Pipette tip adapter

a technology of air displacement and pipette, which is applied in the direction of laboratory glassware, laboratory glassware, chemistry apparatus and processes, etc., can solve the problems of cross contamination, heavy designs that require more power to operate effectively, and cross contamination of different types, so as to reduce mounting and ejection forces, reduce mounting forces, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

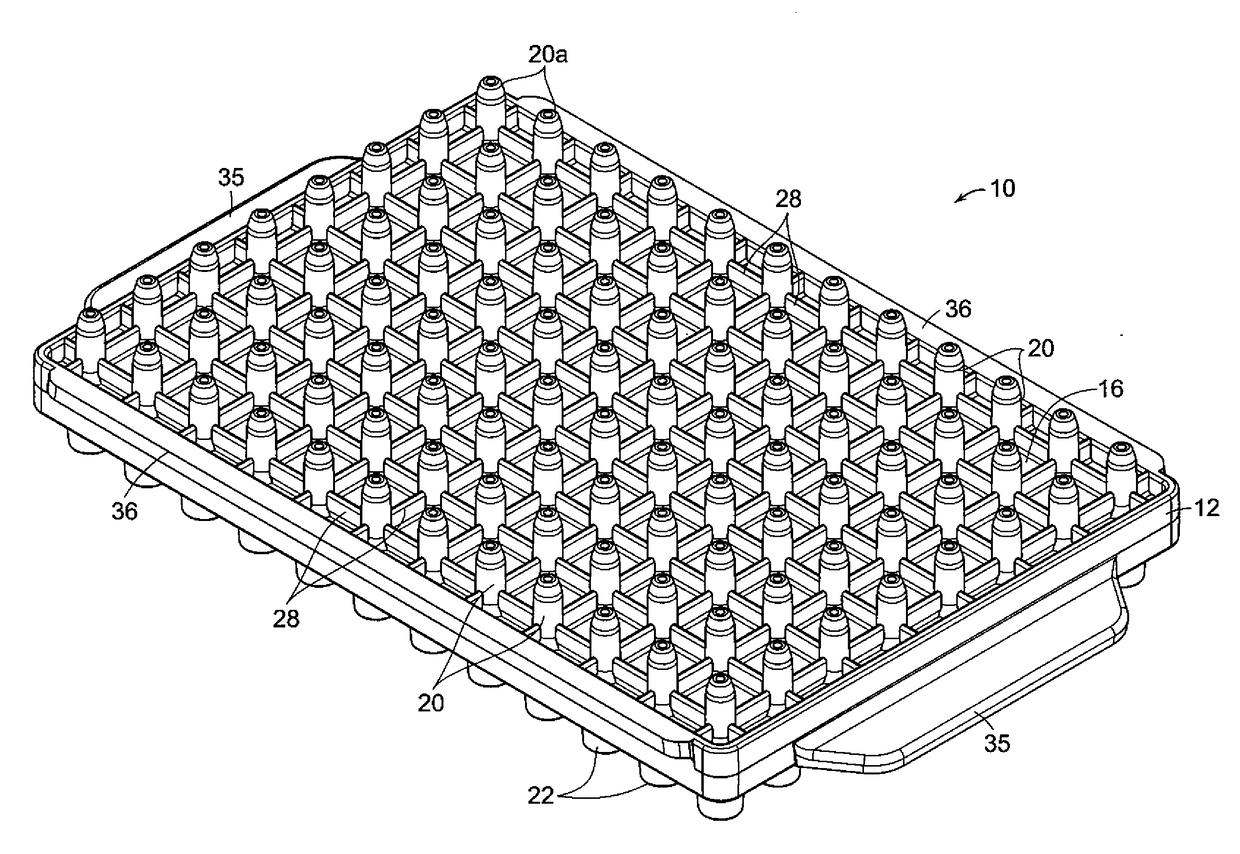

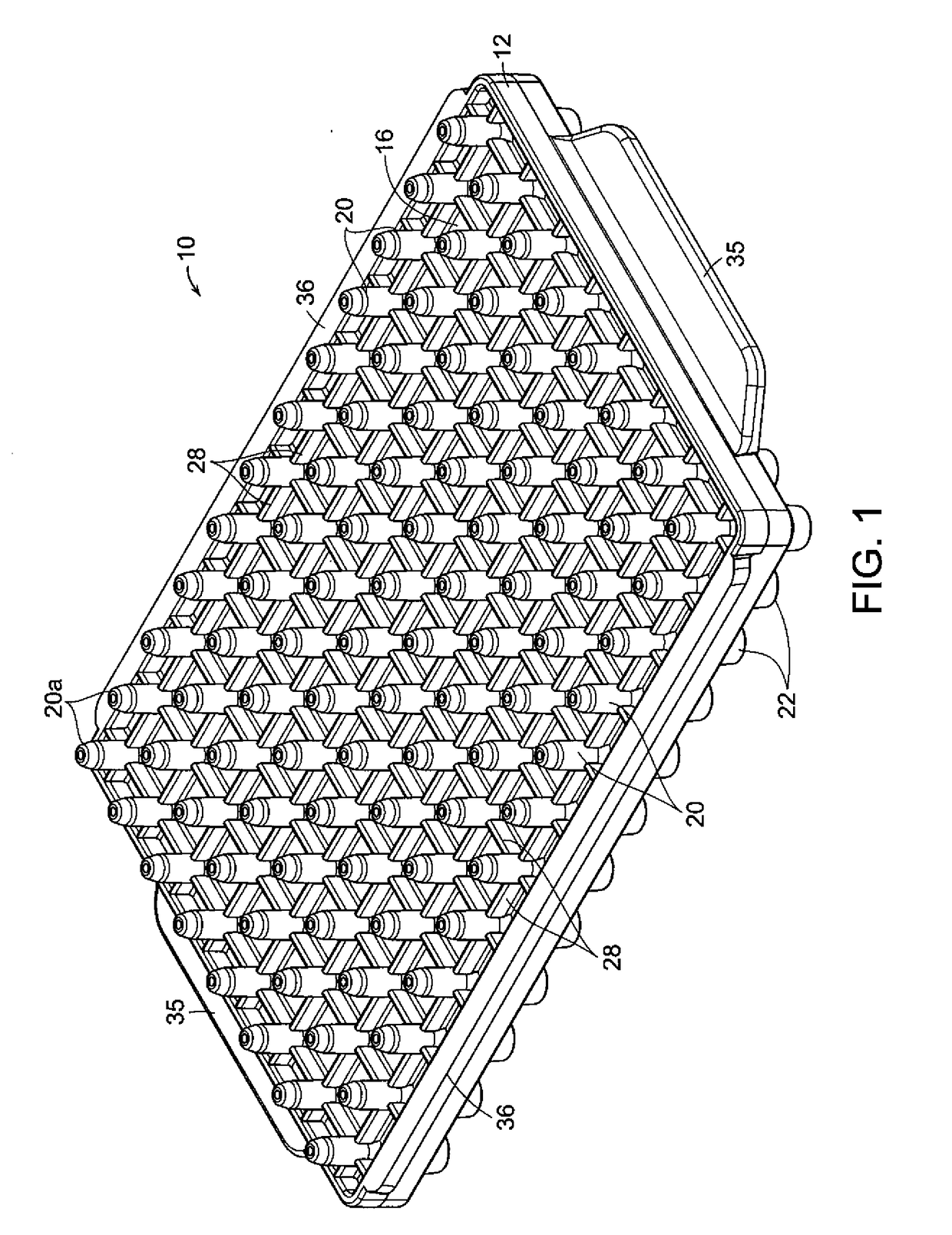

