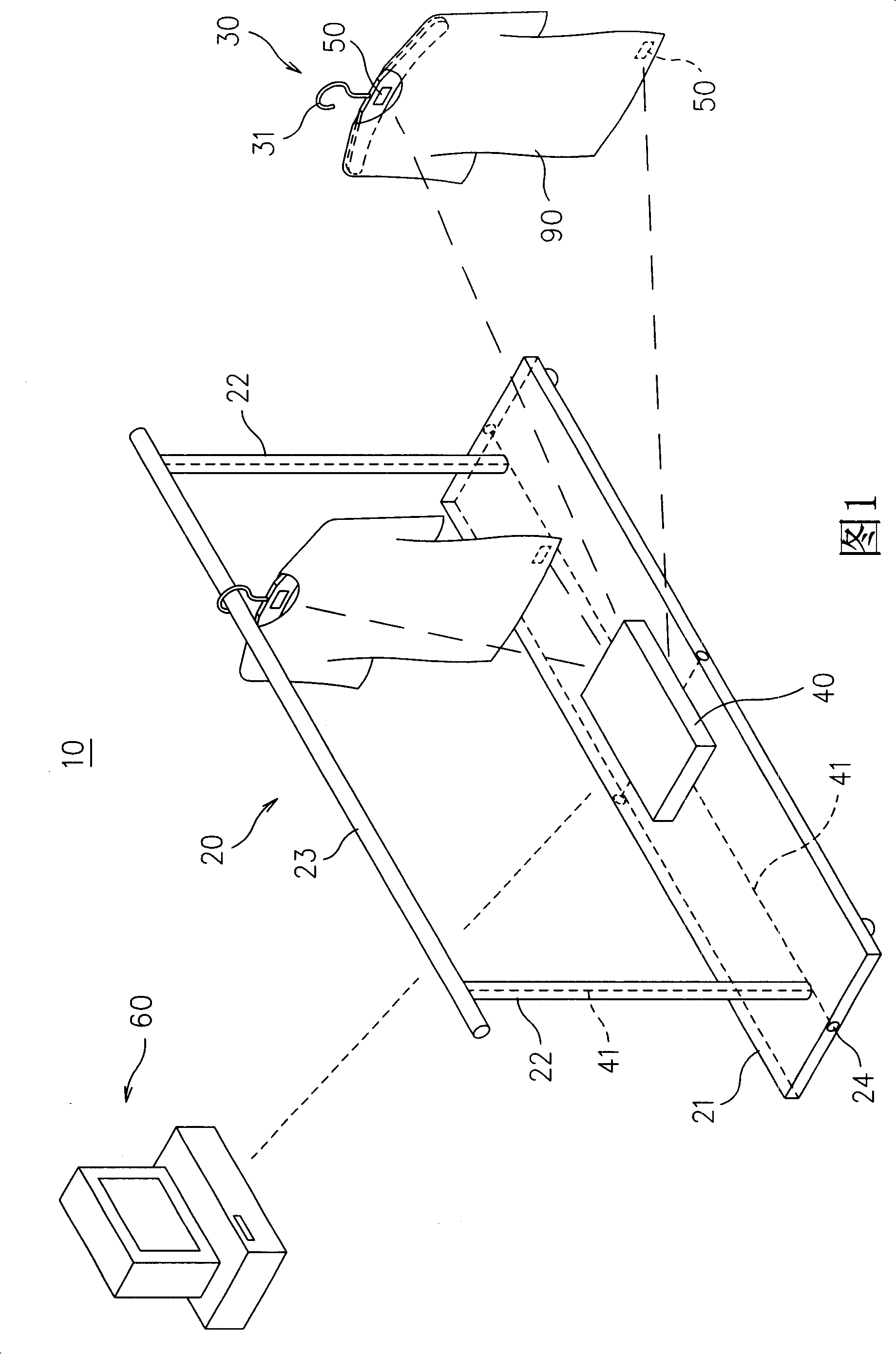

Intelligent exhibition frame

InactiveCN101204279AQuick assemblyReduce construction costSensing record carriersRecord carriers used with machinesData transmissionMoving parts

The invention discloses an intelligence demonstration frame, which substantially comprises at least one frame body and at least one moving part. The frame body is equipped with at least one radio frequency identification reader (RFIDReader) and an antenna. The moving part is equipped with a radio frequency identification tag (RFIDTag). The RFIDTag and the RFIDReader can be used for carrying out radio data transmission, and then the data is transmitted by the RFIDReader to the rear end management platform which is able to carry out a real-time position tracing and quantity management of the moving part.

Owner:IND TECH RES INST

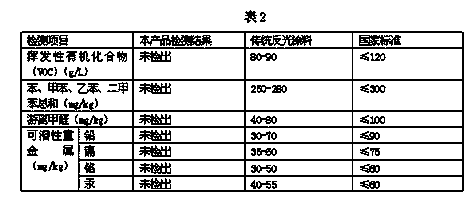

Environment-friendly reflective coating

ActiveCN103865391AImprove waterproof performanceImprove washabilityAntifouling/underwater paintsRosin coatingsWater basedEmulsion

The invention relates to an environment-friendly reflective coating, and belongs to the technical field of coatings. The coating is prepared from the following components in percentage by weight: 10-20% of rosin resin, 9-20% of an acrylic emulsion, 2-8% of an organic pigment, 2-4% of water-based color concentrate, 30-60% of reflective glass beads, 1-2% of a defoamer, 2-3% of a plant insect prevention bacteriostatic agent, 2-5% of ethanol and 10-20% of water. The fineness of the reflective glass beads is 400-450 meshes. The environment-friendly reflective coating has good waterproofness and washability, and is bright and lasting in color, high in reflective rate, non-poisonous, environment-friendly and safe to use.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

