Patents

Literature

343results about How to "Ease of ejection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tampon pledget for increased by-pass leakage protection

InactiveUS20080287902A1Increase in of absorbency capacityIncrease in rate of absorbencyBaby linensTamponsMedicineTamponade

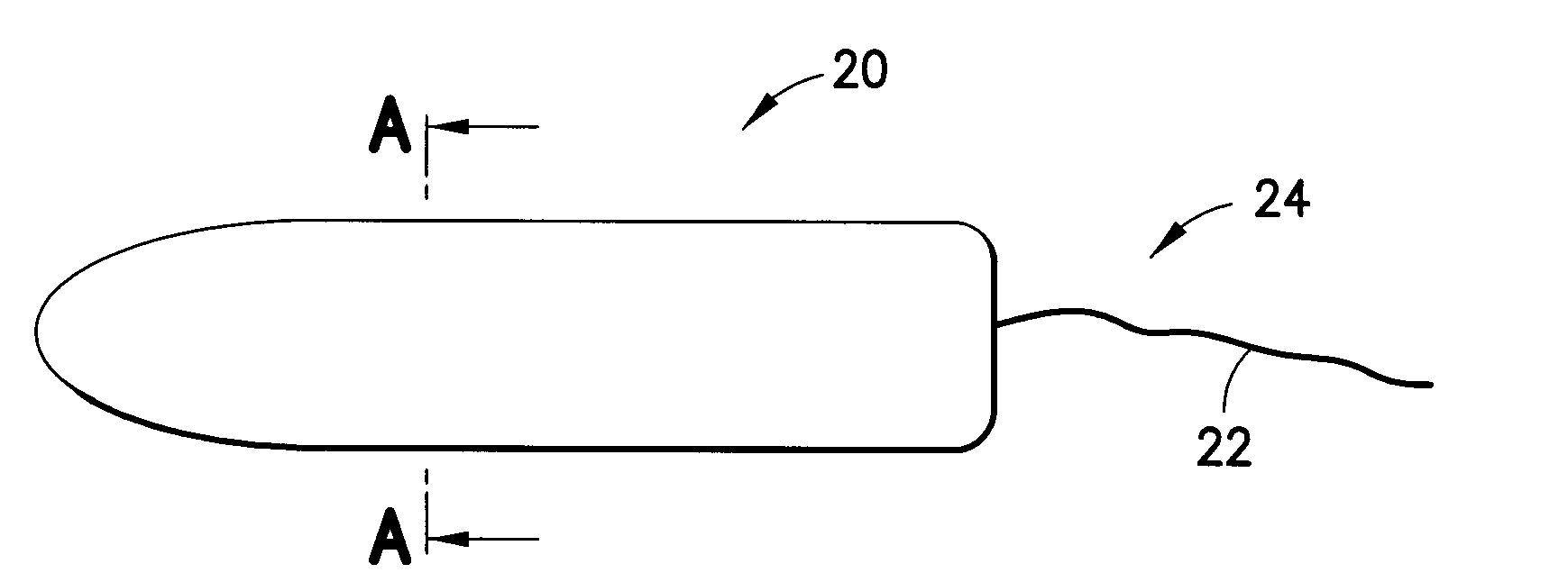

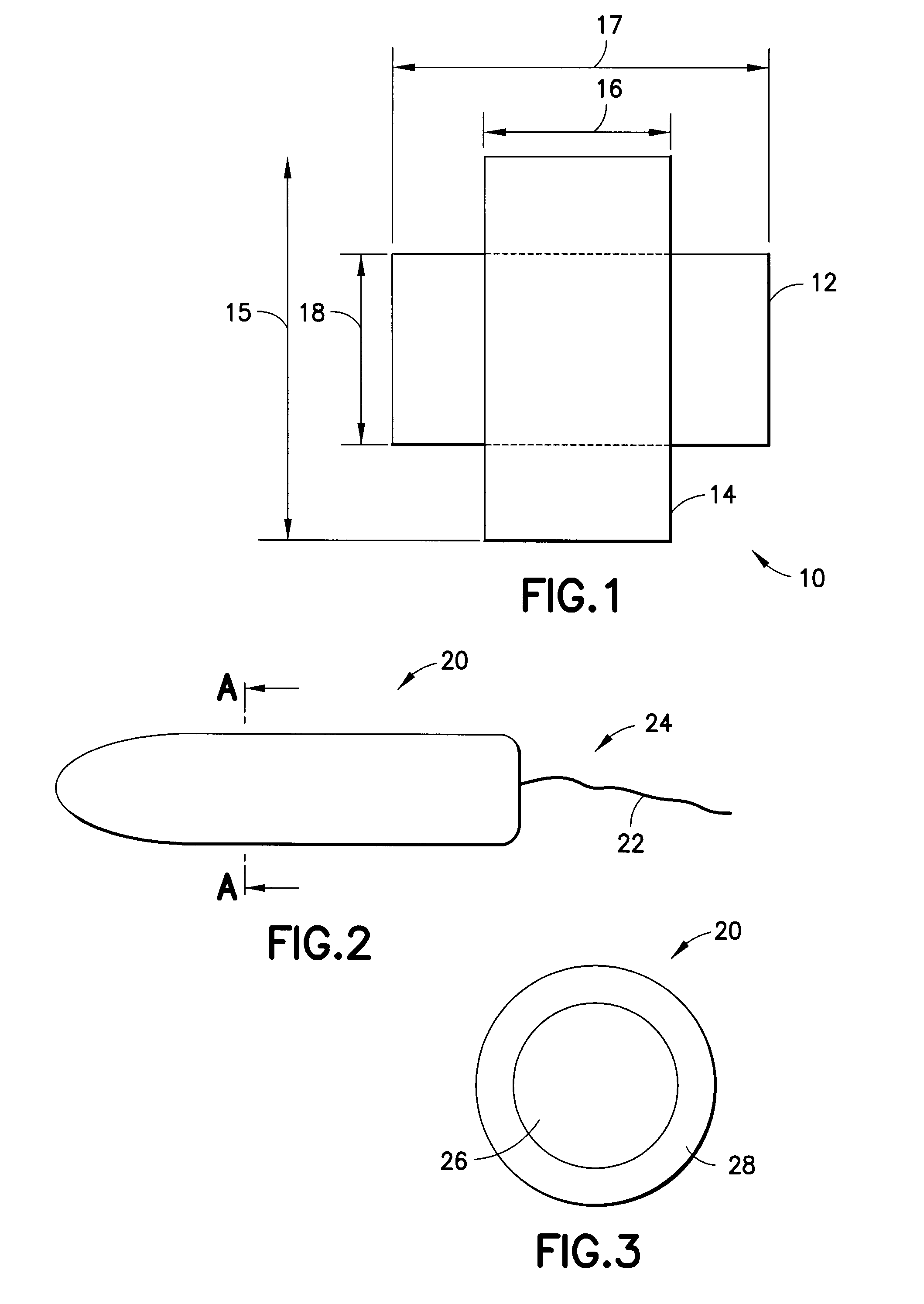

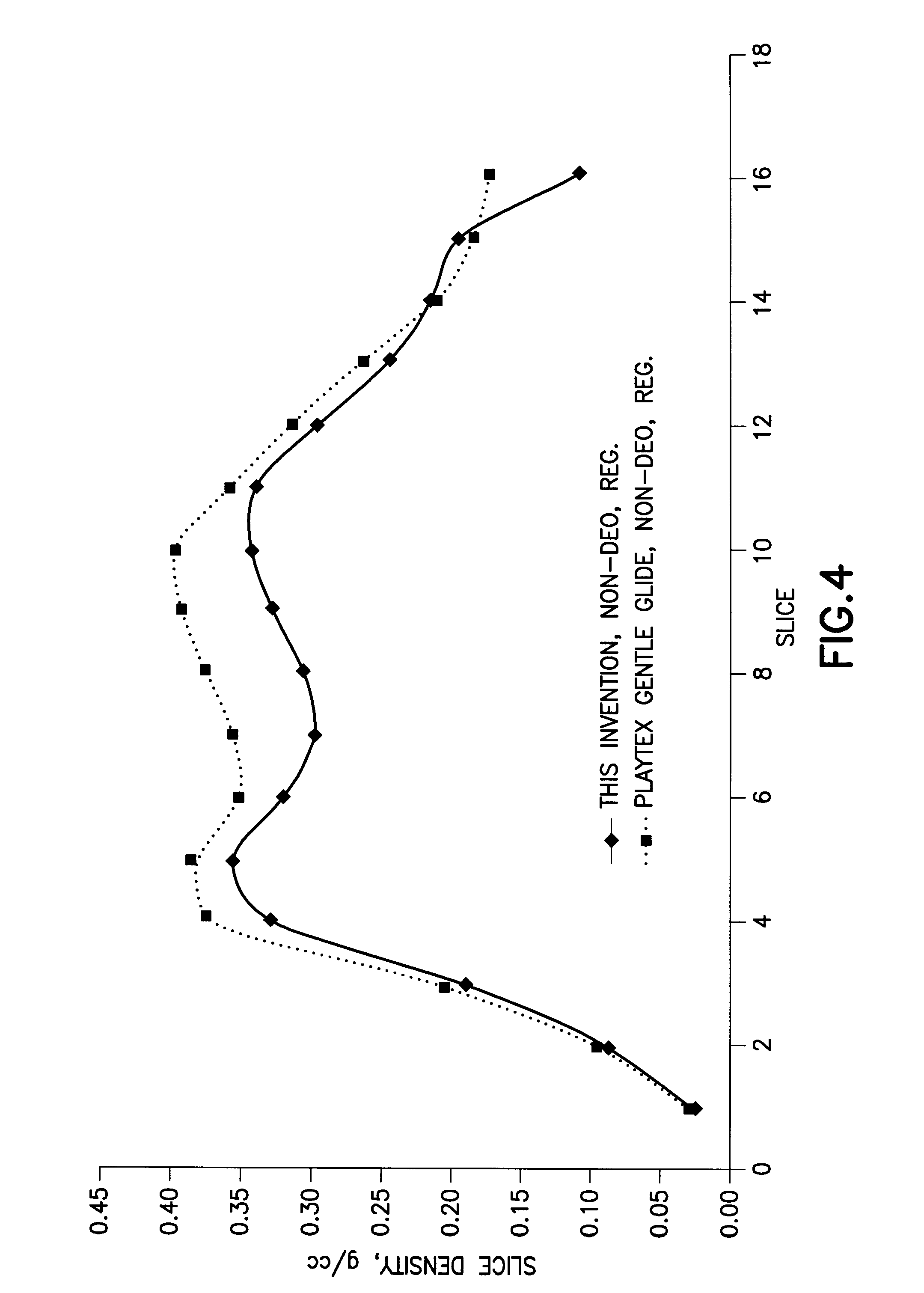

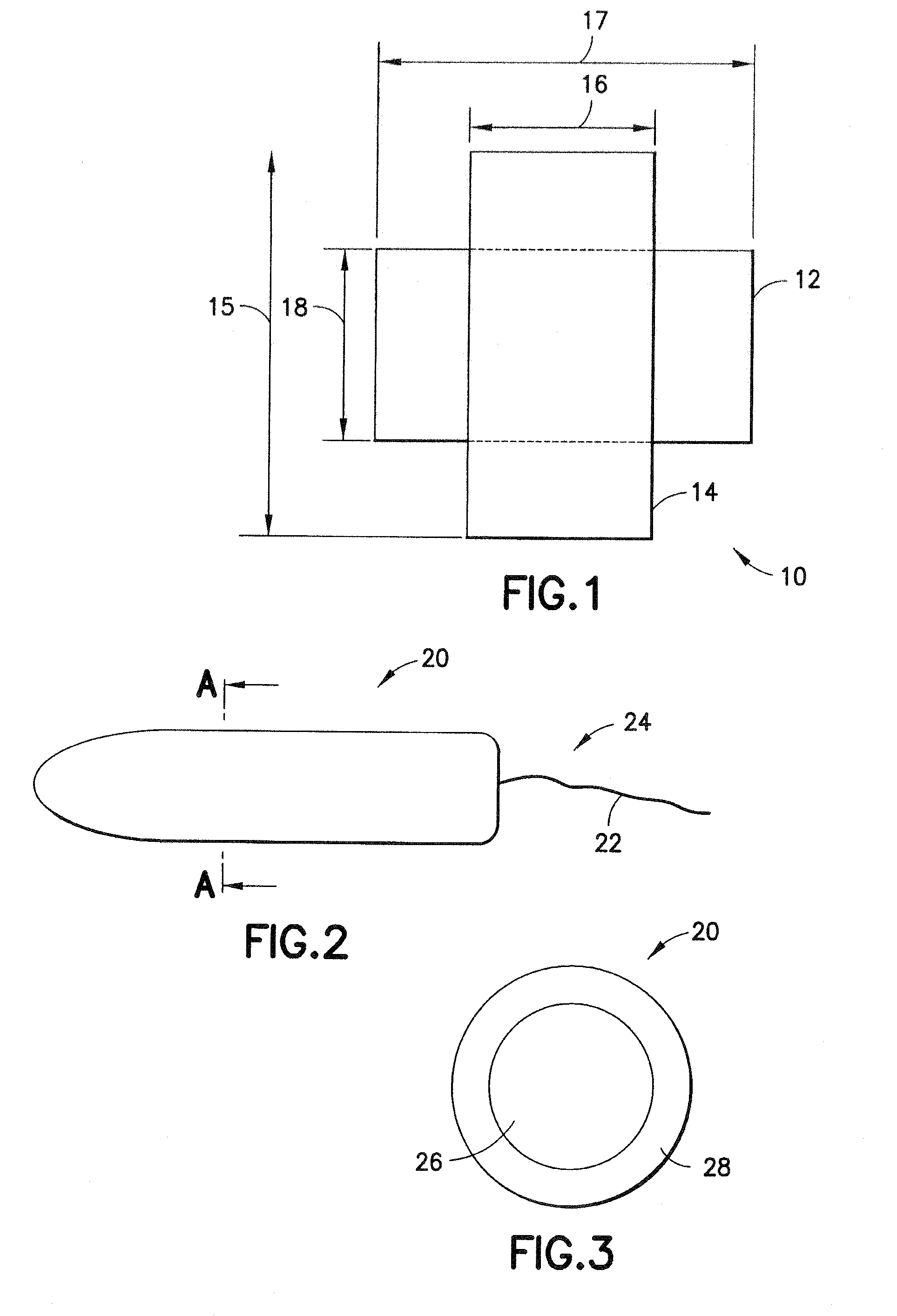

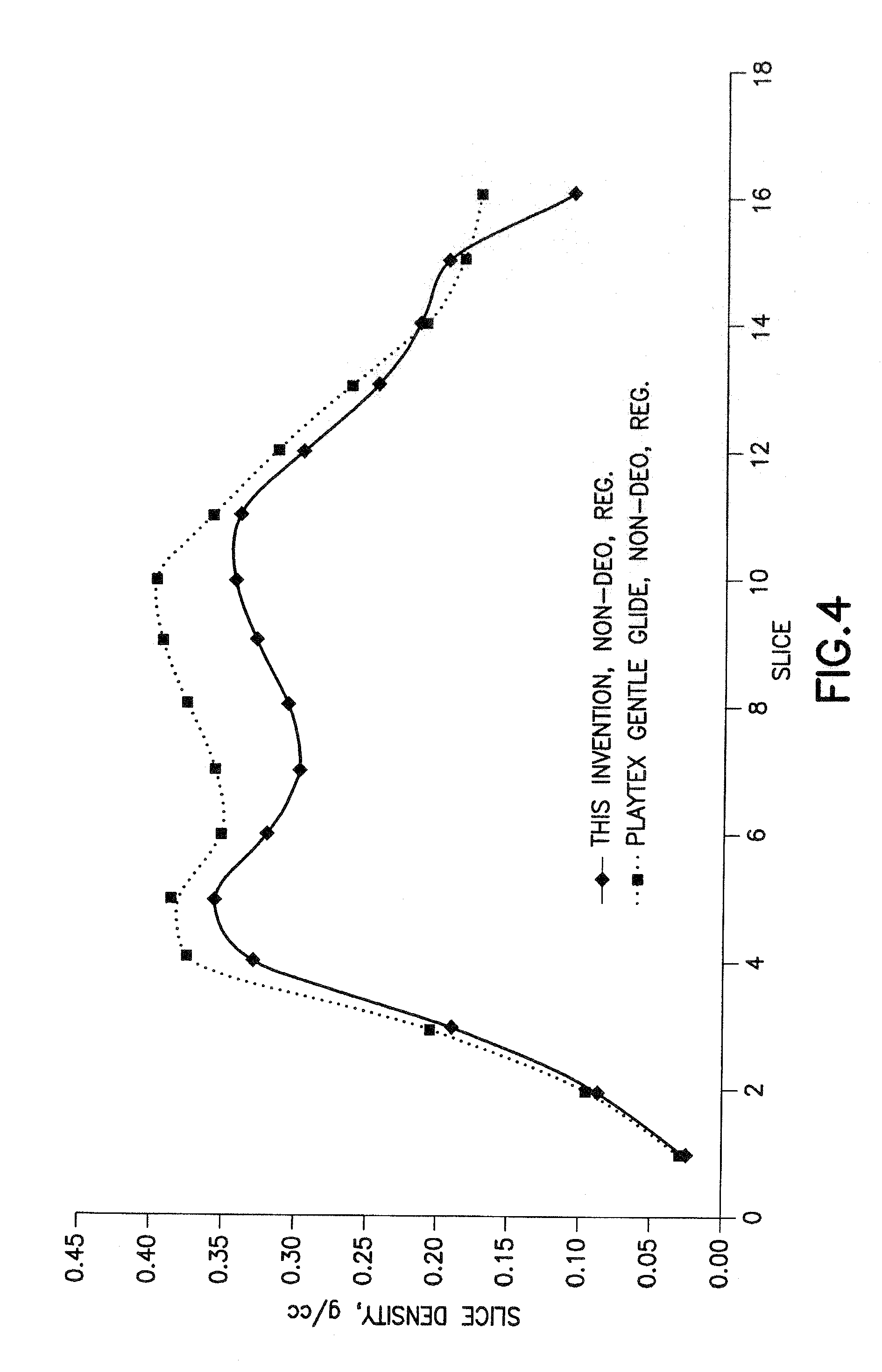

The present invention provides a tampon pledget with one or more of the following properties: increased absorbency rate; high absorbent capacity and fluid retention; rapid expansion potential; and ease of ejection of the pledget from the applicator. Surprisingly, the one or more properties are achieved by using a modified dual cross-pad, folded, compressed tampon pledget design.

Owner:PLAYTEX PROD INC

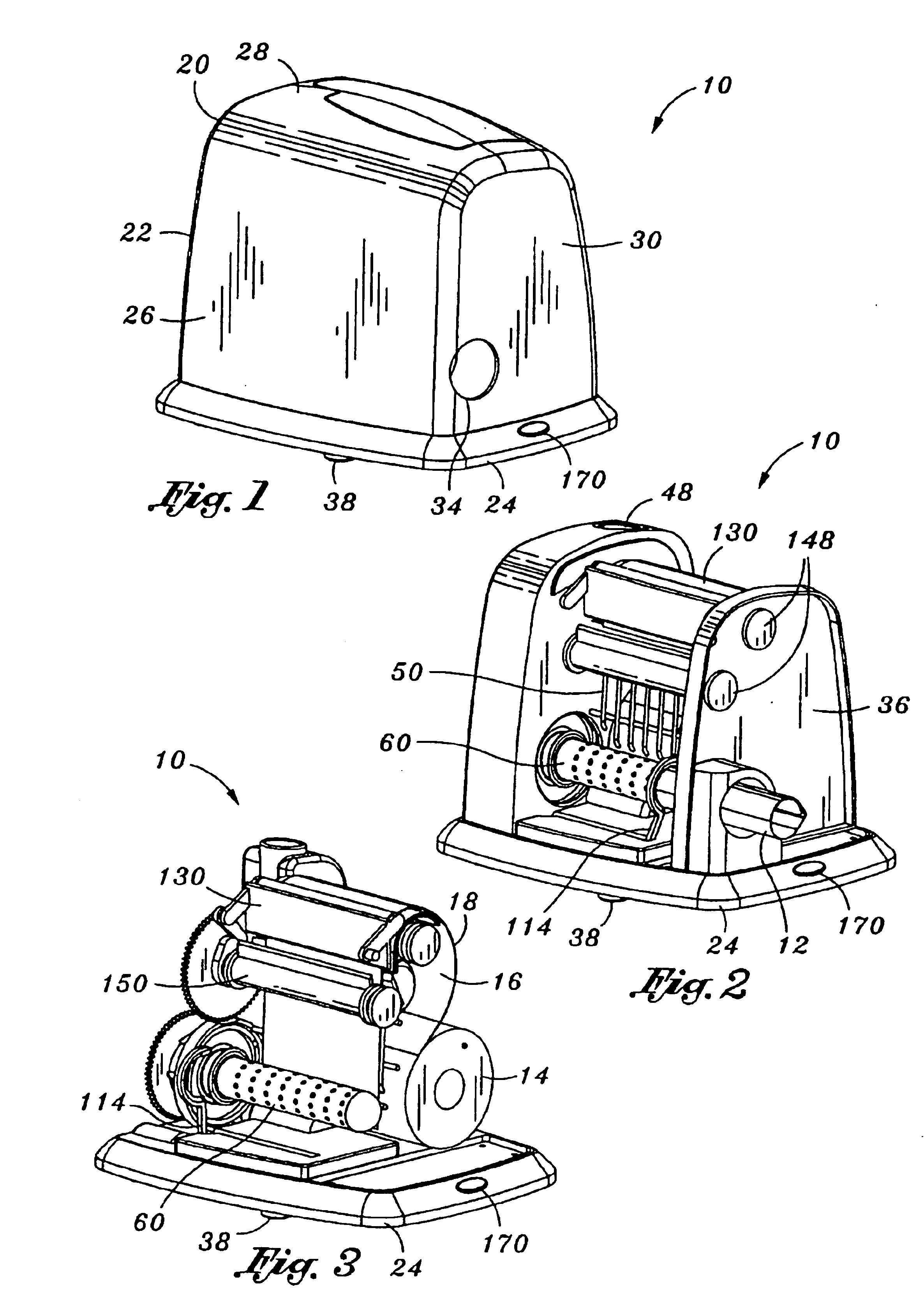

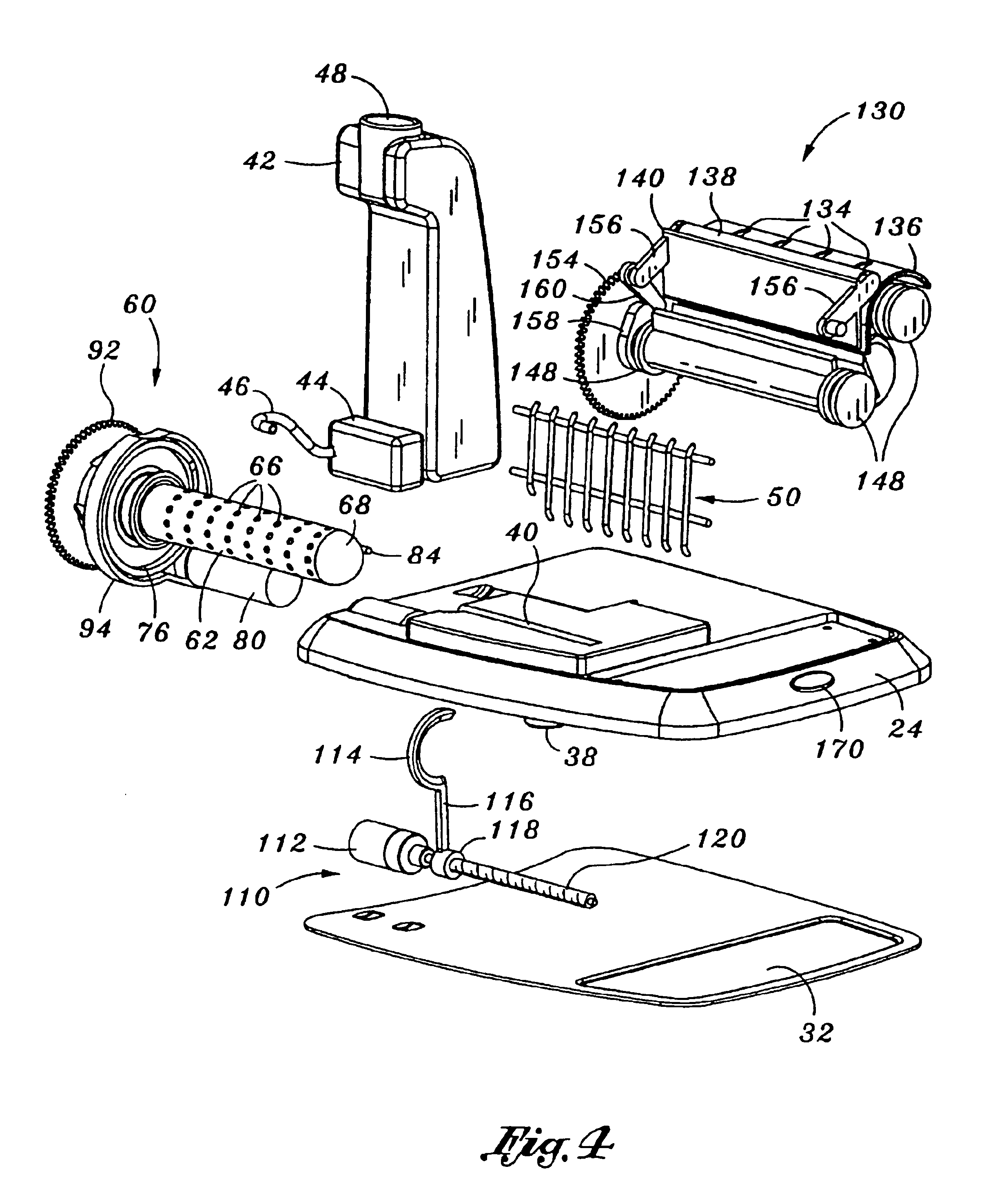

Hygienic wipes steamer

InactiveUS6903307B1Avoid safety hazardEfficient conduction of heatBaking ovenBathroom accessoriesHeating elementBiological activation

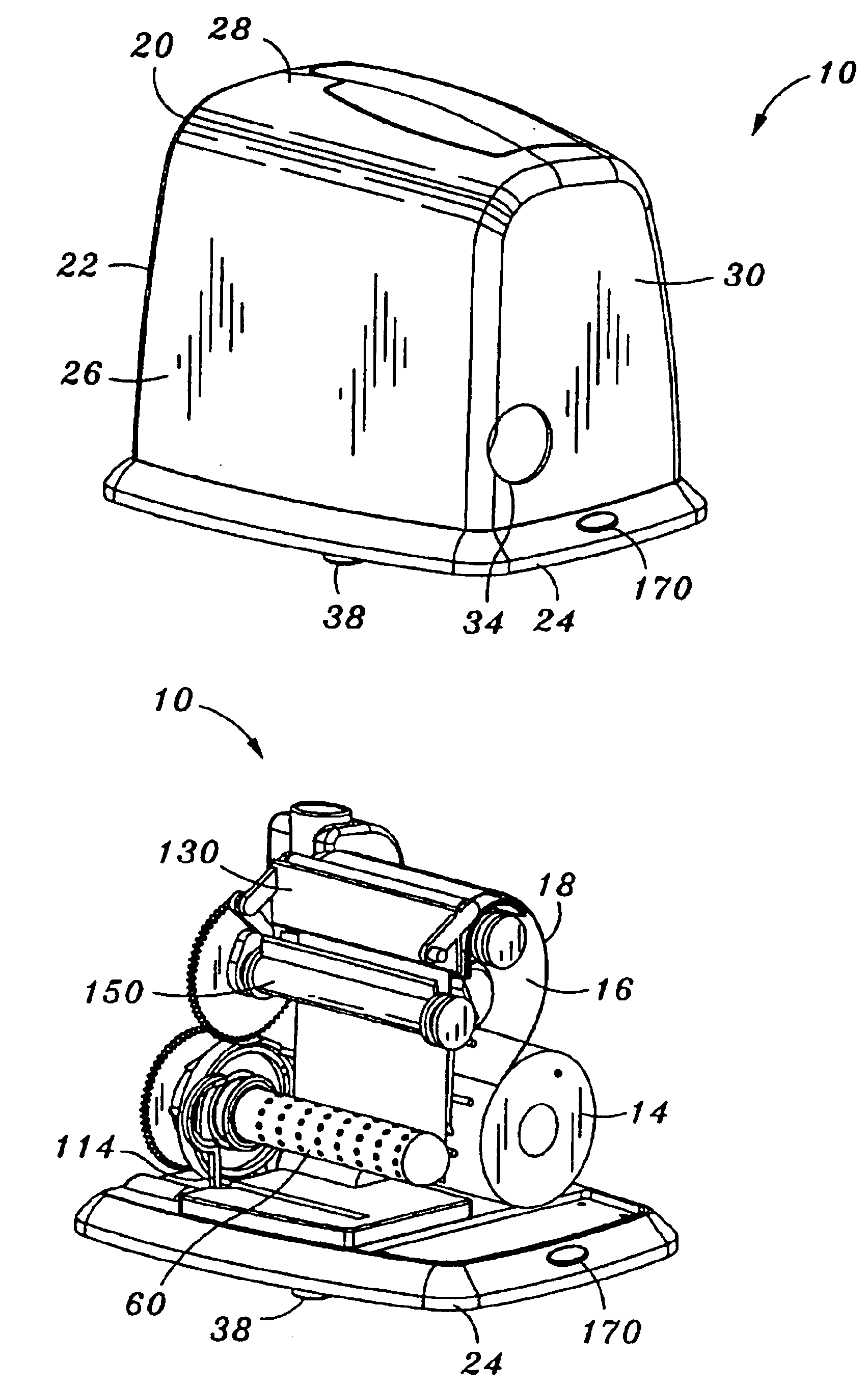

Provided is a hygienic wipes steamer for warming hygienic wipes. The hygienic wipes steamer comprises a housing assembly contains a liquid container, a roller assembly, a heater assembly and an ejector assembly. The liquid container stores a quantity of liquid. The roller assembly rotatably supports a roll of material and cuts the material into individual hygienic wipes during unwinding of the material. The heater assembly has a beating element and has steam holes formed therealong. The heater assembly is in fluid communication with the liquid container and receives hygienic wipes from the roller assembly. Upon activation of the hygienic wipes steamer, liquid flows into the heater assembly from the liquid container and is transformed into steam when heated by the heating element such that the steam passes through the steam holes and warms the hygienic wipe that is supported by the heater assembly. The ejector assembly ejects the warmed hygienic wipes from the hygienic wipes steamer.

