Patents

Literature

36results about How to "Lower ejection force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

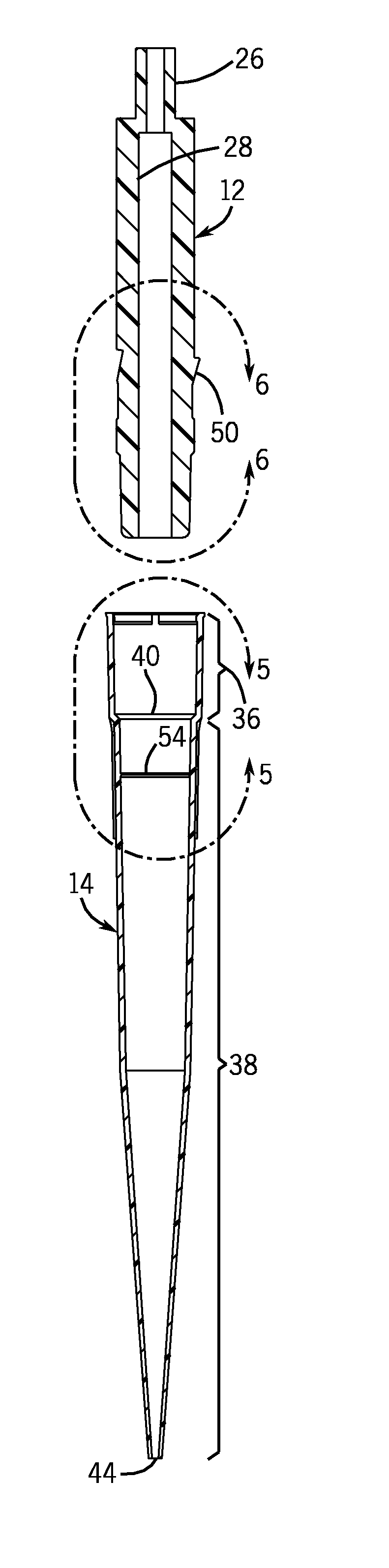

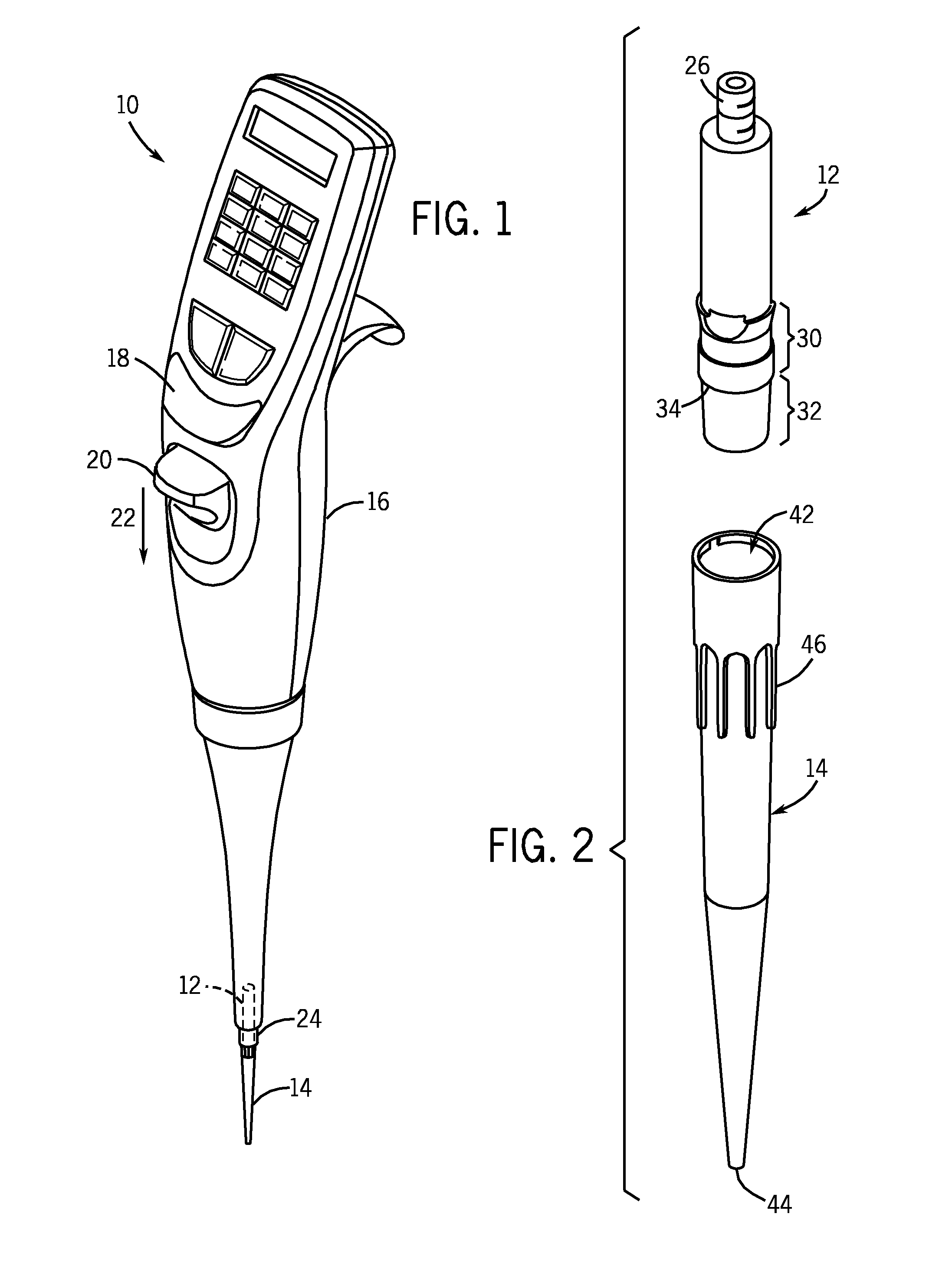

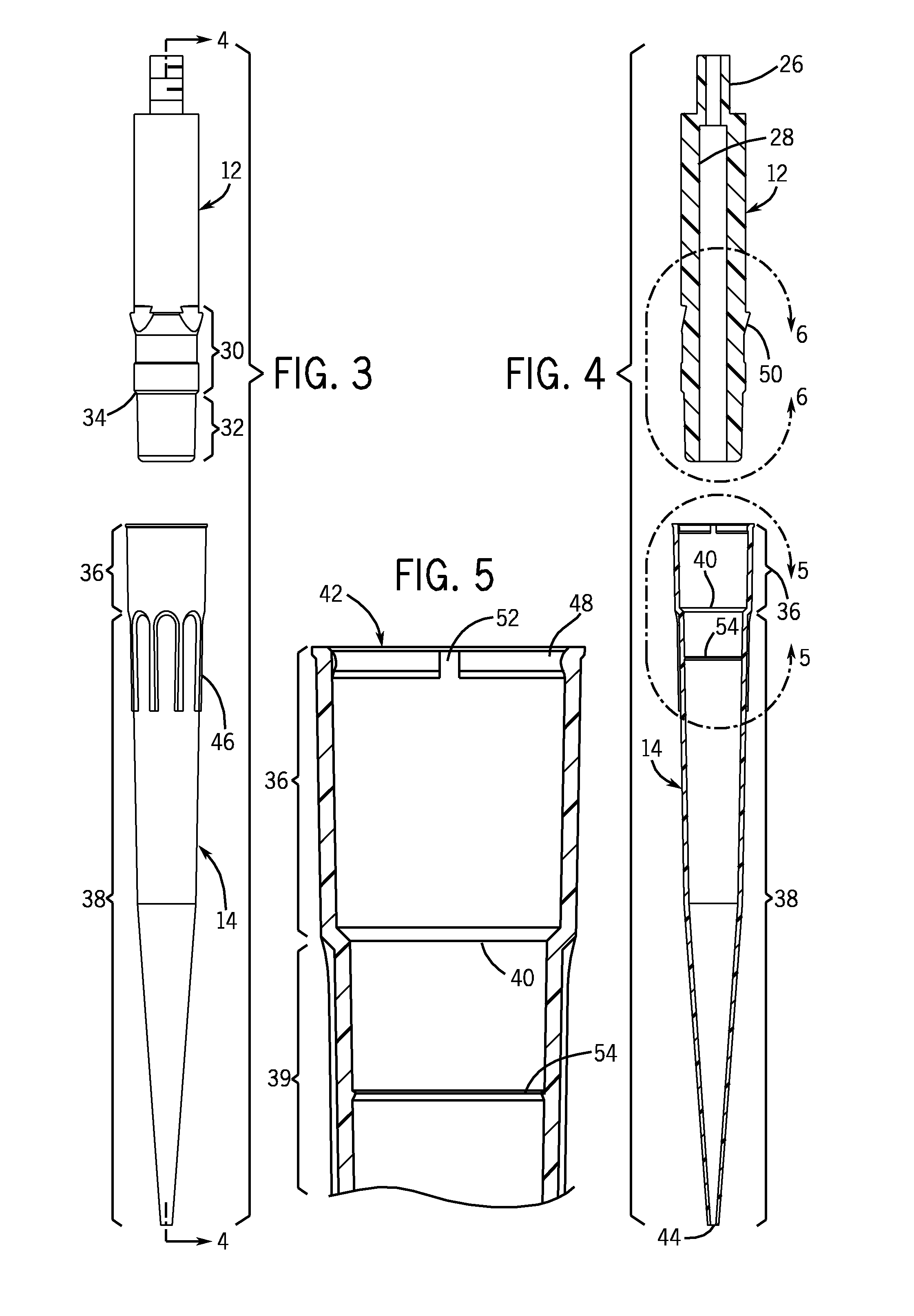

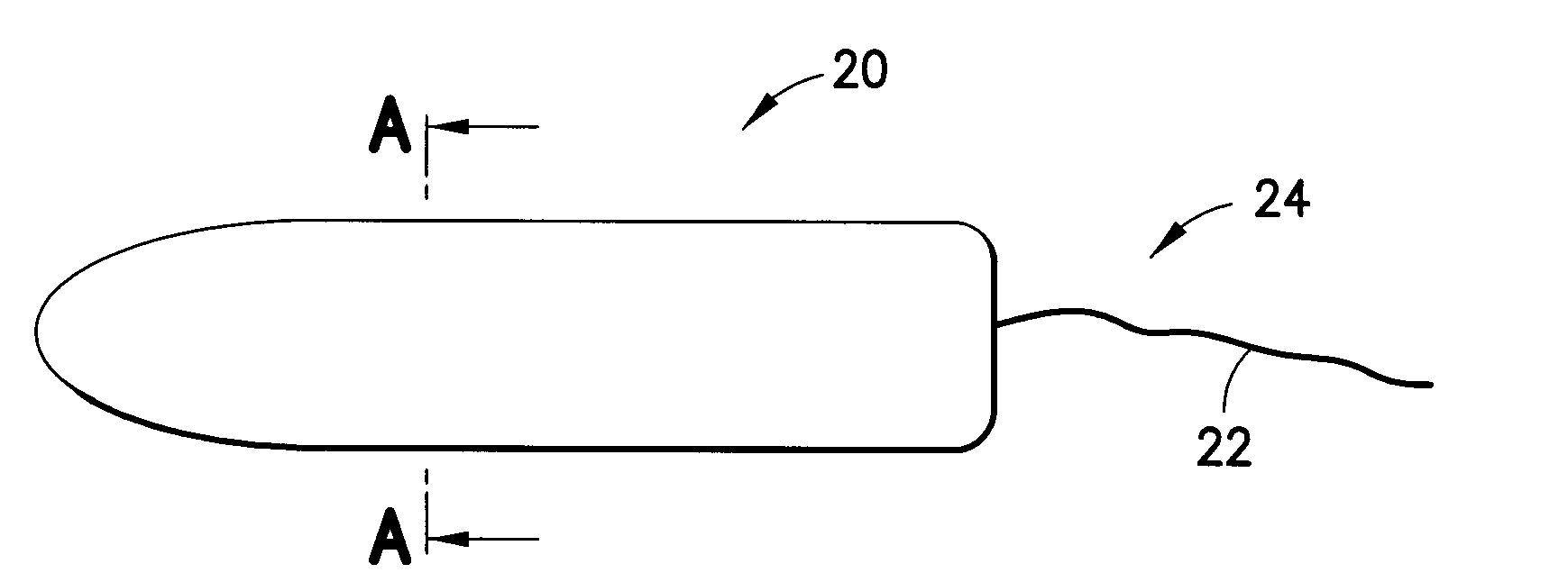

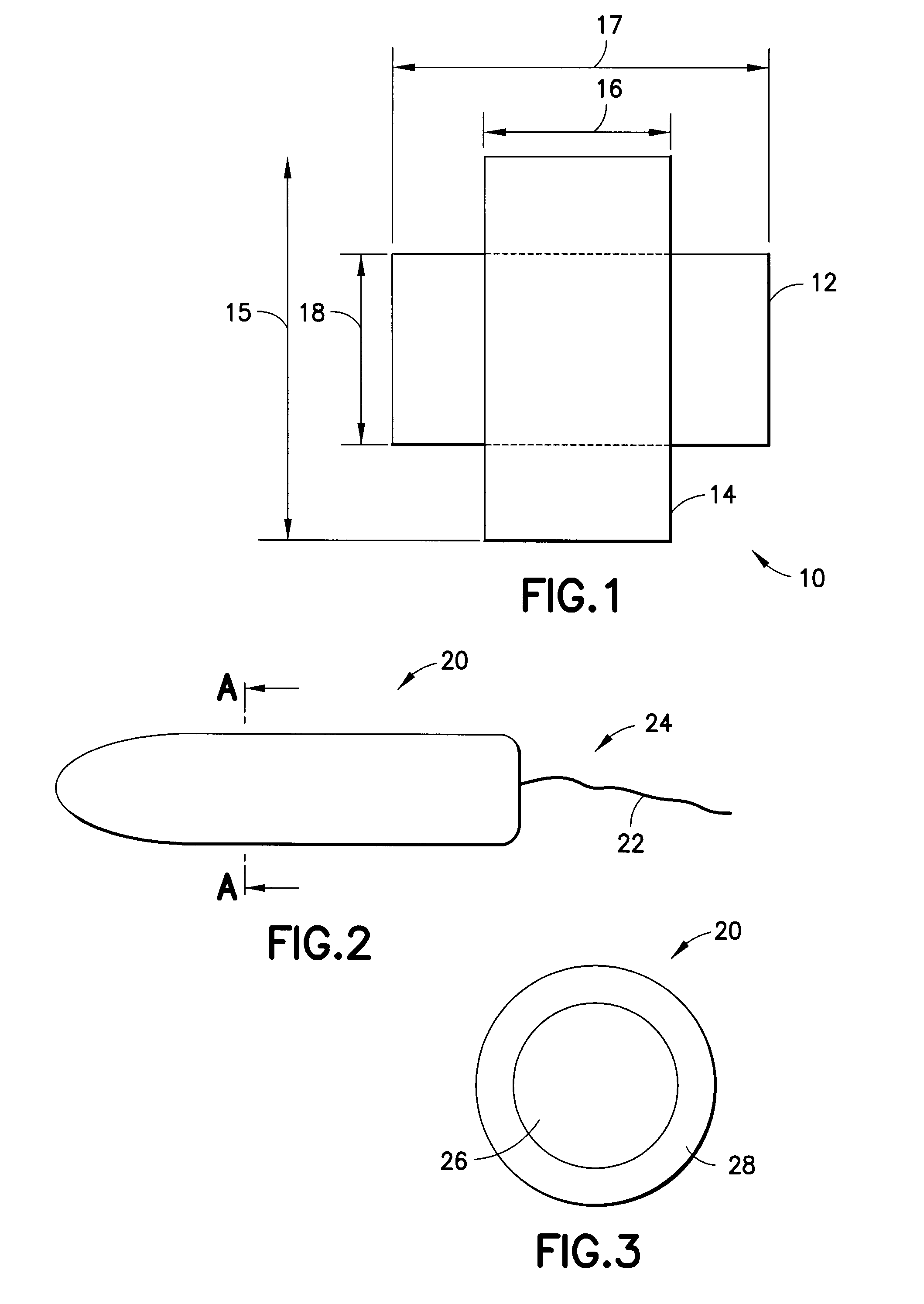

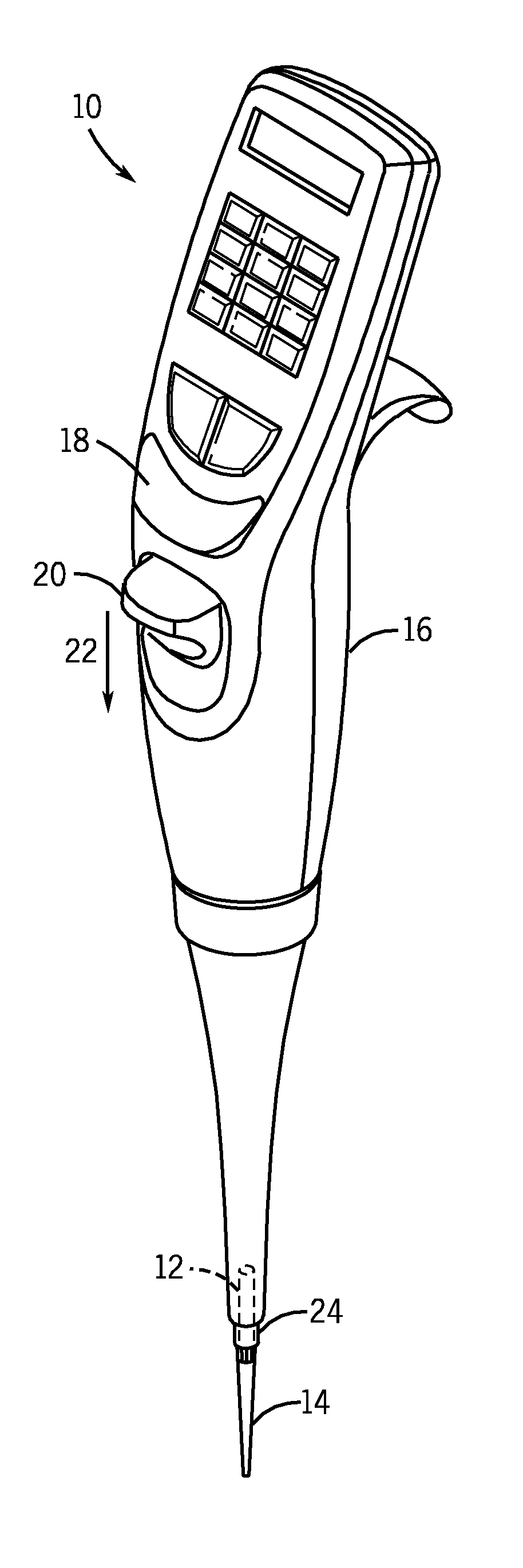

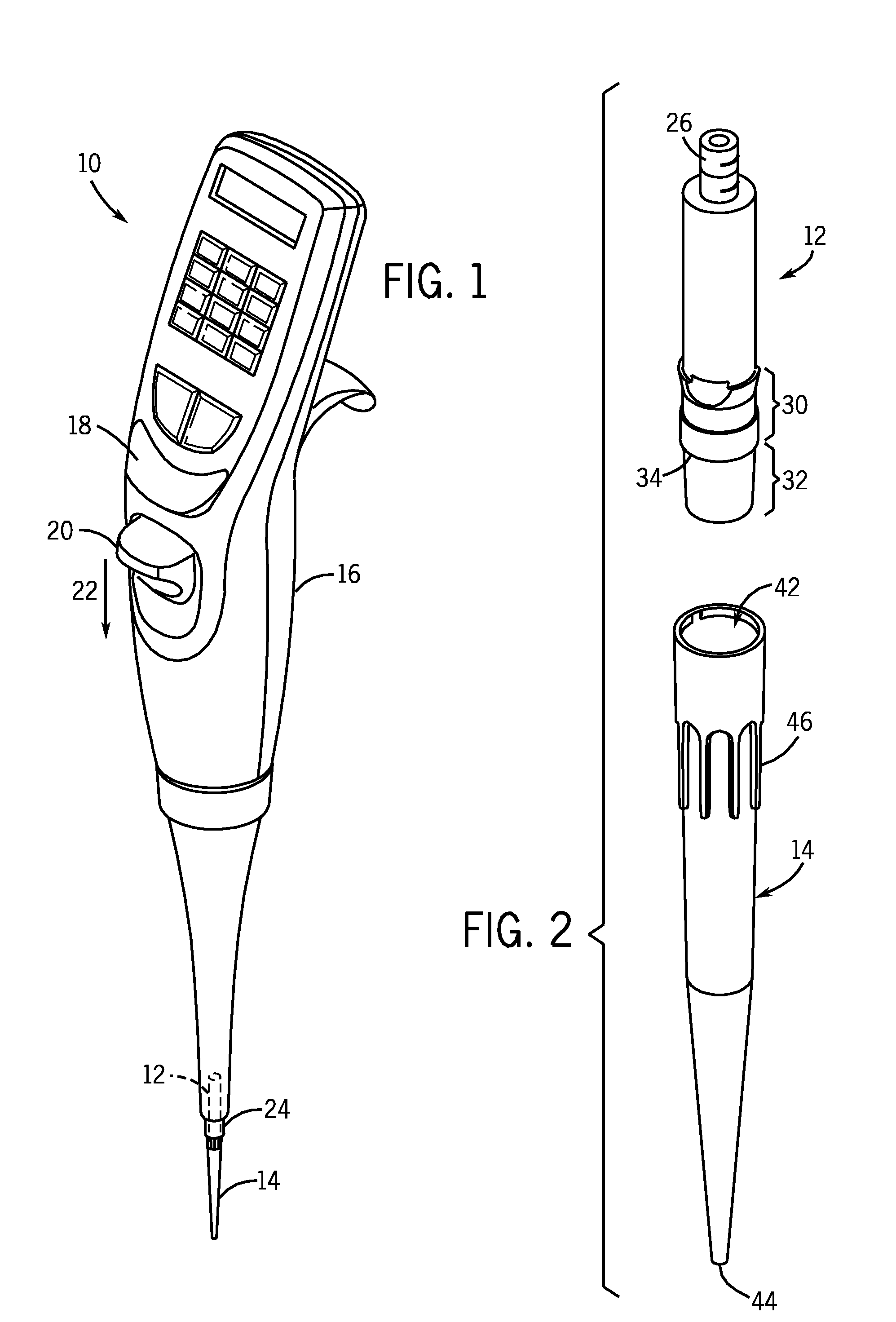

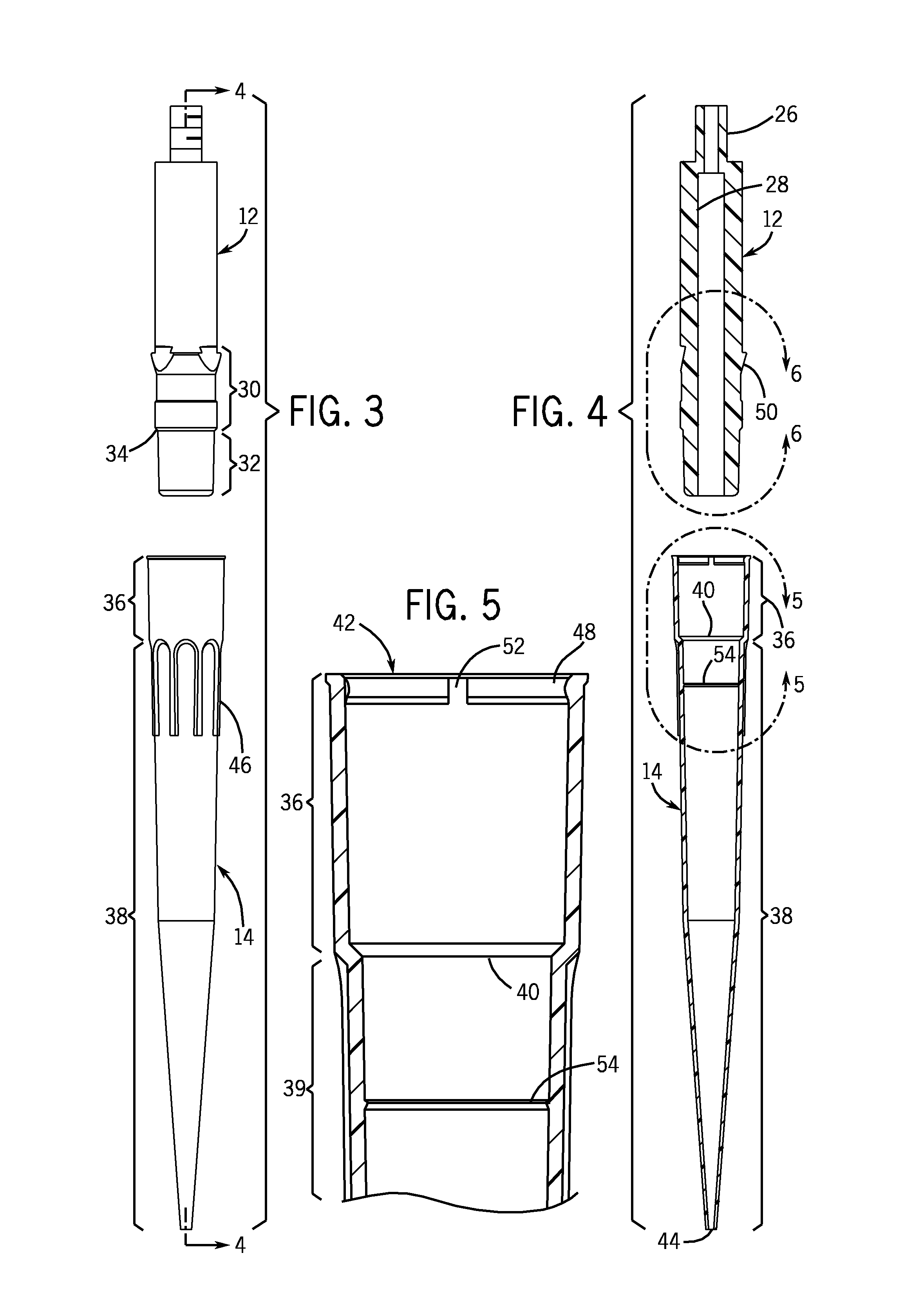

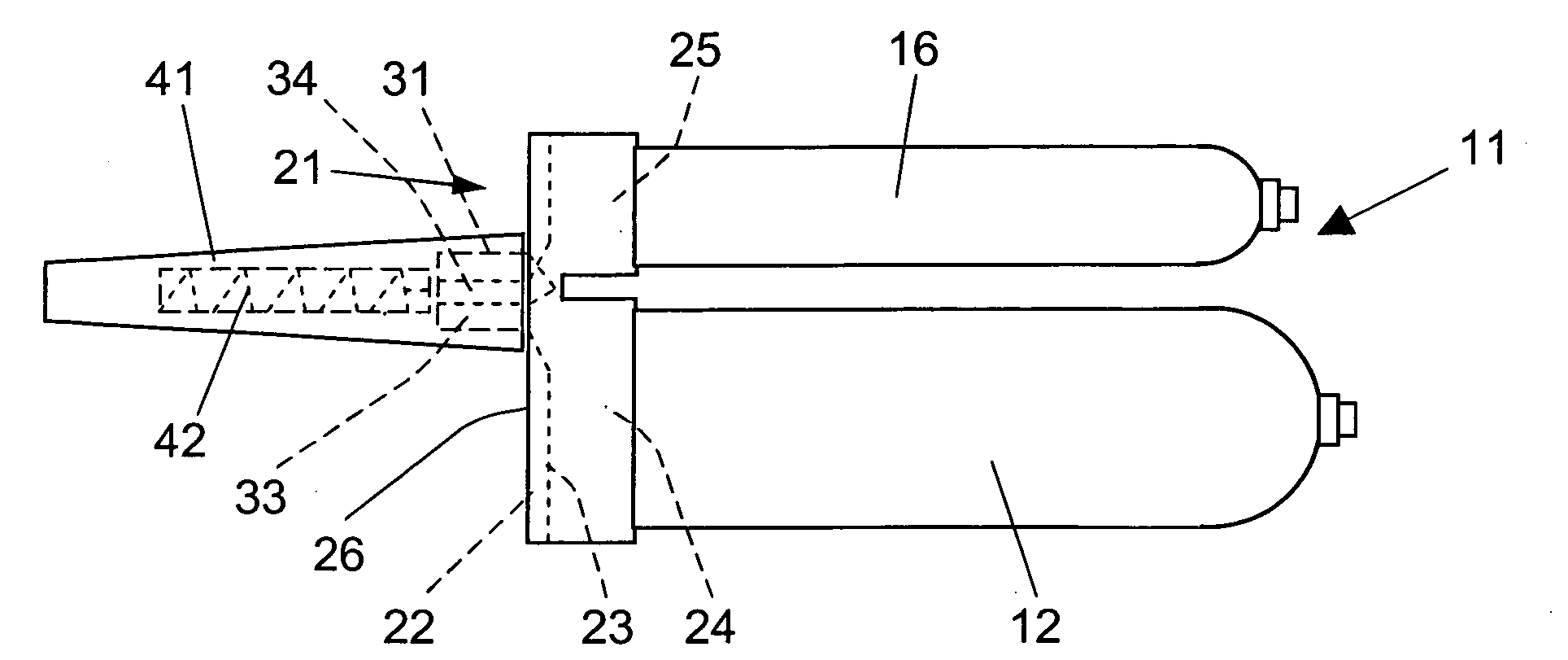

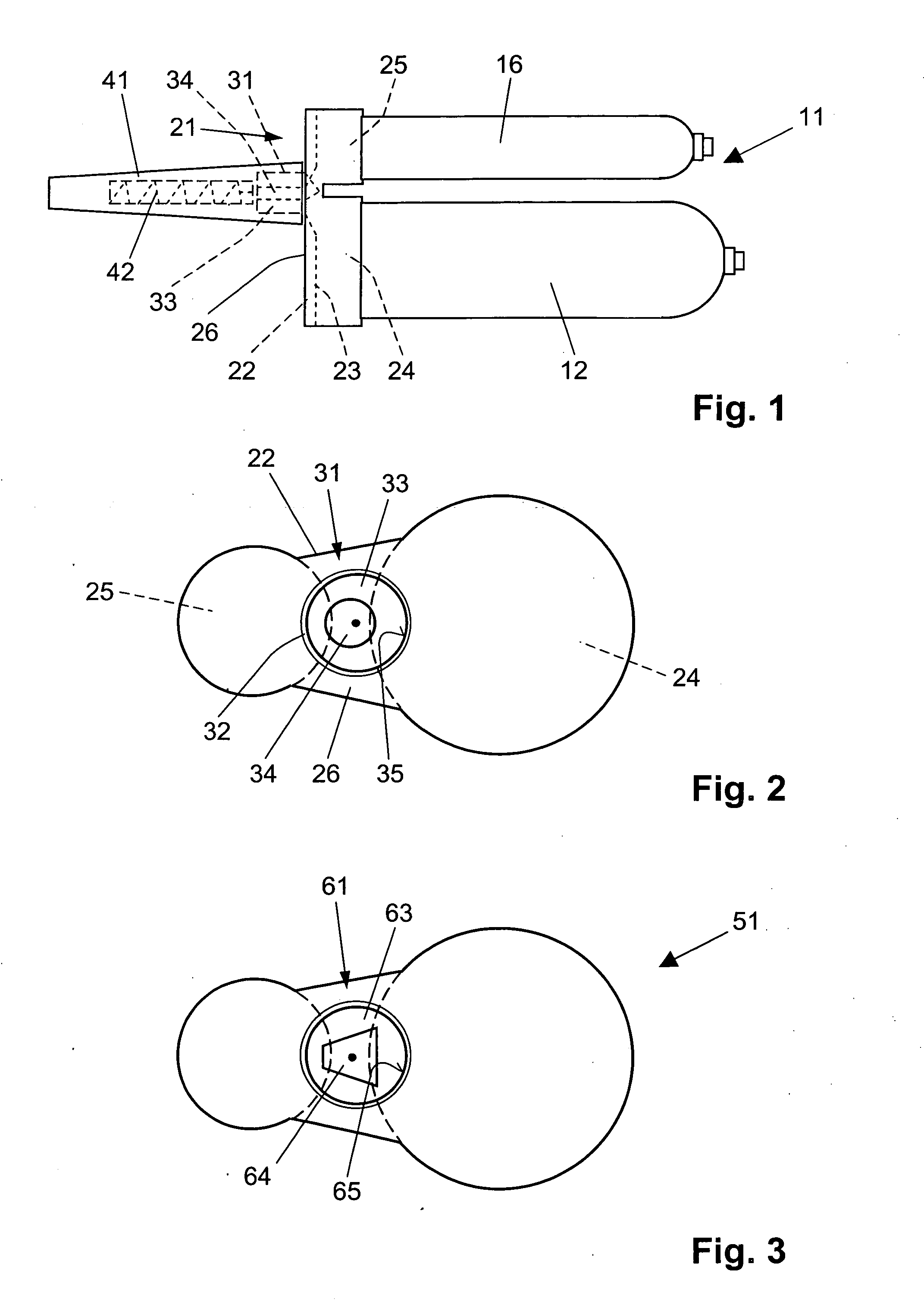

Locking pipette tip and mounting shaft

ActiveUS7662343B2Maintain roundnessFacilitate reliable engagementWithdrawing sample devicesBurettes/pipettesPipetteEngineering

