High-aluminum ceramic filler prepared from gamma aluminum oxide and preparation method of high-aluminum ceramic filler

A technology of high-alumina ceramics and γ-alumina, applied in the field of high-alumina ceramic fillers, can solve the problems of product price increase, inability to adapt, and high industrial cost of high-alumina ceramic fillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: According to industrial alumina 89kg, Turkish colemanite 3.5kg, silica fume 2.5kg, dolomite 2.5kg, ball clay 2.5kg batching, add water 55kg, polyacrylic acid ammonium dispersant 0.2kg, go out after ball milling 36 hours Grinding, spray drying and granulation, rolling enamel into balls, drying and firing in a kiln, heating up linearly at a constant speed , heat preservation at 1100°C for 1 hour, firing temperature at 1410°C, high fire Warming time 2.5 hours , Total firing time 44 hours . The alumina content of the product is 91.05%, XRD analysis shows that ɑ-Al in the porcelain 2 o 3 High content, no γ-Al at all 2 o 3 Existence, the water absorption rate of the product is 4.94%, the crushing resistance of ceramic balls with a diameter of 50mm is greater than 50kN, the acid resistance is 96.8%, the alkali resistance is 94.7%, and the resistance to rapid temperature changes (320°C → 20°C in the air) does not crack more than once, the highest resistanc...

