Patents

Literature

36results about How to "Increase jacking force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

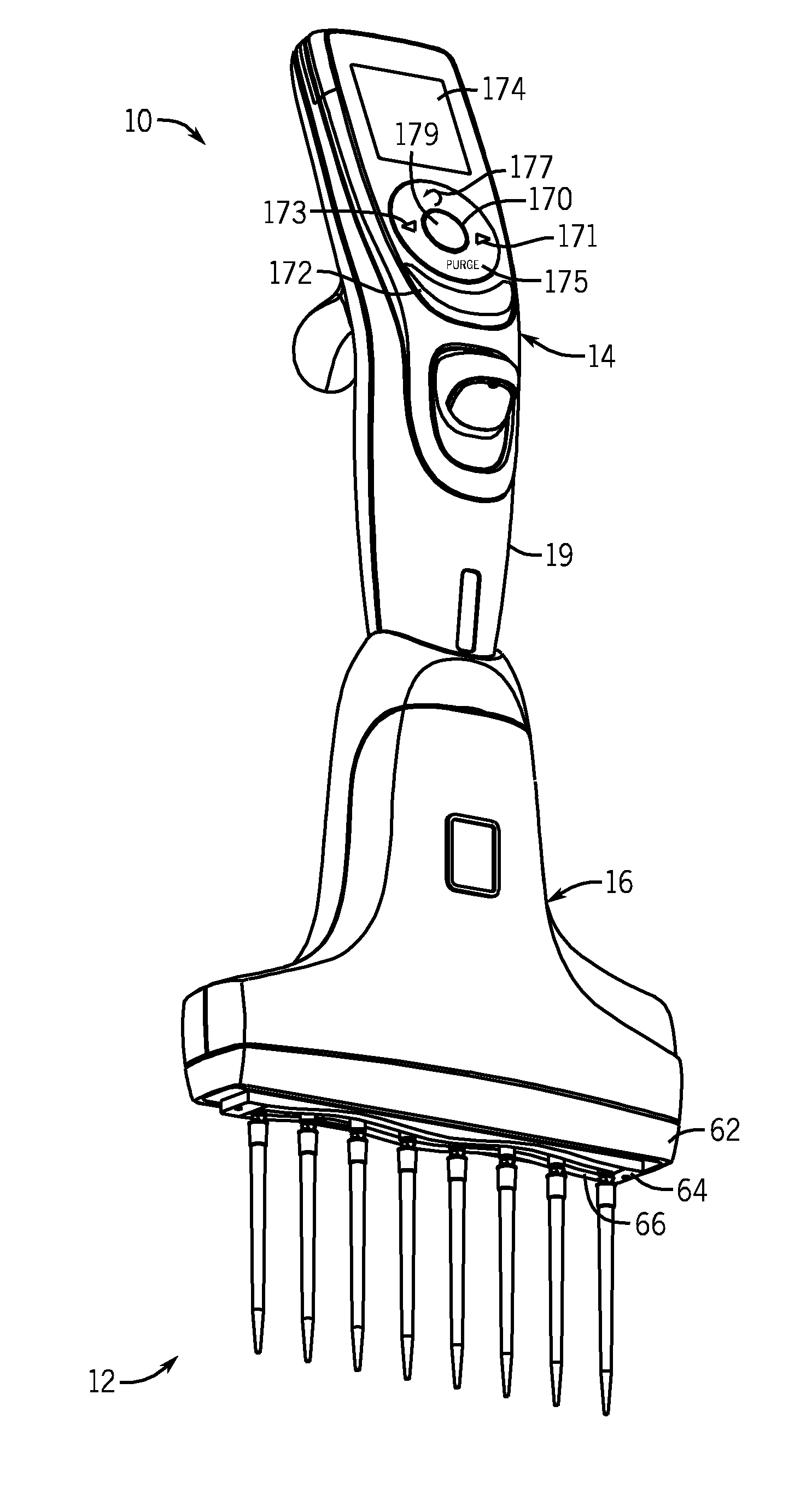

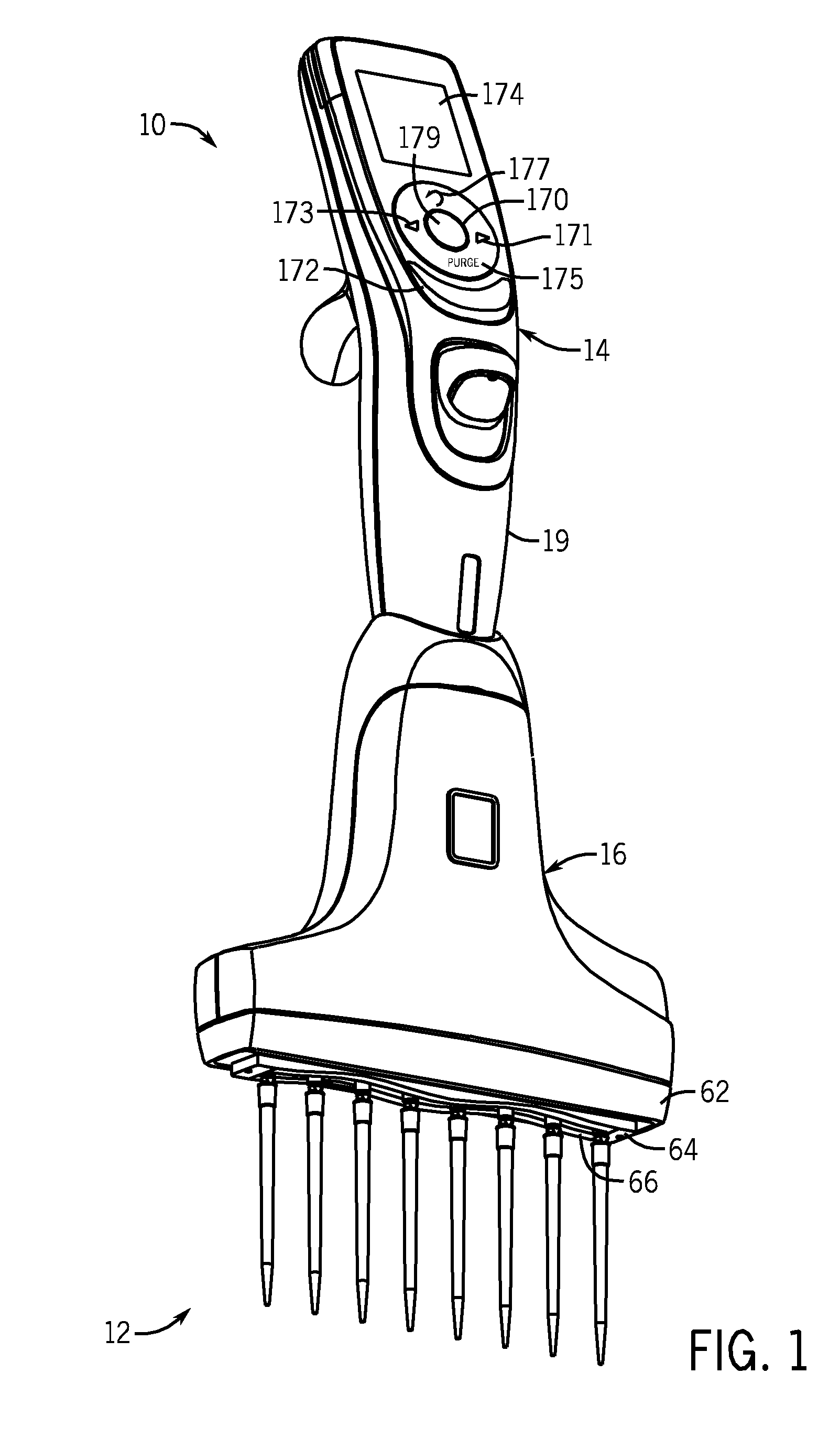

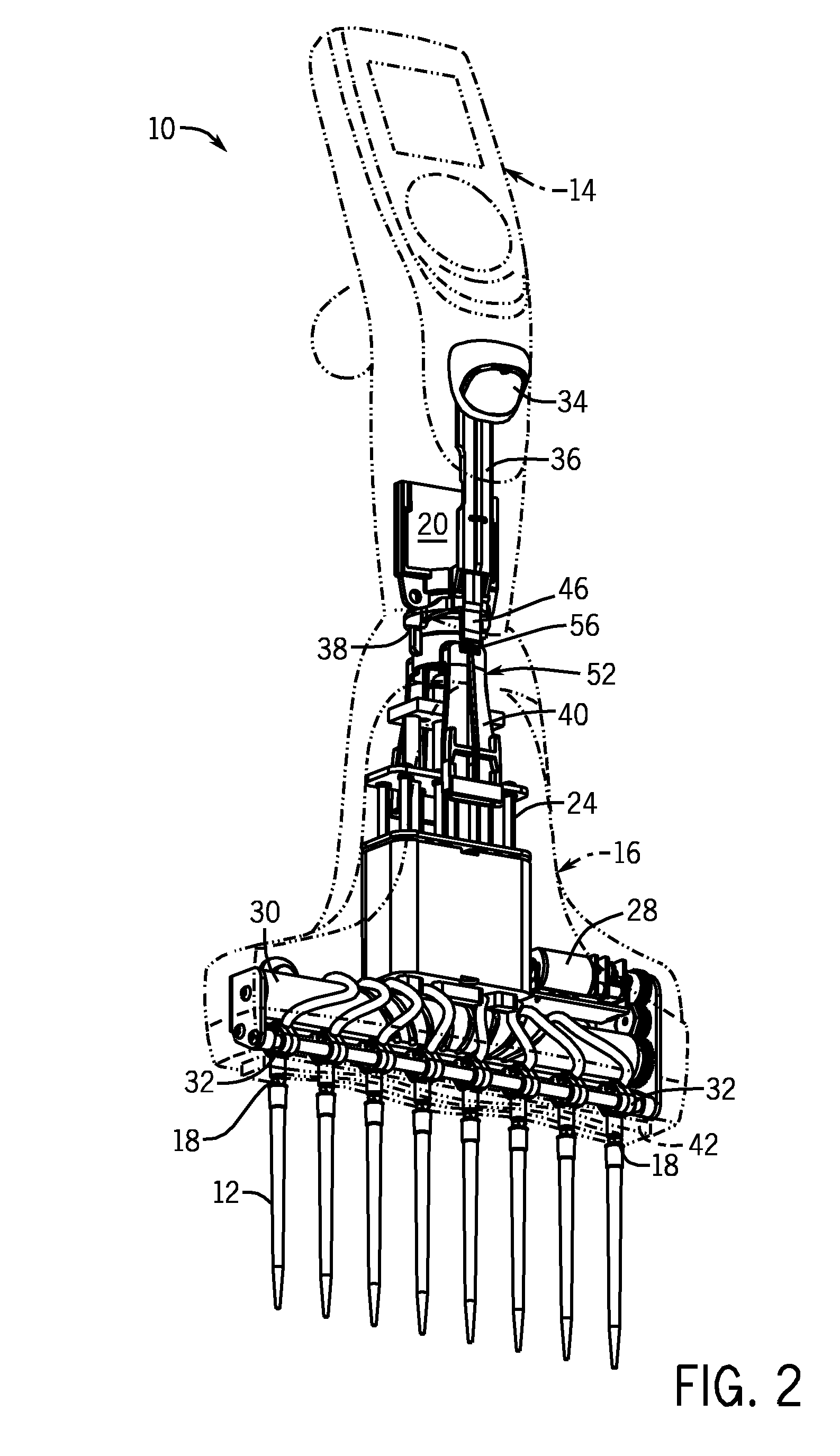

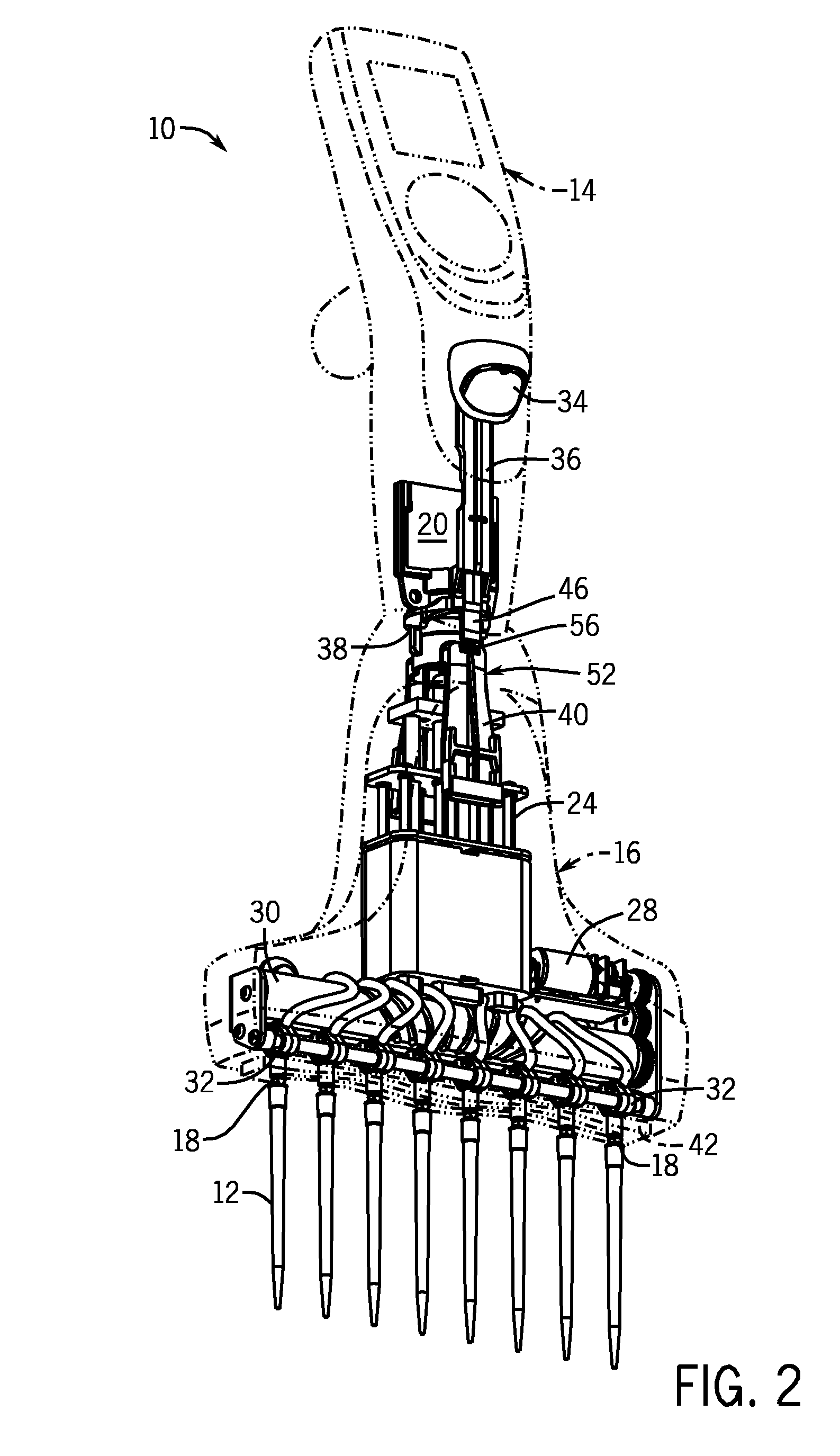

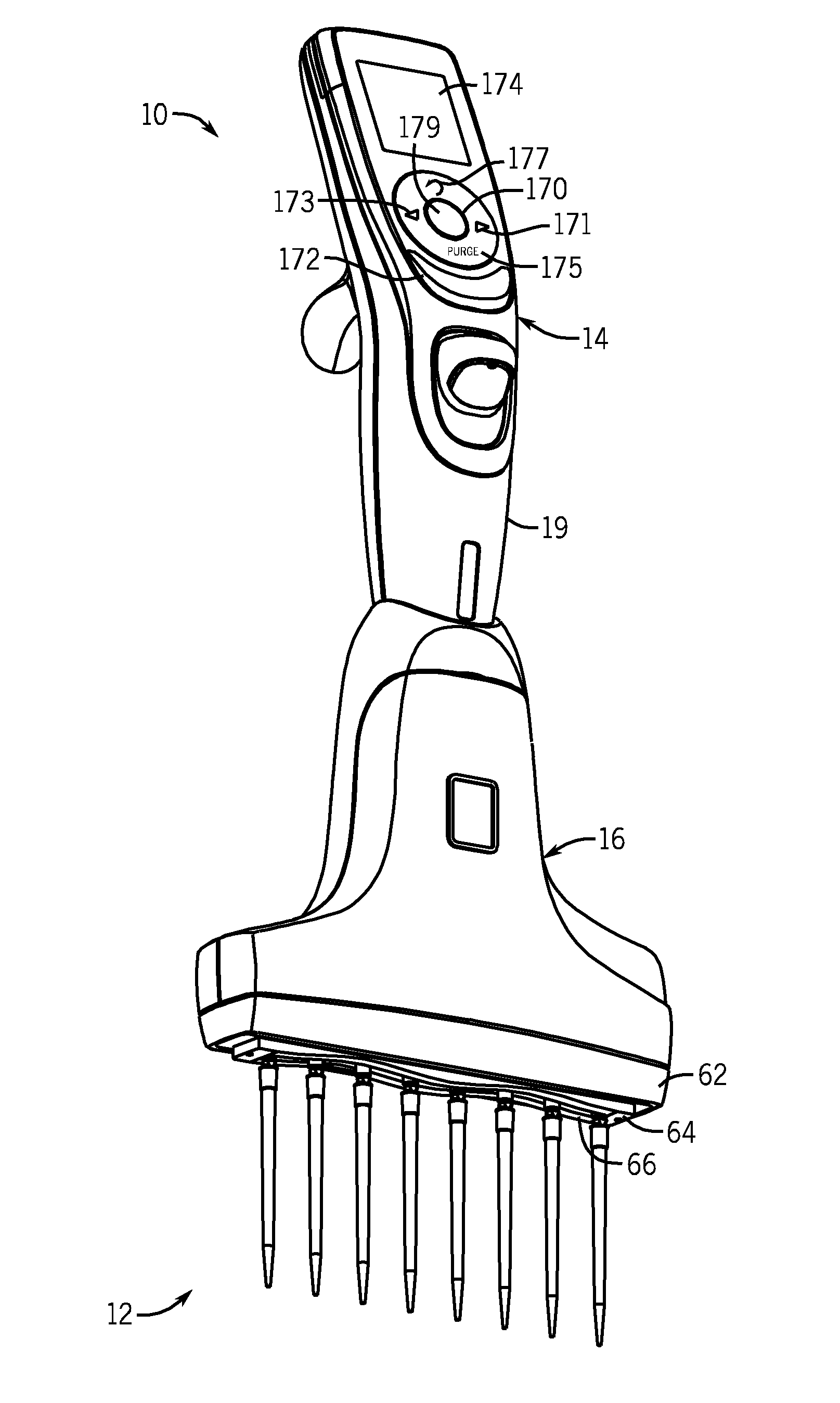

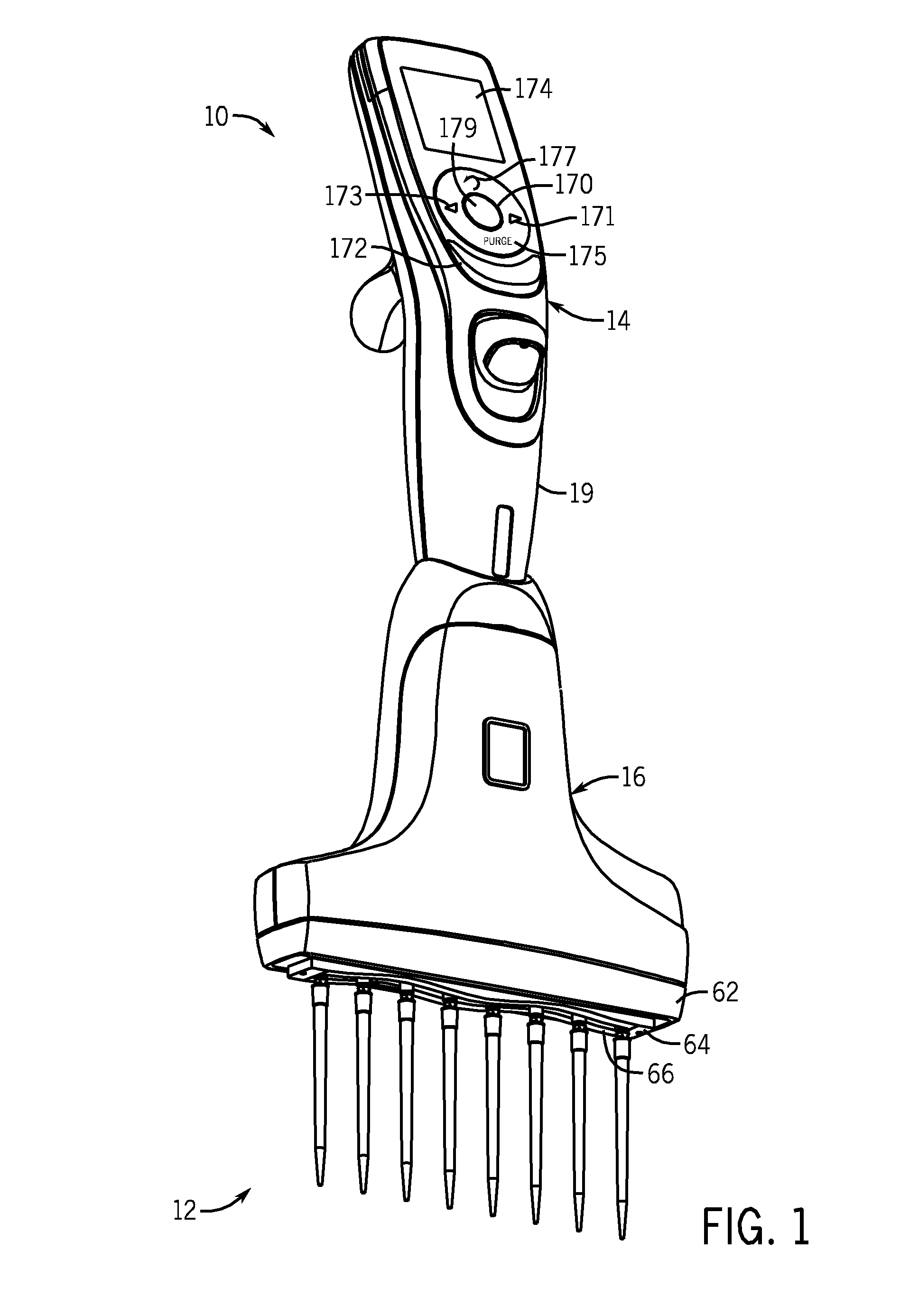

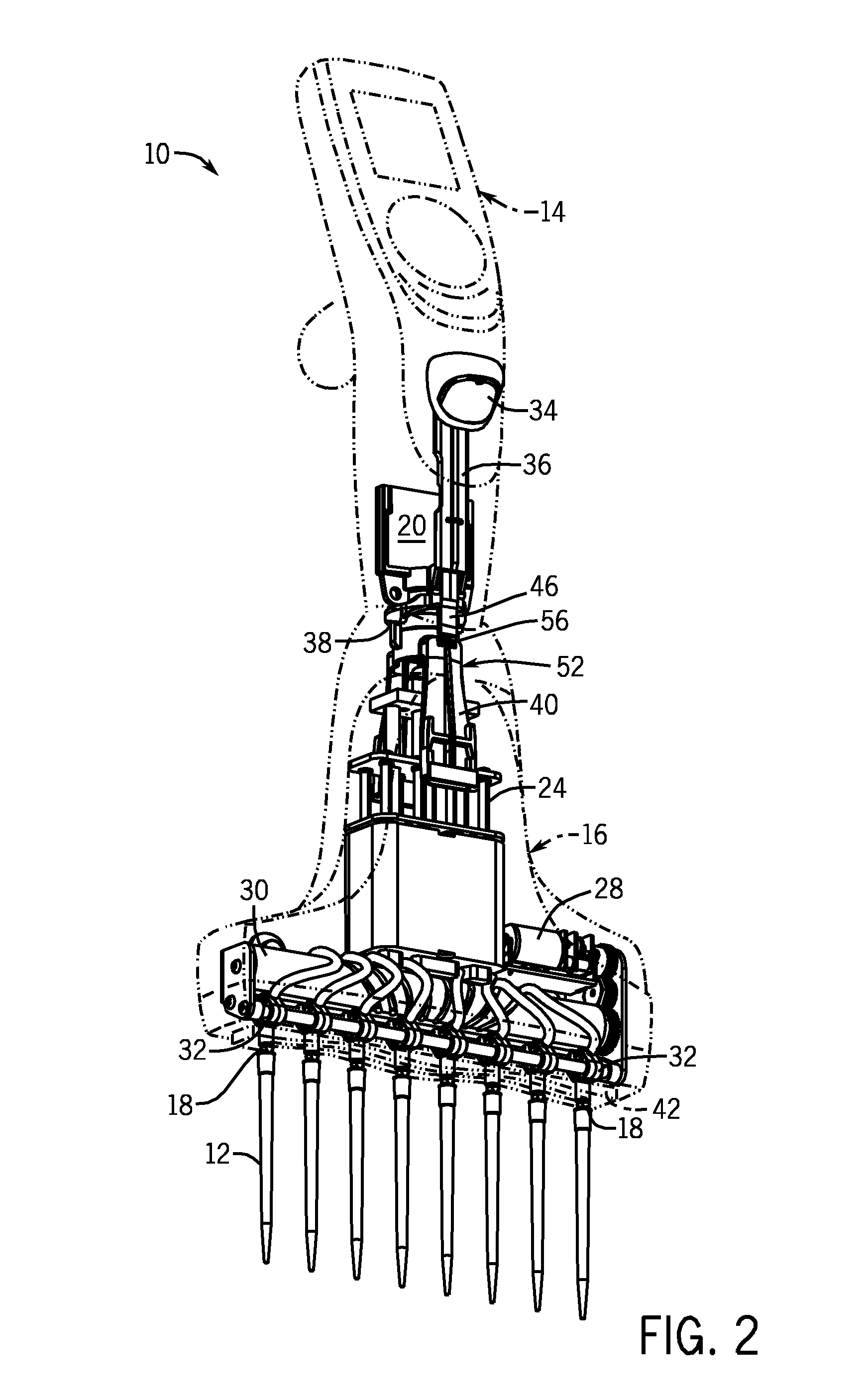

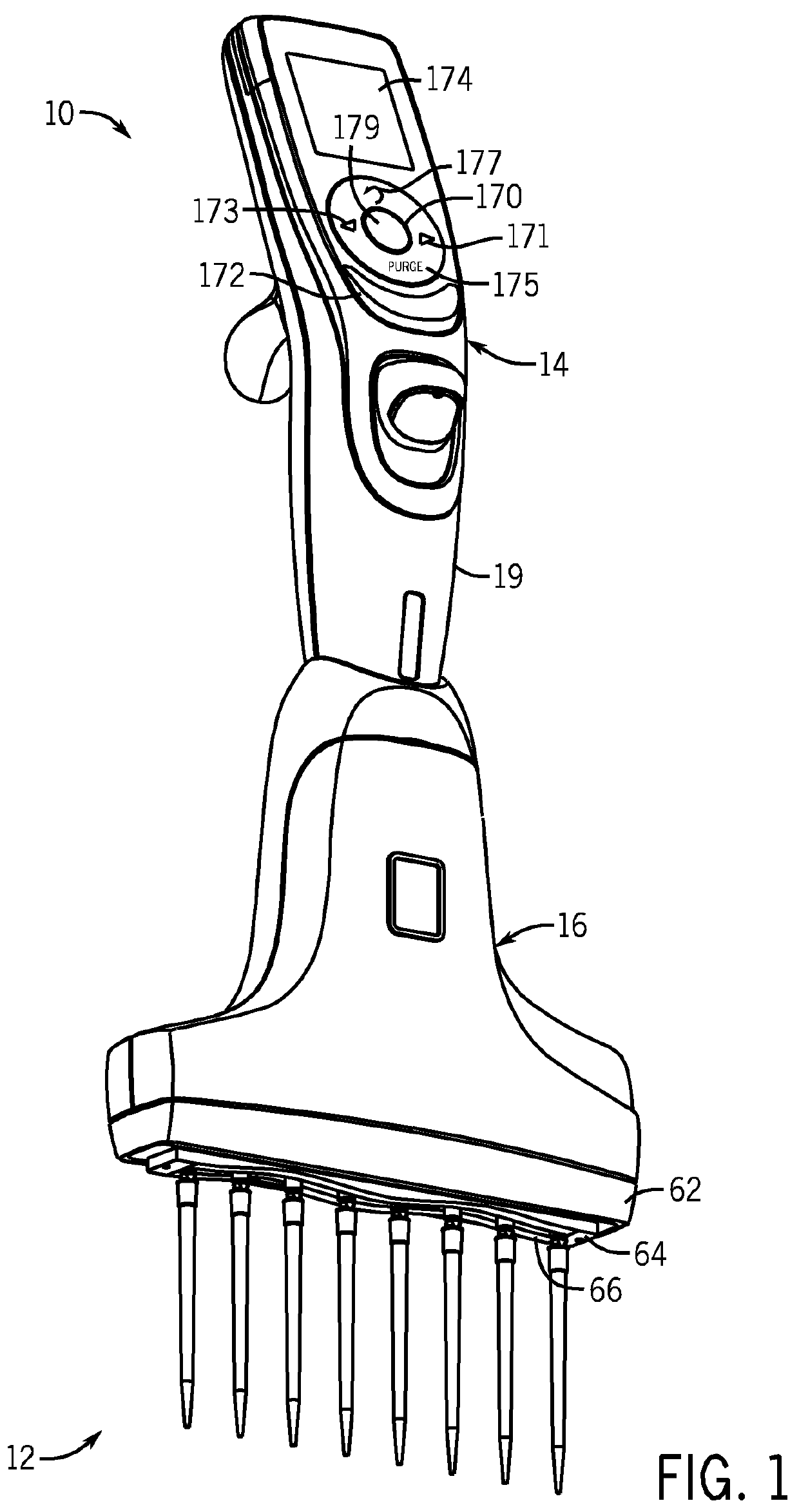

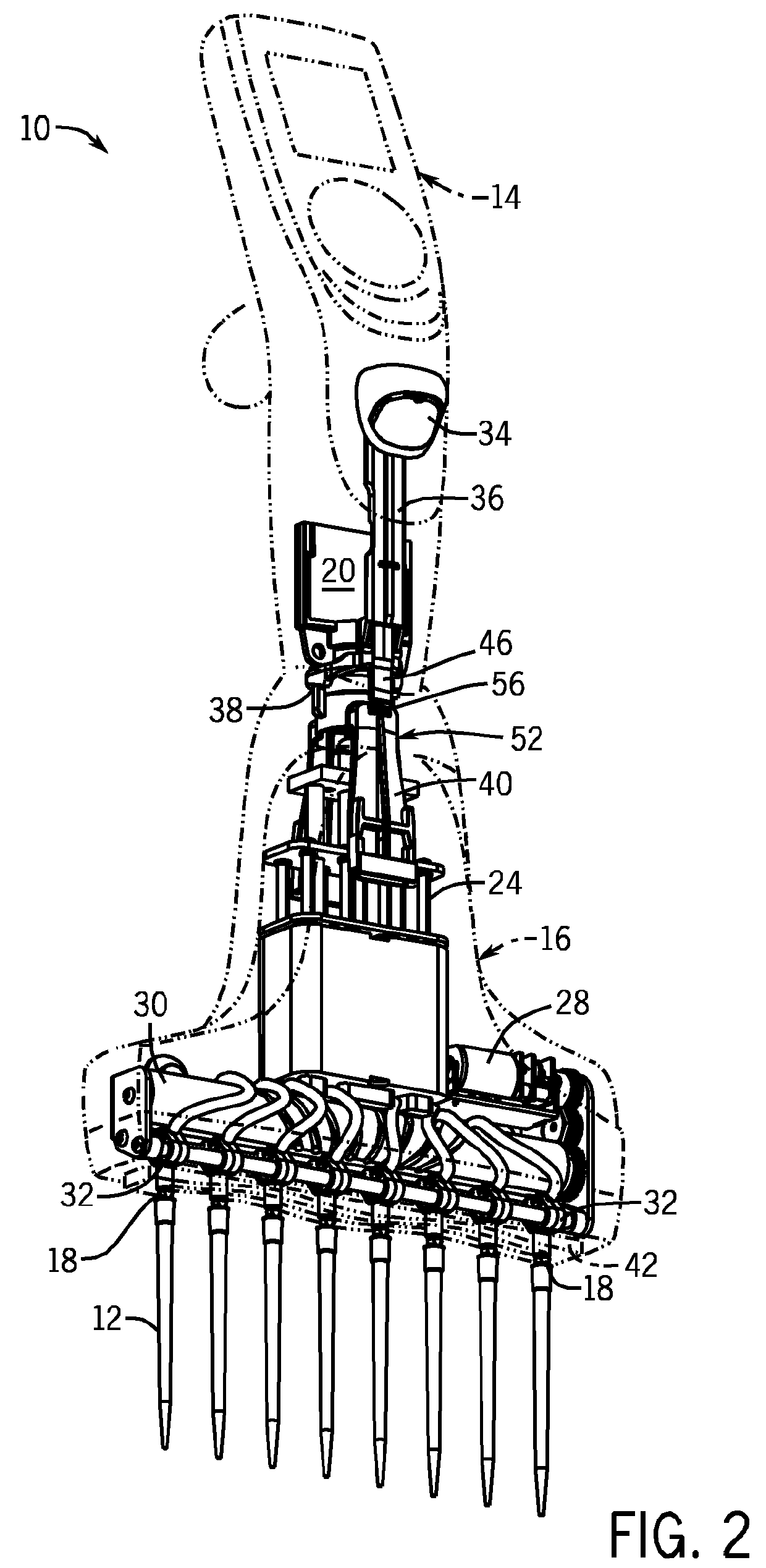

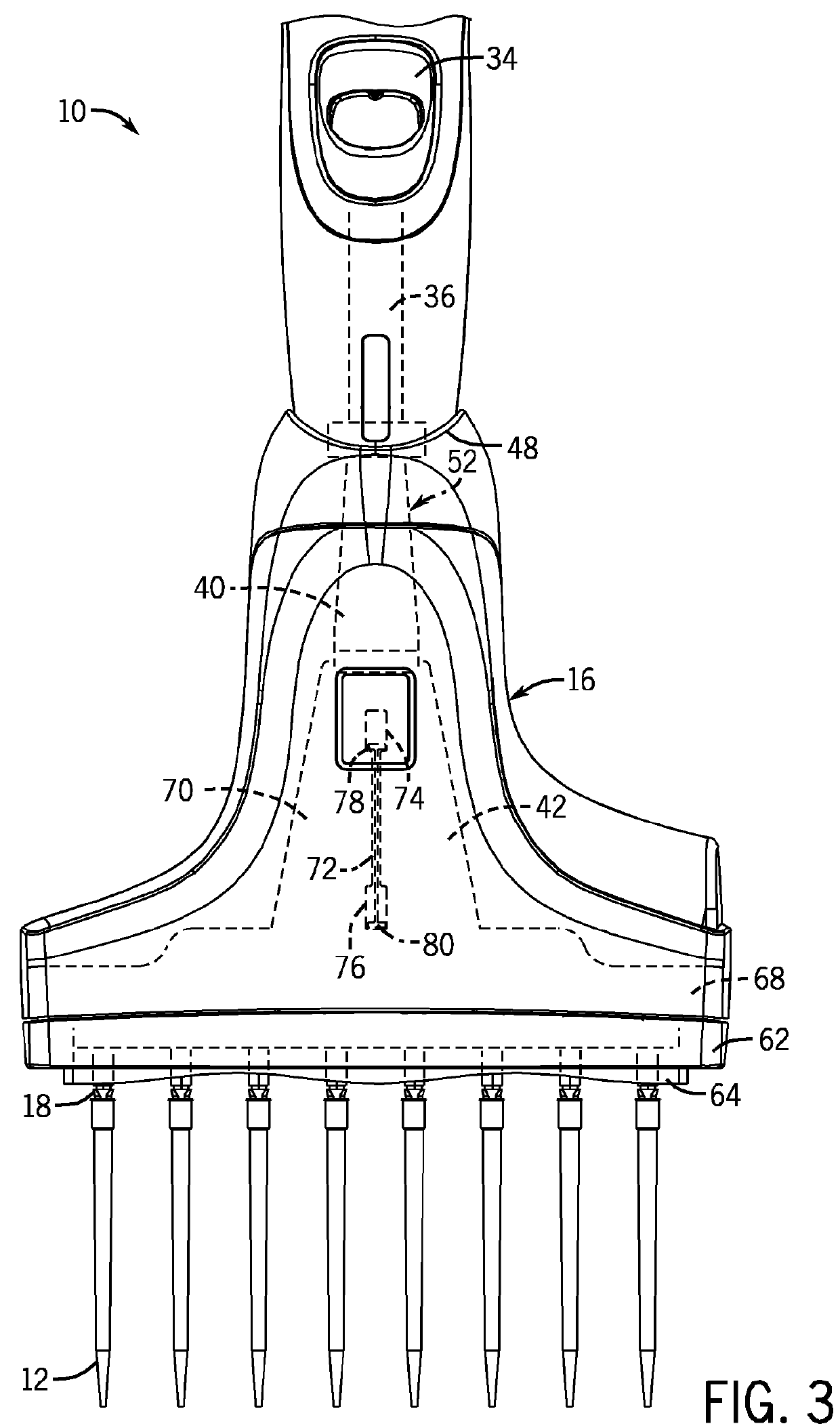

Multi-channel pipettor with repositionable tips

ActiveUS20090274587A1Facilitate effectiveFacilitate ergonomic tip ejectionAnalysis using chemical indicatorsWithdrawing sample devicesMotor drivePipette

A hand-held, multi-channel pipettor has an electronically controlled motor to reposition pipette tips for different center to center spacing. Each repositionable tip fitting assembly has a cam following pin that is driven by cam tracks in a motor driven roller drum. Stationary ports for the multiple aspiration cylinders are strategically placed to simplify management of flexible tubes leading to the repositionable pipette tip fitting assemblies. The pipettor has a user interface that can be operated conveniently by one hand to reposition pipette tips. It has a pipette tip ejection mechanism with a sinusoidal stripper bar.

