Patents

Literature

48results about How to "Good glass performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel casting powder and application thereof

The invention belongs to the technical field of casting powder for continuous casting of iron and steel and relates to novel casting powder and application thereof. The casting powder is made of, by weight, 25-45% of CaO, 15-35% of Al2O3, 27-18% of SiO, 2-5% of MgO, 4-11% of Na2O4, 2-7% of Li2O, 5-12% of F, 3-15% of BaO, 1-3% of MnO and 1-7% of C. The novel casting powder has the advantages of low melting point, low viscosity, moderate crystallizing rate and the like and is especially applicable to continuous casting of high-aluminum steel with C mass percentages being 0.14-0.20%, Al mass percentages being 1.5-2.5% and Mn mass percentages being 21.5-25.0%. The novel casting powder applicable to continuous casting production of high-aluminum steel plates can effectively reduce metal slag reactivity so as to slow down performance deterioration of the casting powder due to metal slag reaction, metal slag interface tension is improved to prevent slag entrapment, excellent lubrication and heat transfer performances of the casting powder are guaranteed, slow cooling of crescent faces is realized, and high-aluminum steel slabs excellent in surface quality can be made by casting.

Owner:CENT SOUTH UNIV

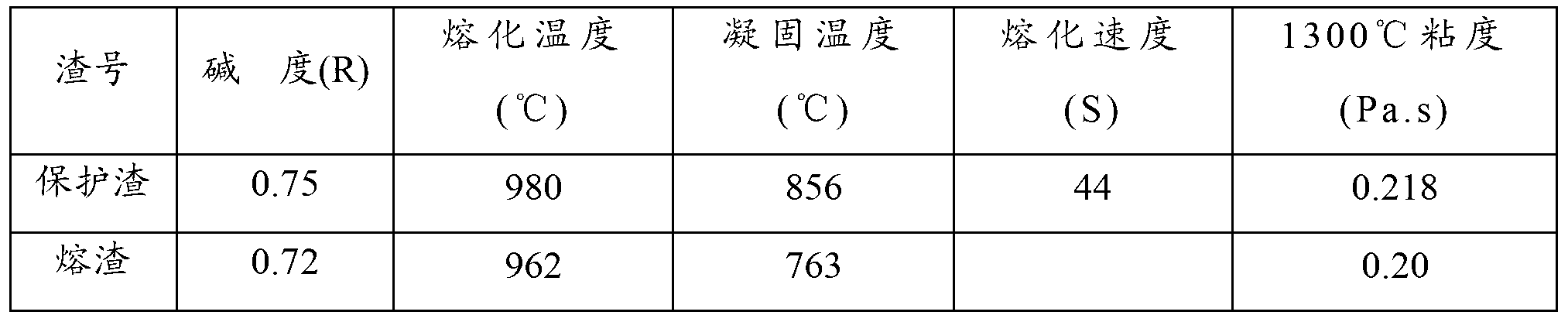

Continuous casting crystallizer covering slag for high-carbon steel

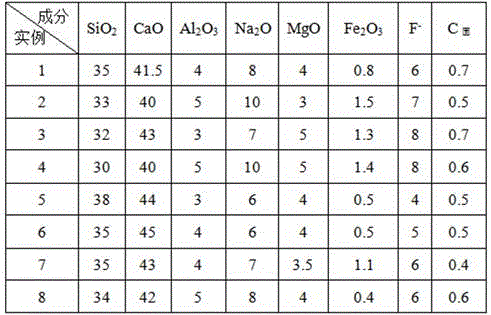

The invention relates to a continuous casting crystallizer covering slag for high-carbon steel. The continuous casting crystallizer covering slag comprises the following components in percentages by weight: 22.90-37.0% of SiO2, 22.5-27.0% of CaO, 4.35-5.0% of MgO, 1.8-6.0% of Al2O3, 2.2-3.0% of Fe2O3, 9.0-12.0% of Na2O, 5.2-6.0% of F, 6.5-9.0% of C, not more than 2.0% of K2O, not more than 1.9% of Li2O, and the balance of water and impurities. According to the continuous casting crystallizer covering slag for high-carbon steel disclosed by the invention, the using amounts of Na2O and CaF2 are properly reduced, K2O and Li2O fluxing is added, and the slag not only has proper physicochemical performance but also has good glass property and lubricating property, so that the quality and yield of casting blanks are greatly improved, and the covering slag has high economic benefit and social benefit.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

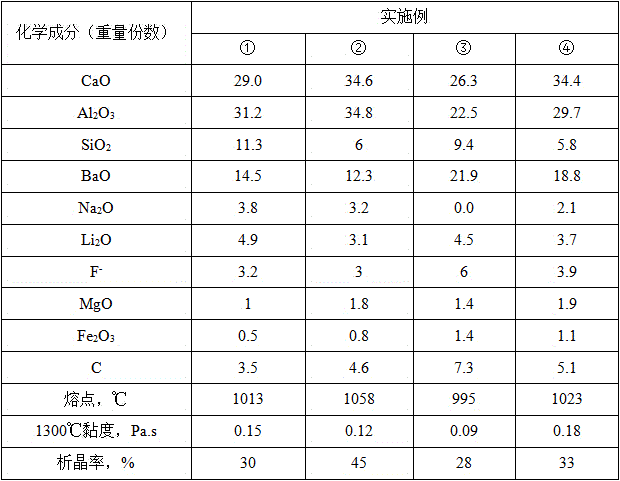

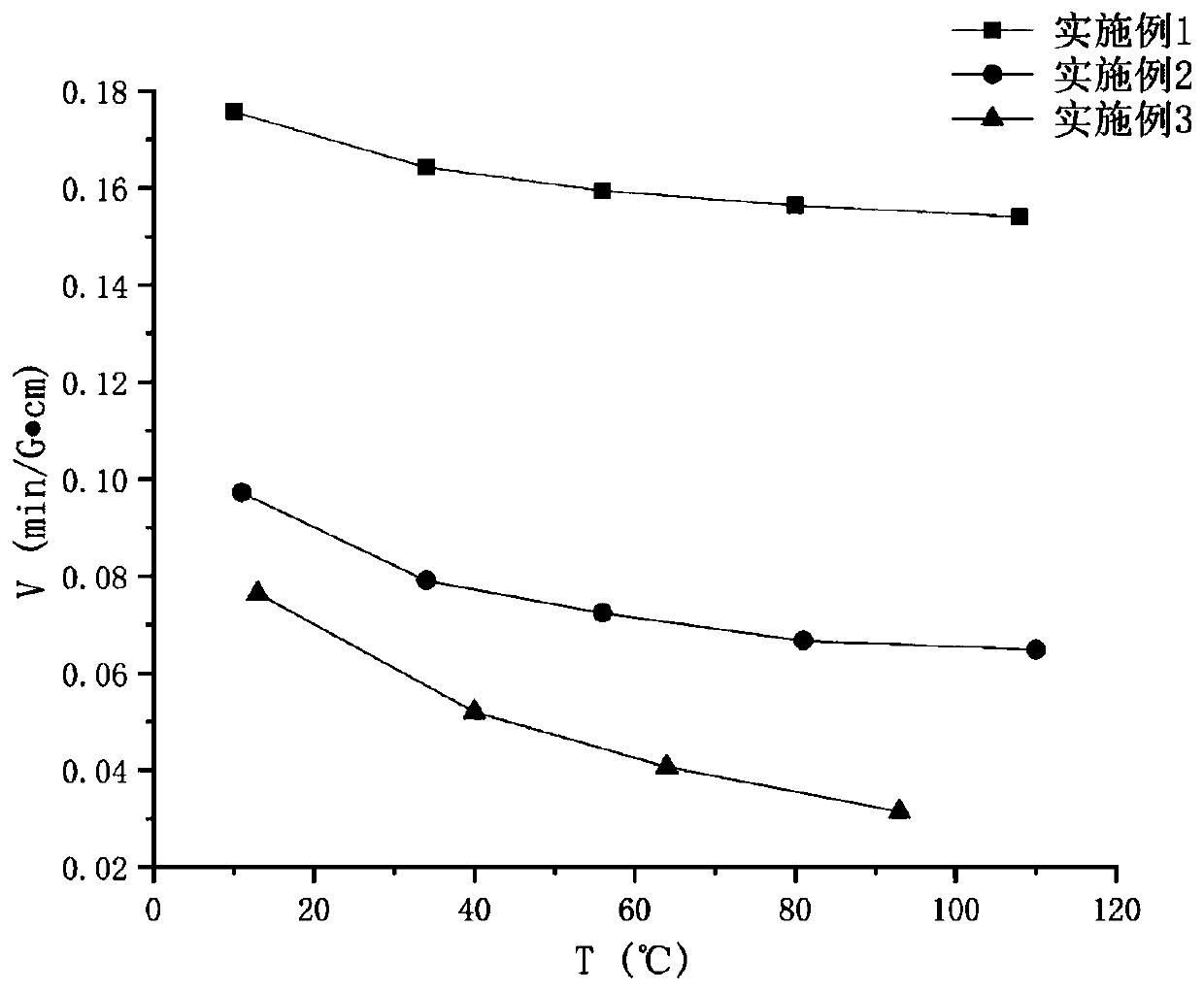

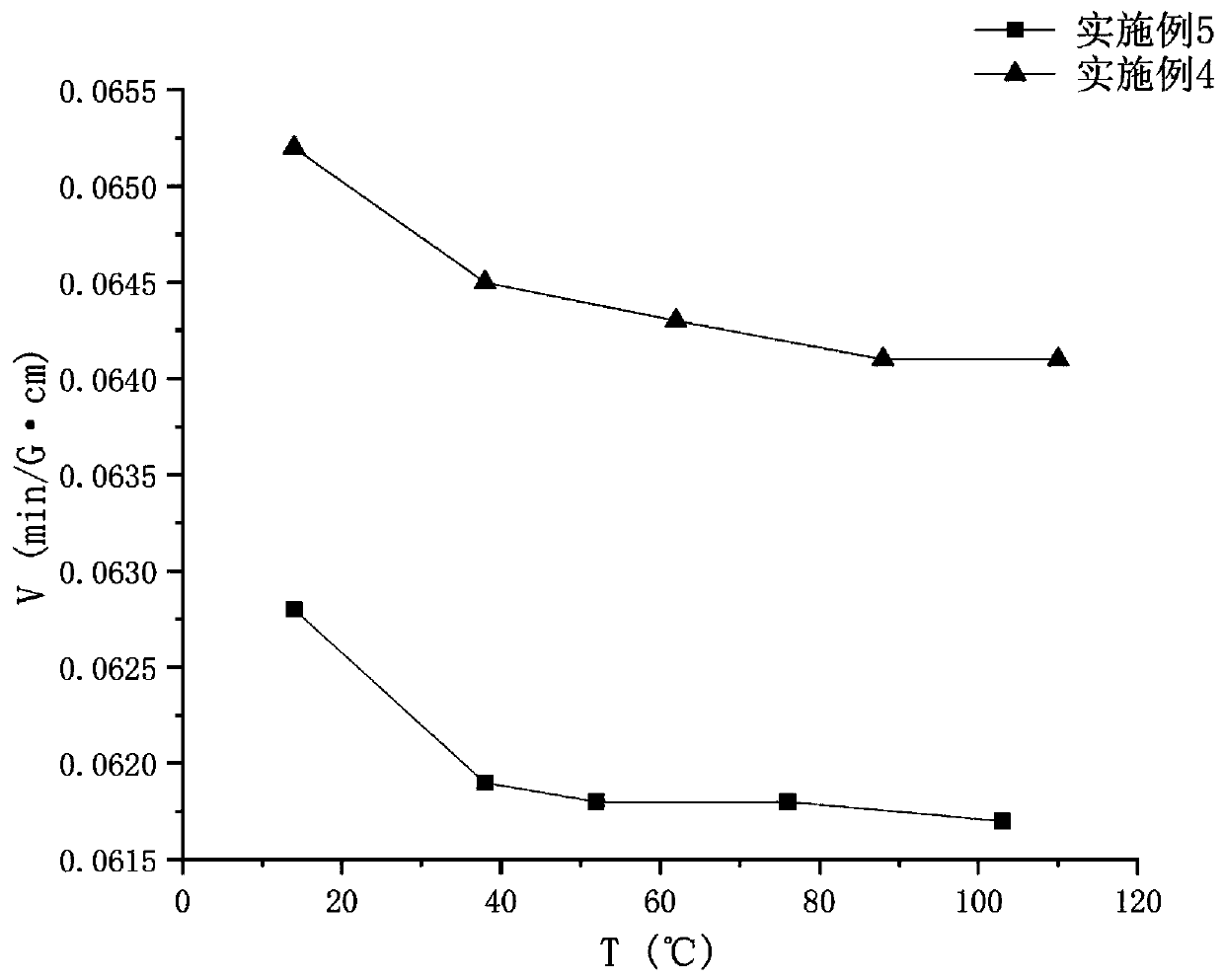

Crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of crystallizer covering slag

The invention provides a crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of the crystallizer covering slag. The covering slag is prepared from the following components in parts by weight: 20-38 parts of CaO, 20-35 parts of Al2O3, 5-18 parts of SiO2, 10-22 parts of BaO, 2-7 parts of Li2O, 5-12 parts of F<->, 1-4 parts of MgO, 2-8 parts of C and Fe2O3 which is less than or equal to 2 parts. According to the preparation method disclosed by the invention, wollastonite, limestone, quartz sand, fluorite, bauxite, barium carbonate, magnesia, soda, lithium carbonate and carbonaceous materials are used as raw materials, and the covering slag is prepared through the following steps of: calculating of consumption, melting, smashing, fine grinding, drying and granulation. The covering slag disclosed by the invention has the characteristics of being low in reactivity and good in property stability, the lubrication and the thermal transmission of casting blanks can be effectively coordinated and controlled, the smooth performing of the continuous casting process of the high-manganese high-aluminum steel can be guaranteed, high-manganese high-aluminum steel continuous casting blanks with excellent surface quality are cast, and multi-heat continuous casting can be realized.

Owner:CHONGQING UNIV

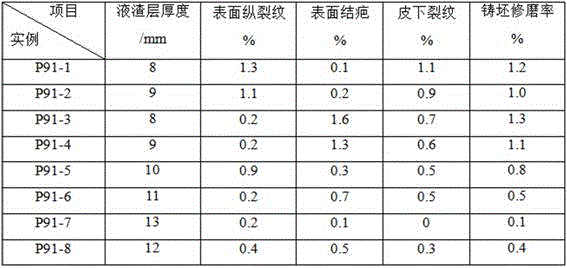

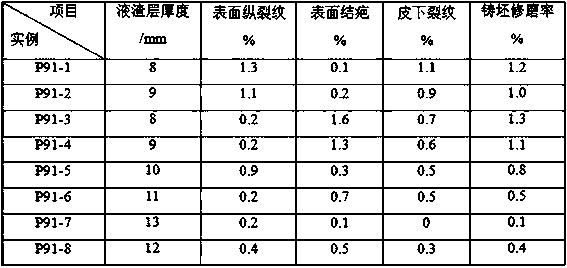

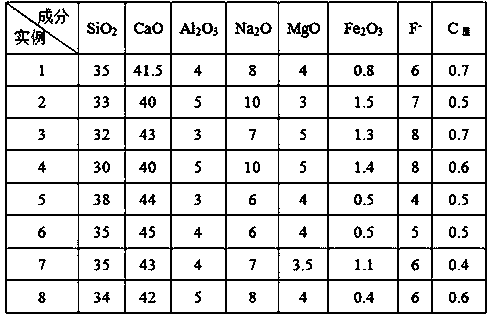

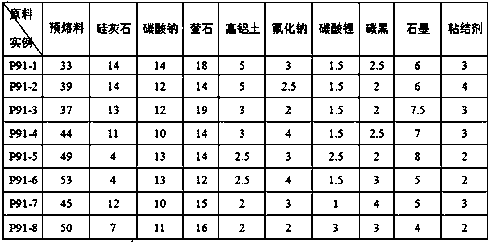

Continuous casting crystallizer casting powder for P91 steam pipeline steel and preparation method of continuous casting crystallizer casting powder

The invention belongs to the technical field of metallurgy materials, and particularly relates to continuous casting crystallizer casting powder for P91 steam pipeline steel and a preparation method of the continuous casting crystallizer casting powder. The casting powder is prepared from, by weight percent, 26.0%-35.0% of SiO2, 27.0%-37.0% of CaO, 0.4%-1.2% of Li2O, not larger than 6.0% of Al2O3, 7%-13% of Na2O, 4%-8% of F-, not larger than 4.0% of MgO, not larger than 1.0% of Fe2O3, 5%-9% of Csolid and 8%-12% of volatile components. The casting powder can achieve crystallizer lubricating during low-temperature casting, a slag film has sufficient crystallization to improve crystallizer heat transfer, P91 steel large round blank surface longitudinal cracks are reduced, and the casting blank quality is improved.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

Continuous casting crystallizer mold powder of sheet billet at high casting speed

InactiveCN103639384AStrong ability to adsorb impuritiesGood glass performanceAlkali metal oxideAlkaline earth oxides

The invention discloses continuous casting crystallizer mold powder of a sheet billet at a high casting speed. The mold powder comprises chemical components in percentage by weight as follows: 34%-44% of CaO, 2%-8% of Al2O3, 20%-30% of SiO2, 1%-9% of MgO, 5%-15% of F, smaller than or equal to 6.5% of Na2O, smaller than or equal to 5% of K2O, smaller than or equal to 6% of Li2O and the balance of carbon and uncontrollable impurities. Content of CaO in the mold powder is high, content of SiO2 in the mold powder is low, accordingly, the degree of purity of molten steel can be improved, simultaneously, MgO and CaO in the mold powder are alkaline earth metal oxides, Li2O, Na2O and K2O are alkali metal oxides, the melting temperature is low, the fluxing effect is achieved, the usage amount of a fluxing agent can be reduced, the probability of various crystal precipitation is reduced, so that the glass performance of the mold powder is improved, and the mold powder has a good lubrication effect at the high casting speed; accurate control on F content meets requirements of surface quality at the high casting speed, and lubrication is improved by means of an appropriate amount of Al2O3; and the mold powder can meet technological requirements of continuous casting of medium carbon steel such as SS400, Q345 and the like, moreover, the mold powder components have stable performance, and sequence casting can be realized.

