Patents

Literature

52results about How to "High punchability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

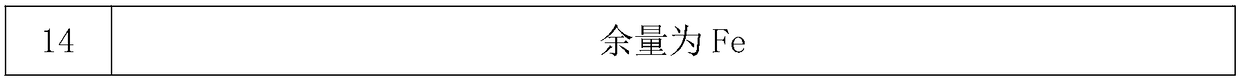

Inventor

Sheet for card, and card

InactiveUS20130075480A1Excellent in of of embossabilityImprove heat resistanceSynthetic resin layered productsBooksCard stockPolymer science

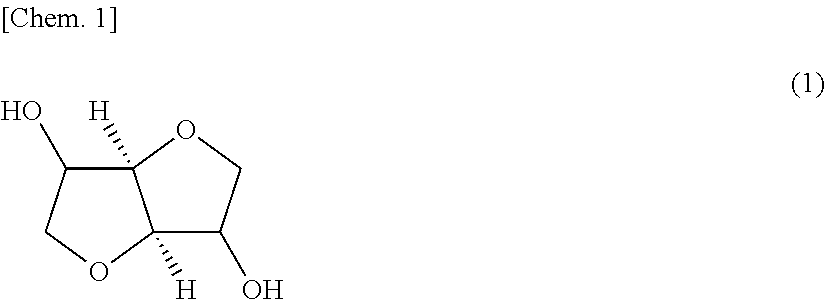

The invention is to provide a sheet for cards which is excellent in terms of all of heat resistance, weatherability, rigidity, punchability, and embossability and which employs a plant-derived resin, and to provide a card. The invention relates to a sheet for cards which has a layer constituted of a resin composition (X) containing, as a main component, a polycarbonate resin (A) that contains structural units (a) derived from a dihydroxy compound represented by the following formula (1) and that has a glass transition temperature lower than 130° C.