Owner:PRINCE LIONHEART

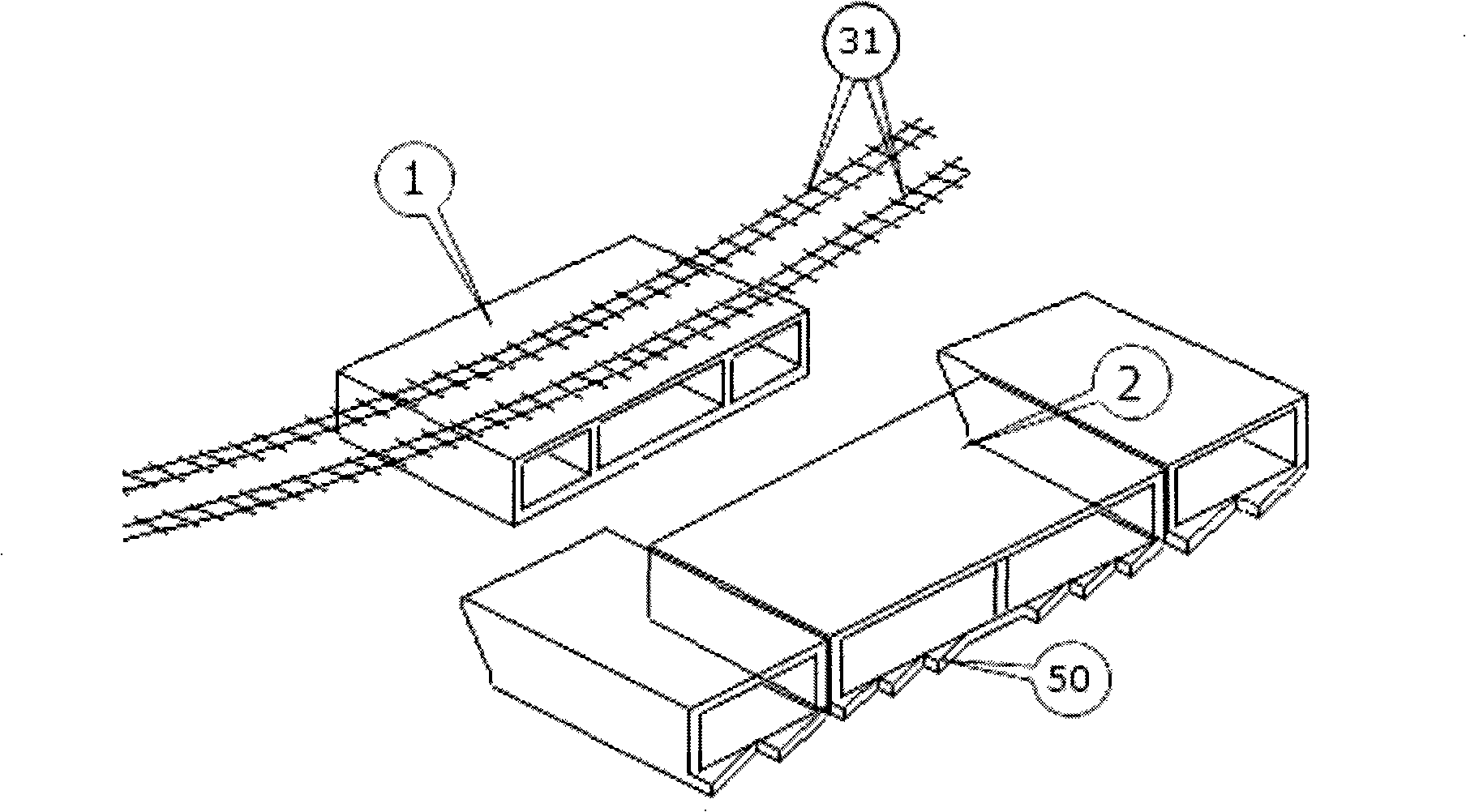

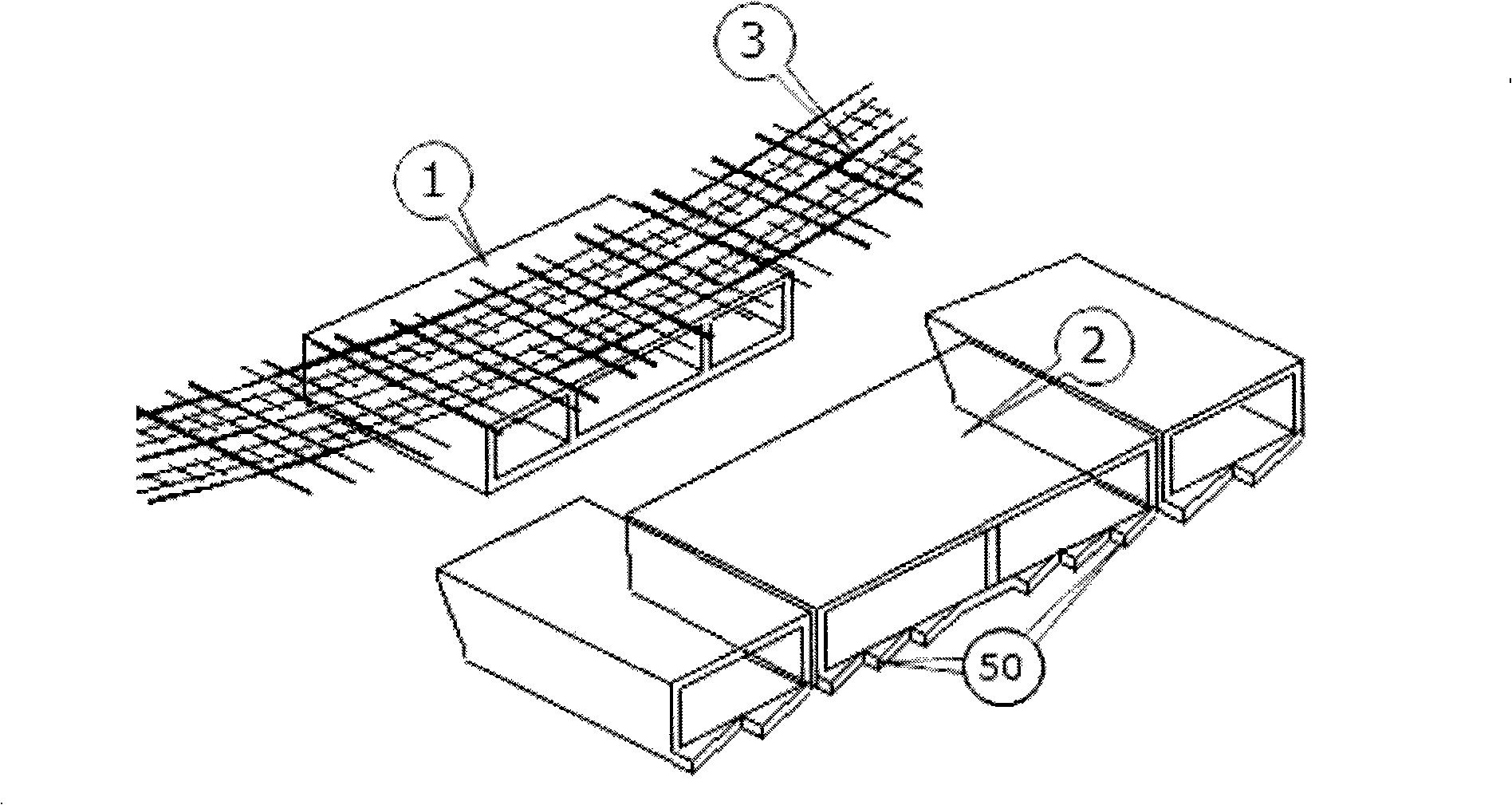

Construction method for replacing old frame bridge by new frame bridge in existing railway lines

InactiveCN101343861AEase of ejectionImprove securityBridge erection/assemblyBridge strengtheningEngineeringSlurry

The invention relates to a construction method for the new frame bridge to replace the old frame bridge on the prior railway. The construction method comprises the required jacking force of the old frame bridge according to the formula; the prior railway line is strengthened; the line strengthening system and the reinforcing steel drawing ring are tightened through a jack; the lately supplemented triangular blocks is arranged at the rear end of the bottom plate of the old frame bridge; a cantilever bracket is arranged; a new bridge back is arranged, and a jacking column and a jacking pickaxe are respectively arranged between the new frame bridge and the new bridge back and between the old frame bridge and the cantilever bracket; a plurality of thixotropic slurry holes are formed on the both sides of the old frame bridge and the bottom surface of the bottom plate, and thixotropic slurry is filled into the thixotropic slurry holes; the old frame bridge is jacked out; when the old frame bridge is jacked out, the new frame bridge is jacked in. Under the precondition that the railway operation is not interrupted, the construction method can rapidly jacked the old frame bridge out, the application scope is wide, and the construction method can not be limited by time and space. In addition, because the conventional reinforcement method of track lock plus the longitudinal and horizontal beam is adopted in the prior railway line, the construction method is suitable for various railway situations such as a straight line section and the curved line section, and the security is high.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

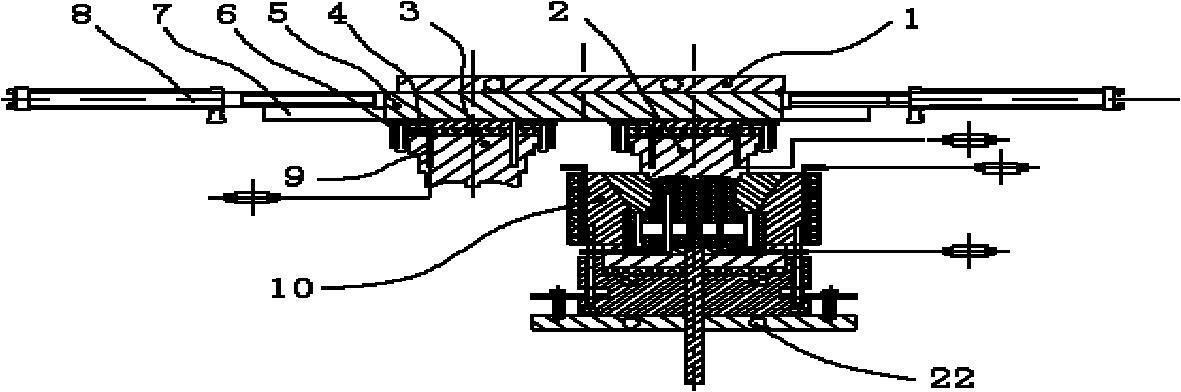

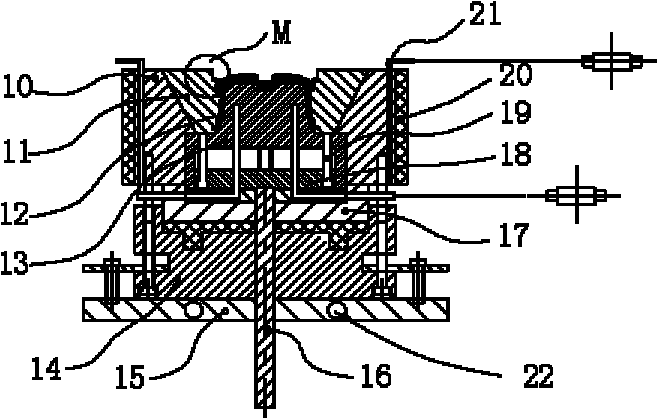

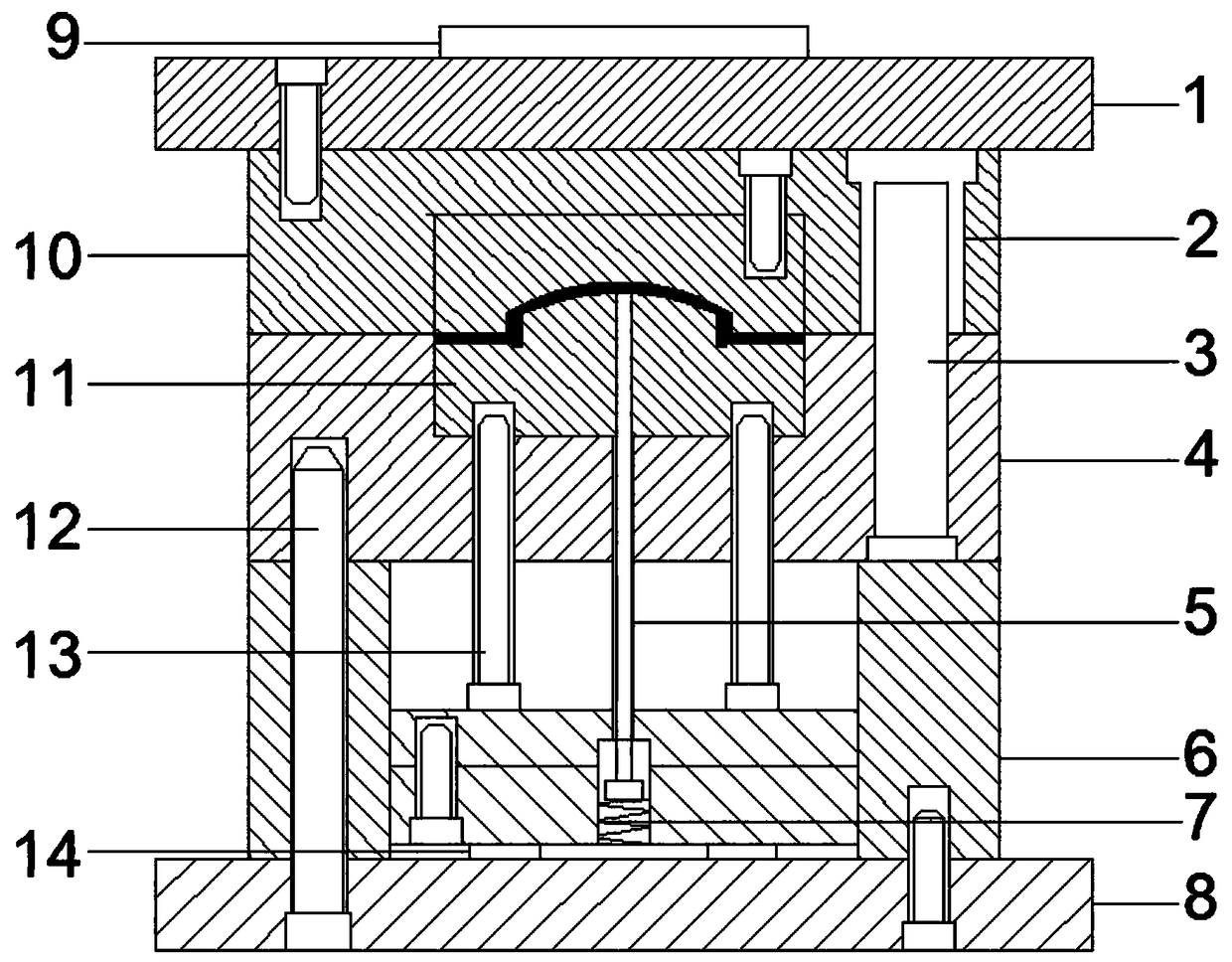

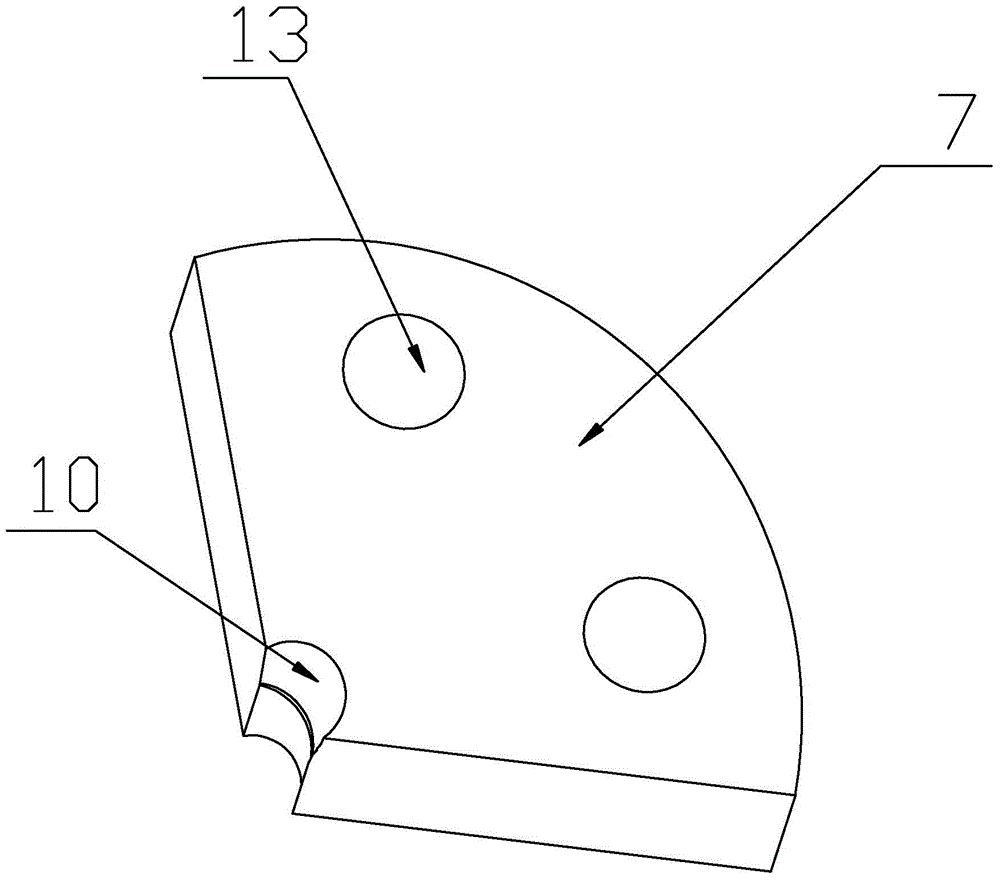

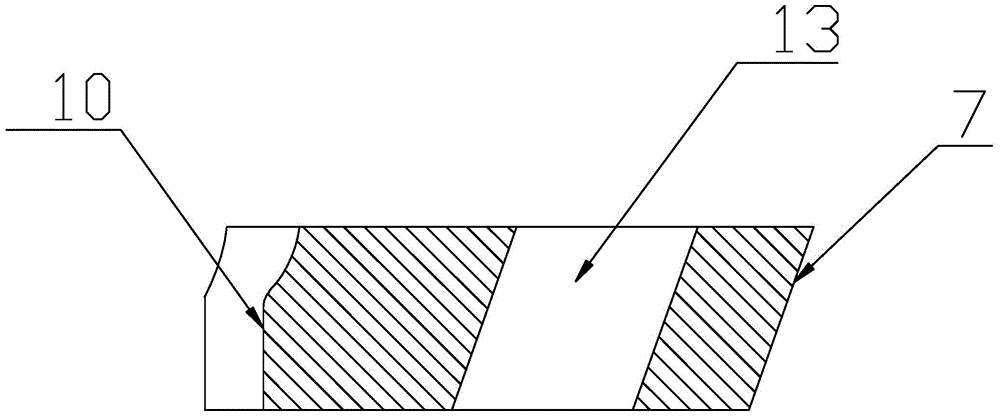

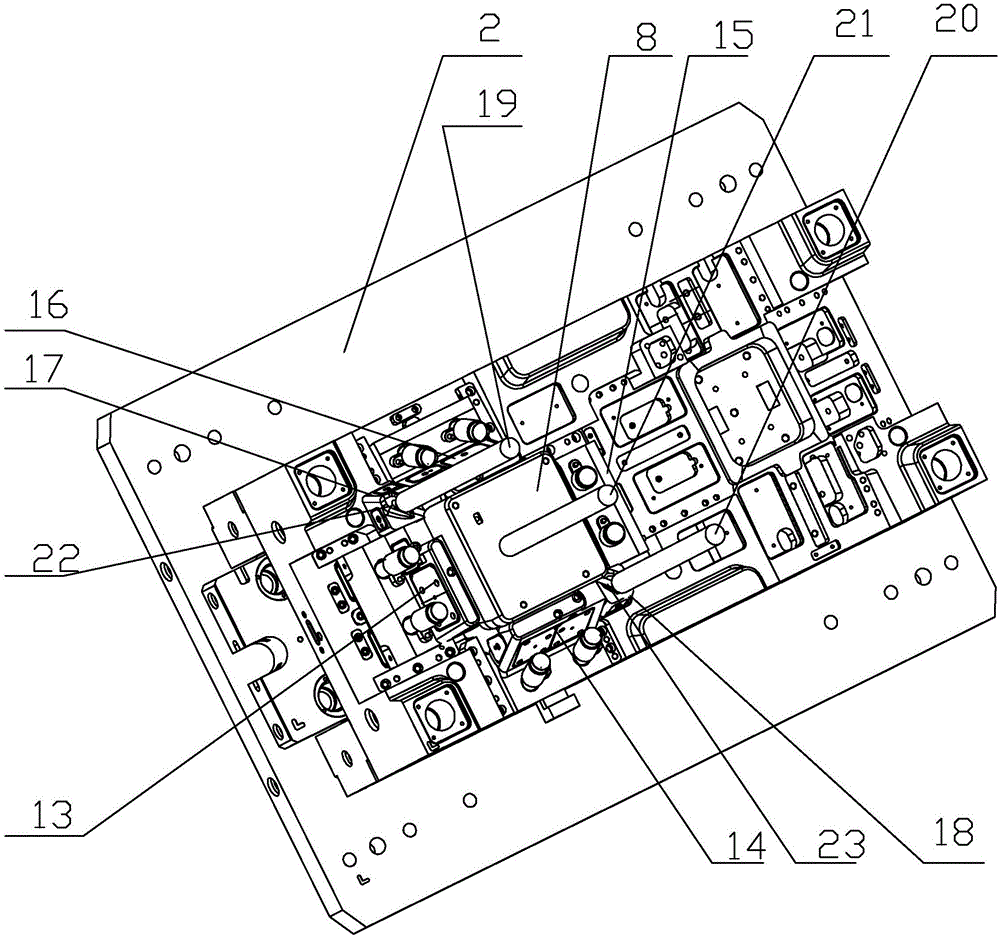

Cutting-free forming die of expansion anchor bolt

ActiveCN101829756AEase of ejectionDense tissueBoltsForging/hammering/pressing machinesEngineeringUltimate tensile strength

The invention discloses a cutting-free forming die of an expansion anchor bolt, which comprises a first station forming die, a second station forming die, a third station forming die and a fourth station forming die in turn, wherein the first station forming die is provided with a knocking platform forming cavity; the second station forming die is provided with a supporting step tail part forming cavity; the third station forming die is provided with a supporting step forming cavity; the fourth station forming die is provided with a taper hole; and a cone forming internal mold is movably sleeved in the taper hole and comprises at least three movable molds which are separated from one another. A blank is processed by cold heading extension bar parts of the first station forming die, the second station forming die and the third station forming die in turn, and then is formed into the head part of the expansion anchor bolt by the movable molds of the fourth station forming die; the formed expansion anchor bolt is not processed by turning, and because the cold heading makes the expansion anchor bolt have the advantages of compact texture, high strength, high tensile property and shear resistance, good product quality and high processing efficiency, and is favorable for large-scale production of the expansion anchor bolt.

Owner:EAGLE METALWARE

LED (Light Emitting Diode) integrated structure, manufacturing method, lamp, display screen, backlight device, projecting device and injection mould of forming plastic part

InactiveCN101963295AReduce distanceRealize high-definition image displayPlanar light sourcesPoint-like light sourceLuminous fluxLight-emitting diode

The invention relates to an LED (Light Emitting Diode) integrated structure comprising a radiating base plate, an LED chip, a lens, a plastic piece of a positioning lens or a forming lens, a conducting wire and a layout circuit conducting layer, wherein two or more than two chip fixing lug bosses which are integrally formed with the radiating base plate are arranged on the radiating base plate, a first through hole of the positioning lens or the forming lens is arranged on the plastic piece of the positioning lens or the forming lens, the chip fixing lug bosses are arranged in the first through hole, the layout circuit conducting layer is extended between the inside wall of the first through hole and the outside walls of the chip fixing lug bosses, one end of the conducting wire is electrically connected with the LED chip, and the other end of the conducting wire is electrically connected with the layout circuit conducting layer which is extended between the inside wall of the first through hole and the outside walls of the chip fixing lug bosses. The LED integrated structure has the advantages of low thermal resistance of an intermediate link, good heat radiating performance, accurate position relation of the lens and the chip, high luminous flux, simple structure, simple assembly, good radiating effect and good optical effect.

