Heating module of multi-layer composite structure and electronic cigarette device

A multi-layer composite and heating mold technology, applied in the field of electronic cigarettes, can solve the problems of high requirements on the surface of the heating wire, complicated operation, slow heating, etc., and achieves improved smoke output, simple production process, control and smoke output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

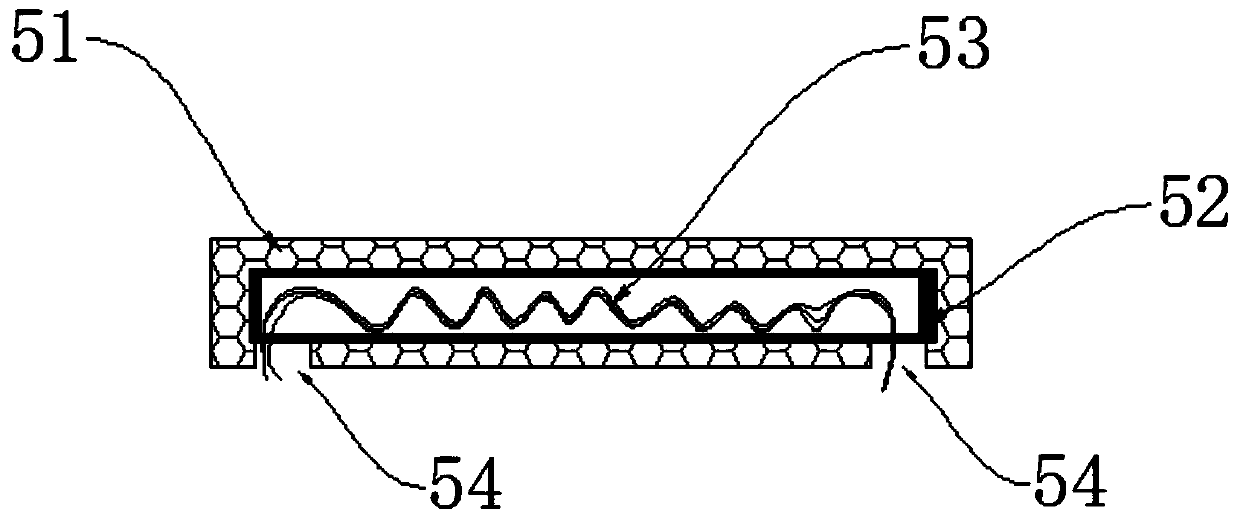

[0028] Such as figure 2 As shown, a heating module of a multi-layer composite structure, the heating module of the multi-layer composite structure includes a heating body 53 and an outer sleeve located outside the heating body 53, wherein the heating body 53 is a carbon fiber heating wire, and the The outer sleeve is sintered from dense quartz glass on the inner layer and porous ceramic material on the outer layer. The outer sleeve is provided with a channel 54 connecting the heating body 53 to the external power supply device. Specifically, the channel 54 includes 2 One, respectively set at both ends of the outer sleeve.

