Patents

Literature

53 results about "Colemanite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Colemanite (Ca₂B₆O₁₁·5H₂O) or (CaB₃O₄(OH)₃·H₂O) is a borate mineral found in evaporite deposits of alkaline lacustrine environments. Colemanite is a secondary mineral that forms by alteration of borax and ulexite.

Steel slag radiation shield concrete and preparation method thereof

ActiveCN101805156AOvercome the problem of segregationIncrease the proportionSolid waste managementColemaniteApparent density

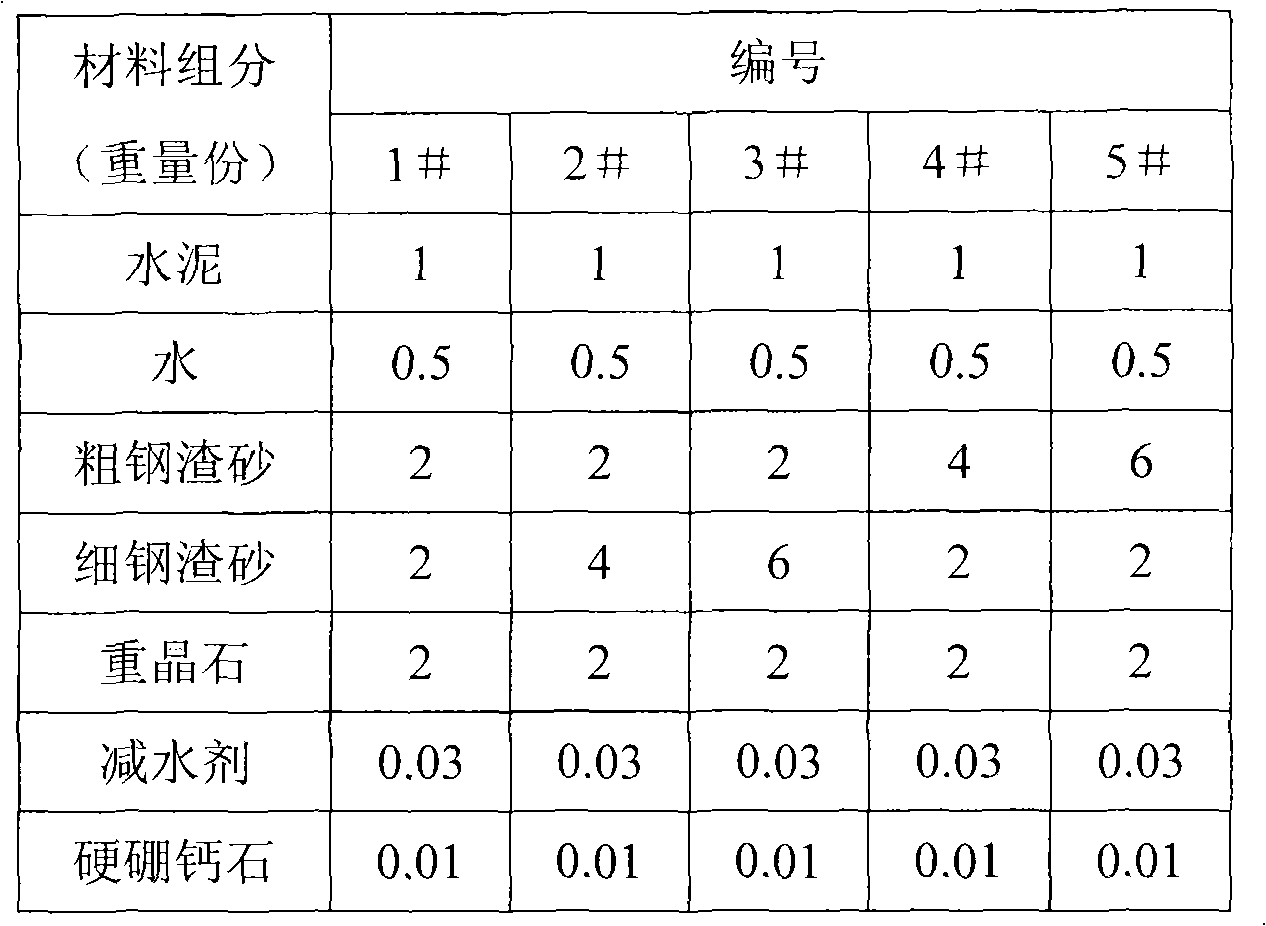

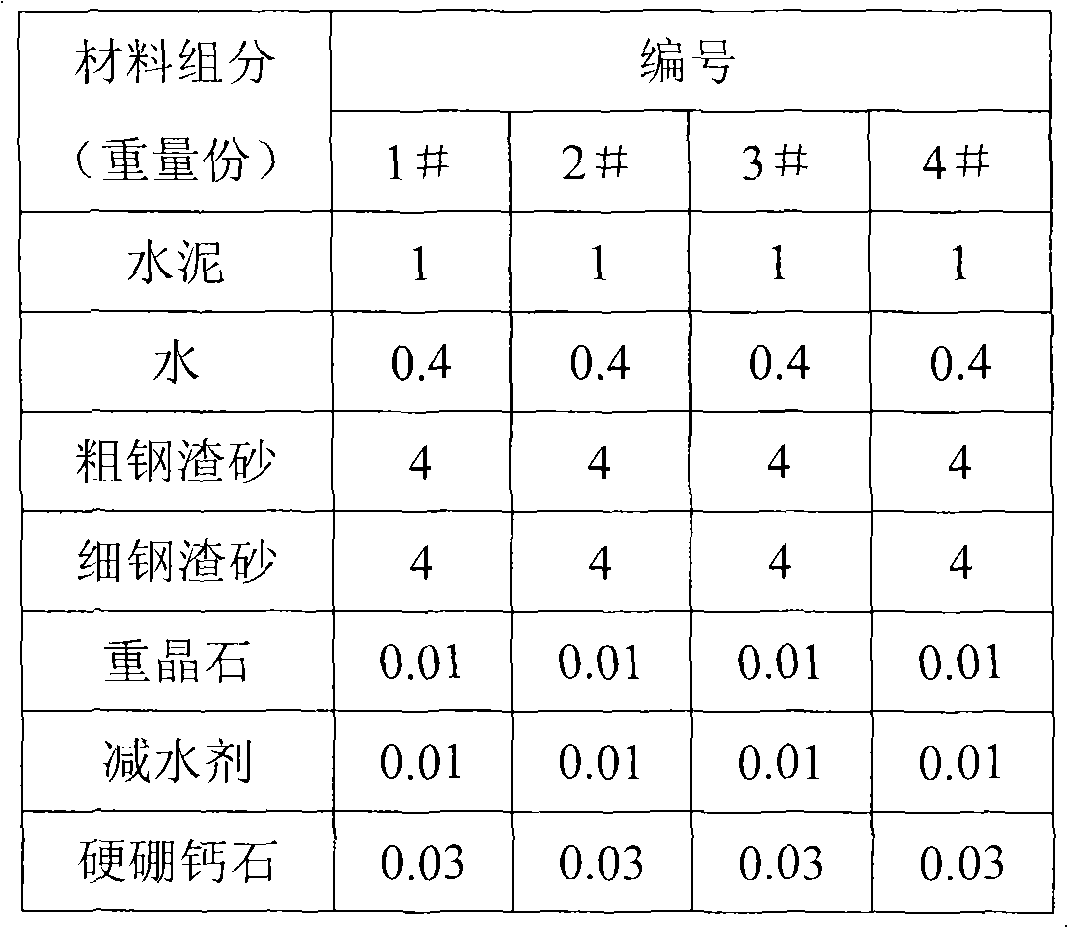

The invention relates to a steel slag radiation shield concrete and a preparation method thereof. The steel slag radiation shield concrete comprises the following components in parts by weight: 1 part of cement, 0.4-0.5 part of water, 4-8 parts of steel slag sand, 0.01-0.03 part of water reducing agent, 0.01-2 parts of barite and 0.01-0.03 part of colemanite, wherein the steel slag sand comprises two kinds of steel slag sand with the particle size ranges of 0-5mm and 5-25mm according to the proportion of 1-3:1-3, and the f.CaO content of the steel slag sand is less than or equal to 3%; the water reducing agent is selected from an FDN water reducing agent and a polycarboxylate water reducing agent; and the apparent density of the steel slag radiation shield concrete is greater than 2900kg / m<3>. The steel slag radiation shield concrete of the invention has good compactness, large apparent density and high strength and meets the requirements of the radiation shield concrete; the invention changes waste steel slag into valuable resources, reduces the environment pollution, simultaneously lowers the consumption of mineral materials, and saves natural resources; and in addition, the steel slag used in the invention has abundant resources, low price and obvious economic benefit.

Owner:MCC BAOSTEEL TECH SERVICE

Carbon-based organic-inorganic compound fertilizer specially used for navel oranges as well as preparation method and application thereof

InactiveCN108503473AIncrease contentIncrease the number ofCalcareous fertilisersMagnesium fertilisersColemaniteAdditive ingredient

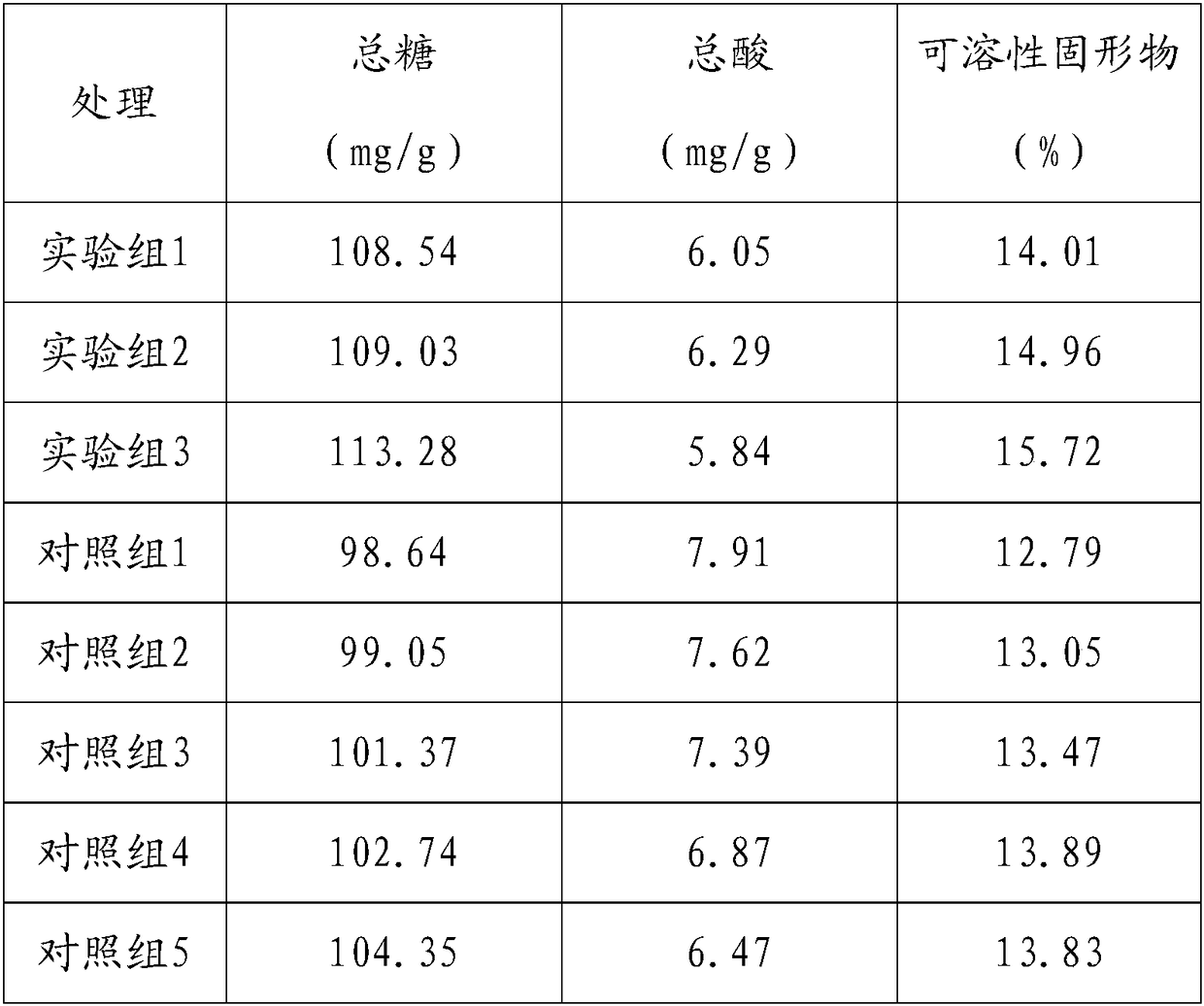

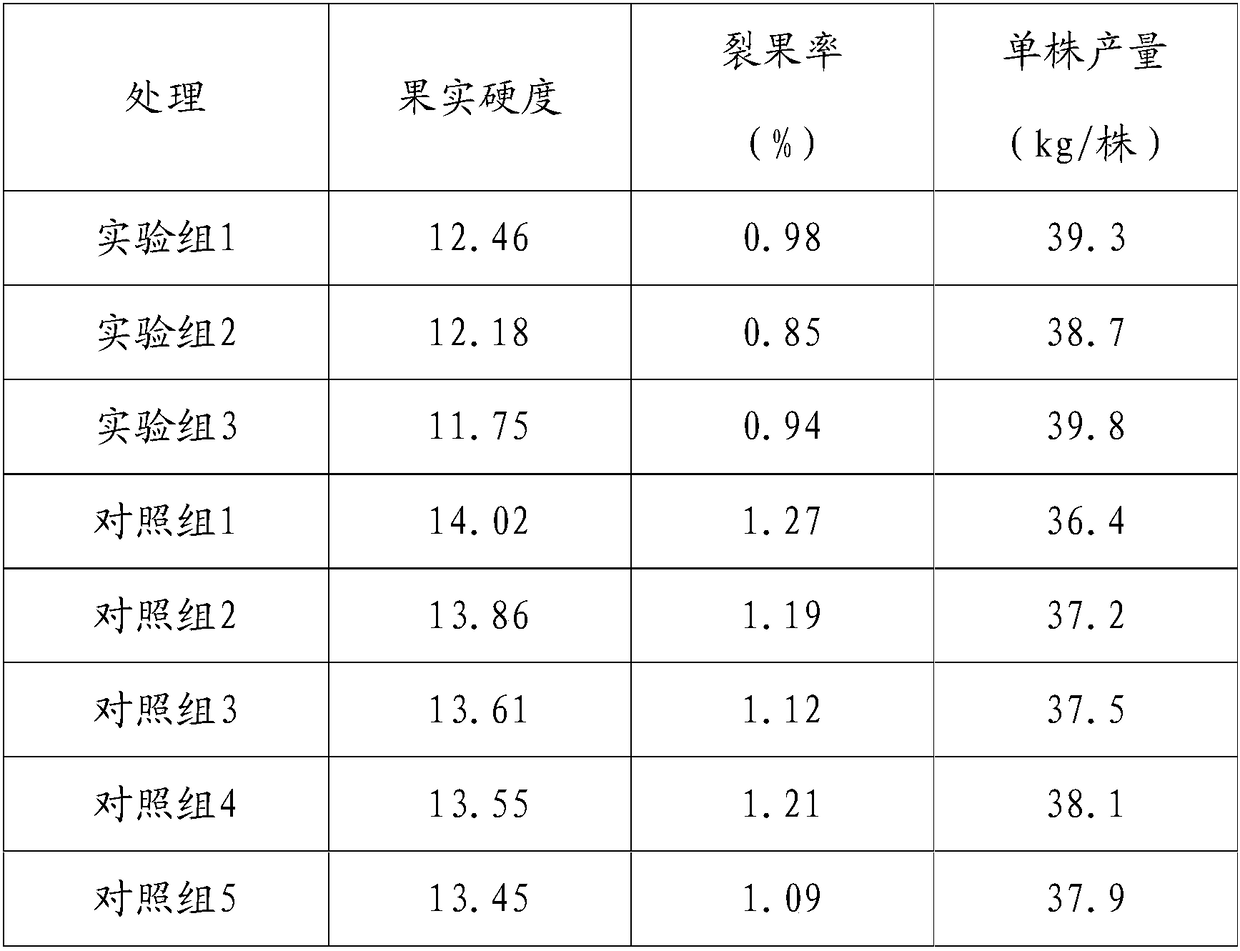

The invention provides carbon-based organic-inorganic compound fertilizer specially used for navel oranges. The carbon-based organic-inorganic compound fertilizer specially used for the navel orangesis prepared from the following raw materials in parts by mass: 21-27 parts of biochar, 13-18 parts of organic fertilizer, 20-27 parts of urea, 0.5-4 parts of urea phosphate, 5-10 parts of monopotassium phosphate, 7-13 parts of potassium sulfate, 1-2 parts of magnesium sulfate, 1.3-2 parts of colemanite, 5-8 parts of castor leaf powder, 3-5 parts of dalmatian chrysan themum powder, 2-5 parts of horseradish powder and 0.07-0.15 part of polyglutamic acid. The invention also provides a preparation method and application of the carbon-based organic-inorganic compound fertilizer specially used for the navel oranges. The carbon-based organic-inorganic compound fertilizer specially used for the navel oranges is comprehensive in nutrients and easy to absorb, can effectively improve physicochemicalstructural characters of soil, is improved in fertilizer utilization rate, contains plant-derived antibacterial insecticidal ingredients, is environmentally friendly, enhances stress resistance, is beneficial to absorption and utilization of fruit trees on the nutrients, promotes growth and improves yield and quality of the fruit trees.

