Patents

Literature

34results about How to "Affect thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Display device

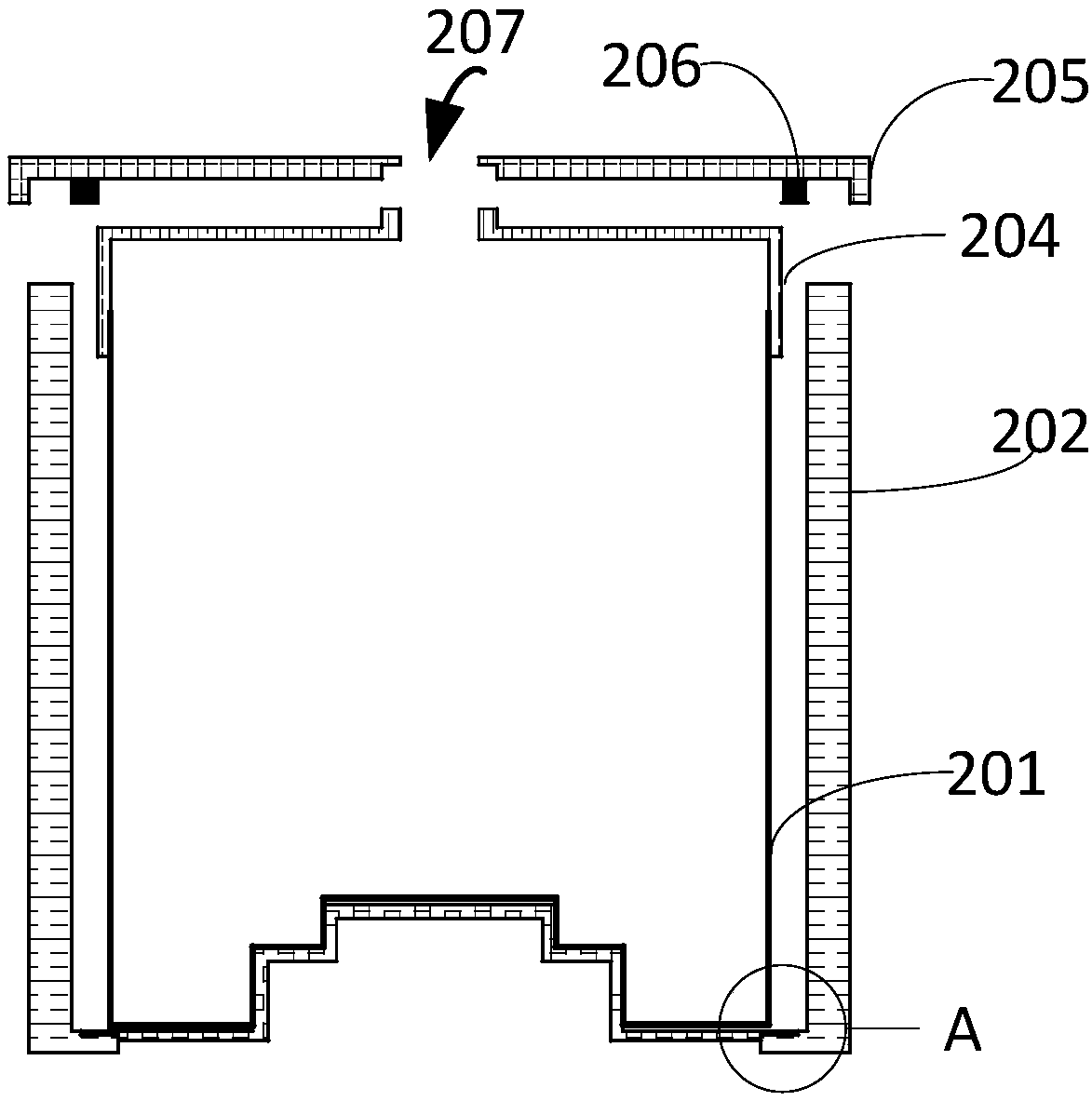

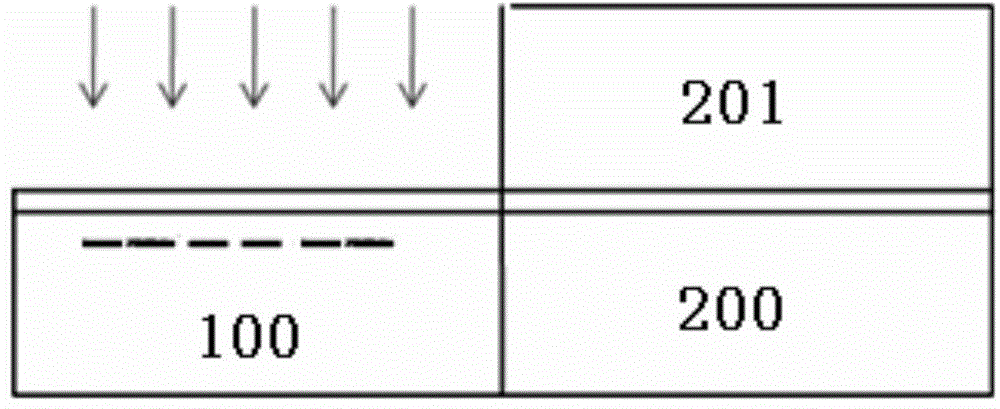

ActiveCN106873063AAffect thicknessAccuracy impactCharacter and pattern recognitionOptical elementsDislocationFingerprint

