Patents

Literature

157 results about "Boron phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boron phosphate is an inorganic compound with the chemical formula BPO₄. The simplest way of producing it is the reaction of phosphoric acid and boric acid. It is a white infusible solid that evaporates above 1450 °C.

Phosphate film-coated powder and preparation method thereof

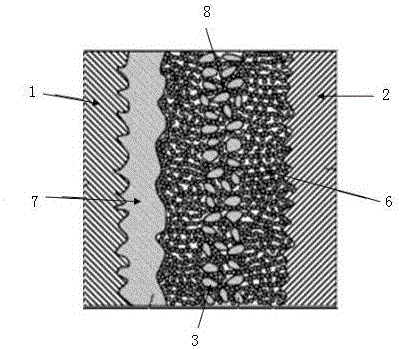

InactiveCN101045828AUniform particlesParticle size distribution andNon-macromolecular adhesive additivesOther chemical processesDepolymerizationDouble decker

This invention relates to a method of preparing envelope powder. The shattering, depolymerization and coating processed at same time, and solid phase acid-base reaction participate the method. This envelope powder possess double-decker or three-layer structure, inner core is composed by oxide or hydrate or inorganic oxysalt, crust composed by inorganic oxysalt, envelope by aluminum phosphate or boron phosphate. This low cost powder be able to used as fortifier, power stuff, colorant and so on, applied to plastic, rubber, ceramics, dope, binder and paper, set foundation for popularization of ultramicro and nanometer powder.

Owner:张义纲 +1

Halogen-free flame-proofing agent

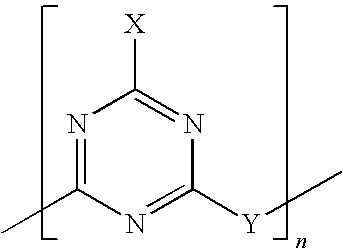

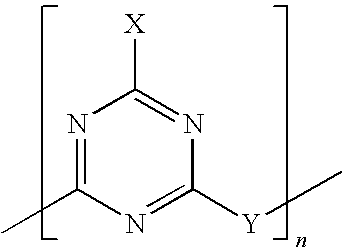

ActiveUS20100298474A1Improve flame retardant performanceLow water solubilityFireproof paintsTriazine derivativeTriallyl isocyanurate

Halogen-free flame retardant for incorporation into a polymer matrix, wherein the flame retardant contains at least ammonium polyphosphate(s) and / or derivatives thereof and an oligomeric or polymeric 1,3,5-triazine derivative or mixtures of several thereof and at least one compound selected from monozinc phosphate, zinc borate, trizinc phosphate, zinc pyrophosphate, zinc polyphosphate, zinc hydroxystannate, zinc stannate, boron phosphate, monoaluminium phosphate, trialuminium phosphate, aluminium metaphosphate and mixtures thereof, precondensed melamine derivatives, melamine salts and adducts, ethylenediamine phosphate, piperazine phosphate, piperazine polyphosphate, 1,3,5-trihydroxyethyl isocyanurate, 1,3,5-triglycidyl isocyanurate and triallyl isocyanurate.

Owner:CHEM FAB BUDENHEIM AG

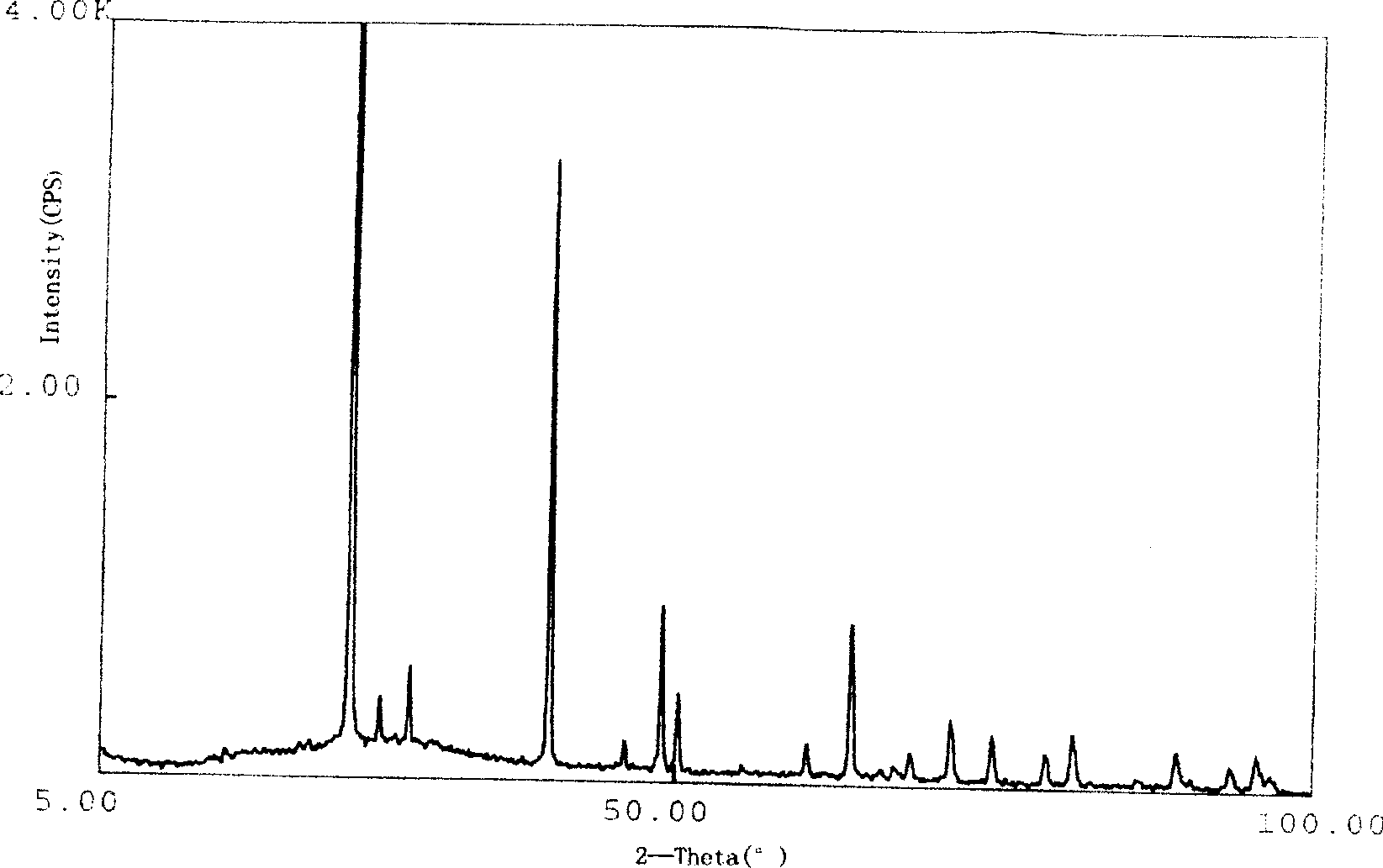

Growth method for fluxing medium of boron phosphate single crystal

InactiveCN101435109ALarge UV cut-off wavelengthShort UV cut-off wavelengthPolycrystalline material growthFrom melt solutionsRoom temperatureLength wave

The invention relates to a growth method of a fluxing agent of boron phosphate monocrystal, which comprises the steps of: 1) proportionally mixing a boron phosphate compound and the fluxing agent, putting the mixture into platinum crucible, and heating till completely fusing in a crystal growing furnace; and then cooling to the temperature being 2 to 15 DEG C above a saturation temperature, thus obtaining a high temperature melt containing boron phosphate and the fluxing agent; and 2) putting seed crystal loaded on a seed rod into the high temperature melt, keeping constant temperature for 10 to 180 minutes, reducing the temperature to saturation temperature, and rotating the seed rod at the speed of 10 to 50 revolution / minute; and reducing the temperature at the speed of 0.1 to 2 DEG C / day, lifting the crystal from the liquid surface after the crystal grows up, and cooling to room temperature at the speed of 20 to 50 DEG C / hour to obtain the boron phosphate monocrystal. The fluxing agent used by the method can reduce the viscosity of the high temperature melt, is beneficial to melt mass transportation in the process of crystal growth, avoids the formation of inclusions in the crystal, and can stably grow the transparent boron phosphate monocrystal which has cm-level size, short ultraviolet cutoff wavelength and good mechanical processing performance, is not easy to crack, does not absorb moisture, and is easy to be stored.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

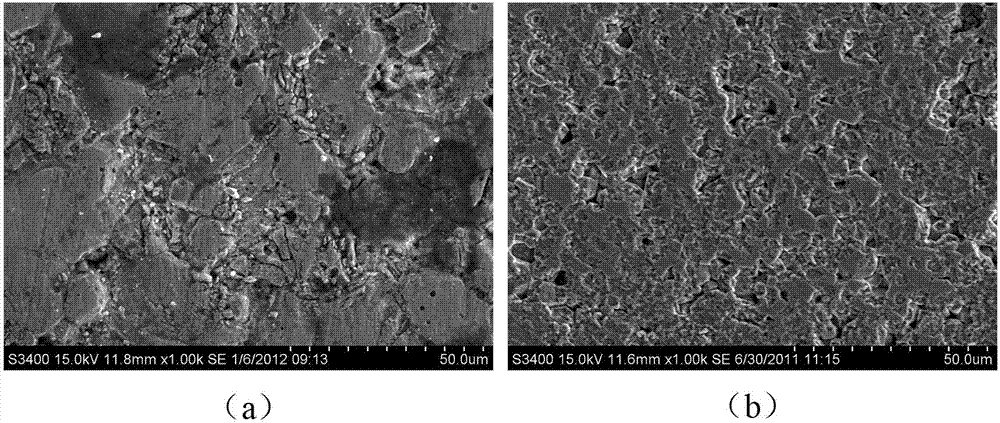

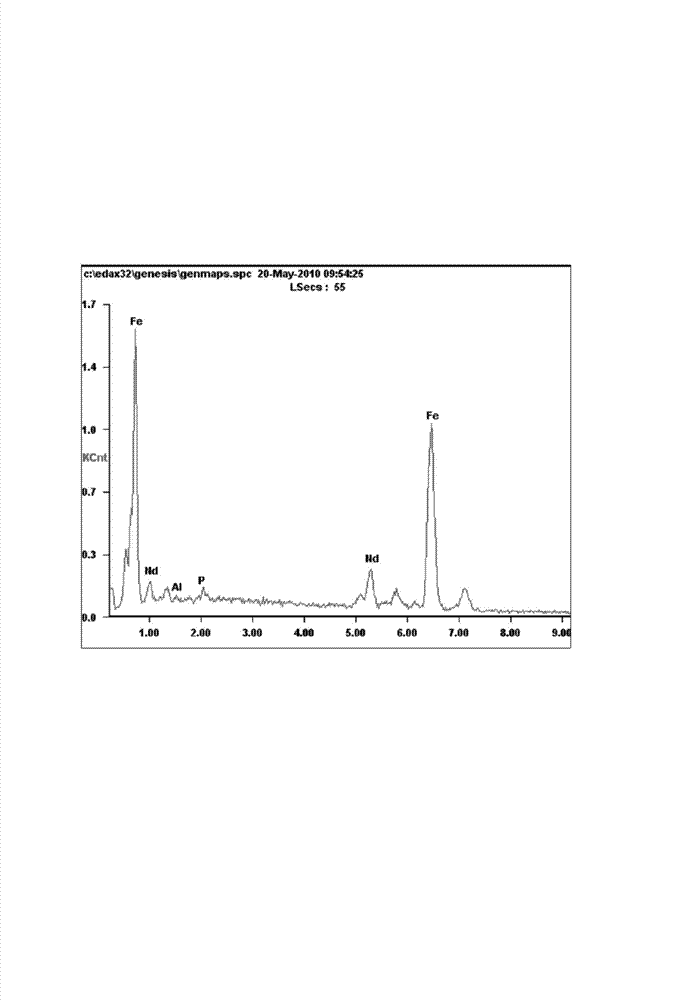

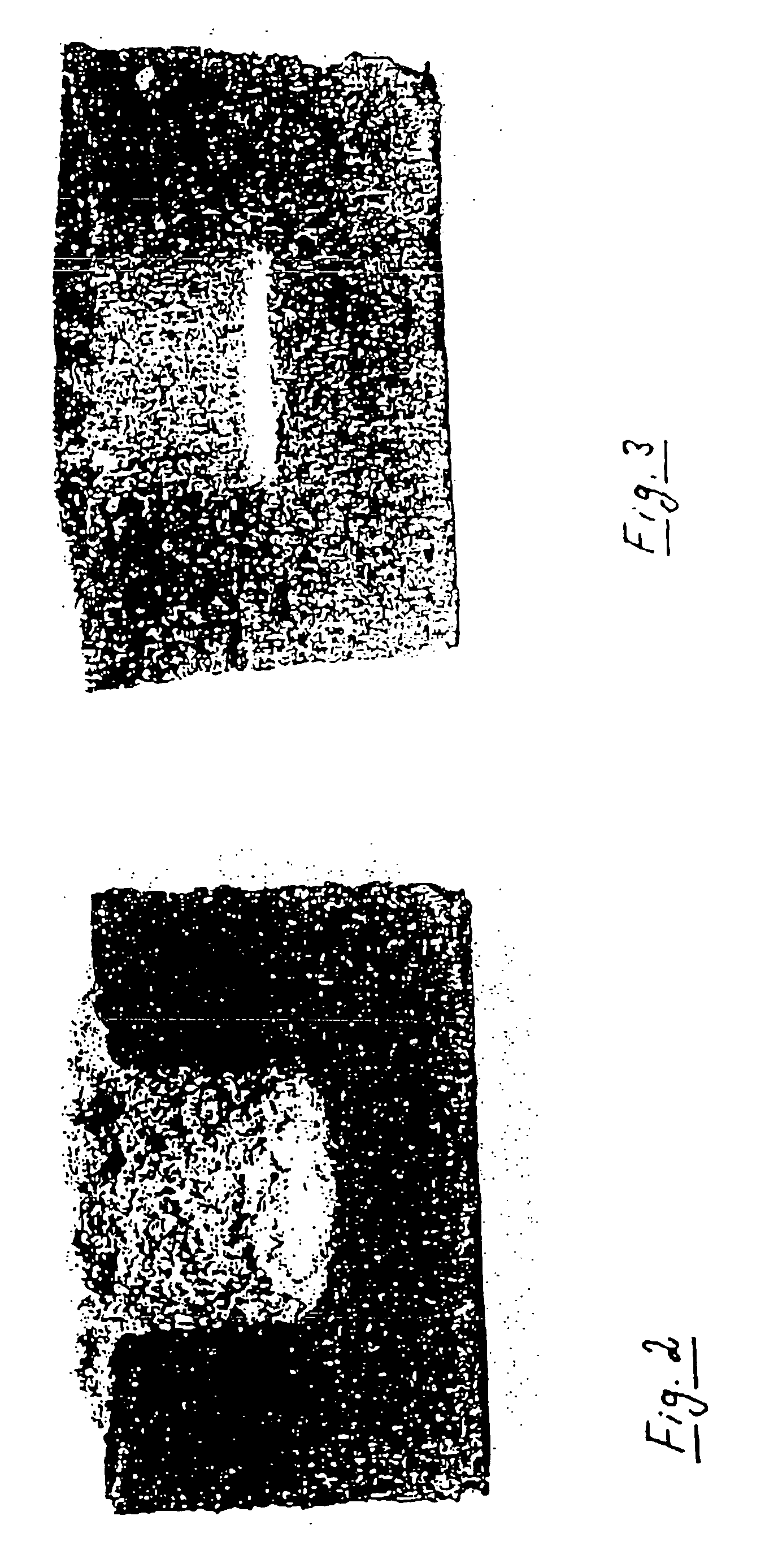

Method for improving corrosion resistance of phosphate coating on surface of neodymium-iron-boron permanent magnet

InactiveCN102965655AImprove corrosion resistanceSimple processMetallic material coating processesPhosphateElectroplating

The invention belongs to the neodymium-iron-boron material surface electroplating field and mainly relates to a method for improving the corrosion resistance of a phosphate coating on the surface of a neodymium-iron-boron permanent magnet, wherein basic oil removal and rust removal through acid washing are performed before phosphorization and drying is performed after phosphorization; a desired surface for phosphorization is obtained by means of controllable acid washing solution; the conventional process of performing surface adjustment after acid washing is omitted; the problem of low corrosion resistance of the existing neodymium-iron-boron phosphate coating and the problem that the conventional process still needs chromic acid passivating treatment after phosphorization in order to improve the corrosion resistance of the phosphate coating are solved; and the obtained film is even and compact in surface and thereby protects the neodymium-iron-boron substrate. The preparation method is simple in process flow, convenient to operate and friendly to the environment.

