LED device containing alkaline earth boron phosphate luminescent powder

A technology of LED devices and borophosphates, applied in semiconductor devices, electrical components, luminescent materials, etc., to achieve high color rendering index, reasonable spectral energy distribution, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (Sr 0.96 Eu 0.04 ) 6 B 1.08 P 4.95 o 20 Preparation: Weigh raw materials

[0023] SrCO 3 : 3.4014g

[0024] Eu 2 o 3 : 0.1689g

[0025] h 3 BO 3 : 0.2671g

[0026] NH 4 h 2 PO 4 : 2.2776g

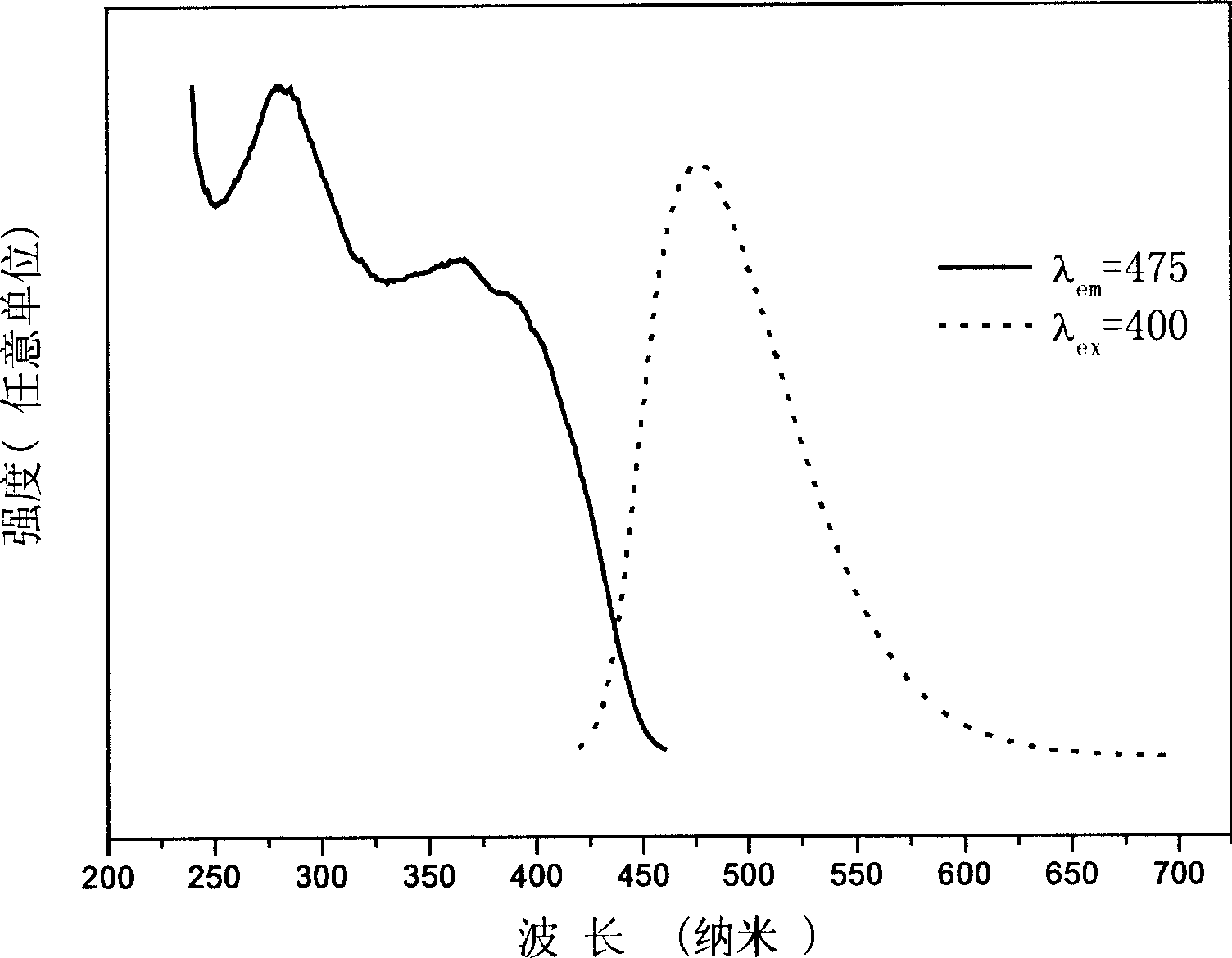

[0027] Grind and mix the raw materials of the mixture evenly, burn in air at 600°C for 1 hour, pulverize, grind and mix evenly after cooling, and then sinter in CO at 1250°C for 5 hours to obtain the alkaline earth borophosphate phosphor product. figure 1 For this phosphor excitation, emission spectrum.

[0028] Ca 8.2 mn 0.6 Eu 1.2 (PO 4 ) 6 Cl 2 Preparation: Weigh the raw materials separately

[0029] CaO: 0.2688g

[0030] MnO 2 : 0.2086g

[0031] Eu 2 o 3 : 0.8448g

[0032] CaHPO 4 .2H 2 O: 4.1302g

[0033] CaCl 2 : 0.4437g

[0034] Burn in air at 600°C for 3 hours, after cooling, pulverize, grind and mix evenly, then burn in charcoal at 1100°C for 5 hours, cool, crush and sieve to obtain the desired phosphor.

