Insulation coating and electrical steel material, and preparation method thereof

A technology for insulating coatings and electrical steels, applied in polyester coatings, epoxy resin coatings, coatings, etc., can solve the problems of heat resistance, insulation adhesion, corrosion resistance and poor punching properties of insulating coatings. Achieve excellent heat resistance, improve equipment utilization, and save equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034]The present invention also provides a method for preparing an electrical steel material, the method comprising: attaching the above-mentioned insulating coating to the electrical steel substrate, and then curing the insulating coating, and the curing temperature is 150- 220°C.

[0035] According to the preparation method of the electrical steel material of the present invention, the curing temperature is further preferably 165-195°C.

[0036] According to the preparation method of the electrical steel material of the present invention, the amount of the insulating coating may be 3-6 grams, more preferably 4.0-5.0 grams per square meter of the surface of the electrical steel substrate.

[0037] According to the preparation method of the electrical steel material of the present invention, the curing time of the curing may be 20-50s, more preferably 30-40s.

[0038] According to the preparation method of the above electrical steel material provided by the present invention...

Embodiment 1-6

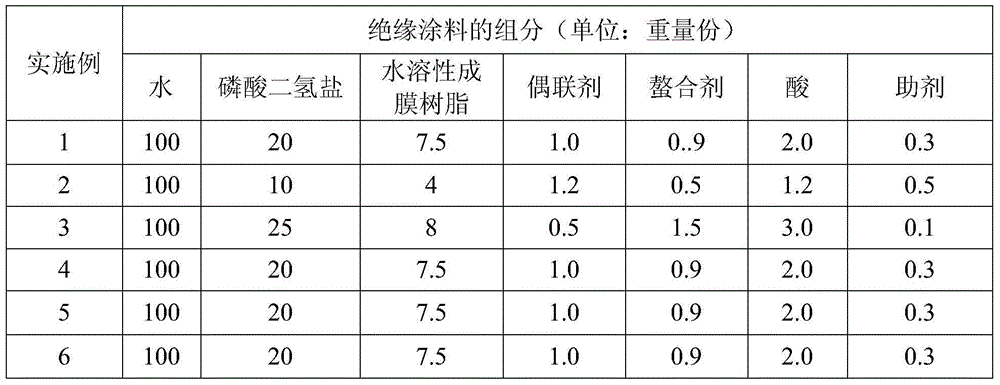

[0045] According to the component contents listed in Table 1, the components were uniformly mixed under stirring conditions to obtain insulating coatings 1-6 respectively.

[0046] Table 1

[0047]

Embodiment 1

[0049] In embodiment 1, the dihydrogen phosphate is zinc dihydrogen phosphate; the water-soluble film-forming resin is water-soluble styrene-acrylic resin (water-soluble styrene-acrylic resin, purchased from Guangzhou Qisheng Chemical Company, the brand is K167), water-soluble cyclic Oxygen film-forming resin (water-soluble epoxy resin, purchased from Shanghai Lujia Water-based Coatings Co., Ltd., brand G08) and water-soluble silicone film-forming resin (water-soluble silicone resin, purchased from Zaoyang Sihai Chemical Co., Ltd., brand SH-9502) equal weight (in terms of solid content) mixture; the silane coupling agent selected by the coupling agent (silane coupling agent, purchased from Nanjing Qianqian Chemical Co., Ltd., the trade mark is KH560); the chelating agent is lignosulfur Calcium acid calcium (analytical pure); Acid is phytic acid; Auxiliary agent is the leveling agent (purchased from Guangzhou Xuanning Chemical Co., Ltd., brand is 2200) of 0.05 weight part, the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com