Owner:SHENYANG POLYTECHNIC UNIV

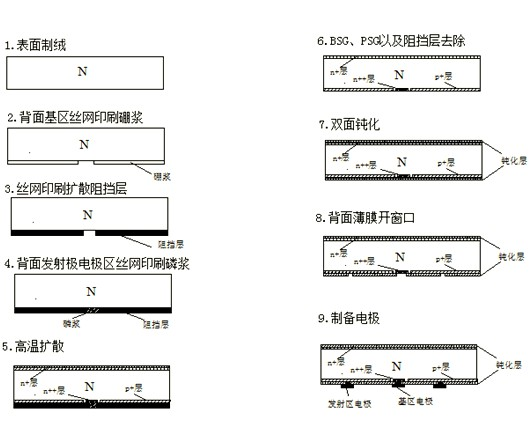

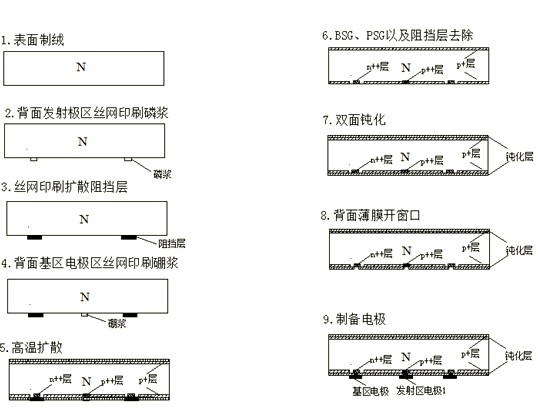

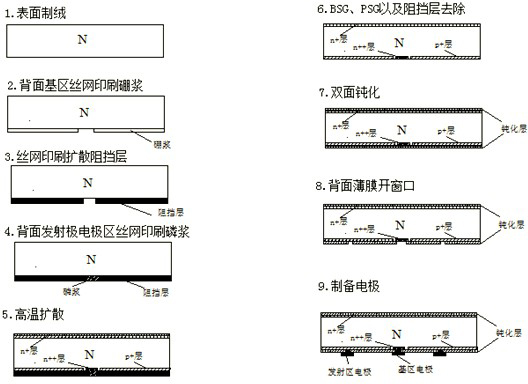

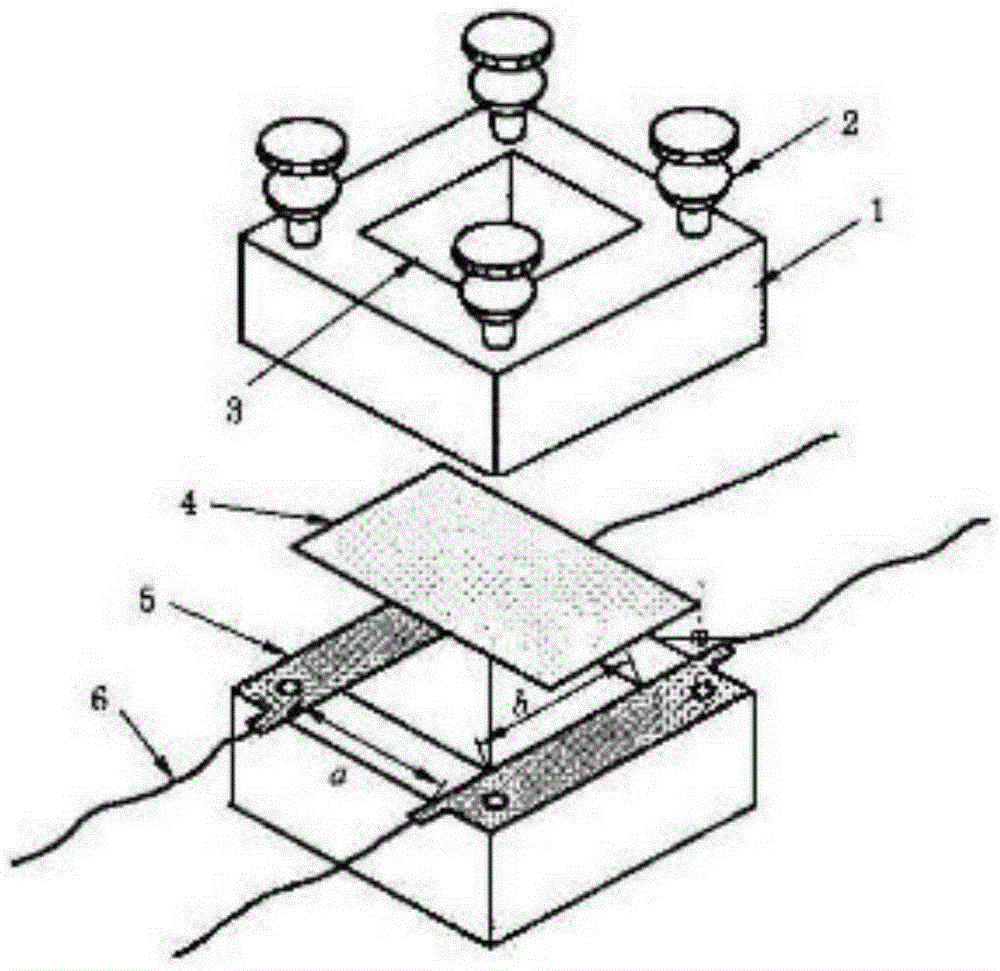

A process for preparing high-efficiency all-back-electrode n-type solar cells by co-diffusion of boron and phosphorus

InactiveCN102280519ASimple manufacturing processReduce manufacturing costFinal product manufactureSemiconductor devicesScreen printingSlurry

The invention discloses a process for preparing high-efficiency full-back electrode n-type solar cells by co-diffusion of boron and phosphorus. ~30min; cover a layer of diffusion barrier layer on the boron paste or phosphor paste, dry at 100~500°C for 5~30min; screen print phosphor paste on the contact area of the base area on the back, dry at 100~500°C for 5 minutes ~30min; high temperature diffusion; first diffuse at 880~1100°C for 10~60min, then cool down to 800~950°C, then feed POCl3 source for phosphorus diffusion for 10~60min; removal of BSG, PSG and barrier layer; double-sided Passivation; open the window on the back film; prepare electrodes.

Owner:ALTUSVIA ENERGY TAICANG

Oil modified epoxy resin superstrong anticorrosive paint for coated aluminum foils

ActiveCN103275602AImprove hydrophobicityReduce adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyester

An oil modified epoxy resin superstrong anticorrosive paint for coated aluminum foils, belongs to a paint coated on a metal plate, and is manufactured through a conventional paint production process. The oil modified epoxy resin superstrong anticorrosive paint is characterized by comprising the components by weight: 20-30% of oil modified epoxy resin, 5-15% of oil soluble phenolic resin, 1-4% of HMMM resin, 0.2-0.8% of boron phosphate, 0.20-0.25% of polyester-imide, and the balance of solvent prepared from butylcellosolve, propylene glycol methyl ether acetate and dibasic ester. The paint is coated on the surface of an aluminum foil coiled material to become a superstrong anticorrosive aluminum foil coiled material, and after trials and tests, compared with the prior art, the oil modified epoxy resin superstrong anticorrosive paint has the beneficial effects as follows: after slat spray test determination, the corrosion evaluation grade of the coated aluminum foil coiled material of which the corrosion area is smaller than 0.01% reaches up to over highest grade 10, but the high corrosion-resistance hydrophilic coated aluminum foil in the prior art cannot reach the corrosion-resistance highest grade 10. The oil modified epoxy resin superstrong anticorrosive paint can be used for not only heat exchange parts but also oceaneering and ship surface decoration and protection.