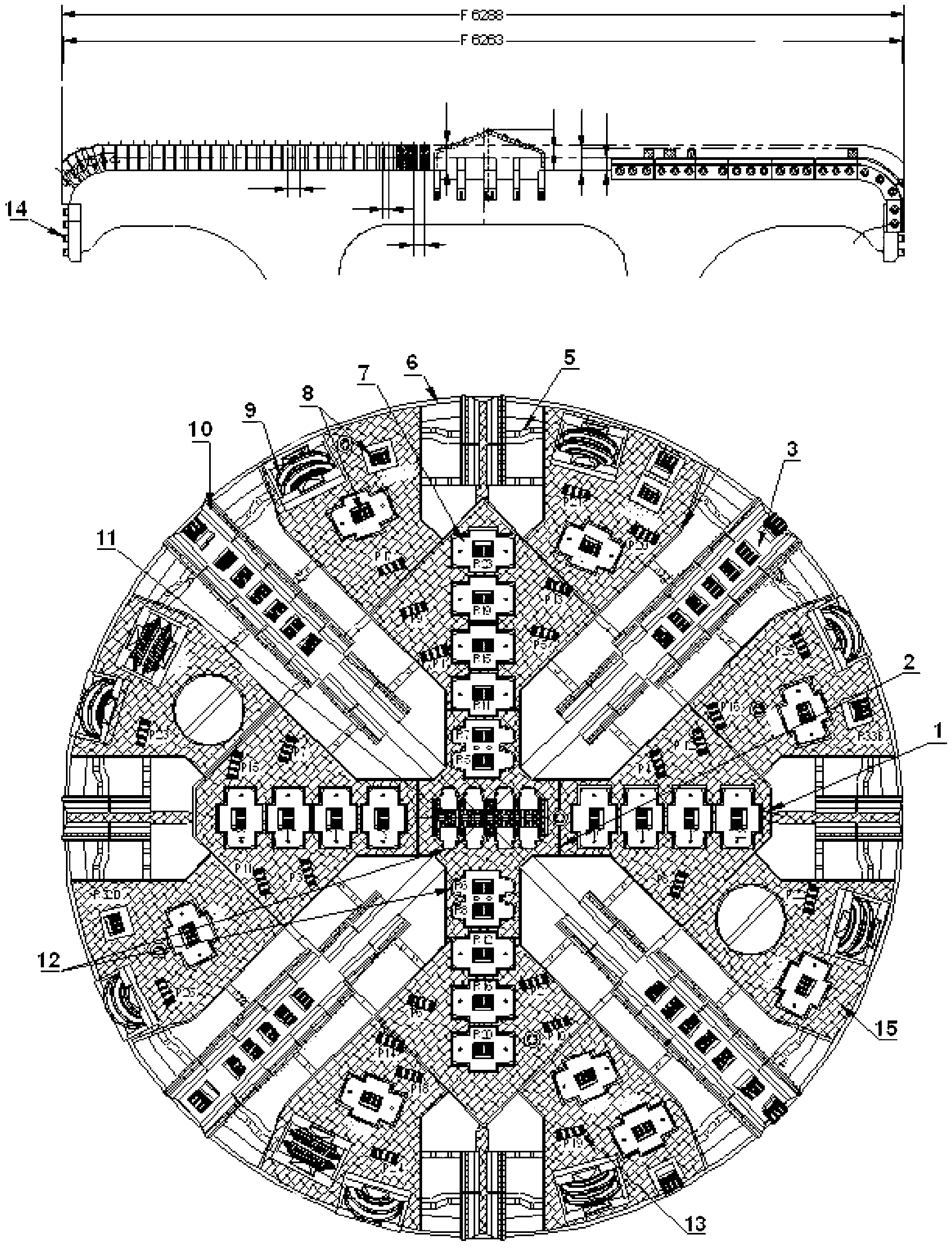

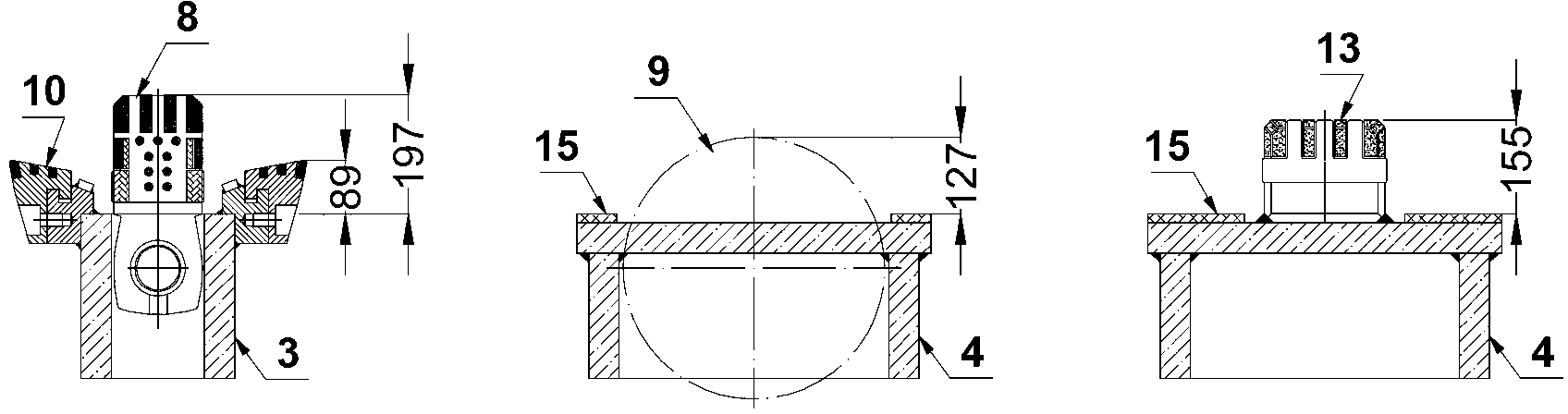

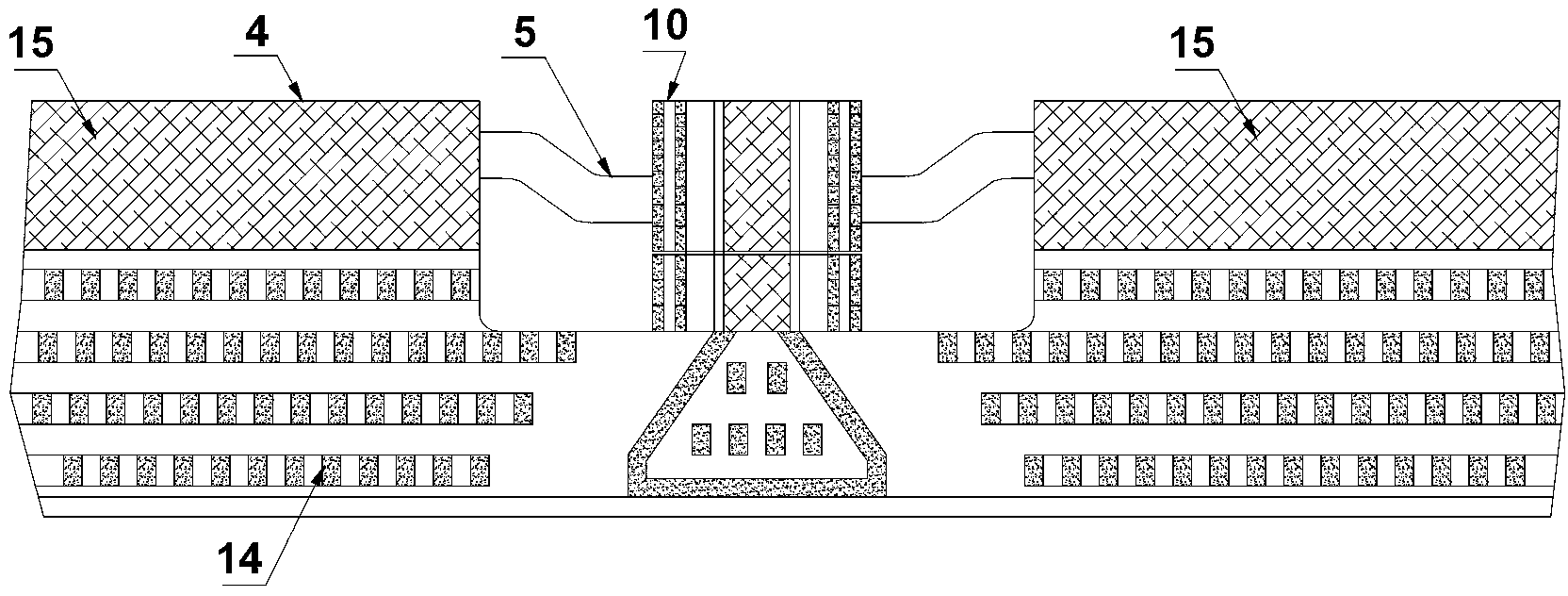

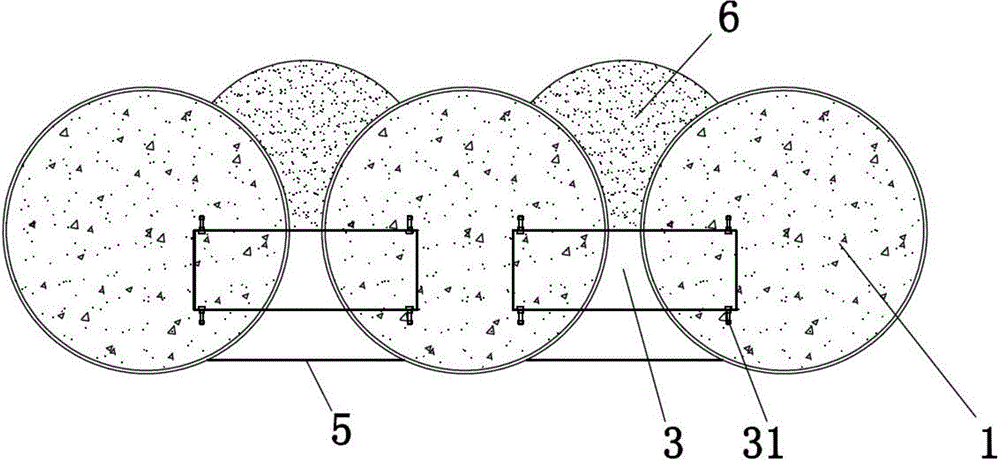

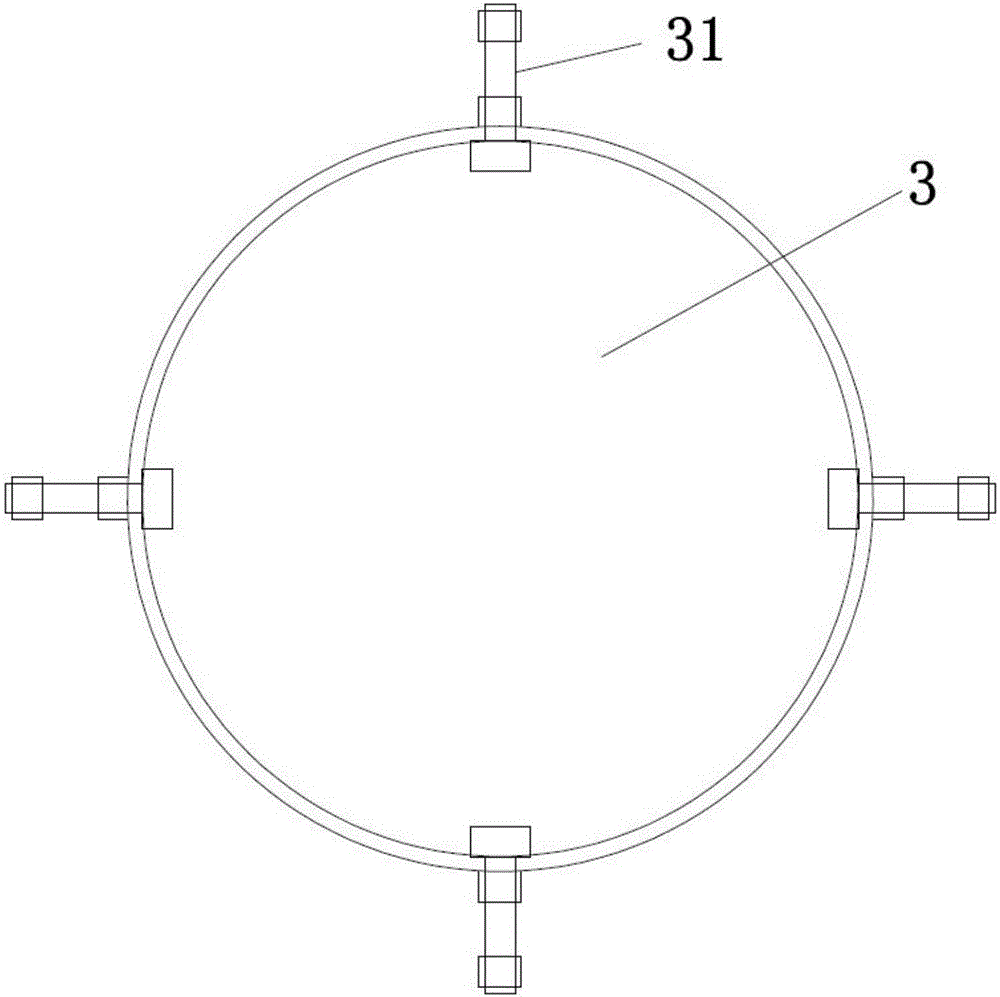

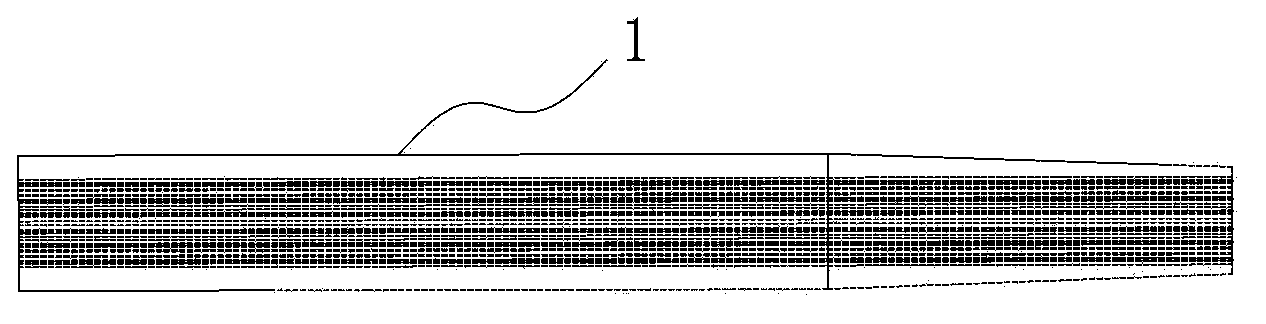

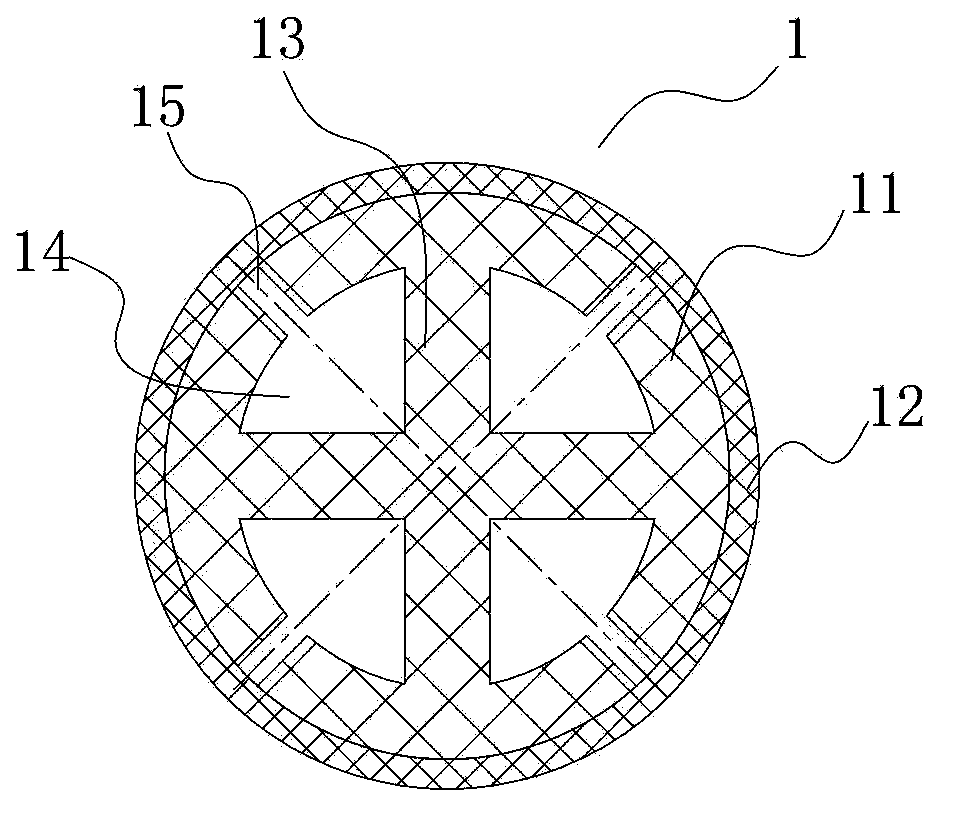

Shield tunneling machine cutter disc used for enriching large-particle-size boulder stratum

The invention relates to a shield tunneling machine cutter disc used for enriching the large-particle-size boulder stratum. The shield tunneling machine cutter disc comprises a cutter disc body and a cutter tool, wherein the circular cutter disc body is structurally provided with four main rib plates which are mutually vertical and crossed in the center position of the cutter disc body, the upper surfaces of the four main rib plates form a main rib plate disc surface, meanwhile, four spokes which are mutually vertical and crossed in the center position of the cutter disc body and are in 45-degree alternate arrangement with the four main rib plates are simultaneously arranged, and the main rib plates are mutually connected with the spokes through steel grids and are welded with the outer circumference annular steel plate of the cutter disc body for forming a penal type shield cutter disc. A heavy tearing cutter, a disc-shaped rolling cutter and a cutter disc panel reinforced protection cutter are fixedly arranged above the main rib plate disc surface, the heavy tearing cutter and a scraping cutter are fixedly arranged above the spokes, a fishtail cutter or a duplex disc-shaped rolling cutter is arranged in the center position of the cutter disc body, a stripped reinforced protection cutter is welded on the outer side of the outer circumference annular steel plate of the cutter disc body, and the outer surface of the cutter disc body is fully paved and welded with the high-intensity chromium carbide wear-resistance steel plate.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO

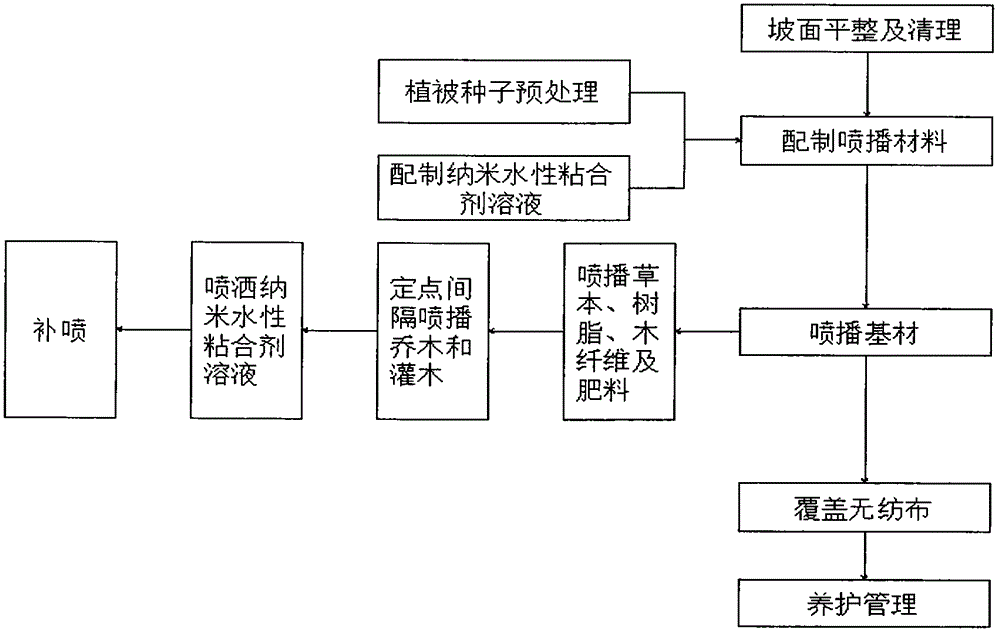

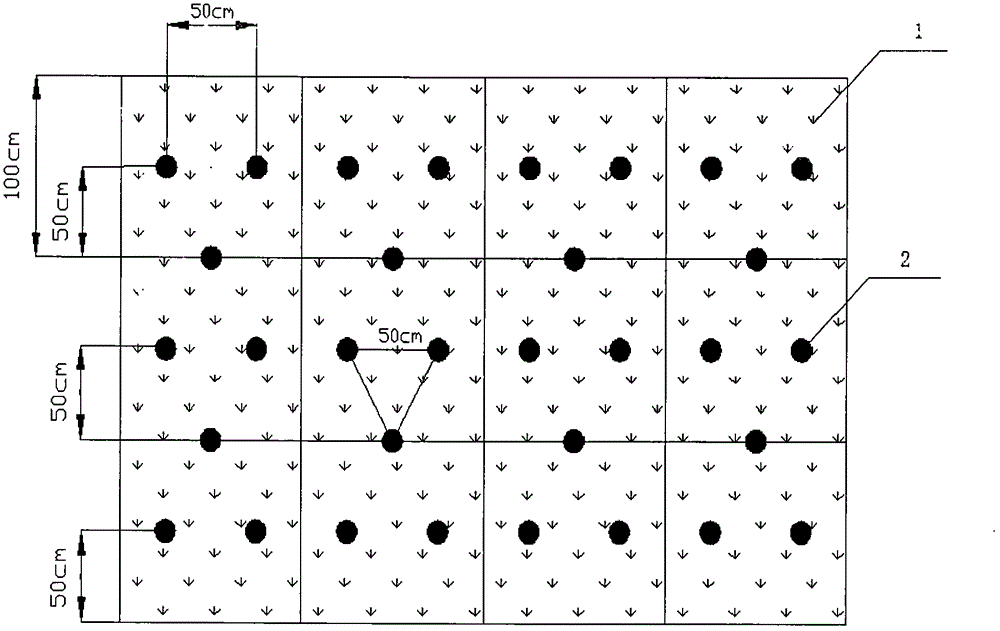

Side slope water and soil conservation and ecological restoration technology based on function materials

InactiveCN104782374AWide variety of sourcesNo pollution in the processExcavationsHorticultureFiberSuper absorbent

The invention relates to a side slope water and soil conservation and ecological restoration technology based on function materials. According to the materials and ratio needed by the technology, 10-15 g / m<2> of nanometer aqueous binder, 60-80 g / m<2> of super absorbent resin, 40 g / m<2> of plant seeds, 35-40 g / m<2> of compound fertilizer particles, 225-250 g / m<2> of wood fibers and 13 g / m<2> of non-woven fabric are included. The technology comprises the steps that a hydraulic spray-sowing process is adopted, after the herbaceous plant seeds, the resin, compound fertilizer and the wood fibers are evenly mixed and spray-sown to the slope surface, tree and shrub plant seeds, compound fertilizer, wood fibers and the like are configured for fixed-point spray-sowing, then nanometer aqueous binder solutions are spray-sown, and finally the non-woven fabric is used for covering and maintenance. The technology has the advantages that the source of the adopted raw materials is wide, environment protection is achieved, pollution is avoided, the price is low, and operation is easy. The two adopted function materials have the good soil fixation and root cultivation effects. According to the adopted plant spray-sowing construction process, the plant spray-sowing cost can be effectively saved, and the plant water and soil conservation and ecological restoration benefits are improved.