Owner:MITSUBISHI CHEM CORP +1

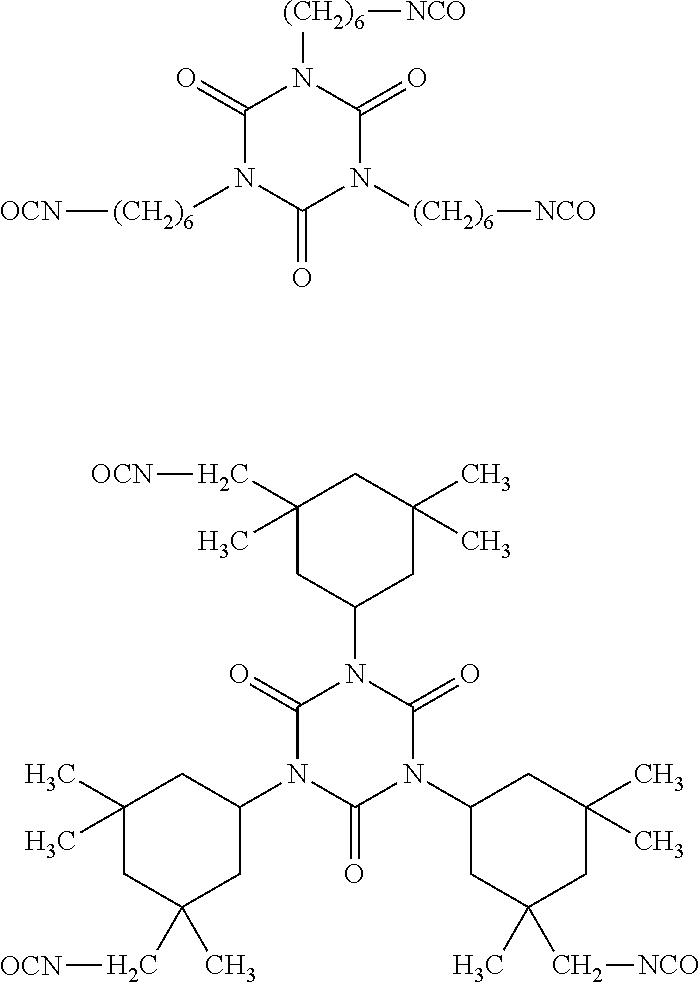

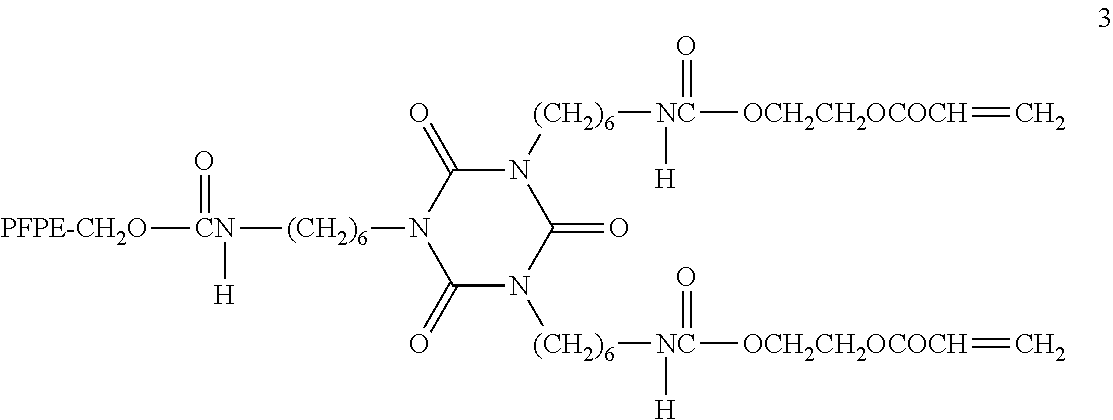

Hard coat agent composition and hard coat film using the same

InactiveUS20130084458A1Maintain good propertiesHigh transparencyMaterial nanotechnologySynthetic resin layered productsMeth-Perfluoropolyether