Owner:ZHENJIANG WANYUAN ELECTRONICS

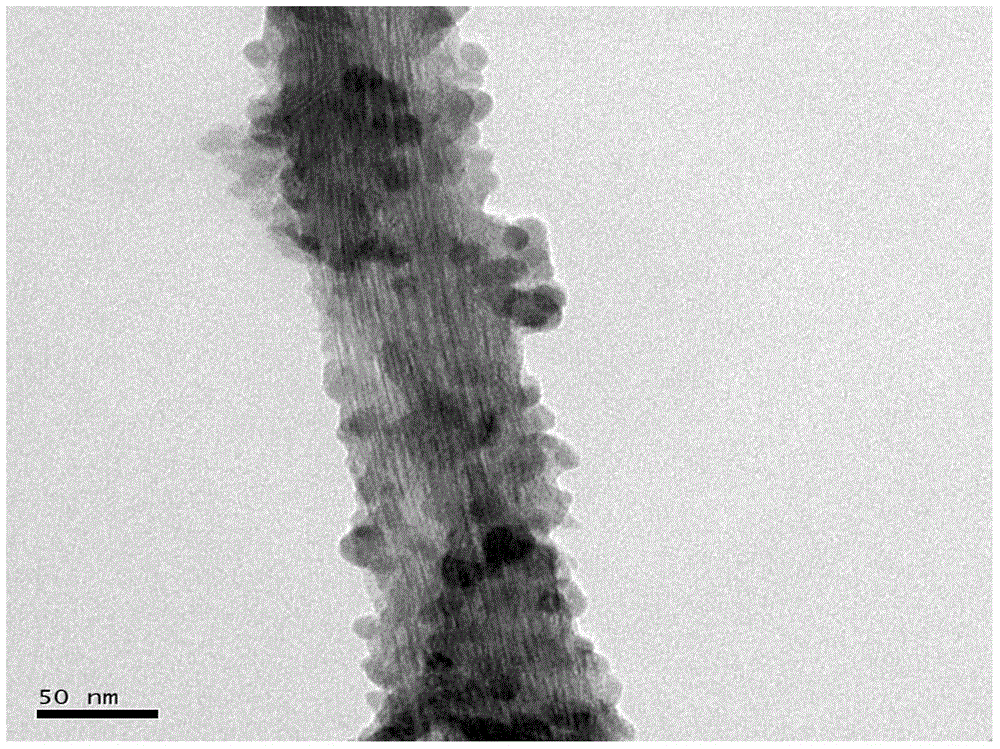

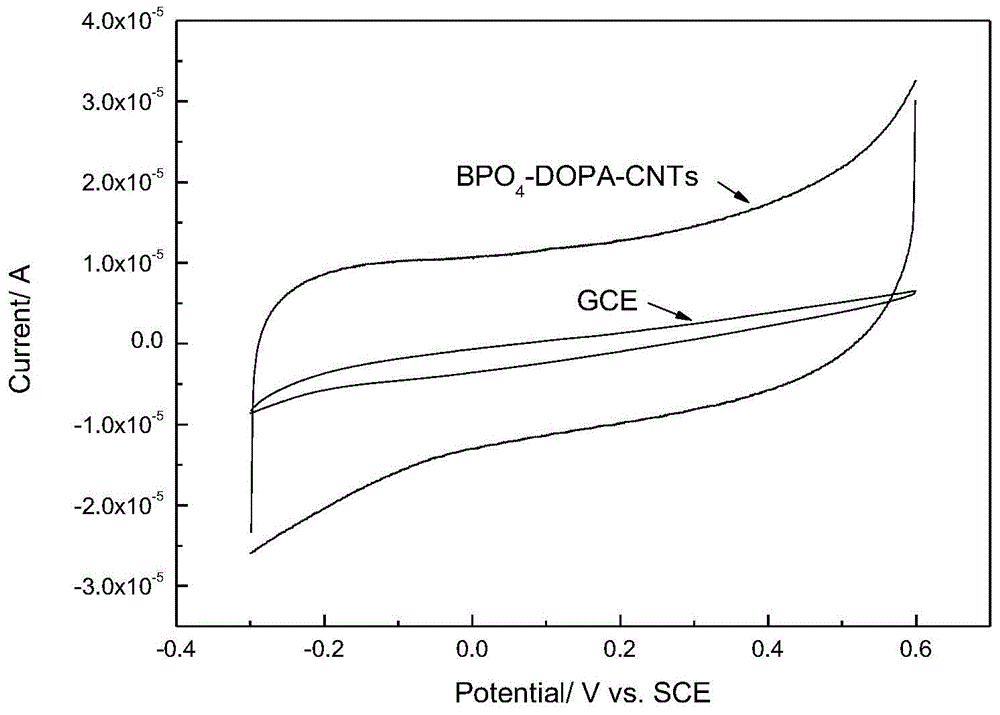

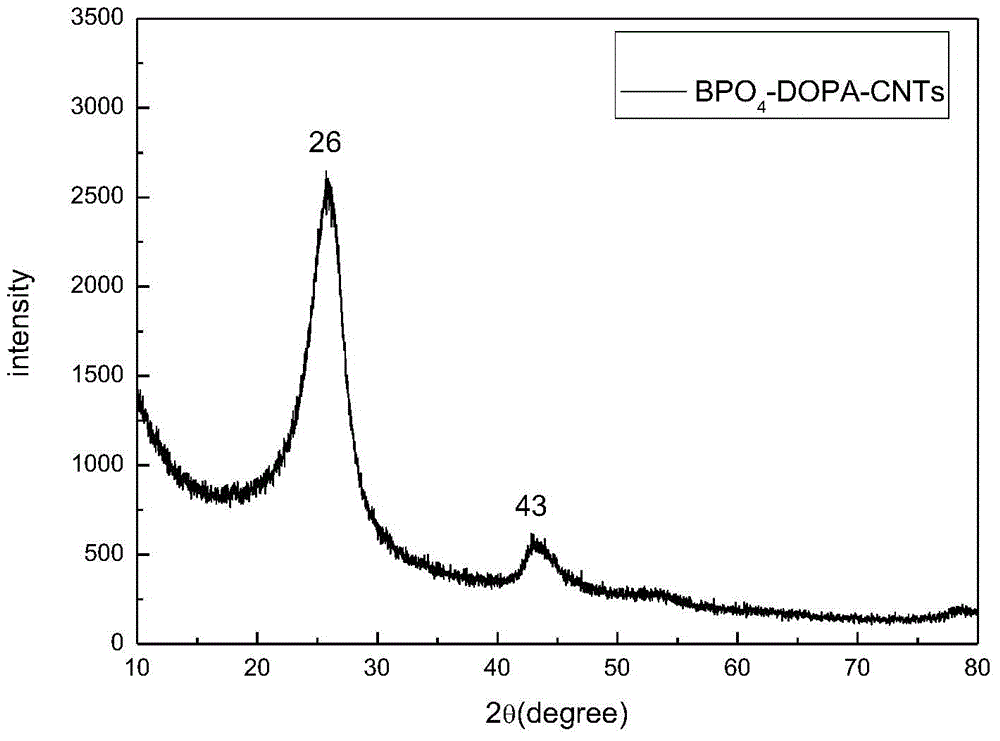

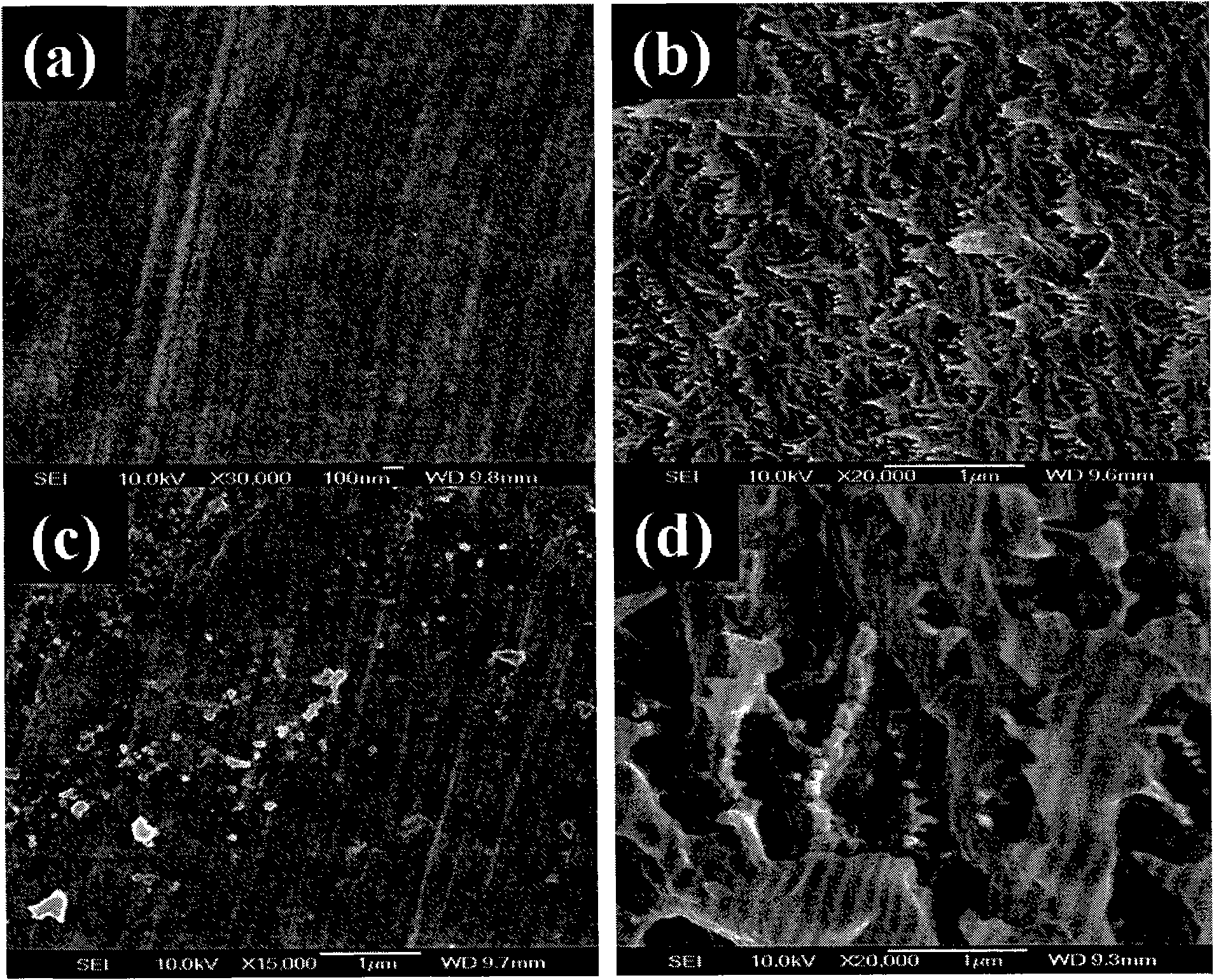

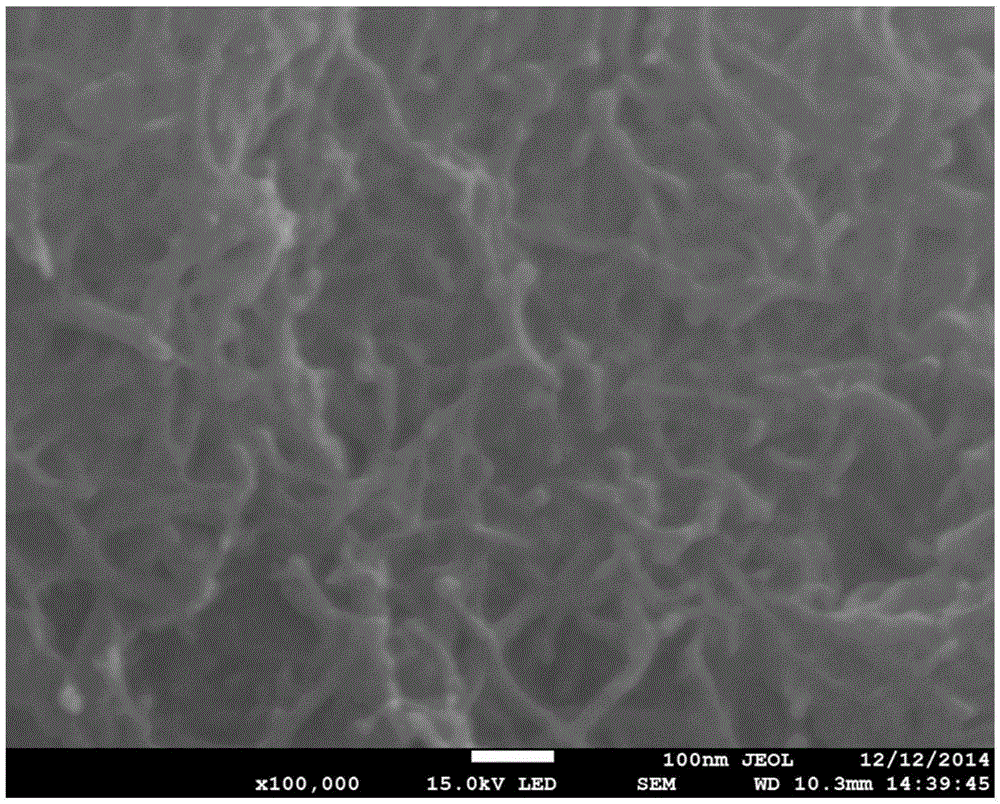

Method for preparing boron phosphate modified carbon nano tube

ActiveCN104555985AThe method of surface functional modification is simpleLow costMaterial nanotechnologyElectricityModified carbon

The invention relates to the technical field of nanometer materials and particularly discloses a method for preparing a boron phosphate modified carbon nano tube. The method comprises the following steps: firstly, under the room temperature, dopamine is in oxidative polymerization reaction in a Tris-HCl buffer solution to modify the surface of the carbon nano tube so as to obtain a poly-dopamine modified carbon nano tube; then, the sol-gel method is adopted to clad boron phosphate on the surface of the poly-dopamine modified carbon nano tube, the reaction is performed for a certain period of time, and finally, the boron phosphate modified carbon nano tube which is uniform and stable in structure is obtained. According to the invention, the cost is low, the steps are simple, the conditions are controllable, a referential method for composite preparation of other types of inorganic substances and nanometer materials is provided, and the obtained product has potential application prospects in the fields of electricity, optics, catalysis and the like.

Owner:HUBEI ENG UNIV

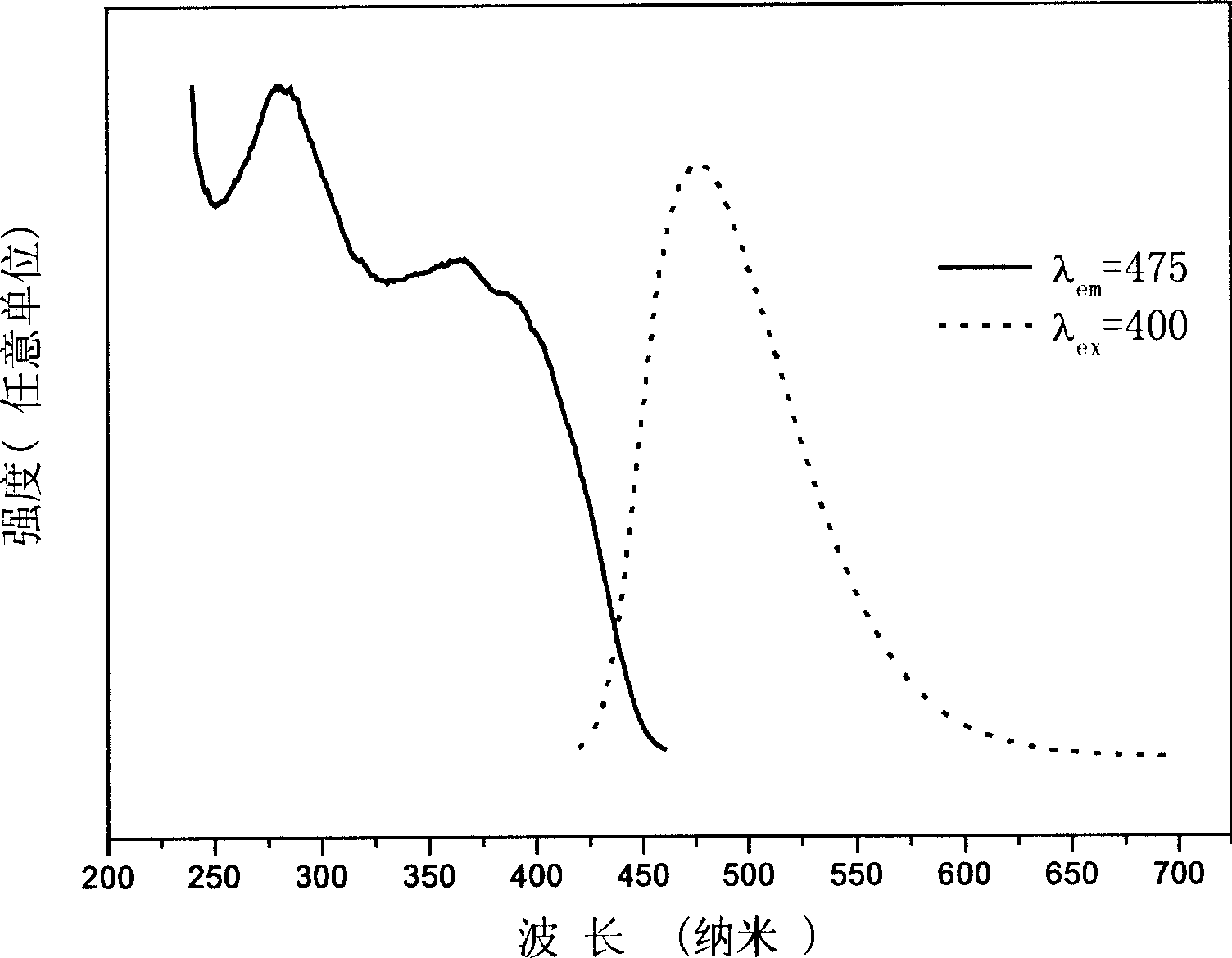

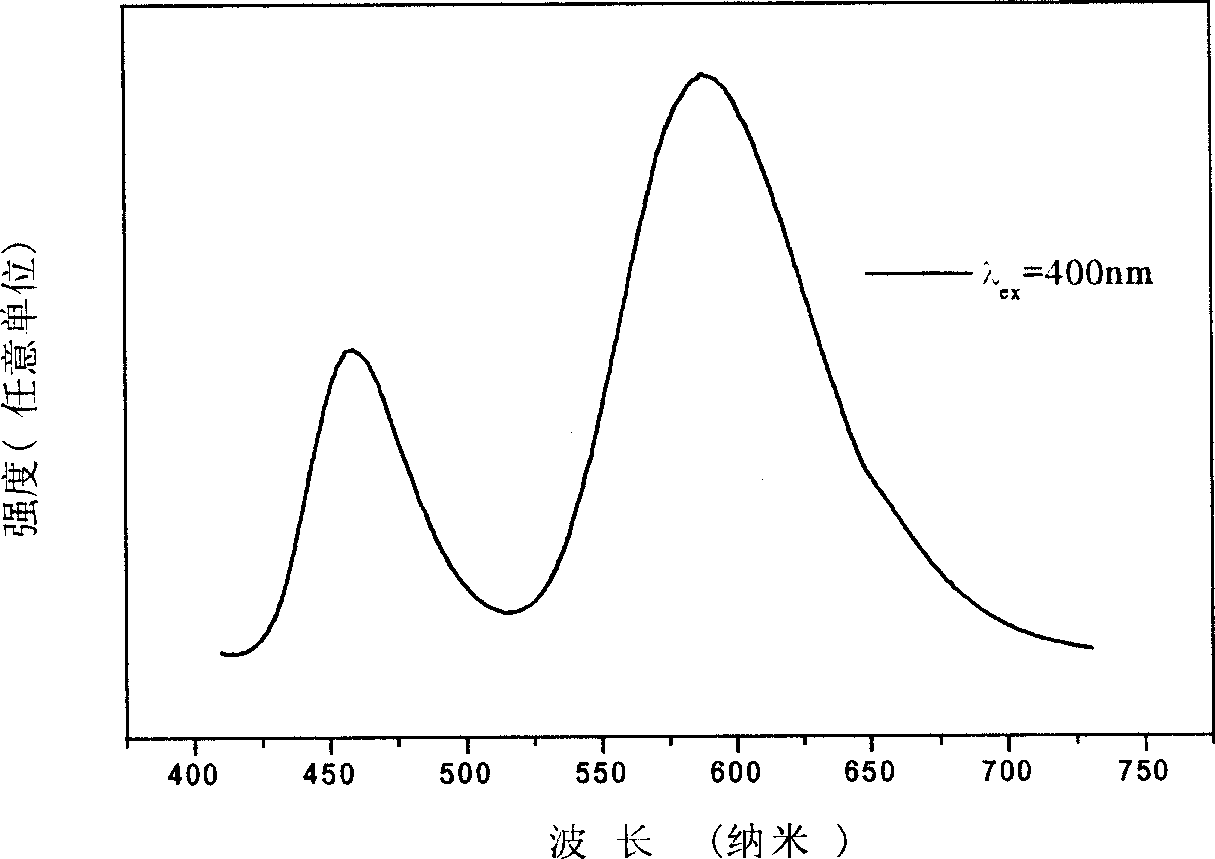

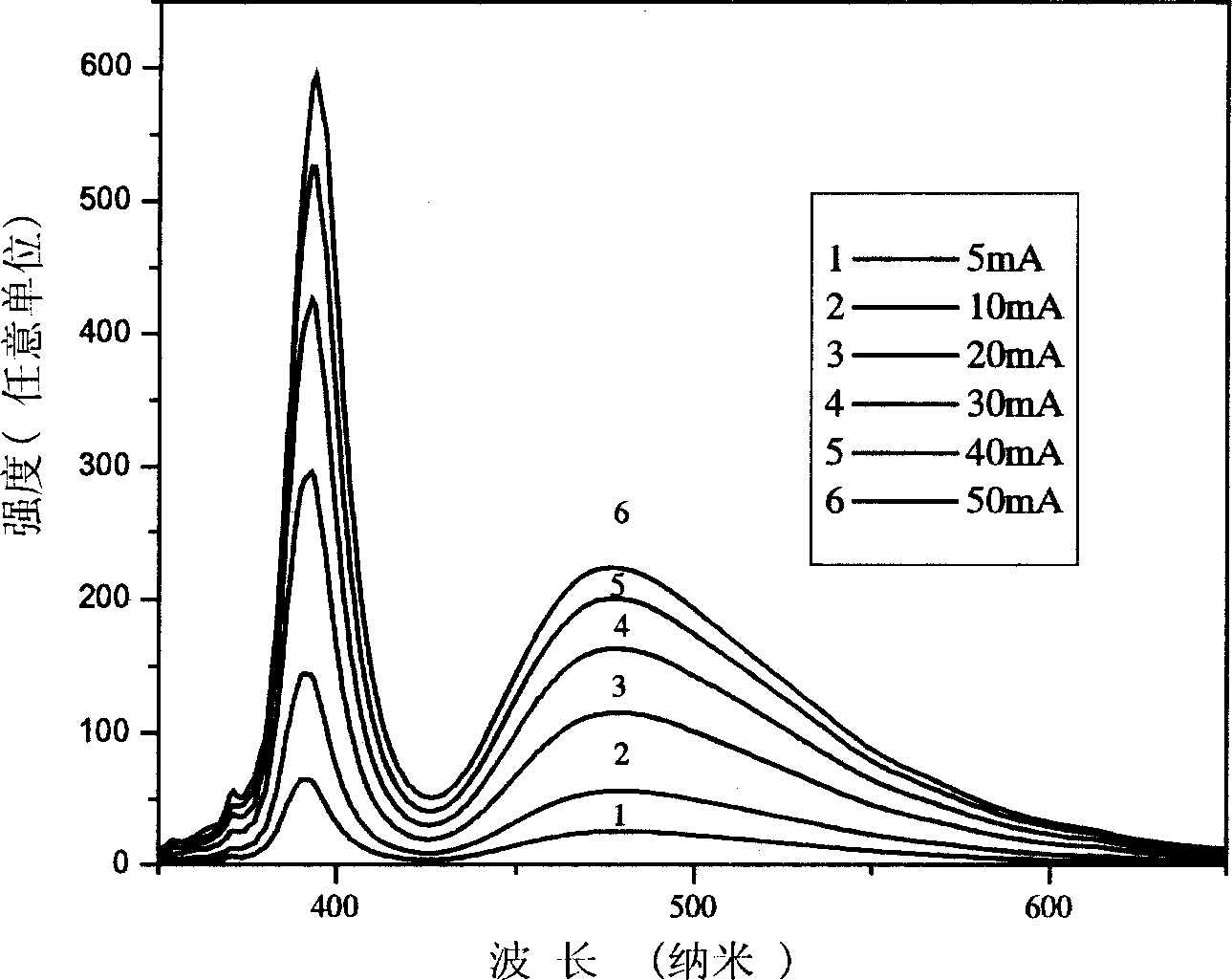

LED device containing alkaline earth boron phosphate luminescent powder

InactiveCN1844306AImprove stabilityImprove consistencyGas discharge lamp usageLuminescent compositionsRare earthEffect light

The invention relates to the LED domain, especially to a LED unit containing fluorescent powder of alkaline earth borophosphate. The LED unit of this invention consists of violet LED grain and rare-earth phosphor, in which the said rare-earth phosphor is alkaline earth borophosphate with a chemical composition expression of (Sr1-xEu2+x)6BmPnO20,0x=0.2,0m1.5, 4.5n5.5 and the said violet LED grain is inorganic semiconductor LED grain of GaN base in which the emitted near ultraviolet lights lie in area between 330nm and 420nm receiving priority in area between 350nm and 410nm. The said alkaline earth borophosphate can be added with other fluorescent powder to constitute bi-component rare-earth phosphor or tri-component rare-earth phosphor to prepare white LED unit. The LED unit of this invention is of high stability and good compatibility, suitable for batch process, and can be used in display and decorative lighting area. The packed white LED unit is of reasonable spectral energy distribution, which can make up for shortcomings of low color index of white light of traditional white LED unit, and has high color index.

Owner:SUN YAT SEN UNIV

Rapid snow melting agent

InactiveCN1667078AReduce corrosionAccelerated corrosionOther chemical processesSodium metasilicateSnow melting

This invention belongs to chemical category, it is complex salt field. It is consisted by water, calcium chloride, magnesium chloride, calcium nitrate, sodium nitrate, urea, sodium molybdate, three boron phosphate, sodium borate, sodium benzoate, sodium metasilicate, sodium nitrate, water quality stabilizer-PTX-CS and other chemical materials. They are compounded by their attribution; there are solid and liquid states. Its sleet melting and snow removing velocity is quickly, environmental capability is good, and it can be used widely above -400C. It can efficiently reduce the corruption to metal and cement concrete. Plant growth can be boost, and deodorization, bactericidin, purification water quality, pavement cleaning and other function can be realized to water after cleaning of ice and snow. For protecting city communication through, reducing traffic accident, and ensuring human body and auto safety, it has good effect. Is it fit for city and country road, freeway, airport, plaza, court and bridge.

