Tank container steam heating device

A technology of steam heating device and tank container, which is applied in the direction of tank trucks, packaging, transportation and packaging, etc. It can solve the problems of poor circulation of condensed water in the heating pipeline, insufficient heating balance, and blockage of the heating pipeline, etc., to achieve The effect of increasing effective discharge channels, smooth discharge, and reducing stock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments do not limit the present invention.

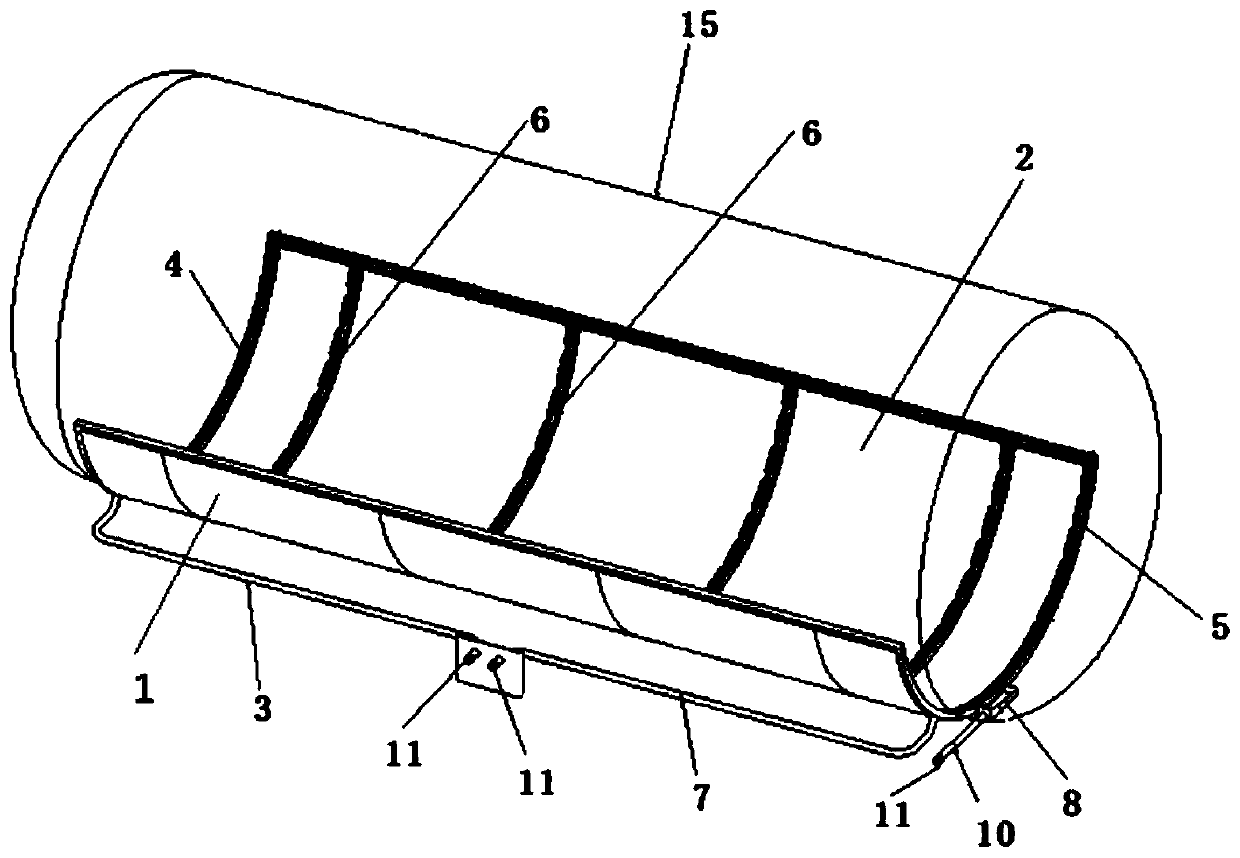

[0038] Such as figure 1 As shown, a tank container steam heating device includes an arc-shaped shell 1 and an arc-shaped heating cover plate 2 .

