Large-span non-floor type cast-in-place beam falsework and construction method thereof

A cast-in-place girder frame, non-floor type technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of high construction cost, waste of resources, long construction period, etc., to reduce construction cost and reduce construction cost , the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

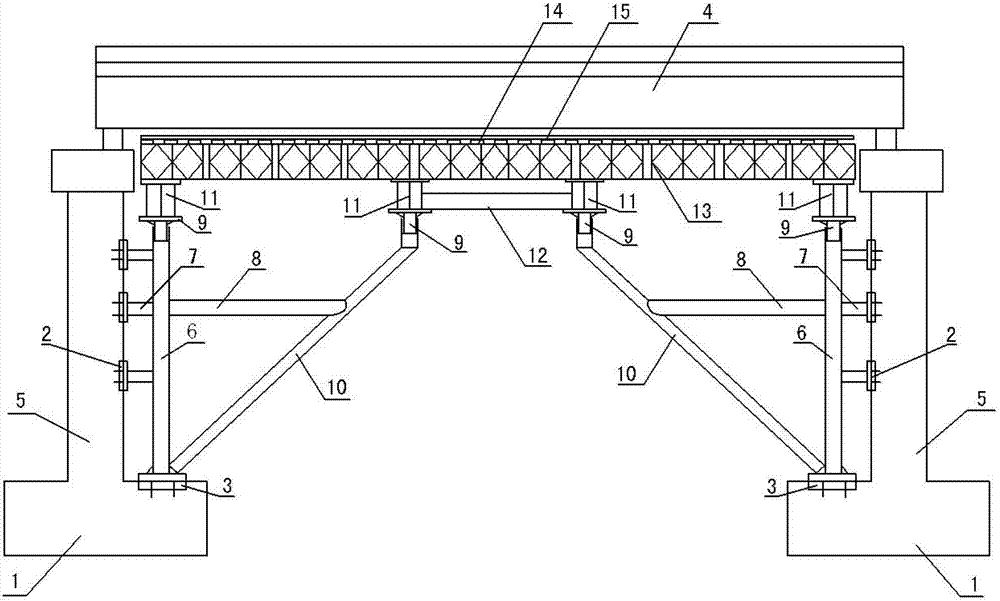

[0026] see figure 1 , the structural form of the large-span non-floor type cast-in-place girder frame in this embodiment is: the two-side supports are symmetrically arranged on the two-side caps 1 and the pier body 5 for supporting the cast-in-place beam 4, and the structure of the two-side supports The form is: on the top of the concrete cap 1, set the pre-embedded steel plate 3 through the anchor bolt; The steel pipe column 6 and the corbel slant support 10 are respectively supported on the pre-embedded steel plate 3 of the platform; the pier body column connecting steel pipe 7 at different height positions is respectively arranged between the embedded steel plate 2 of each pier body and the steel pipe column 6; A corbel horizontal support 8 is arranged between the corbel oblique supports 10; an unloading sand cylinder top cap 9 is respectively arranged on the top of the steel pipe column 6 and the corbel oblique support 10, and a double I-beam 11 is arranged on the unloadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com