Owner:SUN YAT SEN UNIV

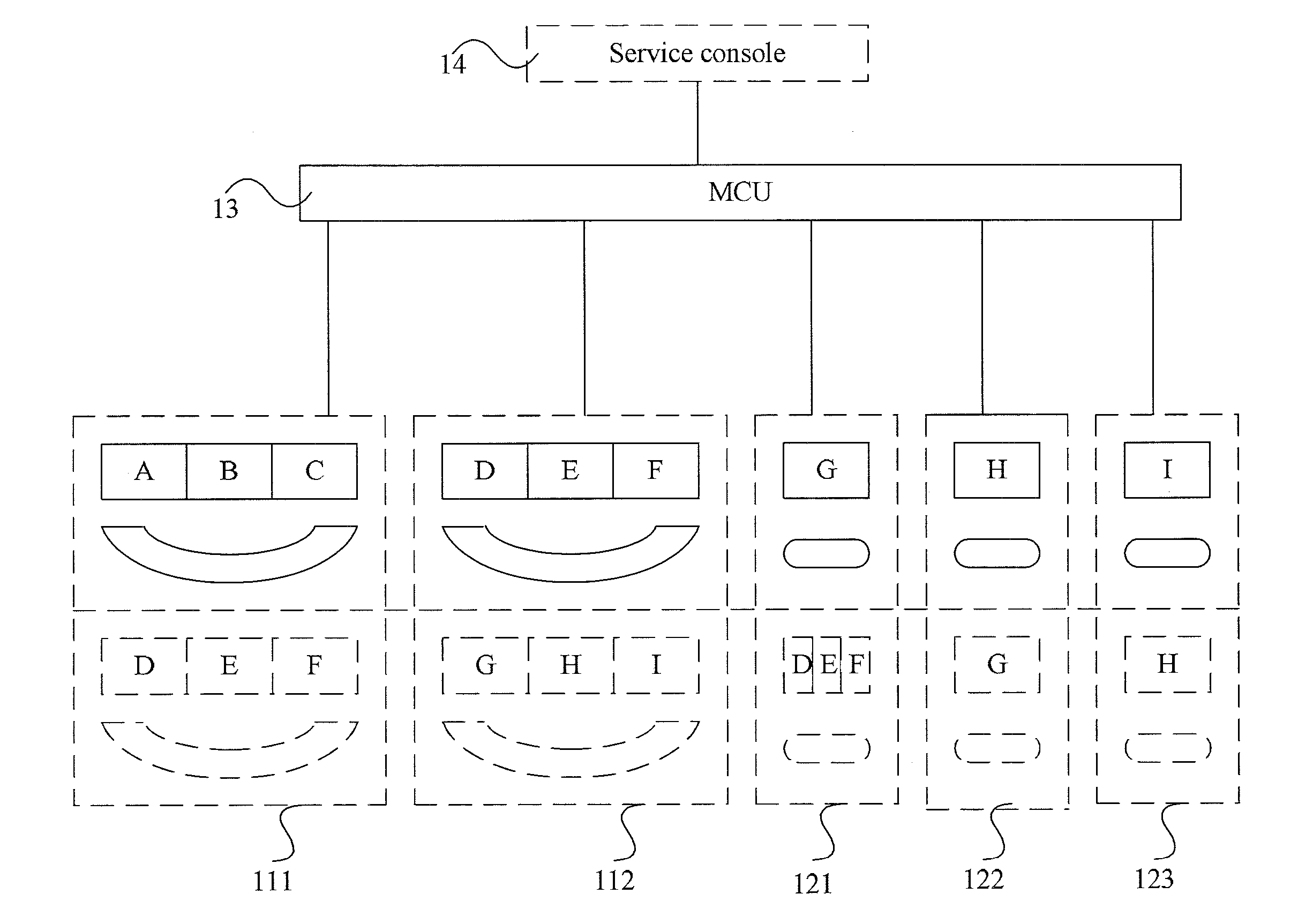

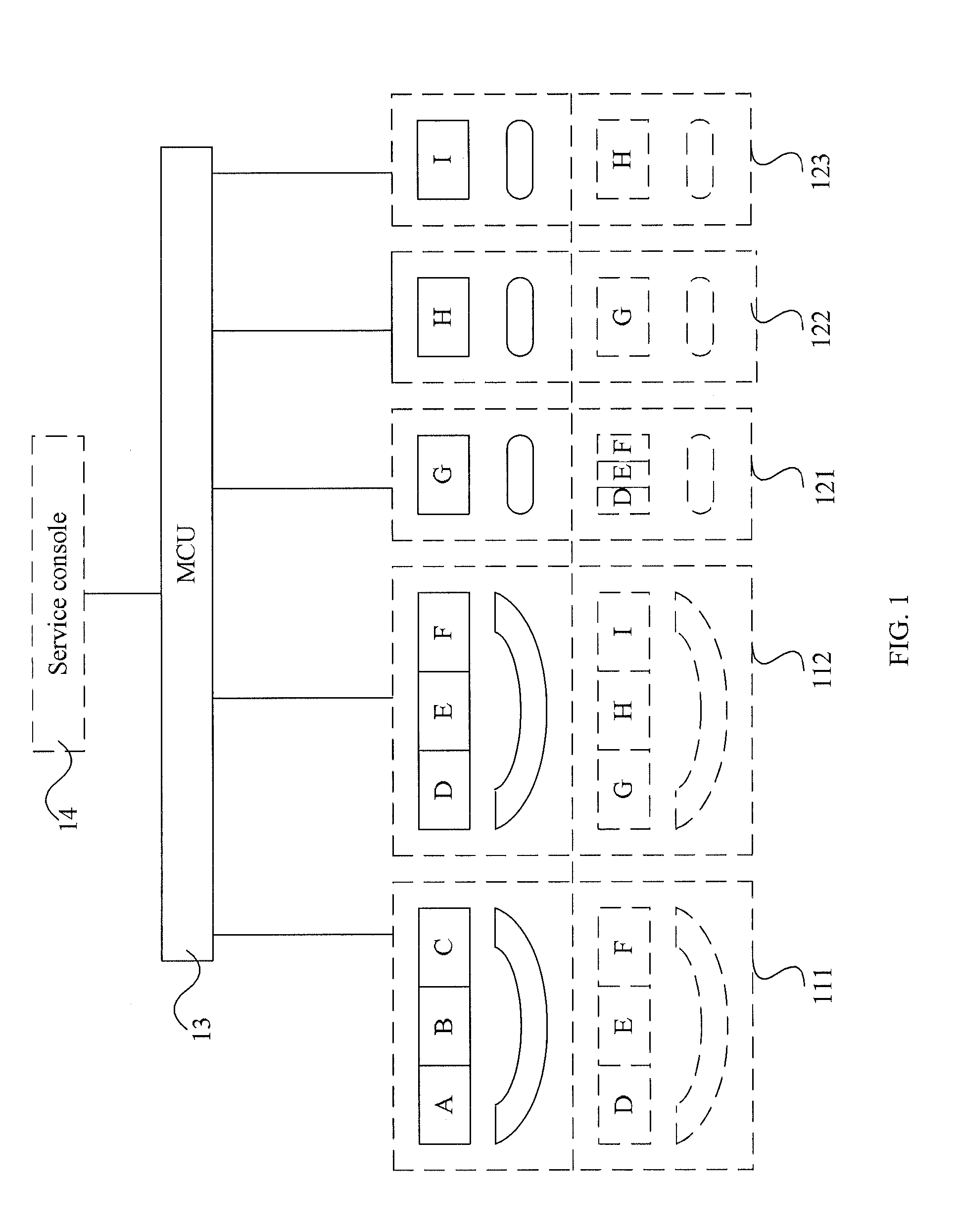

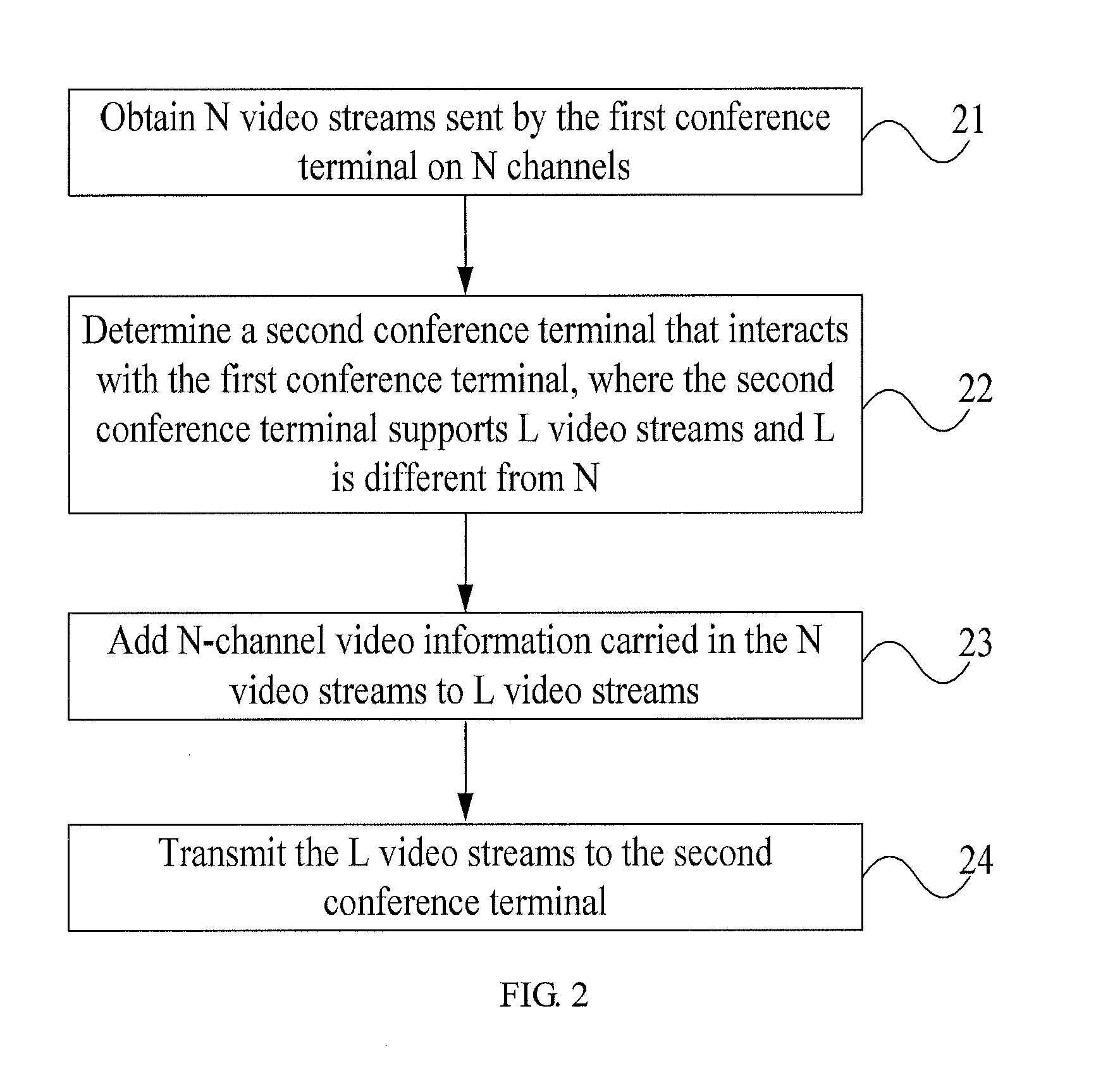

Video and audio processing method, multipoint control unit and videoconference system

InactiveUS20110261151A1Reduce construction costReduce construction costsTelevision conference systemsSpecial service for subscribersInteroperability ProblemN channel

The present invention discloses a video processing method, an audio processing method, a video processing apparatus, an audio processing apparatus, a Multipoint Control Unit (MCU), and a videoconference system. The video processing method includes: obtaining N video streams sent by a first conference terminal on N channels; determining a second conference terminal that interacts with the first conference terminal, where the second conference terminal supports L video streams, and L is different from N; adding N-channel video information carried in the N video streams to L video streams; and transmitting the L video streams to the second conference terminal. The embodiments of the present invention implement interoperability between the sites that support different numbers of media streams, for example, telepresence sites, dual-stream sites, and single-stream sites, thus reducing the construction cost of the entire network.