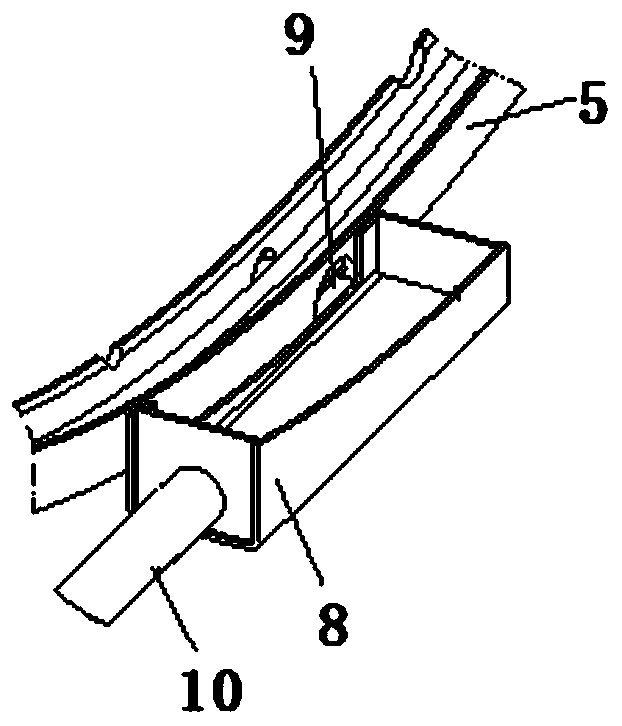

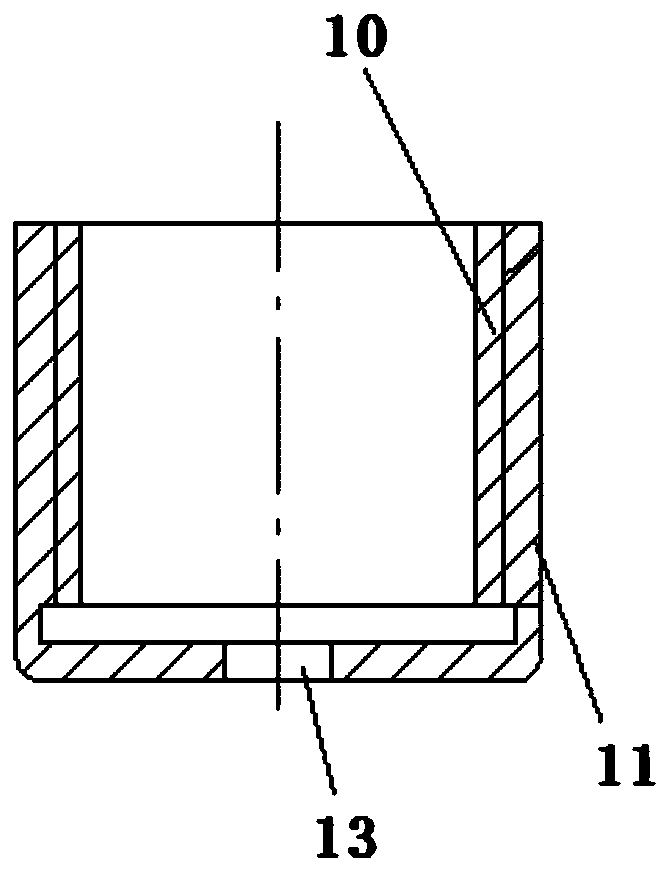

[0039] The shell 1 is sleeved on the outside of the heating cover 2 , and a cavity is formed between the shell 1 and the heating cover 2 . A steam inlet channel 4, a steam outlet channel 5, and a plurality of cavity partitions 6 are arranged in the cavity along the circumference; the steam inlet channel 4 and the steam outlet channel 5 are respectively located at both ends of the cavity along the axial direction, corresponding to the tank body 15 to be heated. At both ends of the front and back, a plurality of cavity partitions 6 are located betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com