Owner:INTEGRA BIOSCI CORP

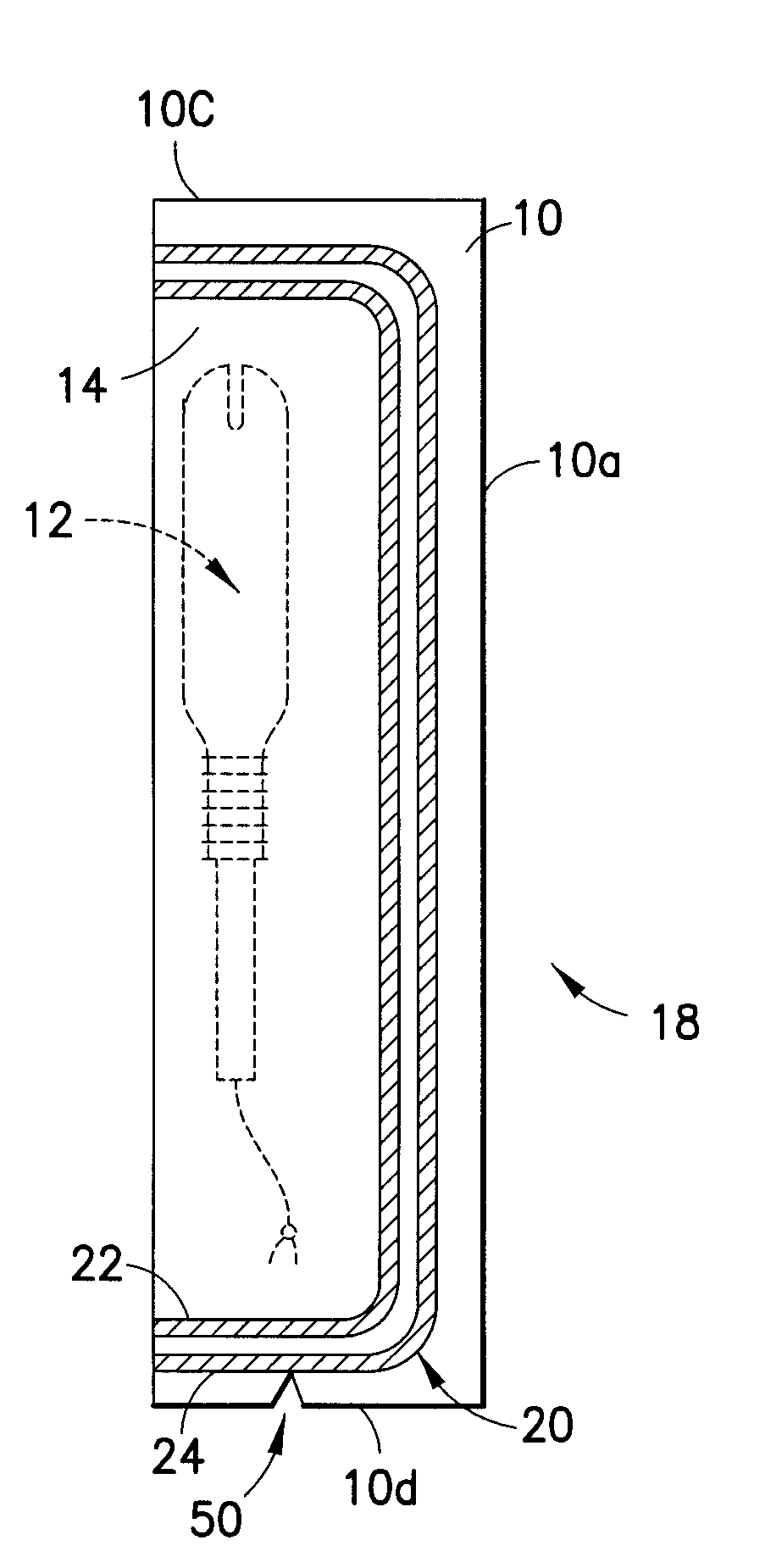

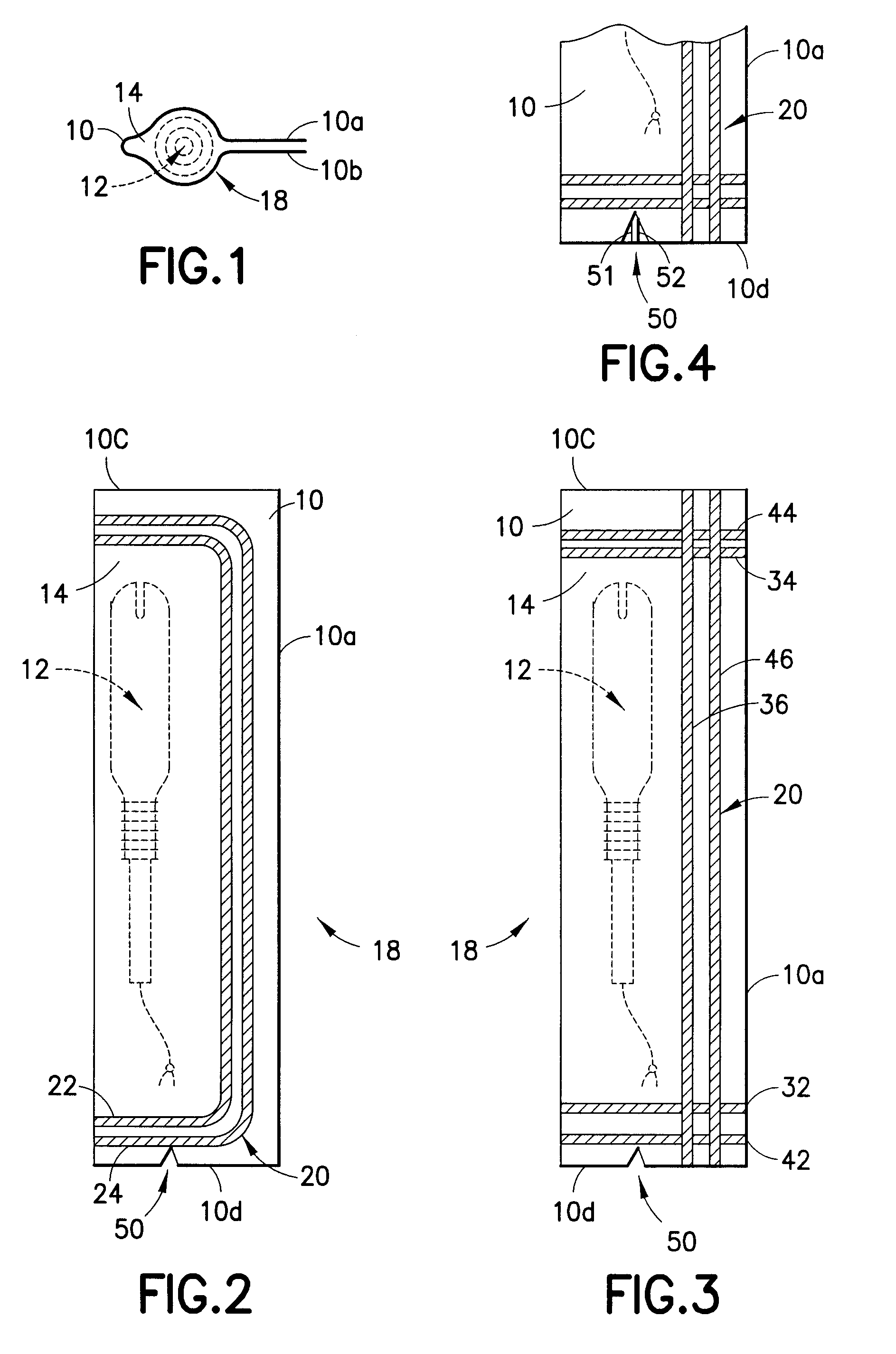

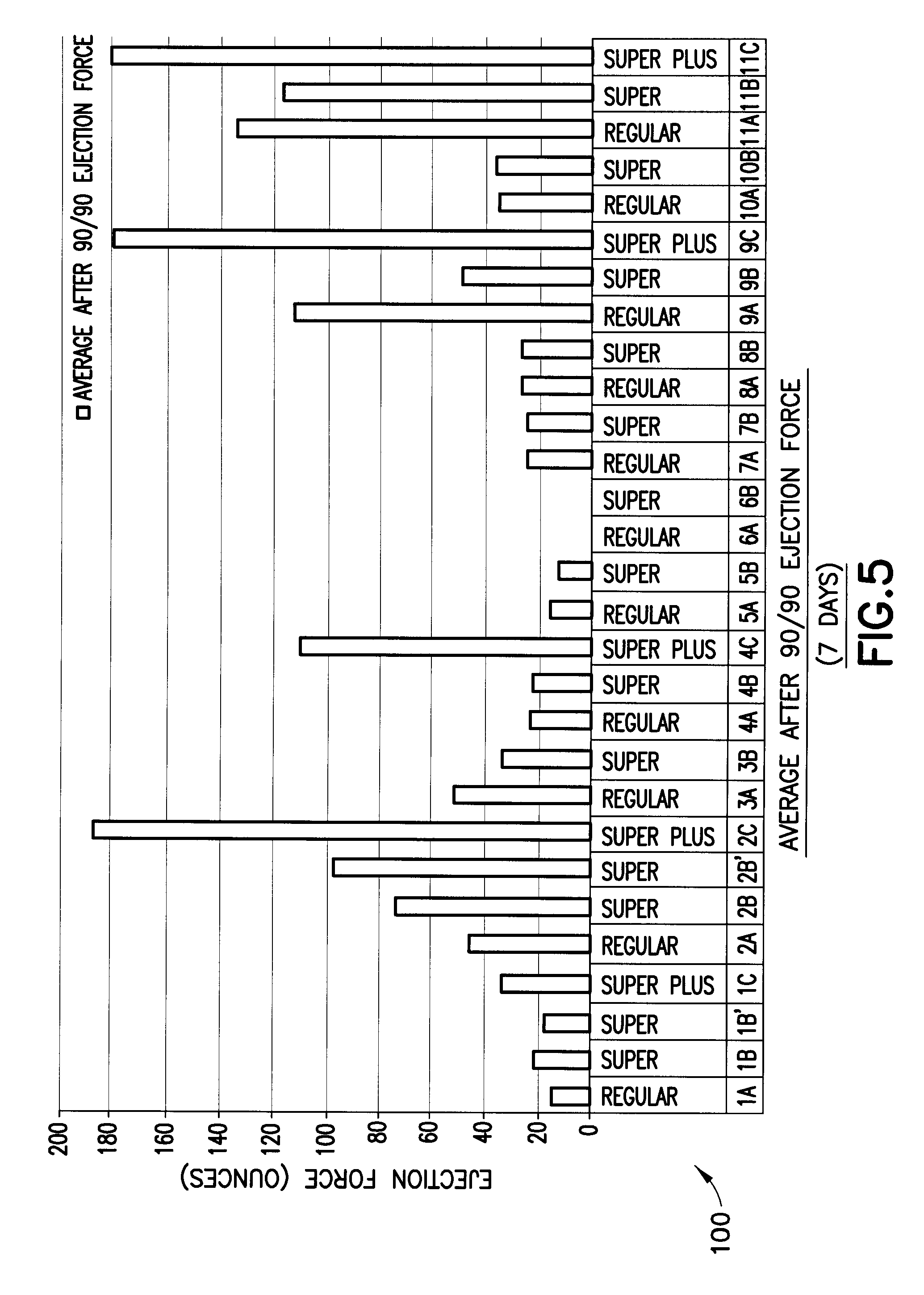

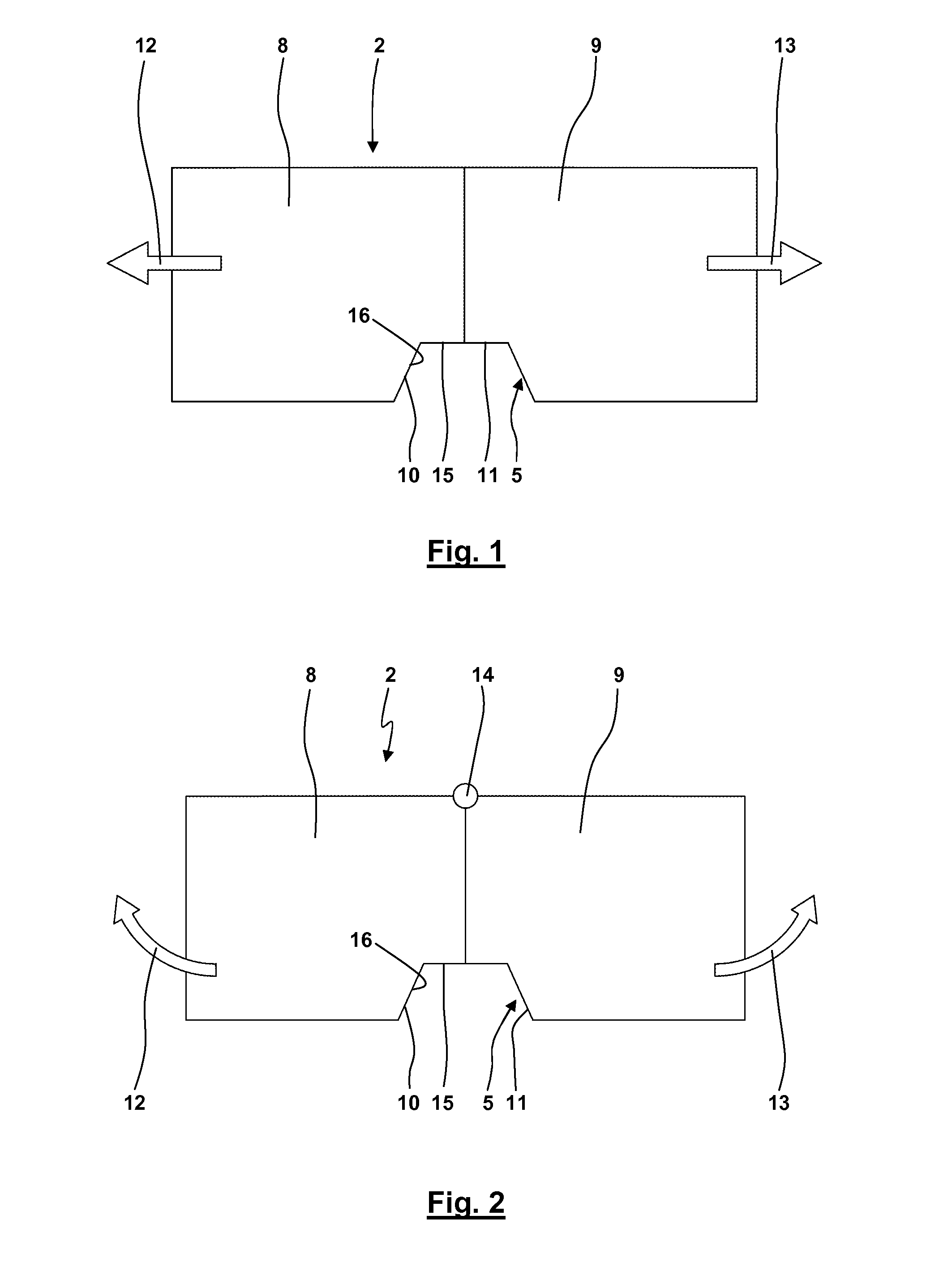

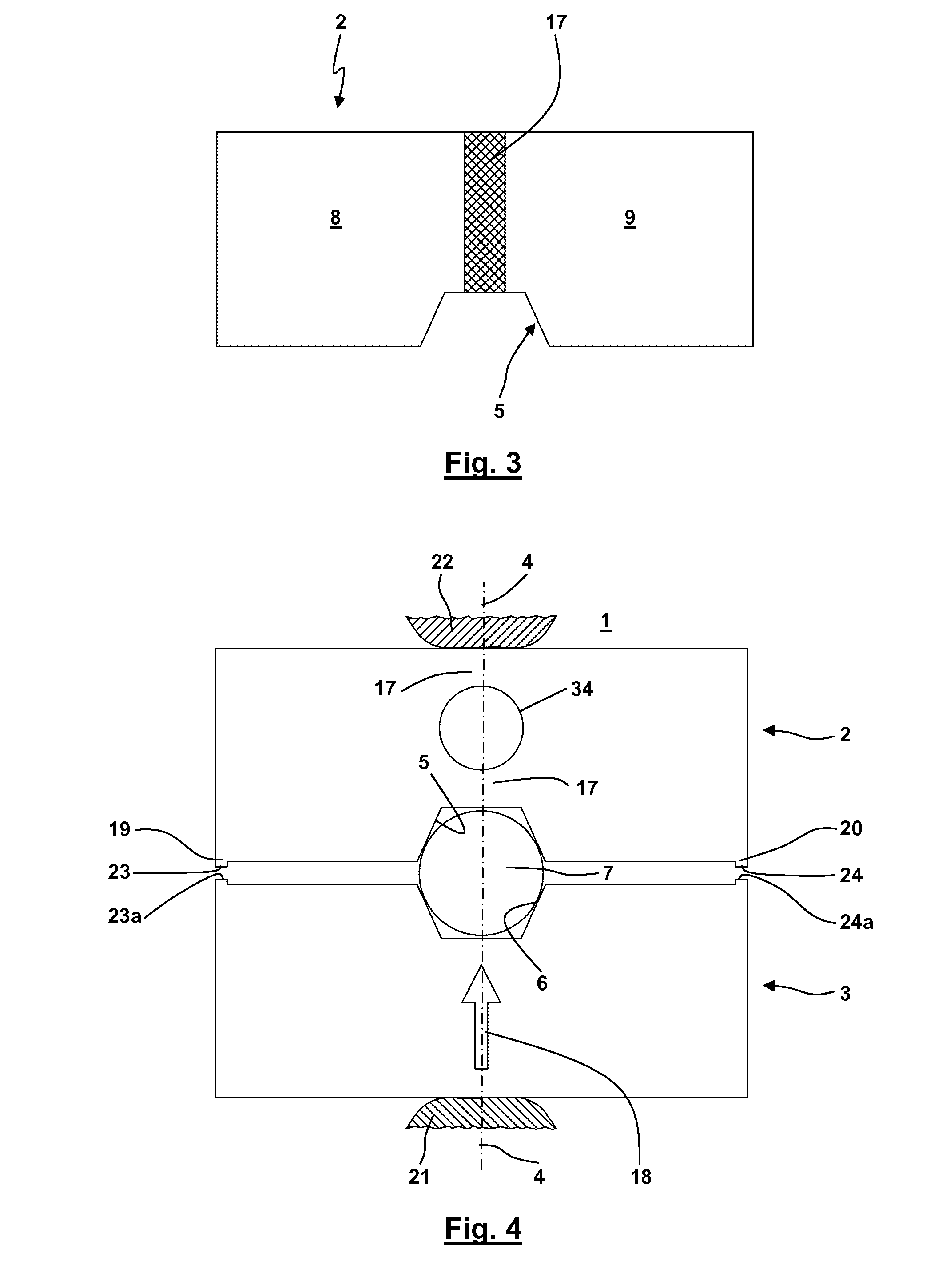

Tampon package and method for making the same

InactiveUS20090247981A1Increase jacking forceStable designDiagnosticsSurgical needlesPolyethylene terephthalatePolyolefin

A tampon package includes a tampon assembly sealed within packaging material. The packaging material is continuously sealed about its perimeter to form an internal air-tight chamber for retaining the tampon assembly therein. The tampon package includes a tampon pledget disposed within an applicator barrel. In one embodiment, the packaging material is made from a water-barrier material. The water-barrier material may be a laminate of polyolefin or polyethylene terephthalate and an ethylene vinyl acetate material.

Owner:EVEREADY BATTERY CO INC

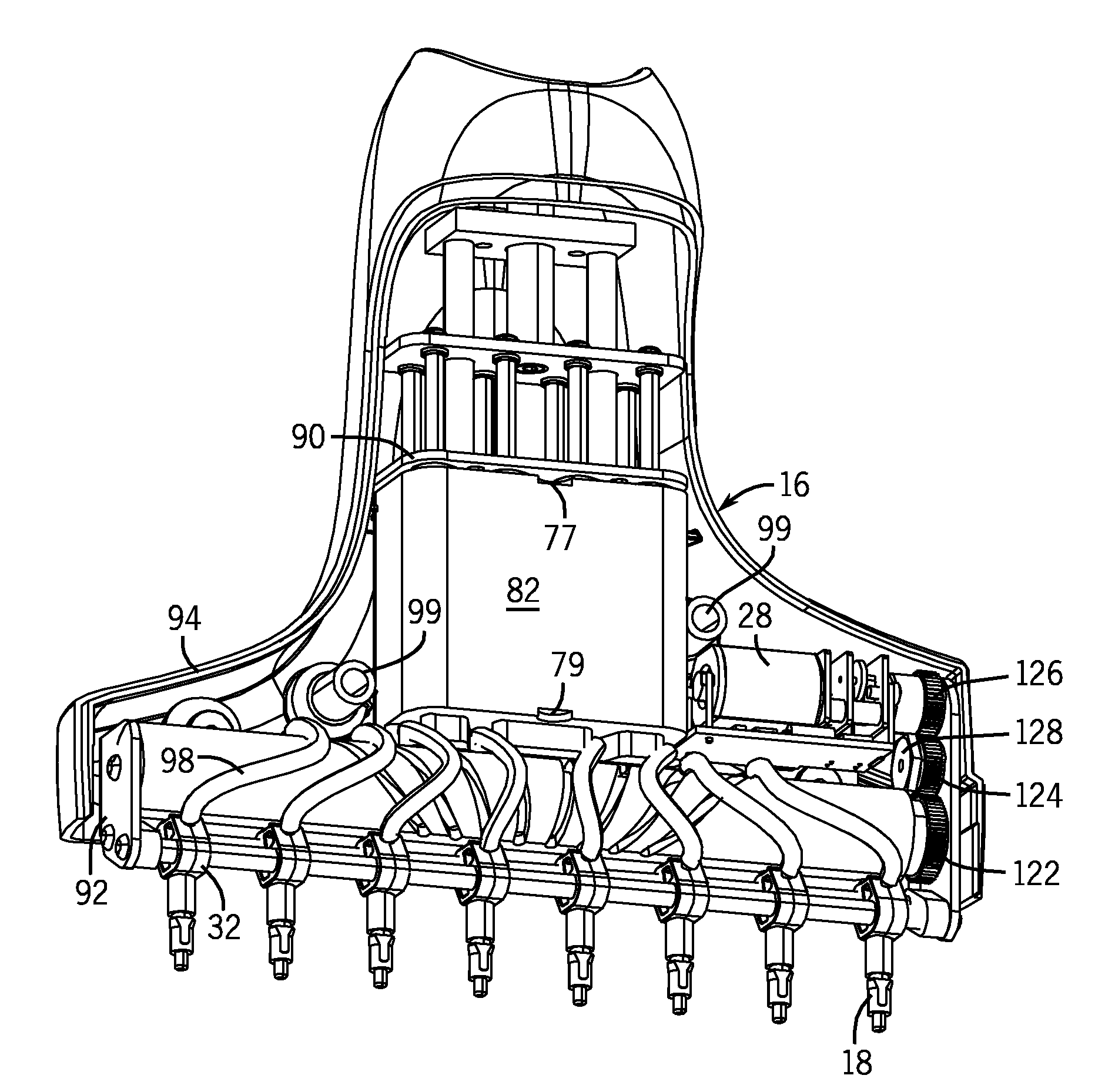

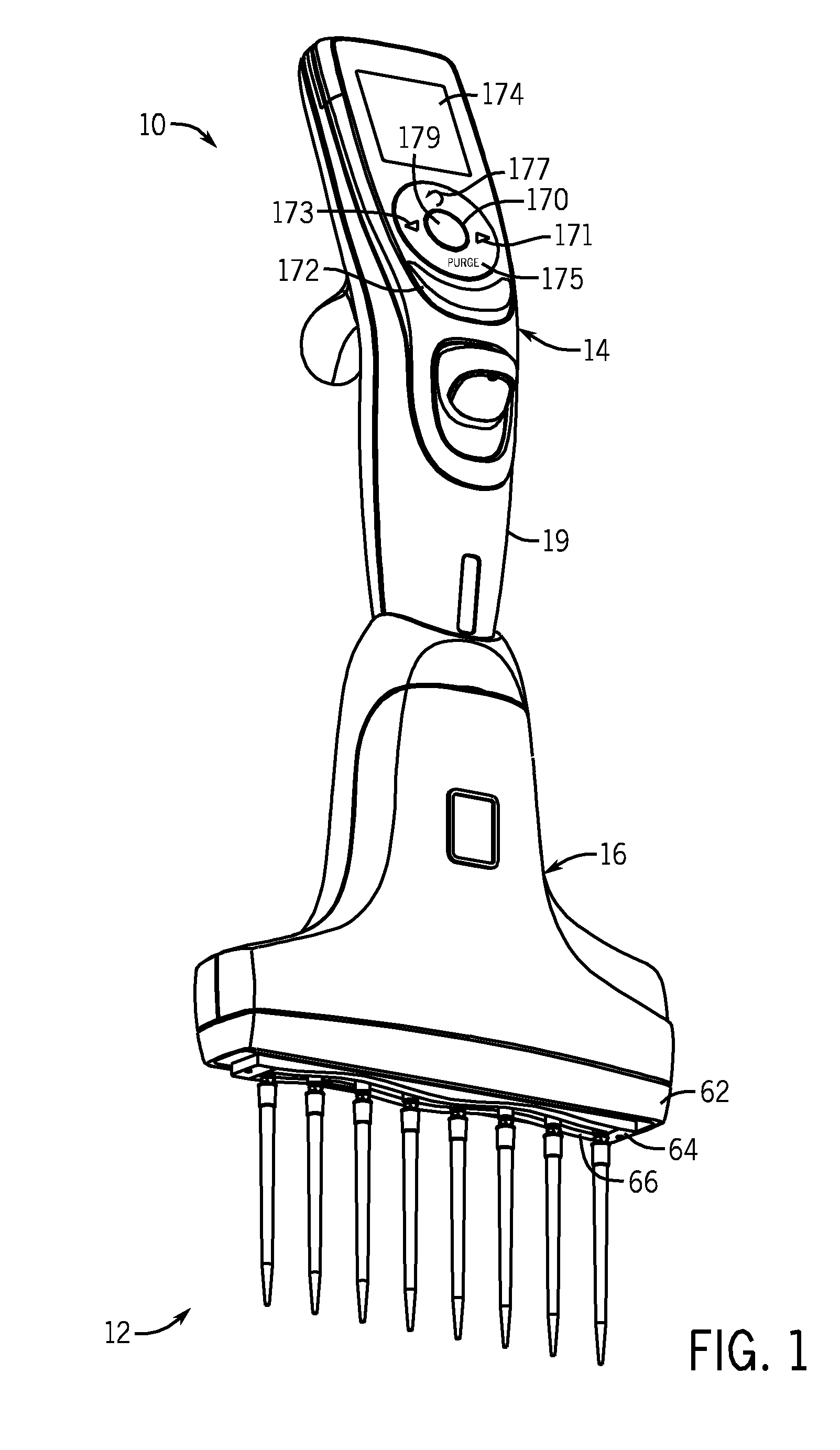

Multi-channel pipettor with repositionable tips

ActiveUS8029742B2Efficient ejectionIncrease jacking forceAnalysis using chemical indicatorsWithdrawing sample devicesMotor drivePipette

A hand-held, multi-channel pipettor has an electronically controlled motor to reposition pipette tips for different center to center spacing. Each repositionable tip fitting assembly has a cam following pin that is driven by cam tracks in a motor driven roller drum. Stationary ports for the multiple aspiration cylinders are strategically placed to simplify management of flexible tubes leading to the repositionable pipette tip fitting assemblies. The pipettor has a user interface that can be operated conveniently by one hand to reposition pipette tips. It has a pipette tip ejection mechanism with a sinusoidal stripper bar.

Owner:INTEGRA BIOSCI CORP

Multi-Channel Pipettor with Repositionable Tips

ActiveUS20150030513A1Facilitate effectiveFacilitate ergonomic tip ejectionBurettes/pipettesMotor drivePipette

A hand-held, multi-channel pipettor has an electronically controlled motor to reposition pipette tips for different center to center spacing. Each repositionable tip fitting assembly has a cam following pin that is driven by cam tracks in a motor driven roller drum. Stationary ports for the multiple aspiration cylinders are strategically placed to simplify management of flexible tubes leading to the repositionable pipette tip fitting assemblies. The pipettor has a user interface that can be operated conveniently by one hand to reposition pipette tips. It has a pipette tip ejection mechanism with a sinusoidal stripper bar.