Owner:HEBEI IRON AND STEEL

Casting powder for continuous casting crystallizer and preparation method of casting powder

The invention discloses casting powder for a continuous casting crystallizer. The casting powder comprises raw materials in parts by weight as follows: 3.5-15 parts of fluorite, 35-55 parts of aedelforsite, 5-15 parts of alkali, 0-2 parts of lithium carbonate, 0-10 parts of diaspore, 0-6 parts of a cement clinker, 1-5 parts of magnesia powder, 2-5 parts of pyrolusite, 0-8 parts of sodium fluoride, 0-5 parts of barium carbonate, 0-5 parts of bentonite, 1-4 parts of coke, 0-8 parts of a carburant, 1-3 parts of carbon black and 1-2 parts of a binder. According to the casting powder, the preparation cost is low; the recovery rate of the casting powder is larger than or equal to 98.5%; the color of the casting powder is uniform; the granularity is uniform; the granulation rate is high; dust is reduced; the melting point of the casting powder is low; the viscosity is low; after the casting powder is added into the crystallizer, the casting powder is melted uniformly and shows excellent spreadability, heat retaining property and adsorptive property; heat is transferred uniformly all around the crystallizer, and the lubrication is excellent; and defects such as concave pits, impurities and the like don't exist on the surface of a casting blank, the internal quality is excellent, and the qualified rate of the casting blank is equal to or larger than 99.8%.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

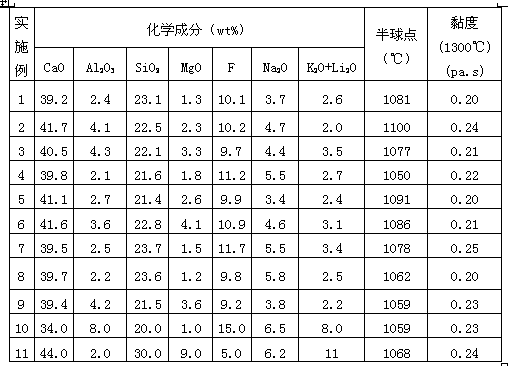

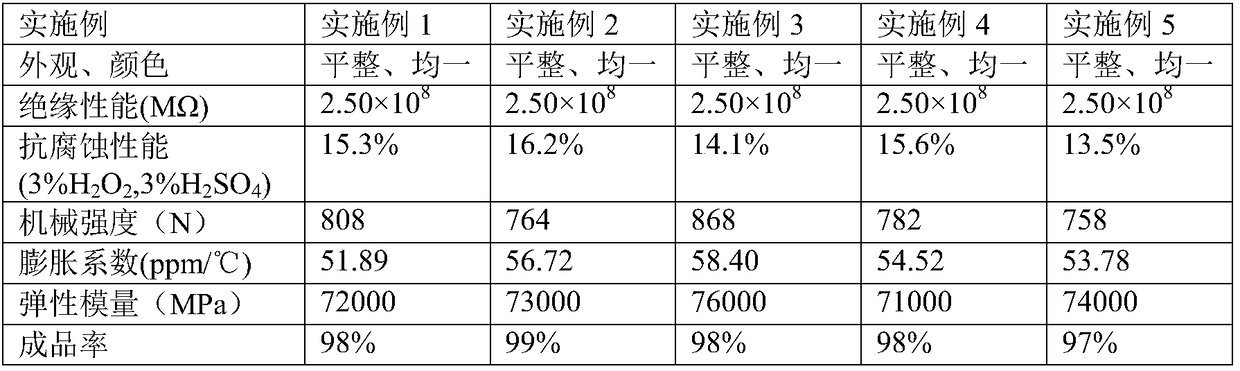

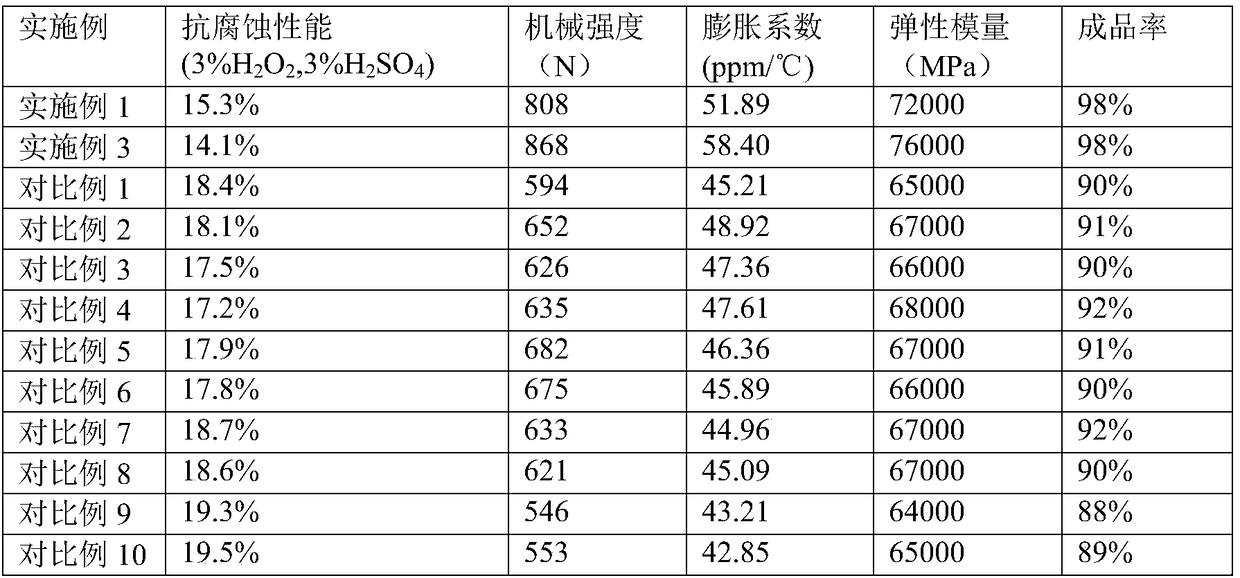

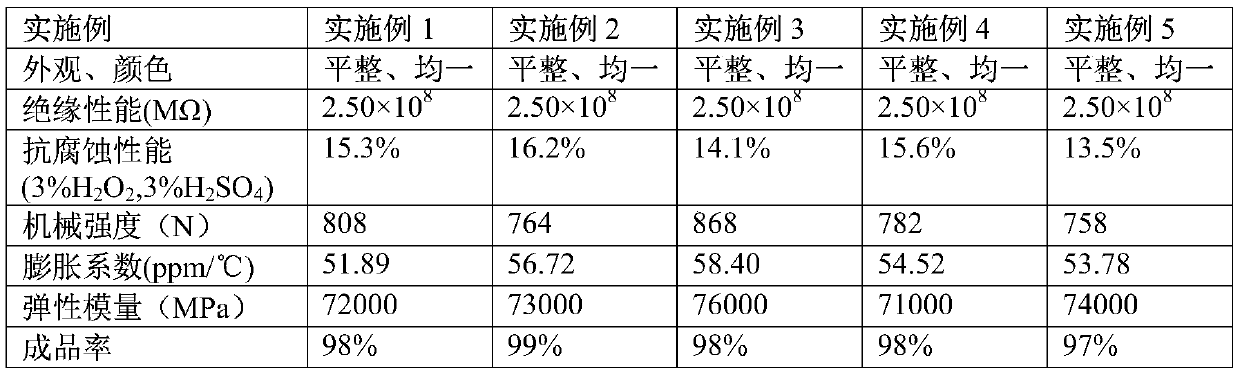

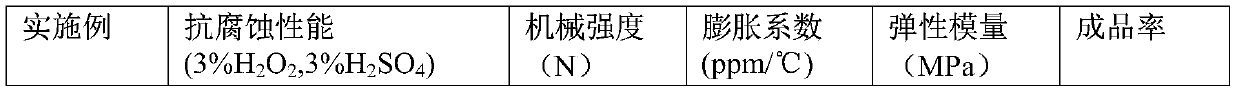

High strength glass fiber, and preparation method thereof

ActiveCN109180009AGuaranteed contentImprove protectionGlass fibre drawing apparatusGlass fiberPyrophyllite

The invention discloses a high strength glass fiber. The high strength glass fiber mainly comprises, by weight, silica sand, kaolin, calcite, fluorite, calciborite, mirabilite, and sodium carbonate. The invention provides a glass fiber raw material formula can be used for replacing pyrophyllite. Glass material preparation uniformity is increased obviously through reasonable control on the mass ratio of a plurality of raw materials, melting efficiency is increased, glass fiber finished product rate is increased, the prepared glass fiber is better in mechanical properties, and production cost isreduced. The invention also provides a preparation method of the glass fiber. No stirring is needed; glass liquid is mixed to be uniform by heat convection in a bath tank, and is used for preparationof glass fiber. The glass fiber prepared based on the formula and the preparation method is high in finished product rate, and excellent in corrosion resistance.

Owner:清远忠信世纪电子材料有限公司

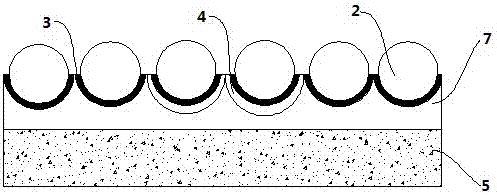

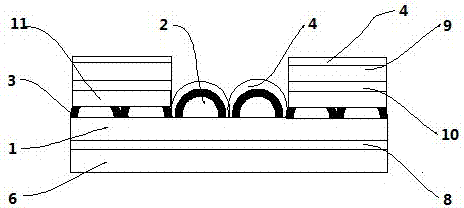

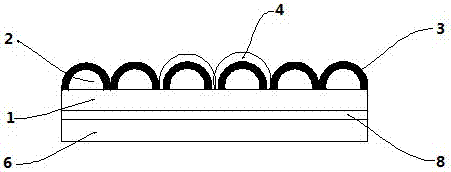

Production method of flame-retardant reflective warning tape

InactiveCN107100103AGood peeling effectSimple preparation processLamination ancillary operationsSynthetic resin layered productsChemistryAdhesive

The invention discloses a production method of a flame-retardant reflective warning tape. The method is characterized by comprising the following steps of 1, implantation of beads, wherein a PE layer I (1) in a PET-PE composite membrane I is heated and softened, then glass beads (2) are embedded in the PE layer I (1), the glass beads (2) are coated with an adhesive, and baking is carried out; 2, membrane covering at intervals, wherein PE layers II in a PET-PE composite membrane II after segmentation are heated and softened, and then the PE layers II are attached with equal distances to obtain spaced bead implantation membranes; 3, aluminizing, wherein the spaced bead implantation membranes in the second step are aluminized to obtain aluminized layers (4), and the PET-PE composite membrane II embedded in focusing layers (3) is peeled off; 4, recombination, wherein an adhesive layer of a pretreated base fabric and adhesive layers of pretreated spaced aluminized bead implantation membranes are recombined to form a flame-retardant adhesive layer (7), the PET-PE composite membrane I embedded on the surfaces of the glass beads (2) is peeled off, and the flame-retardant reflective warning tape is obtained. The production method of the flame-retardant reflective warning tape has the advantages of being simple in process, flat and smooth in touch and obvious in boundary.