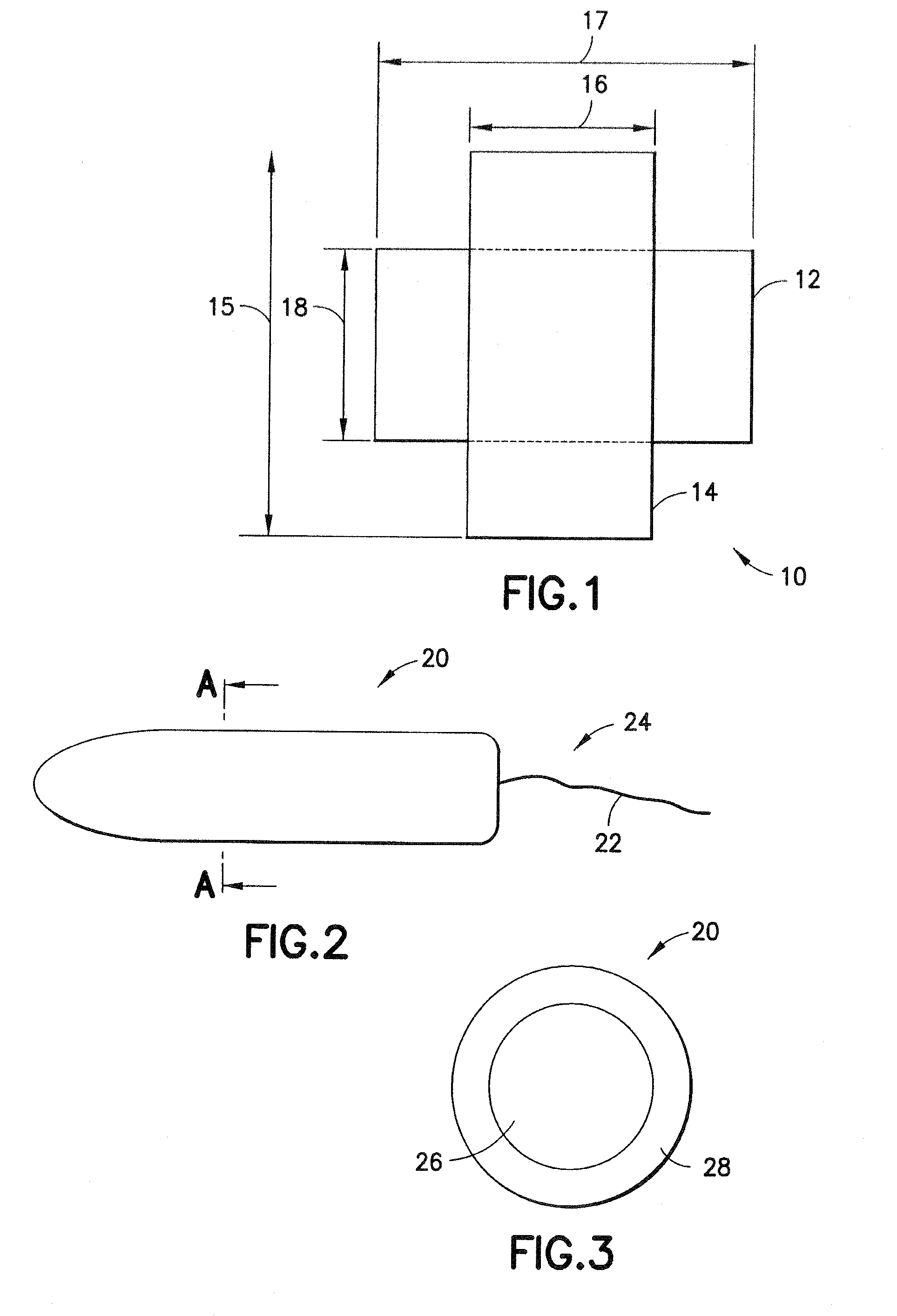

The invention relates to a pipette tip mounting shaft configuration and a disposable pipette tip having a matching configuration. The mounting shaft includes a locking section located above a lower sealing section. The locking section has outwardly extending locking lobes circumferentially spaced around the mounting shaft and located above a stop member that separates the lower sealing section from the upper locking section. When the mounting shaft is fully inserted into the collar of the mating disposable pipette tip, the tip locks onto the mounting shaft. The bore of the pipette tip includes a circumferential shelf separating its upper collar from the tip sealing area which is located below the circumferential shelf. The locking lobes gently flexes and distorts the pipette tip collar out of round as the mounting shaft is inserted in the pipette tip, rather than stretching the tip collar. The circumferential shelf on the pipette tip between the tip collar and the barrel isolates the sealing area at the upper end of the barrel from distortion, thus facilitating reliable sealing engagement.