Owner:INTEGRA BIOSCI CORP

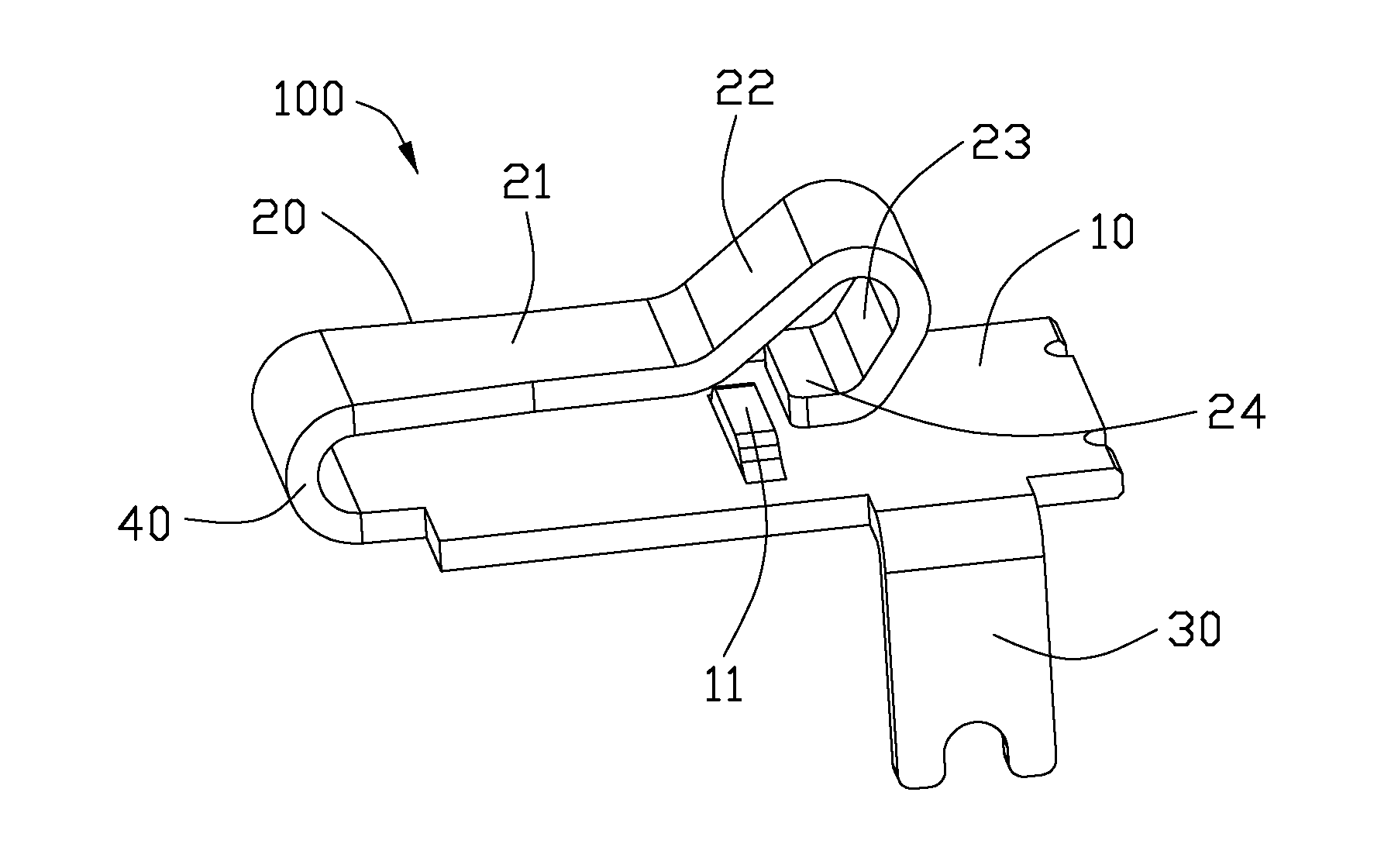

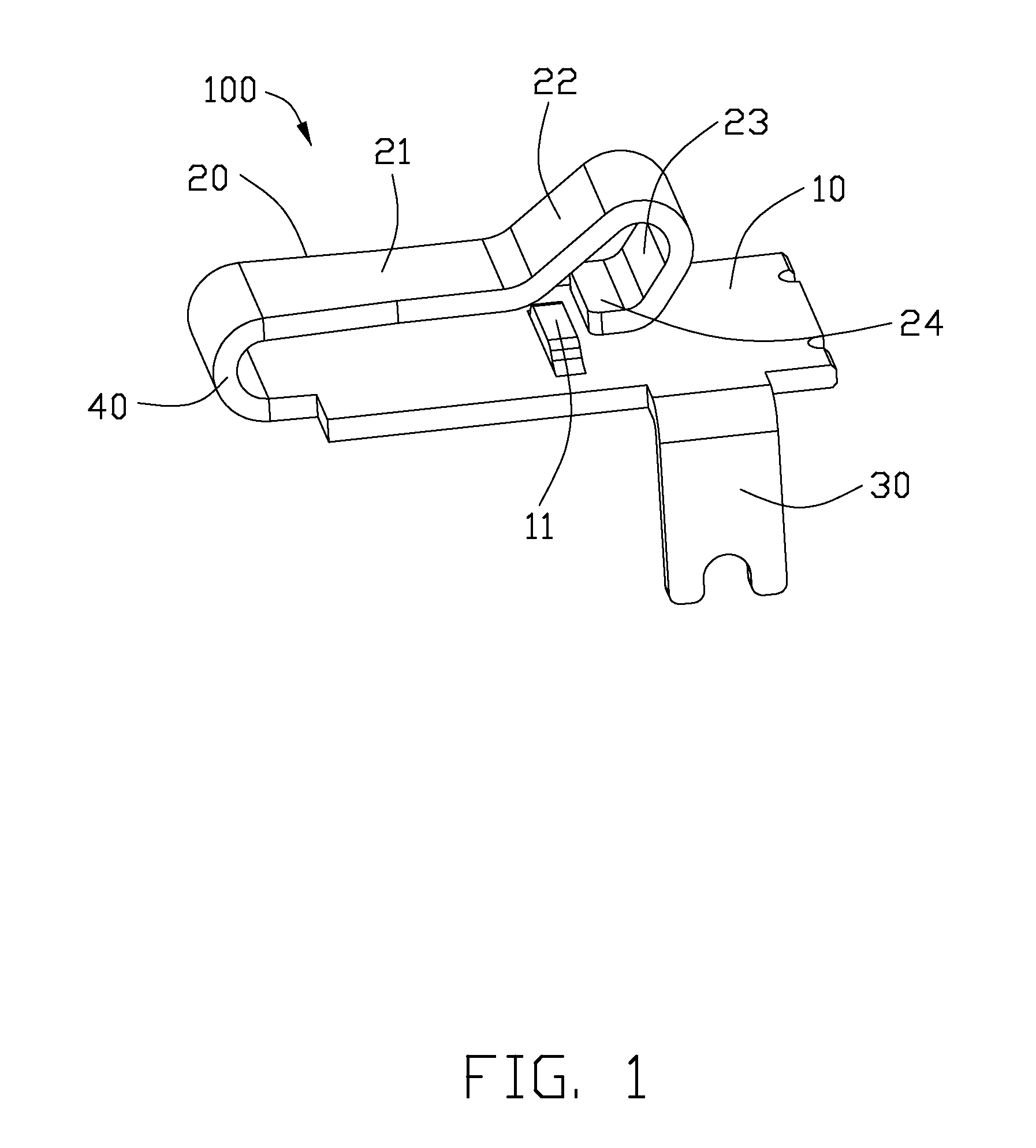

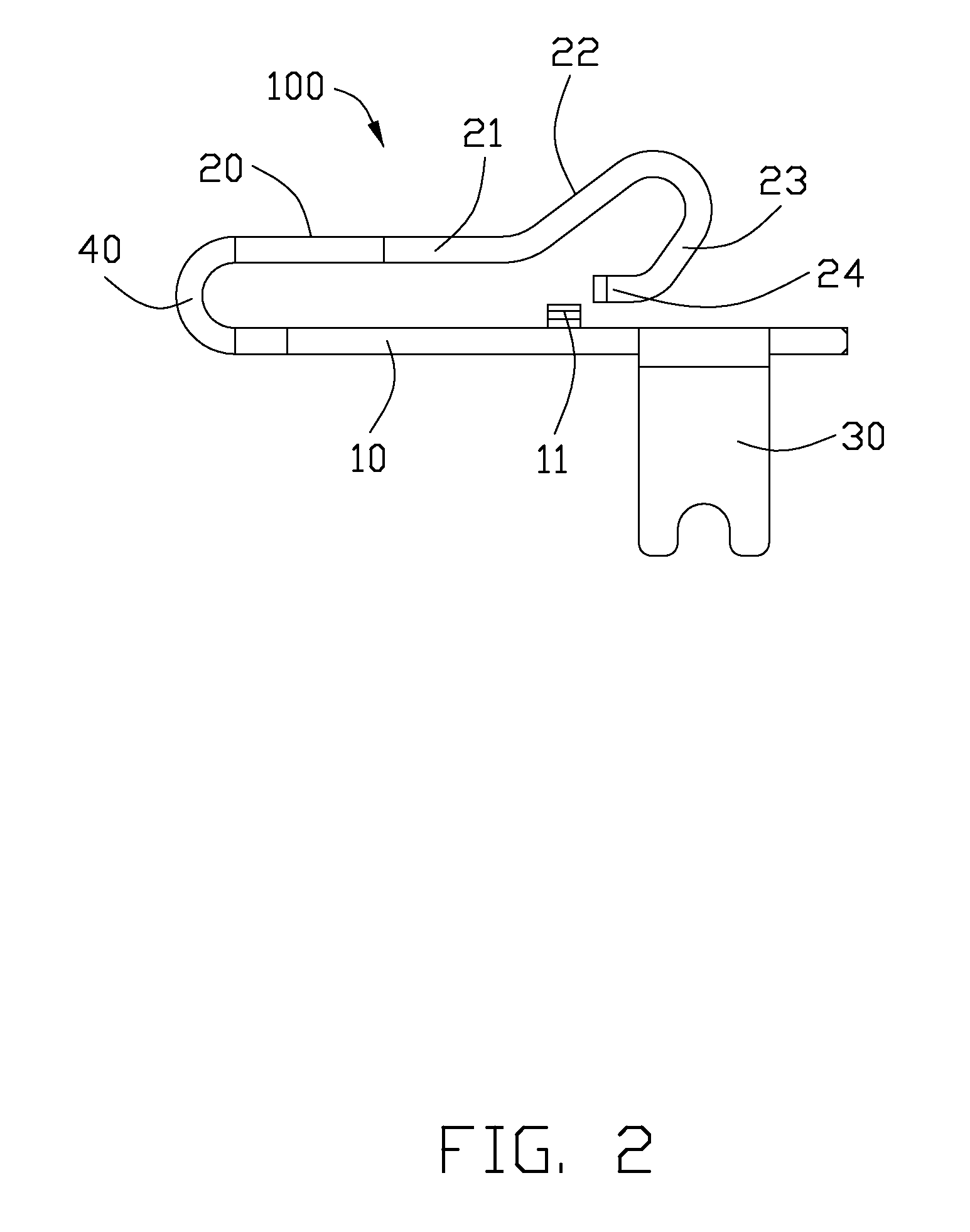

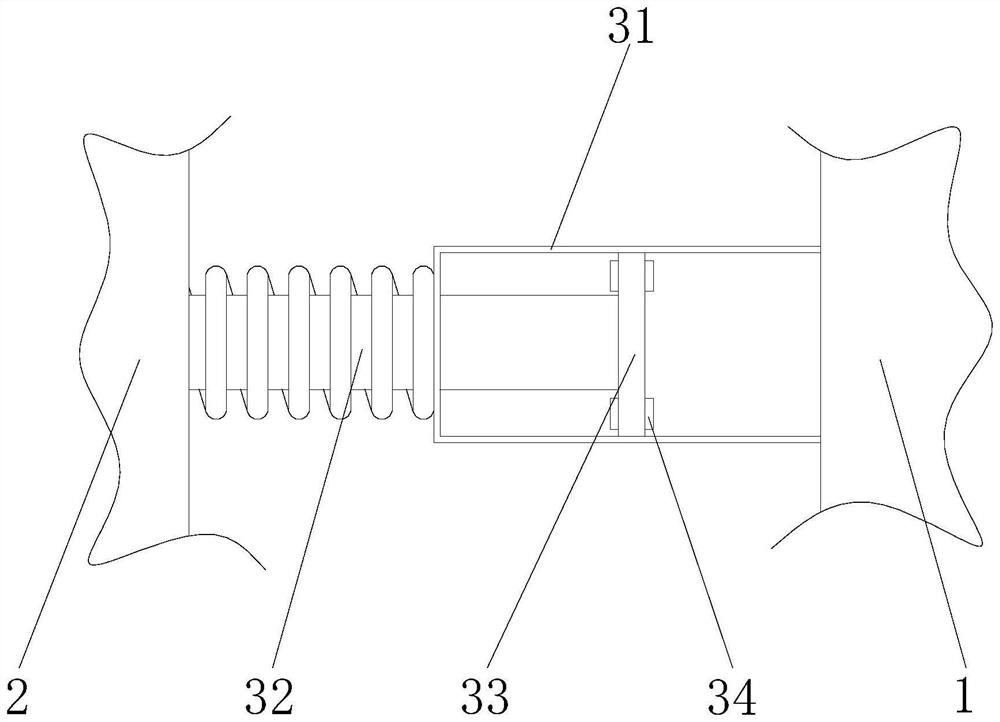

Audio jack connector having low insertion force and high ejection force

InactiveUS8801476B2Lower insertion forceIncrease jacking forceCoupling contact membersTwo-part coupling devicesLow insertion forceEngineering

Owner:HON HAI PRECISION IND CO LTD

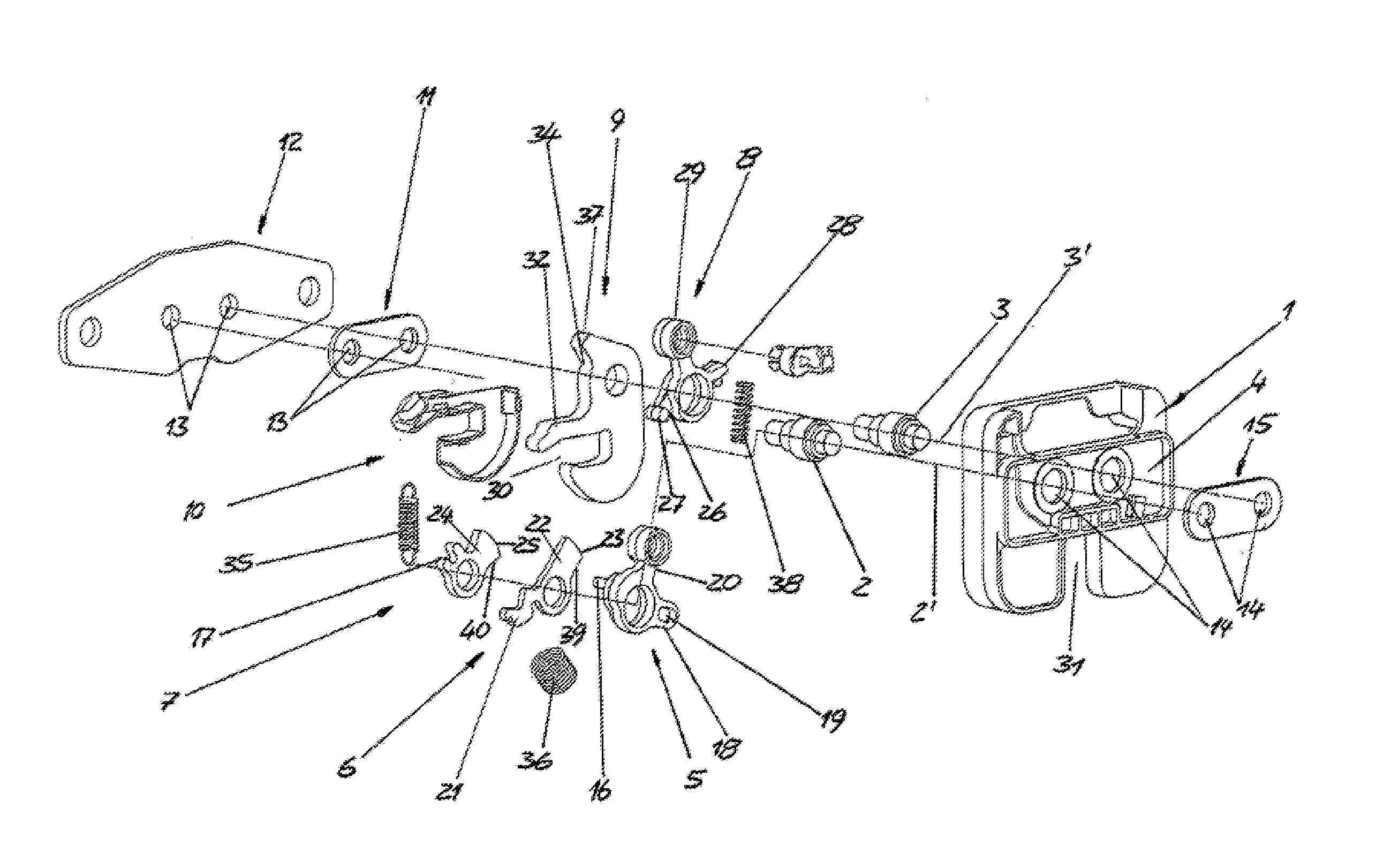

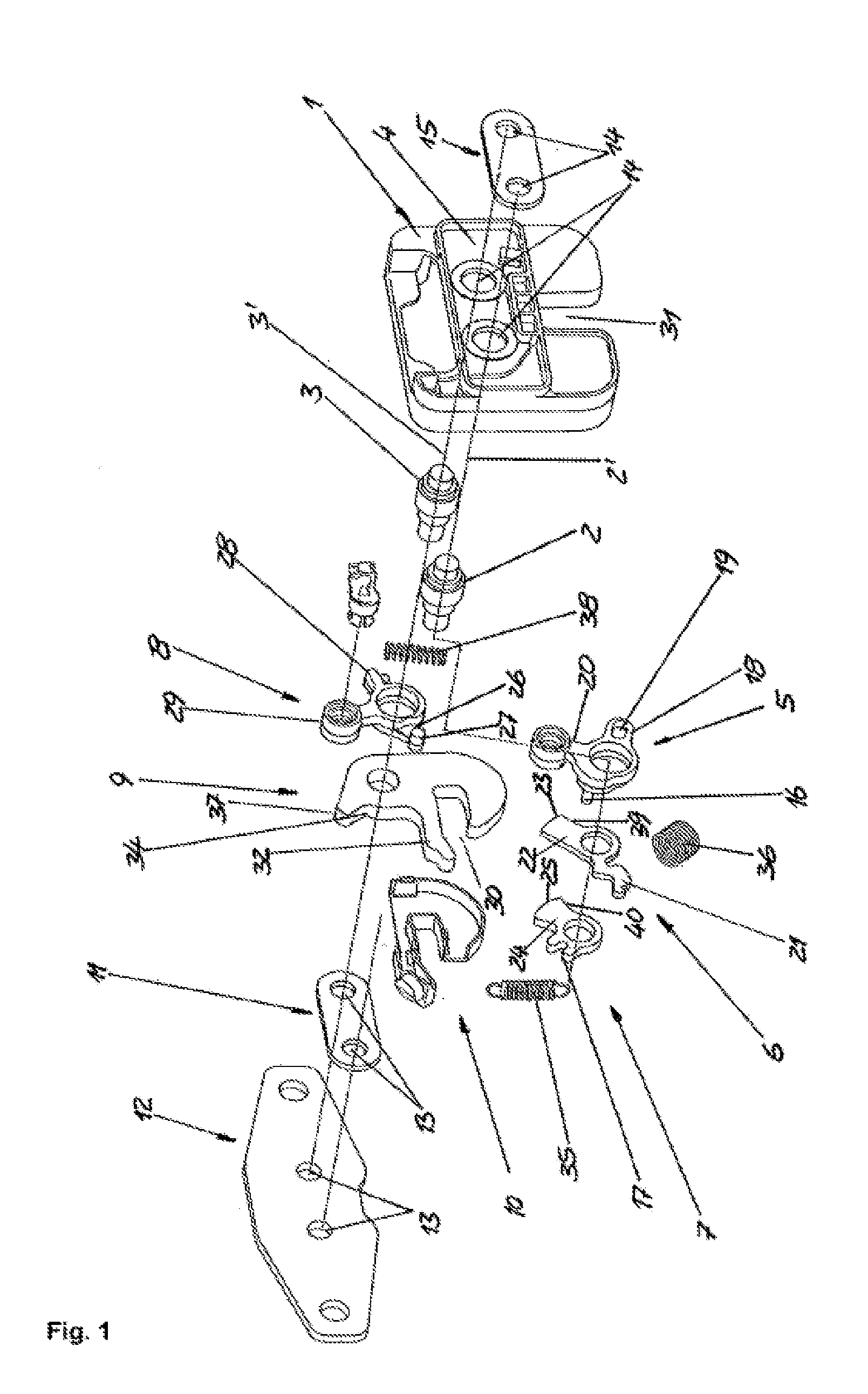

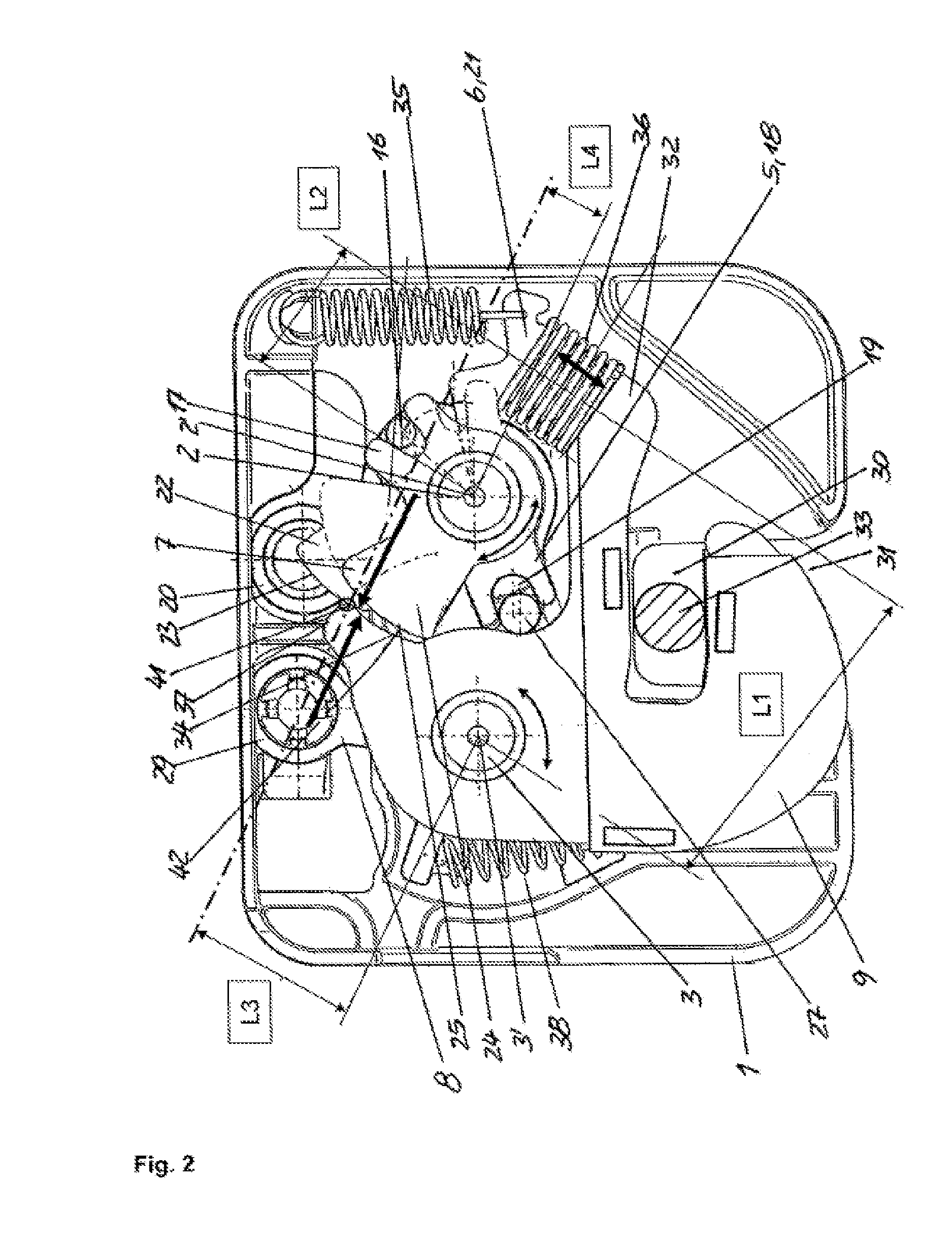

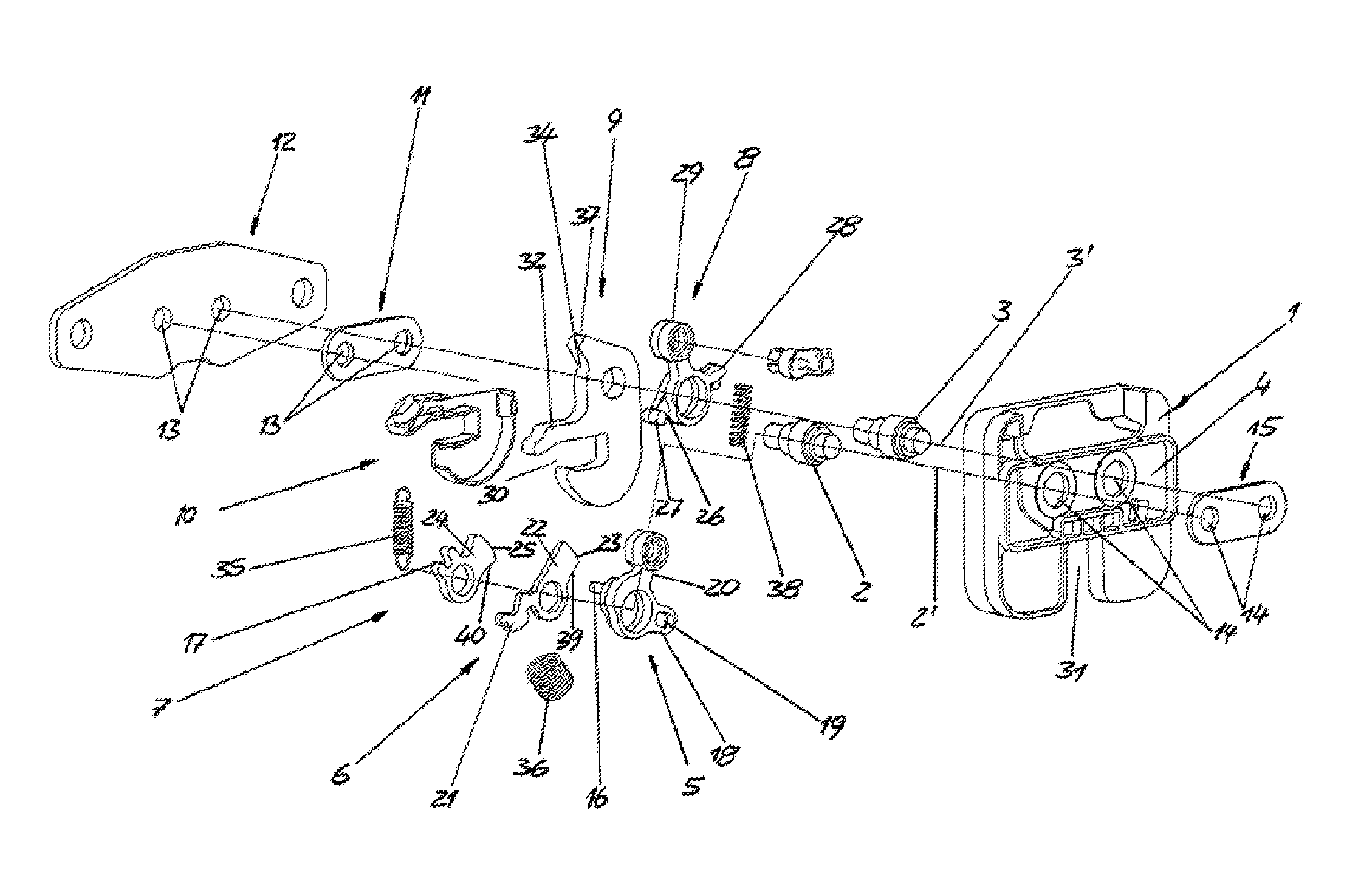

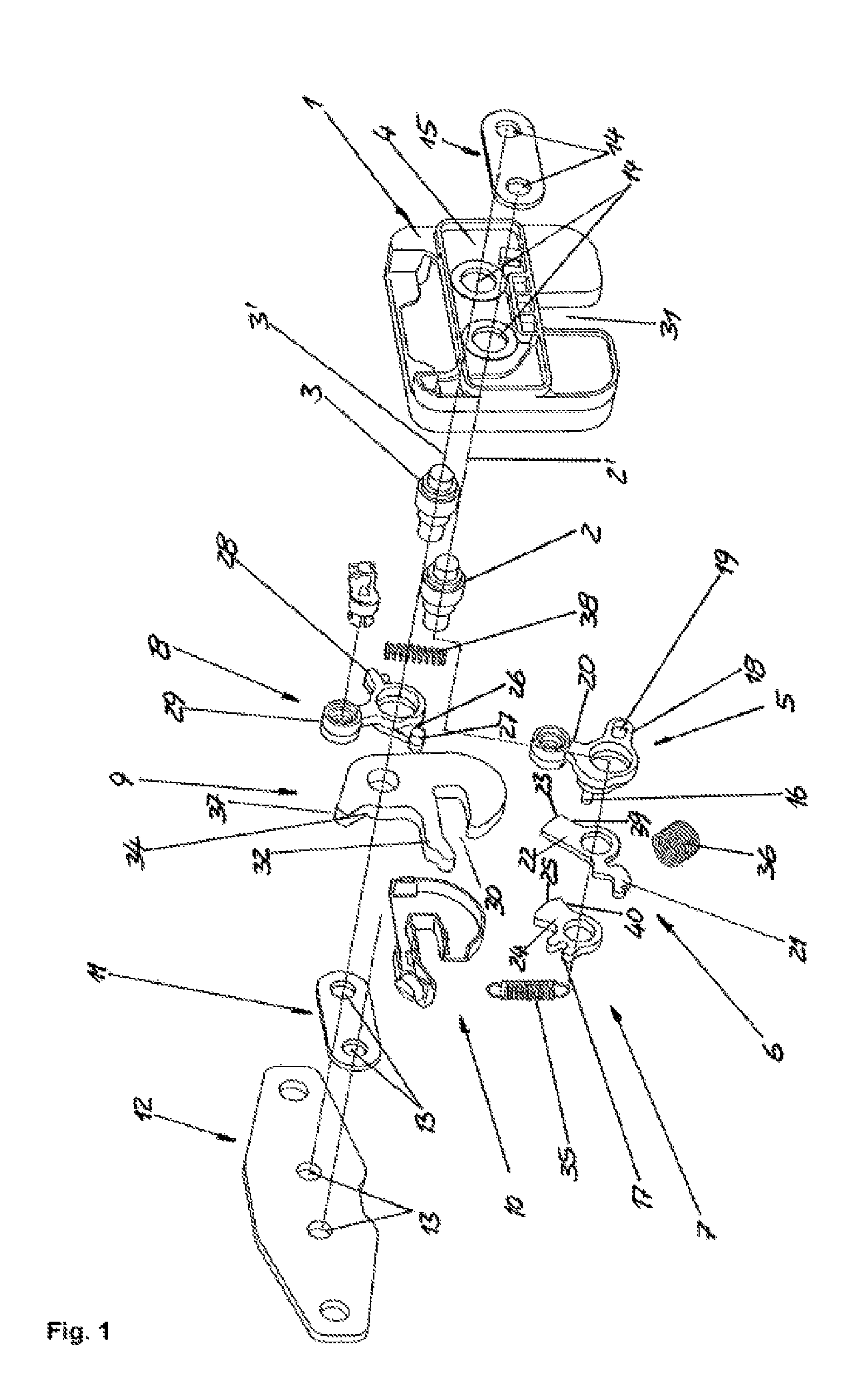

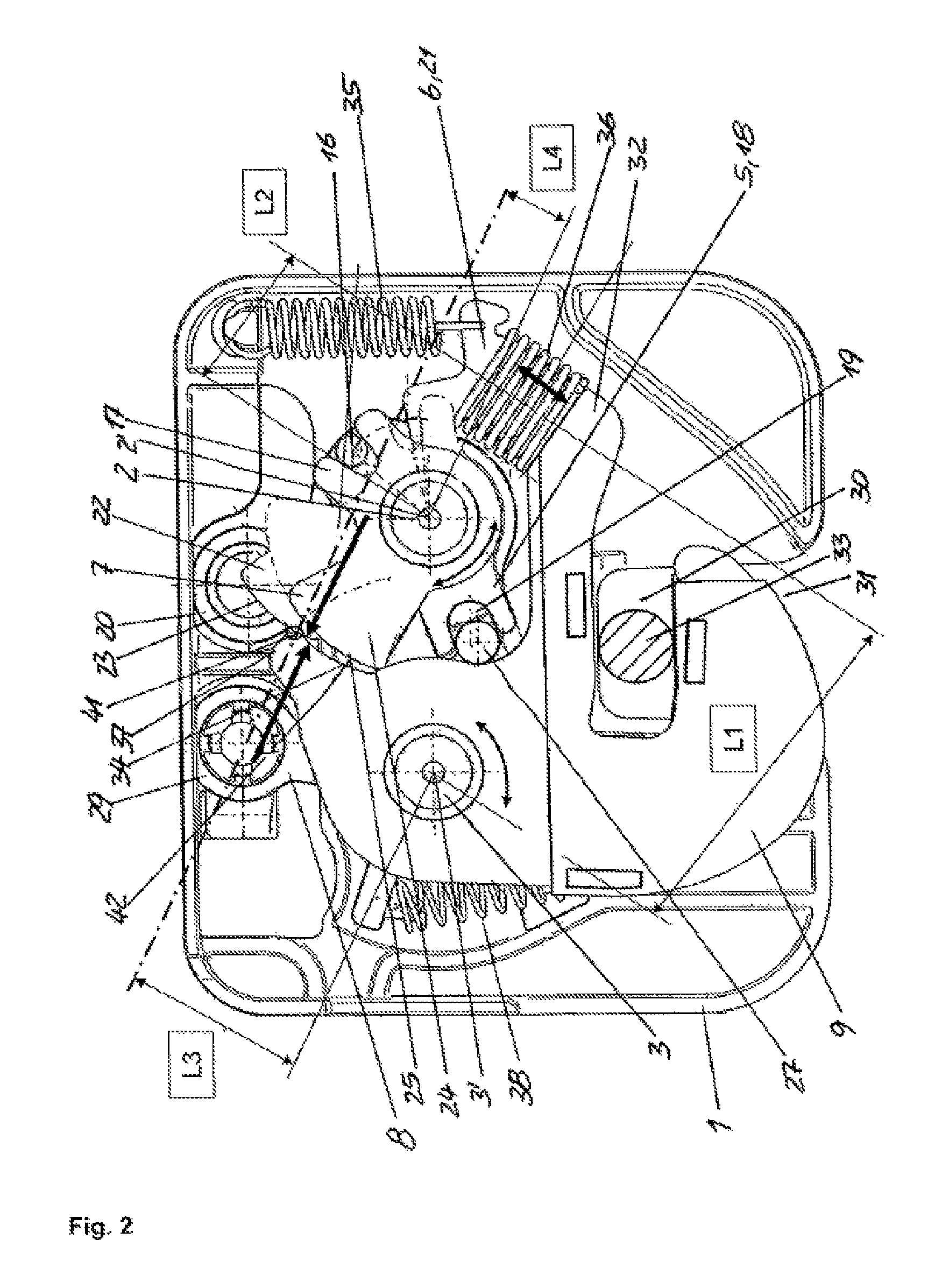

Locking device and vehicle seat

ActiveUS20140306507A1Reduced space required for installationIncrease jacking forceVehicle seatsBuilding locksEngineeringMechanical engineering