Owner:CHENGDU ZHONGJIENENG REFLECTIVE MATERIALS

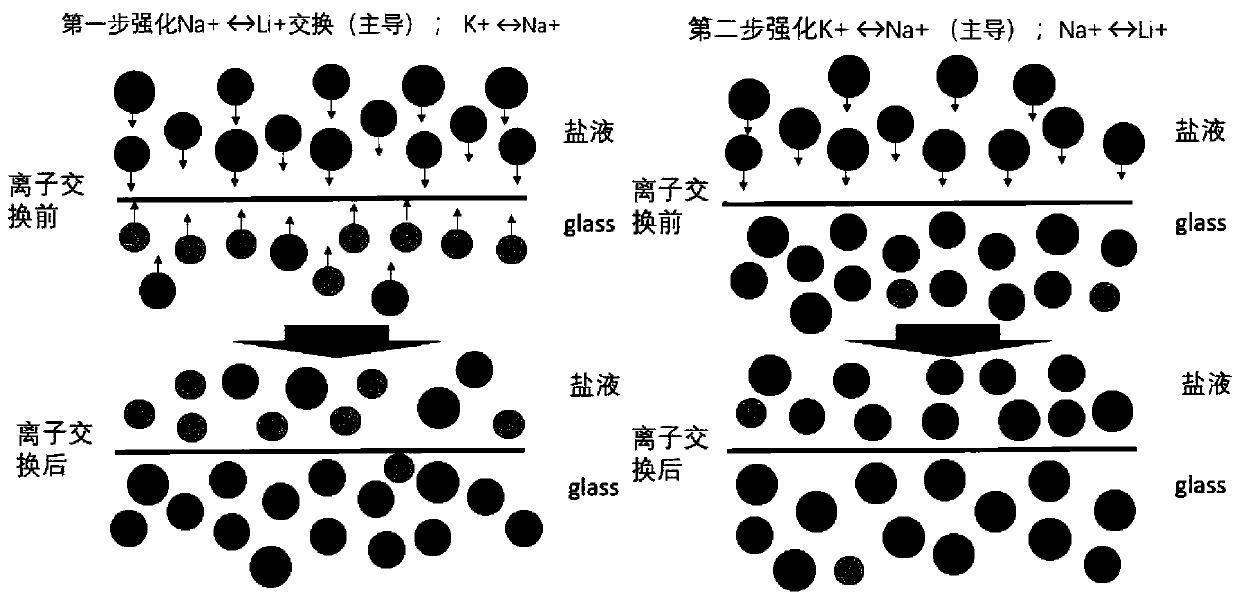

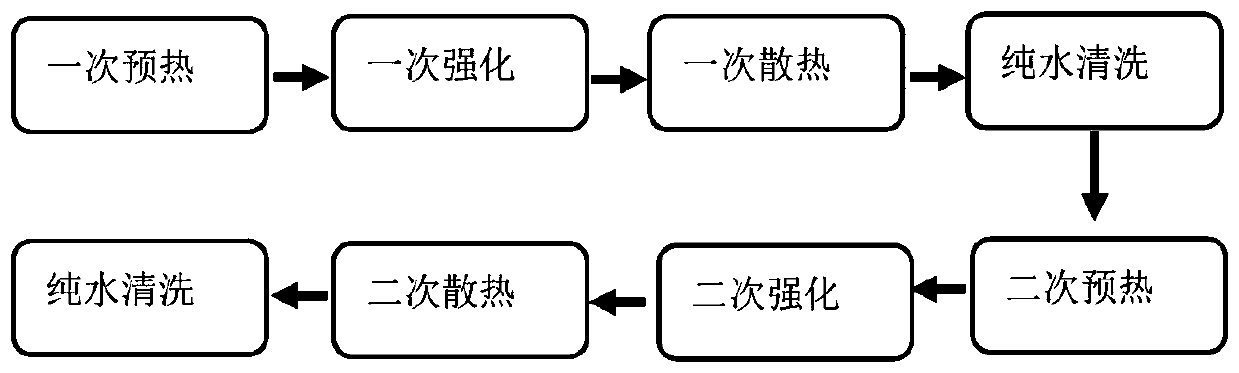

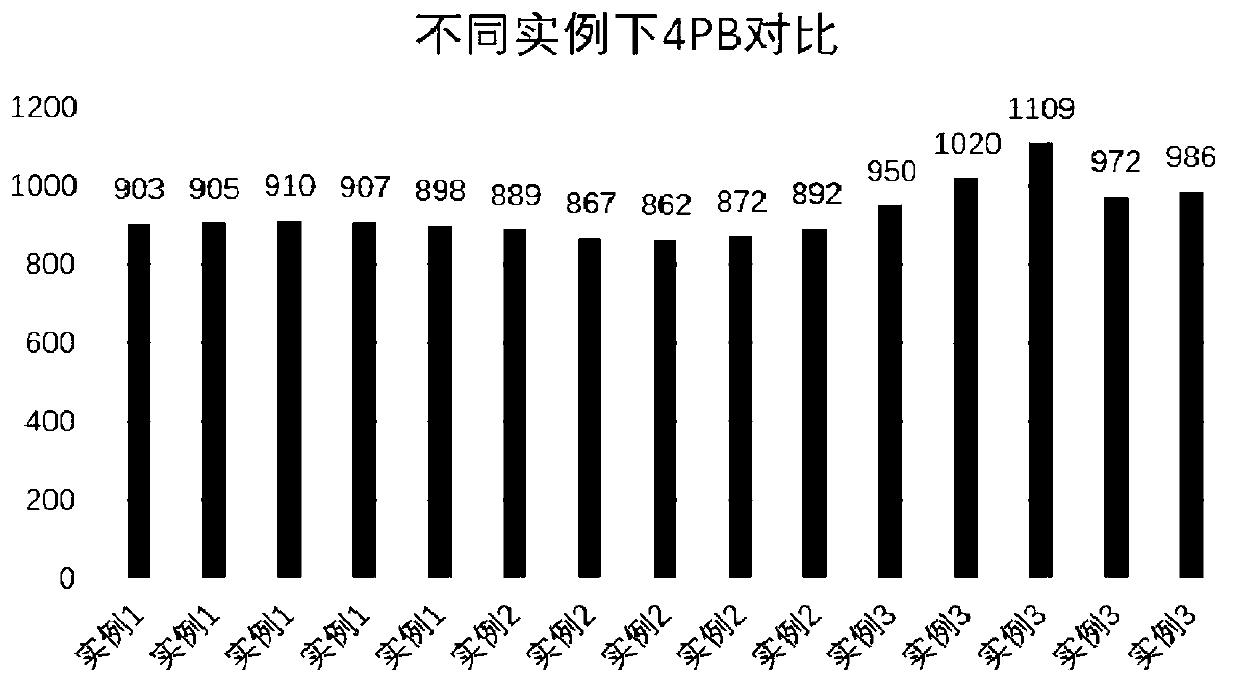

Method for chemically strengthening lithium-aluminum-silicon glass

ActiveCN111087178AIncrease concentrationShorten the strengthening timeCleaning using liquidsPotassium nitrateSalt solution

The invention discloses a method for chemically strengthening lithium-aluminum-silicon glass. The method comprises the following steps: 1) preheating the lithium-aluminum-silicon glass for the first time, and carrying out strengthening for the first time by adopting a mixed molten liquid of potassium nitrate and sodium nitrate as a strengthening salt solution, wherein the temperature of strengthening for the first time is 380-395 DEG C, and the time of strengthening for the first time is 4-6 hours; 2) performing heat dissipation on the glass subjected to strengthening treatment for the first time, and carrying out cleaning by adopting purified water; 3) preheating the glass obtained in the step (2) for the second time, and carrying out strengthening for the second time by adopting the mixed molten liquid of potassium nitrate and sodium nitrate as the strengthening salt liquid, wherein the temperature of strengthening for the second time is 395-410 DEG C, and the time of strengthening for the second time is 2-4 hours; and 4) performing heat dissipation on a product subjected to strengthening for the second time, and carrying out cleaning with the purified water so as to obtain strengthened lithium-aluminum-silicon glass. The method provided by the invention can improve CS and DOL of the product and better monitor the influence of a salt solution on strengthening performance, sothe product has good impact resistance and bending resistance.

Owner:XIANNING NANBO PHOTOELECTRIC GLASS CO LTD +1

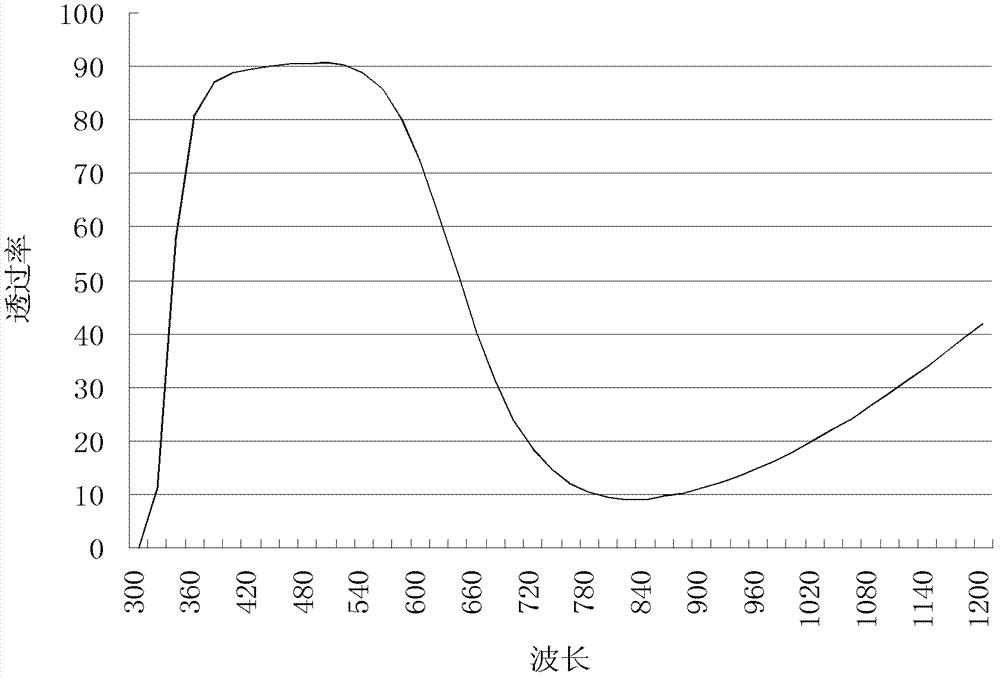

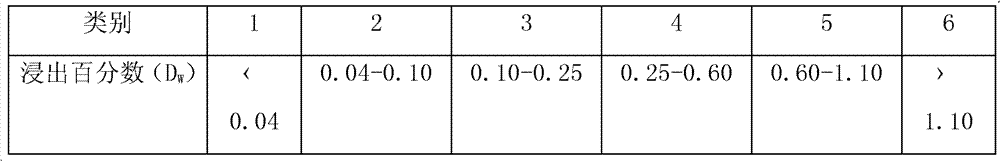

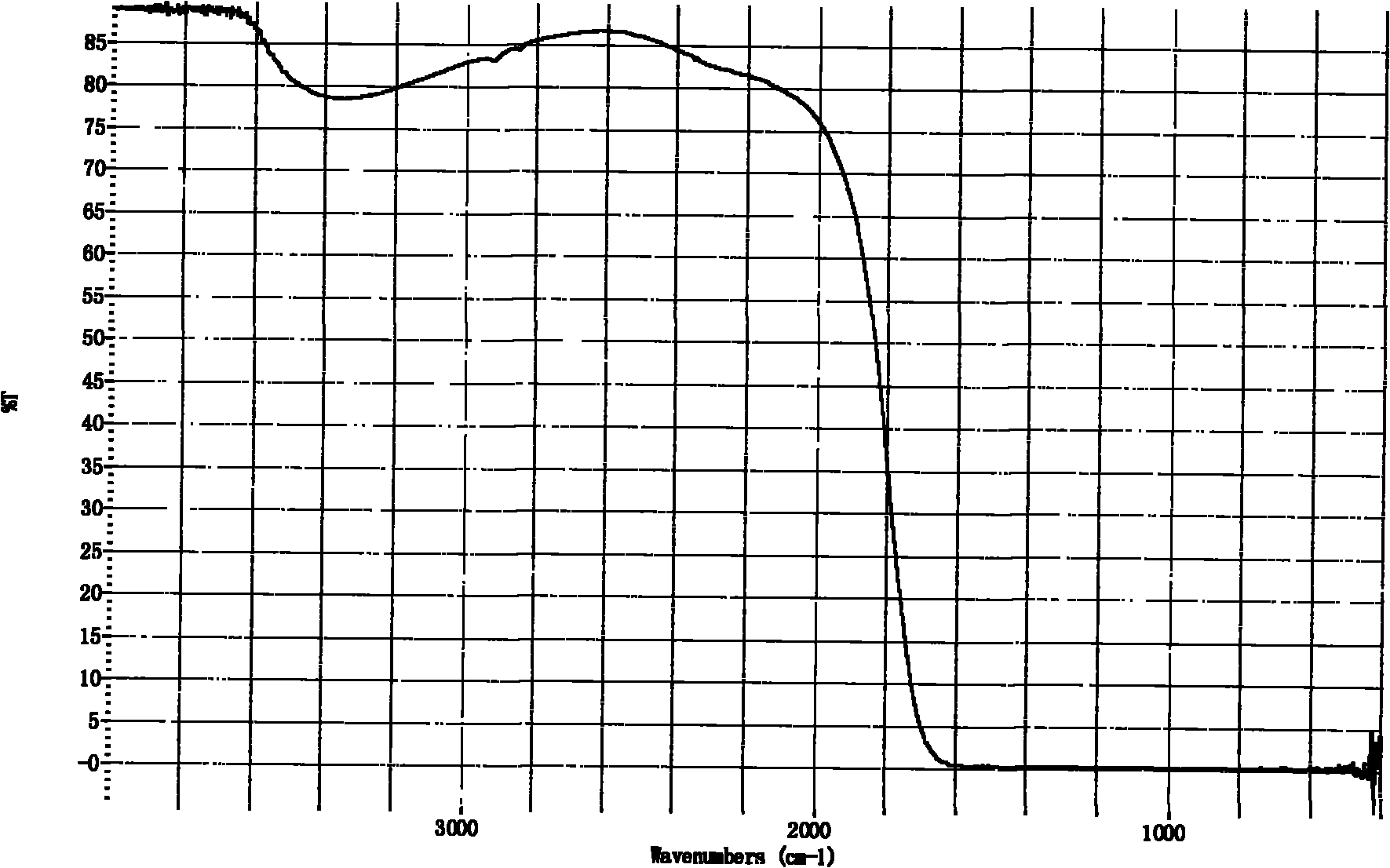

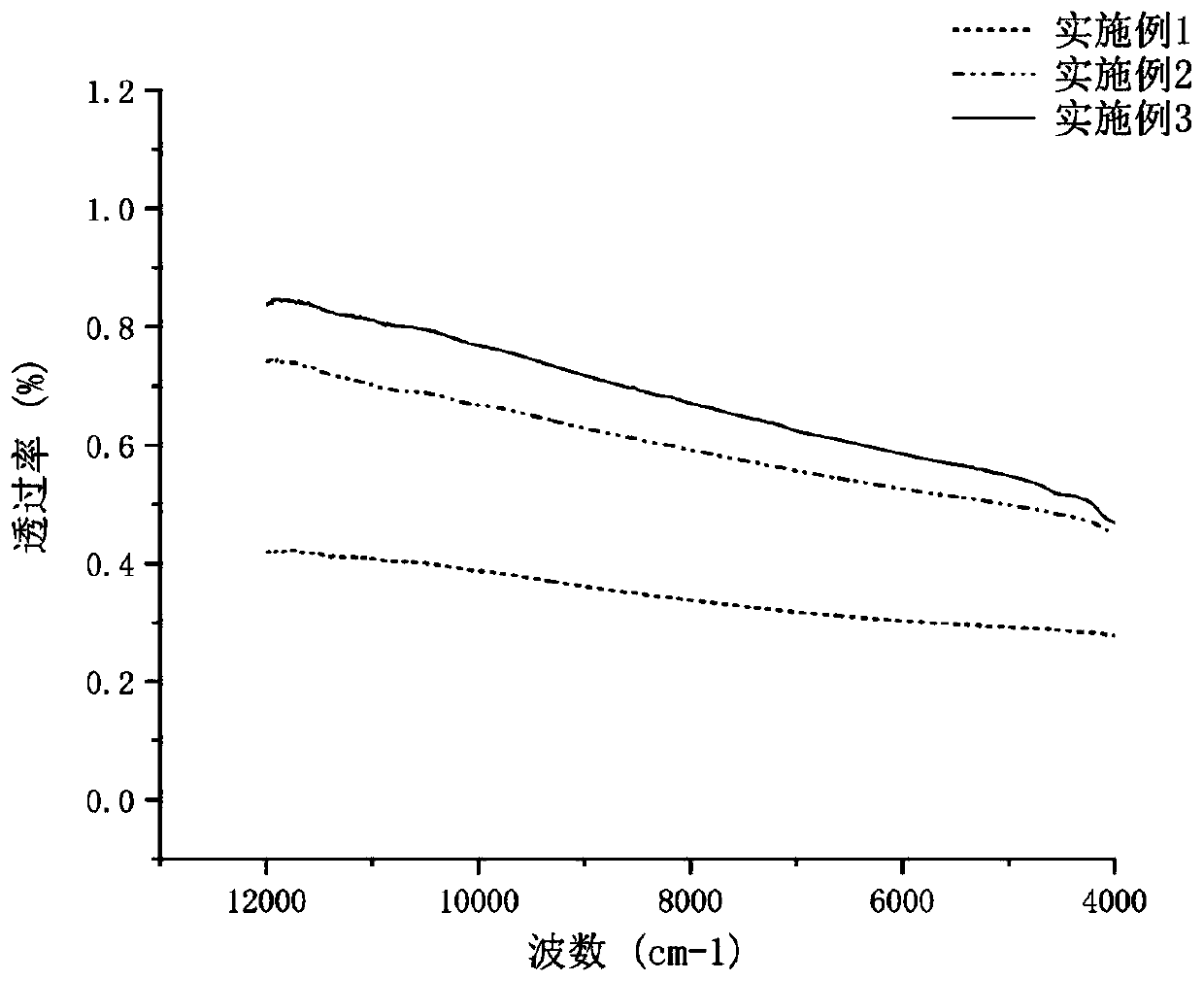

Near-infrared light absorbing glass, element and filter

ActiveCN103359937AGood glass performanceImprove transmittanceSpectral transmittanceChemical stability

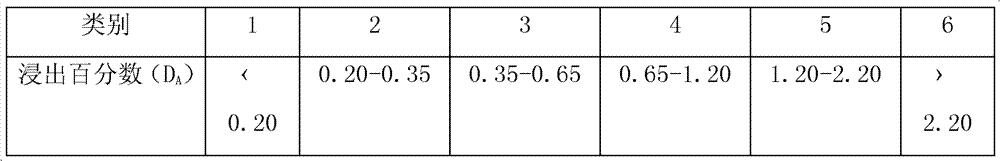

The invention provides an environment-friendly near-infrared light absorbing glass, element and filter with high chemical stability and excellent permeation characteristic in the visible range. When the thickness of the near-infrared light absorbing glass is 0.3 mm, the transmittance at the wavelength of 400 nm is greater than 83%, and the transmittance at the wavelength of 500 nm is greater than 85%; and in the spectral transmittance within the wavelength range of 500 nm to 700 nm, the wavelength range is 631-655 nm when the transmittance is 50%. The near-infrared light absorbing glass contains Al(PO3)3, AlF3, R'F2, ZnO and CuO, wherein the R'F2 represents the sum of MgF2, CaF2, SrF2 and BaF2. The water-resistant action stability DW of the glass reaches Grade 1, and the acid-resistant action stability DA reaches or is superior to Grade 4.