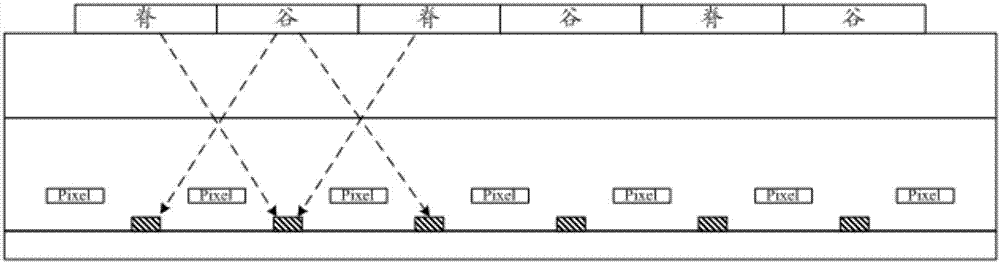

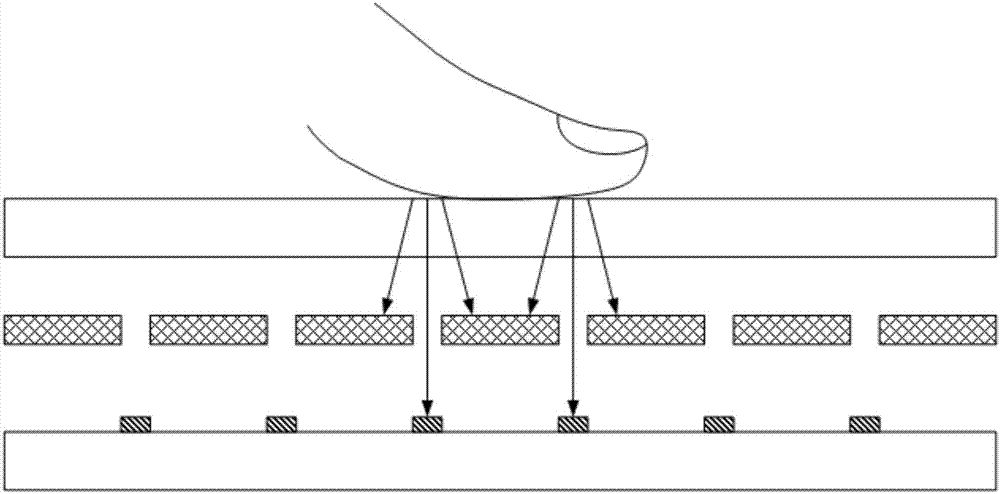

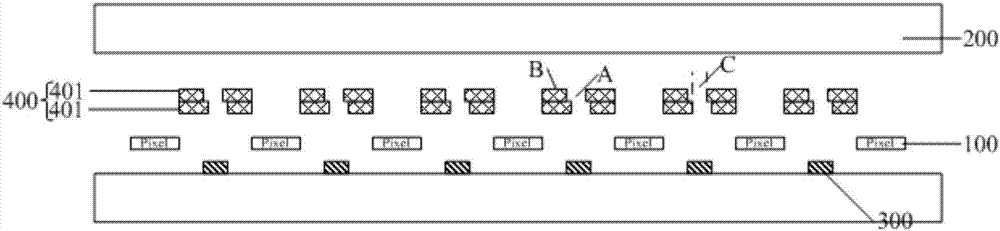

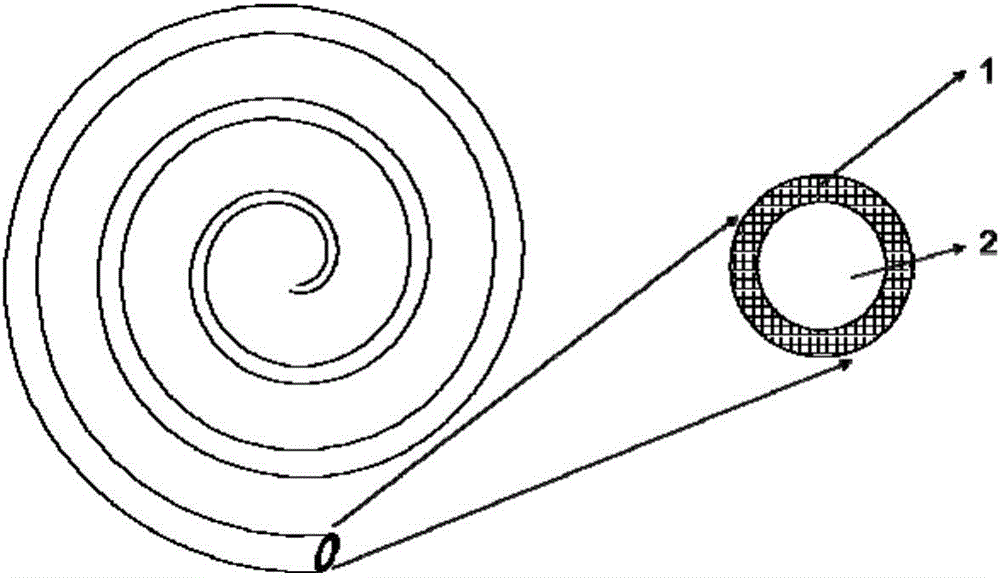

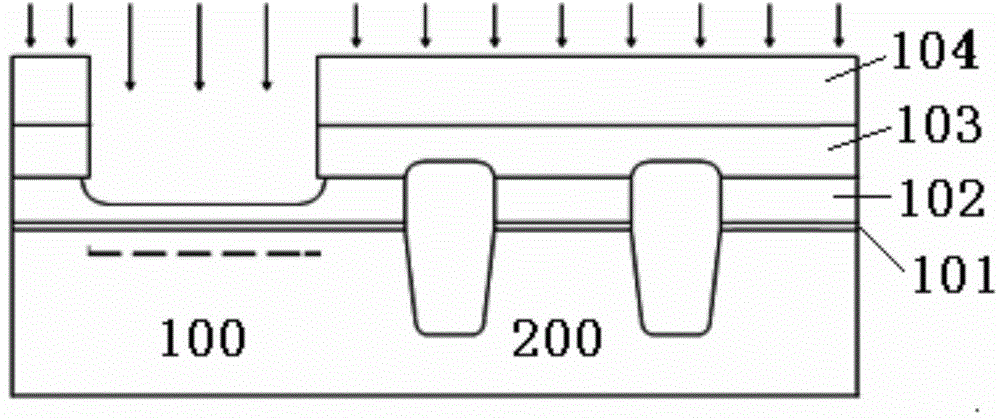

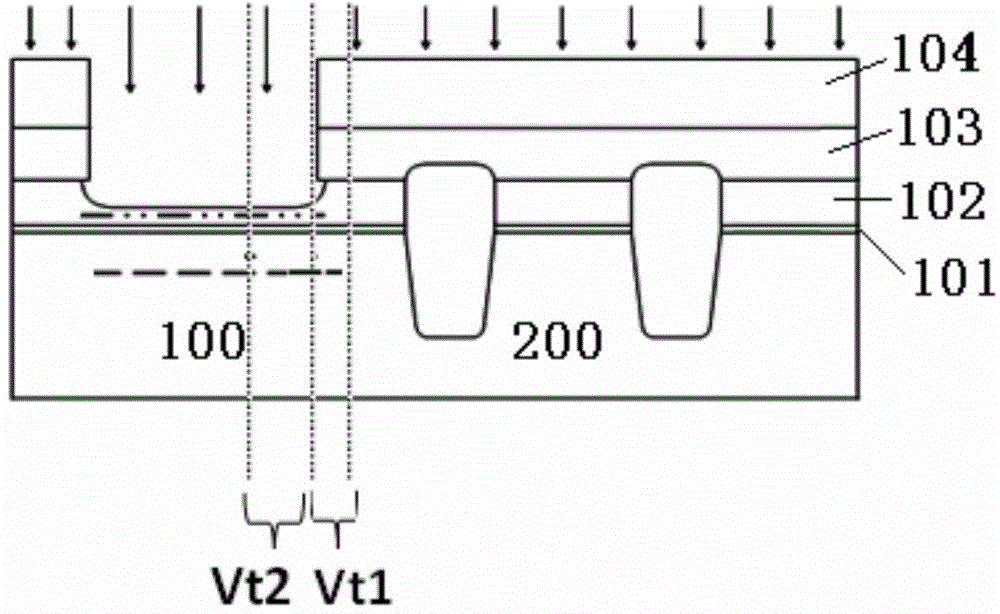

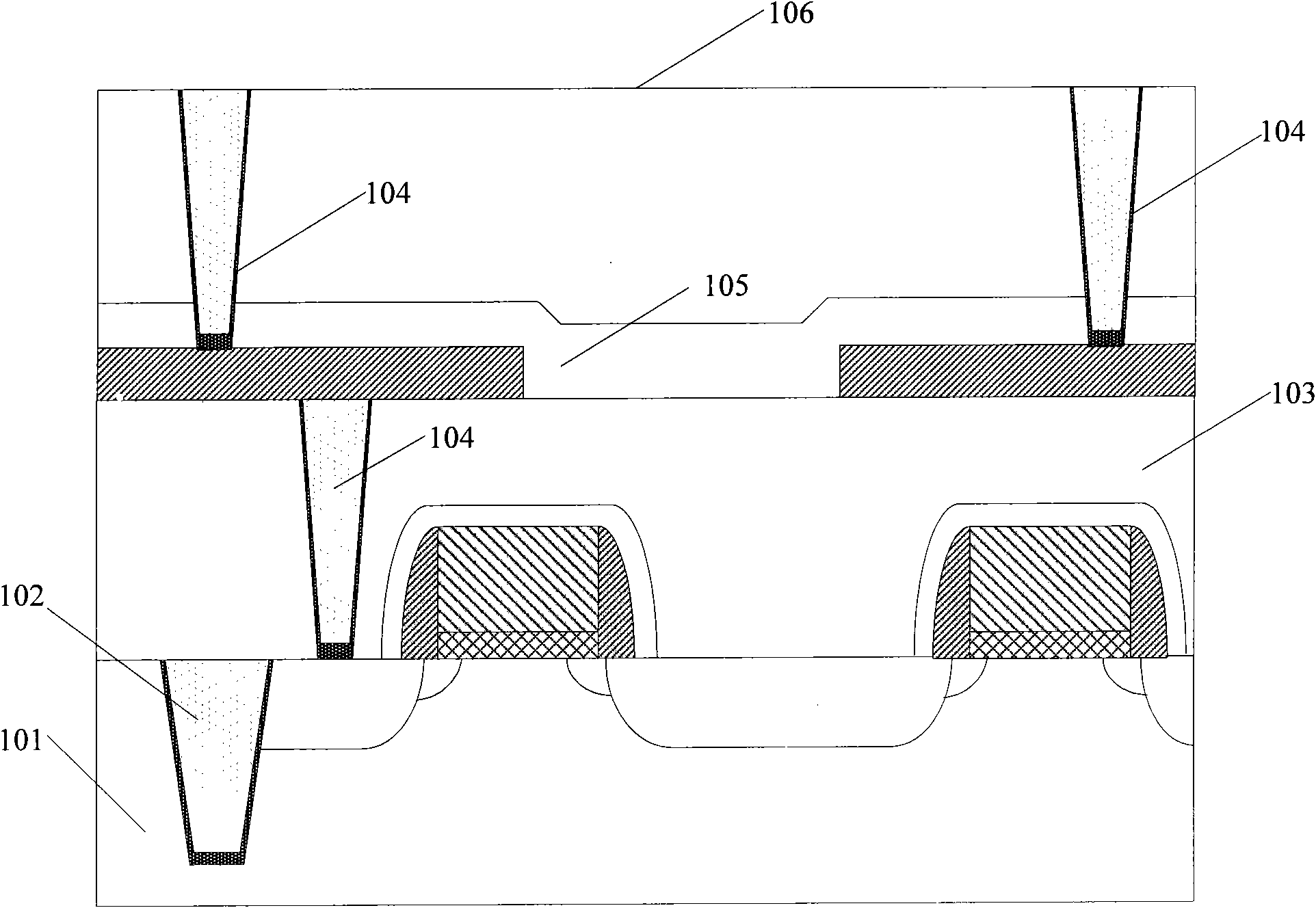

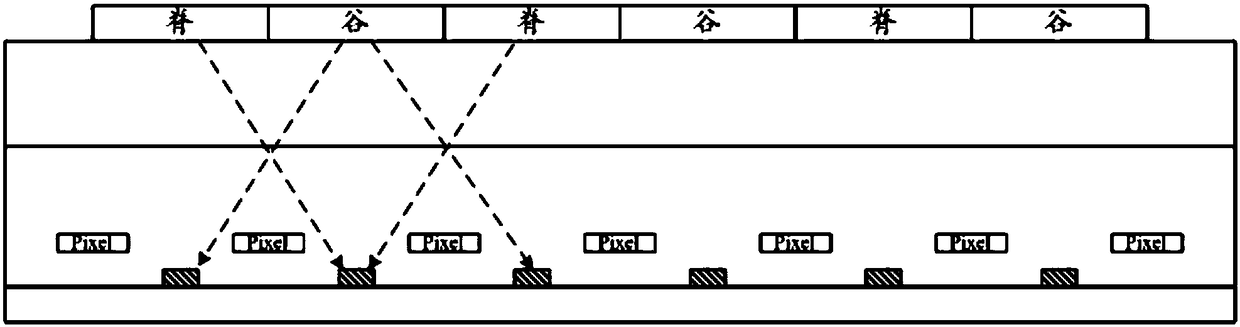

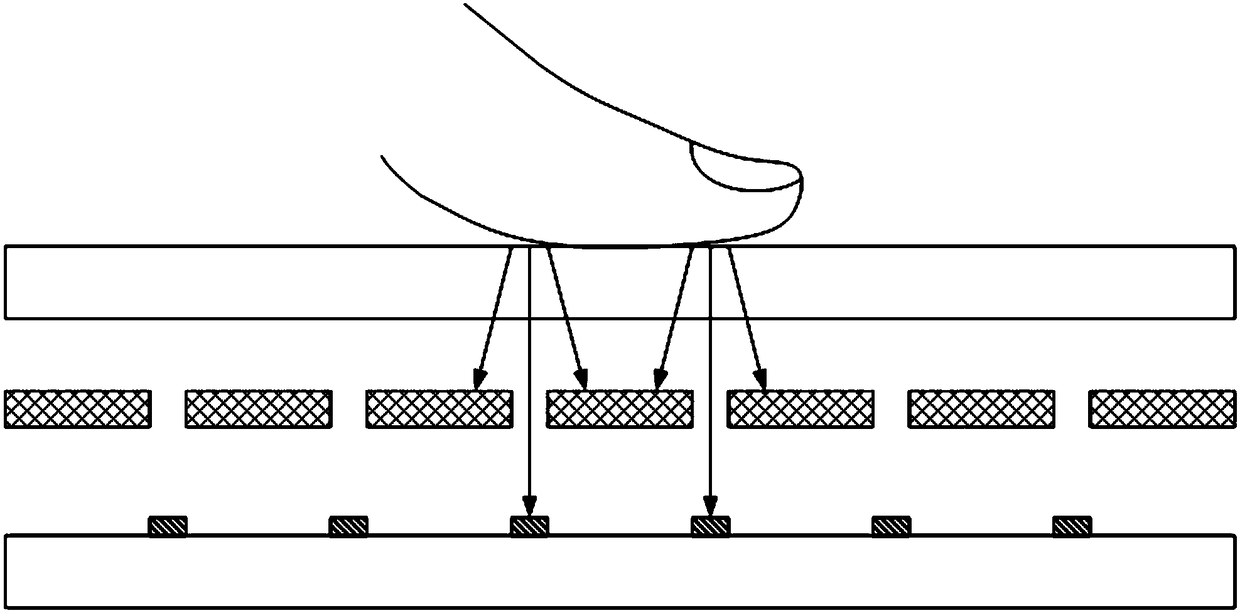

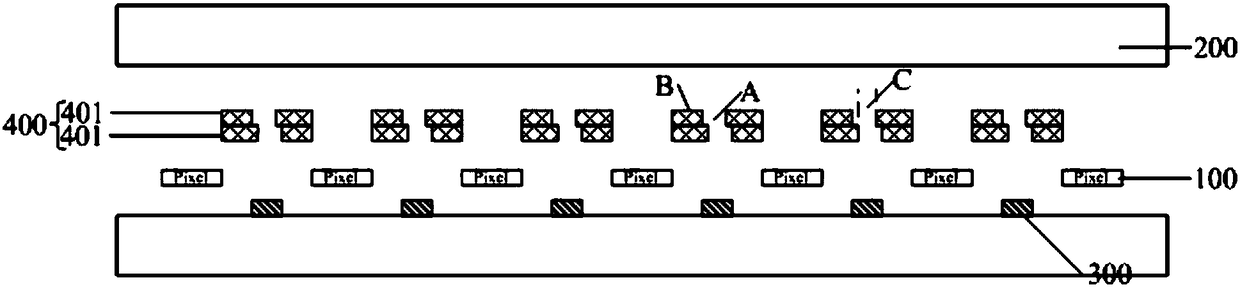

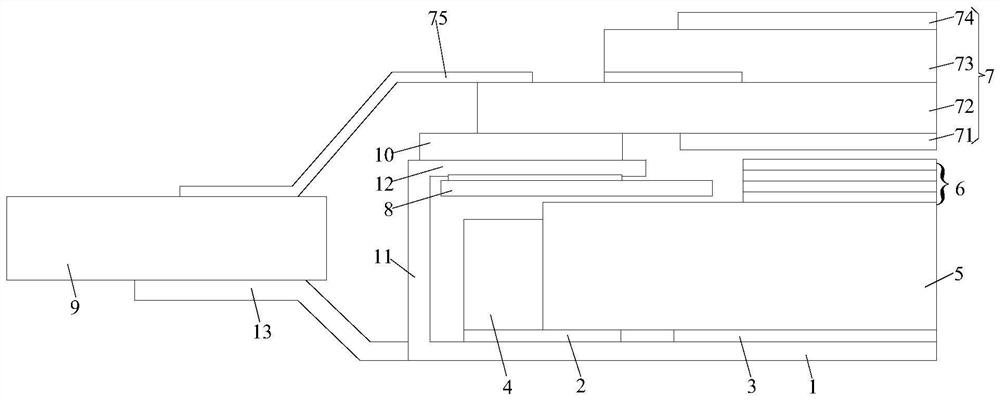

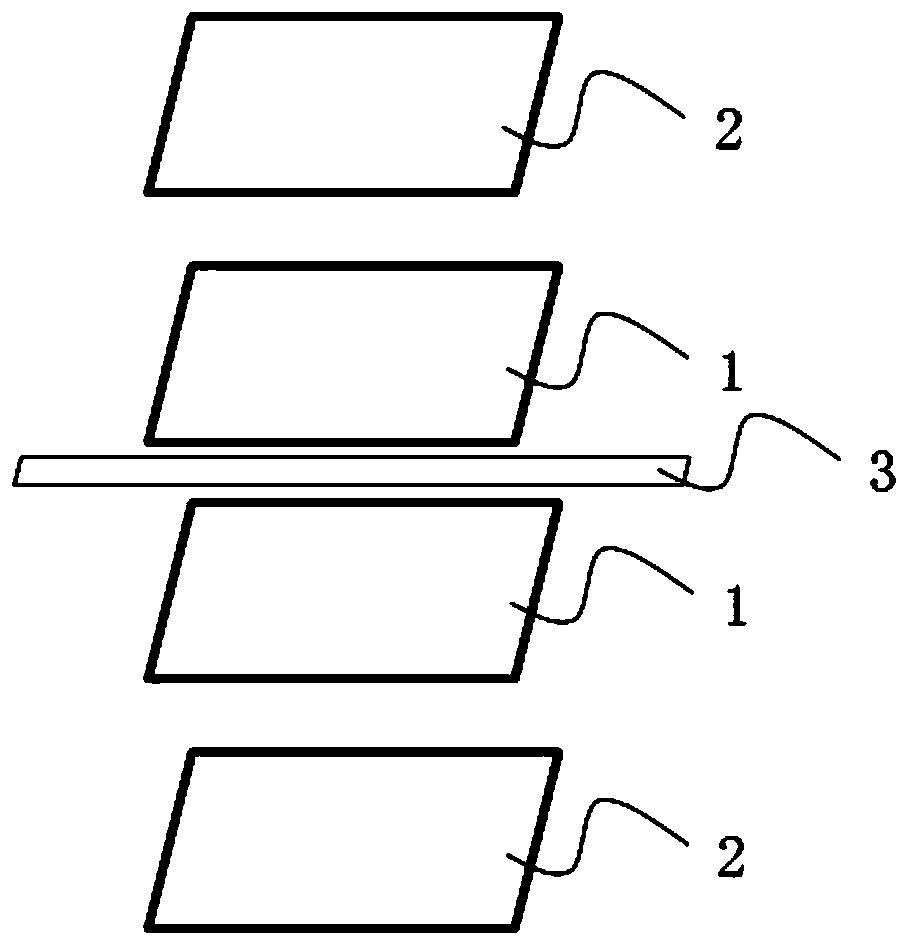

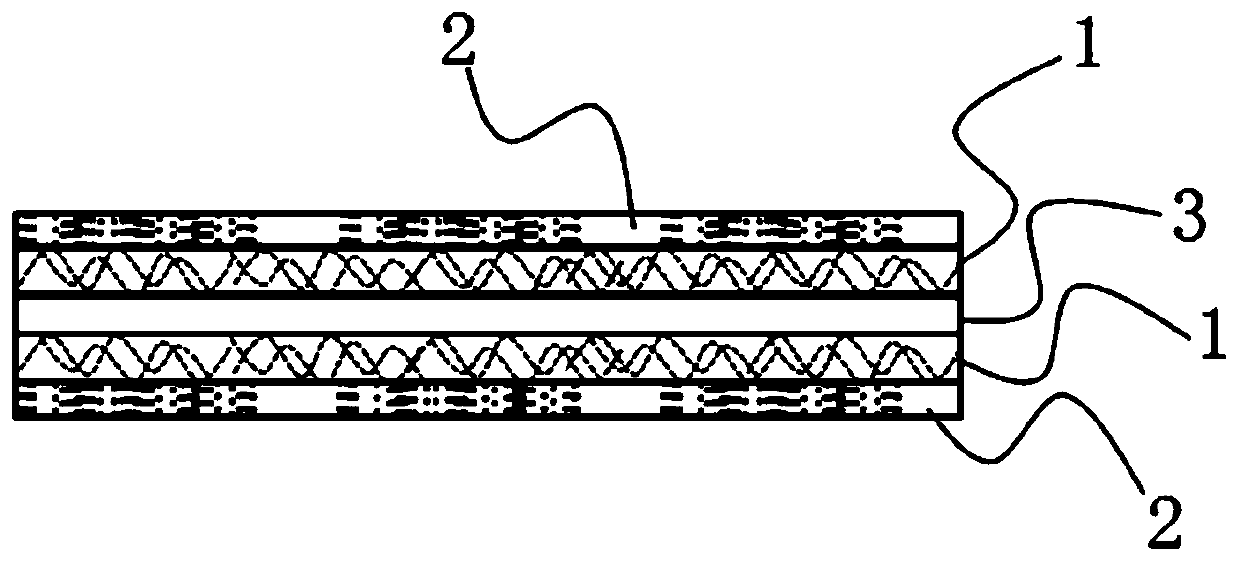

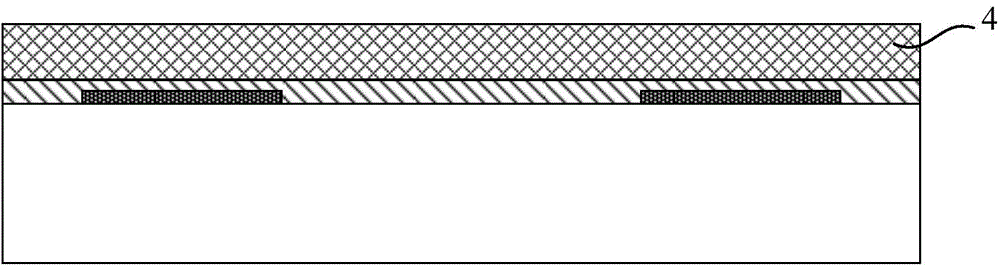

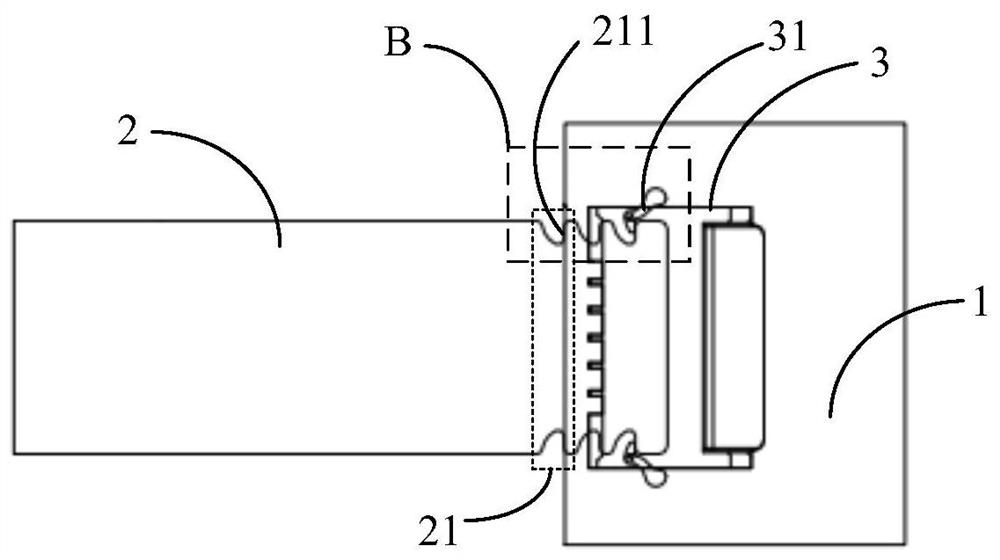

The invention discloses a display device. A filtering structure arranged between a protective cover plate and photosensitive devices is changed into filtering layers which are arranged in a laminated way, each filtering layer includes a light transmission area and a shielding area beyond the light transmission area, central positions of the light transmission areas of the different filtering layers are dislocated partially at least, orthographic projections of the light transmission areas of the different filtering layers in a display panel include an overlapped area, and the area of the overlapped area is the light transmission area of the filtering structure. The dislocation sizes of the central positions of the light transmission areas of the different filtering layers are adjusted to reduce the light transmission area of the filtering structure according to requirements, and thus, the filtering structure is not influenced by precision of manufacturing equipment, and the precision of optical fingerprint identification is improved. After that the light transmission area of the filtering structure is reduced according to requirements, a collimation effect can be ensured, and the filtering structure is prevented from being too thick and further influencing the thickness of the display device.

Owner:BOE TECH GRP CO LTD

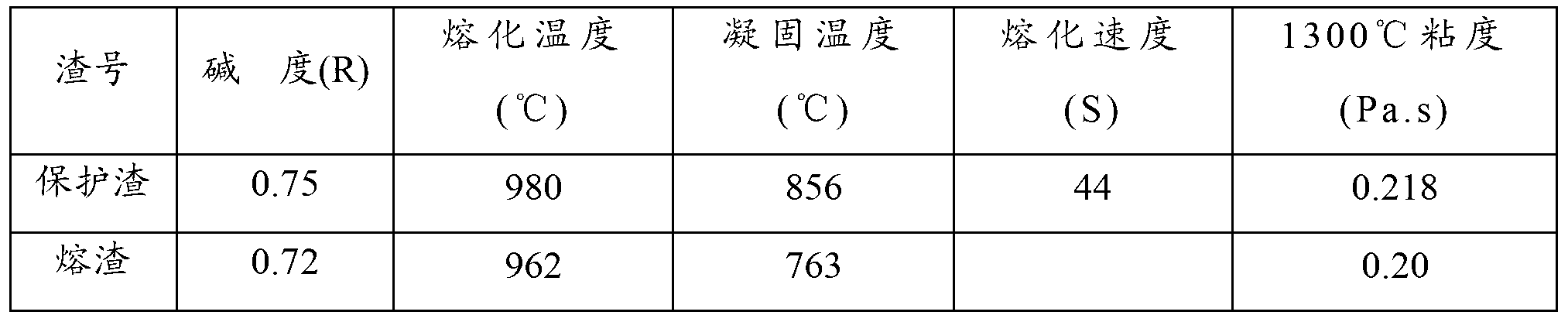

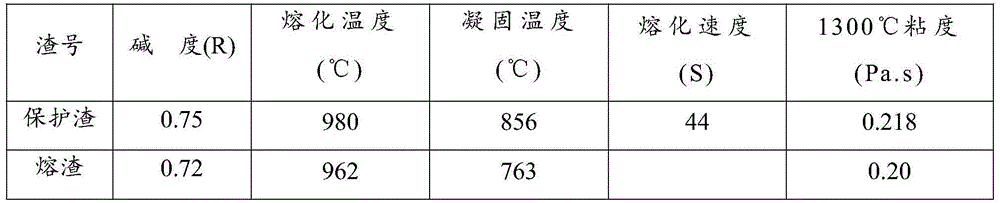

Continuous casting crystallizer covering slag for high-carbon steel

The invention relates to a continuous casting crystallizer covering slag for high-carbon steel. The continuous casting crystallizer covering slag comprises the following components in percentages by weight: 22.90-37.0% of SiO2, 22.5-27.0% of CaO, 4.35-5.0% of MgO, 1.8-6.0% of Al2O3, 2.2-3.0% of Fe2O3, 9.0-12.0% of Na2O, 5.2-6.0% of F, 6.5-9.0% of C, not more than 2.0% of K2O, not more than 1.9% of Li2O, and the balance of water and impurities. According to the continuous casting crystallizer covering slag for high-carbon steel disclosed by the invention, the using amounts of Na2O and CaF2 are properly reduced, K2O and Li2O fluxing is added, and the slag not only has proper physicochemical performance but also has good glass property and lubricating property, so that the quality and yield of casting blanks are greatly improved, and the covering slag has high economic benefit and social benefit.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