Owner:KEIPER SEATING MECHANISMS CO LTD

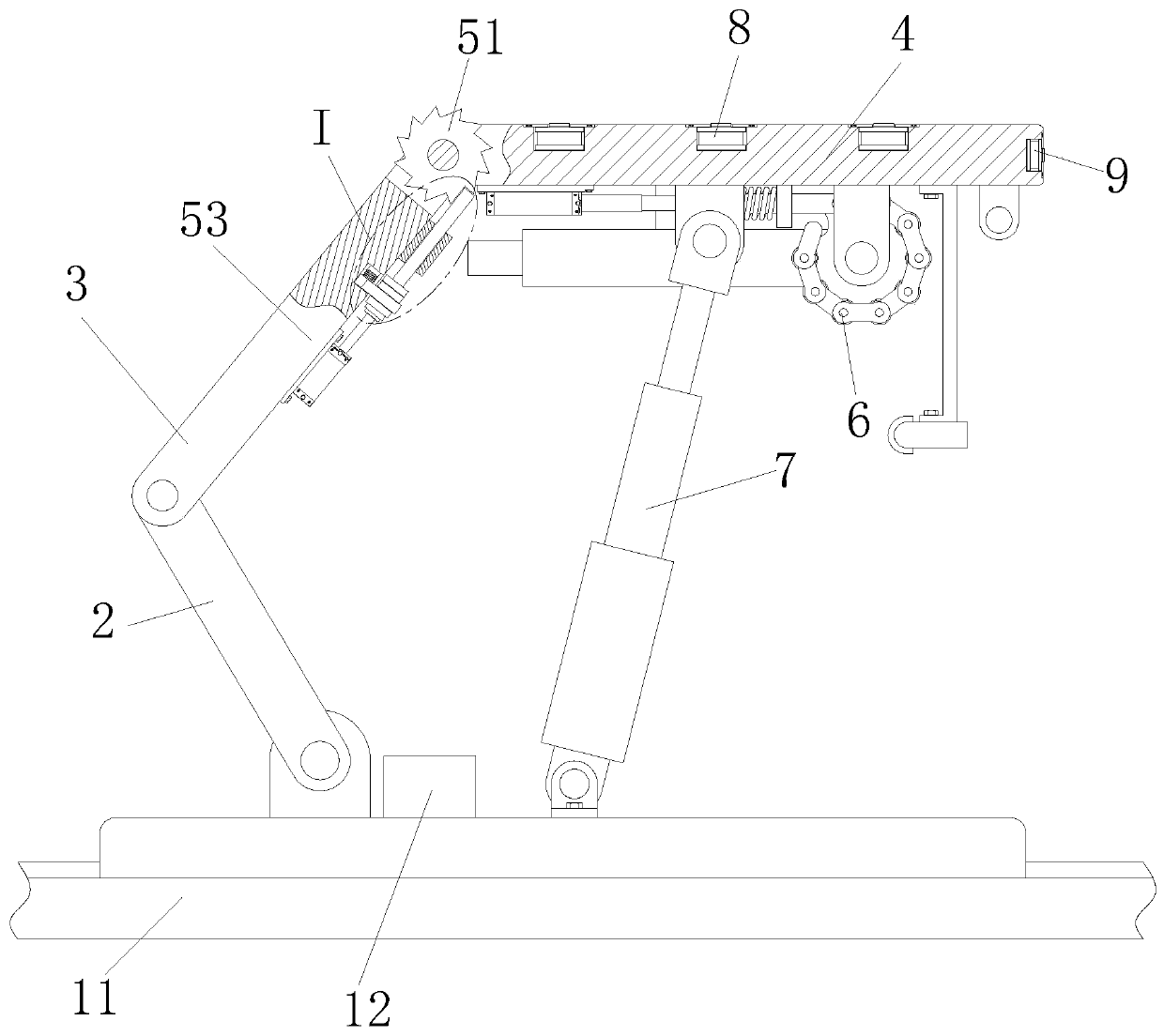

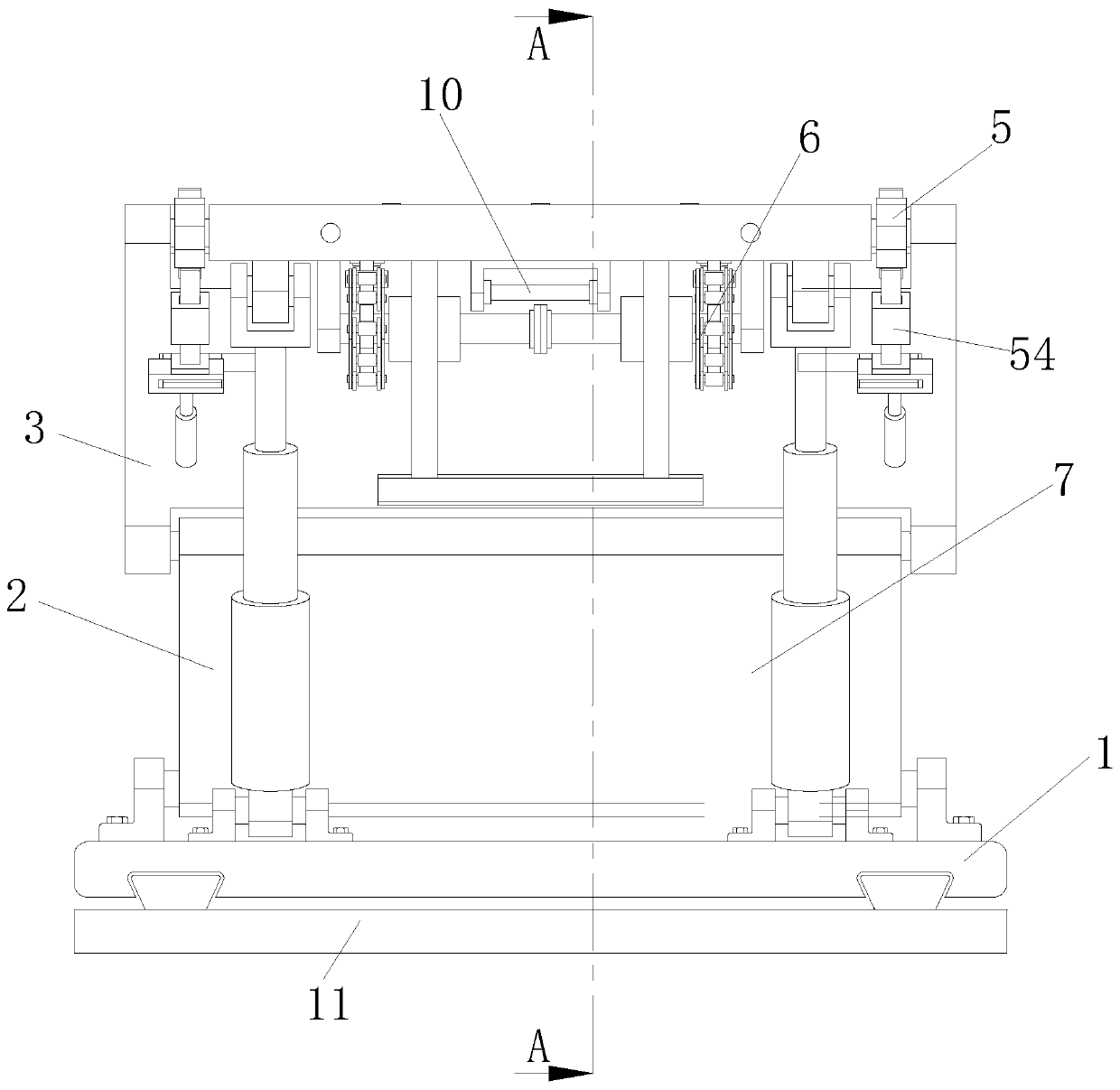

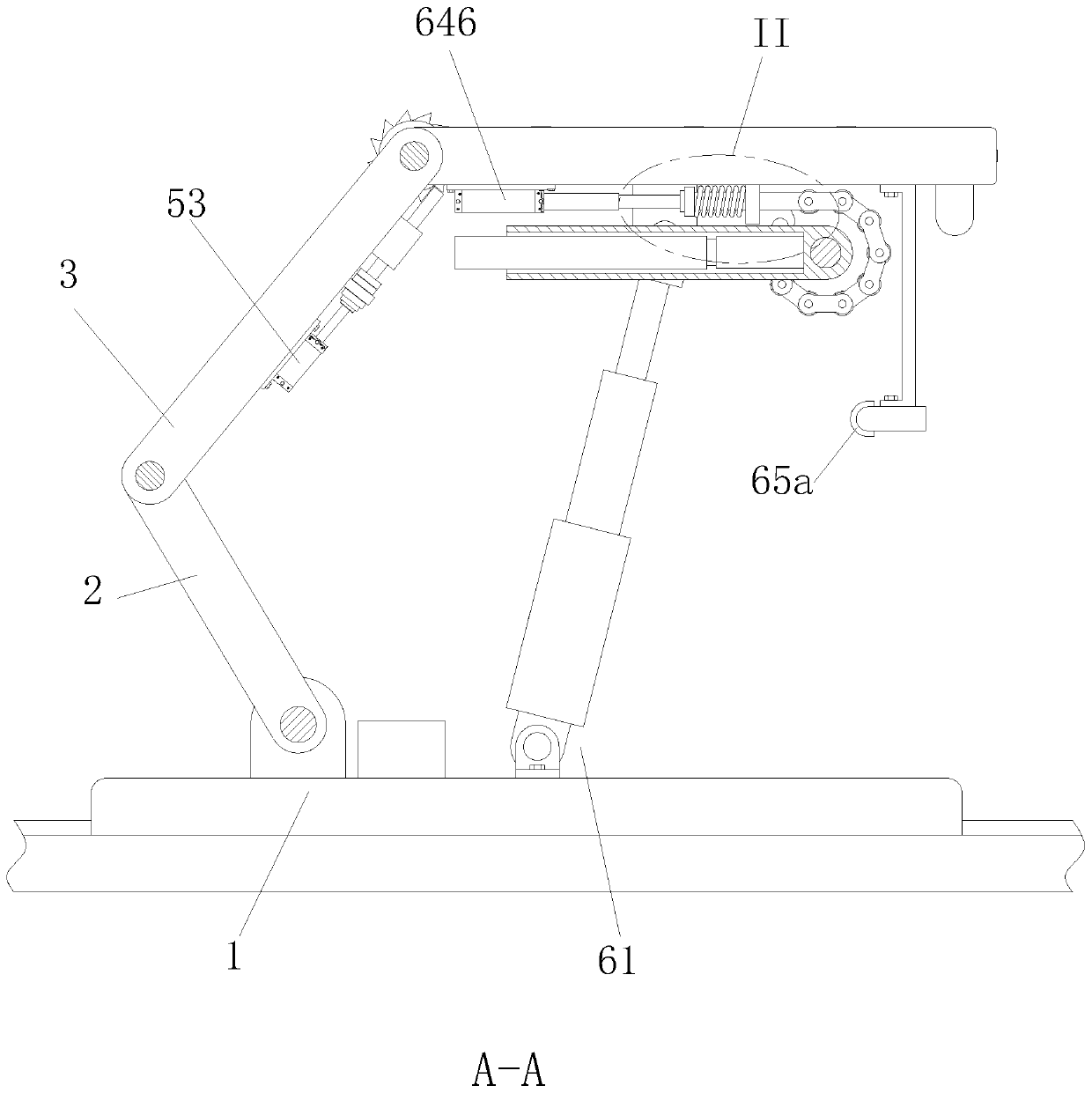

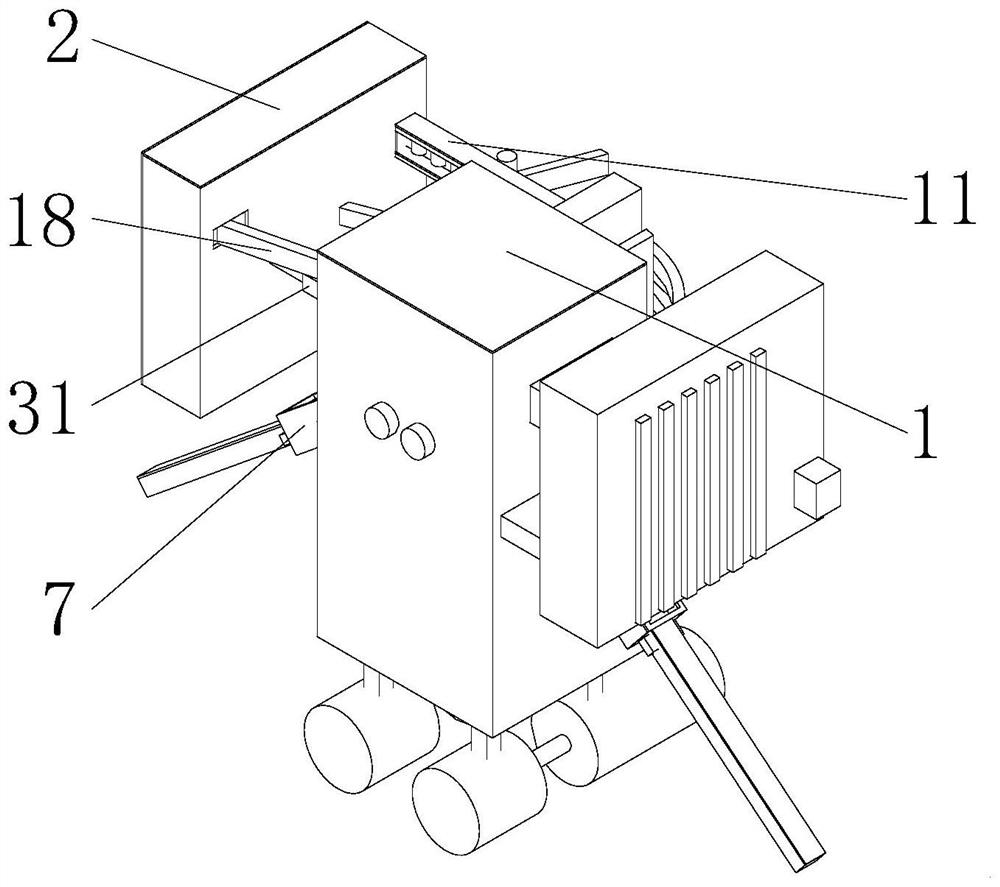

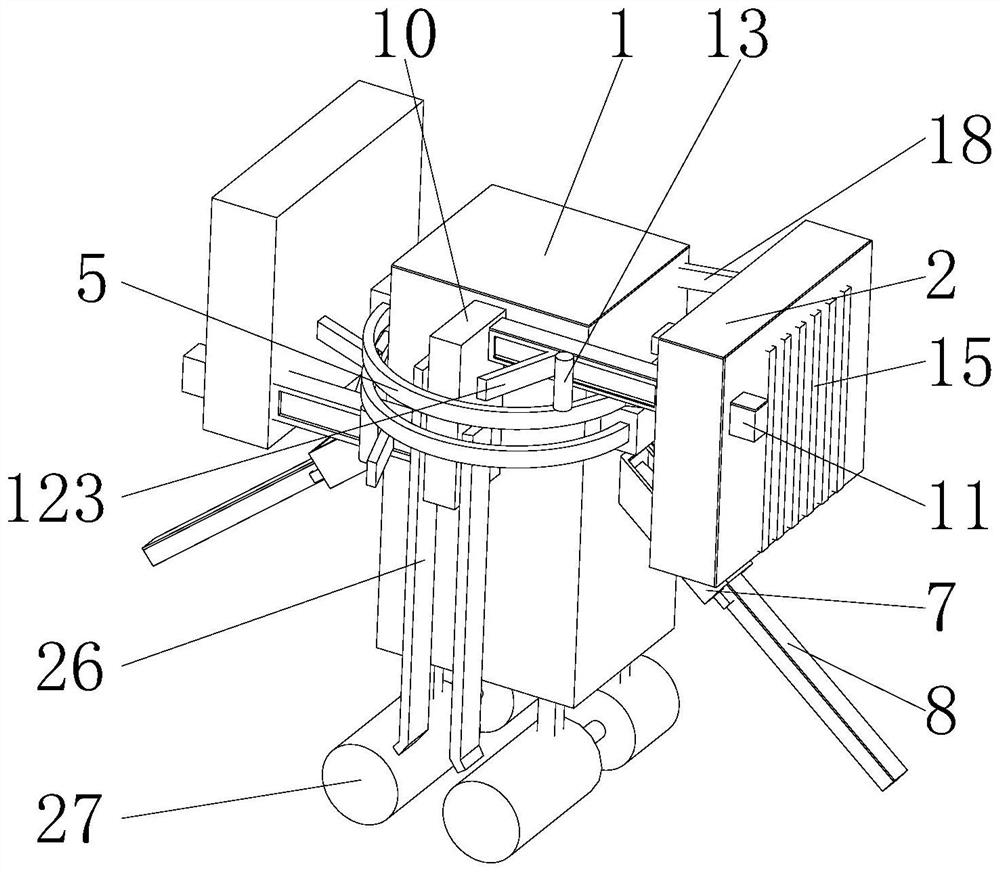

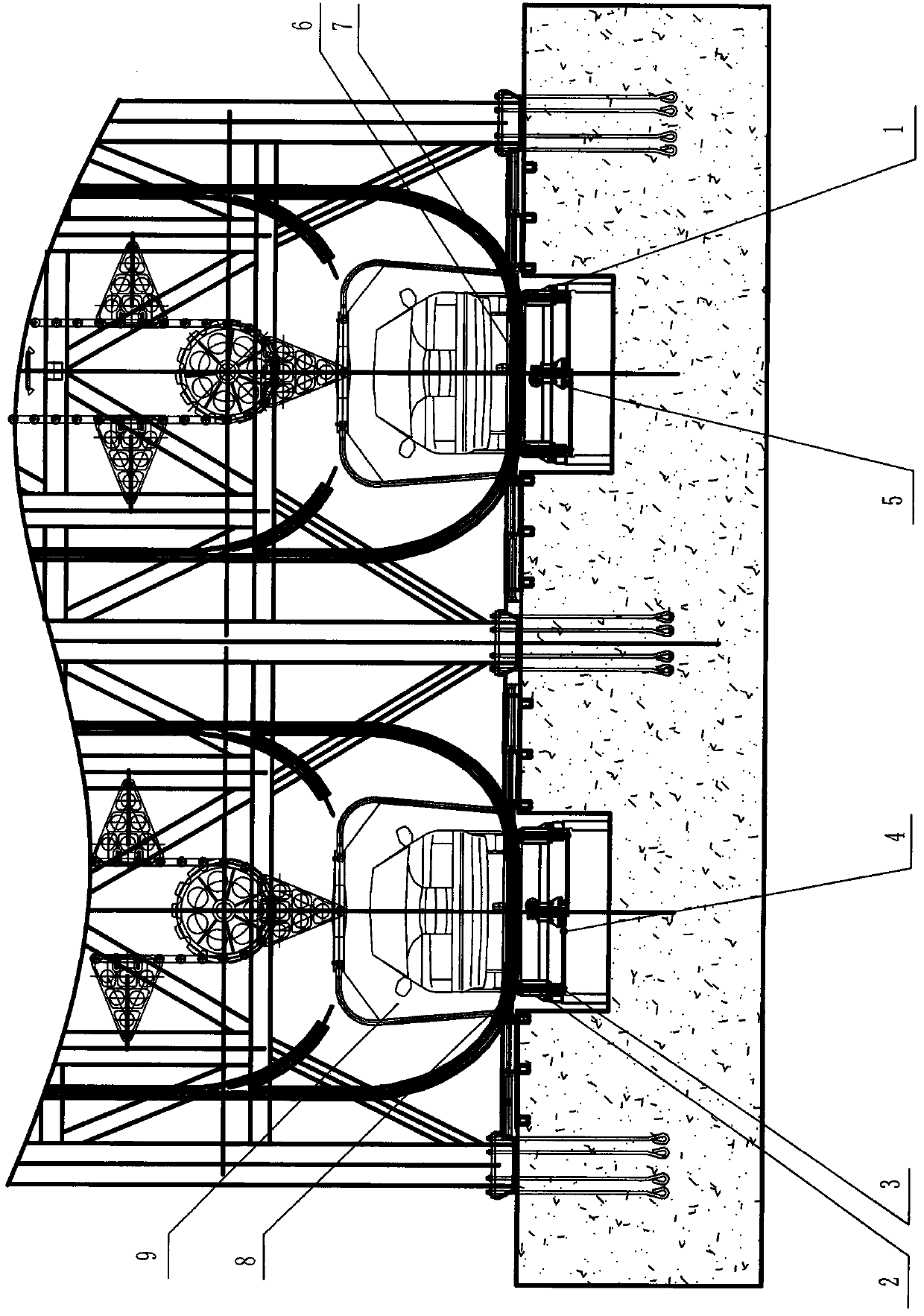

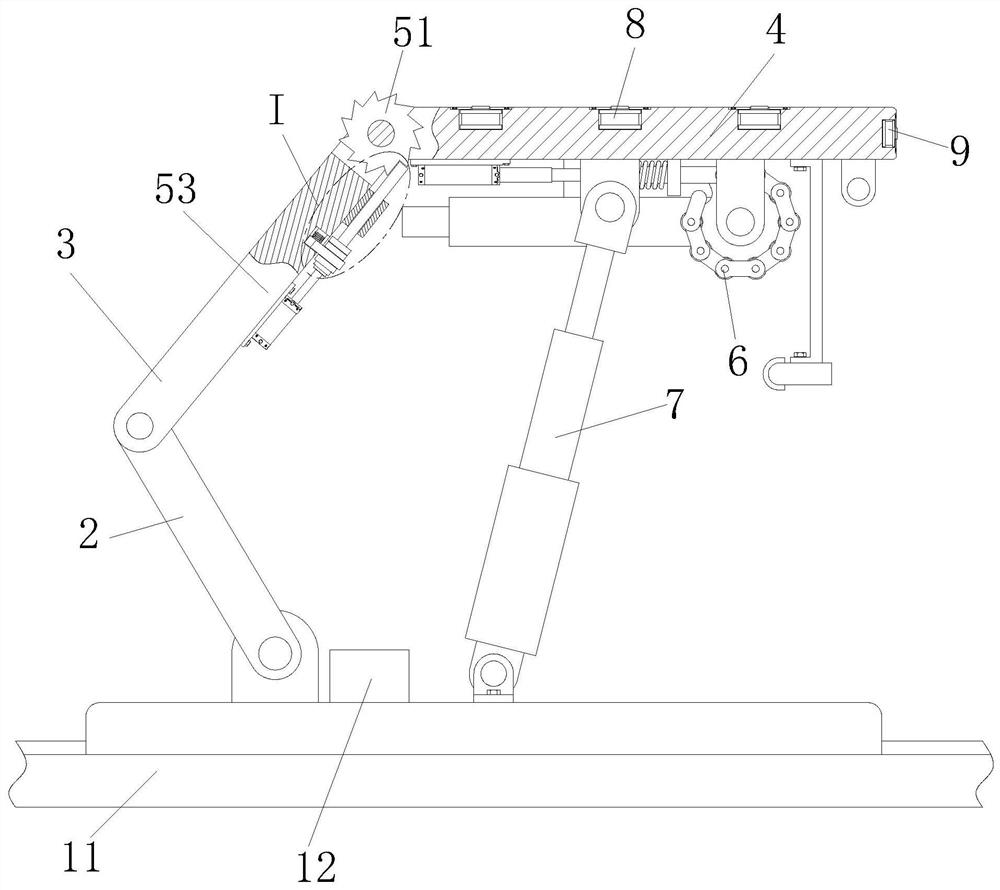

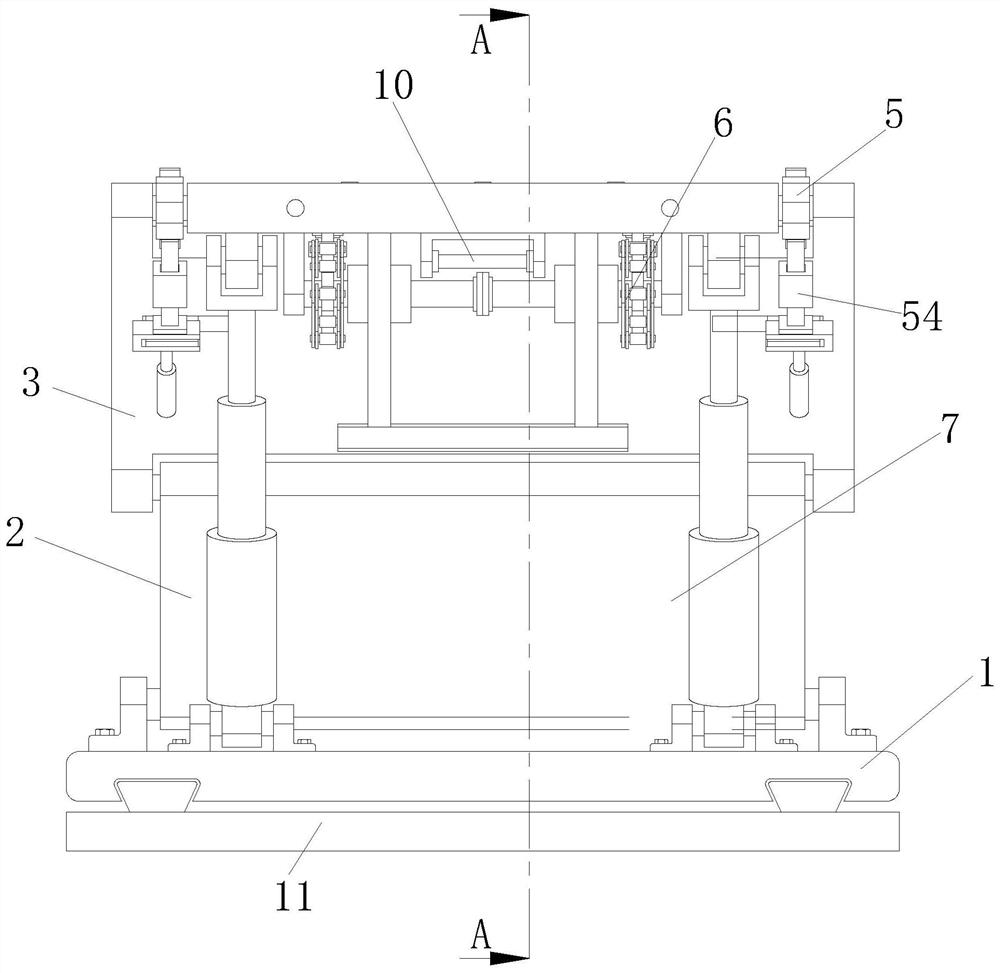

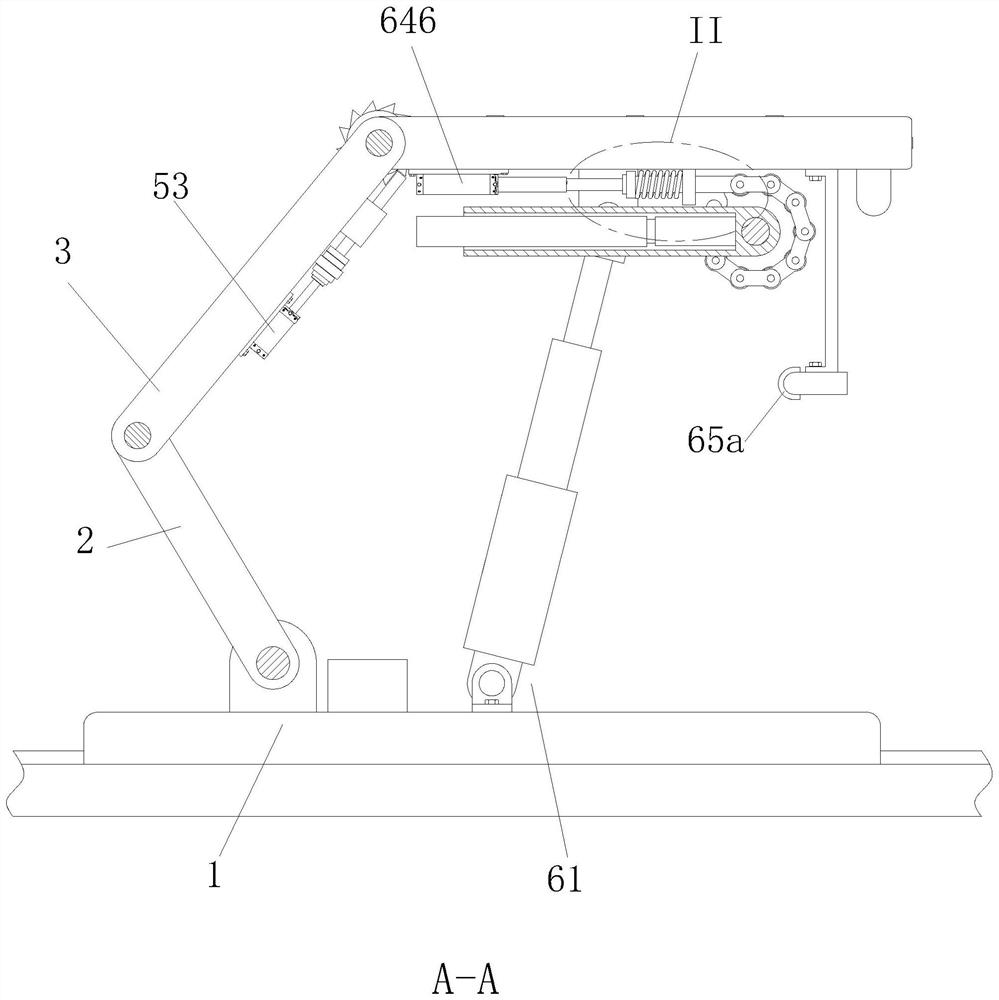

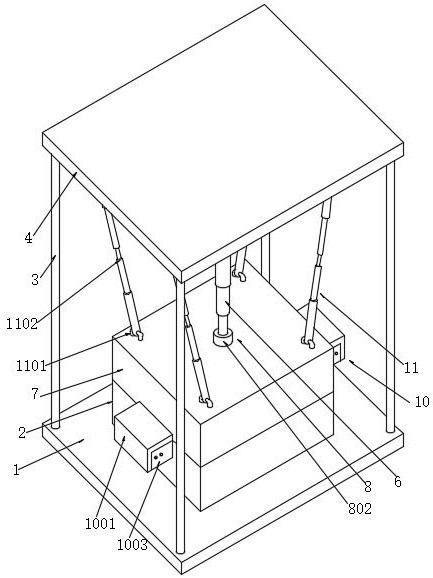

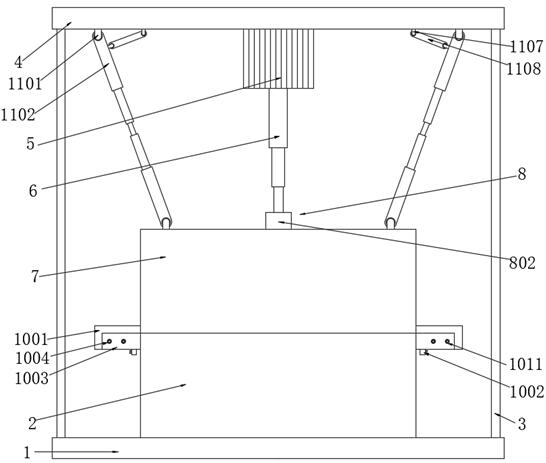

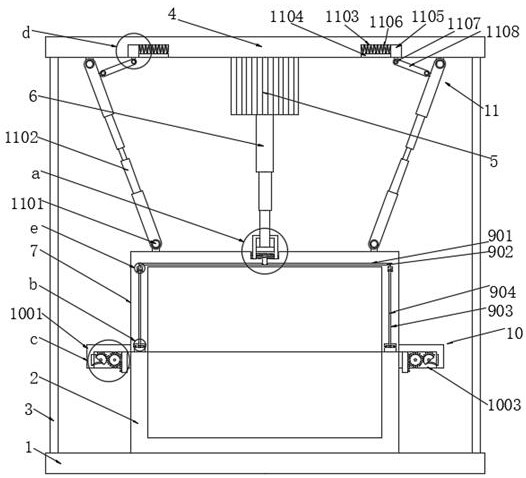

Intelligent coal mine support

ActiveCN110529163APrevent landslidesPrevent overload collapseMining devicesMine roof supportsHydraulic cylinderEngineering

The invention relates to an intelligent coal mine support, which comprises a supporting plate, the supporting plate is installed with a connecting plate in a hinging manner, the connecting plate is connected with a shielding beam, the shielding beam is installed with a top beam in the hinging manner, the supporting plate is provided with a No.1 hydraulic cylinder connected with the top beam in thehinging manner, the top beam is connected with a supporting device which prevents the top beam from being overload rotating, a reinforcing device for increasing the bearing capacity of the top beam is also installed on the top beam; and the No.1 hydraulic cylinder, the supporting device and the reinforcing device are connected with a controller. The intelligent coal mine support can support the top beam through the cooperation of a check rod and a ratchet wheel to prevent the underground collapse caused by the overturn of the top beam; the intelligent coal mine support can enhance the jackingforce of a No. 2 hydraulic cylinder through the cooperation of the reinforcing rod and a U-shaped plate to prevent the collapse of the No. 2 hydraulic cylinder caused by the overturn of the top beamduring the supporting process; the intelligent coal mine support can drive a chain wheel to rotate to release a pendulum rod quickly through a chain, and meanwhile a No. 3 hydraulic cylinder drives asupport rod to support the top beam to prevent the overload collapse of the top beam so as to gain time for workers to escape.

Owner:ANHUI UNIV OF SCI & TECH

High-efficiency disassembling tool for inner ring of bearing

PendingCN109108895AFlexible installationIncrease jacking forceMetal-working hand toolsMechanical engineeringEngineering