Owner:湖南慧谷农业生态研究院有限公司

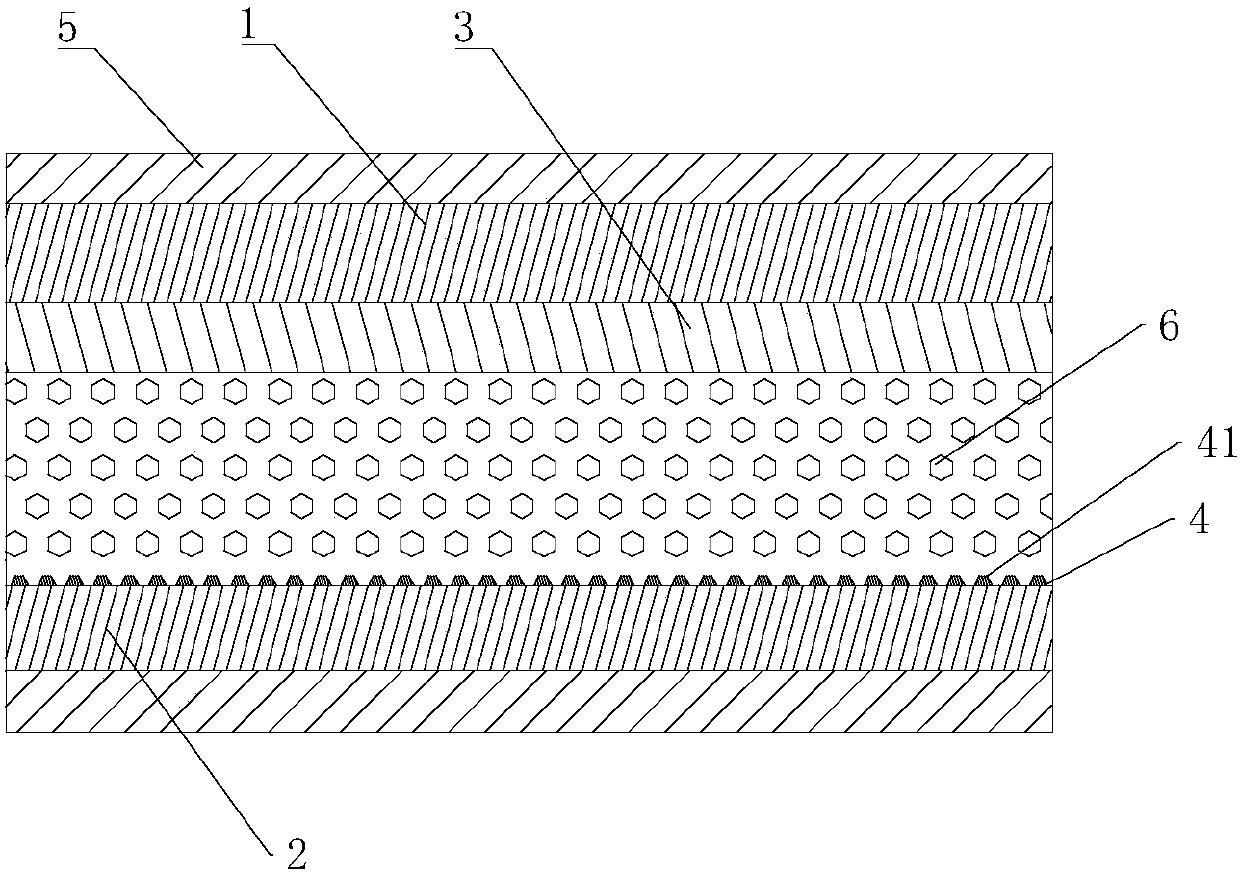

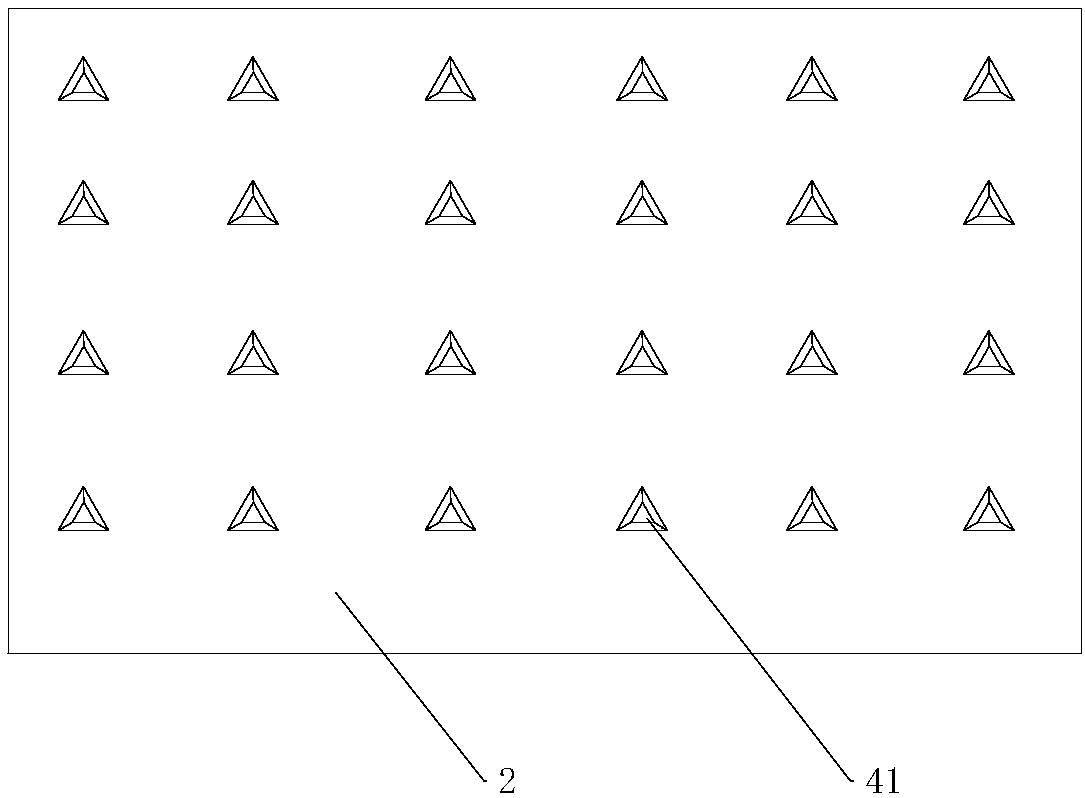

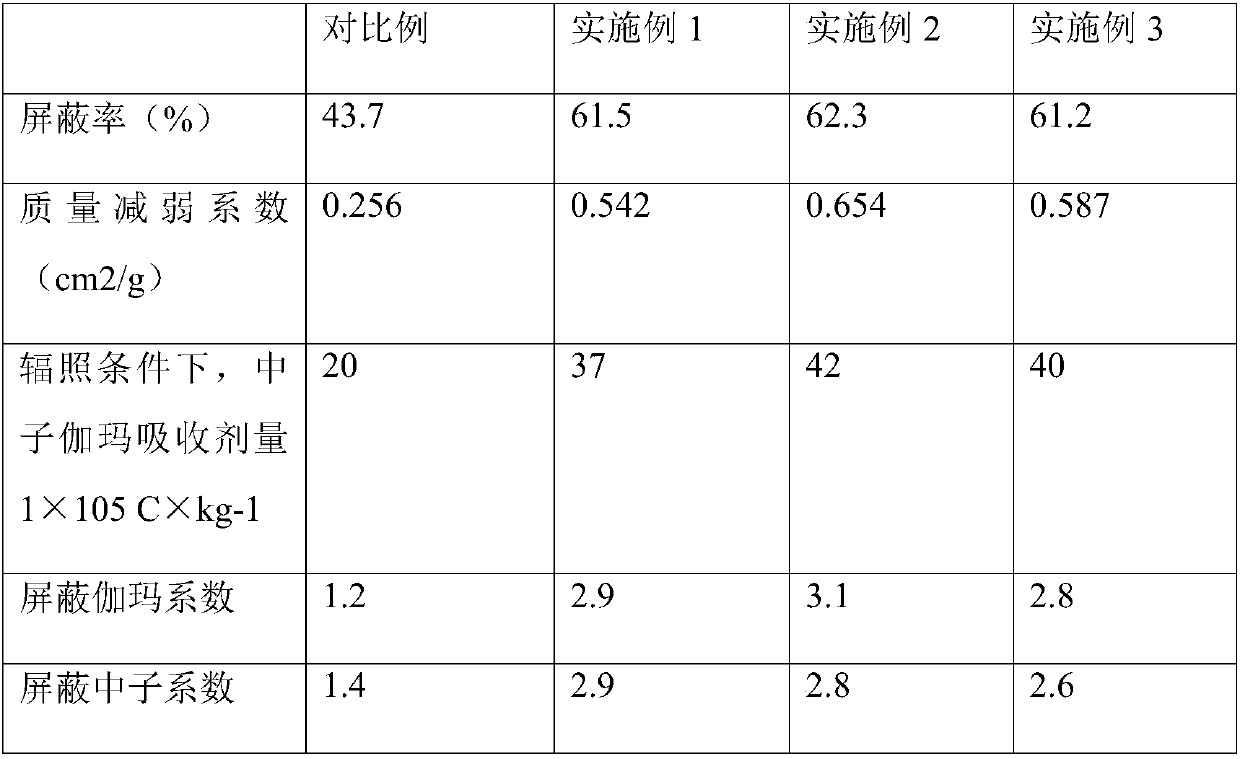

Composite particle material and radiant panel for shielding neutron gamma radiation by high strength

PendingCN107722425AImprove adhesionTotal reflectionSynthetic resin layered productsShieldingFiberColemanite

The invention discloses a composite particle material and a radiant panel for shielding neutron gamma radiation by high strength, and relates to the technical field of radiation-shielding plates. Thecomposite particle material comprises, by mass, 26-33% of high-density polyethylene, 2.2-2.7% of polyvinyl alcohol, 10-12% of lead sand, 2.9-4.0% of boron carbide powder, 1.2-1.5% of polyethylene wax,1.7-2.3% of coupling agents, 0.6-1.2% of colemanite, 1.1-1.4% of aluminum hydroxide, 1.0-1.2% of carbon fibers, 2.1-2.3% of 2, 6-butylated hydroxytoluene, 0.6-1.1% of oleamide, 0.6-0.9% of powdered aluminum and the balance samarium powder and tungsten powder.

Owner:镇江奥特氟科技有限公司

Method for producing glass fiber by using spodumene slag as fluxing clarifier

The invention discloses a method for producing glass fiber by using spodumene slag as a fluxing clarifier. The method comprises the steps of weighing, blending, melting, penetrating, wire drawing, drying and the like. The glass fiber is prepared from the following components in parts by weight: 100-120 parts of kaolin, 150-410 parts of pyrophyllite, 150-200 parts of quicklime, 50-70 parts of dolomite, 50-70 parts of colemanite, 130-310 parts of white afrodite, 20-30 parts of fluorite and 10-30 parts of spodumene slag, and the sum of the parts by weight of the components is 1000. The spodumeneslag is used as the fluxing clarifier, so that the prepared glass fiber can be prevented from deliquescing and caking; and furthermore, the spodumene slag can reduce the fire resistance of the kaolin,and the melting temperature is not needed for keeping stability, so that the difficulty of industrial production is reduced. By adopting the method provided by the invention for producing the glass fiber, the cost is lowered, the pollution of the slag to the environment can also be reduced, and the method has better economic and social benefits.