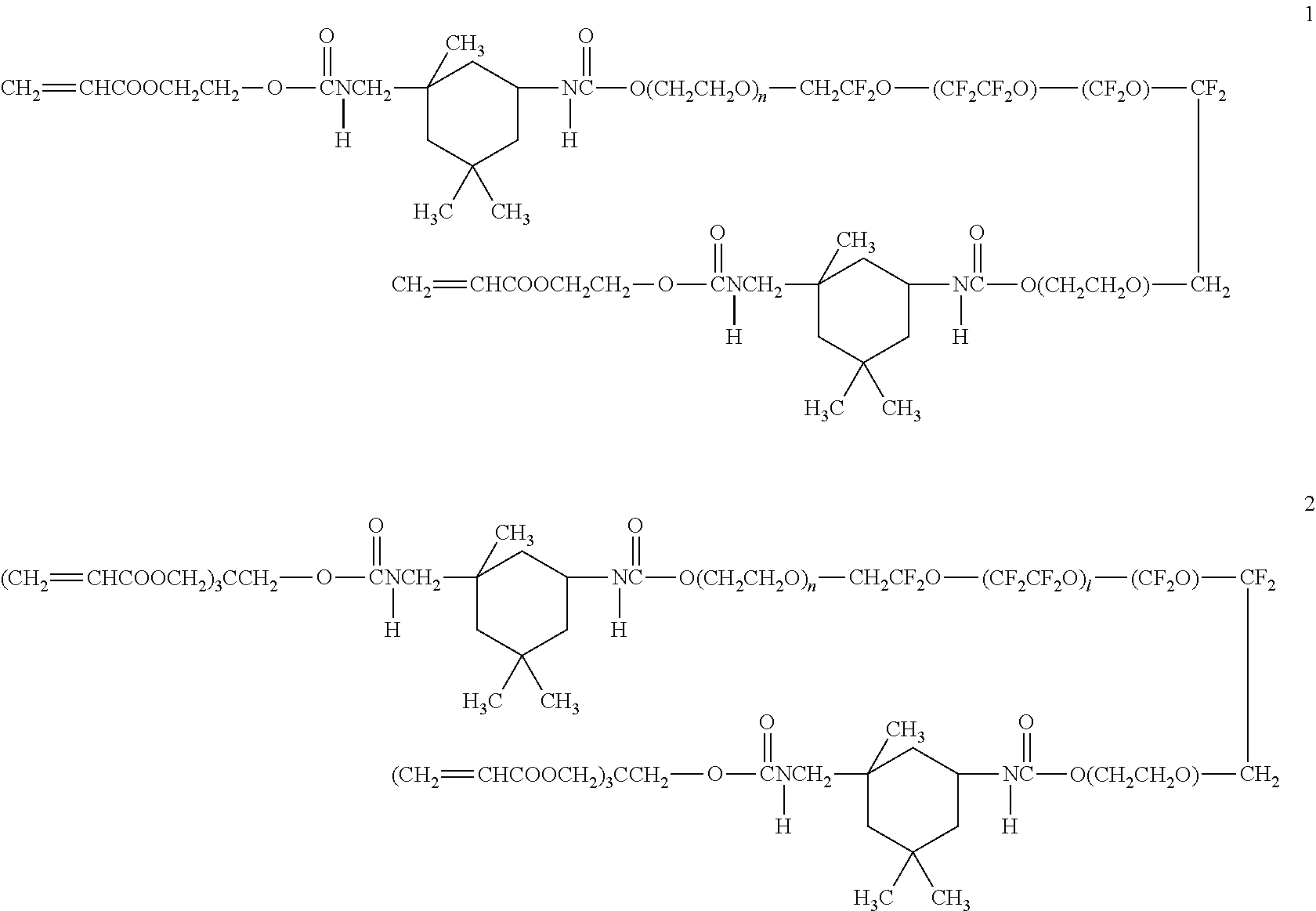

A hard coat agent composition comprising: a urethane acrylate (B) having two or more (meth)acryloyl groups; a first fluorine-containing polyether compound (C) having an active energy ray reactive group via a urethane bond at each of both ends of a molecular chain containing a perfluoropolyether group; a second fluorine-containing polyether compound (D) having an active energy ray reactive group via a urethane bond at one end of a molecular chain containing a perfluoropolyether group and not having an active energy ray reactive group at the other end; and a curable compound (A) having two or more active energy ray polymerizing groups.