Owner:INTEGRA BIOSCI CORP

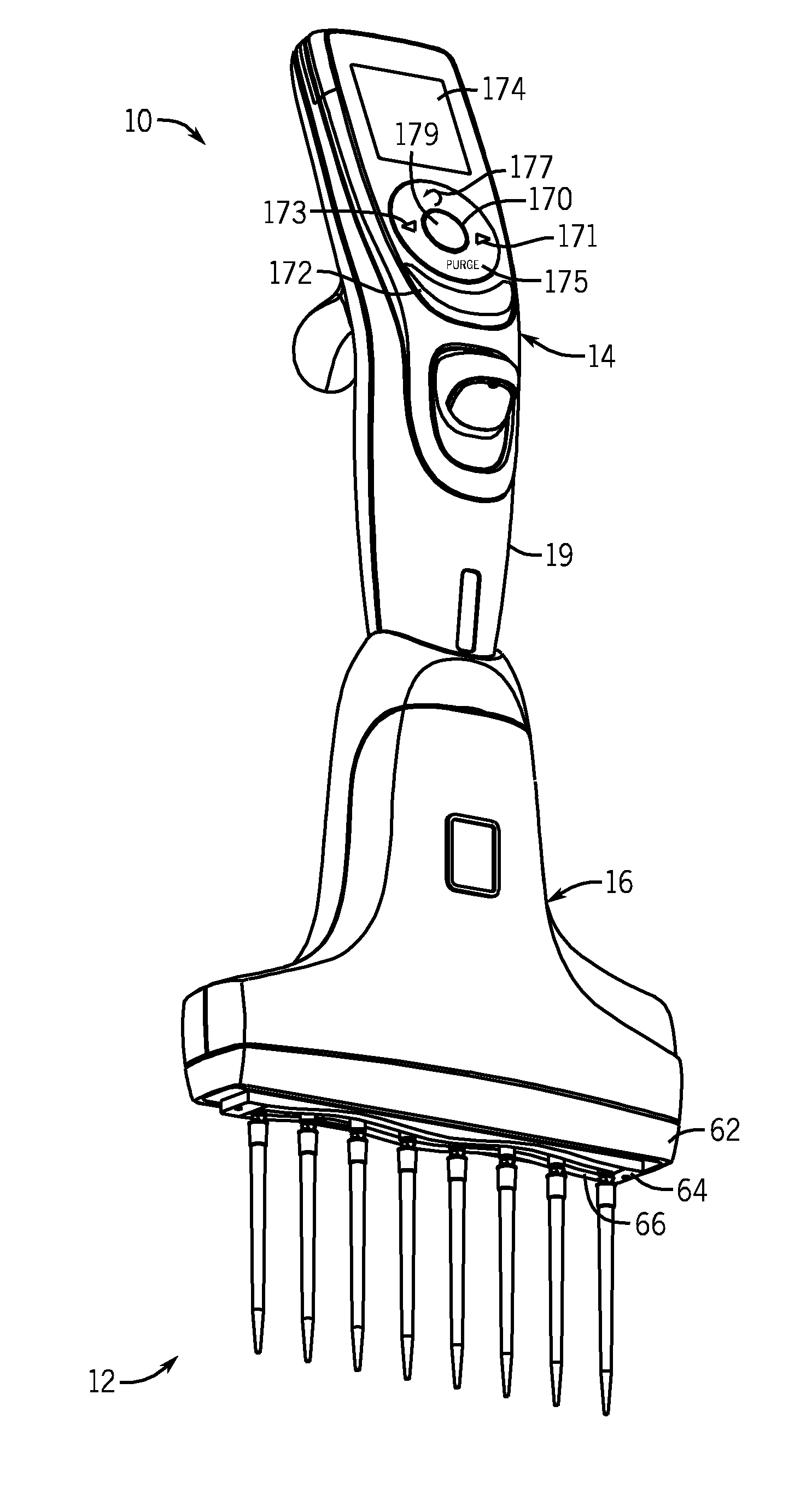

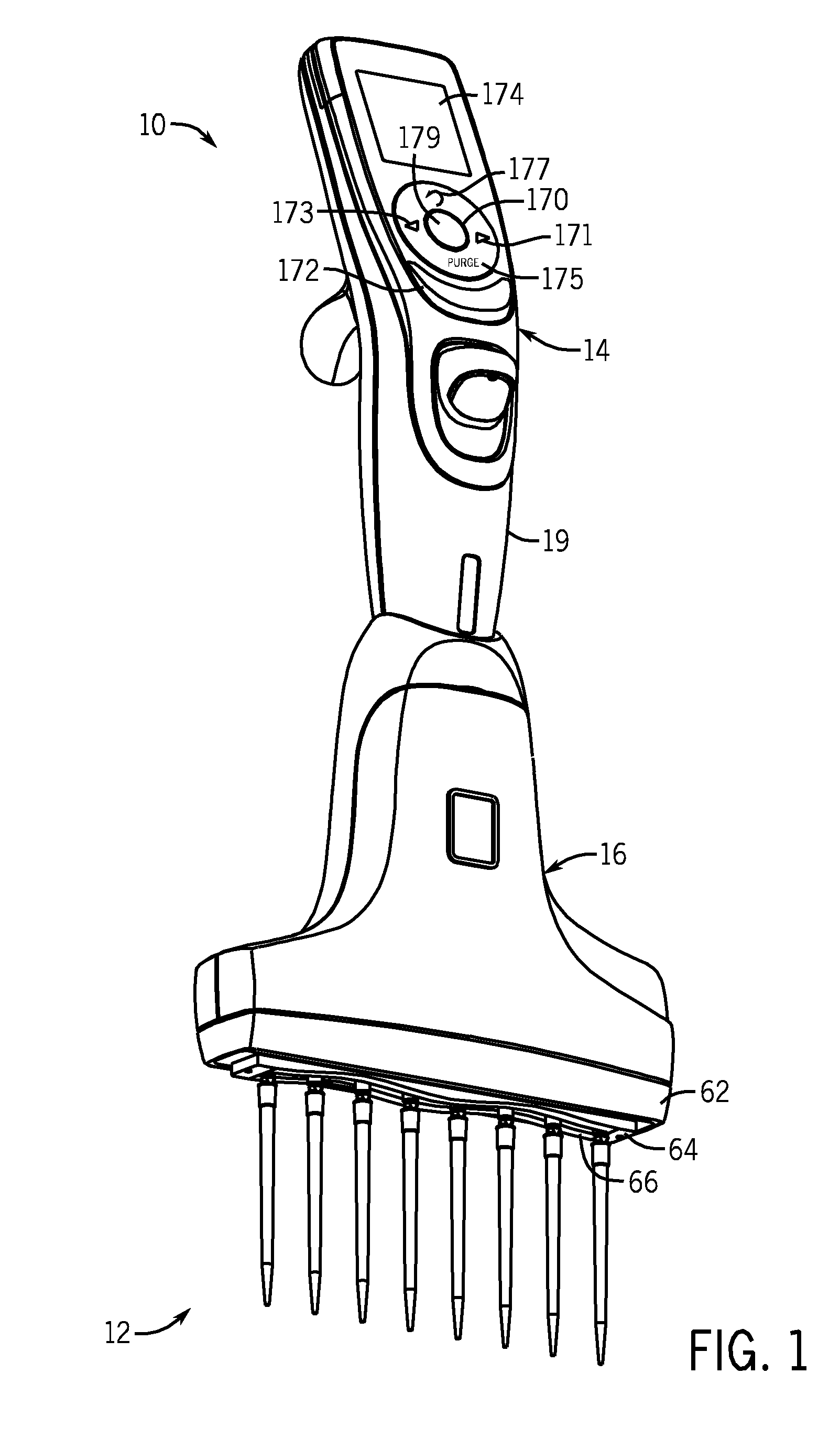

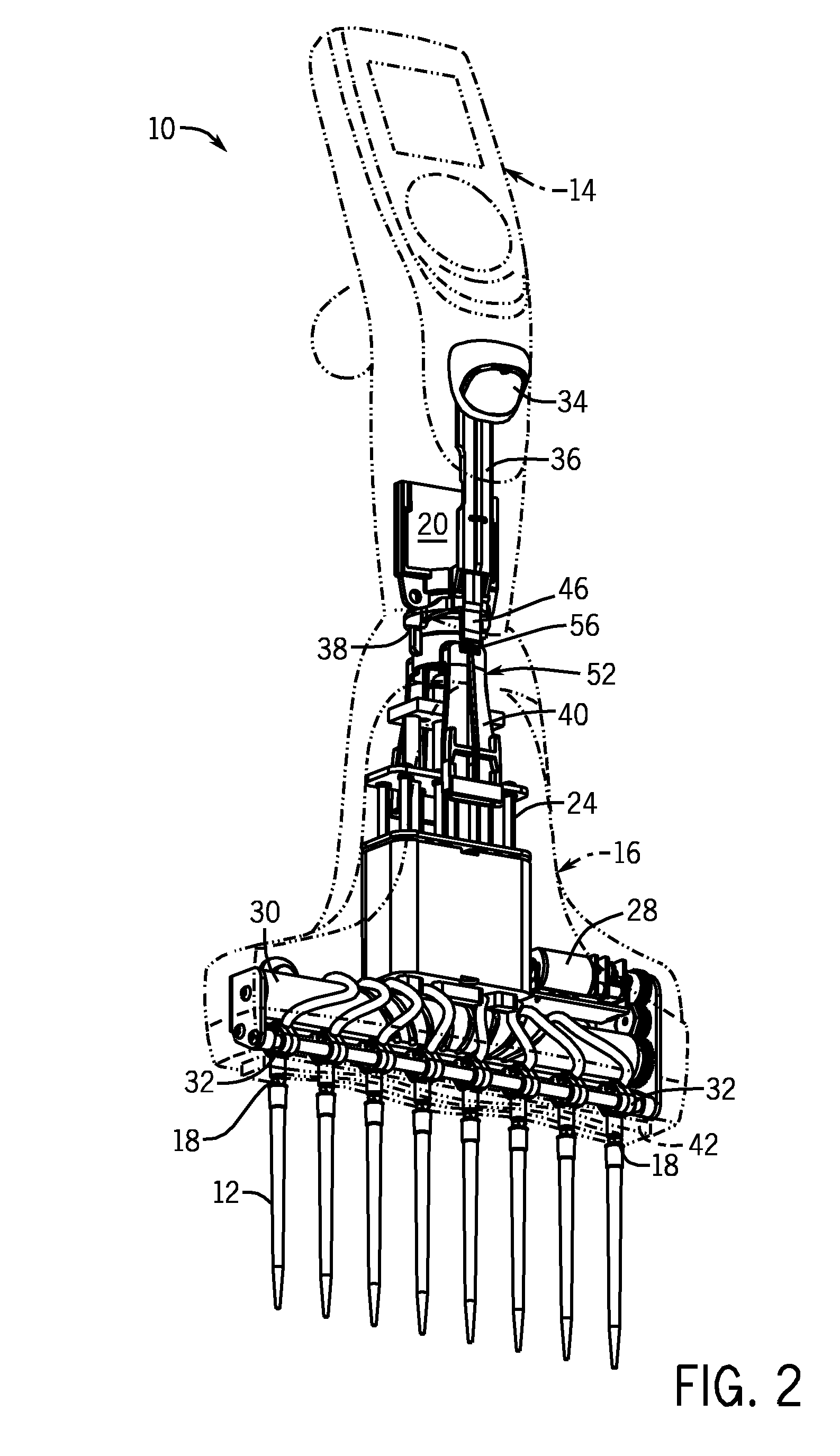

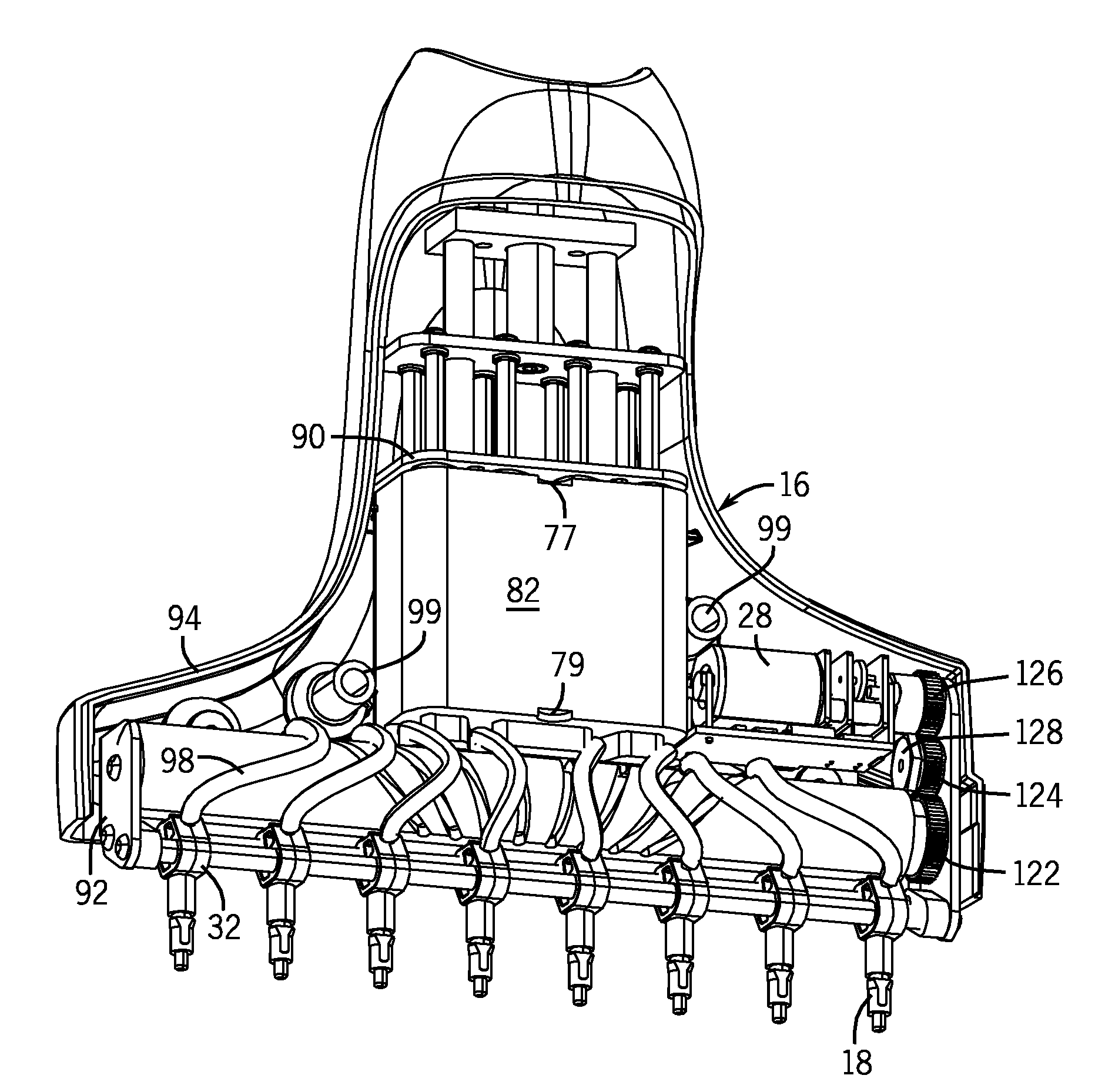

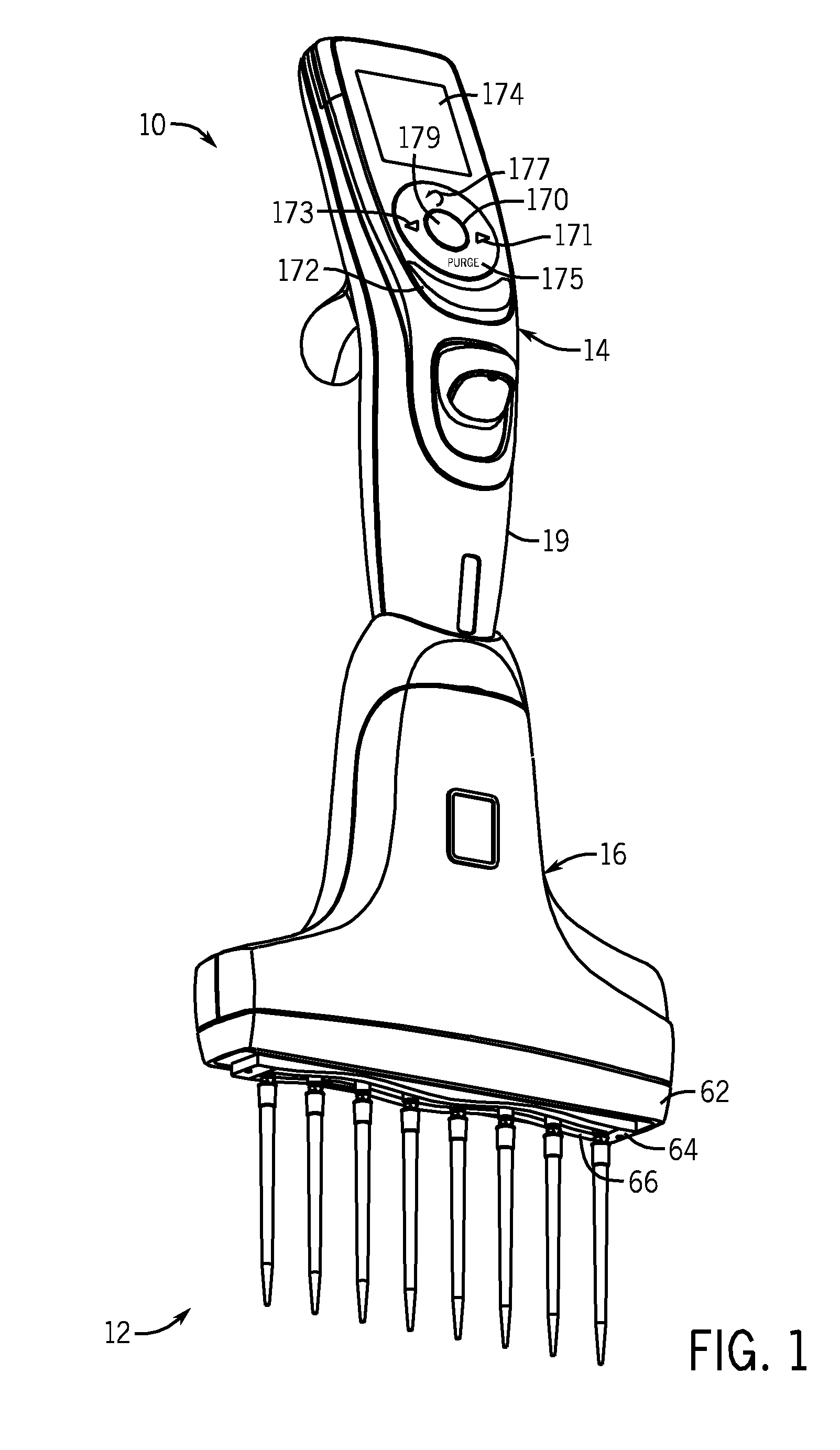

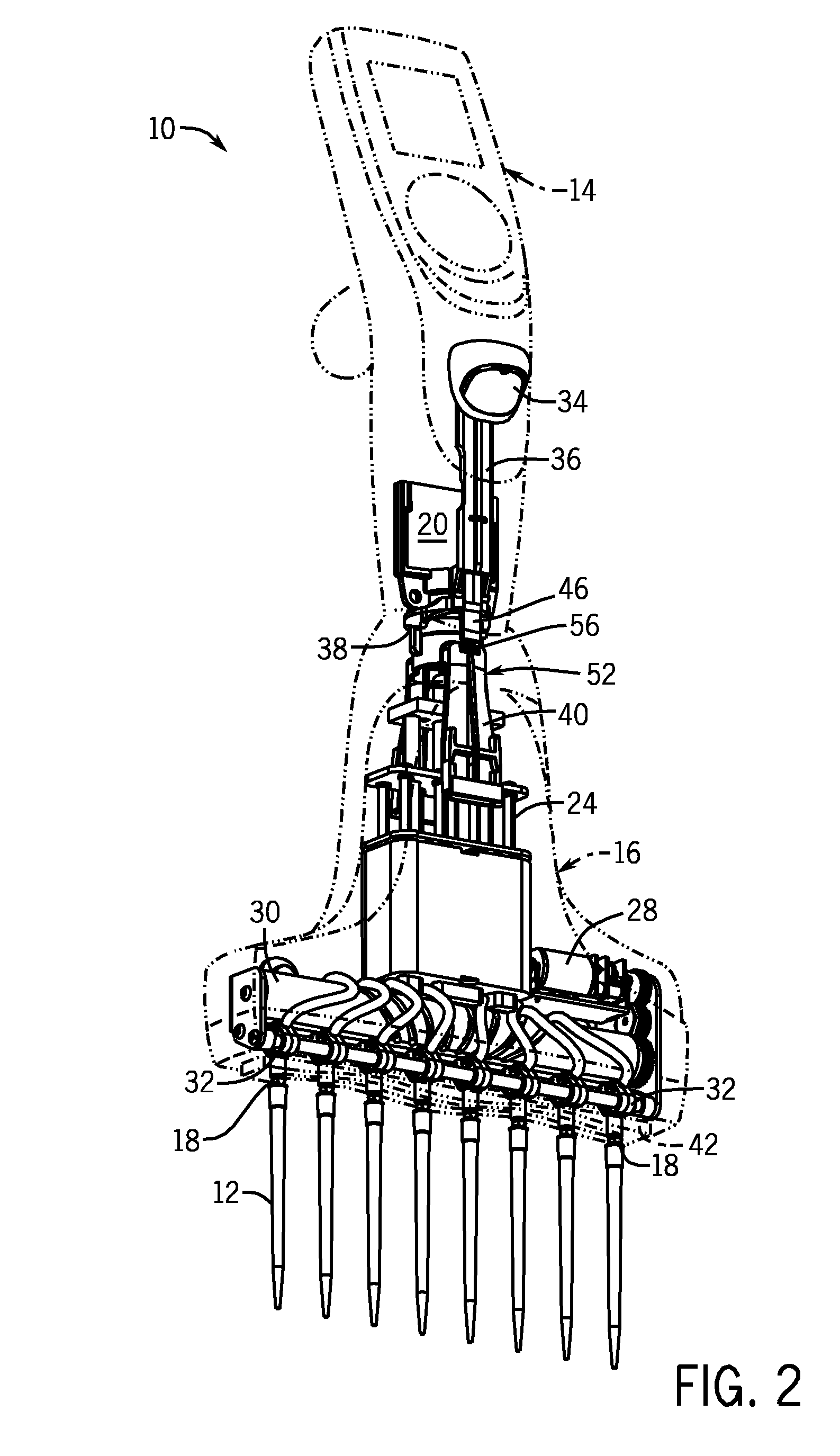

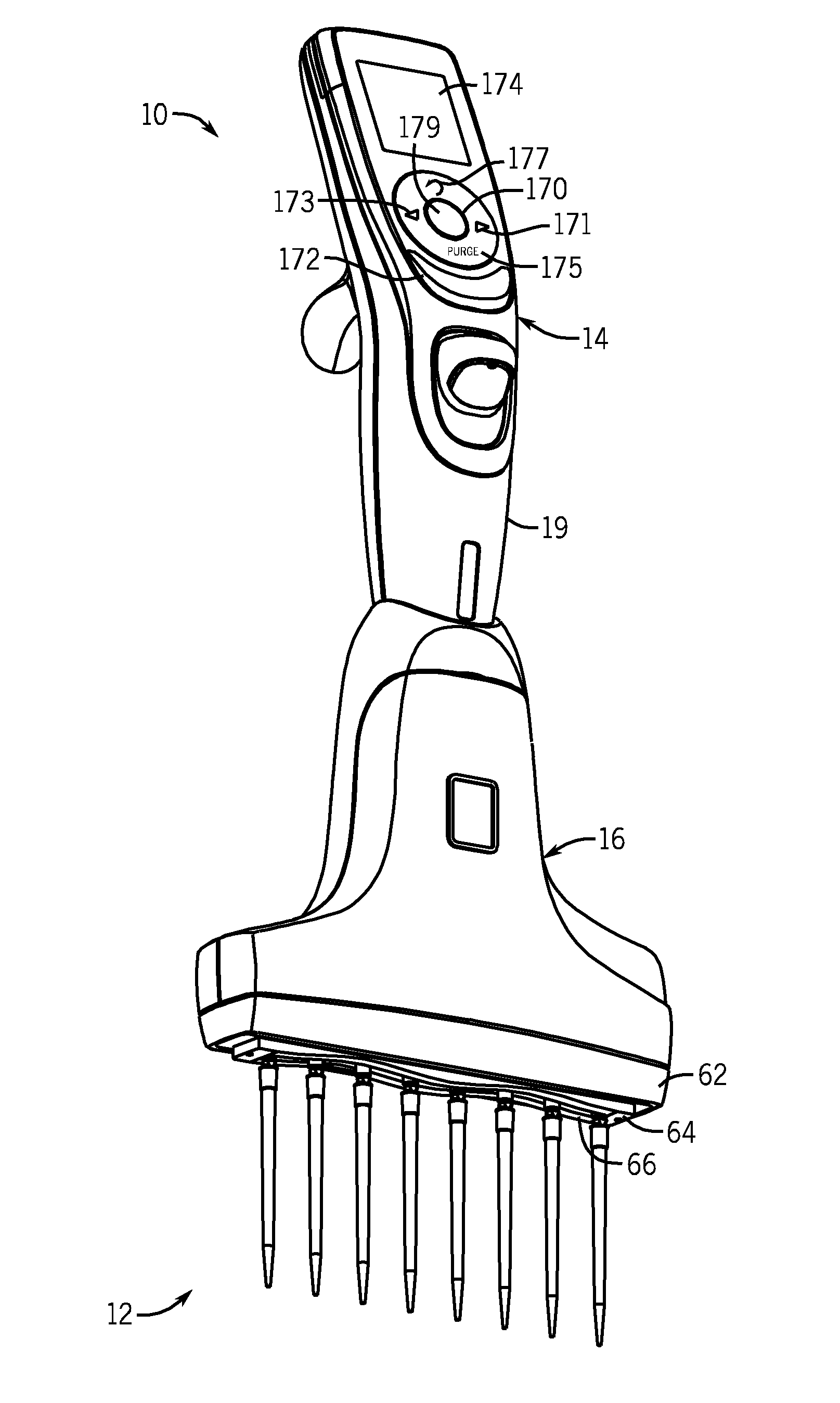

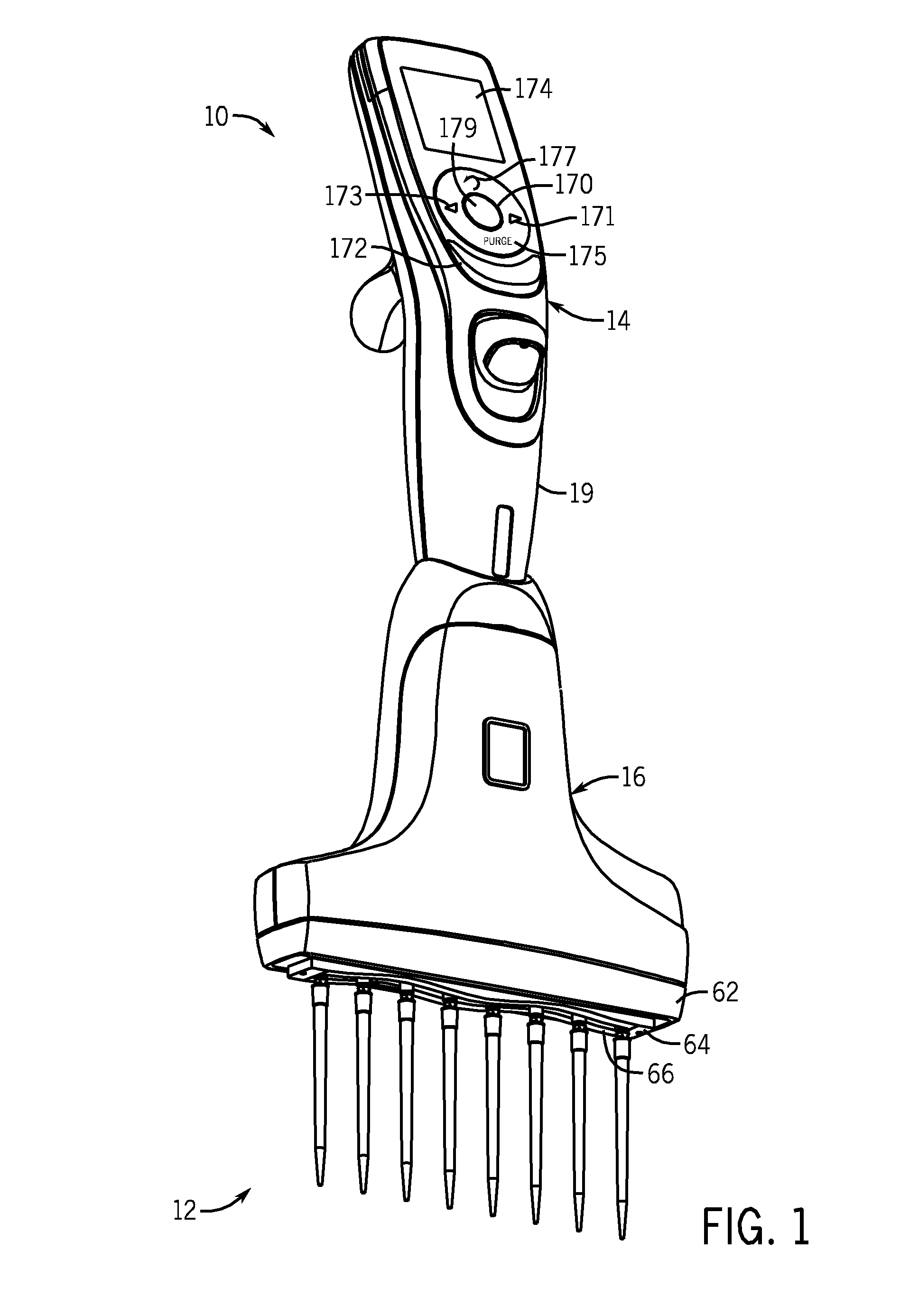

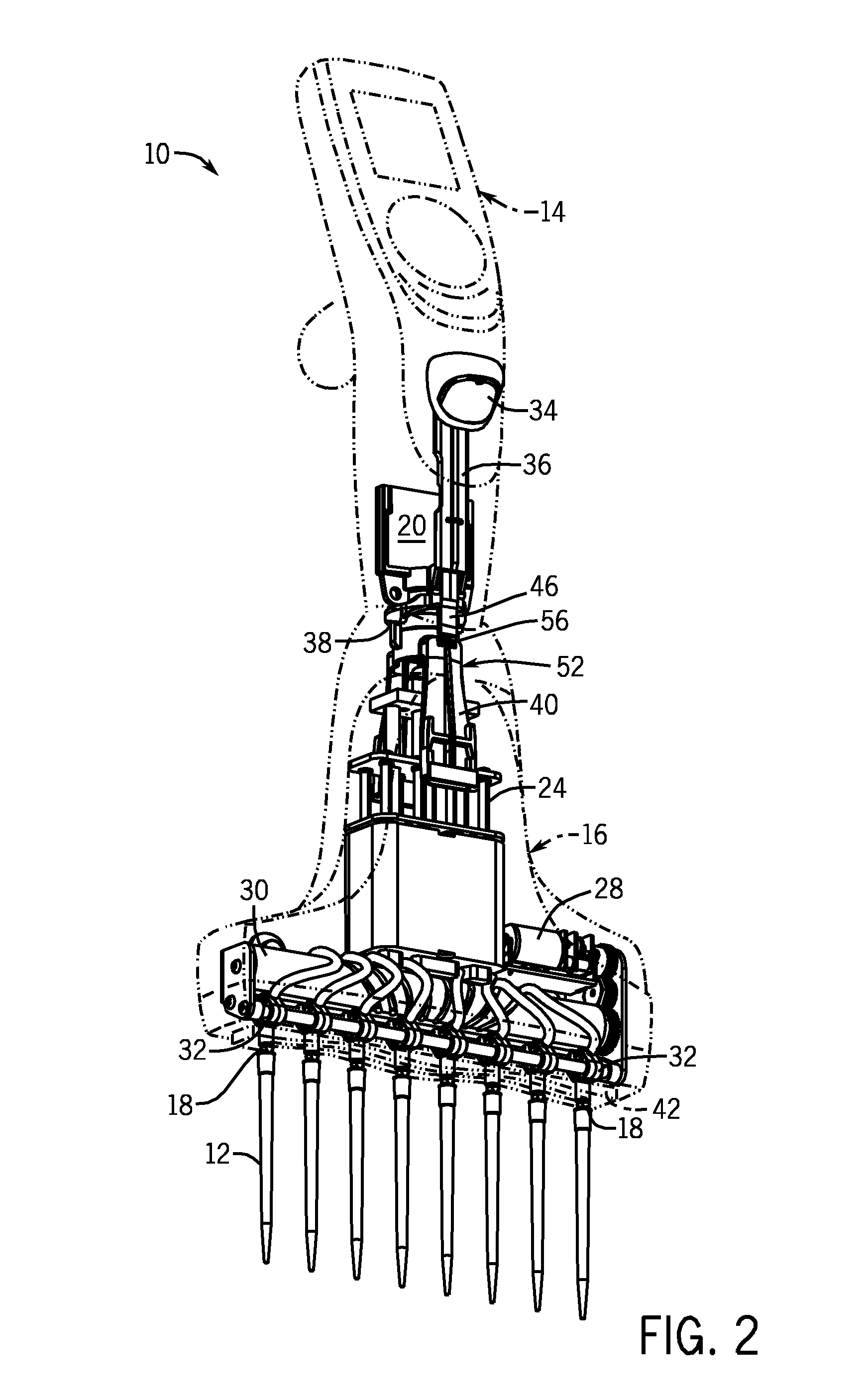

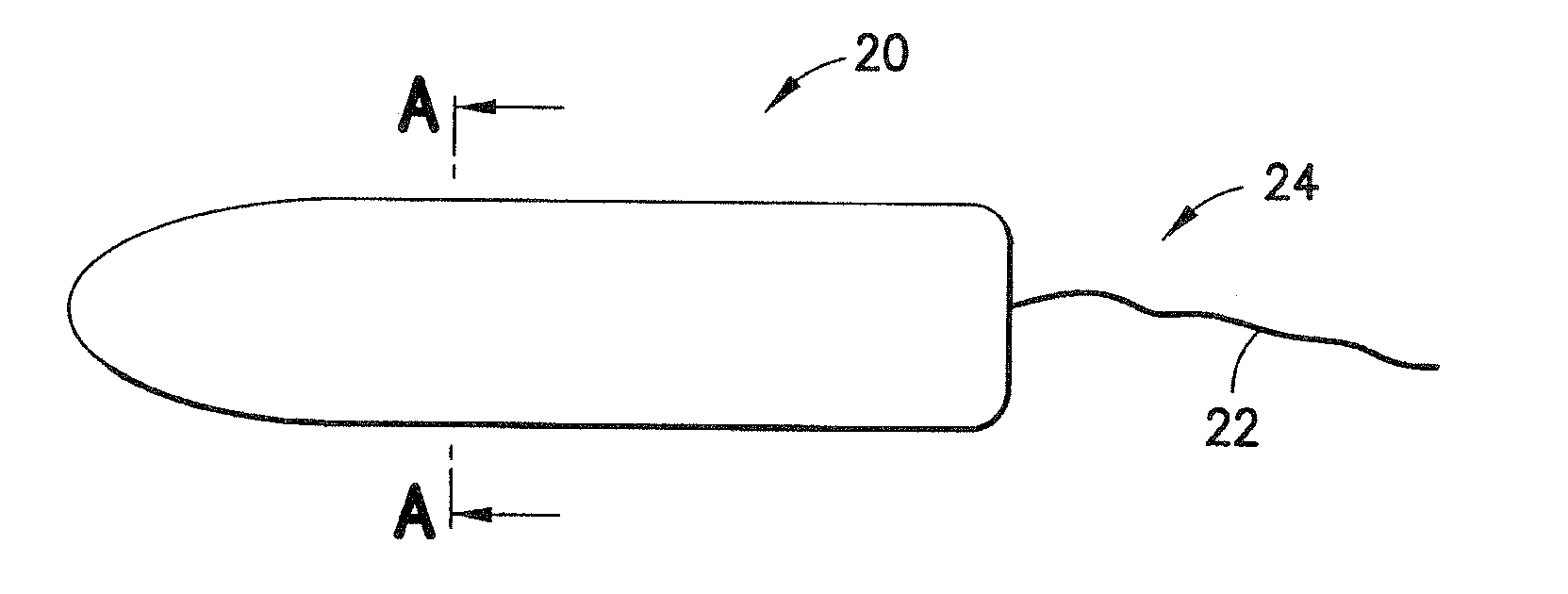

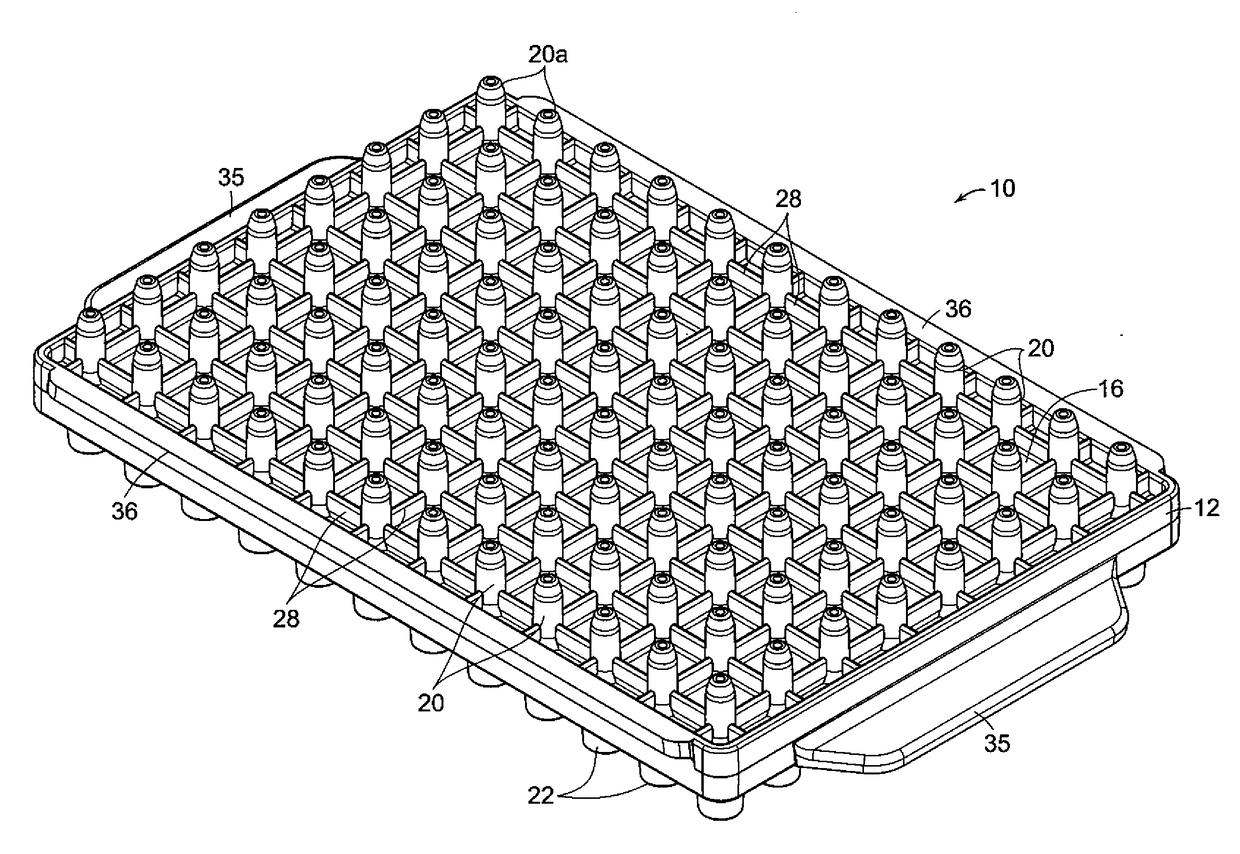

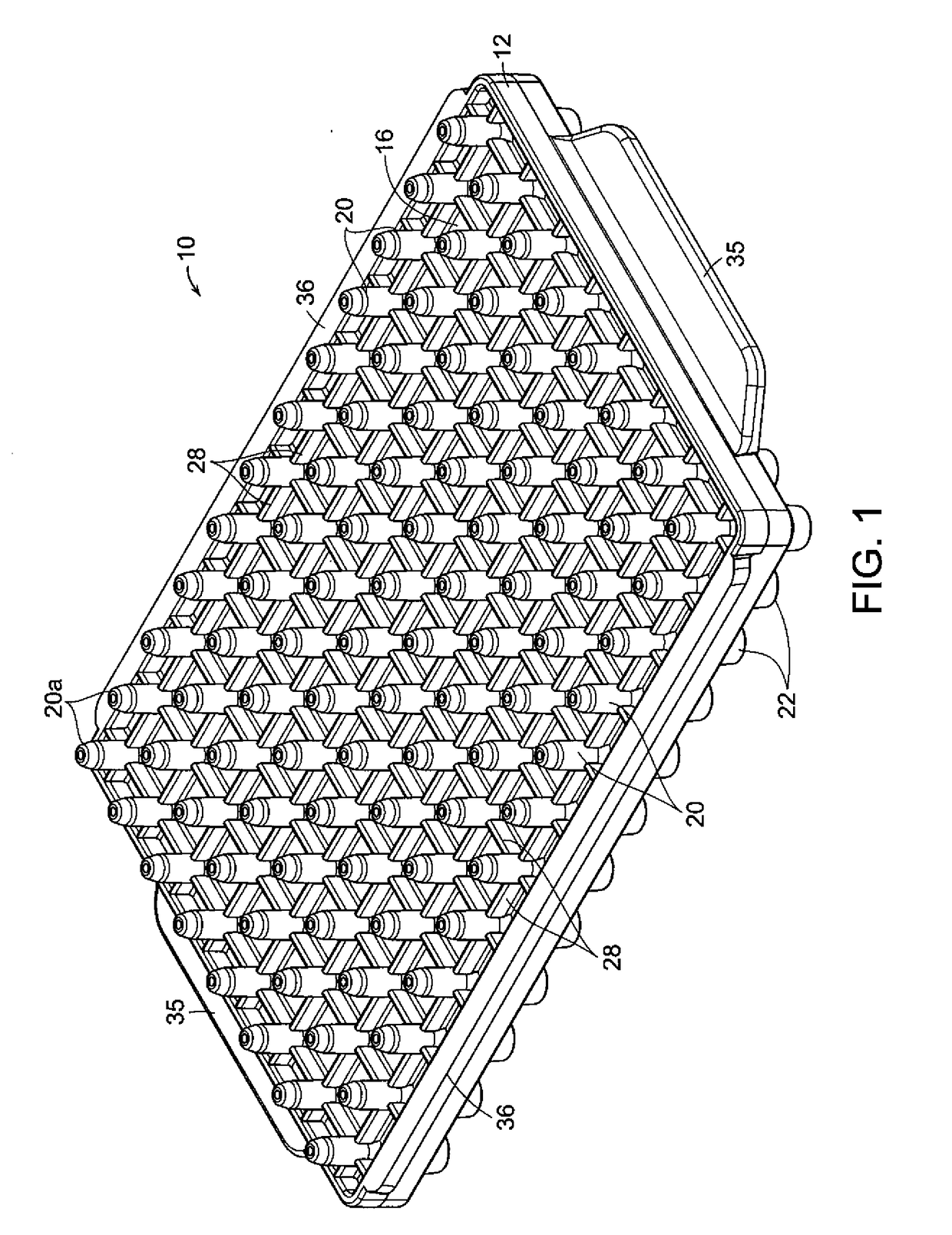

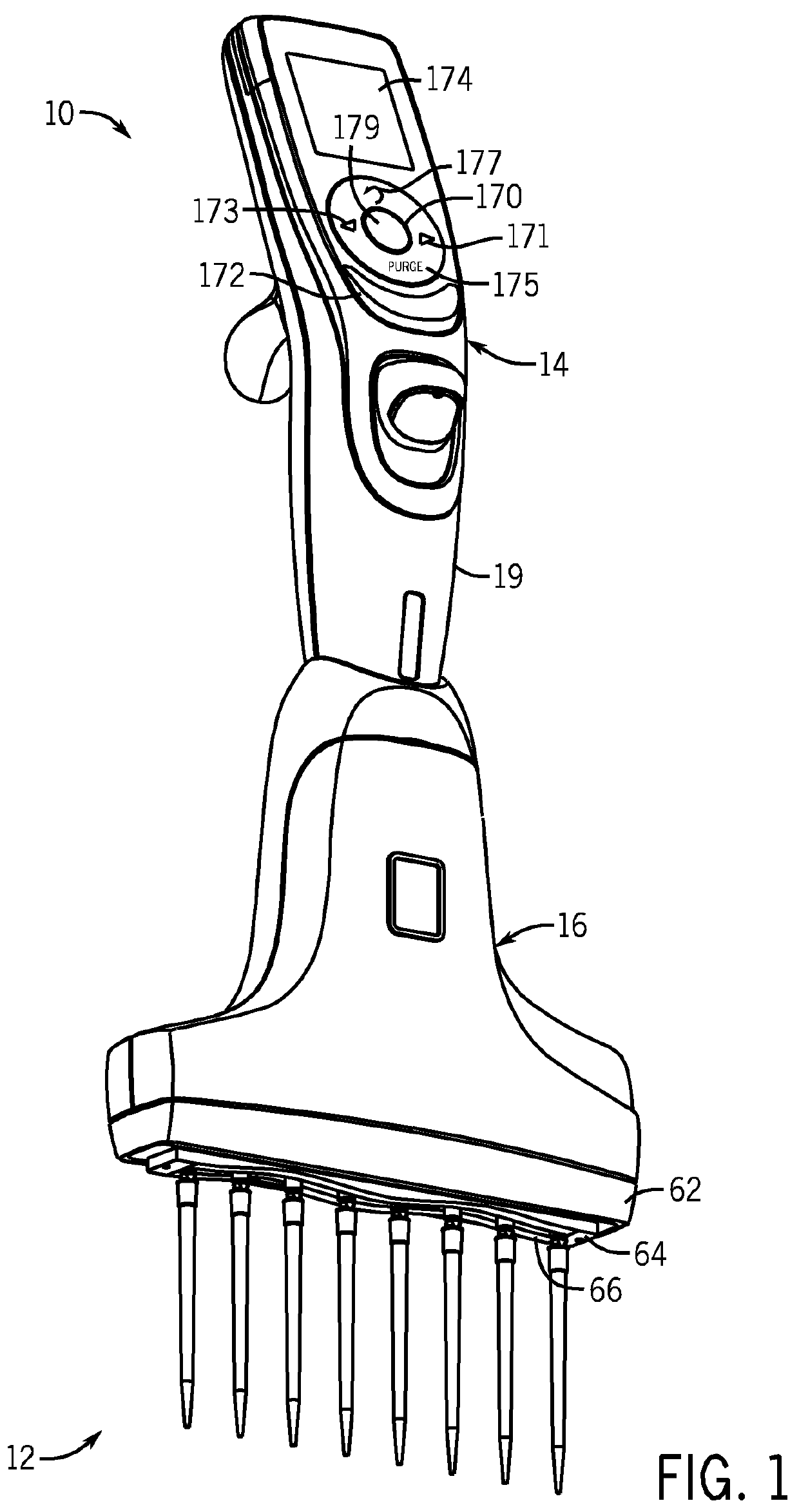

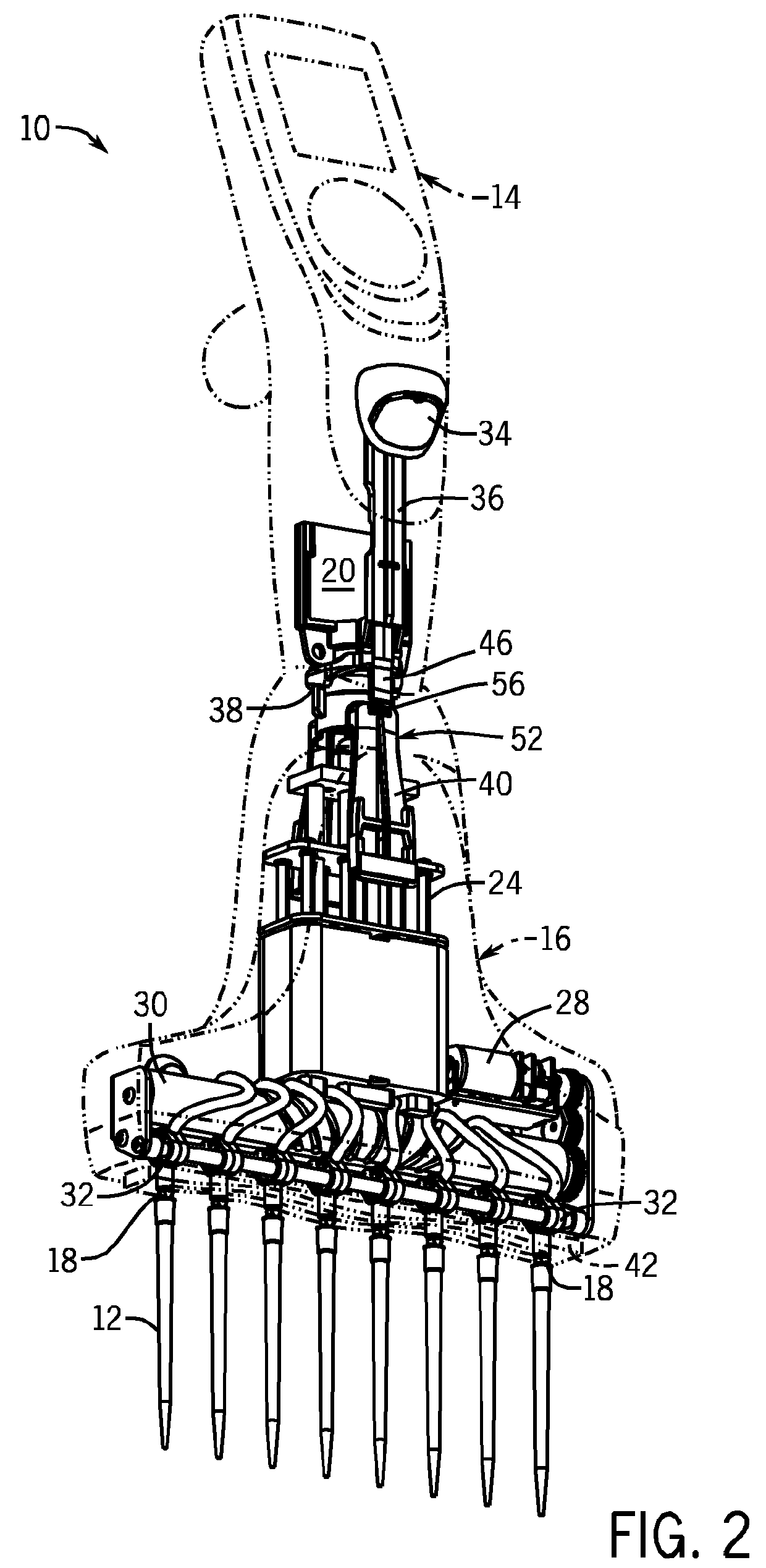

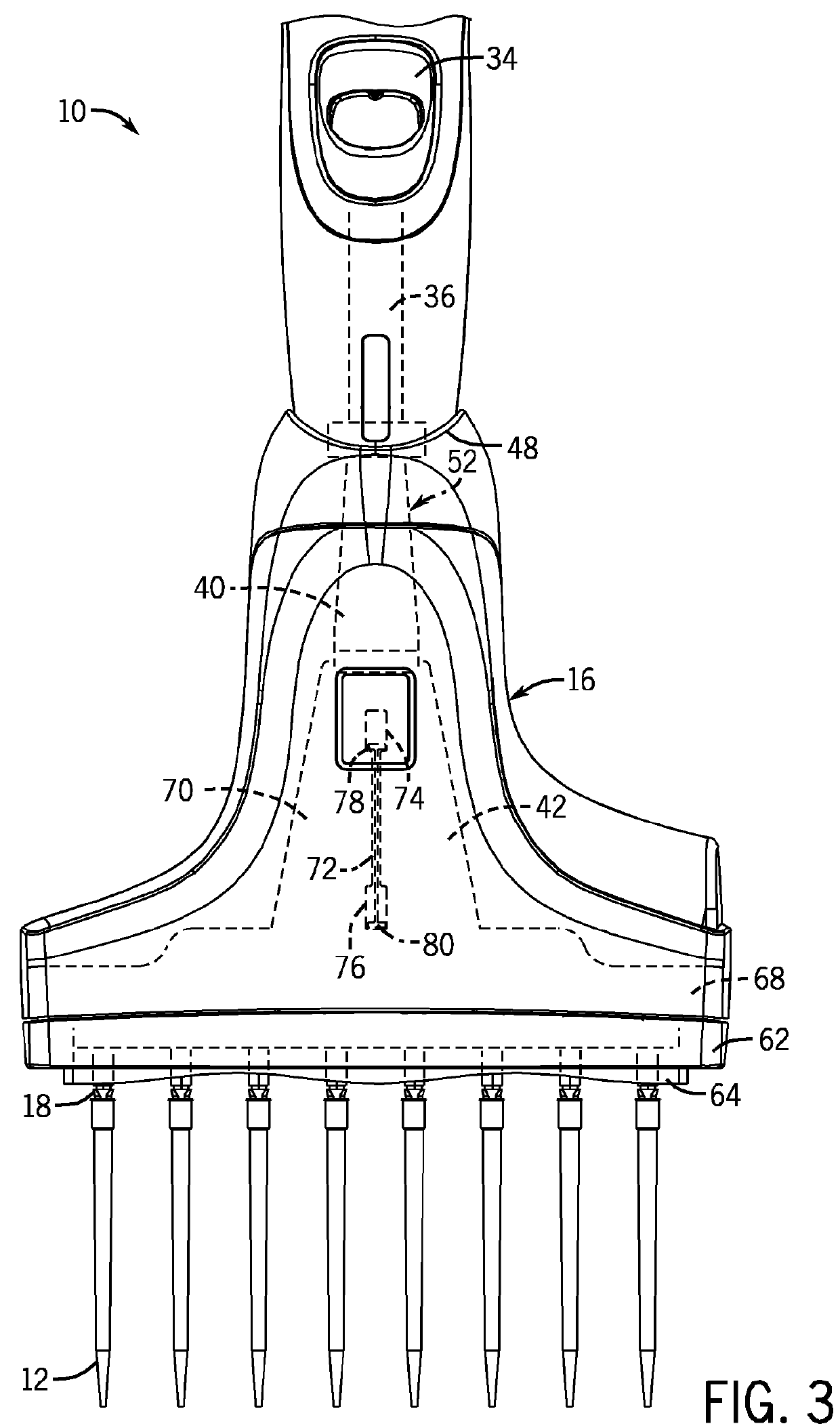

Multi-channel pipettor with repositionable tips

ActiveUS20090274587A1Facilitate effectiveFacilitate ergonomic tip ejectionAnalysis using chemical indicatorsWithdrawing sample devicesMotor drivePipette

A hand-held, multi-channel pipettor has an electronically controlled motor to reposition pipette tips for different center to center spacing. Each repositionable tip fitting assembly has a cam following pin that is driven by cam tracks in a motor driven roller drum. Stationary ports for the multiple aspiration cylinders are strategically placed to simplify management of flexible tubes leading to the repositionable pipette tip fitting assemblies. The pipettor has a user interface that can be operated conveniently by one hand to reposition pipette tips. It has a pipette tip ejection mechanism with a sinusoidal stripper bar.

