Patents

Literature

254results about How to "Guaranteed heating efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

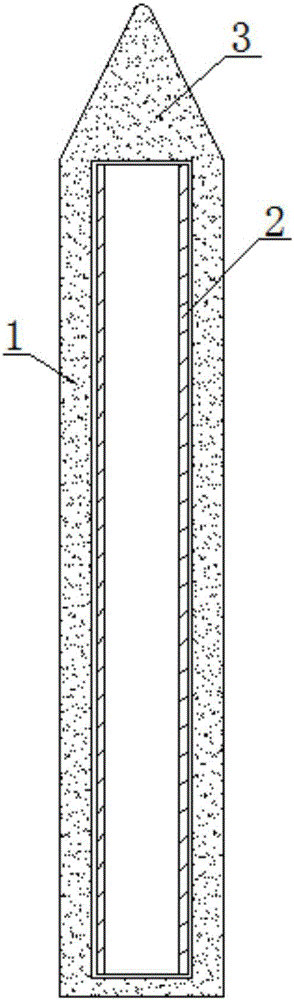

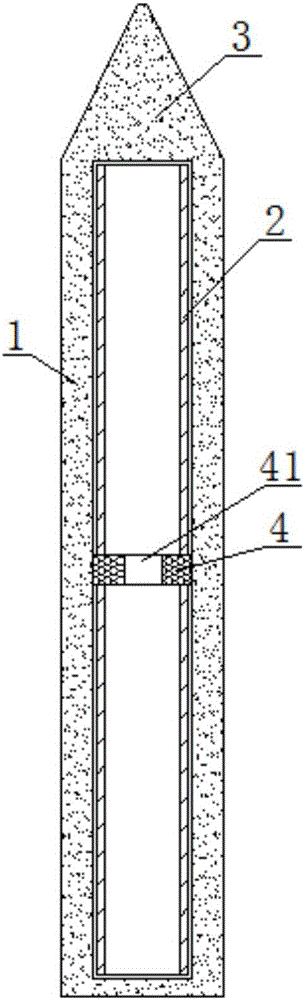

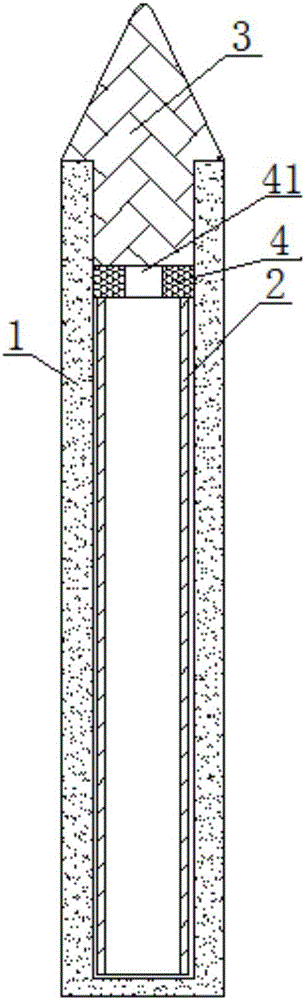

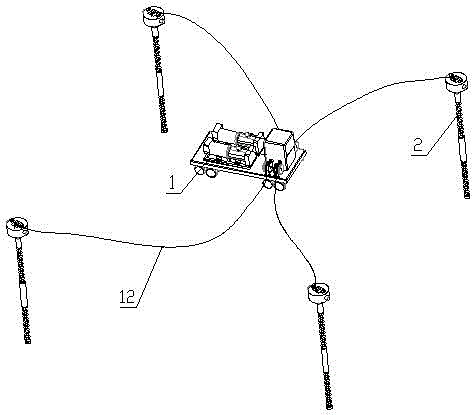

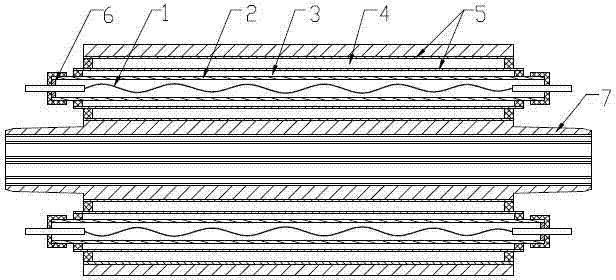

Heating body and curing object matched with heating body, electronic cigarette atomizer and electronic cigarette

PendingCN106617325AImprove yield rateAchieve atomizationTobacco devicesEngineeringAlternating current

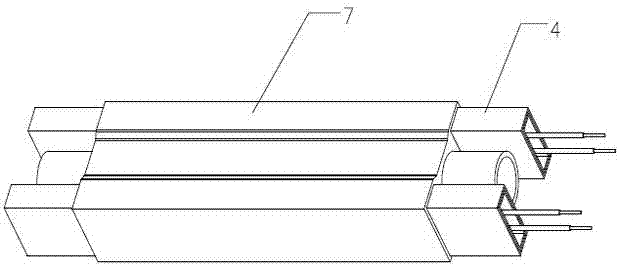

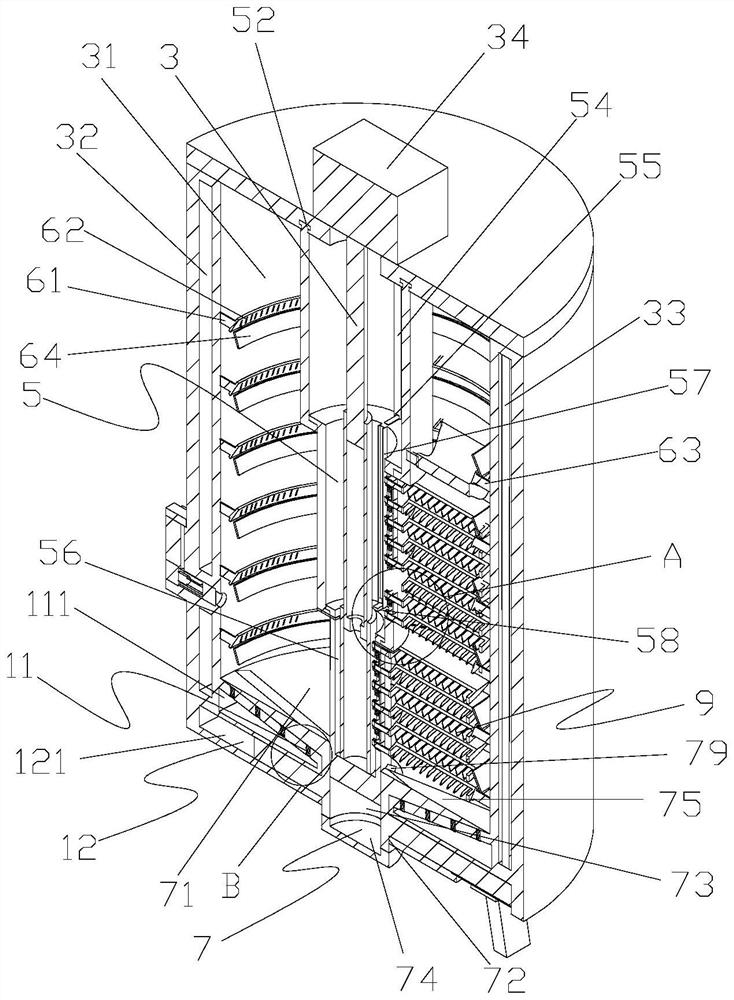

The invention discloses a heating body and a curing object matched with the heating body, an electronic cigarette atomizer and an electronic cigarette. The heating body comprises a glass sleeve and multiple sections of metals which are embedded in the glass sleeve and are capable of generating magnetic induction intensity, a conical body in which the curing object is pierced is arranged at the front end of the glass sleeve; isolating layers for controlling various sections to generate heat independently are arranged between the adjacent metals; and pressure discharge holes are formed in the isolating layers. According to the invention, by conducting self-heating in a mode of electromagnetic induction heating and by generating high-frequency induction current for alternating current through DC conversion, the metals become heated to cure tobacco shreds, so that flavors and fragrances as well as fragrance compounds in the tobacco shreds are volatilized and atomized; by virtue of the glass sleeve, stuffing is prevented from getting oxidized or contaminated by the metals and staged heating is facilitated, so that a heating rate is uniform, curing is conducted fully, a heating rate is moderate and the cured tobacco shreds are pure in fragrance; and in addition, a sachet can be pierced to add relative aromatizing and atomizing aids.

Owner:湖南酷伯新晶电子科技有限公司

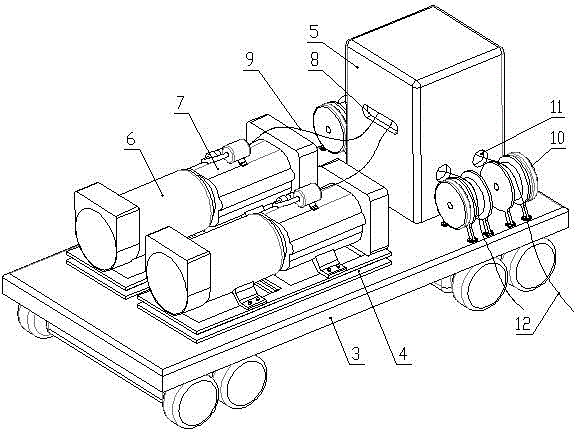

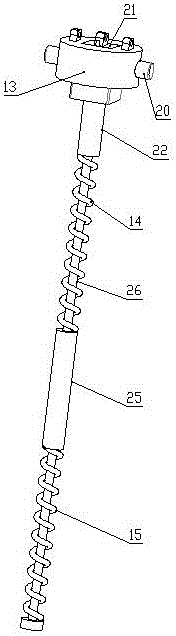

Resistance wire type coal seam heating device

ActiveCN106223916AGuaranteed power generation efficiencyGuaranteed power supplyFluid removalGas removalFracturing fluidEngineering

The invention provides a resistance wire type coal seam heating device. The device comprises a mobile ground power generation system and a plurality of downhole heaters, wherein the mobile ground power generation system provides electric energy for the downhole heaters; each downhole heater comprises a coal seam upper permanent joint, a reinforcement pipe, an upper resistance wire and a lower resistance wire; the coal seam upper permanent joint is formed by an upper cylinder and a lower square cylinder; a square groove is formed in the top of the cylinder; an installing hole is formed in the square cylinder; two fracturing fluid inlet pipe joints are connected at the side parts of the coal seam upper permanent joint; a square joint is assembled in the square groove; the lower end face of the square joint is connected with an installing pipe penetrating through the installing hole; the upper resistance wire is arranged at the upper part of the reinforcement pipe in a sleeving manner and the lower resistance wire is arranged at the lower part of the reinforcement pipe in a sleeving manner. The device has the beneficial effects that the device adopts the method of injecting thermal fracturing fluid; the resistance wires are adopted by heating equipment for heating; a mobile ground power supply vehicle is adopted as main power supply equipment; the device has the advantages of convenience in operation, diverse functions, safety and reliability and capability of fully increasing the gas output.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Graphene polymerized nano-energy heating wire and preparation method thereof

PendingCN110248427AGuaranteed heating effectGuaranteed heating efficiencyHeating element shapesHeating element materialsCross-linkFiber

The invention relates to a graphene polymerized nano-energy heating wire and a preparation method thereof. The heating wire comprises a heating core body and a protective layer. The heating core body is formed by weaving a plurality of polymerized nano-energy wires, the protective layer comprises an insulating layer and a waterproof layer, wherein the insulating layer and the waterproof layer are sequentially arranged from inside to outside, and the protective layer tightly wraps the heating core body. The polymerized nano-energy wires are prepared from the following components: polymerized fibers, graphene, kaolin, antimony, negative ion powder, tourmaline, shale, ceramic balls, a flame retardant, a polar solvent and a cross-linking agent. The graphene polymerized nano-energy heating wire and the preparation method thereof are safe, environmentally friendly, high in heating speed, extremely high in heating efficiency, long in service life, resistant to bending, free of thermal expansion and cold contraction deformation, not likely to be damaged, waterproof, anti-electric shock and fireproof, have the air purification function and the health preserving function, and are simple in preparation method and high in flexibility.

Owner:元然(苏州)新能源科技有限公司

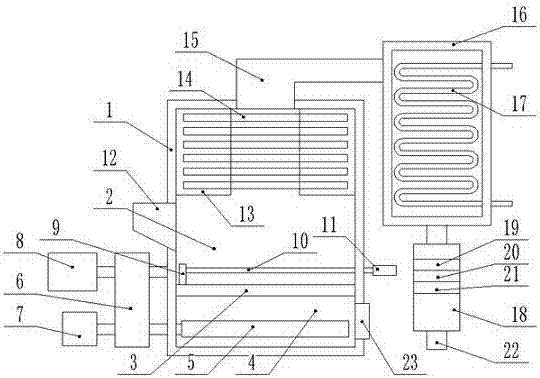

Energy-saving and environment-friendly boiler with preheating function

InactiveCN107421116AIncrease the burning areaBurn fullyCombustion processIndirect carbon-dioxide mitigationCombustionBoiler slag

The invention discloses an energy-saving and environment-friendly boiler with a preheating function. The energy-saving and environment-friendly boiler comprises a shell, a grate, a boiler slag collection trough, a circulating pump and a fan. A vertical material uniformization plate is arranged on the upper surface of the grate. A material passing opening penetrating the two sides is formed in the material uniformization plate. A heat absorption pipe is arranged in the boiler slag collection trough and is located at the bottom of the boiler slag collection trough, and the outer end of the heat absorption pipe communicates with a heat exchanger. Multiple heat conduction columns are horizontally inserted into a water jacket. The other end of a smoke discharging pipe communicates with a waste heat collection box. A heat exchange coiled pipe is mounted in the waste heat collection box. The bottom of the waste heat collection box communicates with a purification box. According to the energy-saving and environment-friendly boiler, the arranged material uniformization plate moves to uniformly pave dye, the combustion area of fuel is large, and contact of the fuel and air is sufficient; and heat in smoke is absorbed by the heat exchange coiled pipe and used for preheating inner heating water, the water temperature increase speed is increased, and the heating efficiency of hot water in the boiler is guaranteed.

Owner:YANCHENG CITY LONG XIANG MACHINERY MFG PLANT

Composite heating wire for electronic cigarettes

InactiveCN106072775AAffect the electrothermal performanceReasonable control of electric heating performanceVacuum evaporation coatingSputtering coatingChemical reactionMetal alloy

The invention provides a composite heating wire for electronic cigarettes. The composite heating wire comprises a core part and a shell part arranged on the outer surface of the core part; the core part is a linear metal heating wire; the shell part comprises at least one inorganic film layer. According to the composite heating wire, the inorganic film layer with chemical inertness covers on a metal alloy heating surface, so that oil fume is prevented from directly contacting metal alloy, chemical reactions between the metal alloy heating wire with chemical activity and oil fume can be effectively prevented, and charring gas and electrothermal property influencing the heating wire can be avoided; furthermore, the heating wire is only a diameter performance surface, and the thickness of the inorganic film layer is reasonably controlled, so that the heating efficiency and flexibility of the composite heating wire can be guaranteed, and the composite heating wire is highly compatible with an existing electronic cigarette structure.

Owner:杭州森翼科技有限公司

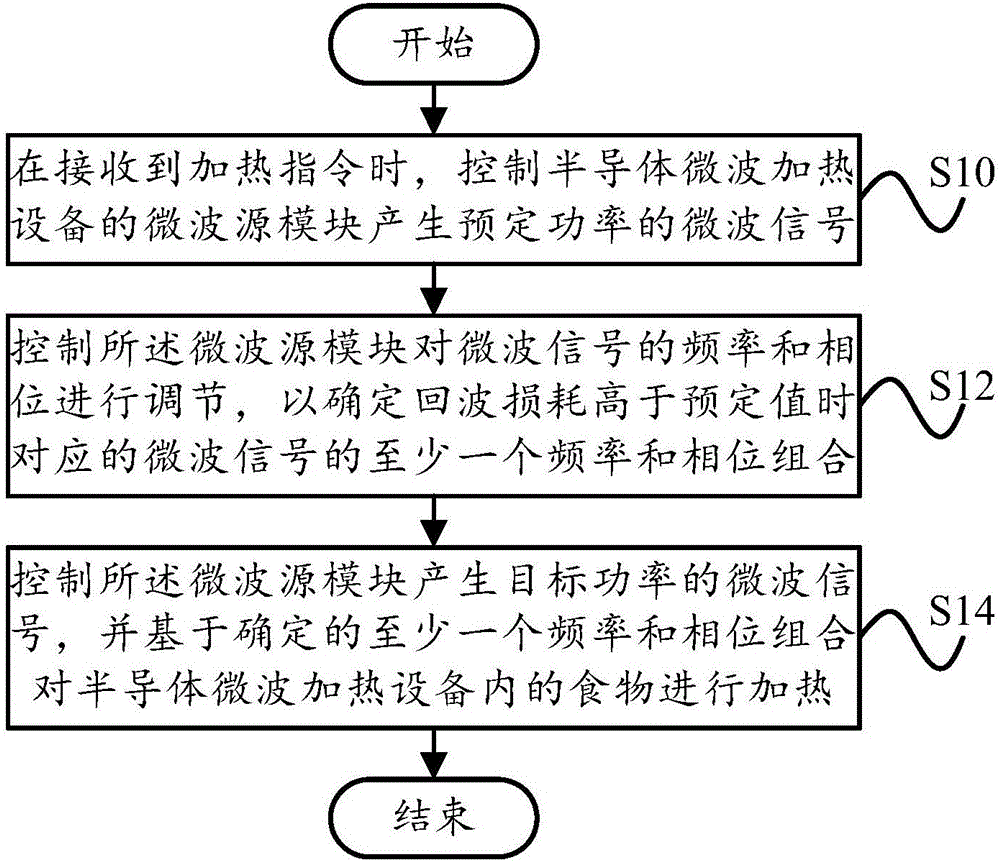

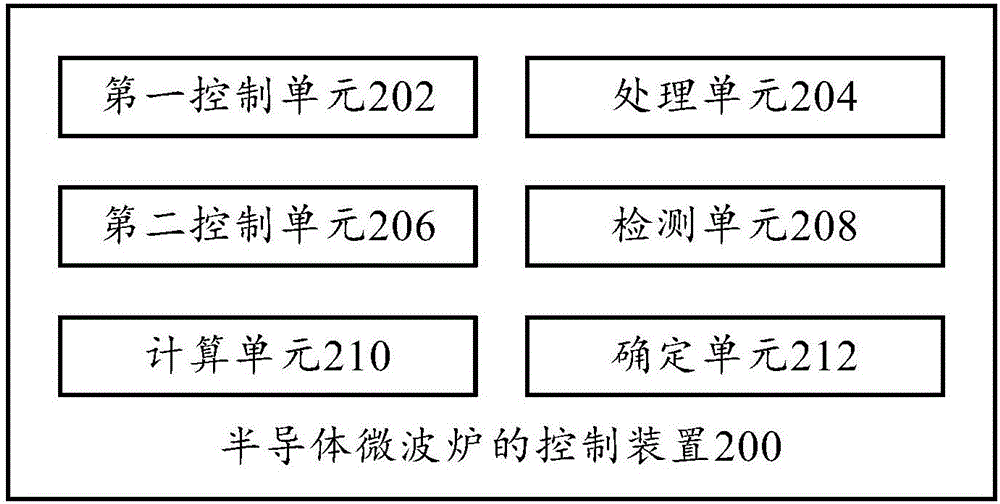

Semiconductor microwave heating device and control method and device of semiconductor microwave heating device

ActiveCN106765357AGuaranteed heating efficiencyHeating evenlyDomestic stoves or rangesLighting and heating apparatusMicrowave signalsReturn loss

The invention provides a semiconductor microwave heating device and a control method and device of the semiconductor microwave heating device. The control method of the semiconductor microwave heating device includes the steps that after a heating instruction is received, a microwave source module of the semiconductor microwave heating device is controlled to generate a microwave signal with the preset power, the microwave source module is controlled to adjust the frequency and the phase of the microwave signal so as to determine at least frequency and phase combination corresponding to the microwave signal when the return loss is higher than the preset value; and the microwave source module is controlled to generate a microwave signal with the target power and is used for heating food in the semiconductor microwave heating device based on at least one determined frequency and phase combination. According to the technical scheme, the heating efficiency of the microwave heating device can be ensured, and in addition, even heating of the food can be achieved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

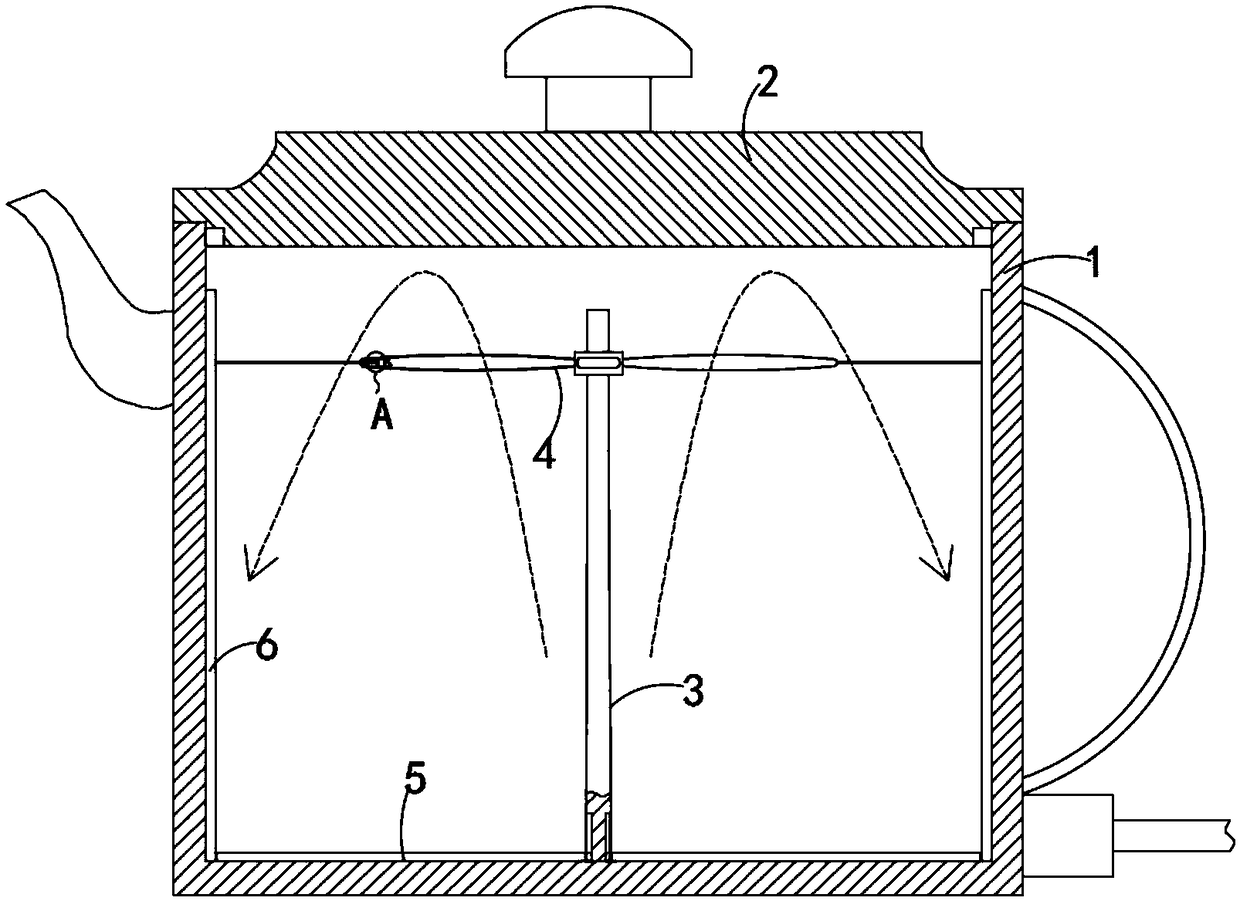

Hot water kettle with scale removing and heat preservation

ActiveCN109106209AWith descaling insulationGuaranteed heating efficiencyWater-boiling vesselsCooking utensils shields/jacketsLimescaleImpeller

The invention belongs to the technical field of hot water bottles, in particular to a hot water kettle with scale removing and heat preservation, including a pot body, a matching lid is arranged at the mouth of the kettle body, the bottom of the kettle body is rotatably connected with a rotating shaft, the rotating shaft is coaxially fixedly connected with an impeller driven by bubbles, sliding holes are arranged on the side walls of the free ends of a plurality of blades of the impeller, sliding rods matching with the sliding holes are arranged, and the sliding rods are freely and fixedly connected with a second scraper for cleaning the inner wall of the kettle body. The advantages are: the invention can drive the blade to rotate through bubbles in boiling water, so that the first scraperand the second scraper can synchronously rotate to remove the scale from the inner wall and the bottom of the hot water kettle, in addition, the steam generated when the water boils has a higher temperature, and the steam generated is collected into the heat preservation chamber to heat preservation the hot water kettle and recover and utilize the heat in the steam.