Owner:CDGM OPTICAL GLASS

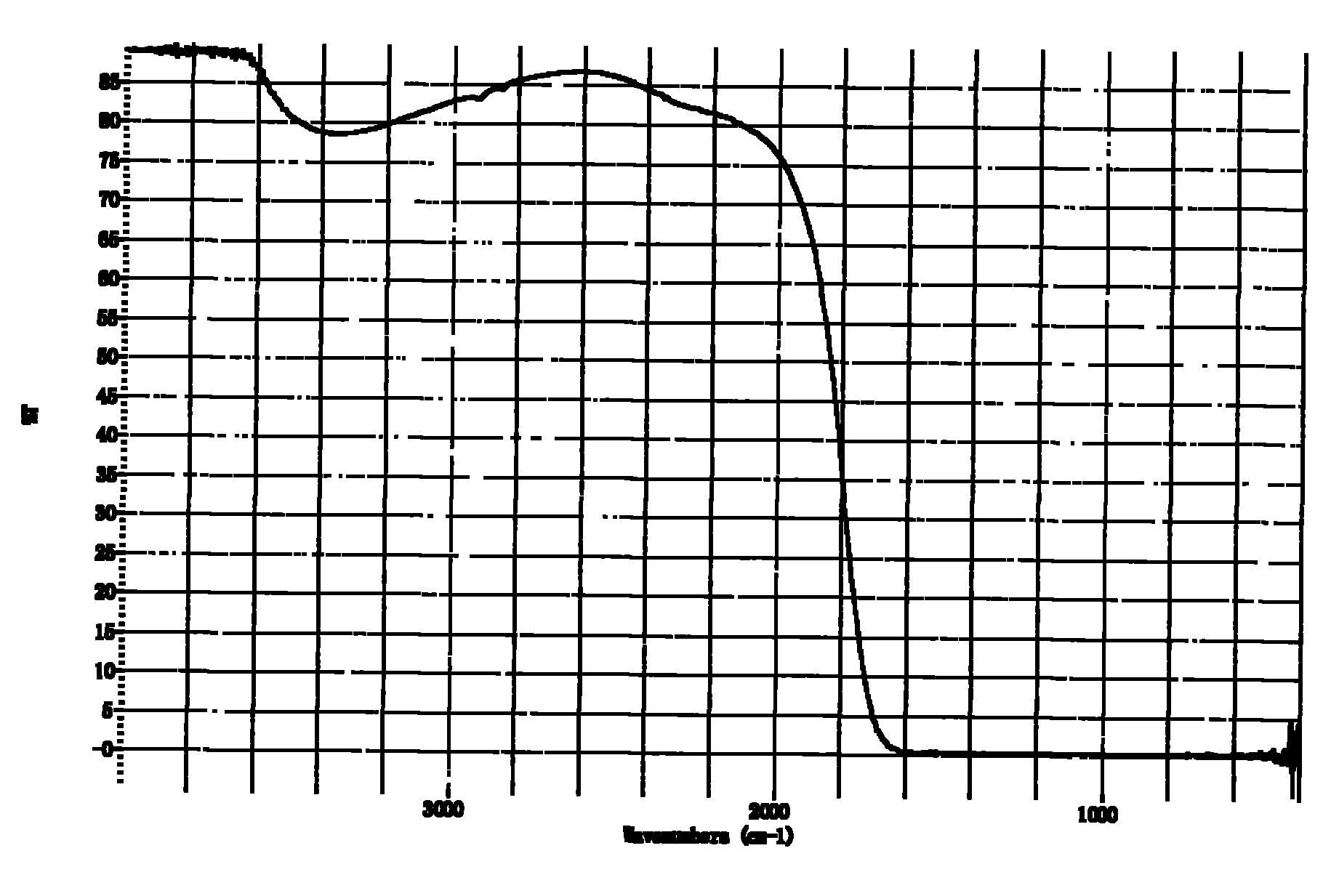

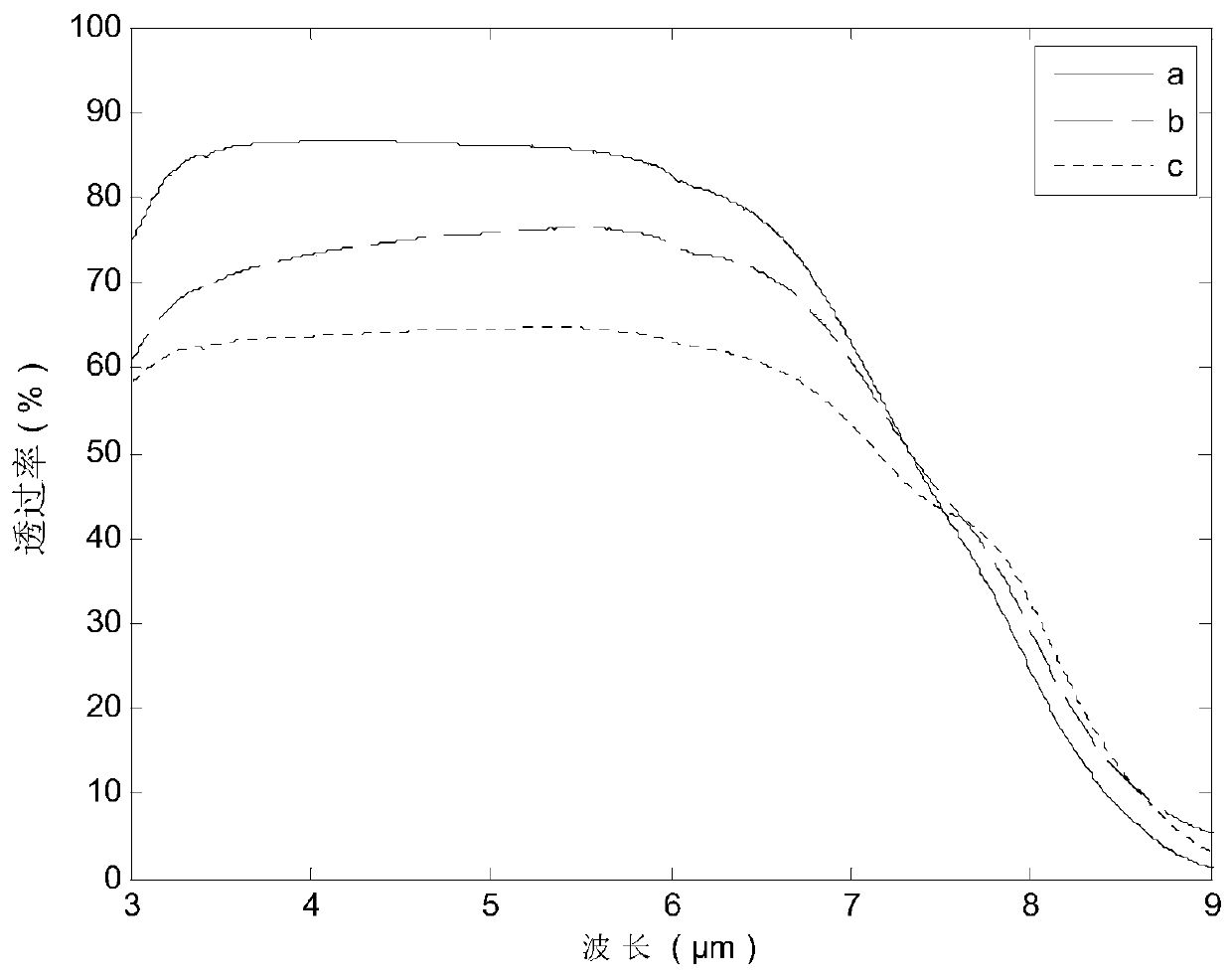

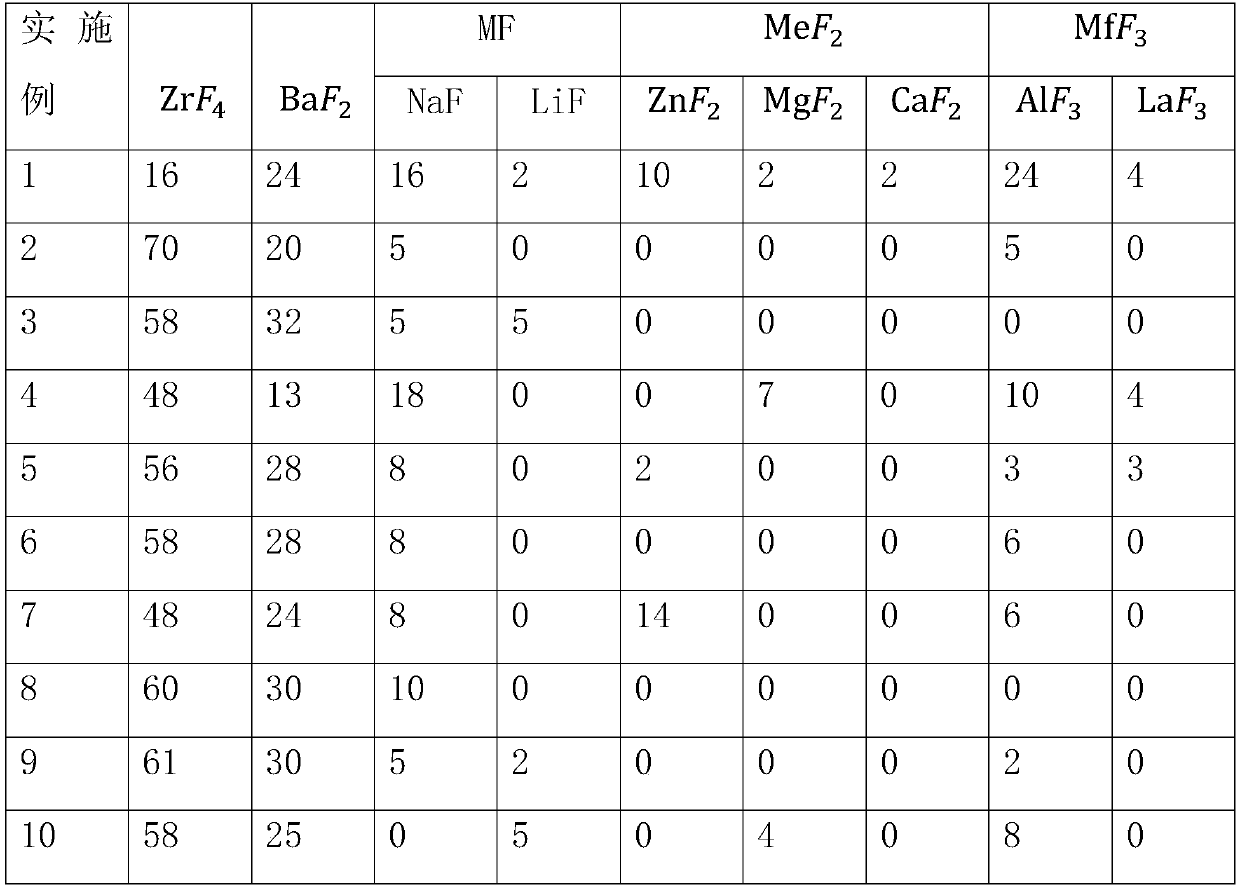

Fluoride glass and a preparing method thereof

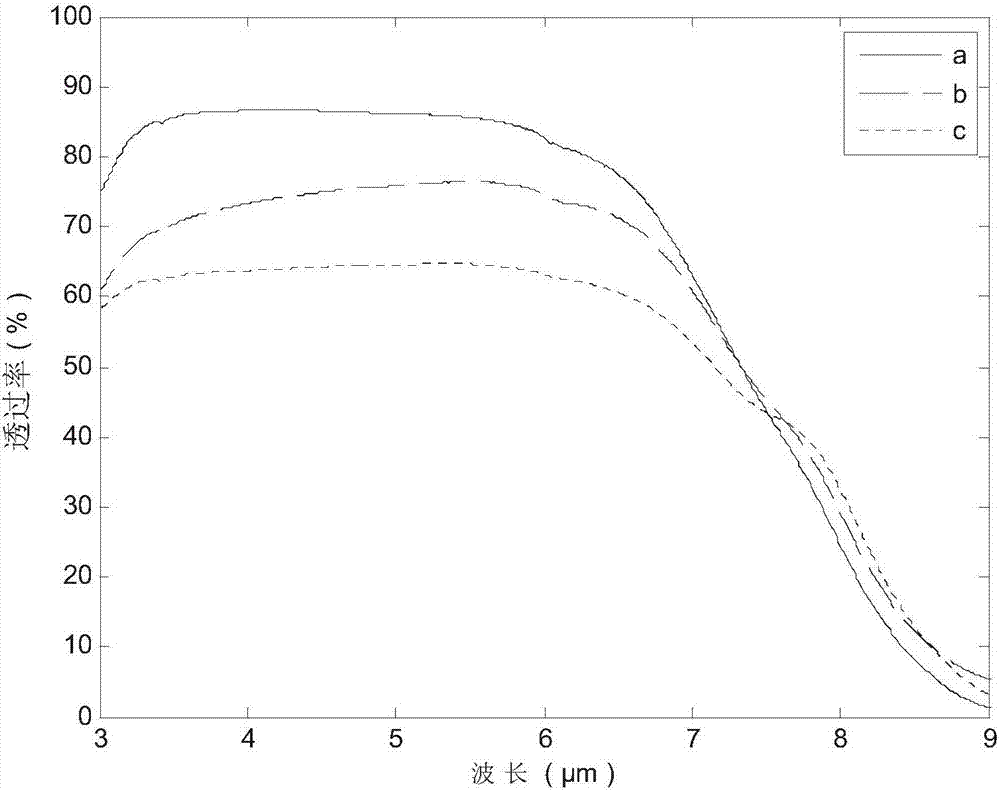

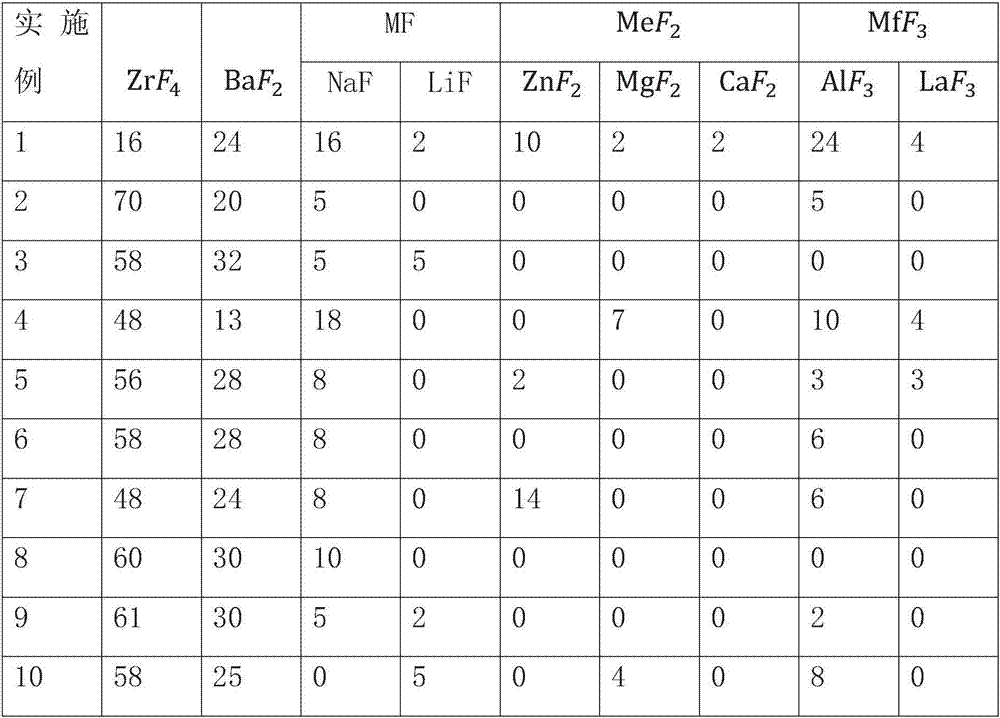

Fluoride glass and a preparing method thereof are disclosed. The fluoride glass includes, in mole percentages, 16-70% of ZrF4, 13-32% of BaF2, 5-18% of MF, 0-14% of MeF2 and 0-28% of MfF3, wherein the M is one or two selected from Na and Li, the Me is one or more selected from Zn, Mg and Ca, and the Mf is one or two selected from Al and La. The fluoride glass has a low cost and is suitable for applications in optical windows of near ultraviolet to middle-infrared wavebands. The cutoff wavelength of the prepared glass is greater than 6 [mu]m. The glass has good glass forming capacity, and is suitable for preparing matrix glass of infrared laser fibers and fiber optic amplifiers and other optical materials. The glass has good glass forming capacity, good chemical stability, and low theoretical loss and is suitable for preparing matrixes of low-loss fluoride fibers and doped fibers.