Owner:INTEGRA BIOSCI CORP

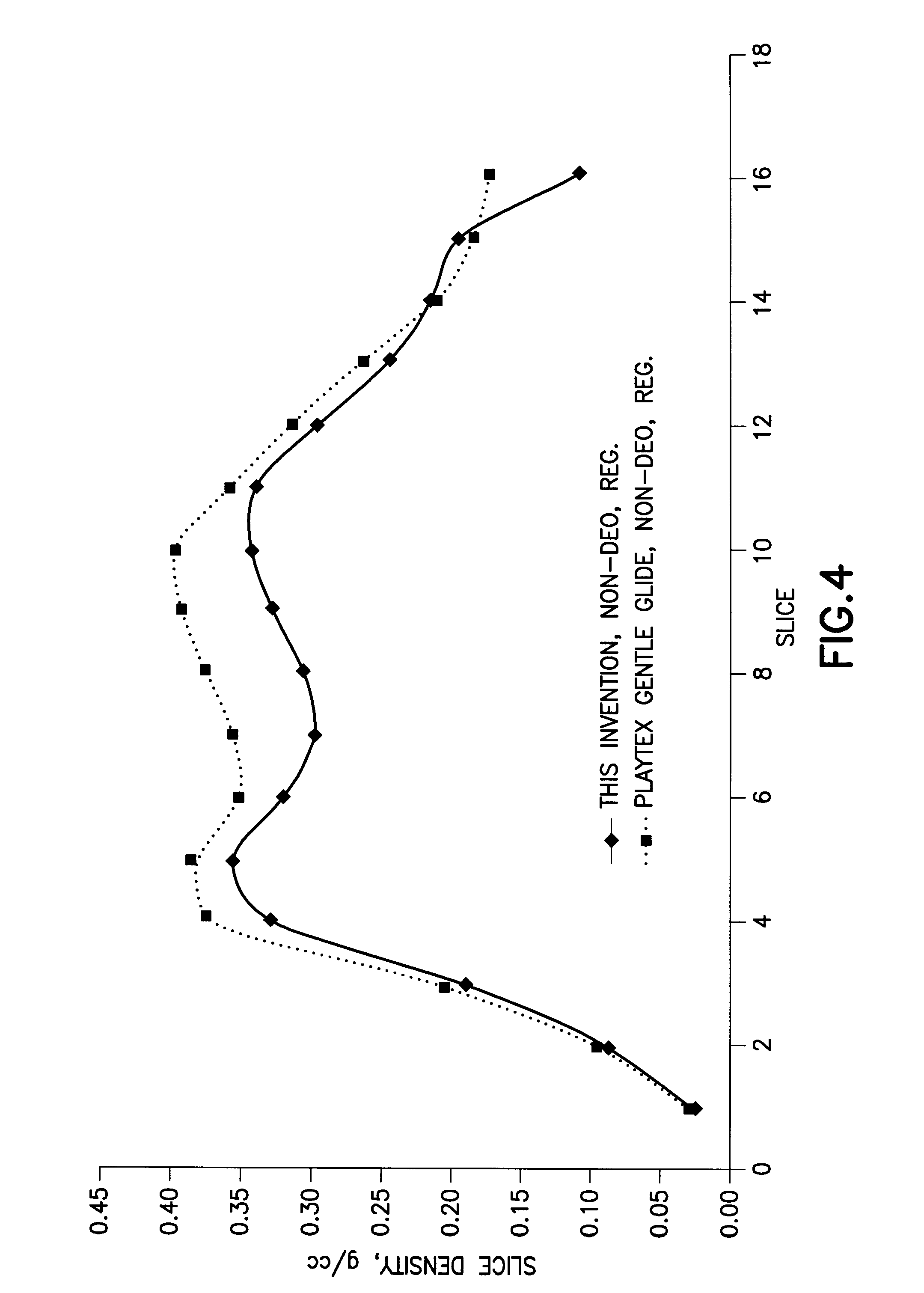

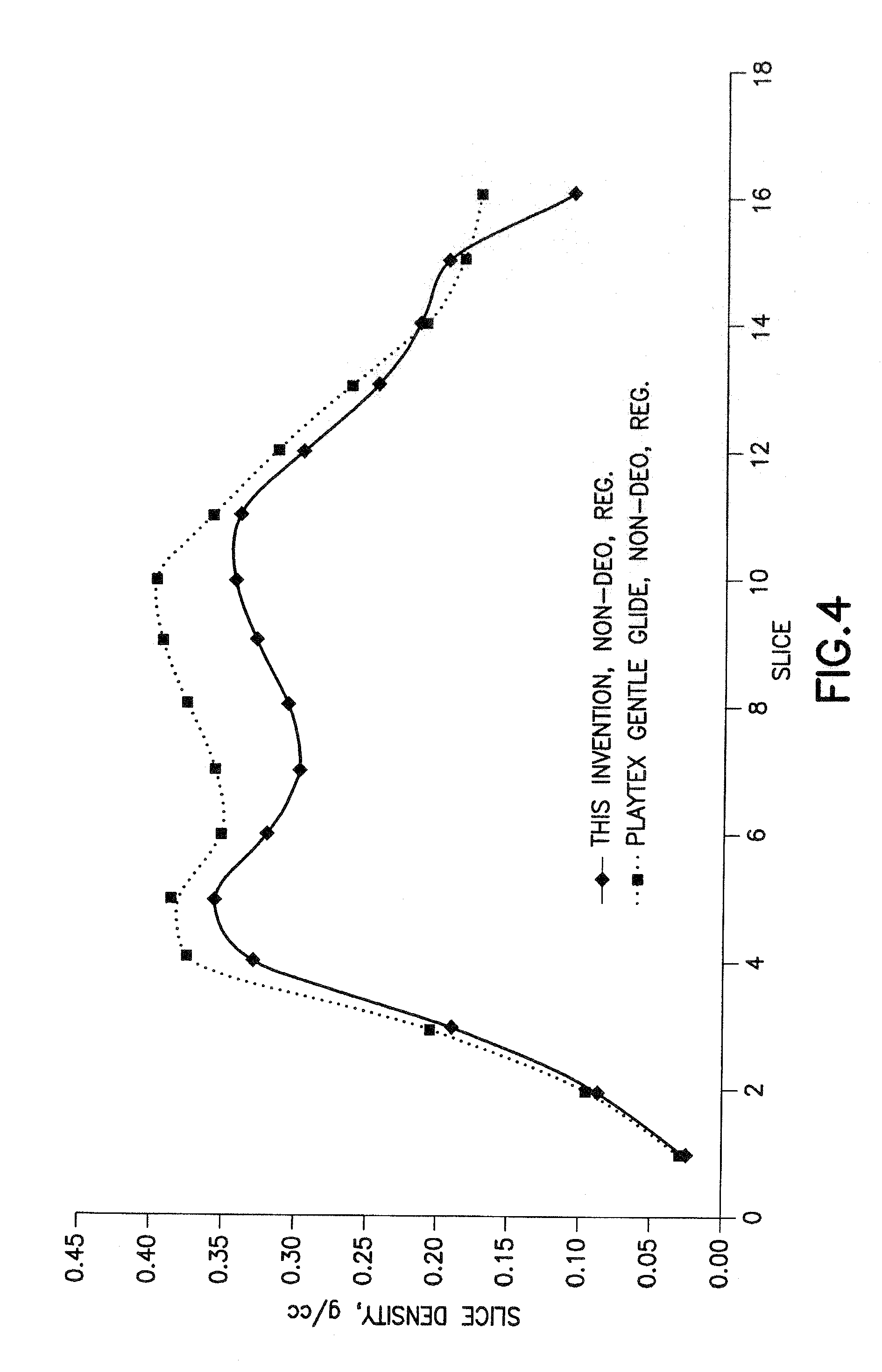

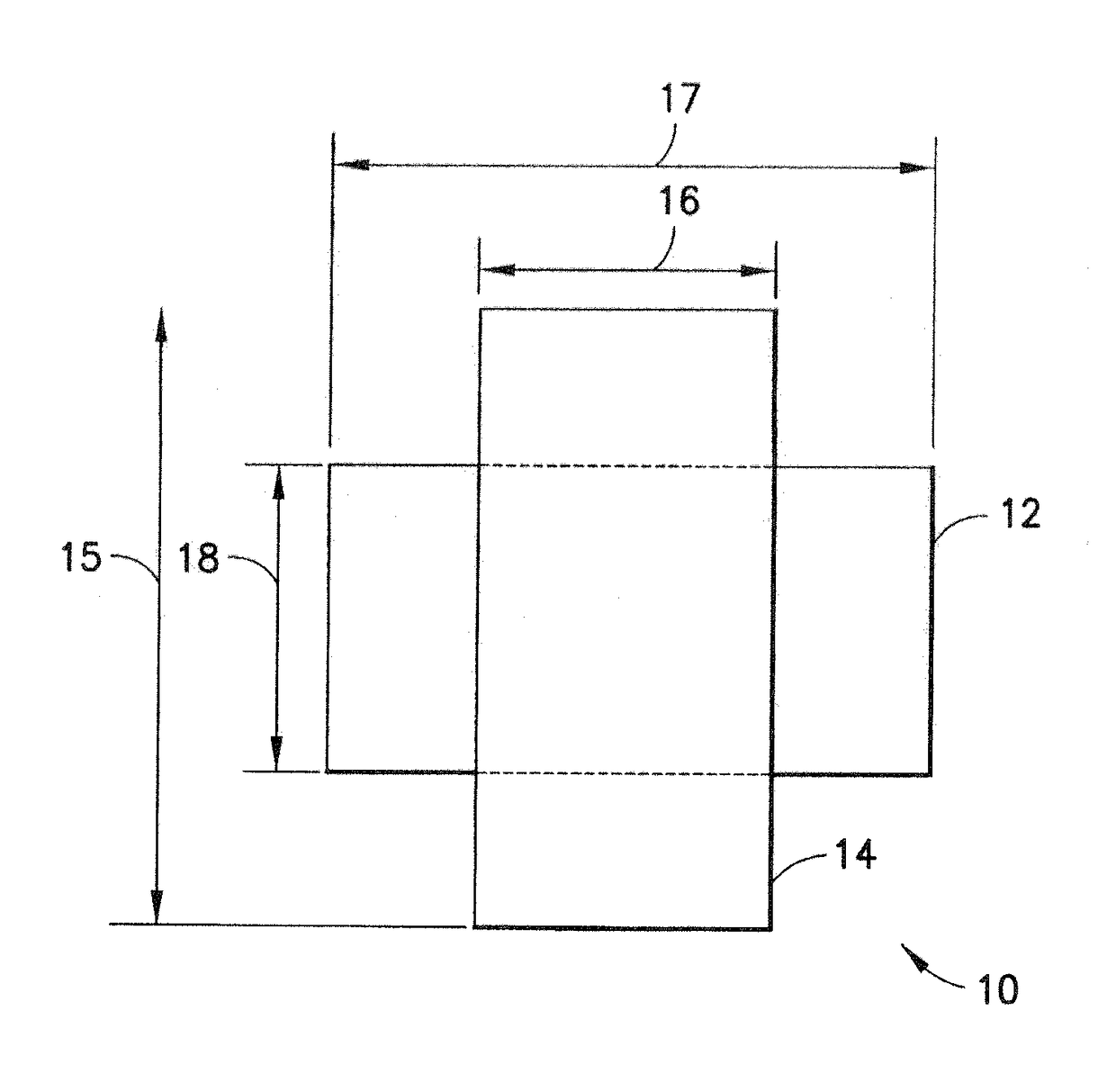

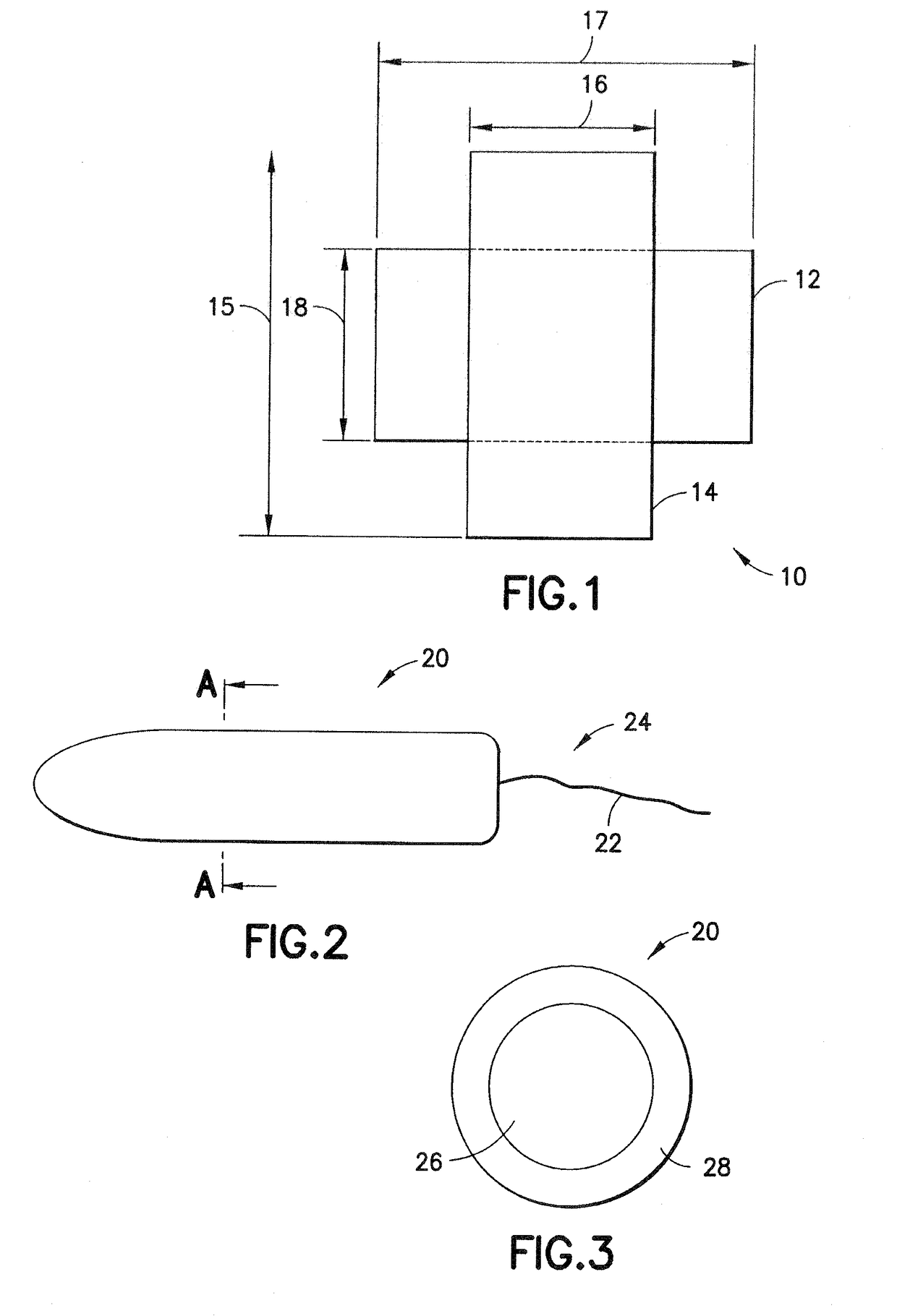

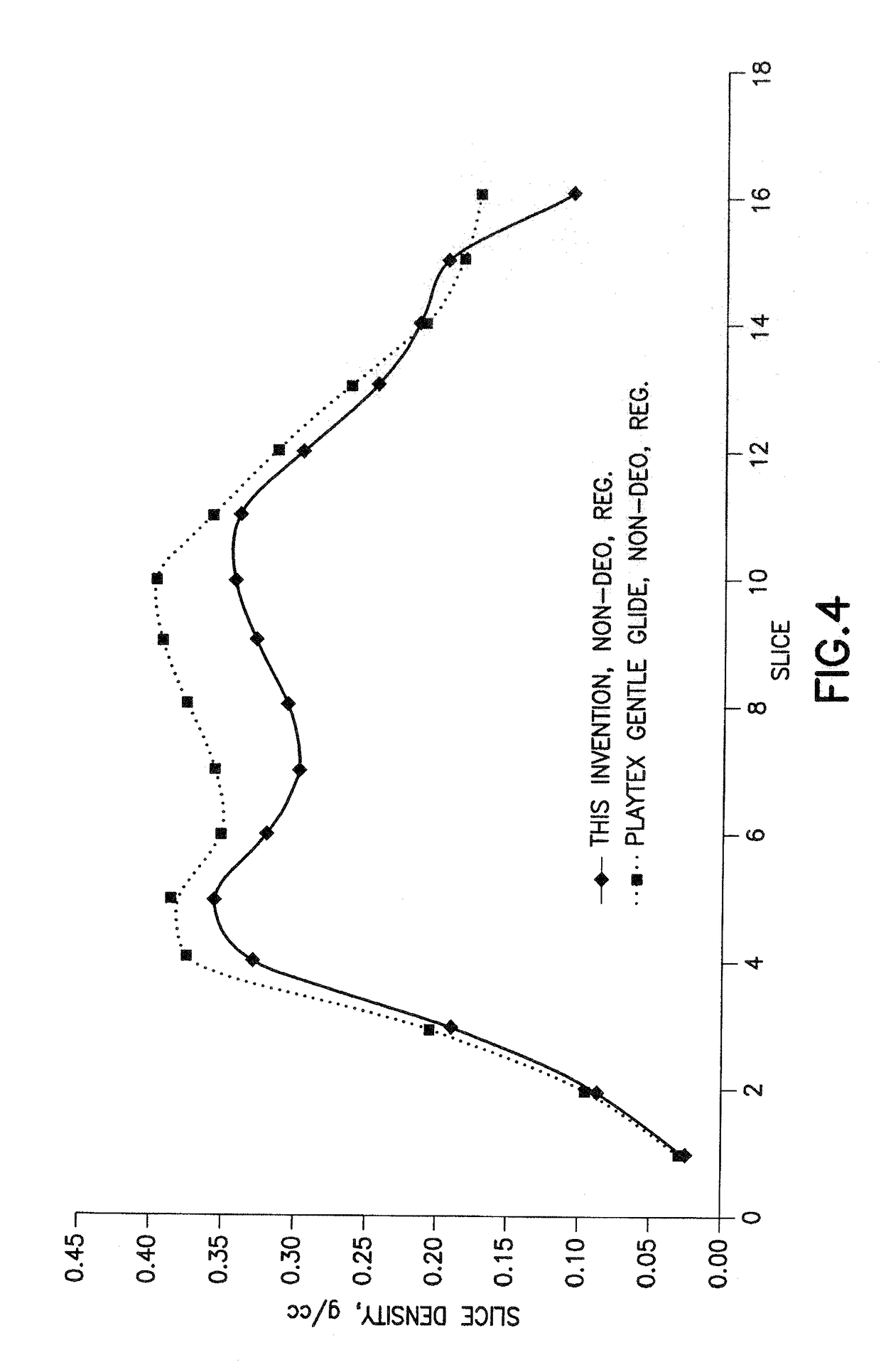

Tampon pledget for increased by-pass leakage protection

InactiveUS20080287902A1Increase in of absorbency capacityIncrease in rate of absorbencyBaby linensTamponsMedicineTamponade

The present invention provides a tampon pledget with one or more of the following properties: increased absorbency rate; high absorbent capacity and fluid retention; rapid expansion potential; and ease of ejection of the pledget from the applicator. Surprisingly, the one or more properties are achieved by using a modified dual cross-pad, folded, compressed tampon pledget design.

Owner:PLAYTEX PROD INC

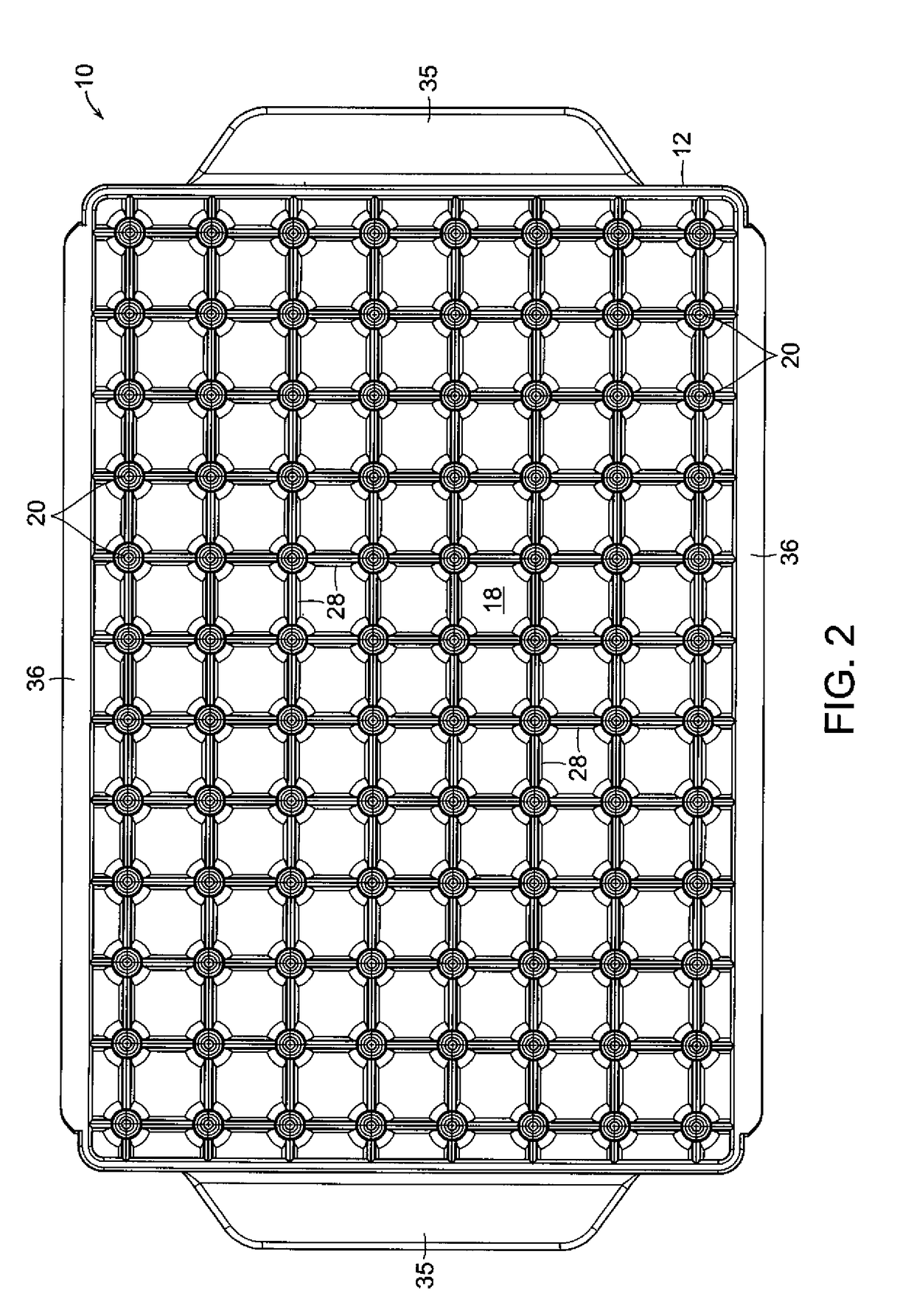

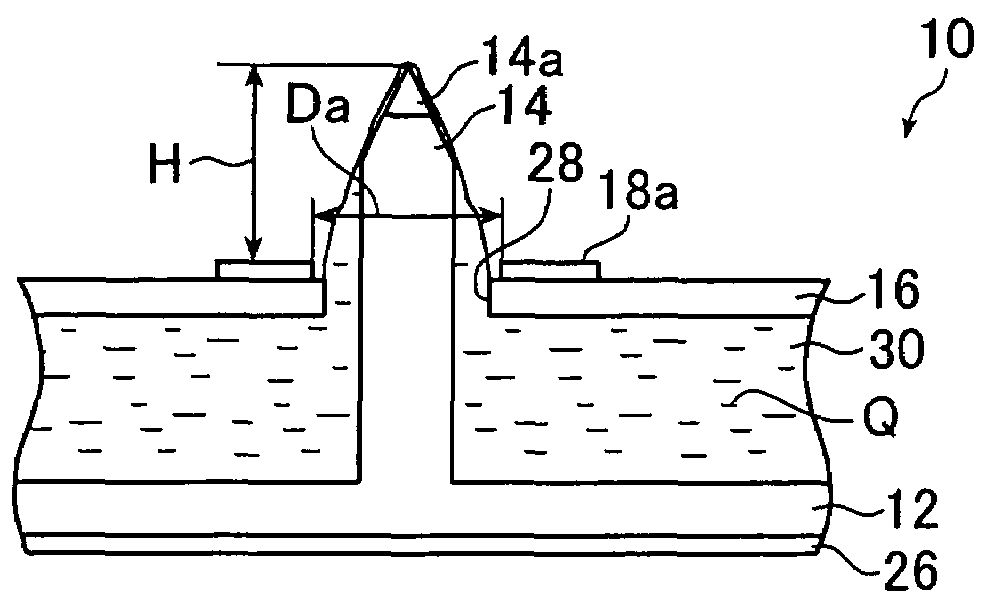

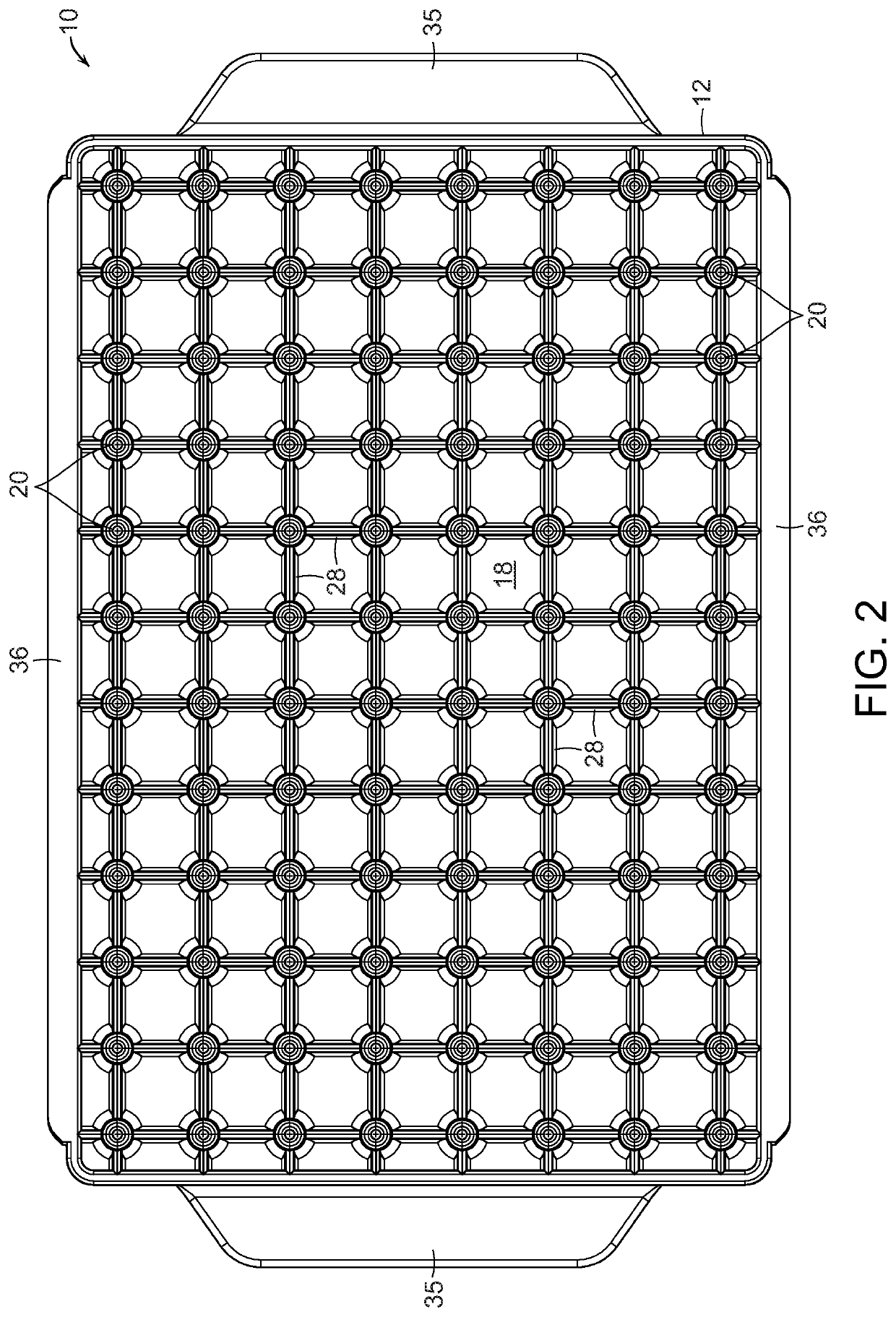

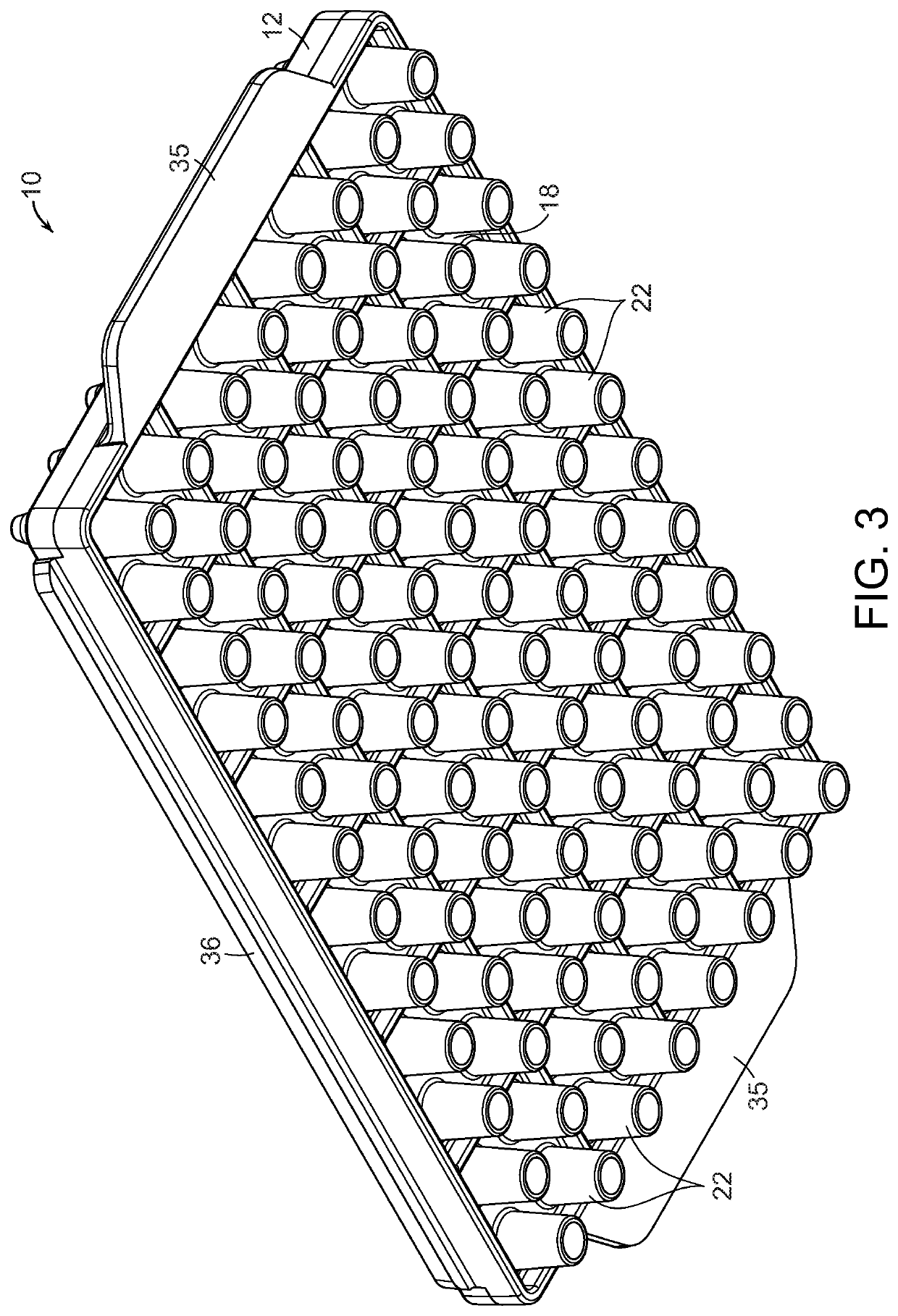

Disposable Pipette Tip

ActiveUS20100034706A1Maintain roundnessFacilitate reliable engagementAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionPipetteHand held

In one aspect, the invention relates to a pipette tip mounting shaft configuration and a disposable pipette tip having a matching configuration. The mounting shaft includes a locking section located above a lower sealing section. The locking section has outwardly extending locking lobes located above a stop member and a lower sealing section located below the stop member. In certain embodiments, the diameter of the mounting shaft below the stop member is reduced in order to lessen insertion and ejection forces, which is particularly helpful for hand-held multi-channel pipettors. In these embodiments, the lower sealing section contains either a frustoconical sealing section, or an annular groove and a sealing ring, such as a flouroelastomeric O-ring seal. When the mounting shaft is fully inserted into the collar of the mating disposable pipette tip, the tip locks onto the mounting shaft. The bore of the pipette tip includes a circumferential shelf or shoulder separating its upper collar from the tip sealing area which is located below the circumferential shelf. The tip collar preferably includes a locking ring located at or near the upper opening for the mounting shaft. The dimensions of the collar, and in particular the distance between its circumferential shelf and the locking ring, are selected to match the dimensions of the mounting shaft between the stop member and the upper end of the locking lobes, thus locking the pipette tip in a secure, reliable position and orientation while using ergonomic insertion and ejection forces. The locking lobes preferably include a ramp portion that gently flexes and distorts the pipette tip collar out of round as the mounting shaft is inserted in the pipette tip, rather than stretching the tip collar. The circumferential shelf on the pipette tip between the tip collar and the barrel isolates the sealing area at the upper end of the barrel from distortion, thus facilitating reliable sealing engagement between the lower sealing section of the mounting shaft and the sealing ring in the upper end of the barrel of the pipette tip.