Owner:HUAWEI DEVICE CO LTD

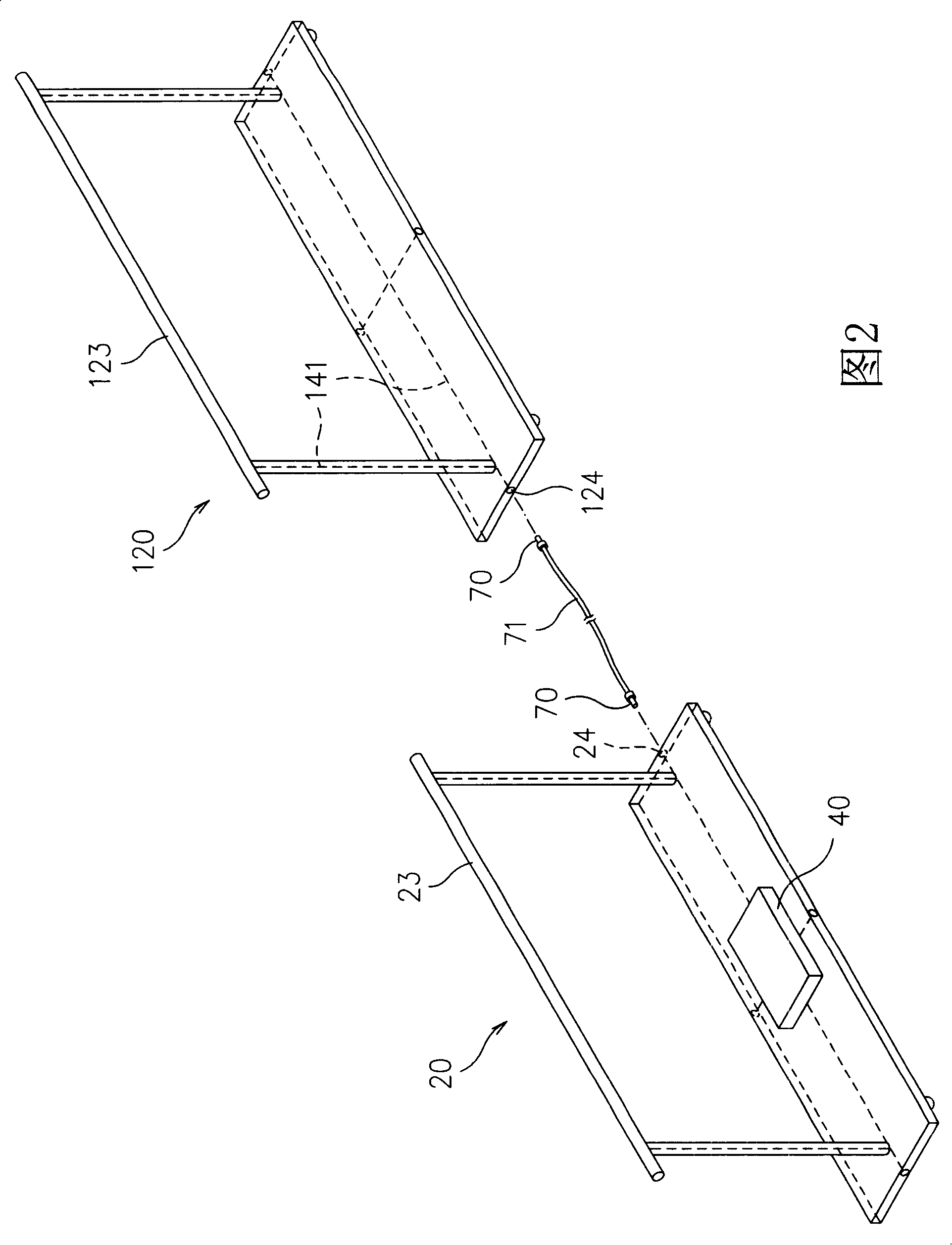

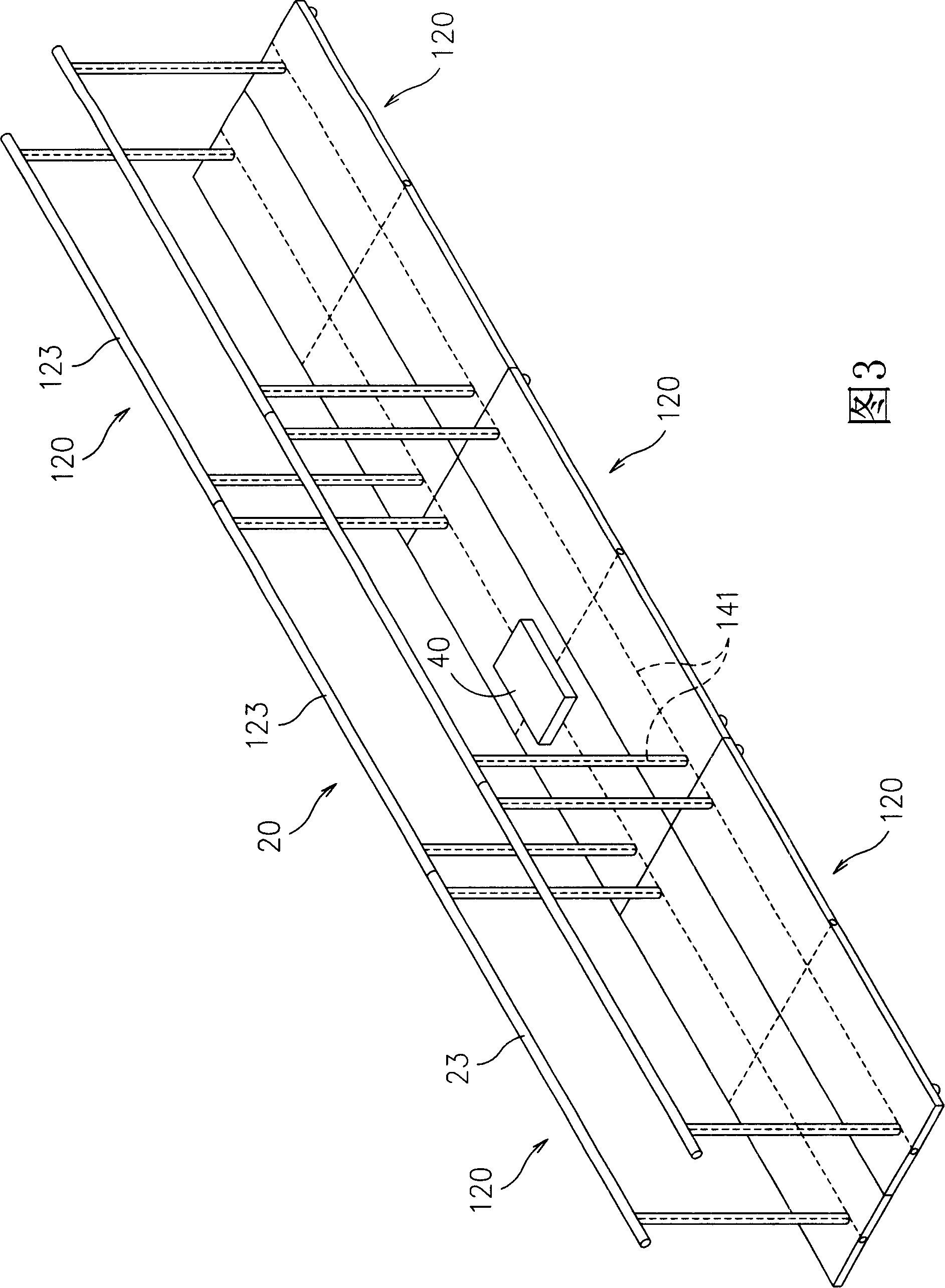

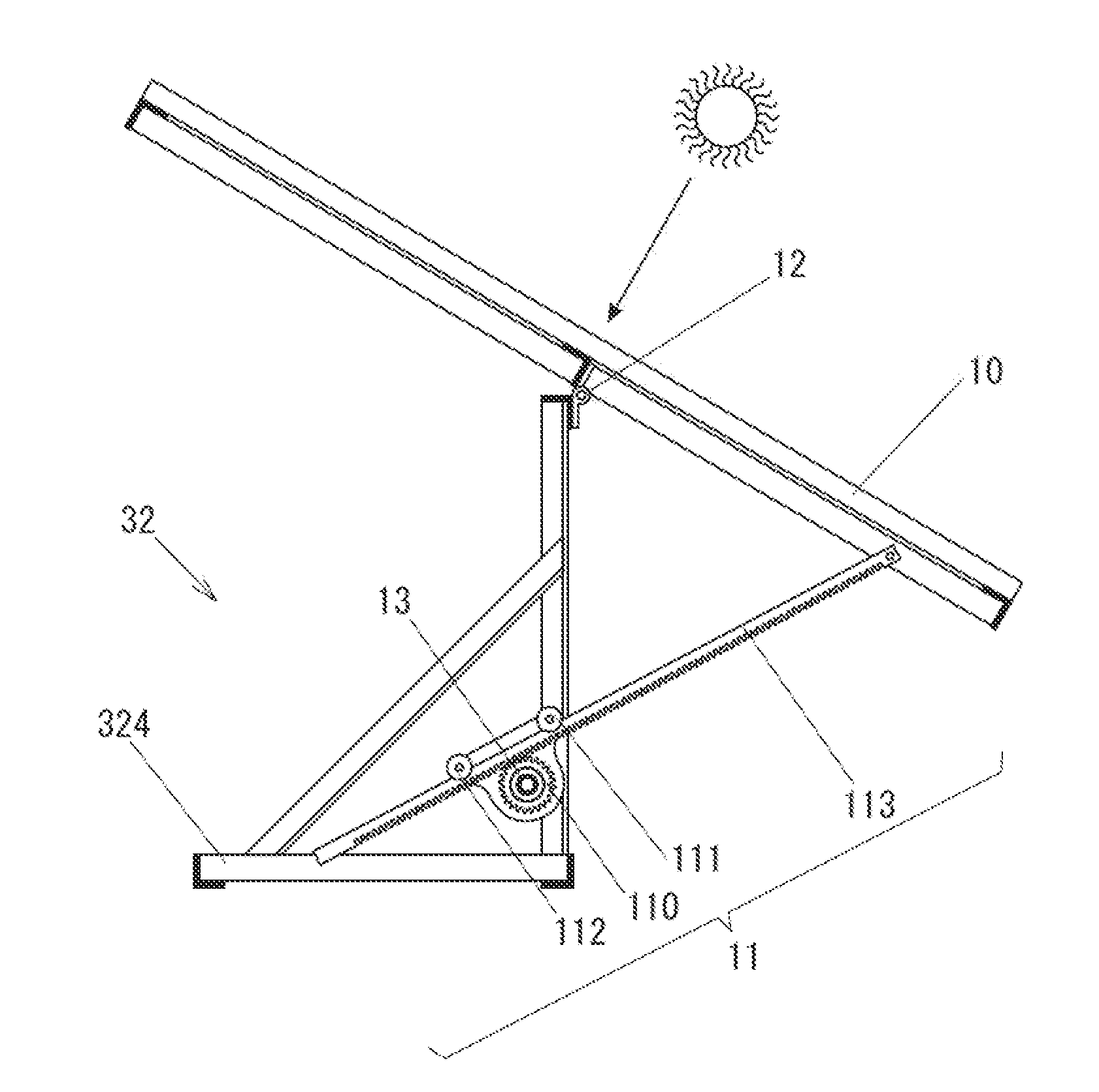

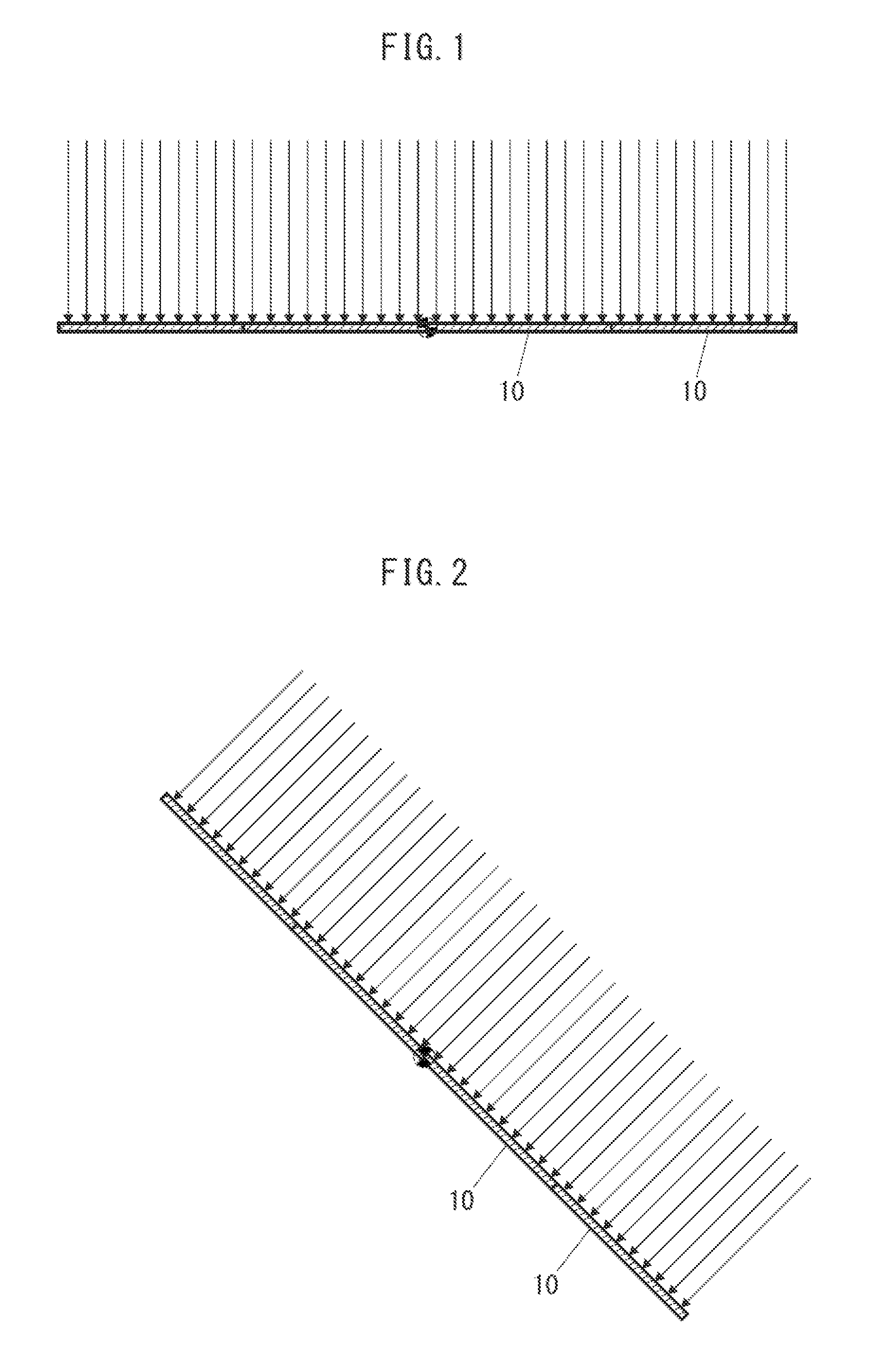

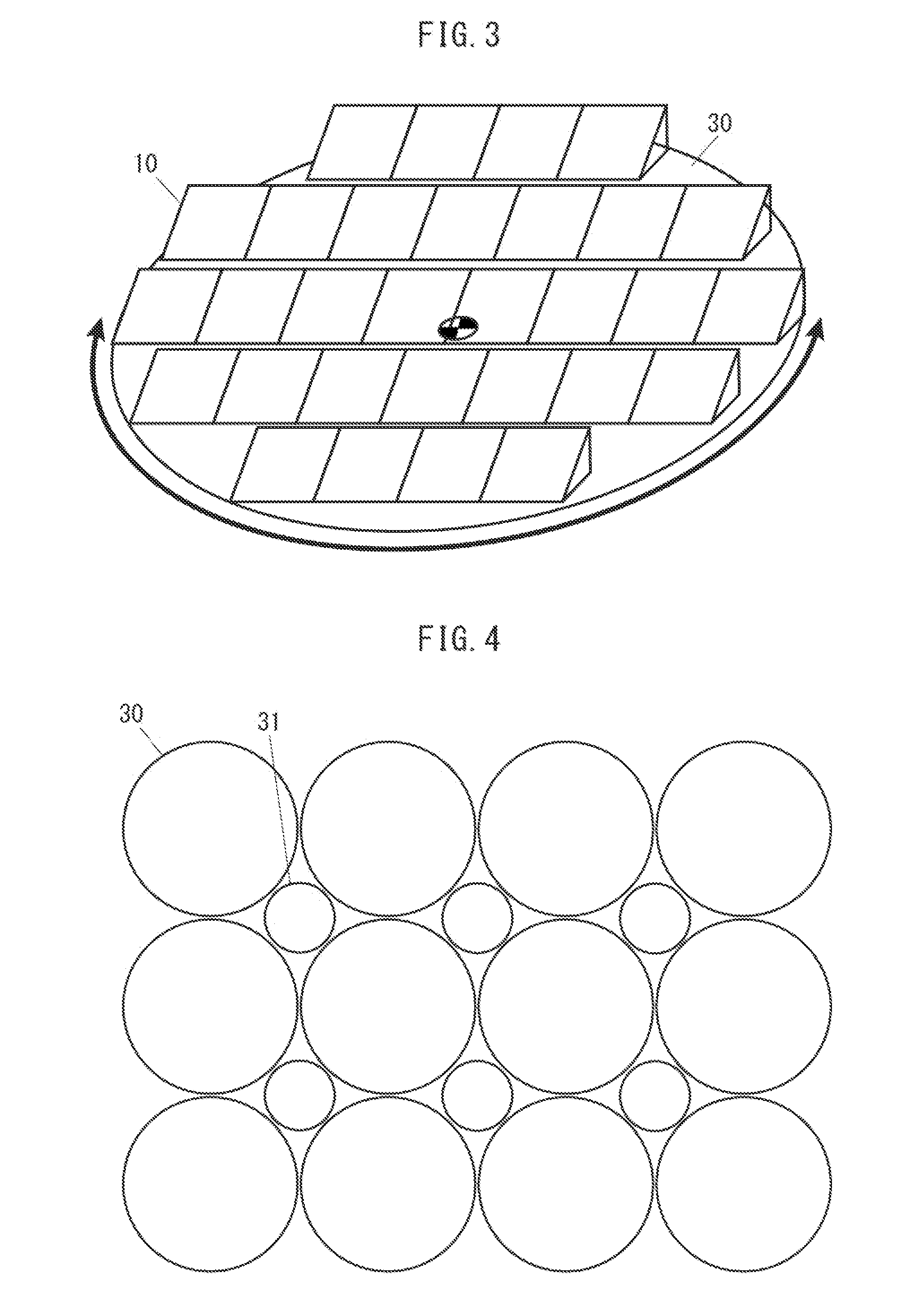

Sun-tracking photovoltaic power generation system

InactiveUS20160020725A1Easily constructReduce construction costPhotovoltaic supportsSolar heating energySun trackingEngineering

A sun-tracking photovoltaic power generation system with a rotating a base having a plurality of photovoltaic power generation panels loaded thereon closely to each other following changes in the solar azimuth angle. A plurality of rails are concentrically laid on an undersurface of the base and wheels are provided to a stand closer to the ground. As a result, it is easier to support the wheels on the same horizontal plane than laying the rails horizontally on a large installation space. Therefore, the construction cost can be reduced and the construction period can be shortened, thereby achieving a large sun-tracking photovoltaic power generation system. Also, because the base is concentrically reinforced by the plurality of rails, the base can be formed by combining, for example, metal L angles, so that a base with a large area can be made light weight at a low cost.