Owner:株洲九方装备驱动技术有限公司 +1

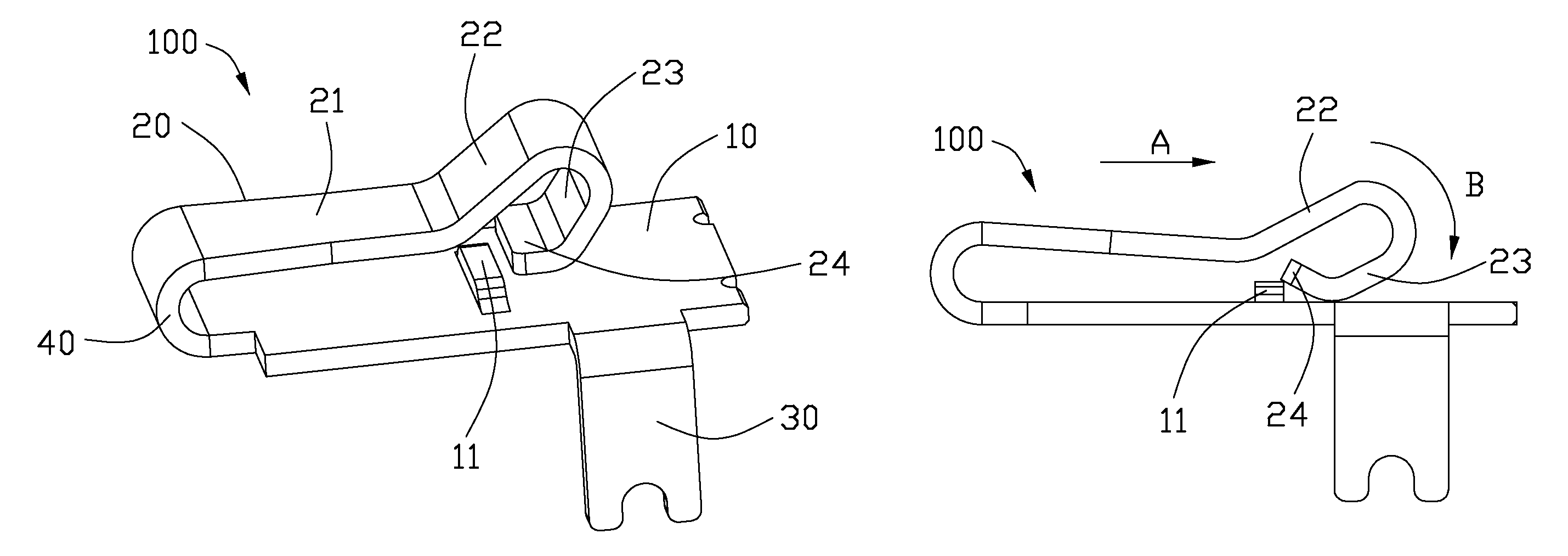

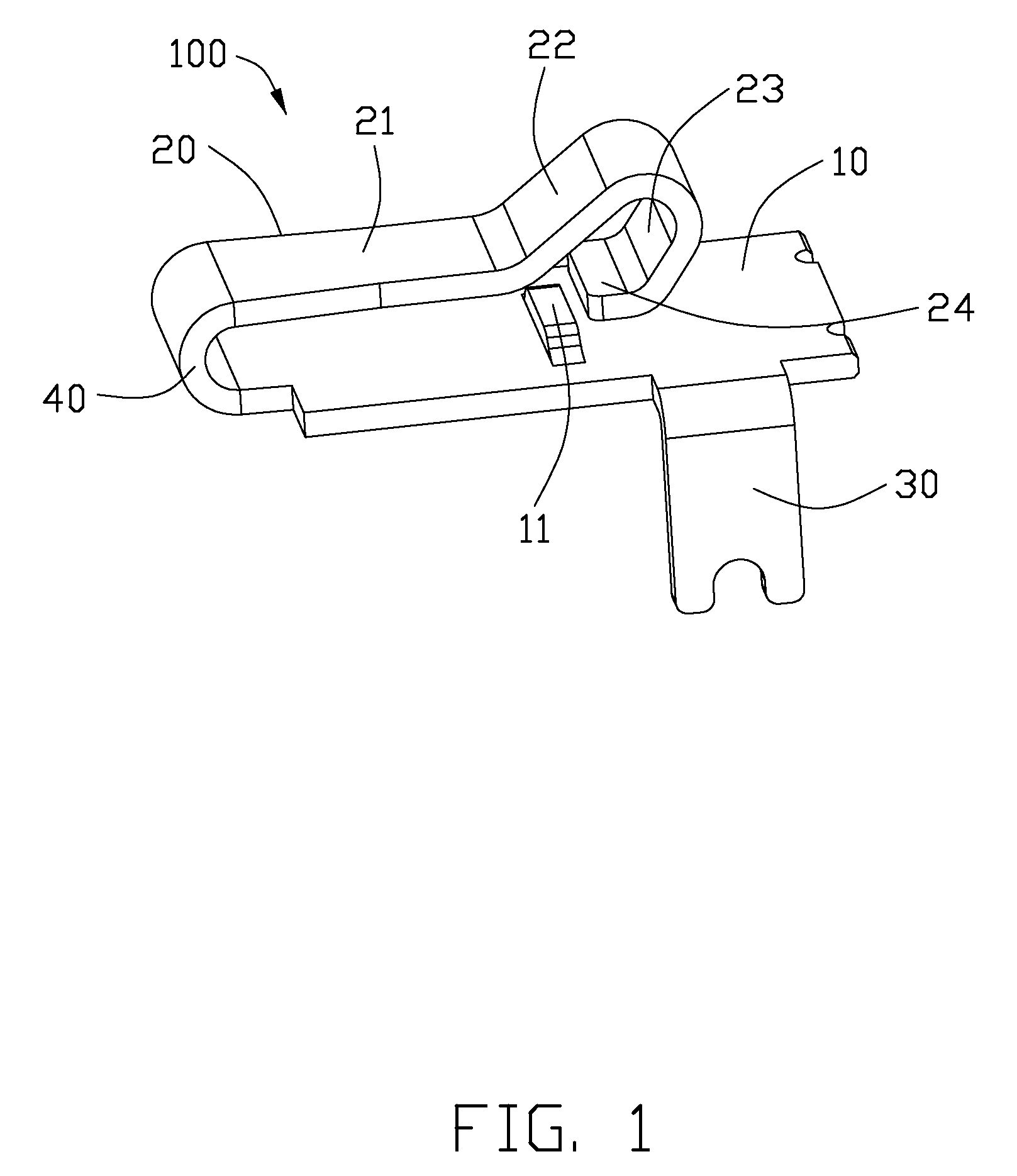

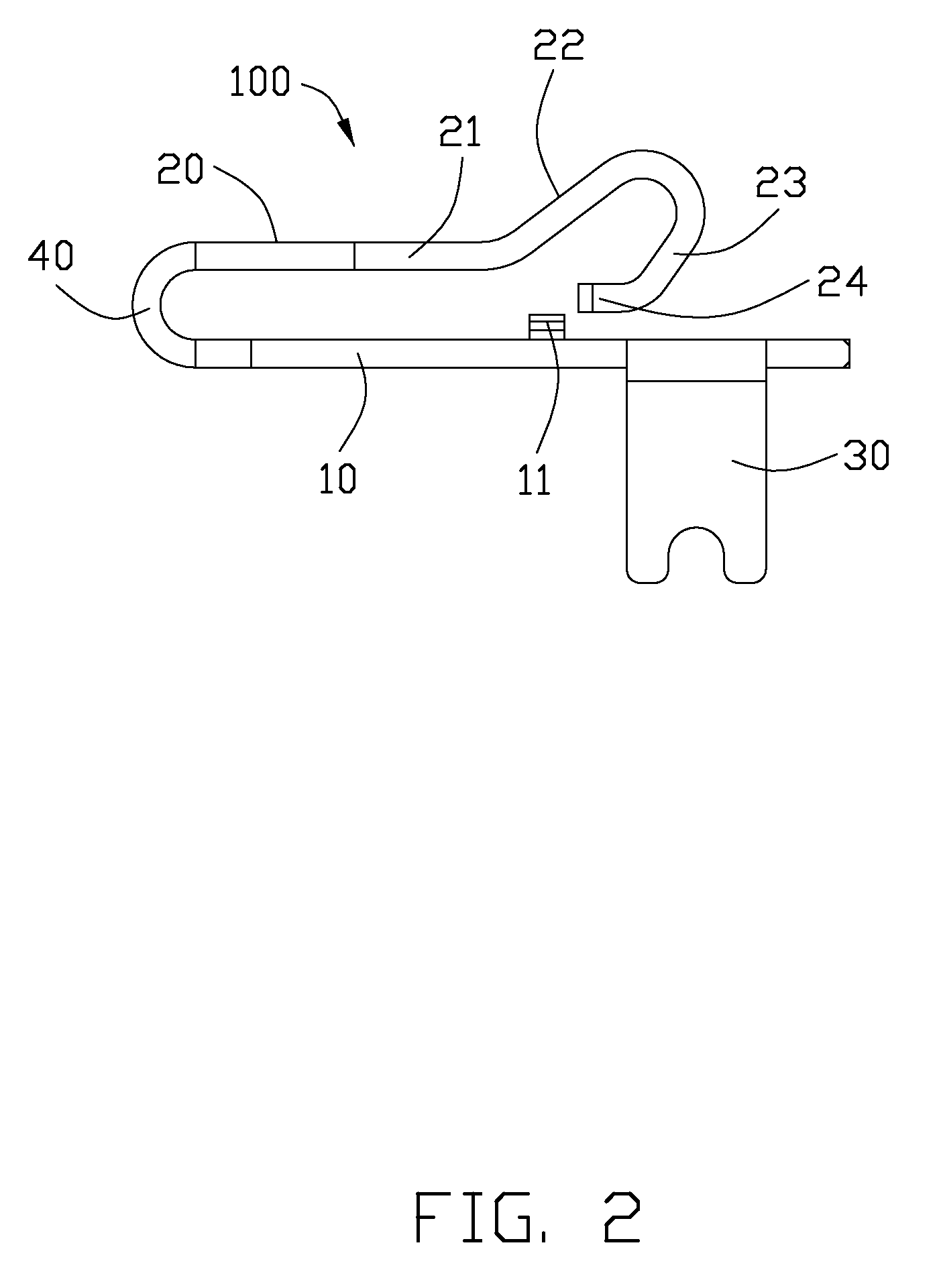

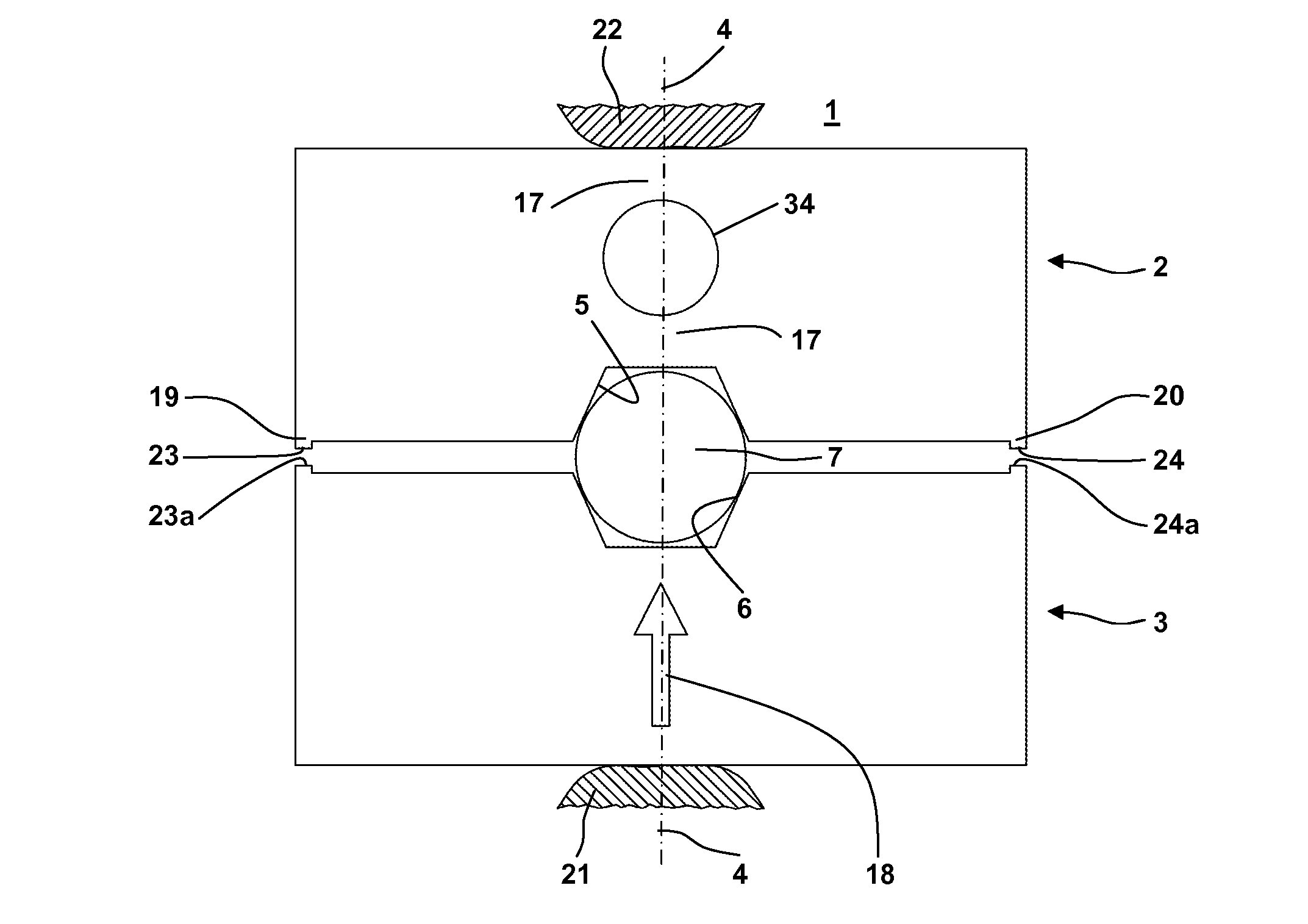

Audio jack connector having low insertion force and high ejection force

InactiveUS20120231679A1Lower insertion forceIncrease jacking forceElectrically conductive connectionsCoupling contact membersLow insertion forceEngineering

An electrical contact (100) of an audio jack connector includes a main portion (10), a soldering portion (30) bending from a lateral edge of the main portion, an elastic portion (20) extending curvedly from a distal end of the main portion to be located above the main portion. The elastic portion has a flexible beam (21), a first arm (22) extending upwardly from the flexible beam and a second arm (23) curvedly bending from the first arm. The first arm and is consistent with a direction along which an audio plug connector is inserted. The second arm is adverse to a direction along which the audio plug connector is withdrawn.

Owner:HON HAI PRECISION IND CO LTD

Crimping Tool

InactiveUS20100242568A1Avoid deformationLittle strengthLine/current collector detailsStripping-off devicesBiomedical engineering

Owner:WEZAG - WERKZEUGFAB

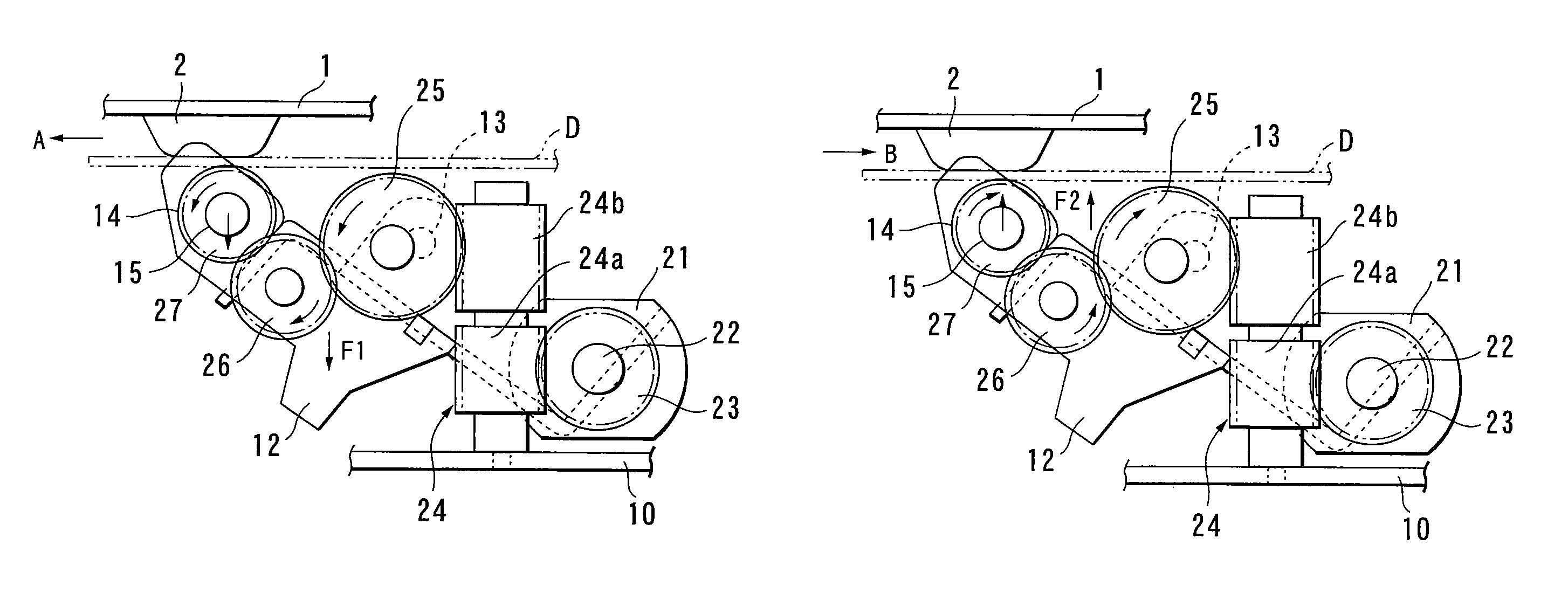

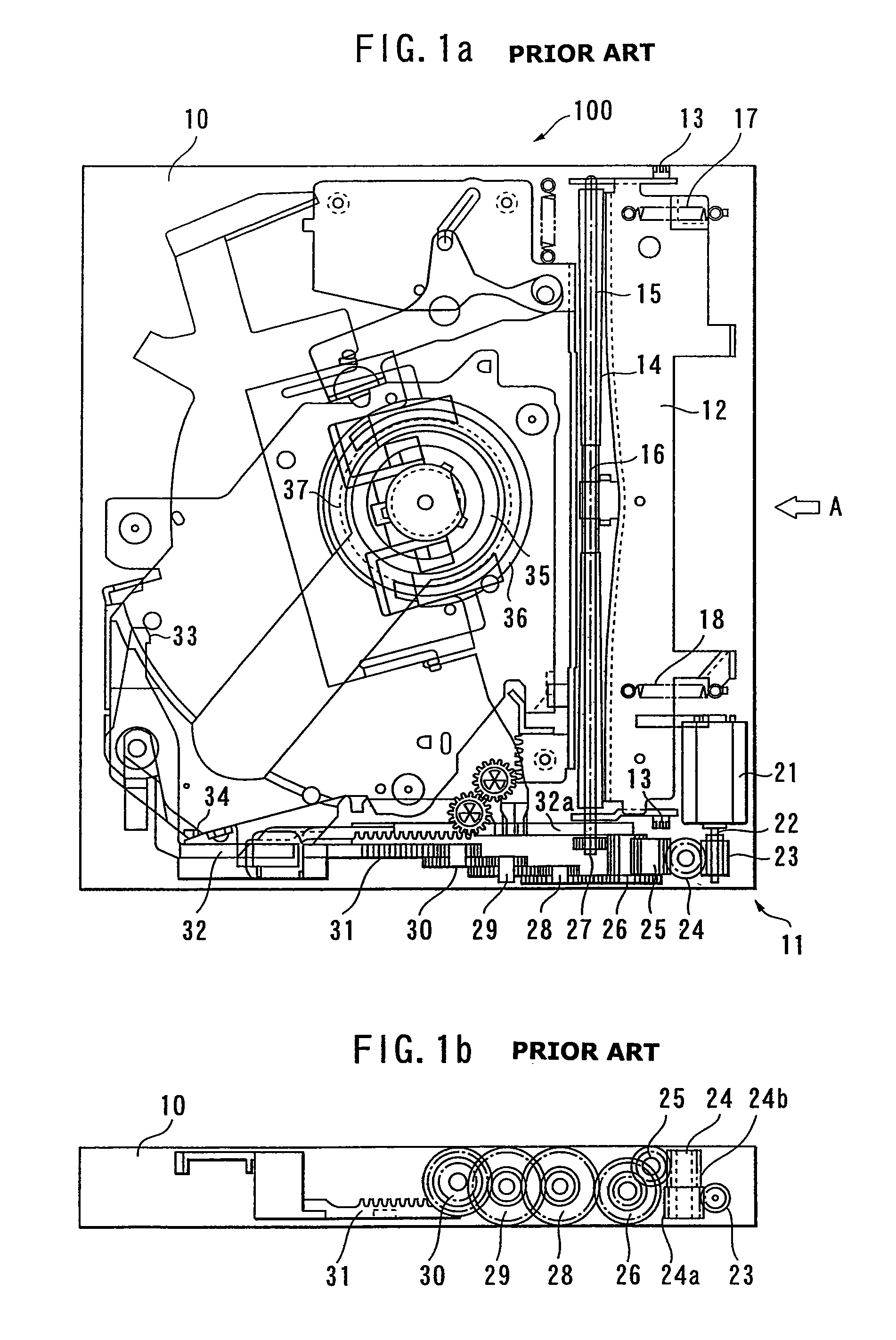

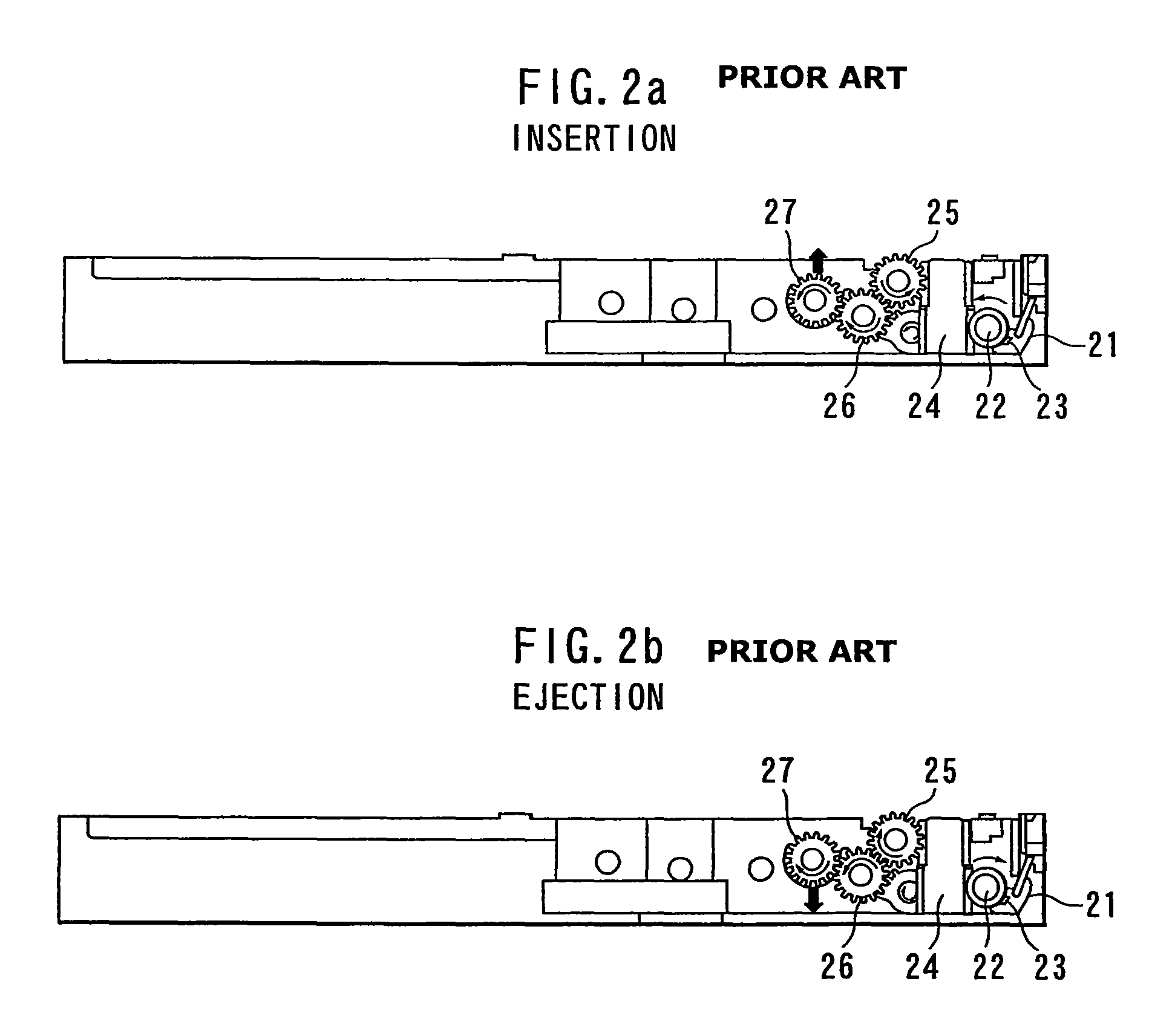

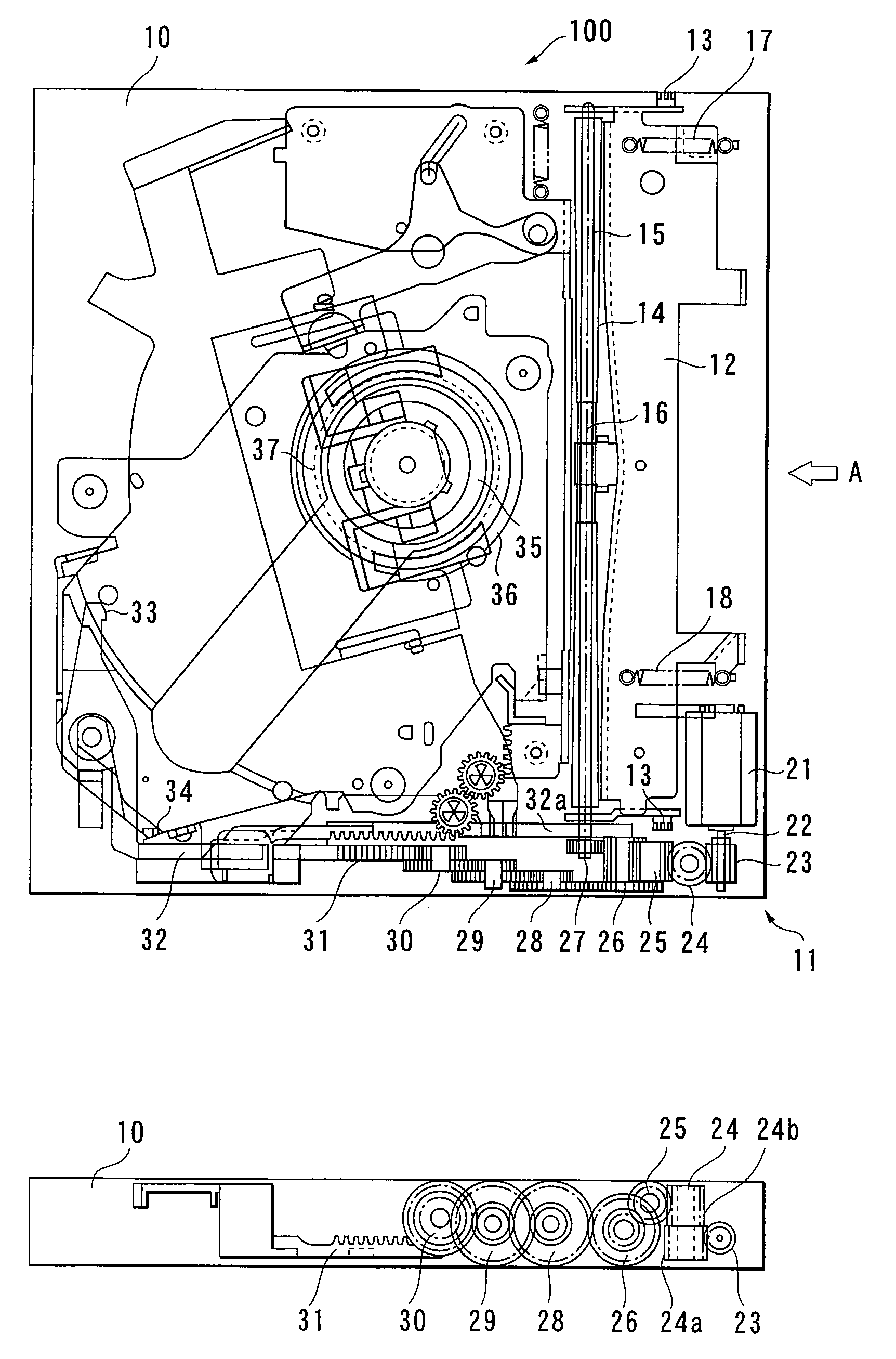

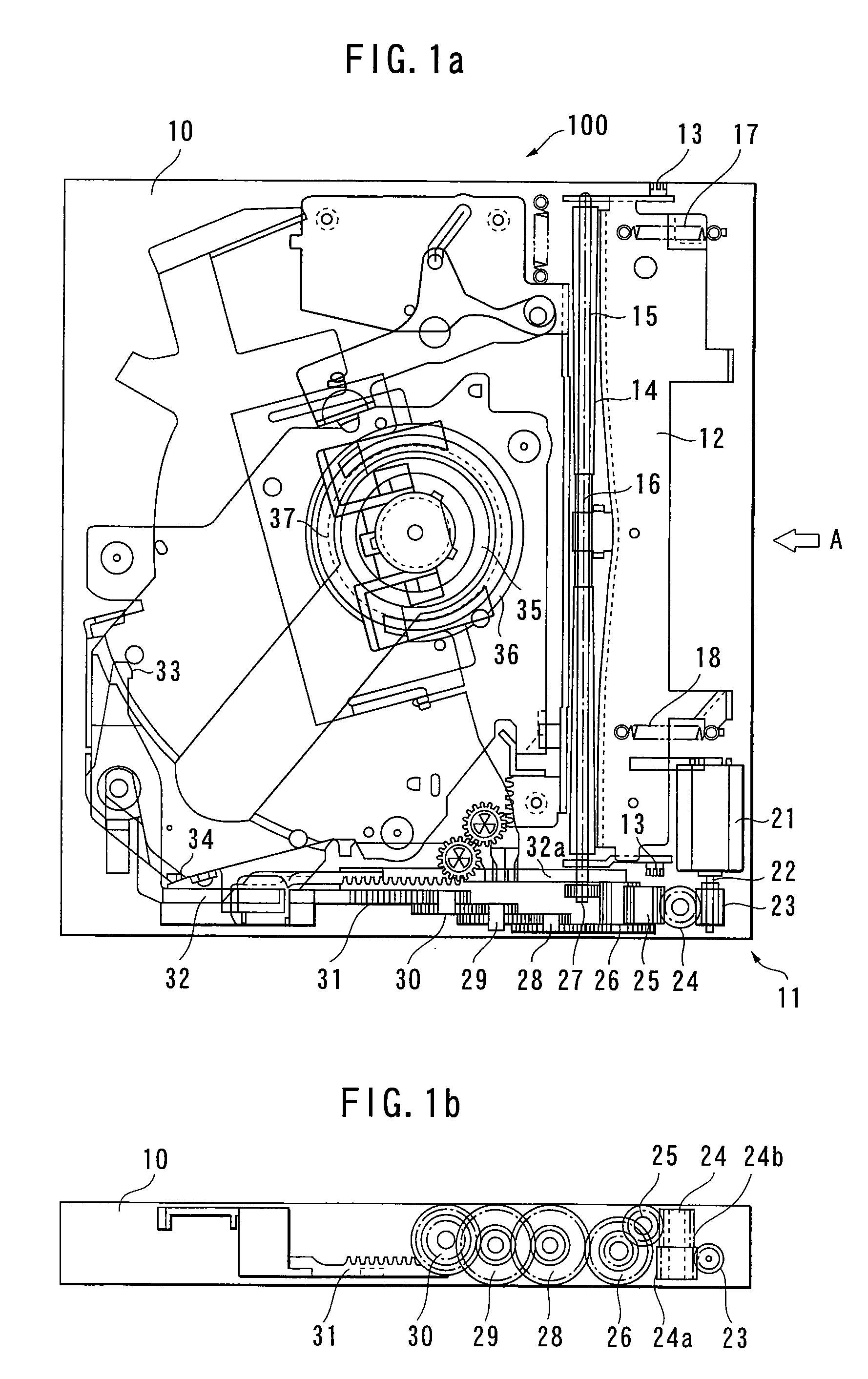

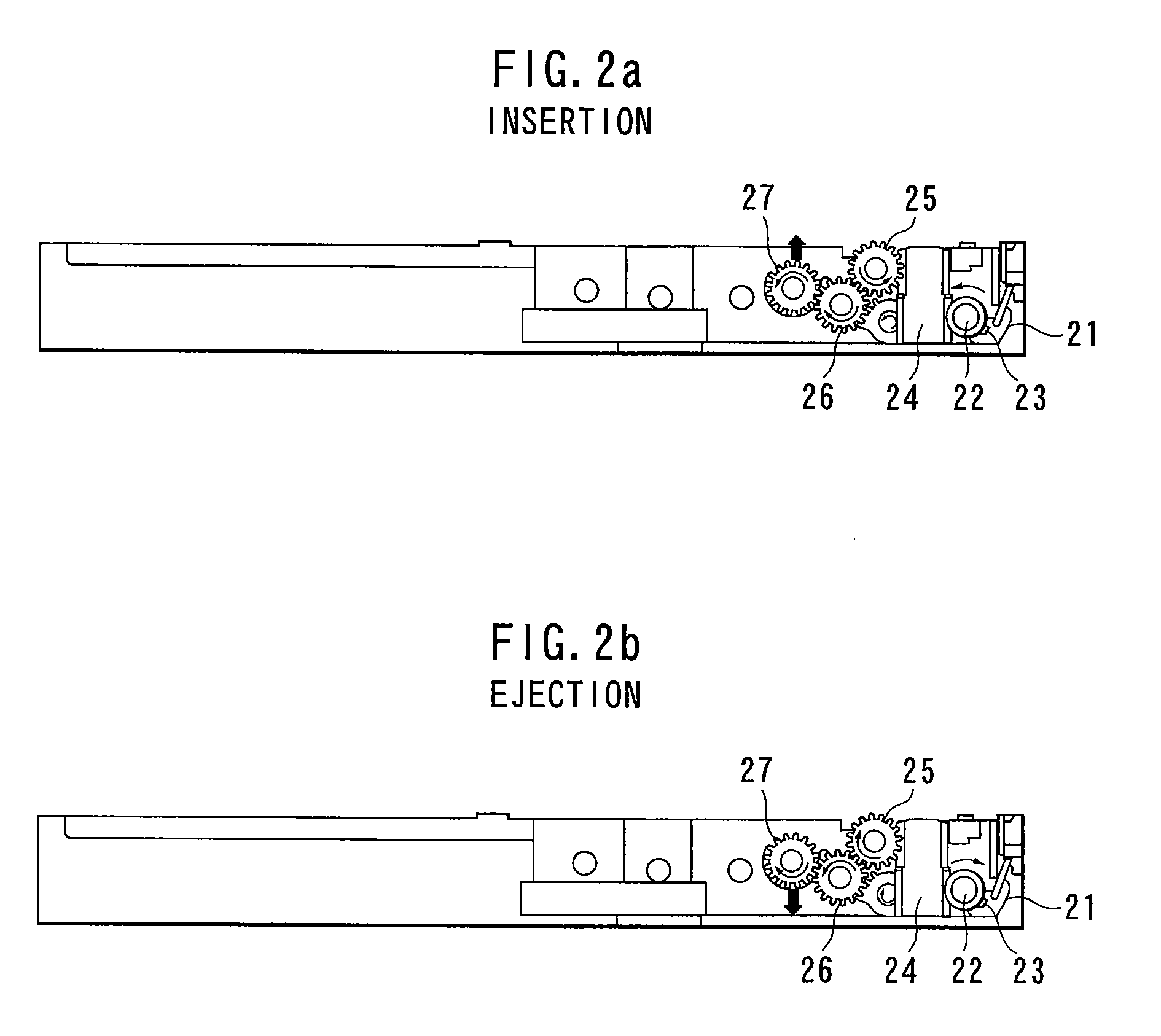

Disk carrying device and optical disk recording/reproducing device

In a disk carrying device including a first idle gear rotatably supported by a lower chassis and a second idle gear for contacting and separating from the first idle gear to perform a rotation operation, the second idle gear and a roller gear meshing therewith are rotatably supported by a feed plate to cause the second idle gear to contact and separate, from below, from the first idle gear rotatably supported by the lower chassis. Because of this configuration, in disk insertion, a downward force F1 acts on the second idle gear and a pushing pressure of the feed roller to a disk D decreases. In disk ejection, an upward force F2 acts on the second idle gear and the pushing pressure of the feed roller to the disk D increases.