Owner:杨东佐

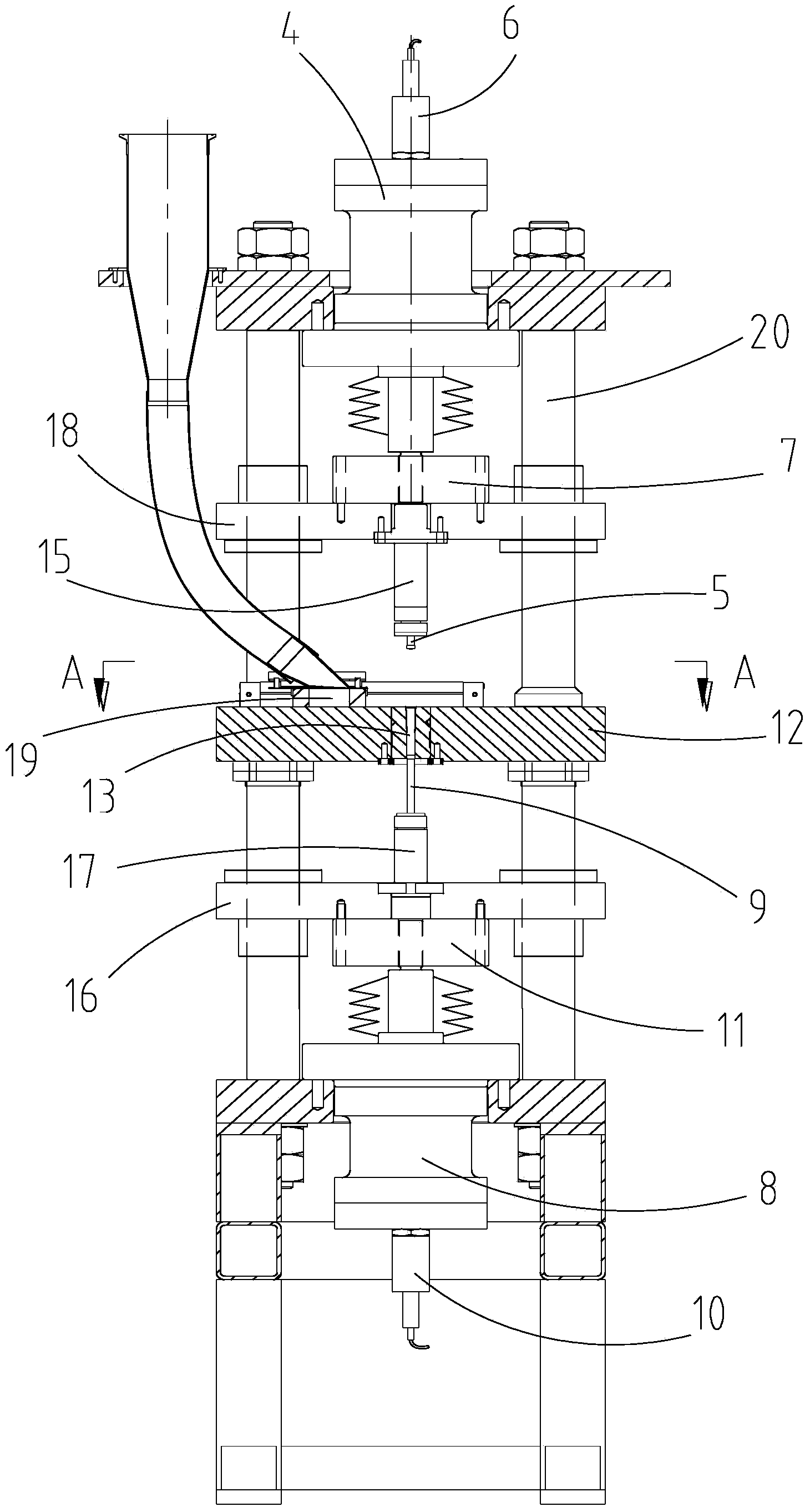

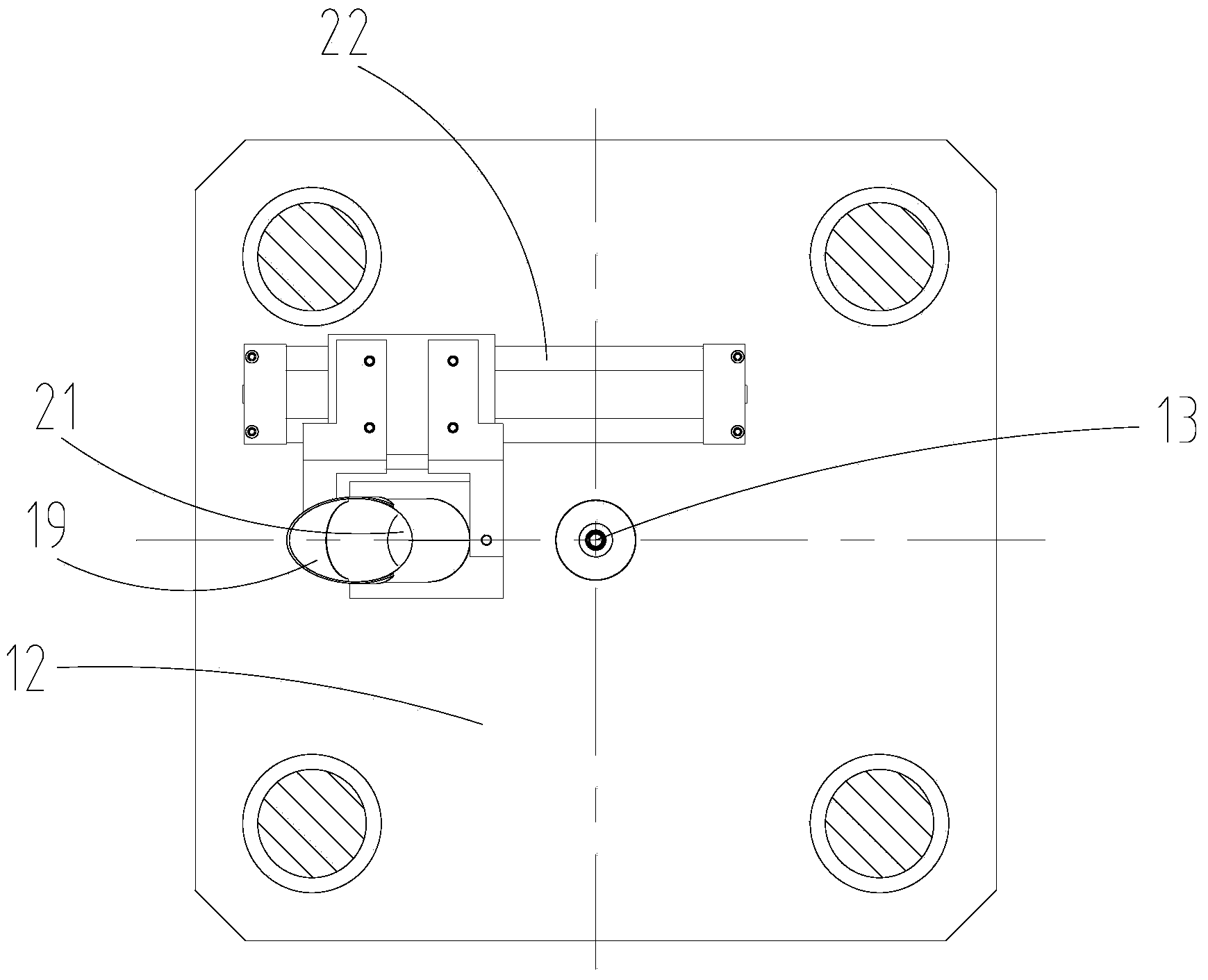

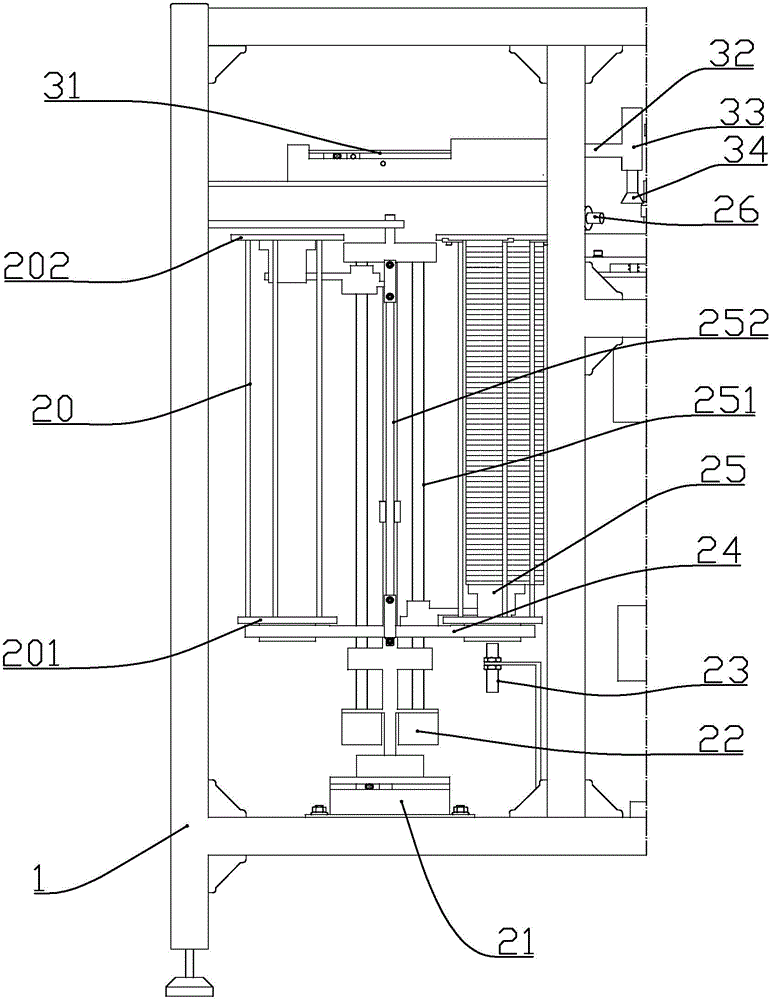

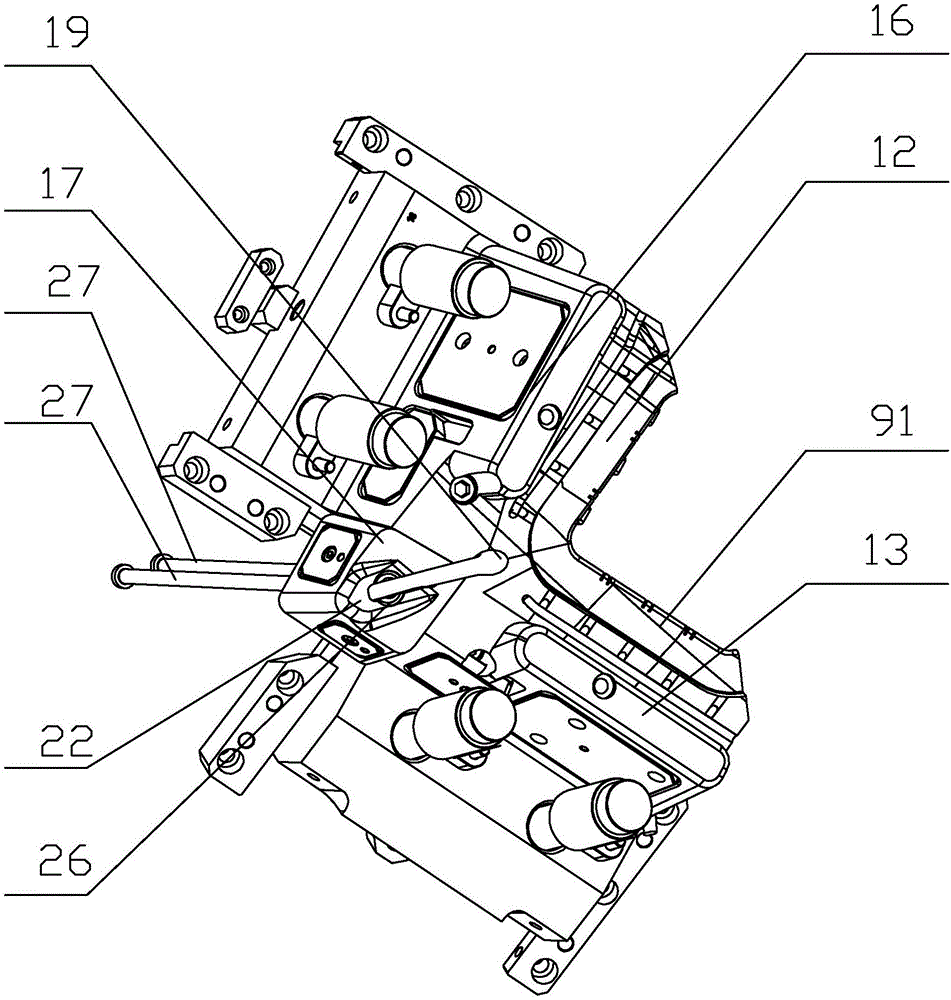

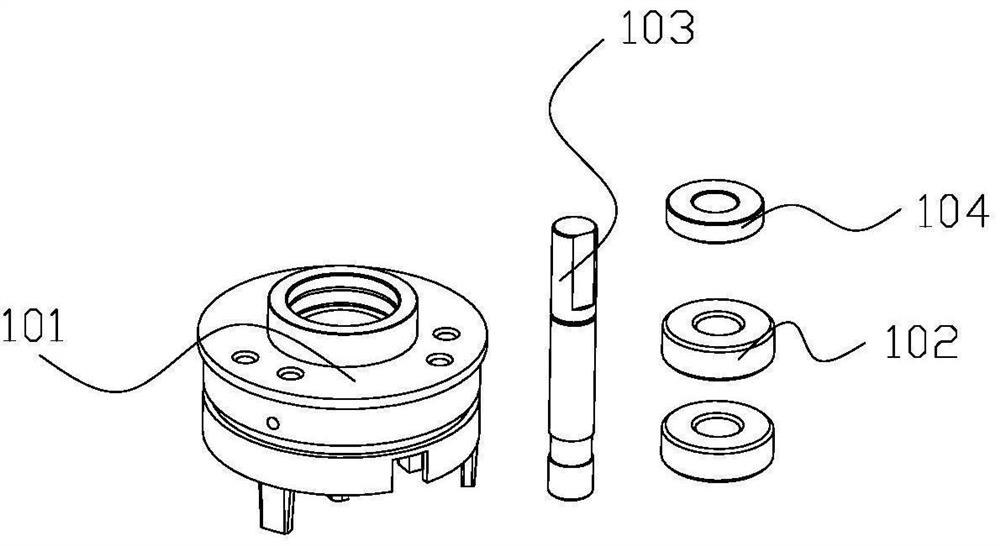

Water sealing stationary ring subgroup assembling machine

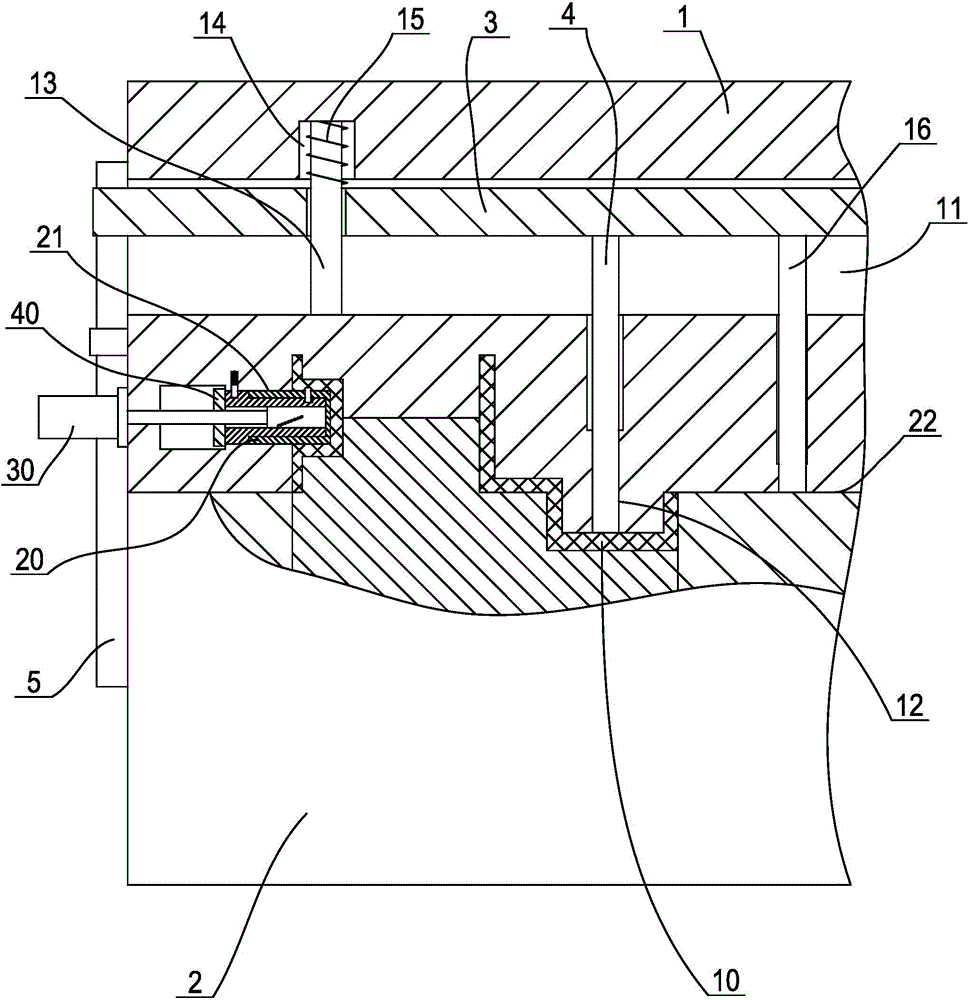

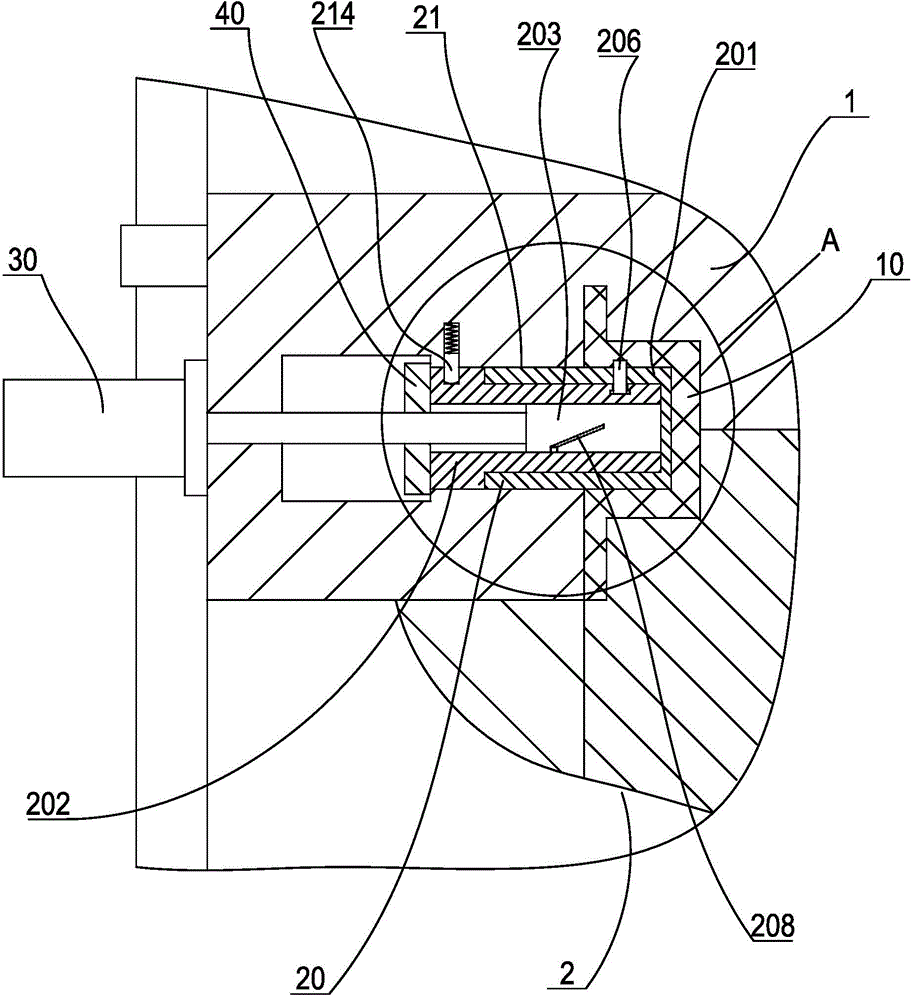

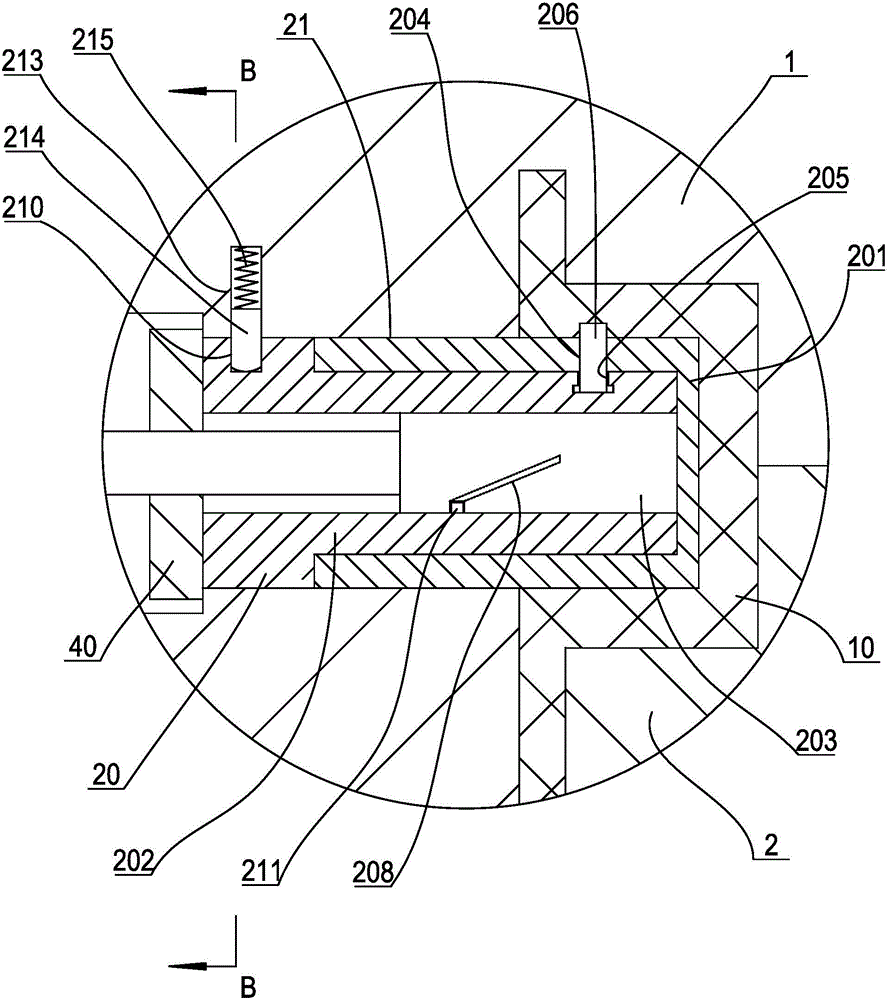

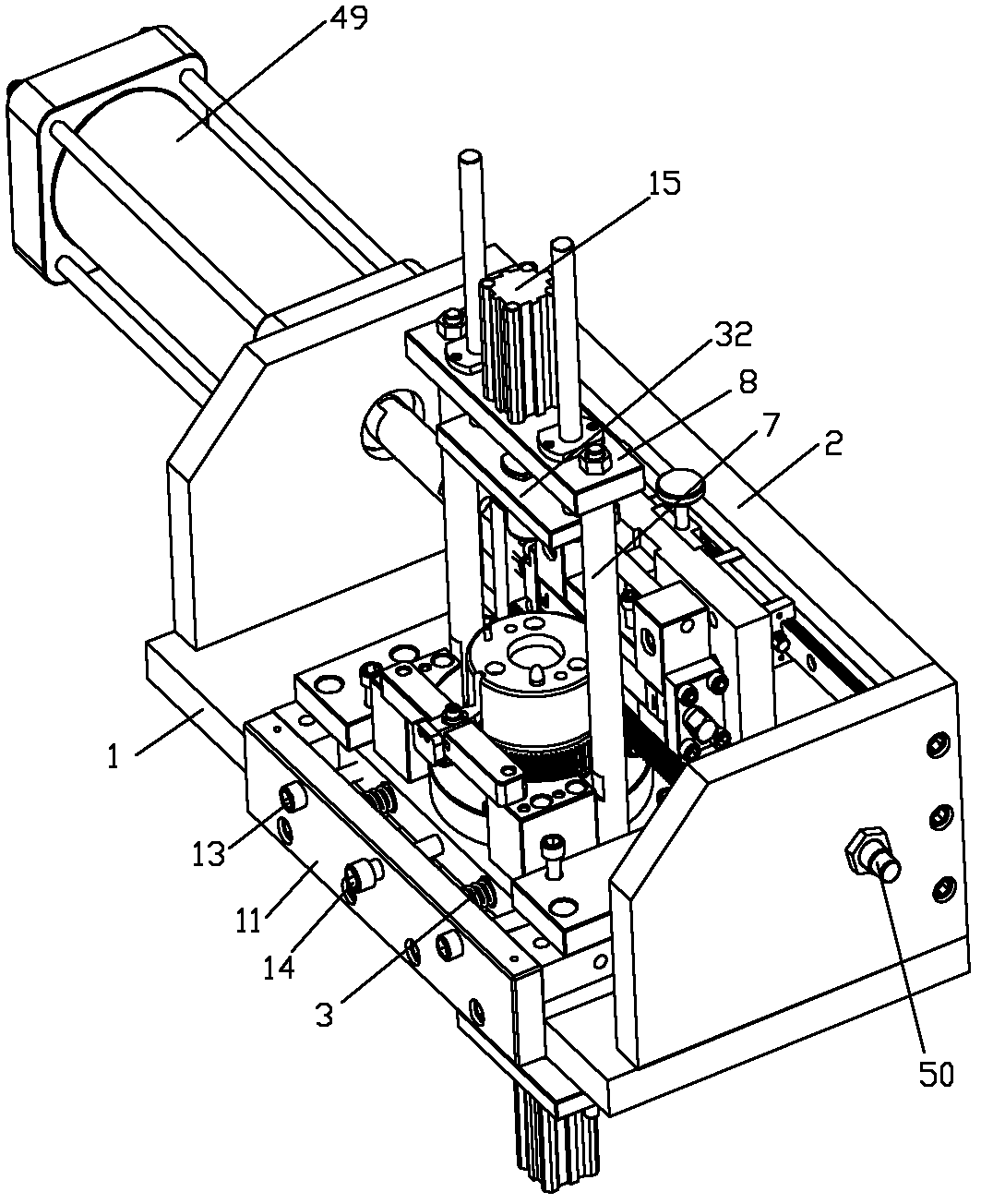

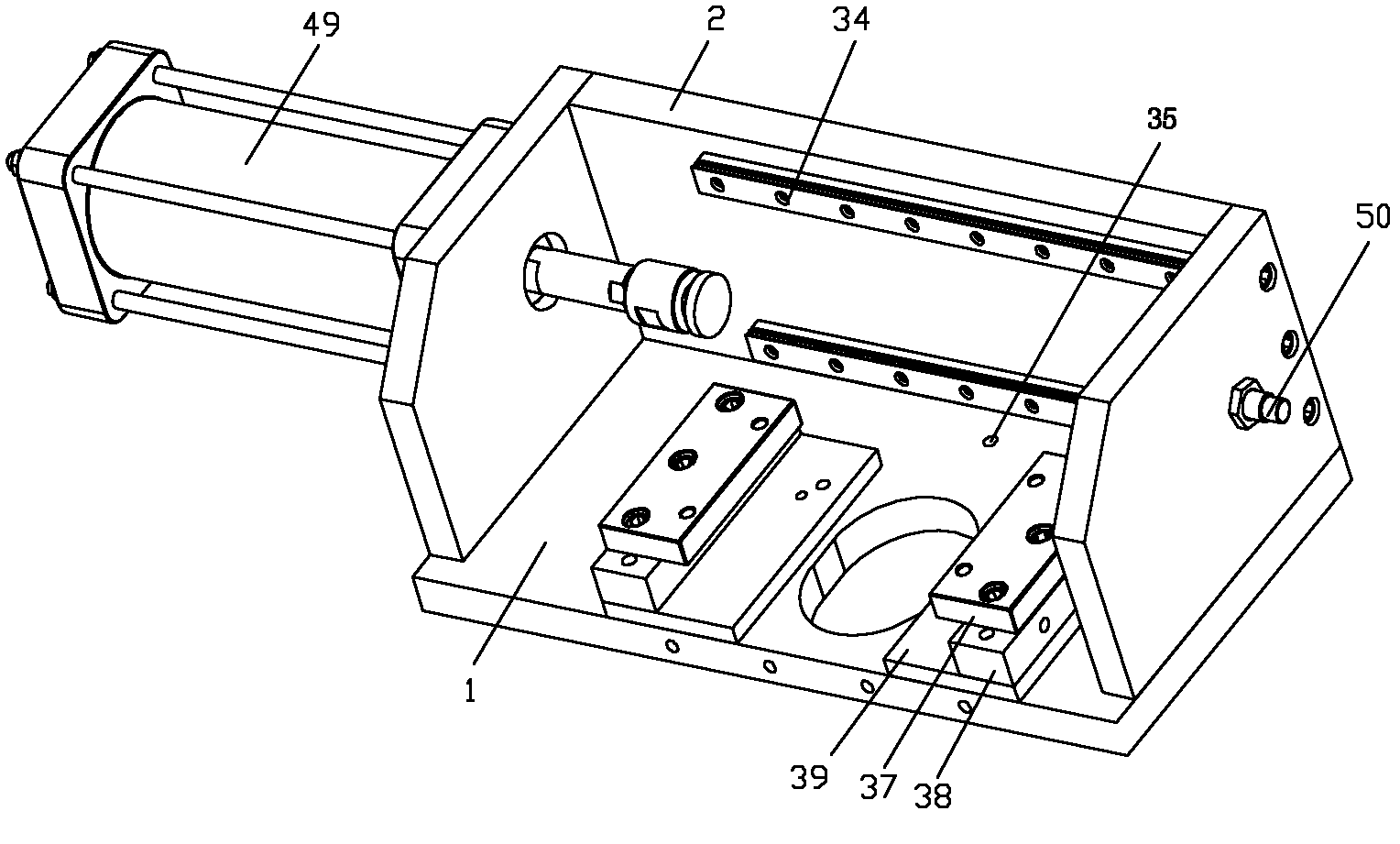

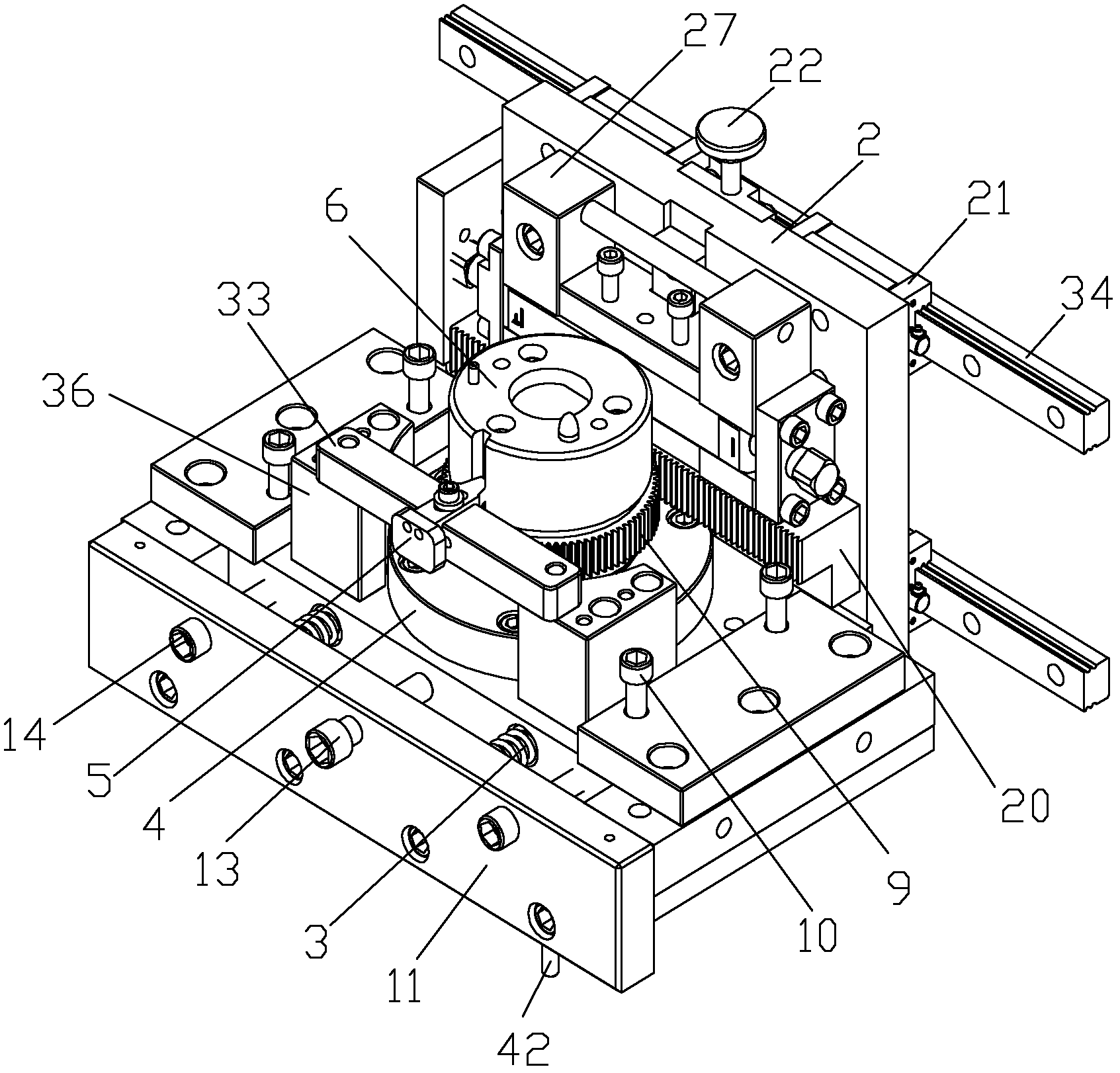

ActiveCN101318289AMeet assembly requirementsEasy to put inAssembly machinesMetal working apparatusEngineeringAssembly machine

The invention discloses an assembly machine for water seal static ring components, which mainly comprises a bottom plate (13), a worktable (12), a lead rail (32), an indenter device I, a pressure plate device, a slide carriage device and mechanical grippers matched with the pressure plate device and the slide carriage device; the worktable (12) is arranged above the bottom plate (13); the indenter device I is arranged at one end of the bottom plate (13); the pressure plate device is arranged below the indenter device I and is also arranged on the bottom plate (13); the axis of a through hole (17) of the pressure plate device and the axis of an indenter I (15) of the indenter device I are in the same line; the minimum diameter of the through hole (17) is larger than the external diameter of the indenter I (15); the slide carriage device is matched with the lead rails (32) arranged on the bottom plate (13) in a sliding way. The assembly machine for water seal static ring components is high in assembly precision and efficiency, simple and convenient in operation.

Owner:NINGBO VULCAN TECH CO LTD

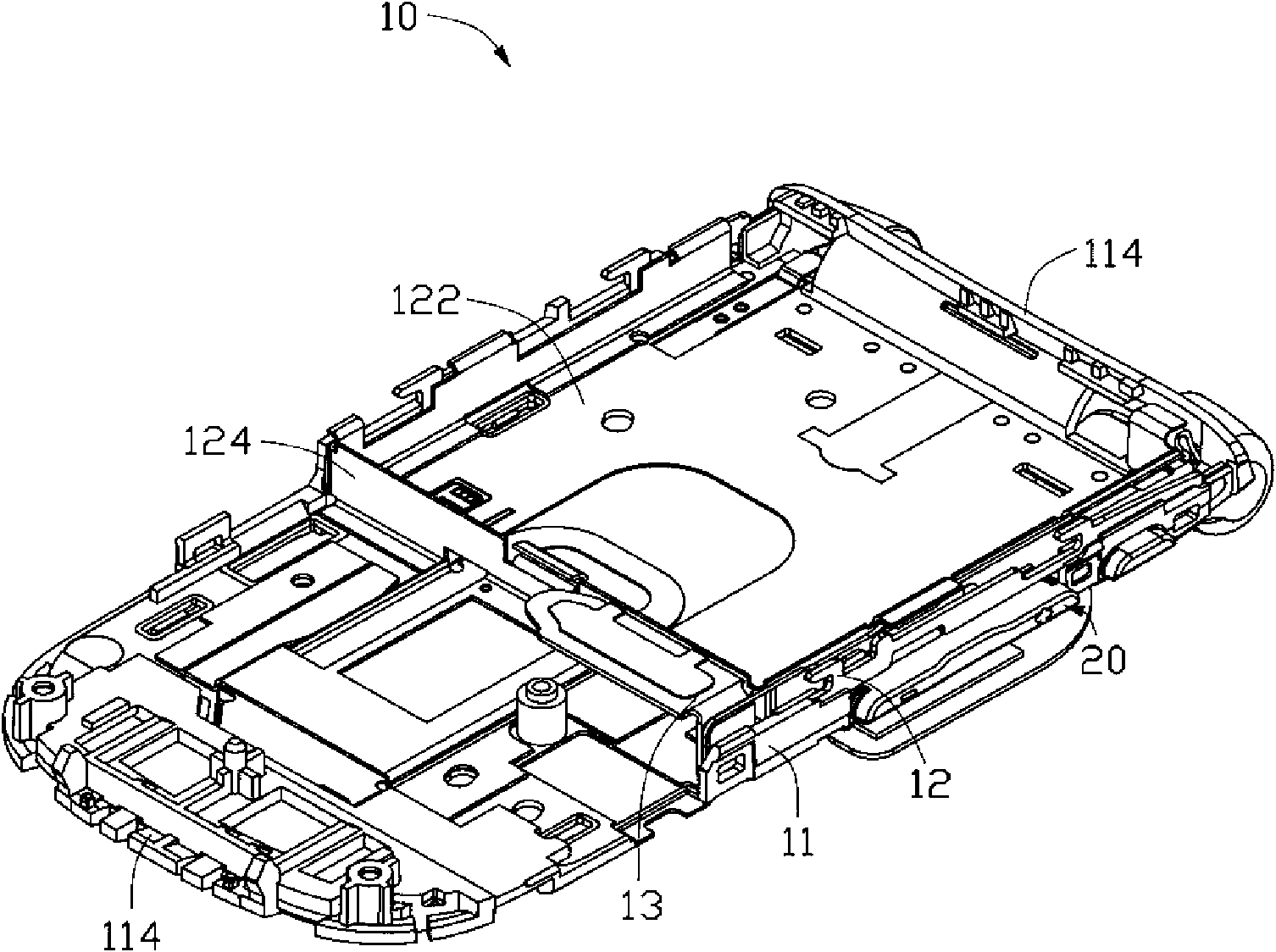

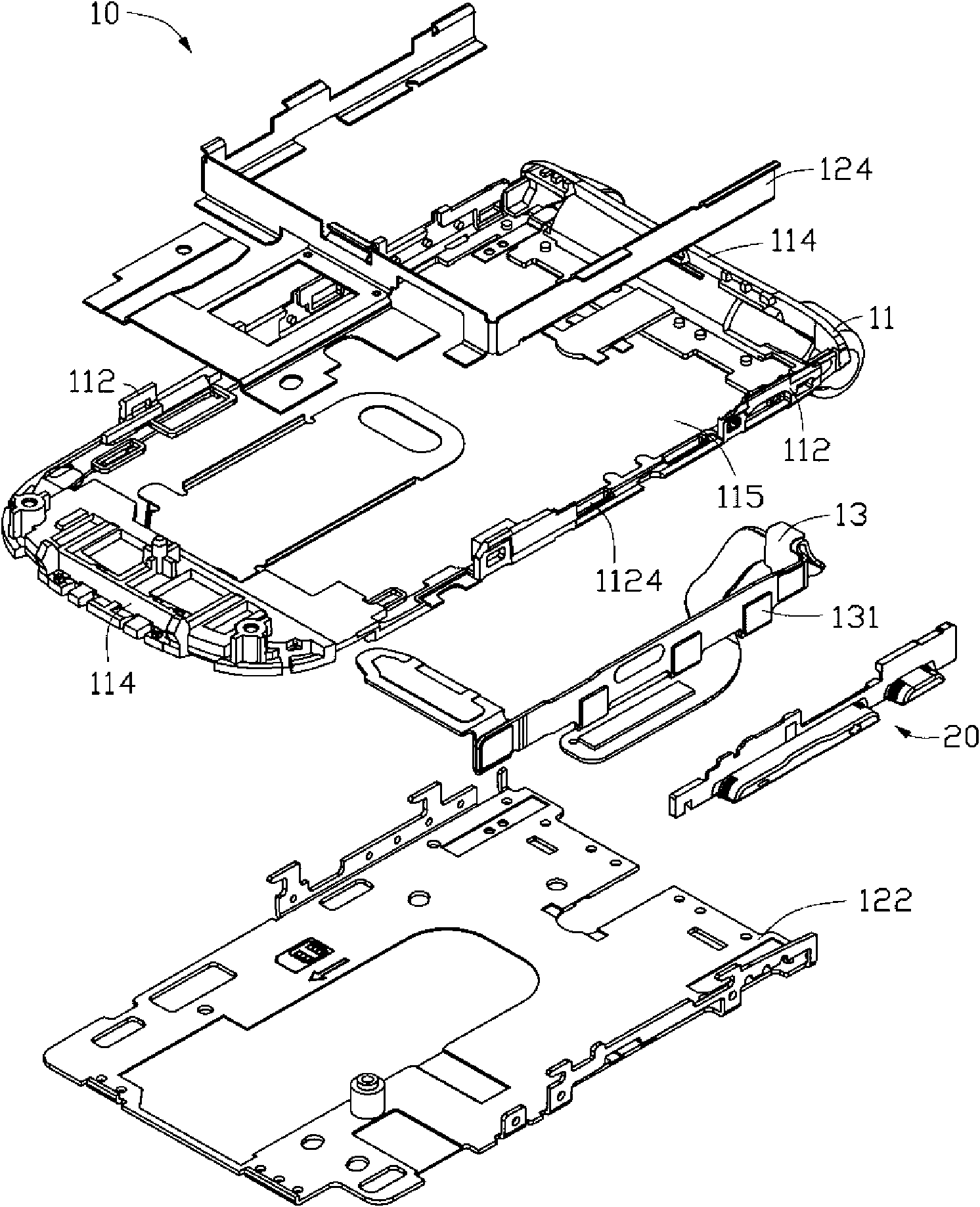

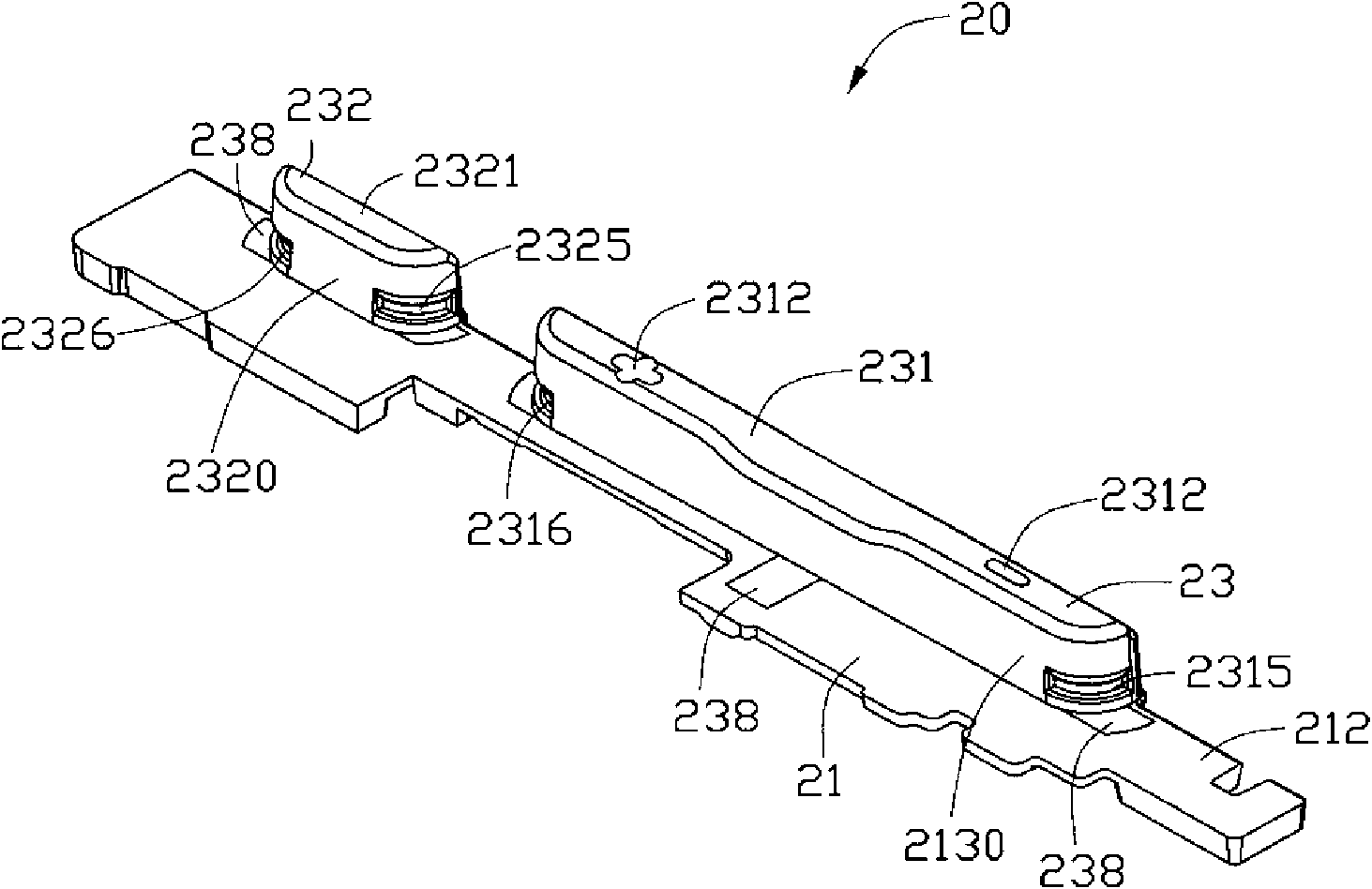

Side key and electronic device applying same

InactiveCN101859659AEase of ejectionAvoid damageEmergency actuatorsEmergency casingsPrinted circuit boardEngineering