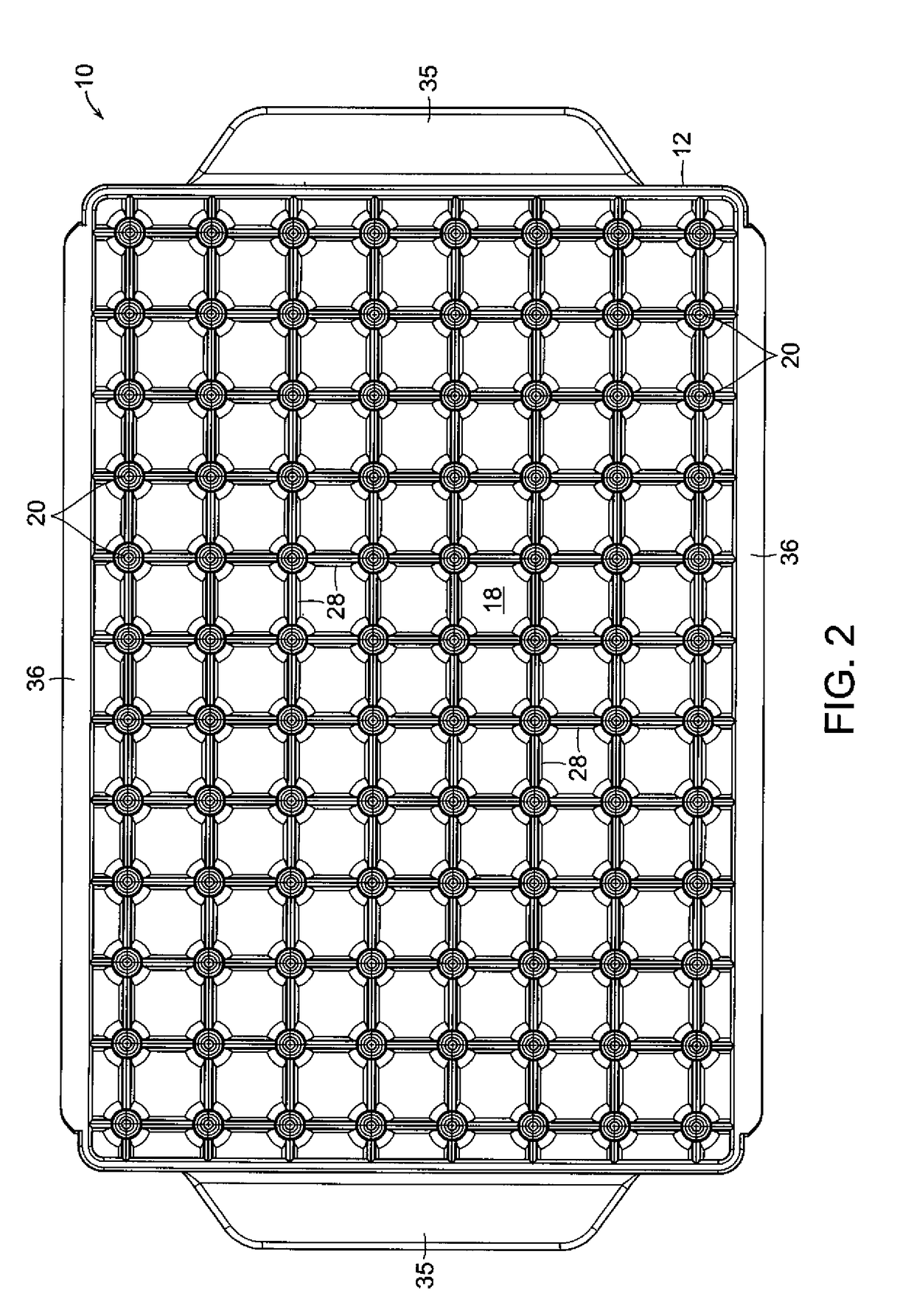

[0024]With reference initially to FIGS. 1- 6, a pipettor tip adapter in accordance with an exemplary embodiment of the present invention is generally indicated at 10. The pipette tip adapter comprises a planar base 12 with an array of openings 14 extending between bottom and top surface 16, 18 of the base.

[0025]Sealing tubes indicated typically at 20 project upwardly from the top surface 16, and tip mounting tubes indicated typically at 22 project downwardly from the bottom surface 18. Pairs of sealing tubes 20 and mounting tubes 22 are arranges coaxially and in communication with respective ones of the openings 14 in the base 12.

[0026]The sealing tubes 20 and tip mounting tubes 22 may be arranged in an array of rows and columns. The spacing of the rows and columns matches the commonly available tip spacing of both multichannel pipettors and associated racks found in the marketplace. These in turn match the well positions of commonly available microtiter plates. Nine and four and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com