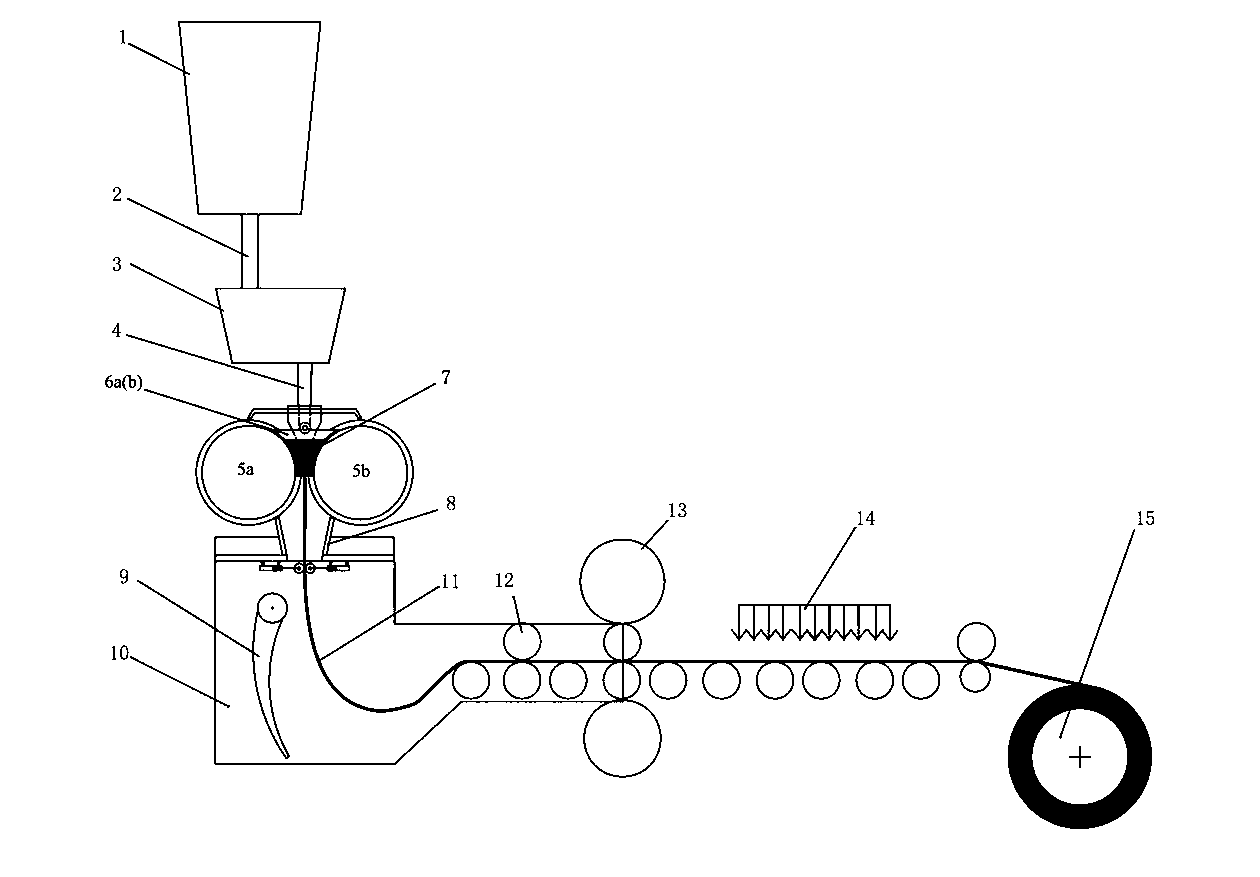

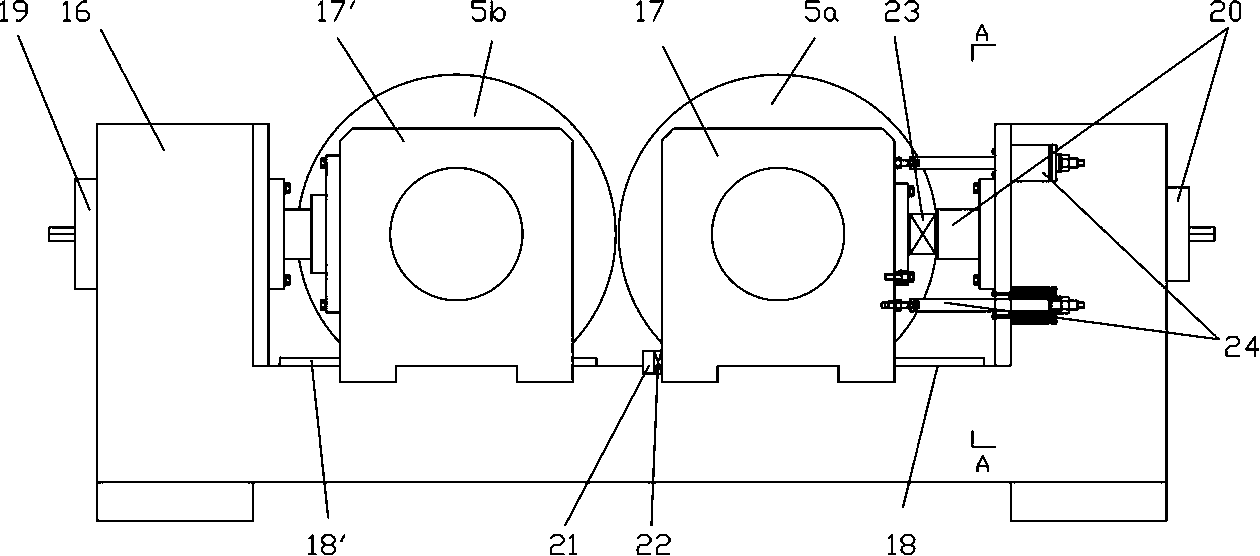

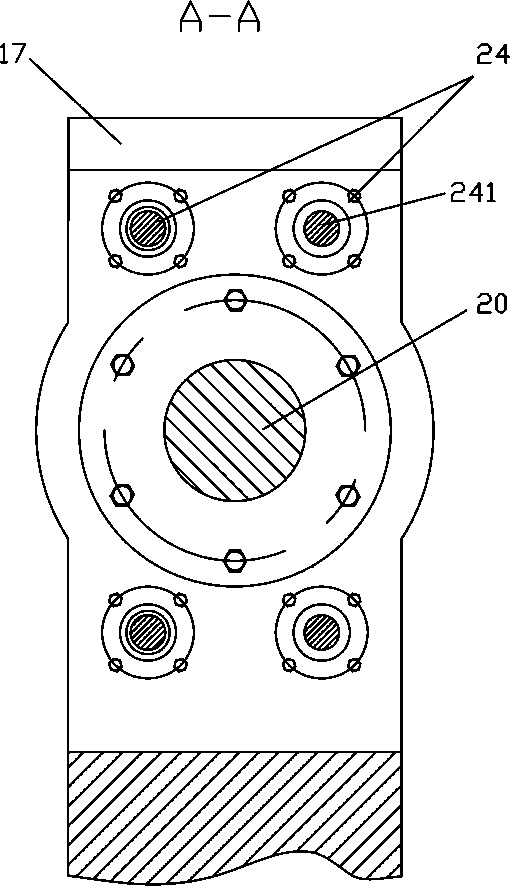

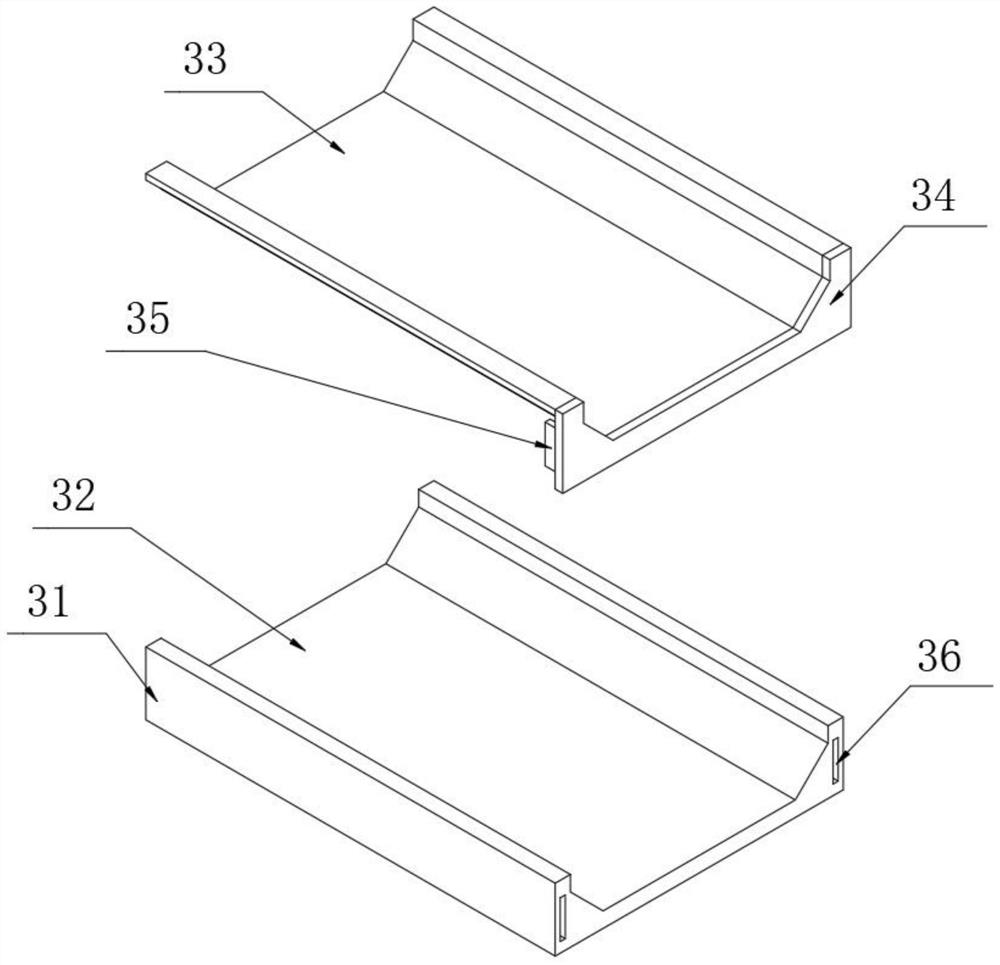

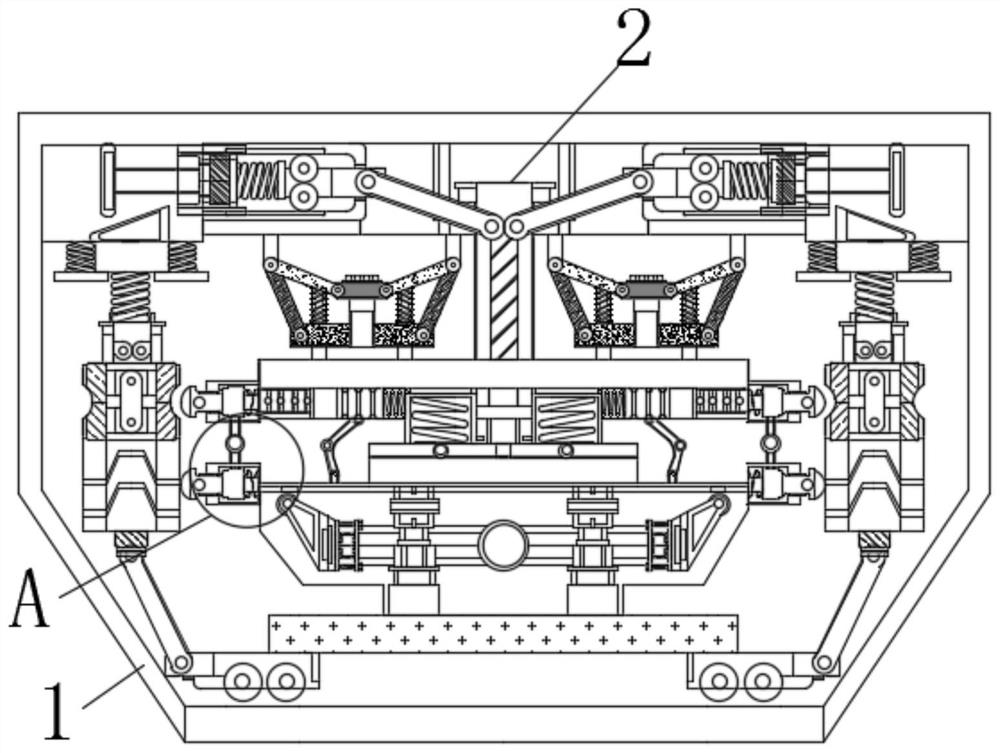

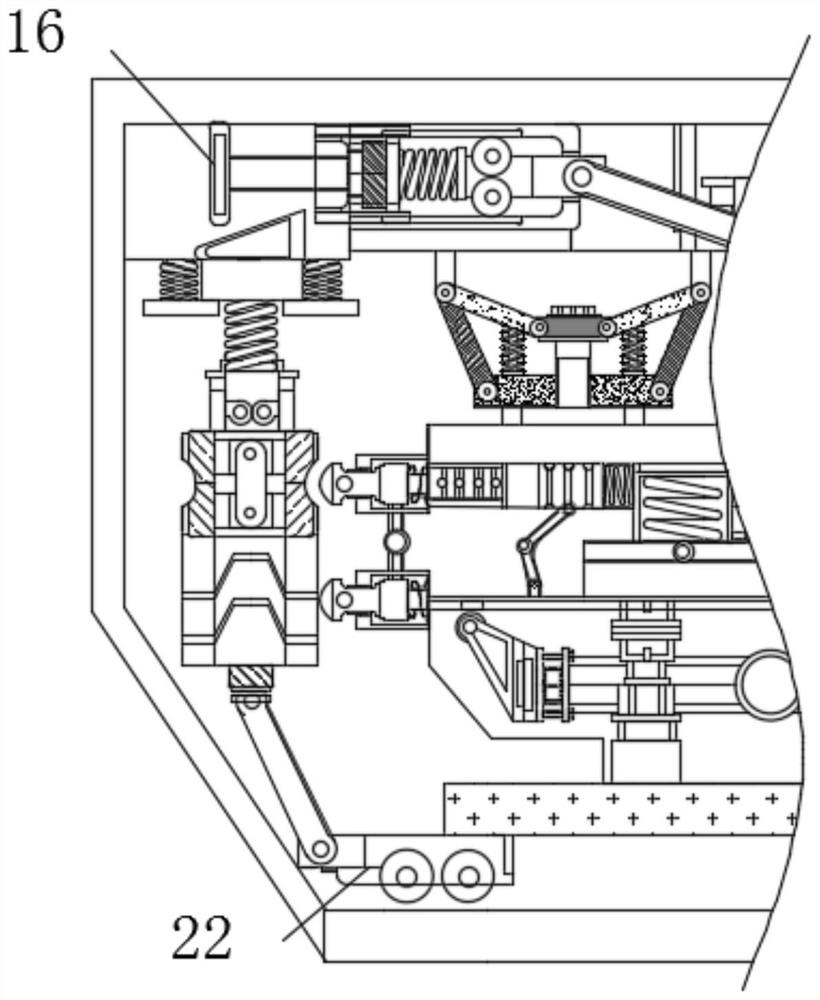

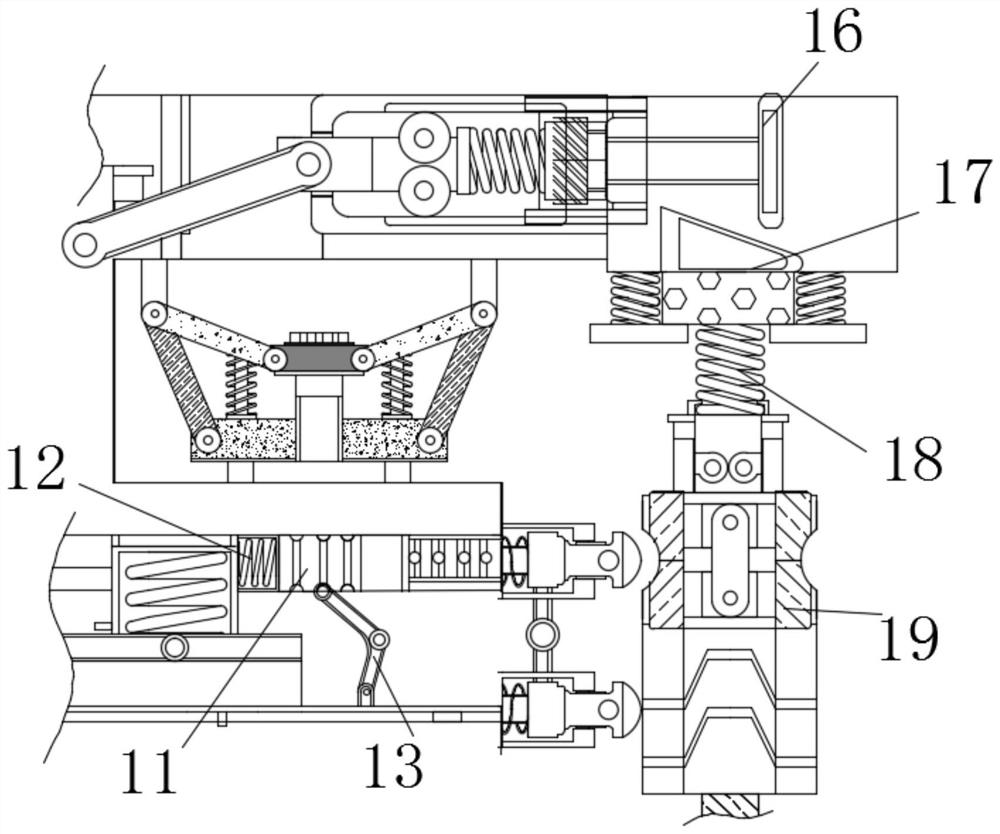

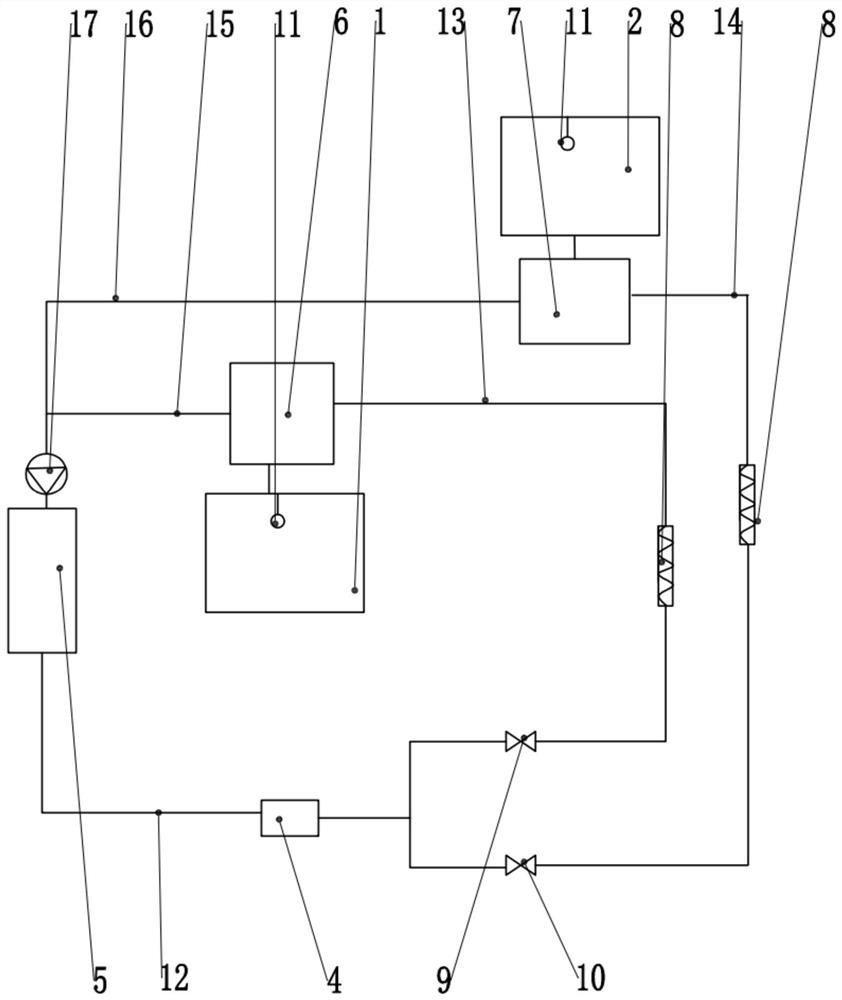

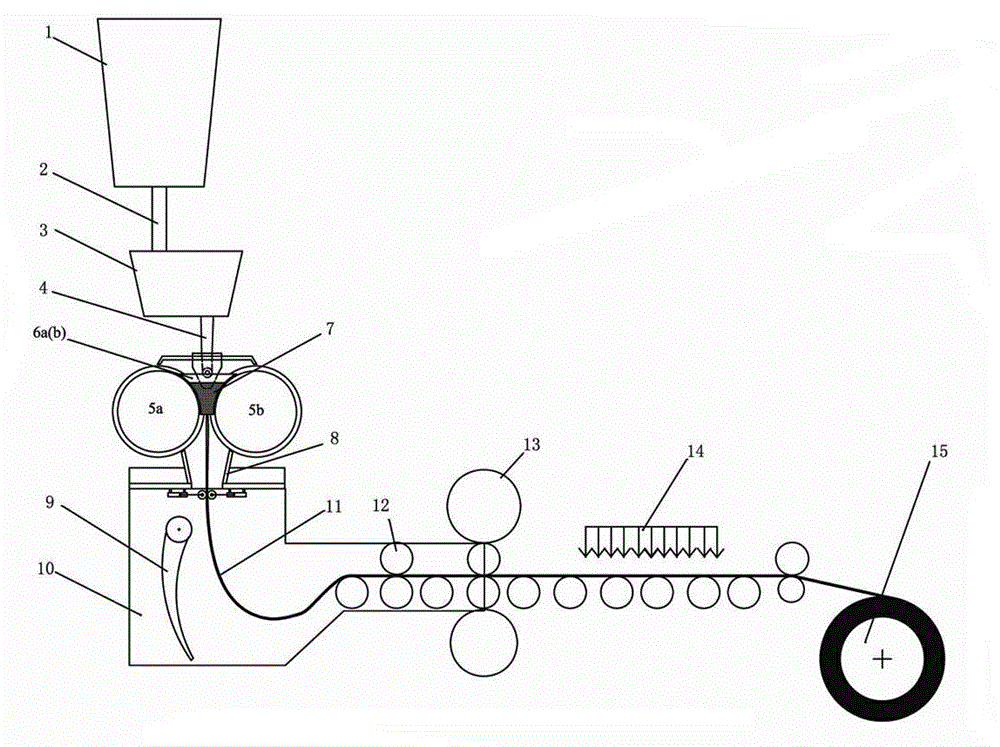

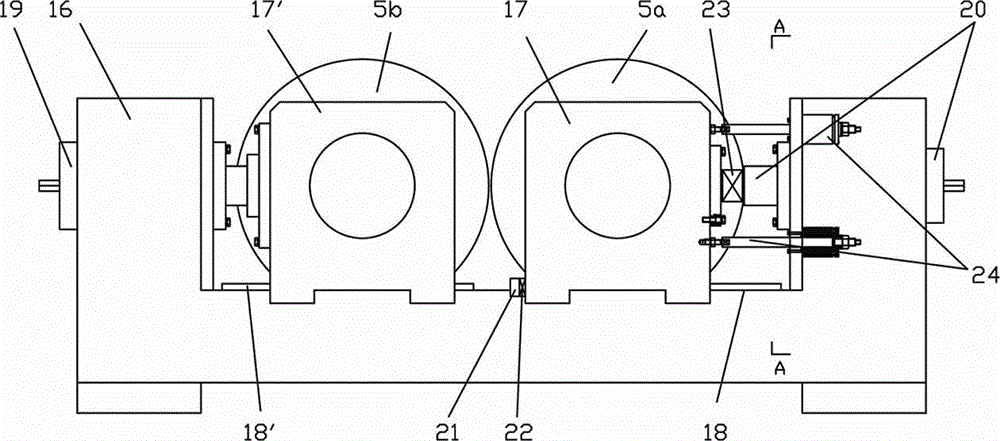

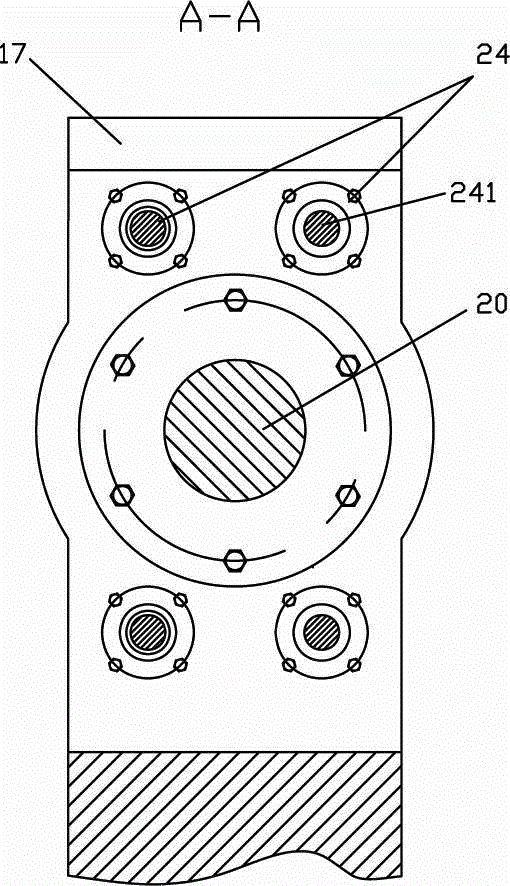

Regulation method and device for double-roll thin-strip continuous casting machine fixing roll

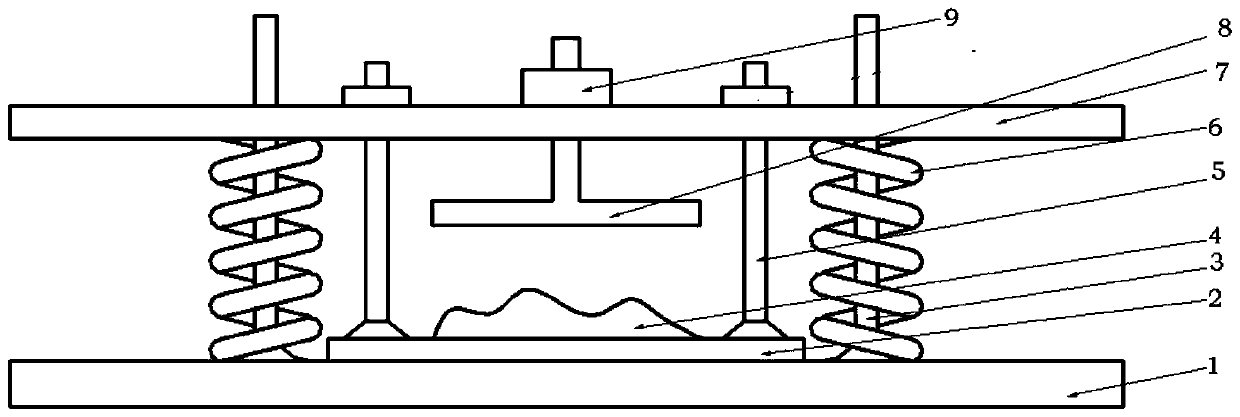

The invention discloses a regulation method and device for a double-roll thin-strip continuous casting machine fixing roll. The regulation method comprises the following steps of: a) a hydraulic cylinder is arranged corresponding to a casting roll continuous casting machine rack on a fixed side, the head part of the hydraulic cylinder is connected with a casting roll bearing pedestal, tensioning mechanisms are respectively arranged above and below the hydraulic cylinder, each tensioning mechanism comprises a draw bar, a spring, a gland and regulation nuts, a stop dog is arranged below the other side of the bearing pedestal, a pressure sensor is arranged between the stop dog and the bearing pedestal, and a cast rolling force sensor is arranged on the front end of the hydraulic cylinder; b) before the casting operation, the hydraulic cylinder on the fixed side pushes the casting roll bearing pedestal to press the stop dog; c) the pressure of the draw bars and the springs is regulated by the regulation nuts, the bearing pedestal, the cast rolling force sensor and the hydraulic cylinder are pressed together until the numerical value of the pressure sensor between the stop dog and the bearing pedestal is zero, and the pressure numerical value detected by the cast rolling force sensor is more than the sum of pressuring pressure FN and the maximum friction force f of the bearing pedestal on a guide rail; and after a casting center line is calibrated, the casting state is waited to start. According to the regulation method and device for the double-roll thin-strip continuous casting machine fixing roll, which are disclosed by the invention, the casting center line positioning precision is guaranteed, the cast rolling force detection degree is improved, and stable casting is realized.

Owner:BAOSHAN IRON & STEEL CO LTD

Composite heating wire for electronic cigarettes

InactiveCN106072775AAffect the electrothermal performanceReasonable control of electric heating performanceVacuum evaporation coatingSputtering coatingChemical reactionMetal alloy

The invention provides a composite heating wire for electronic cigarettes. The composite heating wire comprises a core part and a shell part arranged on the outer surface of the core part; the core part is a linear metal heating wire; the shell part comprises at least one inorganic film layer. According to the composite heating wire, the inorganic film layer with chemical inertness covers on a metal alloy heating surface, so that oil fume is prevented from directly contacting metal alloy, chemical reactions between the metal alloy heating wire with chemical activity and oil fume can be effectively prevented, and charring gas and electrothermal property influencing the heating wire can be avoided; furthermore, the heating wire is only a diameter performance surface, and the thickness of the inorganic film layer is reasonably controlled, so that the heating efficiency and flexibility of the composite heating wire can be guaranteed, and the composite heating wire is highly compatible with an existing electronic cigarette structure.

Owner:杭州森翼科技有限公司

Method for compression to one of battery

InactiveCN1967925AAffect thicknessStable voltageFinal product manufactureNon-aqueous electrolyte cellsEngineeringOrganic glass

The invention relates to a method for pressurizing battery, which comprises: a, based on battery type, selecting matched clamping plate; b, using alcohol to clean clamping plate; c, clamping battery via plates, only exposing polar ear and bubble; d, using long clamper or steel clamper to clamp plates to exhaust; e, pressurizing in pressurizing tank, taking out clamping plates and battery. The clamping plate is not smaller than the battery, with smooth faces, while it will not deform and is made from organic glass plate or bakelite. The invention uses pressurize exhaustion to reduce the thickness difference into 0.1mm.