The invention discloses a side key, which is used for an electronic device of a printed circuit board with a shell or arranged inside a shell. The side key comprises a support and a key body which are molded by double-material injection. The support is connected with the shell of the electronic device, a contact used for triggering the printed circuit board of the electronic device is formed on the support, and the contact and the support are respectively formed on two opposite sides of the support. A groove used for the ejection of the side key during double material injection molding is formed on the surface of the side key, which is connected with the support. The groove enables the molded side key to be ejected out of an injection mold conveniently, thereby improving molding yield, avoiding the damage to the mold if that the side key is kept in the injection mold, and prolonging the service life of the mold. The invention also provides an electronic device applying the side key.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

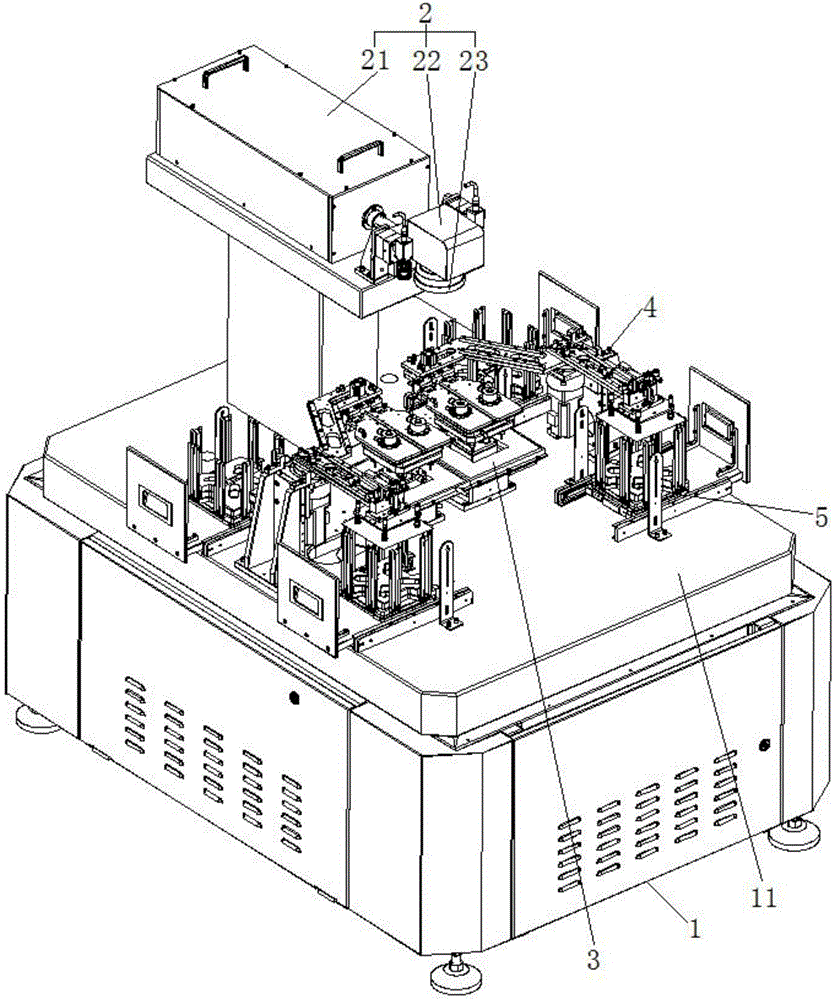

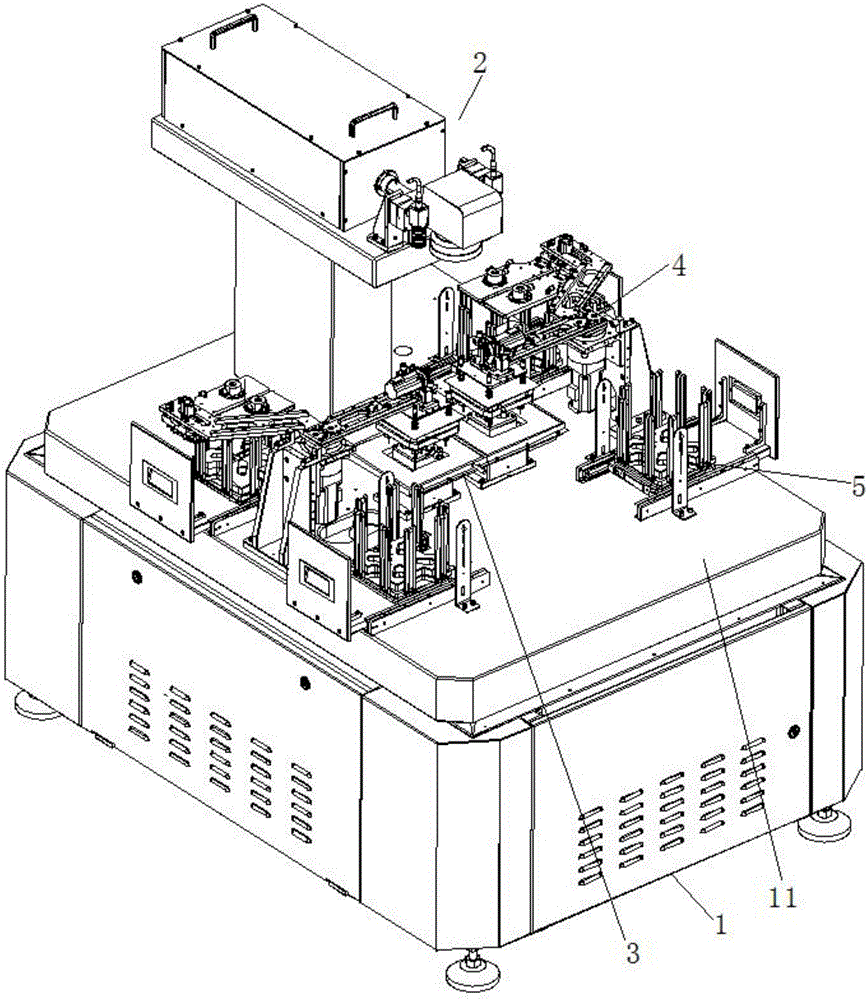

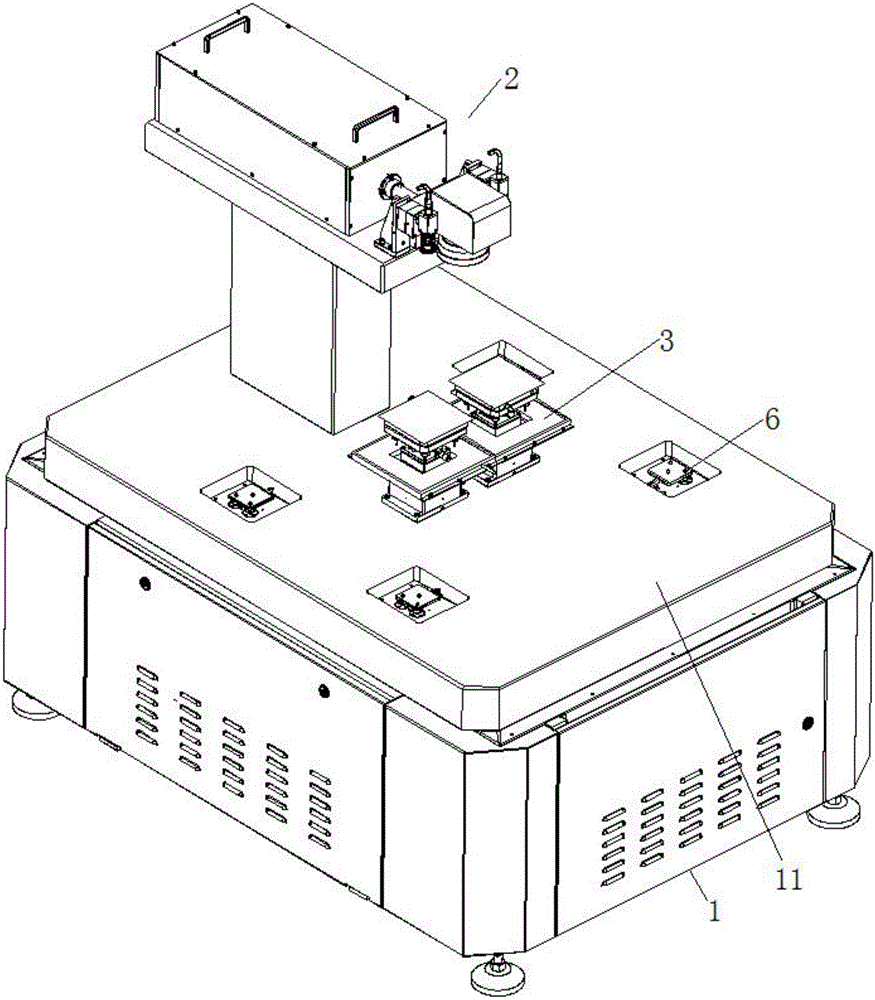

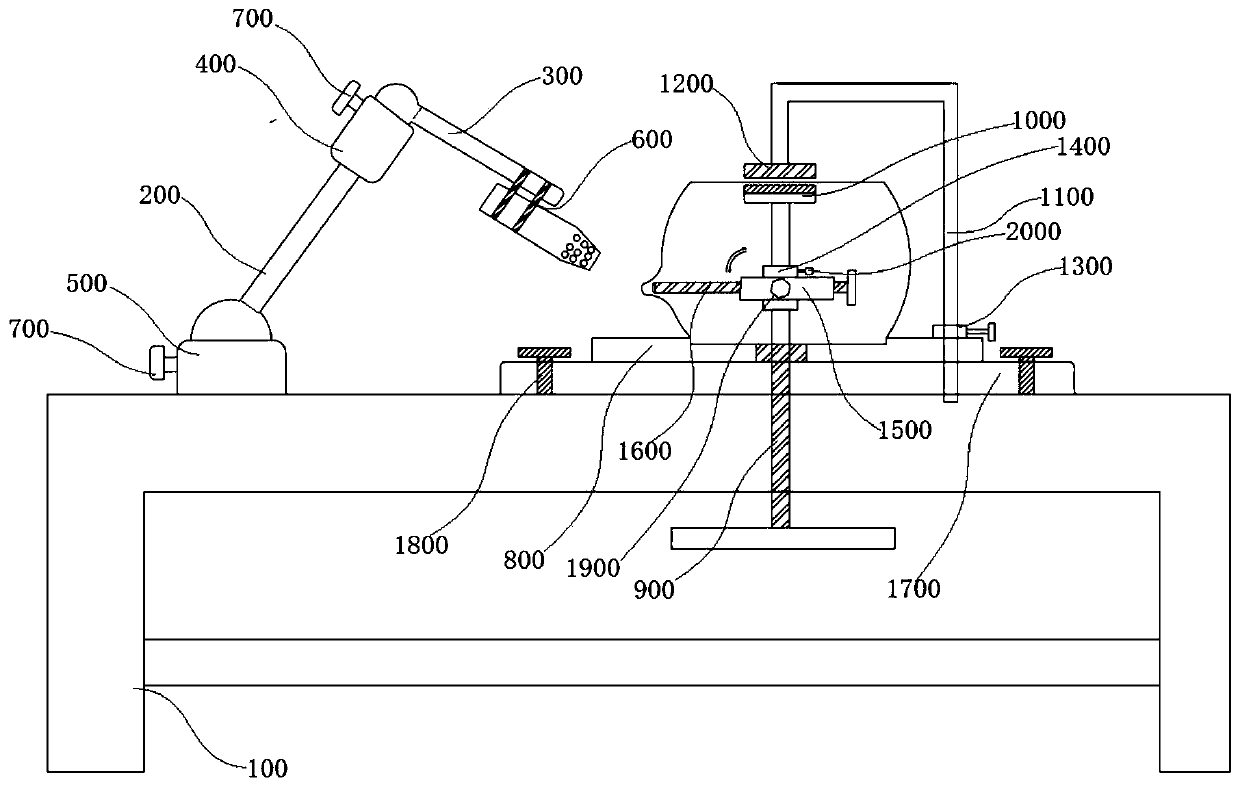

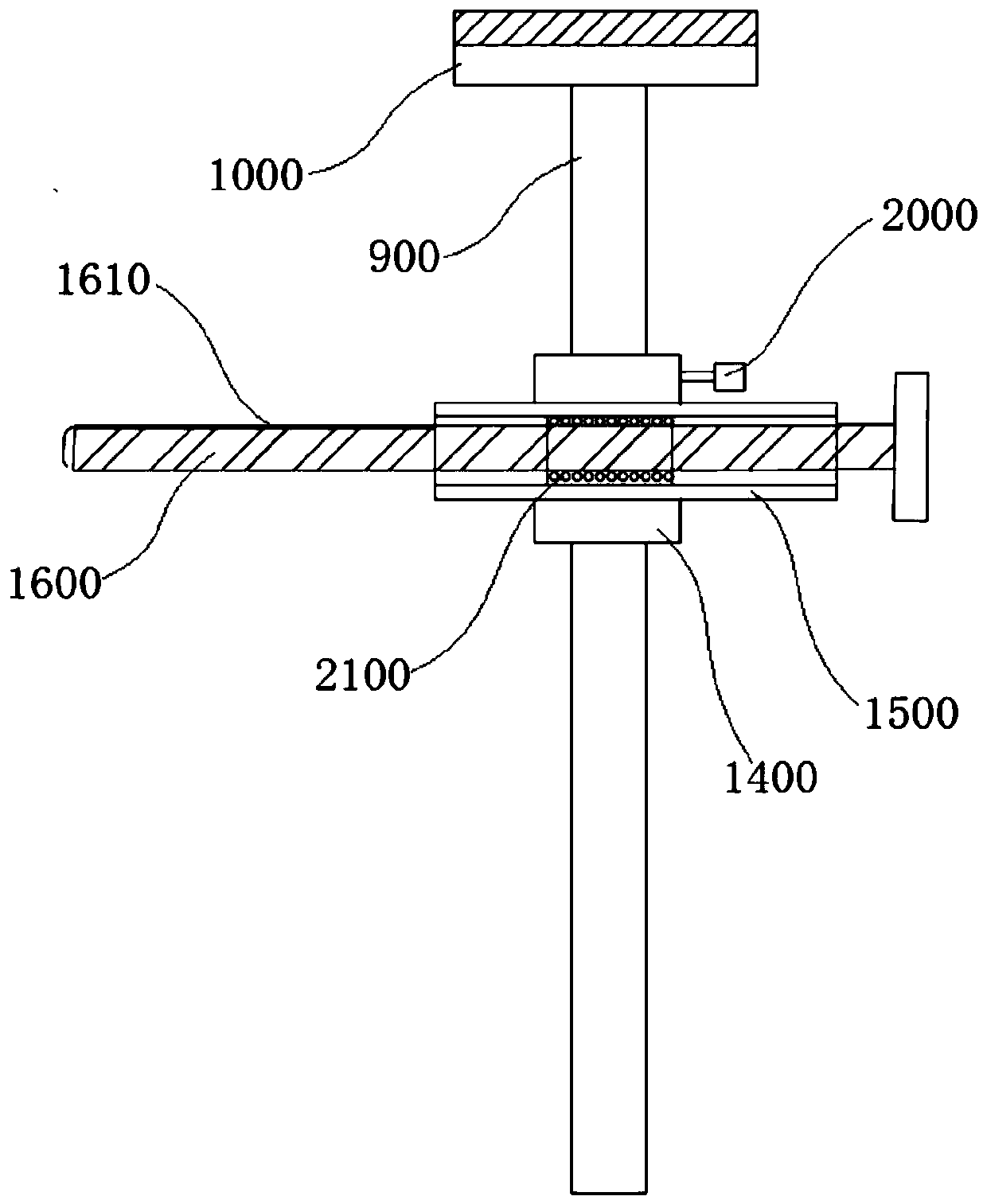

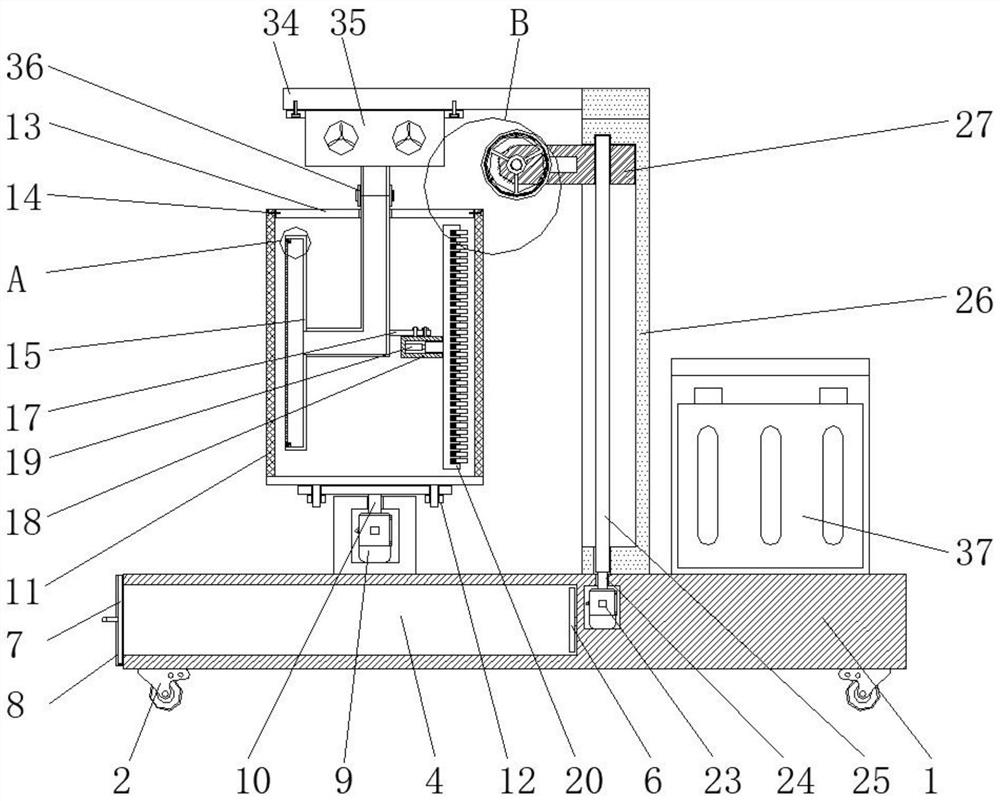

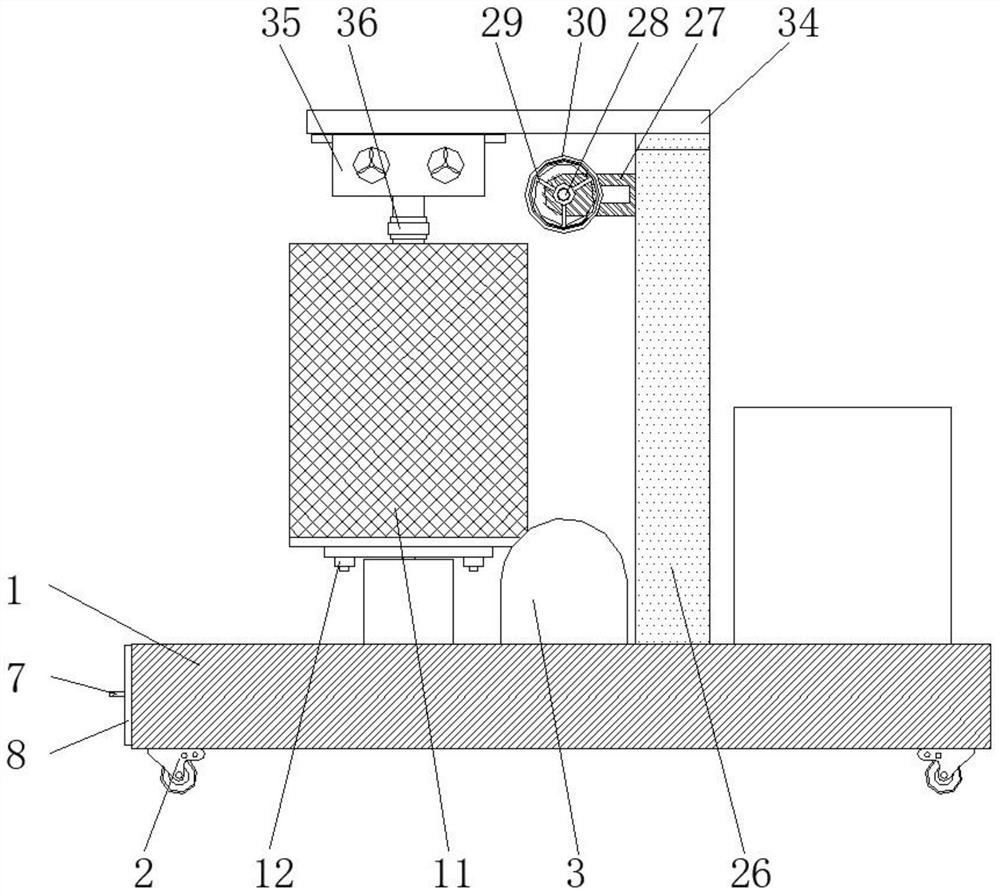

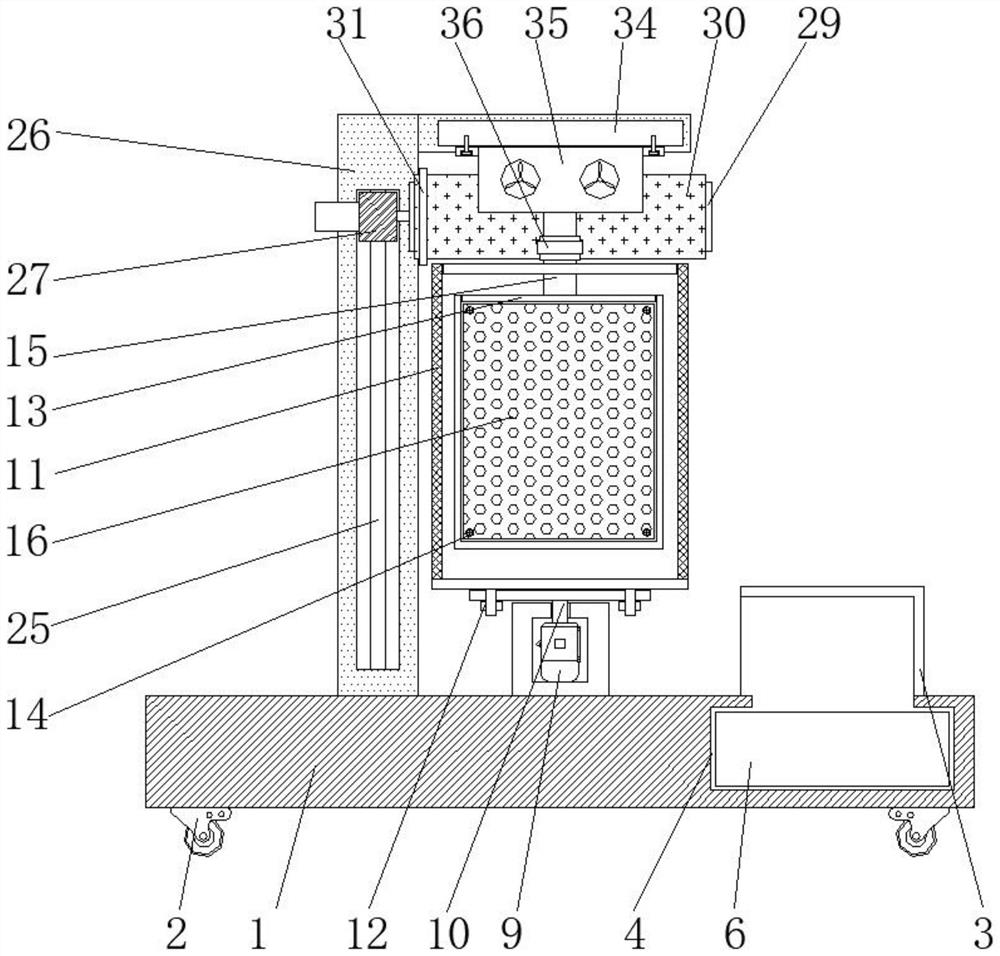

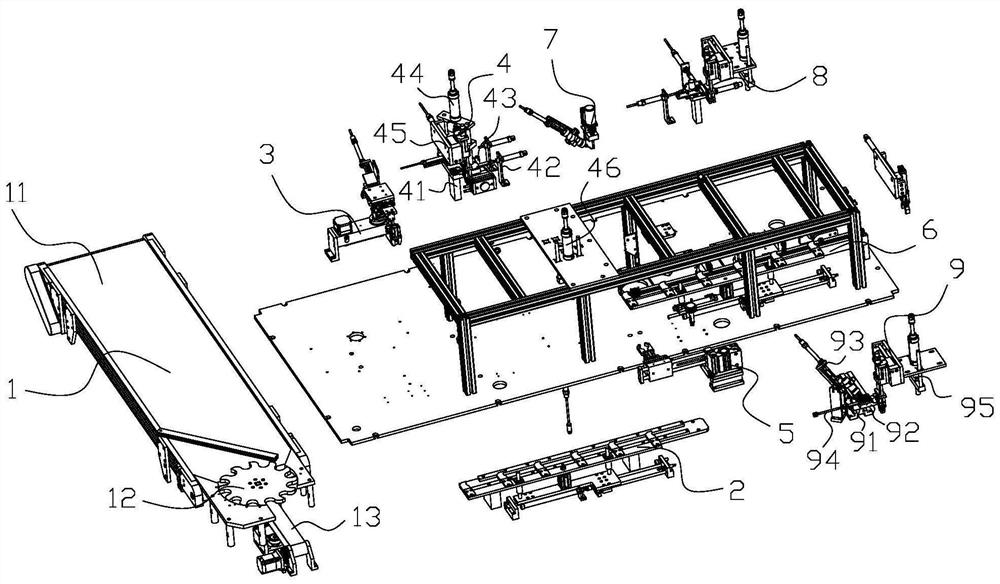

Laser half-cutting machine for crystal silicon solar battery cell

ActiveCN106312337ACause damageEasy to useSemiconductor/solid-state device manufacturingMetal working apparatusLaser scanningEngineering

The invention provides a laser half-cutting machine for a crystal silicon solar battery cell. The laser half-cutting machine for the crystal silicon solar battery cell comprises a case, a laser scanning system, two machining tables and two rotation conveying devices. A working table plate is arranged on the top part of the case; the laser scanning system is arranged on the working table plate; the two machining tables are arranged in parallel and are arranged on the working table plate at an interval; the two rotation conveying devices are arranged on the working table plate; each rotation conveying device comprises a rotation driving device and two mechanical arms; each rotation driving device is fixed to one side of the corresponding machining table; one ends of the two mechanical arms are fixedly connected with driving ends; a taking-out sucking disc is fixed to the other end of one mechanical arm; a fission sucking disc module is fixed to the other end of the other mechanical arm; each rotation driving device drives the two mechanical arms to rotate, so that each taking-out sucking disc and each fission sucking disc module move to positions above the corresponding machining table. The laser half-cutting machine for the crystal silicon solar battery cell has the advantages of convenience in use, high machining efficiency due to continuous machining, and capability of avoiding damage on an anti-reflection film on the front face of the battery cell during a cell breaking process.

Owner:WUHAN DR LASER TECH CORP LTD

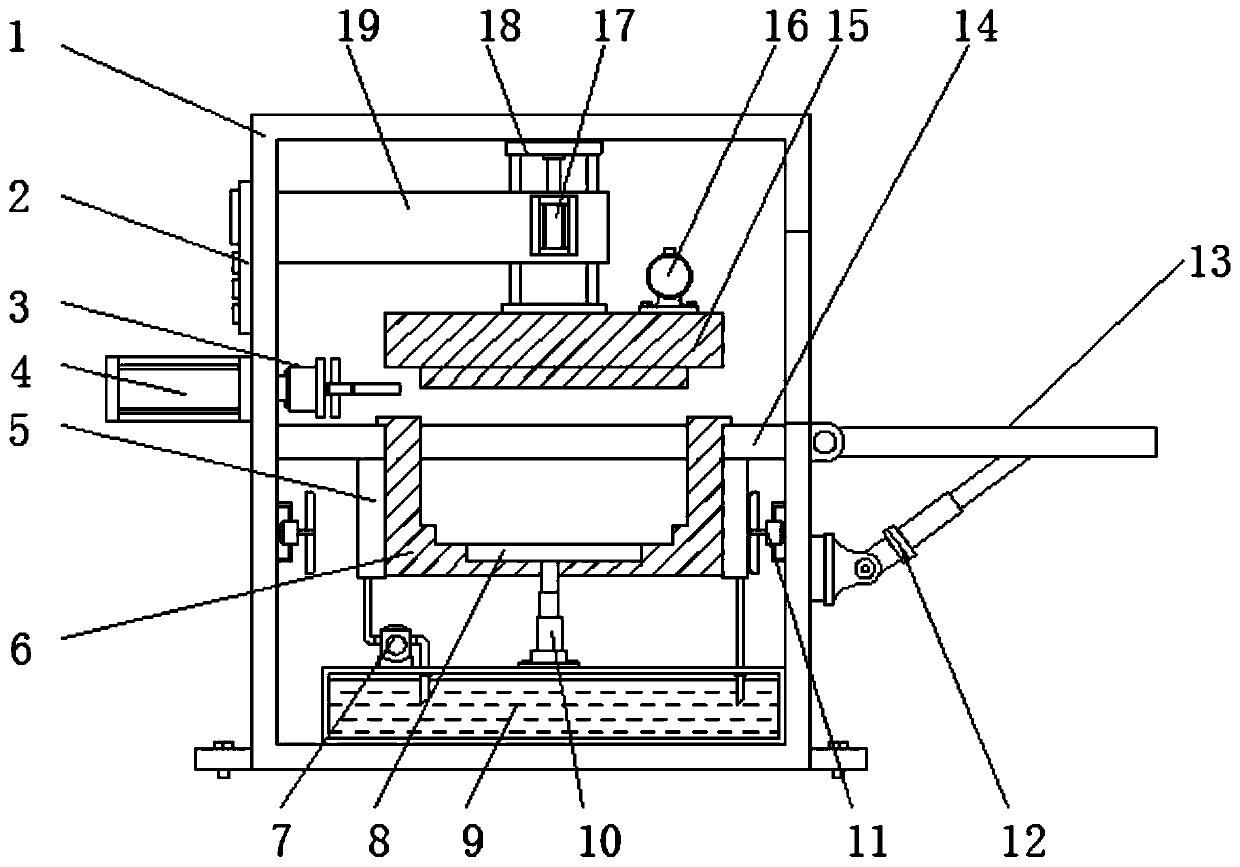

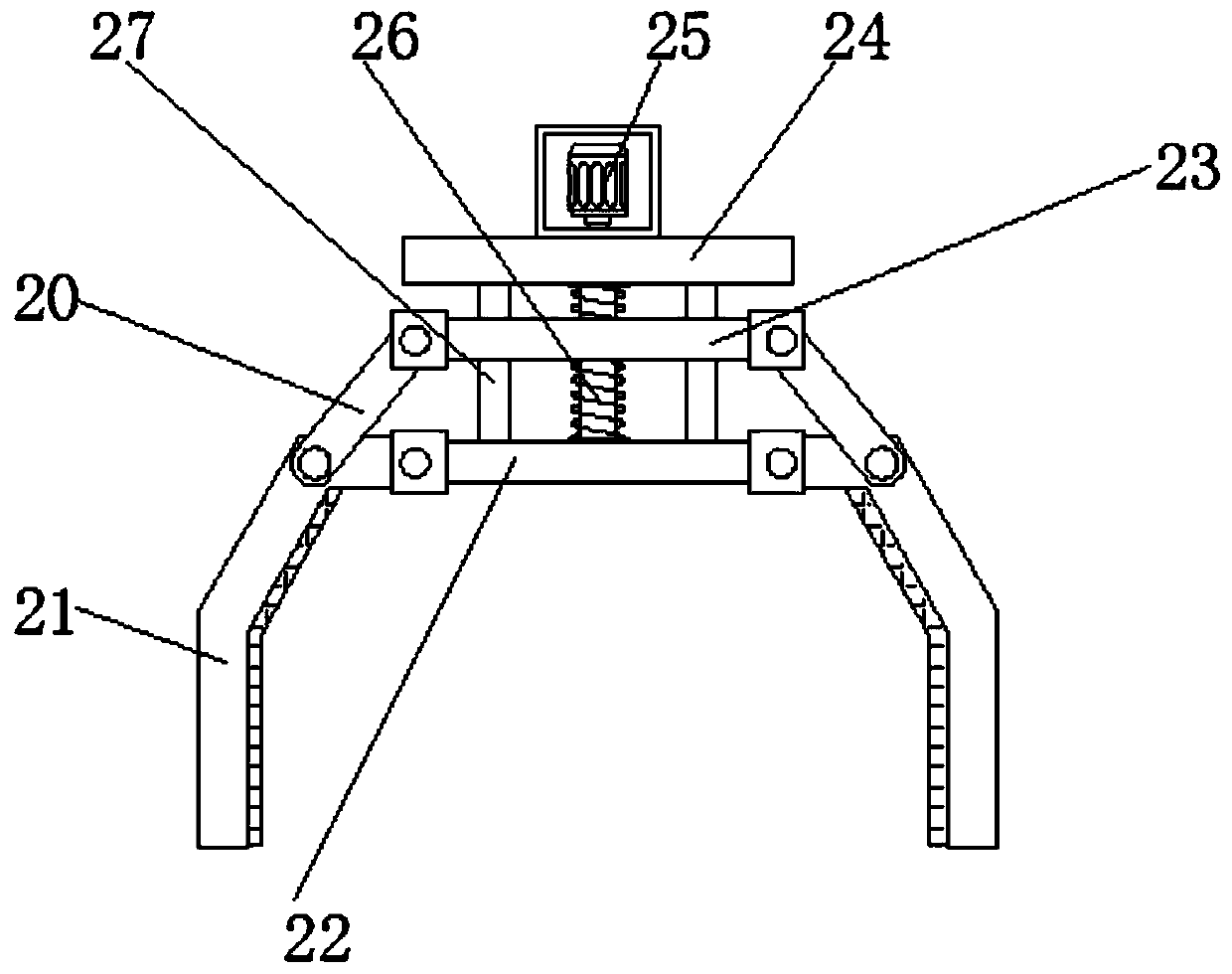

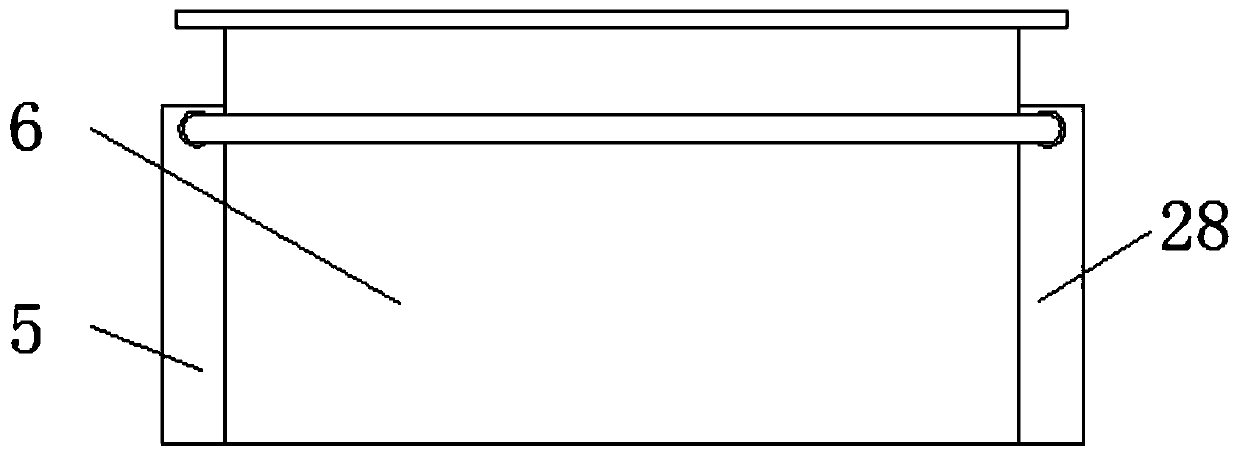

Rapid forming machining die used for machining aluminum part

The invention discloses a rapid forming machining die used for machining an aluminum part. The rapid forming machining die comprises an outer shell, a vibrating motor and a servo motor. A supporting arm is arranged on one side in the shell. An upper die is movably arranged at the bottom end of the supporting arm. The vibrating motor is installed on one side of the top end of the upper die. A partition plate is arranged below the upper die. A lower die is arranged at the top end of the partition plate. A first water cooling fin and a second water cooling fin are arranged on the two sides of thelower die correspondingly. A water tank is arranged at the bottom end in the outer shell. A water pump is installed on one side of the top end of the water tank. A first electric telescopic rod is installed in the middle of the top end of the water tank, and extends into the lower die, and a top plate is arranged in the middle of the top end of the water tank. A first air cylinder is arranged onone side of the outer shell. The output end of the first air cylinder extends into the outer shell and is provided with a mechanical grabbing hand. A controller is installed on one side of the outer shell. The rapid forming machining die facilitates rapid forming and demolding of the aluminum part, the working efficiency is improved, and the rapid forming machining die is easy to use and popularize.