Owner:NEIJIANG HUAYUAN ELECTRONICS MATERIALS

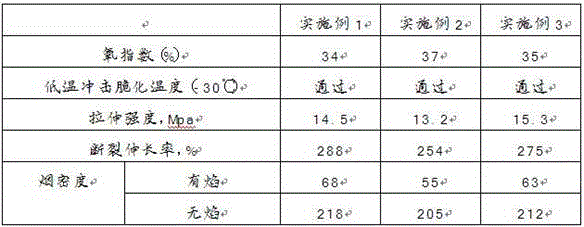

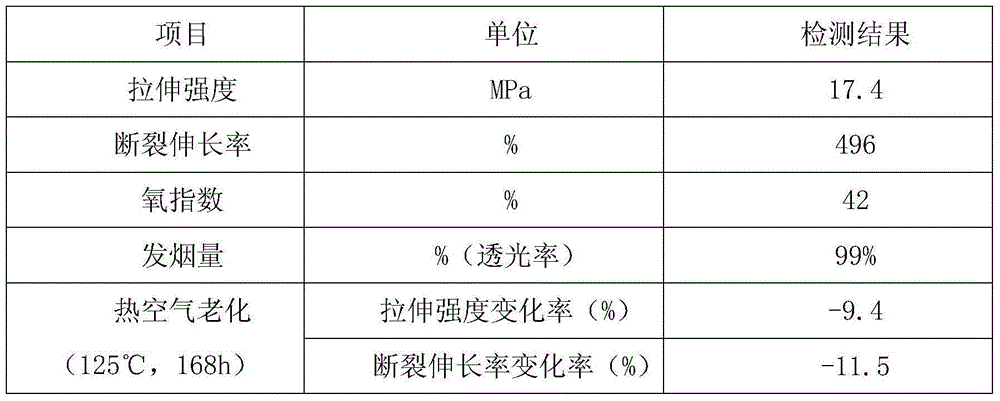

Low-smoke halogen-free flame-retardant crack-resistant cable material and preparation method thereof

InactiveCN105906920AImprove mechanical propertiesLow smoke productionInsulated cablesInsulated conductorsColemaniteAntimony

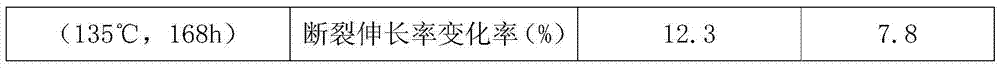

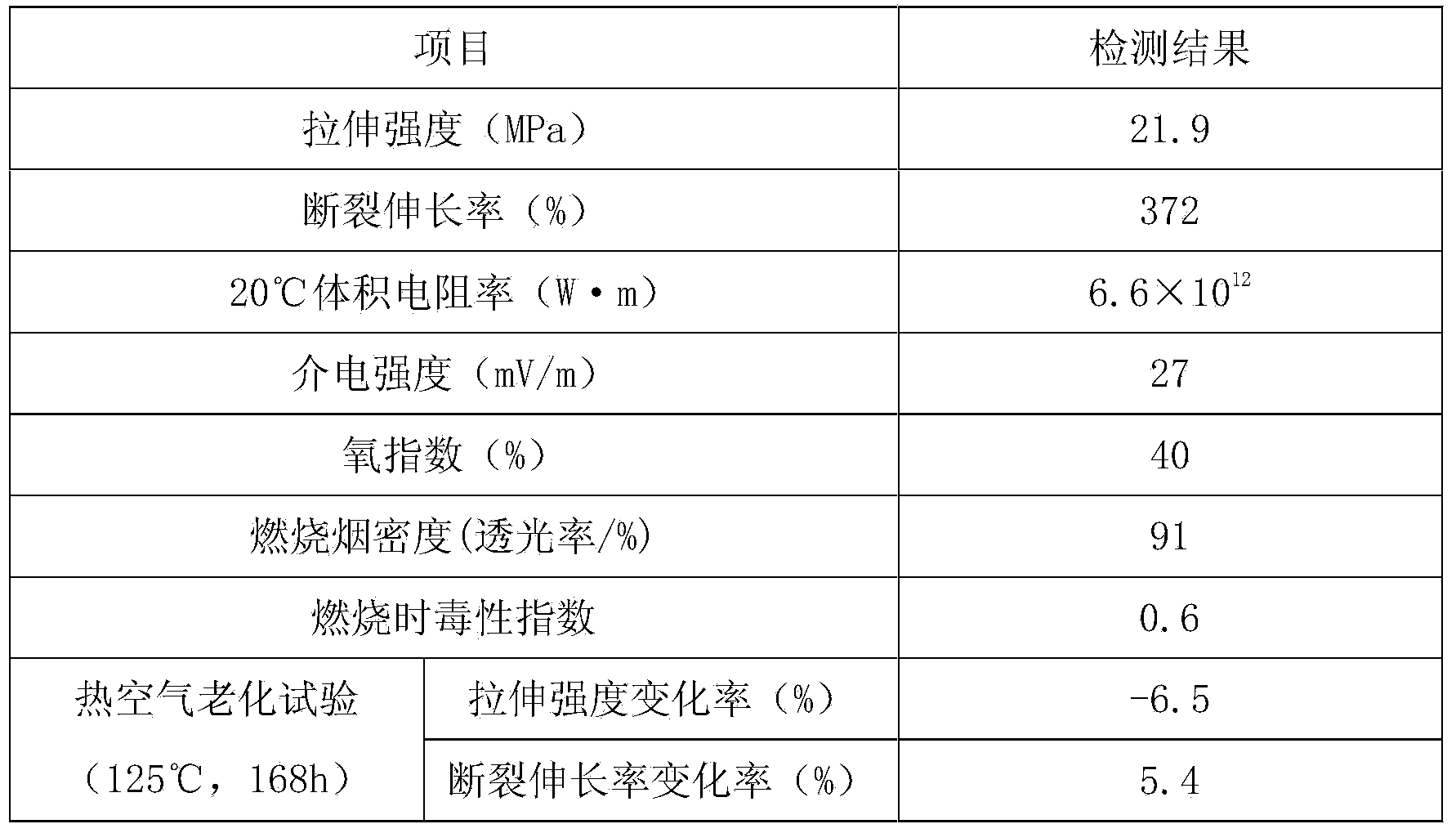

The invention discloses a low-smoke halogen-free flame-retardant crack-resistant cable material and a preparation method thereof. The low-smoke halogen-free flame-retardant crack-resistant cable material is prepared from the following raw materials in parts by weight: 65-75 parts of high-density polyethylene, 30-40 parts of ethylene-vinyl acetate copolymer, 7-9 parts of phenyl alkyl sulfonate, 4-6 parts of diethanolamine borate, 3-5 parts of magnesium dimethyl acrylate, 8-10 parts of magnesium hydroxide, 40-50 parts of tolyl diphenyl phosphate, 4-7 parts of 3-aminopropyltriethoxy silane, 7-9 parts of trimethylsilane-base cage-type polysilsesquioxane, 6-8 parts of organic antimony stabilizer, 5-7 parts of p-phenylenediamine, 30-40 parts of nano colemanite, 8-10 parts of Ome mineral fiber, 8-10 parts of hexachlorocyclotriphosphonitrile, 6-8 parts of carnauba wax, 10-12 parts of polyarylether ether nitrile, 7-8 parts of zirconium carbide, 5-8 parts of fibrous plaster, 4-6 parts of calcium hypophosphite and 8-12 parts of high-wear-resistance carbon black. The cable material has the advantages of favorable flame-retardant effect, less fuming and favorable cracking resistance.

Owner:卢永杰

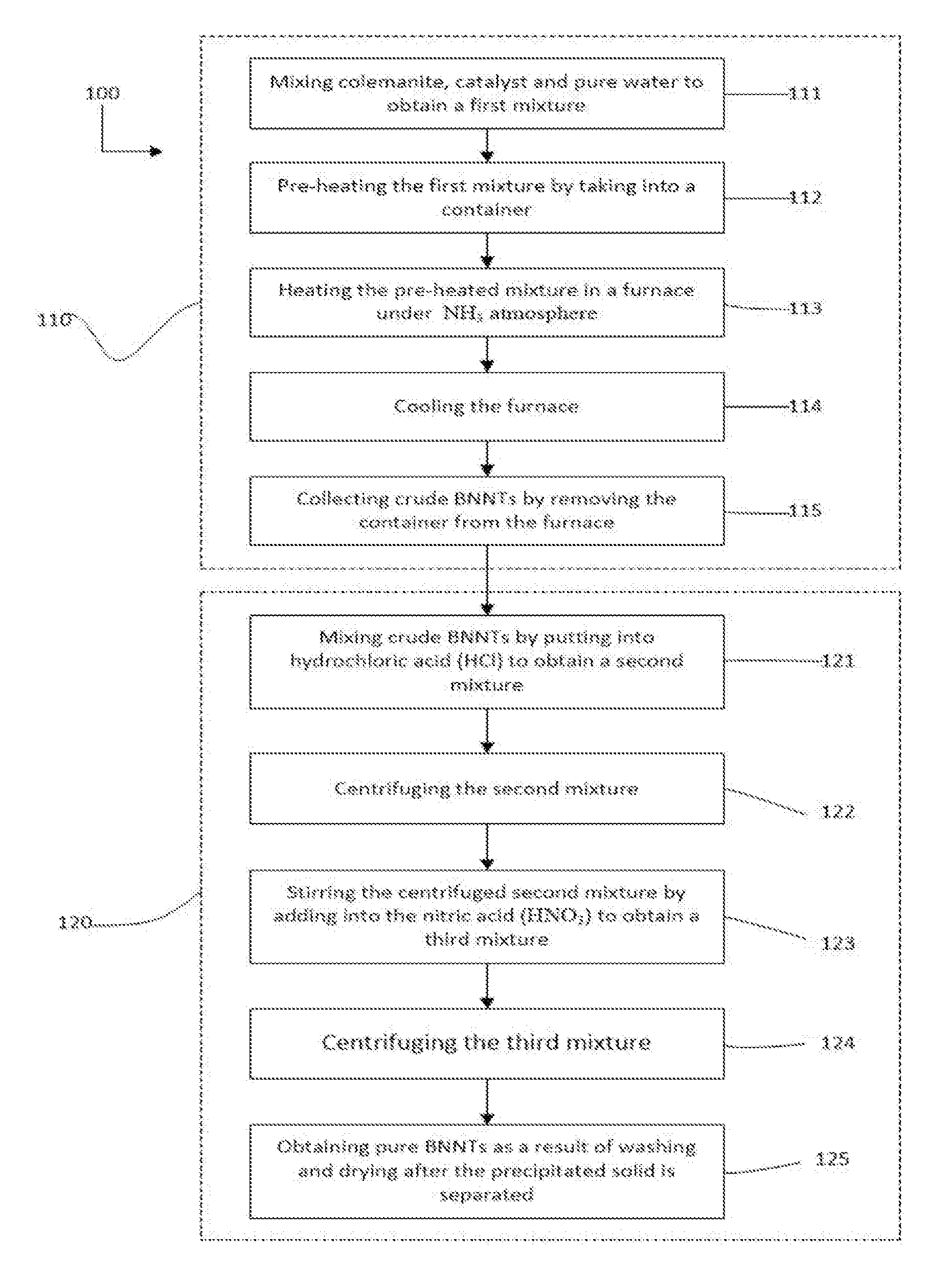

A production method for the boron nitride nanotubes

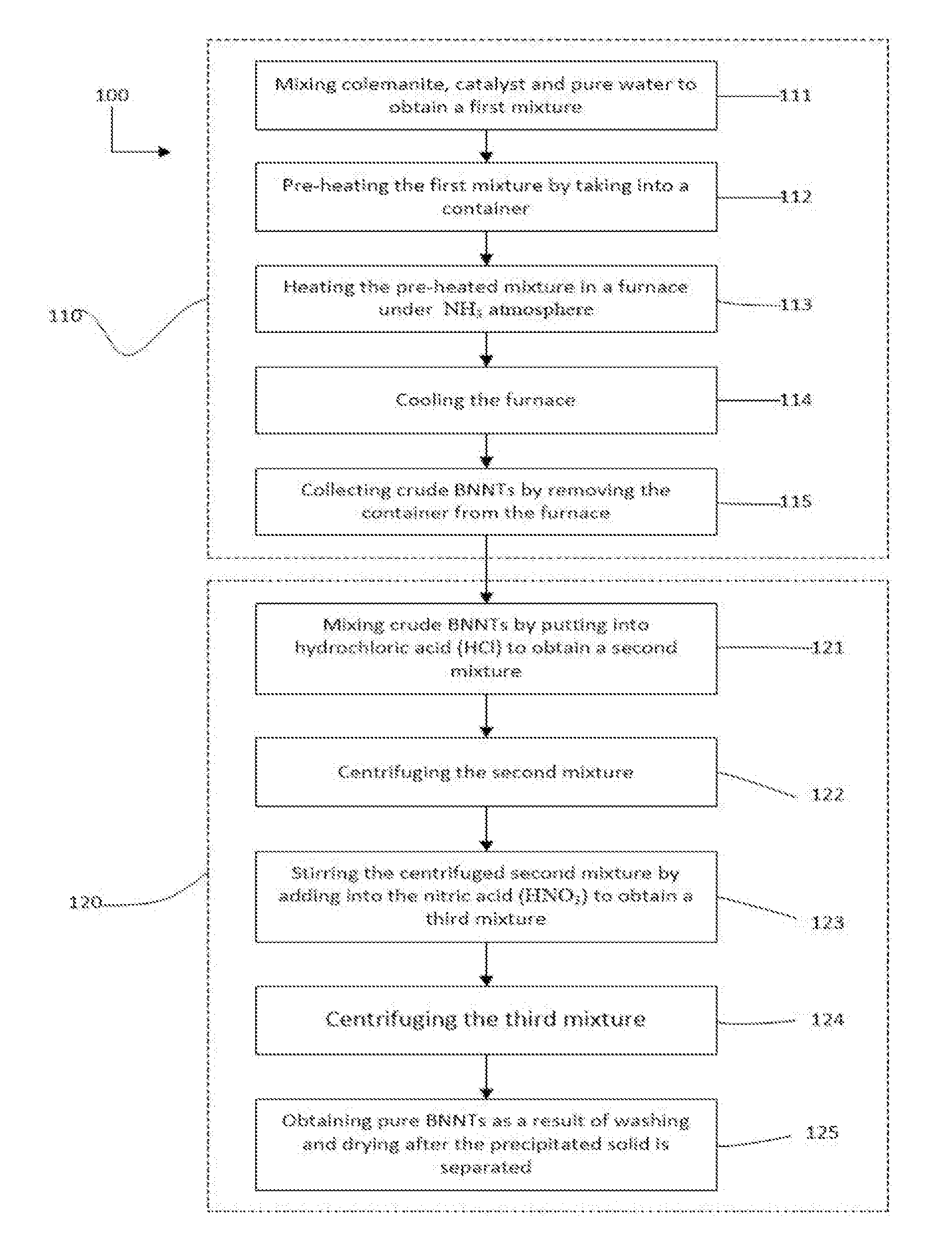

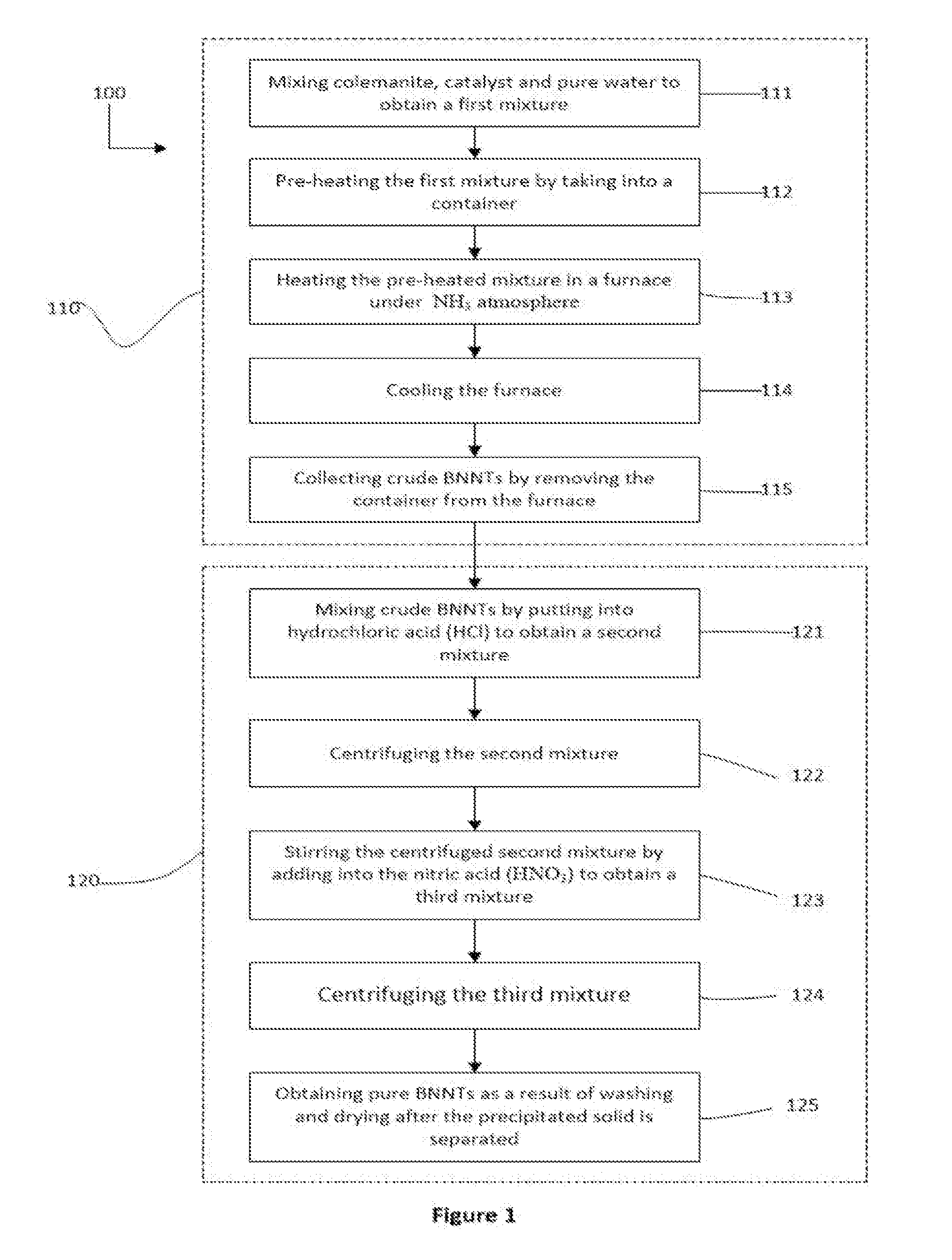

The present invention relates to a method, which essentially comprises the steps of performing crude boron nitride nanotube (BNNT) synthesis (110) and purifying BNNTs obtained in the crude form (120), and wherein direct BNNT production is provided with the use of colemanite that is a borate mineral.