Owner:临沂鸿泰建材有限公司

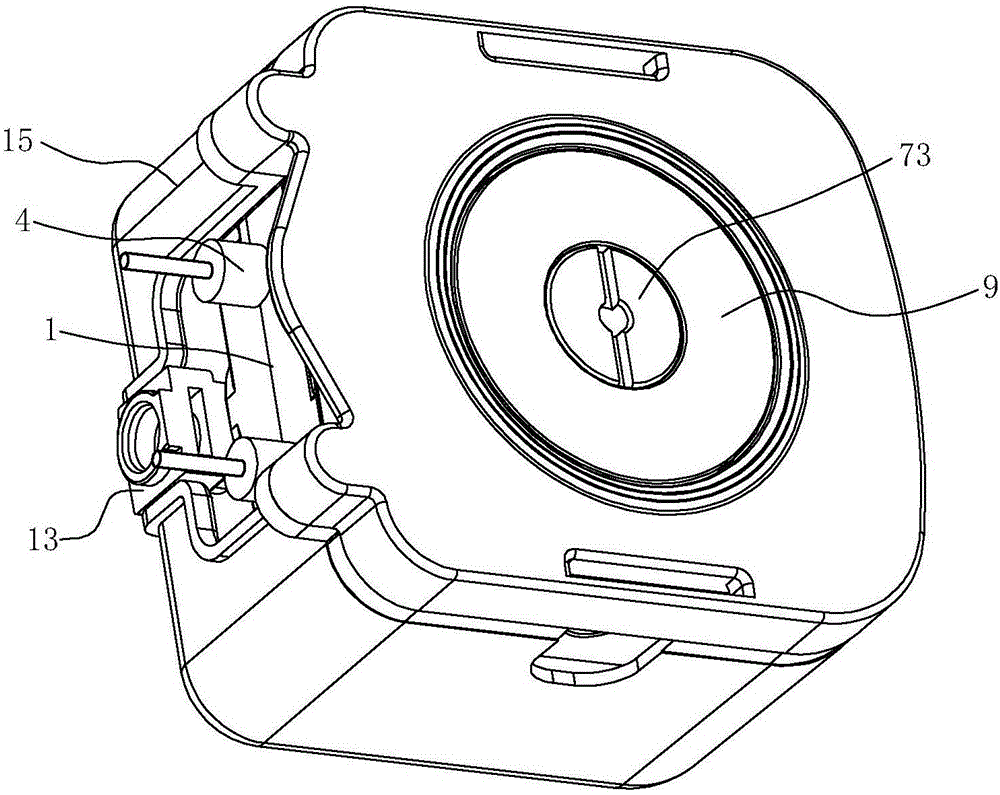

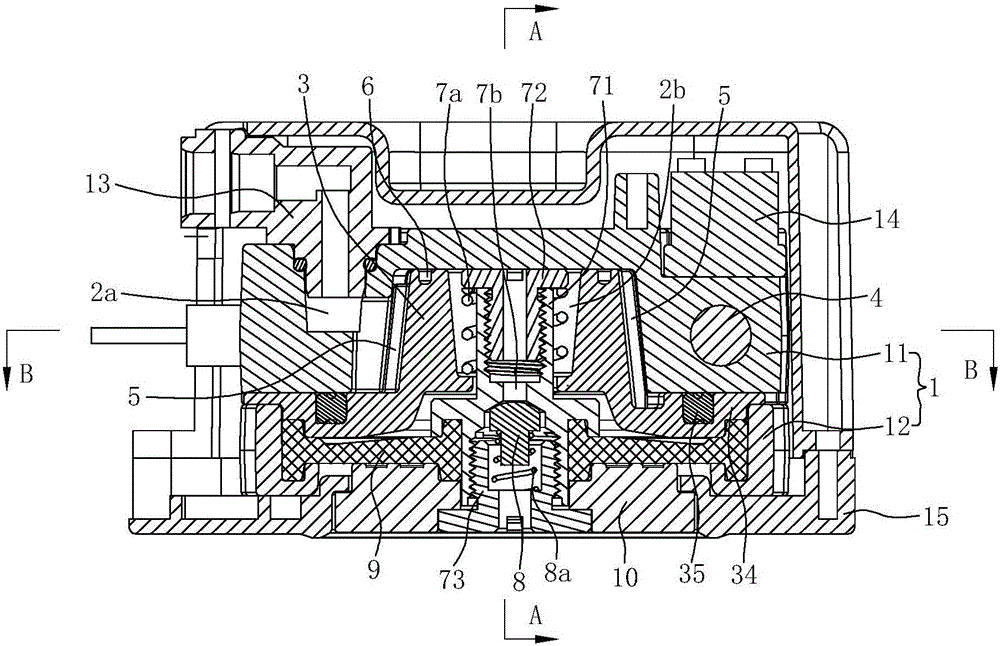

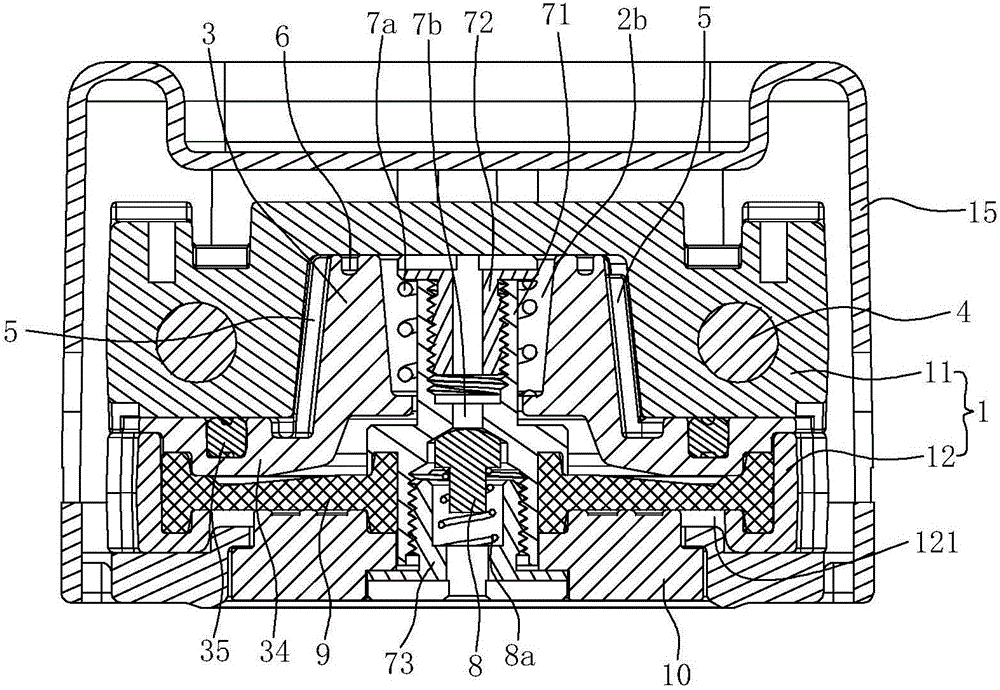

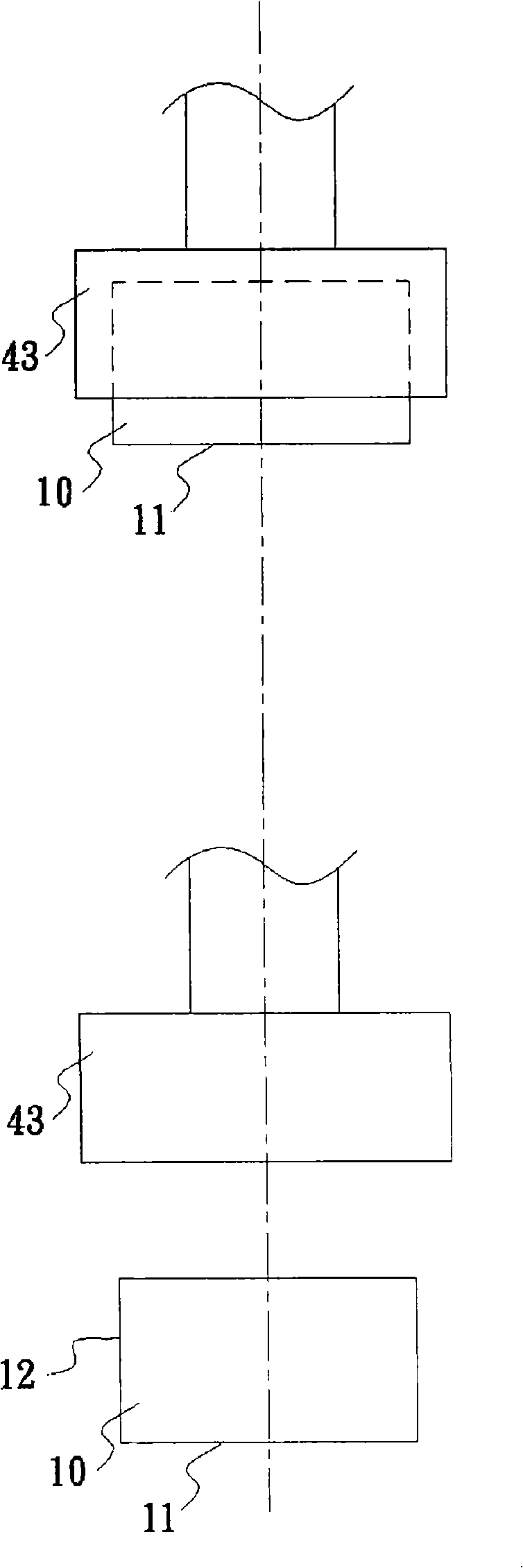

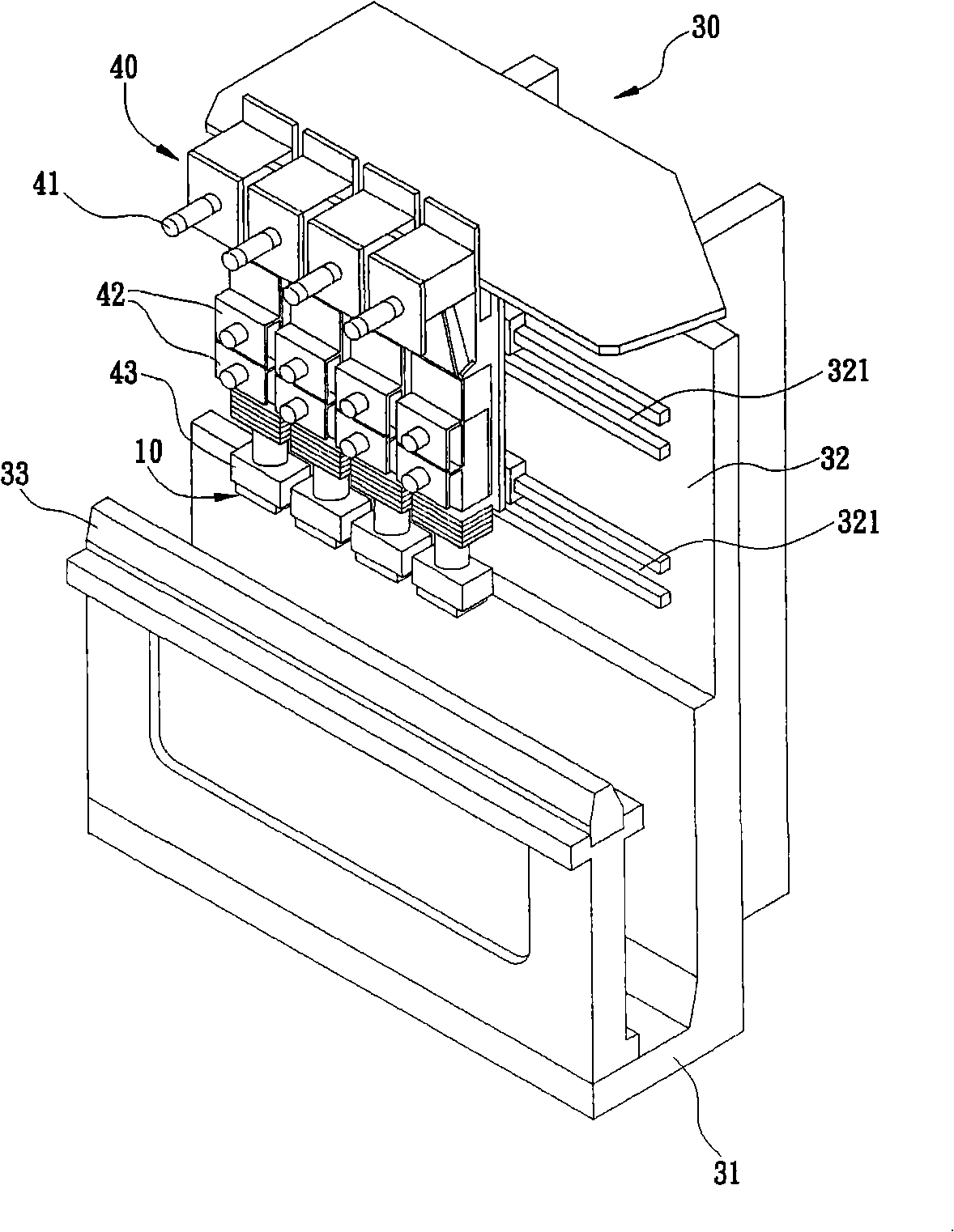

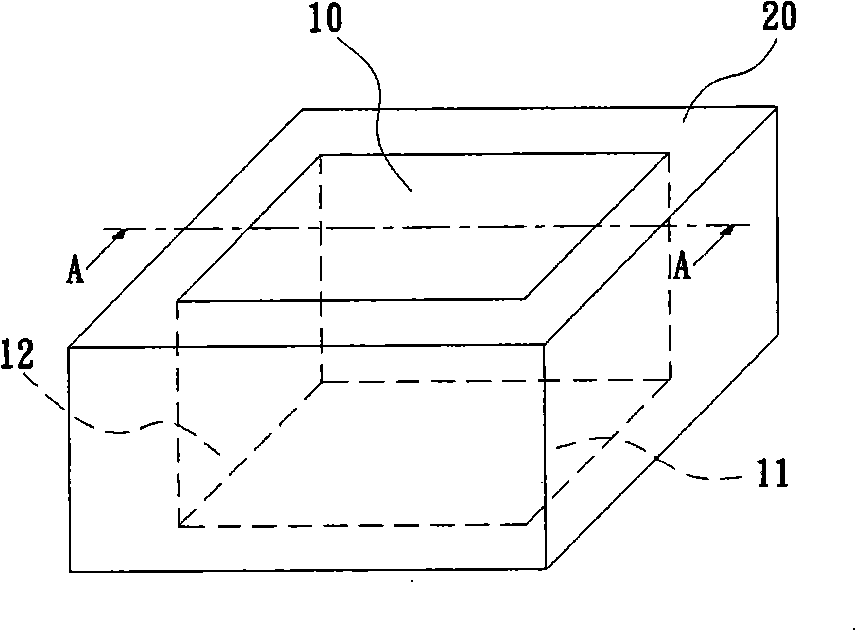

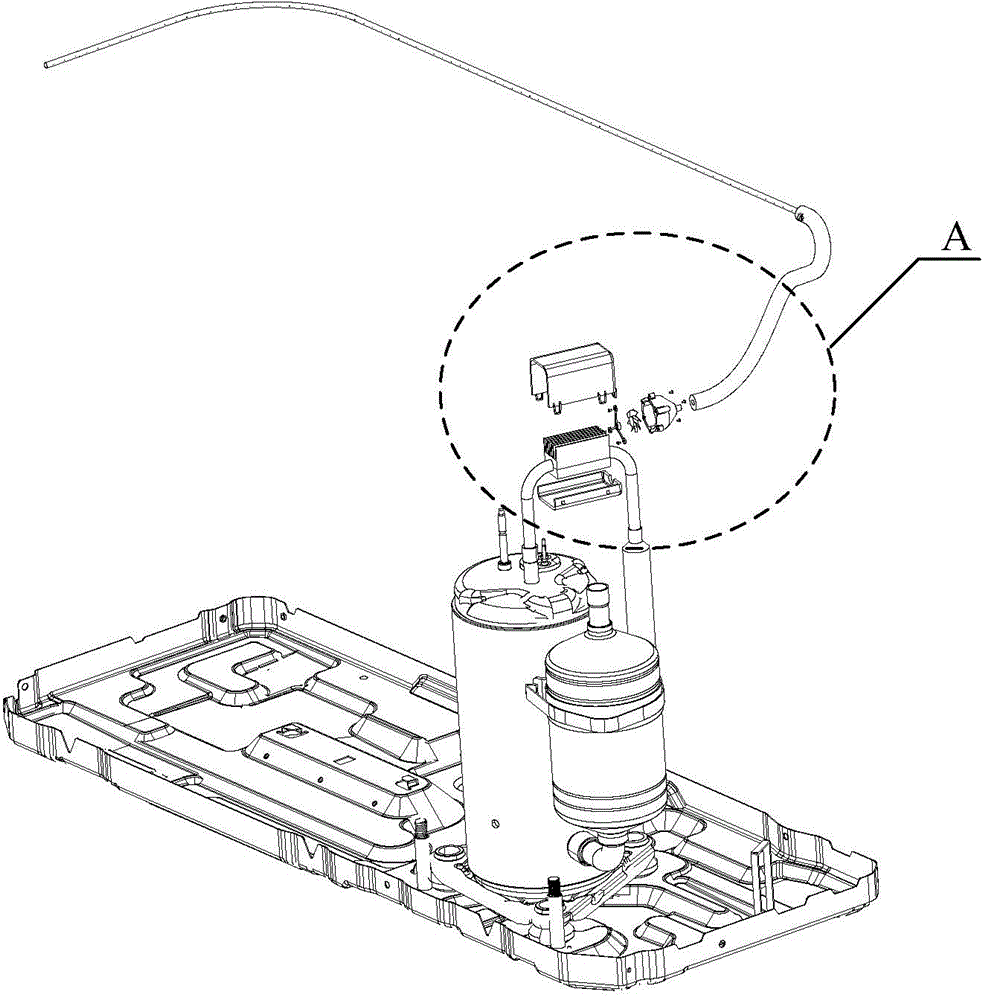

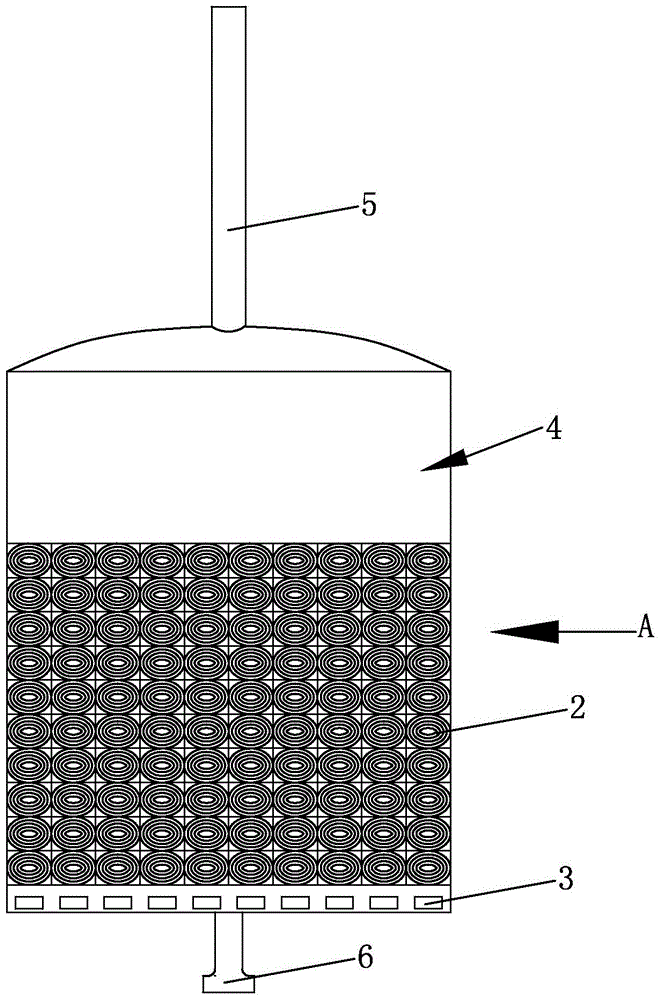

Boiler for beverage extracting device

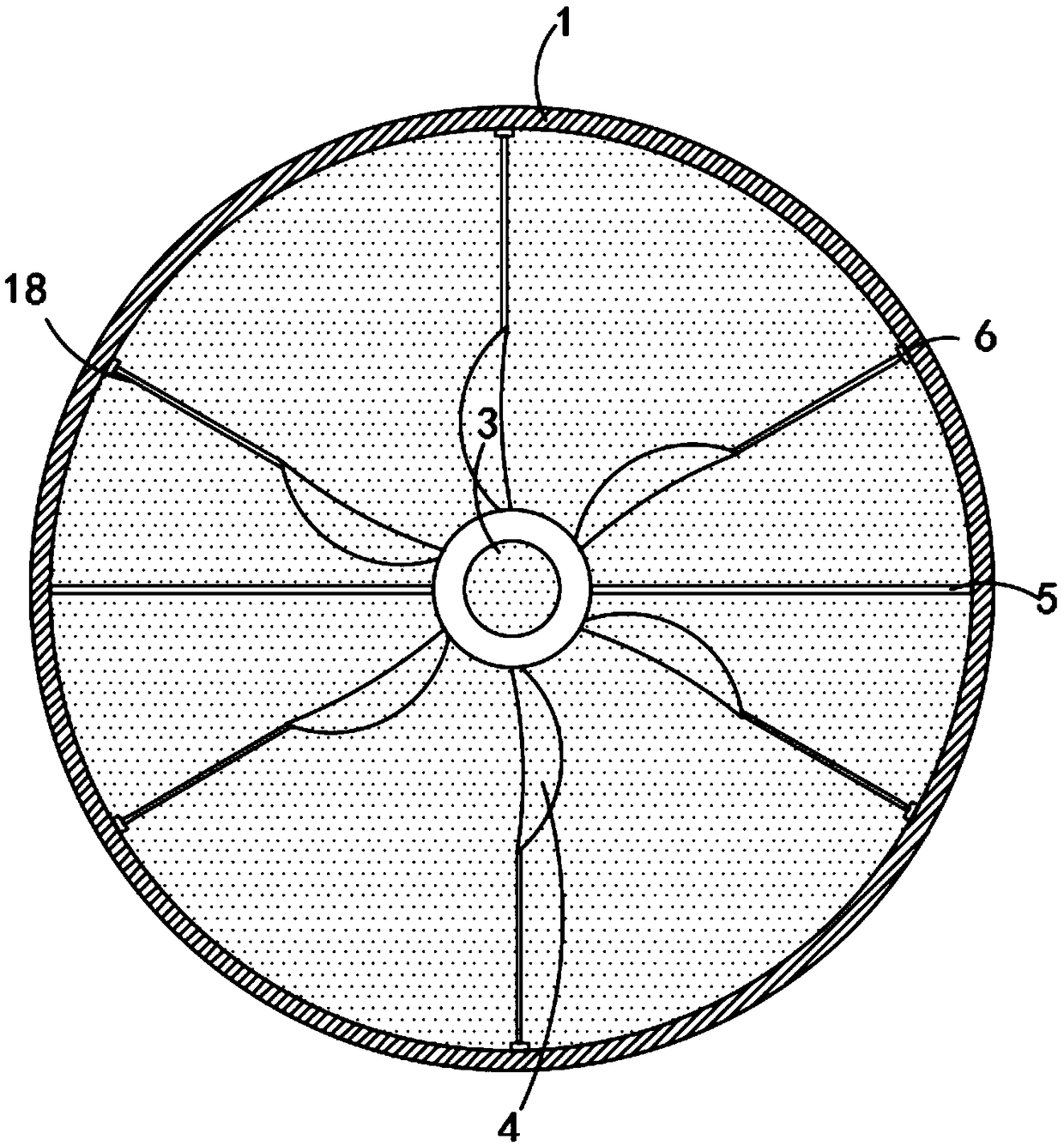

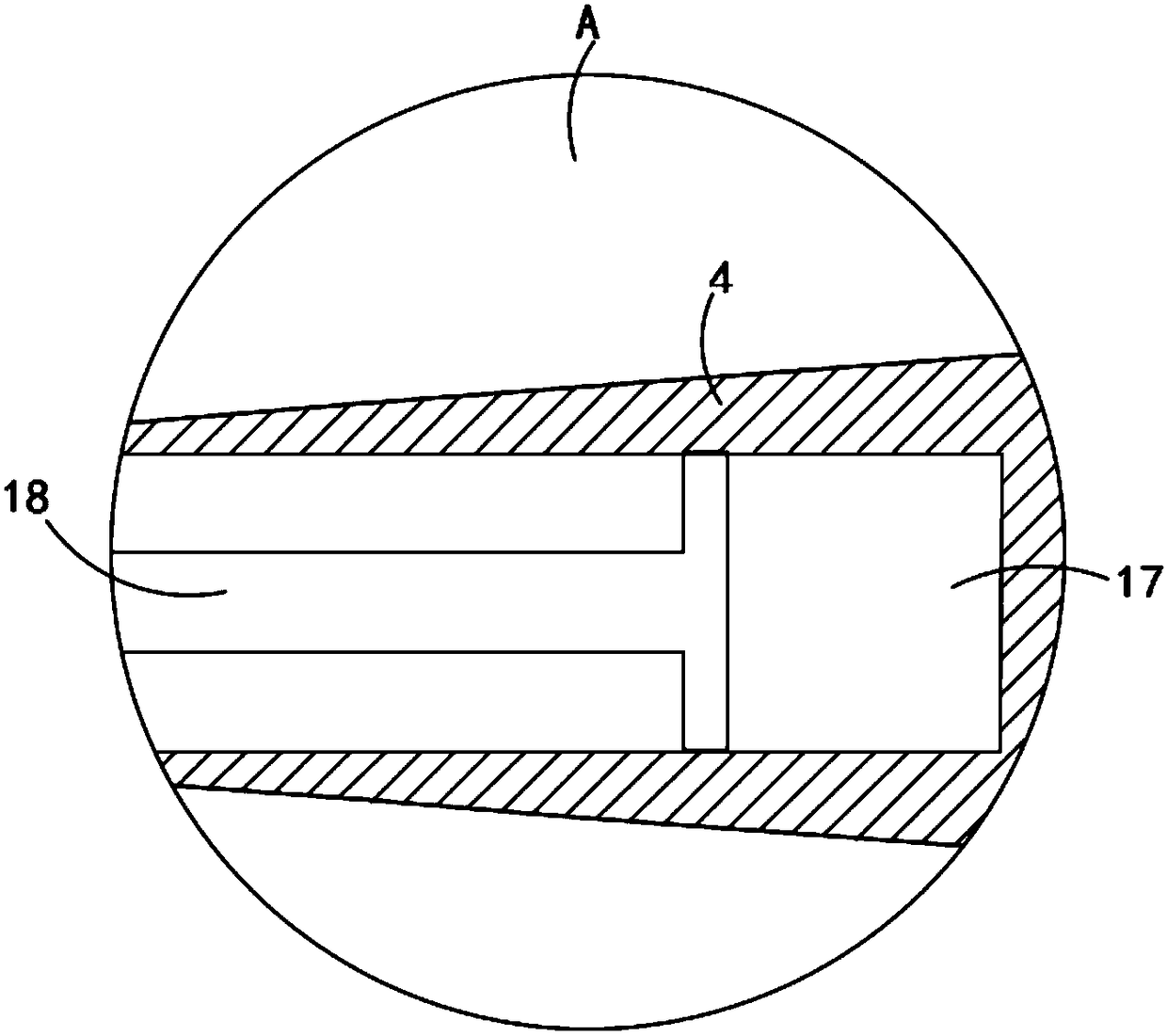

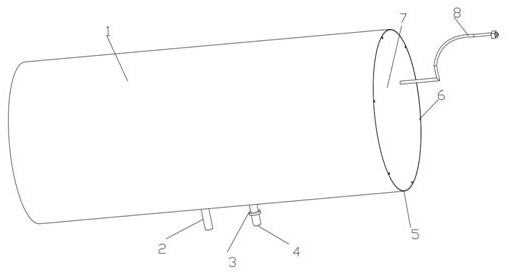

ActiveCN106667270ABeautiful accessoriesPlay a protective effectBeverage vesselsInlet channelWater flow

The invention relates to a boiler for a beverage extracting device. The boiler comprises a boiler body, a heating pipe and a heating runner, wherein the boiler body is equipped with a water inlet channel and a water outlet channel; the boiler is characterized in that the boiler body comprises an outer boiler body and a boiler core; the heating runner comprises an annular runner and a transition runner; the annular runner is arranged along the outer peripheral wall of the boiler core; the transition runner is arranged on the top surface of the boiler core; the initial end of the annular runner is communicated with the water inlet channel; the terminal end of the annular runner is communicated with an inlet of a transition channel; an outlet of the transition channel is communicated with the inlet of the water outlet channel; the annular runner is composed of a plurality of mutually connected upstream runners and downstream runners; one downstream runner is arranged between two adjacent upstream runners; one upstream runner is arranged between the two adjacent downstream runners. The whole heating route is greatly increased by water flow, and meanwhile, the annular runner and the transition runner are directly arranged between the outer boiler body and the boiler core and the heating manner is in direct heating, so that the heating efficiency of the boiler is further guaranteed and the boiler can achieve the effect of quick heating (instant heating).

Owner:NINGBO SEAVER ELECTRIC APPLIANCE

Hot pressing mechanism

InactiveCN101320146ASolve the high temperature that is easy to cause the head to be pressed by heatFix damageNon-linear opticsPressesEngineeringThermal radiation

A hot-press mechanism comprises a hot-press head and a heat insulator; wherein, the hot-press head is provided with a press surface and a side wall which is abutted with the press surface; the heat insulator is covered on the side wall, the range of the heat transfer coefficient of the heat insulator is from 0.13*10-2W / m-K to 2.00 W / m-K, and the heat transfer coefficient of the hot-press head is larger than that of the heat insulator. During the hot press, the heat insulator can reduce the heat which is transferred to a non-hot-press area by the hot-press head through the heat radiation and the heat convection ways to avoid the base plate damage which is caused by high temperature.