Owner:NANTONG ZHONGHUI MOLD CO LTD

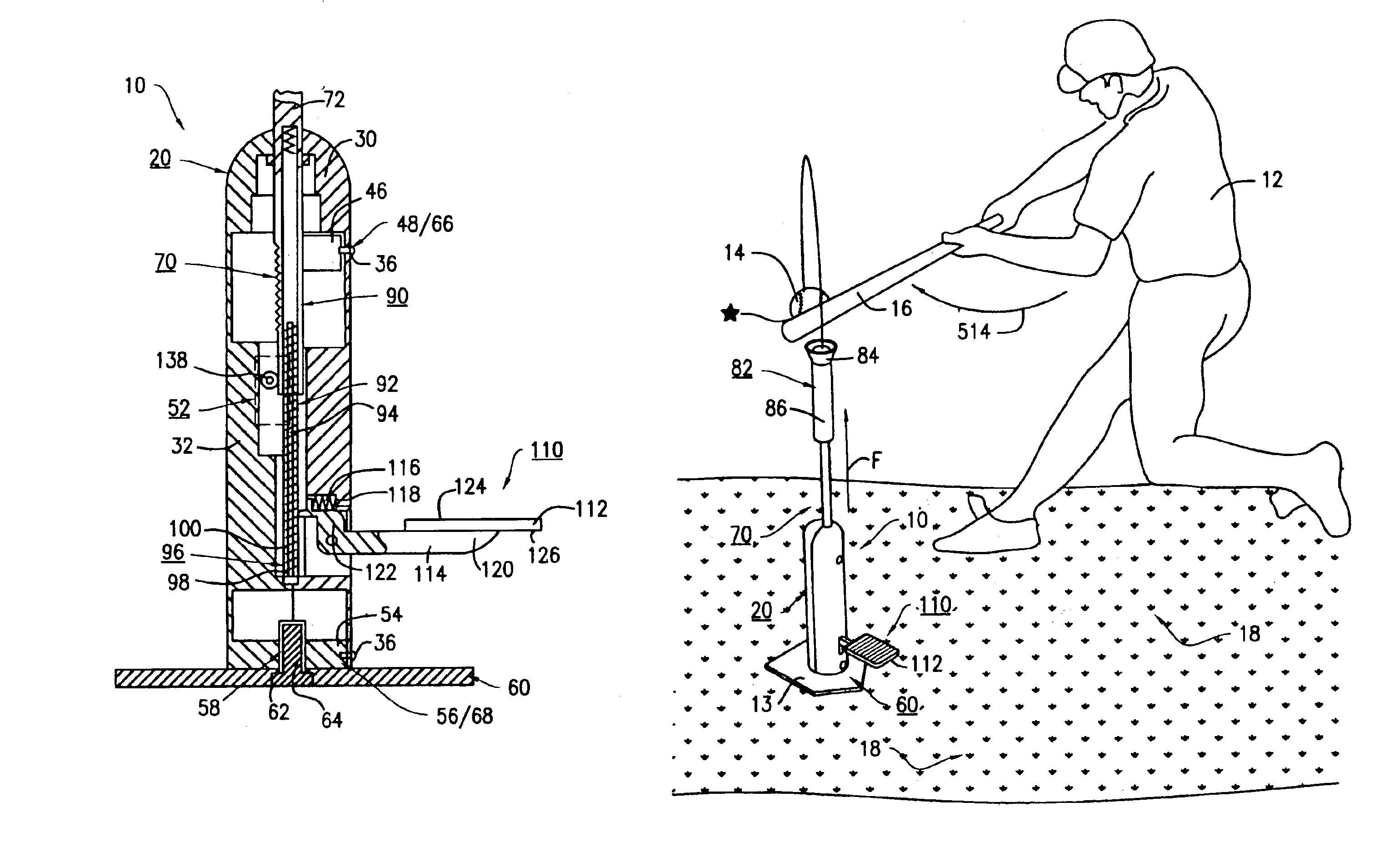

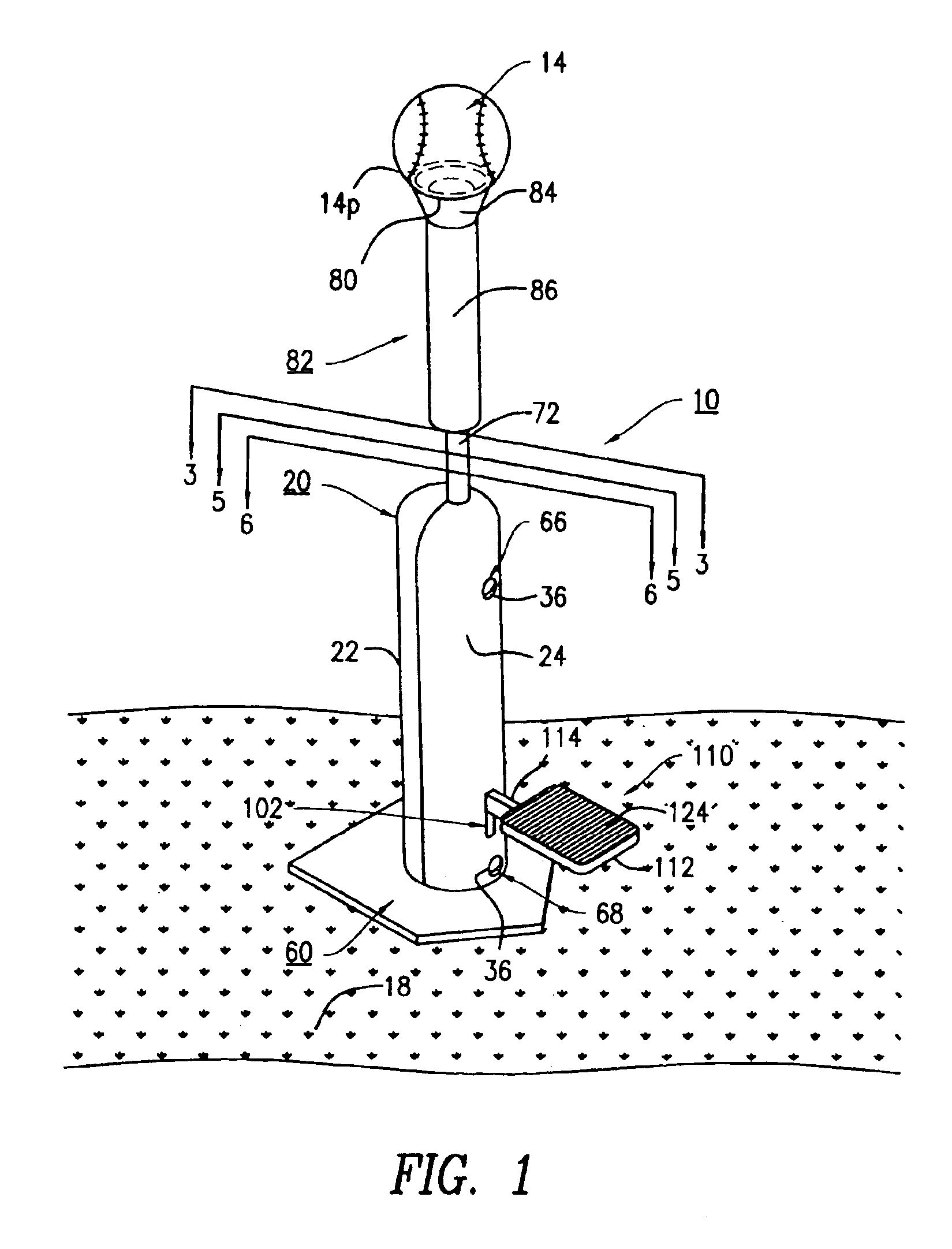

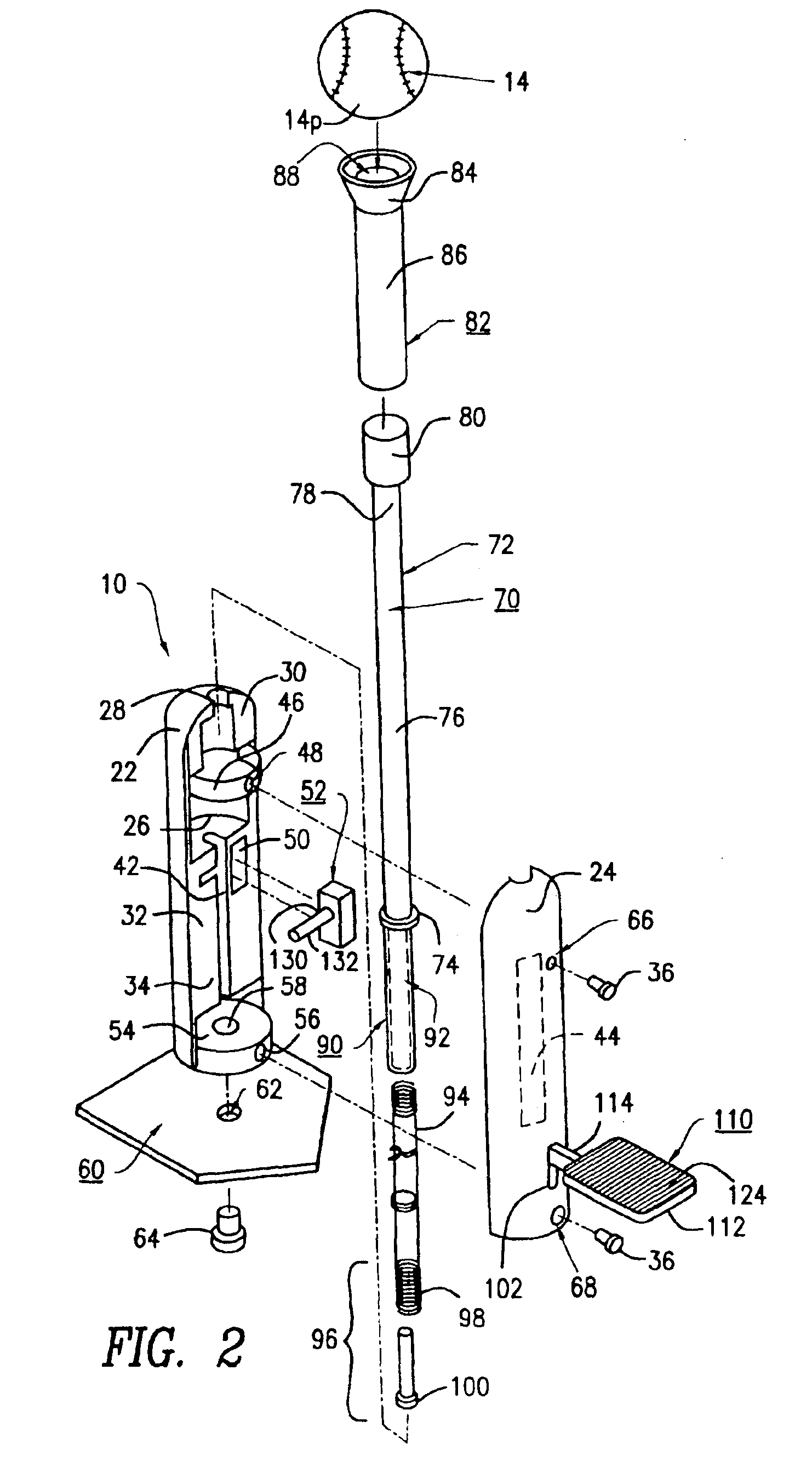

Baseball server apparatus with a delay timer element for providing a delaying time period for serving-up a baseball

A ball server apparatus for conducting batting practice wherein the apparatus ejects a ball into the air and the user swings a bat in order to hit the ejected ball. The ball server apparatus includes a base member connected to a server seat member, the base member for stabilizing the server seat member on a playing surface. The server seat member includes an interior section having a vertical channel extending therethrough; the interior section of the server seat member includes an upper seat section, a middle seat section and a bottom seat section. The ball server apparatus further includes a movable rod having a proximal end and a distal end; the proximal end of the movable rod is within the bottom seat section of the server seat member; the proximal end of the movable rod has an ejection assembly connected thereto; the distal end of the movable rod has a ball seat member connected thereto; and the ball seat member is used for holding a portion of the ball therein. The ball server apparatus includes a foot touch plate assembly for actuating the ejection assembly in order to upwardly move the movable rod within the vertical channel for ejecting the ball from the ball seat member. Additionally, the ball server apparatus includes a delay timer element positioned within the interior section of the server seat member for delaying the ejection of the ball from the seat member in order to allow time for the user to prepare for a swinging movement prior to the ejection of the ball.

Owner:YUANEN LEIH

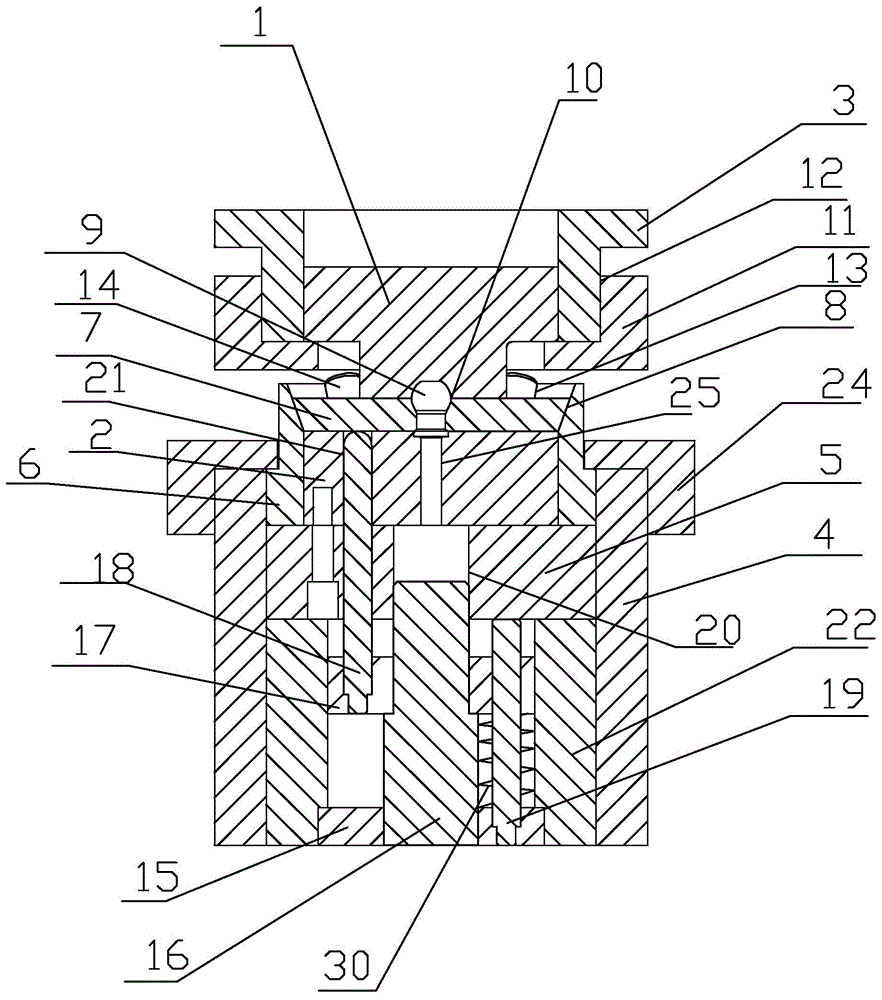

Precision molding device and molding technology for magnesium alloy automobile hub

The invention relates / belongs to the technical field of precision molding devices, in particular to a precision molding device and molding technology for a magnesium alloy automobile hub, and solves the problems of shrinkage porosity, shrinkage cavity, cold lap, large grain size, and the like in the casting process of the magnesium alloy automobile hub. The precision molding device comprises an upper mold assembly and a lower mold assembly, and is characterized in that: the upper mold assembly is provided with a push-and-pull oil cylinder perpendicular to the motion direction of a mold; the push-and-pull oil cylinder is connected with an upper mold connected base plate; an upper mold head is fixed on the lower part of the upper mold connected base plate; and the lower mold assembly is provided with a molding area and a demolding area, wherein the molding area comprises a molding slider and a lower mold core; the molding slider is arranged in a barrel-shaped mold bed, and an outer surface of the barrel-shaped mold bed is provided with a barrel-shaped insulating device; an ejector rod mechanism is arranged in the demolding area. The precision molding device and the molding technology for the magnesium alloy automobile hub have the advantages of less allowance for machining, simple process, convenient operation, fine and dense crystal grains of a wheel, high intensity, and excellent rigidity.

Owner:刘绍东

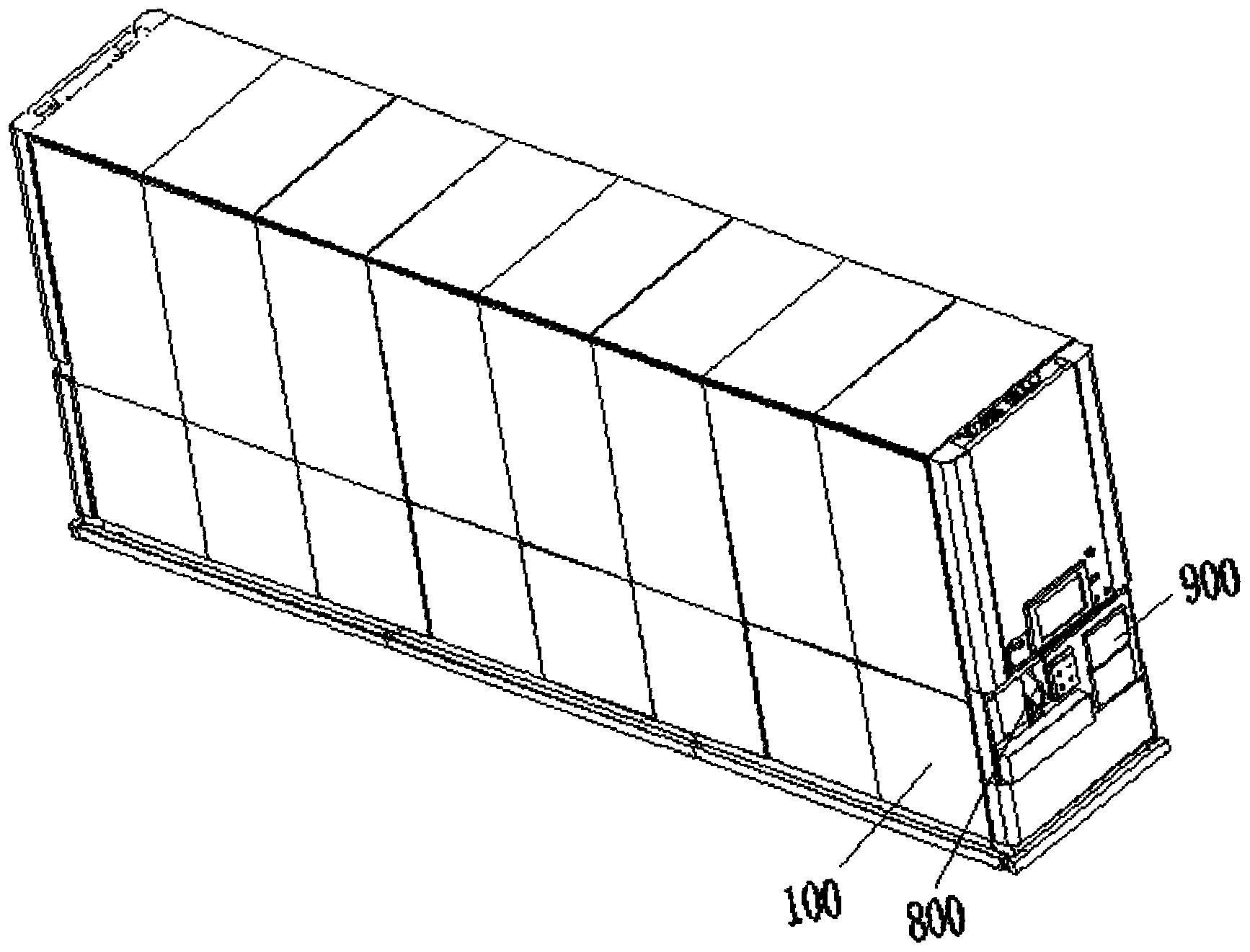

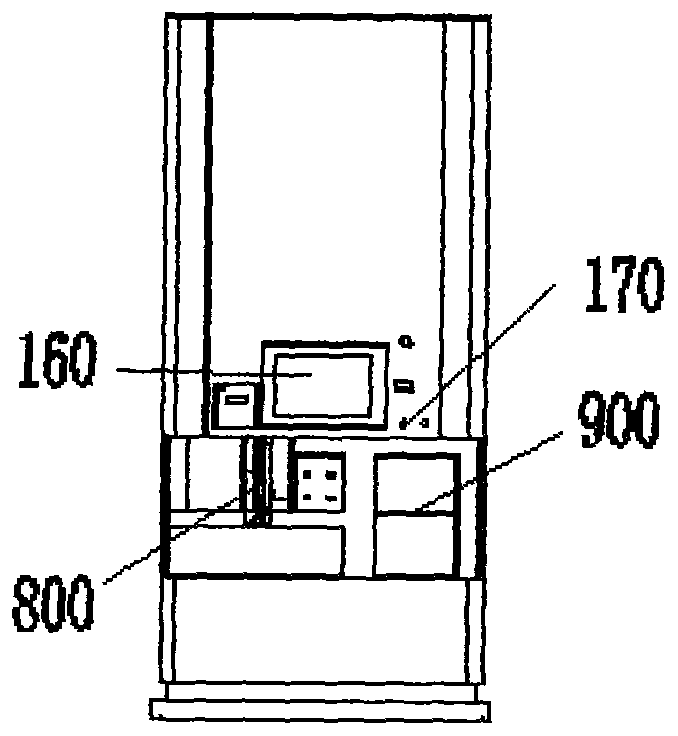

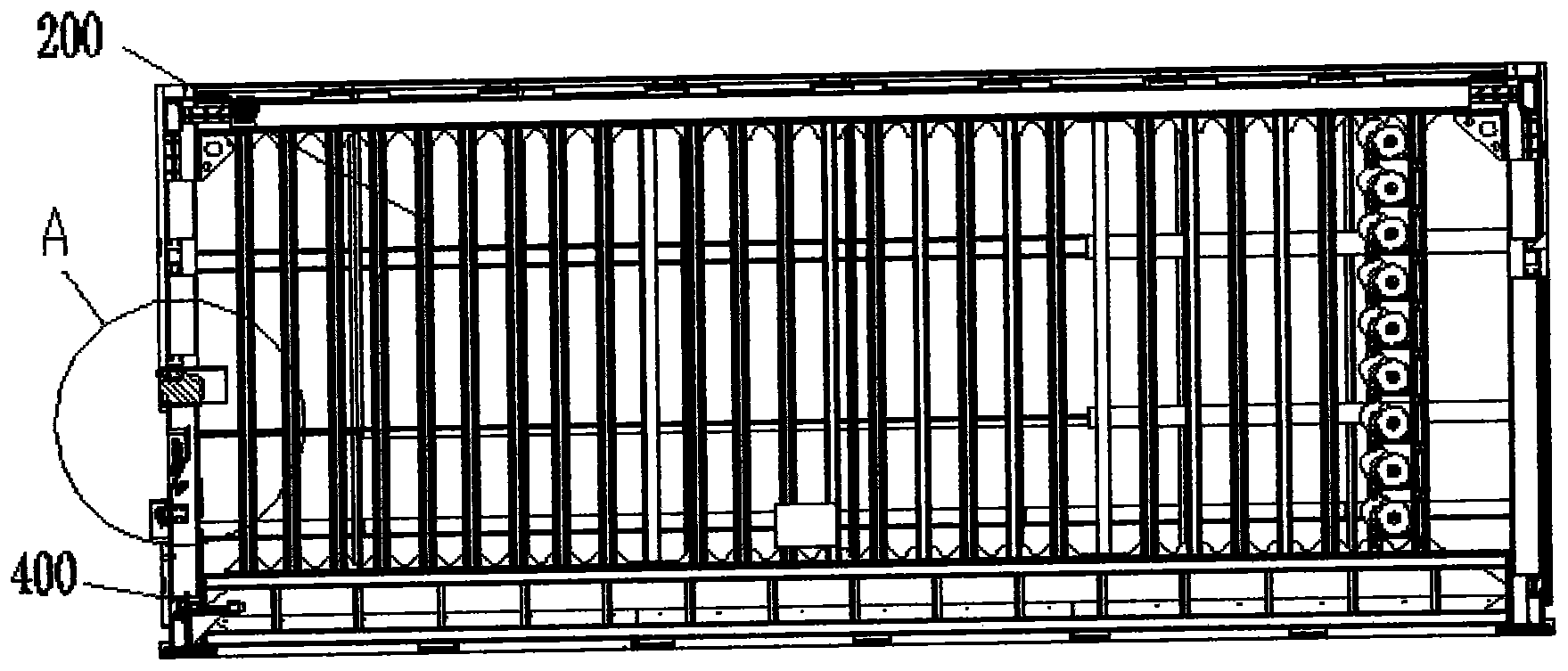

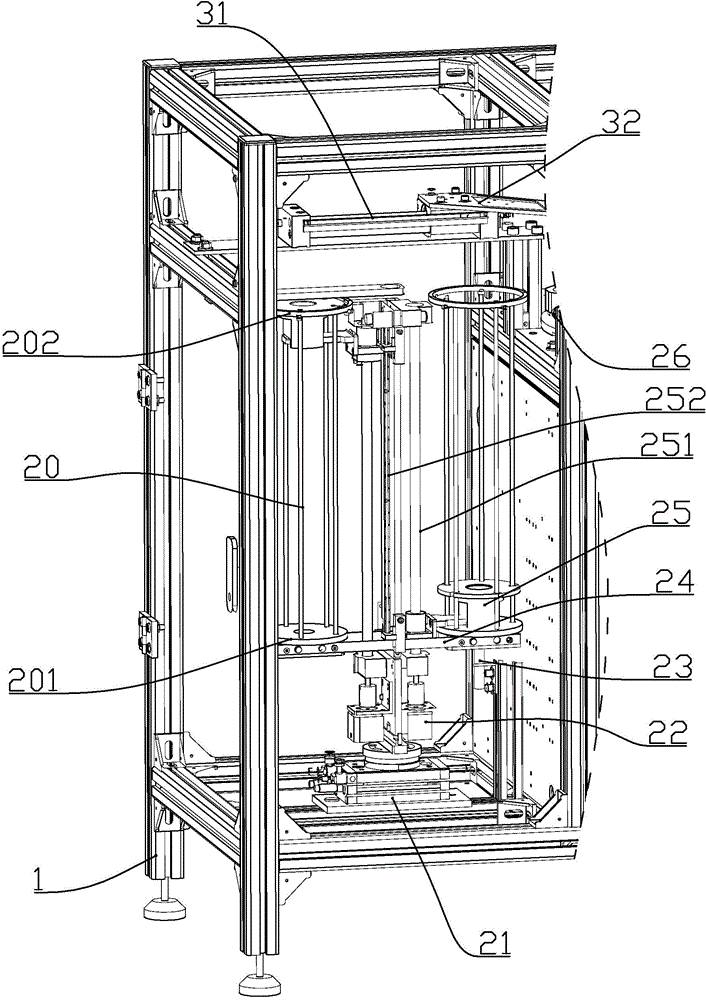

Intelligent container for automatically storing and picking up cargoes one to one

The invention discloses an intelligent container for automatically storing and picking up cargoes one to one. The intelligent container comprises a container body, a fork mechanism, a cargo box structure and an intelligent car, wherein the cargo box structure comprises a rotating cargo box and / or general cargo box, and an ejector mechanism with an ejector is arranged at a part, close to a cargo pick-up port, in the container body; a first storage region and a second storage region for storing the cargoes are arranged in the container body, and the intelligent car is used for conveying the rotating cargo box and / or general cargo box from the first storage region and the second storage region to a part above the ejector of the ejector mechanism; the ejector moves up and down so that a silo of the rotating cargo box oppositely positioned above the ejector rotates. According to the intelligent container provided by the invention, each silo of the rotating cargo box stores single goods, and can singly make rotating movement by taking a rotating shaft as a center of a circle, so that one-to-one storage function is flexibly realized; the cargo boxes are positioned by the magnetic force stably and accurately, the application is flexible, and different user needs can be met.