Owner:YEDITEPE UNIVSI

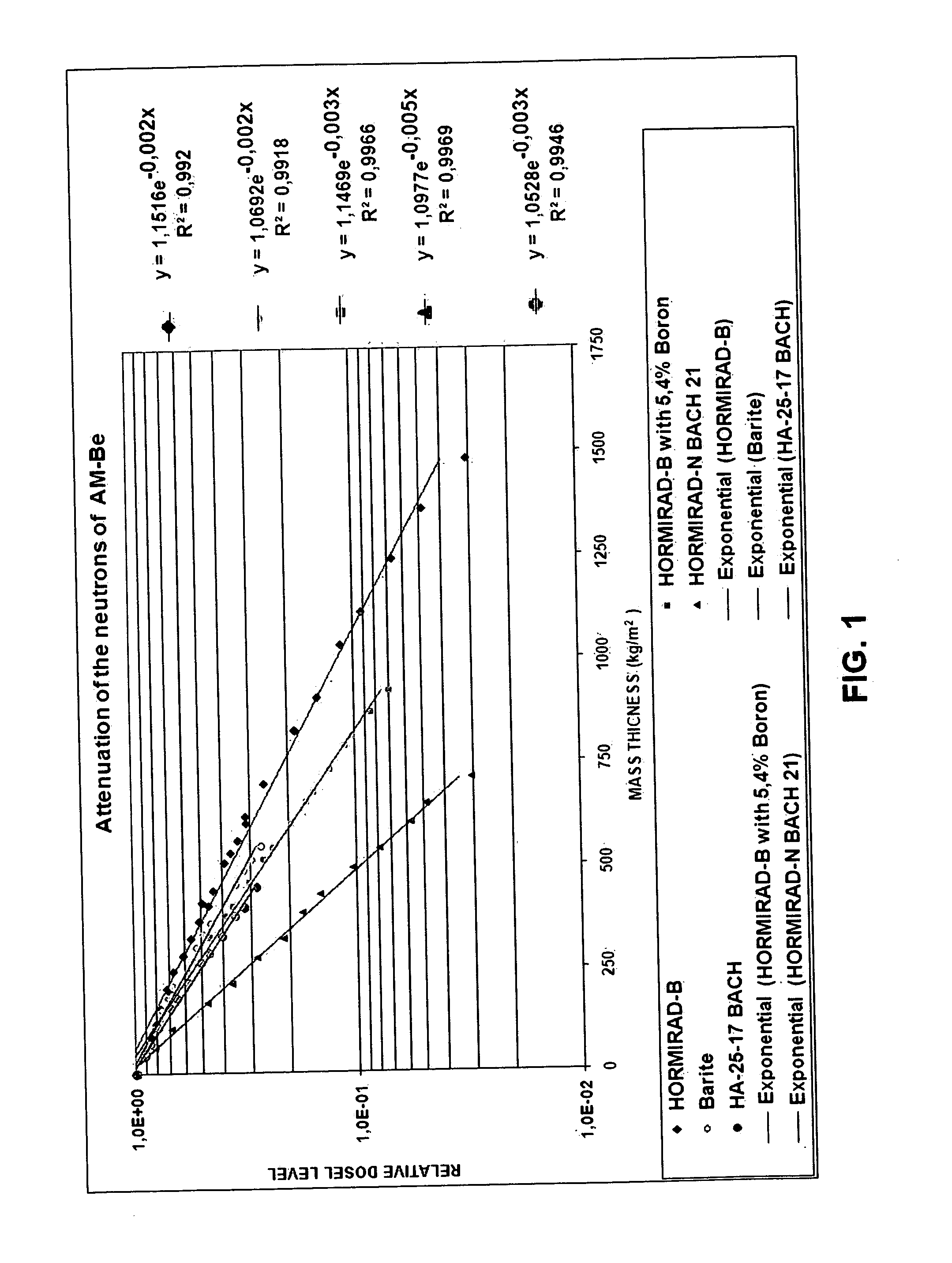

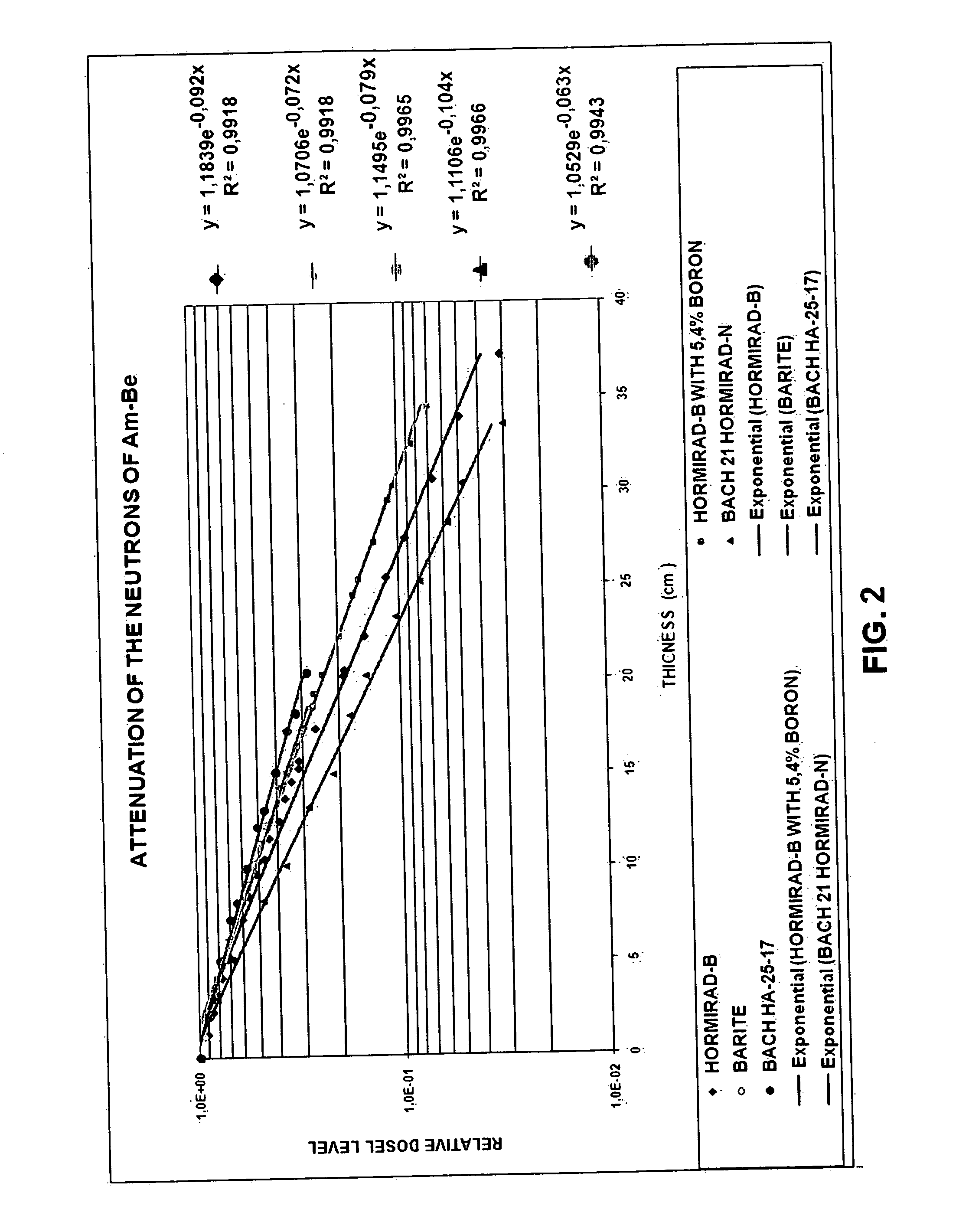

Material for absorption and attenuation of radiations

InactiveUS20130015408A1Improve homogeneityReduce thicknessSolid waste managementOther chemical processesColemaniteUltrasound attenuation

Products for obtaining masses for pouring, bricks, tiles and any other format are achieved, in which participate aggregates and asphaltic binders, as well as also additives for regulating the process. The invention achieves a remarkable increase in the capacity of neutrons, X-rays and / or photons radiation protection, and for this the use of asphaltic hydrocarbon as binder has been envisaged, while as aggregate is used Colemanite in absorption and attenuation of neutrons, Barite in the case of X-rays and Magnetite, Hematite and / or Steel shot in the case of photons.

Owner:ARRAELA

Method for producing alkali-free glass fiber by taking industrial slag as raw material

The invention discloses a method for producing alkali-free glass fiber by taking industrial slag as a raw material. The method comprises the following steps: a) weighing; b) preparing the raw materials; c) melting; d) passing; e) performing wire-drawing; f) drying; and g) performing a post-treatment step, wherein the raw materials comprise the following components in parts by weight: 460-520 parts of industrial aluminum ore, 100-160 parts of quicklime, 70-100 parts of dolomite, 60-80 parts of colemanite, 180-240 parts of white afrodite, 10-30 parts of fluorite and 1-5 parts of soda ash, and the sum of the parts by weight of all the components is 1000. According to the method disclosed by the invention, the alkali-free glass fiber is produced by taking the industrial slag which is rich in silicon aluminum as one of the main raw materials, so that the product quality is ensured, the cost of the raw materials is greatly saved, the environmental pollution is simultaneously reduced, and the method further has great economic benefits and better social benefits.

Owner:NEIJIANG HUAYUAN ELECTRONICS MATERIALS

Alkali-free glass fiber and preparation method thereof

The invention discloses an alkali-free glass fiber. The alkali-free glass fiber is prepared from 200-300 parts of wollastonite, 250-350 parts of pyrophyllite, 50-100 parts of quick lime, 100-200 parts of kaolin, 50-100 parts of dolomite, 10-80 parts of colemanite, 80-160 parts of quartzitic sandstone, 10-30 parts of fluorite and 5-20 parts of mirabilite. According to the prescription disclosed by the invention, the wollastonite is creatively used as a raw material for producing the alkali-free glass fiber, so that the amount of used pyrophyllite and quick lime is reduced, the raw material cost and energy cost are lowered, and a good economic benefit is achieved.

Owner:NEIJIANG HUAYUAN ELECTRONICS MATERIALS

Thermoplastic polyester resin composition

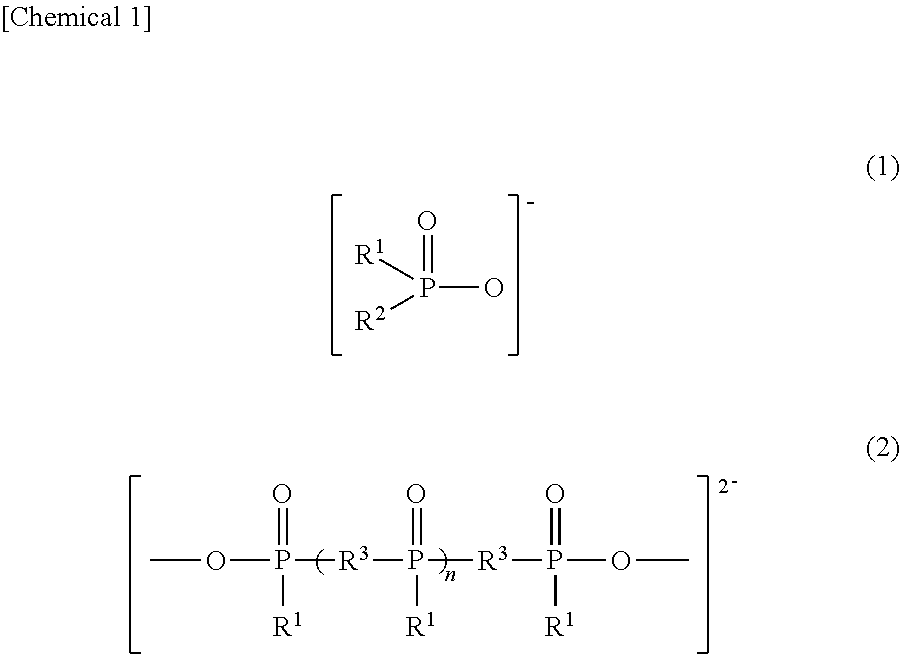

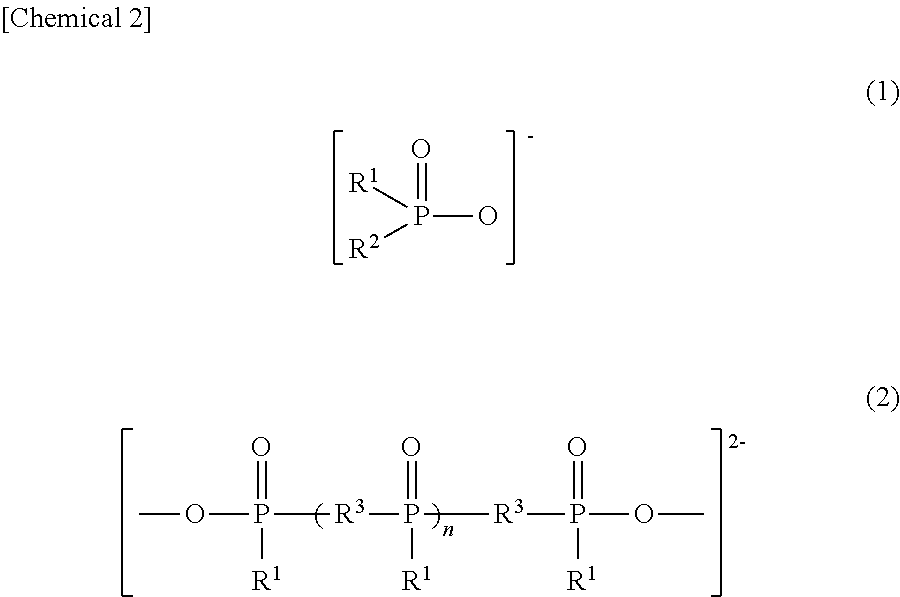

ActiveUS20110184101A1High mechanical strengthImprove featuresGroup 5/15 element organic compoundsArylColemanite

Disclosed is a thermoplastic polyester resin composition excellent in flame resistance, mechanical strength, and laser printability. The thermoplastic resin composition comprising 100 parts by weight of a thermoplastic polyester resin (A), 5 to 60 parts by weight of a phosphinate (B) represented by the following formula (1) or (2), 0.1 to 20 parts by weight of an organosiloxane (C), and 0.01 to 30 parts by weight of a colemanite (D), wherein the organosiloxane (C) is an organosiloxane compound (C-a) comprising organic groups bonding to a silicon atom directly or through an oxygen atom, wherein 40 mole % or more of the organic groups are an aryl group, and / or an organosiloxane polymer (C-b) in the form of solid at 25° C.