Owner:AU OPTRONICS CORP

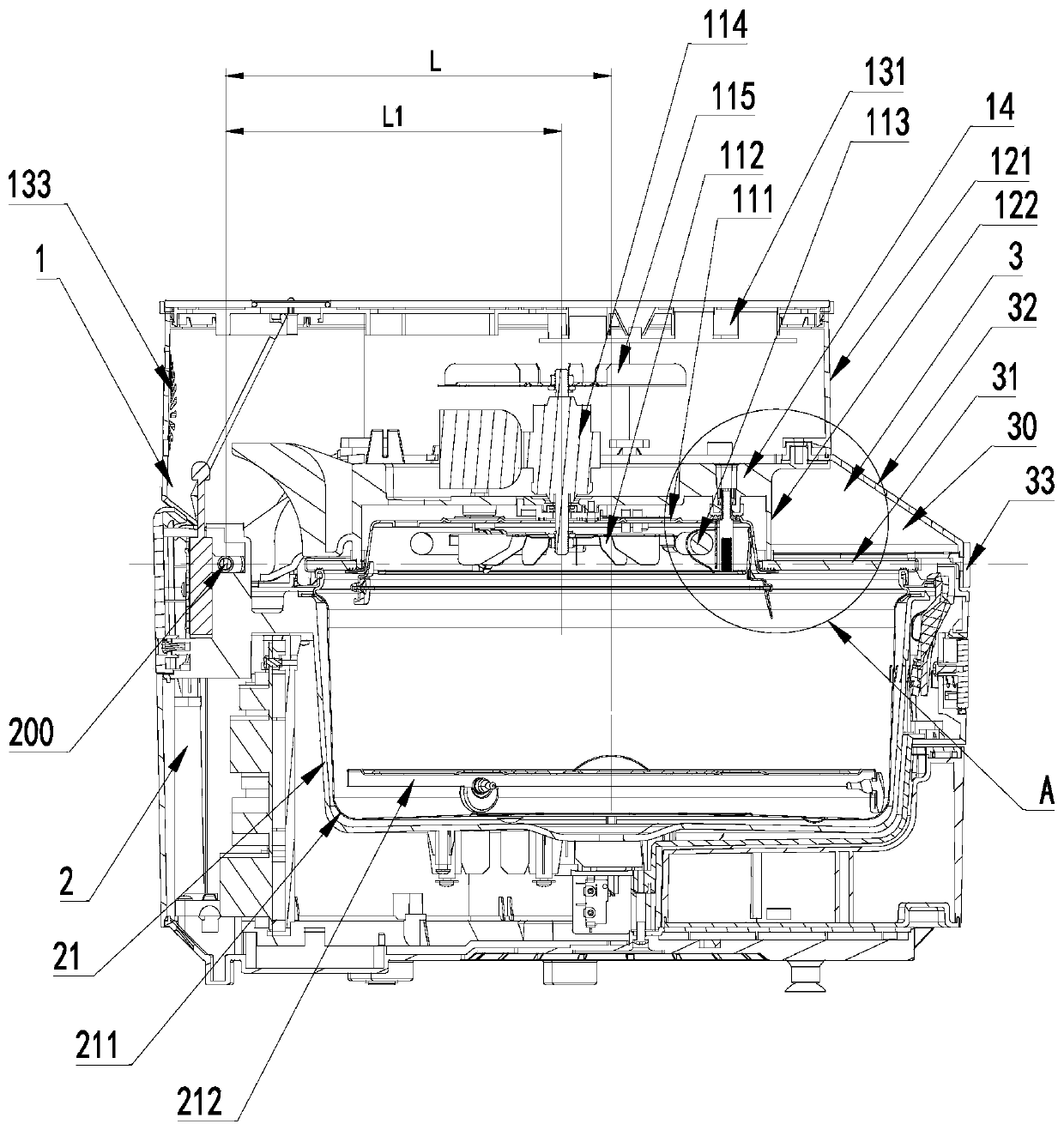

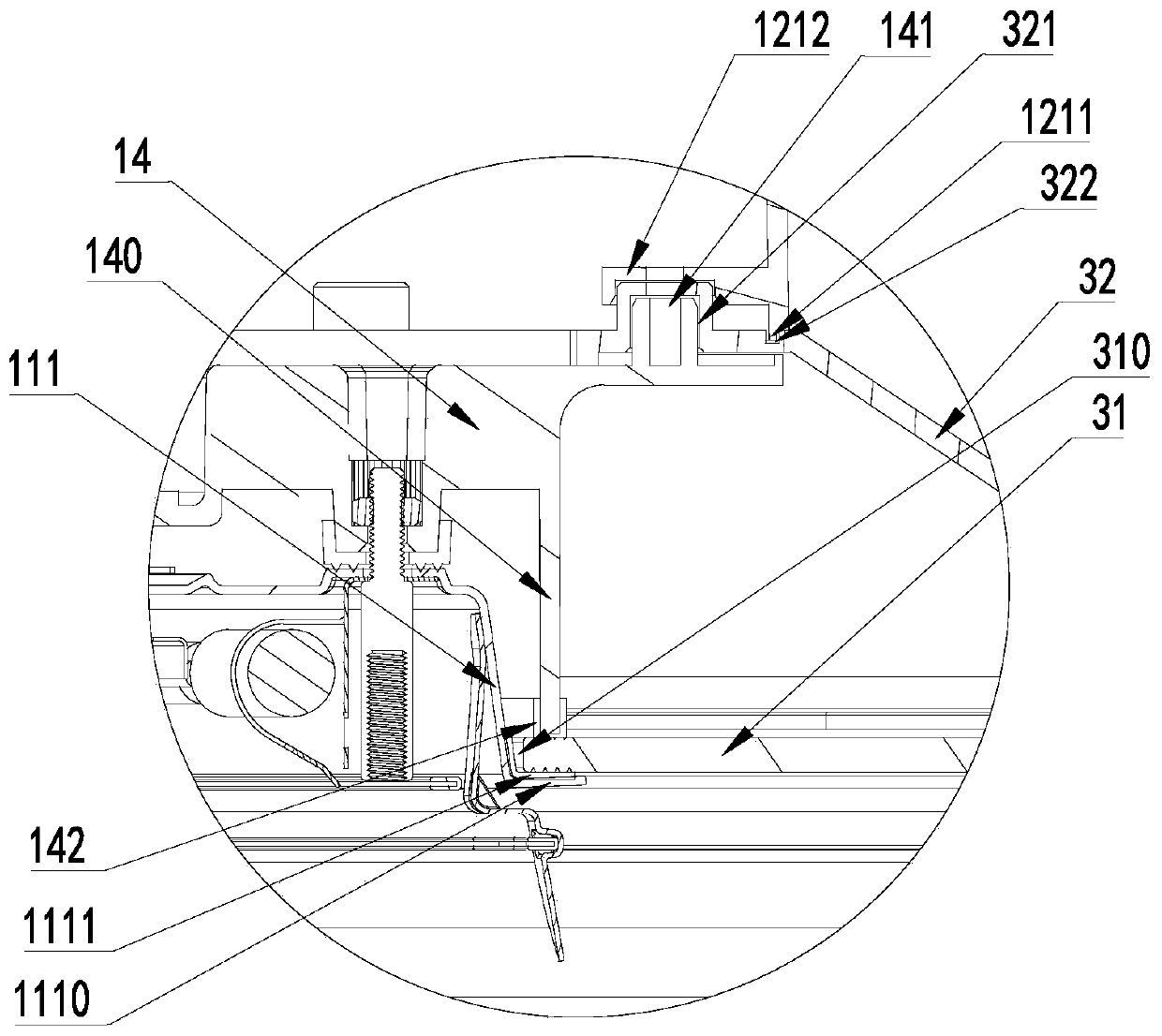

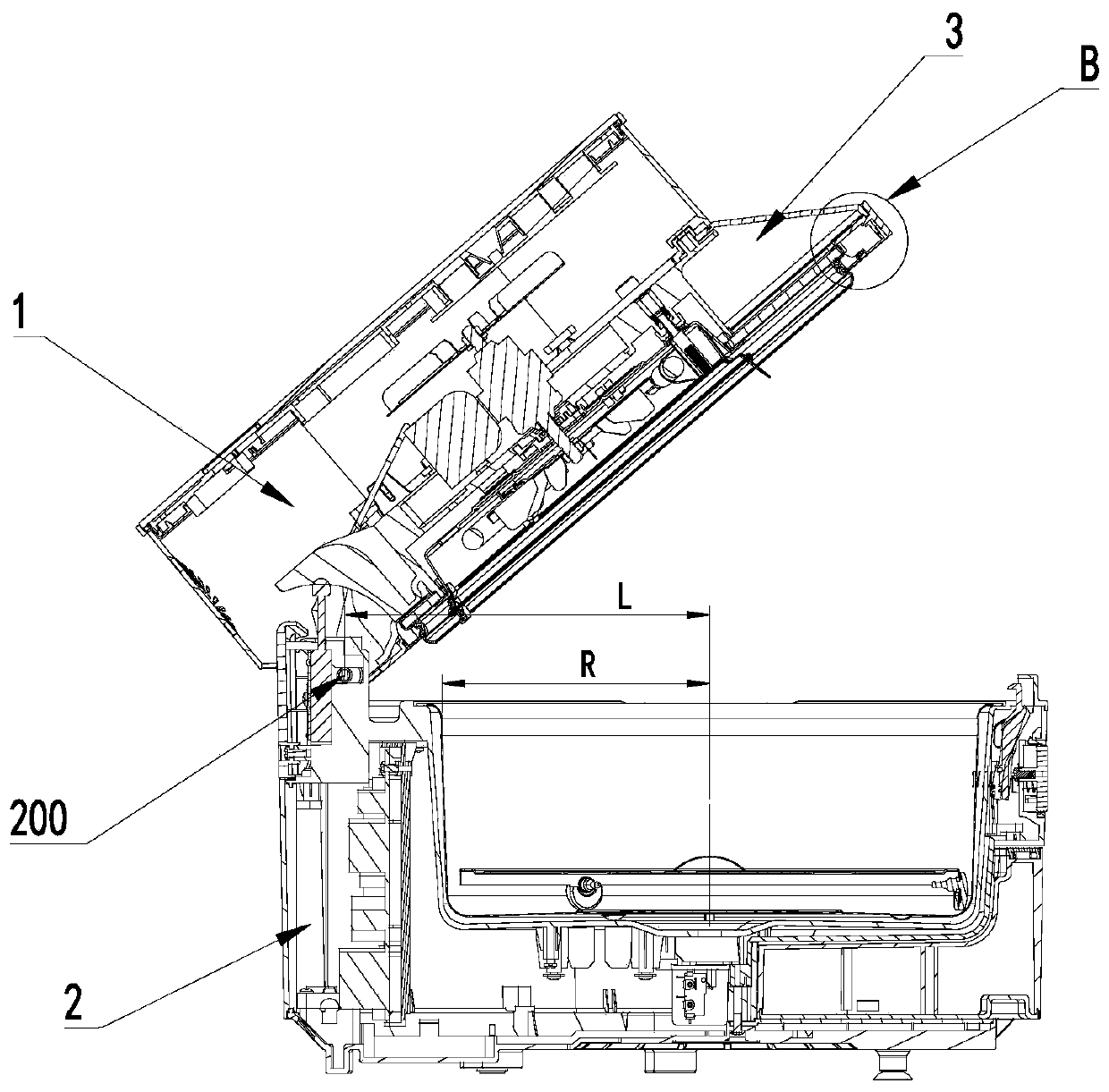

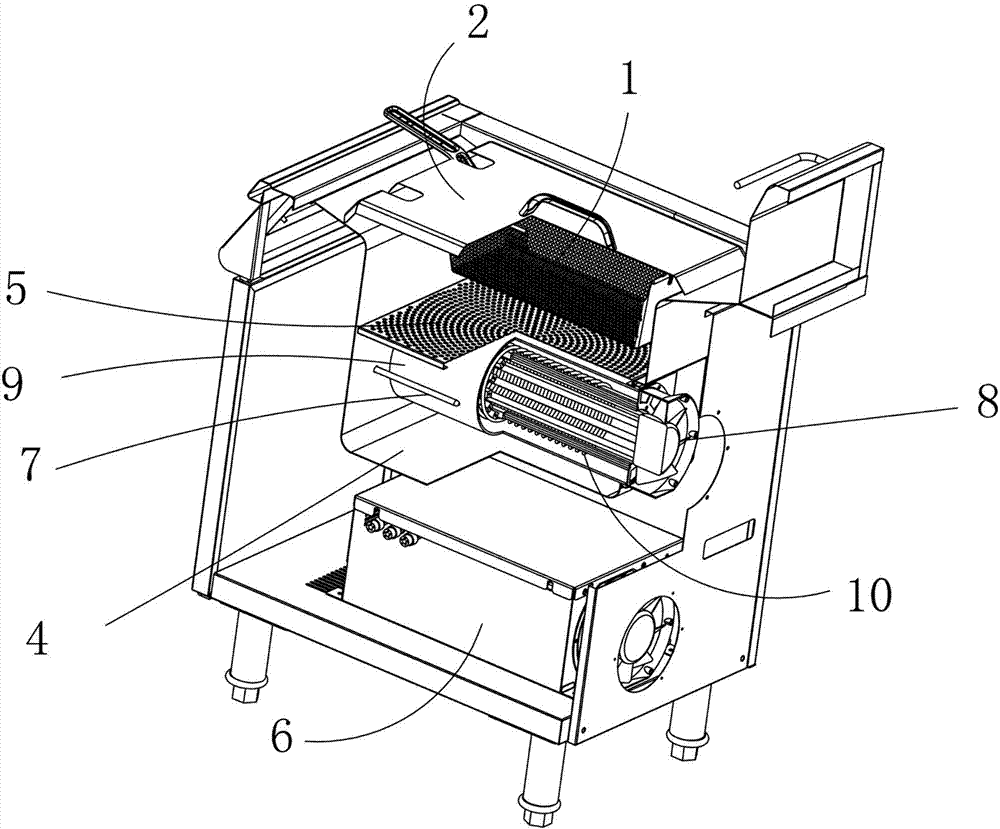

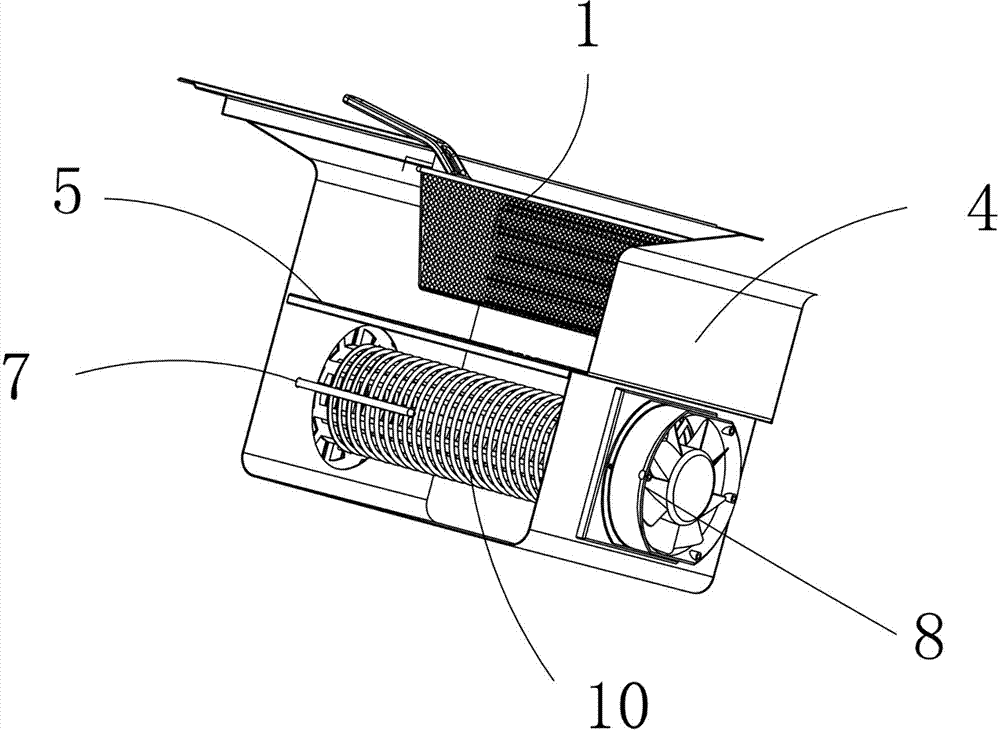

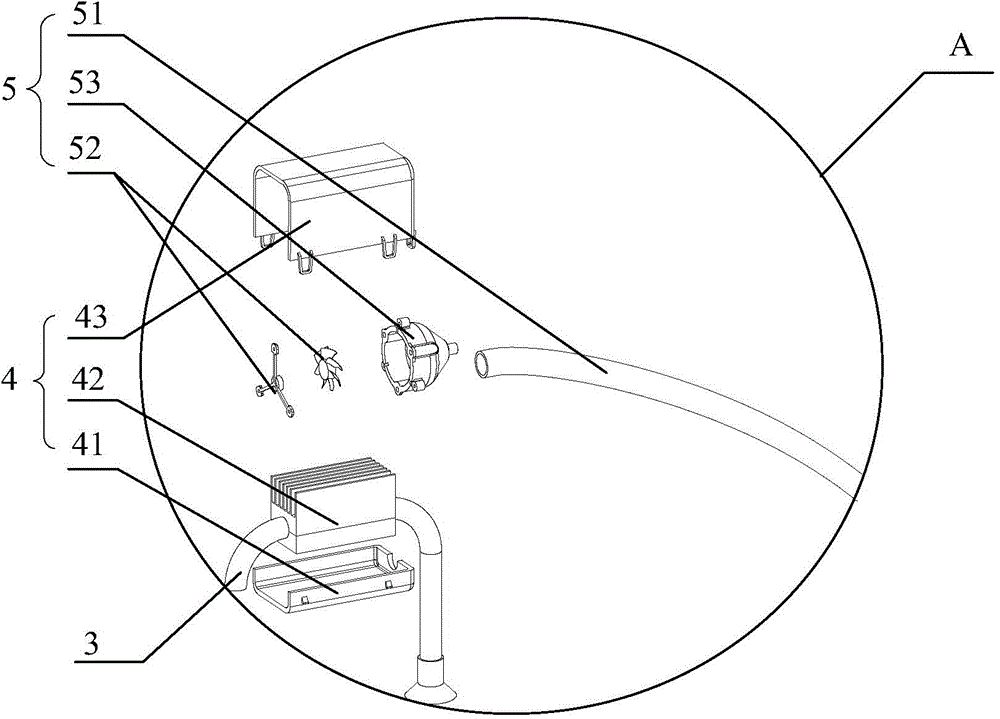

Air fryer reliable in control

ActiveCN110876567AGuaranteed effective use of the areaGuaranteed Proportional DemandCooking-vessel lids/coversLighting elementsEngineeringGravity center

The invention relates to an air fryer stable in control. The air fryer comprises a base and a cover body hinged to the base. A fyer assembly is arranged in the machine base. The fryer assembly comprises an inner pot. A hot air assembly is arranged in the cover body, the hot air assembly comprises an air guide plate, a fan and a heating piece. The fan and the heating piece are positioned below theair guide plate; a transparent visual window is arranged on the cover body, the center of the hot air assembly deviates from the center of the fryer assembly, the distance between the center of the hot air assembly and the hinge center is smaller than the distance between the center of the fryer assembly and the hinge center, and the visual window surrounds the hot air assembly and is located above the inner pot. The hot air assembly is far away from a user relative to the fryer assembly, the area of the visual window located on one side of the user is enlarged, and therefore the user can visually observe the interior of the fryer assembly through the visual window. Meanwhile, the heights of the cover body and the whole air fryer can be effectively reduced, the gravity centers of the coverbody and the whole air fryer are reduced, and when the cover body is opened or closed, the whole air fryer is stably operated.

Owner:JOYOUNG CO LTD

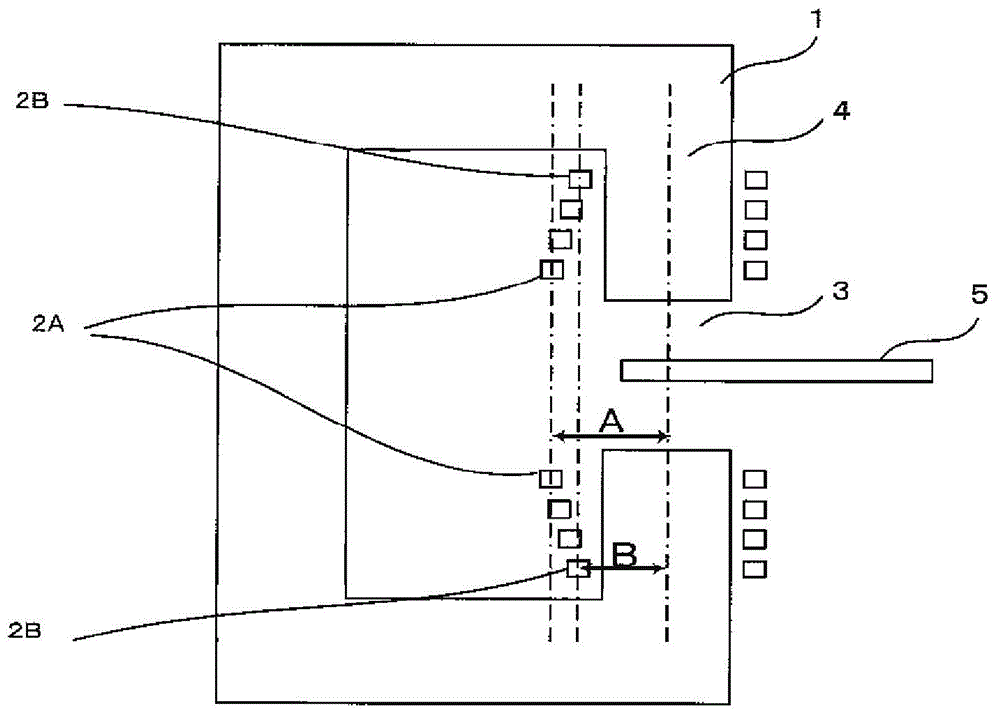

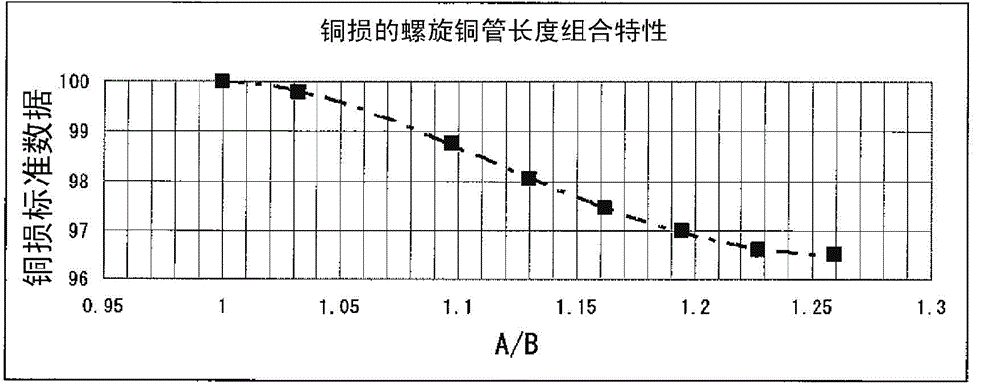

Induction heating apparatus

ActiveCN104918343AAvoid heatingReduce magnetic fluxIncreasing energy efficiencyInduction heating apparatusInductorCopper

Provided is an induction heating apparatus of a C-shaped inductor, which can restrain spiral copper pipe heating, and magnetic flux reduction which is the reason of copper loss, and can not reduce the heating efficiency of the end portion of a heated piece. The induction heating apparatus is in pairs provided with fixed C-shaped inductors formed by C-shaped iron core structures at two end portions of a heat piece in the width direction, characterized in that the C-shaped inductor is composed of a main body iron core portion which is provided with an opening used for passing through a heated piece along the conveying direction of the heated piece; an iron core leg portion in connection with the opening portion and formed in a mode of clamping the opening portion up and down; and a heating coil which clamps the opening portion and winds the up and down iron core leg portion, allows linkage between the heated piece and magnetic flow so as to heat a piece to be heated, and is winded in a mode in which the winding diameter of the heating coil gradually expands towards the end portion of the surface opposite to the opening portion.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

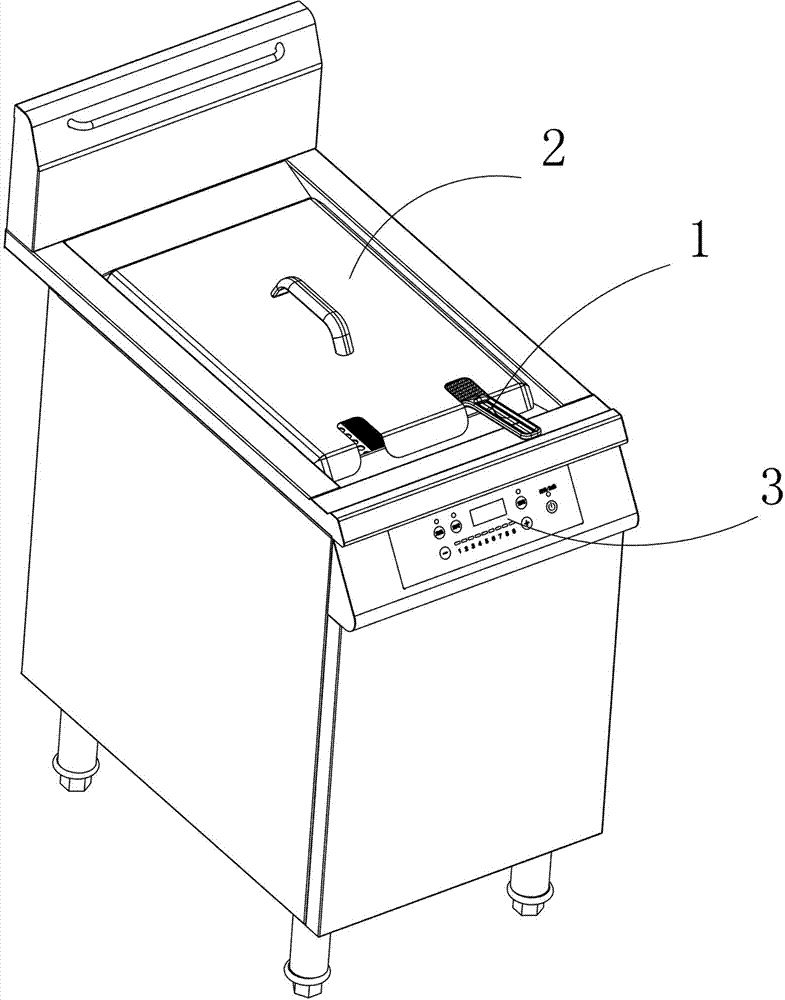

Frying furnace and control method thereof