Owner:INTEGRA BIOSCI CORP

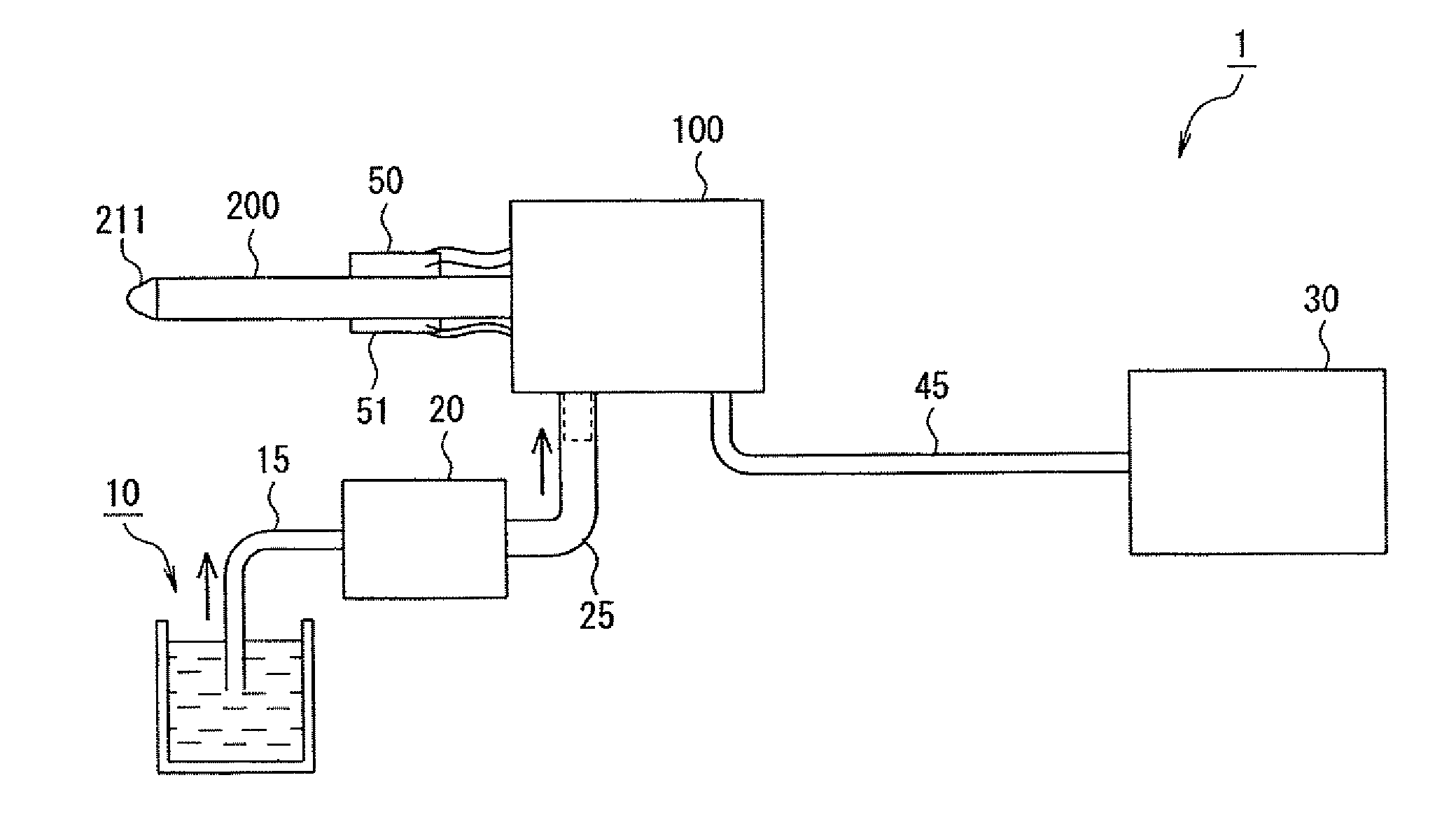

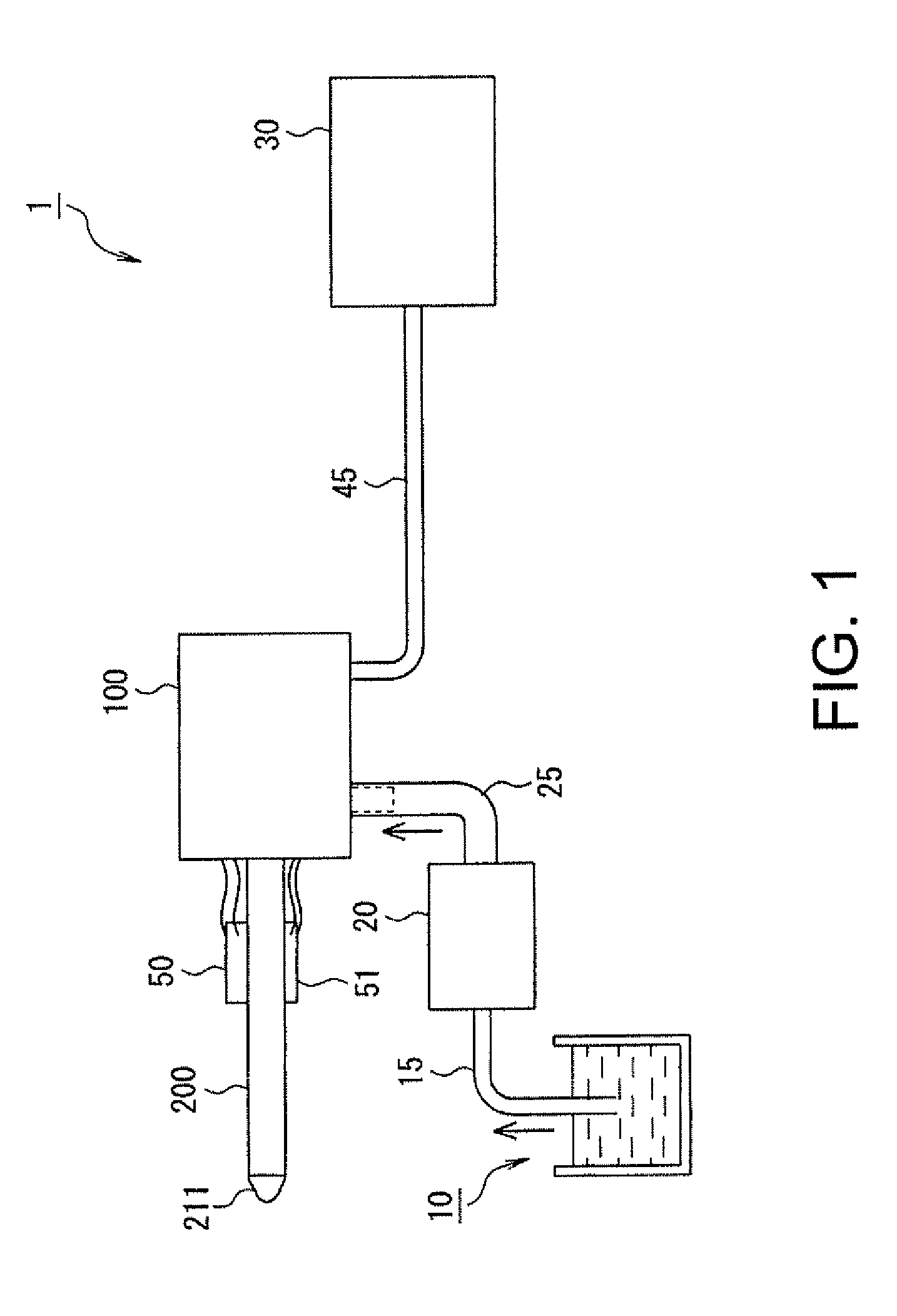

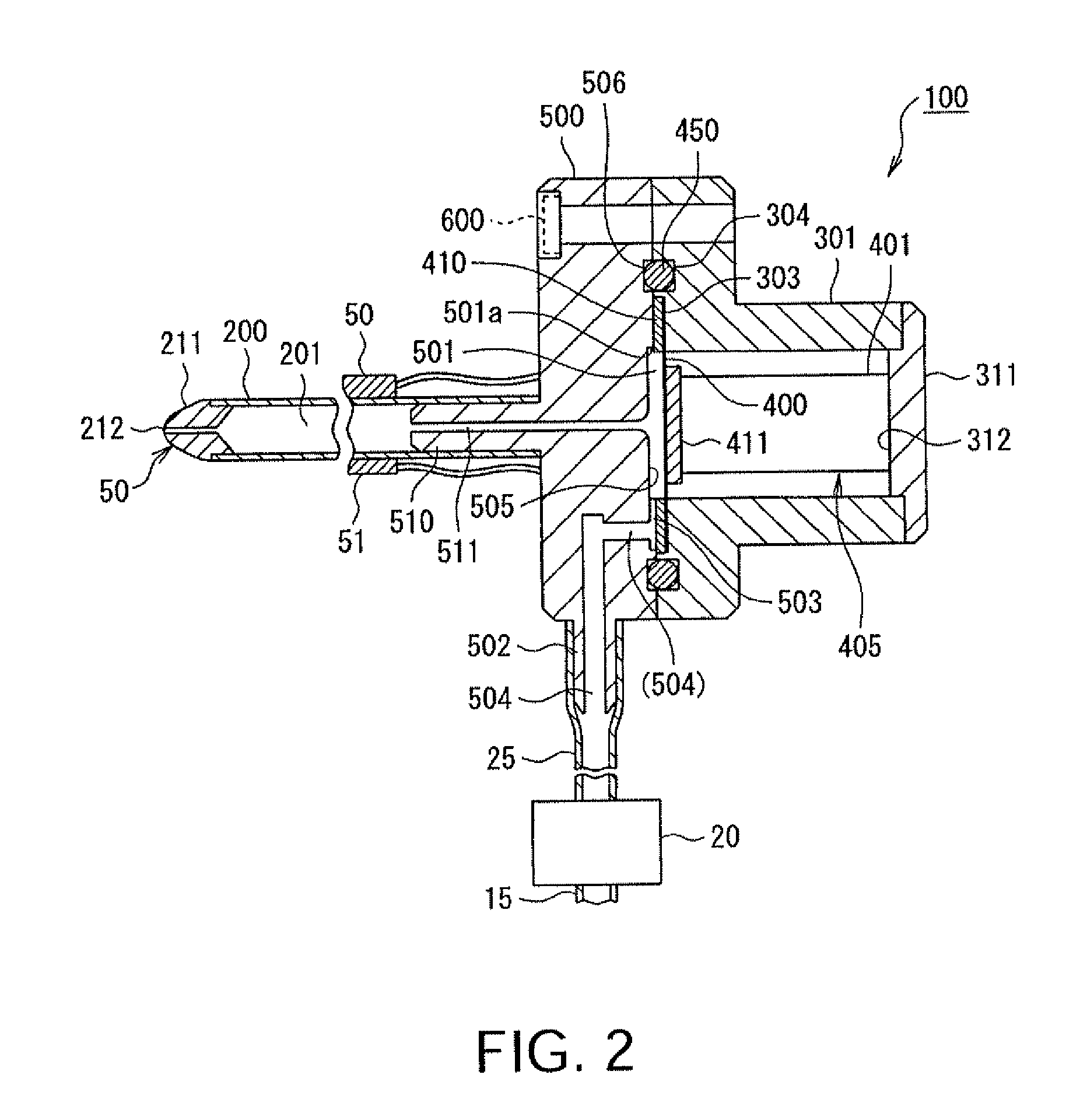

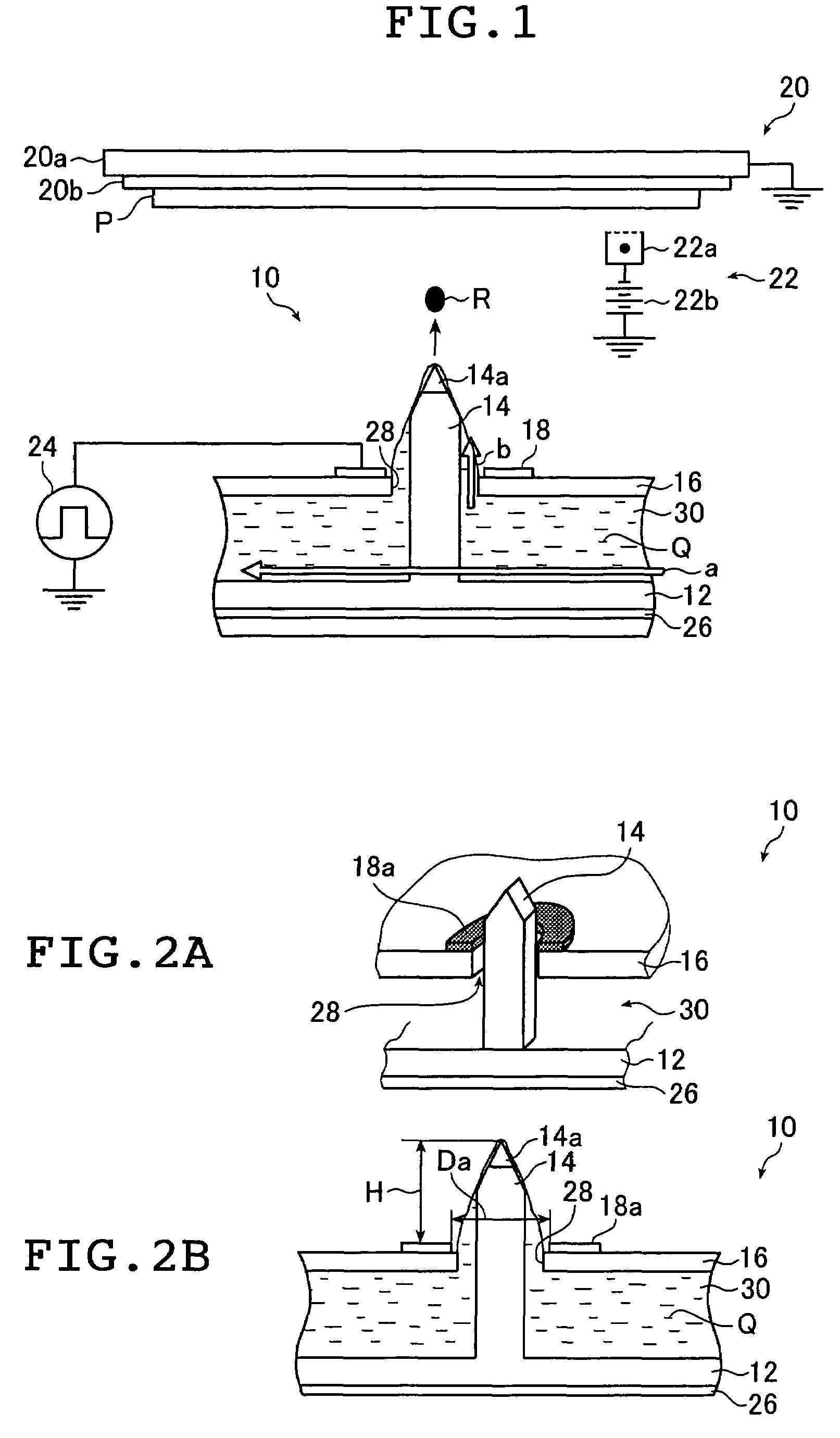

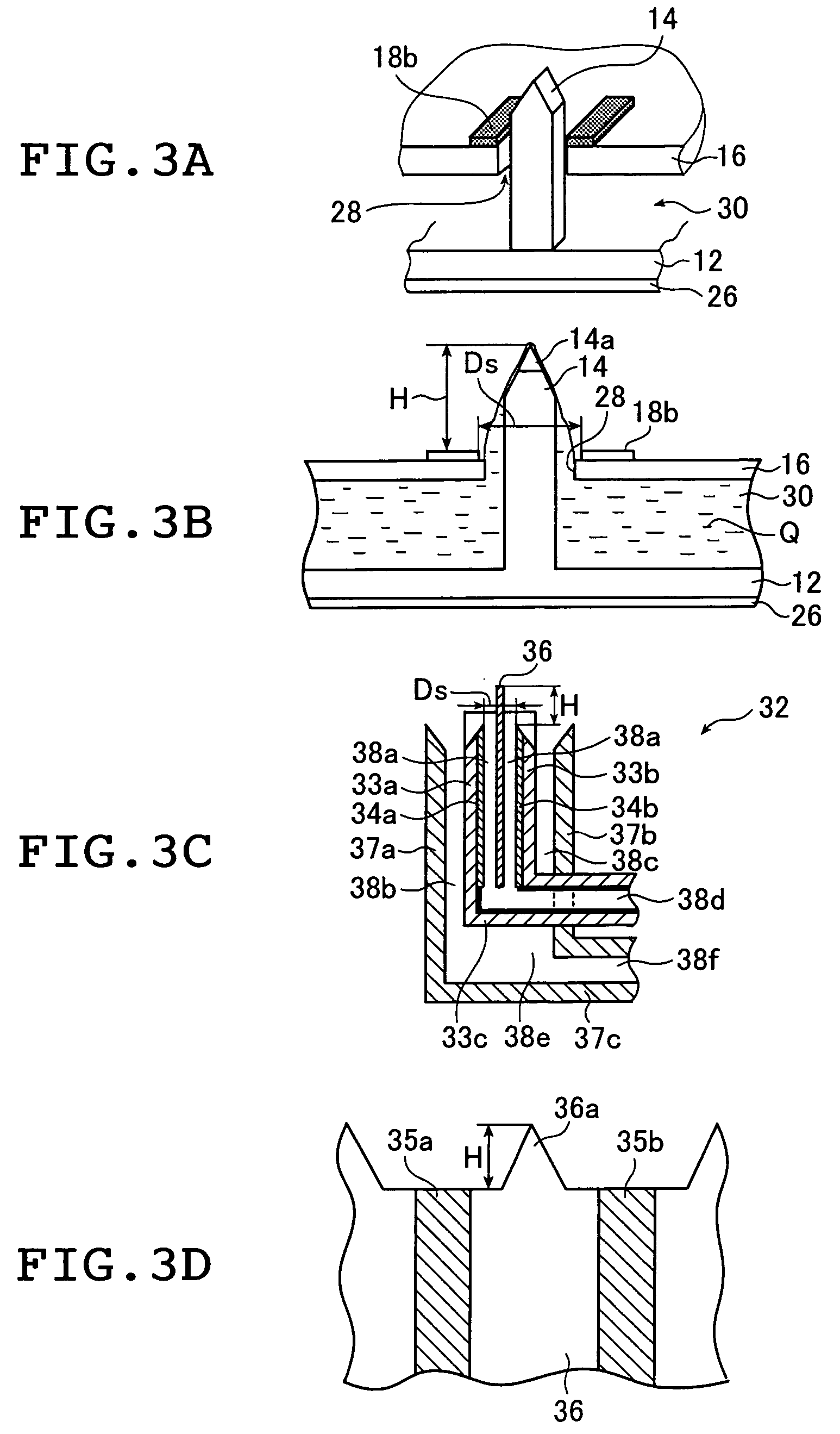

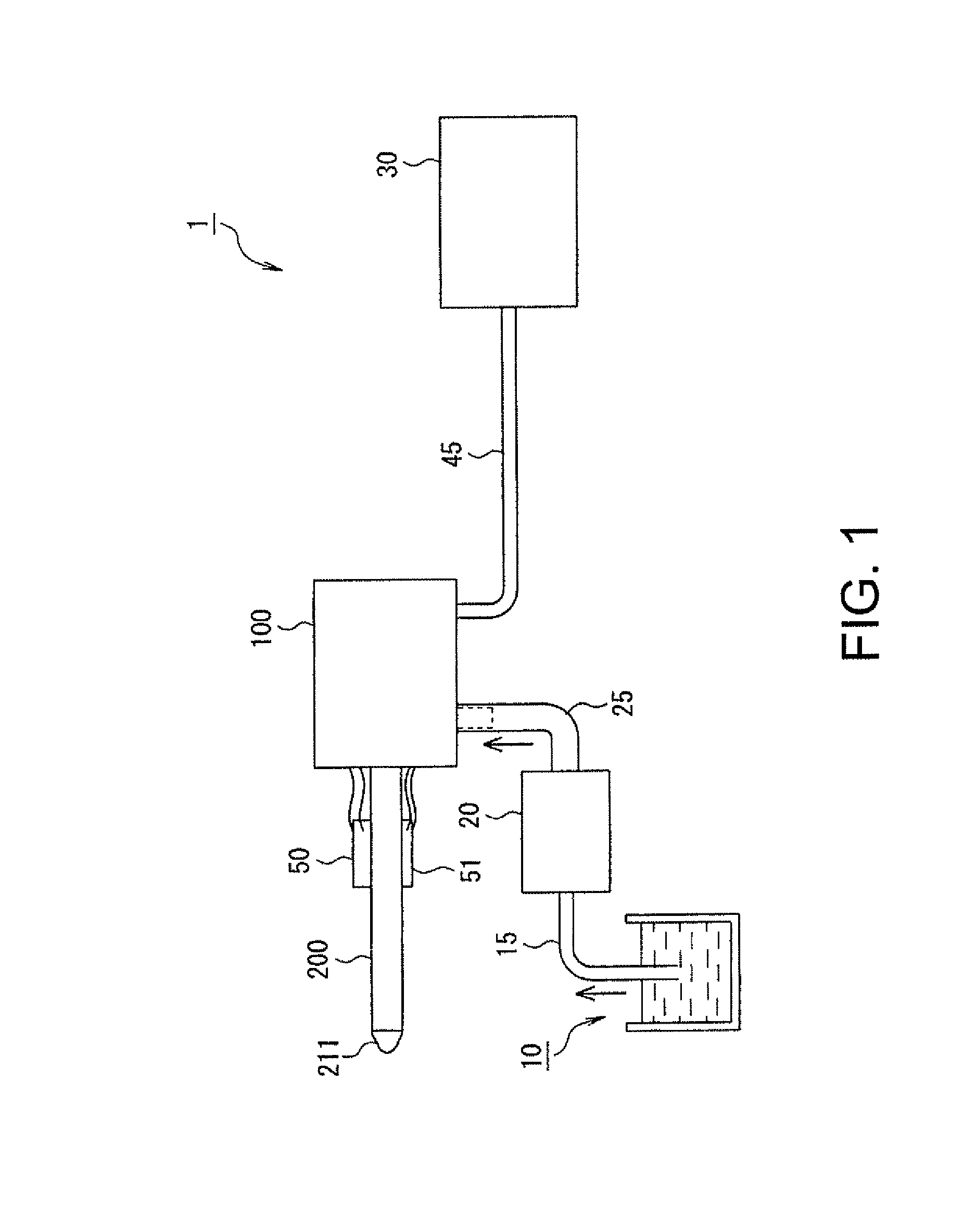

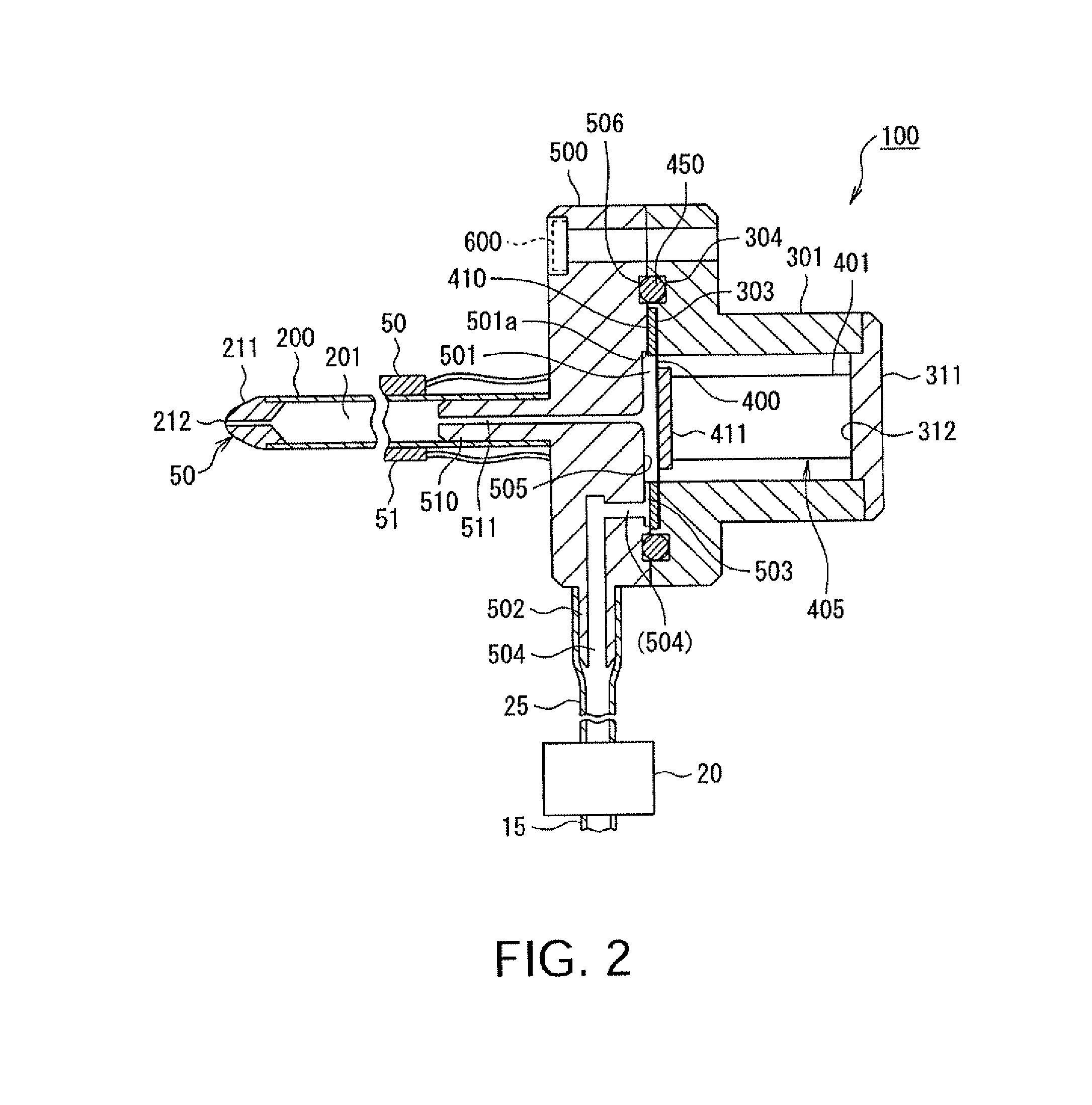

Fluid ejection device, driving method of fluid ejection device, and operating instrument

InactiveUS20100078495A1Lower ejection forceAvoid distractionWatering devicesFluid jet surgical cuttersEngineeringInlet flow

A fluid ejection device includes: a fluid chamber whose capacity is variable; an inlet flow path and an outlet flow path communicating with the fluid chamber; a capacity changing unit which changes the capacity of the fluid chamber; a fluid supplying unit which supplies fluid to the inlet flow path; a fluid ejection opening disposed at an end of the outlet flow path opposite to an end communicating with the fluid chamber; a vibrating unit which vibrates a component in the vicinity of the fluid ejection opening; a vibration detecting unit which detects the level of vibration of the component in the vicinity of the fluid ejection opening; and an operation control unit which controls operation of the capacity changing unit based on the level of the vibration detected by the vibration detecting unit.