Owner:杨毅男

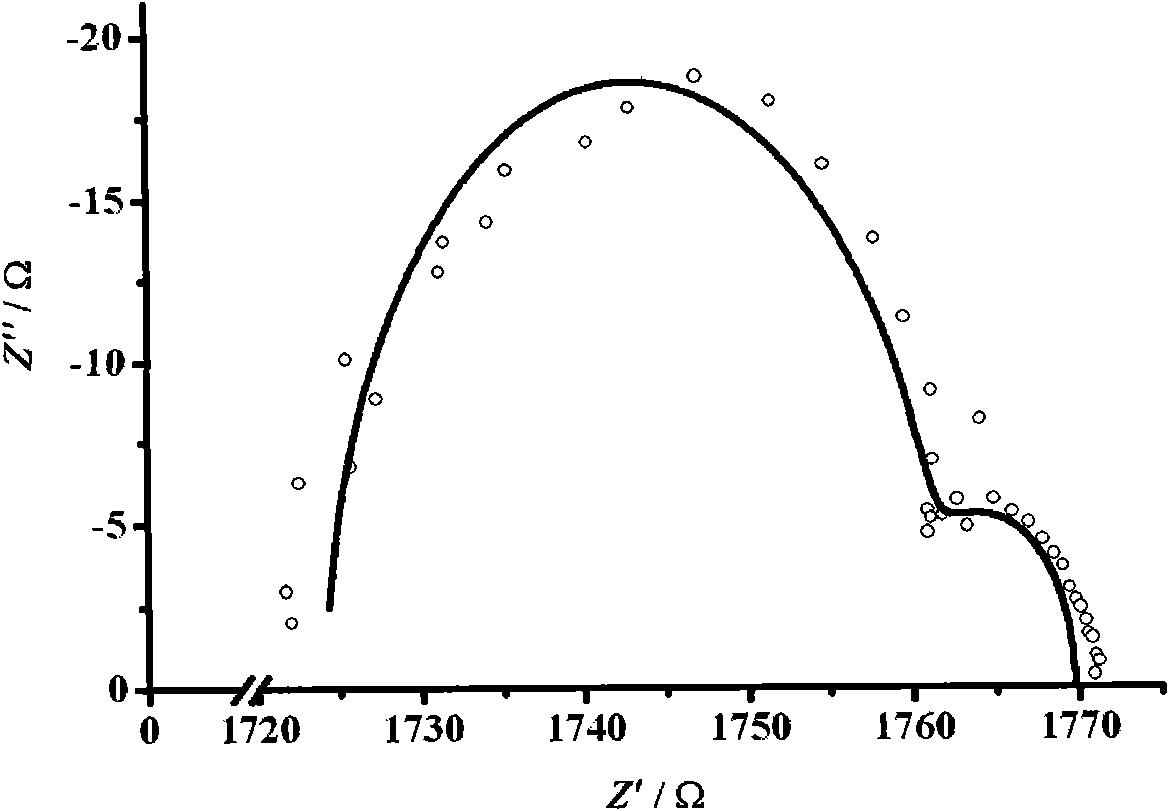

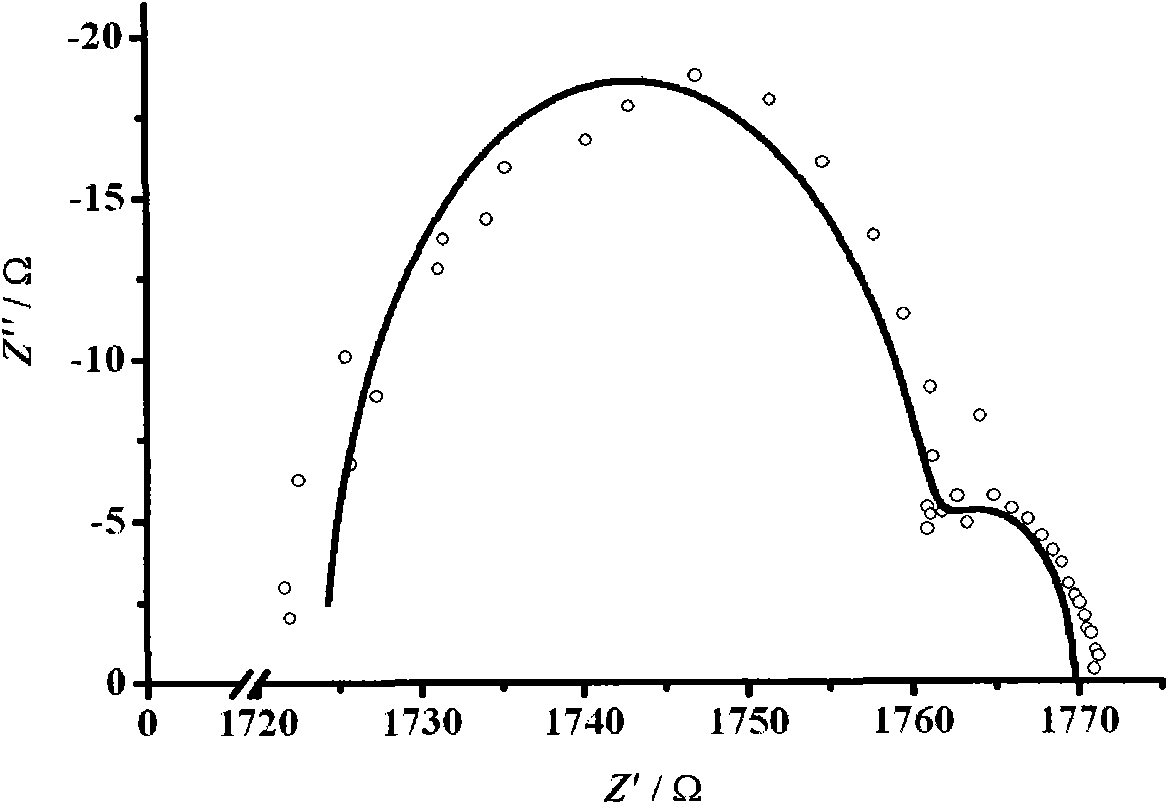

Method for preparing high-temperature-resistant BPO4-ABPBI nanometer composite proton exchange membrane for fuel cell

InactiveCN101891955AFinal product manufactureCell component detailsPhysical chemistryProton exchange membrane fuel cell

The invention relates to preparation of a high-temperature-resistant BPO4-ABPBI (boron phosphate-poly(2,5-benzimidazole)) nanometer composite proton exchange membrane for a proton exchange membrane fuel cell. The preparation mainly comprises the steps of nanometer disperse system preparation, wet film preparation, demoulding, alkaline washing, water washing, acid leaching and the like. The high-temperature-resistant nanometer composite proton exchange membrane prepared by the invention has the advantages of high comprehensive performance, industrial scale production of raw materials, and low overall cost.

Owner:SHANGHAI UNIV

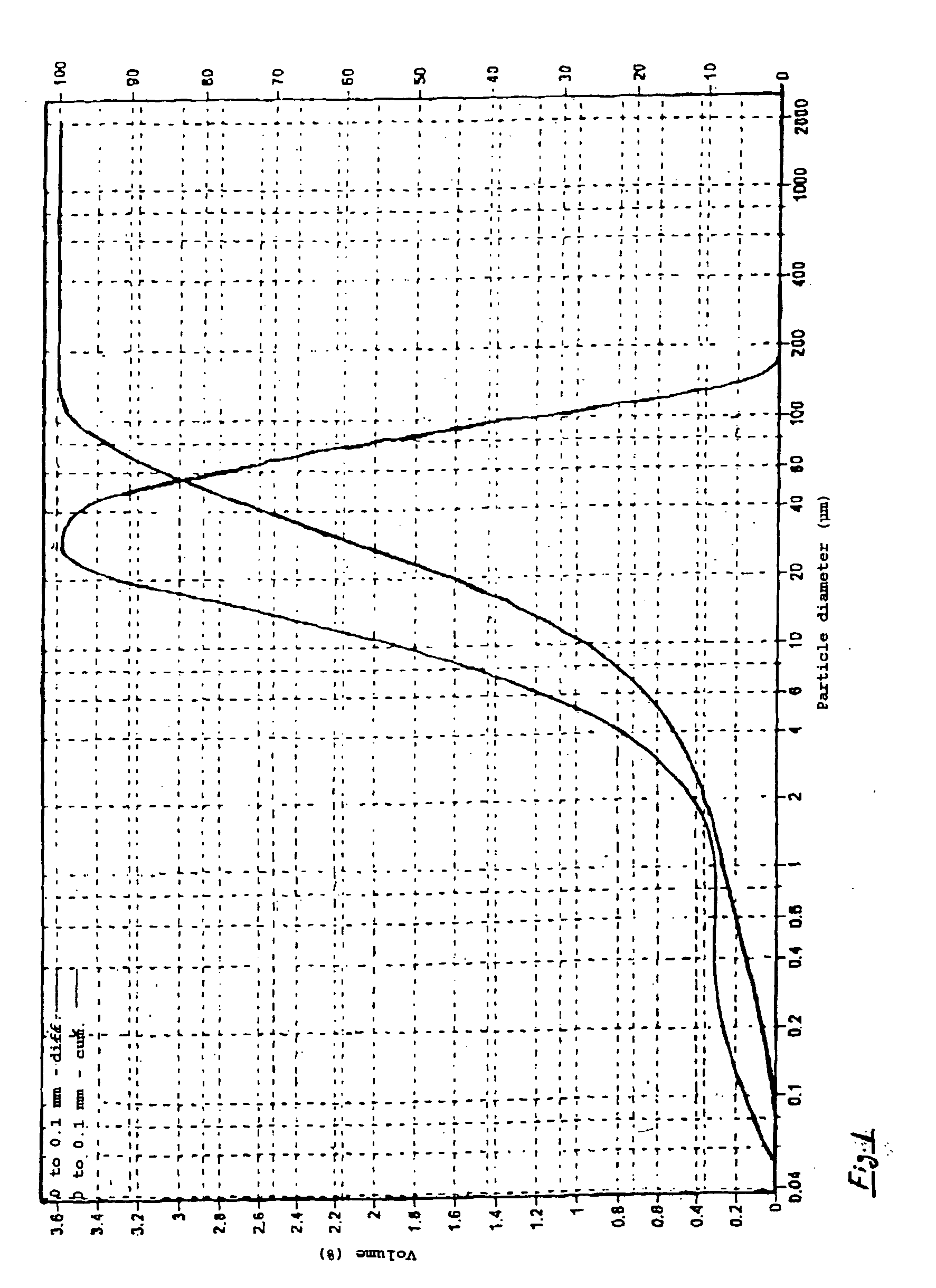

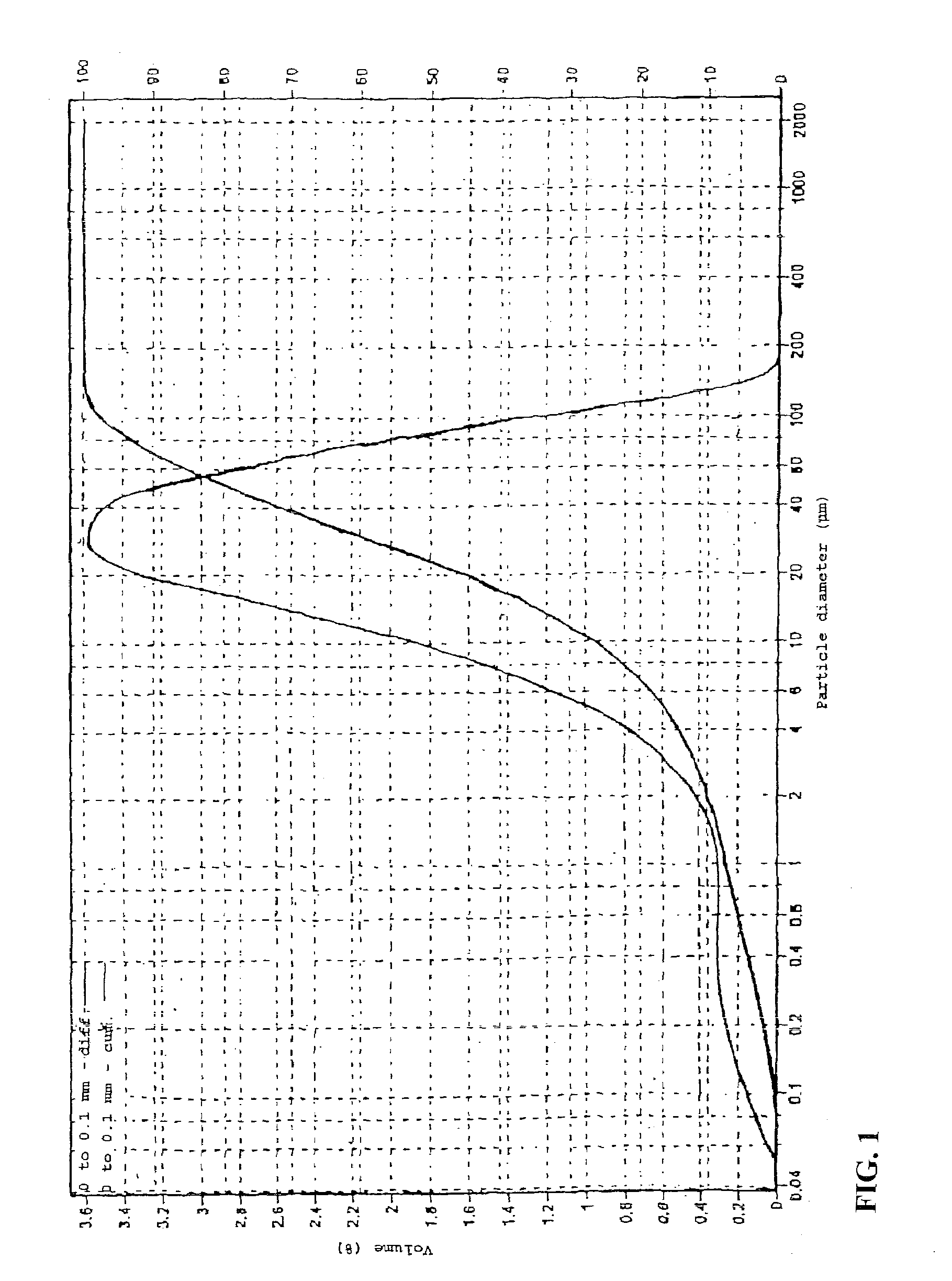

Production method of superfine boron phosphate

The invention relates to a method for effectively manufacturing high-purity superfine boron phosphate with low energy consumption. The method uses boric acid and phosphoric acid as materials, and uses organic solvent as a medium, and comprises the following steps of: mixing the boric acid, the phosphoric acid and the organic solvent; further completing distillation, solvent removal, drying treatment and other processes with catalyst or without catalyst; and acquiring a high-quality superfine boron phosphate product. The superfine boron phosphate prepared by adopting the method has comprehensive cost of materials, labor and energy consumption lower than corresponding cost of other the prior manufacturing methods, and does not pollute environment as other byproducts except water are not generated in the manufacturing process; the manufacturing process is completed at a lower temperature, thereby saving mass energy; and the product has high purity. The method has double significances of environmental protection and energy conservation.

