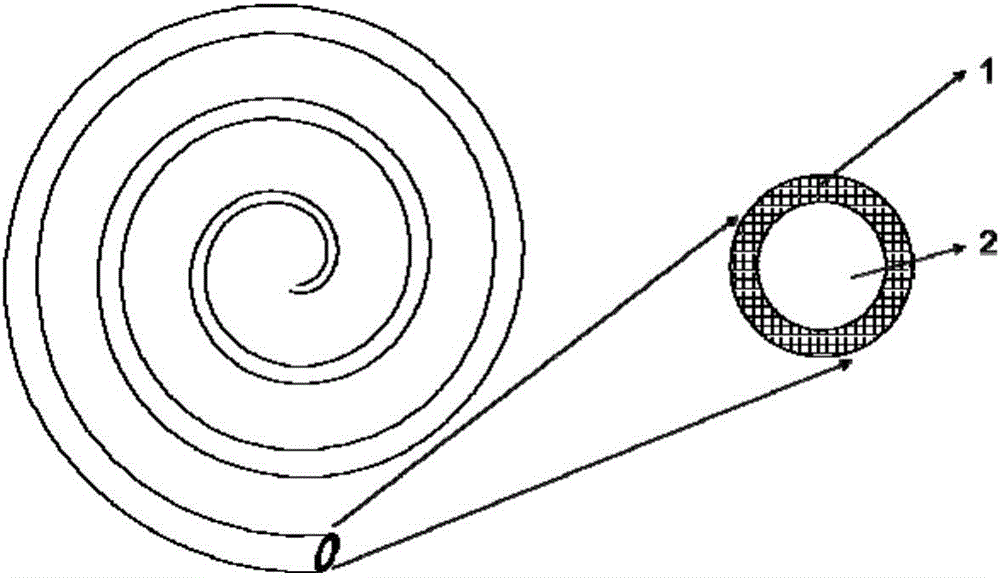

Composite heating wire for electronic cigarettes

A composite heating and electronic cigarette technology, applied in the field of electronic cigarette technology, can solve the problems of carbon deposition, burnt smell, etc., and achieve the effect of avoiding direct contact, ensuring heating efficiency and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Soak a nickel-chromium alloy (model Cr20Ni80) with a diameter of 0.1mm in a mixed solution of orthosilicon acetate: absolute ethanol: distilled water with a molar ratio of 1:15:9.5, and adjust the pH of the solution to 2.8. After stirring for 5 minutes at 100°C, take it out and dry it at 120°C for 1 hour, and finally burn it at 600°C for 2 hours under nitrogen atmosphere to obtain a composite heating wire with a silicon oxide film thickness of about 5 μm. The porosity of the film layer was measured to be 4.2% by weighing method (wetting liquid is electronic cigarette oil).

Embodiment 2

[0028] Place a nickel-chromium alloy (model Cr20Ni80) with a diameter of 0.1 mm in a vacuum of 2×10 -3 In the Pa chamber, keep the temperature at 200°C, and control the gas mass flow ratio of silane (purity 99.99%) / oxygen (purity 99.99%) / ammonia (purity 99.99%) / hydrogen (purity 99.99%) to 3:1: At 1:20, plasma vapor phase chemical deposition (PECVD) with a voltage of 1000V and a power of 2000W was used on the wire substrate for 100min to obtain a composite heating wire with a silicon nitride oxide film thickness of about 2.5μm. The porosity of the film layer was measured to be 1.4% by weighing method (wetting liquid is electronic cigarette oil).

Embodiment 3

[0030] Iron-chromium-aluminum (type 0Cr21Al6Nb) with a diameter of 0.2mm is immersed in a mixed solution of tetrabutyl orthotitanate: absolute ethanol: distilled water with a molar ratio of 2:14:9.5, and the pH value of the solution is adjusted to 7.8. After stirring for 8 minutes, take it out and dry it at 120°C for 1 hour, and finally burn it at 600°C for 2 hours under a nitrogen atmosphere to obtain a composite heating wire with a titanium dioxide film thickness of about 4 μm. The porosity of the film layer was measured to be 6.9% by weighing method (wetting liquid is electronic cigarette oil).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com