The invention discloses a frying furnace which comprises a housing, an oil pan and a strainer for containing food, wherein the strainer is put in an upper oil body of the oil pan, and a hollow metal barrel is suspended at the lower part of the oil pan; the hollow metal barrel is opened on the outer side of the oil pan, and an electromagnetic coil panel is arranged in the hollow metal barrel; a heating movement is also arranged in the housing and supplies alternating current for the electromagnetic coil panel. The frying furnace adopts an electromagnetic heating mode to boiling oil and has the advantages of safety in use, environmental protection, sanitation and electricity saving.

Owner:FOSHAN SHUNDE HIGHWAY ELECTRONICS

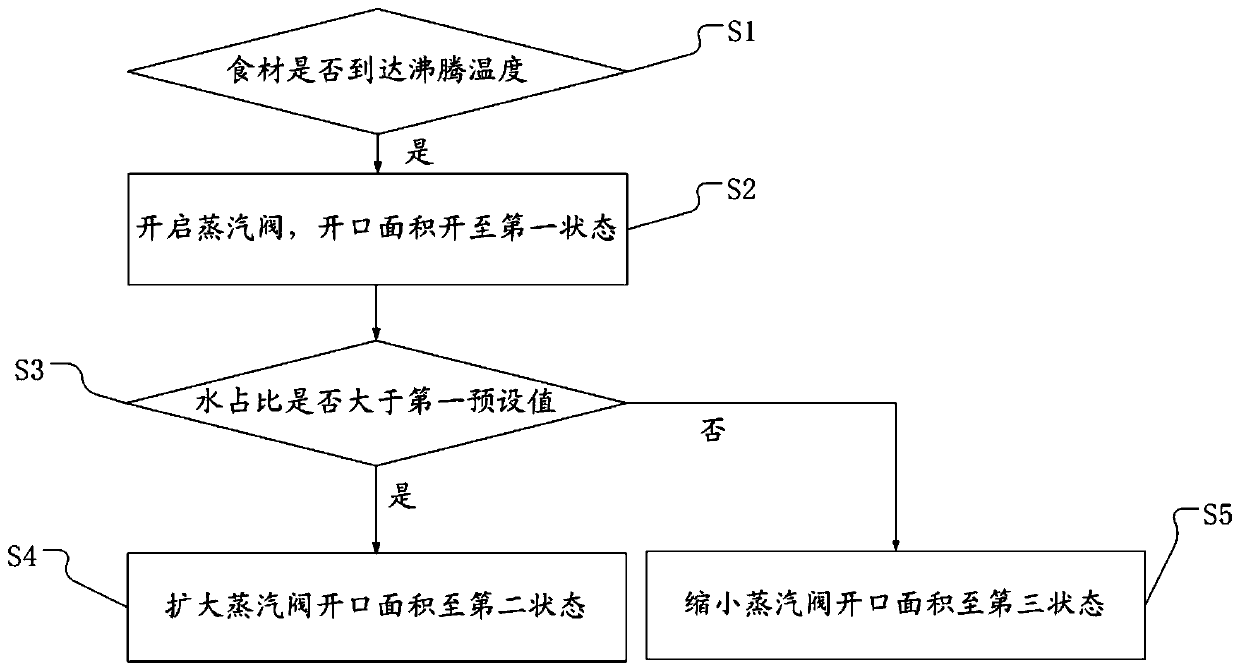

Cooking equipment and control method thereof

The invention provides cooking equipment and a control method thereof. The control method comprises the steps of judging whether foods reach a boiling temperature or not; if yes, opening a steam valve, wherein the opening area of the steam valve reaches a first state; after continuously heating for first preset time, judging that whether a water ratio is more than a first preset value or not; if yes, expanding the opening area of the steam value to a second state; and if no, reducing the opening area of the steam valve to a third state. Due to such a design, the opening area of the steam valveis automatically adjusted according to the detected temperature, the water ratio and working time; quick dissipation of heat and quick escape of vapor are avoided while generation and overflowing ofbubbles are avoided, the contradictory relation between the opening area of the steam valve and heating power is solved, and heating efficiency and user experience are improved.

Owner:GREE ELECTRIC APPLIANCES INC

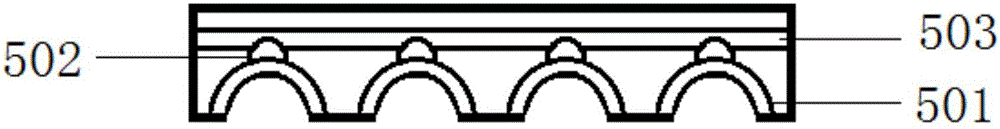

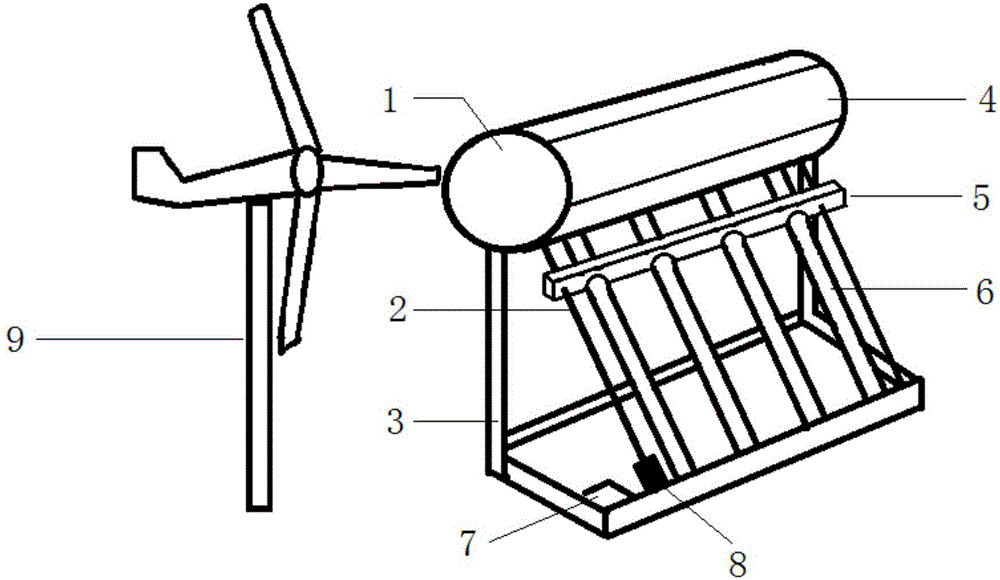

Vacuum pipe cleaning device and solar water heater with same

InactiveCN105865061AAvoid the dangers of manual cleaningSave electricitySolar heating energySolar heat devicesWater storage tankArchitectural engineering

The invention discloses a vacuum pipe cleaning device and a solar water heater with the same. The cleaning device is provided with a plurality of semicircular grooves matched with the external diameter of a vacuum pipe of the water heater. The surface of each groove is wrapped with a sponge material. A water supply pipe is fixedly arranged above the grooves. Water outlets are formed in the positions, corresponding to the grooves, of the water supply pipe, and the water outlets are used for wetting the sponge materials. According to the solar water heater based on the vacuum pipe cleaning device, a water storage tank and the vacuum pipe of the water heater are connected and supported by a water heater support. The vacuum pipe cleaning device is installed on the vacuum pipe of the water heater, and the grooves make contact with the pipe wall. The two sides of the vacuum pipe cleaning device are fixed with guide rails, and the vacuum pipe cleaning device can be driven by a drive device to move back and forth in the axial direction of the vacuum pipe of the water heater. The vacuum pipe cleaning device and the solar water heater with the same have the beneficial effects that the cleaning device is mounted to the solar water heater so as to clean the solar water heater, manual cleaning is replaced, danger caused by manual cleaning is avoided, and the heating efficiency is ensured.