Owner:山西廷烁未来智能装备技术研究院有限公司

Die-casting die capable of secondarily laterally pulling core

The invention discloses a die-casting die capable of secondarily laterally pulling a core. The die-casting die comprises an upper die and a lower die; a main mold core is arranged into a lateral core pulling hole in the upper die, comprising a rotating sleeve, a driving pulling core adapted into the rotating sleeve, and a mold core sleeve, wherein the mold core sleeve is in rotating connection to the small front end of the rotating sleeve; a secondary mould core is arranged at the front part of the mold core; a T-shaped clamping groove of which the depth is gradually increased in the circumferential direction is formed in the rotating sleeve; the lower end of the secondary mould core is clamped into the T-shaped clamping groove; the rear end of a driving pulling core is connected with a driving oil cylinder; a spiral groove is formed in the front part of the driving pulling core; a sliding pin which extends into the rear end of the spiral groove is arranged at the inner sidewall of the rotating sleeve; an arc-shaped groove of which the depth is gradually reduced in the circumferential direction is formed in the outer side surface of the rear end of the rotating sleeve; a spring bolt is arranged in the lateral core pulling hole; a spring bolt pressing spring is arranged at the rear end of the spring bolt. With the adoption of the die, a lateral forming hole and a radial blind hole in the inner wall of the lateral forming hole can be synchronously formed at a time, so that later secondary mechanical processing can be avoided, and the production efficiency can be increased.

Owner:NINGBO BEILUN HUASHENG MOLD FACTORY

Tampon pledget for increased bypass leakage protection

The present invention provides a tampon pledget with one or more of the following properties: increased absorbency rate; high absorbent capacity and fluid retention; rapid expansion potential; and ease of ejection of the pledget from the applicator. Surprisingly, the one or more properties are achieved by using a modified dual cross-pad, folded, compressed tampon pledget design.

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

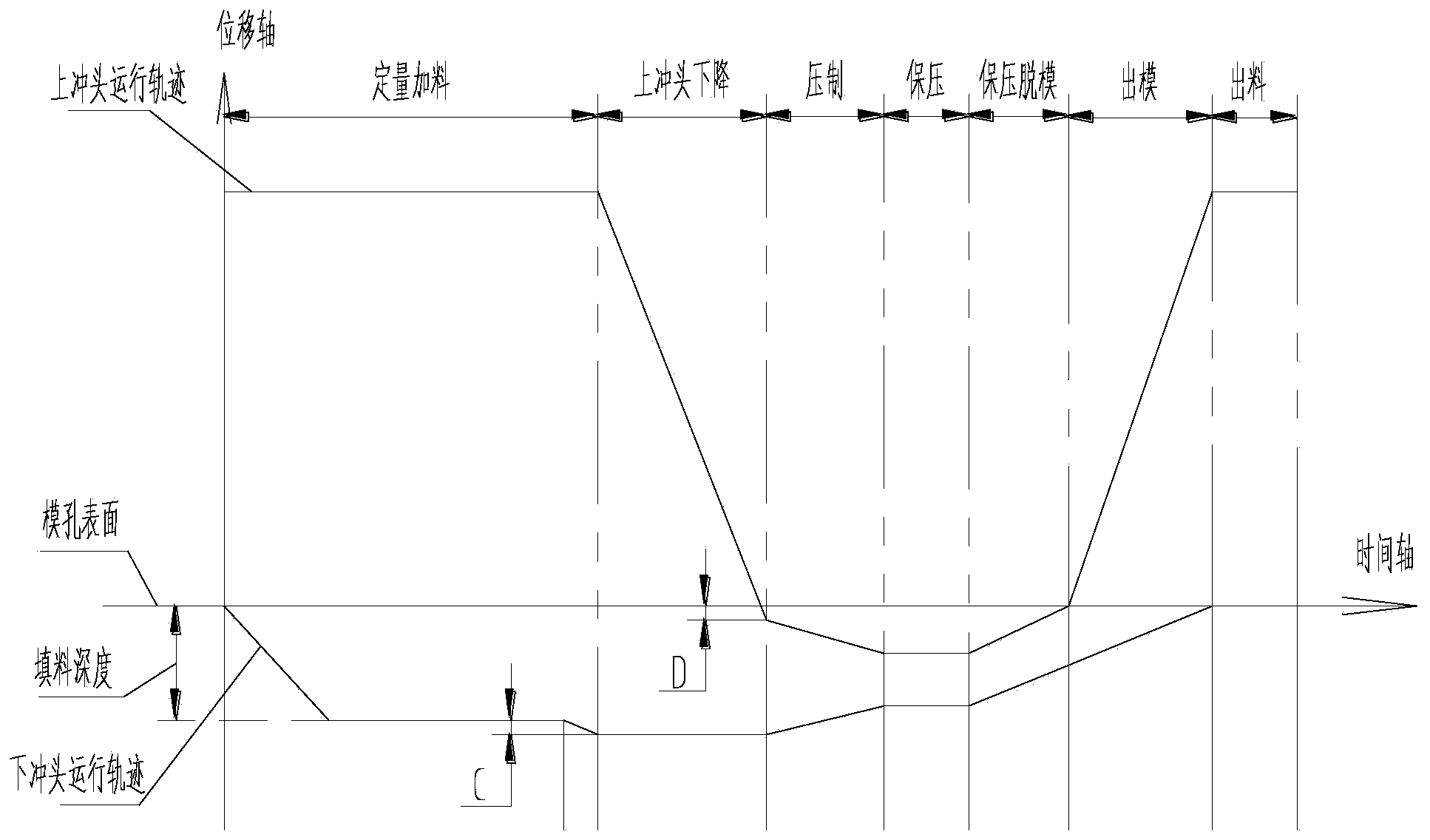

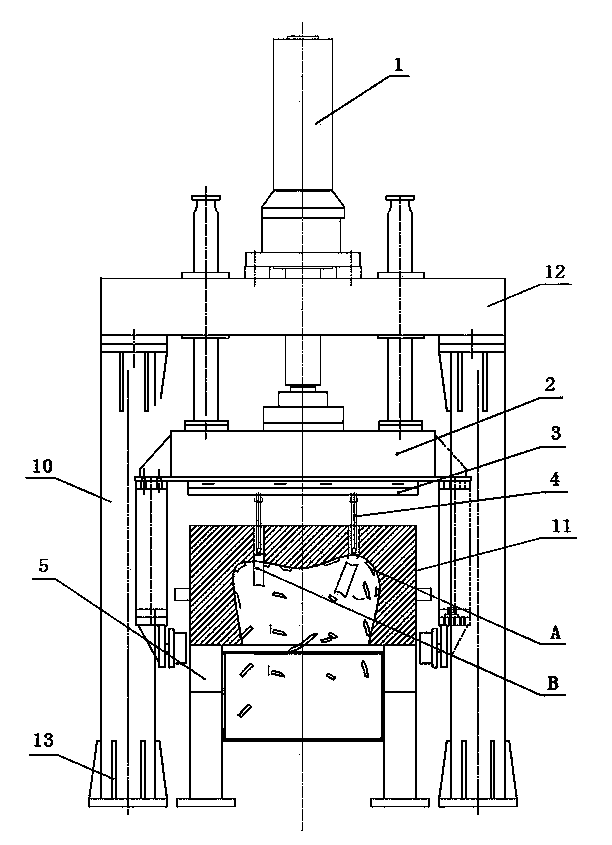

Pressing demoulding method of equal-density pressing machine

The invention discloses a pressing demoulding method of an equal-density pressing machine. The equal-density pressing machine comprises an upper pressing mechanism, a middle mould mechanism and a lower pressing mechanism. The upper pressing mechanism comprises an upper punch which can move up and down, the lower pressing mechanism comprises a lower punch which can move up and down, and the middle mould mechanism is provided with mould holes which correspond to the upper punch and the lower punch. The pressing demoulding method comprises a feeding step, a pressing step, a pressure maintaining demoulding step and a demoulding step. In the pressure maintaining demoulding step, the upper punch and the lower punch move upwards, and pressure maintaining is carried out on a pressed material element until the top end of the pressed material element is flush with the surfaces of mould holes. In the demoulding step, when the pressed material element starts to leave the mould holes, the upper punch is separated from the material element and goes back to the original position, the lower punch moves upwards continuously until the material element is pushed out of the mould holes completely, accordingly, the material element can be effectively prevented from being cracked in the pressure maintaining demoulding step, and cracking caused by the fact that pressure exerted on the top end of the material element exceeds the bearing capacity of the material element can be effectively avoided.

Owner:北京新龙立自动化技术有限公司

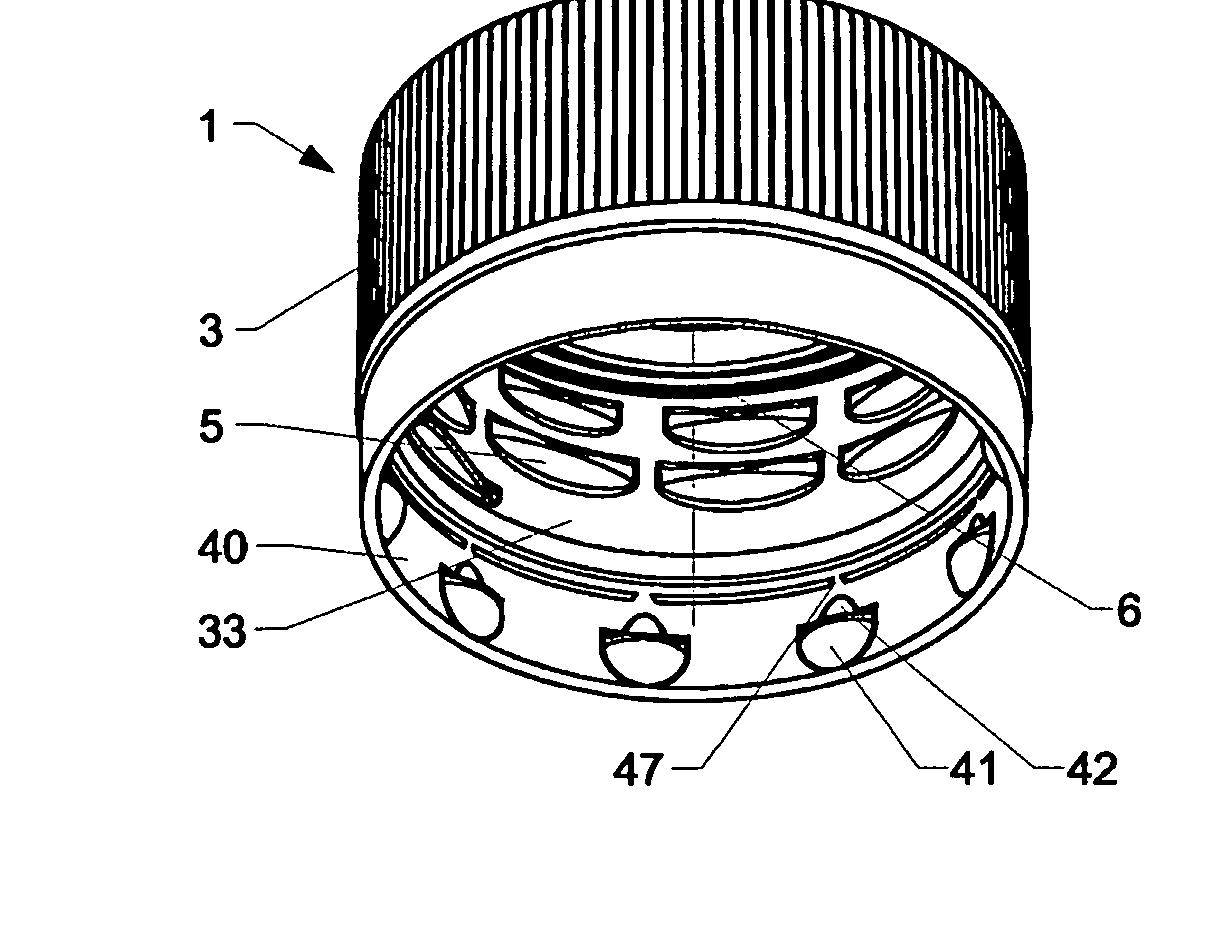

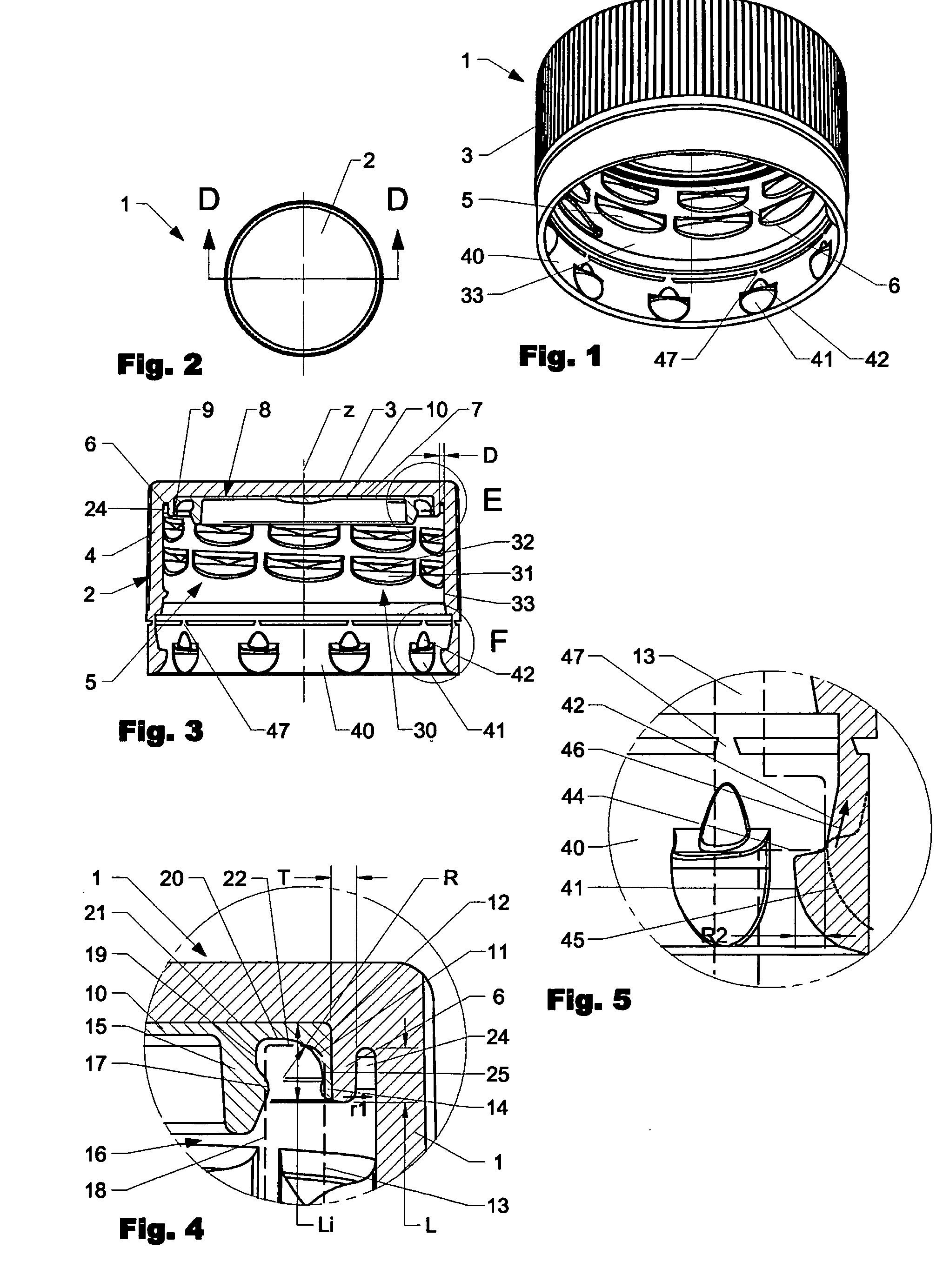

Closure

InactiveUS20080272083A1Ease of ejectionImprove performanceCapsClosure using stoppersEngineeringScrew thread

Owner:CREANOVA UNIVERSAL CLOSURES

Rotary plastic handicraft injection mold and injection molding method thereof

InactiveCN110435072AImprove continuityFacilitate continuous injection moldingEngineeringInjection molding machine

The invention discloses a rotary plastic handicraft injection mold and an injection molding method thereof. The rotary plastic handicraft injection mold comprises a base; the top of the base is fixedly connected with a support through bolts; the upper end of the support is connected with a workbench through a bearing; the lower end of the middle of the workbench is fixedly connected with the output end of a stepping motor; one end of the base is fixedly provided with a second telescopic air cylinder through bolts; and the output end of the second telescopic air cylinder is inserted into the lower end of one lower mould base According to the rotary plastic handicraft injection mold and the injection molding method thereof, through the cooperation of the stepping motor, the workbench, fixedgrooves, limiting blocks, limiting grooves, adjusting support plates and first telescopic air cylinders, the continuous injection molding of the injection mold is facilitated, the mold closing efficiency is high, the sealing performance is good, the injection molding effect is good, through the cooperation of guiding grooves, rubber pads, the limiting grooves, the limiting blocks and the second telescopic air cylinder, the continuous ejection blanking of the lower mold base is convenient, the blanking rate is effectively improved, therefore, the continuity of injection molding work is effectively improved, and the working efficiency is greatly improved.

Owner:义乌市拓一斯玩具有限公司

Vibrating iron-type sand shooting vent cleaning device and method

ActiveCN103706780AEase of ejectionImprove the level of mechanization and automationSand castingEngineering

The invention relates to a vibrating iron-type sand shooting vent cleaning device and method, and belongs to the field of iron-type sand casting equipment. The device comprises an ejecting cylinder, an iron-type conveying roller bed, an iron-type positioning device, a machine frame, an ejecting movable beam, an ejecting rod plate, an iron-type supporting base and a vibrating mechanism, wherein the ejecting cylinder is installed on an upper beam of the machine frame, the ejecting movable beam is fixed to a piston rod of the ejecting cylinder, the ejecting rod plate is provided with ejecting rods, the ejecting rods are fixed to the ejecting movable beam, the position and the number of the ejecting rods on the ejecting rod plate are matched with those of upper iron-type sand shooting vents, the iron-type supporting base is installed on the machine frame, the vibrating mechanism and the iron-type conveying roller bed are both fixed to the ejecting movable beam, and the iron-type positioning device is fixed to the iron-type conveying roller bed. According to the device and method, residual sand in the iron-type sand shooting vents can be conveniently ejected out, vibration force transmitted by the ejecting rods can assist in cleaning residual sand layers in an iron-type inner cavity, energy is saved, and requirements of large-scale iron-type sand casting production are met.

Owner:浙江省机电设计研究院有限公司

Glass kettle forming device and forming process

ActiveCN110950524AImprove smoothnessImprove aestheticsGlass reforming apparatusEngineeringProcess engineering

The invention discloses a glass kettle forming device and forming process. The glass kettle forming device comprises a workbench, a positioning device and a jacking device. The glass kettle forming process comprises the steps of blank positioning, heating angle adjustment, local heating, preliminary jacking, stress application jacking, cutting forming and the like. By improving a traditional highborosilicate glass kettle manufacturing process, the glass kettle is more innovative, practical and attractive; compared with fusion techniques, according to the scheme, the connection smoothness of aspout and a kettle body can be improved, the spout and the kettle body are integrated, the attractiveness can be improved, water can be poured more smoothly through the glass kettle, the limitation of the spout manufacturing process of the traditional high borosilicate heat-resisting glass kettle is broken through, the manufacturing process is relatively simple, and the specification and appearance individuation requirements of the spout part are easy to control.

Owner:SHENZHEN ESID DESIGN LTD

Aluminum alloy die-casting die

The invention discloses an aluminum alloy die-casting die. The aluminum alloy die-casting die comprises a bottom supporting seat, a slide rail, a first sliding seat, a second sliding seat, a first vertical supporting column, a second vertical supporting column, a vertical die holder, a die-casting die holder, a slide way, a lower punch, a hydraulic cylinder A and an inner barrel. One end of the inner barrel is provided with a liquid through nozzle, a die-casting part with an inner center gate is mounted on one side of the inner barrel and internally provided with a die-casting cavity passage with a first flow through port and a second flow through port, a first seal block is mounted on one side of the first flow through port, and a first fixing block is mounted at one end of the first seal block. A transverse seat is arranged above the die-casting die holder, a rail is mounted at the bottom end of the transverse seat, a hydraulic cylinder B is slidably mounted on the rail, and an upper punch is mounted at the bottom end of a hydraulic rod of the hydraulic cylinder B. The aluminum alloy die-casting die has advantages that die casting efficiency of the aluminum alloy die-casting die can be improved, and residual materials can be ejected conveniently.

