Method and system for thin-wall part modal testing based on machine vision

A technology of machine vision and modal testing, which is applied in the testing of machine/structural components, testing of mechanical components, vibration testing, etc., to achieve the effects of guaranteed accuracy, high spatial resolution, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

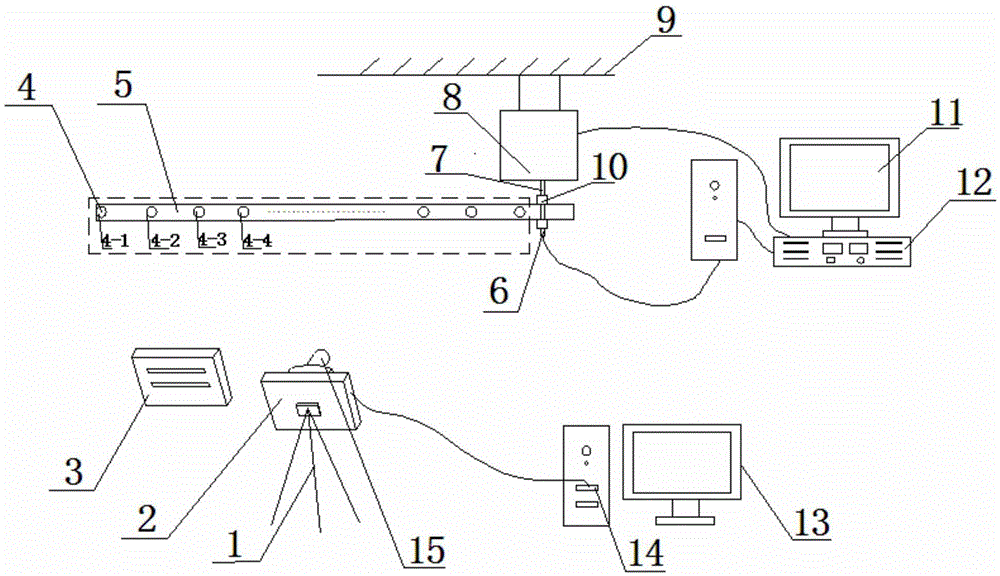

[0044] Such as figure 1 As shown, the present invention includes a tripod 1, a CCD industrial camera 2, an industrial lens 15, an ordinary LED light source 3, a reflective sticker feature point 4, a thin-walled part 5, an acceleration sensor 6, an excitation head 7, an exciter 8, a fixed Support 9, exciter control device 11, power amplifier 12, computer image processing device 13. One end of the thin-walled part 5 is fixed on the excitation head 7 through two nuts 10, and the other end is in a free suspension state. The exciter 8 is suspended on the fixed bracket 9 with a string, and the exciter 8 is connected to the power amplifier 12. , the power amplifier 12 is connected to the vibrator control device 11, an acceleration sensor 6 is installed at the end of the vibrator head 7, and is connected to the vibrator control device 11 through a data l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com