Owner:COLUMBIA PEAK VENTURES LLC

Lubricant powder for powder metallurgy

InactiveUS6511945B1High green strengthEnsure durabilityTransportation and packagingMetal-working apparatusPolyethylene oxideOligomer

The invention concerns new lubricants comprising a combination of a polyethylene oxide and an oligomer amide and an improved metallurgical powder composition comprising a major amount of an iron-based powder and a minor amount of this new lubricant. Furthermore, the invention concerns a method requiring low ejection force and low ejection energy for producing green products having high green strength. The method comprises the steps of mixing an iron-based powder and optional additives with the new lubricant and compacting the obtained powder composition.

Owner:HOGANAS AB

Multi-channel pipettor with repositionable tips

ActiveUS8029742B2Efficient ejectionIncrease jacking forceAnalysis using chemical indicatorsWithdrawing sample devicesMotor drivePipette

A hand-held, multi-channel pipettor has an electronically controlled motor to reposition pipette tips for different center to center spacing. Each repositionable tip fitting assembly has a cam following pin that is driven by cam tracks in a motor driven roller drum. Stationary ports for the multiple aspiration cylinders are strategically placed to simplify management of flexible tubes leading to the repositionable pipette tip fitting assemblies. The pipettor has a user interface that can be operated conveniently by one hand to reposition pipette tips. It has a pipette tip ejection mechanism with a sinusoidal stripper bar.

Owner:INTEGRA BIOSCI CORP

Foil container with foil bag chambers which are arranged next to one another

ActiveUS20090084815A1Lower ejection forceSimple and inexpensive ejectionLiquid flow controllersLiquid transferring devicesEngineeringMechanical engineering

Owner:HILTI AG

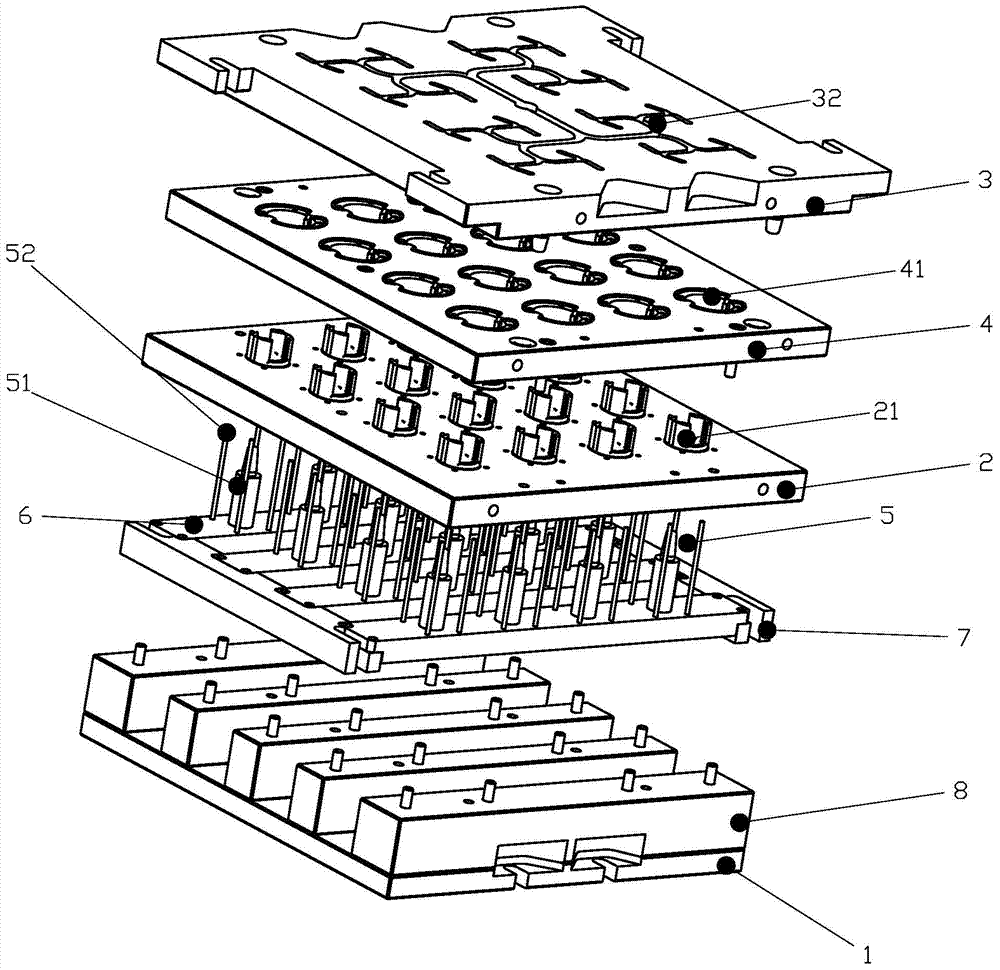

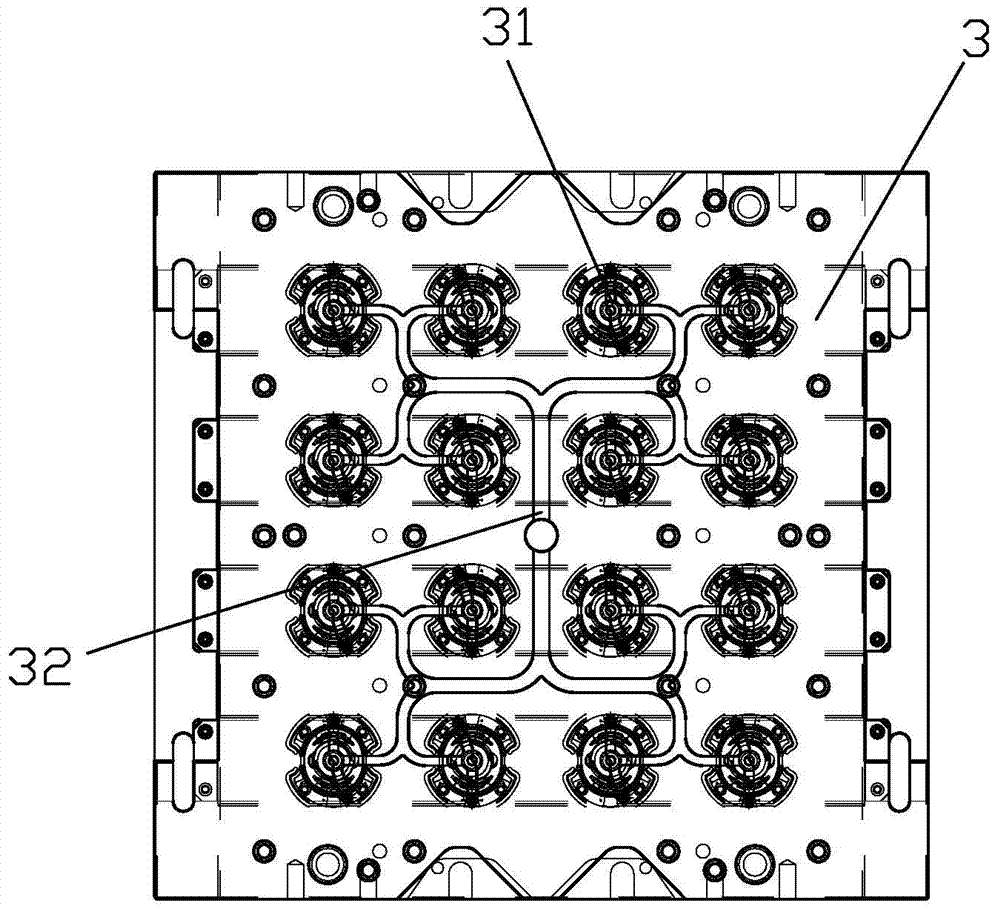

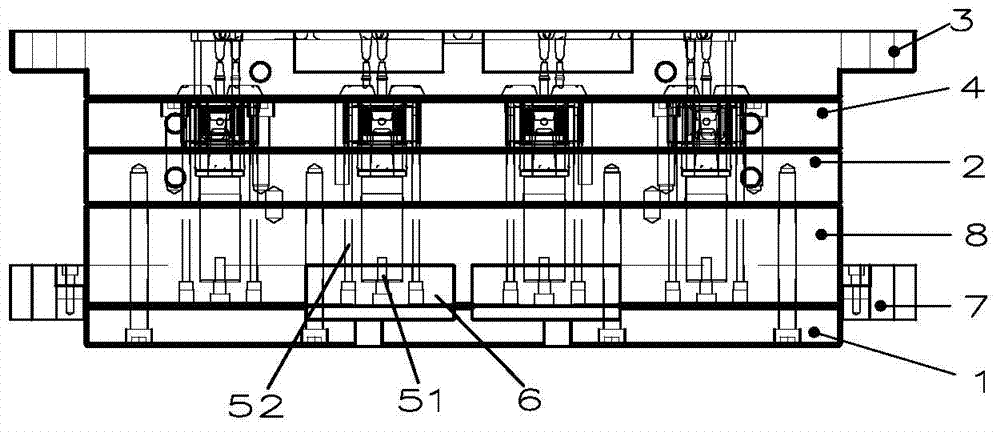

Vulcanizing mold of rubber bushing

The invention discloses a vulcanizing mold of a rubber bushing. The vulcanizing mold comprises a bottom plate, an ejecting mechanism, a lower mold plate, an upper mold plate and a product positioning plate, wherein the ejecting mechanism is arranged on the bottom plate and can move up and down; the lower mold plate is arranged on the ejecting mechanism and is fixed on the bottom plate; the upper mold plate is arranged above the lower mold plate; the product positioning plate is arranged between the lower mold plate and the upper mold plate; the upper mold plate is provided with a plurality of upper cavities and flowing channels communicated with the upper cavities; the lower mold plate is provided with a plurality of lower cavities; the product positioning plate is provided with a plurality of positioning cavities; the ejecting mechanism comprises a plurality of ejecting rod groups; each ejecting rod group comprises a first ejecting rod and a plurality of second ejecting rods which are arranged around the first ejecting rod in a circle; the lower mold plate is provided with a plurality of ejecting hole groups; each ejecting hole group is distributed around one lower cavity along one circle. The vulcanizing mold disclosed by the invention has the advantages that when in demolding, the ejecting mechanism supports an inner-layer lining pipe and an outer-layer lining pipe simultaneously, the stressing of all the parts of the rubber bushing is uniform, and the deformation is unlikely to occur, so that the locking of a product can be prevented, smooth demolding of the product can be guaranteed, the size of the product can be guaranteed, and the rejection rate is reduced.

Owner:NINGBO TUOPU GROUP CO LTD

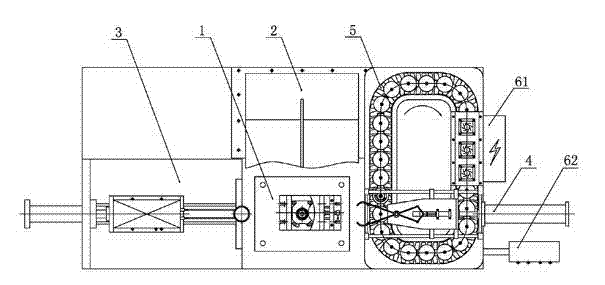

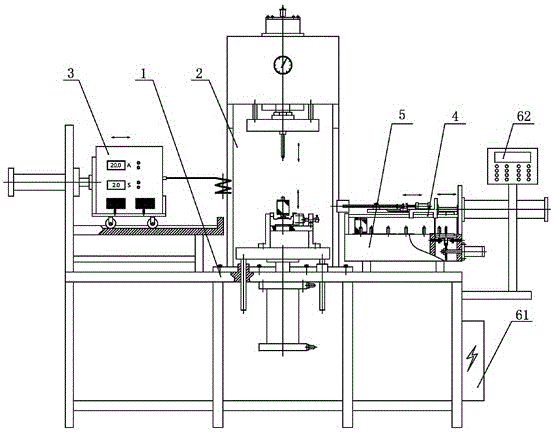

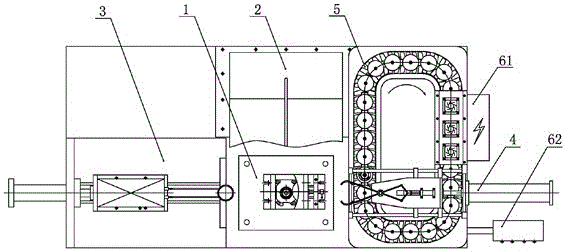

Damage-free compressor rotor heat jacket assembly disassembling device

ActiveCN103203585AReduce the amount of interferenceReduce ejection forceMetal working apparatusEngineeringReusability

The invention discloses a damage-free compressor rotor heat jacket assembly disassembling device. The damage-free compressor rotor heat jacket assembly disassembling device is provided with a jacking mechanism which is capable of lifting vertically, a clamp jig capable of clamping a workpiece is arranged at the top of the jacking mechanism, a high frequency heating device used for heating the workpiece and capable of moving leftwards and rightwards is mounted on the upper left portion of the jacking mechanism, a hydraulic ejection mechanism capable of ejecting out a crankshaft is mounted above the jacking mechanism and the high-frequency heating device, a pressure center of the hydraulic ejection mechanism is coincided with the center of the jacking mechanism, a rotor shifting mechanism capable of clamping a rotor to move leftwards and rightwards is mounted on the upper right portion of the jacking mechanism and below the hydraulic ejection mechanism, a rotor cooling mechanism capable of cooling a rotor shifted from the rotor shifting mechanism is mounted below the rotor shifting mechanism, and the jacking mechanism, the high-frequency heating device, the hydraulic ejection mechanism, the rotor shifting mechanism and the rotor cooling mechanism are connected with a controlling mechanism. The damage-free compressor rotor heat jacket assembly disassembling device has the advantages of simplicity in operation, high disassembling efficiency, small damage to disassembled parts, and good reusability.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