Owner:ELM CO LTD

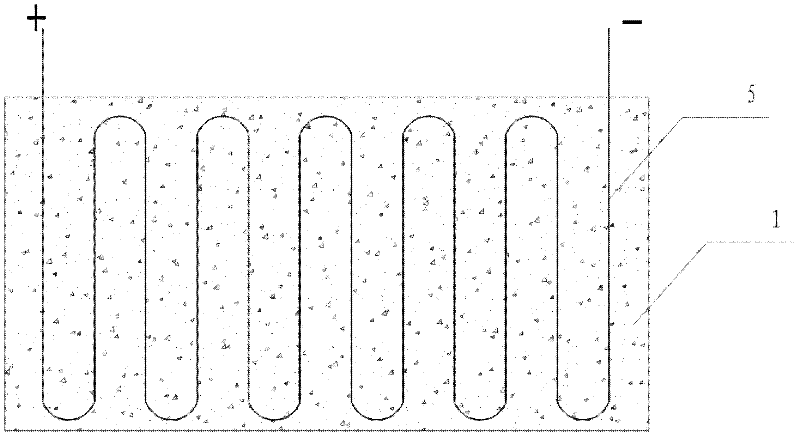

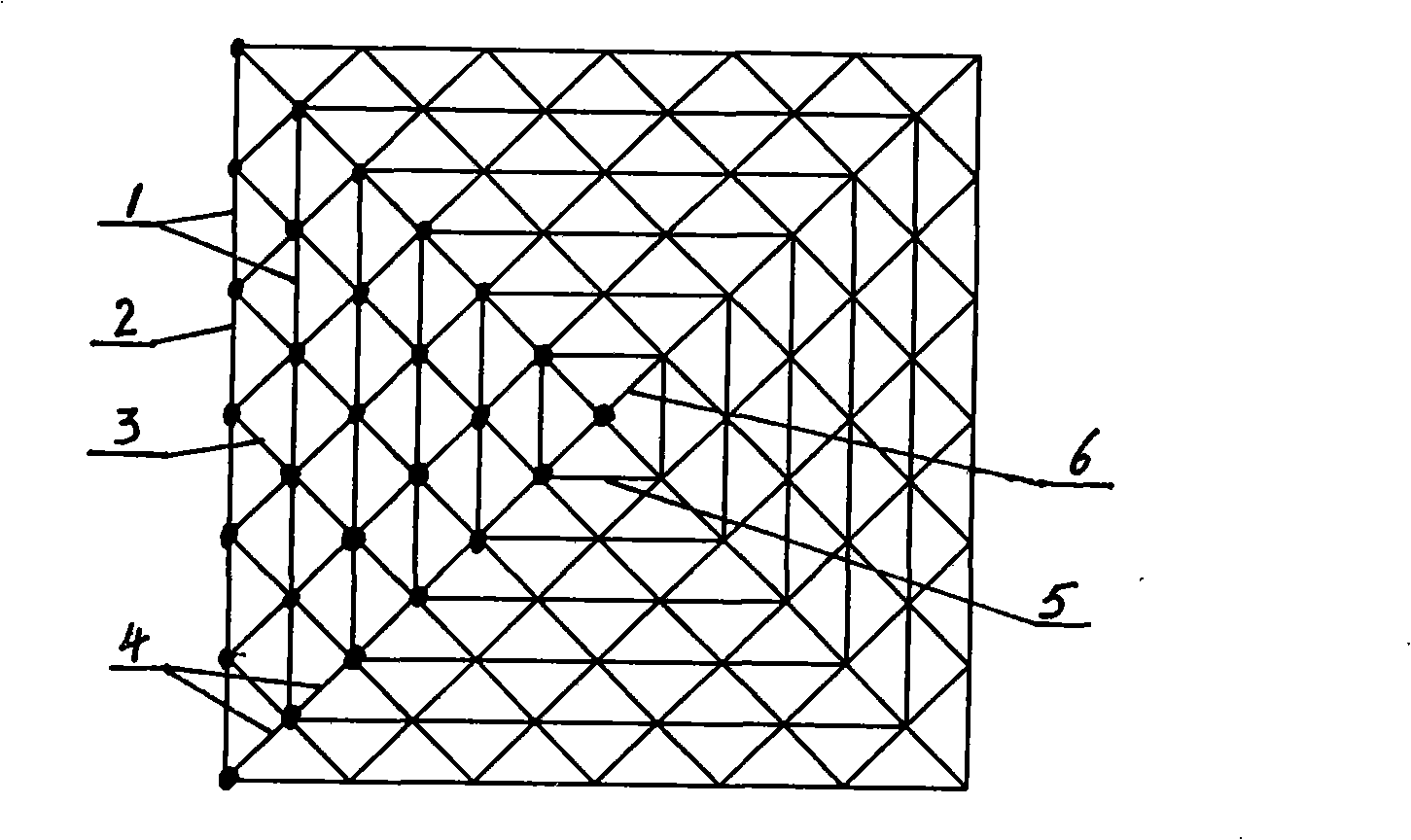

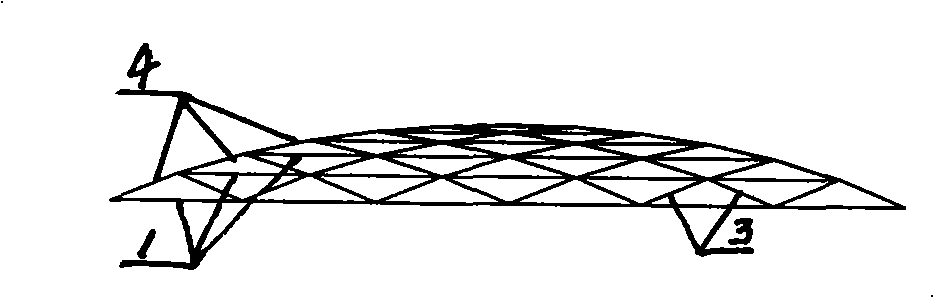

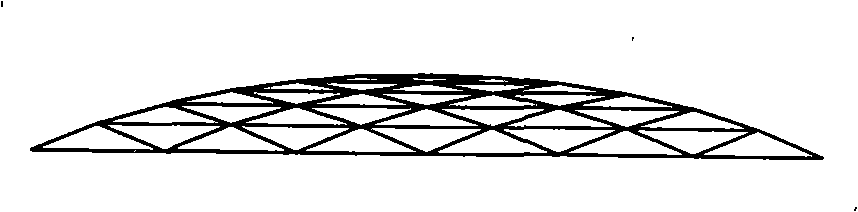

Rectangle plane net shell structure and rectangle plane string supporting dome

InactiveCN101255749AReduce construction costThe construction connection process is matureBuilding roofsArched structuresVertical planePre stress

The present invention relates to a rectangular planar lattice shell structure which comprises a group of similar rectangular ring girders which have centers in one vertical line and are high-and-low distributed in sequence and have diagonals that enlarges gradually. Each rectangular ring girder is obtained by connecting from ring to rod in sequence. A peak connecting rod is provided between the peaks of adjacent rectangular ring grid. An edge connecting rod is provided between the edges of the grid. Two ends of the edge connecting rod are respectively connected with the node of the adjacent girder-side circumferential rod. The opposite positions of rectangular ring girder at the center are provided with two central connecting rods. The connecting rods form a central node at the intersection. The rectangular plane suspend-dome is added with a stretching supporting structure on the base of the lattice shell. The rectangular ring bracing cable is corresponding with the rectangular ring girder. The diagonal bracing cable is arranged in the vertical plane which the diagonal corresponding with the lattice shell is located in. Two ends of the diagonal bracing cable are connected with the peak of the rectangular ring girder at the margin. The place between the intersection of the diagonal bracing cables and the corresponding node of the lattice shell and the place between the intersection of two bracing cables and the corresponding node of the lattice shell are respectively provided with a brace rod. When a pre-stress is exerted in the bracing cable, the lattice shell and the stretching supporting structure form a whole force-bearing structure.