Owner:ZHEJIANG UNIV

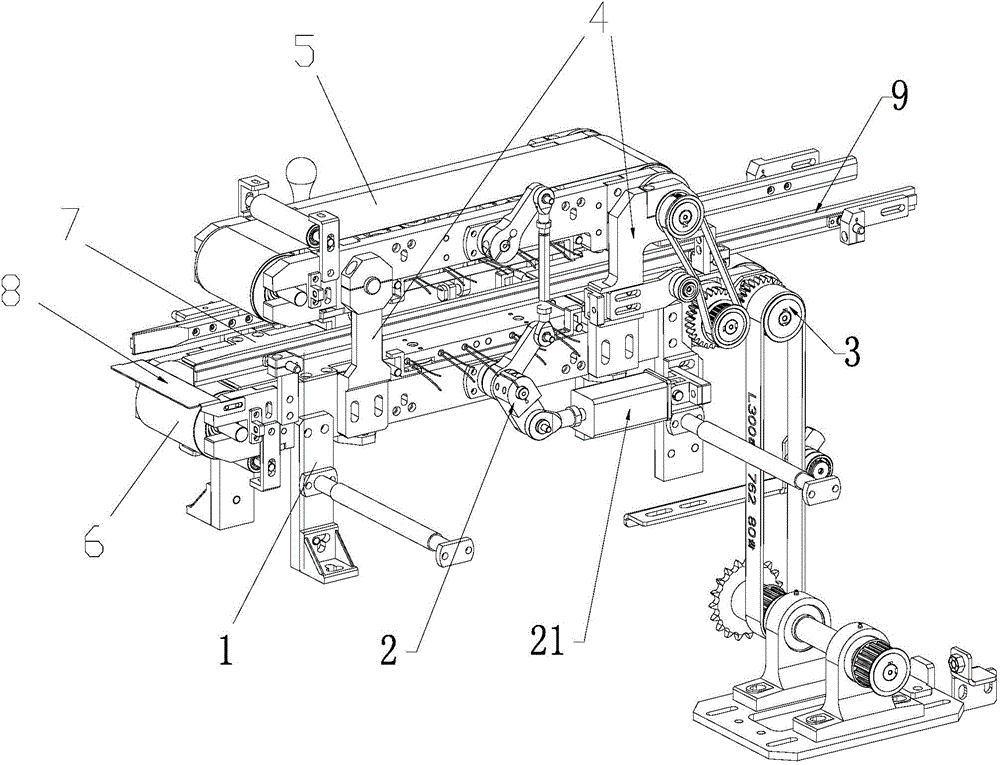

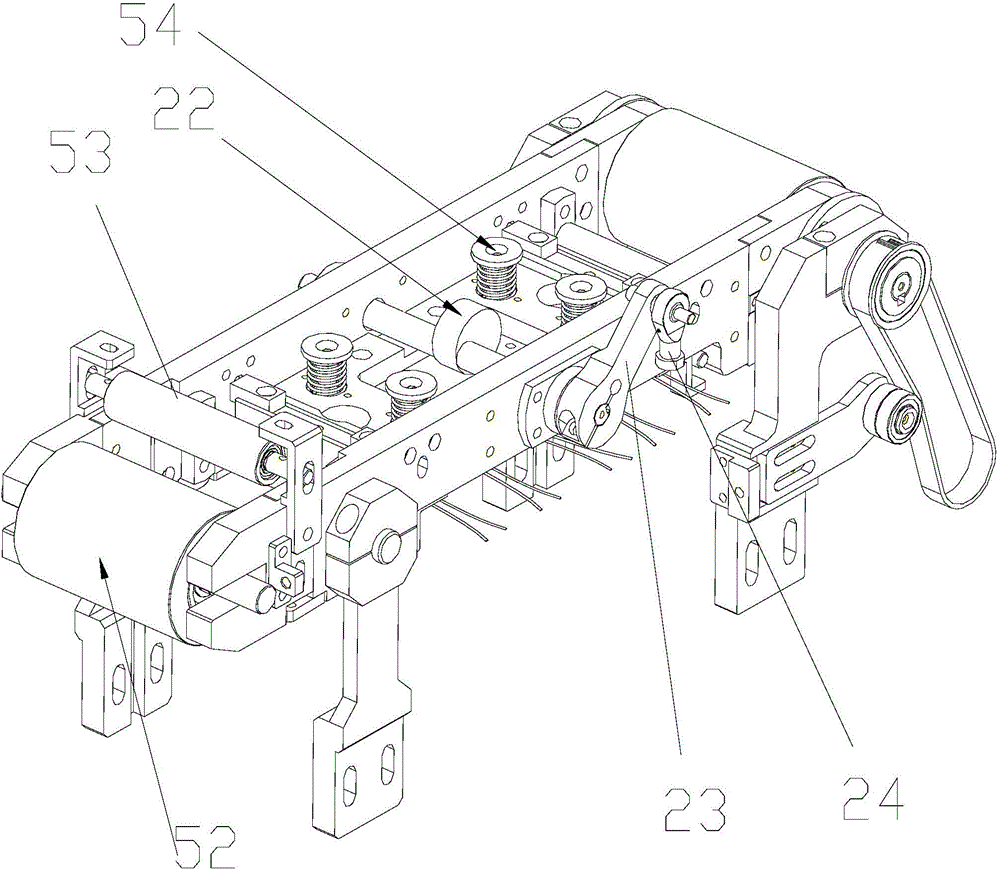

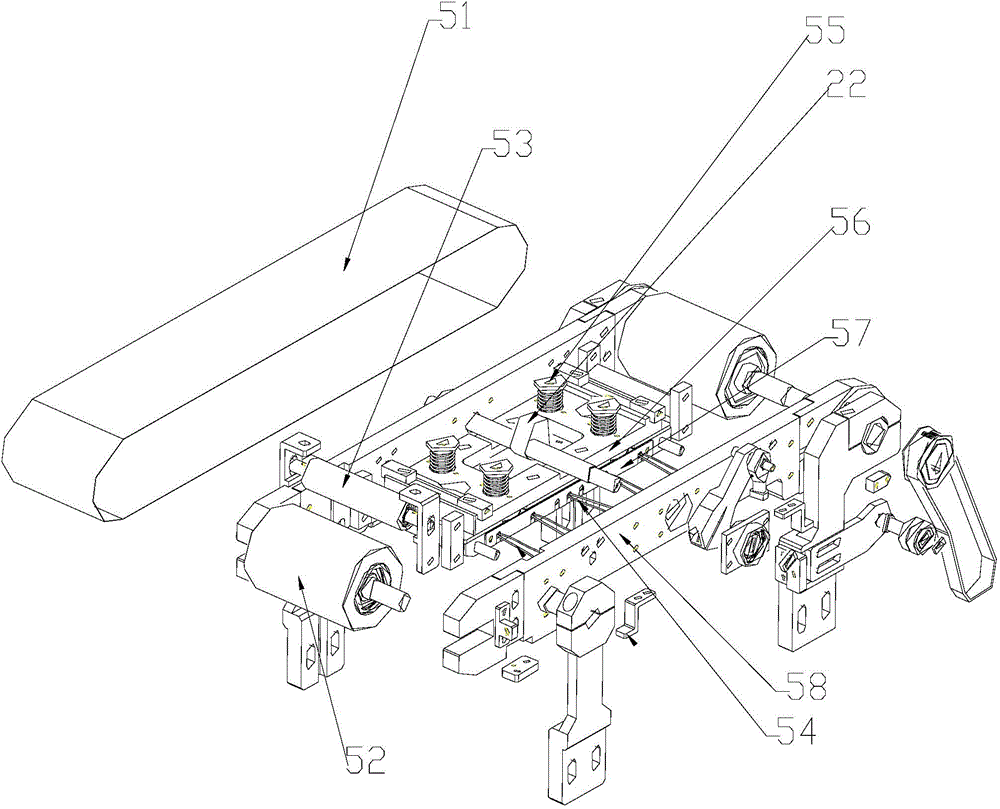

Device for beautifying transparent thermal shrinking films of cigarette packets and application of device

The invention discloses a device for beautifying transparent thermal shrinking films of cigarette packets. The device comprises a rack, a transmission mechanism and a power device for supplying the power to the transmission mechanism, wherein a cigarette packet transferring channel is arranged in the rack; a first belt conveyor mechanism and a second belt conveyor mechanism are arranged on the upper side and the lower side or the left side and the right side of the cigarette packet transferring channel; the first belt conveyor mechanism and the second belt conveyor mechanism are driven by the transmission mechanism to implement linkage, so that belts of the first belt conveyor mechanism and the second belt conveyor mechanism move in the same direction; the first belt conveyor mechanism is fixed on the rack; the second belt conveyor mechanism is mounted on the rack through a distance-adjustable adjustment bracket; belts of the first belt conveyor mechanism and the second belt conveyor mechanism are taken as the conveying power of cigarette packets in the cigarette packet transferring channel and are in contact with two opposite surfaces of each cigarette packet respectively during operation; electric heating plates are arranged in the first belt conveyor mechanism and the second belt conveyor mechanism; the belts on the sides in contact with the cigarette packets are in contact with the electric heating plates and the belts are heated during operation. The device can implement six-sided baking, can achieve high production efficiency while meeting the quality of products, has great promotional value; the products are good in surface quality after being baked.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

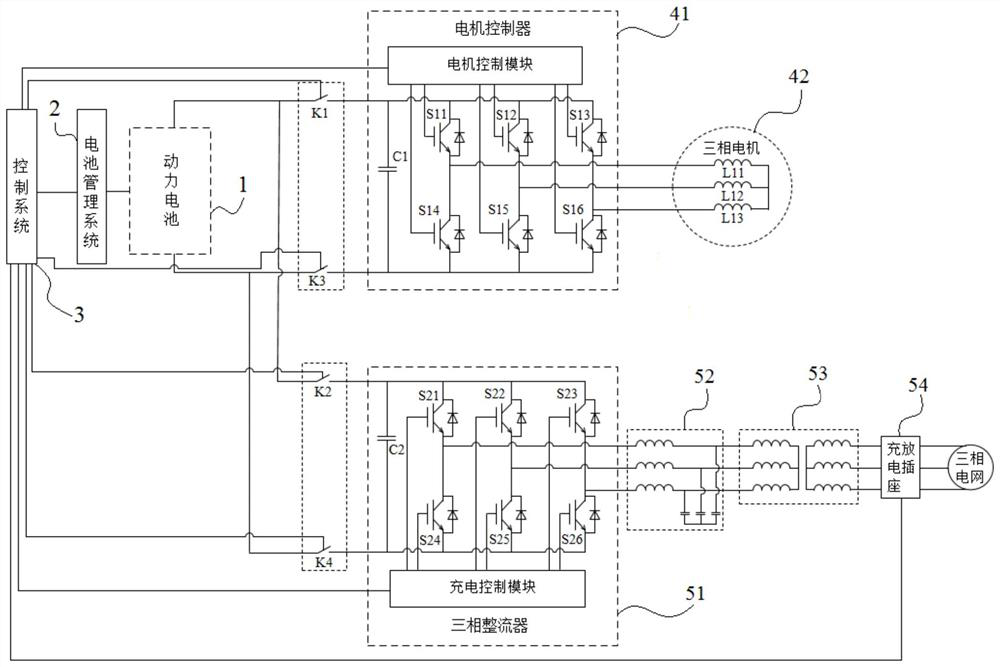

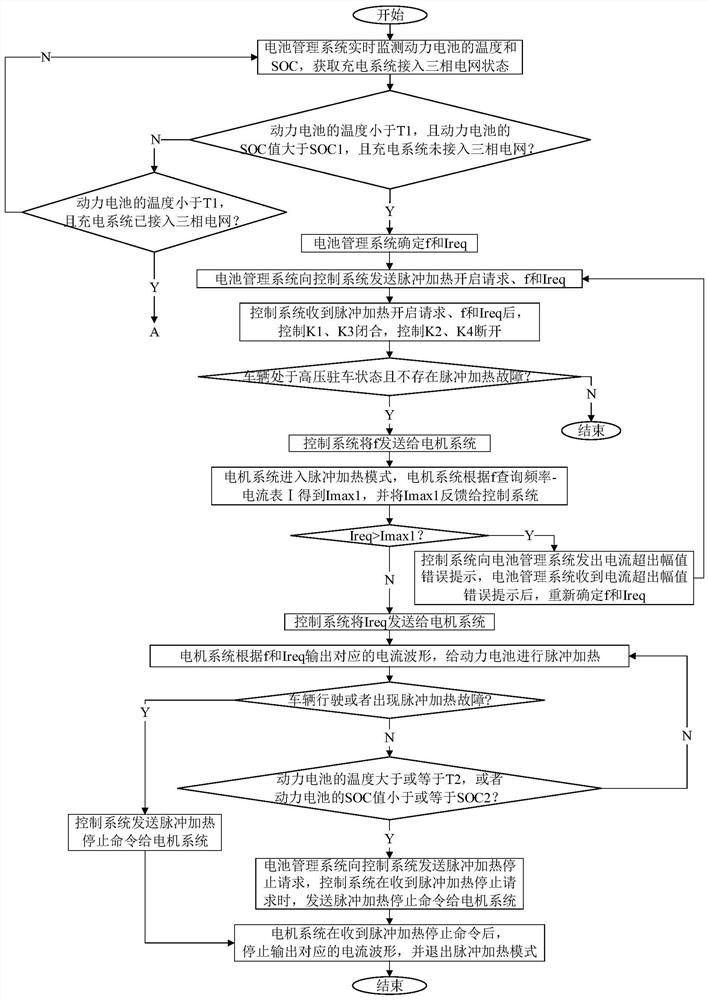

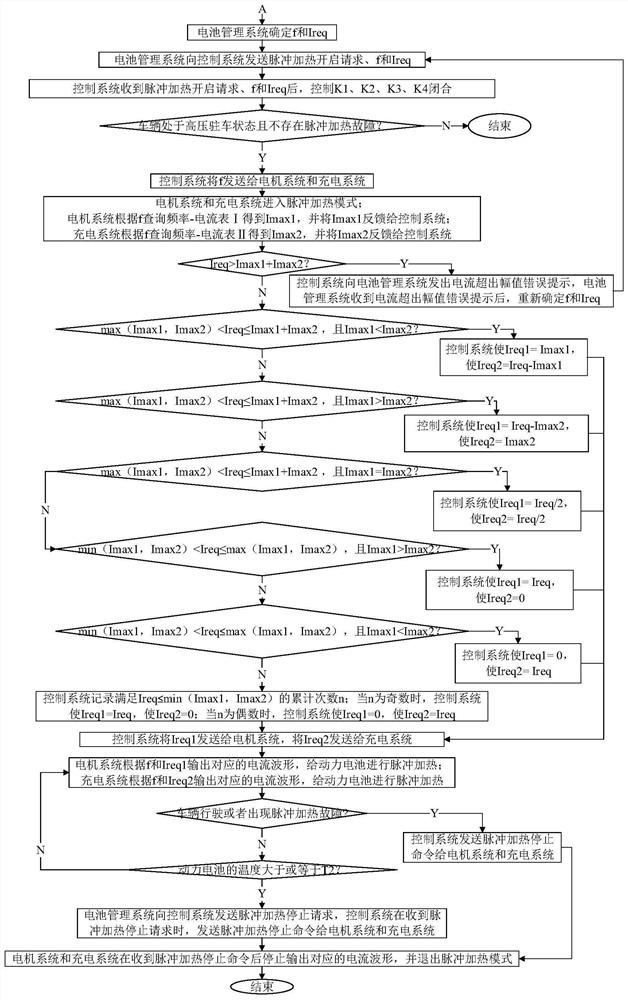

Electric automobile, power battery pulse heating system and heating method

ActiveCN113085659AImprove pulse heating efficiencyIncrease temperatureSpeed controllerCells structural combinationPower batteryElectrical battery

The invention discloses an electric automobile, a power battery pulse heating system and a heating method. The power battery pulse heating system comprises a battery management system, a control system, a motor system, a first controllable switch K1, a second controllable switch K2, a third controllable switch K3, a fourth controllable switch K4 and a charging system. The motor system and the charging system are used for performing pulse heating on the power battery, and compared with single motor system pulse heating or single charging system pulse heating, the pulse current adjustable range is expanded; under the condition that the pulse heating condition is allowed, pulse heating is performed through the motor system and the charging system, so the heating power expansion is realized, the single heating time is shortened, and the pulse heating efficiency of the power battery is also improved. Therefore, the high-frequency large-current rapid charging and discharging process of the power battery is realized, and the purpose of rapidly increasing the temperature of the power battery is achieved by heating the internal resistor of the battery.

Owner:深蓝汽车科技有限公司

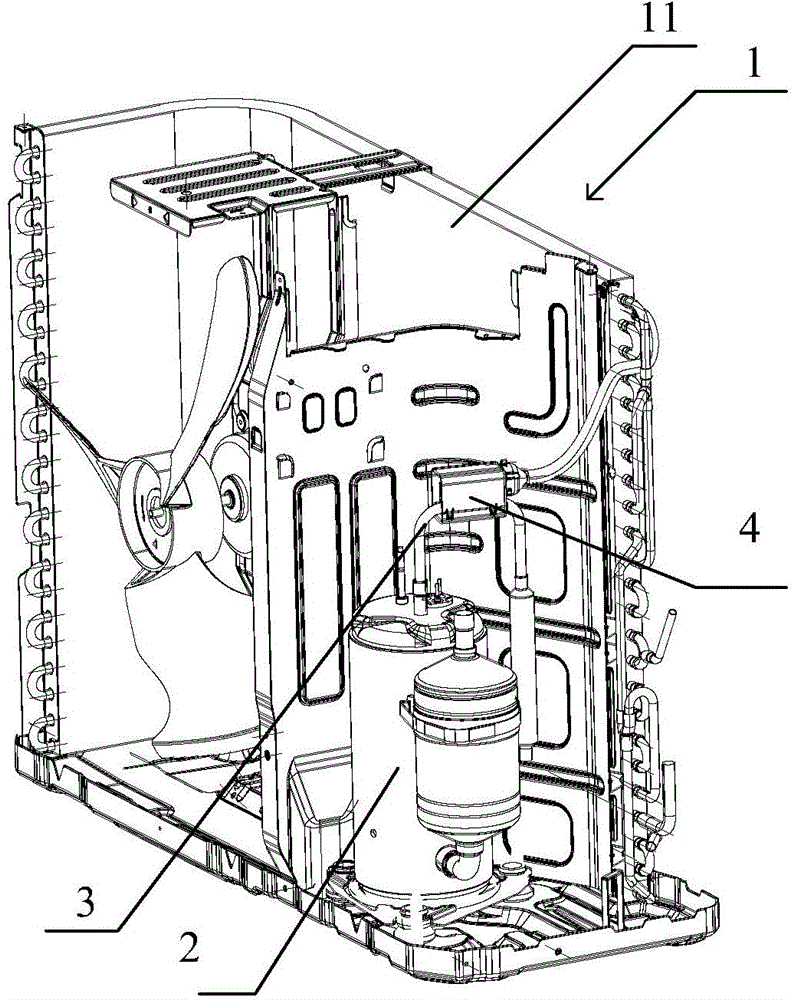

Outdoor unit defrosting device and air conditioner

ActiveCN105318453ANo heat reductionGuaranteed heating efficiencyLighting and heating apparatusAir conditioning systemsFour-way valvePipe fitting

The invention discloses an outdoor unit defrosting device and an air conditioner with the same. The outdoor unit defrosting device comprises a heat exchange module and an air supply module. The heat exchange module is arranged at the position of a refrigerant conveying pipe between an exhaust port of an air conditioner compressor and a four-way valve and used for controlling heat exchange between the refrigerant conveying pipe and outside air. The air supply module comprises an air supply pipe fitting and a fan. The air supply pipe fitting comprises an air inlet and an air outlet, the air inlet of the air supply pipe fitting corresponds to the heat exchange module, the air outlet of the air supply pipe fitting corresponds to a fin of an outdoor unit, and the fan controls air having undergone heat exchange with the heat exchange module to flow into the air supply pipe fitting through the air inlet. Remaining heat generated in the air conditioner running process is conveyed to the fin of the outdoor unit, and thus the outdoor unit defrosting effect is achieved. The shortcoming that the use of the air conditioner by users is affected due to noise resulting from frequent starting and shutdown is overcome. According to the outdoor unit defrosting device, the heating capacity of the air conditioner is not reduced in the defrosting process, and thus the heating efficiency is guaranteed.

Owner:MIDEA GRP CO LTD +1

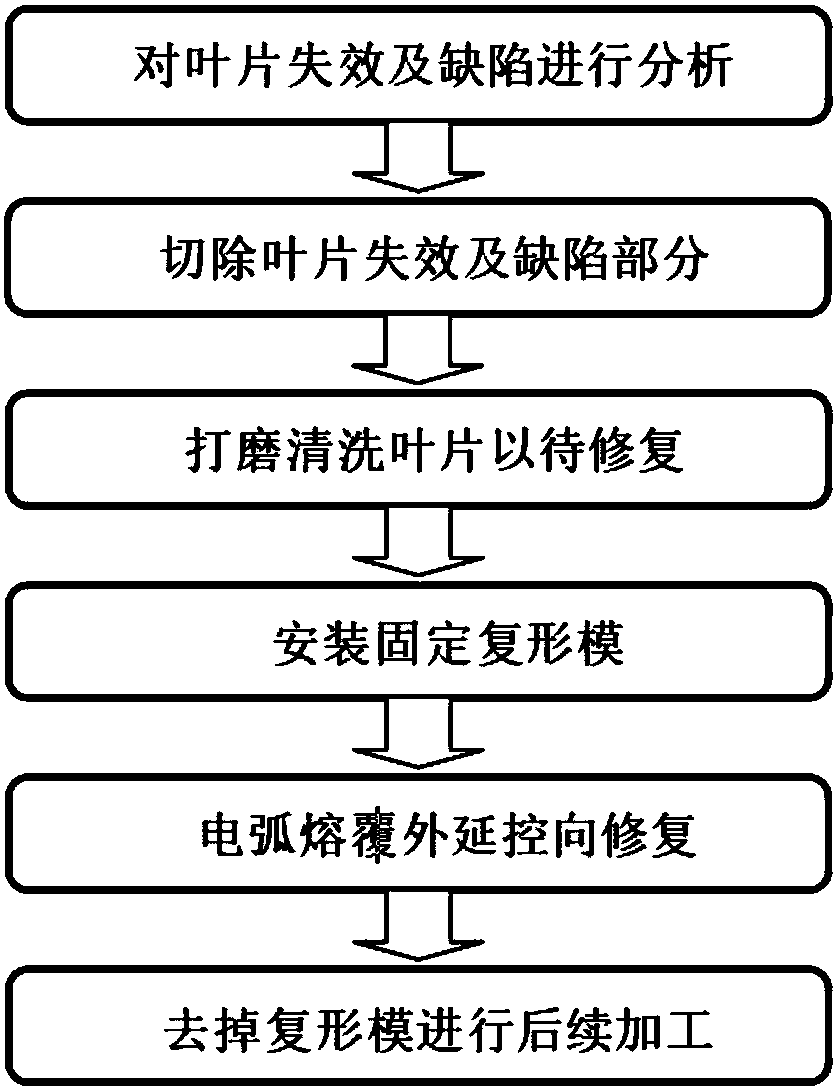

Repair method for complexing of inner flow passages of single-crystal or directional-crystal alloy blades

The invention discloses a repair method for complexing of inner flow passages of single-crystal or directional-crystal alloy blades. The repair method includes step S100, judging and analyzing blade failure and defects before repair; step S200, cutting failure or defective portions of the blades, and polishing and cleaning the blades; step S300, mounting pre-produced and pretreated complexing molds used for guaranteeing high-accuracy complexing of inner flow passage structures of the blades, and fastening the complexing molds in to-be-repaired blade cavities, wherein the complexing molds are core molds with outer surfaces capable of forming blade cavity flow passages through solidification of follow-up blade material melts; step S400, preheating to-be-repaired portions to more than 75% ofa material melting point calculated by Kelvin, and allowing the blade repair portions to extend externally to grow in a direction control way according to a metal melt filling method; step S500, removing the complexing molds after metal cladding, and performing follow-up processing on the blades. The repaired blades meet application requirements of the single-crystal or directional-crystal blades,service life of the blades is prolonged to the greatest extent, and the repair method has great theoretical and practical significance.

