Continuous casting crystallizer covering slag for high-carbon steel

A continuous casting crystallizer and high-carbon steel technology, which is applied in the field of steelmaking-continuous casting, can solve problems such as easy deterioration billet shell and crystallizer lubrication, low melting temperature and viscosity, billet shell bonding breakout, etc., to reduce Cracks, good glassiness and lubricity, effect of ensuring slag loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The mass percentage of the chemical composition of the produced U71Mn steel is: C 0.72%, Si 0.30%, Mn 1.14%, P 0.013%, S 0.013%, the rest is Fe and unavoidable residual impurities. The casting section size is 280mm×380mm high carbon steel billet, and the casting speed is controlled at 0.60-0.75m / min.

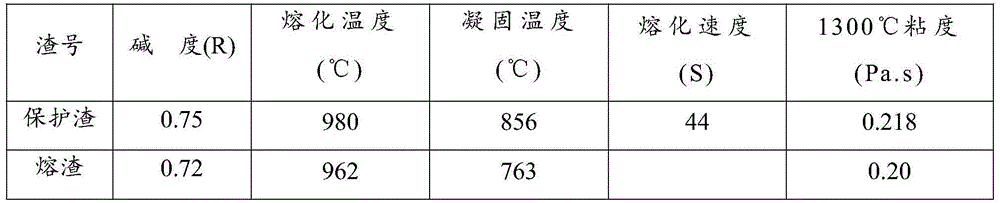

[0022] The mass percentage of the constituents of the mold flux for continuous casting mold for high carbon steel in this embodiment is: SiO 2 35.5%, CaO 26.6%, MgO 4.35%, A1 2 o 3 4.981%, Fe 2 o 3 2.28%, Na 2 O 10.8%, F 5.2%, C 6.8%, K 2 O 1.45%, Li 2 O 0.85%, the rest is water and unavoidable impurities. The melting temperature (hemispherical point) of the mold flux is 980°C, the solidification temperature is 856°C, the viscosity is 0.218 Pa.S at 1300°C, and the basicity R is 0.75. During the production, the mold powder and its molten slag were sampled and tested. The entire casting process is stable, no bonding breakout occurs, the billet quality is good, a...

Embodiment 2

[0026] The mass percentage of the chemical composition of the produced U75V steel is: C 0.74%, Si 0.76%, Mn 0.82%, P 0.013%, S 0.027%, and the rest is Fe and unavoidable residual impurities. The casting section size is 280mm×380mm high carbon steel billet, and the casting speed is controlled at 0.6-0.75m / min.

[0027]The mass percentage of the constituents of the mold flux for continuous casting mold for high carbon steel in this embodiment is: SiO 2 36.3%, CaO 25.9%, MgO 4.56%, A1 2 o 3 5.02%, Fe 2 o 3 2.45%, Na 2 O 10.75%, F 5.8%, C 6.88%, K 2 O 1.56%, Li 2 O 0.645%, the rest is water and unavoidable impurities. The melting temperature (hemispherical point) of the mold flux is 976°C, the solidification temperature is 860°C, the viscosity is 0.24 Pa.S at 1300°C, and the basicity R is 0.71. The entire casting process is stable, no bonding breakout occurs, the quality of the slab is good, and there are no surface longitudinal cracks and sunken defects.

Embodiment 3

[0029] The mass percentage of the chemical composition of the produced U75VG steel is: C 0.72%, Si 0.65%, Mn 0.85%, P 0.014%, S 0.013%, and the rest is Fe and unavoidable residual impurities. The casting section size is 280mm×380mm high carbon steel billet, and the casting speed is controlled at 0.6-0.7m / min.

[0030] The mass percentage of the constituents of the mold flux for continuous casting mold for high carbon steel in this embodiment is: SiO 2 36.1%, CaO 26.1%, MgO 4.86%, A1 2 o 3 4.98%, Fe 2 o 3 2.53%, Na 2 O 10.85%, F 5.35%, C 6.5%, K 2 O 1.61%, Li 2 O 0.72%, the rest is water and unavoidable impurities. The melting temperature (hemispherical point) of the mold flux is 978°C, the solidification temperature is 862°C, the viscosity is 0.23 Pa.S at 1300°C, and the basicity R is 0.72. The entire casting process is stable, no bonding breakout occurs, the quality of the slab is good, and there are no surface longitudinal cracks and sunken defects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com