Owner:HENAN UNIVERSITY

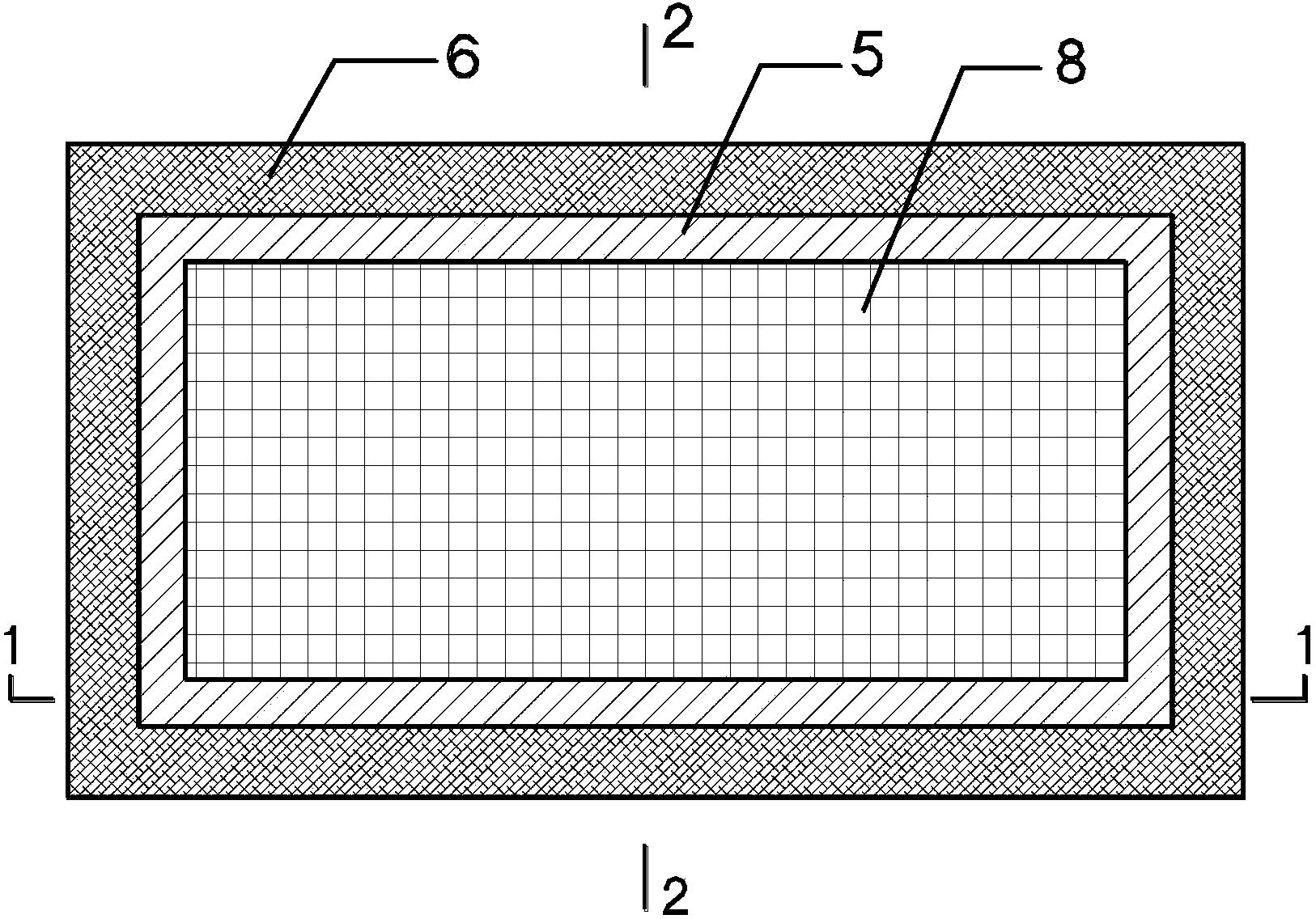

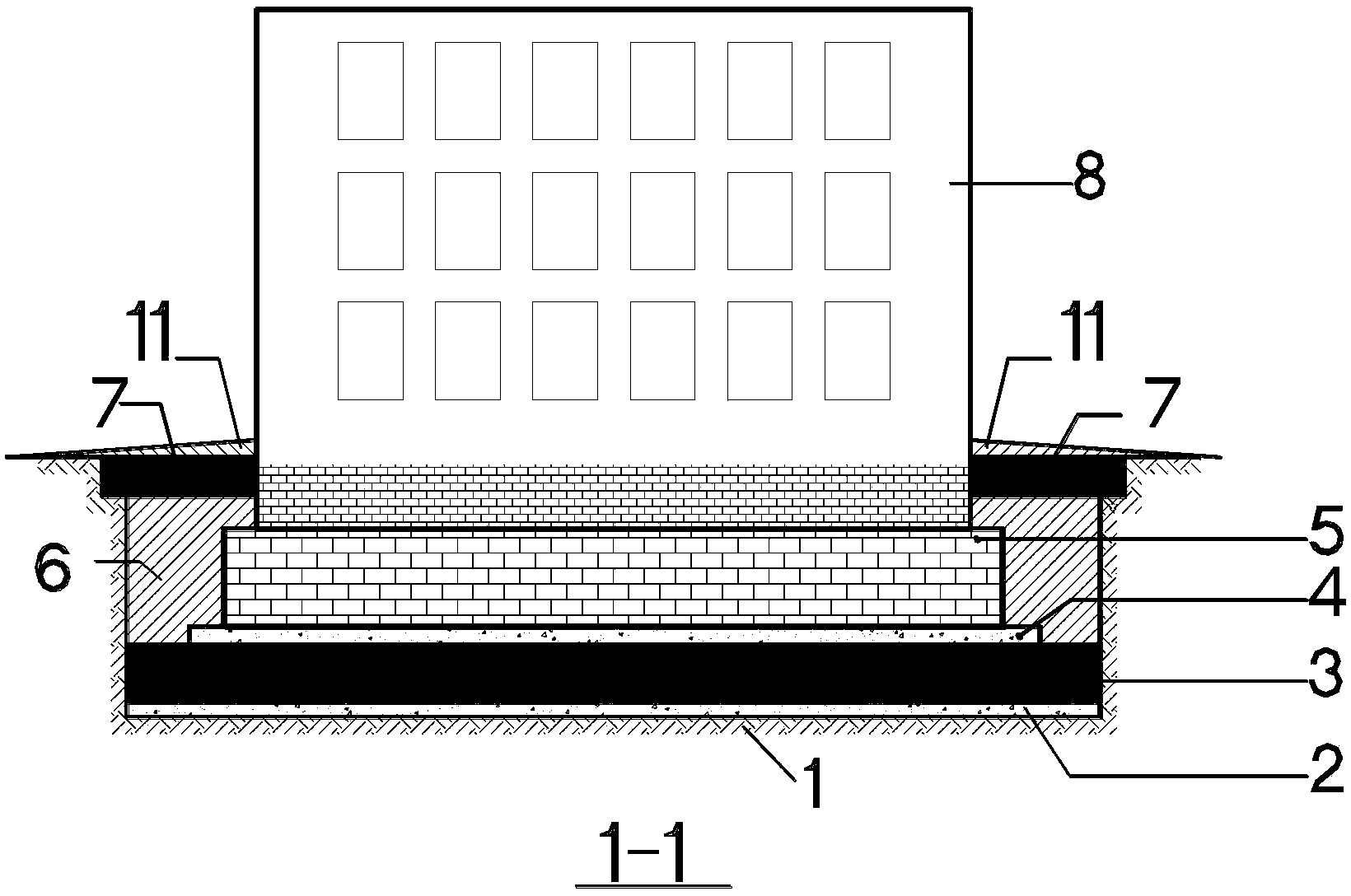

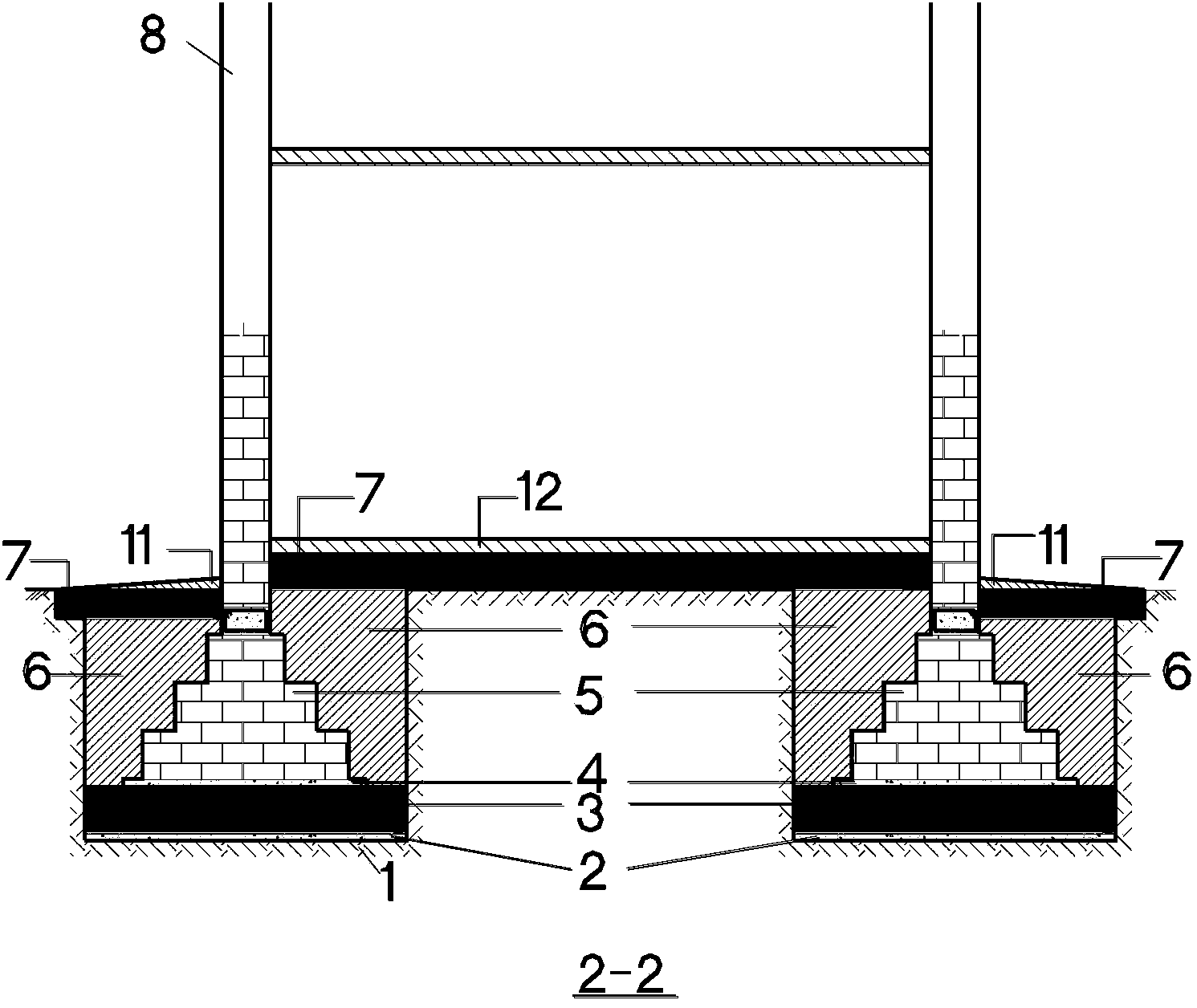

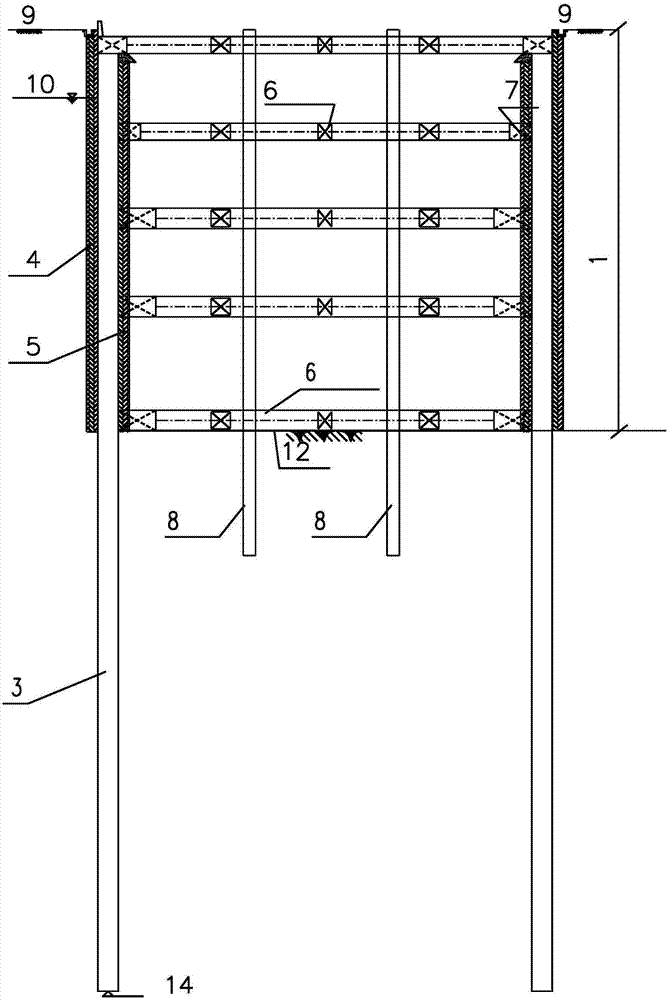

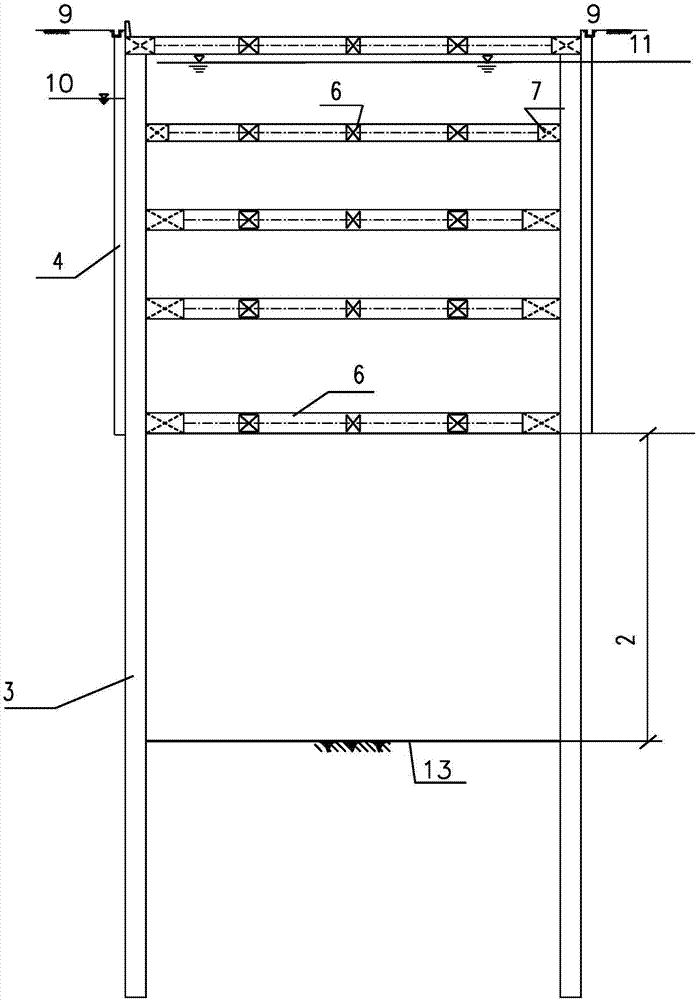

High-pressure-bearing square deep foundation pit applicable to water-rich sand gravel stratum and excavation method of high-pressure-bearing square deep foundation pit

ActiveCN107119691ASolve the problem that the excavation cannot be dewatered and drainedSolve the problem that excavation is feasible but has many defectsProtective foundationExcavationsReinforced concreteRebar

The invention discloses a high-pressure-bearing square deep foundation pit applicable to a water-rich sand gravel stratum and an excavation method of the high-pressure-bearing square deep foundation pit. The foundation pit comprises a dewatering excavation area on the upper portion of the foundation pit and a water entrainment excavation area on the lower portion of the foundation pit. A dewatering well is arranged in the dewatering excavation area. A pit external groove sidewall reinforcing device and a pit internal groove sidewall reinforcing device are arranged inside and outside a diaphragm wall of the whole dewatering excavation area correspondingly. The whole dewatering excavation area is further provided with at least two reinforced concrete waist supporting beams and reinforced concrete supports. The water entrainment excavation area is provided with muddy water sucking equipment and filtered water recharge equipment, and multiple stages of settling ponds are arranged outside the foundation pit correspondingly. The stepped excavation method that the reinforced concrete supports are arranged and unwatering excavation is adopted on the upper portion and water entrainment excavation is adopted on the lower portion is adopted. The construction quality of the diaphragm wall is effectively ensured, the probability that water seepage, water burst and sand burst appear in the diaphragm wall is lowered, the excavation safety of the foundation pit is ensured, the excavation schedule of the foundation pit is accelerated, and the excavation cost of the foundation pit is reduced.

Owner:中交(南京)建设有限公司

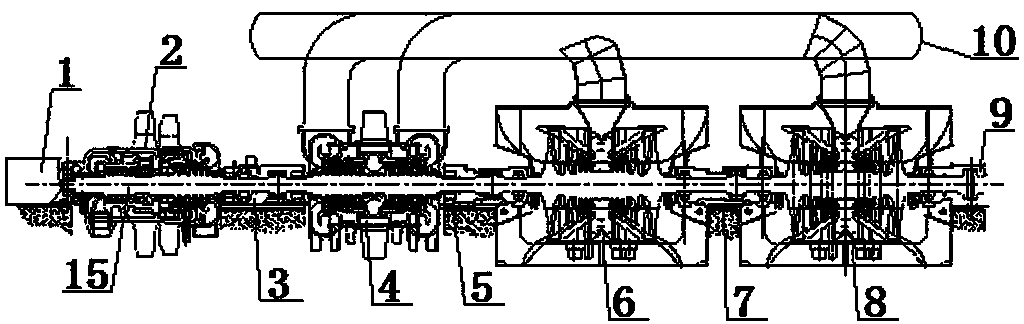

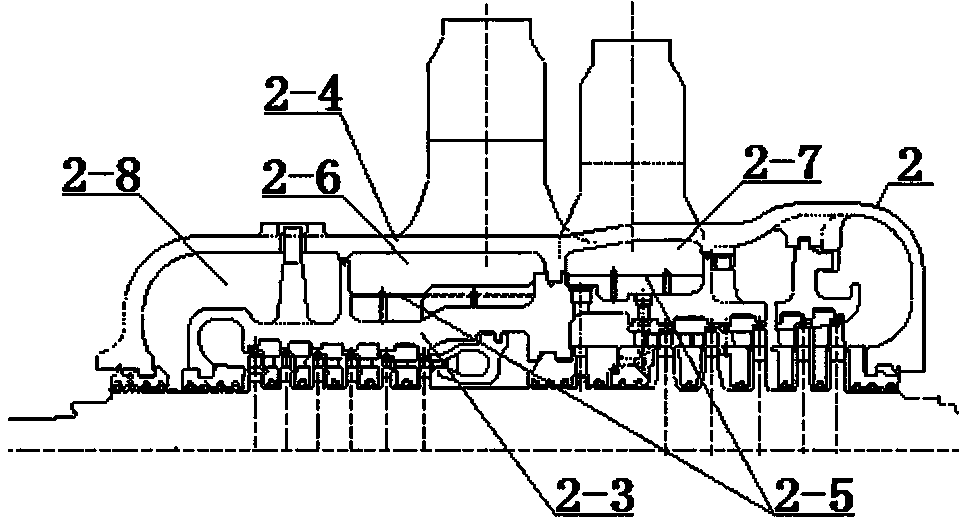

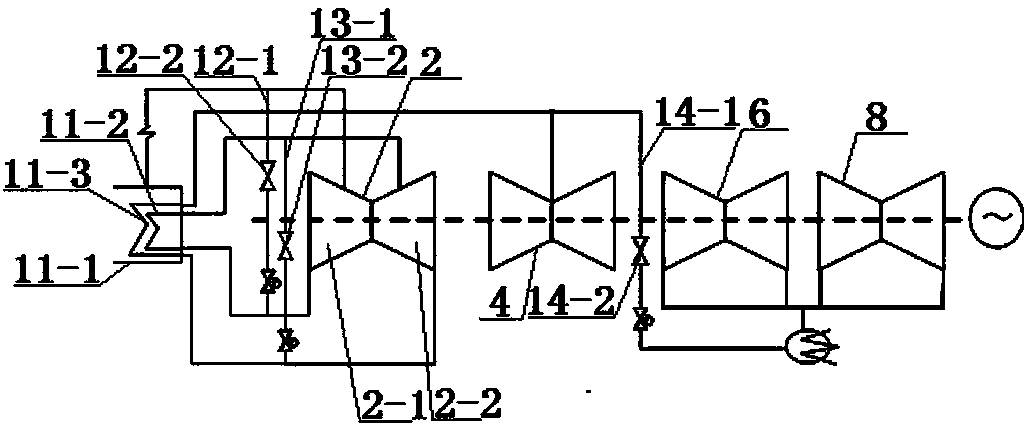

Ultra-supercritical secondary re-heating steam turbine set

InactiveCN103670550ADoes not affect safety and reliabilityDoes not affect runnabilityEngine componentsSteam engine plantsUltra high pressureEngineering

The invention discloses an ultra-supercritical secondary re-heating steam turbine set. The ultra-supercritical secondary re-heating steam turbine set comprises a first bearing box, an ultra high pressure-high pressure cylinder, a second bearing box, a medium-pressure cylinder, a third bearing box, a first low-pressure cylinder, a fourth bearing box, a second low-pressure cylinder and a turning gear box which are assembled on a rotor in sequence. The capacity of the steam turbine set is 1000-1300MW, the ultra high pressure-high pressure cylinder is of a cylinder combined structure, the pressure of a steam inlet of an ultra high pressure part is 30-35MPa, the temperature is 600 DEG C, the pressure of a primary re-heating steam inlet of a high pressure part is 10MPa, the temperature is 610-630 DEG C, the medium-pressure cylinder, the first low-pressure cylinder and the second low-pressure cylinder are respectively of a double-flow-division structure, the medium-pressure cylinder provides steam for the first low-pressure cylinder and the second low-pressure cylinder respectively through communication pipes, the pressure of a secondary re-heating steam inlet of the medium-pressure cylinder is 2.8MPa, and the temperature is 610-630 DEG C. The ultra-supercritical secondary re-heating steam turbine set has the advantages of being large in capacity, high in parameter, small in occupied space, low in investment cost, stable and reliable in operation and obvious in economical benefit, saving energy, reducing consumption and the like.