Owner:HUAZHONG UNIV OF SCI & TECH

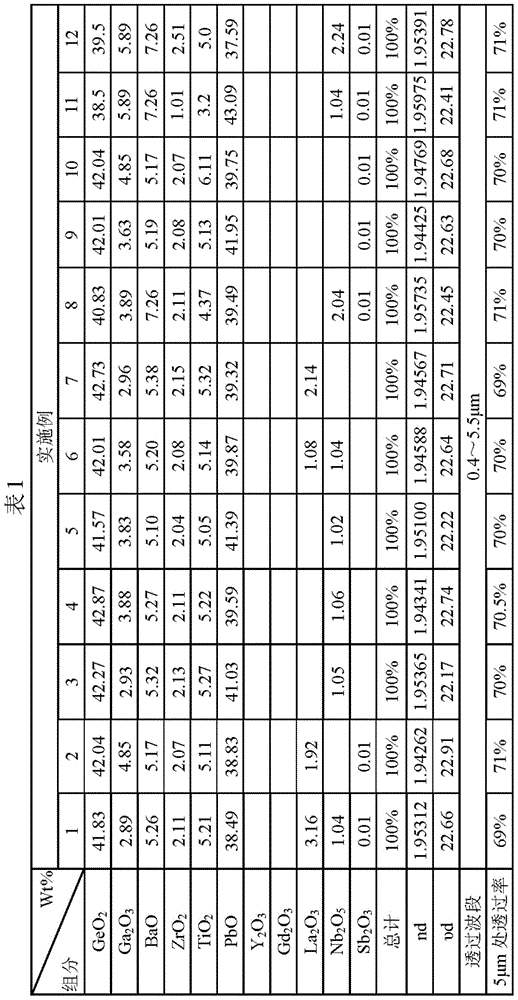

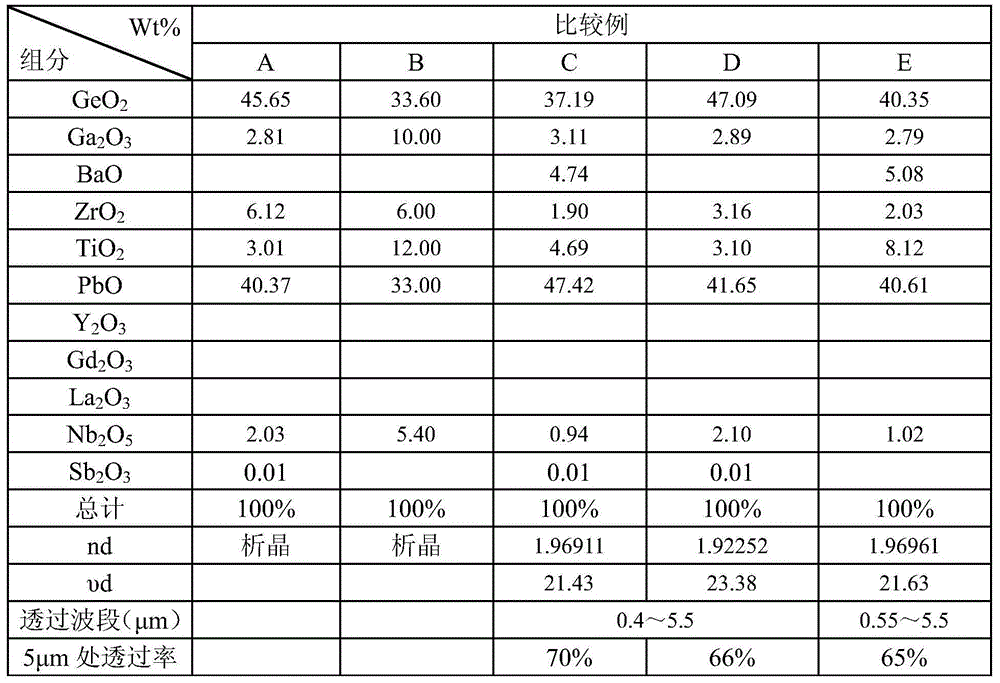

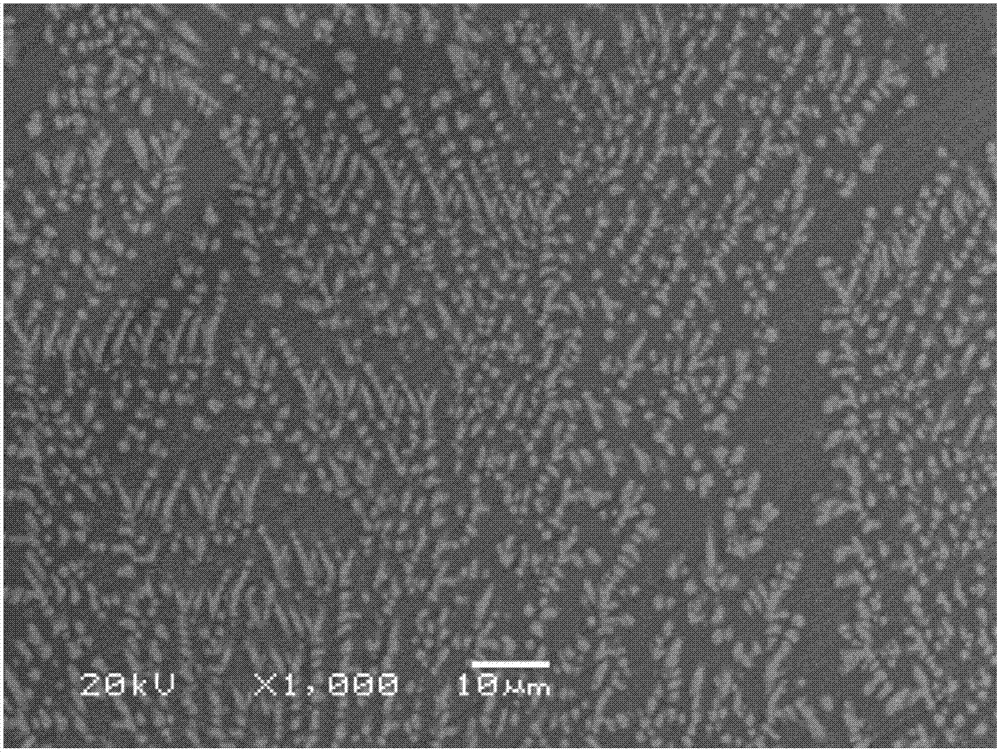

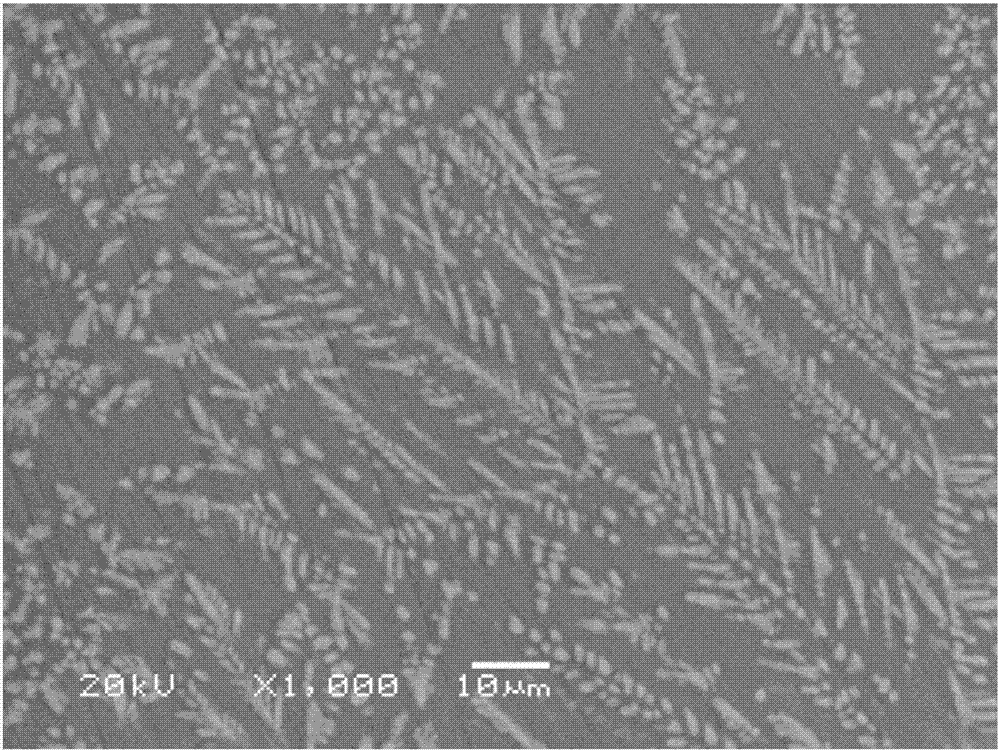

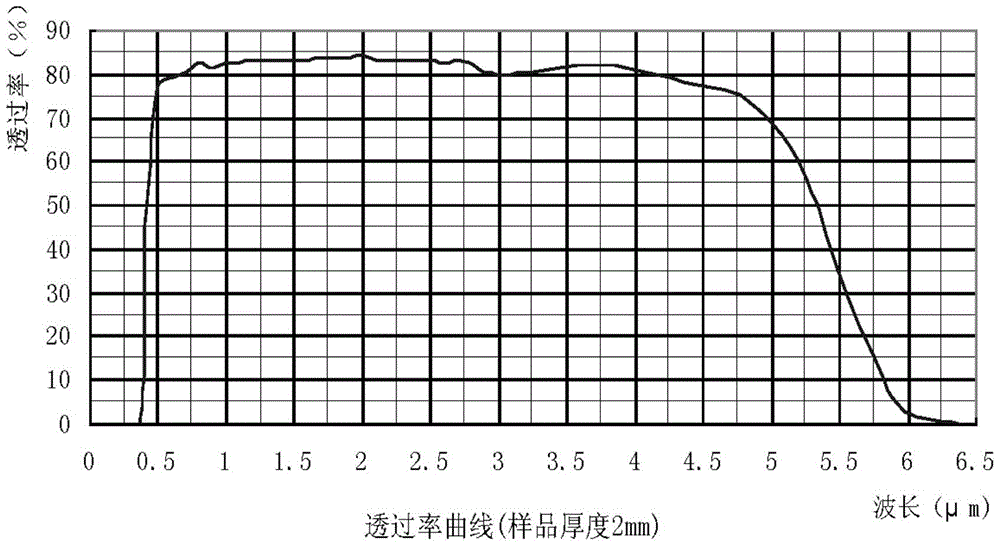

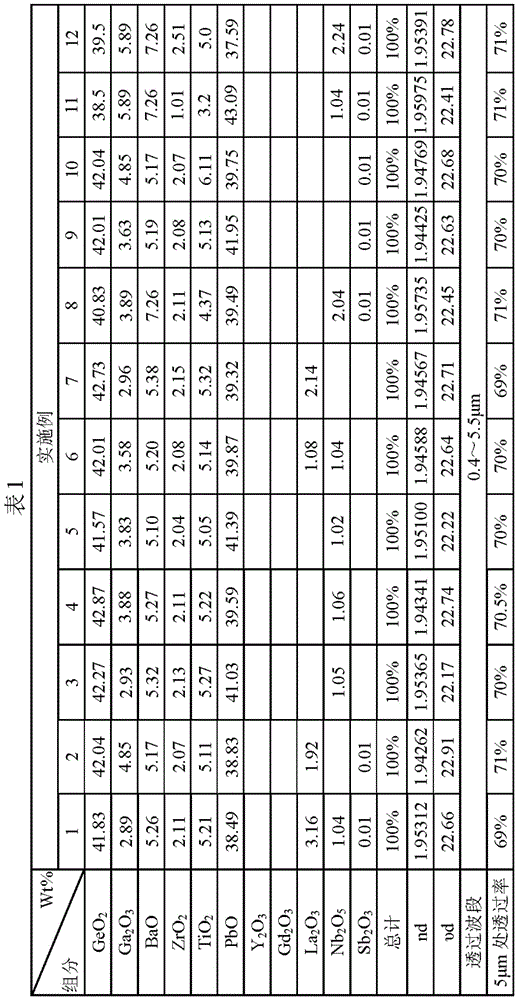

Optical glass

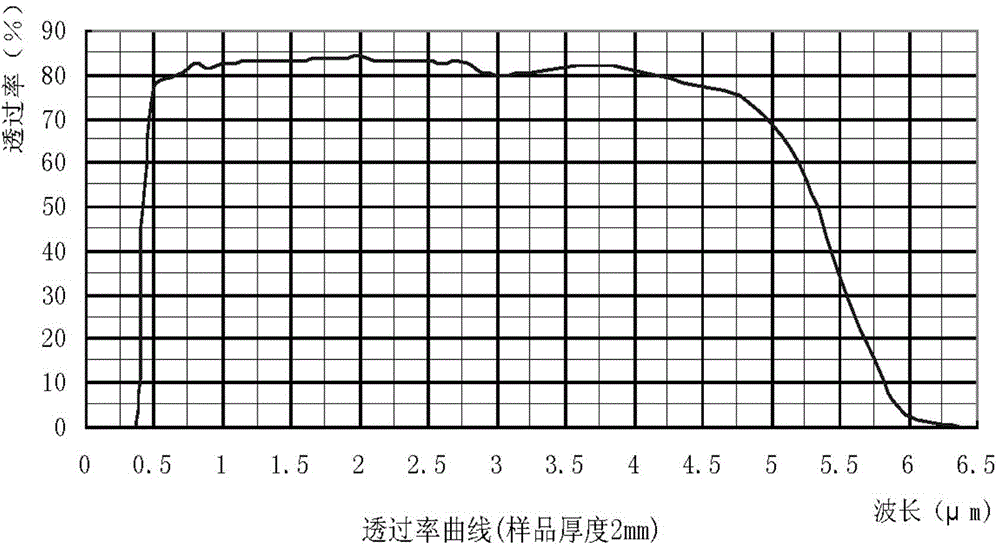

The invention relates to optical glass, and provides infrared-transmitted germanium-gallate optical glass which is suitable for volume production and secondary profiling, and is high in refraction and high in dispersion. The glass contains GeO2, Ga2O3, BaO, ZrO2, TiO2 and PbO as necessary components, and does not contain thorium, cadmium or arsenic; the refractive index (nd) is 1.94-1.96; and the abbe number (upsilon d) is 21-23. The optical glass disclosed by the invention has good physical and chemical properties and infrared spectrum transmitting performance, and is mainly applied to infrared-transmitted windows and optical path lenses; the infrared cutoff wavelength is greater than 5.5 microns; and the ultraviolet cutoff wavelength is smaller than 400nm.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

ZrO2-contained vehicle TWIP steel protection slag and application thereof

The invention discloses ZrO2-contained vehicle TWIP steel continuous casting crystallizer protection slag and application thereof. The protection slag consists of the following oxide components in percentage by mass: 20-40% of CaO, 8-20% of SiO, 13-30% of Al2O3, 5-12% of Na2O, 1-6% of Li2O, 3-16% of BaO, 2-8% of MnO2, 4-13% of F-, 1.5-3.5% of ZrO2, 1.3-2.4 of (CaO+BaO) / Al2O3, 1.9-2.5 of CaO / SiO2, and 1.6-2.2 of Al2O3 / SiO2. The protection slag can be preferably applied to the continuous casting process of TWIP steel with 15-25 mass% of Mn and 2-4 mass% of Al.