Owner:XI AN JIAOTONG UNIV

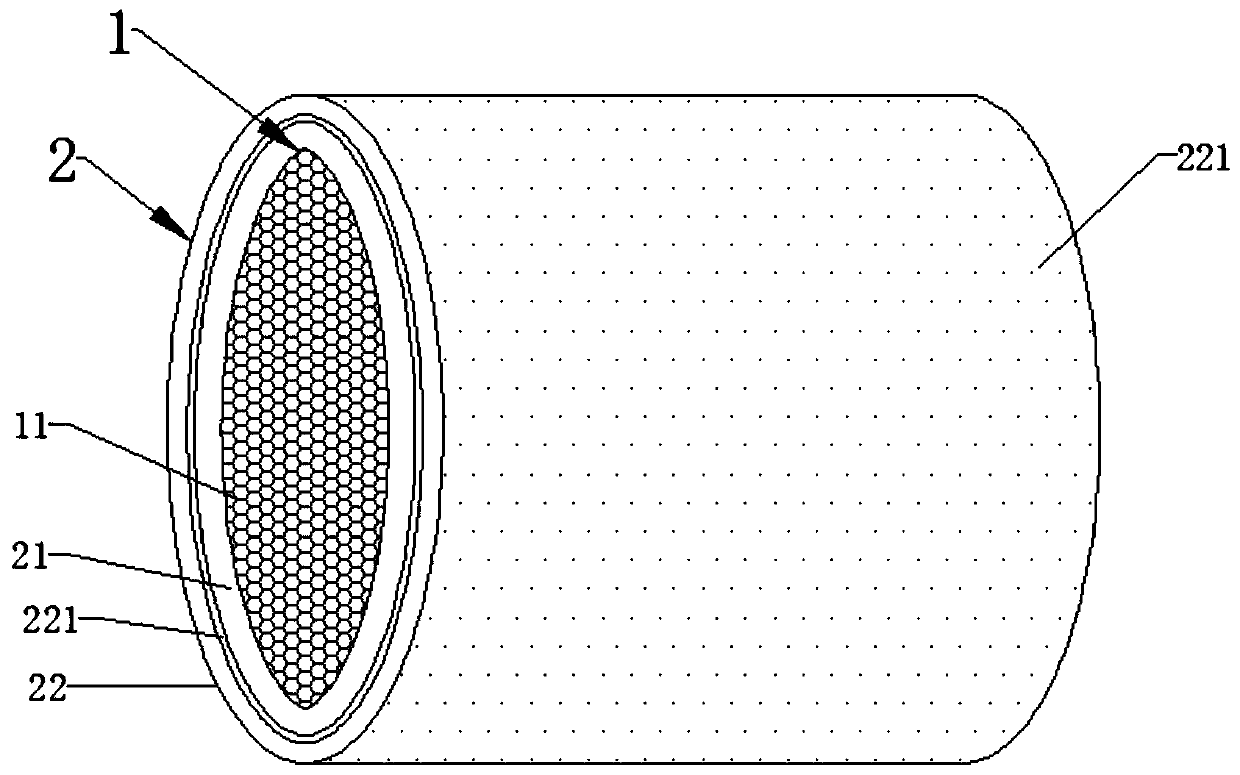

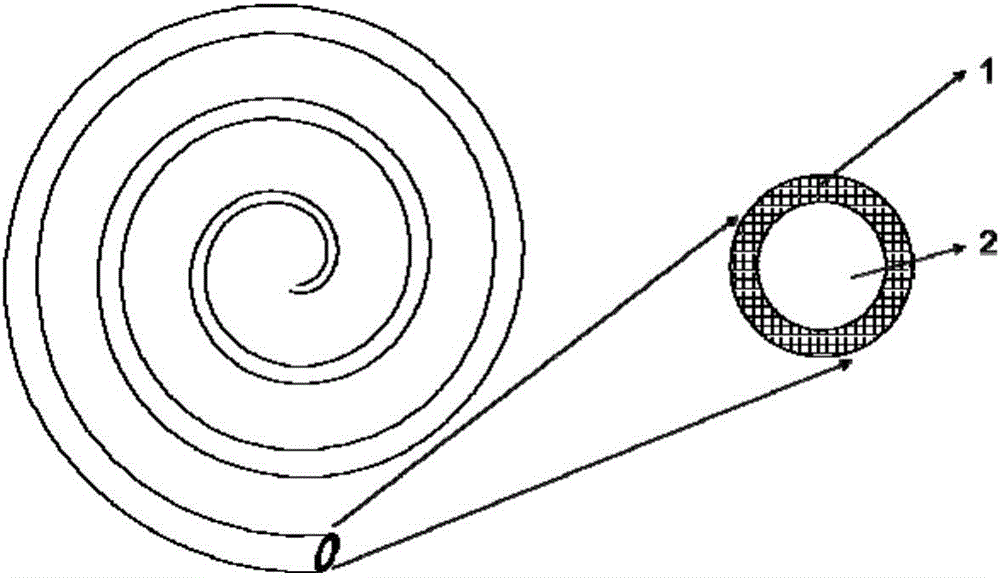

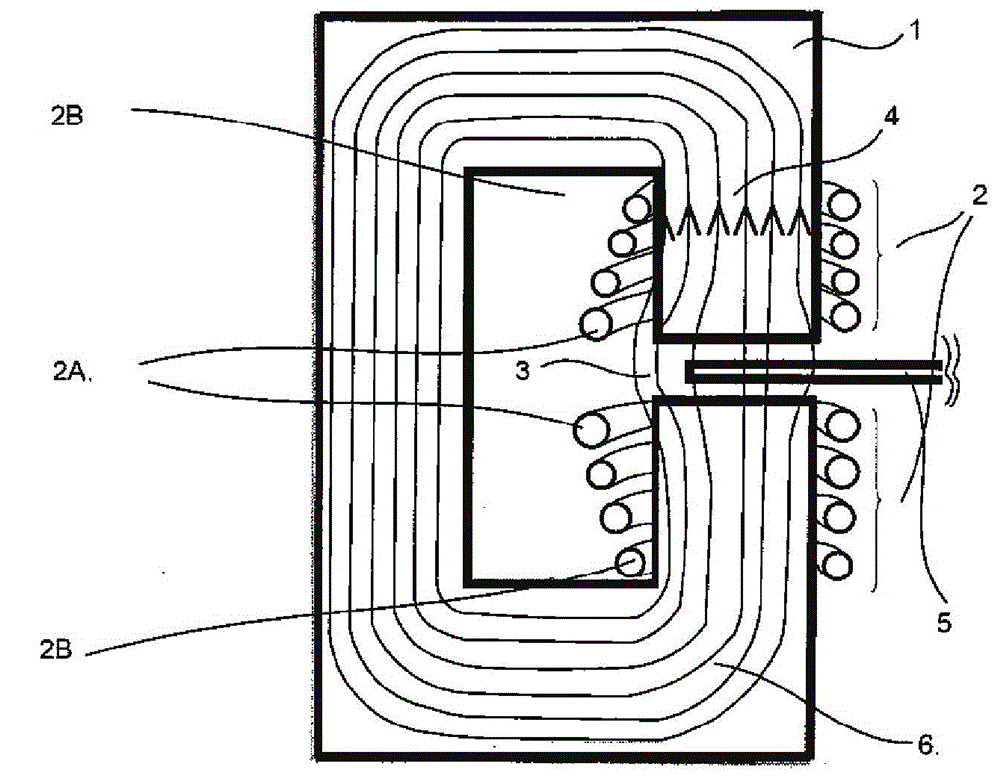

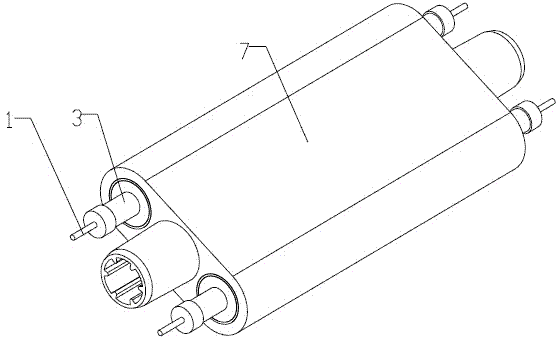

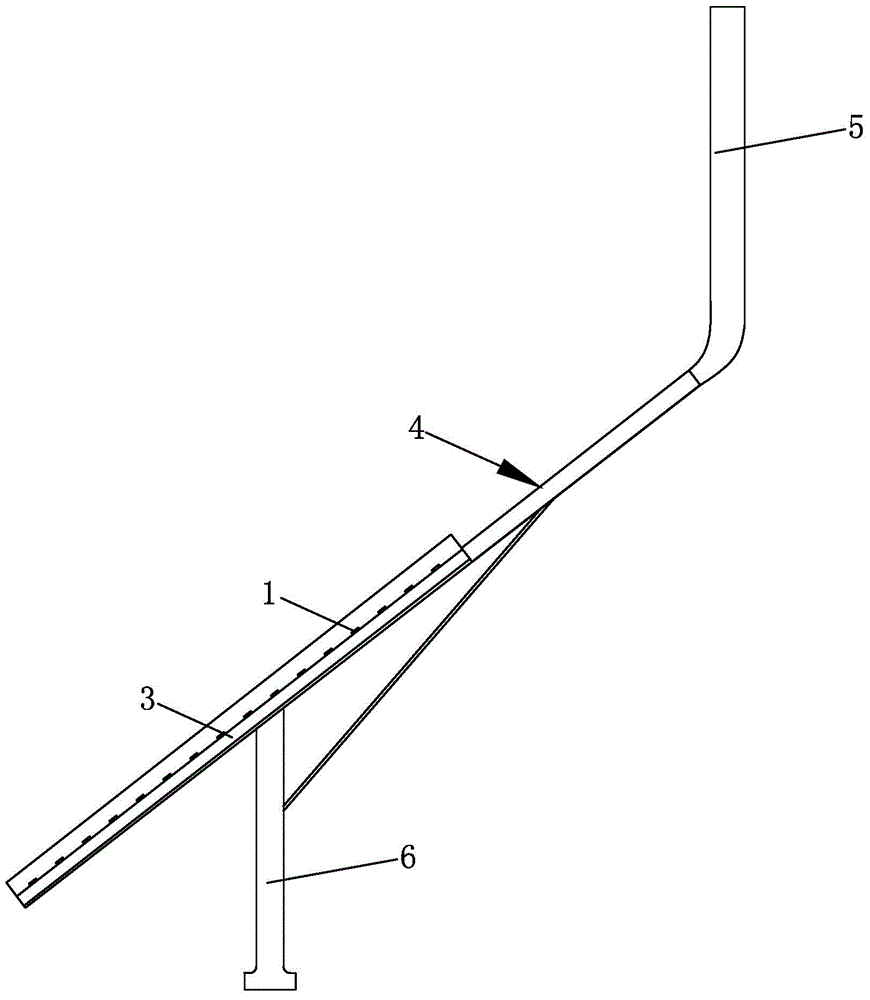

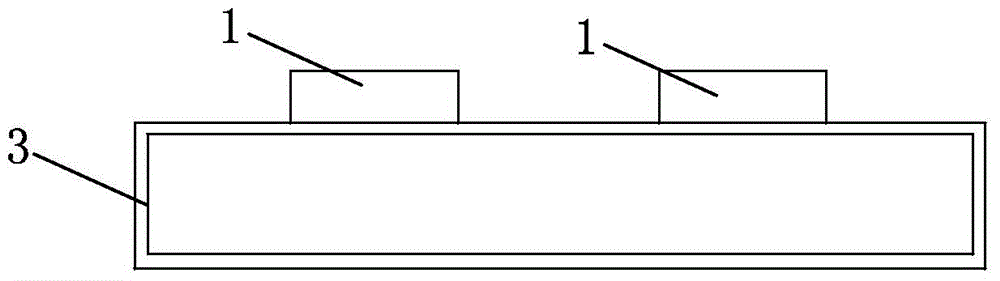

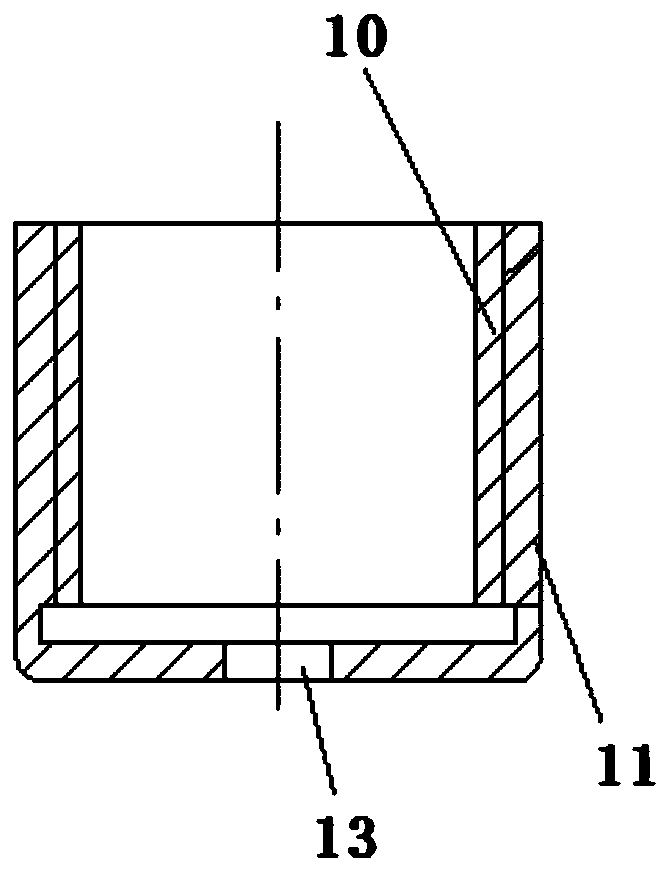

Low-faradism footbath machine heating device

InactiveCN102654312AReduce inductionWith double insulationFluid heatersElectrical connectionElectrical bonding

The invention discloses a low-faradism footbath machine heating device which comprises a heating element (1), wherein a metal shielding layer (2) kept in electrical connection with the heating element and capable of reducing faradism is arranged on the outer side of the heating element (1). A basic insulating layer (3) is arranged between the metal shielding layer (2) and the heating element (1), and a basic insulating layer (3) is arranged on the outer side of the metal shielding layer (2). According to the invention, by arranging the metal shielding layer outside the heating element of a footbath machine, the faradism of the heating device in work can be remarkably reduced; and meanwhile, two heat-conduction insulating layers are encapsulated on the surface of the shielding layer so that the heating device has double-insulation performance, and the product is safe and reliable on the premise of guaranteeing the heating efficiency.

Owner:佛山市顺德区美承健康科技有限公司

Intelligent water heater based on Internet of Things system

InactiveCN111765628AEasy to scrape outGuaranteed cleanlinessHollow article cleaningWater heatersSolenoid valveEngineering

The invention relates to an intelligent water heater based on an Internet of Things system in the technical field of water heaters. The intelligent water heater comprises an outer barrel which is provided with a door panel and an inner cylinder, and the inner cylinder is provided with a circular plate; an upper liquid level sensor and a lower liquid level sensor are arranged on the circular plate,and the circular plate is provided with a heating pipe, a temperature sensor, a circuit board and a mounting rack; the circuit board is provided with a cable, a single chip microcomputer and a GMS communication module, and the mounting rack is provided with a driving motor which is provided with a threaded rod; the threaded rod is provided with a cross sliding plate, and the circular plate is provided with a sliding rod; the cross sliding plate is provided with a scraping ring and a cleaning structure, and the threaded rod is provided with a scraping rod; and the inner cylinder is provided with a water outlet pipe and a water inlet pipe, and the water inlet pipe is provided with a solenoid valve. According to the intelligent water heater, through the scraping ring moved back and forth, dirt on the inner wall of the inner cylinder is easy to scrape; the cleaning degree of the inner wall of the inner cylinder, the heating rate, the heating efficiency and the normal use of the water heater are ensued.

Owner:张晓卫

Concentrating photovoltaic battery air-cooled heat dissipation system

InactiveCN105071766AImprove cooling effectExtended service lifePhotovoltaicsPhotovoltaic energy generationFresnel lensAir heating

The invention discloses a concentrating photovoltaic battery air-cooled heat dissipation system which comprises a set of concentrating photovoltaic battery sheets. The concentrating photovoltaic battery sheets are arranged into an inclined concentrating photovoltaic battery array. The concentrating photovoltaic battery array and a Fresnel lens above the concentrating photovoltaic battery array form a component. Heat dissipation rectangular tubes are arranged side by side beneath the concentrating photovoltaic battery array. Air outlets on the upper ends of the heat dissipation rectangular tubes are inserted into the lower part of an air cavity of the same air heating component. The upper part of the air cavity of the air heating component is connected with a chimney. The air heating component and all heat dissipation rectangular tubes are arranged on a mounting bracket. The mounting bracket is fixed on a dual-shaft tracker. According to the invention, energy consumption is avoided; the reliability is high; temperature difference is used for heat dissipation; heat of the condensation photovoltaic battery array is well dissipated; the service life of the concentrating photovoltaic battery array is ensured; and the problem that the heat dissipation intensity of a traditional passive heat dissipation method does not match a heat dissipation demand is solved.

Owner:CHONGQING UNIV OF TECH

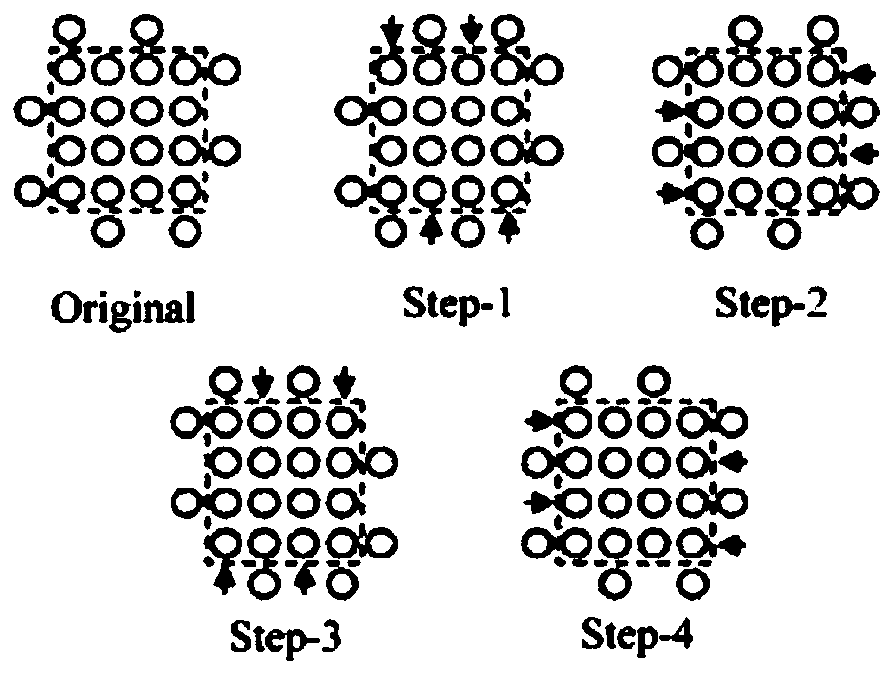

Multi-rotation-type asphalt material storage equipment

InactiveCN112878141AIncrease stirring intensityImprove stirring efficiencyRoads maintainenceEngineeringAsphalt

The invention discloses multi-rotation-type asphalt material storage equipment, and belongs to the technical field of asphalt processing. The equipment comprises a group of supporting vertical rods which are distributed in a circumferential array, and further comprises a heat exchange liquid inlet pipe and a heat exchange liquid outlet pipe; the top ends of the supporting vertical rods are fixedly connected with an outer tank, the top face of the outer tank is fixedly connected with the heat exchange liquid inlet pipe through a connecting plate, and the bottom face of the outer tank is fixedly connected with the heat exchange liquid outlet pipe through a connecting plate; and a heating outer cavity and a storage cavity which are isolated from each other are formed in the outer tank from outside to inside, an inner container is rotationally connected to the inner wall of the storage cavity through a bearing, a screen drum communicated with the storage cavity is rotationally connected to the inner wall of the inner container through a bearing, and the circumferential side face of the screen drum is rotationally connected with the outer tank. Through the design of a driven shaft rod, a heat exchange inner shaft pipe, a driven gear and a driving main gear, a one-way stirring structure of a stirring mechanism of a transmission asphalt storage device is changed into a multi-rotation-direction stirring structure, and through the implementation of the multi-rotation-direction stirring structure, the material stirring strength and stirring efficiency of the equipment can be effectively improved.