Owner:PANASONIC CORP

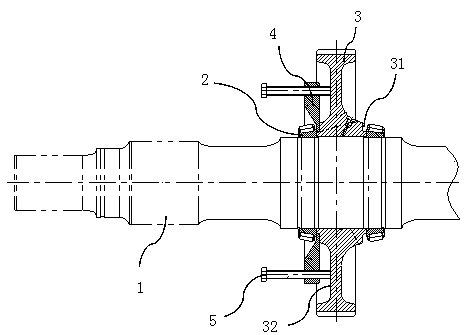

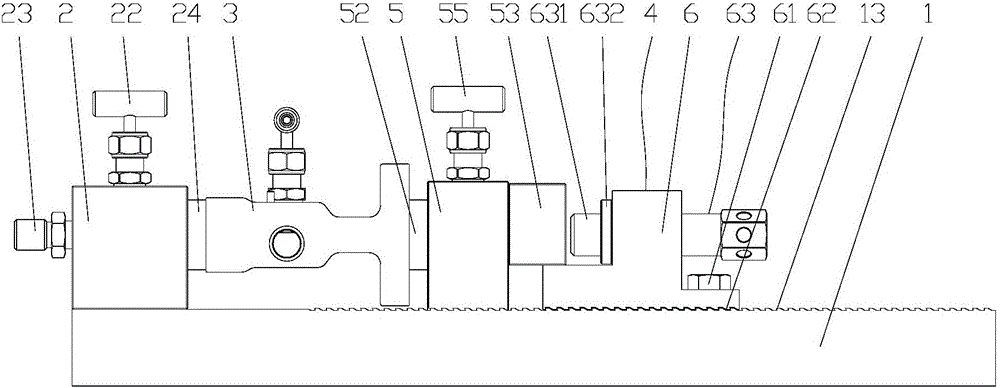

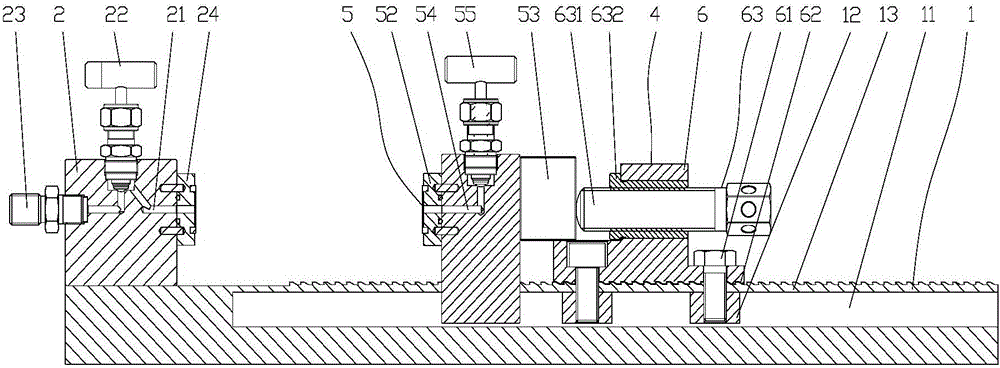

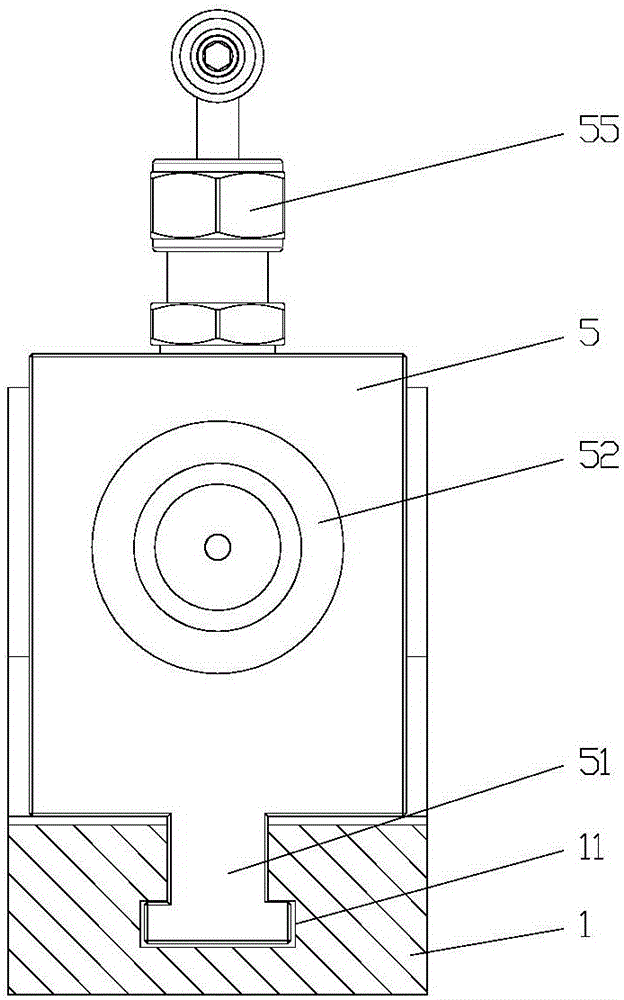

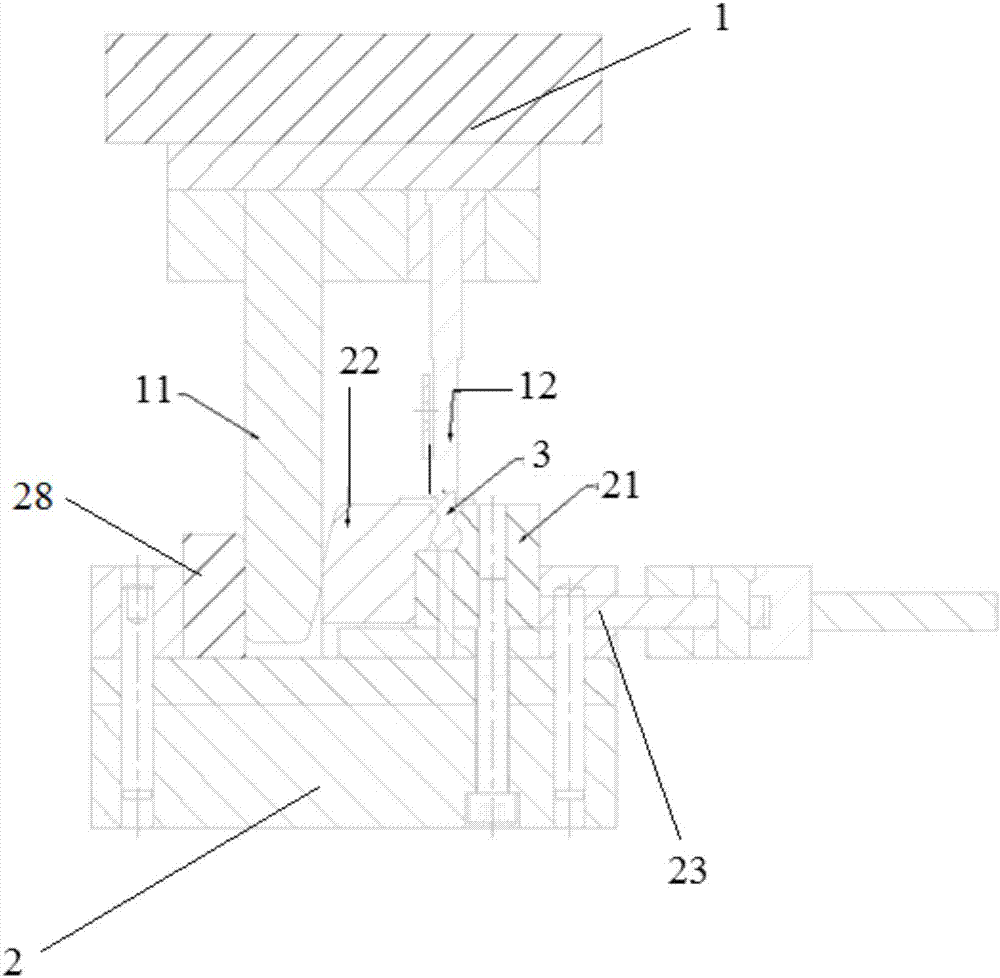

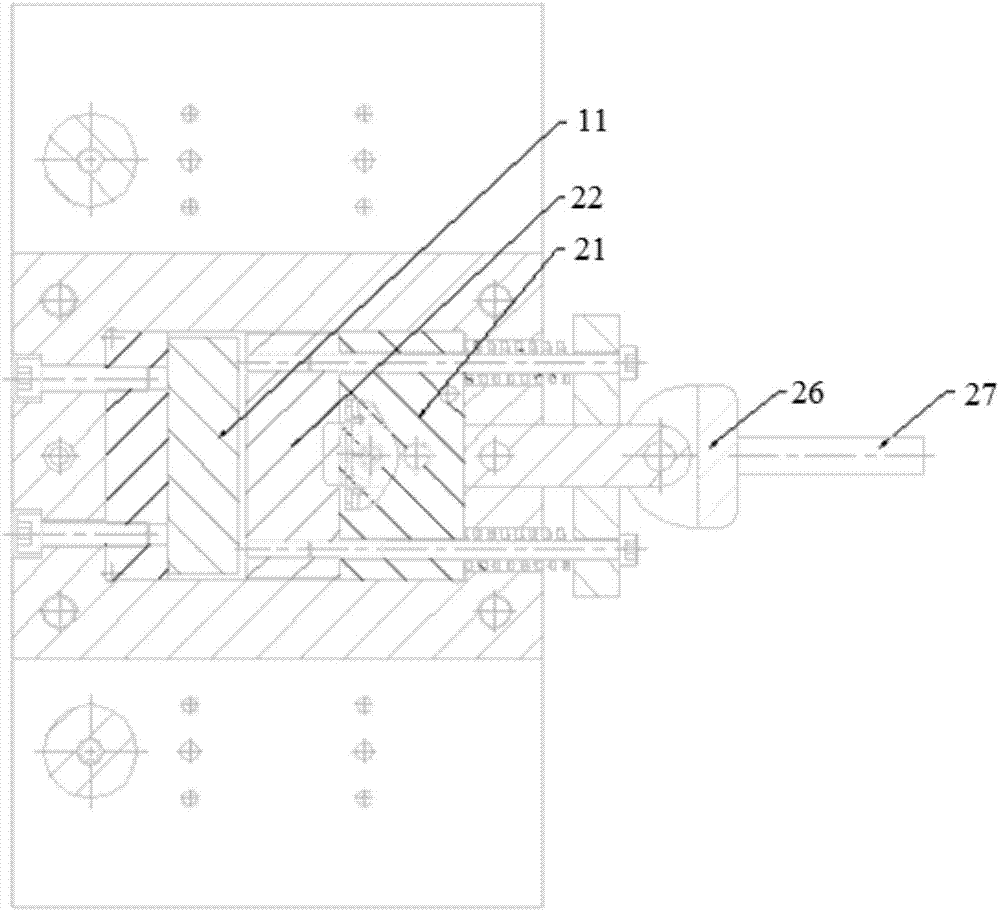

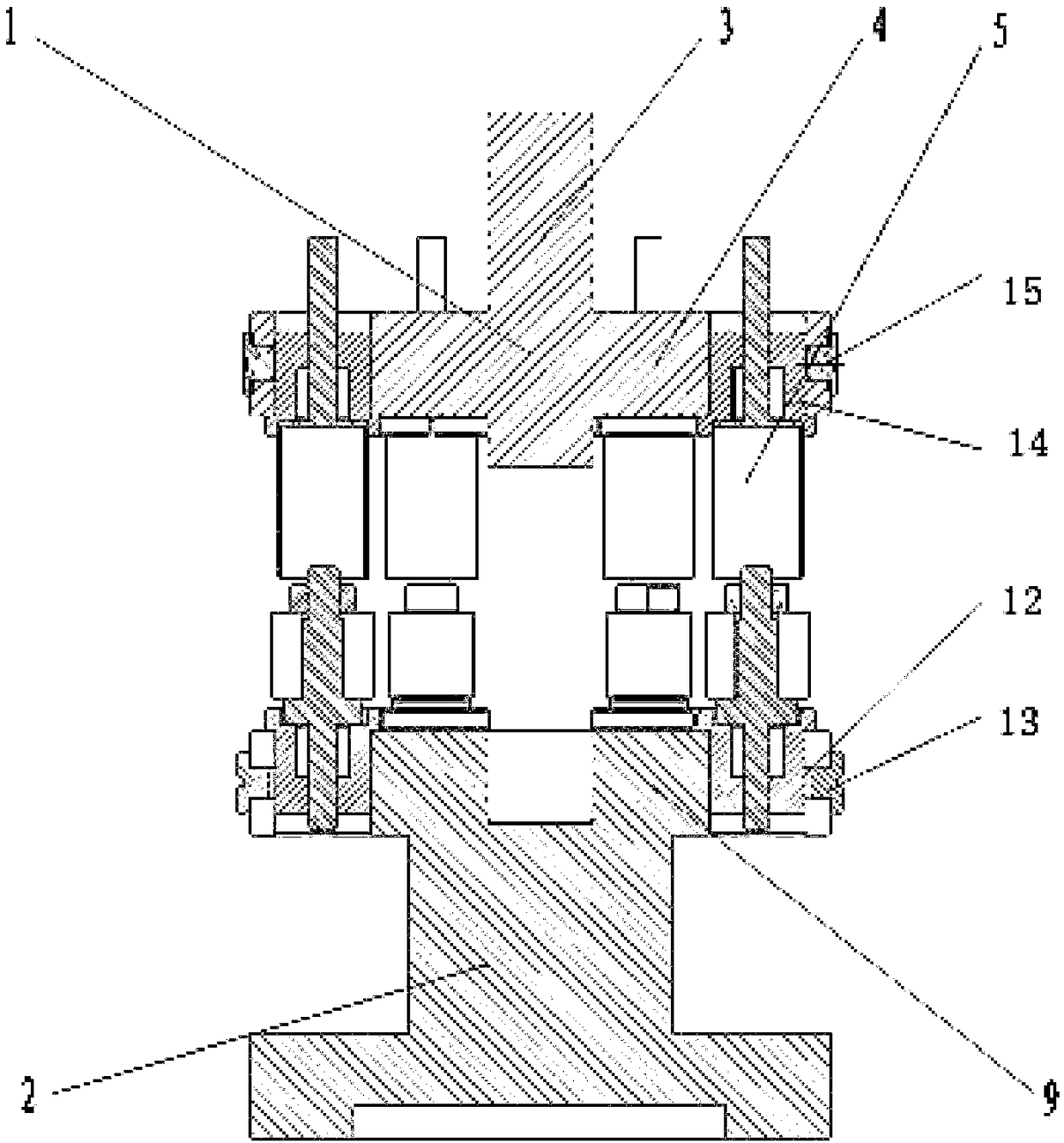

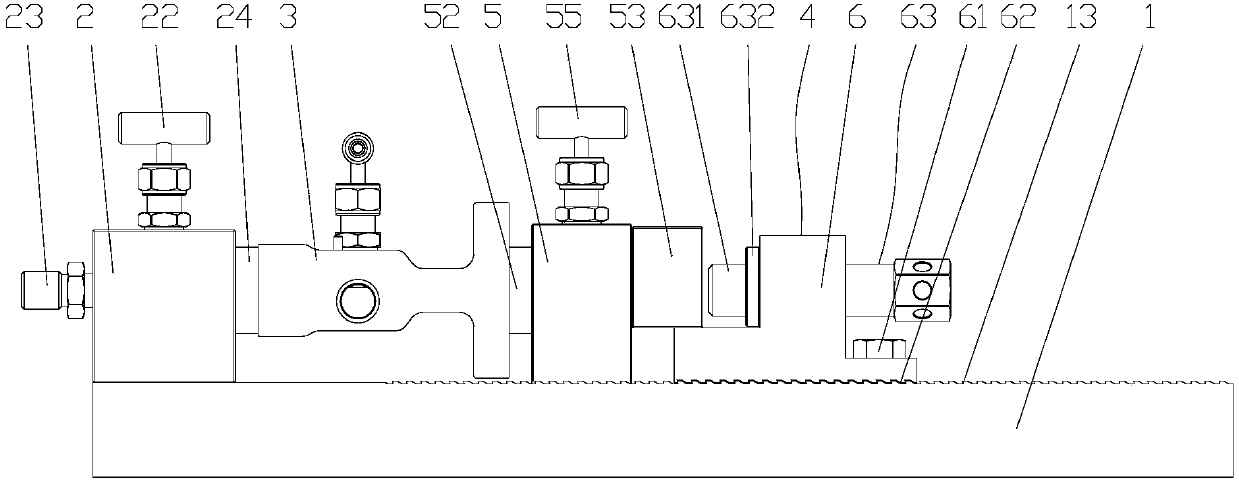

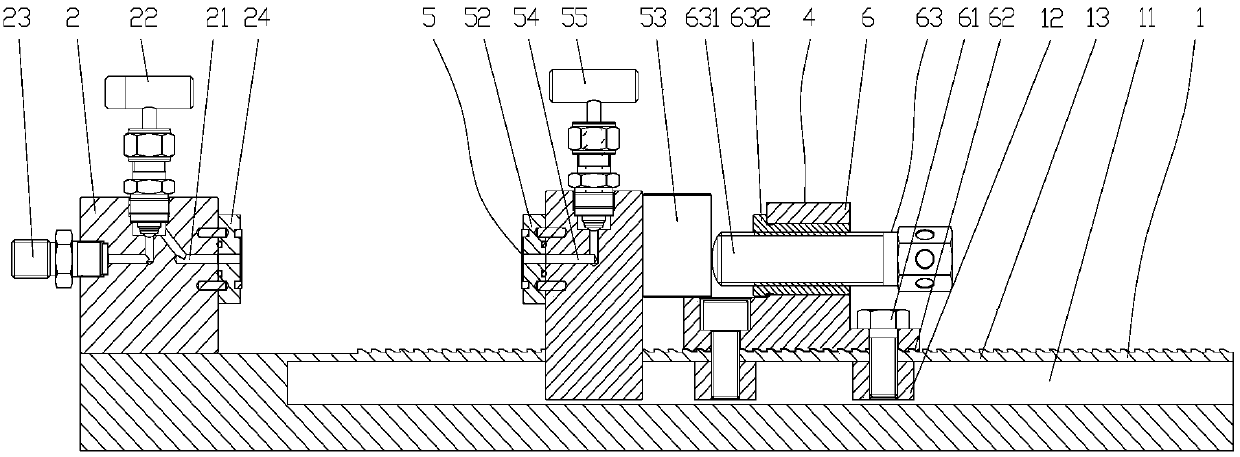

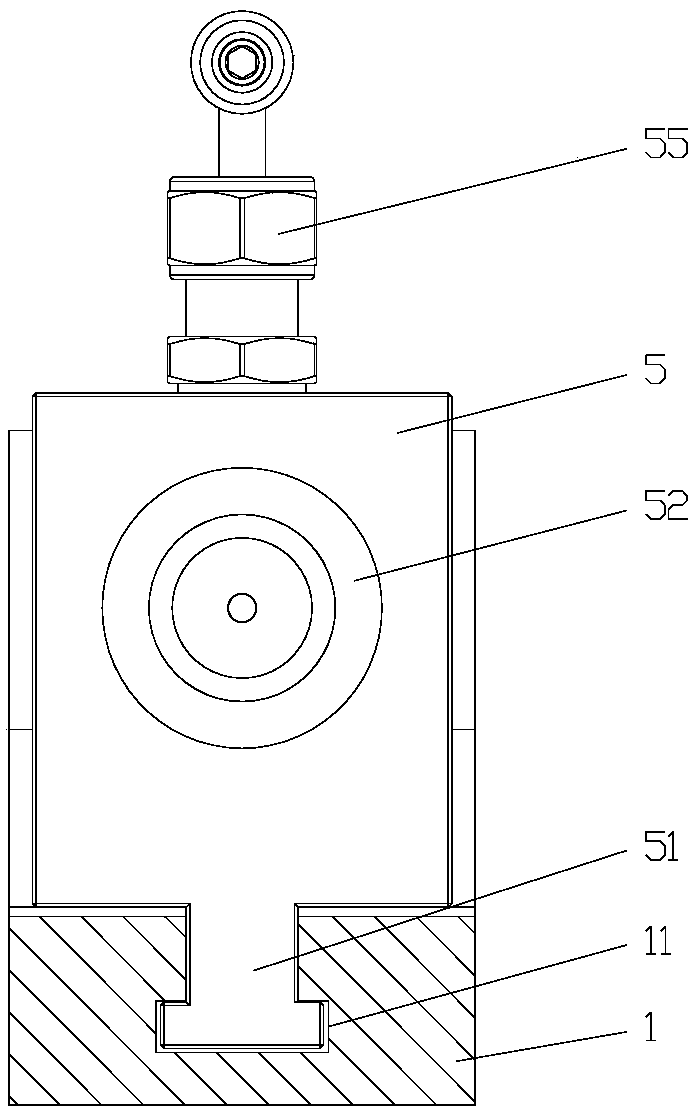

Flange instrument valve sealing testing device

ActiveCN105699018AJudgment of water tightnessDisassembly safetyDetection of fluid at leakage pointEngineeringFlange

The invention relates to a flange instrument valve sealing testing device which comprises a base. A stationary clamp seat which is internally provided with a pressure conveying channel is fixedly arranged at one end of the base. The other end of the vase is provided with a movable clamping seat. The base is provided with a T-shaped rail. At least one T-shaped slide block is embedded into the T-shaped rail. The upper surface of the base is provided with a sawtooth-shaped rail. The movable clamping seat comprises an abutting supporting seat and a movable supporting seat. The movable supporting seat is arranged between the stationary clamp seat and the abutting supporting seat. The bottom of the movable supporting seat is provided with a T-shaped part which is slidably connected with the T-shaped rail. One end of the movable supporting seat is provided with a first sealing cover assembly which is used for sealing the outlet of the instrument valve. The abutting supporting seat is connected with the T-shaped slide block through a fastener. The abutting supporting seat is fixed on the base. The lower surface of the abutting supporting seat is provided with unidirectional stopping sawteeth which are connected with the sawtooth-shaped rail, thereby preventing movement of the abutting supporting seat to the other end of the base. The abutting supporting seat is provided with a pushing mechanism which is used for pushing the movable supporting seat for making the instrument valve abut against the stationary clamp seat.

Owner:FUJIAN WIDE PLUS PRECISION INSTR

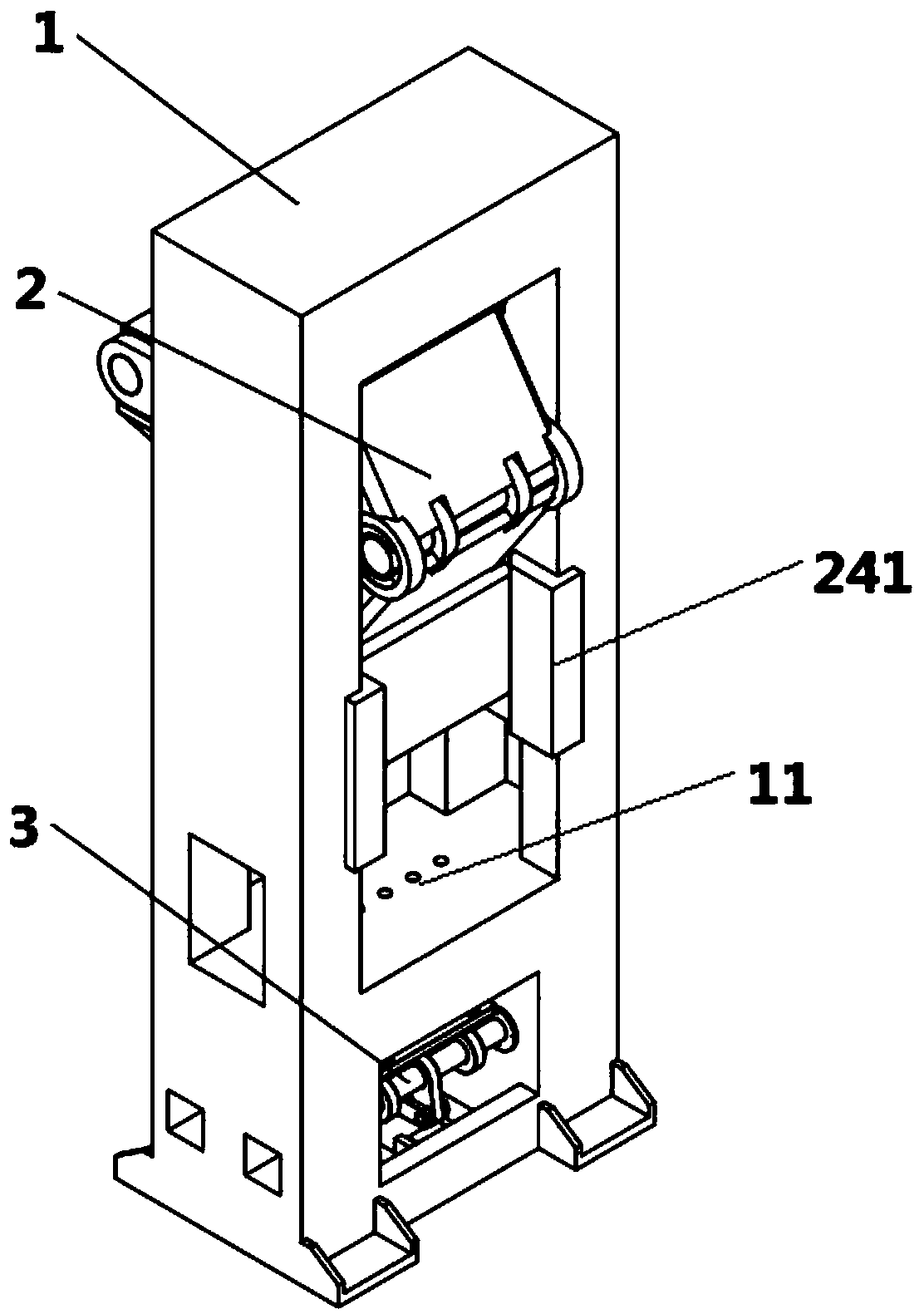

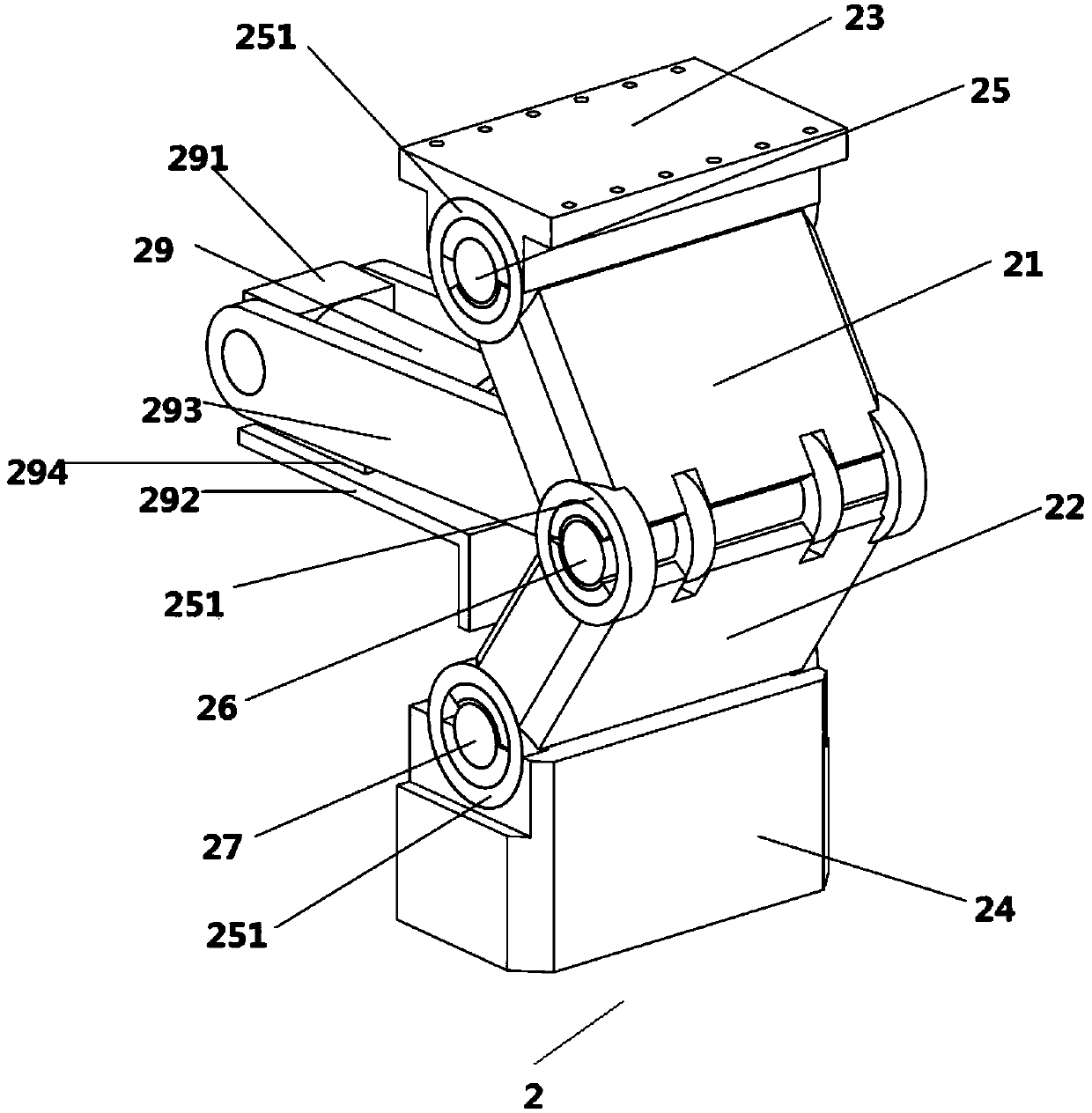

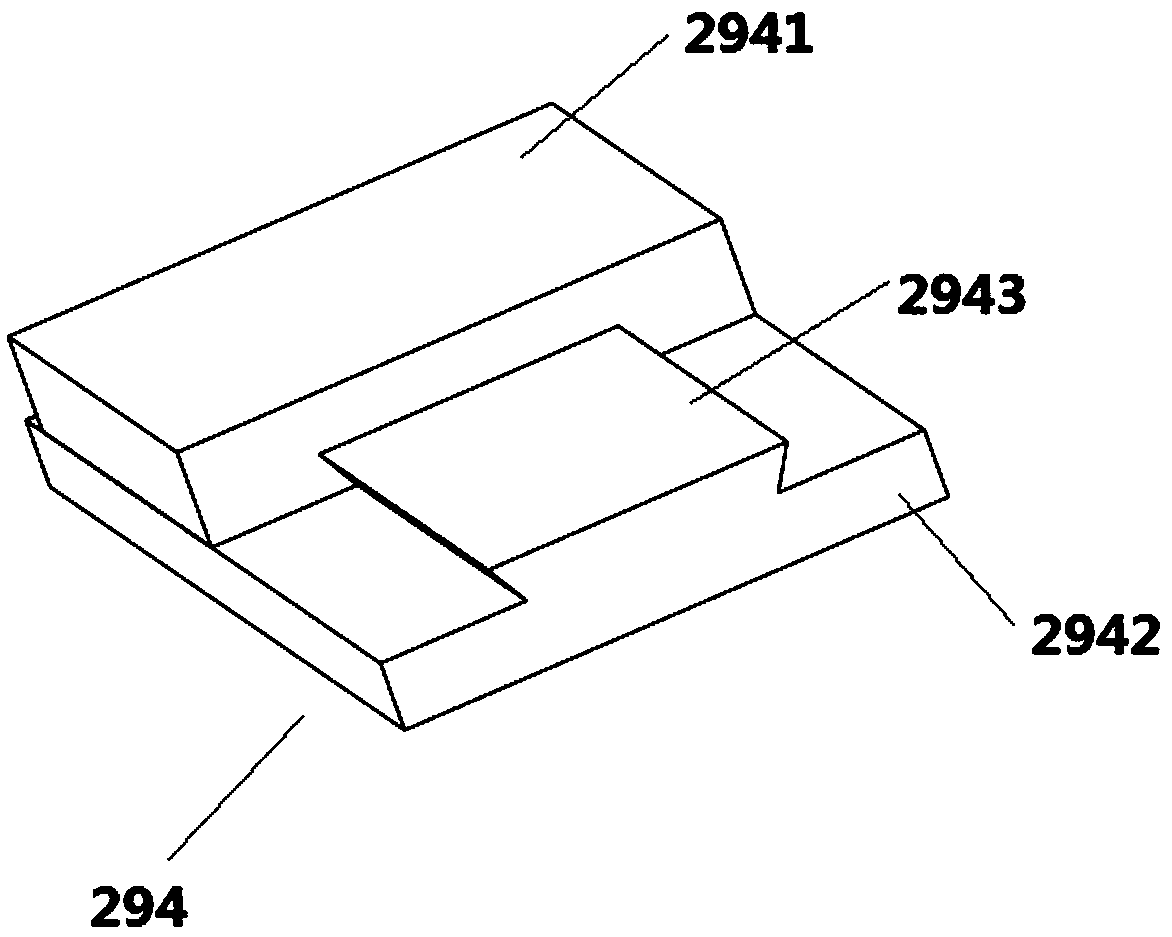

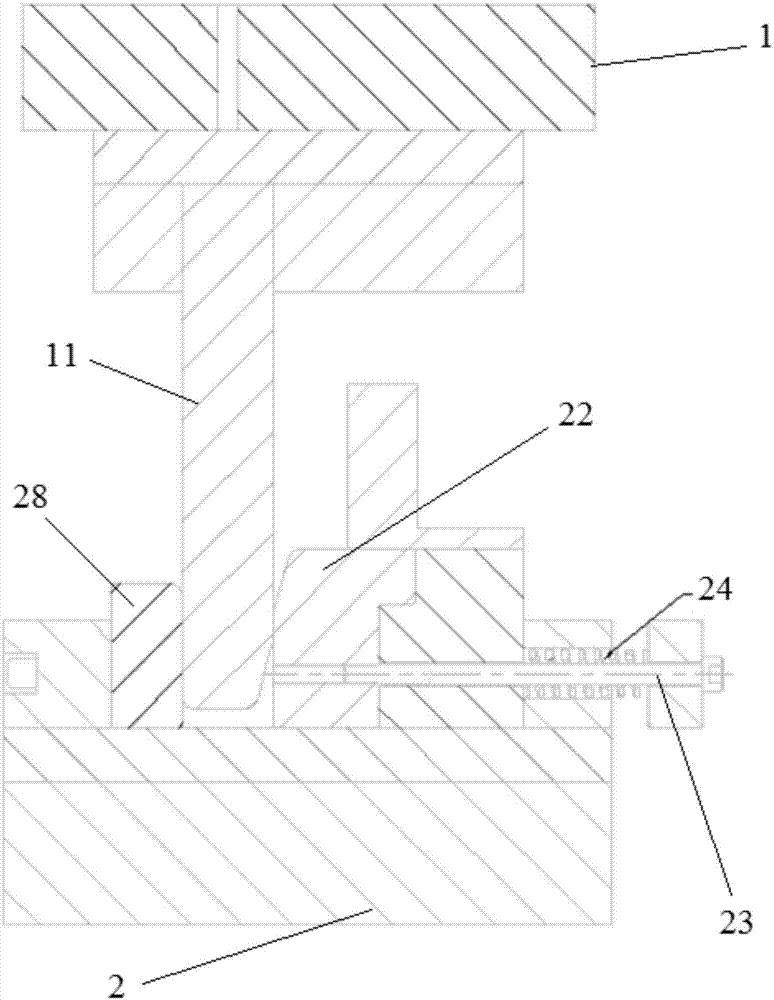

Pressurizing toggle joint punching machine

The invention discloses a pressurizing toggle joint punching machine which comprises a rack, a sliding block assembly and an ejection assembly. The sliding block assembly and the ejection assembly areoppositely arranged on the rack, the rack is provided with a through hole allowing the ejection assembly to extend out, the ejection assembly comprises an ejection rod device and a connecting rod device, the ejection rod device is arranged at the upper end of the connecting rod device, and the ejection rod device ascends and descends along with ascending and descending of the connecting rod device. The pressurizing toggle joint punching machine has the beneficial effects that the manner that an oil cylinder drives a toggle joint is adopted, driving force of the oil cylinder is increased, 5-7times of driving force can be increased, cost is saved, and the production efficiency is improved; and a unique lower ejection structure is adopted, according to the characteristics that ejection force needed in the early period during ejection is large and the ejection force needed after a product is loosened is small are used, a single-edge cam is used for ejection in the early period during ejection, the lever principle is used, the ejection force is increased, two-edge cams are used in the later period for ejection at the same time, and the ejection stroke is increased.

Owner:JIAXING DA DAO FORGING TECH CONSULTING LTD

Special-shaped injection molding part production mold with rapid mold opening function

The invention discloses a special-shaped injection molding part production mold with a rapid mold opening function. The special-shaped injection molding part production mold with the rapid mold opening function comprises an upper mold, a transmission assembly and a fixing assembly, wherein the transmission assembly is arranged on the upper mold; and the fixing assembly is fixedly connected onto the transmission assembly. When a hydraulic lifting rod controls the upper mold to move downwards, a sliding plate is controlled by the telescopic end of the hydraulic lifting rod to continue to move downwards to press a moving plate, so that an abutting rod gradually extends downwards in a penetrating hole, and the abutting rod is conveniently controlled to extrude a first transmission rod; a second transmission rod can be extruded through transverse movement of the first transmission rod, so that the second transmission rod moves downwards in a longitudinal moving cavity; the second transmission rod penetrates through an open hole in the downward moving process and extrudes a moving block in a moving cavity, so that the moving block can compress a first reset spring in the moving cavity to transversely move, then a fixing rod is driven to be inserted into a fixing hole through an inserting hole, the connectivity of the upper mold and the lower mold can be enhanced, and upper hot air jacking in the injection molding process of the upper mold is avoided.