Owner:MITSUBISHI ENG PLASTICS CORP

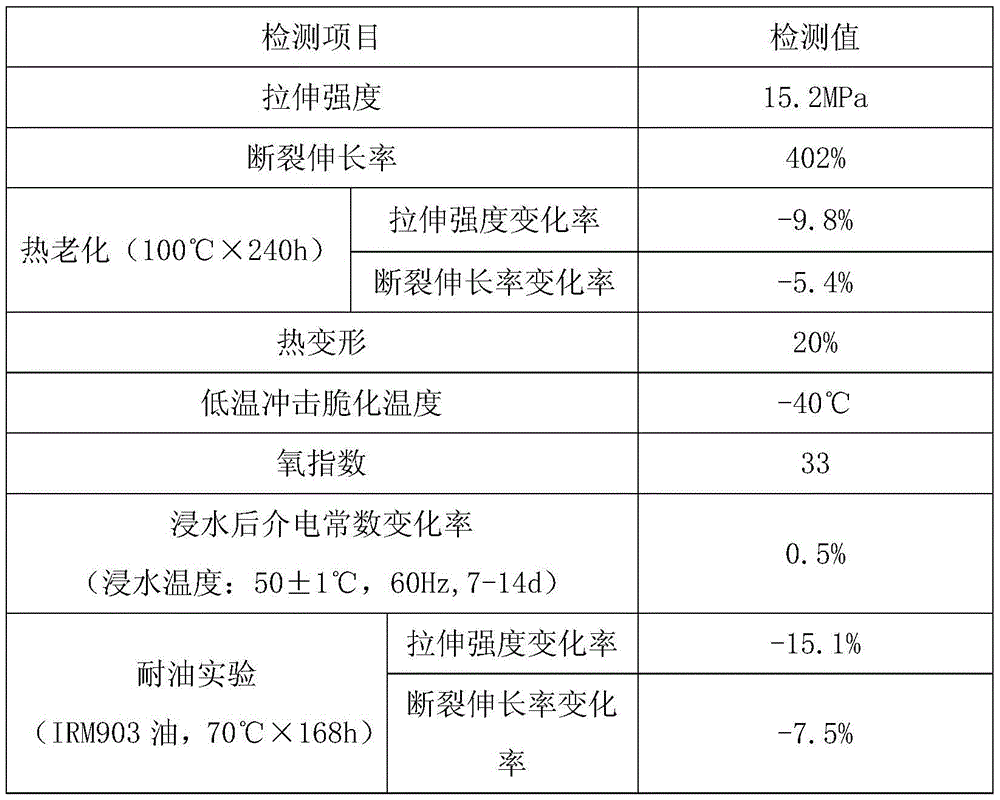

Anti-deformation heat preservation compound ethylene propylene diene monomer cable material and preparation method thereof

The invention relates to a cable material, in particular to an anti-deformation heat preservation compound ethylene propylene diene monomer cable material and a preparation method thereof. The anti-deformation heat preservation compound ethylene propylene diene monomer cable material is prepared from, by weight parts, 0.01-0.02 part of nano silver, 18-25 parts of colemanite powder, 12-16 parts of white carbon black, 4-5 parts of magnesium oxide, 1-2 parts of methacrylic acid, 6-8 parts of dravite, 40-50 parts of ethylene propylene diene monomer, 0.5-1 part of silane coupling agent KH-560, 3-5 parts of antimonous oxide, 5-8 parts of tetrabutyl titanate, 4-6 parts of dioctyl phthalate, 20-28 parts of butyronitrile rubber, 1-2 parts of accelerant CBS, 5-8 parts of color concentrate, 1-2 parts of dicumyl peroxide and 2-3 parts of adjuvant. According to the cable material, the ethylene propylene diene monomer and the butyronitrile rubber are taken as basic materials, modified and processed dravite composite filler is taken as the auxiliary materials, and the curability of the compound rubber is improved effectively.

Owner:ZHONGGUAN CABLE CO LTD

Radiation-proof anti-cracking heat-insulating concrete

The invention discloses radiation-proof anti-cracking heat-insulating concrete. The concrete comprises the following components in parts by weight: 70-100 parts of cement, 10-20 parts of zirconia, 4-12 parts of silica powder, 5-10 parts of sodium silicate, 10-20 parts of sodium fluosilicate, 10-20 parts of barite, 5-12 parts of carbon fiber, 4-12 parts of colemanite, 3-9 parts of TPU, 8-18 parts of Cyanolite honeycomb powder, 5-12 parts of polyethylene methyl ether methacrylate, and 3-9 parts of calcium lignosulphonate. A preparation method is simple, the prepared concrete has excellent radiation-proof, anti-cracking and heat-insulating performances, and overcomes the defects that the concrete in the prior art is poor in toughness, low in strength and easy to crack.

Owner:BEIJING JUNXIU CONSULTATION CO LTD

High temperature resistance rubber material for vehicles

InactiveCN105400013APracticalImprove high temperature resistanceArtifical filament manufactureRubber materialColemanite

The invention discloses a high temperature resistance rubber material for vehicles, which is prepared through raw materials with parts by weight: polyacrylonitrile 24-27, graphite 12-13, coal ash microspheres 3-4, lauryl sodium sulfate 0.7-1, liquid acrylonitrile butadiene rubber 42-55, methacrylic acids 0.6-1, nitrile rubbers 52-60, butadiene styrene rubber 20-25, colemanite 17-20, benzoyl peroxide 0.4-0.6, vulcanizing agent N,N'-m-phenylenedimaleimide (PDM) 2-3, liquid paraffin 2-3, an anti-aging agent D1-2, double fourteen carbon alcohol esters 1-2, clays 13-15, pyrophyllite in powder 7-8 and magnesium stearate 1-2. The high temperature resistance rubber material for the vehicles is excellent in high temperature resistance, cheap in raw materials, low in production cost and strong in practicality, has excellent application prospect when being used for the vehicles, and is simple in preparation method and easy for industrialization.

Owner:安徽创奇乐智能游乐设备有限公司

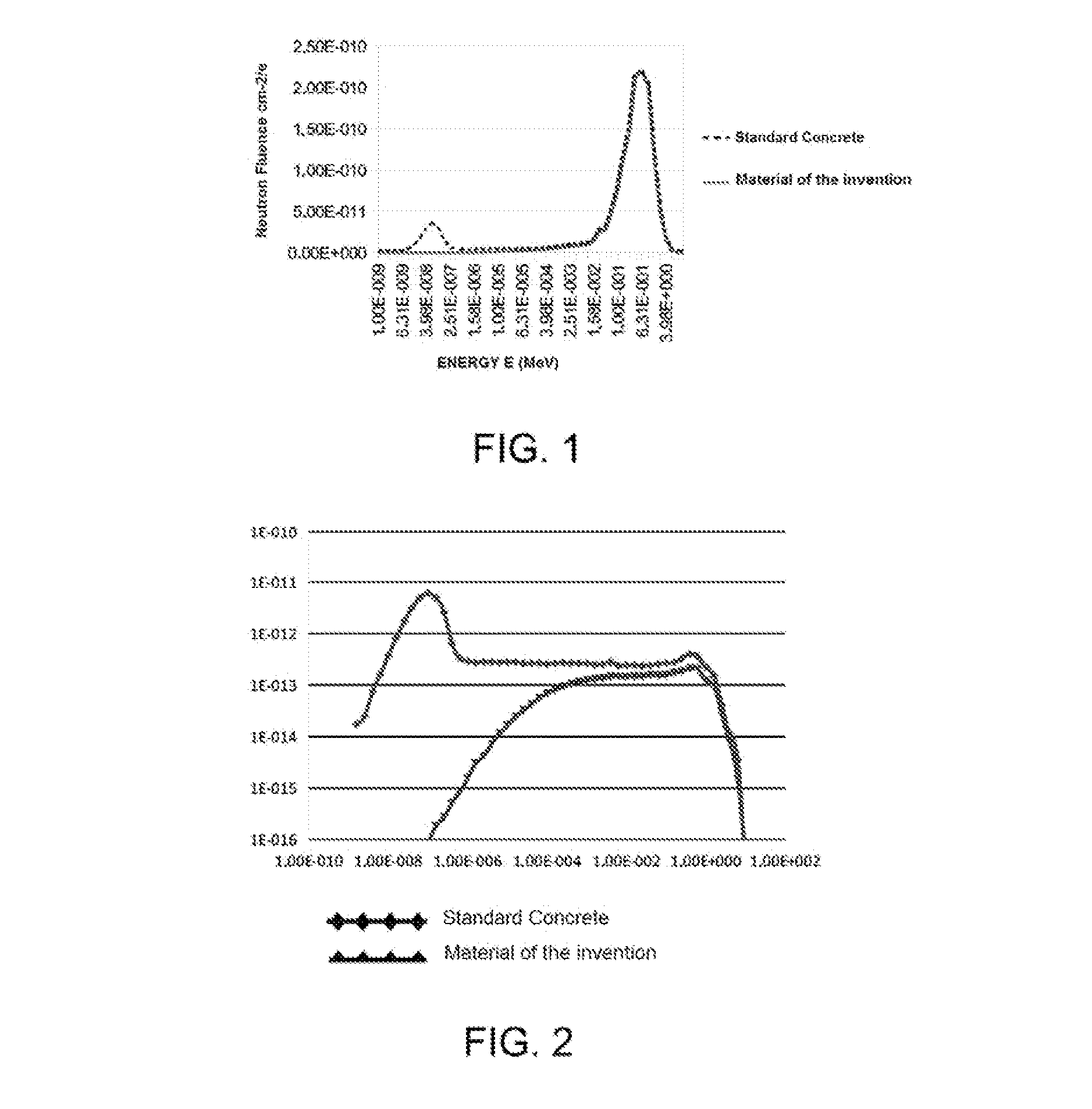

Mass for manufacturing products with a high neutron radioprotection capacity

The invention relates to a mass for manufacturing products with a high neutron radioprotection capacity which, like that of any conventional concrete, is structured based on cement or mixture thereof with calcium sulfate (anhydrite), aggregates, water and chemical additives modifying the characteristics of the concrete. According to the invention, said mass uses as an aggregate colemanite and variable parts of borax, with a very continuous grain size to achieve a perfect homogeneity in the mass, determining an optimal barrier effect against neutron radiations, which allows considerably decreasing the wall thickness, without adversely affecting the barrier effect. The mass is suitable for obtaining poured concrete, concrete for bricks, concrete for slabs and dry mortar, which can be used in building radioactive premises such as radiotherapy and brachytherapy bunkers, radiology walls, etc. This concrete has no structural capacity.

Owner:CONSTR TECNICAS DE RADIOTERAPIA

Steel slag sand-river bottom sludge composite lightweight partition plate and manufacturing method thereof

The invention discloses a steel slag sand-river bottom sludge composite lightweight partition plate. The partition plate is characterized by being prepared from the following raw materials by weight: 20 to 25 parts of cement, 12 to 16 parts of silico-calcium slag, steel slag sand, 8 to 11 parts of colemanite, 1.3 to 2.4 parts of maleic anhydride, 4 to 6 parts of silicone acrylic emulsion, 1 to 3 parts of alumina, 2 to 5 parts of alkylphenol polyoxyethylene, 1.3 to 3.2 parts of triethanolamine, 12 to 16 parts of crushed crude pearlite, 0.6 to 2.3 parts of calcium hydrate, 13 to 18 parts of bottom sludge, 18 to 22 parts of wheat straw, 15 to 18 parts of coconut shell, 3 to 6 parts of an auxiliary agent and a proper amount of water. The lightweight partition plate prepared by compounding of steel slag sand and river bottom sludge has is light in weight and low is cost, has the characteristics of good heat-preserving and thermal insulation effect, good corrosion resistance, excellent hanging force, high strength, sturdiness, durability and beautiful appearance, and has wide market prospects.

Owner:蚌埠华东石膏有限公司

Material for absorption and attenuation of neutrons

ActiveUS20130008350A1Improve homogeneityReduce thicknessShieldingRadioactive decontaminationColemaniteUltrasound attenuation

Masses for obtaining poured concrete, concrete for bricks, concrete for tiles or mortar are known, in which Portland cement and Colemanite, water and additives to regulate the process are involved as aggregate.The invention achieves a remarkable increase in the capacity of neutron radiation protection of the material. For this, Portland cement is replaced by Alumina cement and a new component is inserted into the mass, specifically anhydrous calcium sulfate, the Colemanite staying as aggregate.