Owner:曾坚义

Peeling device and intelligent equipment

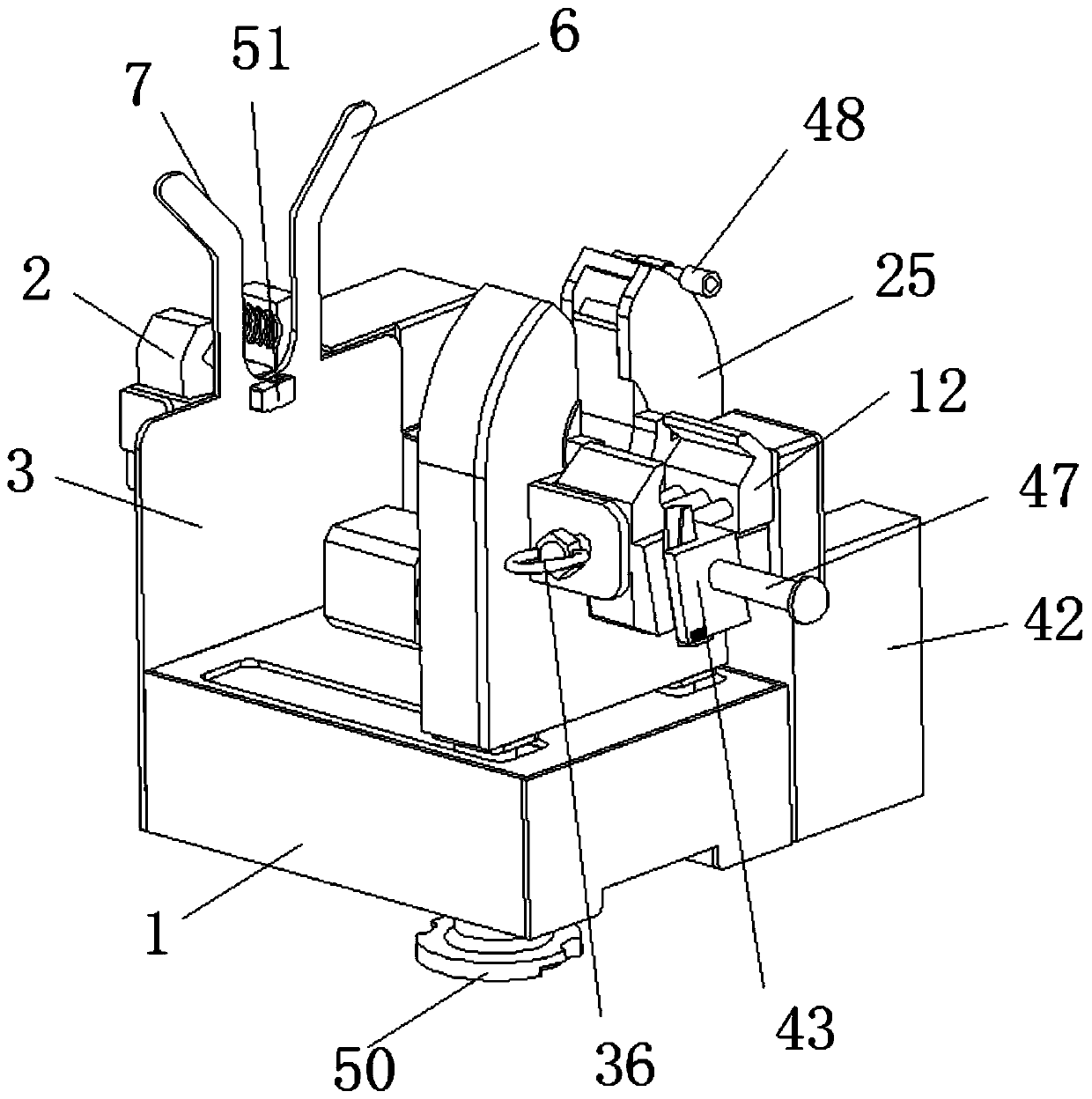

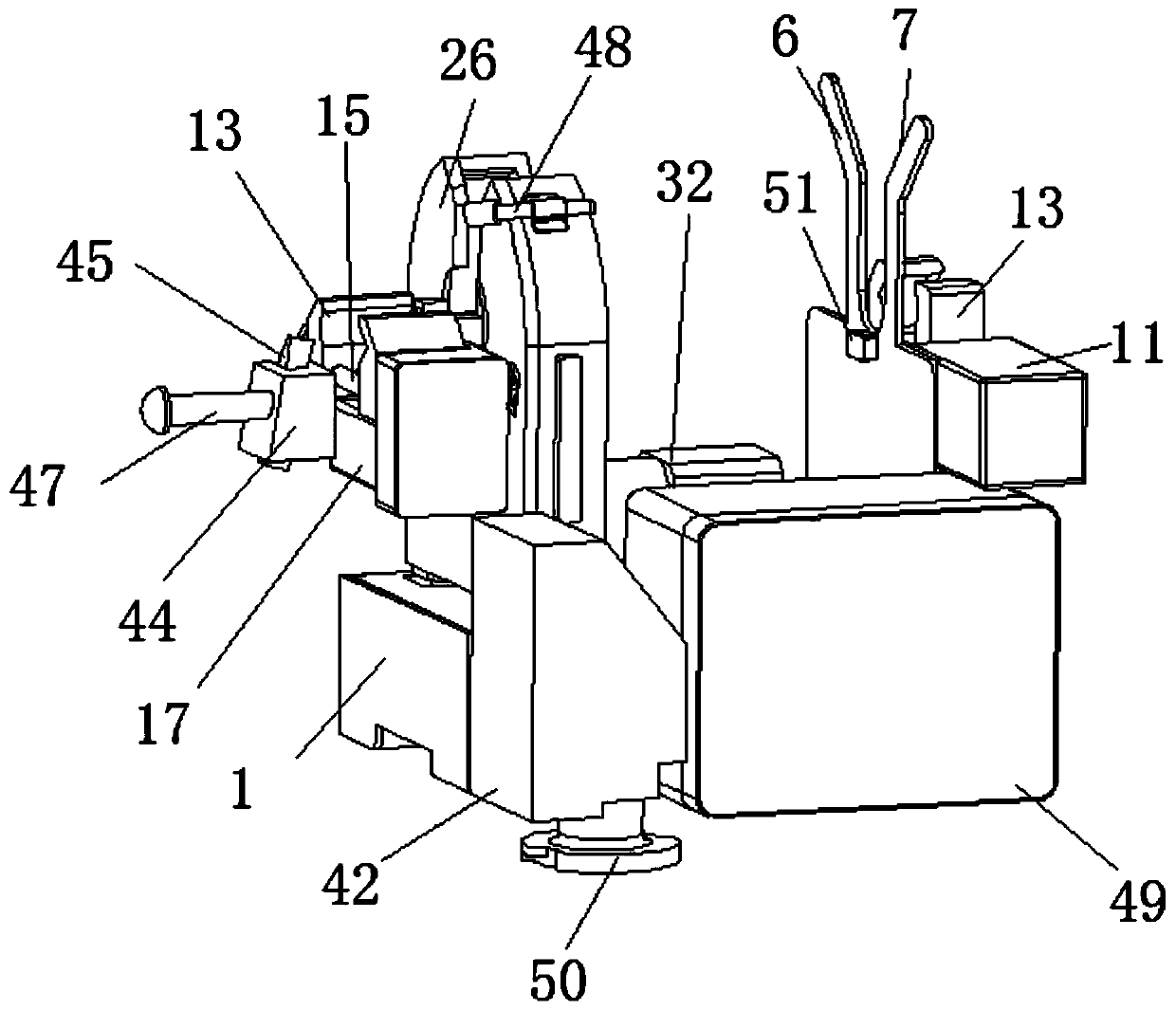

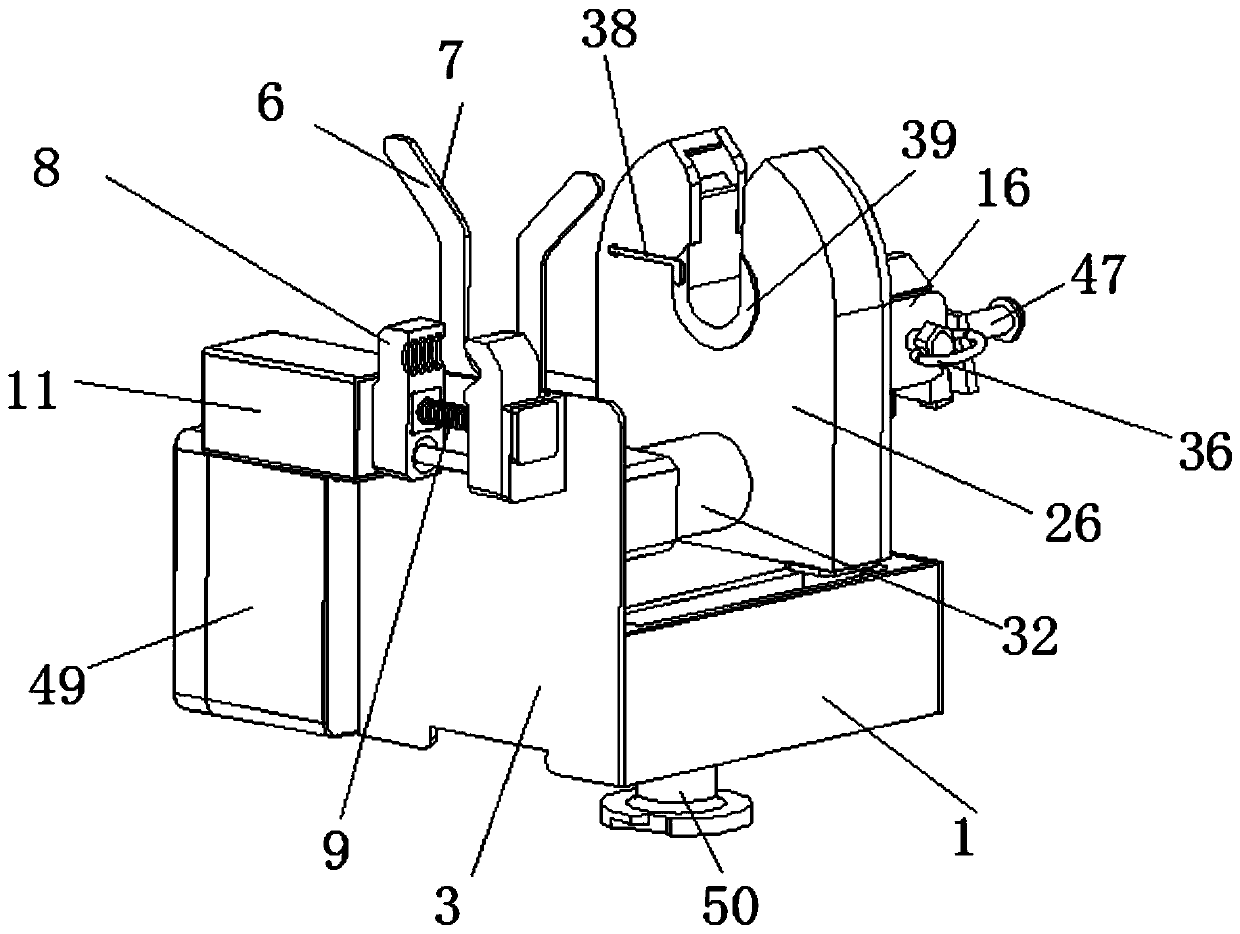

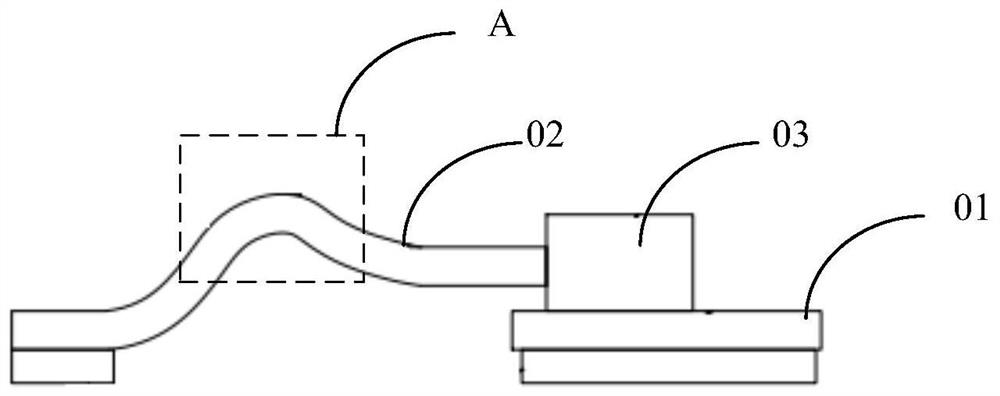

PendingCN111211522APrevent rotationHigh degree of automationApparatus for removing/armouring cablesElectric power equipmentEngineering

The invention belongs to the technical field of power equipment and relates to a peeling device and intelligent equipment. The peeling device comprises a base, a first clamping mechanism, a second clamping mechanism and a controller; the base is installed on a moving arm and is internally provided with a walking mechanism; the first clamping mechanism and the second clamping mechanism are arrangedon the base; the second clamping mechanism is connected with a rotating mechanism arranged on the walking mechanism; a cutting mechanism is arranged on the second clamping mechanism; a main wire is placed on the first clamping mechanism and the second clamping mechanism; the controller is connected with the walking mechanism, the first clamping mechanism and the rotating mechanism; the controllerdrives the rotating mechanism to rotate so as to drive the cutting mechanism to cut the main wire; and the cutting mechanism drives the walking mechanism to drive the rotating mechanism to move towards the first clamping mechanism. With the peeling device and the intelligent equipment adopted, a relatively long insulating sheath can be peeled off.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +1

Surface corrosion preventing treatment method based on aluminum profiles

InactiveCN111659594AScientific and reasonable structureEasy to useLiquid surface applicatorsSpraying apparatusMetallurgySprayer

The invention discloses a surface corrosion preventing treatment method based on aluminum profiles. The surface corrosion preventing treatment method comprises the following steps that the aluminum profiles are fixedly arranged on a conveying belt, and the aluminum profiles automatically advance forwards along with the conveying belt; when the aluminum profiles advance into a treatment machine body, an anti-corrosion coating is sprayed to the surfaces of the aluminum profiles, a rotation mechanism drives the aluminum profiles to rotate, and spraying of the aluminum profiles is more uniform; anadsorption mechanism is utilized for absorbing and filtering the coating scattered into equipment in the spraying process; the aluminum profiles obtained after spraying are placed on the conveying mechanism one by one, and the aluminum profiles are backwards conveyed; and a cleaning mechanism can clean the surface of the conveying belt rotating to the position below the treatment machine body. Through cooperative usage of a high-pressure sprayer and an anti-corrosion special material spraying box, automatic spraying is conducted on the surfaces of the aluminum profiles, and the work efficiency is improved.

Owner:陈燕珊

Evaporation coating device

ActiveCN107805782AEasy to replaceHeating evenlyVacuum evaporation coatingSolid-state devicesCrucibleEvaporation

The invention relates to an evaporation coating device which comprises a crucible main body, a side surface heating device and a bottom heating device, wherein the side surface heating device is arranged around the crucible main body, and the bottom heating device is arranged under the crucible main body. The bottom heating device can move up and down in the height direction of the side surface heating device and support the crucible main body to rise to a position which is higher than the side surface heating device. According to the evaporation coating device, by means of the arrangement ofthe heating device on the bottom of the crucible main body, the crucible main body is made to be capable of moving up and down, the maintenance efficiency is improved, the maintenance time is shortened, and unnecessary procedures are reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

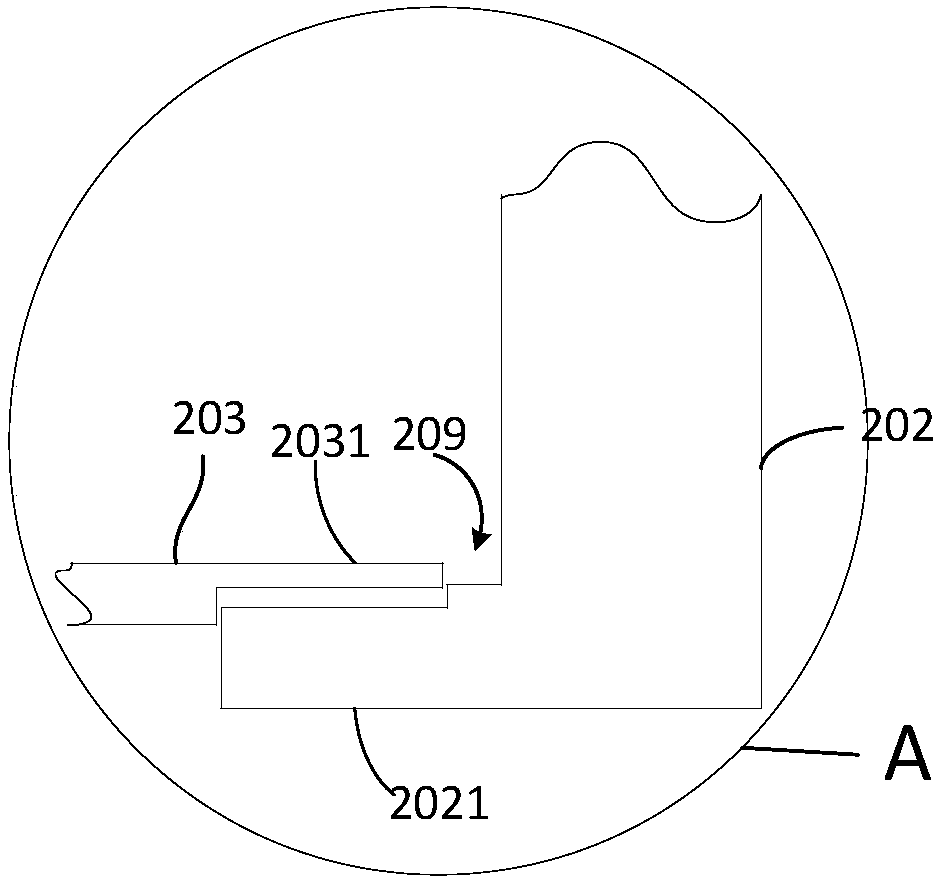

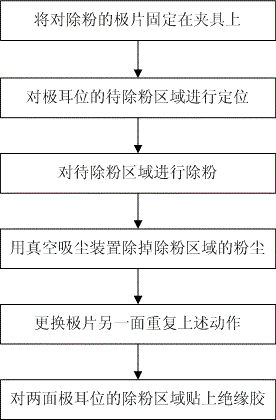

Method for removing powder and attaching glue for tab locations of pole pieces

InactiveCN106299227AEffective in removing powderEliminate effectiveCell component detailsMetallurgyPole piece

The invention discloses a method for removing powder and attaching glue for tab locations of pole pieces. The method includes steps of S1, fixedly placing the pole pieces with the powder required to be removed on fixtures; S2, positioning regions, with the powder required to be removed, of the tab locations in laser firing or grinding modes; S3, starting laser light to fire the regions, with the powder required to be removed, of the tab locations to remove the powder or grinding the regions, with the powder required to be removed, of the tab locations to remove the powder in the grinding modes; S4, starting a vacuum dust collection device to clean dust generated due to laser firing or grinding in the regions with the powder required to be removed; S5, turning the pole pieces over, repeatedly carrying out previous steps and completely removing the powder at the tab locations on the other surface of each pole piece; S6, attaching the insulating glue onto the regions, without the powder, of the tab locations on two surfaces of each pole piece by the aid of double-side glue attaching equipment. The method has the advantages that the powder at the tab locations of the pole pieces can be effectively removed by the aid of the method, the thicknesses of the regions without the powder are assuredly identical to the thicknesses of other film-coated regions, and accordingly the thicknesses and the appearance of batteries can be guaranteed against being affected.