Owner:余冬标

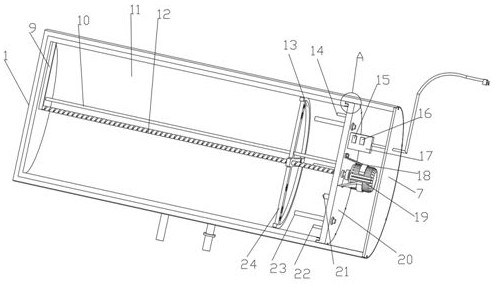

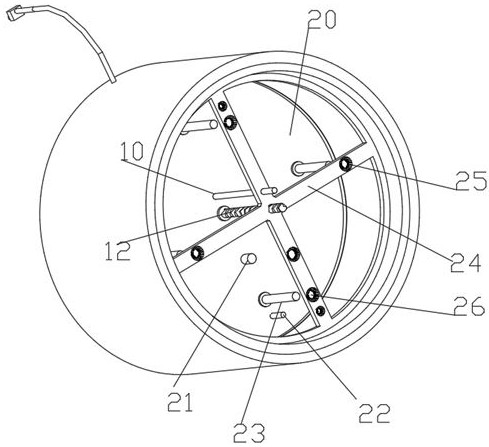

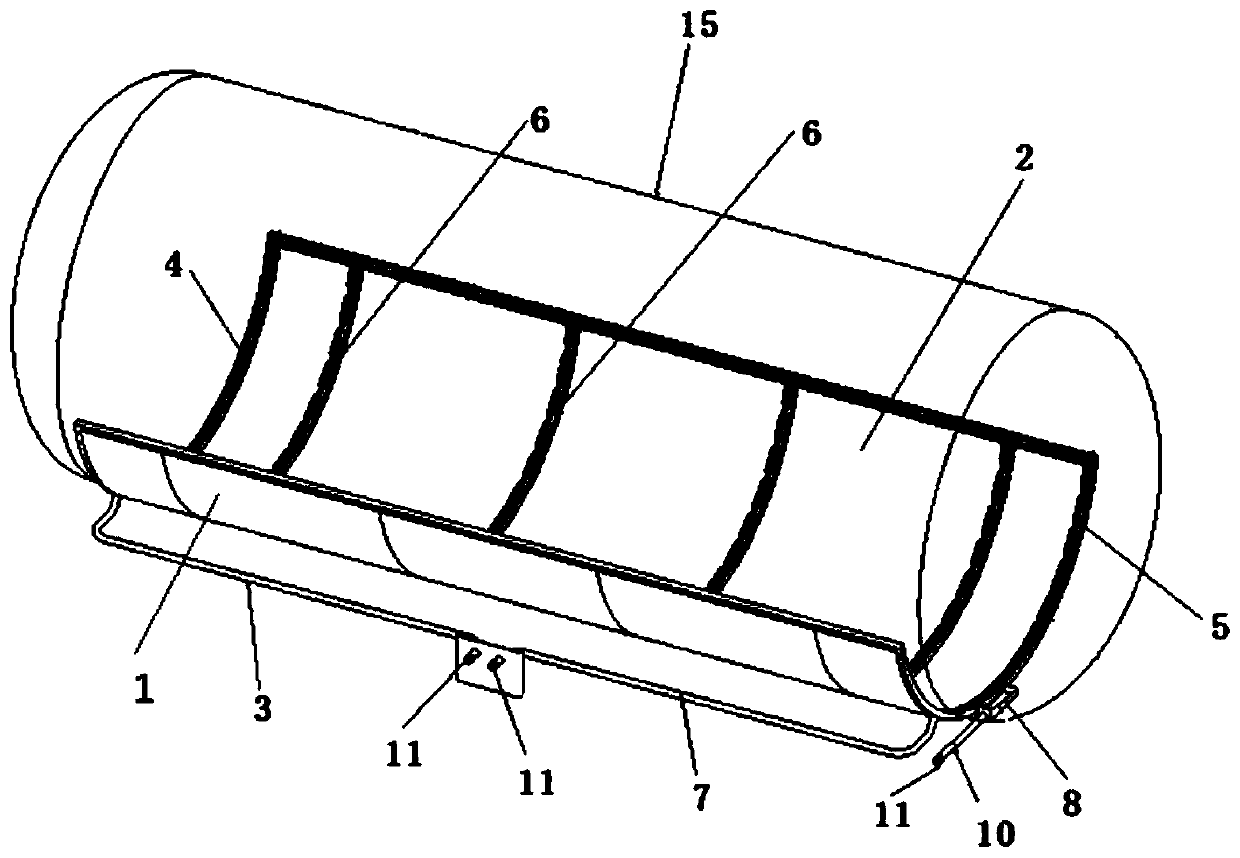

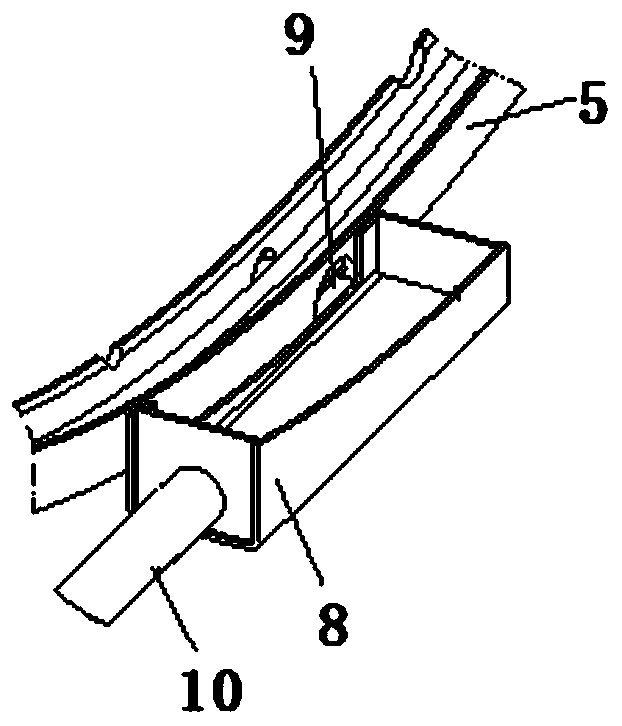

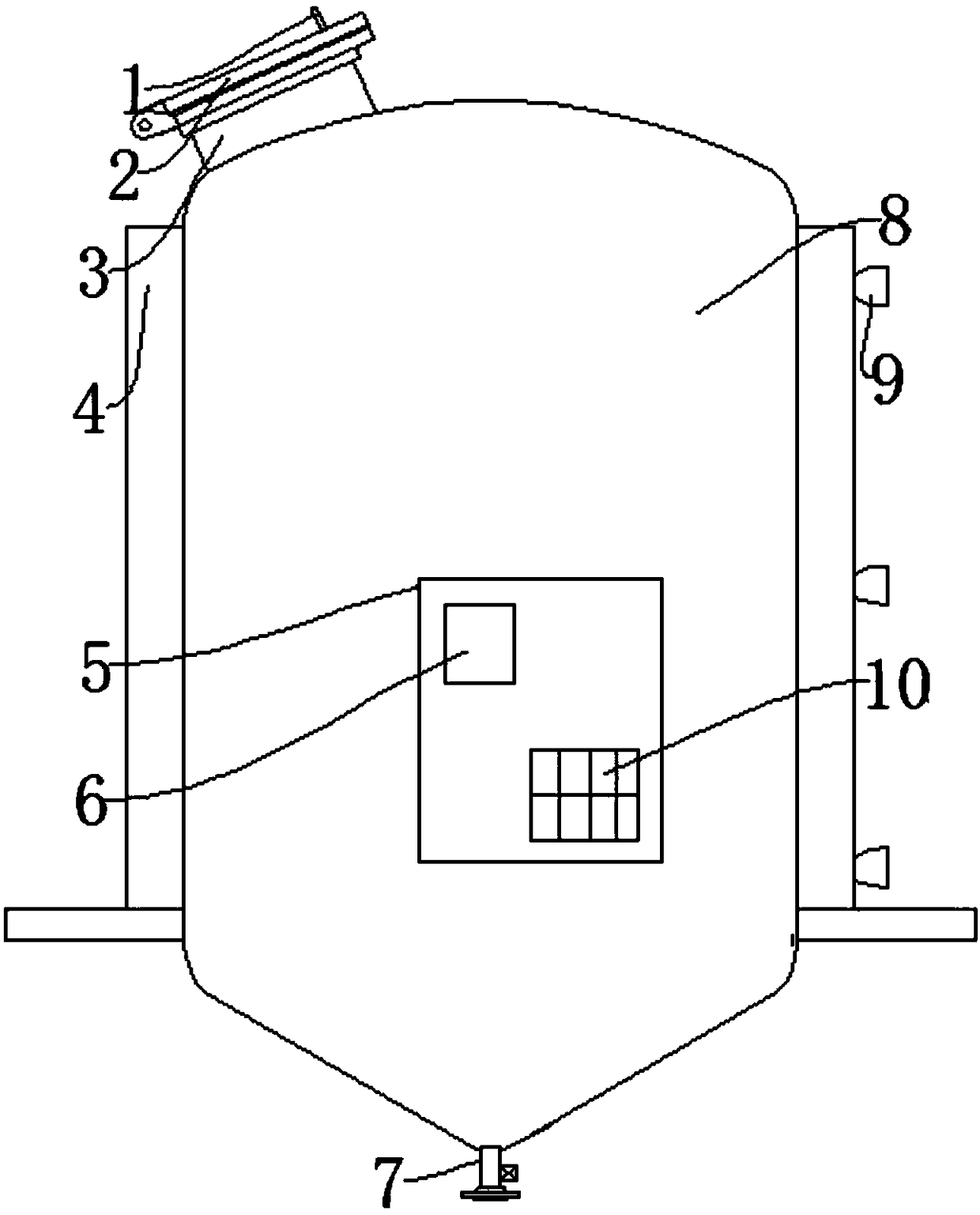

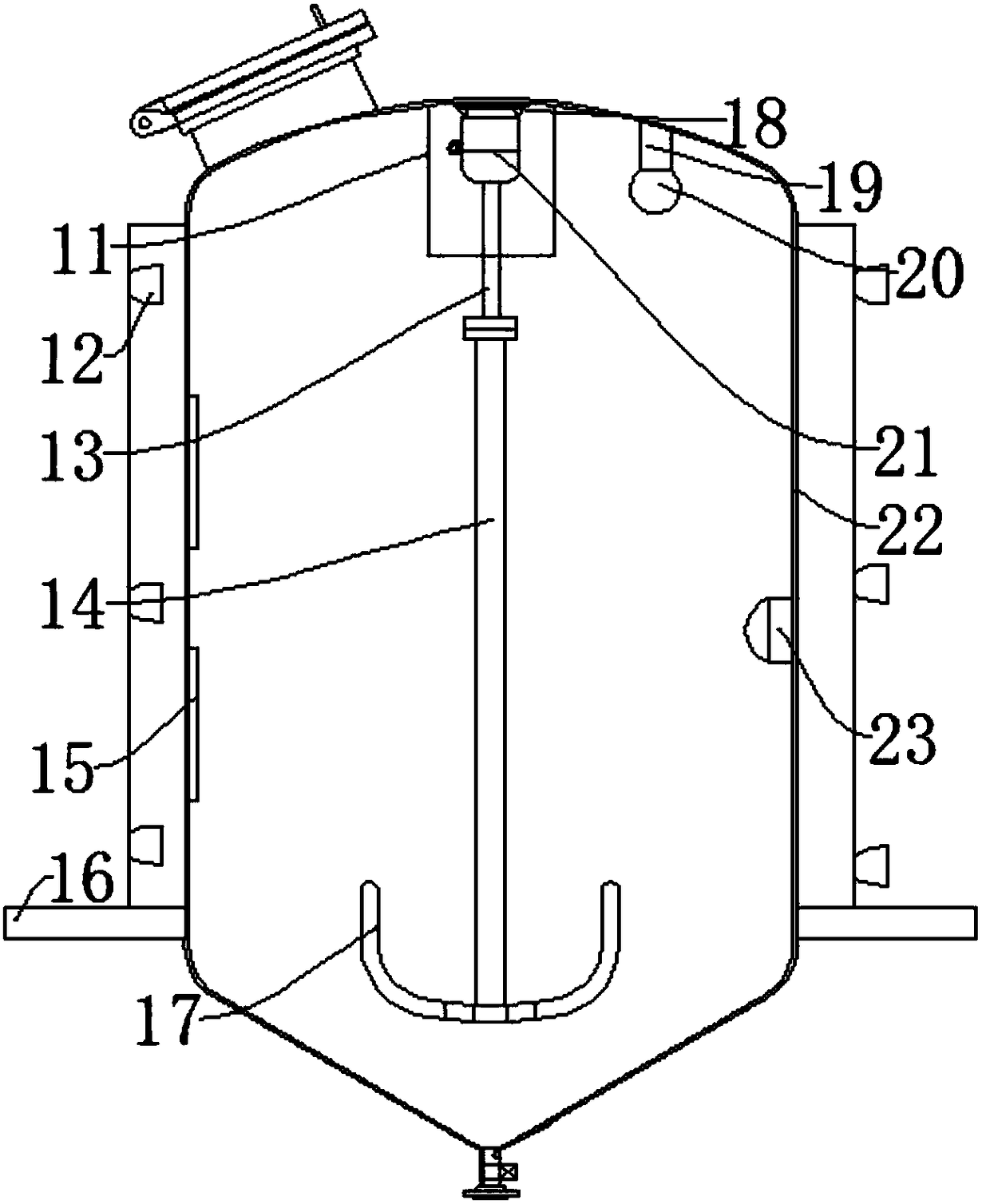

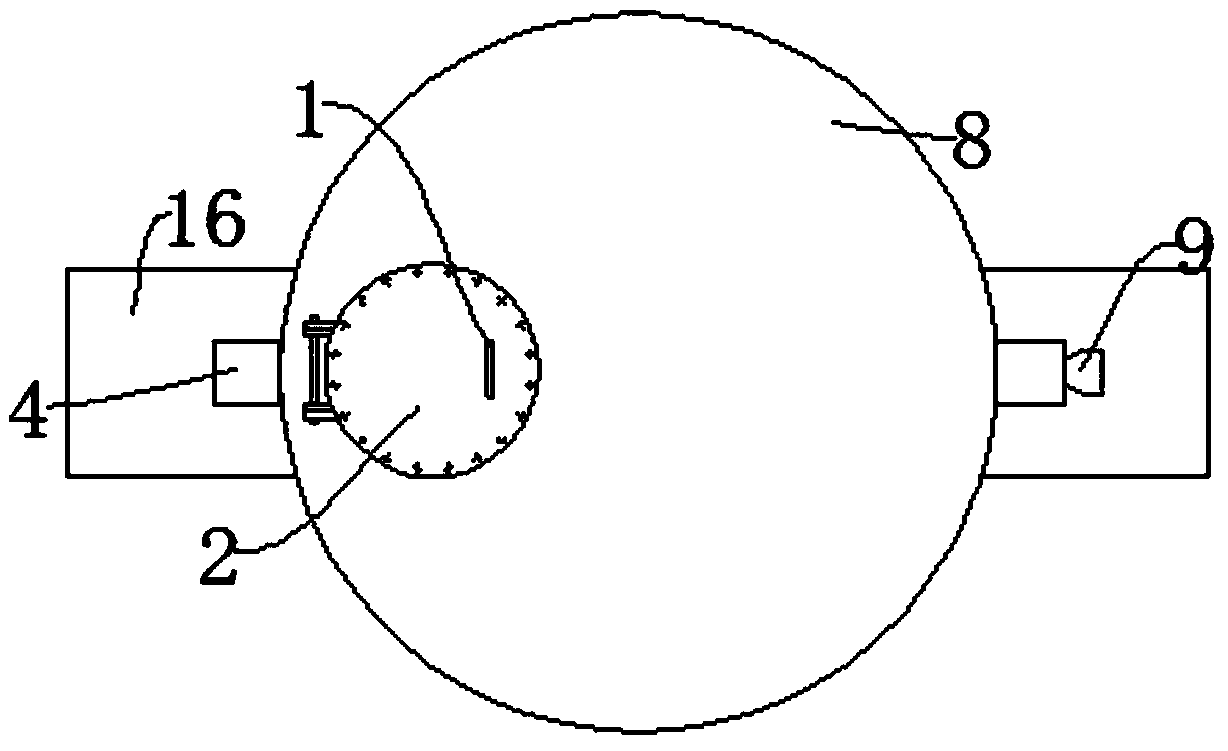

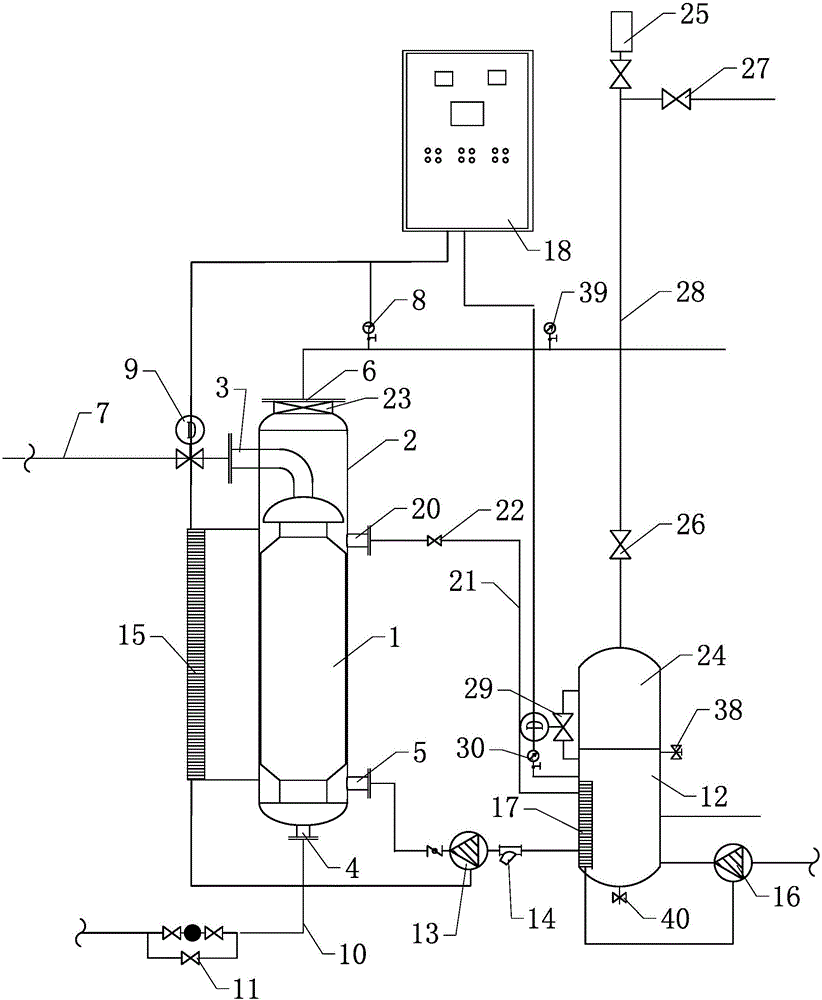

Tank container steam heating device

PendingCN110844373AHeating evenlyRealize closed loopLarge containersTank wagonsEngineeringHeat balance

The invention belongs to a container steam heating device. In order to solve the technical problem that an extra-tank heating system of a tank container in the prior art is low in heating efficiency and insufficient in heating balance degree, and condensed water generated by a heating pipeline in a low-temperature environment is poor in circulation, a tank container steam heating device is provided. The tank container steam heating device comprises an arc-shaped shell and an arc-shaped heating cover plate, the shell is arranged outside the heating cover plate in a sleeving mode, a cavity is formed between the shell and the heating cover plate, a steam inlet channel, a steam outlet channel and a plurality of cavity partition plates are arranged in the cavity in the circumferential direction, the plurality of cavity partition plates are located between the steam inlet channel and the steam outlet channel to divide the cavity into a plurality of heating areas which sequentially communicate with one another, steam passing holes and condensed water passing holes are formed in the inner side of the steam inlet channel, steam passing holes and condensed water passing holes are formed in the cavity partition plates, steam passing holes and condensed water passing holes are formed in the inner side of the steam outlet channel, and condensed water discharge ports are formed in the outerside of the steam outlet channel.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

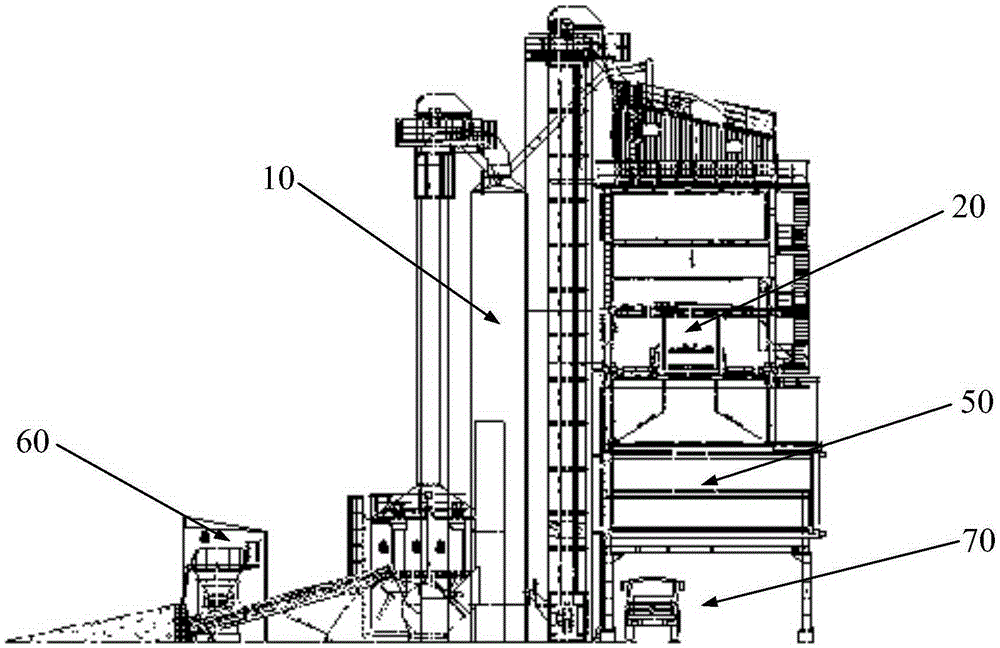

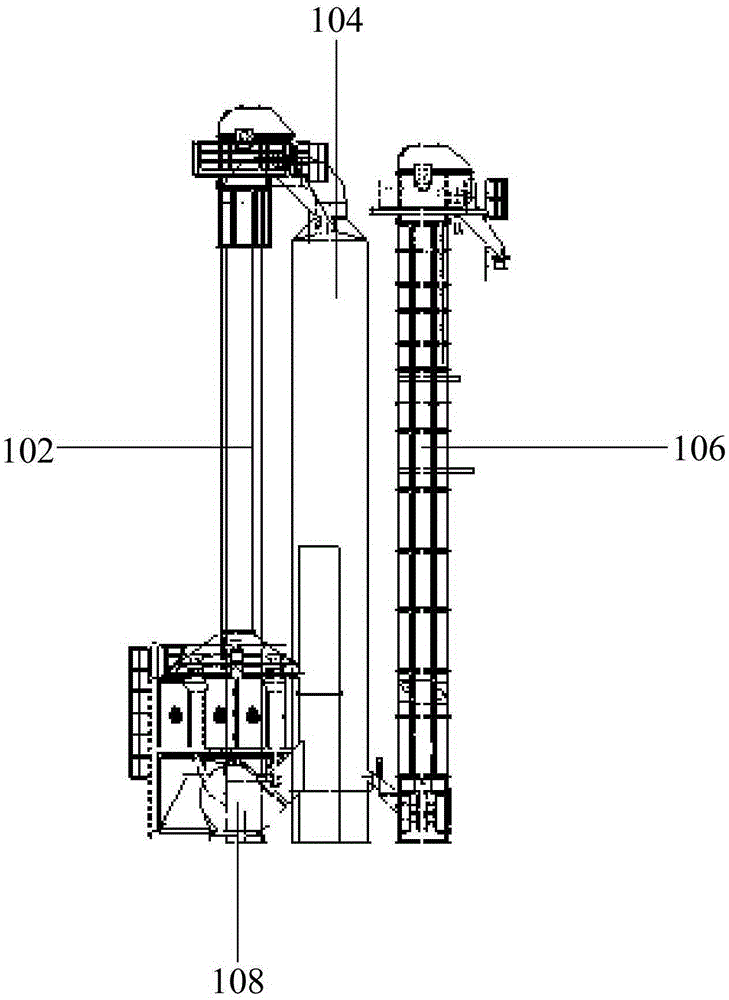

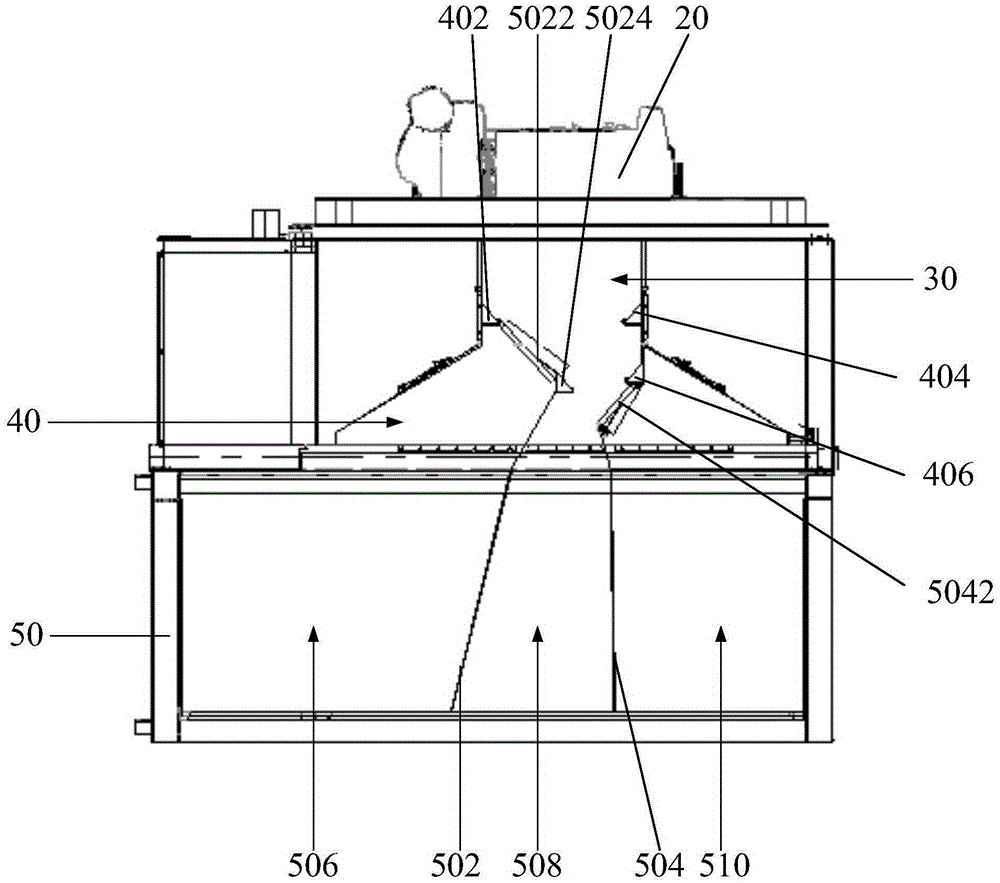

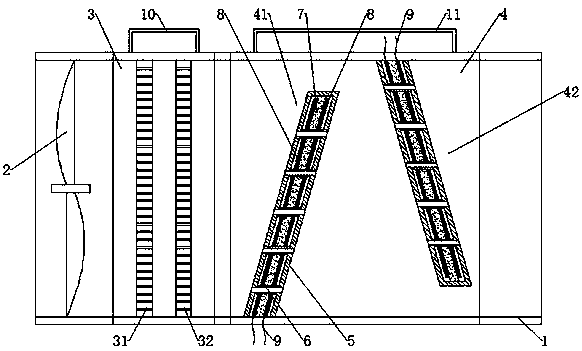

Asphalt mixing plant

The invention provides an asphalt mixing plant. The asphalt mixing plant comprises a charging device, a drying device, a mixing device and a finished product warehouse which are in sequential communication, wherein the drying device comprises a cold aggregate elevator, a sealing drying tower and a hot aggregate elevator which are in sequential communication; the cold aggregate elevator communicates with a discharge opening of the charging device, and a discharge opening of the hot aggregate elevator communicates with a feed opening of the mixing device; the sealing drying tower is arranged between the cold aggregate elevator and the hot aggregate elevator, so that in the drying process, dust and smoke can be effectively prevented from overflowing, the pollution of the dust and flue gas is eliminated, the requirement for environmental protection in the production process is met, and the environmental protection performance in the production process is improved.