Owner:昆山篙陵兴金属制品有限公司

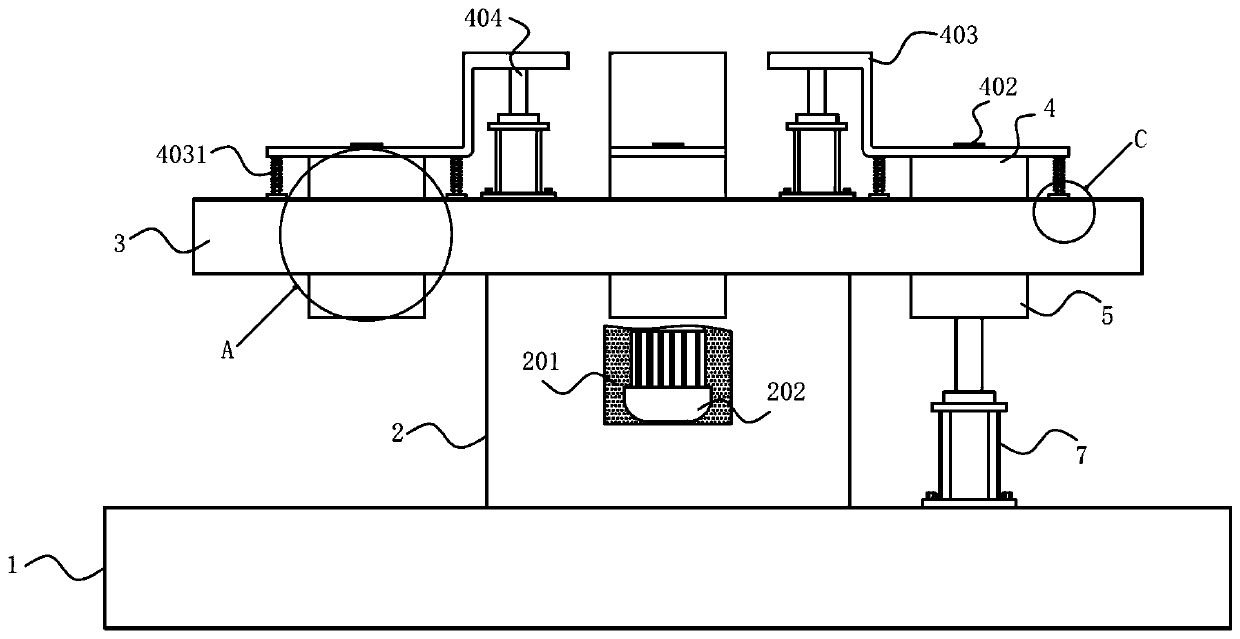

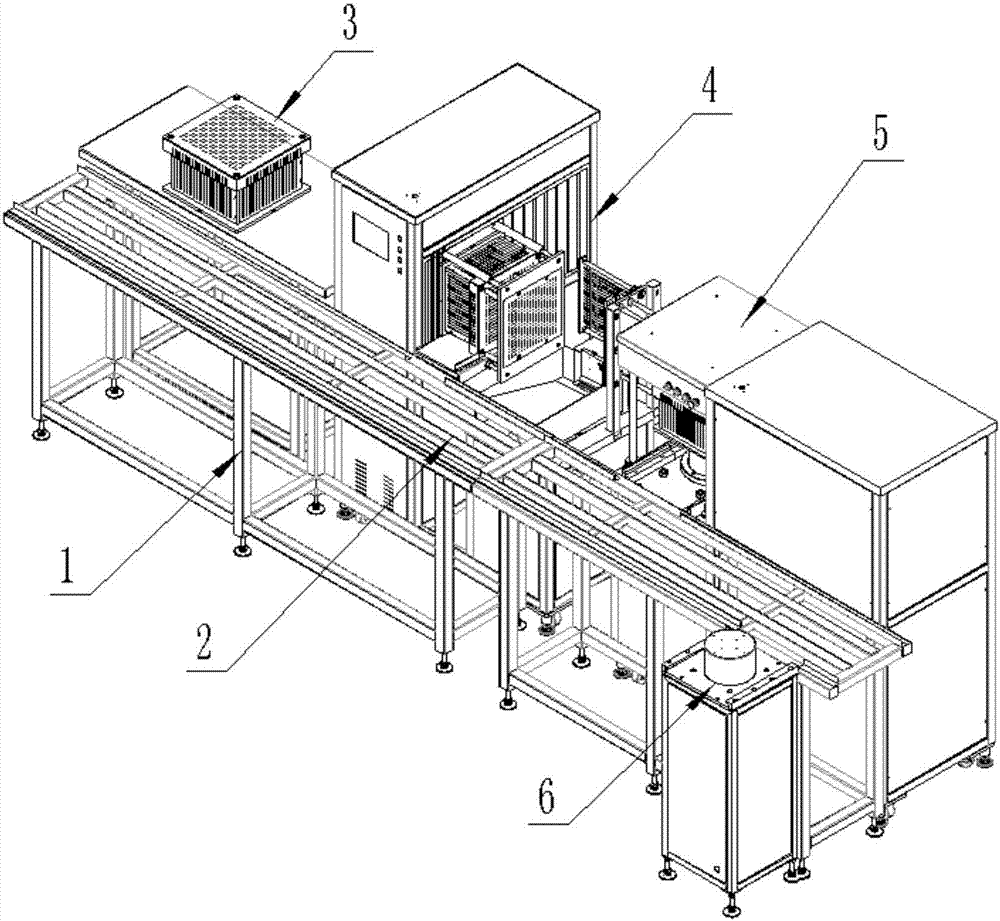

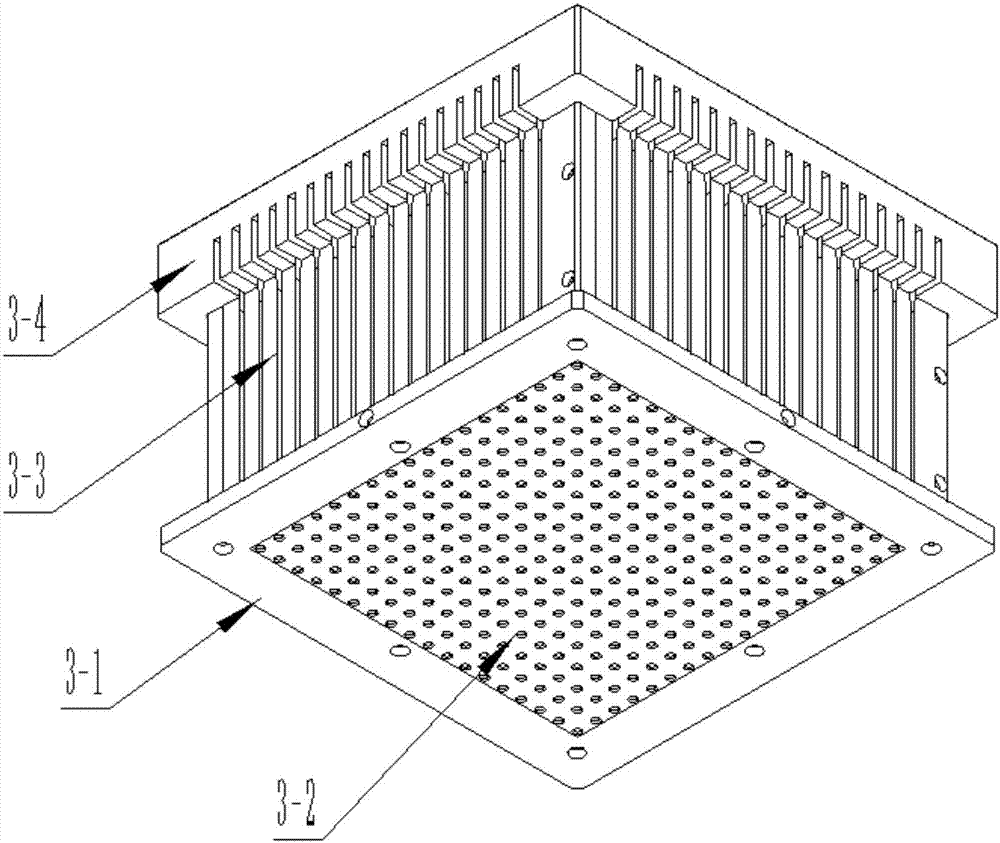

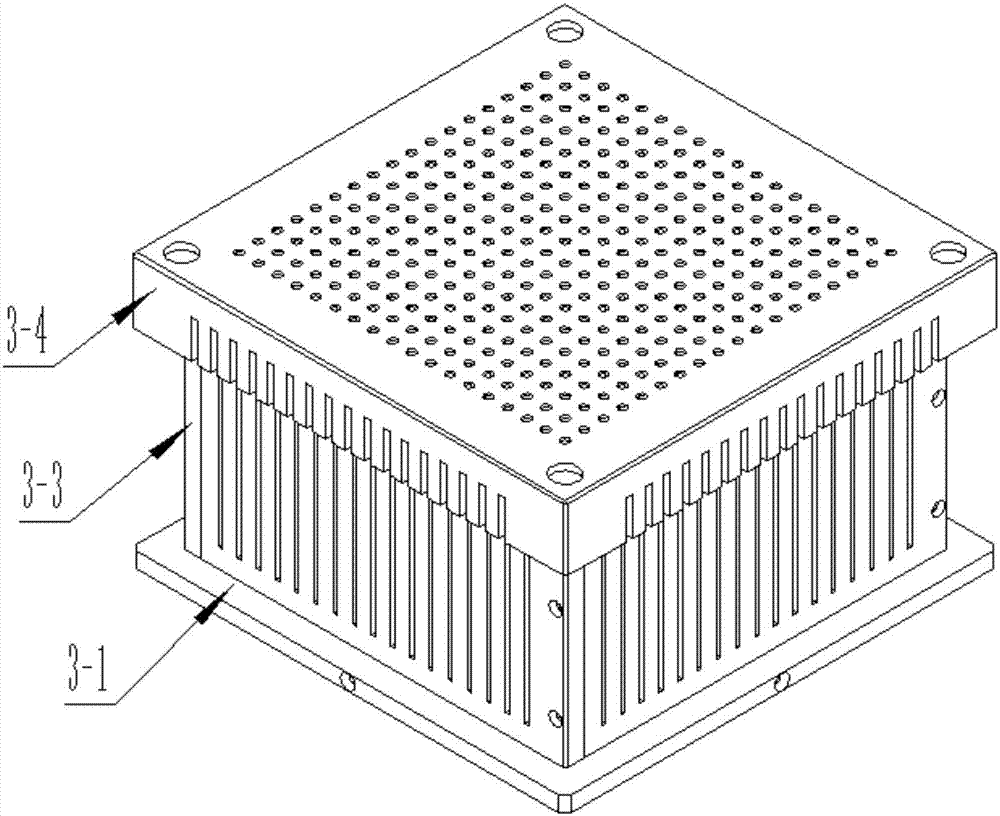

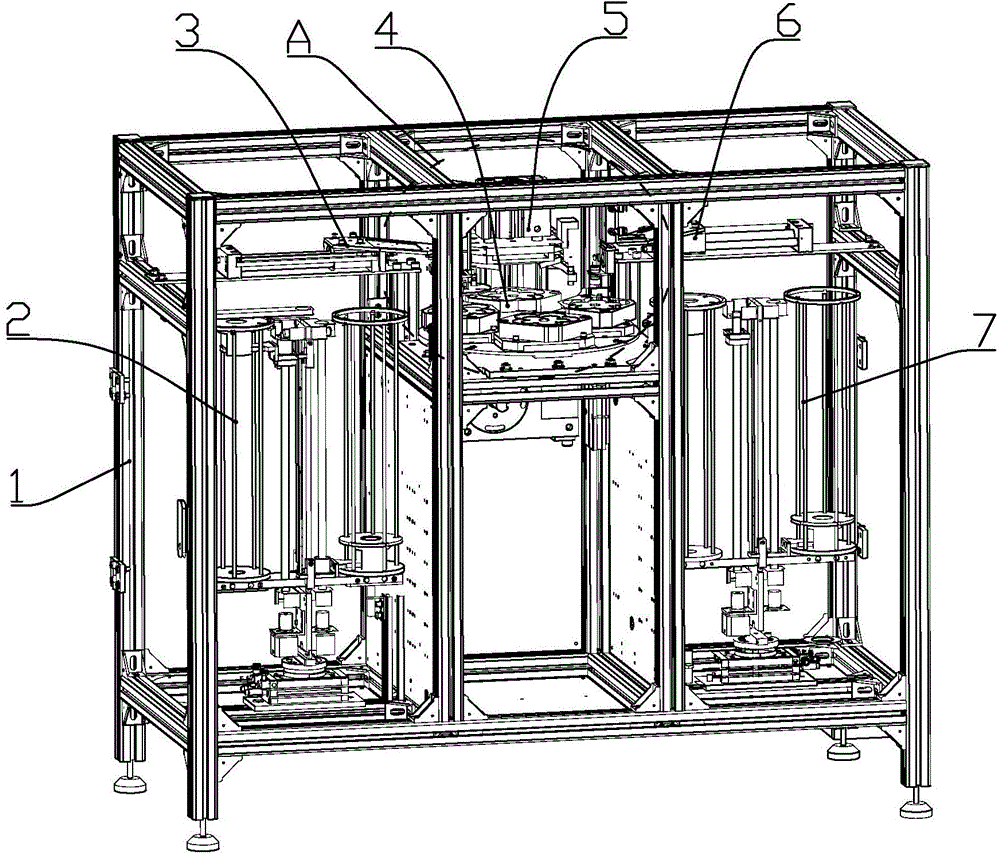

Automatic meat cutting and bunching machine

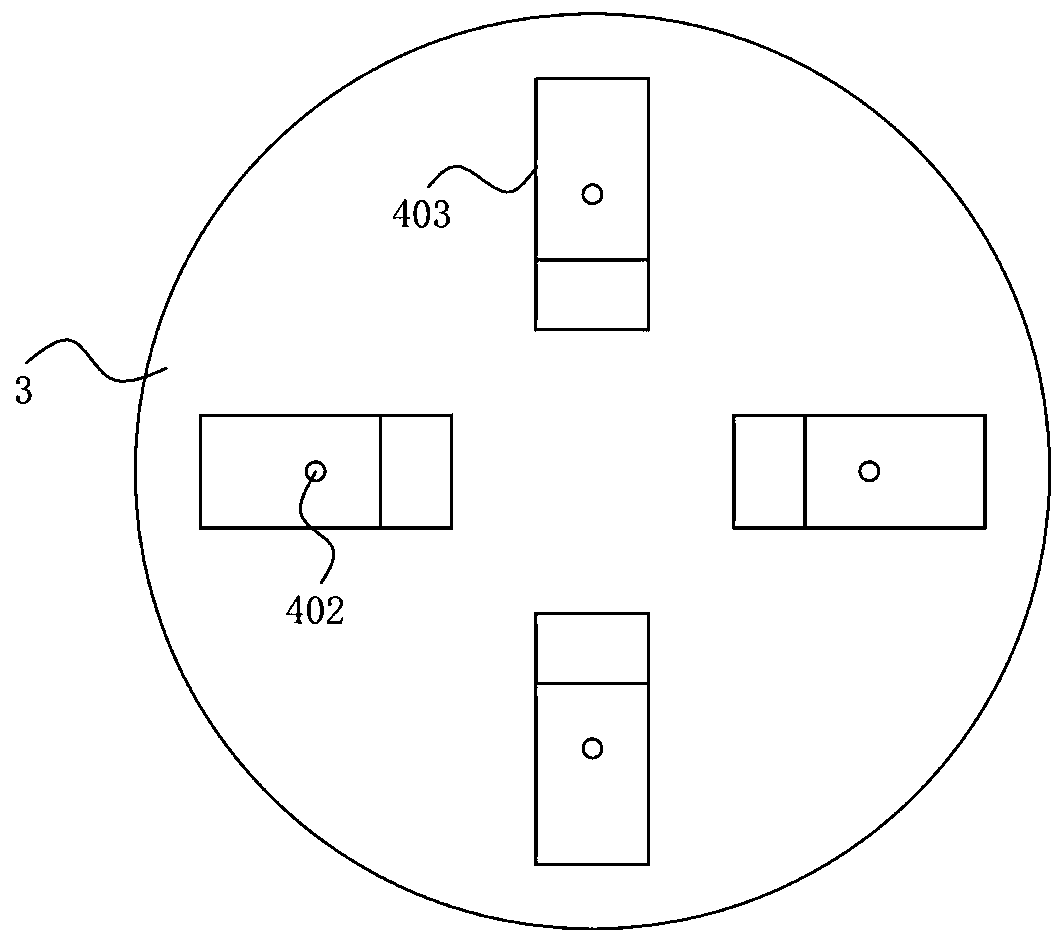

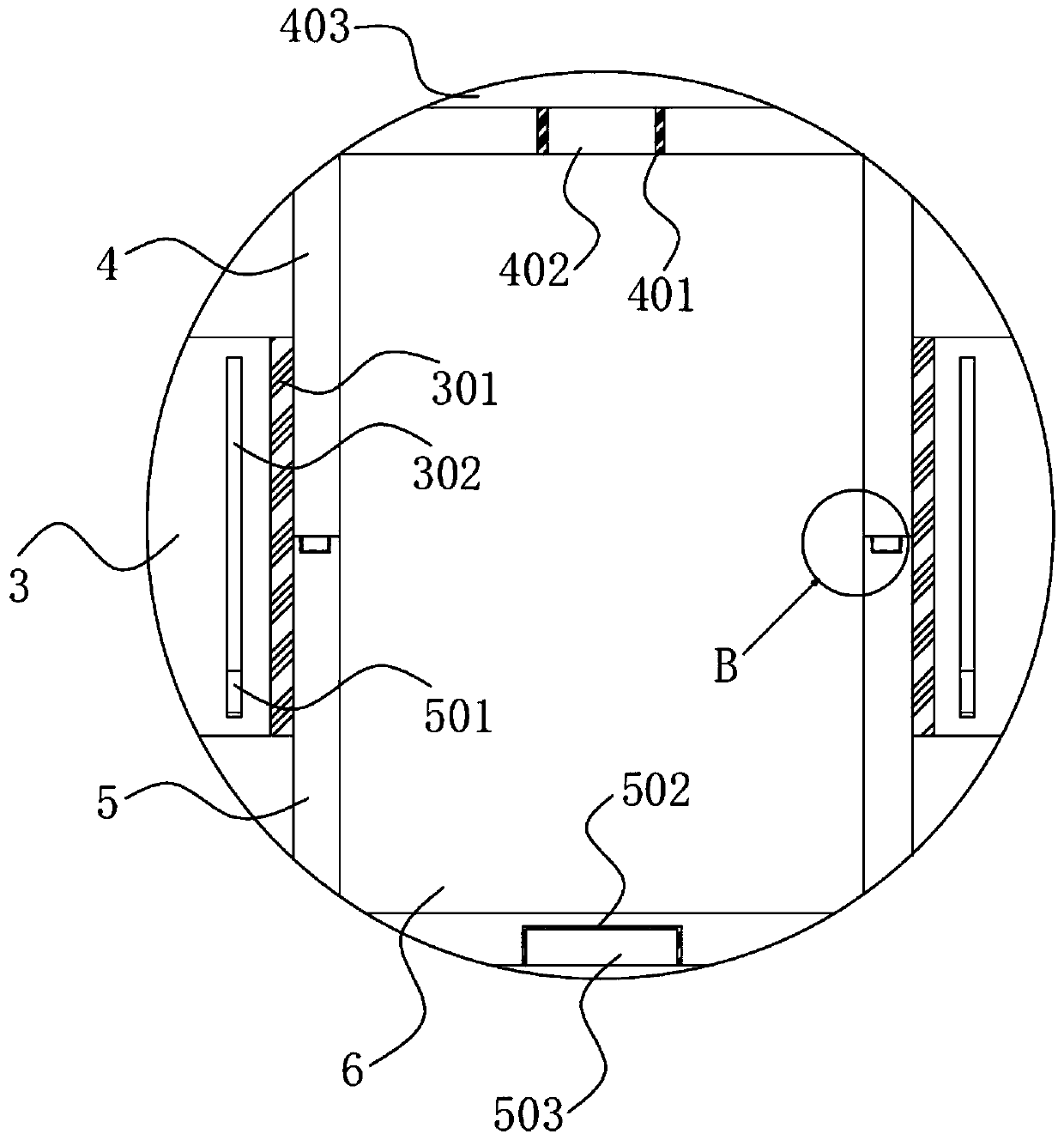

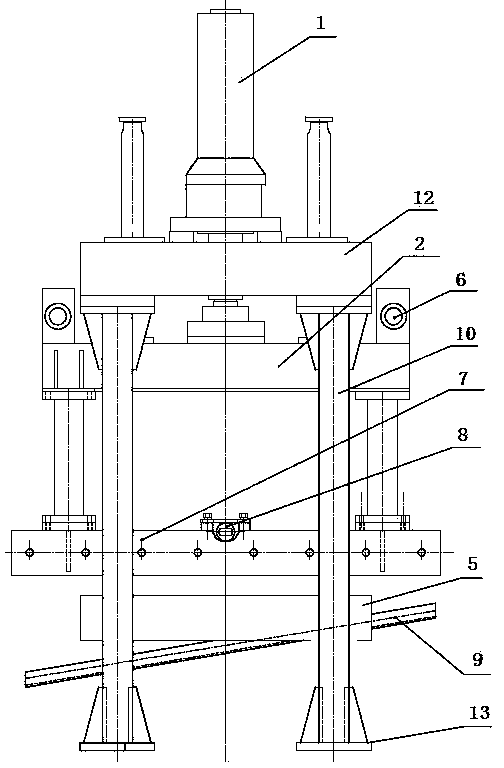

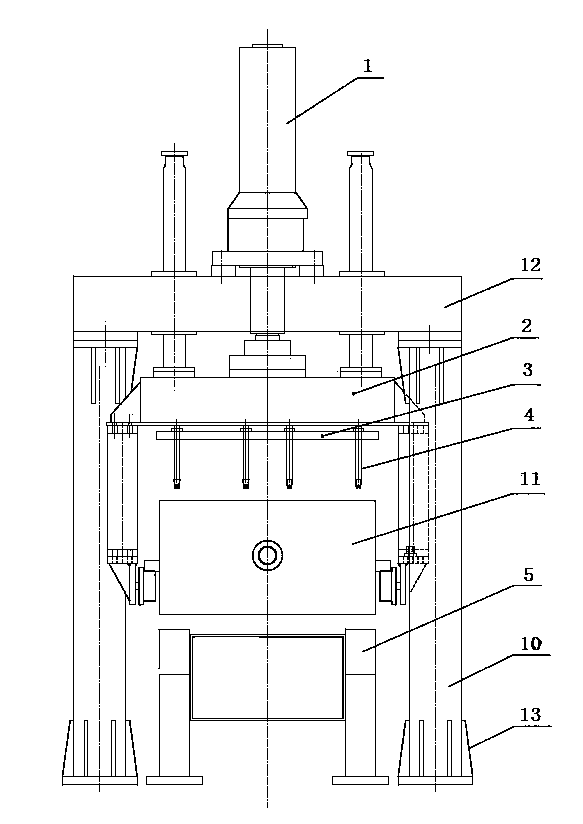

ActiveCN107950627ACompact structureSimple and fast operationMeat packaging/handling/transportingPutting meat on skewersEngineeringSmall footprint

The invention relates to the technical field of meat processing machinery, in particular to an automatic meat cutting and bunching machine. The automatic meat cutting and bunching machine comprises asliding chute 2 arranged on a rack 1, a meat piling device 3, as well as an automatic bunching device 4, an automatic cutting device 5 and a meat bunch ejector device 6 which are arranged near the sliding chute 2 in sequence. The automatic meat cutting and bunching machine is simple in structure, simple and convenient to operate, low in cost, small in occupied area, stable in operation, safe, reliable, high in efficiency and long in service life, bunching and meat cutting can be realized safely and automatically, and the efficiency is high, so that the defect that the traditional operation ofmanual meat cutting and manual bunching is low in efficiency and unsafe is solved.

Owner:北京正兴天宝自动化科技有限公司

Discharging system of full-automatic mould pressing moulding equipment

The invention discloses a discharging system of full-automatic mould pressing moulding equipment. The discharging system comprises a rack and a lower mould circulation conveying mechanism installed on the rack, and a lower mould is installed on the lower mould circulation conveying mechanism; a discharging mechanism is installed above the lower mould circulation conveying mechanism on the rack; the discharging mechanism comprises a material transferring air cylinder b horizontally installed on the rack, a material transferring board b connected with a piston rod of the material transferring air cylinder b, a discharging air cylinder longitudinally installed on the material transferring board b and a suction cup connected with a piston rod of the discharging air cylinder, wherein the piston rod of the discharging air cylinder is downward; an ejecting air cylinder used for ejecting out a moulded raw material from bottom to top is installed under a rotary table located at a station of the discharging mechanism on the rack. The ejecting air cylinder cooperates with an upper ejector pin and a lower ejector pin to eject the raw material out of the lower mould conveniently after the raw material is moulded; meanwhile, the discharging air cylinder cooperates with the suction cup to suck the moulded raw material, automation degree is high, and production efficiency is improved.

Owner:XIAN ZHONGKE PHOTOELECTRIC PRECISION ENG CO LTD

Novel casting equipment

InactiveCN109365795AEasy to adjust orientationEase of ejectionMolten metal conveying equipmentsArchitectural engineeringElectromagnetic valve

The invention discloses novel casting equipment. The novel casting equipment comprises a base and a support column; a cavity is formed in the inner side of the support column; a motor is fixedly arranged at the bottom end in the cavity; a lead screw is fixedly arranged at an output end of the motor; nuts are in threaded connection to the surface of the lead screw; one sides of the two nuts are fixedly connected with two ends of an electric guide rail; a first through hole is formed in the bottom of a casting barrel; a high-temperature resisting electromagnetic valve is fixedly arranged in thefirst through hole; an extension rod groove is formed in the middle part of the base; and an extension rod is fixedly arranged in the extension rod groove. In the novel casting equipment, through arrangement of an electric rotating shaft, the casting barrel is driven to rotate to conveniently adjust the direction; through arrangement of the motor, the casting barrel can be driven to move up and down by the lead screw and the nuts; through arrangement of the electric guide rail, the casting barrel can be driven to move left and right; and through arrangement of the extension rod and a movable block, molded matters are conveniently ejected out.

Owner:甘肃欣福门窗工程有限公司

Die with secondary ejection forced demolding

The invention relates to a die with secondary ejection forced demolding. The die comprises a fixed die seat plate, a guide sleeve, a guide column, a moving template, an ejector pin, a cushion block, afirst spring, a moving die seat plate, a glue injection hole and a fixed template; the middle part of the moving die seat plate is provided with the glue injection hole; the bottom side of the movingdie seat plate is provided with the fixed template; the fixed template is connected with the fixed die seat plate through a bolt; the right side edge of the fixed template is internally provided withthe guide sleeve; the guide sleeve is connected with the fixed template in an embedded manner and is internally provided with the guide column; the top end of the guide column is connected with the guide sleeve in the embedded manner; the lower side of the fixed template is provided with the moving template; and the moving template is connected with the fixed template through the guide column. Through improvement on the die with secondary ejection forced demolding, the die with secondary ejection forced demolding has the advantages of rapidness in demolding, shortening in demolding time and improvement on production efficiency and thus effectively solves the problems and the deficiencies proposed in the background.