Owner:四川赛尔雷新能源科技有限公司

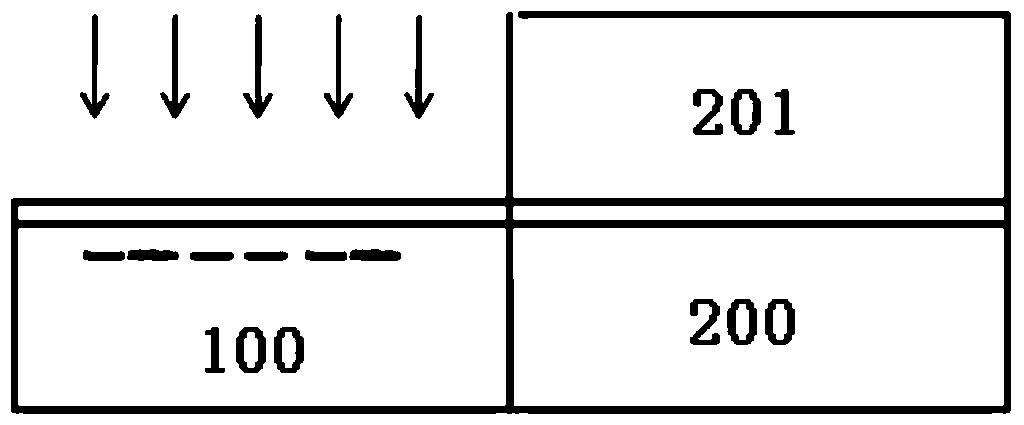

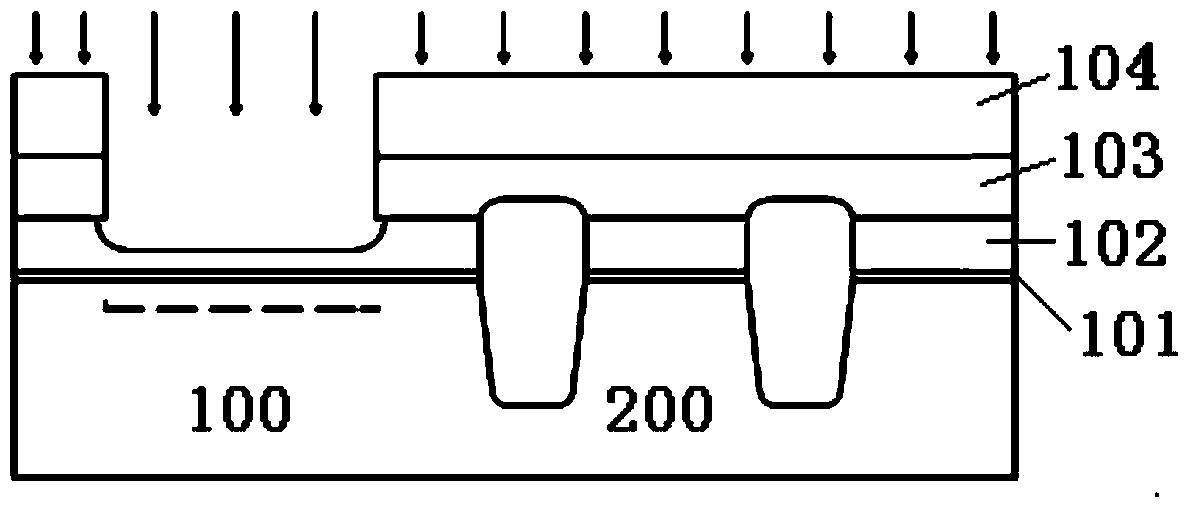

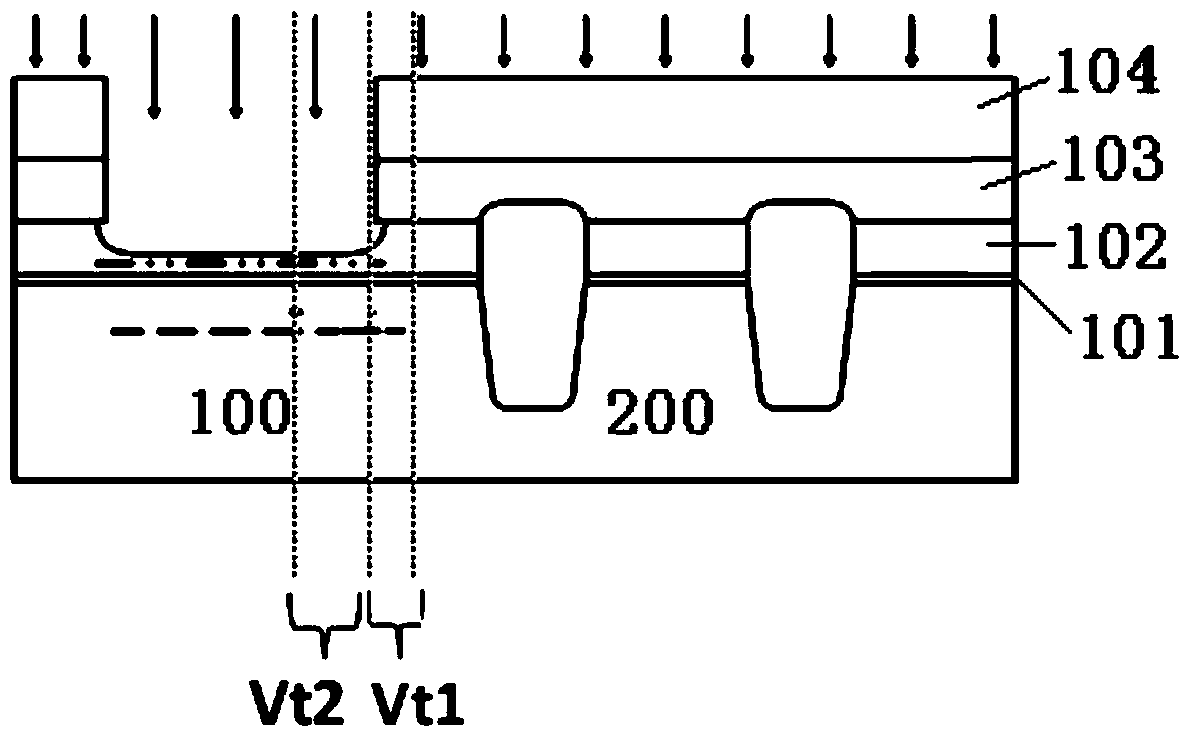

Method for stabilizing flash memory unit word line threshold voltage

ActiveCN104538364AThreshold Voltage StabilityAffect thicknessSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringPhotoresist

The invention provides a method for stabilizing flash memory unit word line threshold voltage. The method includes the steps that photoresist is distributed on a silicon wafer, the photoresist on an active area of the silicon wafer is removed, and the photoresist on the peripheral portion of the silicon wafer is left; first injection treatment is executed on a flash memory unit forming area of the active area of the silicon wafer, and an injection condition of the first injection treatment is selected so that an expected floating gate lower threshold can be formed on a final flash memory unit; the flash memory unit forming process is executed on the silicon wafer so that the flash memory unit can be formed on the flash memory unit forming area of the active area; second injection treatment is executed on the active area of the silicon wafer so that doping can be formed on the positions, corresponding to the silicon wafer area, of word lines on the two sides of the flash memory unit, and an injection condition of the second injection treatment is selected so that an expected word line lower threshold can be formed on the final flash memory unit, wherein ion injection is not carried out on the flash memory unit forming area in the flash memory unit forming process.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

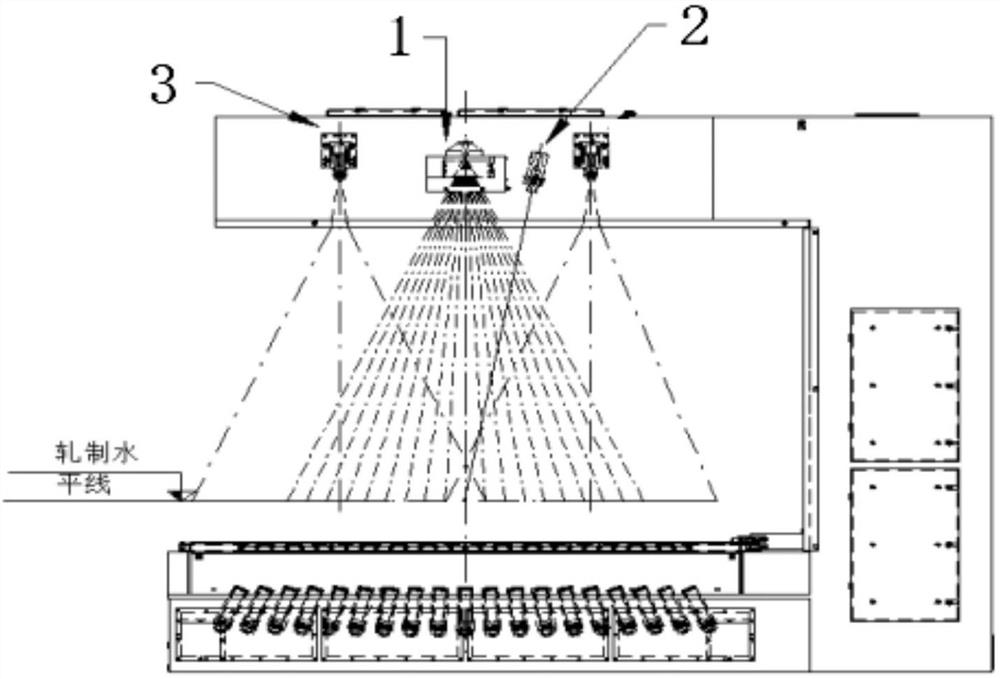

Temperature compensation method and device for improving detection precision of ray type thickness gauge

ActiveCN112496056AAccurate measurementAvoid influenceMeasuring devicesCleaning using gasesControl systemEngineering

The invention provides a temperature compensation method and device for improving the detection precision of a ray type thickness gauge. According to the scheme, the device comprises the thickness gauge and a scanning type pyrometer, the scanning type pyrometer detects the temperature of the whole cross section of strip steel, and a collected signal is connected to a special processor for processing; the collected signal is transmitted to a thickness gauge control system through a serial port or the Ethernet and other manners, and temperature compensation coefficients of all points in the width direction are calculated through a temperature compensation calculation program block in the thickness gauge control system; and a deviation value is set, and the temperature compensation coefficients are calculated by adopting a temperature average value in the width direction when the temperature detection values of two adjacent points exceed a deviation value or the temperature detection value of a certain point suddenly changes to exceed a deviation range. Thickness detection precision can be improved, thickness calculation and detection are prevented from being affected by an abnormal temperature zone, the purpose of accurately measuring the thickness, convexity and wedge shape of the strip steel is achieved, and meanwhile the product quality and the production stability are improved.

Owner:RIZHAO STEEL HLDG GROUP

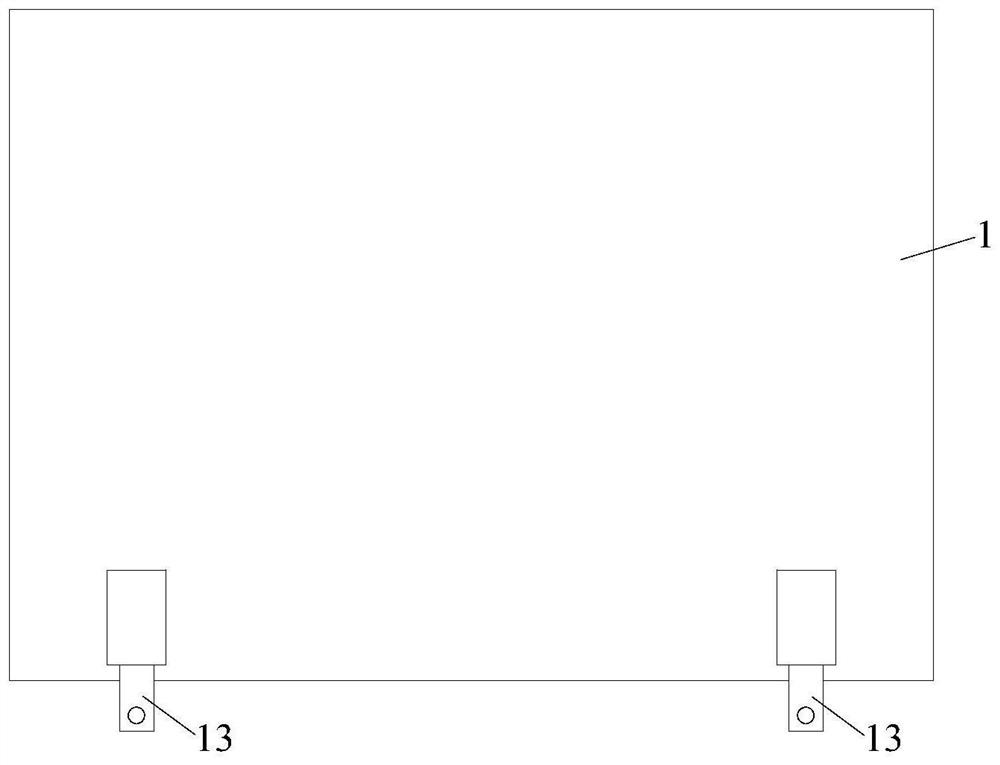

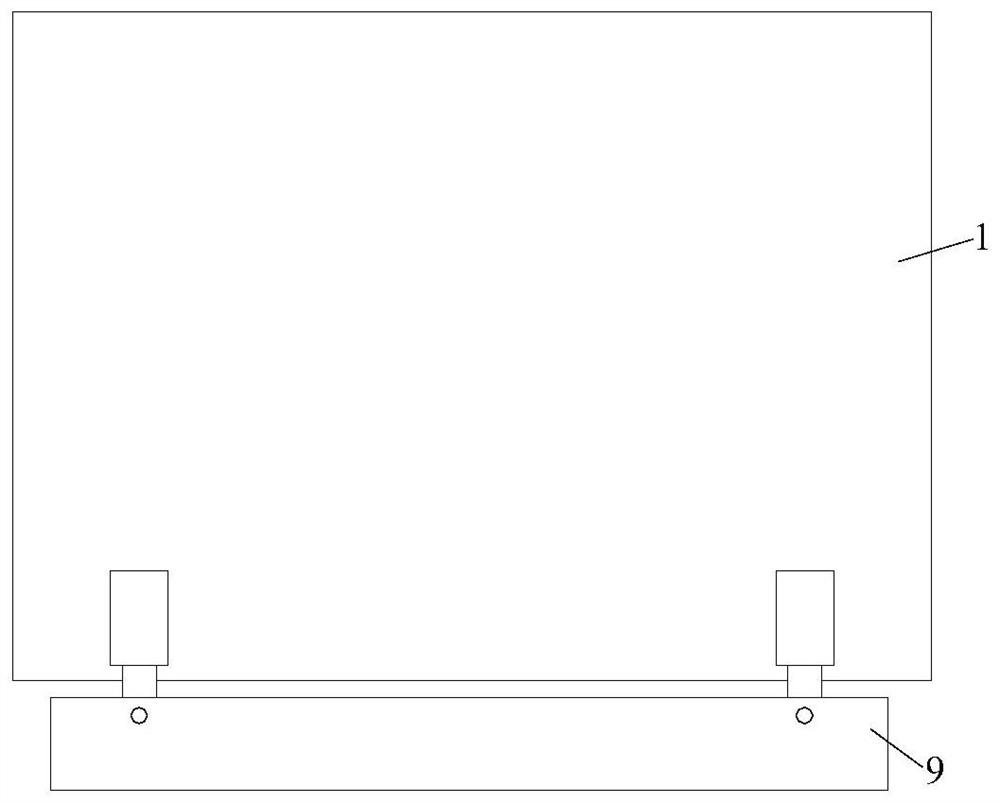

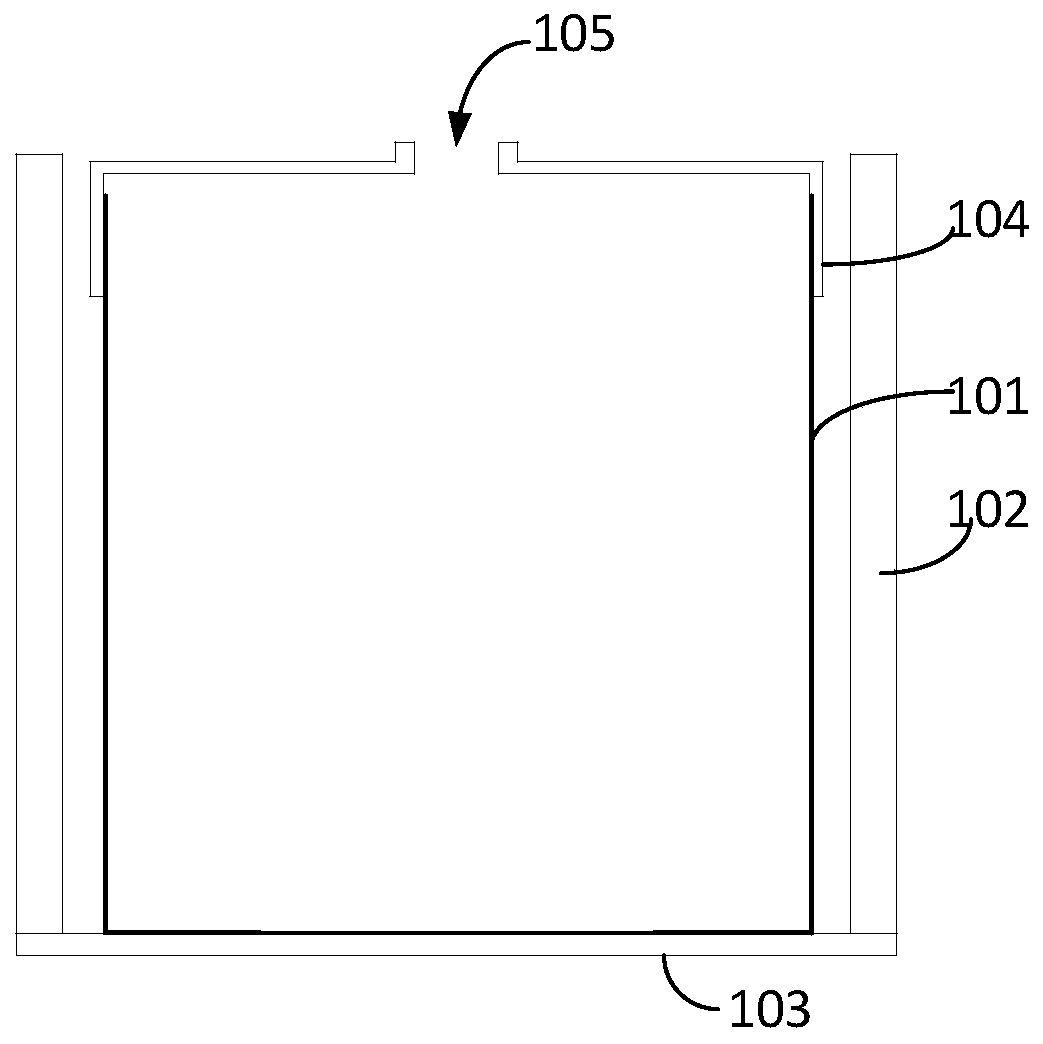

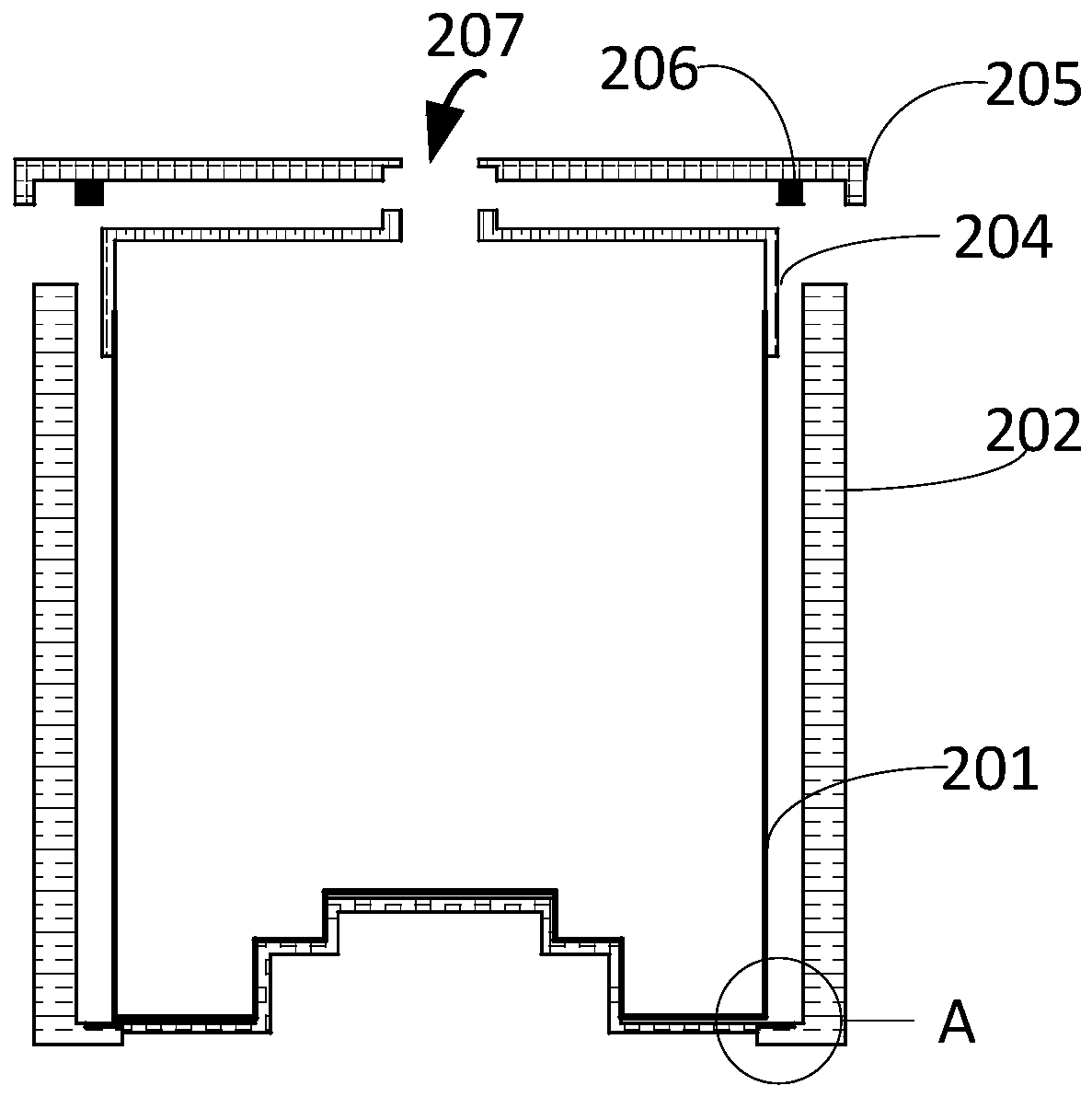

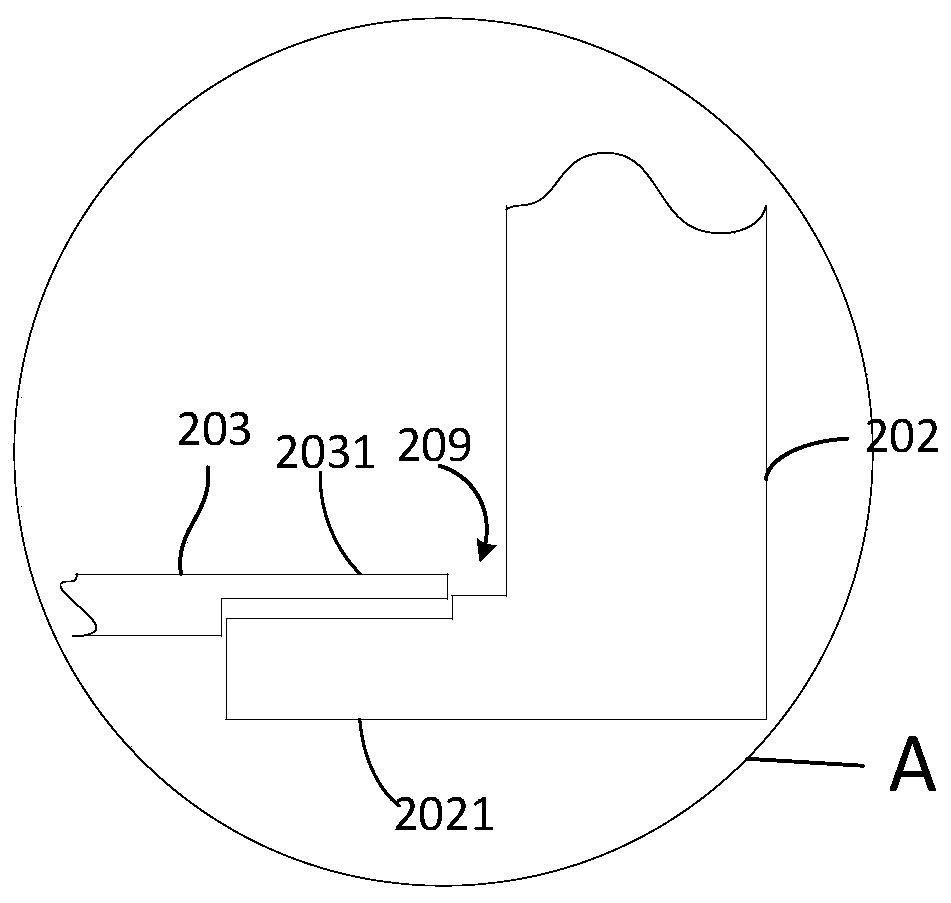

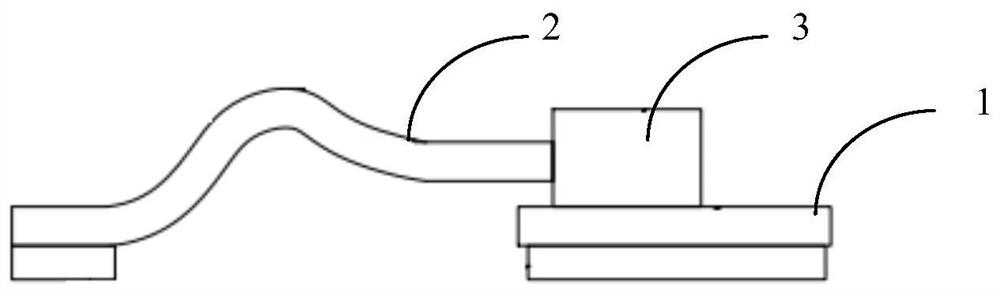

Display panel and display device

ActiveCN109410770AAffect thicknessConducive to ultra-thinIdentification meansDisplay deviceBackplane