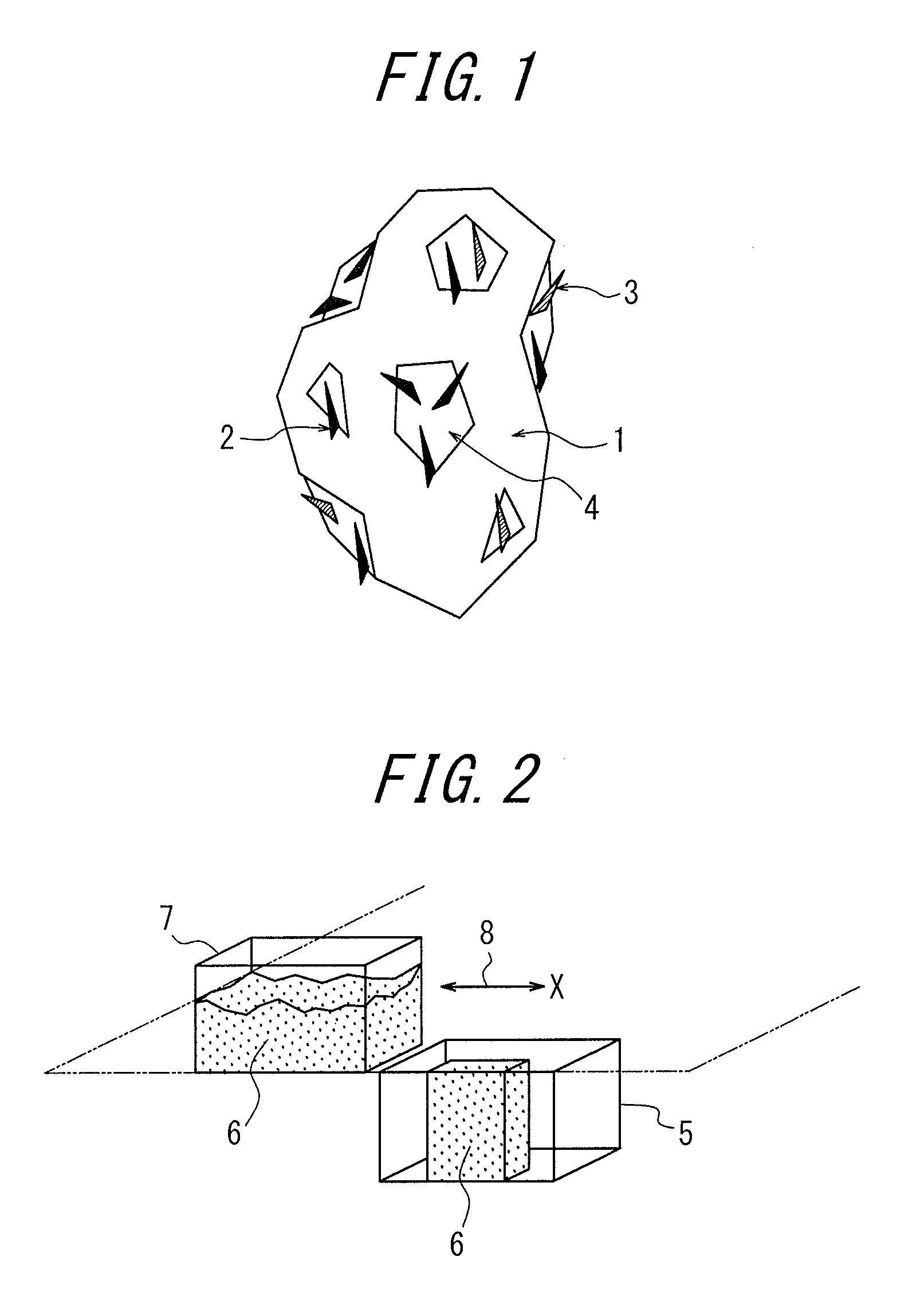

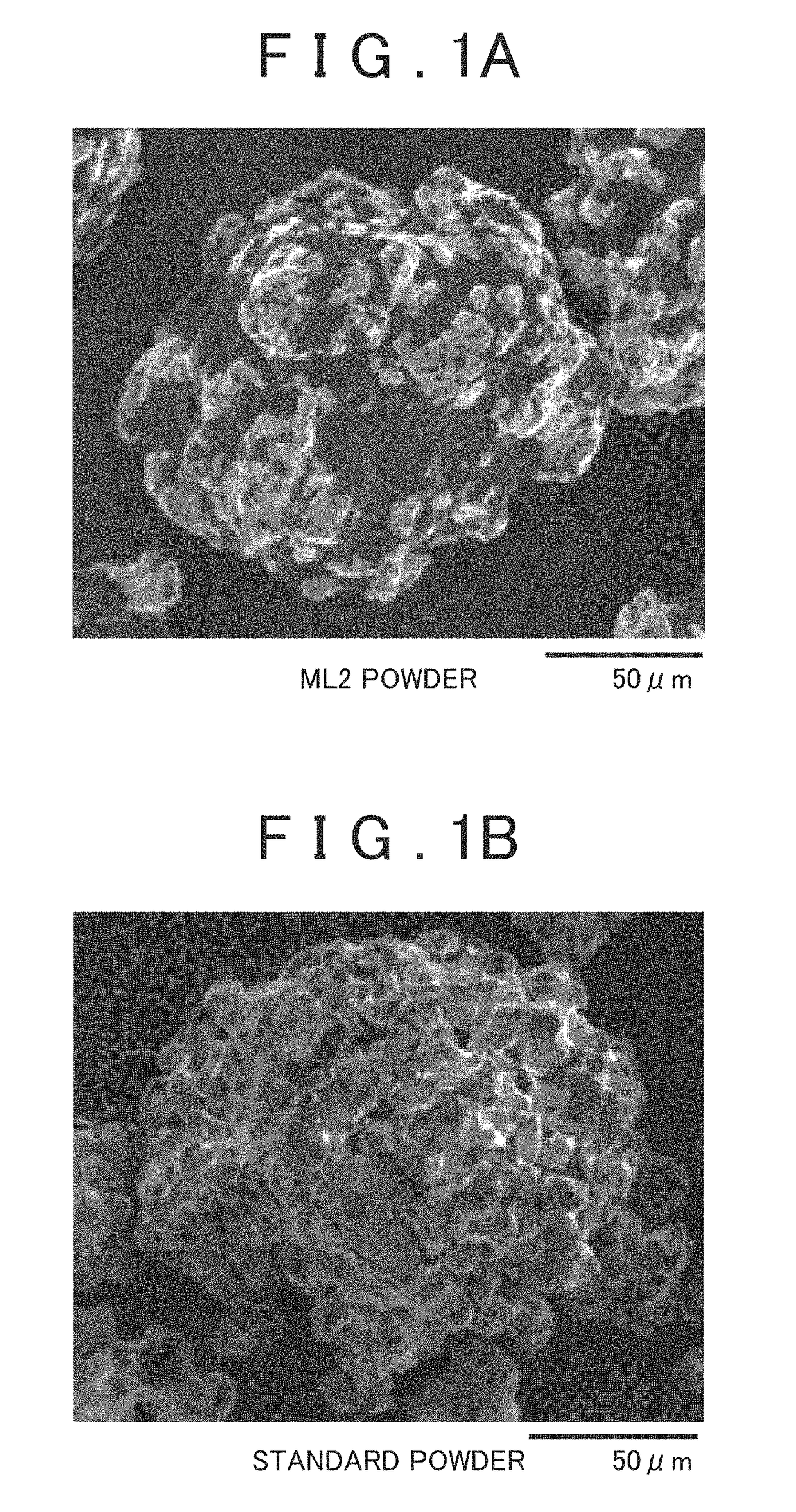

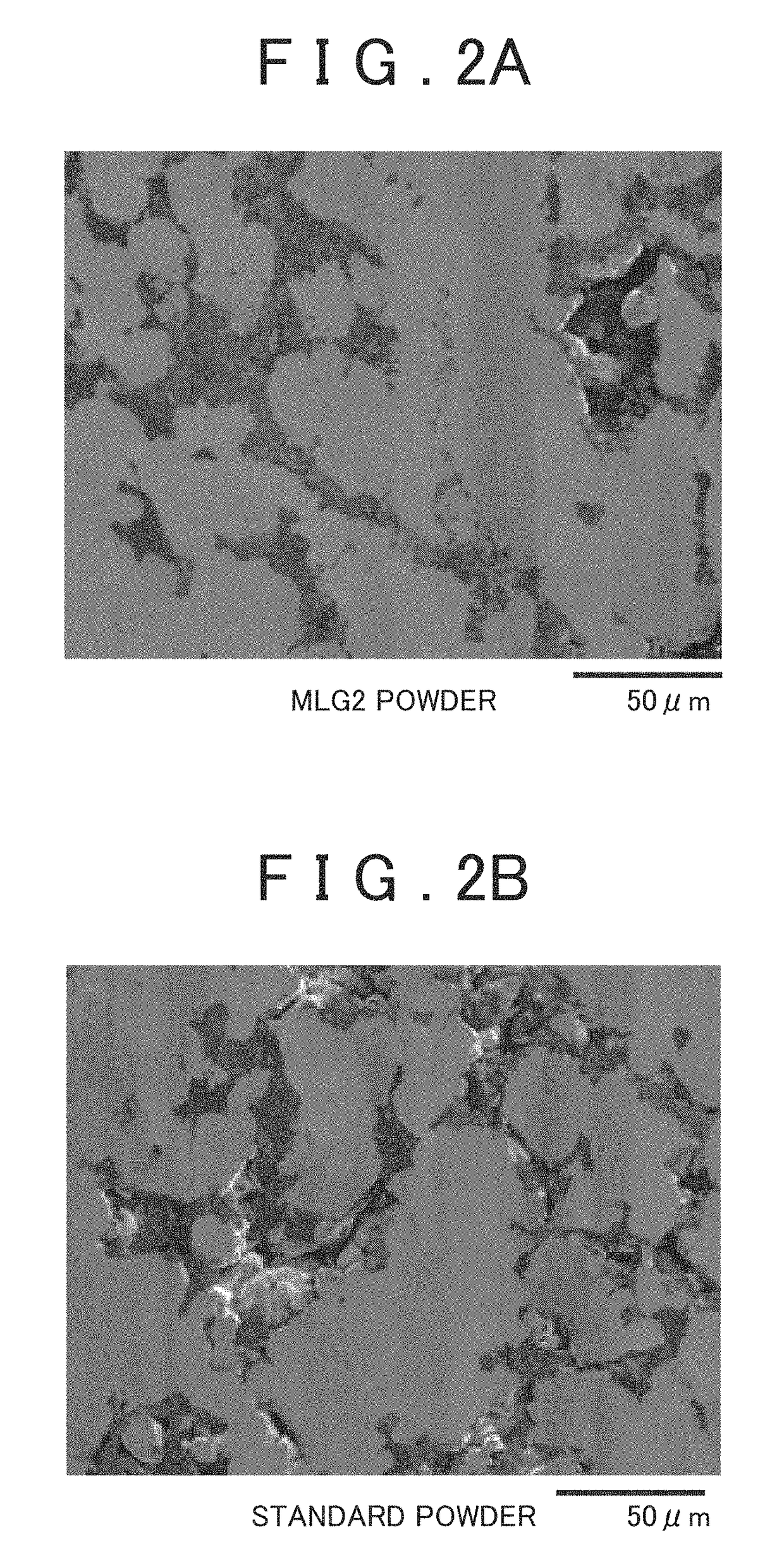

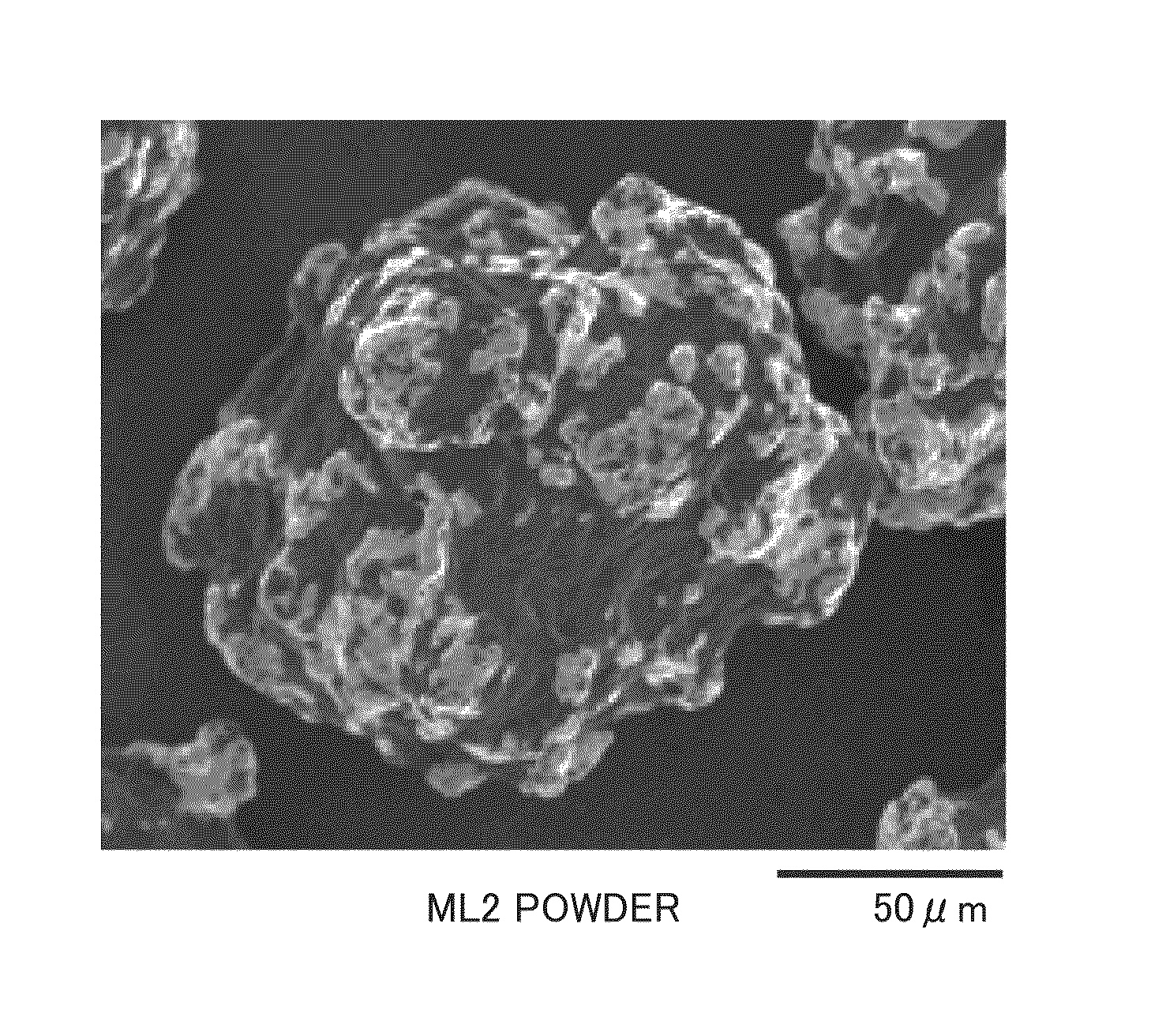

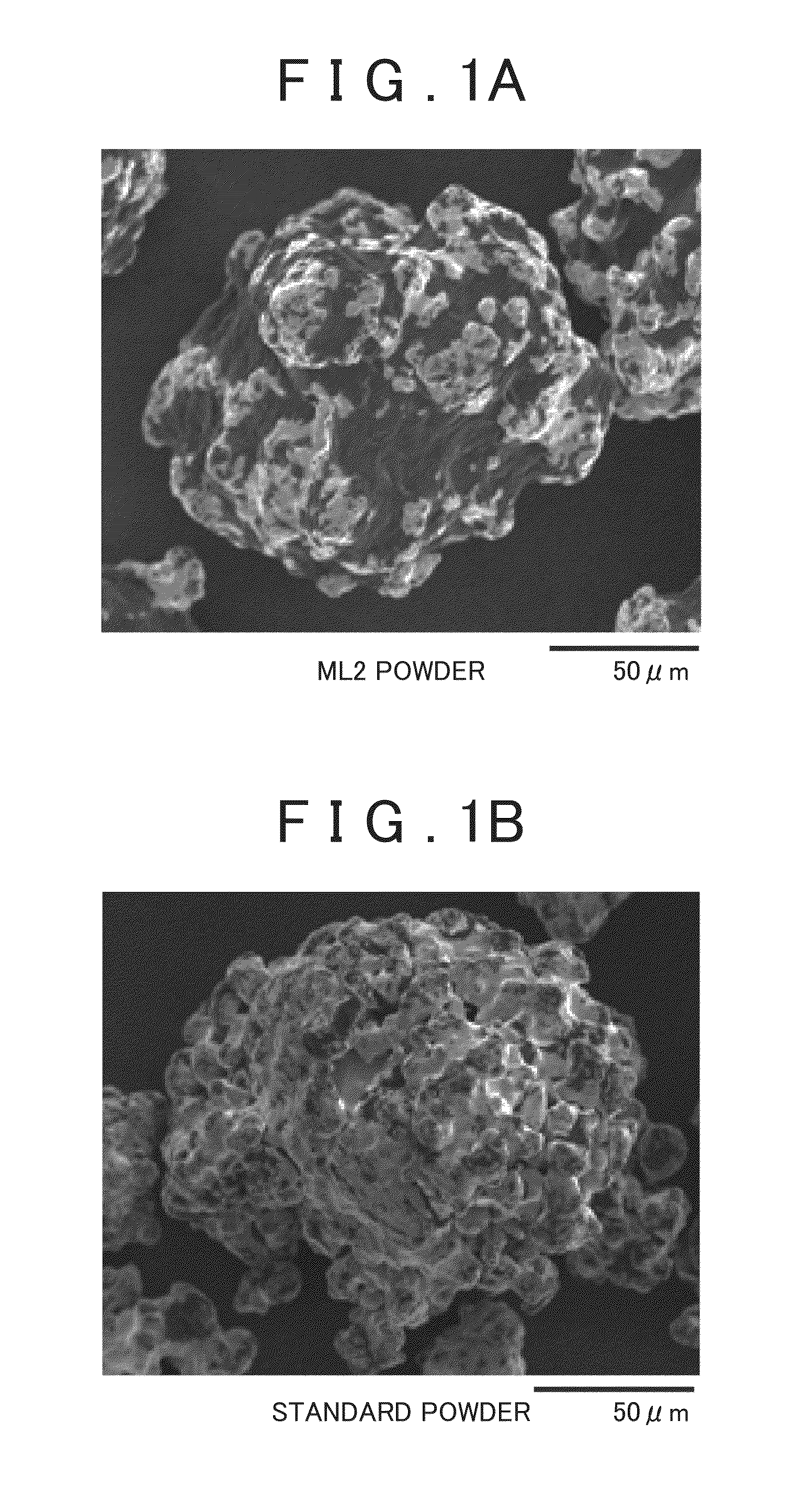

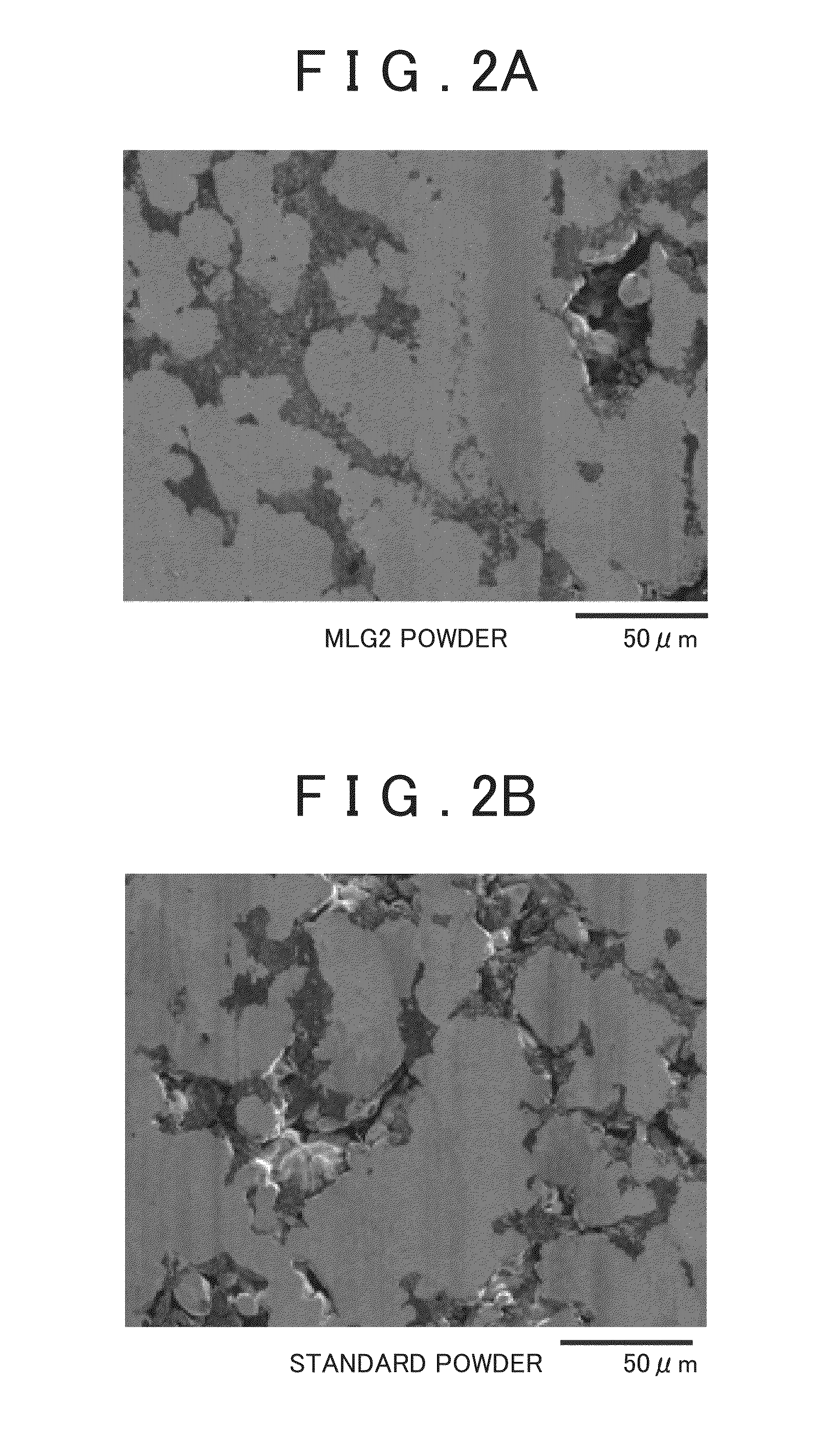

Iron-based powder for powder metallurgy

ActiveUS20150314372A1Poor appearanceNice appearanceSynthetic resin layered productsMetal-working apparatusThin walledPowder metallurgy

An iron-based powder for powder metallurgy effectively prevents agglomeration of a lubricant, has excellent flowability, can evenly fill thin-walled cavities, keeps the ejection force after formation low, and does not lower sintered body strength by adhering either or both of an alloy component and a cutting ability improving agent to the surface of iron powder with a binder that has a melting point of 150° C. or lower, adhering carbon black to the surface of the binder, and setting the amount of free binder to 0.02 mass % or less.

Owner:JFE STEEL CORP

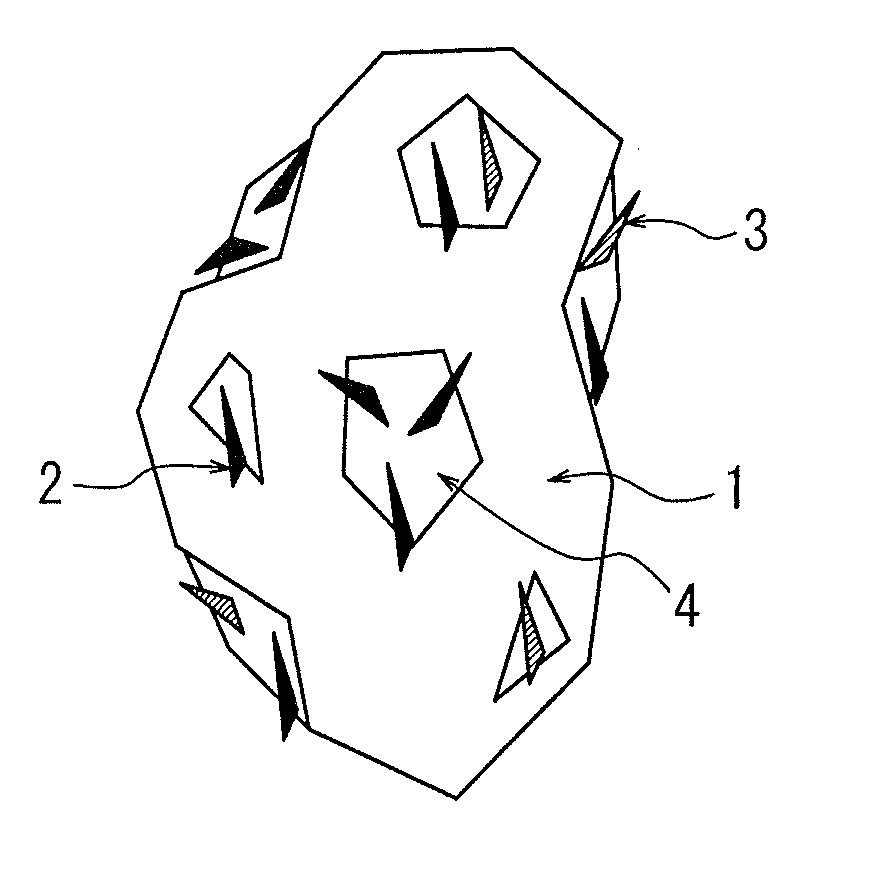

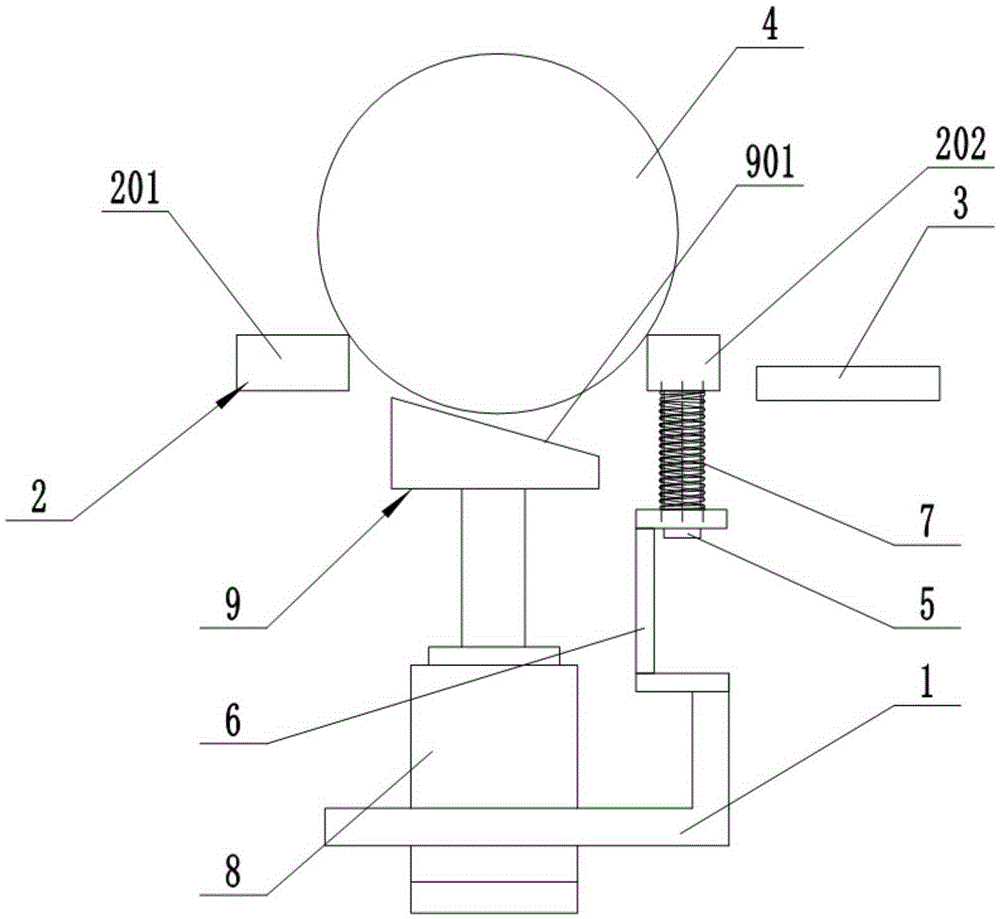

Powder metal composition containing micronized deformable solids and methods of making and using the same

ActiveUS20070048166A1Lower ejection forceHigh densityTransportation and packagingMetal-working apparatusViscous liquidLubrication

The present invention provides powder metal compositions and methods of making and using the same. Powder metal compositions according to the invention include base metal particles, a lubricant that transforms from a solid phase material to a viscous, liquid phase material during pressing, and a micronized deformable solid material. The micronized deformable solid material fills at least a portion of the void space between the base metal particles during pressing, which allows at least a portion of the lubricant to migrate as a viscous liquid phase material to the interface between the surface of the green compact and the wall of the mold cavity to provide lubrication that reduces the ejection force necessary to remove the green compact from the mold cavity.

Owner:JOHNSON ELECTRIC NORTH AMERICA

Multi-Channel Pipettor with Repositionable Tips

ActiveUS20150030513A1Facilitate effectiveFacilitate ergonomic tip ejectionBurettes/pipettesMotor drivePipette

A hand-held, multi-channel pipettor has an electronically controlled motor to reposition pipette tips for different center to center spacing. Each repositionable tip fitting assembly has a cam following pin that is driven by cam tracks in a motor driven roller drum. Stationary ports for the multiple aspiration cylinders are strategically placed to simplify management of flexible tubes leading to the repositionable pipette tip fitting assemblies. The pipettor has a user interface that can be operated conveniently by one hand to reposition pipette tips. It has a pipette tip ejection mechanism with a sinusoidal stripper bar.

Owner:INTEGRA BIOSCI CORP

Tampon pledget for increased bypass leakage protection

The present invention provides a tampon pledget with one or more of the following properties: increased absorbency rate; high absorbent capacity and fluid retention; rapid expansion potential; and ease of ejection of the pledget from the applicator. Surprisingly, the one or more properties are achieved by using a modified dual cross-pad, folded, compressed tampon pledget design.

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

Pipette tip adapter

An adapter for connecting an array of pipette tips having through bores with conical upper ends to a multichannel air displacement pipettor having a plurality of ports with compliant internal sealing surfaces. The adapter comprises a planar base with an array of openings extending between its top and bottom surfaces. Sealing tubes project upwardly from the top surface, and tip mounting tubes project downwardly from the bottom surface, with pairs of sealing tubes and tip mounting tubes being arranged coaxially and in communication with respective ones of the openings in the base. The tip mounting tubes are externally dimensioned and configured for insertion into the conical upper ends of the pipette tips, and the sealing tubes are externally configured and dimensioned for insertion into the ports of the pipettor and into sealing interengagement with their compliant internal sealing surfaces.

Owner:AVIDIEN TECH

Ink jet head and recording apparatus using the same

InactiveUS7275812B2Reduce voltageBroaden your optionsPrintingEngineeringElectrical and Electronics engineering

The ink jet head records an image on a recording medium by ejecting ink containing charged fine particles by means of an electrostatic force, and includes an ink guide, an ink flow path that supplies the ink to the ink guide and an ejection electrode that ejects the supplied ink. The ejection electrode includes a surrounding electrode arranged so as to surround an outer periphery of the ink guide with a spacing, or side-by-side electrodes arranged on both sides of the ink guide so as to oppose each other with a spacing. A ratio between an effective inside diameter of the surrounding electrode or an effective spacing between the side-by-side electrodes, and a distance from the surrounding electrode or the side-by-side electrodes to a tip end of the ink guide protruding on the side of the recording medium is set in a range of 1:0.5 to 1:2 or 1:0.7 to 1:2.8, respectively.

Owner:FUJIFILM HLDG CORP +1

Iron-based powder for powder metallurgy

ActiveUS7867314B2Improve liquidityHigh strengthTransportation and packagingMetal-working apparatusIron powderUltimate tensile strength

Flowability-improving particles containing 50 to 100% by mass of carbon black are adhered to surfaces of iron powder through a binder to provide an iron-based powder for powder metallurgy which has excellent flowability and which is capable of uniformly filling a thin-walled cavity, compaction with high ejection force, and maintaining sufficient strength of a sintered body in subsequent sintering.

Owner:JFE STEEL CORP

Fluid ejection device, driving method of fluid ejection device, and operating instrument

InactiveUS8998938B2Lower ejection forceAvoid distractionWatering devicesFluid jet surgical cuttersEngineeringInlet flow

A fluid ejection device includes: a fluid chamber whose capacity is variable; an inlet flow path and an outlet flow path communicating with the fluid chamber; a capacity changing unit which changes the capacity of the fluid chamber; a fluid supplying unit which supplies fluid to the inlet flow path; a fluid ejection opening disposed at an end of the outlet flow path opposite to an end communicating with the fluid chamber; a vibrating unit which vibrates a component in the vicinity of the fluid ejection opening; a vibration detecting unit which detects the level of vibration of the component in the vicinity of the fluid ejection opening; and an operation control unit which controls operation of the capacity changing unit based on the level of the vibration detected by the vibration detecting unit.

Owner:COLUMBIA PEAK VENTURES LLC

Tampon pledget for increased bypass leakage protection

The present invention provides a tampon pledget with one or more of the following properties: increased absorbency rate; high absorbent capacity and fluid retention; rapid expansion potential; and ease of ejection of the pledget from the applicator. Surprisingly, the one or more properties are achieved by using a modified dual cross-pad, folded, compressed tampon pledget design.

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

Iron-based powder for powder metallurgy

ActiveUS9352393B2Nice appearanceSintered body strengthMetal-working apparatusCoatingsIron powderAlloy

Owner:JFE STEEL CORP

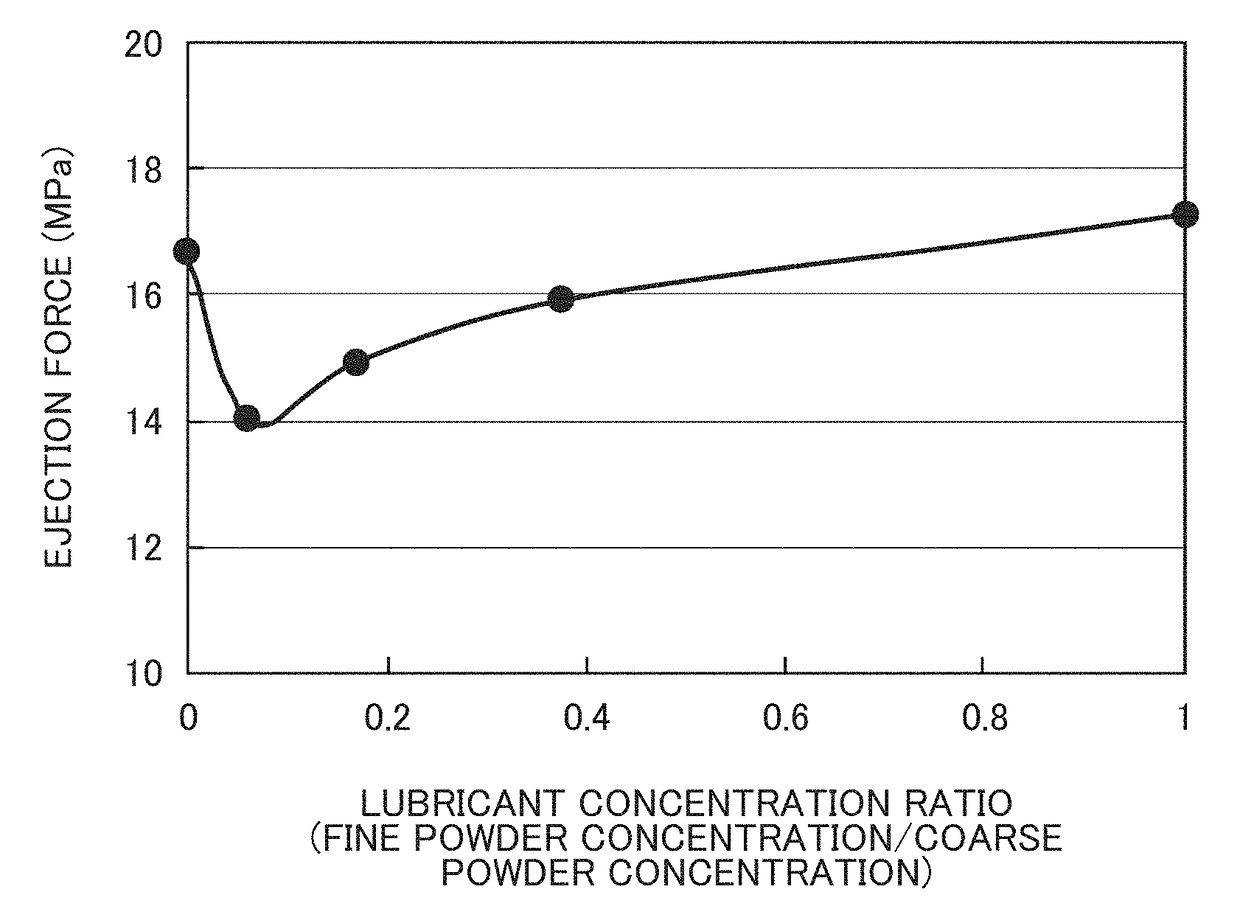

Powder for molding, lubricant-concentrated powder and method for producing metal member

ActiveUS9815114B2Increase volumeGood molding effectMetal-working apparatusThin material handlingLubricantCeramic materials

Owner:TOYOTA JIDOSHA KK

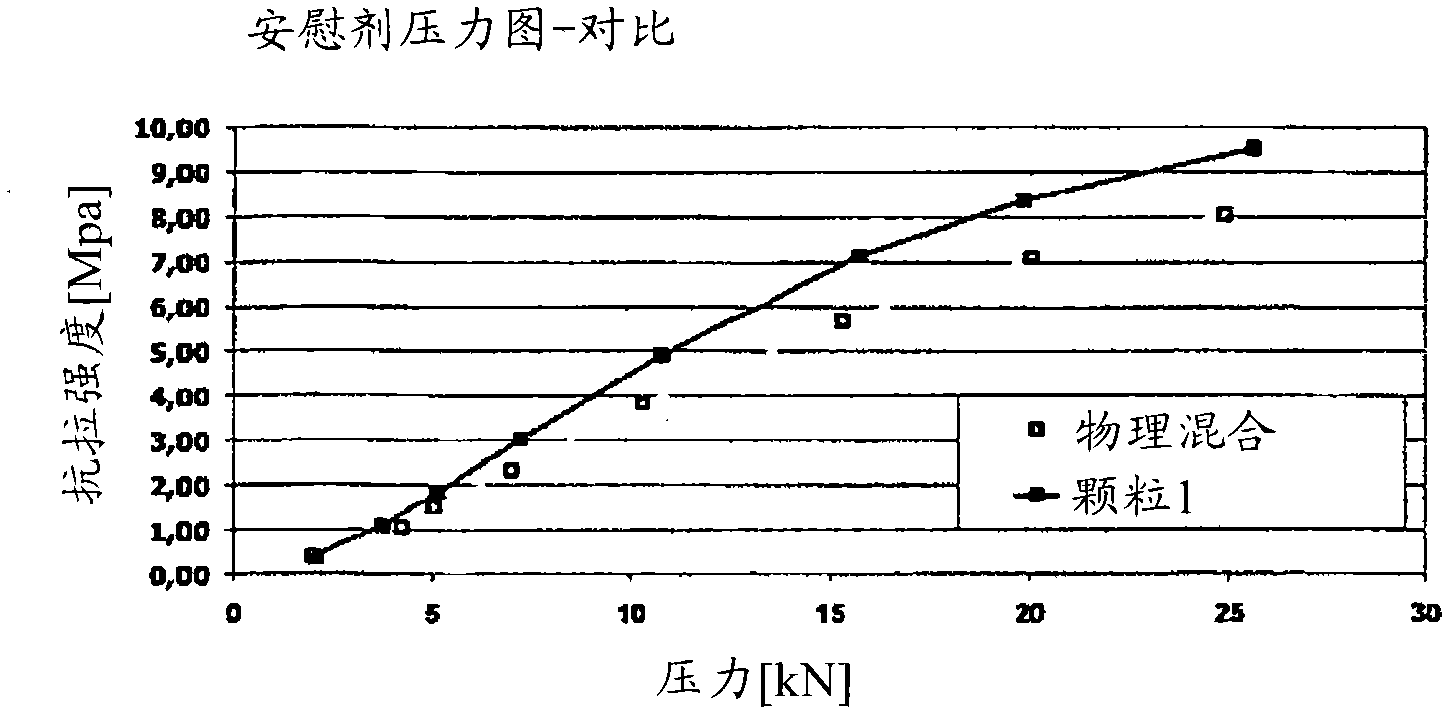

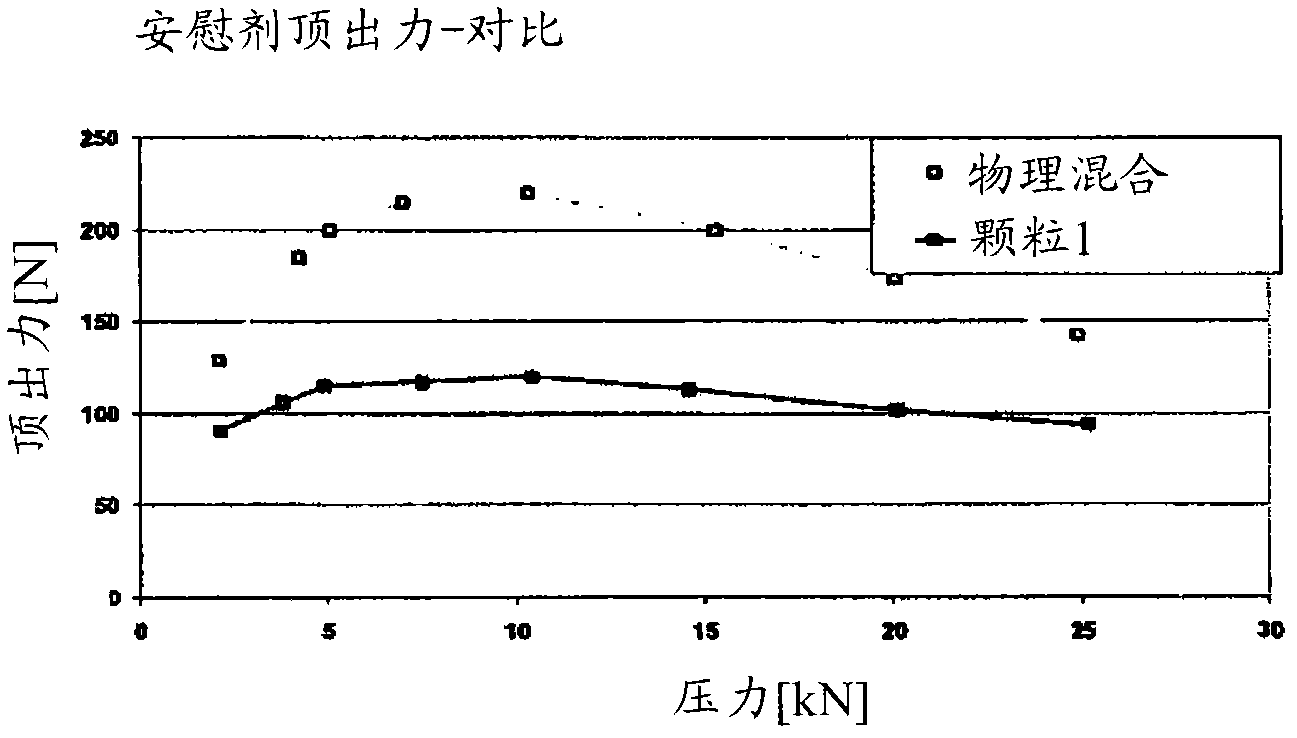

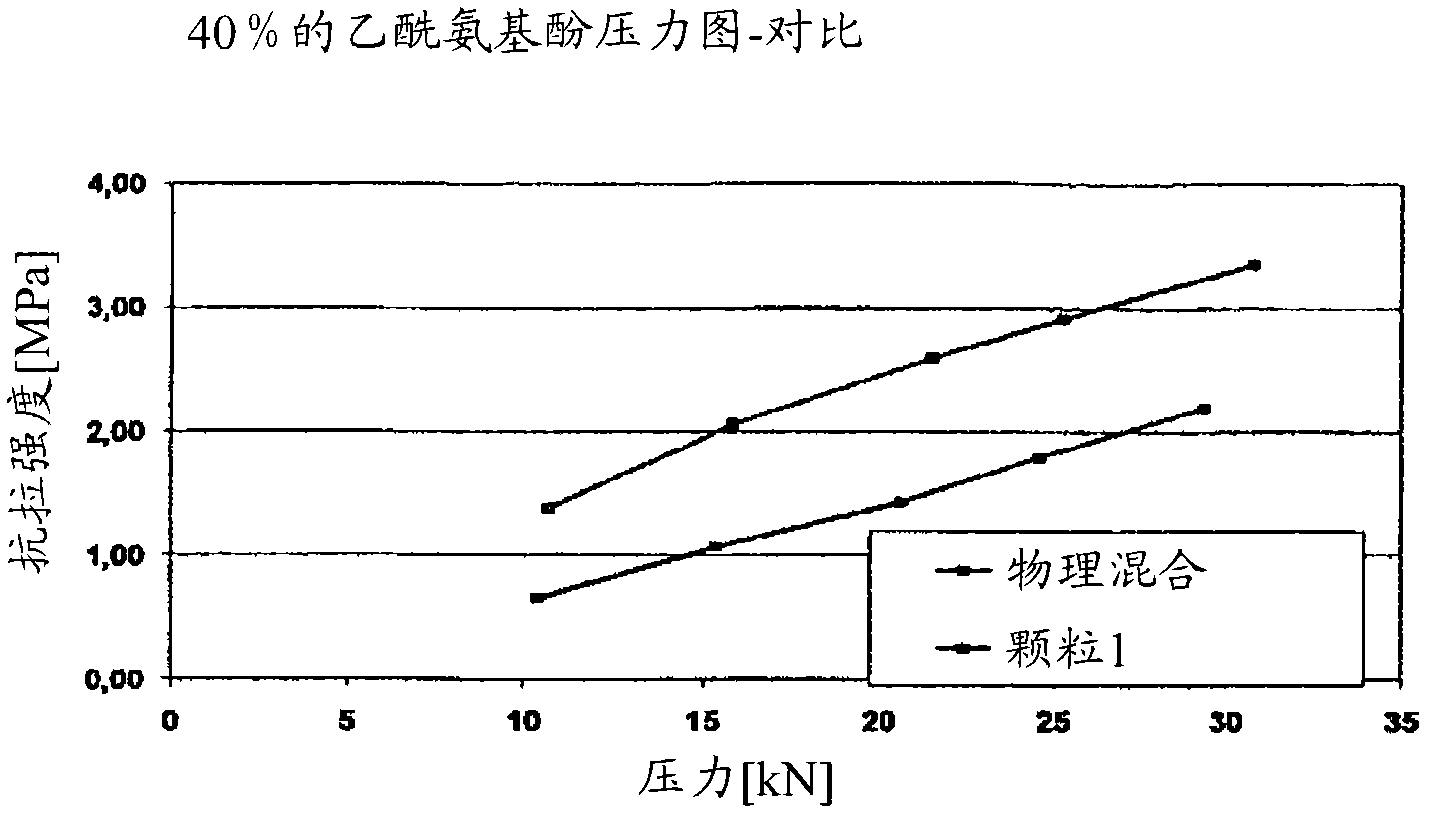

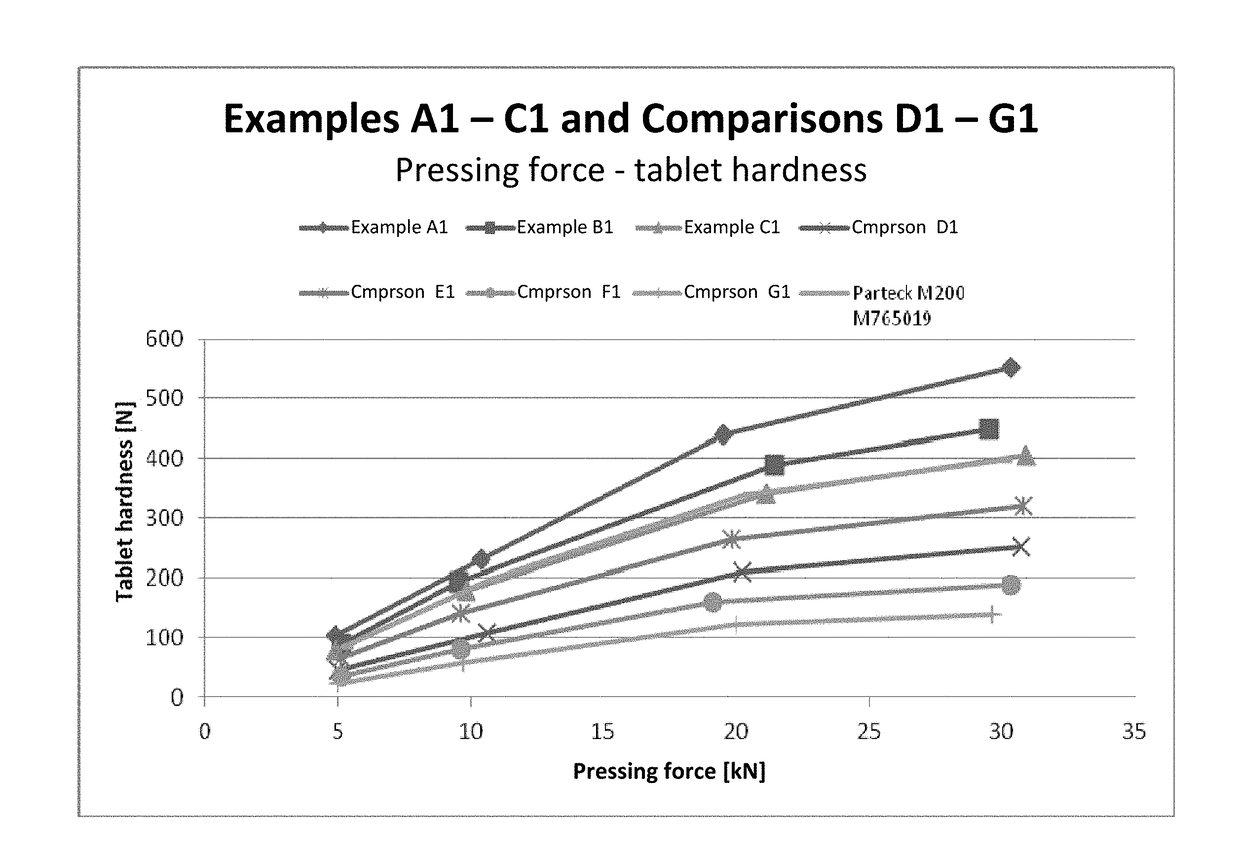

Process and apparatus for producing a tabletting aid and also a tabletting aid and tabletting mixture

InactiveCN101970093AEvenly distributedLower ejection forcePill deliveryPharmaceutical non-active ingredientsDecompositionLubricant

The invention relates to a process for producing a tabletting aid, which comprises the following process steps: - at least two of the following components are provided: a filler / binder; a lubricant; a flow regulator; a decomposition accelerator; the components provided are mixed with one another.