Owner:ARRAELA

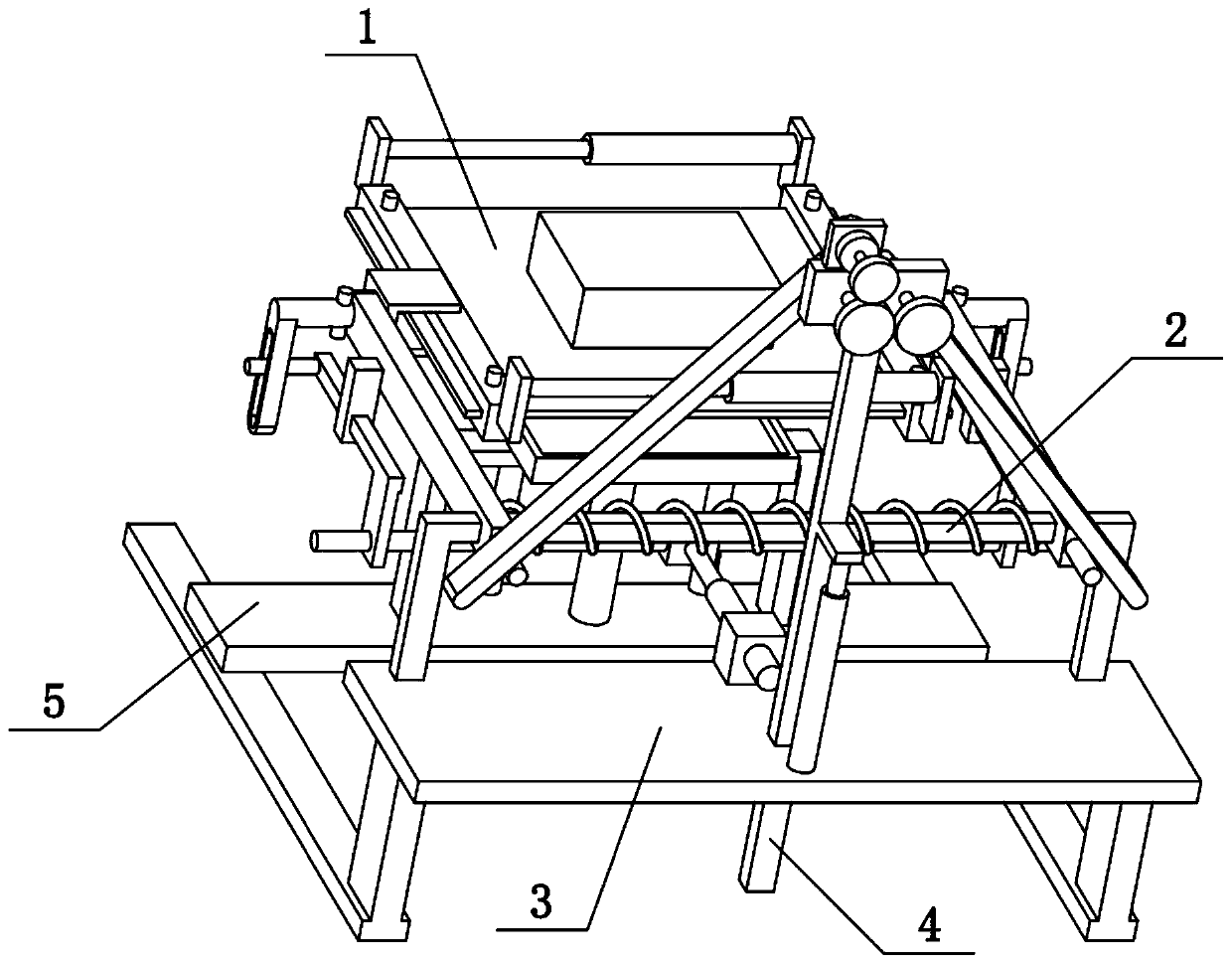

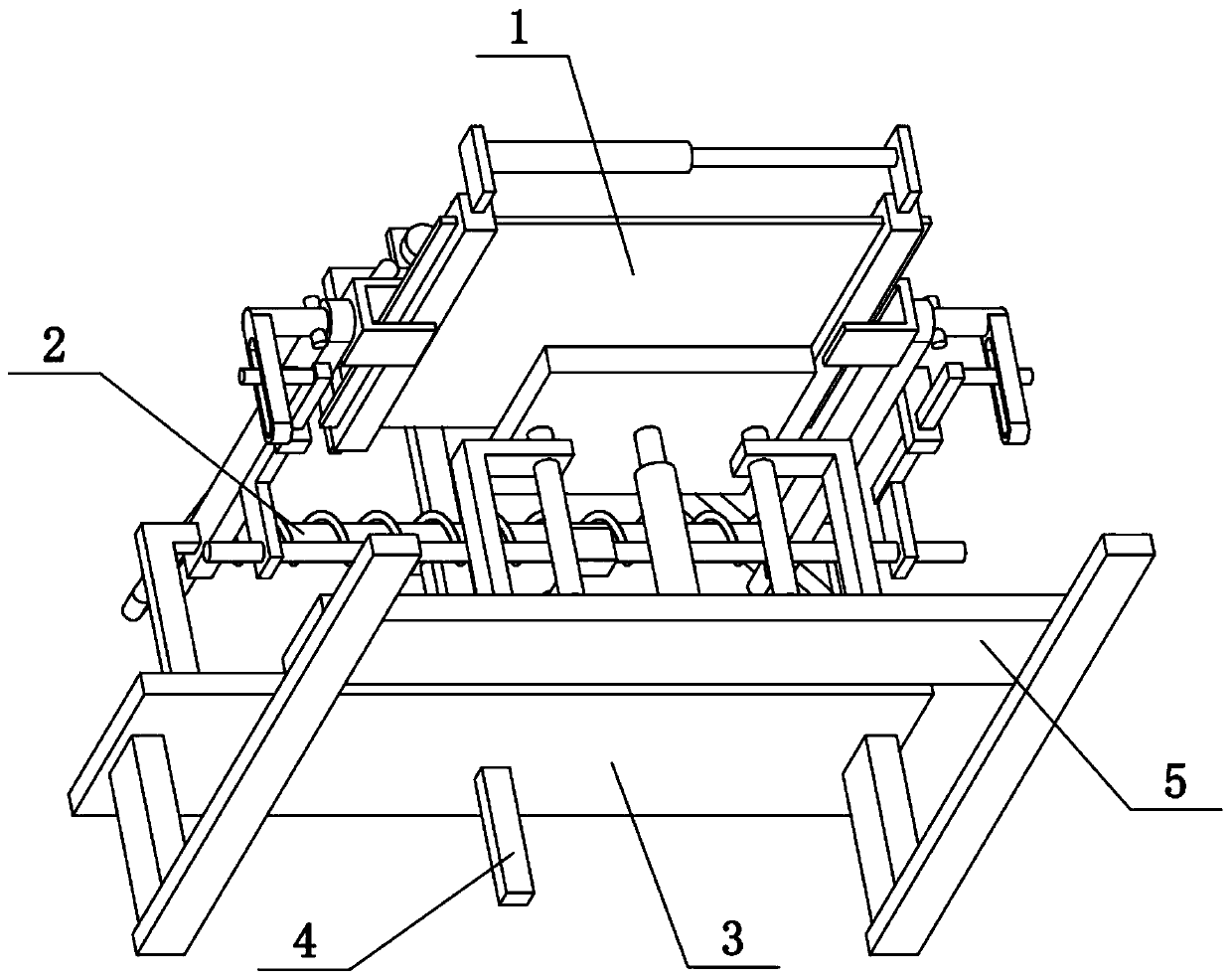

Concrete and preparing system and preparing method thereof

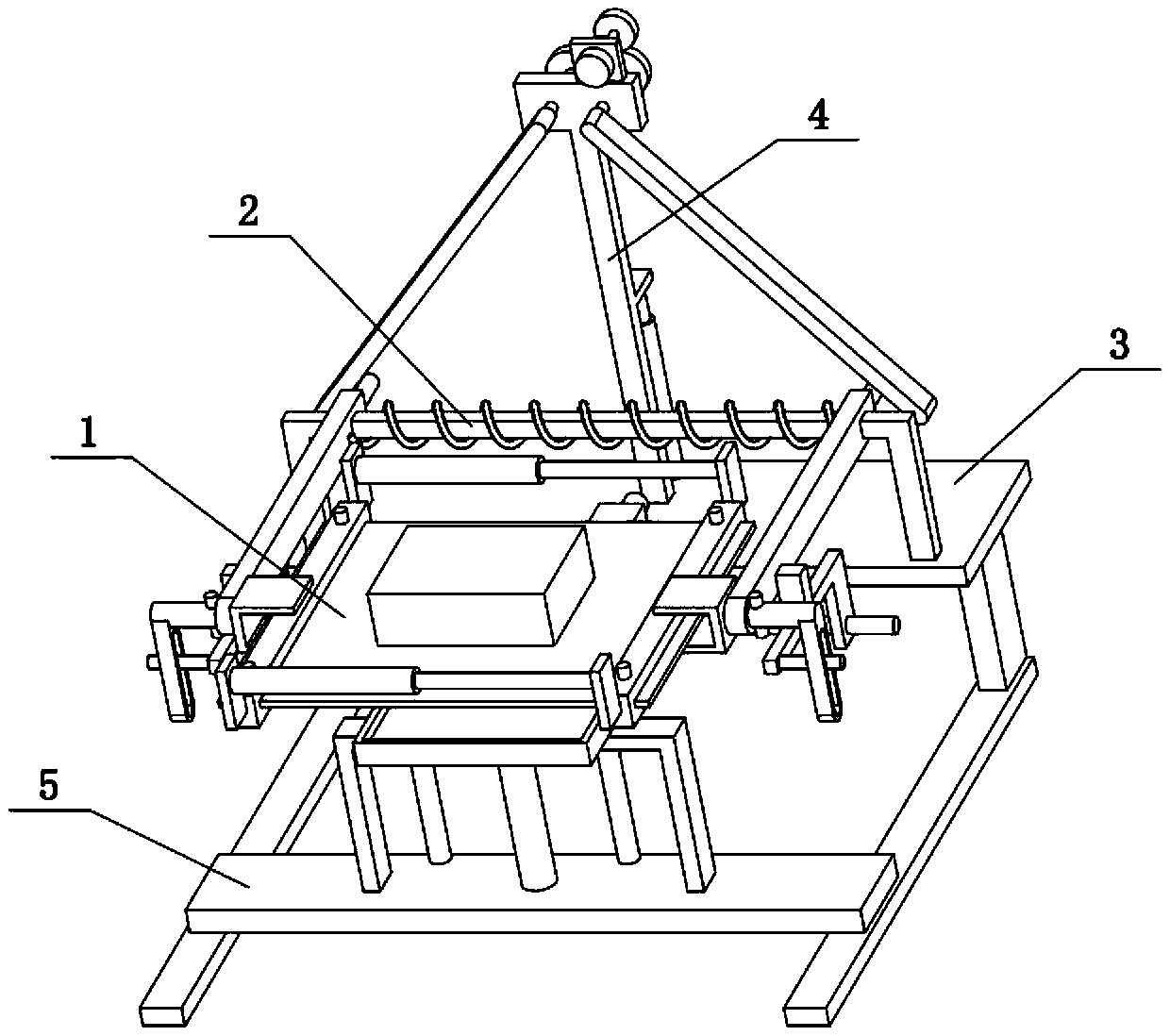

The invention relates to the field of concrete preparing, in particular to concrete and a preparing system and a preparing method thereof. The concrete is composed of raw materials including, by weight part, 10 parts of water, 1 part of silica powder, 2 parts of sodium fluosilicate, 4 parts of colemanite, 3 parts of polyurethane particles, 5 parts of metacrylic acid ester, 0.5 part of an excitingagent, 0.5 part of a water reducing agent and 2 parts of mineral powder. The method comprises the steps that firstly, the concrete raw material is placed in a plastic woven bag, and a concrete bag isplaced on textile cloth; secondly, when lower portions of two inclined pressing rods get close to each other, two convex cylinders are pressed to get close to each other, and two left and right movingrods slide on a transverse rod to get close; and thirdly, the lower portions of the two inclined pressing rods are away from each other, due to the effect of a compression spring, the two left and right moving rod rapidly get away, the textile cloth is rapidly changed into the tensioning state, bagged concrete on the textile cloth is topped up rapidly, and the topping up action is repeated continuously.

Owner:南京龙航混凝土有限公司

Flame-retardant and anti-static polycarbonate composite material for sockets and preparation method of composite material

InactiveCN105131555AImprove flame retardant performanceImprove antistatic performanceColemaniteGas phase

The invention discloses a flame-retardant and anti-static polycarbonate composite material for sockets and a preparation method of the composite material. The composite material is prepared from raw materials in parts by weight as follows: 80-100 parts of polycarbonate, 20-30 parts of polyvinyl chloride, 8-10 parts of SEBS, 2-4 parts of tributyl citrate, 3-5 parts of aluminum-doped nano-zinc oxide, 5-10 parts of zinc molybdate, 10-15 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, 3-5 parts of brominated epoxy resin, 5-8 parts of vinyltriethoxysilane, 14-18 parts of calcined kaolin, 6-7 parts of barium metaborate, 3-4 parts of bis(2-hydroxy-4-methoxyphenyl)methanone, 8-10 parts of hexagonal boron nitride, 8-10 parts of ethylene terephthalate, 6-8 parts of fumed silica, 35-45 parts of colemanite powder, 4-6 parts of sodium metaantimonite, 12-14 parts of ammonium polyphosphate, 5-9 parts of pentaerythritol stearate and 7-8 parts of dimethicone. The polycarbonate composite material has excellent flame-retardant and anti-static properties, good mechanical properties, high strength, good heat resistance and chemical resistance and excellent electric properties and is low in cost, wide in application range and easy to popularize.

Owner:张文哲

Fertilizers containing slow and fast release sources of boron

ActiveUS10717682B2Quick releaseReduce solubilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersColemaniteSoil science