The invention relates to the technical field of display, and provides a display panel. The display panel comprises a back plate, a circuit board and a display module. The circuit board is connected with the whole face of the back plate. The display module is arranged on the face, away from the back plate, of the circuit board so that the circuit board can support the display module. The circuit board is connected with the whole face of the back plate. A bracket in the prior art is prevented from being adopted. The back plate is large in area and high in strength and cannot upwarp under vibration or collision, and it is avoided that the circuit board goes beyond the upper surface of the display panel and affects the overall thickness of the display panel. The display module is arranged on the face, away from the back plate, of the circuit board so that the circuit board can support the display module. The display module is supported by the circuit board, there is no need to specially arrange the structure for supporting the display module, and the ultra-thinning of the display panel is facilitated.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

Processing device for fireproof cable with metal sheath

PendingCN114093579AReasonable structureClearPretreated surfacesCoatingsEngineeringStructural engineering

The invention discloses a processing device for a fireproof cable with a metal sheath. According to the technical scheme, the processing device for the fireproof cable comprises a processing table, one side of the top of the processing table is fixedly connected with a fixed vertical plate, one side of the fixed vertical plate is provided with a limiting processing mechanism, the limiting processing mechanism comprises a limiting sleeve and an annular sleeve, the limiting sleeve is located on one side of the fixed vertical plate, supporting vertical plates are arranged at the two ends of the limiting sleeve correspondingly, and the two ends of the limiting sleeve penetrate through the two supporting vertical plates correspondingly and are fixedly connected with the supporting vertical plates. The processing device for the fireproof cable with the metal sheath has the beneficial effects that unnecessary troubles caused by non-uniform spraying of a fireproof coating during cable processing are reduced, and the problems that the surface of the cable is not smooth, the fireproof performance of the cable is reduced and normal use requirements cannot be met due to the fact that the coating is generally and directly coated outside the cable by an existing cable processing device, but the fireproof coating is not uniformly sprayed in the coating process and the thicknesses of the fireproof coating sprayed outside the cable are different are solved.

Owner:JIANGXI ZHONGSHENG METAL

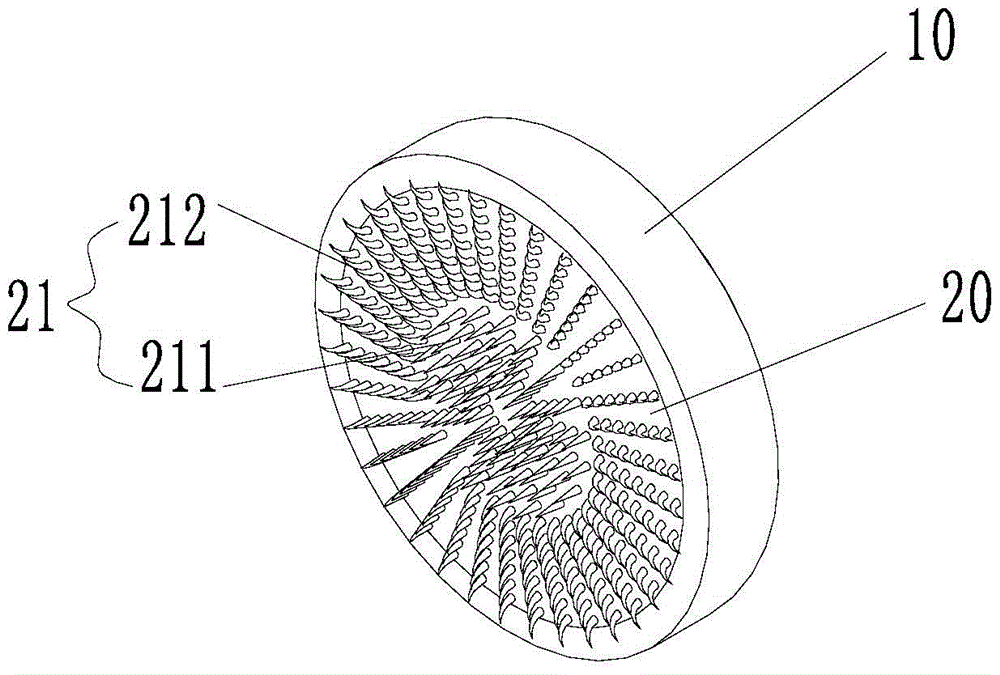

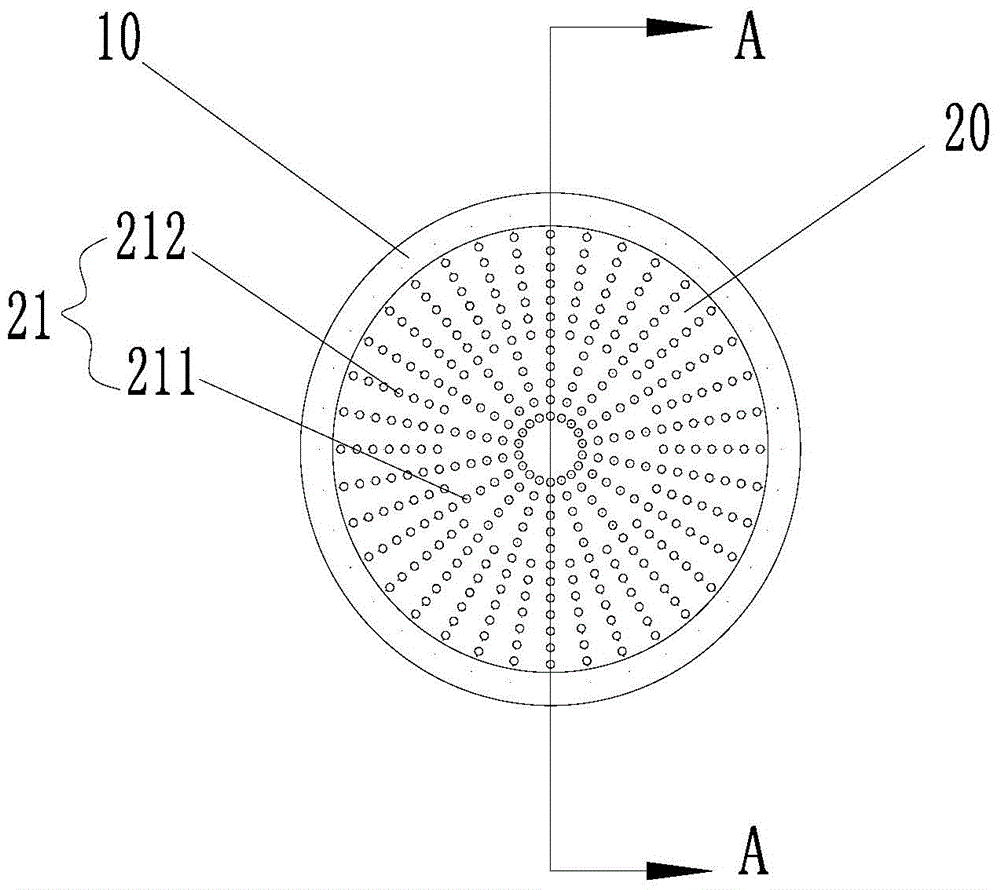

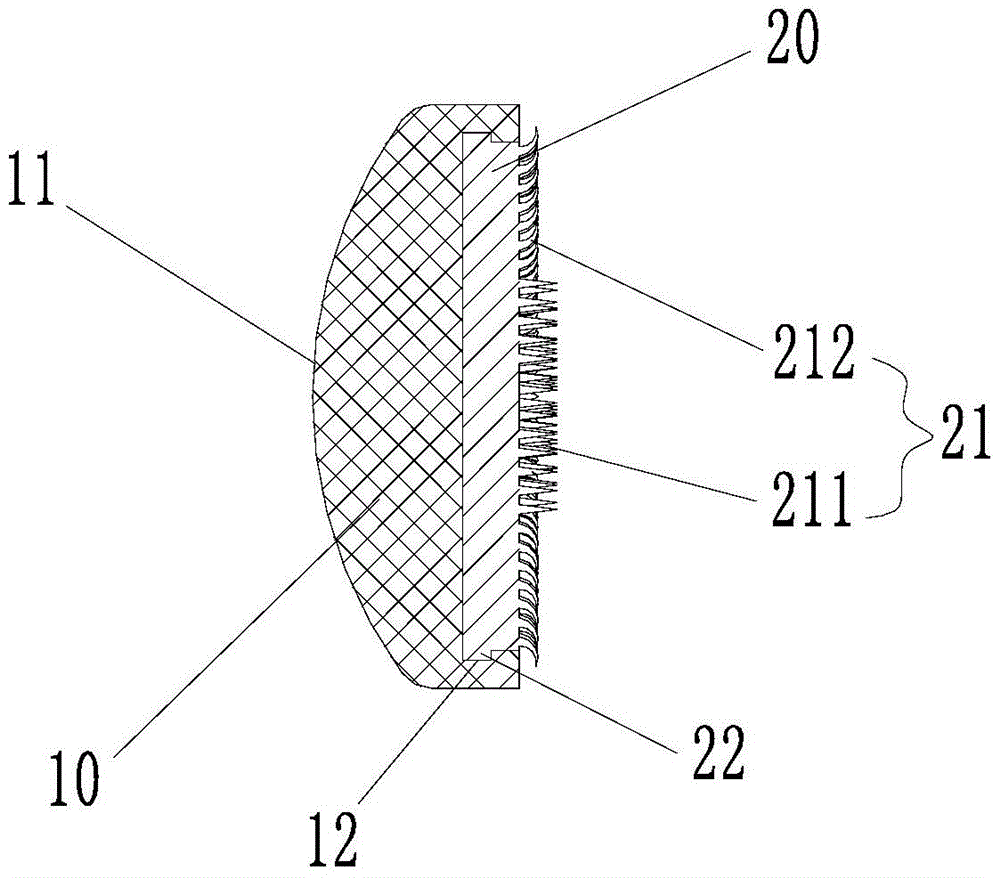

Patella prosthesis

ActiveCN104799979BReplacement effect is goodAffect thicknessJoint implantsKnee jointsPatella prosthesisMedicine

The invention provides a patellar prosthesis, which comprises a metal basal body, the metal basal body is provided with a mating surface, and after the mating surface is processed by laser texturing, a plurality of pointed structures (21) are formed. The technical scheme of the invention effectively solves the problems that patellar prosthesis-fixing bolts in the prior art cannot take both patellar blood supply and prosthesis fixation into consideration and the patellar replacement effect is not good.

Owner:BEIJING AKEC MEDICAL

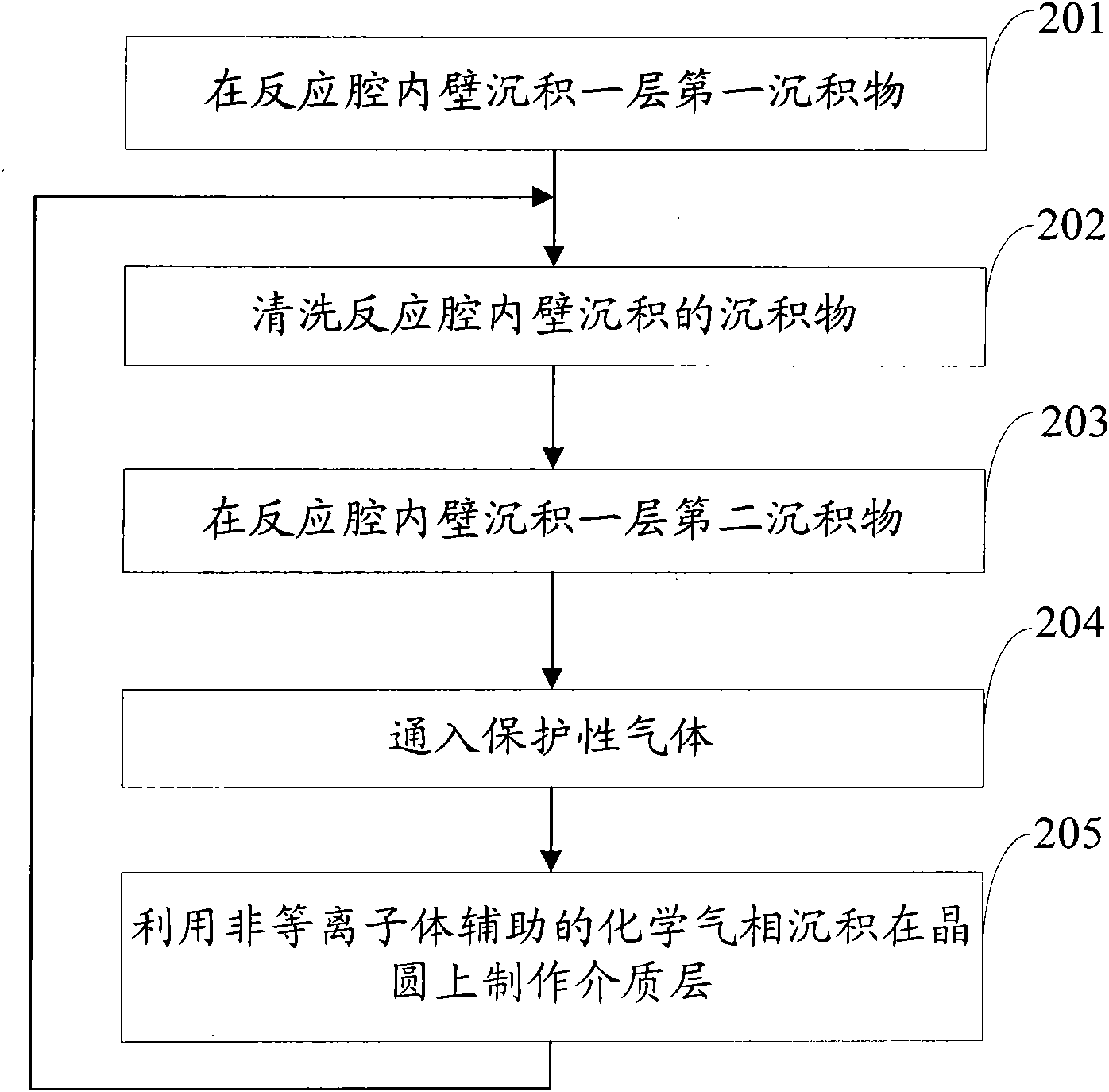

Chemical vapor deposition method assisted by non-plasma

ActiveCN102080217BSmall range of variationAffect thicknessChemical vapor deposition coatingGas phaseAtmospheric pressure

The invention provides a chemical vapor deposition method assisted by non-plasma. The method comprises the following steps: cleaning sediment deposited on the inner wall of a reaction cavity before placing a wafer in the reaction cavity, depositing a layer of second sediment on the inner wall of the reaction cavity, and regulating the time of introducing protective gas according to the air pressure in the reaction cavity; and after placing the wafer in the reaction cavity, preparing a dielectric layer on the wafer by using the chemical vapor deposition method assisted by the non-plasma. By using the method, the sediment deposited on the inner wall of the reaction cavity is cleaned before placing the wafer in the reaction cavity so as to clean the sediment remained on the inner wall of the reaction cavity, then a layer of second sediment is deposited on the inner wall of the reaction cavity so that the environments in the reaction cavity are consistent with the environment when the wafer is placed in the reaction cavity to manufacture the dielectric layer; and through cleaning the reaction cavity and regulating the introduction time of the protective gas, the severe variation of the temperature in the reaction cavity is avoided so as to influence the thickness of the sequentially manufactured dielectric layer, and the variation range of the thickness of the dielectric layer is reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Loading Method of Solder Paste for Reworked Printed Boards of Surface Mount Devices

ActiveCN108463062BGuaranteed loading qualityEasy to operatePrinted circuit assemblingPrinted circuits repair/correctingSurface mountingRework

Owner:10TH RES INST OF CETC

Continuous casting crystallizer protective slag for medium-carbon rare earth steel plate

The invention discloses continuous casting crystallizer protective slag for a medium-carbon rare earth steel plate. The protective slag comprises, by mass percentage, 32.0-40.0% of CaO, 25.0-30.0% ofSiO2, 1.0-2.5% of MgO, 2.3-4.5% of Al2O3, 0.1-4.0% of MnO, 0.0-0.6% of Fe2O3, 7.0-12.0% of Na2O, 7.0-12.0% of F, 8.0-16.0% of C, 0-1.0% of K2O, 0-1.0% of Li2O and the balance water and inevitable impurities. The protective slag is high in alkalinity, low in viscosity and low in oxidization performance, has good physical and chemical properties, and can significantly improve the yield of casting blanks.