[0035] White light LED packaging: m...

Embodiment 2

[0037] (Sr 0.84 Eu 0.16 ) 6 B 0.6 P 5.24 o 20 Preparation: Weigh raw materials

[0038] SrCO 3 : 2.9762g

[0039] Eu 2 o 3 : 0.6756g

[0040] h 3 BO 3 : 0.1484g

[0041] (NH 4 ) 2 HPO 4 : 2.7680g

[0042] After grinding and mixing the raw materials of the mixture evenly, calcine at 500°C for 3 hours in air, pulverize, grind and mix evenly after cooling, and then sinter at 1000°C for 4 hours in a mixed atmosphere of hydrogen and nitrogen to obtain the product.

[0043] Ca 5 Sr 3.9 mn 0.9 Eu 0.2 (PO 4 ) 6 Cl 2 Preparation: Weigh the raw materials separately

[0044] SrCO 3 : 1.1220g

[0045] MnO 2 : 0.3130g

[0046] Eu 2 o 3 : 0.1408g

[0047] CaHPO 4 2H 2 O: 3.4418g

[0048] SrHPO 4 : 0.7345g

[0049] SrCl 2 : 0.6341g

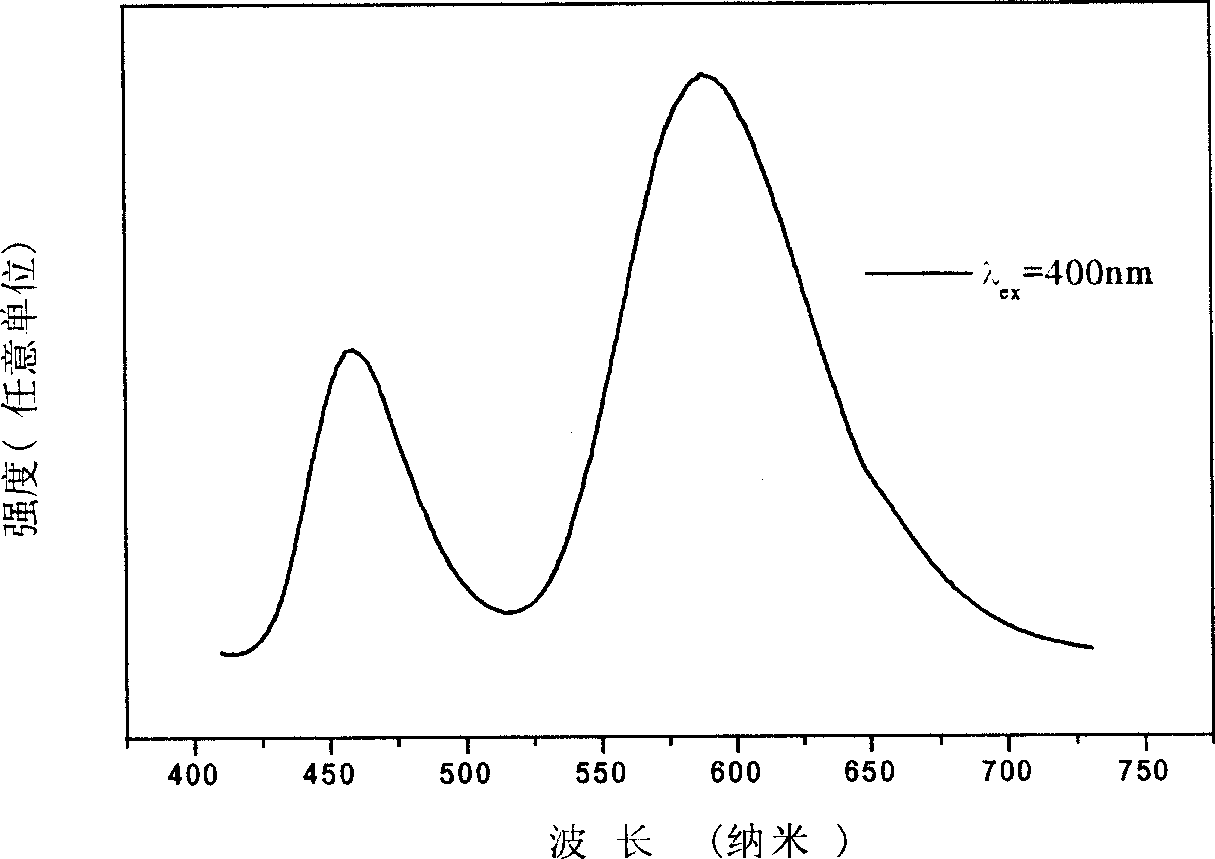

[0050] Burn in air at 650°C for 1 hour, cool, pulverize, grind and mix evenly, then burn at 900°C for 6 hours in an ammonia reducing atmosphere, cool, crush and sieve to obtain the desired phosphor. figure 2 is the emissio...