Owner:欧斯普模具科技南通有限公司

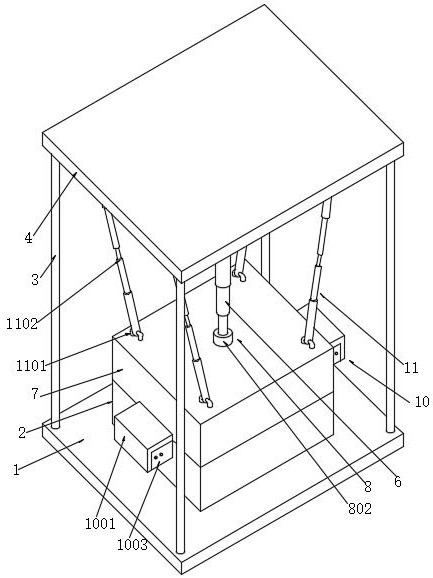

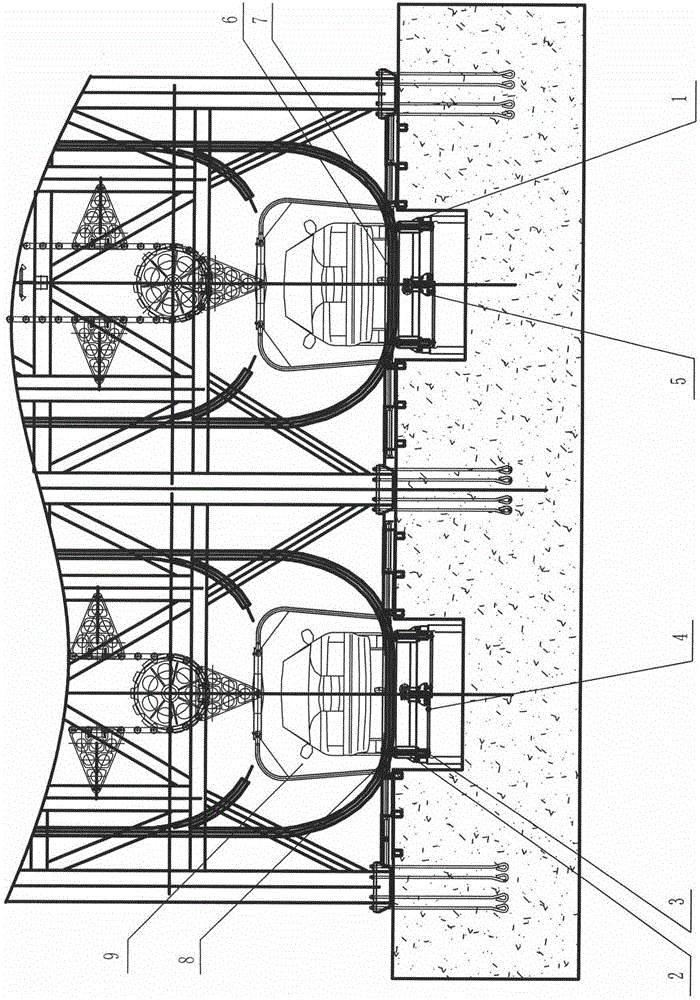

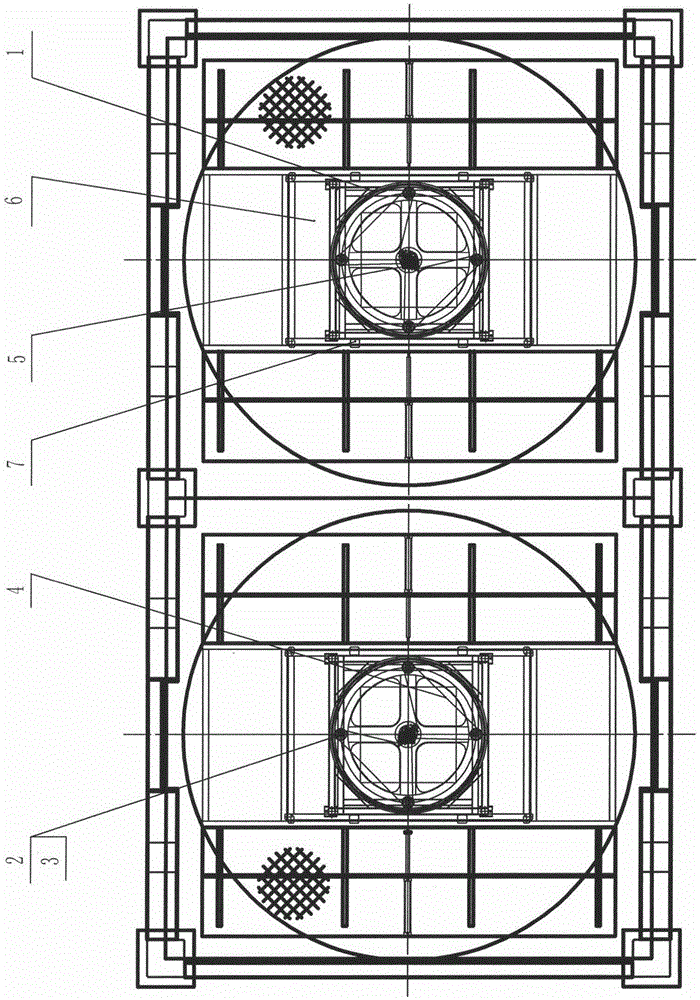

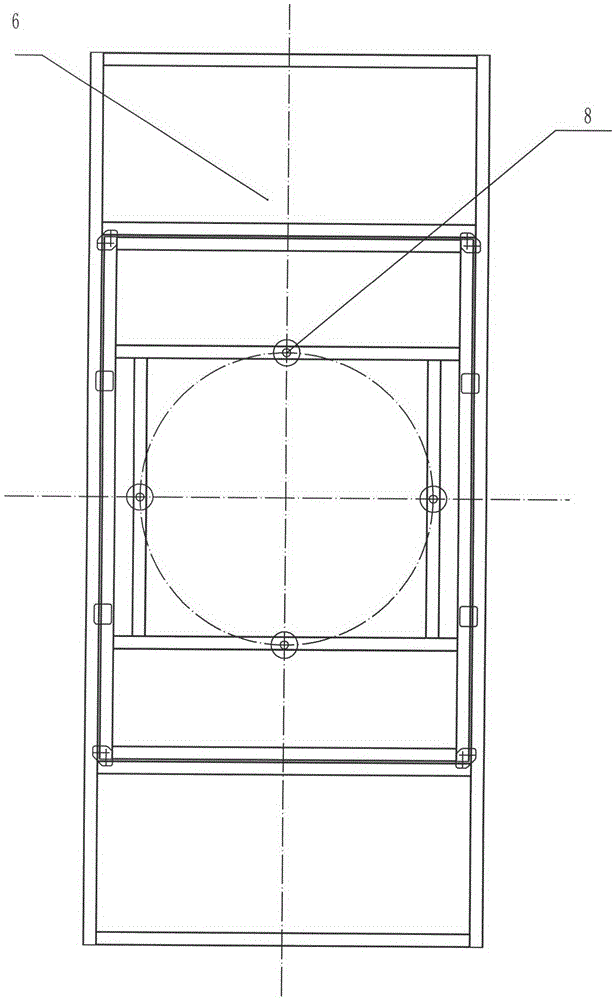

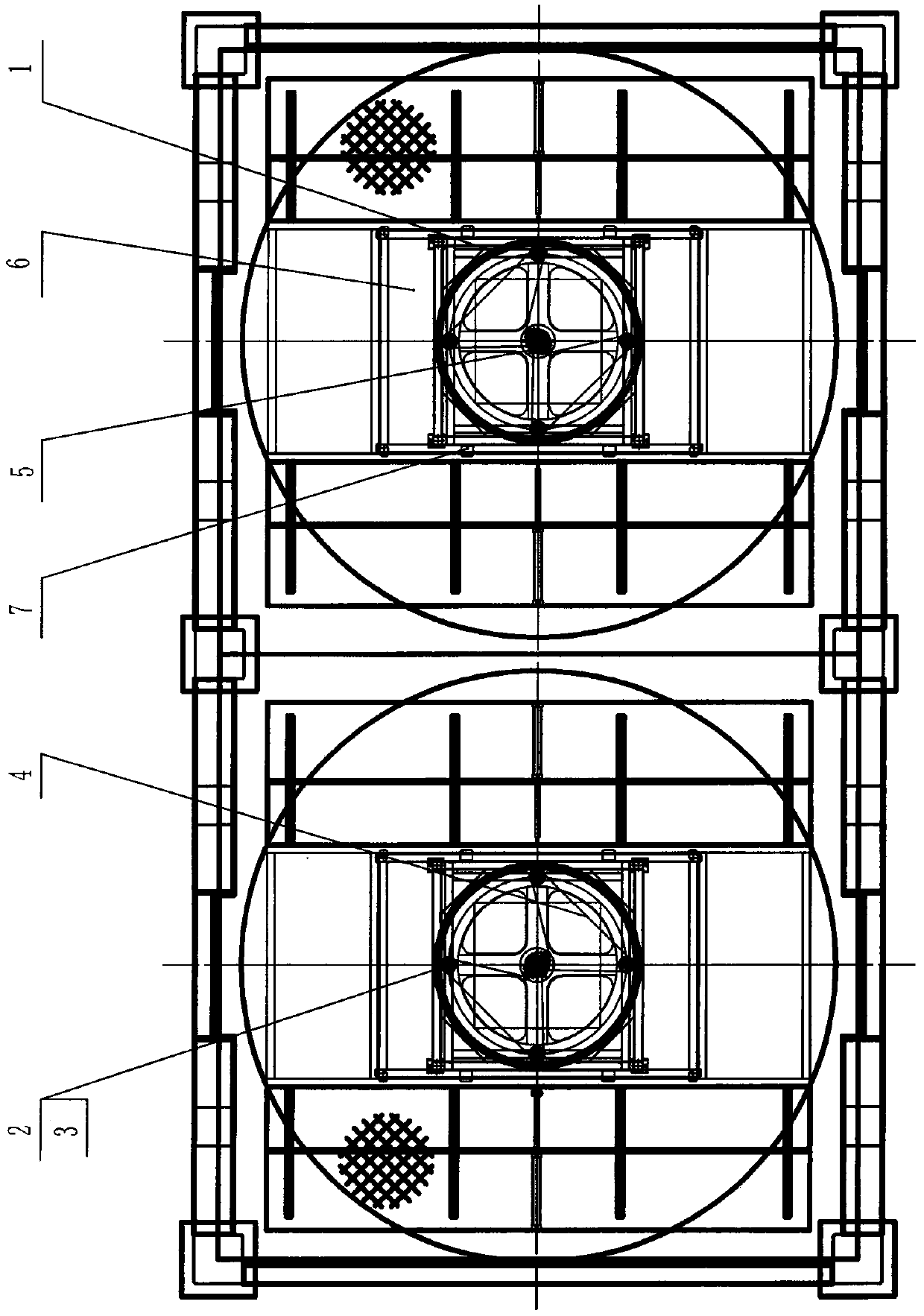

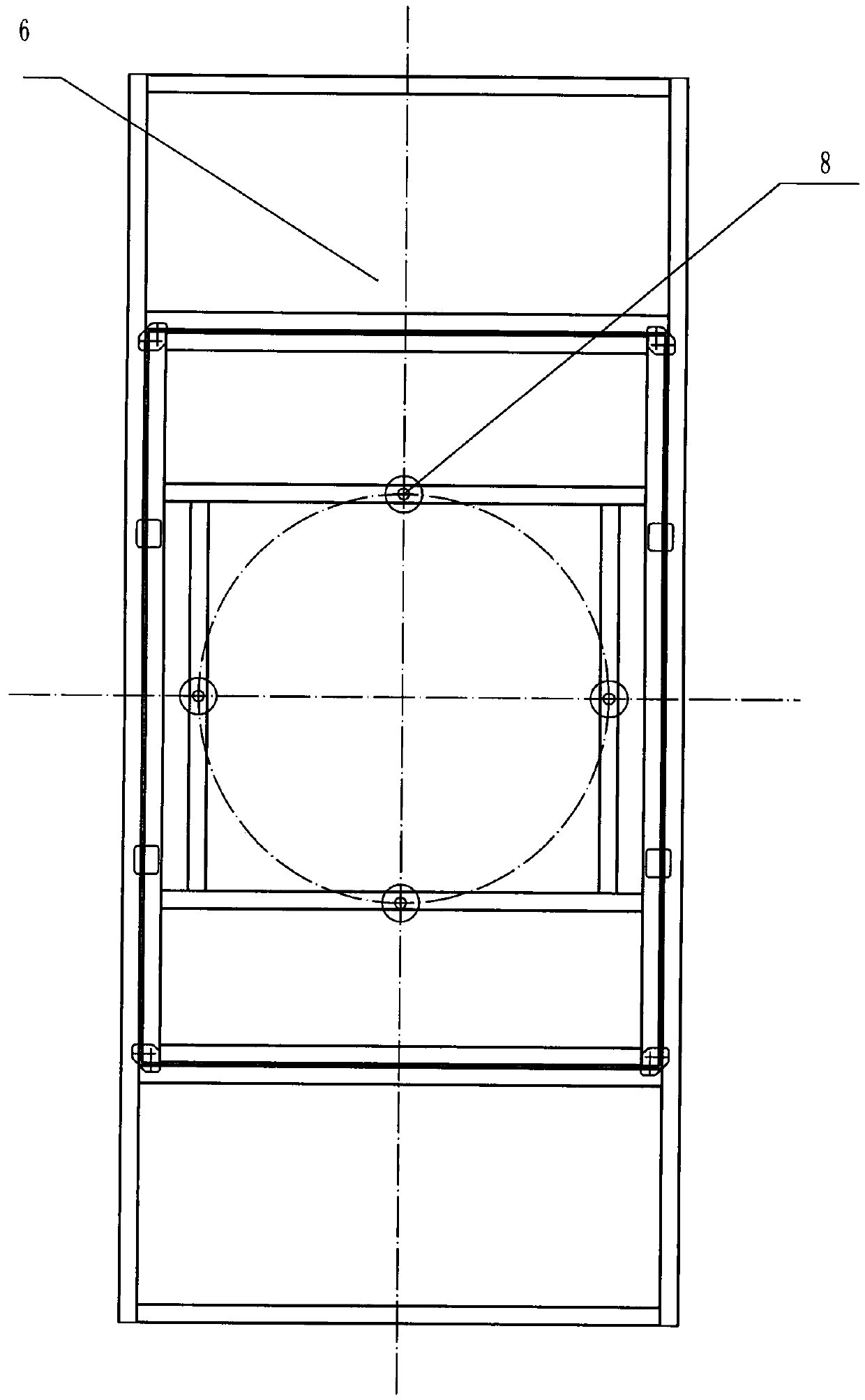

Vertical circulation type intelligent stereo garage u-turning mechanism

A vertical circulation type intelligent stereo garage u-turning mechanism comprises a jacking device and a rotating device. The rotating device comprises a rotating fluted disc which is located on a base and is connected with and bears the jacking device and a motor reducing gear driving the rotating fluted disc to rotate. The jacking device is composed of a jacking lead screw installed on the rotating fluted disc, a synchronous belt wheel, a synchronous belt and a jacking motor reducing gear. The jacking device and a car containing plate are of a separated structure. Stable rotation and high operation efficiency are achieved, the jacking force of the jacking device is improved, and the internal garage space needed in the steering u-turning motion process of the u-turning mechanism is reduced. The u-turning mechanism is used for automobile u-turning when cars are stored in an intelligent stereo garage, a vertical circulation type intelligent stereo garage and a twin-tower vertical circulation type intelligent stereo garage.

Owner:张庆发

Locking device and vehicle seat

ActiveUS9533606B2Reduced space required for installationIncrease jacking forceVehicle seatsBuilding locksMechanical engineeringEngineering

Owner:KEIPER SEATING MECHANISMS CO LTD

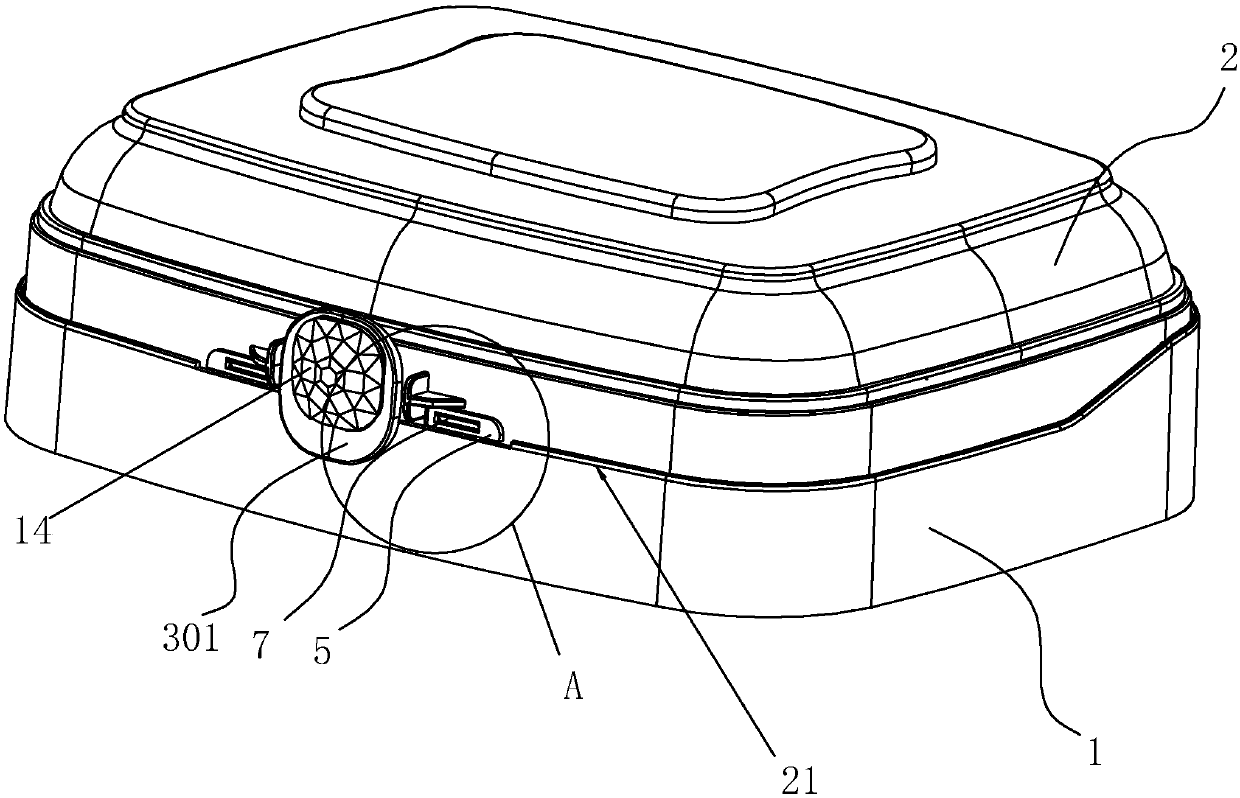

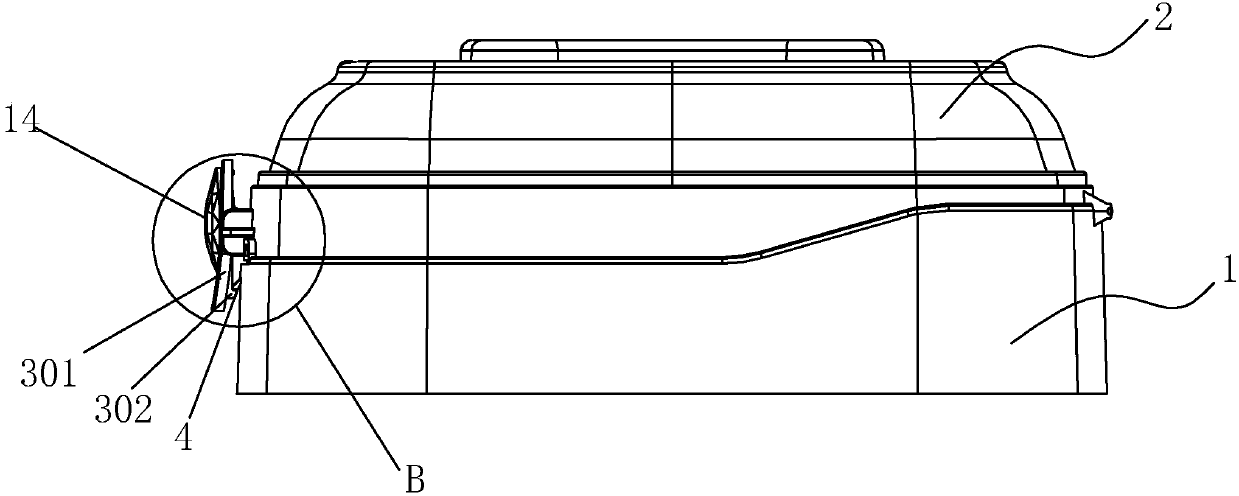

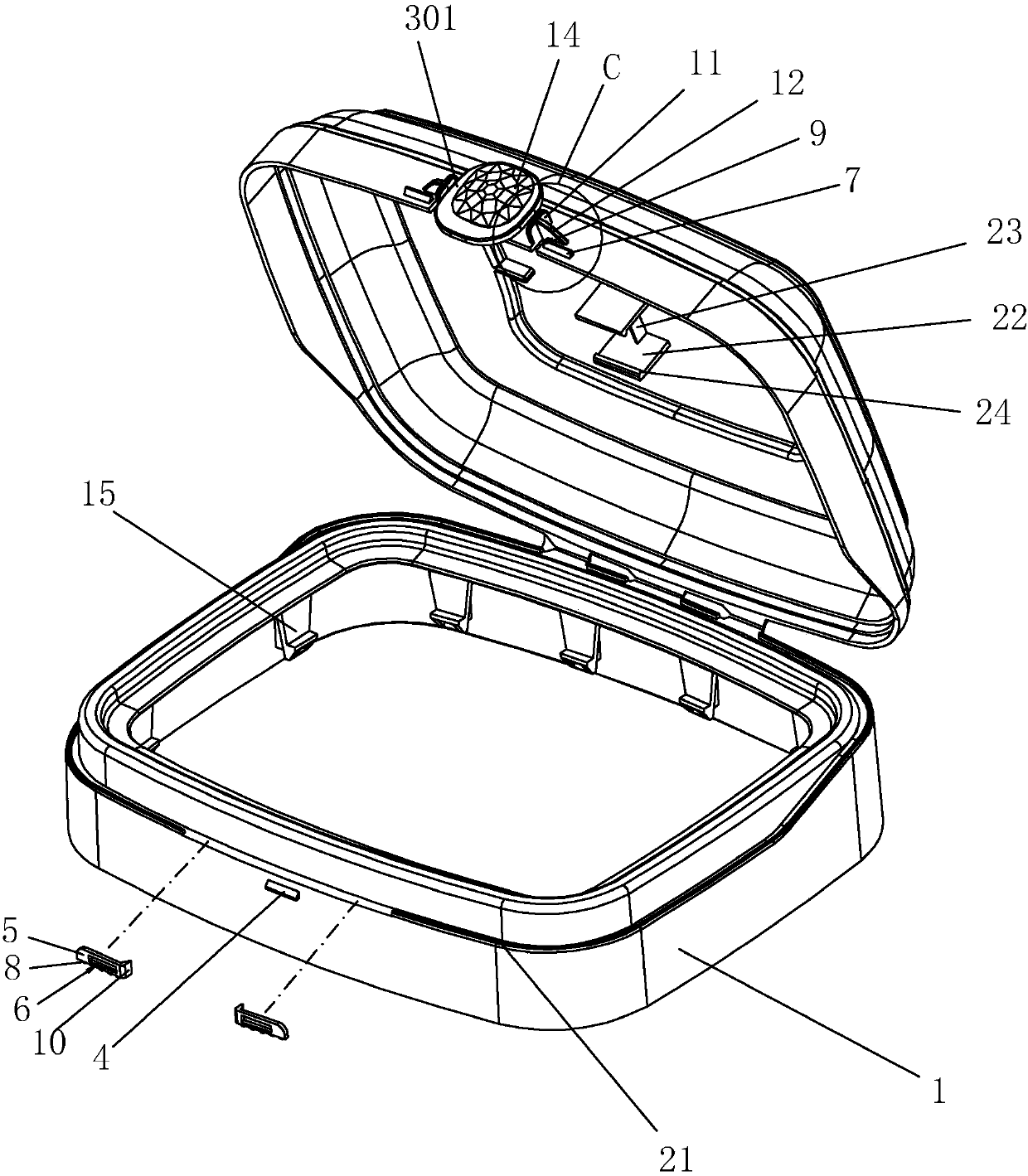

Container cover and milk powder can

InactiveCN107618746AIncrease jacking forcePrevent hands offClosure with auxillary devicesJarsEngineering

The invention discloses a container cover and a milk powder can. According to the technical scheme, the container cover is characterized by comprising a retainer ring buckled to the upper end of a container, and an overturning cover arranged at the upper end of the retainer ring, wherein one side of the overturning cover is hinged to one side of the retainer ring, the side, far away from the hinged end, of the overturning cover is provided with a first buckling piece, the retainer ring is provided with a second buckling piece which is buckled to the first buckling piece, the upper edge of theretainer ring is provided with a sealing strip easy to tear, the sealing strip easy to tear is provided with a buckling opening, and the parts, located on the two sides of the first buckling piece, ofthe overturning cover are provided with buckling blocks which are buckled to the buckling opening. In the actual milk powder can transportation process, the overturning cover can be tightly buckled to the retainer ring during jolting, the snap joint structure is firm and stable, and milk powder is prevented from sprinkling.