Owner:BAOTOU IRON & STEEL GRP

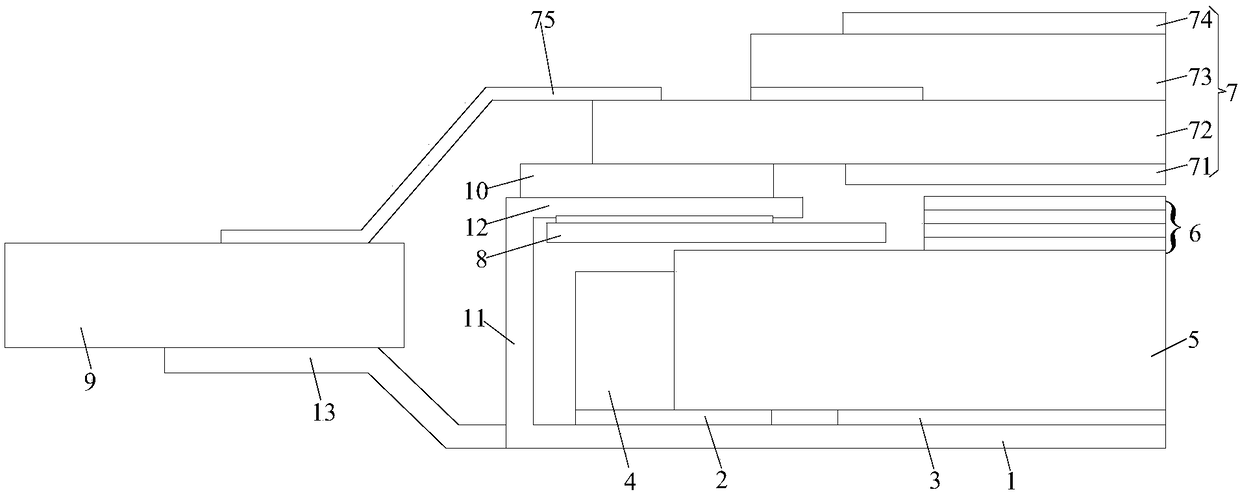

Rapid transverse slicing machine

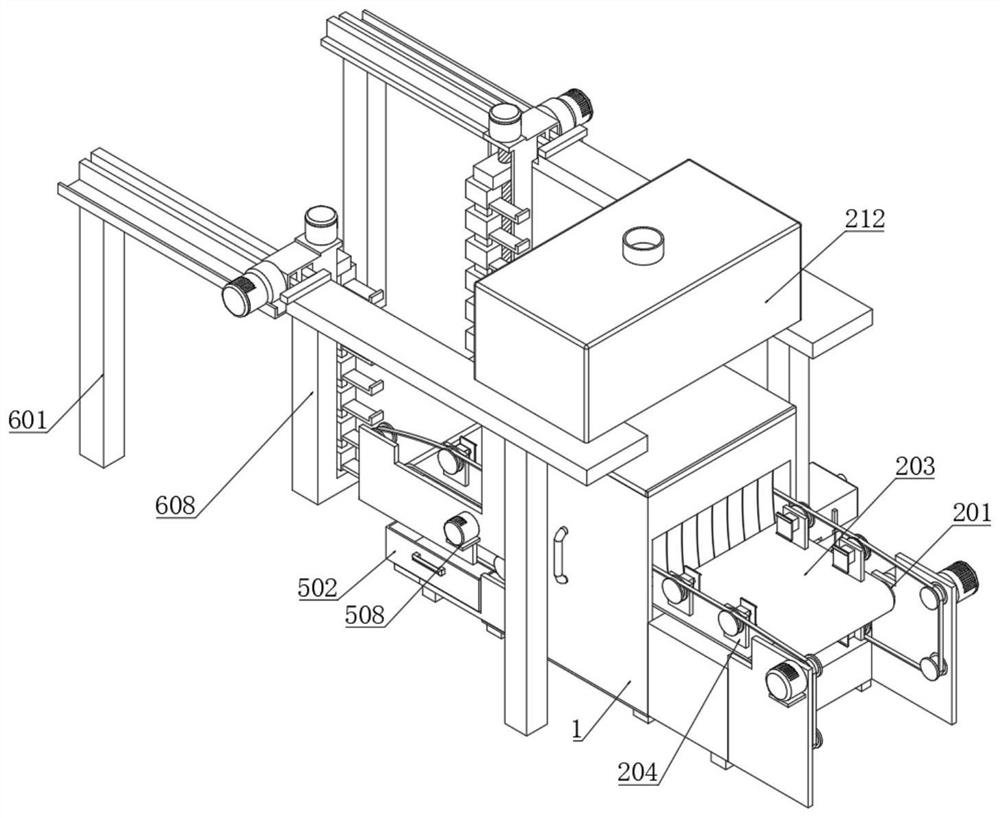

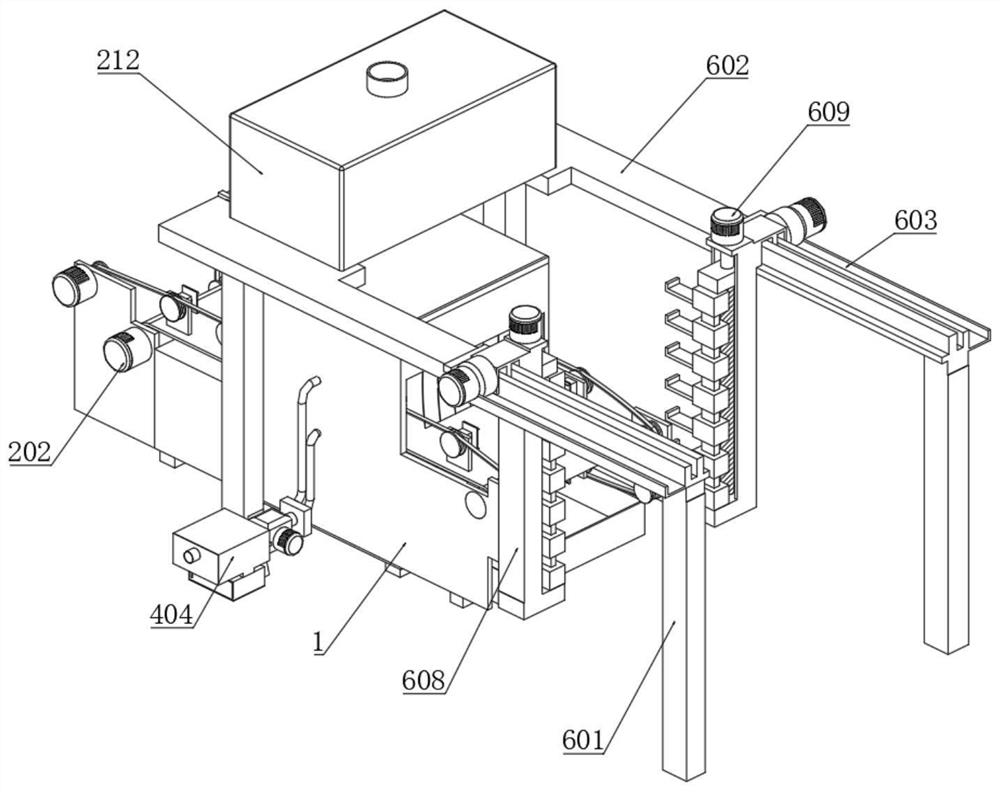

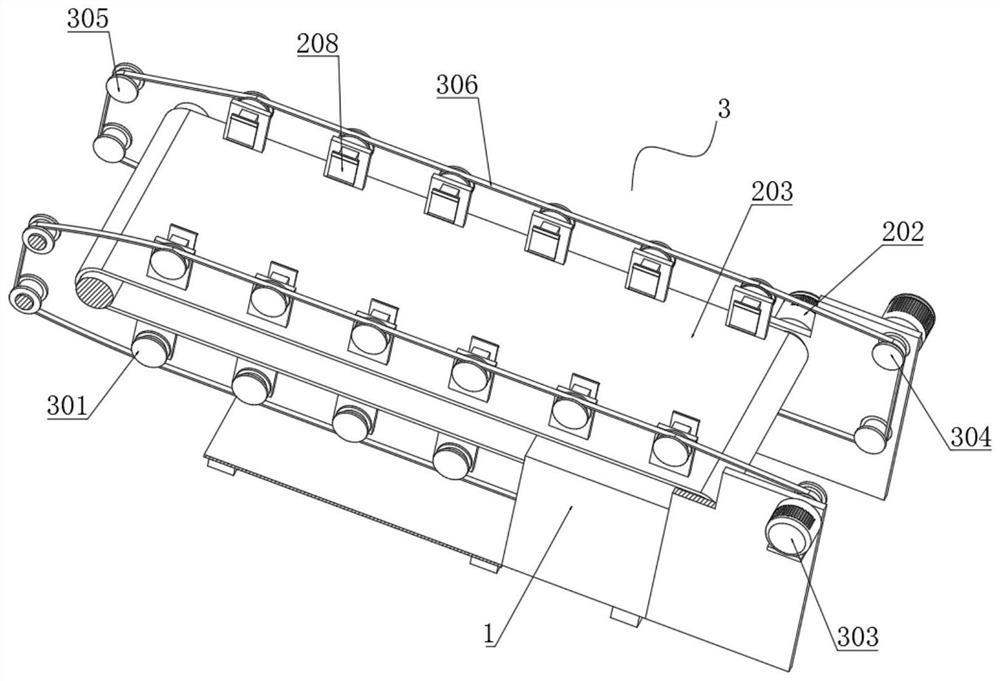

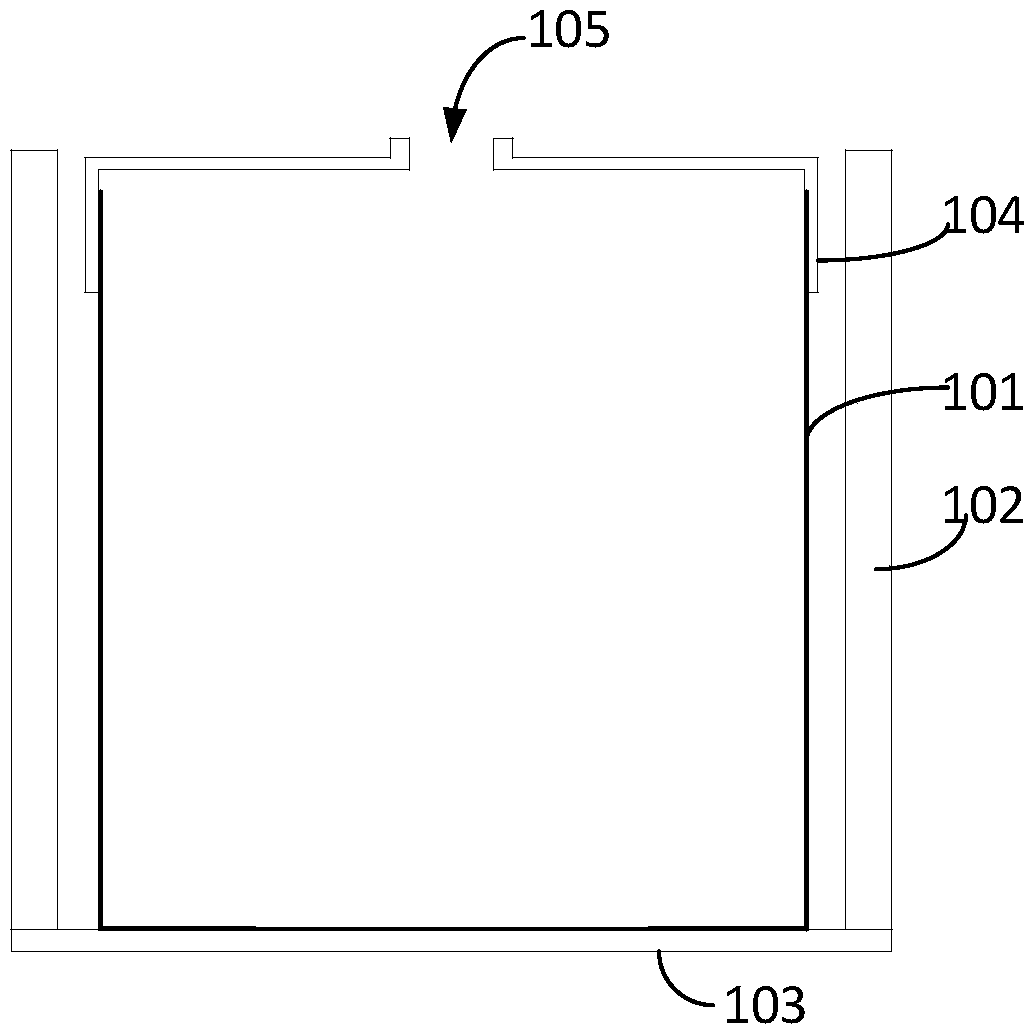

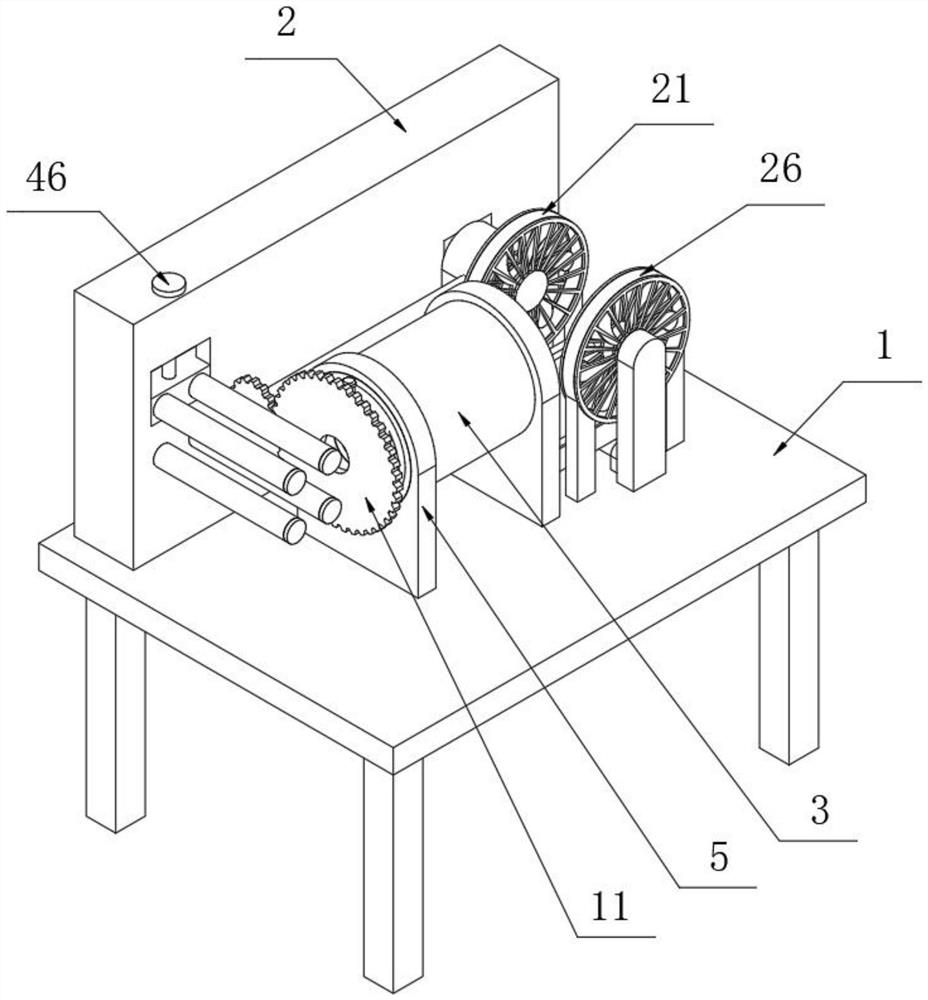

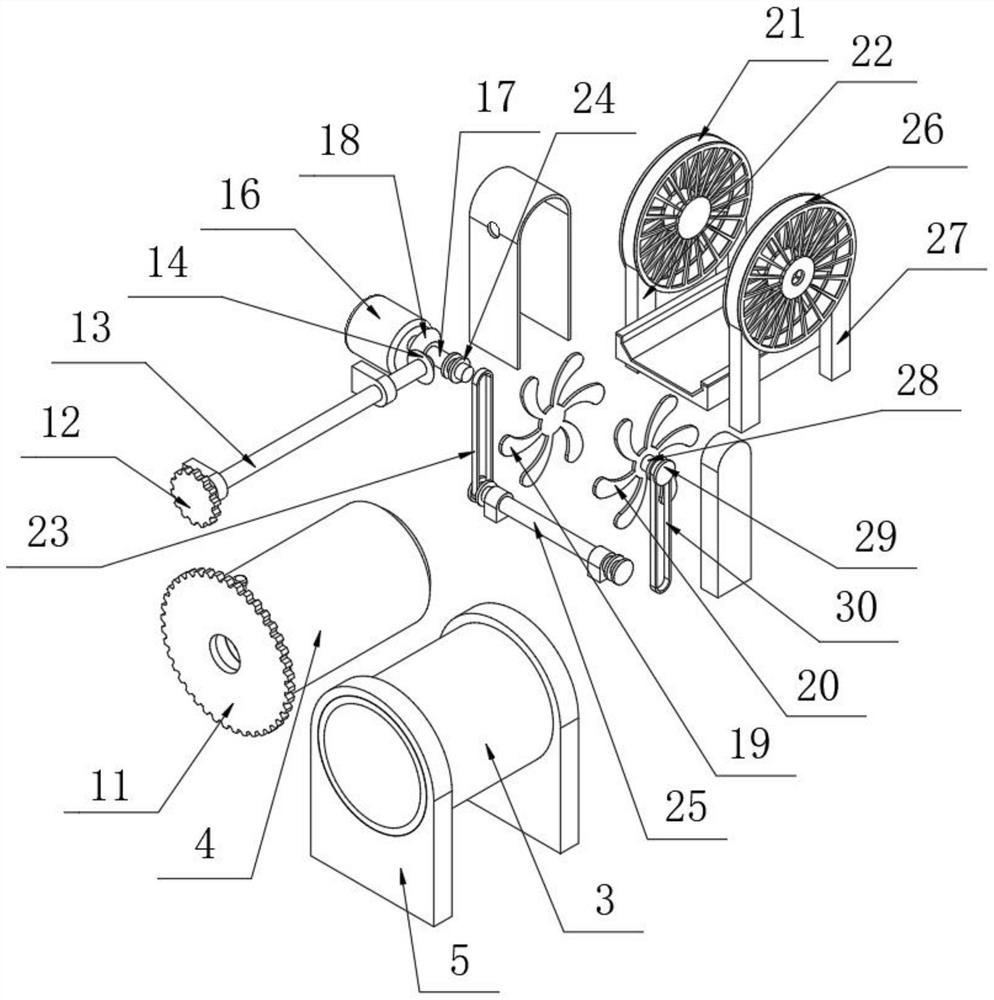

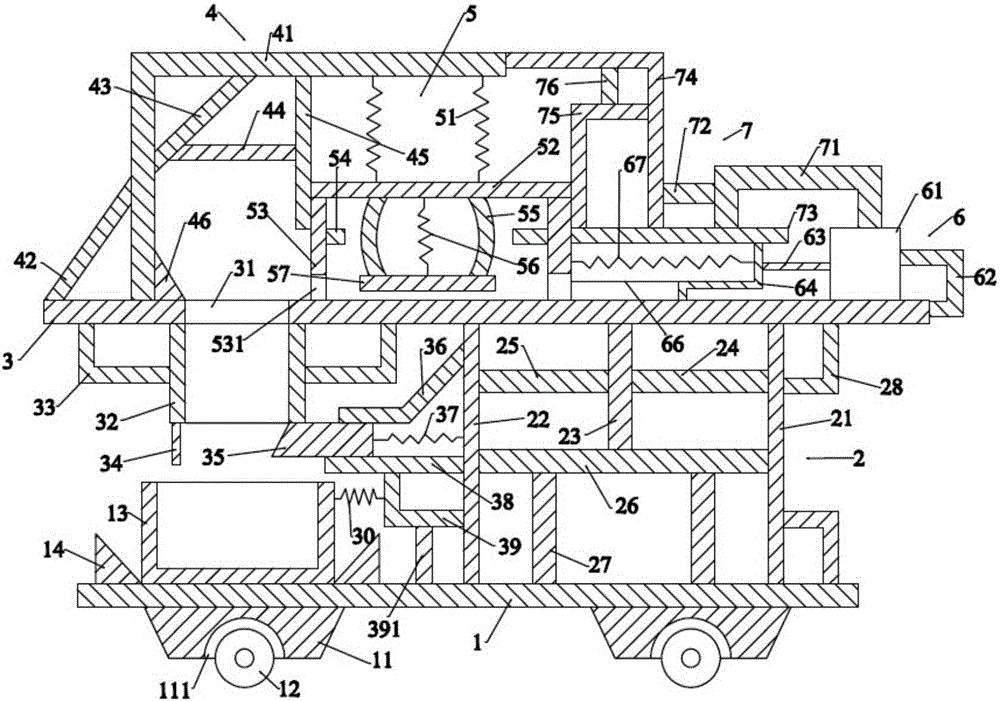

A rapid transverse slicing machine comprises a bottom board (1), a support device (2), a supporting board (3), a supporting device (4), a fixing device (5), an air cylinder device (6) and a positioning device (7), wherein a first supporting block (11), first idler wheels (12), a collection box (13) and a first positioning block (14) are arranged on the bottom board (1); the support device (2) comprises a first supporting rod (21), a second supporting rod (22), a third supporting rod (23), a first cross rod (24) and a second cross rod (25); and the supporting board (3) is provided with a first through hole (31), a discharge frame (32), a second support (33), a first vertical board (34), a limiting block (35), a first positioning rod (36), a first spring (37) and a second positioning rod (38). The rapid transverse slicing machine can effectively fix food when the food is cut, and prevent the situation that slicing is affected due to infirm fixing of the food during cutting.

Owner:ZHEJIANG QIANGMENG IND

Printing equipment capable of stably controlling printing gap and reducing solder projection and collapse

The invention relates to the technical field of printing, and provides printing equipment capable of stably controlling a printing gap and reducing solder projection and collapse. The printing equipment comprises a machine body, a push block is movably connected in the machine body, a push rod is fixedly connected to the bottom of the push block, and a moving frame is fixedly connected to the bottom of the push rod. According to the printing equipment capable of stably controlling the printing gap and reducing solder projection and collapse, a drive mechanism drives the push block to move, the push block and the push rod are used in cooperation to push the moving frame, the moving frame enables a printing plate to move for printing through parallel plates, when the printing plate inclines, the parallel plates incline to enable a balance lever to deviate, the balance lever extrudes pressure-sensitive ceramic through contact blocks, the pressure-sensitive ceramic is pressed to enable electromagnets to be powered on, the power-on amount is related to the magnitude of the pressure borne by the pressure-sensitive ceramic, the electromagnets attract iron blocks to move after being powered on, the iron blocks and turning rods jointly act to change the inclination angle of the printing plate, the printing plate is parallel to the horizontal plane again, the printing gap is kept stable, and thus solder projection is prevented.