Owner:J RETTENMAIER & SOEHNE GMBH CO KG ROSENBERG

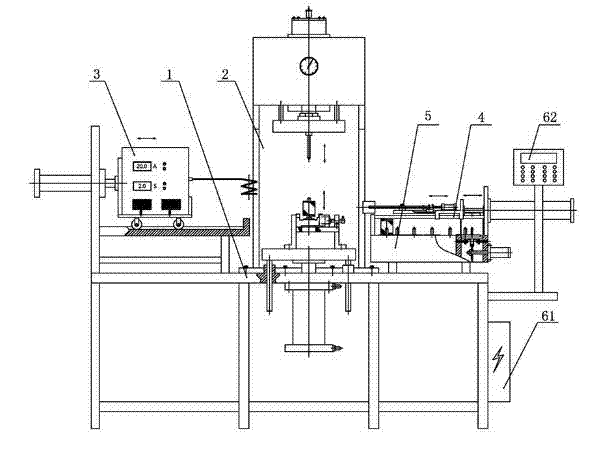

Non-destructive disassembly device for compressor rotor shrink sleeve assembly

The invention discloses a damage-free compressor rotor heat jacket assembly disassembling device. The damage-free compressor rotor heat jacket assembly disassembling device is provided with a jacking mechanism which is capable of lifting vertically, a clamp jig capable of clamping a workpiece is arranged at the top of the jacking mechanism, a high frequency heating device used for heating the workpiece and capable of moving leftwards and rightwards is mounted on the upper left portion of the jacking mechanism, a hydraulic ejection mechanism capable of ejecting out a crankshaft is mounted above the jacking mechanism and the high-frequency heating device, a pressure center of the hydraulic ejection mechanism is coincided with the center of the jacking mechanism, a rotor shifting mechanism capable of clamping a rotor to move leftwards and rightwards is mounted on the upper right portion of the jacking mechanism and below the hydraulic ejection mechanism, a rotor cooling mechanism capable of cooling a rotor shifted from the rotor shifting mechanism is mounted below the rotor shifting mechanism, and the jacking mechanism, the high-frequency heating device, the hydraulic ejection mechanism, the rotor shifting mechanism and the rotor cooling mechanism are connected with a controlling mechanism. The damage-free compressor rotor heat jacket assembly disassembling device has the advantages of simplicity in operation, high disassembling efficiency, small damage to disassembled parts, and good reusability.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

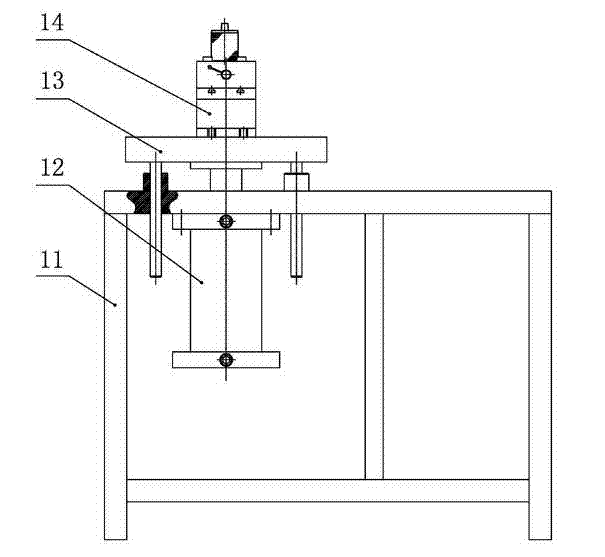

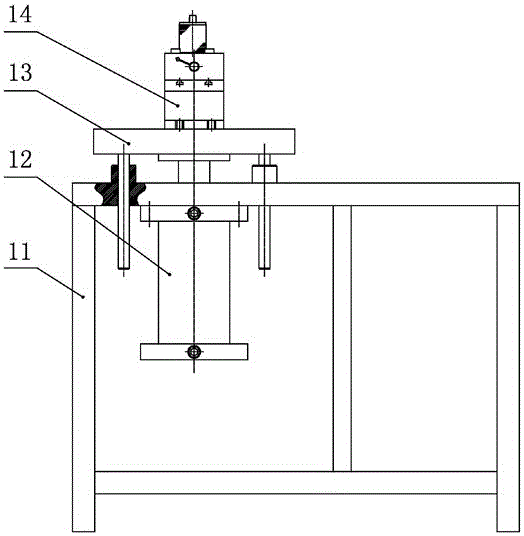

Ejection device for machining drill stem

InactiveCN105382611AAvoid unstable outputSimple structureMetal working apparatusHydraulic cylinderEngineering

The invention relates to an ejection device for machining a drill stem. The ejection device comprises a supporting frame; a drill stem supporting base and a connection platform are arranged above the supporting frame, the drill stem supporting base comprises a fixed base and a movable base which are arranged in a spaced mode, the drill stem is placed between the fixed base and the movable base, and the upper surface of the movable base is lower than the upper surface of the connection platform; the movable base is movably installed on a bracket through a vertical guide rod, the bracket is fixedly connected with the supporting frame, and the guide rod is sleeved with a vertical spring arranged between the bracket and the movable base; an ejection mechanism is arranged below the drill stem and comprises an ejection hydraulic cylinder and an ejection block installed at the upper end of an piston rod of the ejection hydraulic cylinder, a cylinder body of the ejection hydraulic cylinder is fixedly connected with the supporting frame, and the upper surface of the ejection block is provided with an ejection bevel inclining in the output direction of the drill stem. The ejection device for machining the drill stem is simple in structure and reasonable in design; by means of an elastic lifting type supporting structure, the ejecting force can be reduced, moreover, the drill stem can be prevented from being output unstably, and the working reliability of the ejection device is high.

Owner:WUXI ZHONGDI DRILLING EQUIP

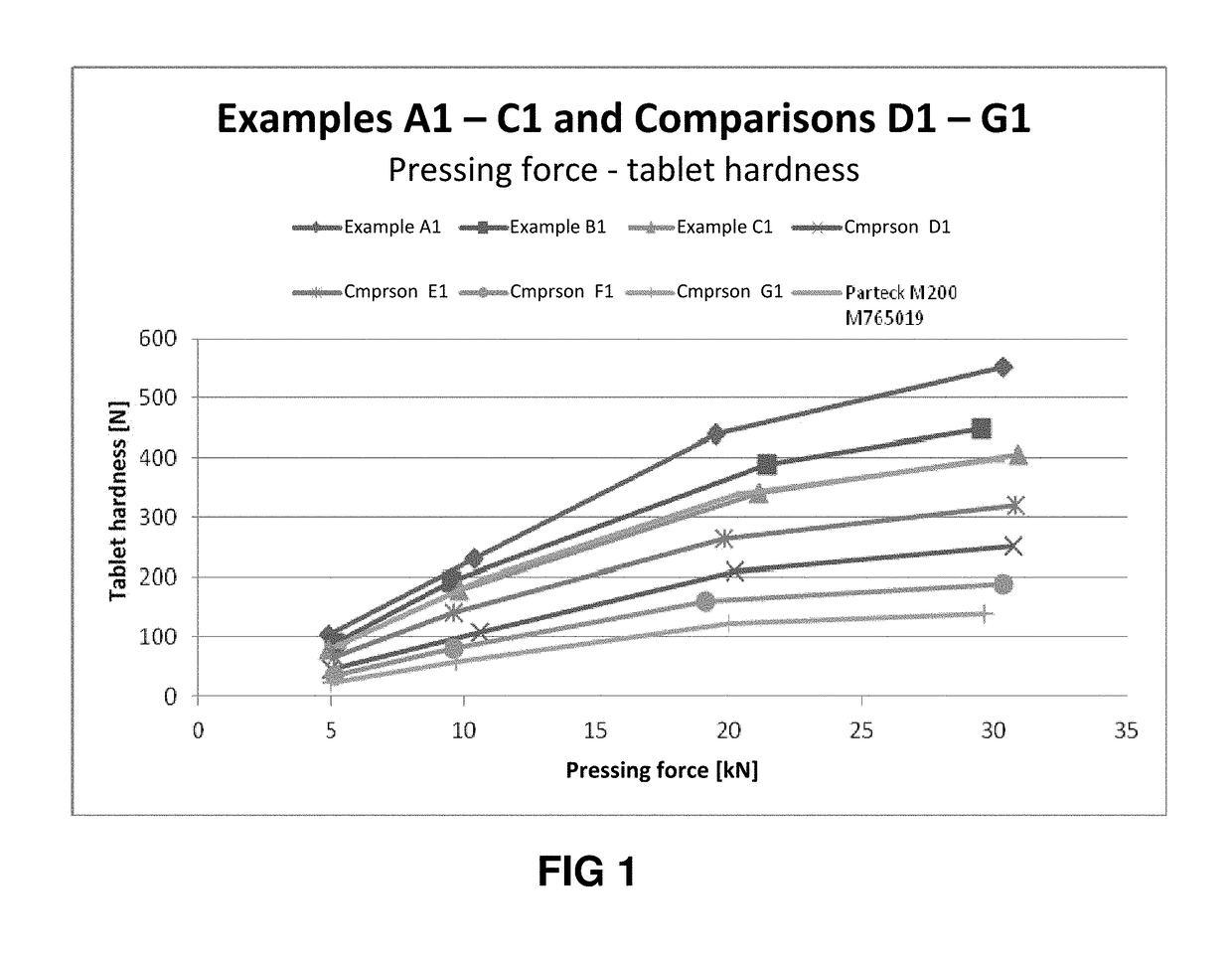

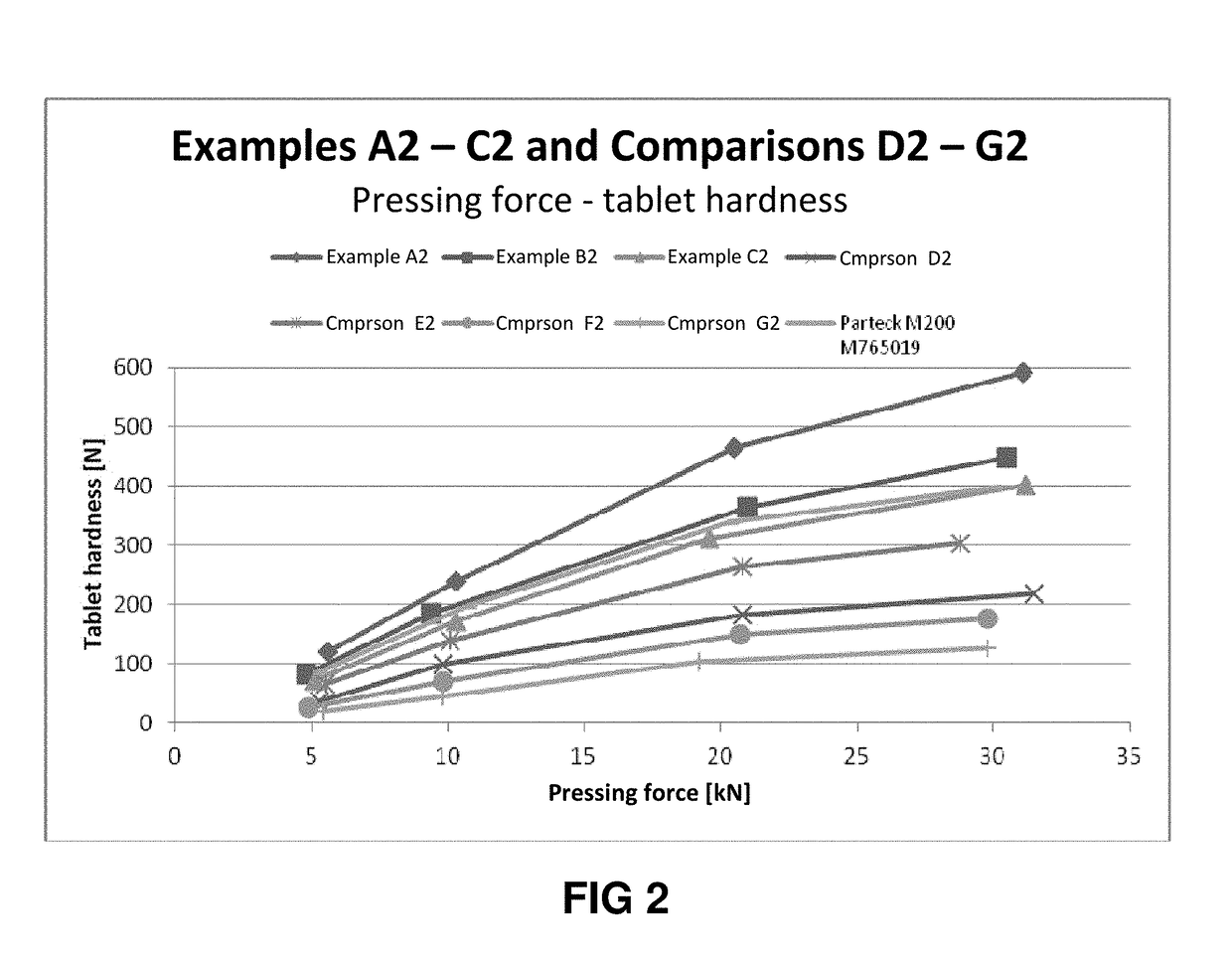

Directly compressible composition comprising microcrystalline cellulose

InactiveUS20170209380A1Lower ejection forceHigh tablet hardnessPill deliveryPolyvinyl alcoholFine grain

The present invention relates to a directly compressible composition for the production of tablets which comprise fine-grained polyvinyl alcohols (PVAs) and fine-grained microcrystalline celluloses (MCCs) in a co-mixture. The present invention also relates to the use of this mixture and to a process for the preparation thereof.

Owner:MERCK PATENT GMBH

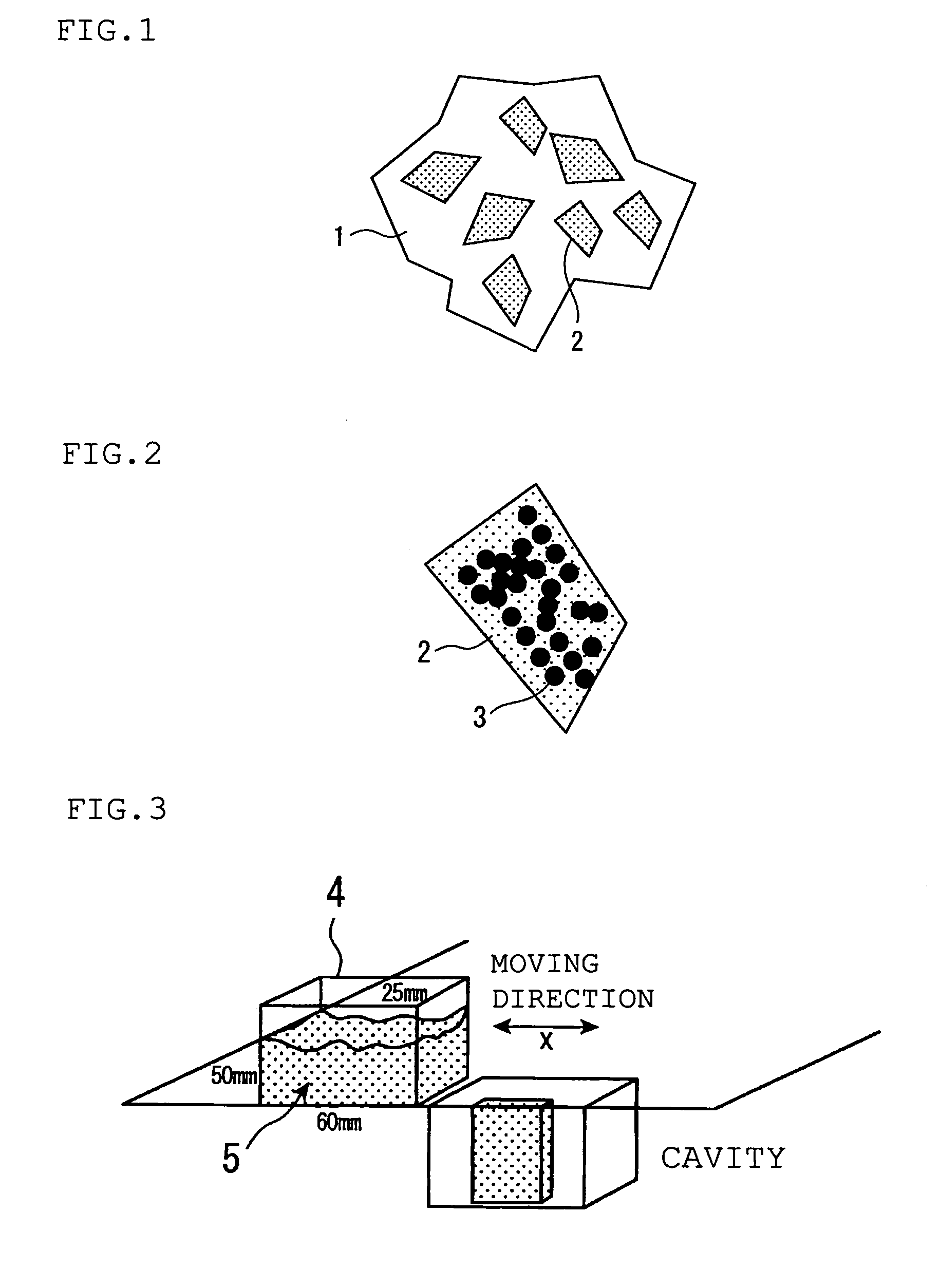

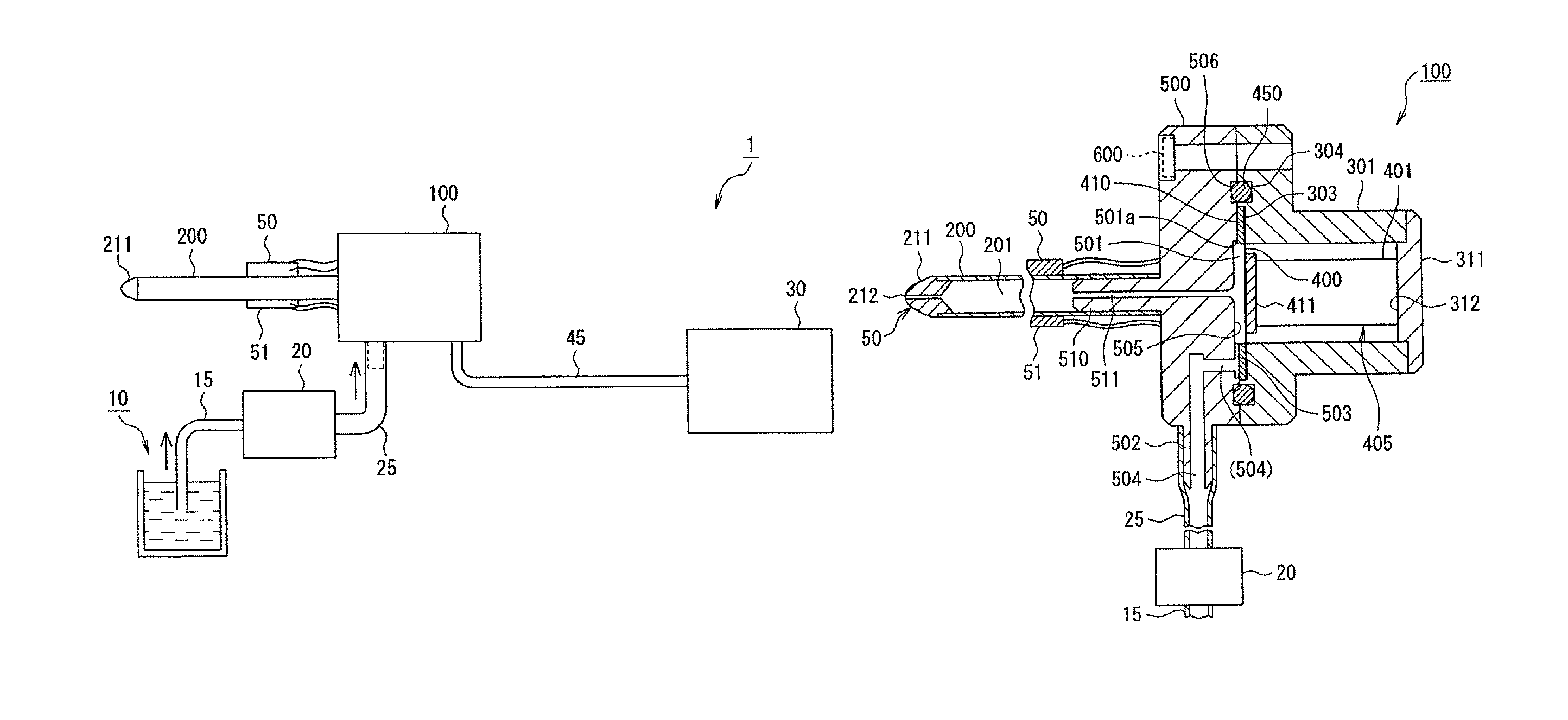

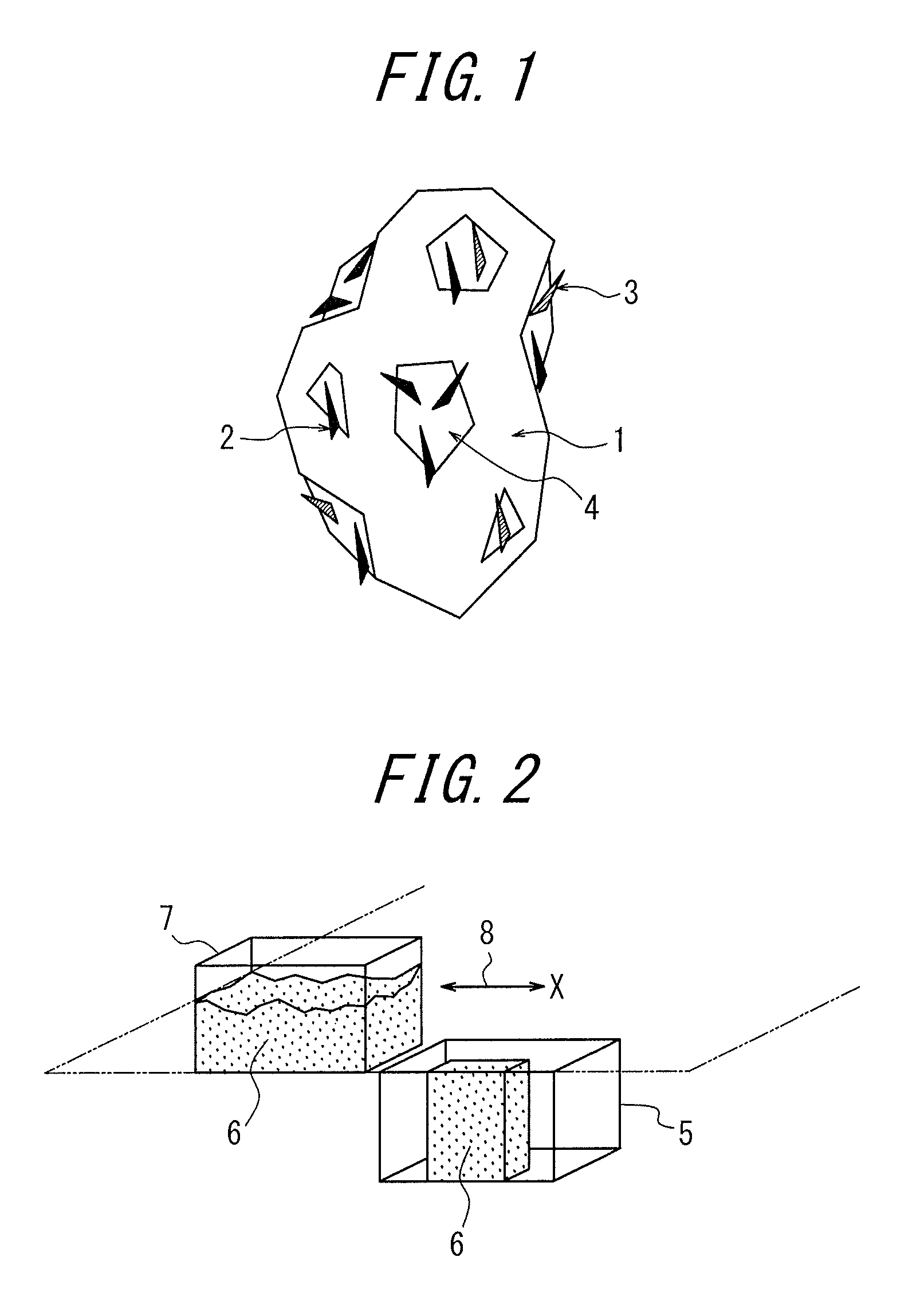

Iron-based mixed powder for powder metallurgy

In an iron-based powder, 0.01% to 5.0% by mass of a flaky powder having an average particle size of longitudinal size of 100 or less, a thickness of 10 μm or less, and an aspect ratio (longitudinal size-to-thickness ratio) of 5 or more with respect to the iron-based mixed powder is contained, whereby the flowability of an iron-based mixed powder is increased, the density of a green compact is increased, and ejection force is greatly reduced after compaction, thereby accomplishing an increase in product quality and a reduction in production cost.

Owner:JFE STEEL CORP

Pipette tip adapter

ActiveUS20200330980A1Reduces mountingLower ejection forceBurettes/pipettesSupporting apparatusPipetteStructural engineering

An adapter for connecting an array of pipette tips having through bores with conical upper ends to a multichannel air displacement pipettor having a plurality of ports with compliant internal sealing surfaces. The adapter comprises a planar base with an array of openings extending between its top and bottom surfaces. Sealing tubes project upwardly from the top surface, and tip mounting tubes project downwardly from the bottom surface, with pairs of sealing tubes and tip mounting tubes being arranged coaxially and in communication with respective ones of the openings in the base. The tip mounting tubes are externally dimensioned and configured for insertion into the conical upper ends of the pipette tips, and the sealing tubes are externally configured and dimensioned for insertion into the ports of the pipettor and into sealing interengagement with their compliant internal sealing surfaces.

Owner:AVIDIEN TECH

Process and apparatus for producing a tabletting aid and also a tabletting aid and tabletting mixture

InactiveCN101970093BEvenly distributedLower ejection forcePill deliveryPharmaceutical non-active ingredientsEngineeringExcipient

Owner:J RETTENMAIER & SOEHNE GMBH CO KG ROSENBERG

Multi-channel pipettor with repositionable tips

A hand-held, multi-channel pipettor has an electronically controlled motor to reposition pipette tips for different center to center spacing. Each repositionable tip fitting assembly has a cam following pin that is driven by cam tracks in a motor driven roller drum. Stationary ports for the multiple aspiration cylinders are strategically placed to simplify management of flexible tubes leading to the repositionable pipette tip fitting assemblies. The pipettor has a user interface that can be operated conveniently by one hand to reposition pipette tips. It has a pipette tip ejection mechanism with a sinusoidal stripper bar.

Owner:INTEGRA BIOSCI CORP

Powder for molding, lubricant-concentrated powder and method for producing metal member

ActiveUS20140271327A1Increase volumeGood molding effectSynthetic resin layered productsMetal-working apparatusShell moldingMaterials science

A powder for molding is a mixture of first constituent particles, which are made up of first metal base particles, and second constituent particles, which are made up of second metal base particles. A first lubricant concentration that is a mass proportion of a first internal lubricant adhered to the surface of the first metal base particles with respect to the total of the first constituent particles, is greater than a second lubricant concentration that is a mass proportion of a second internal lubricant that is adhered to the surface of the second metal base particles with respect to the total of the second constituent particles.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com