Owner:CENT SOUTH UNIV

Infrared transmitting germanate glass and preparation method thereof

The invention relates to infrared transmitting germanate glass and a preparation method thereof, and belongs to the technical field of germanate glass. The invention mainly provides infrared transmitting germanate glass with excellent physiochemical performance and infrared transmitting performance and a preparation method thereof. The germanate glass comprises the following components of: 35 to 45 percent of GeO2, 15 to 30 percent of M2O3, 25 to 40 percent of M'O, 0 to 15 percent of M''O2 and 0 to 5 percent of La2O3, wherein M2O3 is Al2O3, Ga2O3 and the like; M'O is MgO, CaO, BaO and the like; and M''O2 is ZrO2, TiO2 and the like. The preparation method comprises the following steps of: a, weighing raw materials, and mixing uniformly in a ball-milling tank; b, melting in a platinum crucible; c, after melting, introducing dry gas on the surface of glass liquid to remove moisture in the glass liquid, and stirring, homogenizing and clarifying by using a platinum stirrer simultaneously; d, homogenizing and clarifying the liquid, and forming in a die; and e, annealing. The infrared transmitting germanate glass has the excellent physiochemical and infrared performance, the transformation temperature is between 650 and 750 DEG C, the infrared cut-off wavelength is more than 6 micrometers, the ultraviolet cut-off wavelength is less than 400 nanometers, and the vickers hardness is more than 650 kgf / mm<2>. The invention is mainly used for the infrared transmitting germanate glass and the preparation method thereof.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

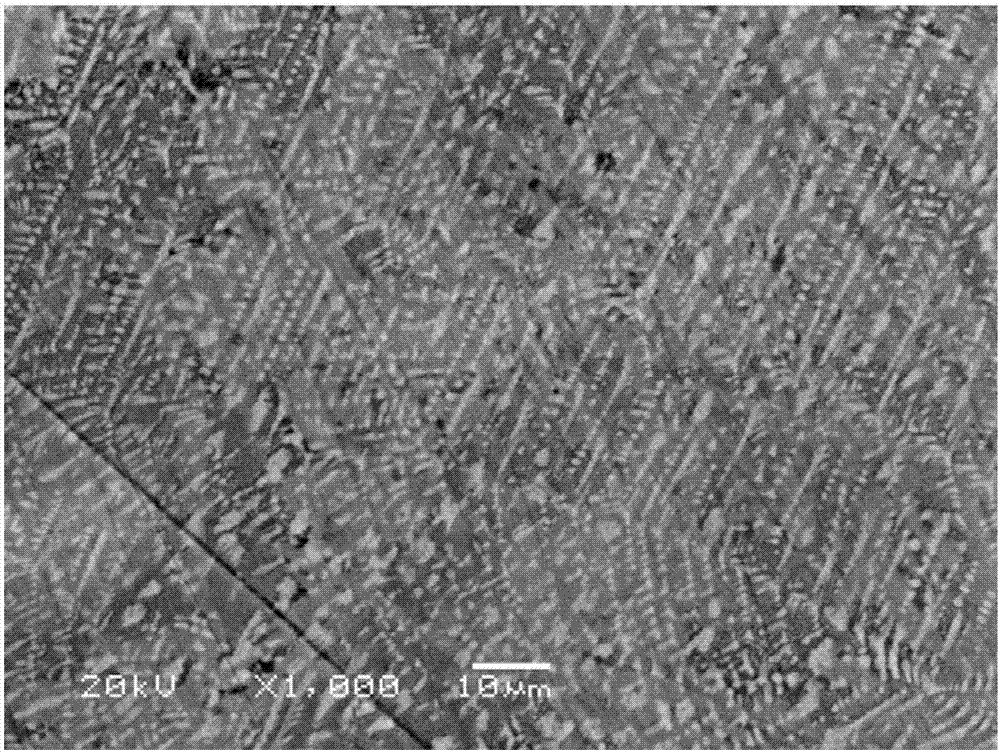

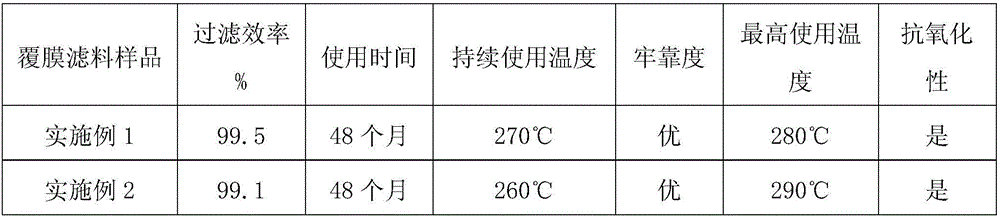

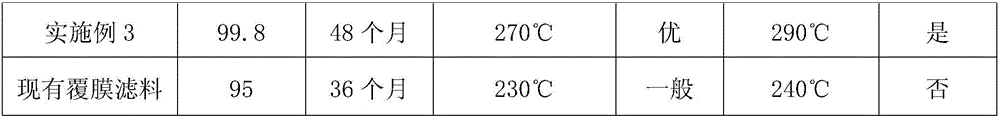

Oxidation-resistant high-temperature-resistant polytetrafluoroethylene film covered filter material, and preparation method thereof

InactiveCN106515163AImprove antioxidant capacityExtended service lifeSynthetic resin layered productsLaminationAntioxidantLead phosphate

The invention belongs to the technical field of plastic film, and discloses an oxidation-resistant high-temperature-resistant polytetrafluoroethylene film covered filter material. The oxidation-resistant high-temperature-resistant polytetrafluoroethylene film covered filter material comprise an upper layer, a middle layer, and a lower layer; the upper layer is a polytetrafluoroethylene film layer, the middle layer is a polytetrafluoroethylene binding layer, and the lower layer is a filter material layer. The polytetrafluoroethylene film is mainly prepared from, by weight, 8 to 10 parts of polytetrafluoroethylene, 0.5 to 1.5 parts of an antioxidant, 0.5 to 1.5 parts of triethyl acetyl citrate, 1 to 2 parts of molybdenum disulfide, 2 to 4 parts of lead sulfate tribasic, 1 to 1.5 parts of dibasic lead phosphate, and 1 to 2 parts of polysiloxane. The polytetrafluoroethylene binding layer is mainly prepared from, by weight, 2 to 3 parts of a polytetrafluoroethylene dispersion liquid, 0.5 to 1.5 parts of an anti-aging agent, 1.5 to 2.5 parts of a foaming agent, and 0.5 to 1.5 parts of a thickening agent. The oxidation-resistant high-temperature-resistant polytetrafluoroethylene film covered filter material is high in dedusting efficiency, is long in service life, is high in oxidation resistance, and can be widely used for treatment of high temperature dust.

Owner:张峰

A kind of high-strength glass fiber and its preparation method

ActiveCN109180009BGuaranteed contentImprove protectionGlass fibre drawing apparatusGlass fiberPyrophyllite

The invention discloses a high strength glass fiber. The high strength glass fiber mainly comprises, by weight, silica sand, kaolin, calcite, fluorite, calciborite, mirabilite, and sodium carbonate. The invention provides a glass fiber raw material formula can be used for replacing pyrophyllite. Glass material preparation uniformity is increased obviously through reasonable control on the mass ratio of a plurality of raw materials, melting efficiency is increased, glass fiber finished product rate is increased, the prepared glass fiber is better in mechanical properties, and production cost isreduced. The invention also provides a preparation method of the glass fiber. No stirring is needed; glass liquid is mixed to be uniform by heat convection in a bath tank, and is used for preparationof glass fiber. The glass fiber prepared based on the formula and the preparation method is high in finished product rate, and excellent in corrosion resistance.

Owner:清远忠信世纪电子材料有限公司

Alkaline refining slag is used in the slag adjustment method of producing slag cotton

The invention relates to the technical field of metallurgical waste slag reuse, in particular to a slag adjustment method for producing high-quality slag wool with alkaline refining slag. It is characterized in that: for the alkaline refining slag produced in the process of steelmaking or ferroalloy refining, aluminum ash slag containing aluminum, spodumene and boron anhydride are used as slag adjusting agents in sequence to reduce the alkalinity and oxidation of refining slag and improve Fiber-forming properties of slag.

Owner:JIANGSU UNIV

Preparation method of powder for new materials

InactiveCN105623315AGood dispersionEasy to preparePigment treatment with organosilicon compoundsPigment physical treatmentDispersityLithium chloride

The invention discloses a preparation method of powder for new materials. The preparation method includes following steps: S1, performing primary processing: selecting high-quality sericite raw ore, performing rough breaking the sericite raw ore, and using a rolling machine for rolling to obtain particles A; S2, performing secondary processing: placing the particles A in a reaction kettle, adding lithium chloride into the reaction kettle, setting a weight ratio of the particles A to lithium chloride to be 1-3:4-7, fully stirring at temperature of 70-90 DEG C for 20-40 min, and adding gamma-aminopropylmethyldiethoxysilane into the reaction kettle, fully stirring at temperature of 80-100 DEG C for 10-30 min to obtain a mixture B; S3, performing ultrasonic treatment: placing the mixture B in an ultrasonic wave generator for ultrasonic treatment for 2-4 h to obtain a mixture C, wherein ultrasonic power is 200-300 W; S4, drying and sterilizing. The preparation method is simple and high in production quantity, and the powder for the new materials is high in dispersity, glossy and suitable for popularization.

Owner:ANHUI HENGHAO SCI & TECH

Low-oxidizability continuous casting covering slag

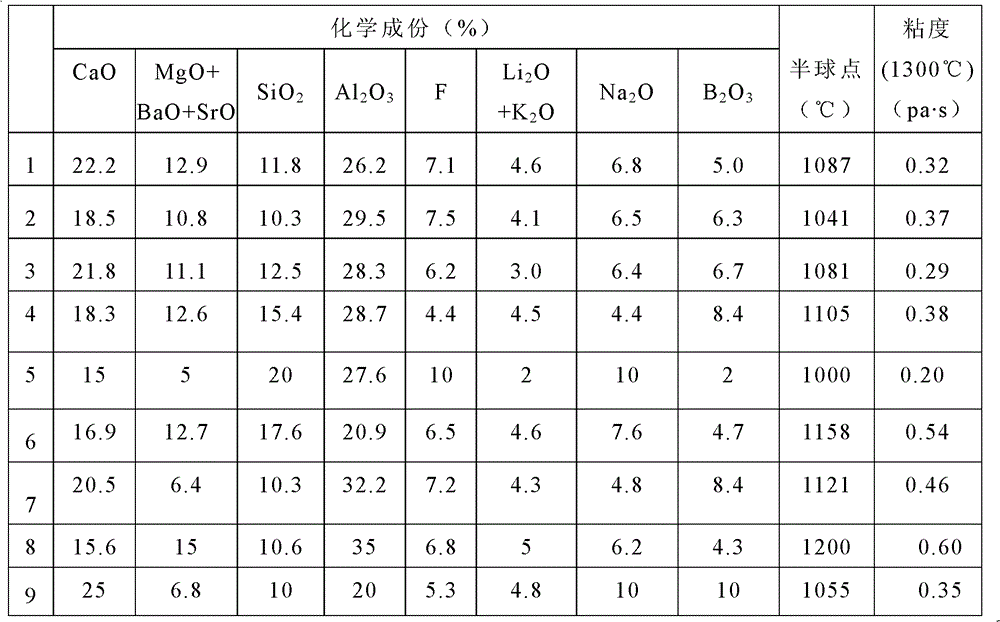

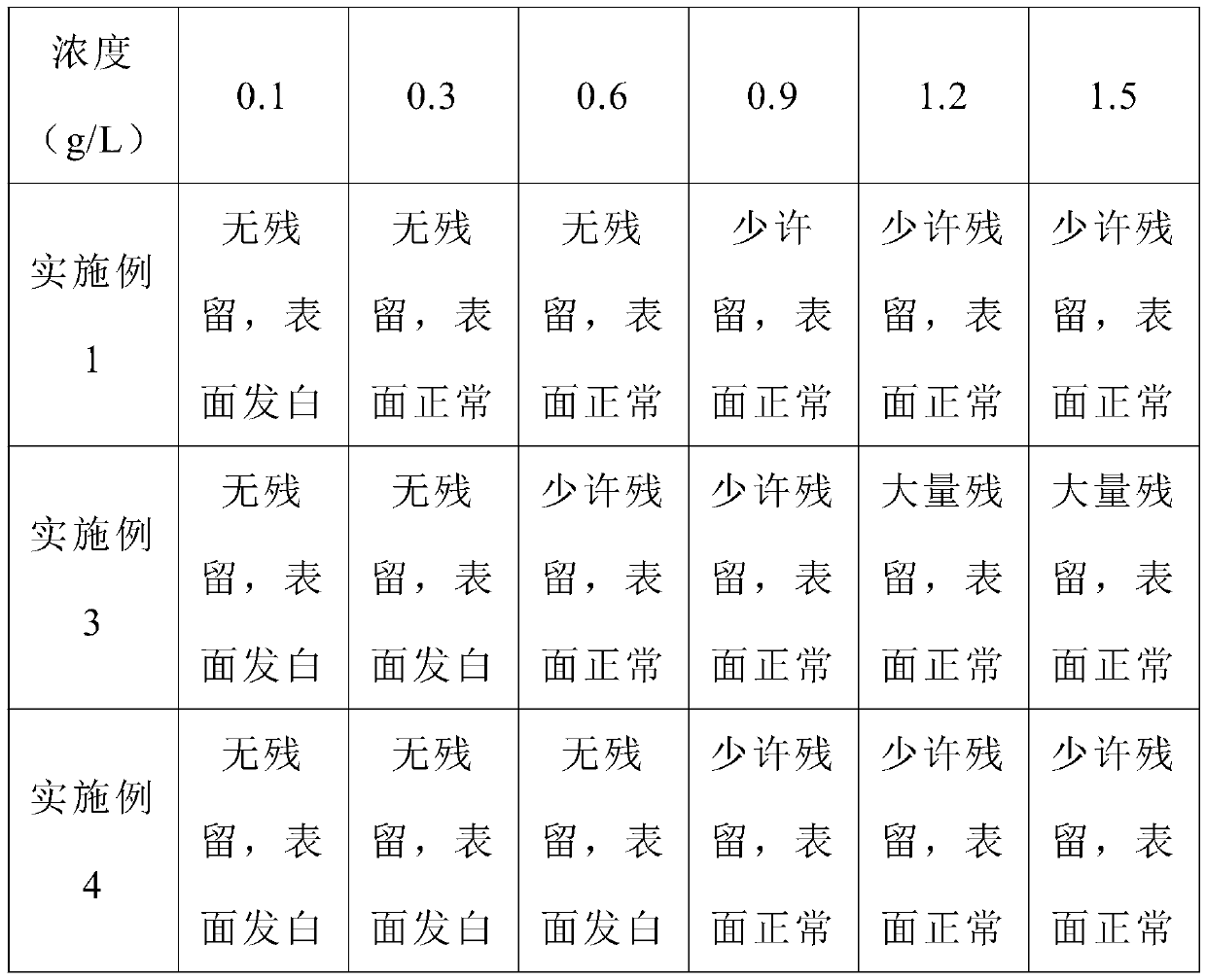

The invention discloses a low-oxidizability continuous casting covering slag comprising the following chemical components in percentage by weight: 15-25% of CaO, 20-35% of Al2O3, 10-20% of SiO2, 2-5% of Li2O+K2O, 2-10% of B2O3, F<=10%, Na2O<=10%, 5-15% of MgO+BaO+SrO, and the balance of carbon and inevitable impurities. Furthermore, the hemispheric point temperature of the continuous casting covering slag is controlled within a range from 1000 DEG C to 1200 DEG C, and the viscosity is controlled within a range from 0.2 pa. s to 0.6 pa. s. Practices show that the low-oxidizability continuous casting covering slag has good combination property and meets the requirements of continuous casting processes of steel types, i.e. TRIP (Transformation-Induced Plasticity) steel with high-content oxidizable elements i.e. Al, Ti or rare earth, and the like, silicon steel, container steel, and the like and realize the multi-furnace continuous casting.

Owner:武汉钢铁有限公司

Laser stripping method applied to automobile lamp

ActiveCN110052716AAvoid damageReduce the binding forceSpecial surfacesCoatingsOptoelectronicsMaterials science

The invention discloses a laser stripping method applied to an automobile lamp and belongs to the technical field of laser stripping. The stripping method includes the main stripping processes that firstly, automobile lamp paint spraying treatment is conducted; secondly, acid treatment is conducted; thirdly, nano bombard treatment is conducted; and fourthly, auxiairy laser stripping is conducted.Nano particles reducing laser energy are added during bombard treatment, a sucrose auxiliary solution is extruded during laser stripping, and therefore the damage of laser to an automobile lamp is further reduced. By means of the adopted laser stripping method, the laser stripping efficiency can be effectively improved, in addition, an automobile lamp base material is protected, and the damage rate of the automobile lamp base material is reduced during laser stripping.