Owner:DONGFANG TURBINE CO LTD

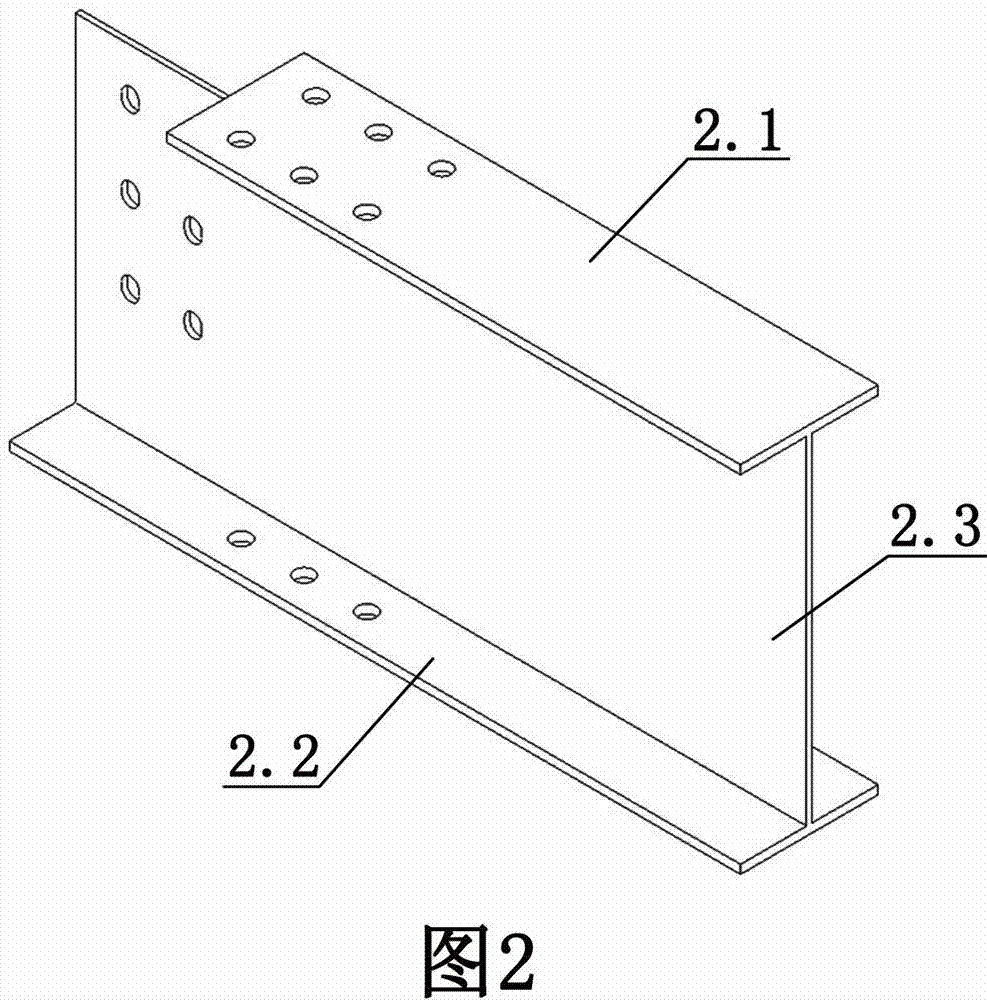

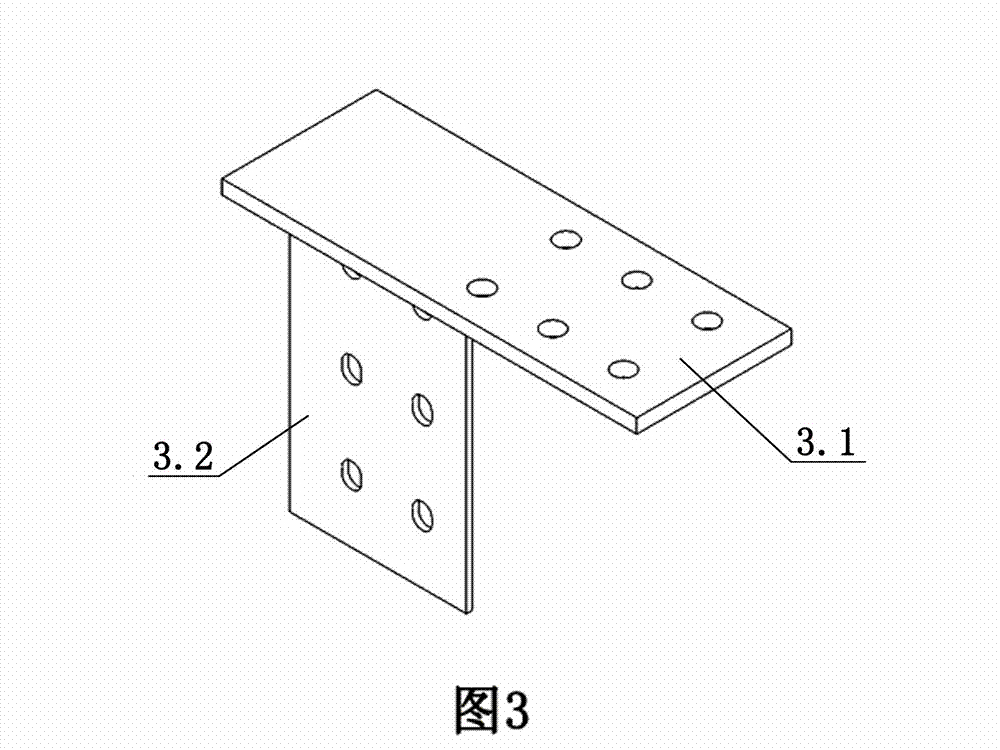

H-shaped steel beam and H-shaped steel column strong-axis variable-beam height fabricated node and construction method thereof

InactiveCN102733489AMeet the requirements of prefabricated constructionHigh node stiffnessBuilding material handlingSteel columnsFlange

The invention discloses an H-shaped steel beam and H-shaped steel column strong-axis variable-beam height fabricated node and a construction method thereof. The node comprises an H-shaped steel column, an H-shaped steel beam, a T-shaped connection piece, an L-shaped connection piece and bolts; the T-shaped connection piece consists of an upper flange plate connection plate which is arranged horizontally, and a web connection plate which is perpendicular to the bottom surface of the upper flange plate connection plate; the upper flange plate connection plate is connected with an upper flange plate through the bolts; the web connection plate is connected with a web through the bolts; the L-shaped connection piece consists of a lower flange plate connection plate which is arranged horizontally and a column connection plate which is perpendicular to the lower flange plate connection plate downward; the lower flange plate connection plate is connected with a lower flange plate through the bolts; and the column connection plate is connected with a column flange plate of the H-shaped steel column through the bolts. All accessories required by the node are prefabricated in a factory, the requirement of equal-strength connection in the process of changing the section of the H-shaped steel beam in a certain range can be met, high-strength bolts are adopted by a construction field node so as to realize the fabricated connection, and the node is high in rigidity and high in connection speed, and can meet the requirement of the fabricated construction of a steel structure.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

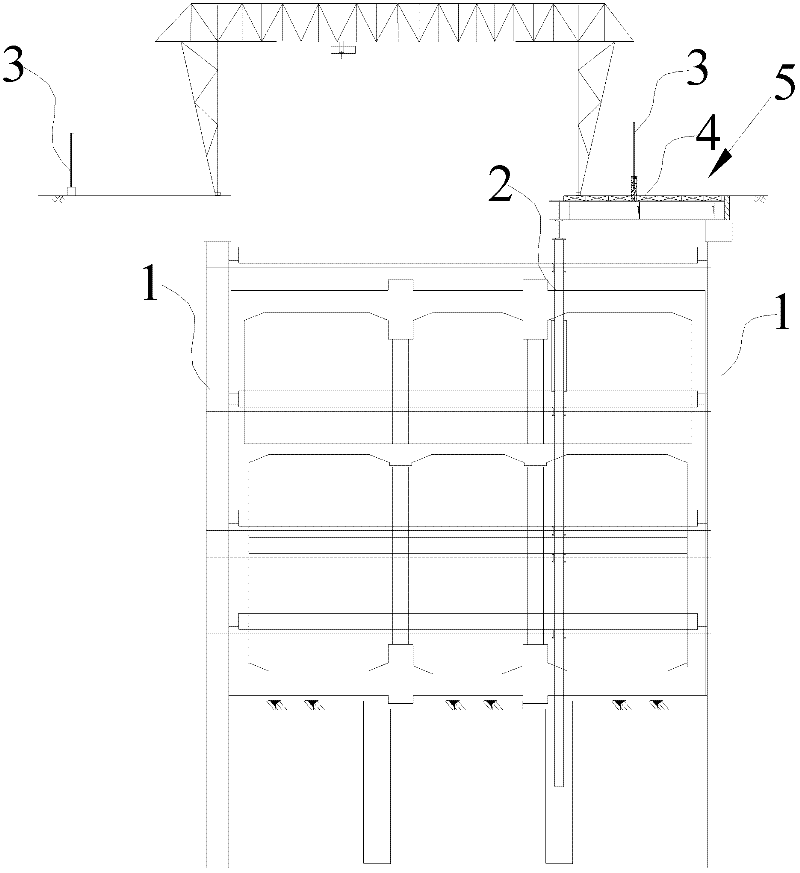

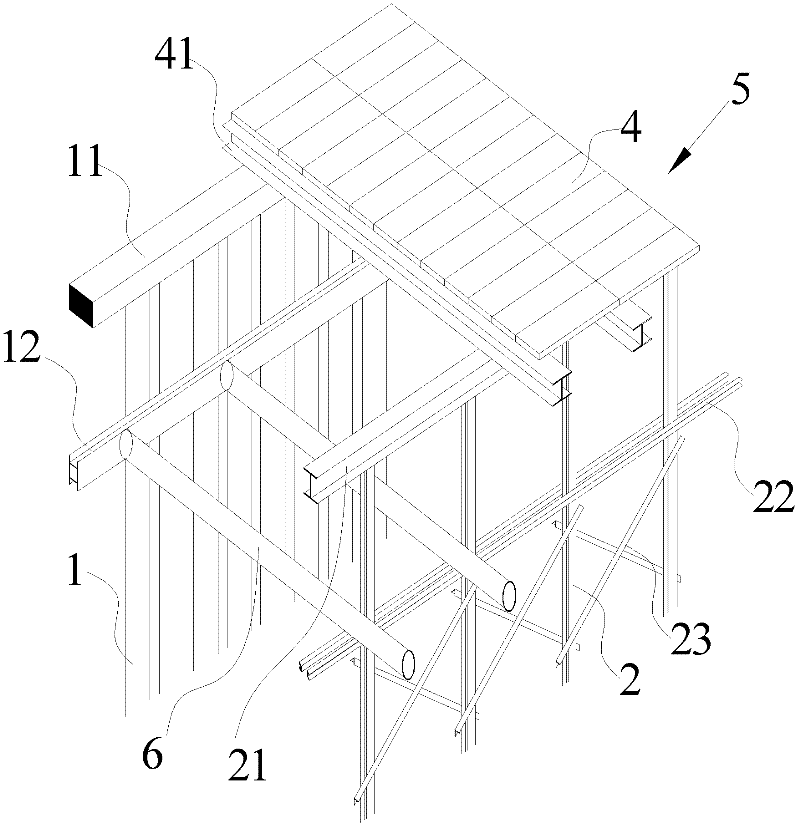

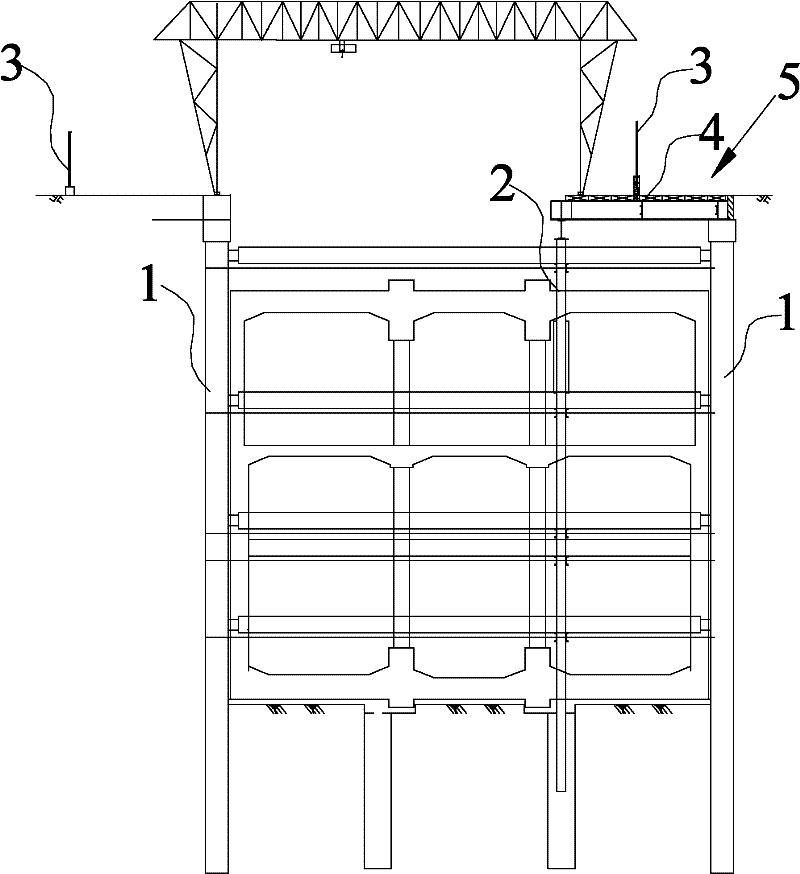

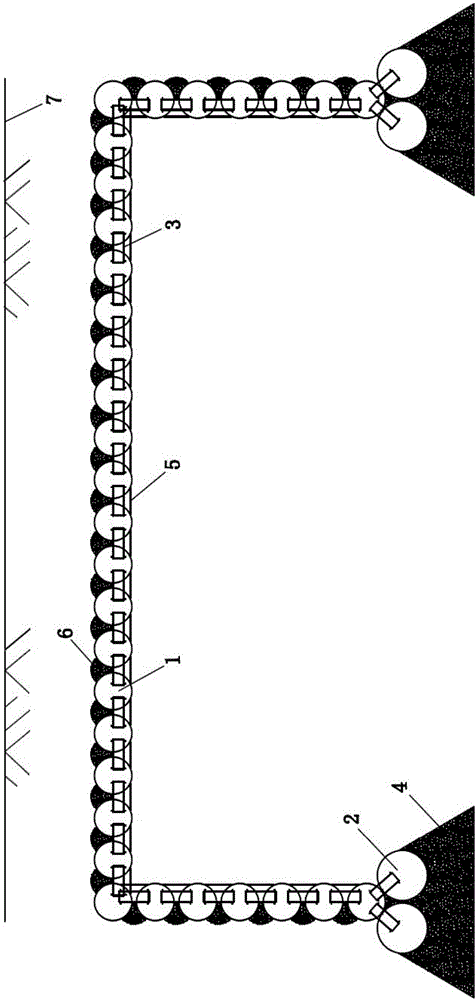

Novel steel pipe curtain structure supporting and protecting system and construction method thereof