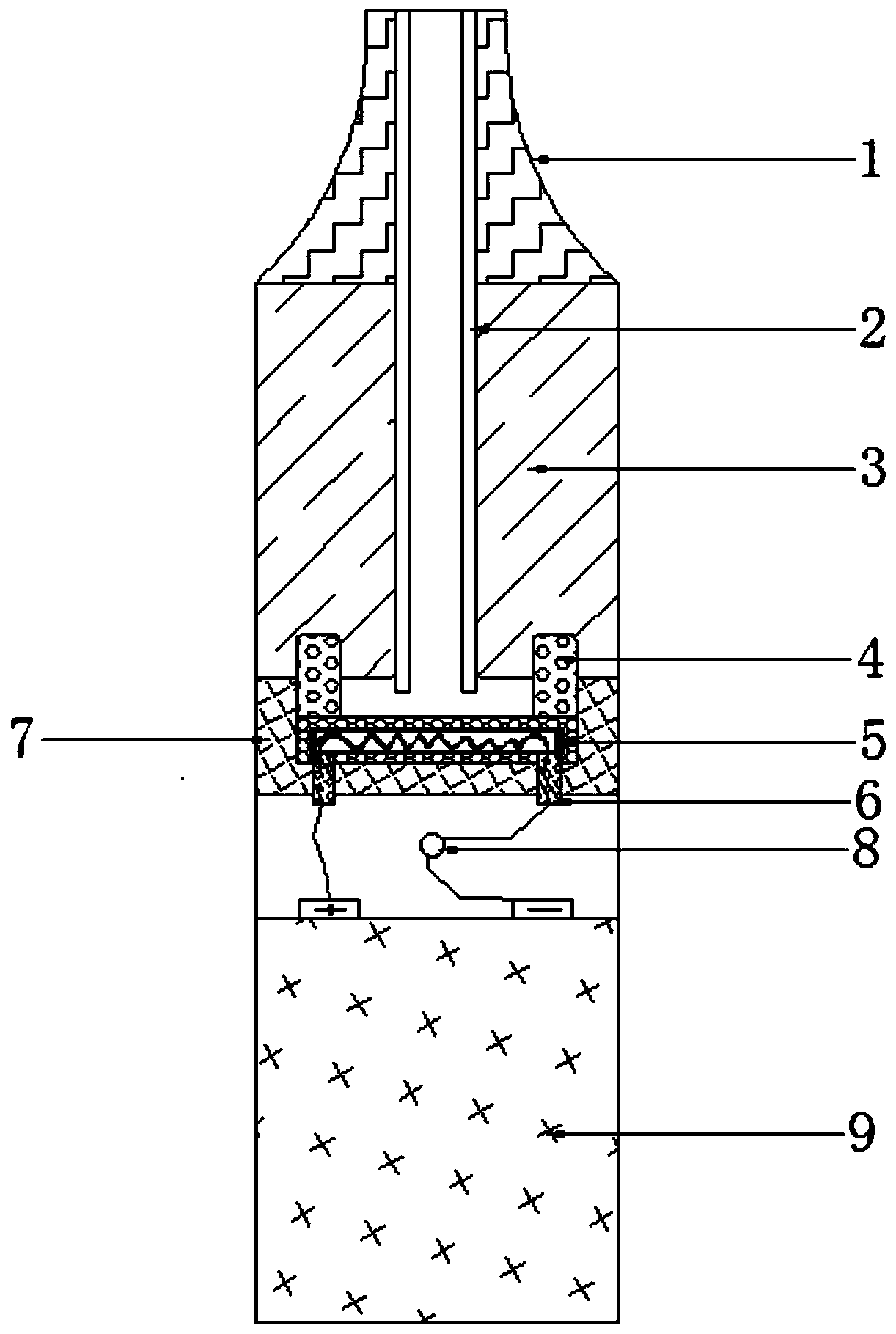

[0029] Such as figure 1 As shown in , an electronic cigarette containing a heating module with a multilayer composite structure, including 1 is a mouthpiece, 2 is an atomizing cylinder, 3 is an oil reservoir, 4 is an oil-conducting porous ceramic, and 5 is a multilayer composite structure. As for the heating module, 6 is a contact electrode, 7 is a base,...

Embodiment 2

[0034] A heating module with a multilayer composite structure and an electronic cigarette using the heating module with a multilayer composite structure, the structure of which is the same as that of Embodiment 1, except that:

[0035] The outer layer of porous ceramics 51 has a thickness of 4mm and a porosity of 40%. The oil-conducting porous ceramic 4 has a thickness of 3mm and a porosity of 20%. The inorganic material 52 is made of zirconia, and the thickness of the zirconia is 0.8 mm. The heating body 53 is made of tungsten heating wire, and the diameter of the tungsten heating wire is 0.5 mm.

Embodiment 3

[0037] A heating module with a multilayer composite structure and an electronic cigarette using the heating module with a multilayer composite structure, the structure of which is the same as that of Embodiment 1, except that:

[0038] The outer layer of porous ceramics 51 has a thickness of 3mm and a porosity of 70%. The oil-conducting porous ceramic 4 has a thickness of 5mm and a porosity of 30%. The inorganic material 52 is titanium trioxide, the thickness of the titanium dioxide is 1 mm, and the heating body 53 is a PTC alloy heating wire, and the diameter of the PTC alloy heating wire is 2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com