Owner:刘启波

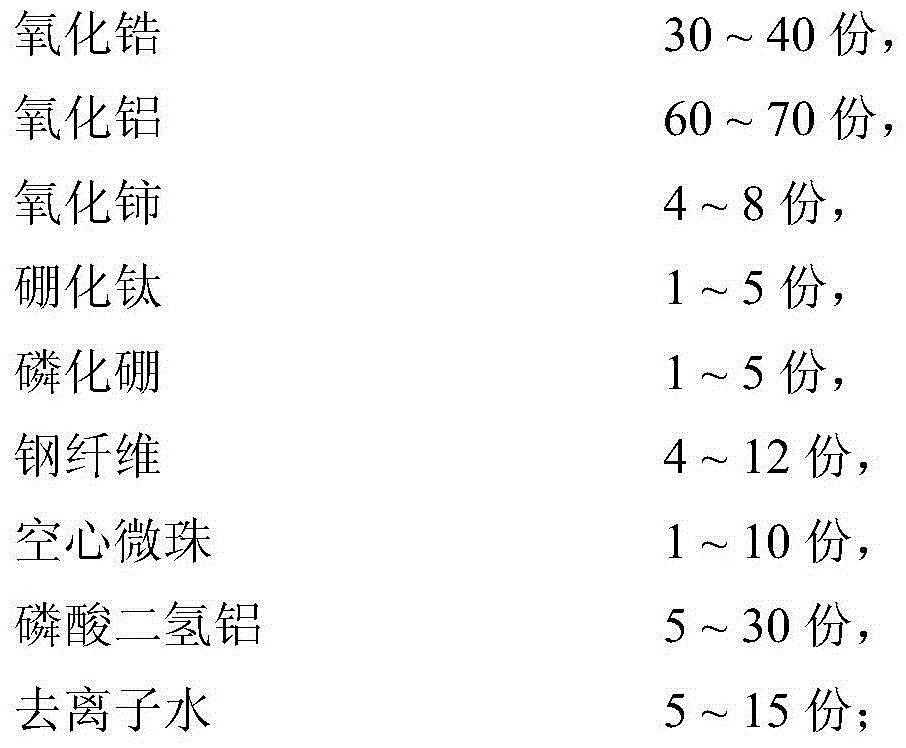

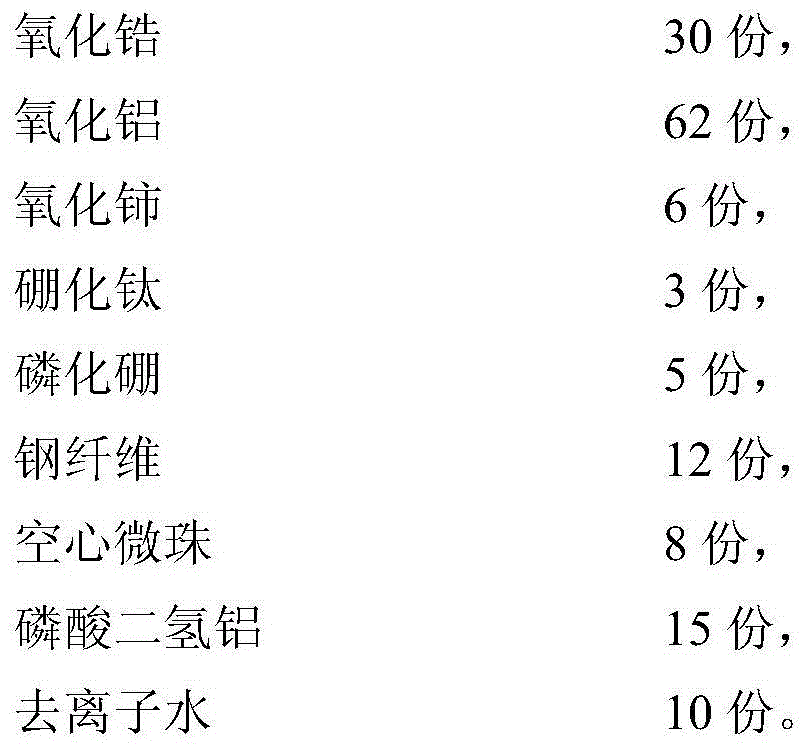

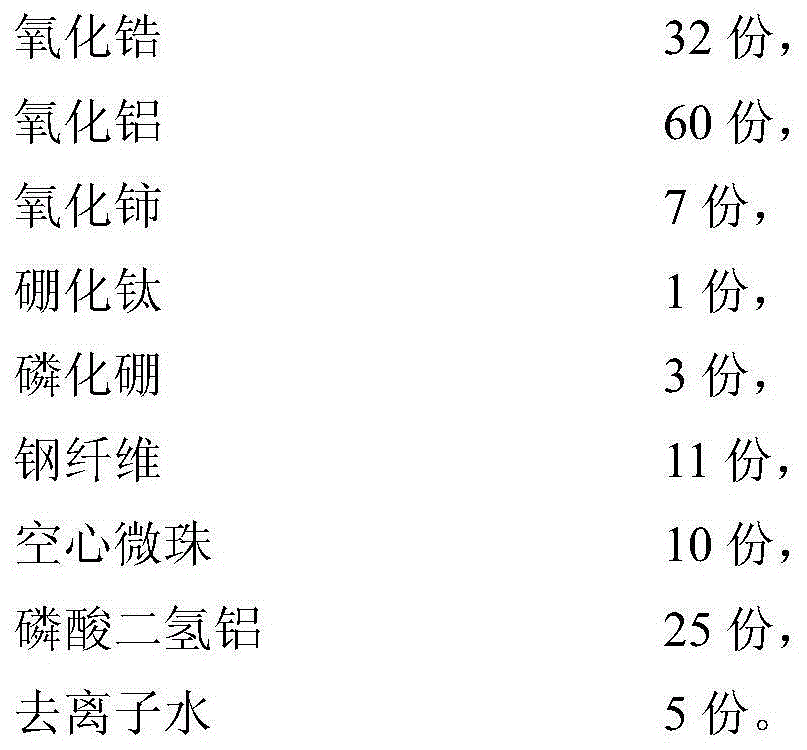

Ceramic coating for pot and preparation method thereof

ActiveCN104532229AHigh hardnessAvoid crackingLiquid/solution decomposition chemical coatingFiberCeramic coating

The invention relates to a ceramic coating for a pot. The ceramic coating for the pot is characterized by comprising, by weight, 30-40 parts of zirconium oxide, 60-70 parts of aluminum oxide, 4-8 parts of cerium oxide, 1-5 parts of titanium boride, 1-5 parts of boron phosphate, 4-12 parts of steel fiber, 1-10 parts of hollow microspheres, 5-30 parts of aluminium dihydrogen phosphate and 5-15 parts of deionized water, wherein the surfaces of the steel fiber is provided with a Ni-P alloy cladding layer. The invention further relates to a preparation method of the ceramic coating. The aluminium dihydrogen phosphate has good suspension effect and good cohesiveness, is easily dispersed in the materials evenly, has good heat impact resistant performance and accordingly ensures that ceramic does not breaks after a pot body is repeatedly heated and cooled. The aluminium dihydrogen phosphate has good chemical stability and heat stability, so that the ceramic coating does not cause threat to the health of a human body. The hollow microspheres can remarkably improve the abrasion resisting performance of the ceramic coating, the ceramic coating is not easily damaged, and the service life of the ceramic pot is effectively prolonged.

Owner:NINGBO XIERMEI KITCHENWARE

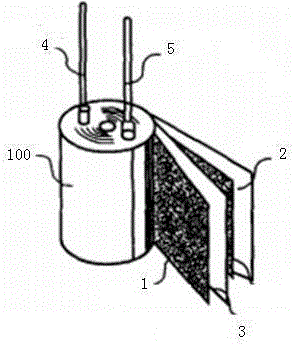

Processing liquid and solid-state electrolytic capacitor with same

InactiveCN106548872AHigh voltageIncrease capacitySolid electrolytic capacitorsCapacitor electrolytes/absorbentsBenzoic acidCapacitance

The invention proposes a processing liquid, and relates to the technical field of a solid-state electrolytic capacitor. The processing liquid comprises a solute and a solvent, wherein the solute is an organic or inorganic acid compound, the solvent comprises a water polymer material and an organic solvent, the organic or inorganic acid compound is selected from one or more of phosphoric acid, boric acid, benzoic acid, adipic acid, azelaic acid, sebacic acid, isophthalic acid, phthalic acid, maleic acid, benzene sulfonic acid and citric acid, and the water polymer material is selected one or more of polyethylene alkylene glycol, polyvinyl alcohol, polyethylene glycol glyceryl alcohol ester, polyethylene glycol glyceryl alcohol ester, polyethylene glycol sorbitol ether, polyethylene glycol, polybutylene glycol, polyethylene glycol and polyethylene oxide which has non-volatile characteristic. The processing liquid and a traditional dispersion liquid are used in a matching way, thus, the development of the dispersion liquid is prevented, the production period is shortened, and the cost is reduced.

Owner:CAPXON ELECTRONIC (SHENZHEN) CO LTD

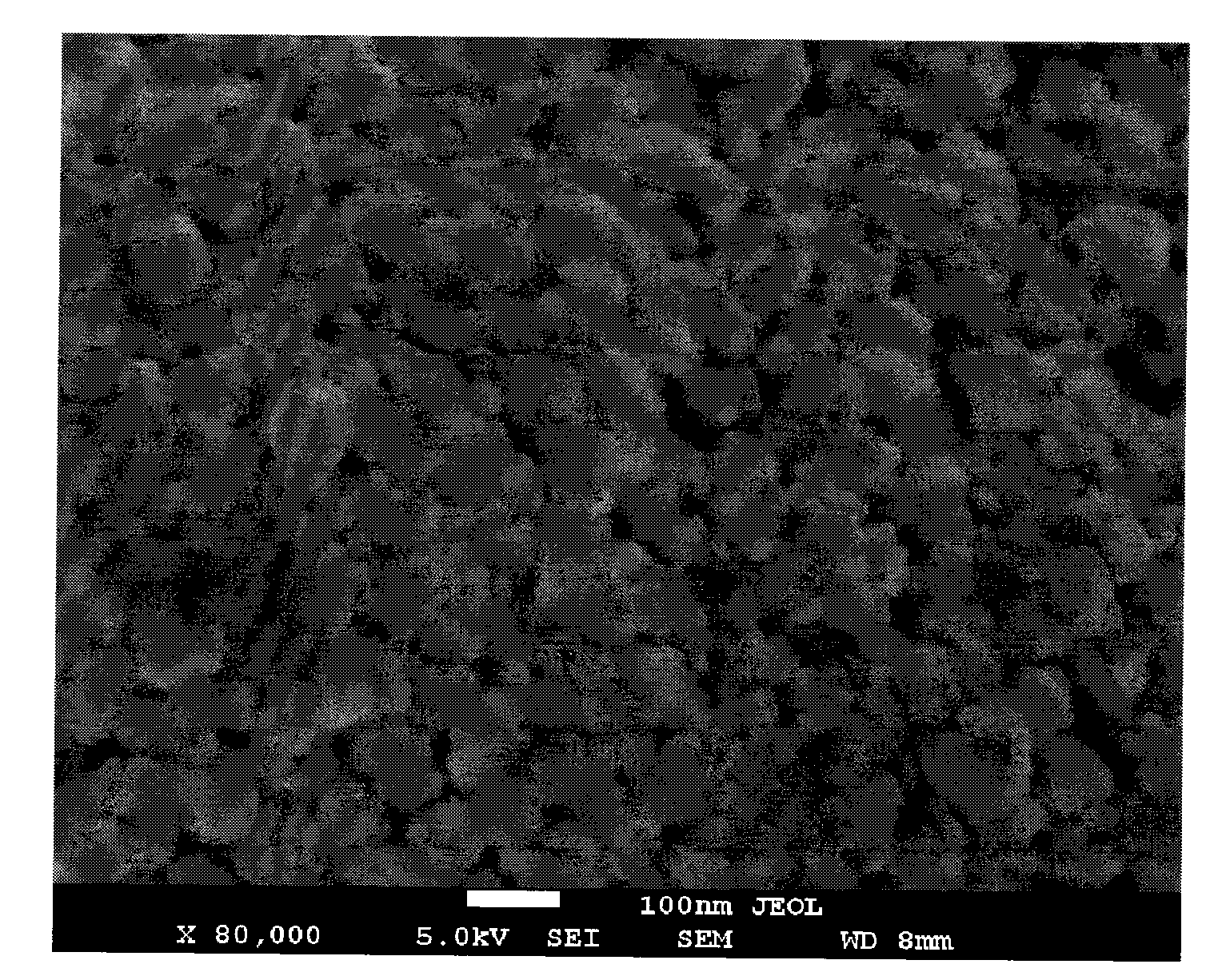

Nano-grade boron phosphate rapid preparation method with microwave radiation low-temperature solid-phase reaction method

InactiveCN102757063AShorten the timeReduce energy consumptionNanotechnologyBoron compoundsPhosphoric acidSolid state reaction method

The invention discloses a nano-grade boron phosphate rapid preparation method. According to the invention, phosphoric acid (or P2O5) is adopted as a phosphorus source; boric acid (or B2O3) is adopted as a boron source; the materials are accurately weighed according to a molar ratio that P2O5:B2O3=0.8-1.2:1, and are subjected to ultrasonic dispersion, or are subjected to solid-phase grinding with a small amount of water; the obtained material is subjected to a reaction for 0.5-30min under the effect of microwave irradiation; and without any other treatment, the nano-grade boron phosphate product can be directly obtained. The preparation method provided by the invention is advantaged in short preparation time, low energy consumption, cheap and easy-to-obtain raw materials, and simple process. The method is green and environment-friendly. The method is suitable for industrialized productions of high-quality boron phosphate.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

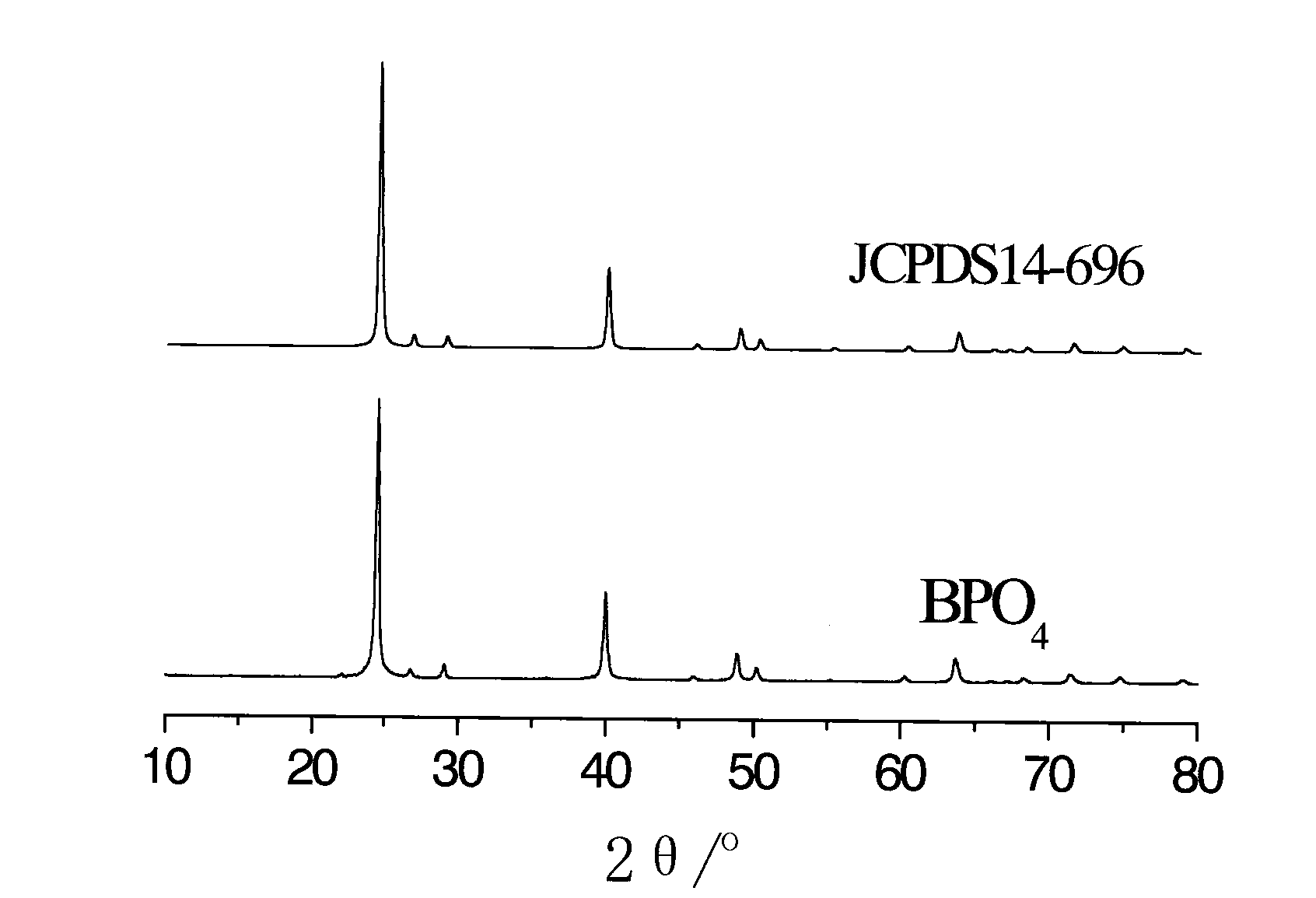

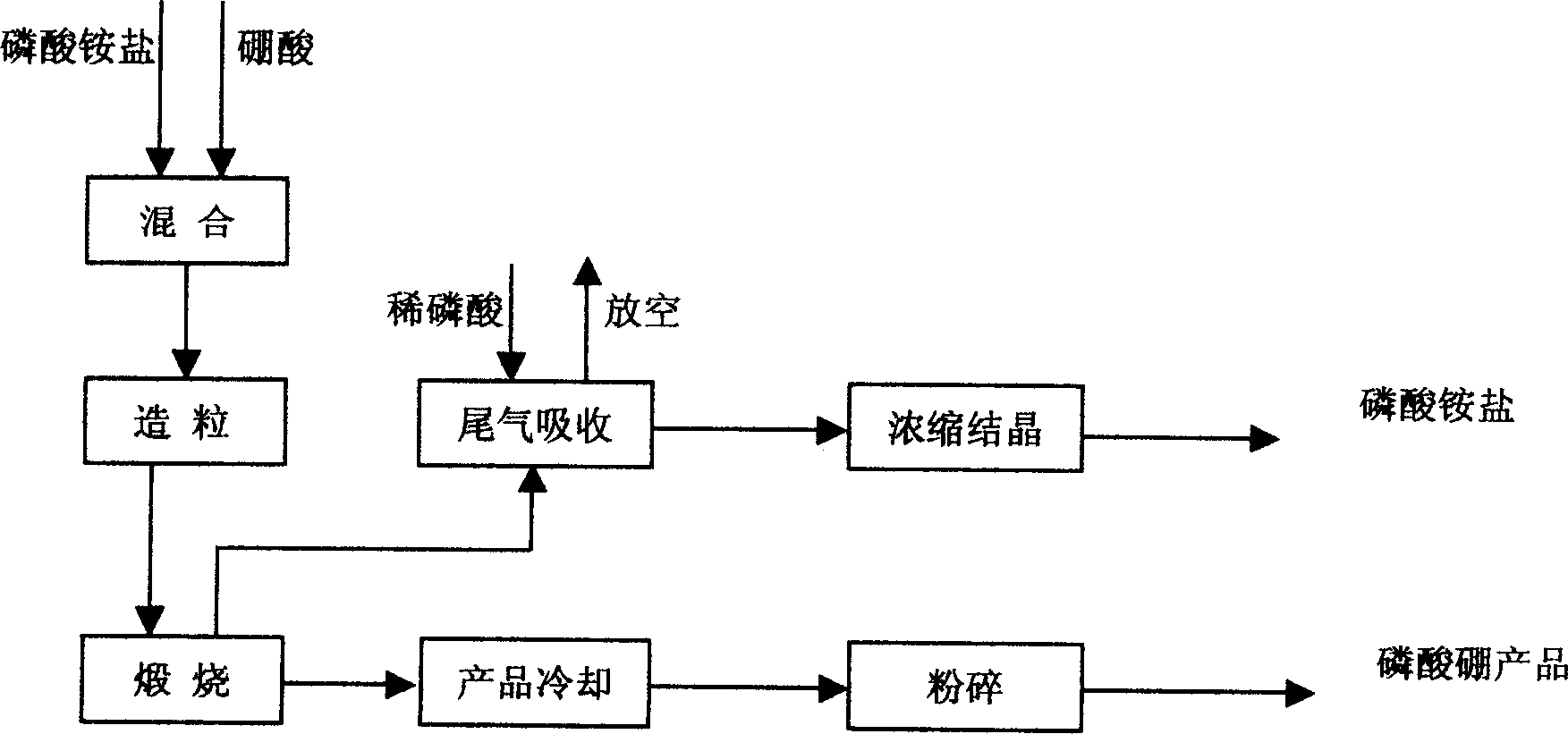

Boron phosphate preparation method

InactiveCN1762805AShort reaction timeReduce manufacturing costBoron compoundsPhosphoric acidSolid state reaction method