Owner:大茂伟瑞柯车灯有限公司

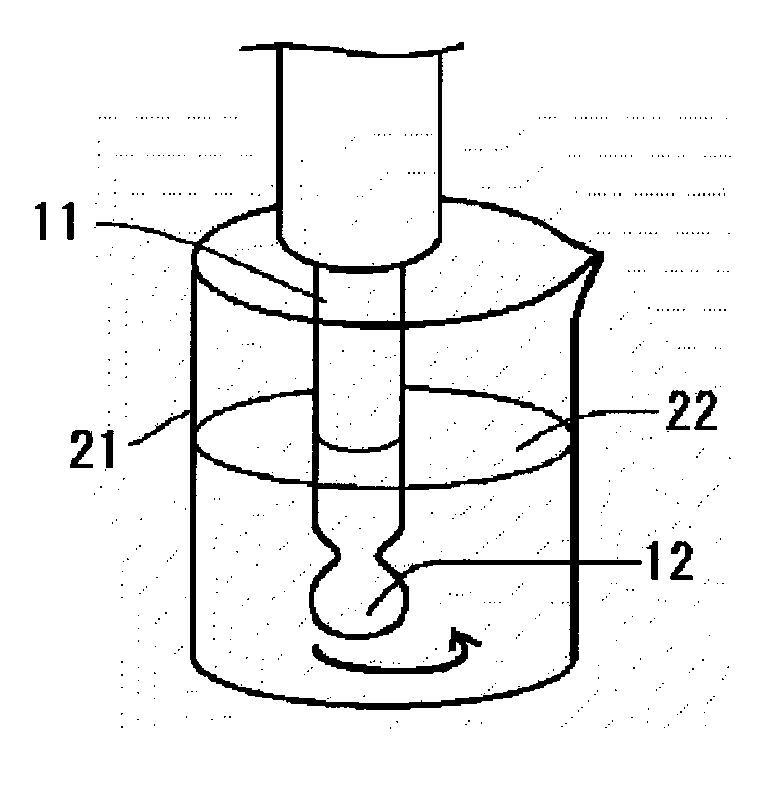

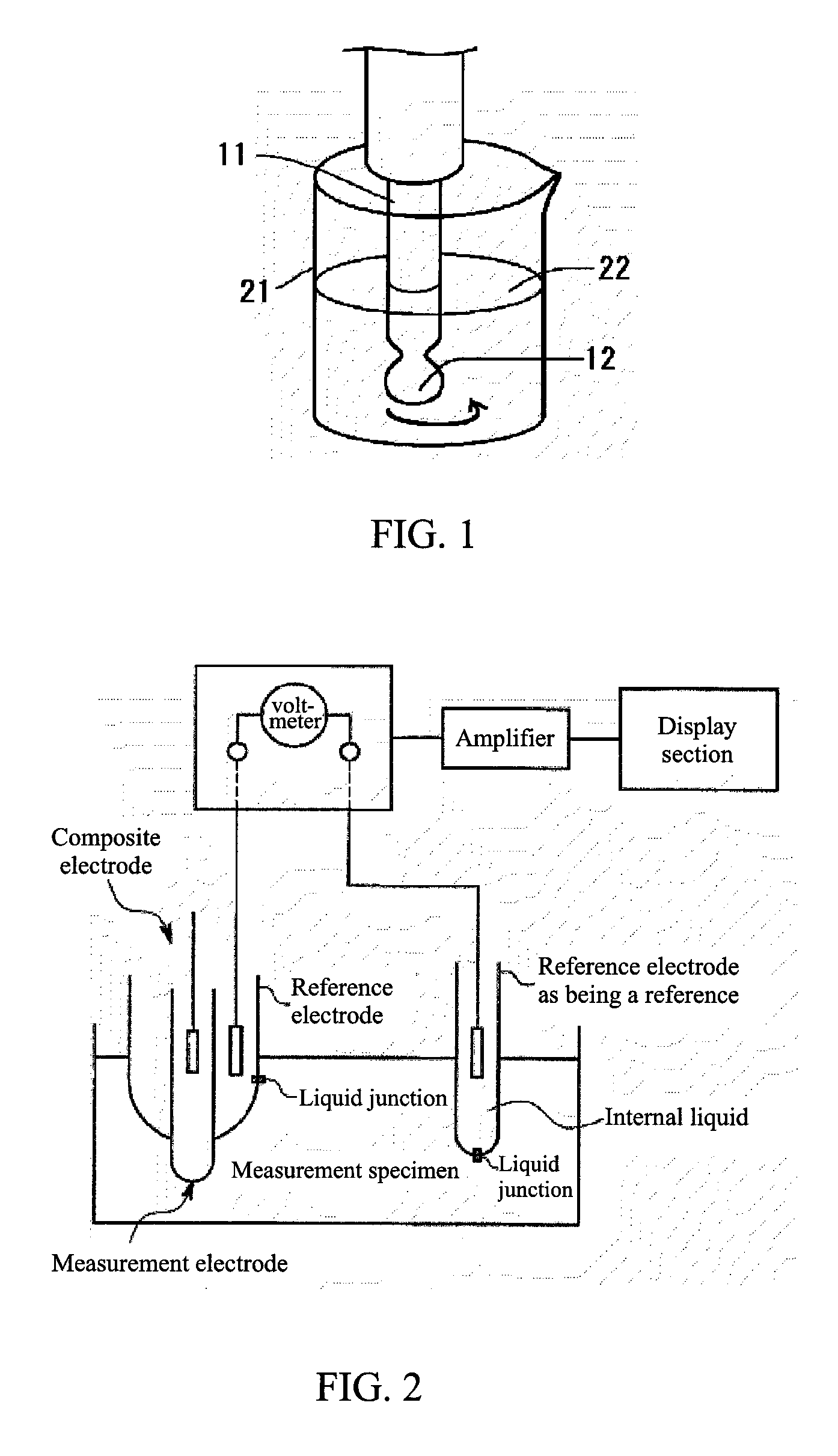

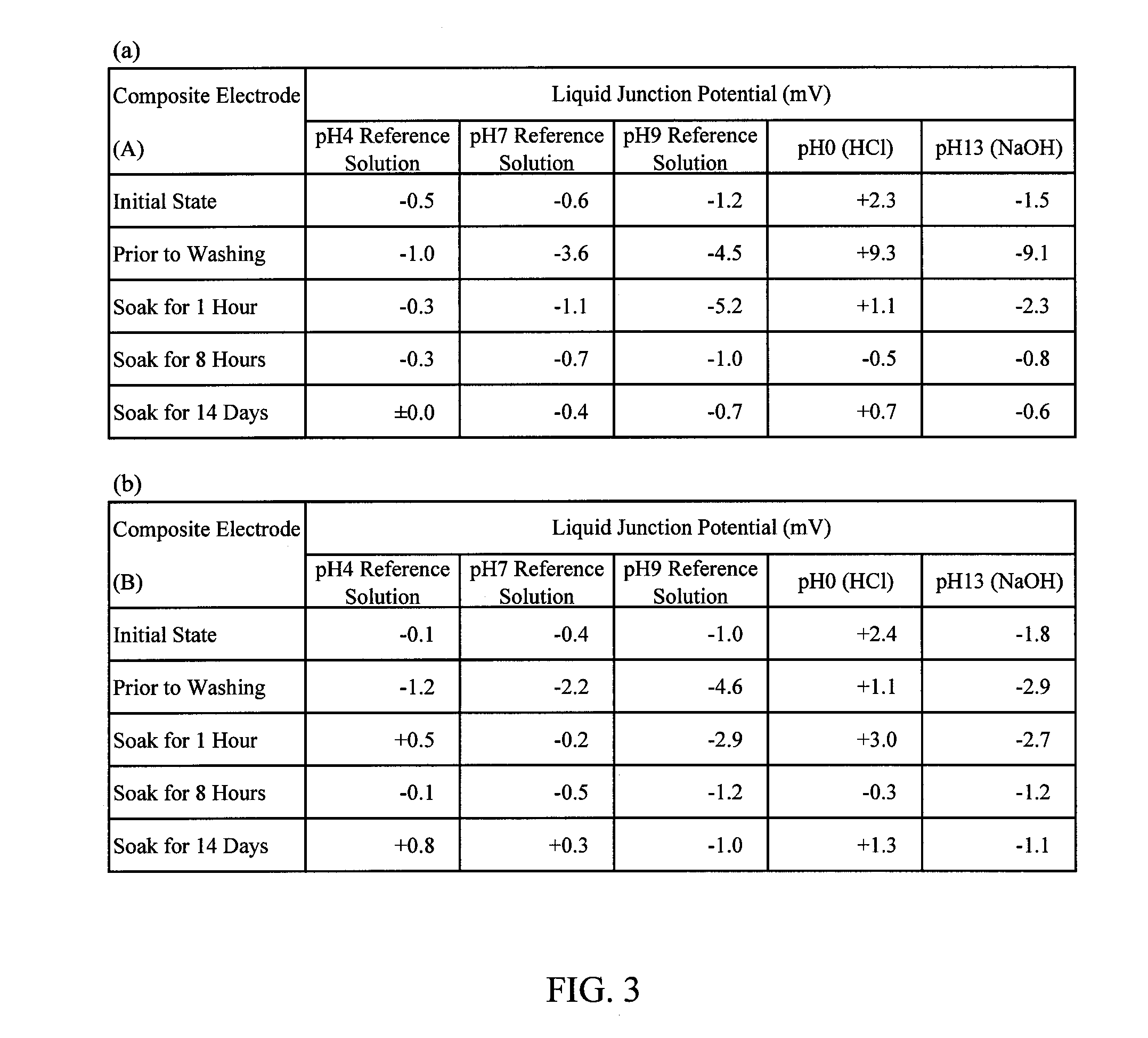

Washing storage solution for glass electrode and the like

InactiveUS20100051053A1Restore it performanceImprove performanceElectrostatic cleaningCleaning using liquidsSodium thiosulfateTitanium oxide

This invention provides a washing storage solution (22), which can substantially completely remove contaminants such as transition metals and alkali metals deposited on the surface of a glass electrode that comprises a glass comprising lithium and can restore performances as an electrode such as responsiveness and reproducibility in the measurement to an initial state or a state better than the initial state. The washing storage solution (22) is characterized by comprising at least one reducing reagent having a reduction behavior. Examples of reducing reagents include hydroxylammonium chloride, sodium hyposulfite, sodium hydrogen sulfite, sodium thiosulfate, sodium hypophosphite, ascorbic acid, and titanium oxide.

Owner:HORIBA LTD

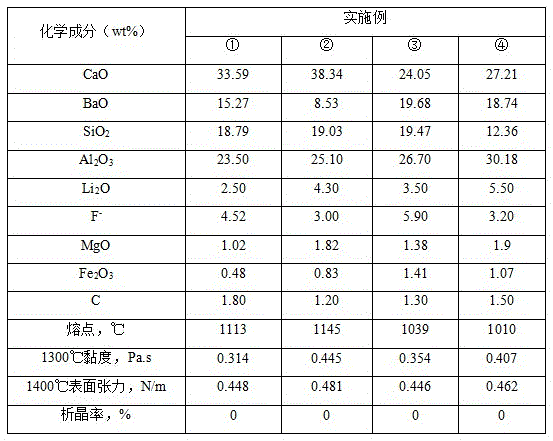

Crystallizer covering slag for continuous casting of auto sheet

InactiveCN105537546AIncrease interfacial tension of slag steelReduce the occurrence of slagSlagProduction rate

The invention provides crystallizer covering slag for continuous casting of an auto sheet. The covering slag comprises, by weight, 23%-40% of CaO, 8%-20% of BaO, 10%-20% of SiO2, 20%-35% of Al2O3, 2.5%-5.5% of Li2O, 3%-6% of F<->, 1%-2% of MgO and 1%-2% of C. The physical performance of the crystallizer covering slag can meet the requirements of the melting point of 1,000-1,150 DEG C, 1,300-DEG C viscosity of 0.3-0.5 Pa.s and 1,400-DEG C surface tension of 0.4-0.5 N / m, and has the advantages of being high in viscosity, large in surface tension, low in reactivity, good in lubricity and high in absorbing included slag. When the crystallizer covering slag is applied to the producing and casting process of auto sheet steel, the slag-inclusion occurrence rate of a continuous casting sheet billet of the auto sheet steel can be decreased and even eliminated, and the drawing speed can be increased to increase the production rate.

Owner:TANGSHAN XINYANCHANG TECH CO LTD

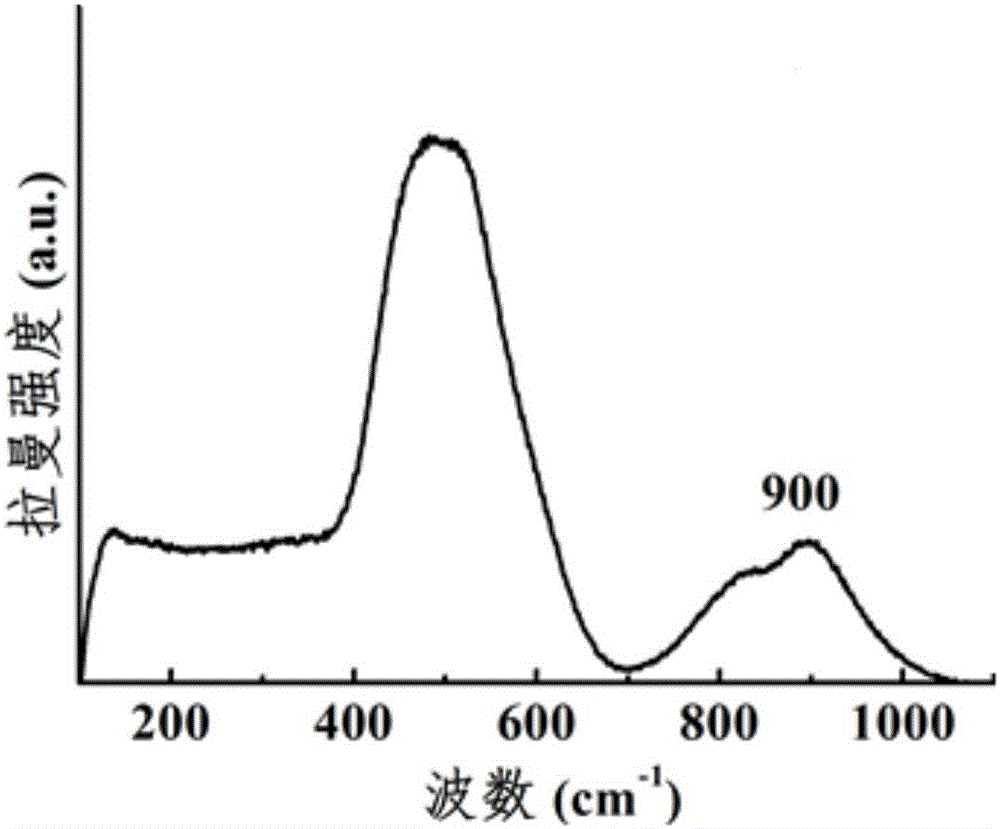

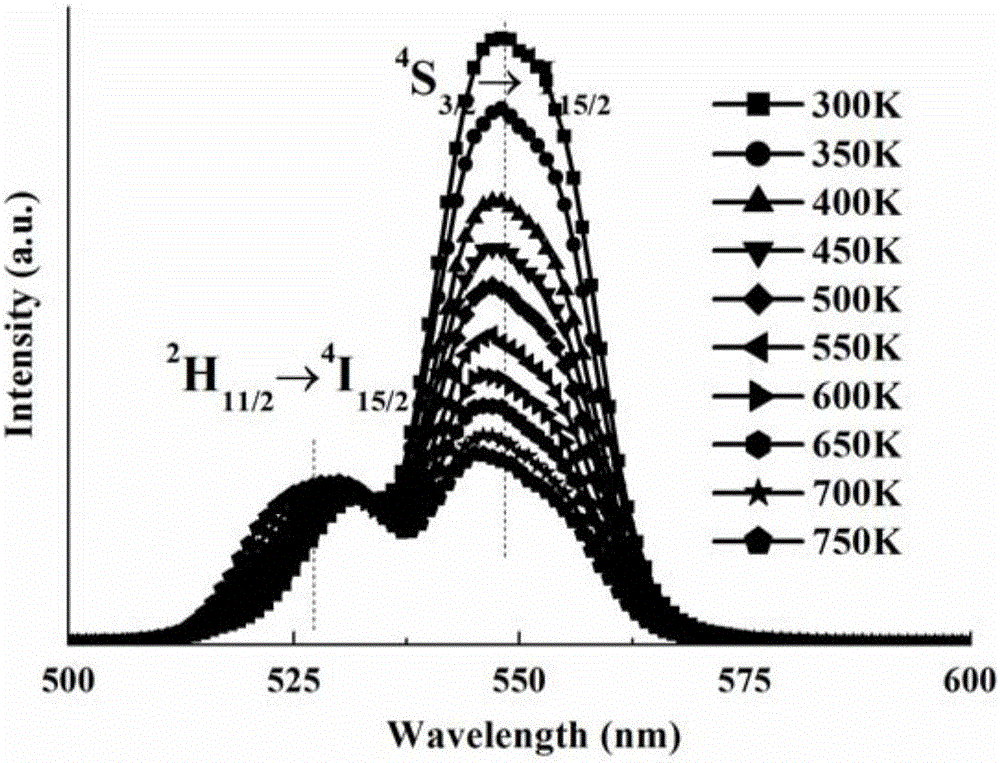

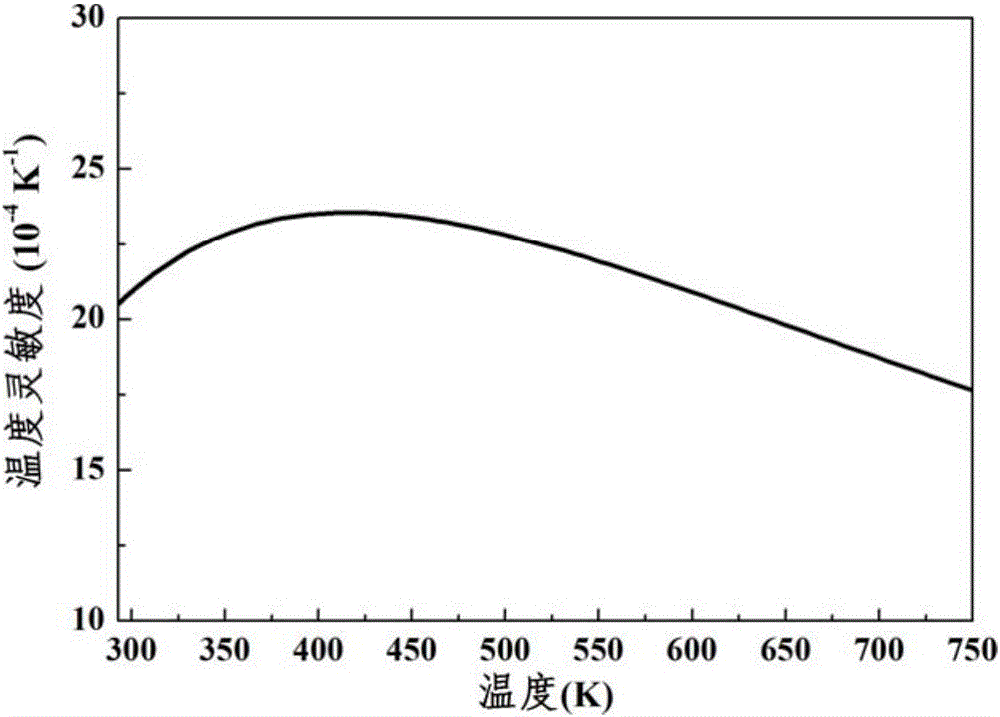

High-temperature optical sensing material erbium-ytterbium-codoped lead-free fluogermanate glass and preparation method thereof