Embodiment 3

[0053] (Sr 0.94 Eu 0.06 ) 6 BP 5 o 20 Preparation: Weigh raw materials

[0054] SrCO 3 : 3.3305g

[0055] Eu 2 o 3 : 0.2534g

[0056] h 3 BO 3 : 0.2473g

[0057] NH 4 h 2 PO 4 : 2.3006g

[0058] Grind and mix the raw materials of the mixture evenly, burn at 550°C for 3 hours in the air, pulverize, grind and mix evenly after cooling, and then sinter at 1100°C for 4 hours in a mixed atmosphere of hydrogen and nitrogen to obtain the product.

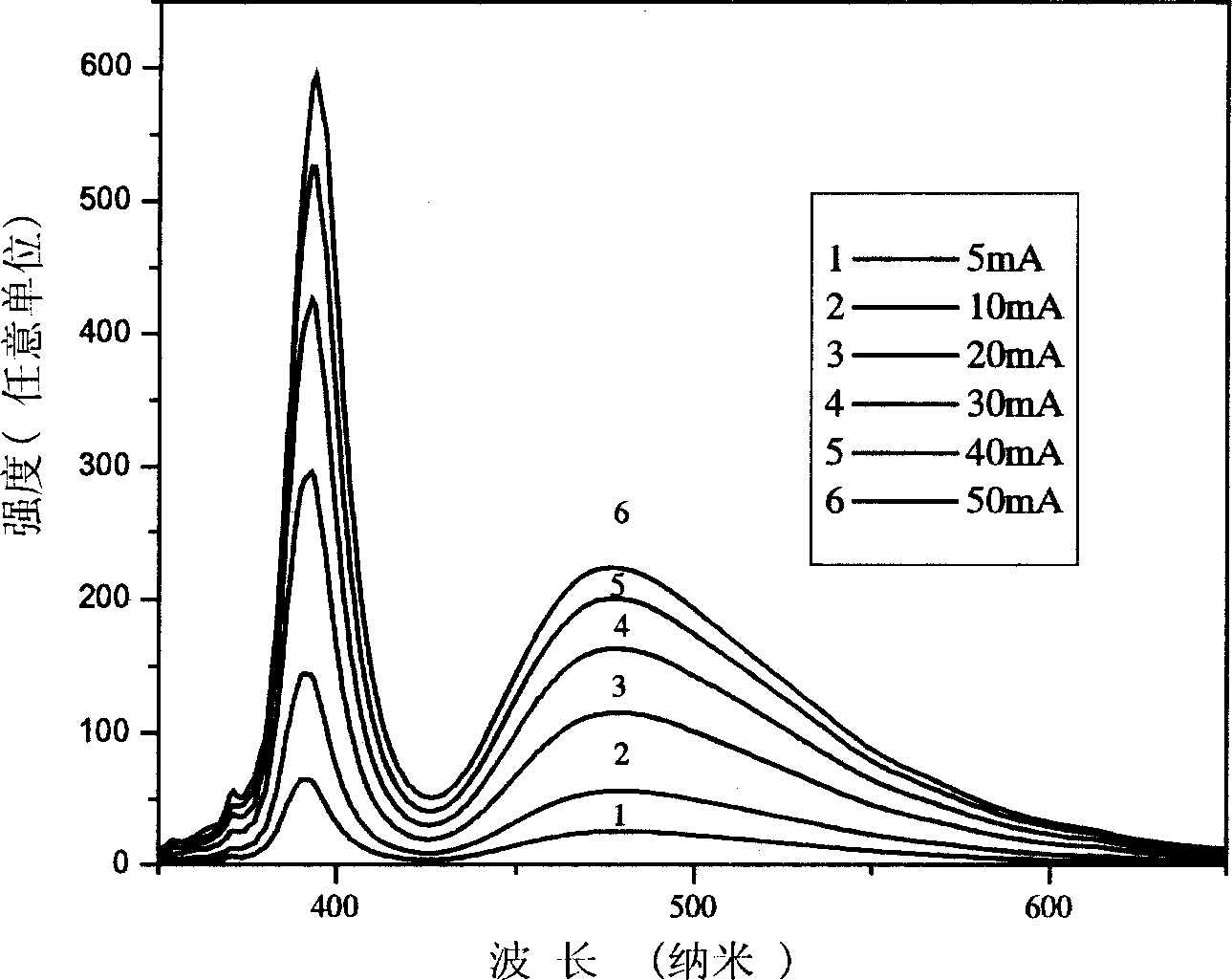

[0059] Blue-green LED packaging: mix the obtained phosphor powder with epoxy resin at a weight ratio of 1:5 to make a slurry, then directly coat the slurry on the surface of the purple LED crystal grains by coating, and finally cure and form at 150°C , That is, the LED device is obtained. Rare-earth phosphor absorbs light from the violet LED chip and emits blue-green light. The color coordinate parameters of the blue-green LED converted by ultraviolet LED are mainly determined by the phosphor powder. The consistency of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com