Owner:桂图加

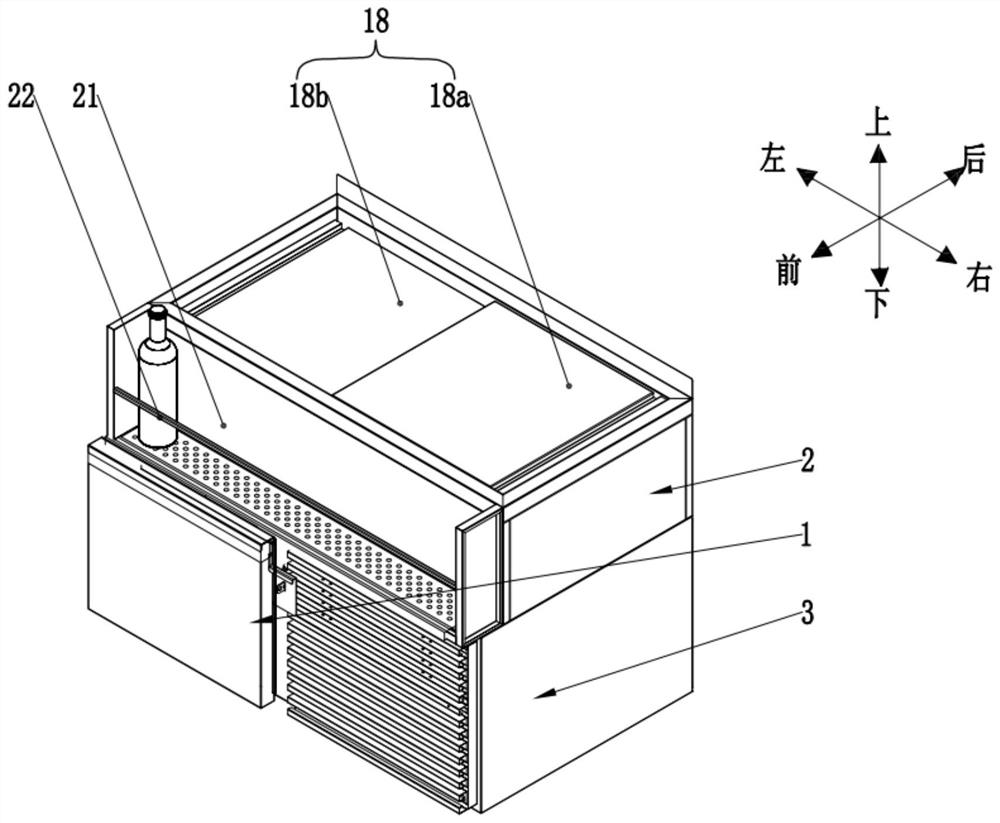

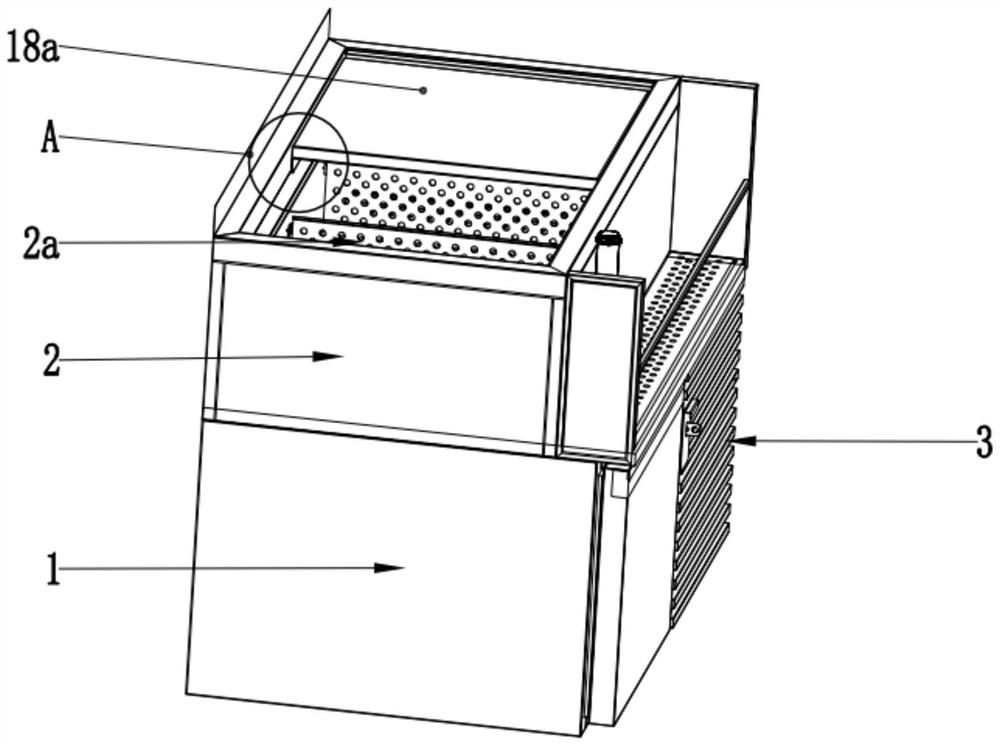

Wine mixing cabinet capable of realizing partitioned temperature control

PendingCN113803934AReduce installationReduce volumeLighting and heating apparatusDomestic refrigeratorsTemperature controlCapillary Tubing

A wine mixing cabinet capable of realizing partitioned temperature control comprises a freezing chamber, a refrigerating chamber, a heat dissipation chamber, a heat dissipation assembly, a refrigerating assembly and a temperature control assembly; the refrigerating assembly comprises a first condenser, a compressor, a first evaporator, a second evaporator and a capillary tube, the compressor and the condenser are installed in the heat dissipation chamber, the first evaporator and the second evaporator are installed in the refrigerating chamber and the freezing chamber respectively, the first evaporator acts on refrigerating of the refrigerating chamber, the second evaporator acts on refrigerating of the freezing chamber, and the first evaporator and the second evaporator share one condenser and one compressor. Installation of extra equipment is reduced, so that the size and manufacturing difficulty of the wine mixing cabinet can be reduced.

Owner:广东星星制冷设备有限公司

a display device

ActiveCN106873063BAffect thicknessAccuracy impactCharacter and pattern recognitionOptical elementsDisplay deviceEngineering

The invention discloses a display device. The filter structure arranged between a protective cover plate and a plurality of photosensitive devices is changed to be composed of a plurality of filter layers stacked. Each filter layer has a light-transmitting area and a In the light-shielding area other than the light-transmitting area, the central positions of the light-transmitting areas of each filter layer are at least partially displaced, so that the orthographic projection of the light-transmitting area of each filter layer on the display panel has an overlapping area, and the overlapping area The area of is the light transmission area of the filter structure. By adjusting the misalignment of the central position of the light-transmitting area of each filter layer, the light-transmitting area of the light-filtering structure can be reduced as required, so that the light-filtering structure is not affected by the precision of the manufacturing equipment, and the accuracy of optical fingerprint recognition is improved. In addition, reducing the light transmission area of the filter structure as required can prevent the thickness of the display device from being affected by the filter structure being too thick while ensuring the collimation effect.

Owner:BOE TECH GRP CO LTD

Display panel and display device

ActiveCN109410770BAffect thicknessConducive to ultra-thinIdentification meansDisplay deviceEngineering

The present invention relates to the field of display technology, and proposes a display panel. The display panel includes a backplane, a circuit board, and a display module; the circuit board is connected to the entire surface of the backplane; Enable the circuit board to support the display module. The entire surface of the circuit board is connected to the backplane, avoiding the use of brackets in the prior art. The backplane has a large area and high strength, and will not be warped due to vibration or collision, so that it will not cause damage to the backplane The circuit board exceeds the upper surface of the display panel, affecting the overall thickness of the display panel; the display module is arranged on the side of the circuit board away from the back plate, so that the circuit board can support the display module. By supporting the display module through the circuit board, it is not necessary to specially arrange a structure for supporting the display module, which is beneficial to the ultra-thinning of the display panel.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

Structure for improving performance of MPI substrate FPC antenna and preparation method

ActiveCN111405751AImprove performanceSimple structureFlexible printed circuitsCircuit susbtrate materialsPhysicsBi layer

The invention provides a structure for improving the performance of an MPI substrate FPC antenna and a preparation method. The structure comprises a plurality of groups of base layers and surface layers which are periodically and alternately arranged, the base layers are hydrophilic and elastic polymer material layers, the surface layers are made of a fluorinated siloxane material, and the base layers and the surface layers are mutually combined through coupling acting force to form special acting bonds, so that a complete and firm flexible-rigid double-layer coating structure is formed. According to the structure for improving the performance of an MPI substrate FPC antenna and the preparation method provided by the invention, the surface of an MPI substrate FPC antenna formed by combining the base layers and the surface layers is provided with low-polarity fluorine-containing molecular groups, the dielectric constant epsilon(r) is not larger than 3, the dielectric constant is reduced, the total thickness is 0.3-5 [mu]m, the thickness of the antenna is not affected, the elastic base layers can also absorb part of external stress, a certain deformation and displacement space is provided, and no negative influence is caused to the space design flexibility of the antenna.

Owner:上海科谷纳新材料科技有限公司

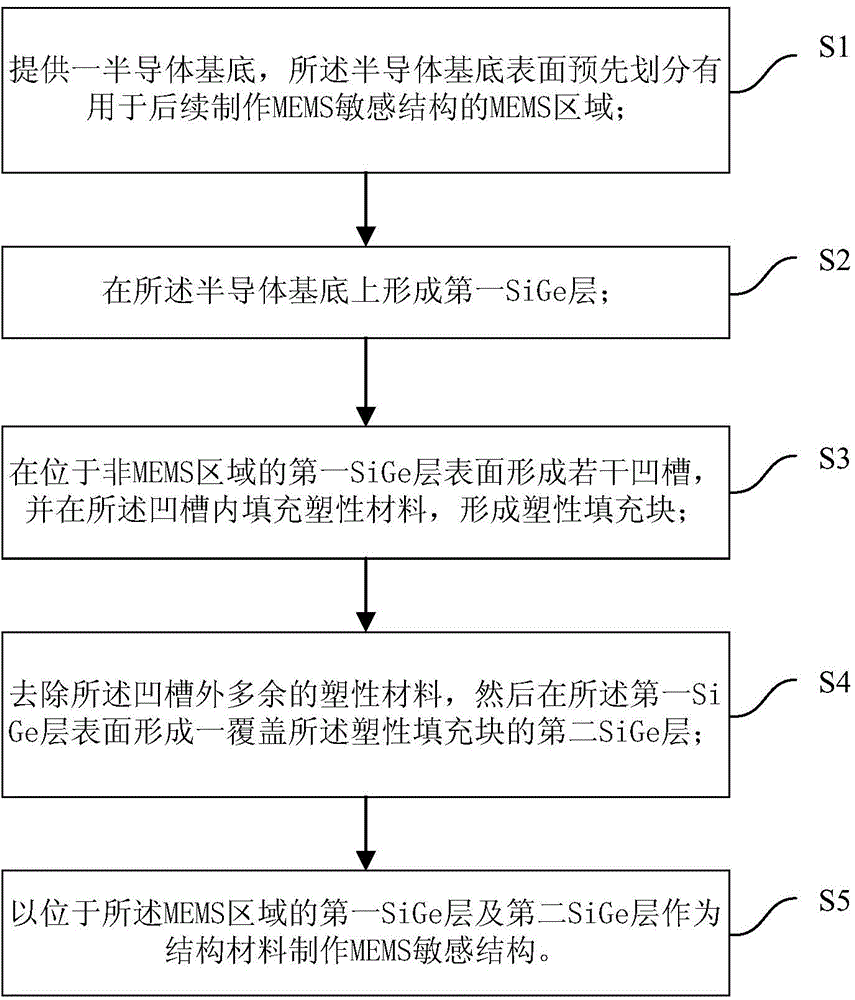

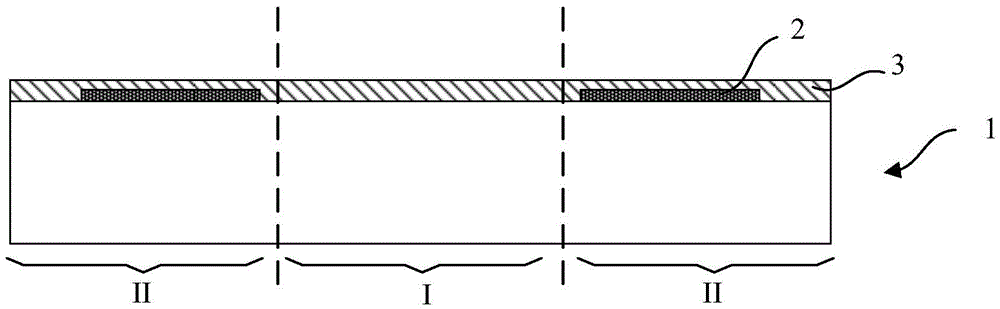

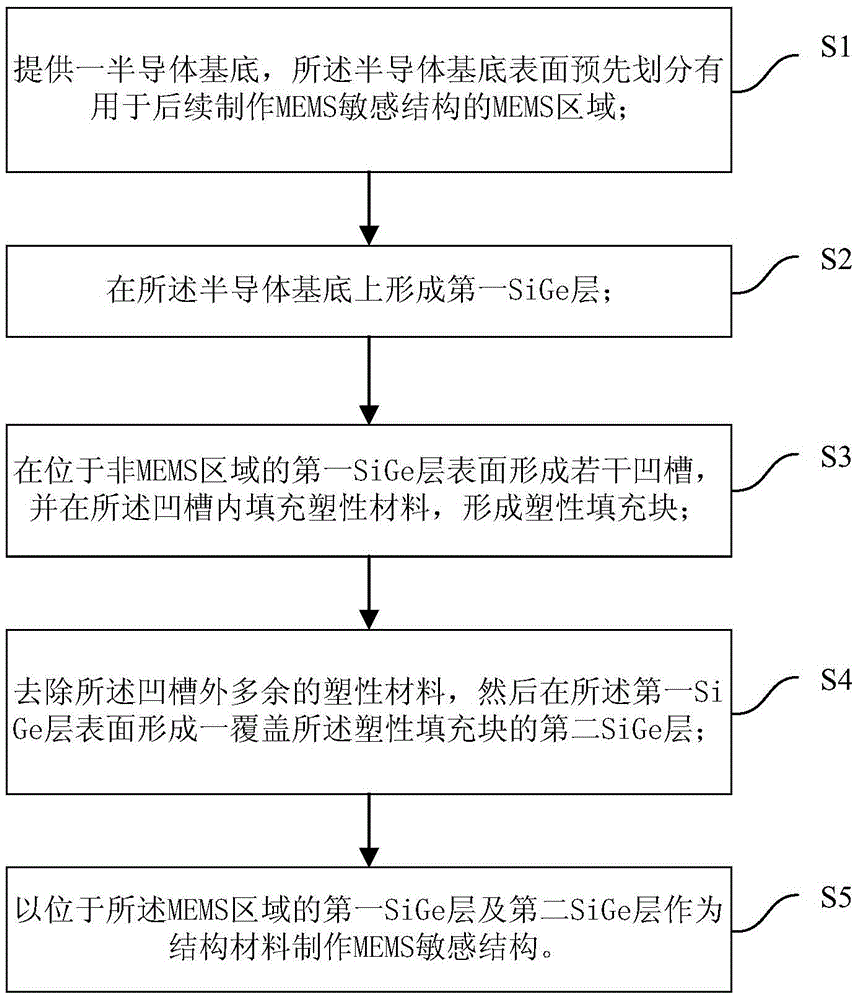

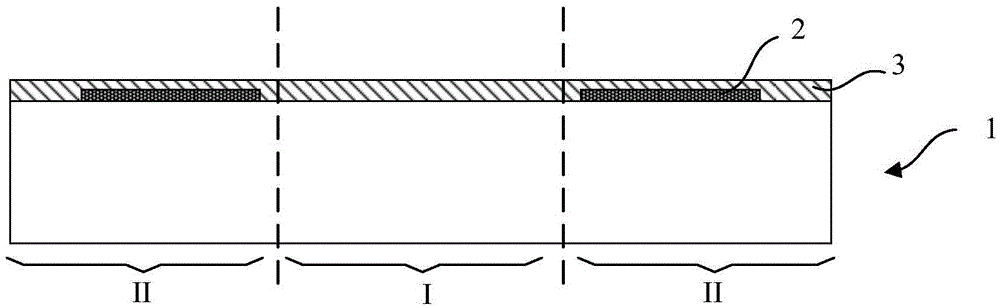

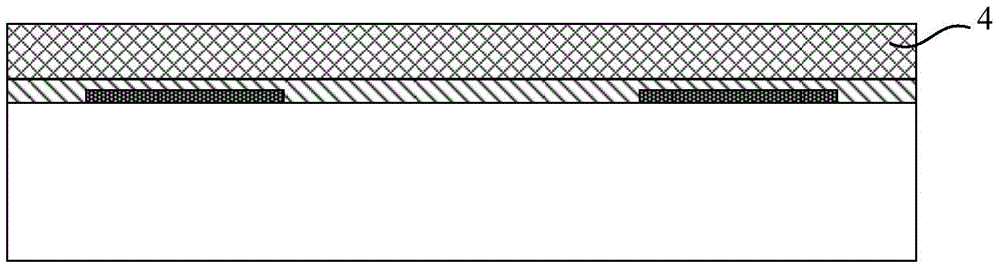

Manufacturing method of MEMS device

ActiveCN104944361AFunctional impactReduce functionDecorative surface effectsChemical vapor deposition coatingElectrical conductorPlastic materials

The invention provides a manufacturing method of an MEMS device. The manufacturing method at least comprises the following steps: S1, providing a semiconductor substrate, wherein an MEMS region for the post-production of an MEMS sensitive structure is divided in advance on the surface of the semiconductor substrate; S2, forming a first SiGe layer on the semiconductor substrate; S3, forming a plurality of grooves in the surface of the first SiGe layer positioned on a non-MEMS region, and filling the grooves with a plastic material so as to form a plastic filling block; S4, removing residual plastic materials outside the grooves, and then forming a second SiGe layer covering the plastic filling block on the surface of the first SiGe layer; and S5, manufacturing the MEMS sensitive structure by taking the first SiGe layer and the second SiGe layer, which are positioned on the MEMS region, as structural materials. According to the manufacturing method provided by the invention, the plastic filling block is added into the SiGe layers, and the stress in the plastic filling block is absorbed by utilizing the plastic deformation capacity of the plastic filling block, so that the stripping phenomenon of the SiGe layer is prevented effectively; furthermore, the plastic filling block is positioned in the non-MEMS region, and the functions of the device cannot be affected.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

An evaporation device

ActiveCN107805782BEasy to replaceHeating evenlyVacuum evaporation coatingSolid-state devicesThermodynamicsCrucible

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Continuous casting crystallizer covering slag for high-carbon steel

The invention relates to a continuous casting crystallizer covering slag for high-carbon steel. The continuous casting crystallizer covering slag comprises the following components in percentages by weight: 22.90-37.0% of SiO2, 22.5-27.0% of CaO, 4.35-5.0% of MgO, 1.8-6.0% of Al2O3, 2.2-3.0% of Fe2O3, 9.0-12.0% of Na2O, 5.2-6.0% of F, 6.5-9.0% of C, not more than 2.0% of K2O, not more than 1.9% of Li2O, and the balance of water and impurities. According to the continuous casting crystallizer covering slag for high-carbon steel disclosed by the invention, the using amounts of Na2O and CaF2 are properly reduced, K2O and Li2O fluxing is added, and the slag not only has proper physicochemical performance but also has good glass property and lubricating property, so that the quality and yield of casting blanks are greatly improved, and the covering slag has high economic benefit and social benefit.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Regulation method and device for double-roll thin-strip continuous casting machine fixing roll

The invention discloses a regulation method and device for a double-roll thin-strip continuous casting machine fixing roll. The regulation method comprises the following steps of: a) a hydraulic cylinder is arranged corresponding to a casting roll continuous casting machine rack on a fixed side, the head part of the hydraulic cylinder is connected with a casting roll bearing pedestal, tensioning mechanisms are respectively arranged above and below the hydraulic cylinder, each tensioning mechanism comprises a draw bar, a spring, a gland and regulation nuts, a stop dog is arranged below the other side of the bearing pedestal, a pressure sensor is arranged between the stop dog and the bearing pedestal, and a cast rolling force sensor is arranged on the front end of the hydraulic cylinder; b) before the casting operation, the hydraulic cylinder on the fixed side pushes the casting roll bearing pedestal to press the stop dog; c) the pressure of the draw bars and the springs is regulated by the regulation nuts, the bearing pedestal, the cast rolling force sensor and the hydraulic cylinder are pressed together until the numerical value of the pressure sensor between the stop dog and the bearing pedestal is zero, and the pressure numerical value detected by the cast rolling force sensor is more than the sum of pressuring pressure FN and the maximum friction force f of the bearing pedestal on a guide rail; and after a casting center line is calibrated, the casting state is waited to start. According to the regulation method and device for the double-roll thin-strip continuous casting machine fixing roll, which are disclosed by the invention, the casting center line positioning precision is guaranteed, the cast rolling force detection degree is improved, and stable casting is realized.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for stabilizing threshold voltage of word line of flash memory cell

ActiveCN104538364BThreshold Voltage StabilityAffect thicknessSolid-state devicesSemiconductor devicesSilicon chipPhotoresist

The invention provides a method for stabilizing the threshold voltage of the word line of a flash memory cell, comprising: arranging photoresist on a silicon chip, and removing the photoresist on the active area of the silicon chip, leaving the photoresist; the first implantation process is performed on the flash memory cell formation area of the active region of the silicon wafer, wherein the implantation conditions of the first implantation process are selected so that the desired floating gate lower threshold is formed in the final flash memory cell; the silicon wafer Performing a flash memory cell formation process to form a flash memory cell on the flash memory cell formation area of the active area; performing a second implantation process on the active area of the silicon wafer so as to form a doped silicon wafer area corresponding to the word line on both sides of the flash memory cell , wherein the implantation conditions of the second implantation process are selected such that a desired word line lower threshold is formed in the final flash memory cell. Wherein, no ion implantation is performed on the formation region of the flash memory unit during the formation process of the flash memory unit.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

A kind of manufacturing method of mems device

ActiveCN104944361BFunctional impactReduce functionDecorative surface effectsChemical vapor deposition coatingElectrical conductorPlastic materials

The invention provides a manufacturing method of an MEMS device. The manufacturing method at least comprises the following steps: S1, providing a semiconductor substrate, wherein an MEMS region for the post-production of an MEMS sensitive structure is divided in advance on the surface of the semiconductor substrate; S2, forming a first SiGe layer on the semiconductor substrate; S3, forming a plurality of grooves in the surface of the first SiGe layer positioned on a non-MEMS region, and filling the grooves with a plastic material so as to form a plastic filling block; S4, removing residual plastic materials outside the grooves, and then forming a second SiGe layer covering the plastic filling block on the surface of the first SiGe layer; and S5, manufacturing the MEMS sensitive structure by taking the first SiGe layer and the second SiGe layer, which are positioned on the MEMS region, as structural materials. According to the manufacturing method provided by the invention, the plastic filling block is added into the SiGe layers, and the stress in the plastic filling block is absorbed by utilizing the plastic deformation capacity of the plastic filling block, so that the stripping phenomenon of the SiGe layer is prevented effectively; furthermore, the plastic filling block is positioned in the non-MEMS region, and the functions of the device cannot be affected.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

Display module and display device

PendingCN113972519AInhibit sheddingSolve archingCoupling device detailsTwo-part coupling devicesComputer hardwareFlexible circuits

The invention belongs to the technical field of display equipment, and discloses a display module and a display device. The display module comprises a main flexible circuit board, a touch flexible circuit board and a connector used for enabling the touch flexible circuit board to be connected with the main flexible circuit board; the connector comprises a socket arranged on the main flexible circuit board, and the plugging end of the socket is provided with a connection terminal set and first limiting mechanisms located on the two sides of the connection terminal set; and the insertion end of the touch flexible circuit board comprises a golden finger and second limiting mechanisms located on the two sides of the golden finger. When the insertion end of the touch flexible circuit board is connected with the plugging end of the socket in an inserted mode, the first limiting mechanisms and the second limiting mechanisms can be clamped in a matched mode, so that the length of the portion, inserted into the socket, of the insertion end of the touch flexible circuit board can be adjusted through cooperation of the first limiting mechanisms and the second limiting mechanisms. According to the display module, the problem that the touch flexible circuit board falls off from the socket of the connector can be avoided, and the problem that a neck hunches up after the touch flexible circuit board is plugged into the main flexible circuit board can be effectively solved.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com