Owner:HUNAN SANY ROAD MACHINERY

Chemical dosing device and method for sewage treatment system

InactiveCN108380093AAvoid clotsEasy to observe and understandTransportation and packagingRotary stirring mixersChemical storageAutomatic control

The invention discloses a chemical dosing device and method for a sewage treatment system. The chemical dosing device comprises a tank body, a mounting plate, a limiting block and a feeding pipe, wherein the mounting plate is arranged on a side face of the tank body; the limiting block is arranged at the bottom of the mounting plate. The chemical dosing device disclosed by the invention has the beneficial effects that a servo motor drives a stirring roller to rotate and chemicals can be stirred; a feedback control circuit composed of a temperature sensor, a control host and an electric heatingplate can be used for keeping heat of the chemicals in the device to a pre-set temperature value, so as to prevent the chemicals from being caked in a chemical storage process; meanwhile, the plurality of devices can be spliced through grooves and bulges, so that various chemicals are added; a feedback control circuit composed of a flow sensor, a control host and a solenoid valve can be used forautomatically controlling a chemical dosing amount to a pre-set value; meanwhile, the chemical amount in the tank body can be monitored in real time through an infrared camera and is displayed on a display screen, so that utilization functions of the device are enriched and the device is easily popularized and utilized in a large range.

Owner:天津市众源环保工程有限公司

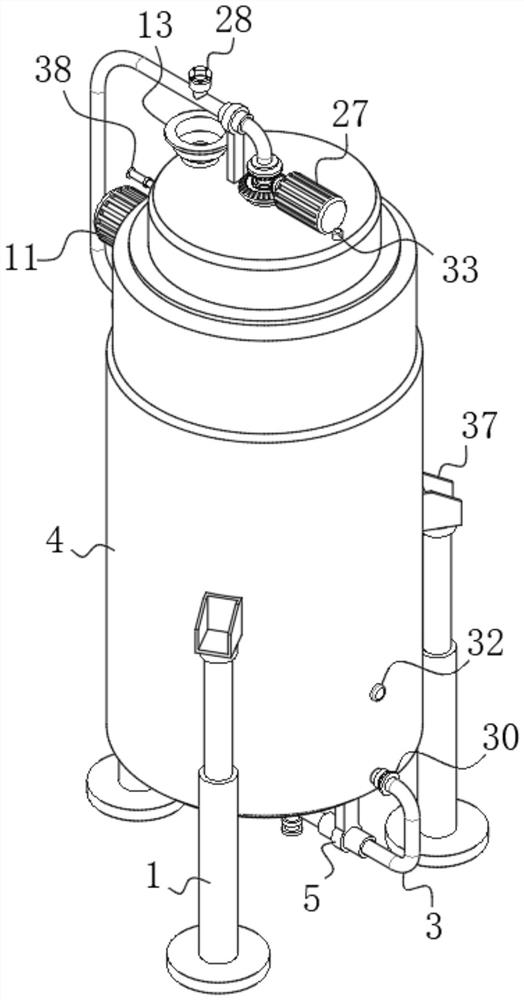

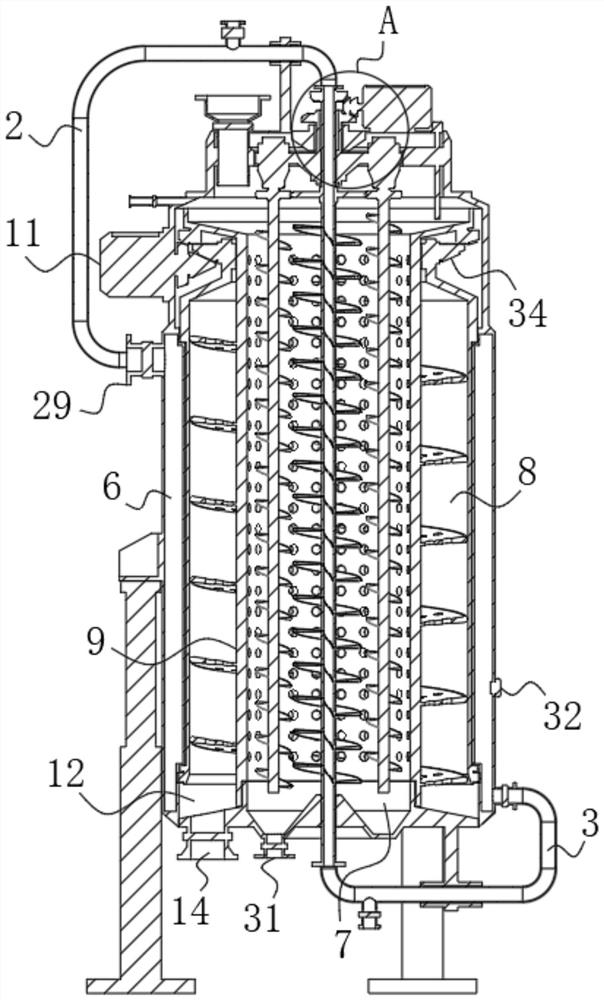

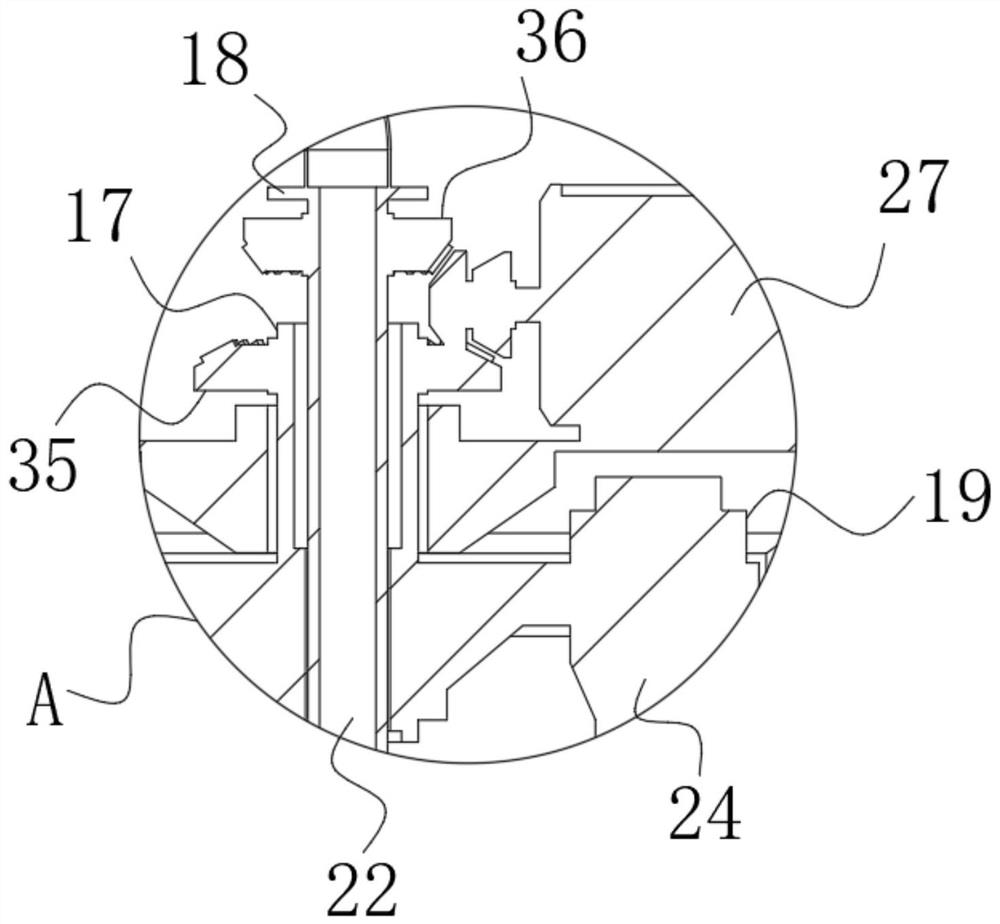

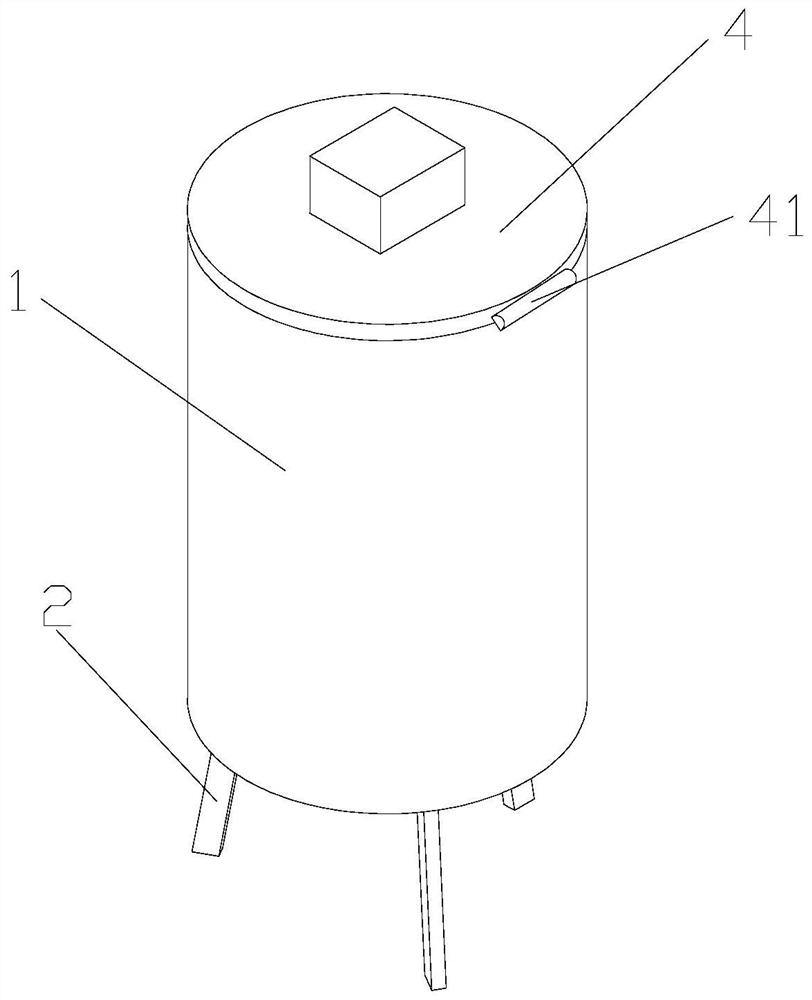

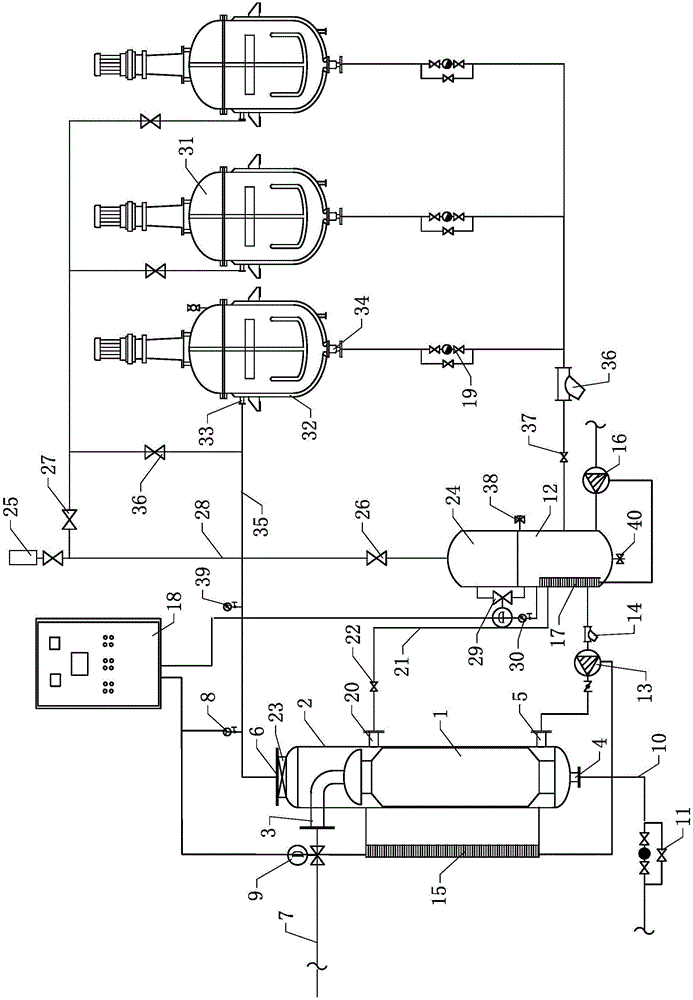

Heparin sodium production equipment based on secondary enzymolysis method

ActiveCN112044386APrevent precipitationImprove responseChemical industryChemical/physical/physico-chemical stationary reactorsElectric machineryHeparin sodium

The invention discloses heparin sodium production equipment based on a secondary enzymolysis method. The heparin sodium production equipment comprises a cylinder body, supporting legs, a stirring device, a cover plate, a first rotating piece and a detection structure, the stirring device comprises a stirring cavity formed in the cylinder body, a first cavity formed in the inner wall of the cylinder body, a heating pipe arranged in the first cavity, a motor arranged on the cover plate, a telescopic stirring structure arranged below the cover plate, and a first auxiliary structure arranged on the side wall of the stirring cavity; the device also comprises a discharging structure arranged at the bottom of the stirring cavity; through the arrangement of the telescopic stirring structure, a stirring shaft can be contracted after stirring is completed, and the stirring shaft is opened in the form of a flip cover, so that the design height of a tank body is higher, an occupied area is reduced, accommodating volume of equipment is increased, and the interior of the equipment is more convenient to clean; Heating efficiency is effectively guaranteed in a side wall heating mode, internal temperature balance is guaranteed, and preparation efficiency is improved.

Owner:PUJIANG CAREX BIOTECH

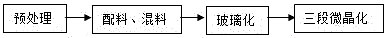

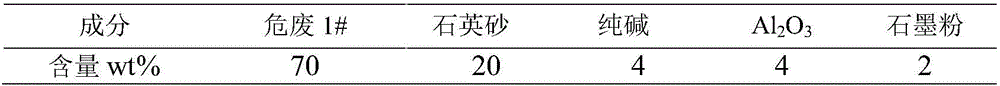

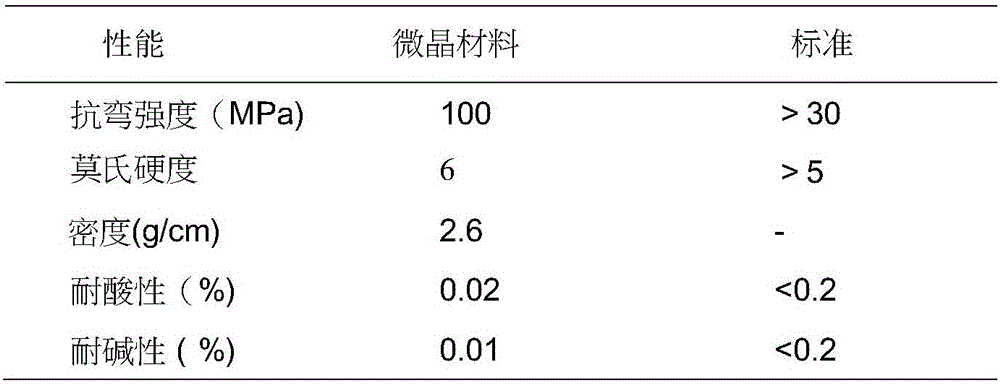

Method for harmless and resourceful treatment of metallurgical hazardous waste

InactiveCN106365439AReduce energy consumptionShorten drying timeSolid waste disposalTransportation and packagingPre treatmentMolten glass

The invention relates to a method for harmless and resourceful treatment of metallurgical hazardous waste and belongs to the technical field of comprehensive utilization of resources and environment protection. The method for harmless and resourceful treatment of the metallurgical hazardous waste comprises the following specific steps that 1, pretreatment is performed, wherein microwaves are adopted to dry hazardous waste and an auxiliary material respectively, and the dried hazardous waste and the auxiliary material are ball-milled and screened; 2, material preparation and mixing are performed, wherein a screen underflow is taken, material preparation and mixing are performed in proportion to obtain a mixture; 3, vitrification is performed, wherein vitrification treatment is conducted on the mixture by adopting a traditional heating mode or microwave high-temperature molten glass; 4, three-section type micro-crystallization is performed, wherein treatment is performed by adopting microwaves and a three-section type micro-crystallization heat treatment method to obtain a microcrystal material. The method is simple in preparation process, high in resourceful degree and low in cost and has a remarkable social benefit and an economic value.

Owner:李国标

Efficient temperature control system and temperature control method thereof

ActiveCN105892521AMeet heating requirementsImprove heat utilizationTemperature control using electric meansTemperature controlEngineering

The invention discloses an efficient temperature control system. The efficient temperature control system includes a low pressure steam generation apparatus and at least one reaction vessel, wherein a clamping sleeve is arranged in the reaction vessel; the clamping sleeve is provided with a low pressure steam inlet and a condensate liquid outlet; the low pressure steam inlet utilizes a low pressure steam conveying pipe to communicate with a low pressure steam outlet of the low pressure steam generation apparatus; and the low pressure steam generated from the low pressure steam generation apparatus enters the clamping sleeve to perform temperature control heating on the reaction vessel. The invention also provides a temperature control method for implementing the efficient temperature control system. The efficient temperature control system and the temperature control method thereof can save the industrial steam, are high in the heat energy utilization rate, can accurately control the temperature of the steam, and also can guarantee that the heating steam is in the low pressure state so that the safety is guaranteed.

Owner:HIMILE MECHANICAL MFG

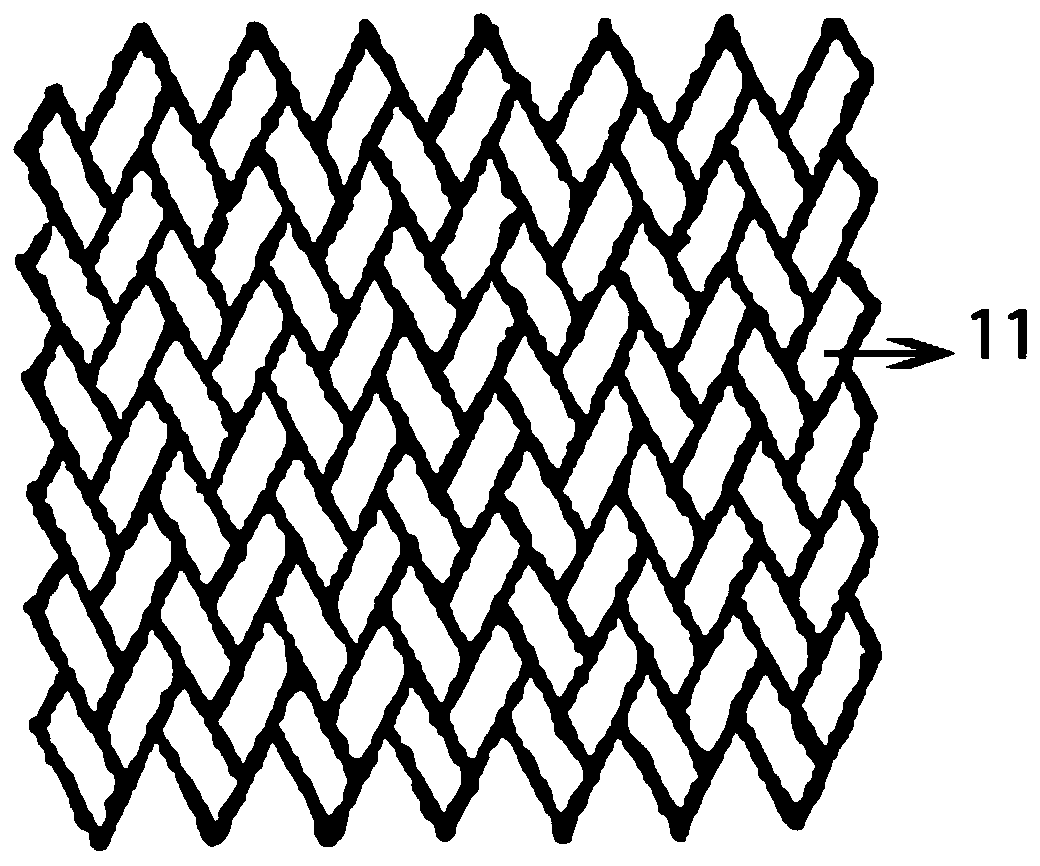

Electric heating non-woven cloth

InactiveCN101188879AGuaranteed efficiencyGuaranteed heating efficiencyNon-woven fabricsHeating element materialsSocial benefitsCarbon fibers

The invention discloses an electrothermal non-woven fabric with high heat emitting efficiency and safe heat generating. A barrier-shaped fabric is fabric-manufactured on a loom by adopting strong chinlon along the radial direction as well as carboform filament or the carboform filament and strong chinlon yarn along the transverse direction; the barrier-shaped fabric is used as an interface layer and is laid in a parallel way to form the non-woven fabric, two surfaces of which are covered by short fiber fibrous reticulum mixed by natural cotton fiber short fiber or polyester cotton, and are reinforced by water-jetting, therefore, the use ratio of the carboform is ensured, the interplay is avoided when the carboform conducts at the same time, the heat emitting efficiency is high, the process is simple, the productive value of products is improved, and the invention has better economic and social benefits.

Owner:SHENGHONG GRP CO LTD

Novel air flue type PTC heater

The invention provides a novel air flue type PTC heater which comprises a square air pipe. A fan, a filter area and at least one heating area are sequentially arranged in the square air pipe from leftto right. The filter area comprises a primary filter net plate and a secondary filter net plate which are vertically arranged, the heating area comprises a first PTC porous heating plate and a secondPTC porous heating plate which are arranged in a left-right mode, the top of the first PTC porous heating plate is inclined rightwards, a gap is reserved between the top and the inner wall of the square air pipe, the bottom of the second PTC porous heating plate is inclined rightwards, and a gap is reserved between the bottom and the inner wall of the square air pipe. The novel air flue type PTCheater has the advantages that gas sequentially passes through the filter area and the heating area from left to right under the effect of the fan, the gas is filtered by the filter area before reaching the heating area, accordingly, dust and steam in gas can be effectively filtered, dust accumulation and dirt forming are avoided on the inner wall of the square air pipe and the PTC porous heatingplates in the heating area, influences of dust accumulation on heating efficiency are reduced, and the dust removal frequency and the maintenance cost are reduced.

Owner:NANJING LVZHICHENG PATENT TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com