Owner:昆山科一达精密模具有限公司

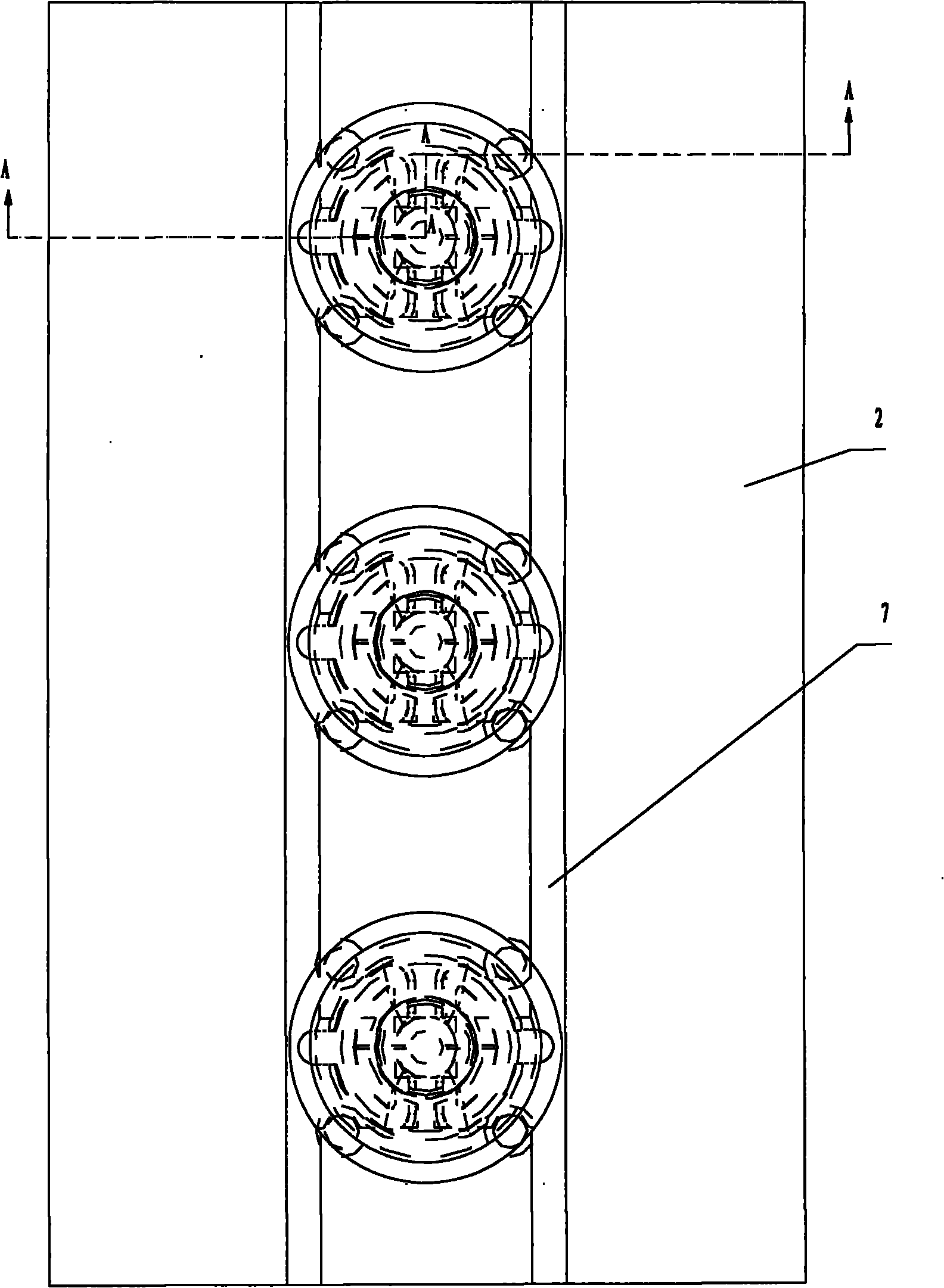

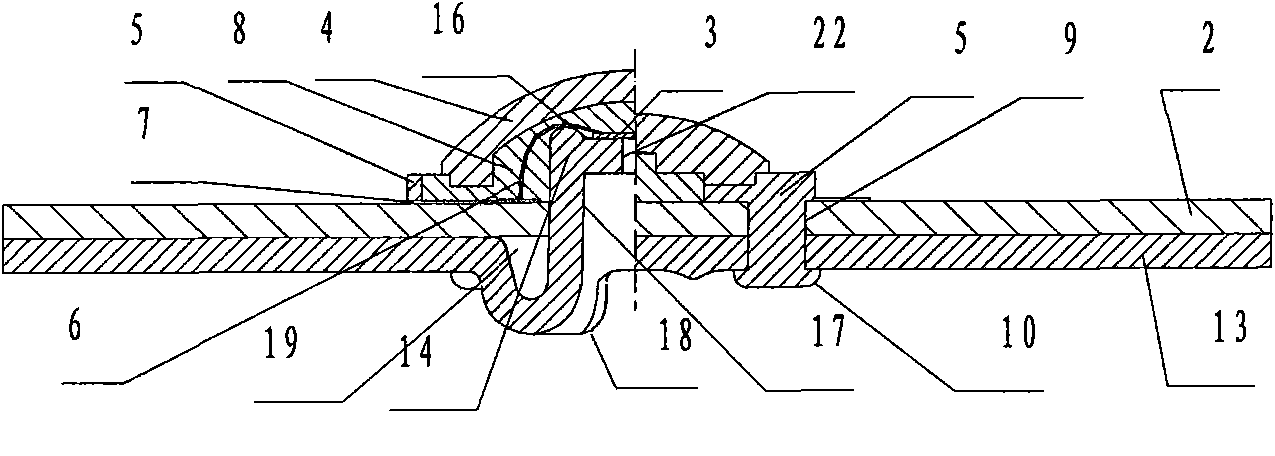

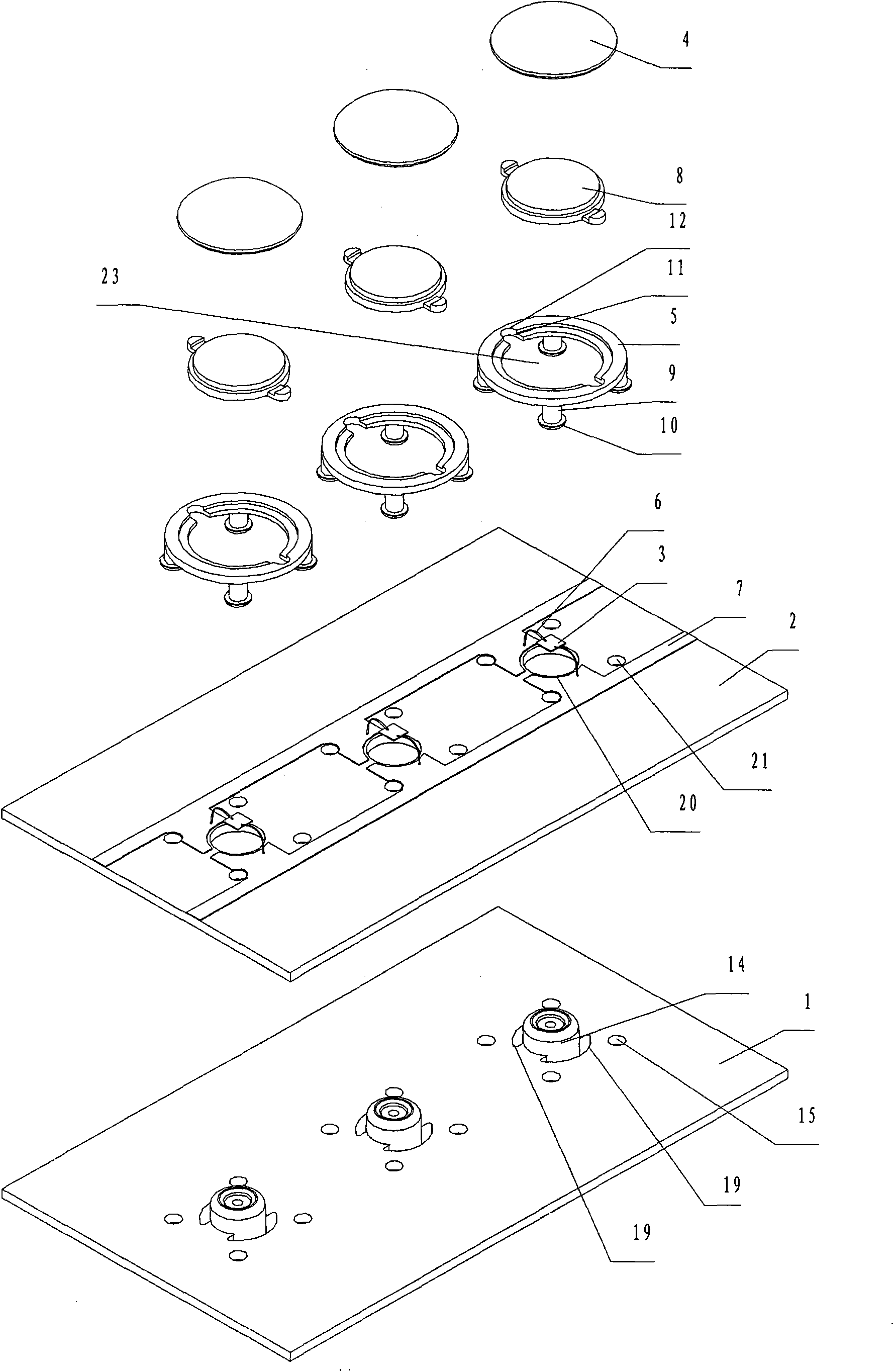

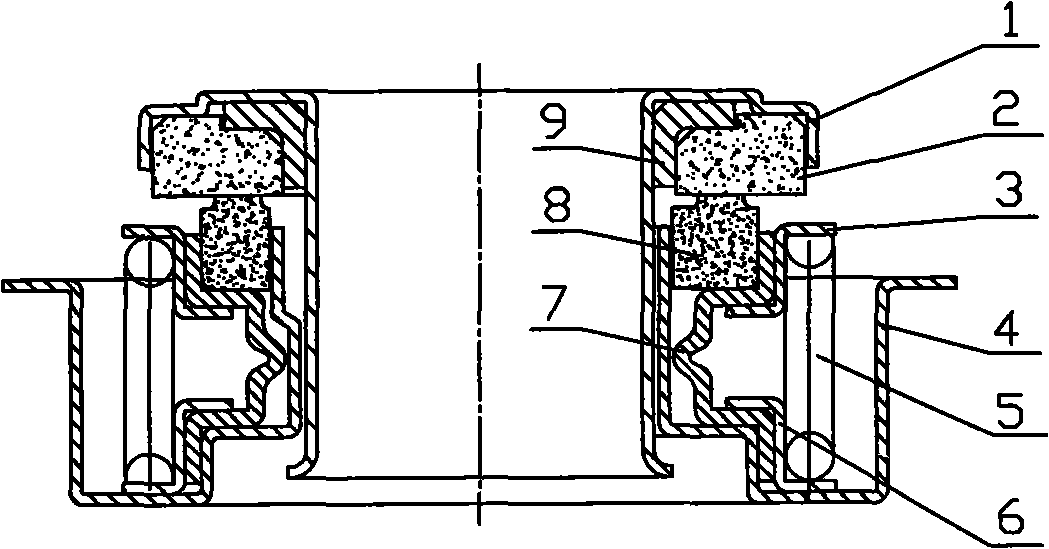

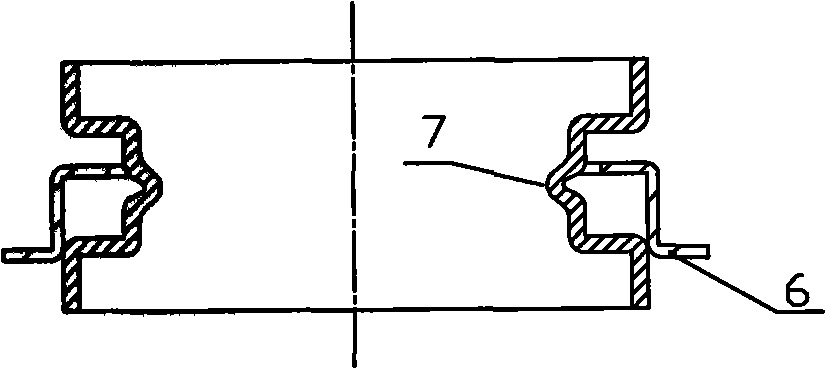

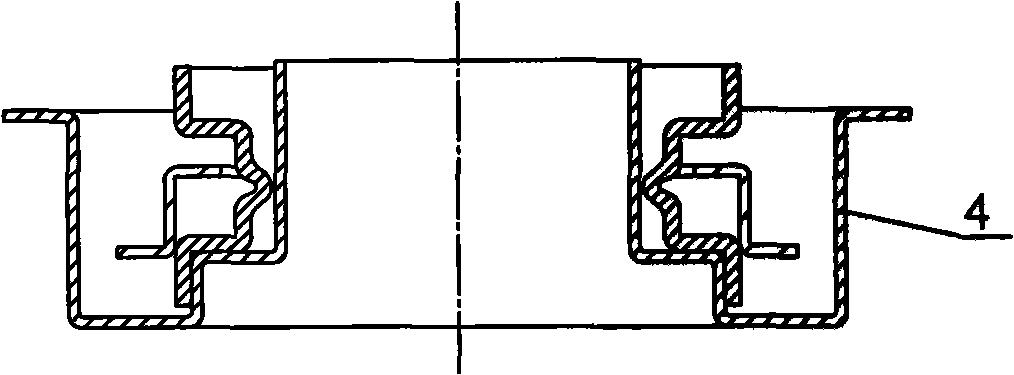

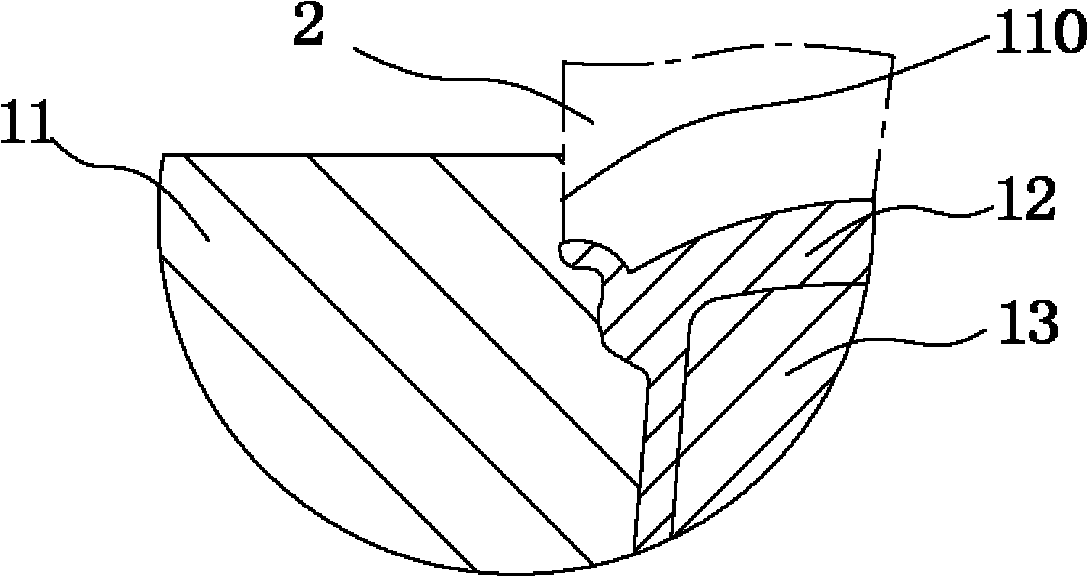

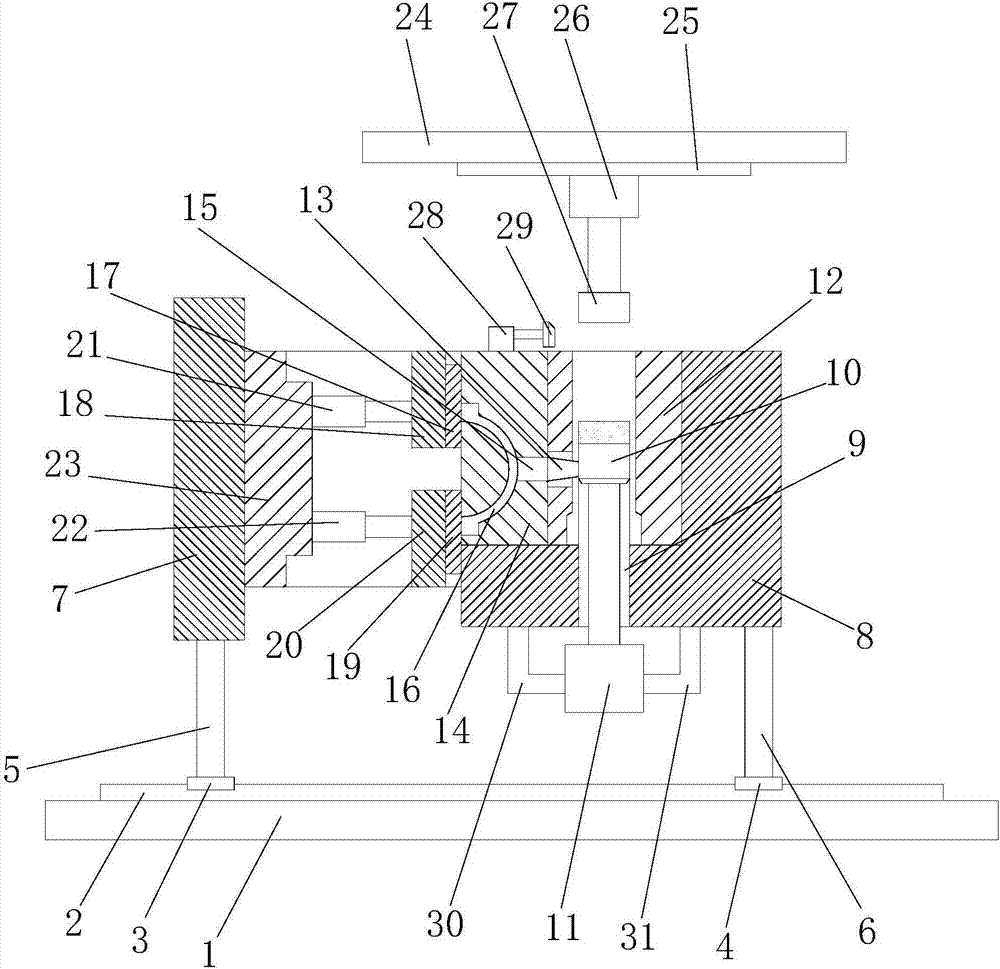

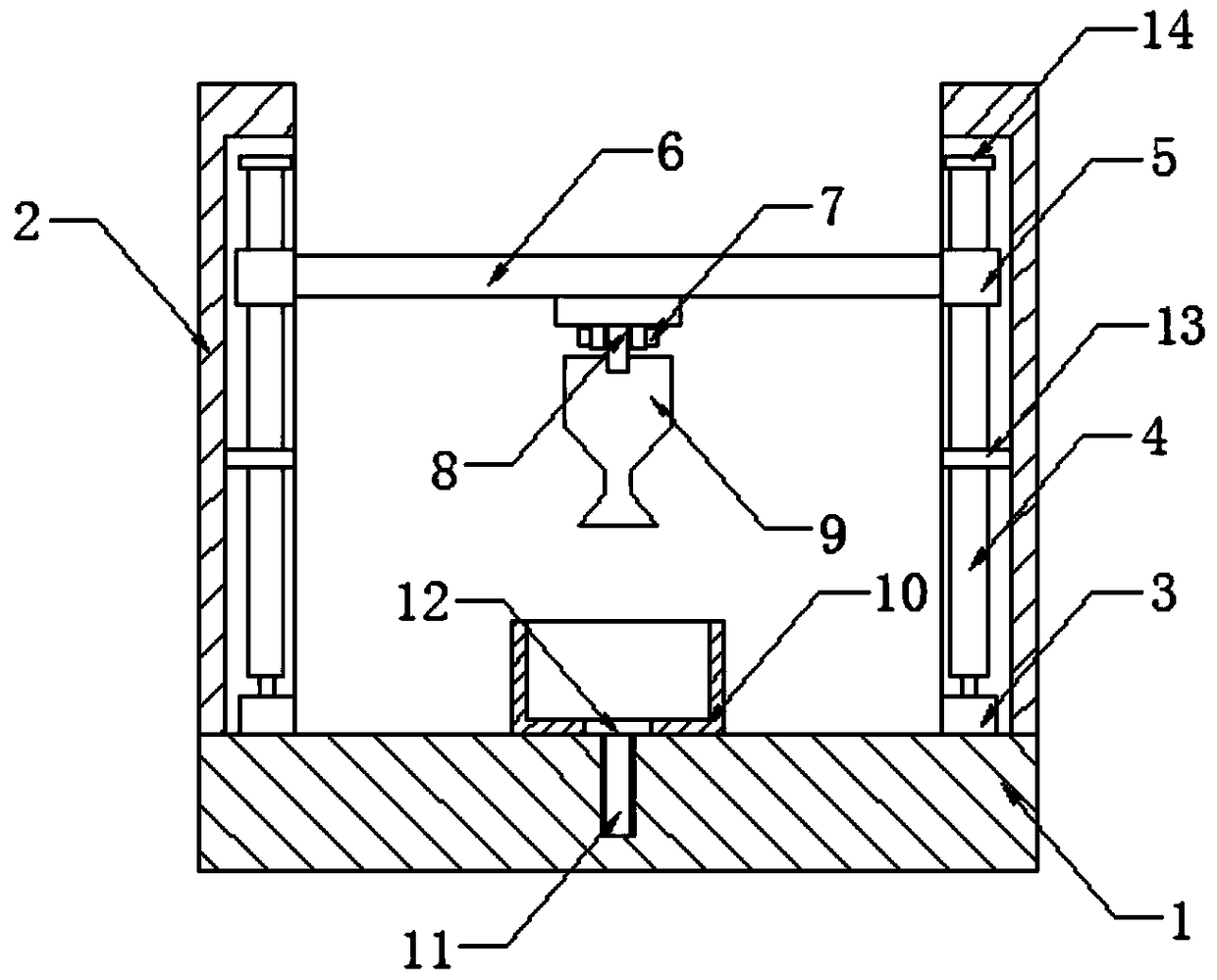

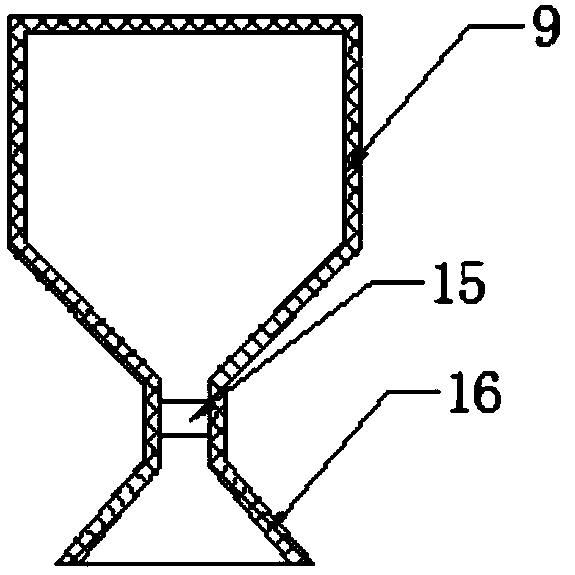

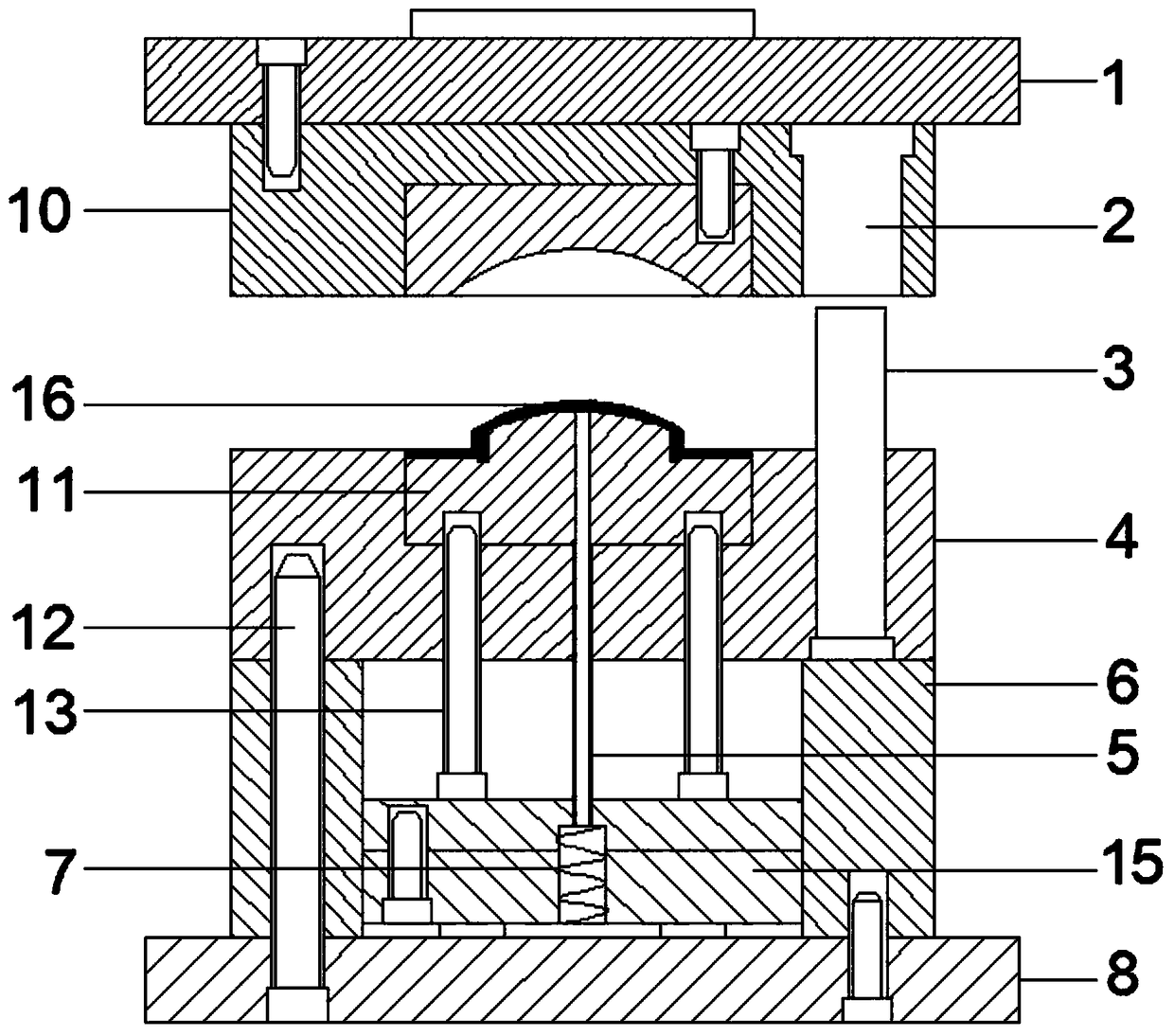

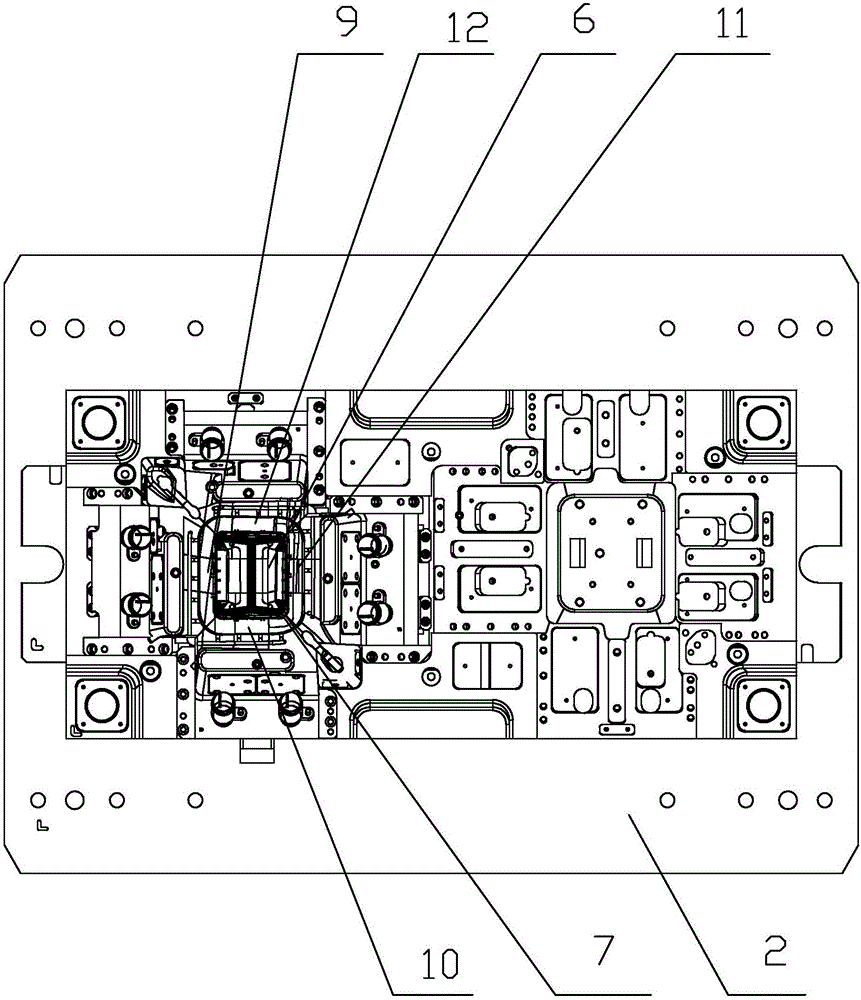

Cold extrusion mold for ball pin

ActiveCN104985013ASmall machining allowanceSave raw materialsExtrusion diesUltimate tensile strengthMaterials science

The invention discloses a cold extrusion mold for a ball pin. The cold extrusion mold comprises an upper mold body (1), a lower mold body (2), an upper mold sleeve (3), a lower mold sleeve (4) and a product (9). The upper mold body (1) is fixed to the interior of the upper mold sleeve (3), and the lower mold body (2) is fixed to the interior of the lower mold sleeve (4); a lower mold base plate (5) is arranged in the lower mold sleeve (4), and is located at the bottom of the lower mold body (2); the product (9) comprises a ball head (27), a neck portion (28) and a rod portion (29) and further comprises a haff guide mold (6) and at least three haff blocks (7); the haff guide mold (6) is fixed to the interior of the lower mold sleeve (4), and a first through hole (8) is formed in the middle of the haff guide mold (6); and the lower mold body (2) is located in the first through hole (8), and the haff blocks (7) are located in the haff guide mold (6). By means of the cold extrusion mold for the ball pin, the machining allowance of the ball pin is lesser, the strength is higher, and the cost is lower.

Owner:NINGBO YONGXIN AUTO COMPONENTS MFG

Wadding removing device for non-woven fabric processing

ActiveCN111874633AConvenient for centralized processingSo as not to damageBulk conveyorsConveyor partsElectric machineryWoven fabric

The invention discloses a wadding removing device for non-woven fabric processing. The device comprises a base, a baffle, a first motor, an air draft pipeline, a bearing cylinder and a battery pack, agroove is formed in the left end face of the base, a first electric telescopic rod is fixed to the right side wall of the groove, and a rotating box is rotatably connected to the top of the base; andthe air draft pipeline penetrates through a top cover to be connected with a filter net, the top of the bearing cylinder penetrates through the bottom of a support and is in threaded connection witha fastener, a sliding rail is fixed to the upper end face of the base, a roller is rotatably connected to the front side of a sliding block, a hydraulic cylinder is fixed to the right side of the front end face of the sliding block, and a top plate is fixed to the left side of the top of the sliding rail. According to the wadding removing device for non-woven fabric processing, after broken wadding in a side face hole of the rotating box is ejected out, the roller and a wadding sticking barrel can move downwards along with the sliding block, meanwhile, the wadding sticking barrel can rotate along with the roller, the wadding sticking barrel and the outer side wall of the rotating box are attached together, and the ejected broken wadding can be conveniently stuck down.

Owner:昆山洁宏无纺布制品有限公司

Transfer making machine

The invention discloses a transfer making machine. A supporting plate is arranged on a bottom plate. A sliding plate assembly capable of moving along the left-and-right direction of the bottom plate is in slide fit with the side wall surface of the supporting plate. A transmission rack and a matrix supporting device are arranged on the lateral surface of the sliding plate assembly, which is deviated from the supporting plate. The transmission rack is positioned below the matrix supporting device. A matrix is arranged in the matrix supporting device. A bearing seat is arranged on the bottom plate. A spindle is arranged in the bearing seat. A transmission gear and a flywheel positioning seat are respectively and circumferentially fixed together with the spindle. The flywheel positioning seat is positioned above the transmission gear. The transmission gear is meshed with the transmission rack. The transfer making machine replaces conventional stamping equipment to process clear characters on a cylindrical part. The characters have consistent depths. The accuracy of engraved lines and engraved characters, which are distributed along the circumference at a regulated angle can reach the range of less than plus and minus 0.5 degree.

Owner:SHIHLIN ELECTRIC CHANGZHOU

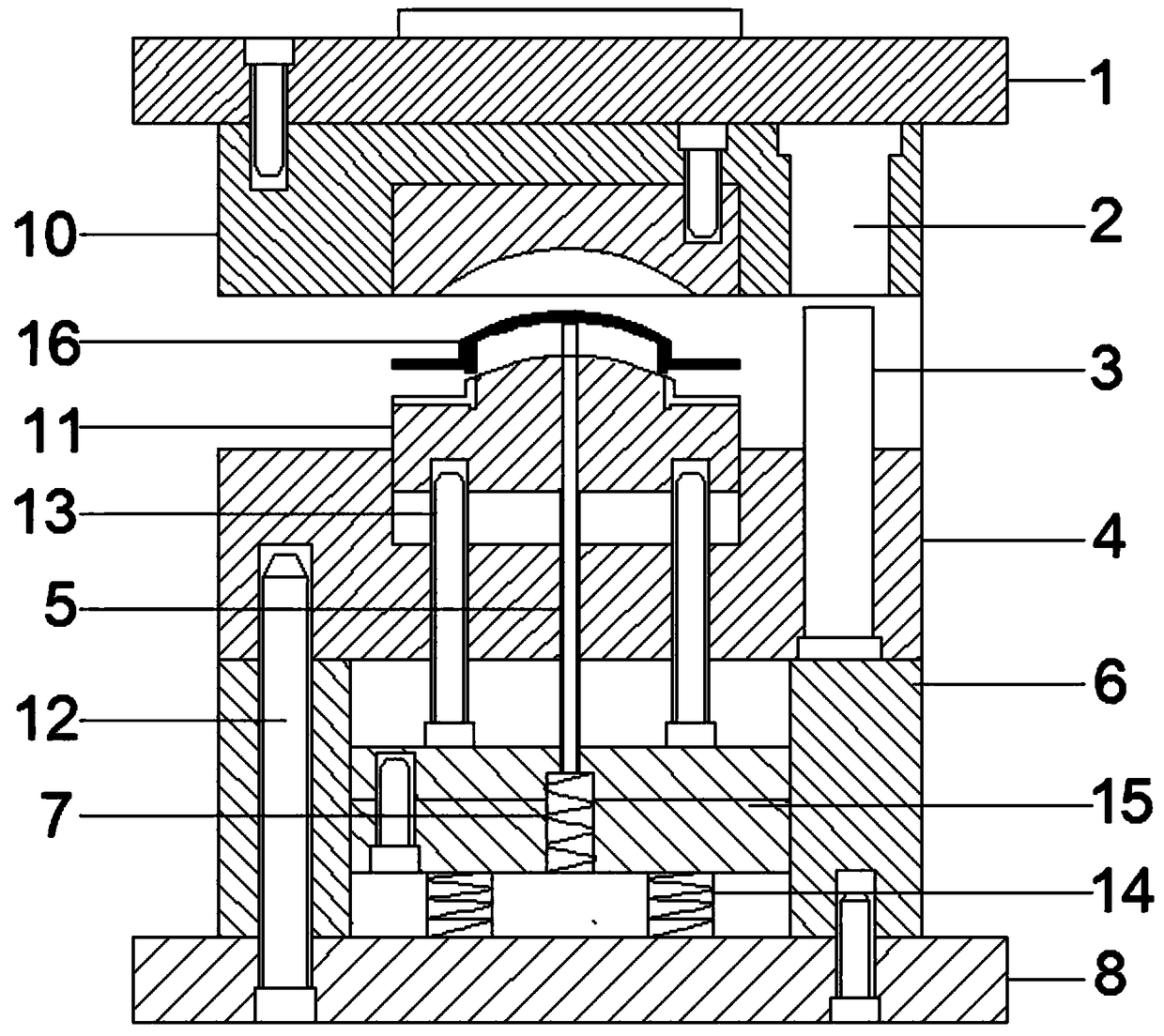

Airbag cover injection mold

The invention discloses an airbag cover injection mold. The airbag cover injection mold comprises an upper mold plate (1), a lower mold plate (2), a mold foot (3), a cover plate (4), a sprue (5) and a product (6). The lower mold plate (2) is fixed to the mold foot (3). The upper mold plate (1) is located between the lower mold plate (2) and the cover plate (4). The sprue (5) is arranged on the cover plate (4). An upper mold cavity (6) is arranged on the lower surface of the upper mold plate (1). A lower mold cavity (7) is arranged on the upper surface of the lower mold plate (2). A cavity used for forming the product (6) is arranged between the upper mold cavity (6) and the lower mold cavity (7). An upper mold core (8) used for forming the upper surface of the product (6) is arranged in the upper mold cavity (6). The airbag cover injection mold provided by the invention is low in cost, high in production efficiency and simple in structure, and the product quality is good.

Owner:NINGBO FANGZHENG TOOL

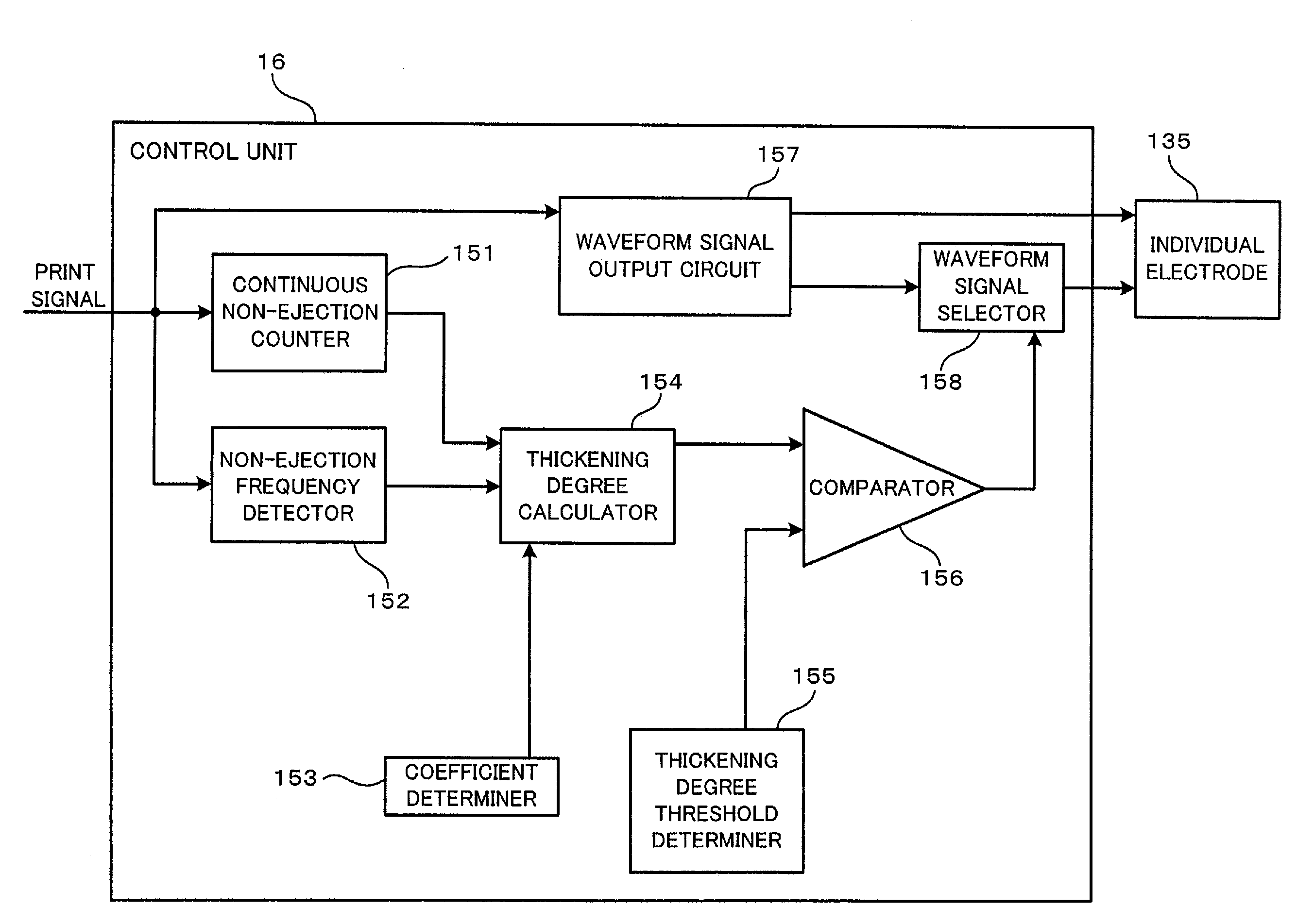

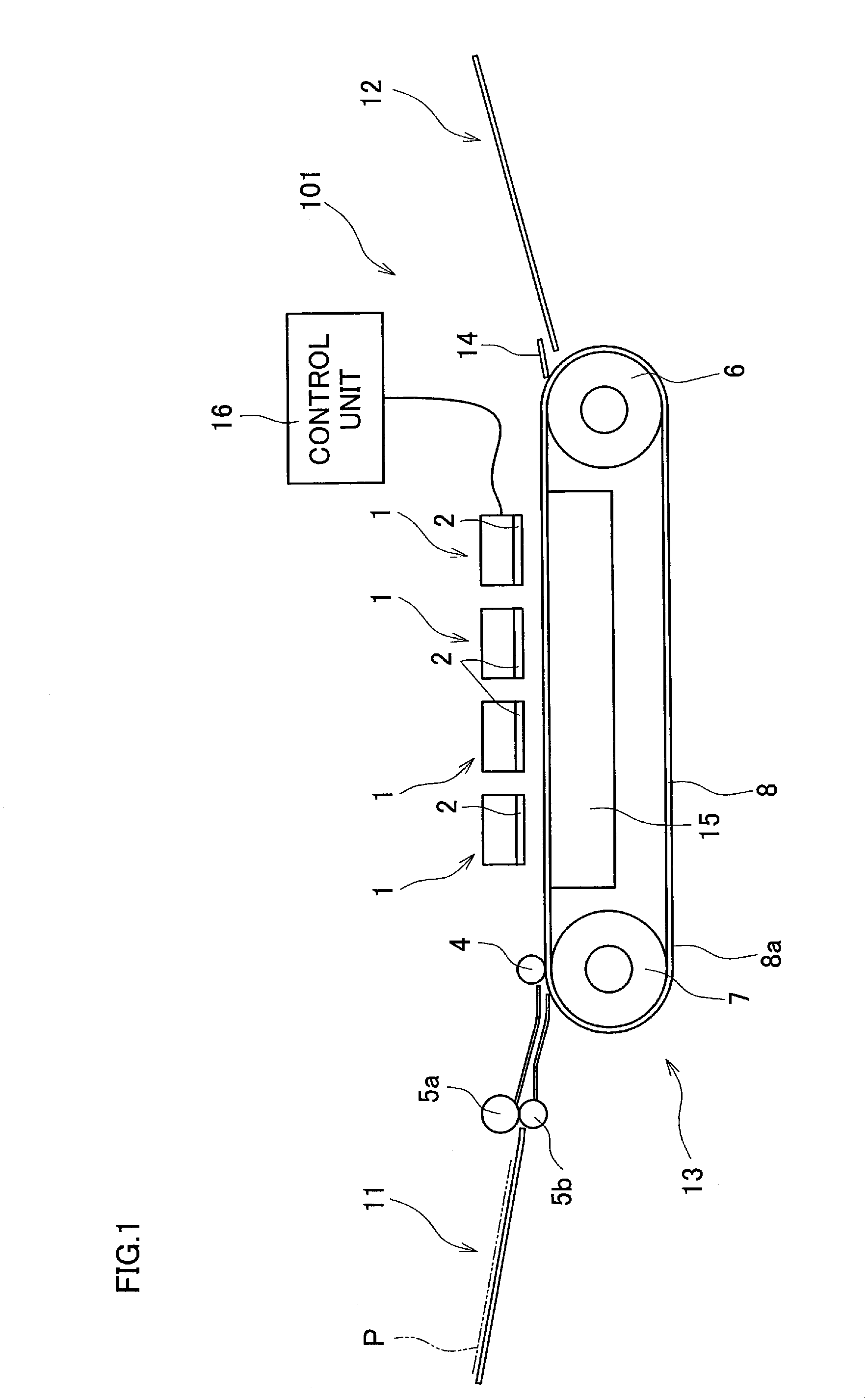

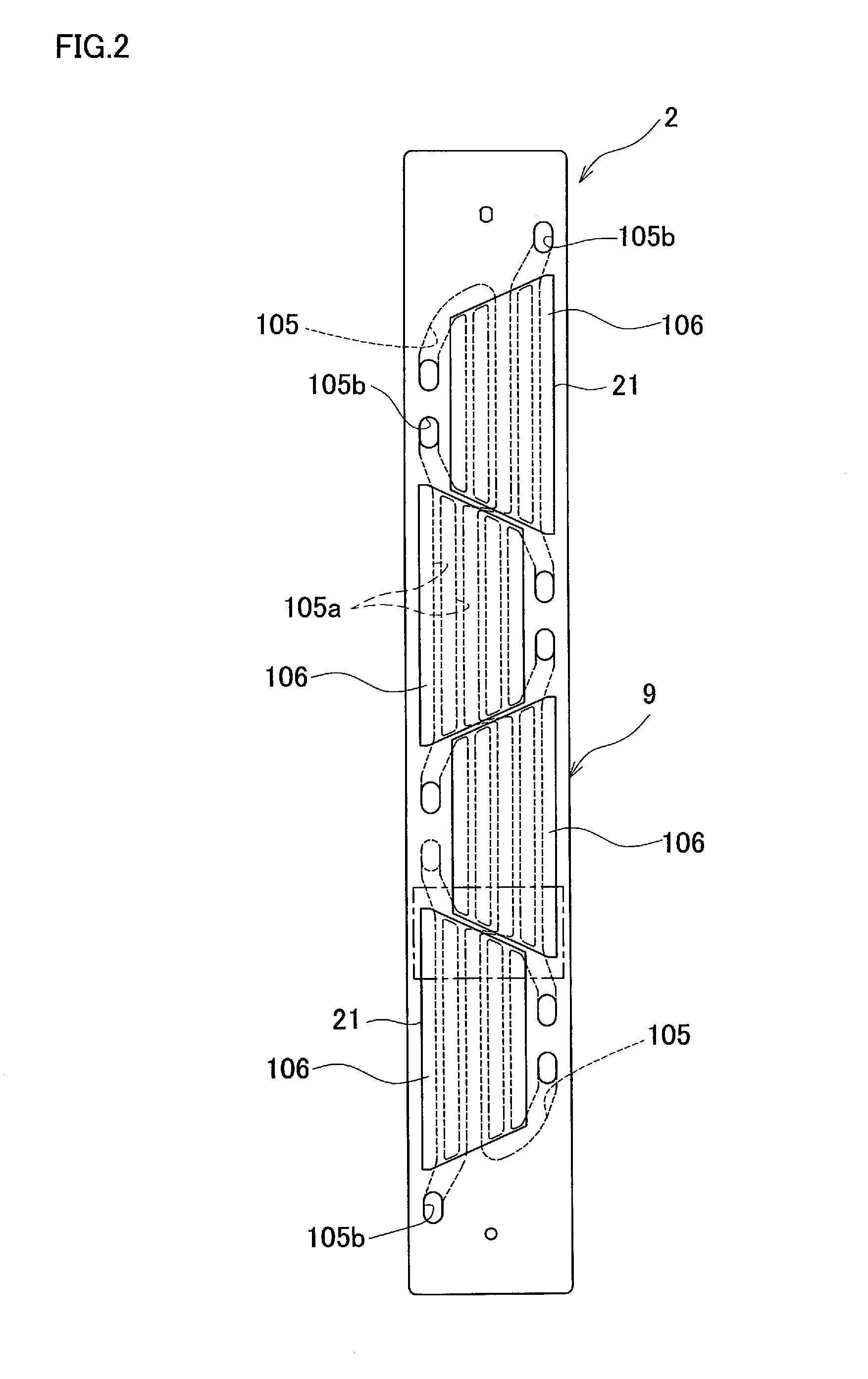

Ink-jet recording apparatus

ActiveUS7452045B2Quality improvementIncrease printing speedInking apparatusTypewritersEngineeringElectrical and Electronics engineering

A waveform signal output circuit selectively outputs, to an ejection energy applier, either one of a first waveform signal so as to make an ink droplet ejected from a nozzle and a second waveform signal so as not to make an ink droplet ejected from the nozzle. A continuous non-ejection counter counts a continuous non-ejection number. A ejection history memory stores therein an ejection history. A non-ejection frequency detector detects a non-ejection frequency. A thickening degree determiner determines a thickening degree of ink in the nozzle. A waveform signal selector makes the waveform signal output circuit output the second waveform signal to the ejection energy applier when an ink droplet is not ejected in the current printing cycle and in addition a thickening degree is equal to or greater than a predetermined value.

Owner:BROTHER KOGYO KK

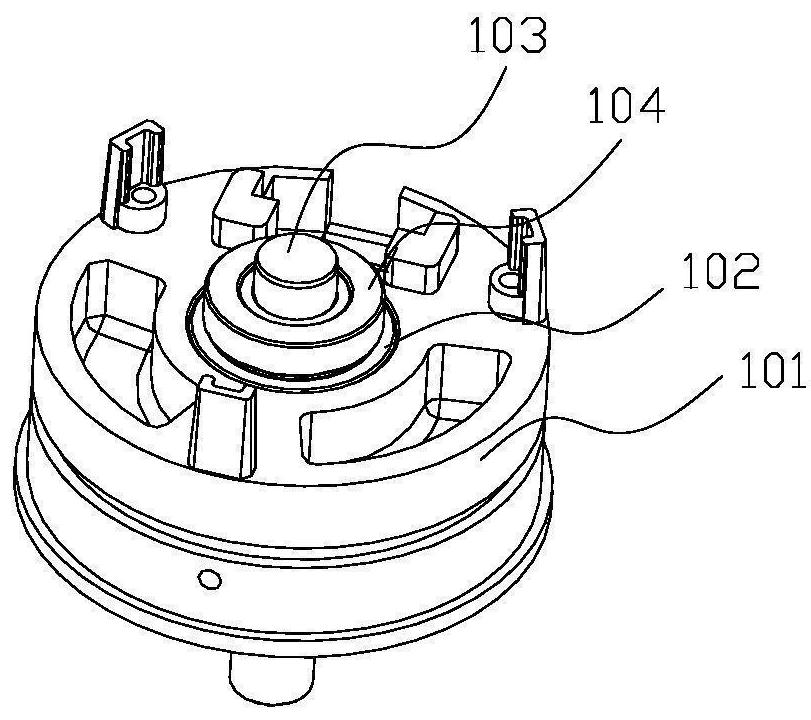

Shaft sleeve feeding and assembling device for sensor production and shaft sleeve assembling method for sensor production

InactiveCN111822239APrevent fallingPrevent slipping out and fallingLiquid surface applicatorsMaterial gluingRotational axisManufacturing engineering

The invention belongs to the technical field of automatic sensor production, and discloses a shaft sleeve feeding and assembling device for sensor production. The shaft sleeve feeding and assembling device for the sensor production comprises a shaft sleeve feeding vibrator, a shaft sleeve connecting assembly, a shaft sleeve gluing assembly, a shaft sleeve pushing assembly and a shaft sleeve transferring and assembling assembly; the shaft sleeve feeding vibrator is arranged on a rack in the front-back direction, the shaft sleeve connecting assembly is connected with the discharging end of the shaft sleeve feeding vibrator and used for supporting a shaft sleeve and driving the shaft sleeve to rotate, the shaft sleeve gluing assembly is arranged on one side of the shaft sleeve feeding vibrator and used for gluing the inner ring of the shaft sleeve, the shaft sleeve pushing assembly is used for pushing out the glued shaft sleeve, and the shaft sleeve transferring and assembling assembly isused for transferring and assembling the shaft sleeve. The shaft sleeve feeding and assembling device and the shaft sleeve assembling method have the advantages that the assembling efficiency and theassembling quality of the shaft sleeve and a rotating shaft are improved, and the overall assembling quality of a sensor is improved.

Owner:林勤鑫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com