Owner:TDK CORPARATION

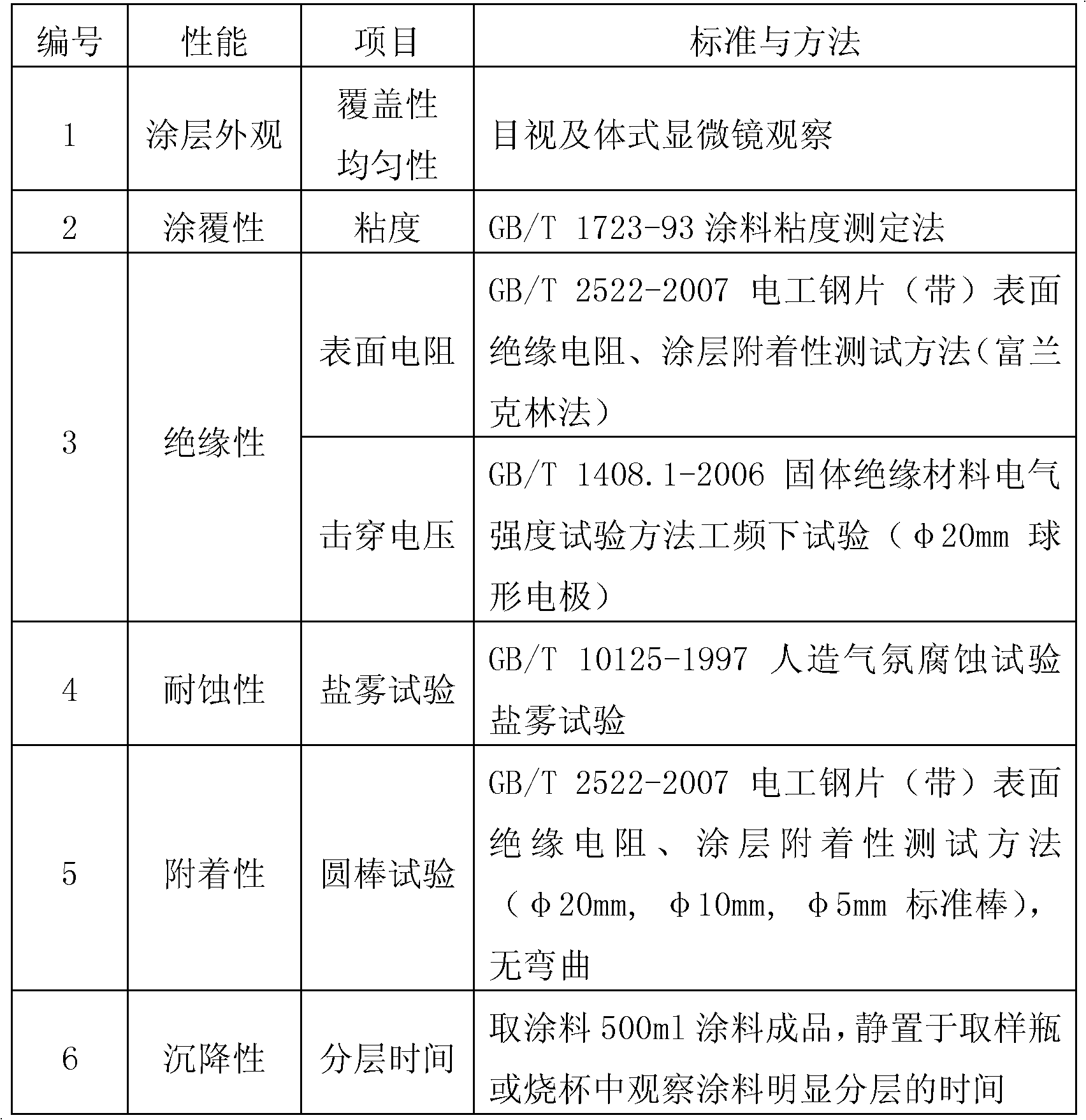

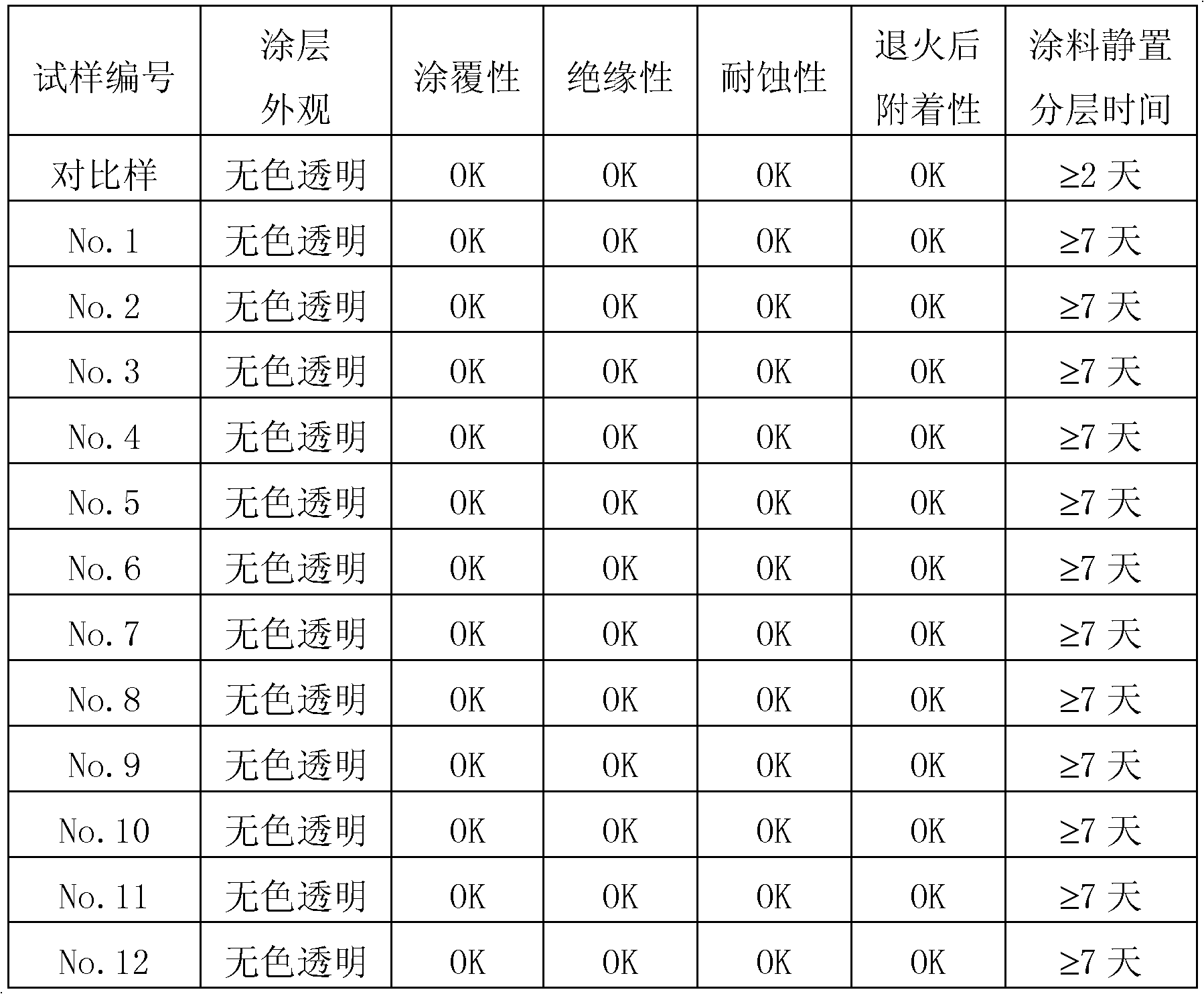

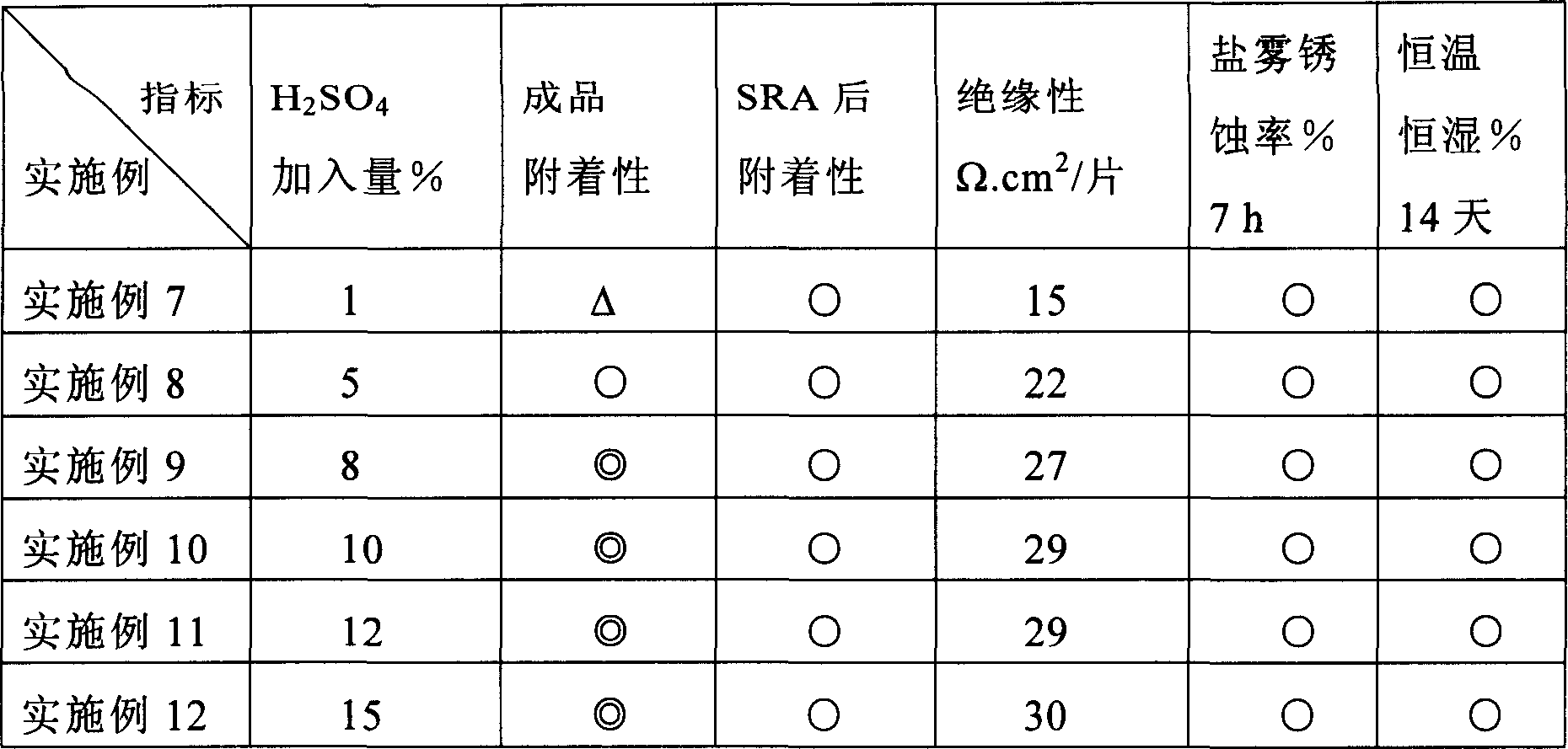

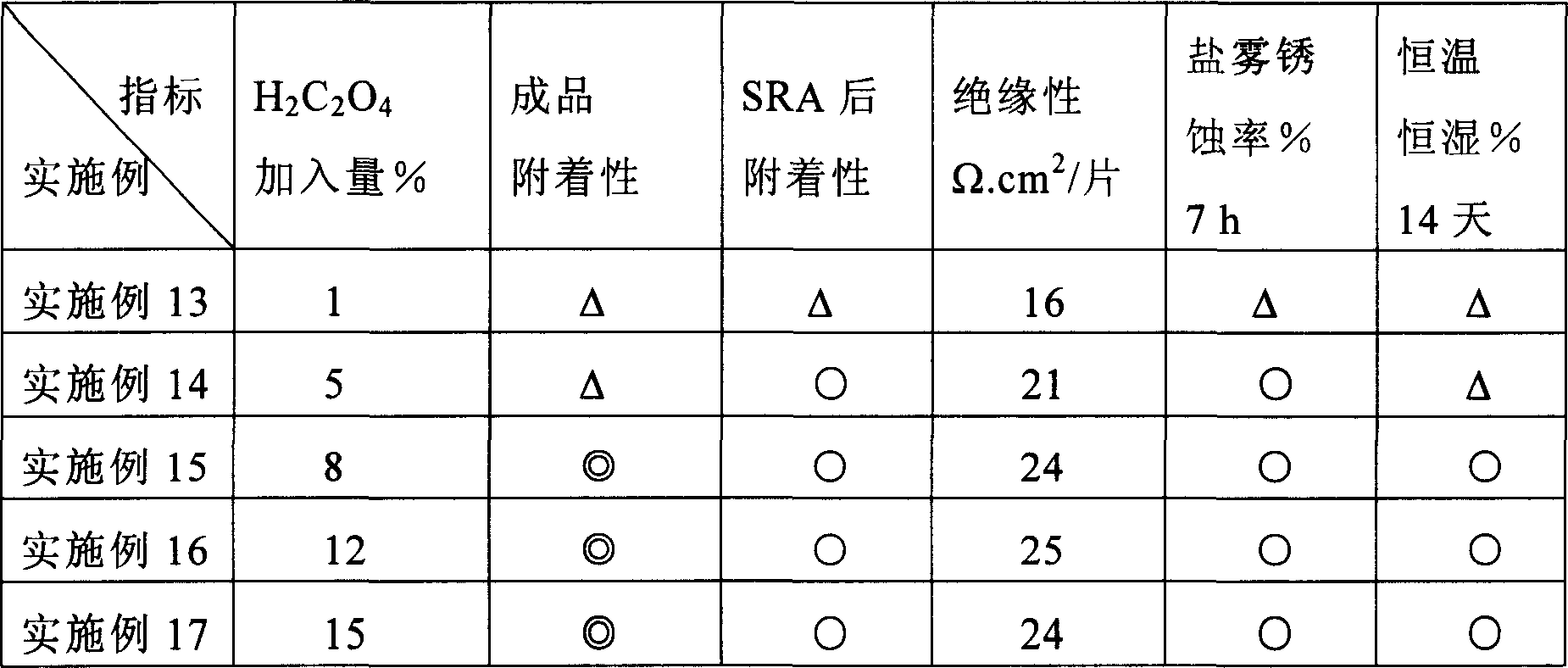

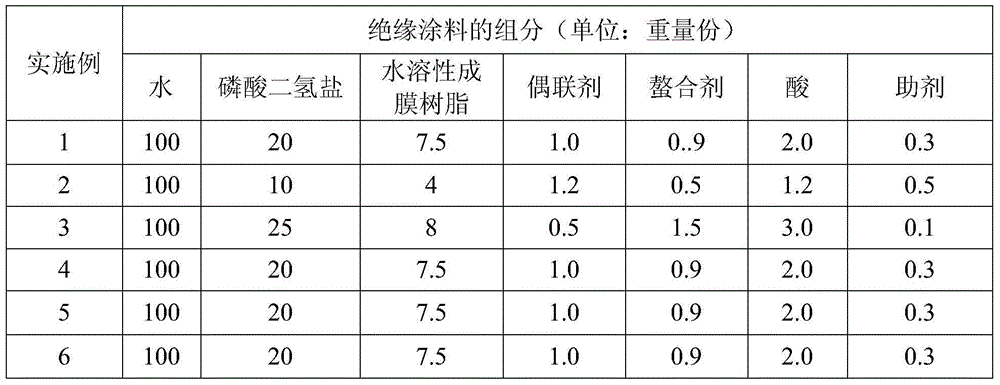

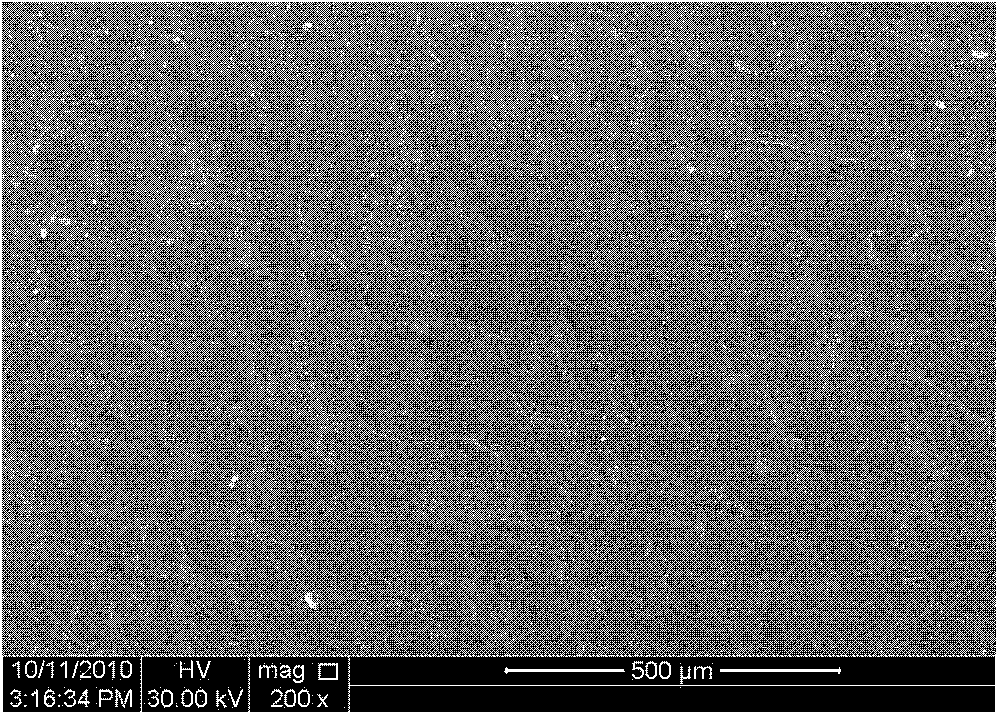

Aqueous environment-friendly insulation coating of anti-settling electric steel and preparation method thereof

InactiveCN102153896AImprove insulation performanceImprove corrosion resistanceMetallic material coating processesDispersityAdditive ingredient

The invention relates to an aqueous environment-friendly insulation coating of anti-settling electric steel and a preparation method thereof. The