Owner:浙江卓康医疗科技有限公司

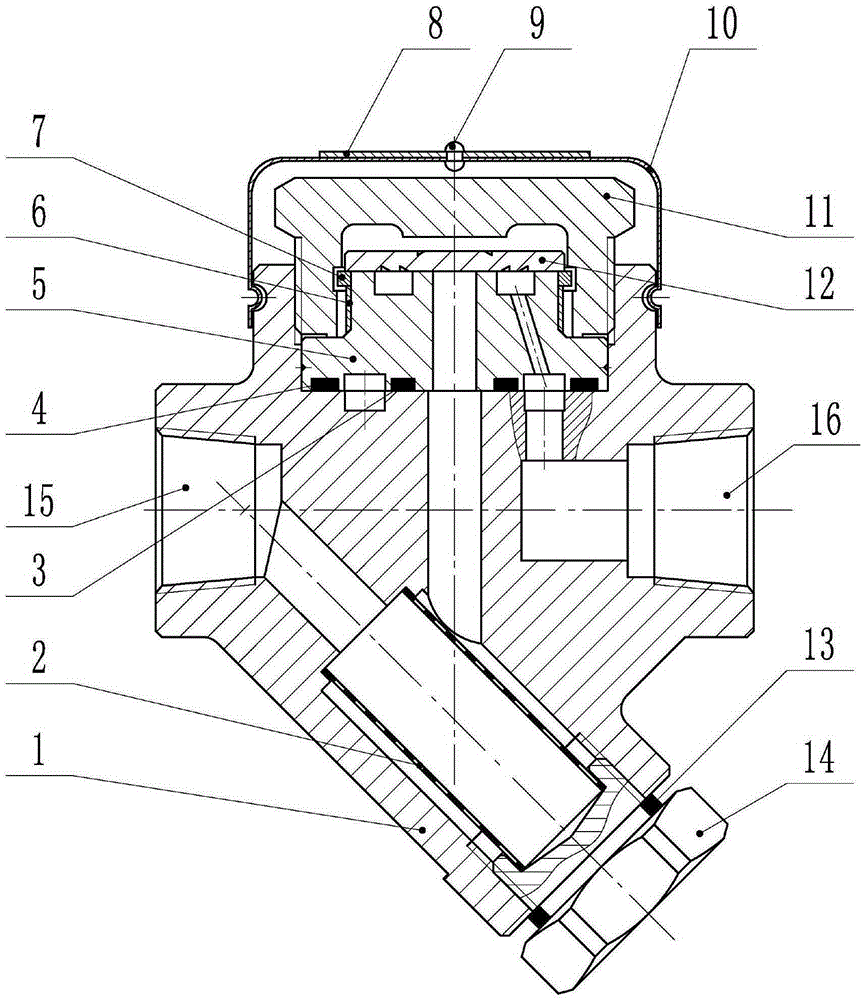

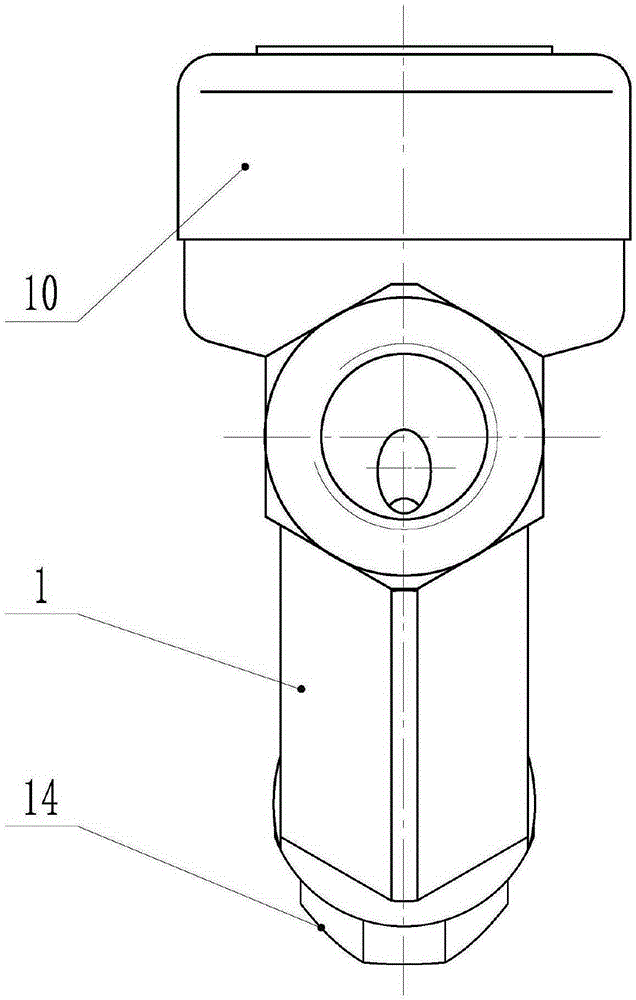

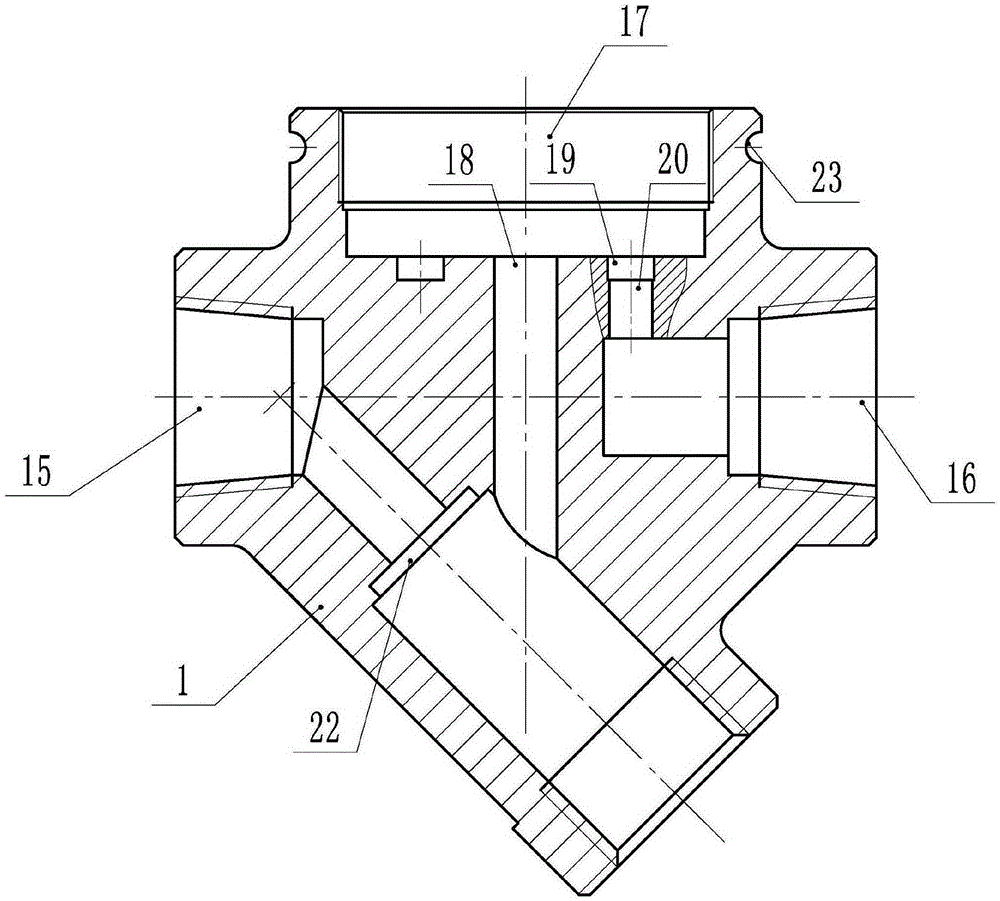

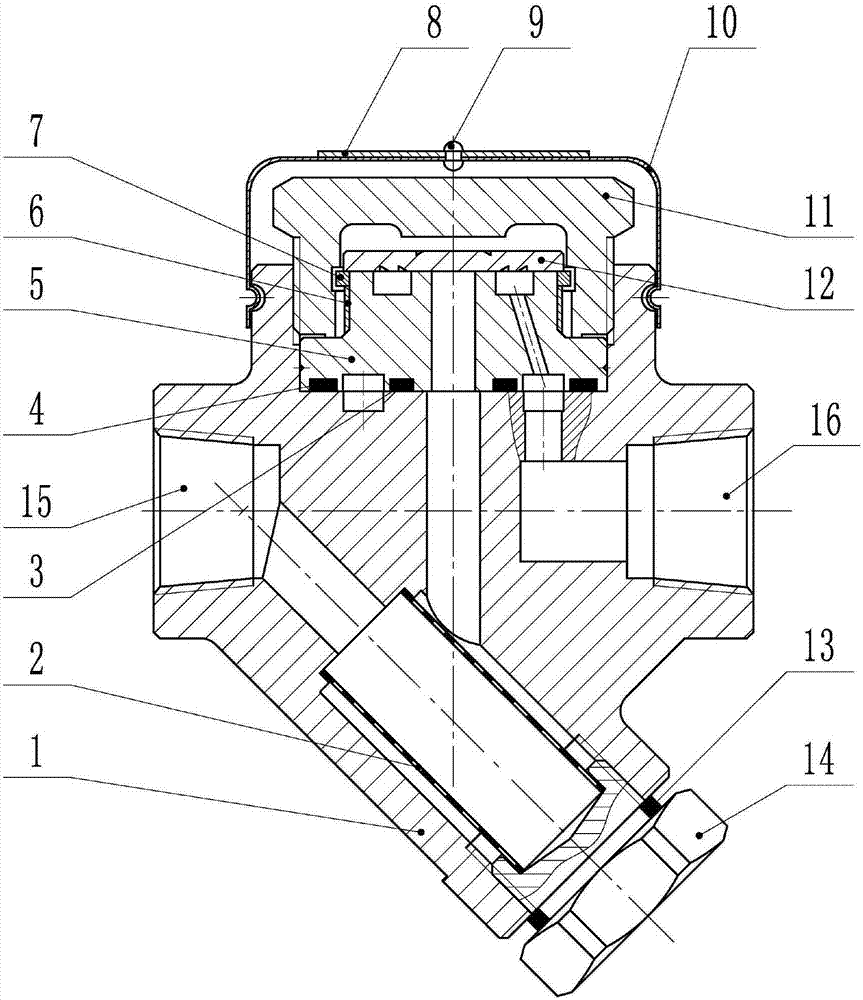

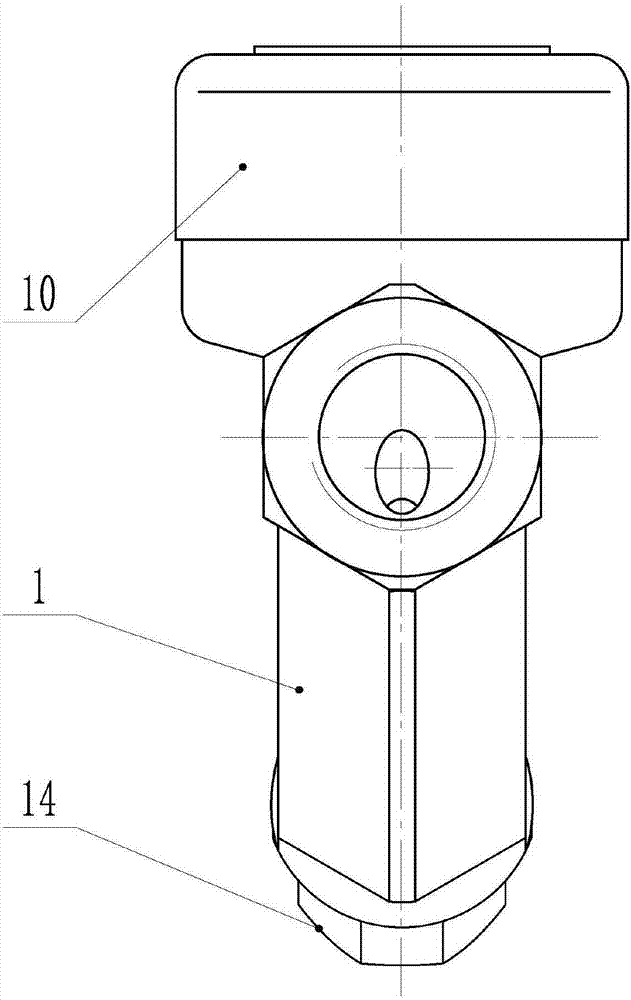

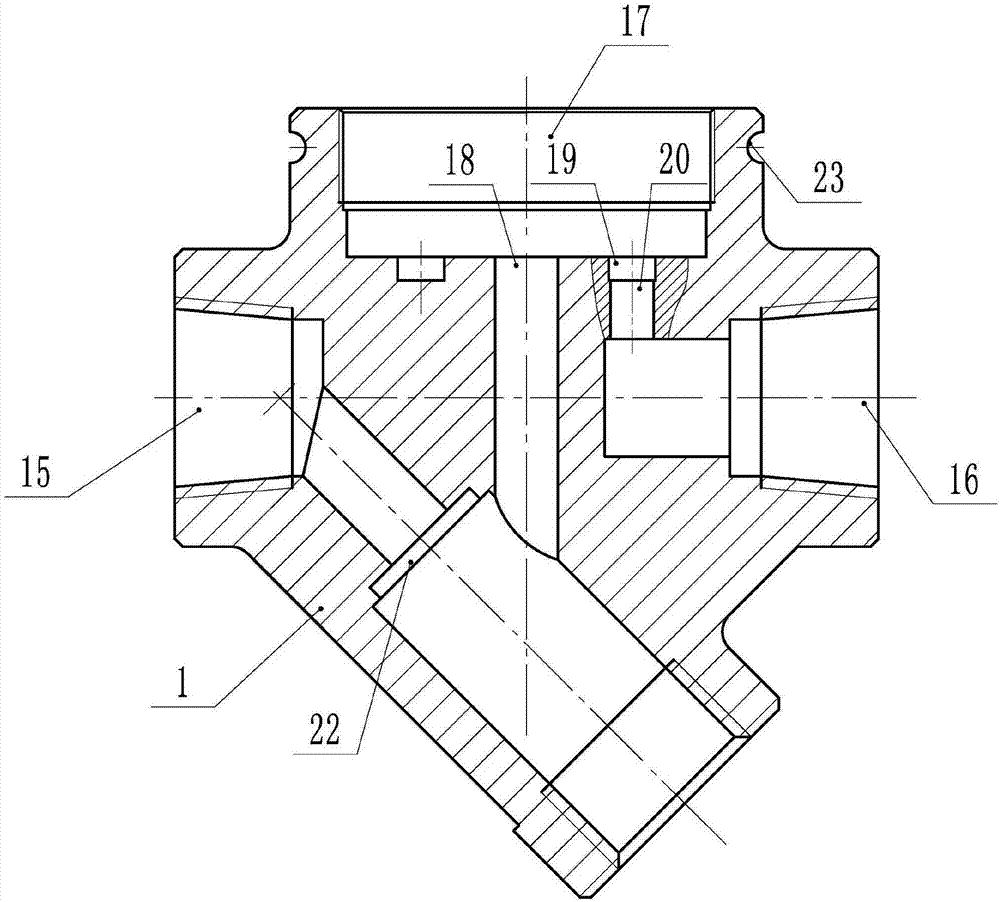

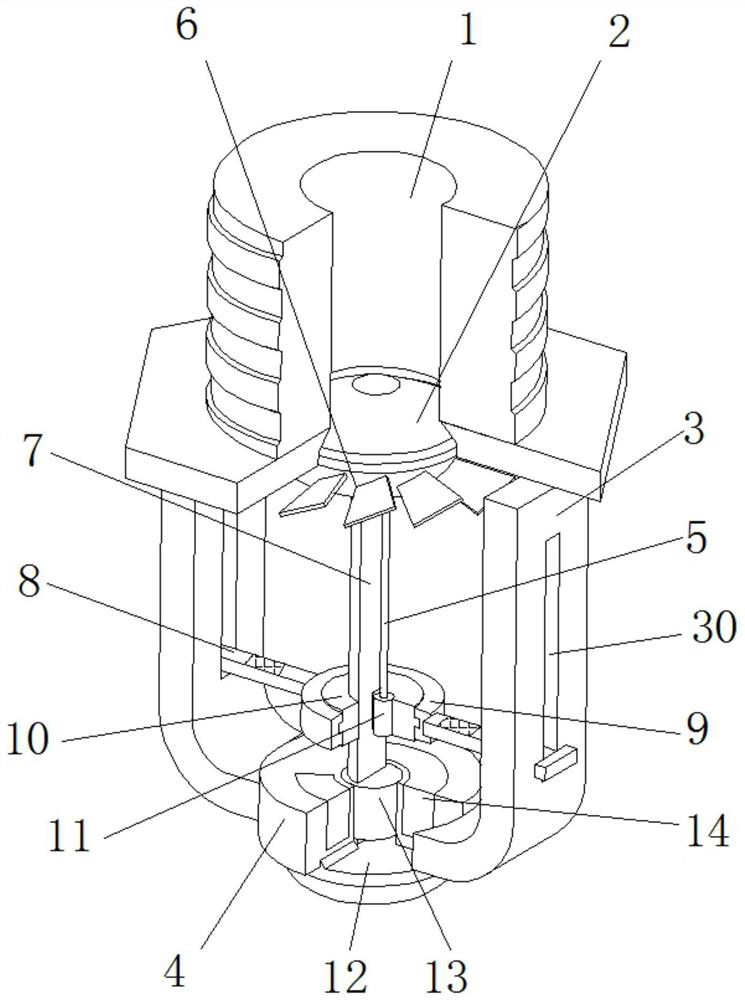

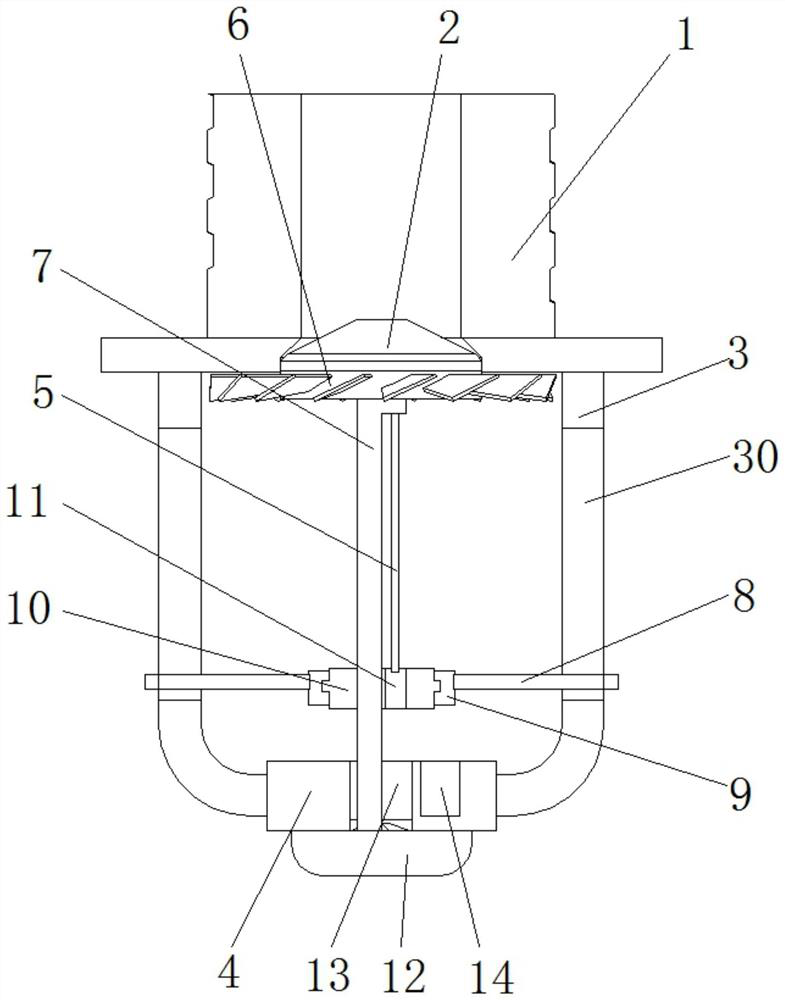

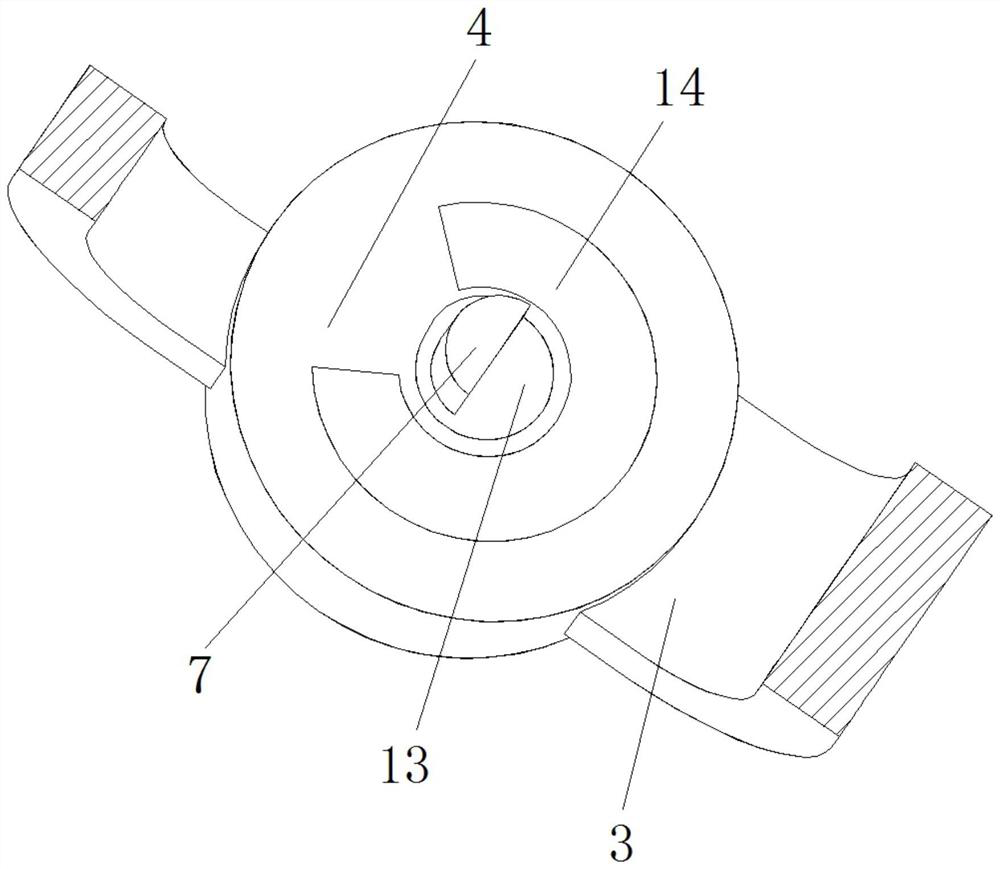

Quick-unlocking steam hydrophobic valve

The invention relates to a quick-unlocking steam hydrophobic valve. The quick-unlocking steam hydrophobic valve is characterized in that a water inlet is formed in the left side of a Y-shaped valve body, and a water outlet is formed in the right side of the Y-shaped valve body; a sealing gasket I and a sealing gasket II are arranged in a gasket groove I and a gasket groove II in the bottom face of a valve seat; a C-shaped tensioner ring and a supporting cushion are arranged at the upper end of the valve seat in sequence; the valve seat is arranged in a cavity in the upper end of the Y-shaped valve body, and an inverted-V-shaped groove type valve plate is placed at the upper end of the valve seat; an inner table type valve deck is connected with a thread in the cavity in the upper end of the Y-shaped valve body; a semicircular boss in an air isolation hood is connected with a semicircular ring groove in the side face of the upper end of the Y-shaped valve body in a nested mode; a filter net is arranged in a stepped hole in the lower end of the Y-shaped valve body, a sealing gasket III is arranged in a plug screw, and the plug screw is connected with the stepped hole in a threaded mode. According to the quick-unlocking steam hydrophobic valve, the fatal defect that a thermo-motive type steam hydrophobic valve cannot exhaust air and non-condensable gas automatically is overcome, meanwhile, the performance of the thermo-motive type steam hydrophobic valve is improved, and the service life of the thermo-motive type steam hydrophobic valve is prolonged. A manual, electric and pneumatic valve can be replaced, the action is reliable, the environment-friendly effect is obvious, parameters are high and cost is low.

Owner:GANSU HONGFENG MASCH CO LTD

Riveting die used for ball head rivet and sheet metal part

The invention relates to a riveting die used for a ball head rivet and a sheet metal part. The riveting die comprises an upper die and a lower die. A riveting punch used for pressing the ball head rivet and the sheet metal part for achieving riveting is arranged on the lower surface of the upper die. A clamping block assembly used for clamping and placing the ball head rivet and the sheet metal part is machined on the upper surface of the lower die. The clamping block assembly comprises a static clamping block and a movable clamping block which are in butt joint and are matched to form a riveting cavity matched with the ball head rivet and the sheet metal part. A guide hole is formed in the lower die in the horizontal direction, and a push rod moving along the guide hole is installed in the guide hole. One end of the push rod stretches out of the lower die, and the other end of the push rod is connected with the movable clamping block and drives the movable clamping block to move on the lower die. Compared with the prior art, the contact area between the ball head rivet and the clamping block assembly is large, during riveting punching, the ball head deformation of the ball head rivet is small, the size is stable, the riveting strength is also greatly improved, and the ejecting force and torsion are improved, are stable and the like.

Owner:SHANDONG AOLIN CAR FITTINGS

Disk carrying device and optical disk recording/reproducing device

ActiveUS20100218205A1Reduce loadSmoothly carry a diskRecord information storageOptical discElectric motor

A disk carrying device and an optical disk recording / reproducing device. The disk carrying device comprises a first idle gear rotatably supported on a lower chassis and a second idle gear rotatingly operated by coming into contact with or separating from the first idle gear. The second idle gear and a roller gear meshed with the second idle gear are rotatably supported on a feed plate, and the second idle gear is brought into contact with or separated from the first idle gear, from the underside, which is rotatably supported on the lower chassis. By this, when a disk is inserted, a downward force F1 acts on the second idle gear, and the pressing force of a feed roller on the disk (D) is decreased and, therefore, the rotating load of a disk carrying motor can be reduced when the carrying of the disk is completed. When the disk is discharged, an upward force F2 acts on the second idle gear and the pressing force of the feed roller on the disk (D) is increased and, therefore, the disk (D) can be smoothly discharged even if the disk (D) is deflected.

Owner:PANASONIC CORP

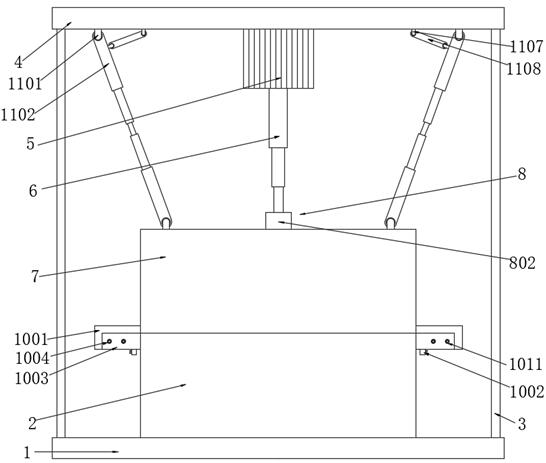

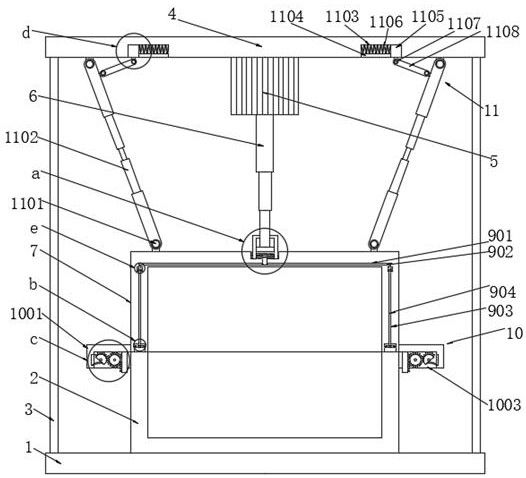

Improved power distribution cabinet with safety protection function

InactiveCN113612136AWith safety protection functionPrevent dumpingSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsSlide plateElectrical and Electronics engineering

The invention discloses an improved power distribution cabinet with a safety protection function, and relates to the technical field of power distribution cabinets. The improved power distribution cabinet comprises a power distribution cabinet body; an anti-collision plate is arranged outside the power distribution cabinet body; a buffer mechanism is arranged between the anti-collision plate and the power distribution cabinet body; the buffer mechanism comprises a fixing pipe, a first sliding rod, a first sliding plate and a through hole, the fixing pipe is fixedly embedded in the outer wall of the power distribution cabinet body, one end of the first sliding rod penetrates through and is slidably installed on the fixing pipe, the other end of the first sliding rod is fixedly embedded in the outer wall of the anti-collision plate, and the anti-collision plate is connected with the outer wall of the fixing pipe. According to the improved power distribution cabinet with the safety protection function, the safety performance of the power distribution cabinet can be comprehensively improved through the buffering and anti-toppling mechanism between the anti-collision plate and the fixing pipe, an impacted object can be ejected out through a second sliding block during collision, damage to the anti-collision plate is reduced; and a cabinet door is locked from the interior of the power distribution cabinet during collision, workers are protected, and the safety protection capability is improved.

Owner:陆强胜

Multi-channel pipettor with repositionable tips

A hand-held, multi-channel pipettor has an electronically controlled motor to reposition pipette tips for different center to center spacing. Each repositionable tip fitting assembly has a cam following pin that is driven by cam tracks in a motor driven roller drum. Stationary ports for the multiple aspiration cylinders are strategically placed to simplify management of flexible tubes leading to the repositionable pipette tip fitting assemblies. The pipettor has a user interface that can be operated conveniently by one hand to reposition pipette tips. It has a pipette tip ejection mechanism with a sinusoidal stripper bar.

Owner:INTEGRA BIOSCI CORP

A quick release steam trap

ActiveCN105276368BGuaranteed heating efficiencyEasy dischargeSteam trapsEnvironmental effectSteam trap

The present invention relates to a quick release steam trap. The characteristics of the present invention are: the left side of the Y-shaped valve body is provided with a water inlet, and the right side is provided with a water outlet; the gasket groove I and the gasket groove II on the bottom surface of the valve seat are respectively filled with gaskets I and II; The upper end is equipped with a C-shaped expansion ring and a supporting pad in turn. A valve seat is installed in the cavity at the upper end of the Y-shaped valve body, and a ∧-shaped groove valve plate is placed on the upper end of the valve seat. The inner platform bonnet is threadedly connected to the upper cavity of the Y-shaped valve body; the semicircular boss in the air isolation cover is nestedly connected to the semicircular groove on the upper side of the Y-shaped valve body. The step hole at the lower end of the Y-shaped valve body is equipped with a filter screen, the screw plug is equipped with a sealing gasket III, and the screw plug is threaded with the step hole. The invention solves the fatal defect that the thermodynamic steam trap cannot automatically discharge air and non-condensable gas, and at the same time improves the performance and service life of the thermodynamic steam trap. It can replace manual, electric and pneumatic valves, with reliable action, remarkable environmental protection effect, high parameters and low price.

Owner:GANSU HONGFENG MASCH CO LTD

Spray head for fire fighting

InactiveCN113262417AImprove the immunityAvoid complete disassemblyFire rescueEngineeringStructural engineering

The invention relates to the technical field related to fire fighting equipment, and discloses a spray head for fire fighting. The spray head comprises a mounting block, wherein a water outlet channel is formed in the inner wall of the mounting block, a plugging block used for plugging the water outlet channel is movably arranged at the bottom of the mounting block, and supporting arms are fixedly arranged on the two sides of the bottom of the mounting block respectively. According to the spray head, a fixed magnetic block is arranged on a fixing seat, meanwhile, a cutting block is attracted by the fixed magnetic block, the cutting block supports the plugging block through a driving shaft and a detection rod, so that after the detection rod is broken, the cutting block is manually pushed to realize that the plugging block plugs the water outlet channel of the mounting block, and the purpose of plugging at any time is achieved; and moreover, through the interaction between the adsorption force between the cutting block and the fixed magnetic block and the water flow, a water dispersing disc can move up and down in a reciprocating mode, change of the water dispersing area of the water dispersing disc is realized, and finally the purposes of real-time plugging without cutting off a main switch and changing the water dispersing area are achieved.

Owner:温谟宇

Vertical cycle intelligent three-dimensional garage U-turn mechanism

A vertical circulation type intelligent stereo garage u-turning mechanism comprises a jacking device and a rotating device. The rotating device comprises a rotating fluted disc which is located on a base and is connected with and bears the jacking device and a motor reducing gear driving the rotating fluted disc to rotate. The jacking device is composed of a jacking lead screw installed on the rotating fluted disc, a synchronous belt wheel, a synchronous belt and a jacking motor reducing gear. The jacking device and a car containing plate are of a separated structure. Stable rotation and high operation efficiency are achieved, the jacking force of the jacking device is improved, and the internal garage space needed in the steering u-turning motion process of the u-turning mechanism is reduced. The u-turning mechanism is used for automobile u-turning when cars are stored in an intelligent stereo garage, a vertical circulation type intelligent stereo garage and a twin-tower vertical circulation type intelligent stereo garage.

Owner:张庆发

An intelligent coal mine support

ActiveCN110529163BPrevent landslidesPrevent overload collapseMining devicesMine roof supportsRatchetHydraulic cylinder

The invention relates to an intelligent coal mine support, comprising a supporting plate, the supporting plate is hingedly installed with a connecting plate, the connecting plate is connected with a cover beam, the cover beam is hingedly installed with a top beam, and the supporting plate is hingedly installed There is a No. 1 hydraulic cylinder connected to the top beam. The top beam is connected with a supporting device to prevent the top beam from overloading and rotating. The top beam is also equipped with a reinforcement device to increase the bearing capacity of the top beam. The No. 1 hydraulic cylinder, Both the support device and the reinforcement device are connected to a controller. The invention supports the top beam through the cooperation of the non-return rod and the ratchet to prevent the top beam from turning over and causing underground landslides, endangering the safety of workers; the invention enhances the jacking force of the No. 2 hydraulic cylinder through the cooperation of the reinforcing rod and the U-shaped plate, preventing The damage to the No. 2 hydraulic cylinder causes the top beam to turn over and cause landslides; the invention drives the chain wheel to rotate and quickly releases the swing rod through the chain, and at the same time, the No. 3 hydraulic cylinder drives the support rod to support the top beam to prevent the top beam from being overloaded and collapsed, buying time for workers to escape.

Owner:ANHUI UNIV OF SCI & TECH

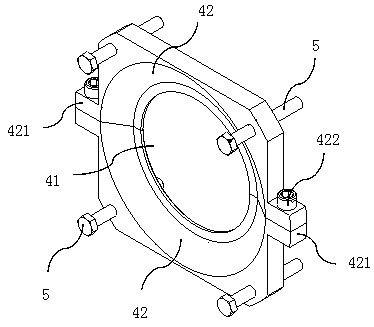

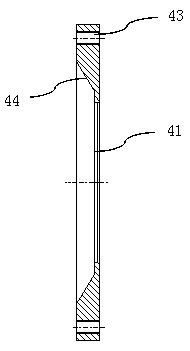

A kind of sleeve cutting processing device of boron carbide material workpiece

ActiveCN105269089BRealize automatic processingEfficient stock removalElectrical-based machining electrodesWorking accessoriesSlagBoron carbide

The invention belongs to the technical field of machining, and particularly relates to a nested cutting machining device for a boron carbide material workpiece. The nested cutting machining device comprises an electric spark machine tool, an electrode mounting body which is mounted on a spindle of the electric spark machine tool, and a workpiece mounting body which is mounted on a platform of the electric spark machine tool. Boron carbide material part workblank which is machined through the nested cutting machining device is high in precision of dimension, form and position and high in surface roughness precision, the thickness of an electric corrosion layer can be effectively controlled, and the problem that cracks and collapsing slag are likely to be generated when boron carbide materials are machined is solved.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

A mold for producing special-shaped injection parts with fast mold opening function

The invention discloses a mold for producing special-shaped injection molded parts with the function of rapid mold opening, which comprises an upper mold, a transmission assembly and a fixing assembly. The upper mold is provided with a transmission assembly, and the transmission assembly is fixedly connected with a fixing assembly. When the hydraulic lifting rod controls the upper die to move downward, the telescopic end of the hydraulic lifting rod controls the sliding plate to continue to move down and press the moving plate, so that the resisting rod gradually extends downward in the perforation, which is convenient for controlling the resisting rod to squeeze the transmission rod 1. The transmission rod 2 can be squeezed by the lateral movement of the transmission rod 1, so that the transmission rod 2 can move downward in the longitudinal movable chamber, and the transmission rod 2 can pass through the opening during the downward movement, and the movement in the moving chamber can be controlled. The block is squeezed, so that the moving block can compress the return spring in the moving cavity to move laterally, and then drive the fixed rod to penetrate the fixed hole through the jack hole, which can enhance the connection between the upper die and the lower die, and avoid the upper die. During the injection molding process, the upper hot air lifts up.

Owner:欧斯普模具科技南通有限公司

A sealing test device for flange instrument valves

ActiveCN105699018BJudgment of water tightnessDisassembly safetyDetection of fluid at leakage pointEngineeringFlange

The invention relates to a flange instrument valve sealing testing device which comprises a base. A stationary clamp seat which is internally provided with a pressure conveying channel is fixedly arranged at one end of the base. The other end of the vase is provided with a movable clamping seat. The base is provided with a T-shaped rail. At least one T-shaped slide block is embedded into the T-shaped rail. The upper surface of the base is provided with a sawtooth-shaped rail. The movable clamping seat comprises an abutting supporting seat and a movable supporting seat. The movable supporting seat is arranged between the stationary clamp seat and the abutting supporting seat. The bottom of the movable supporting seat is provided with a T-shaped part which is slidably connected with the T-shaped rail. One end of the movable supporting seat is provided with a first sealing cover assembly which is used for sealing the outlet of the instrument valve. The abutting supporting seat is connected with the T-shaped slide block through a fastener. The abutting supporting seat is fixed on the base. The lower surface of the abutting supporting seat is provided with unidirectional stopping sawteeth which are connected with the sawtooth-shaped rail, thereby preventing movement of the abutting supporting seat to the other end of the base. The abutting supporting seat is provided with a pushing mechanism which is used for pushing the movable supporting seat for making the instrument valve abut against the stationary clamp seat.

Owner:FUJIAN WIDE PLUS PRECISION INSTR

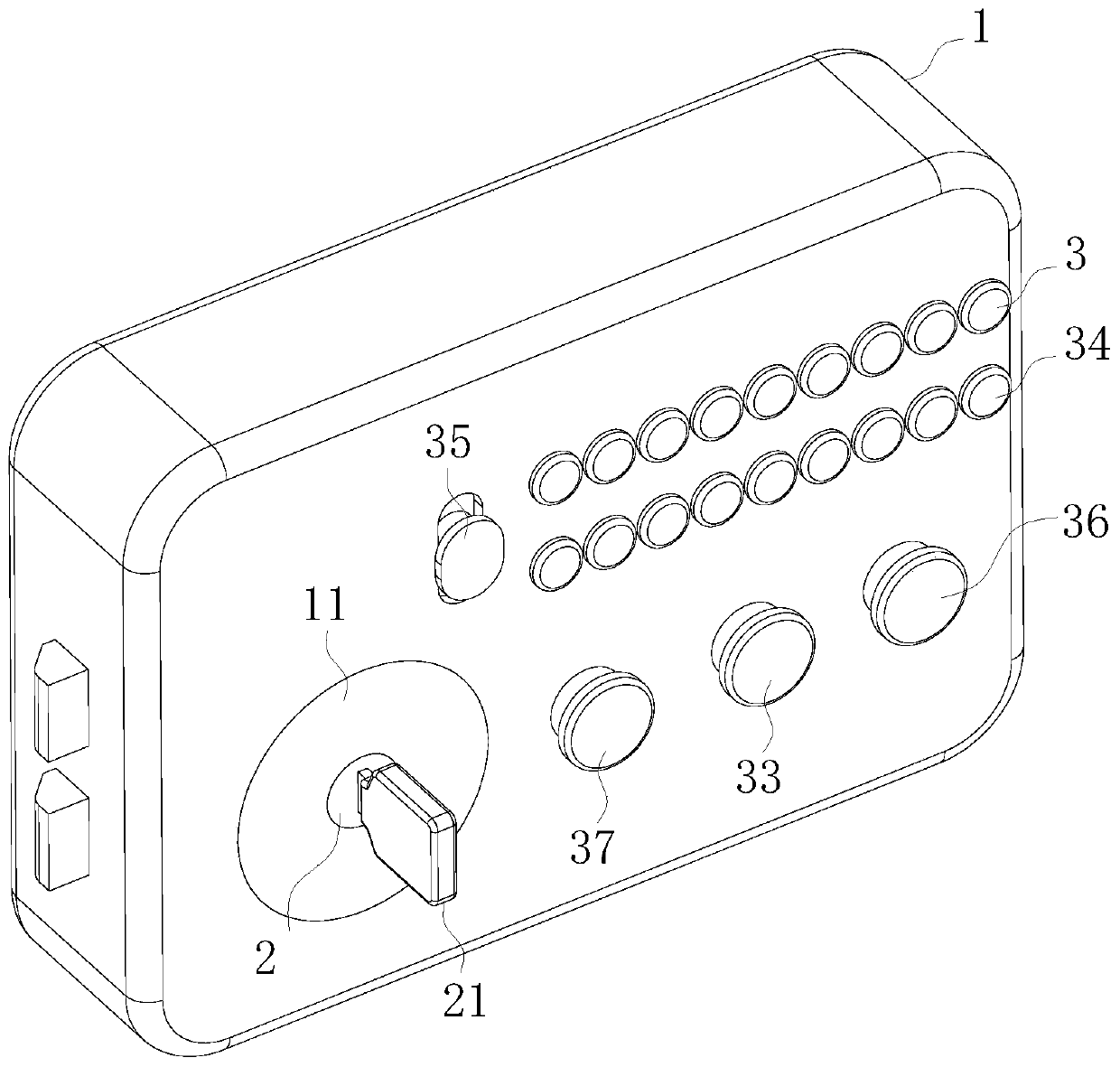

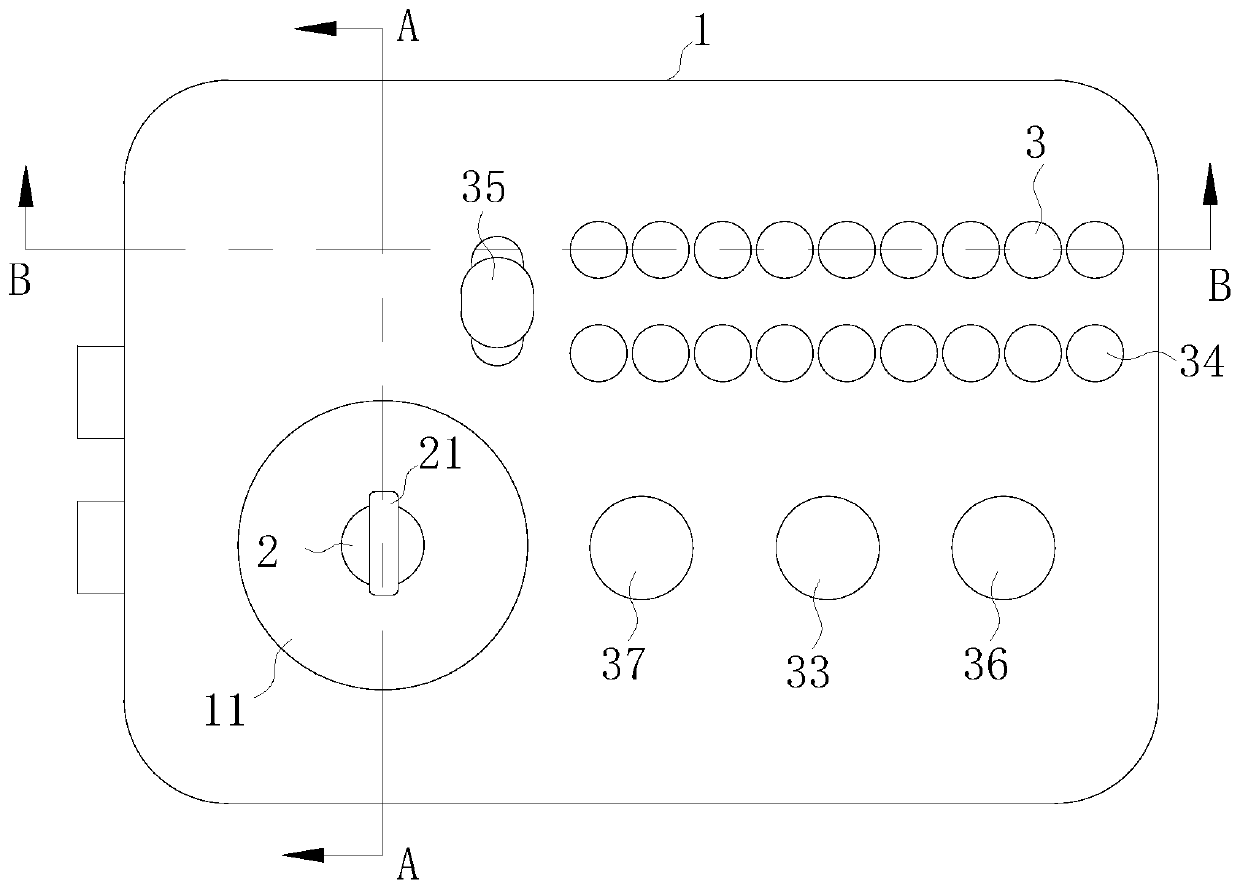

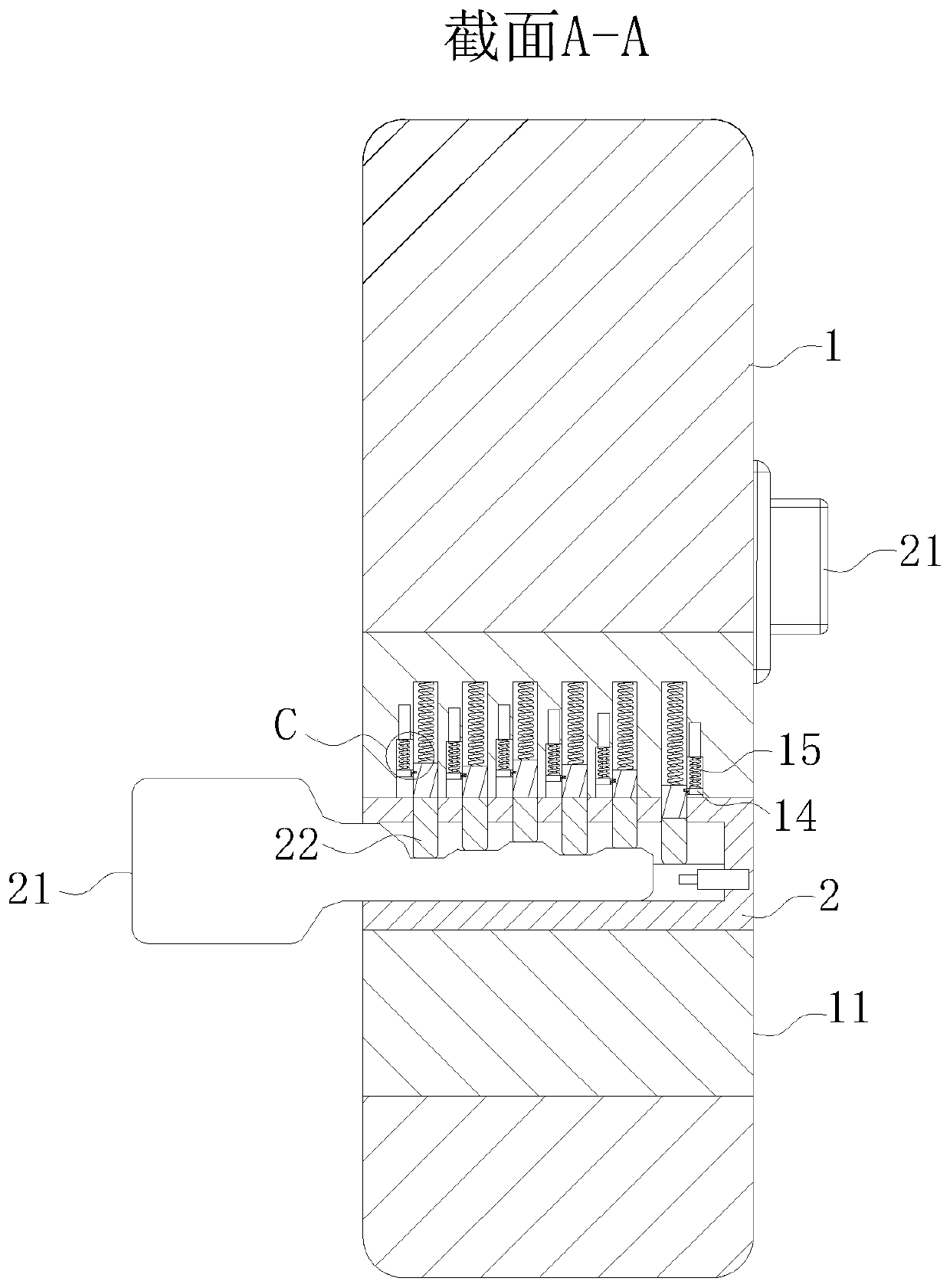

Security door lock

ActiveCN111350418AImprove securityAvoid copyingElectric permutation locksStructural engineeringMechanical engineering

The invention belongs to the technical field of door locks, and particularly relates to a security door lock. The security door lock comprises a lock shell, a rotating column and a password button. The front end surface of the lock shell is fixedly connected with a core column close to the lower right corner position of the lock shell. The front end surface of the core column is rotatably connected with the rotating column at the axial position of the core column. The front end surface of the rotating column is provided with an insertion hole. A key is inserted into the insertion hole. The outer cambered surface of the rotating column is provided with uniformly distributed through holes over the rotating column. Sliding holes are formed in the inner cambered surfaces of the core column andare located at through hole positions. First sliding columns are slidably connected to the interiors of the sliding holes up and down. Second sliding columns are slidably connected to the interiors of the through holes. The front end surface of the lock shell is provided with uniformly distributed password buttons on the upper right position of the core column. By means of the security door lock,the cost of door lock breaking and dismantling is effectively avoided. The security door lock is simple in structure and high in practicability, does not need electric power, is wide in application range, and is suitable for requirements of different environments.

Owner:渭南市金盾护卫有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com