ActiveCN106746621AImprove energy utilizationImprove luminous efficiencyLuminescent compositionsCeiling temperatureErbium doping

The invention discloses a high-temperature optical sensing material, i.e., erbium-ytterbium-codoped lead-free fluogermanate glass. Through adding erbium and ytterbium ions into fluogermanate glass, high doping of the erbium and ytterbium ions in the fluogermanate glass can be achieved, the energy utilization efficiency and luminescence efficiency of pumping can be further increased, high-sensitive temperature sensing can be achieved in relatively short optical fibers, and the practicability of temperature sensors is improved. Compared with the former erbium-doped optical glass sensing materials, the erbium-ytterbium-codoped lead-free fluogermanate glass disclosed by the invention has the advantages that inherent disadvantages of fluoride glass, sulfide glass and silicate (borate) glass as optical sensing materials are overcome, the working ceiling temperature and temperature sensing sensitivity are relatively high, and the erbium-ytterbium-codoped lead-free fluogermanate glass can be extensively applied to the field of microwave heating and temperature measurement through being made into optical fibers.

Owner:CHINA JILIANG UNIV

A kind of fluoride glass and preparation method thereof

ActiveCN107285627BReduce usageFew ingredientsGlass shaping apparatusFiber amplifierChemical stability

Fluoride glass and a preparing method thereof are disclosed. The fluoride glass includes, in mole percentages, 16-70% of ZrF4, 13-32% of BaF2, 5-18% of MF, 0-14% of MeF2 and 0-28% of MfF3, wherein the M is one or two selected from Na and Li, the Me is one or more selected from Zn, Mg and Ca, and the Mf is one or two selected from Al and La. The fluoride glass has a low cost and is suitable for applications in optical windows of near ultraviolet to middle-infrared wavebands. The cutoff wavelength of the prepared glass is greater than 6 [mu]m. The glass has good glass forming capacity, and is suitable for preparing matrix glass of infrared laser fibers and fiber optic amplifiers and other optical materials. The glass has good glass forming capacity, good chemical stability, and low theoretical loss and is suitable for preparing matrixes of low-loss fluoride fibers and doped fibers.

Owner:HUAZHONG UNIV OF SCI & TECH

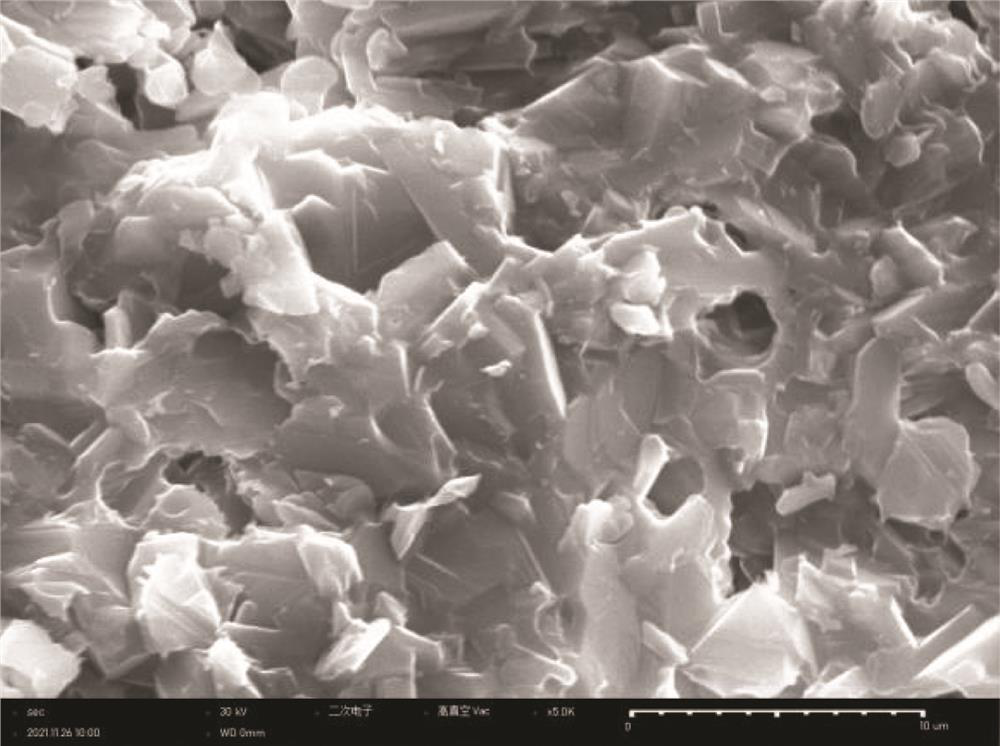

Special kaolin for crystallizer covering slags as well as preparation method and application of special kaolin

The invention discloses special kaolin for crystallizer covering slags, belongs to the technical field of continuous casting of cast steel and aims to effectively harmonize contradiction of covering slag lubrication ingot casting and heat transfer control in a continuous casting process. The special kaolin for the crystallizer covering slags comprises the following components in parts by weight: 65-66 parts of SiO2, 25-26 parts of Al2O3, 1.5-2 parts of Fe2O3, 1-2 parts of CaO and 1-2 parts of MgO. The special kaolin disclosed by the invention is applied to production of the crystallizer covering slags which are applied to a continuous casting process of the cast steel.

Owner:胡毅婧

High crystallinity and high lubricity mold powder for continuous casting

The invention discloses crystallizer casting powder for high-crystallinity high-lubricity continuous casting. The crystallizer casting powder comprises, by weight, 40%<CaO<46.5%, 22%<SiO2<30%, 6.8%<F-<7.8%, a compound formed by one or two or three of ZnO, B2O3 and BaO, 7%<Li2O+Na2O<15%, Al2O3<3%, MgO<3%, Fe2O3<2%, 2%<C<15% and the balance impurities, wherein 4%<the compound<26%, ZnO<8%, B2O3<8%, and BaO<10%. The crystallizer casting powder effectively coordinates contradiction between lubricating of casting blanks by using the casting powder and controlling of heat transfer in a continuous casting process of peritectic steel plates. The casting powder improves casting blank lubrication, simultaneously guarantees the capacity of the casting powder of evenly transferring heat, is favorable for improving casting blank quality in the continuous casting process of the peritectic steel, balances heat flow of the upper portion and the lower middle portion of the crystallizer, increases the thickness of blank casings when being discharged from the crystallizer, and can improve pulling speed and production efficiency.

Owner:CHONGQING UNIV

Optical glass

The invention relates to an optical glass. The invention provides a high refraction, high dispersion infrared germanium gallate optical glass suitable for batch production and secondary pressing. The glass contains GeO2, Ga2O3, BaO, ZrO2, TiO2 and PbO as essential components, does not contain thorium, cadmium and arsenic, the refractive index (nd) is between 1.94 and 1.96, and the Abbe number (υd) is between 21 and 23 between. The optical glass of the present invention has good physical and chemical properties and infrared spectrum transmission performance, the infrared cut-off wavelength is greater than 5.5 μm, and the ultraviolet cut-off wavelength is less than 400 nm, and is mainly used for infrared transmission windows and optical path lenses.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

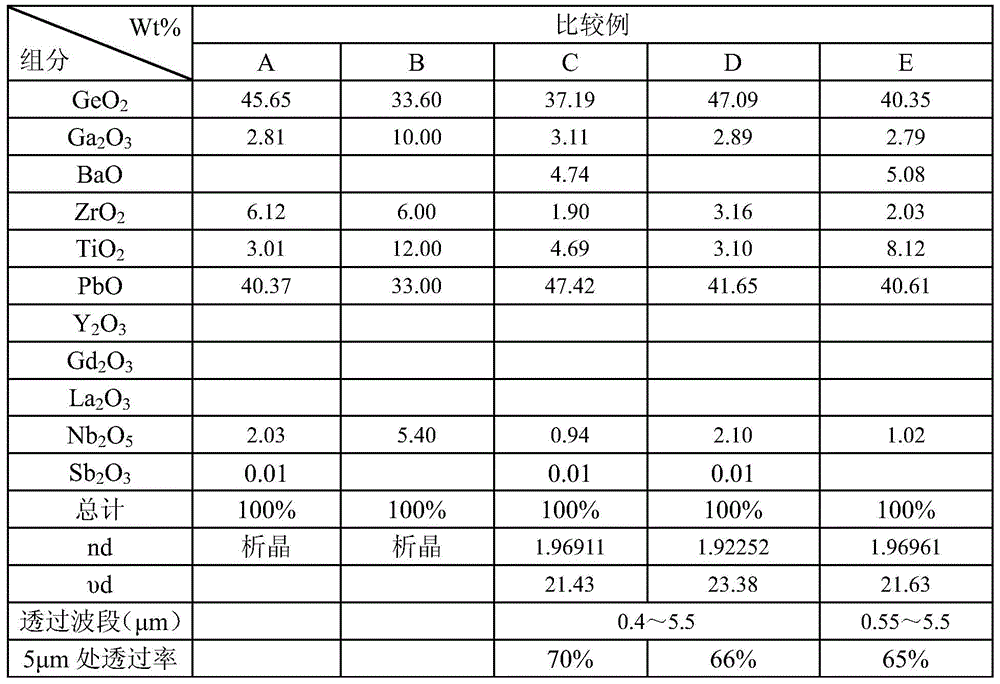

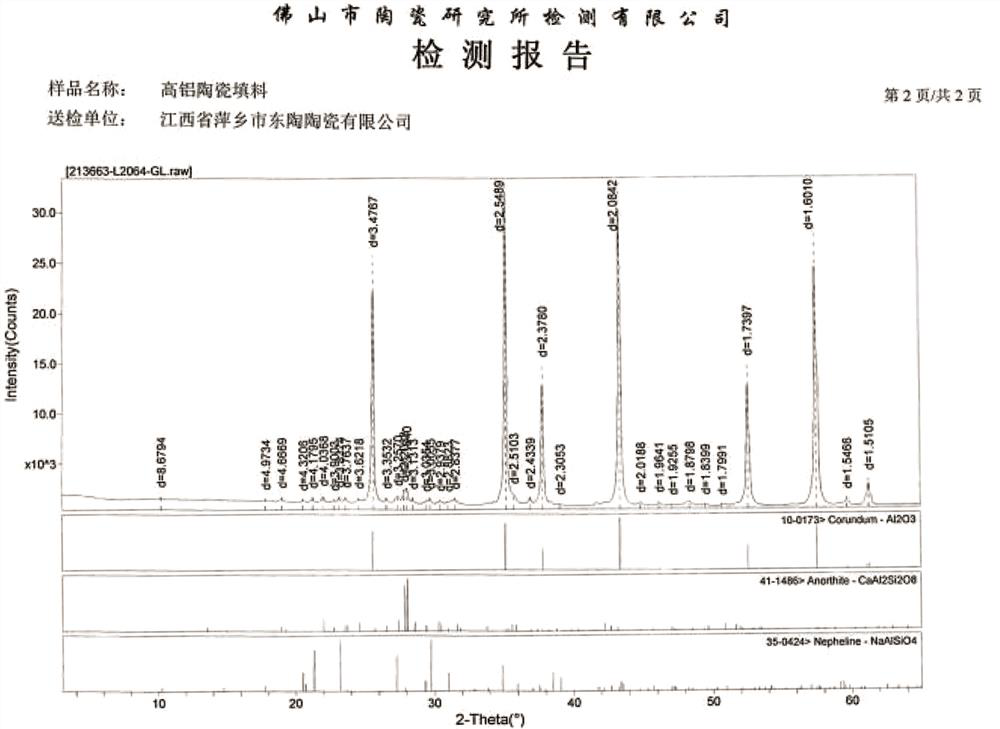

High-aluminum ceramic filler prepared from gamma aluminum oxide and preparation method of high-aluminum ceramic filler

ActiveCN114014640AAlleviate the problem of firing crackingGood glass performanceChemical industryBall clay

The invention discloses a high-aluminum ceramic filler prepared from gamma aluminum oxide and a preparation method of the high-aluminum ceramic filler. The high-aluminum ceramic filler is prepared from 83-94 wt% of an aluminum oxide raw material with a main crystal phase being gamma-Al2O3, 2-5 wt% of a borate mineral or a synthesized borate compound, 1-4 wt% of ball clay, 1-4 wt% of nano silicon dioxide, 1-4 wt% of a calcium-magnesium complex mineral and 0-7 wt% of calcined aluminum oxide powder. According to the invention, the technological process is simplified, the procedure of converting gamma-Al2O3 into alpha-Al2O3 through calcination is not needed, the high-aluminum ceramic filler is directly prepared from gamma-Al2O3, carbon emission and energy consumption are greatly reduced, the product percent of pass is high, and the performance reaches or exceeds the standard requirement of the chemical industry. The high-aluminum ceramic filler can be used as a supporting or covering material for chemical reaction tower (device) beds in petrochemical industry, coal chemical industry, chemical fertilizer, nonferrous metallurgy and the like.

Owner:朱建良

Heavy metal borate glass with high v value and low temperature coefficient, preparation method and application

The invention provides a high V-value and low-temperature coefficient heavy metal borate glass as well as a preparation method and the application thereof. The preparation method comprises the following steps: sufficiently mixing PbO and B2O3 or H3BO3 and Bi2O3, melting, and clarifying; or adding a rare-earth oxide or a transition metal oxide, performing stirring homogenization, and implementing amelting-casting method, so as to obtain the high V-value and low-temperature coefficient heavy metal borate glass. The heavy metal borate glass provided by the invention is low in manufacturing cost,has a high Verdet constant and very low temperature dependency, can be widely applied to design of various magnetic-optical devices, and needs no temperature compensation technique; the glass is excellent in magnetorotation property, has near-infrared permeability up to 85%, and is applicable to manufacturing of various magnetic-optical devices such as magnetic-optical current sensors, magnetic-optical switches, magnetic-optical modulators and magnetic-optical isolators.

Owner:HUAZHONG UNIV OF SCI & TECH

A kind of mold slag for continuous casting mold for p91 steam pipeline steel and its preparation method

The invention belongs to the technical field of metallurgy materials, and particularly relates to continuous casting crystallizer casting powder for P91 steam pipeline steel and a preparation method of the continuous casting crystallizer casting powder. The casting powder is prepared from, by weight percent, 26.0%-35.0% of SiO2, 27.0%-37.0% of CaO, 0.4%-1.2% of Li2O, not larger than 6.0% of Al2O3, 7%-13% of Na2O, 4%-8% of F-, not larger than 4.0% of MgO, not larger than 1.0% of Fe2O3, 5%-9% of Csolid and 8%-12% of volatile components. The casting powder can achieve crystallizer lubricating during low-temperature casting, a slag film has sufficient crystallization to improve crystallizer heat transfer, P91 steel large round blank surface longitudinal cracks are reduced, and the casting blank quality is improved.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com