ActiveCN106761768AMake up for the shortcomings of very weak forceIncrease profitTunnelsTransverse stiffnessBearing capacity

The invention discloses a novel steel pipe curtain structure supporting and protecting system and a construction method thereof and relates to the technical field of underground excavation supporting and protecting. According to the novel steel pipe curtain structure supporting and protecting system and the construction method thereof, the problem that in the prior art, stress between joints of adjacent steel pipes in a pipe curtain structure is weak, so that a large number of temporary supports need to be erected to guarantee stability of the overall structure is solved. The novel steel pipe curtain structure comprises first steel pipes, second steel pipes and third steel pipes; and the multiple first steel pipes are arranged in sequence to form an n-shaped structure, every two adjacent first steel pipes are connected through the third steel pipes, two supporting feet of the n-shaped structure formed by the first steel pipes are provided with two second steel pipes which are located at the same horizontal plane, and concrete is injected into the first steel pipes, the second steel pipes and the third steel pipes. According to the novel steel pipe curtain structure supporting and protecting system and the construction method thereof, the transverse stiffness and the bearing capacity of the pipe curtain supporting and protecting system are improved, a large number of temporary supports do not need to be erected, construction cost is reduced, the construction period is shortened, the construction procedure is simplified, ground surface settlement is effectively prevented, and the construction quality is improved.

Owner:NORTHEASTERN UNIV

Water-absorbing fiber percolation pipe and dewatering device

InactiveCN103410210ASuction and discharge in timeImprove drainage efficiencyGround-workGround pavingsFiberGrating

The invention provides a water-absorbing fiber percolation pipe and a dewatering device comprising the same. The water-absorbing fiber percolation pipe comprises at least one water guide pipes and a water-absorbing fiber sleeve. The water guide pipes are mounted in the water-absorbing fiber sleeve in a sleeved manner. The inside of each water guide pipe is separated by at least one grating to form a plurality of axial through water flow passages. Axial through grooves are formed in the water guide pipe walls corresponding to the water flow passages and communicated with the corresponding water flow passages. The water-absorbing fiber percolation pipe and the dewatering device have the advantages of remarkable dewatering effect, long service life and low production and utilization cost.

Owner:周居正

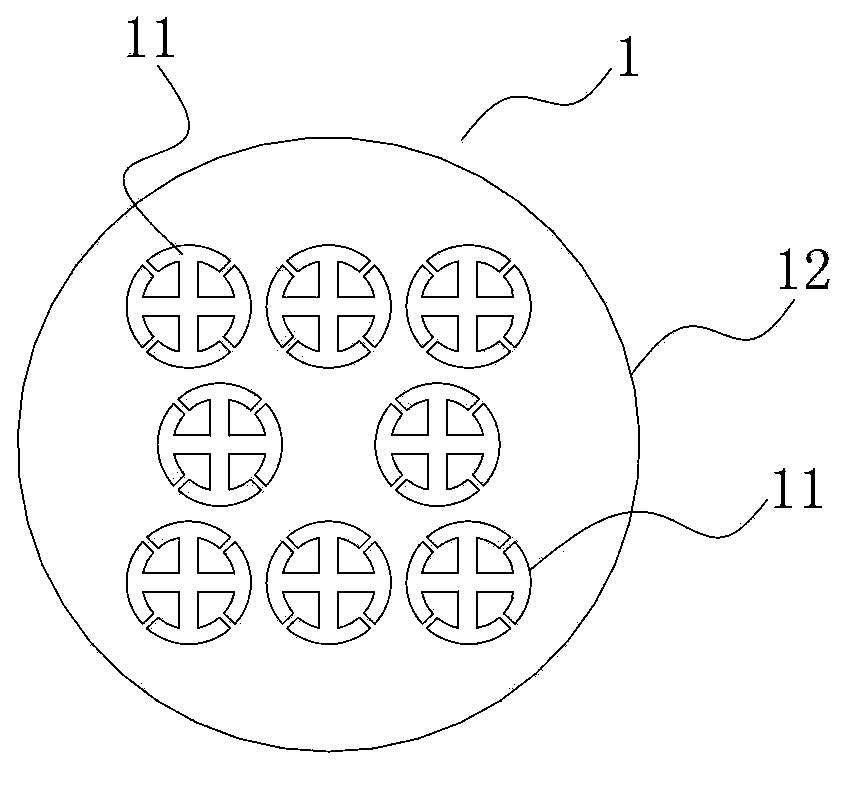

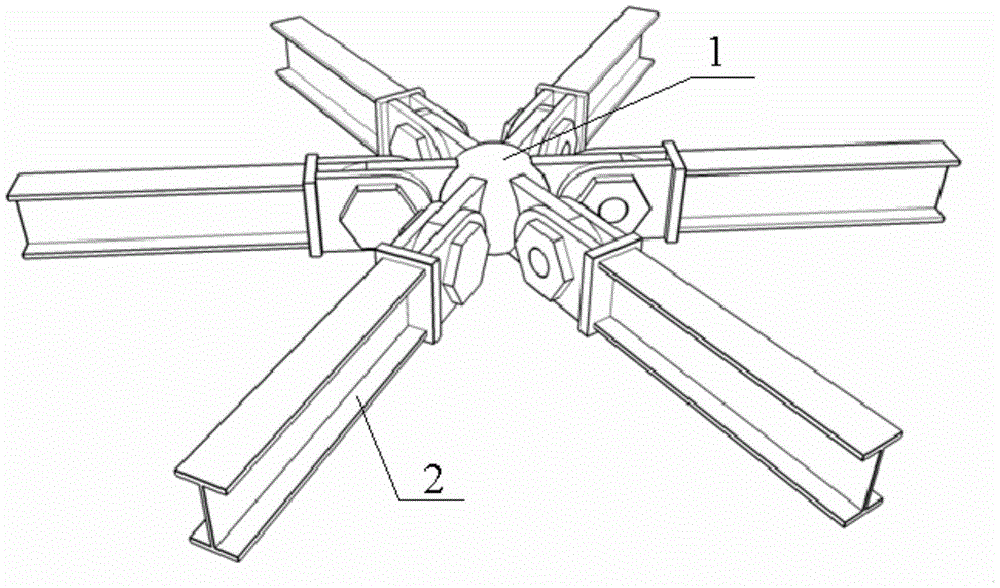

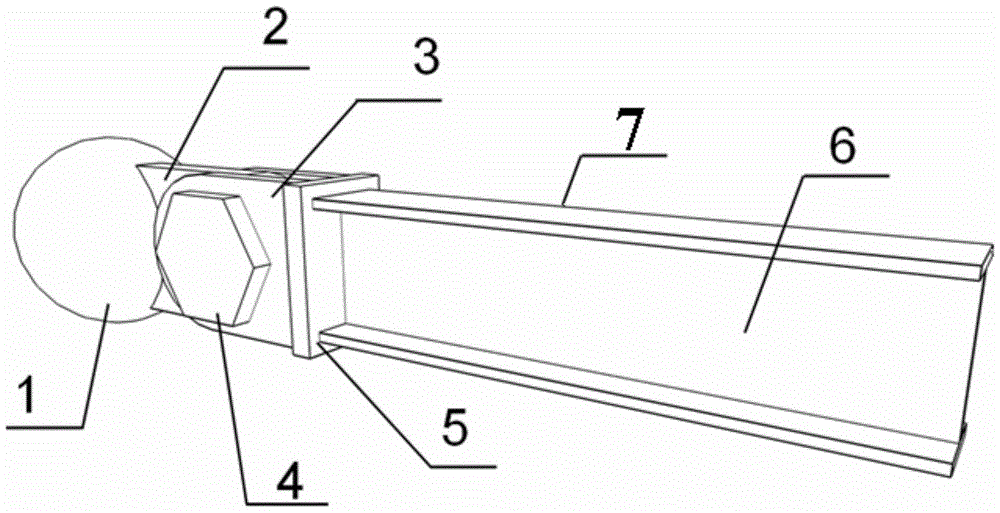

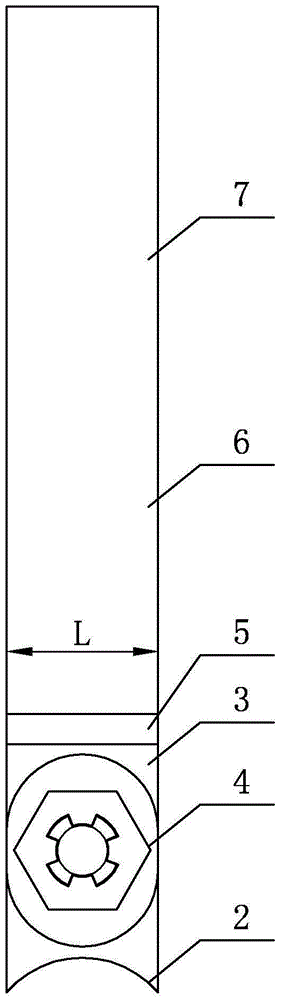

Space assembly type tooth-type joint structure

ActiveCN105220765AIncrease stiffnessImprove rotational stiffnessBuilding constructionsFree formBall joint

The invention provides a space assembly type tooth-type joint structure, and relates to a tooth type joint structure. Problems that assembly type connection joints in the prior art cannot meet requirements of free-form surface single-layer latticed shell structures, ball joints are required to be welded and constructed on site, construction cost is high, construction quality is difficult to guarantee, existing assembly type semi-rigid joints have obvious shortcomings when used in free-form surface single-layer latticed shells, and requirements of rigidity and universality cannot be simultaneously met well are solved. The space assembly type tooth-type joint structure comprises a hollow ball and a connecting assembly, wherein the connecting assembly comprises a middle lug plate, tooth-type bolts, a connecting rod end plate, a connecting rod, a nut and lug plate connecting side plates, wherein the lug plate connecting side plate is fixedly mounted on the connecting rod end plate; the connecting rod is fixedly mounted on the connecting rod end plate; the middle lug plate and the two lug plate connecting side plates are connected to one another through the tooth-type bolts; and the middle lug plate is fixedly mounted on an excircle surface of the hollow ball. The space assembly type tooth-type joint structure is used in the field of civil engineering buildings.

Owner:HARBIN INST OF TECH

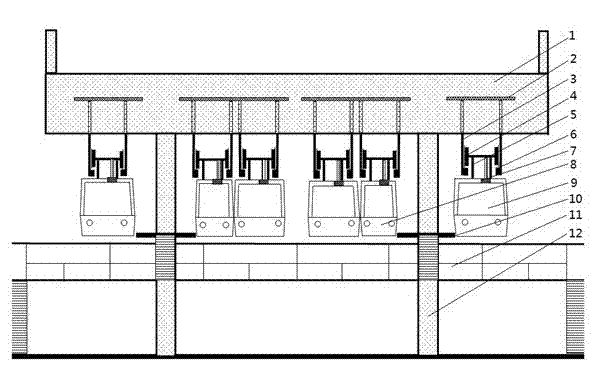

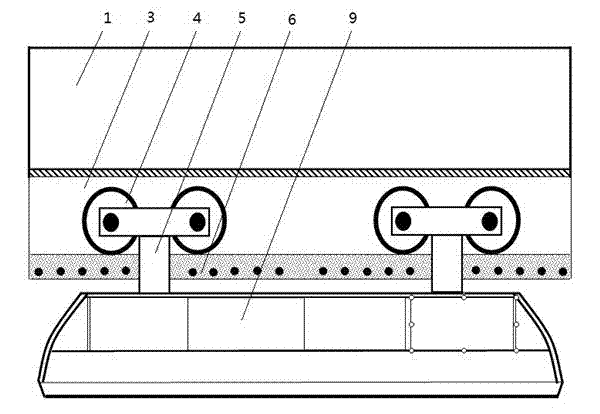

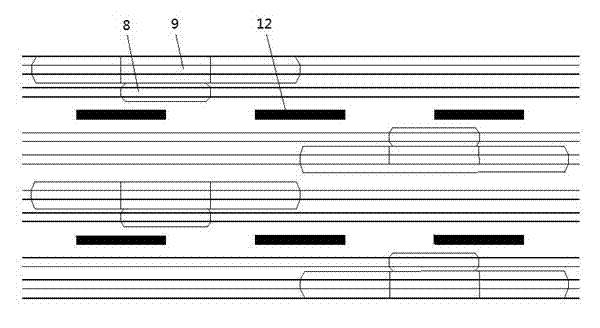

Suspension type track train on bottom surface of bridge body

InactiveCN102765392AEase traffic congestionSmooth trafficElevated railway with suspended vehicleOperational costsTraffic congestion

The invention discloses a suspension type track train on the bottom surface of a bridge body. The track train is characterized in that the spare space on the bottom surface of the bridge body is utilized, projects of constructing a bridge and a suspension type track train are integrated, and vehicles can run on the top surface, the bottom surface and the ground of the bridge body, so that the problem of city traffic congestion is solved, the riding time is shortened, and city carbon emission and city noise are reduced; besides, the construction difficulty is low, the construction safety and the running safety are high, the construction period is short, the construction cost is low, the passenger capacity is large, the running cost is low, the track train is ornamental, and a beautiful scene is provided for a city.

Owner:宫世斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com