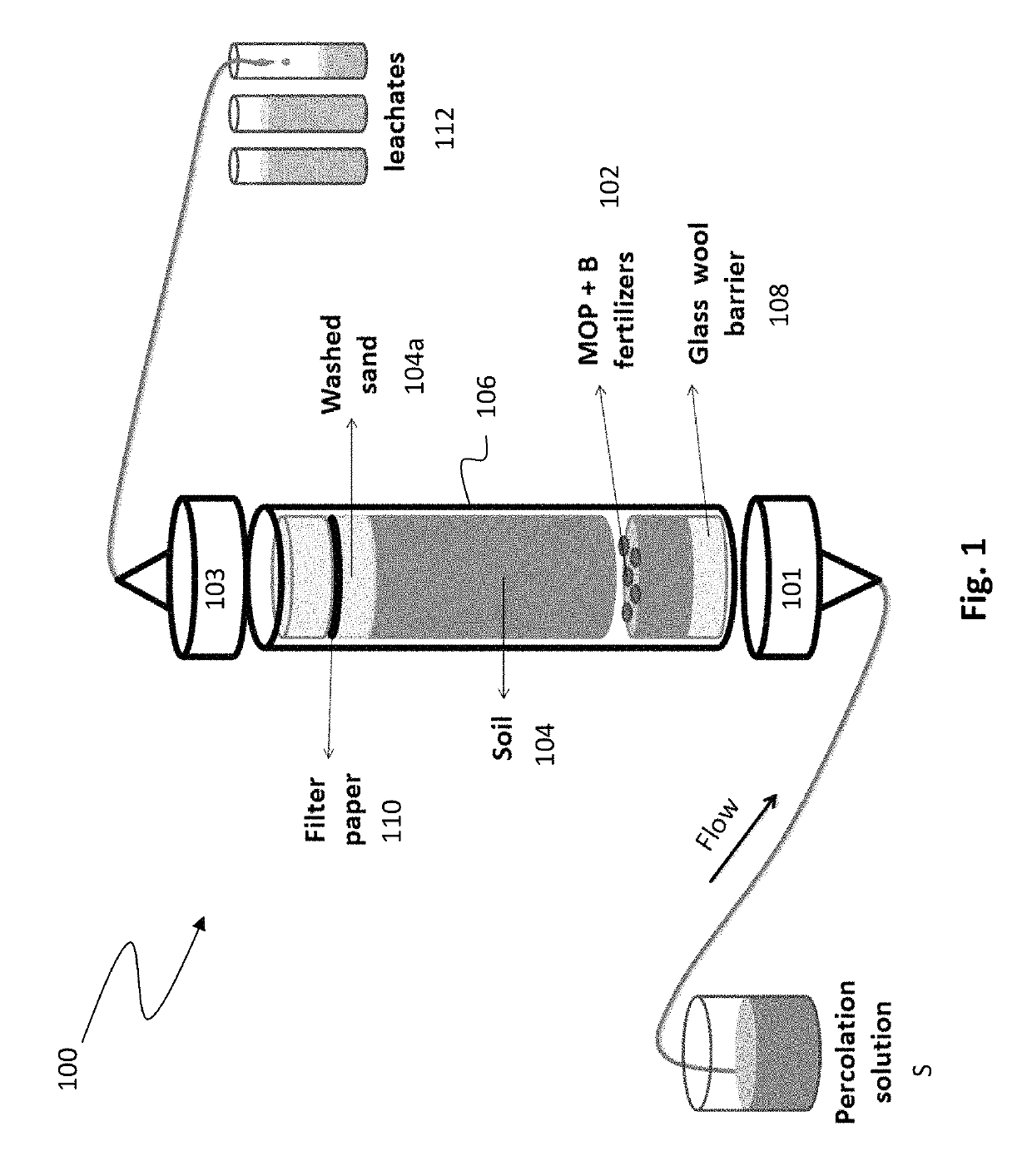

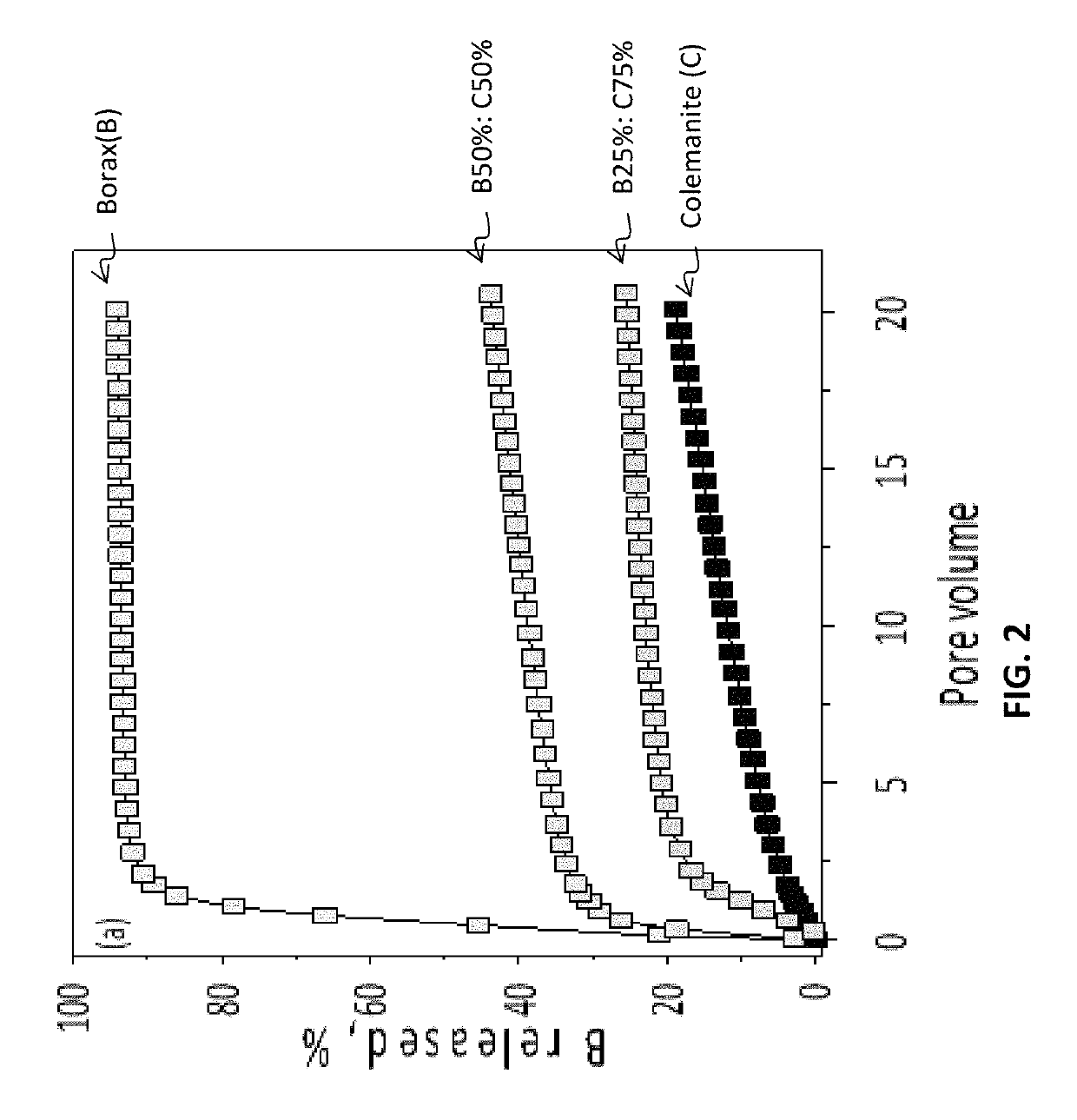

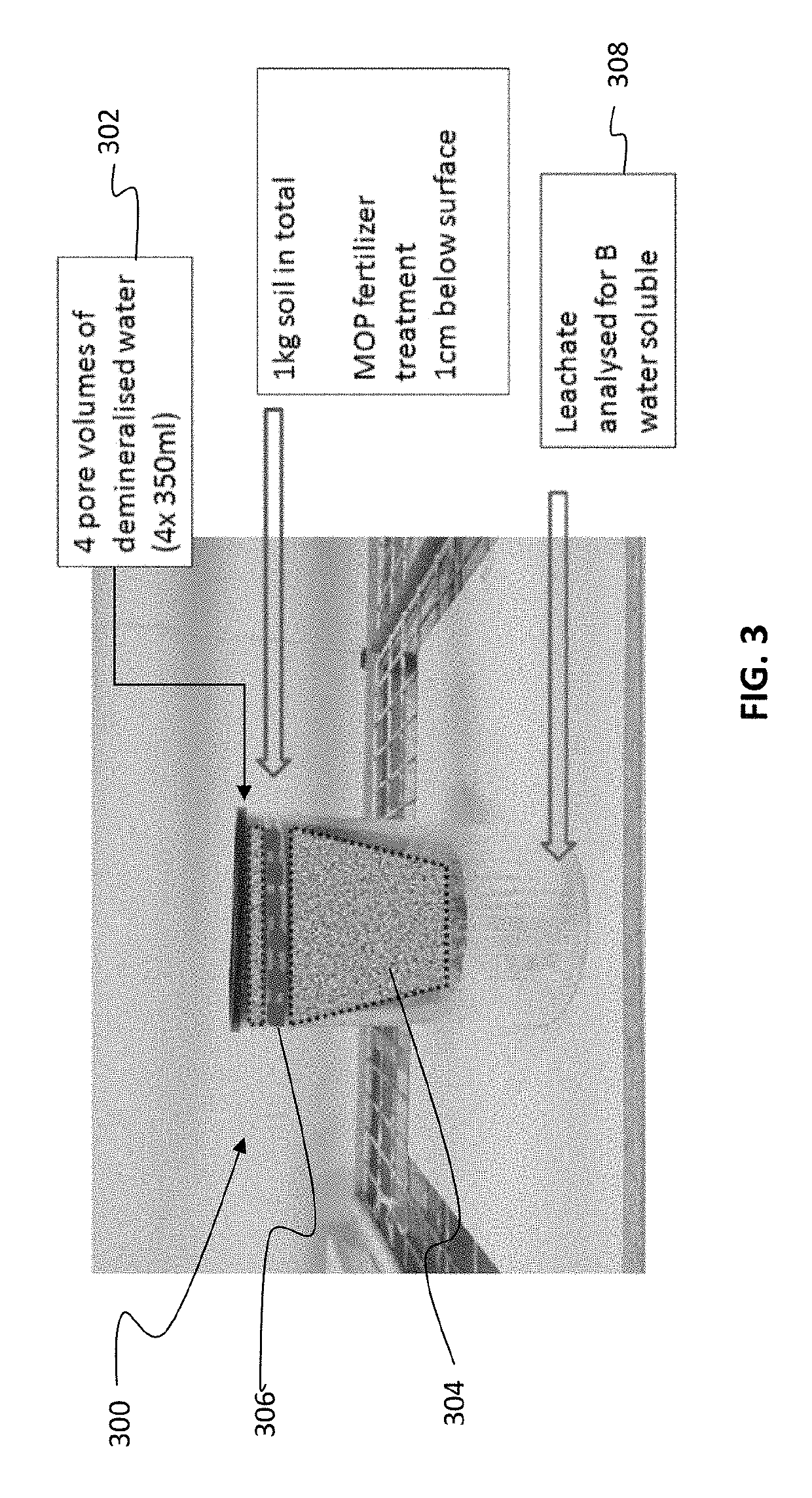

A granular fertilizer product having at least two sources of boron having different solubilities to tailor boron availability during the entire growing season of a plant, while reducing the risk of boron toxicity. A first source of boron can include a sodium-based or highly water soluble boron compound such as sodium tetraborate and / or boric acid, while a second source of boron can include a calcium-based boron compound such as colemanite (CaB3O4(OH)3.(H2O)) (e.g. when the carrier fertilizer is N- or K-based) and / or boron phosphate (BPO4) (e.g. when the carrier fertilizer is P-based). The solubility of the first source of boron is higher than the solubility of the second source of boron such that the sources of boron have different release rates into the soil.

Owner:THE MOSAIC COMPANY

EVA flame-retardation composite material and preparation method thereof

InactiveCN105237864AImprove flame retardant performanceImprove impact resistanceColemanitePolyetherimide

The invention discloses an EVA flame-retardation composite material and a preparation method thereof. The EVA flame-retardation composite material is prepared from, by weight, 44-58 parts of ethylene-vinyl acetate copolymer, 25-35 parts of brominated polystyrene, 18-29 parts of polyetherimide, 11-17 parts of polypentabromobenzyl acrylate, 10-15 parts of rectorite, 6-12 parts of zinc phosphate, 5-9 parts of calcium molybdate, 12-18 parts of hexakis(4-formacylphenoxy)cyclotriphosphazene, 3-6 parts of sodium pyroantimonate, 4-7 parts of dibismuth trioxide, 16-22 parts of colemanite, 8-12 parts of isopropyl phenyl diphenyl phosphate, 3-5 parts of basic lead carbonate and 4-8 parts of low molecular weight polypropylene. EVA is blended and modified with brominated polystyrene, polyetherimide, polypentabromobenzyl acrylate and other polymer materials with good compatibility with the EVA, so the flame retardation performance of the EVA is improved, and the impact resistance, the chemical stability and the fatigue resistance of the EVA are improved.

Owner:CHUZHOU YOUSHENG HIGH POLYMER MATERIAL

High-temperature-resistant high-fire-resistant polyimide film and preparation method thereof

InactiveCN106009667AImprove high temperature resistanceGood chemical resistanceColemaniteN-phenylmaleimide

The invention discloses a high-temperature resistant and highly flame-retardant polyimide film and a preparation method thereof, which is prepared from the following raw materials in parts by weight: o-phenylenediamine 50-55, pyromellitic anhydride 105-115, N, N-dimethylacetamide 25-30, furfural resin 28-34, nano-silicon nitride 8-14, colemanite 5-10, tris(2-chloropropyl) phosphate 13-17, dioxygen trioxide Antimony 6‑9, Hexachlorocyclopentadiene 10‑15, Aluminum Hypophosphite 7‑11, Melamine Formaldehyde Resin 12‑18, N‑Phenylmaleimide 3‑6, Dimethylbiphenyl Diisocyanate 2 ‑5, ammonium chloride 1‑2, p-hydroxybenzenesulfonic acid 1‑2. Inorganic raw materials such as colemanite added in the present invention cooperate with organic raw materials such as furfural resin to act as heat-resistant modifiers in polyimide films, which can improve the high temperature resistance, chemical resistance and impact resistance of materials The added inorganic raw materials such as aluminum hypophosphite and organic raw materials such as hexachlorocyclopentadiene cooperate with each other, and are used as flame retardant modifiers in polyimide films, so that the prepared materials have high flame retardancy and Self-extinguishing.

Owner:刘禾青

Modified colemanite and melamine polyphosphate flame-retardant synergistic corrosion-resistant coating

InactiveCN106752421AImprove flame retardant performanceImprove aging resistanceFireproof paintsChloropene polymer coatingsColemaniteTemperature resistance

The invention discloses modified colemanite and melamine polyphosphate flame-retardant synergistic corrosion-resistant coating. The modified colemanite and melamine polyphosphate flame-retardant synergistic corrosion-resistant coating is prepared from the following raw materials in parts by weight: 60 to 65 parts of chlorosulfonated polyethylene rubber latex, 35 to 40 parts of neoprene latex, 7 to 8 parts of polyoxyethylene aliphatic alcohol ether, a proper amount of deionized water, 2.5 to 3 parts of a silane coupling agent KH 560, 2 to 3 parts of lanthanum oxide, 1.5 to 2 parts of dicerium trioxide, a proper amount of a nitric acid solution at the concentration of 65 percent by weight, an ammonium bicarbonate solution at the concentration of 50 percent by weight, 10 to 12 parts of rutile type titanium dioxide, 1.5 to 2 parts of polyalkylene glycol, 2 to 3 parts of sodium-based montmorillonite, 4 to 5 parts of melamine polyphosphate, 4 to 5 parts of colemanite, 1 to 1.5 parts of oleic acid and a proper amount of absolute ethanol. The composition emulsion has flame retardance, high-temperature resistance and excellent adhesive force; a paint film is tough and anti-ageing; the process is simple and convenient in industrial control; and the corrosion-resistant coating is applied to surface corrosion prevention of metal equipment, pipelines, cylinders and the like, and prolongs the service time of equipment.

Owner:闻承岳

Method for producing glass fiber by using pulping and paper-making white mud

The invention discloses a method for producing glass fiber by using pulping and paper-making white mud. Raw materials comprise 18-23 parts of white mud calcined powder, 33-38 parts of pyrophyllite, 5-8 parts of dolomite, 5-8 parts of colemanite, 25-30 parts of quartzitic sandstone, 8-10 parts of kaolin, 1.8-2 parts of albite, 2.5-2.9 parts of fluorite, and 0.4-0.6 parts of a composite clarifying agent. The production method comprises the following steps: the raw materials are well mixed according to the ratio, and are melted; and the mixture is drawn, such that the glass fiber is obtained. According to the invention, white mud is adopted as a glass fiber production main raw material. White mud open storage can be reduced through comprehensive utilization; white mud environment pollution can be reduced; white mud can be turned from waste into a valuable matter; and produced glass fiber has higher strength.

Owner:NEIJIANG HUAYUAN ELECTRONICS MATERIALS

Production method for the boron nitride nanotubes

The present invention relates to a method, which essentially comprises the steps of performing crude boron nitride nanotube (BNNT) synthesis (110) and purifying BNNTs obtained in the crude form (120), and wherein direct BNNT production is provided with the use of colemanite that is a borate mineral.