The present invention discloses preparation process of boron phosphate. The material includes boric acid as boron source and mixture of ammonium phosphate and phosphoric acid as phosphorus source and has molar ratio between B2O3 and P2O5 of 0.9-1.1. The homogeneously mixed material is pelletized in a pelletizer and calcined at 300-1000 deg.c in a rotary kiln for 1-3 hr to synthesize boron phosphate through high temperature solid phase reaction; and the synthesized boron phosphate from the rotary kiln is further cooled and crushed to obtain the required boron phosphate product. The present invention synthesizes boron phosphate through one-step high temperature solid phase reaction, and has short reaction period, simple technological process, low production cost and high product quality.

Owner:YUNNAN CHEM RES INST

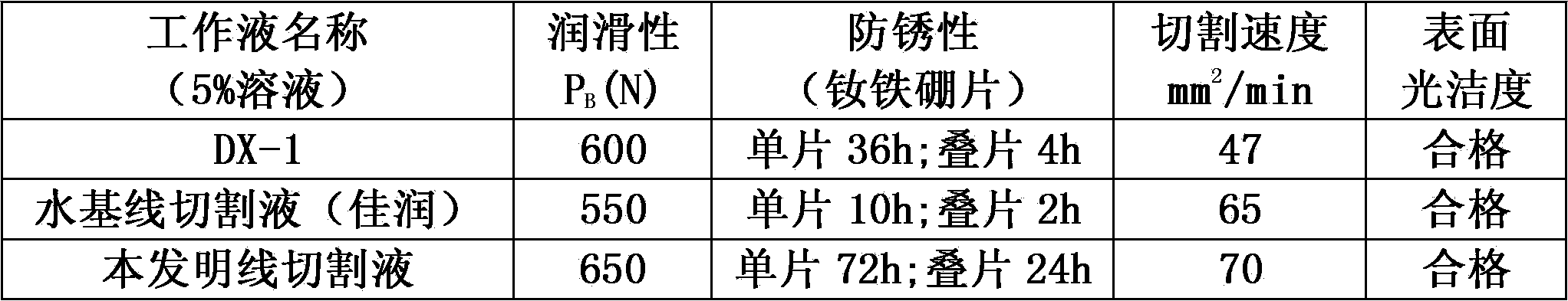

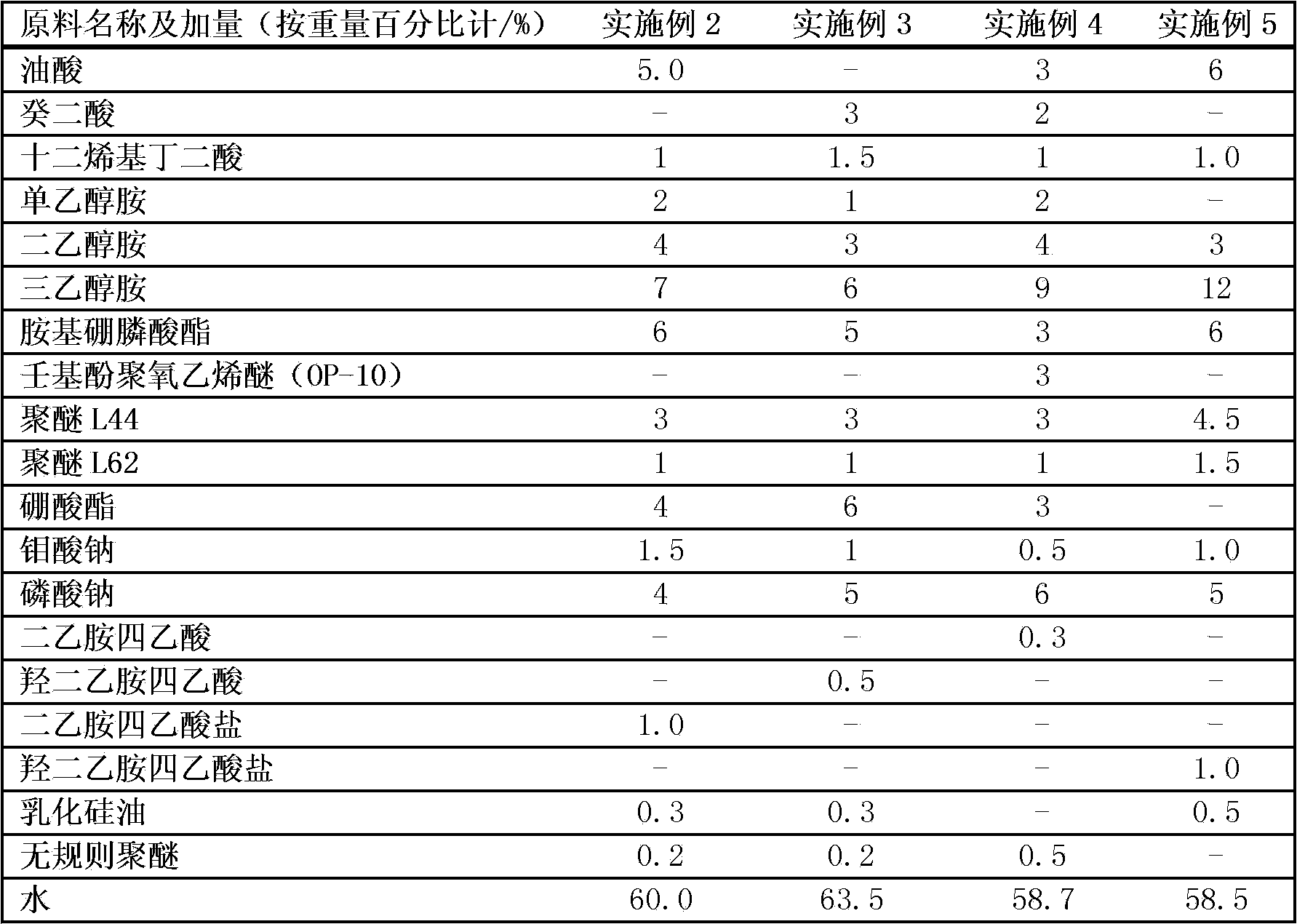

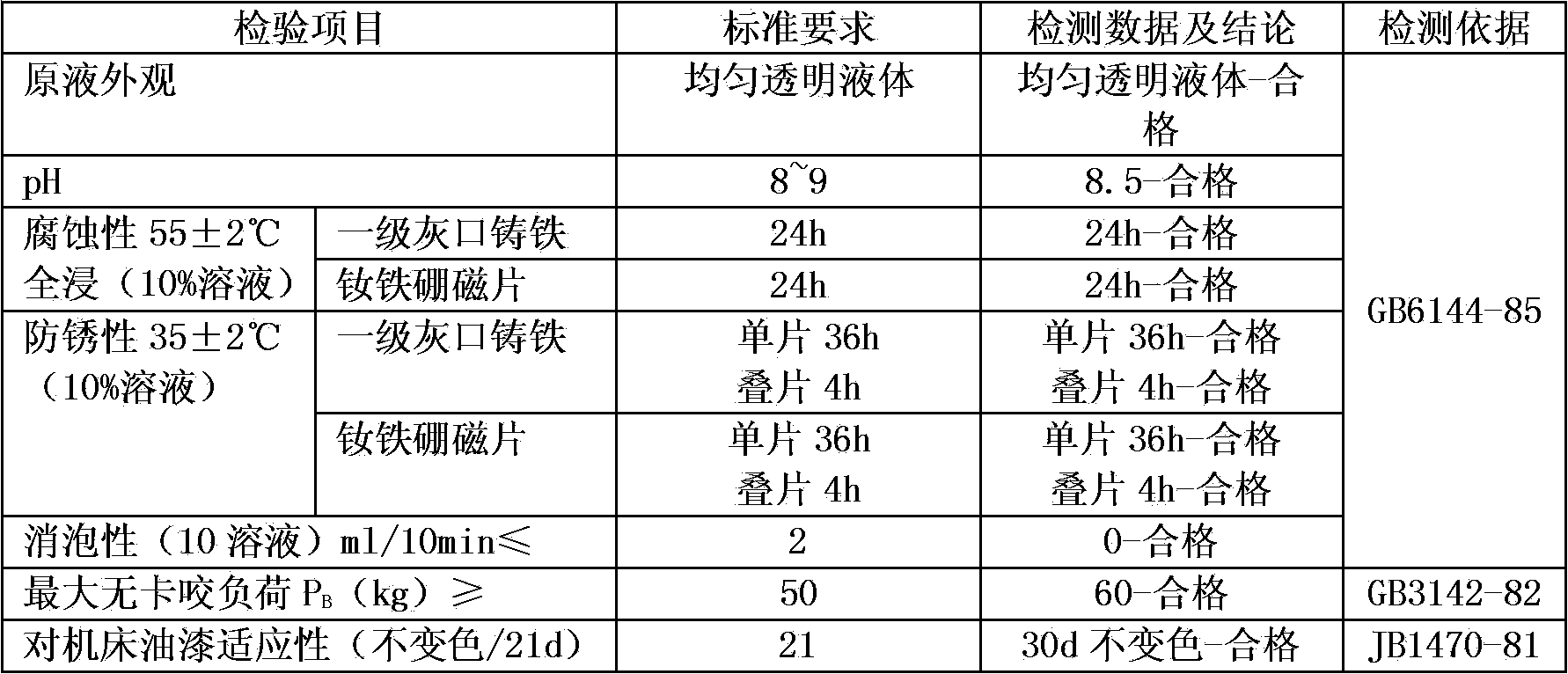

Linear cutting fluid for neodymium-iron-boron permanent magnet material

InactiveCN103725387AImprove conductivityImprove the lubrication effectLubricant compositionHard waterMaterials processing

A linear cutting fluid for a neodymium-iron-boron permanent magnet material is characterized by comprising the compositions in percent by weight: 3%-9% of an aliphatic acid, 10%-15% of ethanolamine, 3%-6% of an amino boron phosphate, 5%-10% of a cleaning agent, 6%-9% of an antirust agent, 0.3%-1.0% of a hard water resistant agent, 0.3%-1.0% of an antifoaming agent and the balance water. The preparation method of the linear cutting fluid comprises: adding the aliphatic acid into a reaction kettle according to the amount of the formula, heating to 60-70 DEG C, adding ethanolamine with stirring, continuing to heat to 120-150 DEG C and reacting for 2 h, then cooling to 80 DEG C, successively adding the amino boron phosphate, the cleaning agent, the antirust agent, the antifoaming agent, the hard water resistant agent and water, and continuing to stir for 2 hours to obtain the finished product. The linear cutting fluid provided by the invention is low in cost, can realize long-acting antibiosis, belongs to environment-friendly product, is specially used in neodymium-iron-boron permanent magnet material processing technology, and has good cutting, cooling and rust resisting effects.

Owner:SHENYANG POLYTECHNIC UNIV

Phosphorus-containing ZSM-5 molecular sieve, preparation method and applications thereof

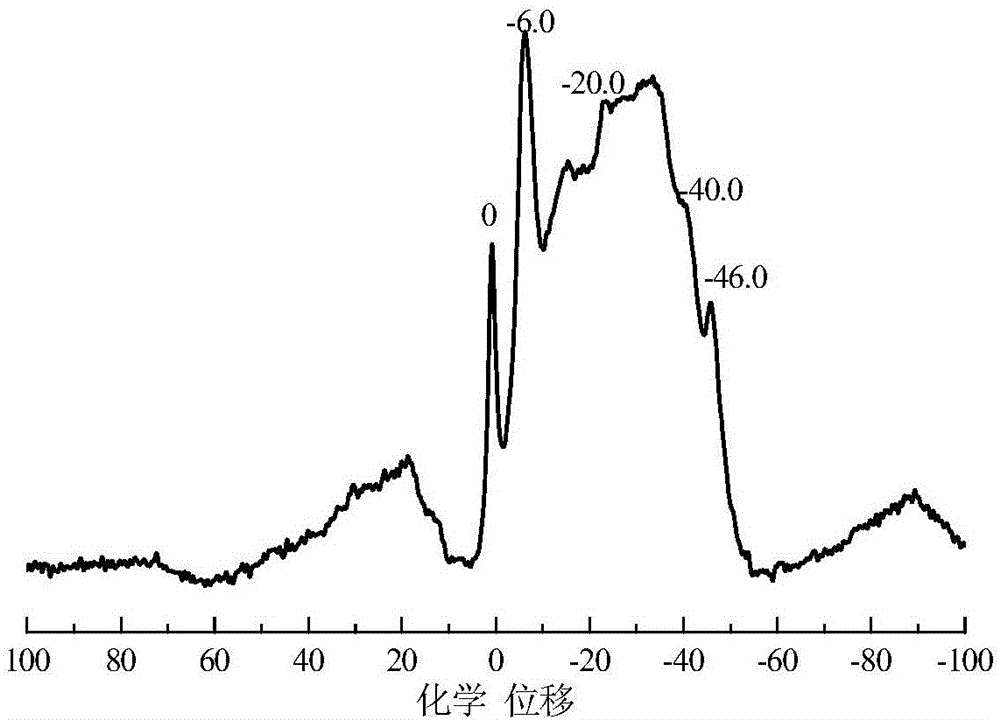

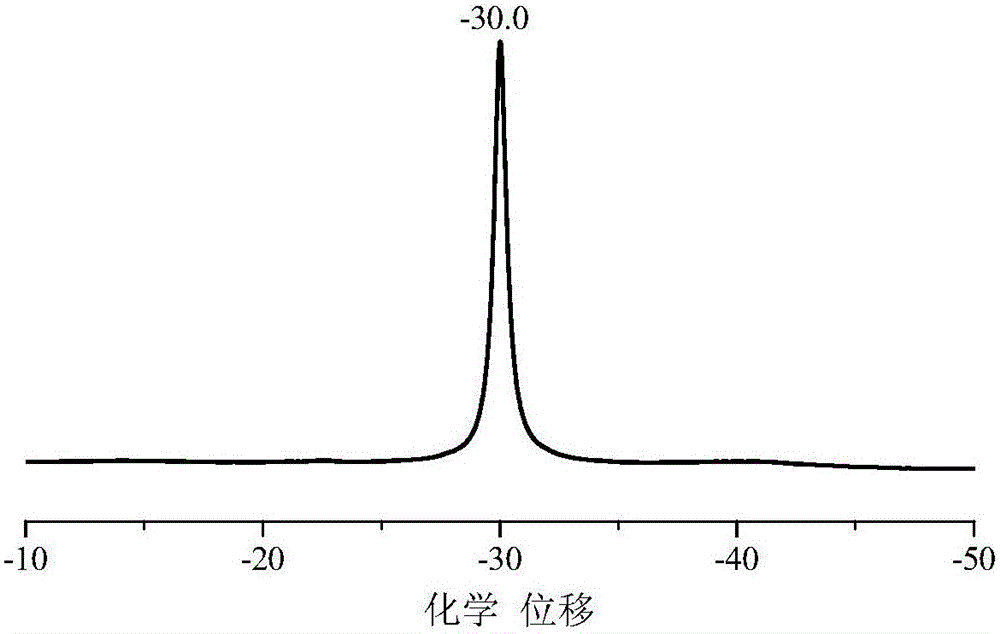

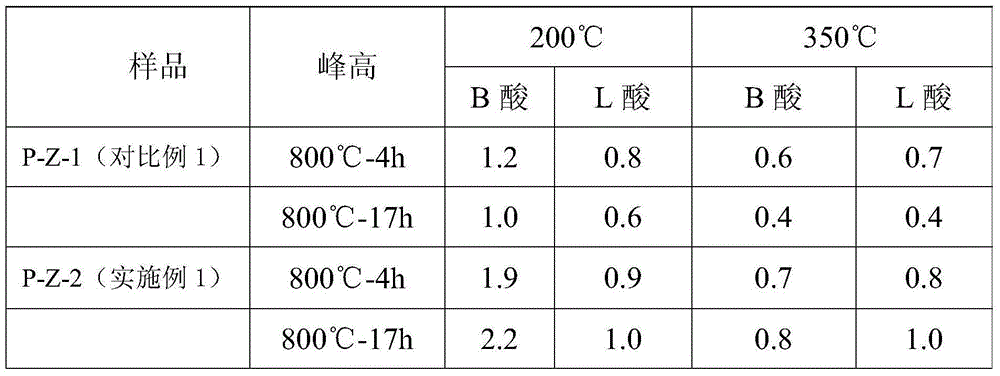

InactiveCN106395853AImprove conversion rateHigh yieldMolecular sieve catalystsBulk chemical productionMolecular sieveMolecular physics