Embodiment 2

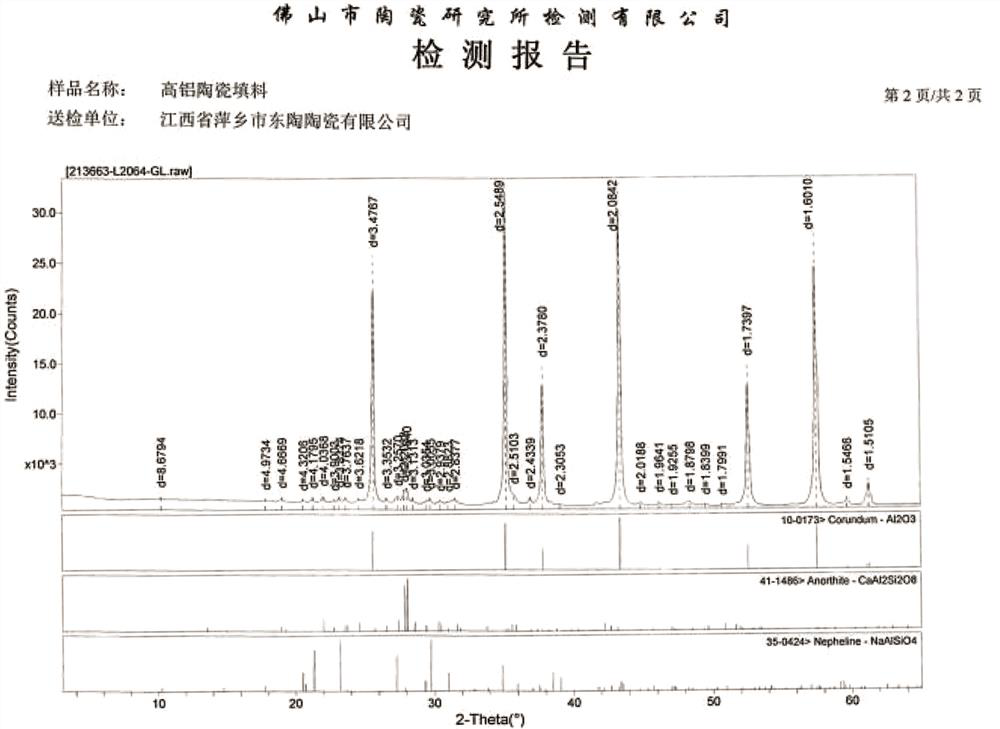

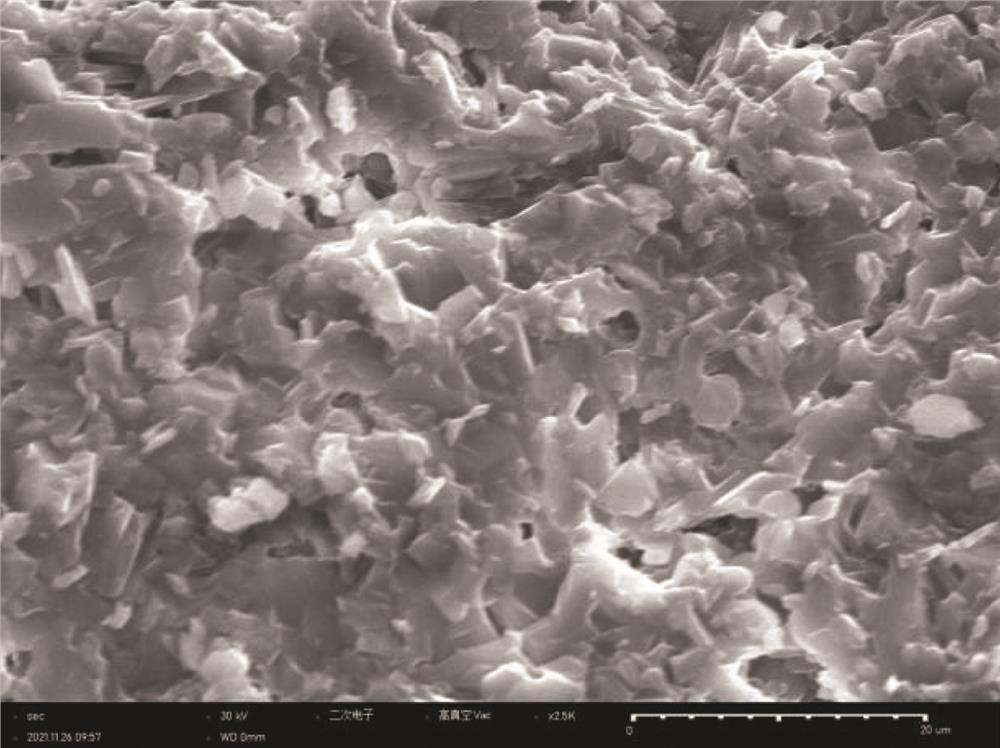

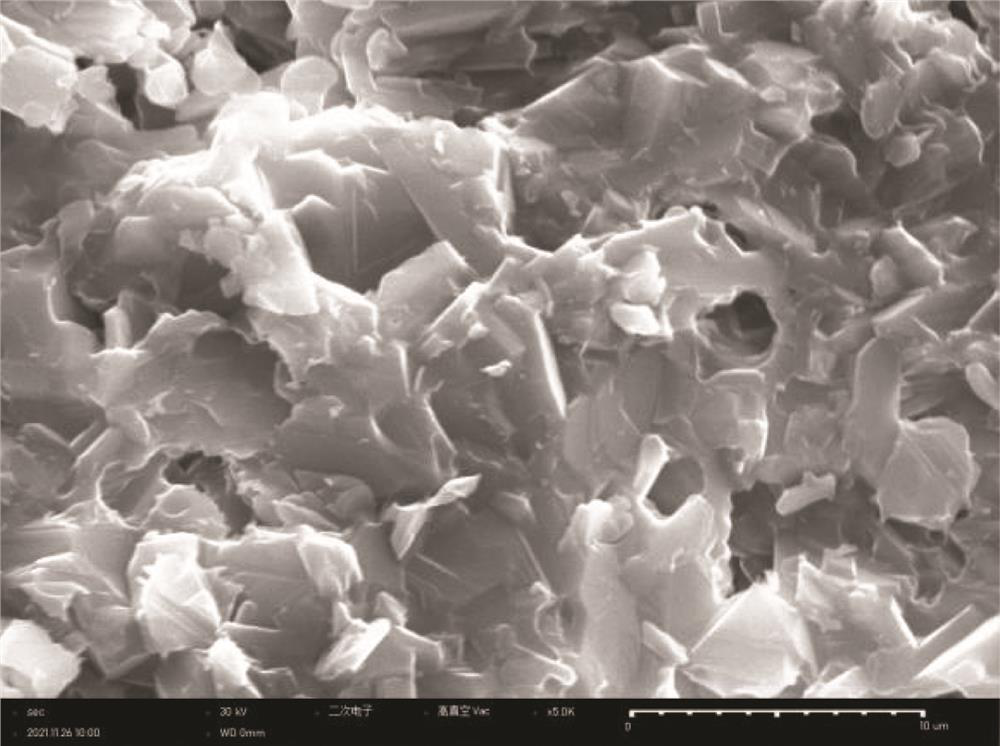

[0056] Embodiment 2: According to industrial alumina 89kg, Turkish colemanite 3.5kg, silica fume 2.5kg, dolomite 2.5kg, ball clay 2.5kg batching, add water 55kg, polyacrylic acid ammonium dispersant 0.2kg, go out after ball milling 36 hours Grinding, spray drying and granulation, rolling enamel into balls, drying and firing in a tunnel kiln, heating at a uniform speed, The total firing time is 45 hours, including 2 hours at 1100°C , the firing temperature is 1410°C, and the high-fire holding time is 2 hours . The alumina content of the product is 91.09%. After XRD semi-quantitative analysis by Foshan Ceramics Research Institute Co., Ltd. (test report number: L2064 / W211024-03), the ɑ-Al in the porcelain parts 2 o 3 The content is about 64%, anorthite about 4%, nepheline 1%, amorphous phase about 31%, no γ-Al at all 2 o 3 exists (see attached figure 1 ), using the SNE-3000MS electron microscope to observe the porcelain pieces, and get the attached figure 2 , 3 , 4 pho...

Embodiment 3

[0057] Embodiment 3: press industrial alumina 89kg, Turkey colemanite 3.5kg, silica fume 2.5kg, dolomite 2.5kg, ball clay 2.5kg batching, add water 55kg, Sodium citrate dispersant 0.2kg, milled after 36 hours, spray-dried and granulated, rolling and enameled into balls, dried and fired in a tunnel kiln, and the temperature was raised linearly at a uniform speed. The total firing time is 45 hours, the firing temperature is 1410°C, the highest Fire holding time 2.5 hours . The alumina content of the product is 91.02%, and the XRD analysis of ɑ-Al in the porcelain parts 2 o 3 The content is very high, and there is still a very small amount of γ-Al 2 o 3 Existence, the water absorption rate of the product is 4.36%, the crushing resistance of ceramic balls with a diameter of 50mm is greater than 50kN, the acid resistance is 96.2%, the alkali resistance is 94.1%, and the resistance to rapid temperature changes (320°C → 20°C in the air) does not crack more than once, the highe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crushing resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com