Owner:YEDITEPE UNIVSI

Neutron protective body plug and material thereof

ActiveCN102176328AImprove flame retardant performanceMaintain stabilityNuclear energy generationShieldingColemanitePolyvinyl alcohol

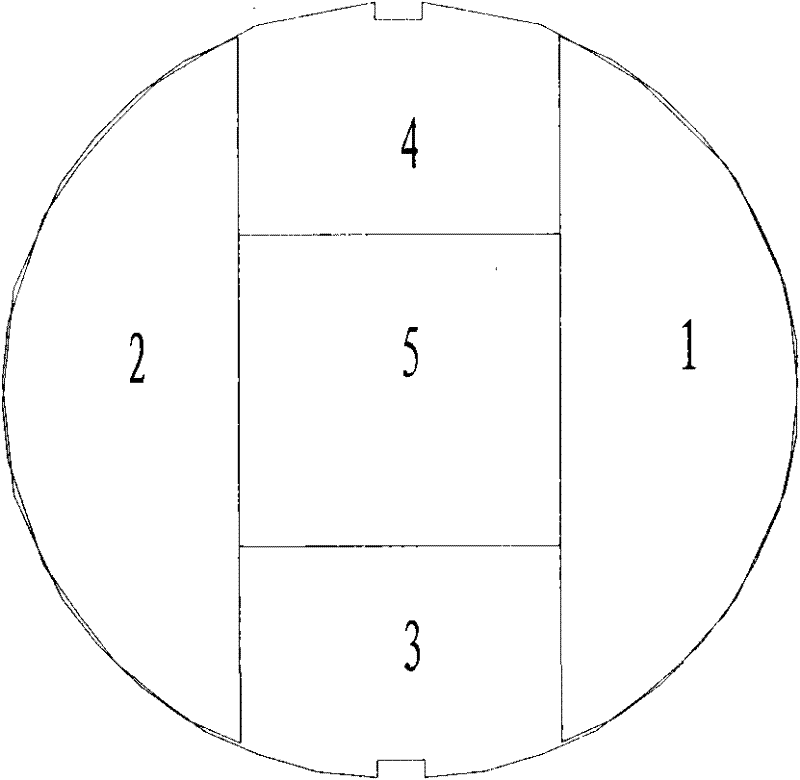

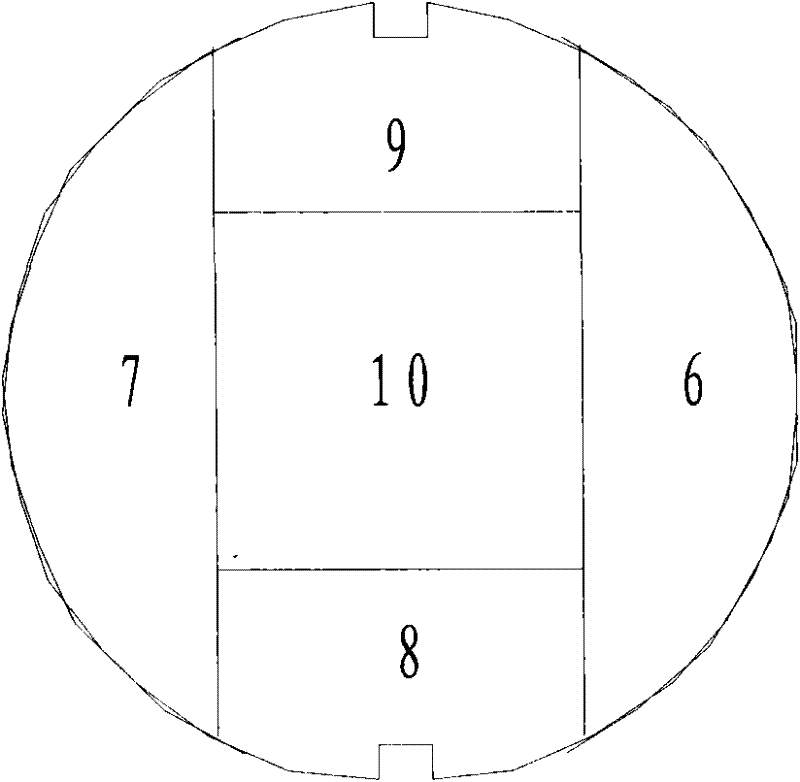

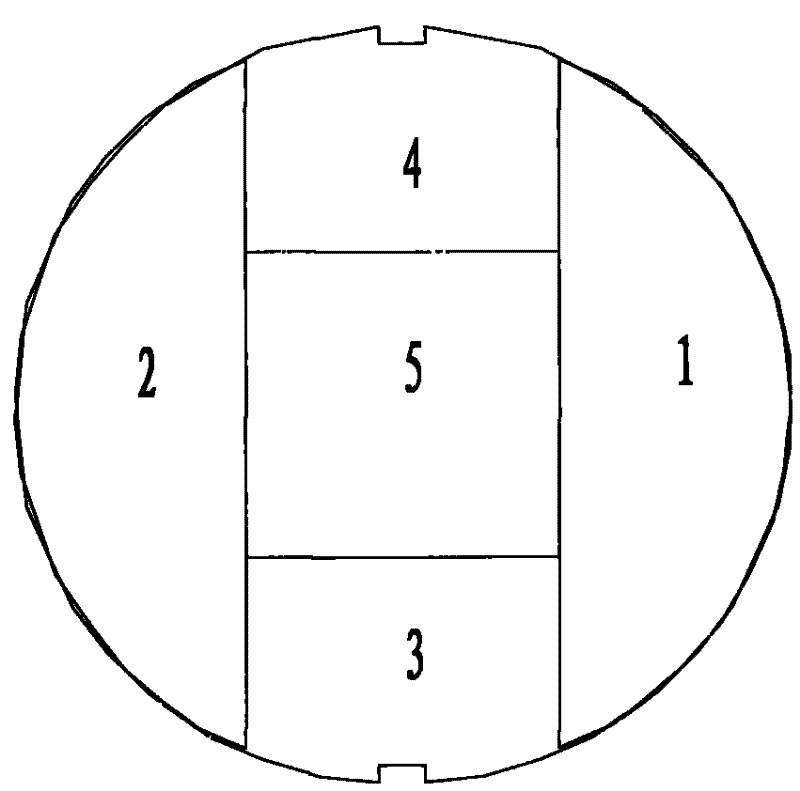

The invention discloses a neutron protective body plug and a material thereof, and the plug is composed of front and rear blocks (3,4,8,9), left and right blocks (1,2,6,7) and middle blocks (5,10), wherein the front and the rear blocks (3,4,8,9), the left and the right blocks (1,2,6,7) and the middle blocks (5,10) are arranged on an upper layer and a lower layer and are symmetrical in shape respectively, the external circles of the front and the rear blocks and the left and the right blocks of the upper layer and the lower layer are all arc curved surfaces, and the middle blocks are of a quadrangular-prism shape; and a cylindrical structure is formed after the blocks are combined, and grooves with same widths but different depths are respectively processed on the arc curved surfaces of the front and the rear blocks of the upper layer and the lower layer so as to ensure that the grooves are rightly engaged after the upper layer and the lower layer are combined. The material of the neutron protective body plug comprises the following components: 30-40% of polyethylene, 10-20% of chlorinated polyethylene, 6-14% of polyvinyl alcohol, 25-35% of aluminium hydroxide and 5-10% of colemanite; and the neutron protective body plug comprises the elementary components with the contents as follows: not less than 9.0% of aluminium, not less than 0.85% of boron, not less than 1.10% of calcium, not less than 40% of carbon, not less than 3.5% of chlorine, not less than 7.5% of hydrogen, not less than 25% of oxygen and not less than 1.0% of impurity. The neutron protective body plug can effectively absorb and shield radiation generated by a neutron-ray, and has stability and fine mechanical strength under thermal neutron radiation.

Owner:HENAN SHUANGFU TECH CO LTD

Moistureproof and flame-retardant insulated cable for instruments

InactiveCN108034123AImprove insulation performanceImprove defectsInsulated cablesInsulated conductorsEpoxyColemanite

The invention discloses a moistureproof and flame-retardant insulated cable for instruments. The cable comprises a conductor and a sleeve tube; an insulating layer is arranged outside the conductor, and the conductor and the insulating layer which is arranged outside the conductor are arranged in the sleeve tube; a gap is provided between the sleeve tube and the insulating layer, and the gap is fully filled with an epoxy resin foaming material; the sleeve tube comprises the following components in parts by mass: 40-50 parts of EVA resin, 20-25 parts of terpolymer EP rubber, 15-25 parts of an ethylene-vinyl alcohol copolymer, 15-20 parts of colemanite, 5-7 parts of polyacrylamide, 3-4 parts of norbornane diisocyanate, 5-10 parts of calcium carbonate, 8-12 parts of glass fibre, 6-10 parts ofdecabromodiphenyl ethane, 10-15 parts of polyvinylidene fluoride, 3-7 parts of sodium dodecyl sulfate, 10-13 parts of diatomite, 1-3 parts of chlorinated paraffin, 3-8 parts of crosslinked polyvinylpyrrolidone, 5-10 parts of a fire retardant, 3-5 parts of a curing agent, 2-3 parts of a silane coupling agent, and a proper amount of deionized water. The product has good moisture prevention and flame retardation effects.

Owner:SUZHOU HAOYAN PRECISION MOLD CO LTD

Fluoride-free environment-friendly thermos bottle preform material

The invention discloses a fluoride-free environment-friendly thermos bottle preform material. The fluoride-free environment-friendly thermos bottle preform material consists of the following raw materials in parts by weight: 40-45 parts of quartz sands, 10-15 parts of calcite, 6-10 parts of lepidolite, 4-6 parts of aluminum phosphate, 5-7 parts of colemanite, 1-2 parts of antimonous oxide, 3-5 parts of calcium chloride, 0.1-0.2 part of lanthanum oxide, 2-3 parts of sodium sulfate, 5-7 parts of aluminum oxide, 0.8-2 parts of ammonium dihydrogen phosphate, 0.1-0.2 part of stannous oxide, 2-4 parts of fluxing agent and 3-5 parts of molding promoter. The fluoride-free environment-friendly thermos bottle preform material disclosed by the invention almost realizes no fluoride residue, and is healthy and environment-friendly; the added molding promoter lowers a thermal expansion coefficient of glass, and enables the obtained finished product to have higher hardness and mechanical strength after various raw materials are molded, so that spoilage of a preform is reduced, waste is reduced and resources are saved.

Owner:韩新怀

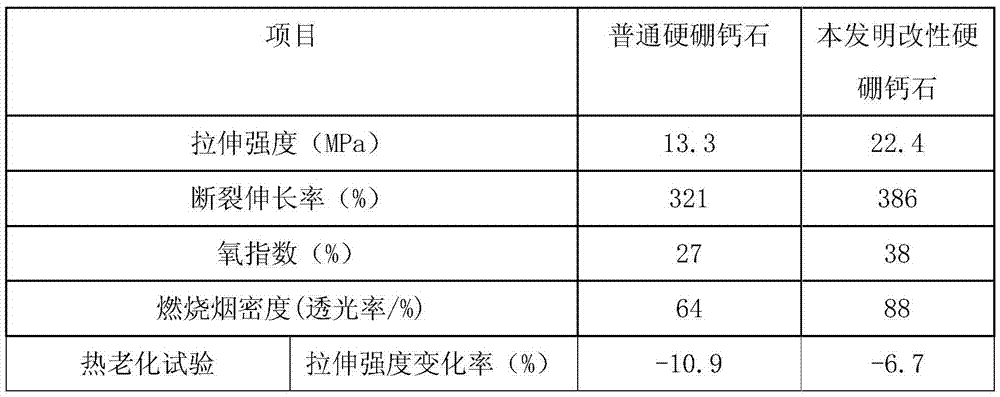

Modified colemanite for low-smoke, halogen-free and flame-retardant cable sheath material and preparation method of modified colemanite

InactiveCN105448405AImprove flame retardant performanceGood dispersionInsulated cablesInorganic insulatorsColemanitePhosphoric acid

The invention discloses modified colemanite for a low-smoke, halogen-free and flame-retardant cable sheath material and a preparation method of the modified colemanite. The modified colemanite is prepared from the following raw materials in parts by weight: 25-40 parts of colemanite, 18-32 parts of boehmite, 4-7 parts of 1,2-propylene carbonate, 5-8 parts of jojoba oil, 1-2 parts of magnesium naphthenate, 1-2 parts of lanthanum malic acid, 5-10 parts of seashells mud, 4-8 parts of zinc phosphate, 3-6 parts of melamine cyanurate, 2-3 parts of lanolin ceryl alcohol polyoxypropylene ether, 5-10 parts of tricresyl phosphate, 4-8 parts of trimethyl borate, 1-2 parts of p-tert-butyl catechol and 3-6 parts of a compound additive. The modified colemanite disclosed by the invention is good in flame retardant efficiency; after the modified colemanite is added, the smoke density of a polymer and a toxic gas can be greatly reduced; meanwhile, no irritant halogen hydride gas is generated; and the modified colemanite is safe, environment-friendly and wide in application range.

Owner:ZHONGGUAN CABLE CO LTD

High-strength wear-resistant rubber cable material

InactiveCN105985546AImprove reinforcement effectGood chemical stabilityRubber insulatorsBuilding insulationsColemaniteWear resistant

The invention discloses a high-strength wear-resistant rubber cable material which is prepared from the following raw materials in parts by weight: 2-3 parts of polyisobutylene, 8-10 parts of colemanite, 13-16 parts of brucite powder, 4-5 parts of aluminum phosphate, 5-7 parts of asphalt, 1-1.5 parts of 2,6-di-tert-butyl-para-cresol, 55-60 parts of chloroprene rubber, 1-2 parts of anti-aging agent RD, 55-70 parts of natural rubber, 0.8-1.3 parts of TAIC (triallyl isocyanurate), 56-64 parts of styrene-butadiene rubber, 30-40 parts of hollow glass microsphere, 1-1.3 parts of silane coupling agent kh550, 2-3 parts of elacostearic acid, 12-16 parts of epoxy resin E44, 0.06-0.1 part of diethylenetriamine, 0.1-0.2 part of accelerator NS, 2.6-3 parts of silane coupling agent kh570 and a right amount of distilled water. The prepared rubber cable has favorable thermal aging resistance, and thus, can be used under high-temperature conditions for a long time. The rubber cable is very flexible, has the advantages of excellent comprehensive mechanical properties and favorable flame retardancy, and thus, is worthy of popularization.

Owner:JING FENG GRP

Indoor halogen-free and flame-retardant communication optical cable sheathing compound and preparation method thereof

InactiveCN104292608AImprove flame retardant performanceHalogen-free and low-smokeFibre mechanical structuresColemaniteHigh rise

The invention discloses an indoor halogen-free and flame-retardant communication optical cable sheathing compound and a preparation method thereof. The sheathing compound is prepared by the following raw materials in parts by weight: 52-74 parts of linear low density polyethylene, 27-43 parts of liquid crystal high-molecular polymer, 10-15 parts of neopentyl glycol dibenzoate, 18-26 parts of a reworked material, 1.5-2.5 parts of lithium aluminum di-n-butylamide, 2-4 parts of polyoxyethylene glyceryl ether trioleate, 16-24 parts of polyphenyl thioether, 3-5 parts of magnesium oleate, 2-4 parts of PPG-n castorate, 1-2 parts of phenylethyl resorcinol, 4-8 parts of melamine cyanurate, 5-10 parts of diethyl ethanephosphonate, 15-20 parts of colemanite powder, 10-15 parts of diethyl aluminium hypophosphite and 1-2 parts of Xylyl dibutylbenzofuranone. The sheathing compound has the characteristics of high flame retardancy, no halogen, low smoke, high mechanical strength, good flexibleness and excellent heat resistance and ageing performance, has a wide application range, is suitable for underground constructions, large public buildings, high-rise buildings and other indoor places demanding much on smoke density, acidity and flame retardancy, and has great economic benefits and social benefits.

Owner:安徽电信器材贸易工业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com