The invention relates to a phosphorus-containing ZSM-5 molecular sieve, which is characterized in that only a phosphorus shape characteristic peak exists in the 31P MAS-NMR spectrum of the molecular sieve, and the chemical shift of the characteristic peak is at -30.0+ / -2 ppm. According to the present invention, a ZSM-5 molecular sieve and boron phosphate are mixed to make the phosphorus loading capacity of the ZSM-5 molecular sieve at least be 0.1 wt% (calculated as P2O5), and drying and calcining are performed to obtain the phosphorus-containing ZSM-5 molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

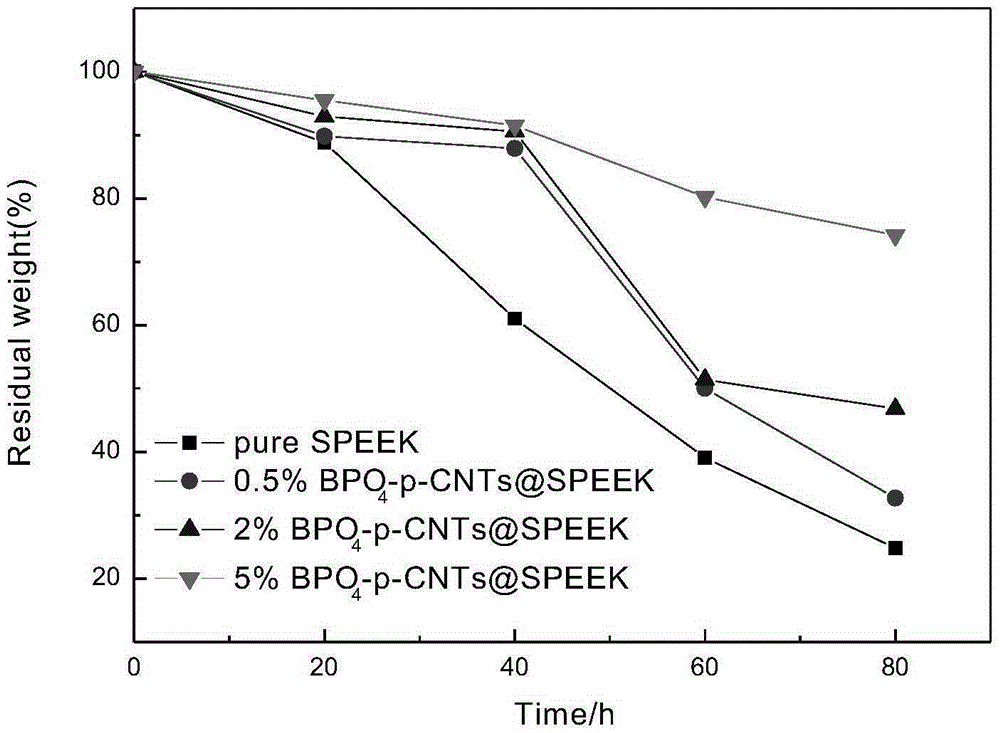

Method for preparing boron phosphate coated carbon nanotube composite proton exchange membrane

The invention belongs to the technical field of fuel cell proton exchange membranes, and particularly discloses a method for preparing a boron phosphate coated carbon nanotube composite proton exchange membrane. According to the method, sulfonated polyether ether ketone is used as the base material, and boron phosphate coated carbon nanotubes are used as the dopant, so that the membrane is prepared. The composite proton exchange membrane prepared through the method is excellent in overall performance. Moreover, the preparation technology is simple, the material cost is low, and the method can be applied to proton exchange membrane fuel cells.

Owner:HUBEI ENG UNIV

Refractory shaped body with increased alkali resistance

The invention relates to a refractory batch and to a process for its production. The batch comprises a refractory metal oxide main component containing Al2O3; the refractory metal oxide main component containing 40 to 60% by weight of Al2O3; a phosphate bond, in particular, the phosphate bond being produced by at least one of a phosphoric acid and a monoaluminum phosphate; finely particulate SiC having a grain size of <0.2 mm, the batch containing 3 to 15% by weight of the finely particulate SiC; and the grain size distribution of the SiC being selected so that more than 2.0% of the SiC, based on a total quantity of the batch, is <0.045 mm, whereby said batch excludes the presence of boron phosphate.

Owner:REFRATECHNIK HLDG GMBH

Anti-corrosion paint special for scaffold

InactiveCN105086745AImprove propertiesImprove heat resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySilanes

The invention discloses anti-corrosion paint special for a scaffold. The anti-corrosion paint special for the scaffold comprises 20-50 parts of epoxy resin, 10-25 parts of phenolic resin, 5-20 parts of acidic nano-silicon sol, 10-15 parts of diphenyldimethoxysilane, 5-12 parts of a silane coupling agent KH560, 5-20 parts of polyvinyl chloride, 2-10 parts of graphene, 3-10 parts of modified nano-silicon dioxide, 3-10 parts of boron phosphate, 3-10 parts of nano-zinc oxide, 5-15 parts of zinc borate, 1-5 parts of mica powder, 5-15 parts of ethylene glycol ethyl ether acetate, 2-10 parts of methyl isobutyl ketone, 2-5 parts of propylene oxide tert-butyl ether, 1-5 parts of diethylene glycol butyl ether, 2-7 parts of propylene glycol methyl ether propionate, 3-8 parts of propylene glycol methyl ether acetate, 3-5 parts of amino resin and 2-5 parts of auxiliaries. The anti-corrosion paint special for the scaffold is good in corrosion resistance and excellent in water resistance and weathering resistance.

Owner:安徽鹏峰新型建材科技有限公司

Efficient environmentally-friendly fire retardant for wood impregnation, and treatment technology thereof

InactiveCN104647522AWith smoke suppressionWith smoke suppression effectWood treatment detailsPressure impregnationRetardation effectAmmonium polyphosphate

The invention discloses an efficient environmentally-friendly fire retardant for wood impregnation, and a treatment technology thereof. The efficient environmentally-friendly fire retardant for wood impregnation comprises, by mass, 10-25% of phosphoric acid, 5-10% of borax, 5-10% of boric acid, 30-45% of water-soluble ammonium polyphosphate, 5-30% of aluminum sulfate and 3-6% of ammonium molybdate. Compared with fire retardants in the prior art, the efficient environmentally-friendly fire retardant has smoke elimination and inhibition effects through the addition of ammonium molybdate, contains P, N and B fire retardation components, and has the advantages of good fire retardation effect, no halogen, low toxicity, no irritation, no corrosion, good stability in the use process, difficult degradation or loss, abundant sources of raw materials, low cost and use convenience.

Owner:高天红

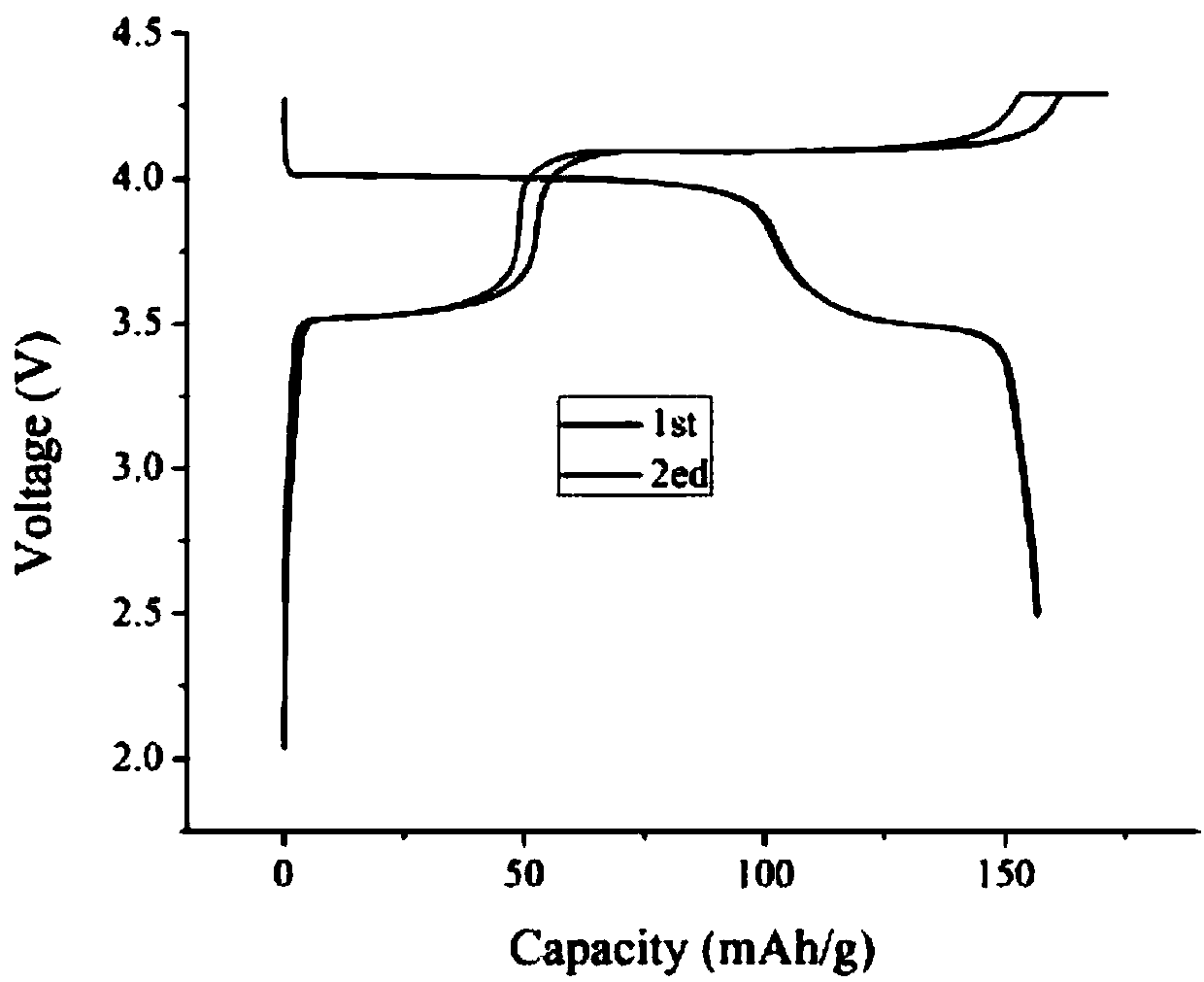

Lithium-doped boron phosphate-modified carbon-coated LMFP positive electrode material and preparation method thereof

ActiveCN107623112ADissolution inhibitionGuarantee normal performanceCell electrodesSecondary cellsModified carbonManganese

The invention discloses a lithium-doped boron phosphate-modified carbon-coated LMFP positive electrode material and a preparation method thereof. The particle sizes of LMFP primary particles are smaller than 80nm; and a carbon coating layer which is 0.1-2nm in thickness is formed on the surface of each LMFP primary particle. The LMFP primary particles are reunited to form carbon-coated LMFP secondary particles of which the particle sizes are 10-50 microns; and gaps between the primary particles in the carbon-coated LMFP secondary particles are filled with lithium-doped boron phosphate. The lithium-doped boron phosphate is a lithium-ion conductor, so that the LMFP primary particles in the secondary particles can be provided with a lithium-ion transport channel, and development of the capacity of active materials in the secondary particles is ensured; and meanwhile, lithium-doped boron phosphate modification is surface coating on the LMFP primary particles, so that dissolution of manganese ions can be suppressed and the cycling stability of the LMFP material is improved.

Owner:中科致良新能源材料(浙江)有限公司

Catalytic cracking catalyst for increasing diesel yield and preparation method of catalytic cracking catalyst

ActiveCN108499600AEasy to prepareTo achieve the goal of producing more dieselCatalytic crackingMolecular sieve catalystsMolecular sieveClay minerals

The invention discloses a catalytic cracking catalyst for increasing diesel yield and a preparation method of the catalytic cracking catalyst. The preparation method comprises steps as follows: (1), raw materials and deionized water are mixed and beaten, and slurry is prepared; (2), the slurry is subjected to spray drying, and a product is roasted and washed; wherein the raw materials comprise non-boron phosphate type boron-containing substances, a molecular sieve, clay mineral and a fourth component with the binding effect. The catalyst has resistance to heavy metal pollution, high diesel yield is realized, and the preparation process is simple.

Owner:REZEL CATALYSTS CORP

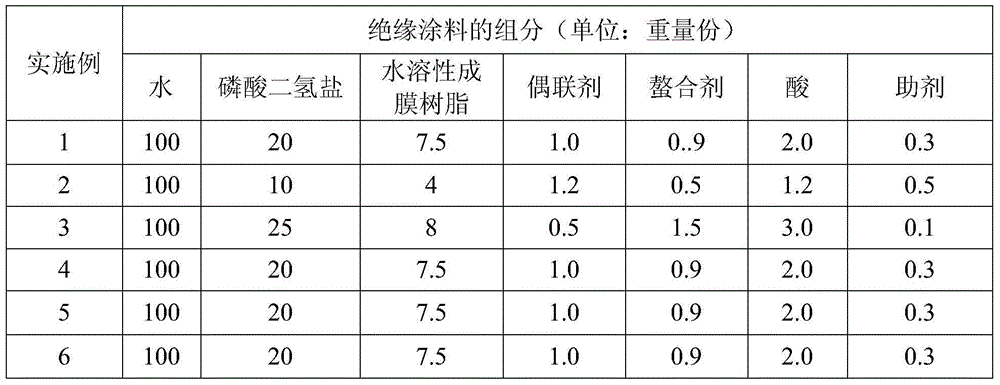

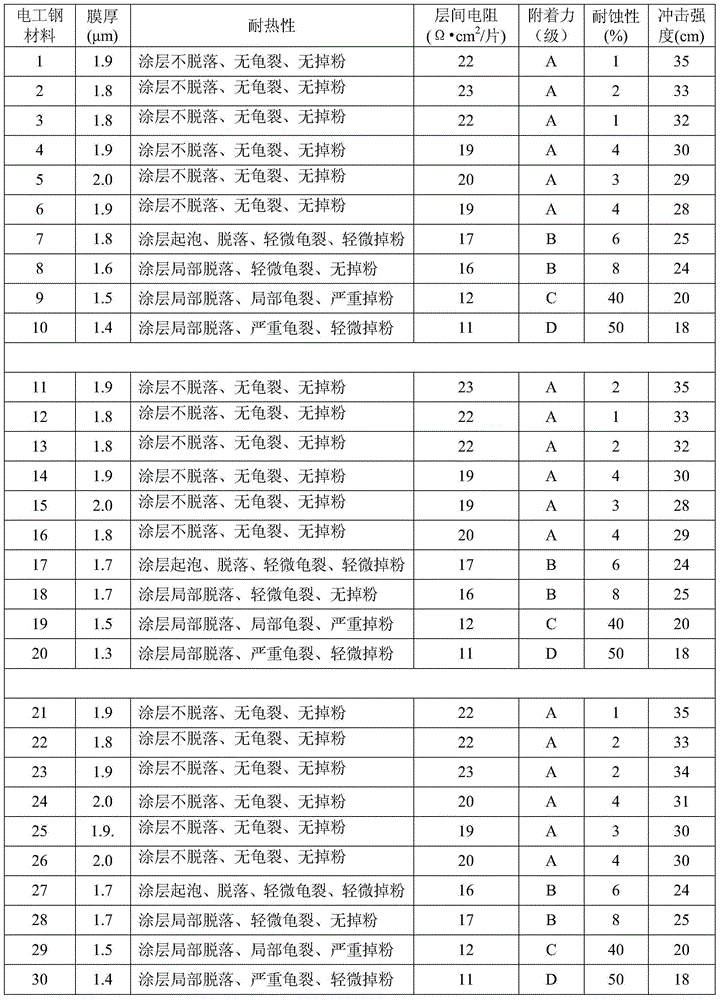

Insulation coating and electrical steel material, and preparation method thereof

ActiveCN103045058BImprove heat resistanceImprove insulation performanceLayered productsEpoxy resin coatingsBenzoic acidPhosphate

The invention provides an insulation coating which is prepared by uniformly mixing a raw material mixture, wherein the raw material mixture comprises dihydrogen phosphate, water-soluble film-forming resin, a coupling agent, acids and water, and the acids is selected from at least one of phosphoric acid, boric acid, fluotitanic acid, acetic acid, oxalic acid, citric acid, maleic acid, benzoic acid, tannic acid, tartaric acid and phytic acid. The invention further provides an electrical steel material. The invention further provides a preparation method of the electrical steel material. The invention further provides the electrical steel material prepared by the above preparation method. The insulation coating provided by the invention can obtain a coating by curing at a lower temperature, and the cured coating has excellent properties such as heat resistance, insulation resistance, adhesion, corrosion resistance, punching resistance, etc.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

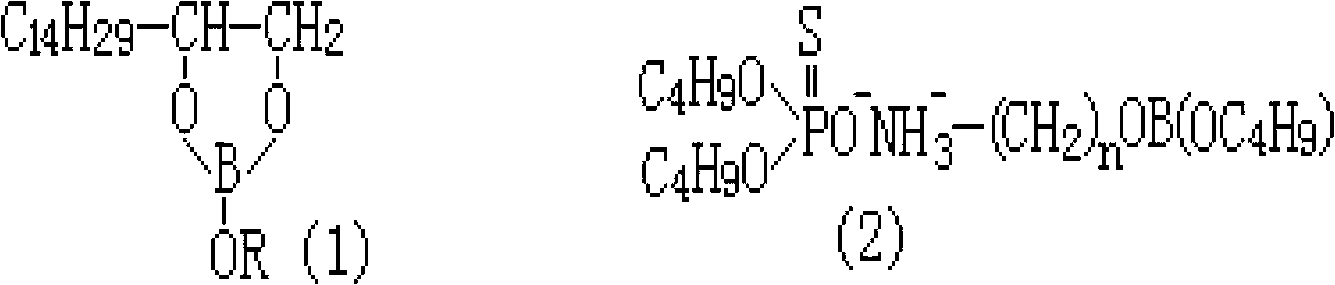

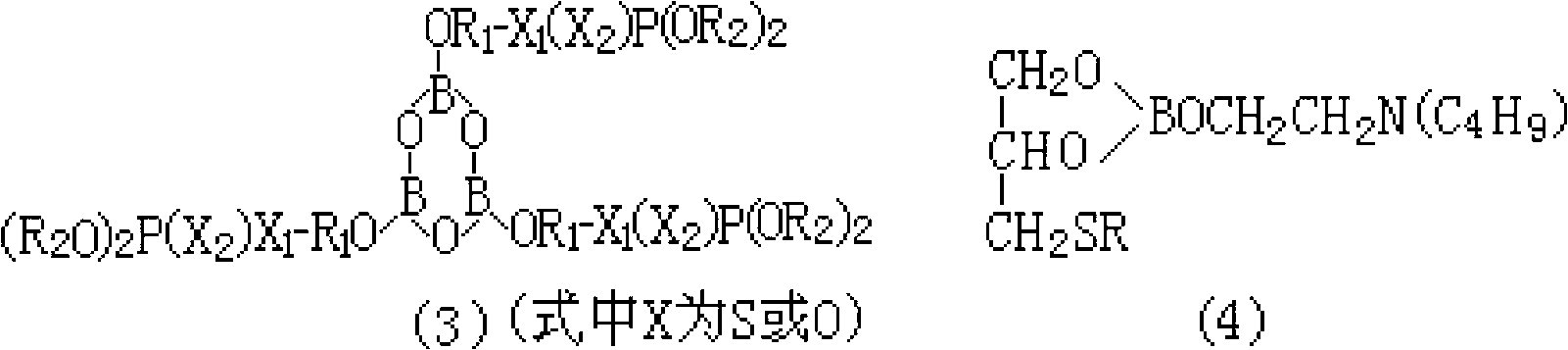

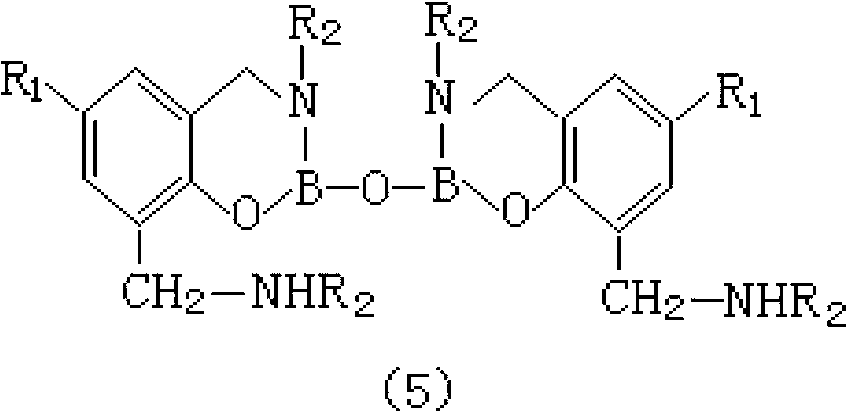

Amido boron phosphate and preparation method of amido boron phosphate

InactiveCN102850396AStrong resistance to hydrolysisImprove the lubrication effectGroup 5/15 element organic compoundsAdditivesWater basedRoom temperature

The invention relates to amido boron phosphate, which comprises the following ingredients: organic amine, dibutyl phosphite, formaldehyde and bononizing agents according to a ratio being 1:(2-3):(2-3):1. A preparation method of the amido boron phosphate comprises the following steps that a, the dibutyl phosphite and the formaldehyde are added into a reaction kettle, then, the organic amine is completely dripped into the reaction kettle under a stirring condition, the temperature in the reaction kettle is controlled to be smaller than or equal to 30 DEG C, and the stirring is continuously carried out for 1 to 2 hours when the temperature in the kettle is not raised; b, the bononizing agents are added into the reaction kettle, a water distribution device is started, temperature is raised to 110 to 130 DEG C through heating, the backflow reaction is carried out for 3 to 5 hours, the reaction is completed when the liquid surface of water in the water distribution device is not increased, cooling is carried out to the room temperature, and a target product is obtained. The synthetized amido boron phosphate belongs to a B-N-P type multifunctional Y lubricating oil additive, when the amido boron phosphate is added into water-base metal processing liquid, the anti-corrosion performance and the anti-rust performance of the processing liquid can be improved, and the lubricating performance of the water-base metal processing liquid can also be improved.

Owner:SHENYANG POLYTECHNIC UNIV

Refractory shaped body with increased alkali resistance

InactiveUS20080261799A1Good alkali resistanceRotary drum furnacesFurnace liningsO-Phosphoric AcidPhosphate

The invention relates to a refractory batch and to a process for its production. The batch comprises a refractory metal oxide main component containing Al2O3; the refractory metal oxide main component containing 40 to 60% by weight of Al2O3; a phosphate bond, in particular, the phosphate bond being produced by at least one of a phosphoric acid and a monoaluminum phosphate; finely particulate SiC having a grain size of <0.2 mm, the batch containing 3 to 15% by weight of the finely particulate SiC; and the grain size distribution of the SiC being selected so that more than 2.0% of the SiC, based on a total quantity of the batch, is <0.045 mm, whereby said batch excludes the presence of boron phosphate.

Owner:LIEVER HEINRICH +2

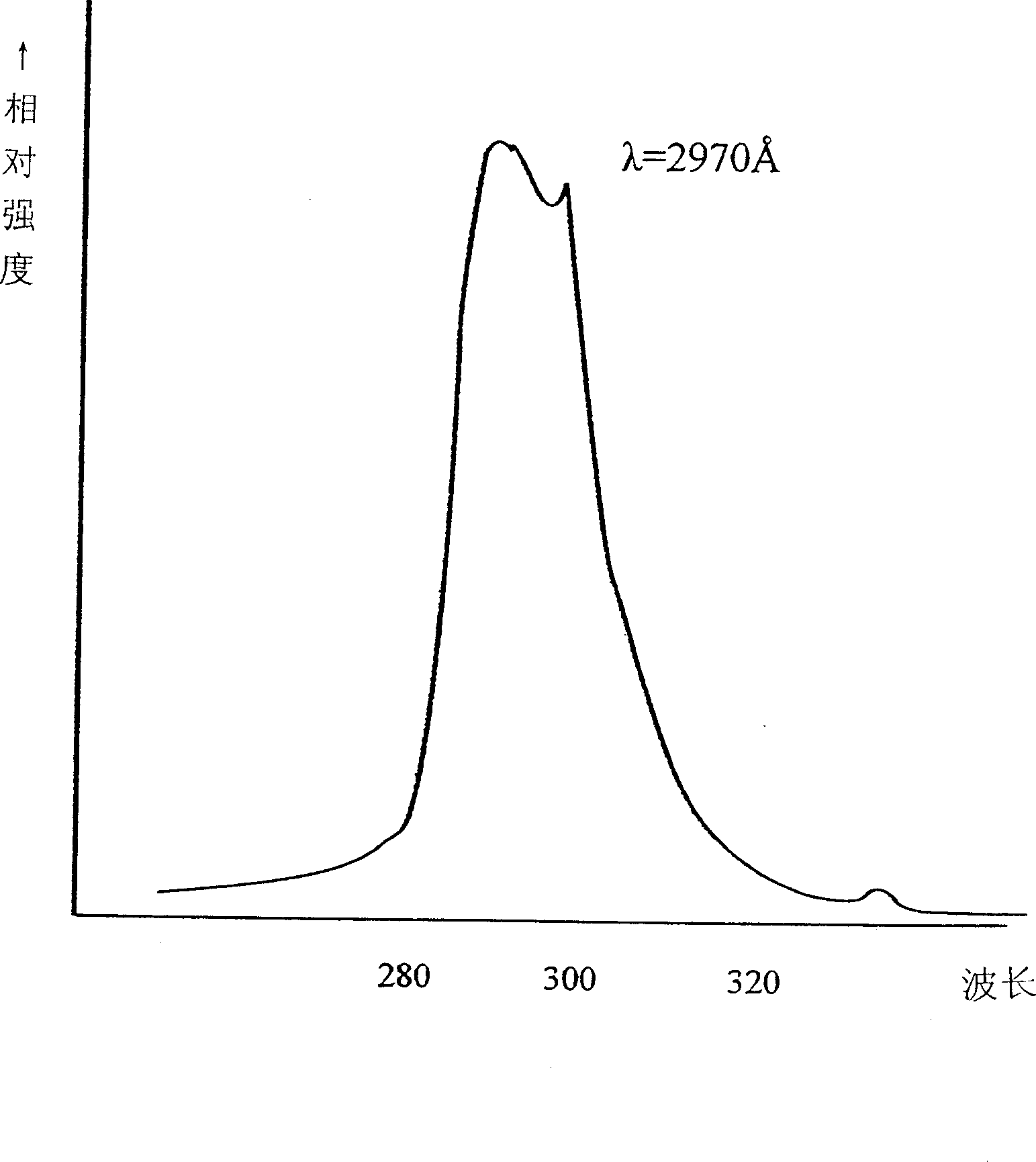

Health-care fluorescent-lamp fluorescent powder against osteoporosis

InactiveCN1982408AHigh strengthNot easy to ageLight therapyLuminescent compositionsAlkaline earth metalPhosphate

A health-care fluorescent-lamp powder can prevent osteoporosis. It is a kind of alkali boron phosphate with expression formula ((Mo)1-3. (B203)1-4. (P205)0.1-1:Pb0.005-1. Y0.01-1), M belongs to one or above of calcium, magnesium, strontium and sulfone, and Y is one or above of rare-earth ion lanthanum, samarium and gadolinium. The process is carried out by mixing one or above of calcium carbonate, strontium carbonate and barium carbonate with one or above of magnesium oxide, boric acid, ammonium dibasic phosphate, lead oxide, lanthanum oxide, gadolinium oxide and samarium sesquioxide and solid-phase firing at high-temperature. It can transmit medium-wave ultraviolet with peak value=2970, convert human-body hypodermic 7-deoxycholesterol into vitaminD3, and improve human-body calcium-phosphorus metabolism. It can be used for health-care fluorescent-lamp in family and hospital.

Owner:王瑛 +2

Imitated silk fabric dyeing and finishing process

InactiveCN105386310AExcellent mothproofImprove mildew resistanceHeat resistant fibresGrip property fibresPolymer scienceHexamethylenetetramine

The present invention discloses an imitated silk fabric dyeing and finishing process comprising the following steps: 1) pre-treatment; 2) dyeing; and 3) finishing, to be more specific, sequentially pouring 1 to 2 parts by weight of hydroxypropyl methylcellulose, 2.1 parts by weight of sodium benzoate, 1.5 parts by weight of peppermint extract and 0.7 part by weight of dichloroacetic acid into 26 parts by mass of deionized water, stirring well; and then simultaneously pouring 0.4 part by weight of Toosendan, 0.2 part by weight of boron phosphate, 0.7 part by weight of hexamethylenetetramine and 0.9 part by weight of polyethylene glycol stearate, continuing stirring until full mixing to prepare a finishing solution; then padding a fabric in the finishing solution, then taking out, and drying at constant temperature. The fabric dyed and finished by the imitated silk fabric dyeing and finishing process has excellent moth-proofing, mouldproof, antibacterial, flame retardant and antistatic performances, and is strong in washability and soft to touch.

Owner:常熟市华威服饰厂

Core-shell phosphor and method of making the same

In accordance with one aspect of the present invention, a core-shell phosphor composition is provided that includes a core comprising at least one material selected from the group consisting of aluminum phosphate, gallium phosphate, calcium phosphate, magnesium phosphate, zinc phosphate and boron phosphate; and a shell at least partially enclosing the core, wherein the shell comprises a shell material having formula (I)La1-x-yCexTbyPO4 (I)wherein, 0<x<0.95, and 0<y<0.5. In accordance to another aspect of the invention a method of making the core-shell phosphor and a light source including the core-shell phosphor are provided.

Owner:GENERAL ELECTRIC CO

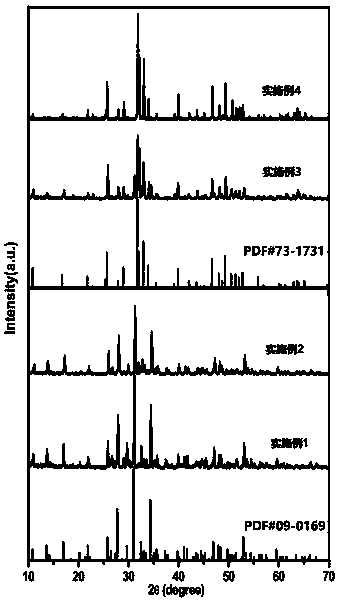

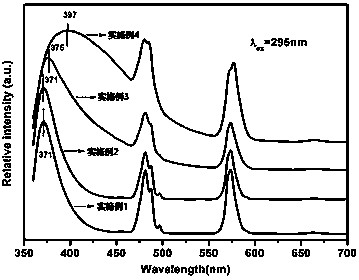

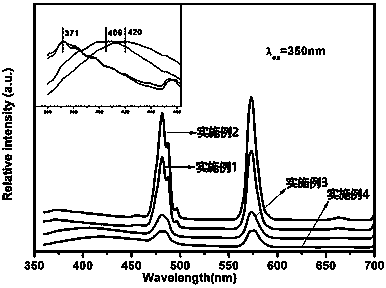

Color-controllable fluorescent powder doped with Ce3+ and Dy3+ and preparing method thereof

ActiveCN108517210ALuminous stabilityLuminescence regulationLuminescent compositionsRare earth ionsCerium

The invention relates to the technical field of light emitting materials, in particular to color-controllable fluorescent powder doped with Ce3+ and Dy3+ and a preparing method thereof. The color-controllable fluorescent powder is characterized by being composed of Ca2.93(P1-xBxO4)<2> to 0.01 Ce 0.06 Dy at the molar ratio, wherein x is larger than or equal to 0 and smaller than or equal to 0.5. Trivalent cerium ions (Ce3+) and dysprosium ions (Dy3+) serve as a light emitting center; the prepared fluorescent powder can emit light stably under the excitation of near ultraviolet light, and various kinds of light colors are mixed to form white light. According to the color-controllable fluorescent powder, by changing the matrix composition of the fluorescent powder, particularly changing the relative content of boron phosphate, light emitting of rare earth ions is controlled, and then the light emitting performance of the fluorescent powder is adjusted and controlled.

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com