insulation coating is formulated from the following components by mass percent: 20-60% of aluminium dihydrogen phosphate, 0.5-5% of silica solution, 1-10% of phosphoric acid, 0.3-2% of nitric acid, 1-5% of magnesium oxide, 0.3-5.5% of rare earth-salt blended solution, 0.5-5.5% of silane coupling agents, 3-20% of anti-settling additives, and the balance of solvent water. In the invention, conventional roller painting technology is adopted for coatingand then a film can be made by proper high-temperature solidification. By multiple actions of physical covering, chemical passivation, phosphorization and the like, a surface insulation coating of a cold rolling electric steel plate without orientation has the advantages of good adhesiveness, high insulativity (namely resistance and puncture voltage between high-rises), high corrosion resistance,high temperature resistance and the like, as well as environmental protection without chrome or harmful ions. The insulation coating is widely applicable to the surface coating of the cold rolling electric steel plate without orientation, has a better anti-settling property, better dispersity and a better levelling property, leads coating operation on site to be more convenient and faster, and can effectively avoid the segregation of paint ingredients and the fluctuation of coating performances.

Owner:SHANGHAI QIJIA CHEM

Semi-inorganic environment-friendly insulating paint for non-oriented silicon steel and coating preparation method thereof

The invention discloses a semi-inorganic environment-friendly insulating paint for non-oriented silicon steel and a coating preparation method thereof, and belongs to the technical field of non-oriented silicon steel paint. The semi-inorganic environment-protecting insulating paint for the non-oriented silicon steel is prepared by the following components by mass percent: 5-40% of aluminum dihydrogen phosphate, 0.5-10% of manganese dihydrogen phosphate, 1-12% of zinc dihydrogen phosphate, 0.5-1.5% of zinc oxide, 0.1-1% of magnesium oxide, 1.0-7% of boric acid, 5.0-27% of resin, 2.0-6.0% of organic solvent, 0.1-0.8% of other auxiliaries, and the balance of water. The paint is an environment-friendly paint free from chromium; at the same time, the coating is uniform in brightness, better in corrosion resistance than the ordinary phosphate coating, and good in insulation, adhesiveness, punching, weldability, heat resistance and corrosion resistance. In addition, the source of the semi-inorganic environment-friendly insulating paint for the non-oriented silicon steel is rich, so that the production cost is low, and the paint can be widely applied.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

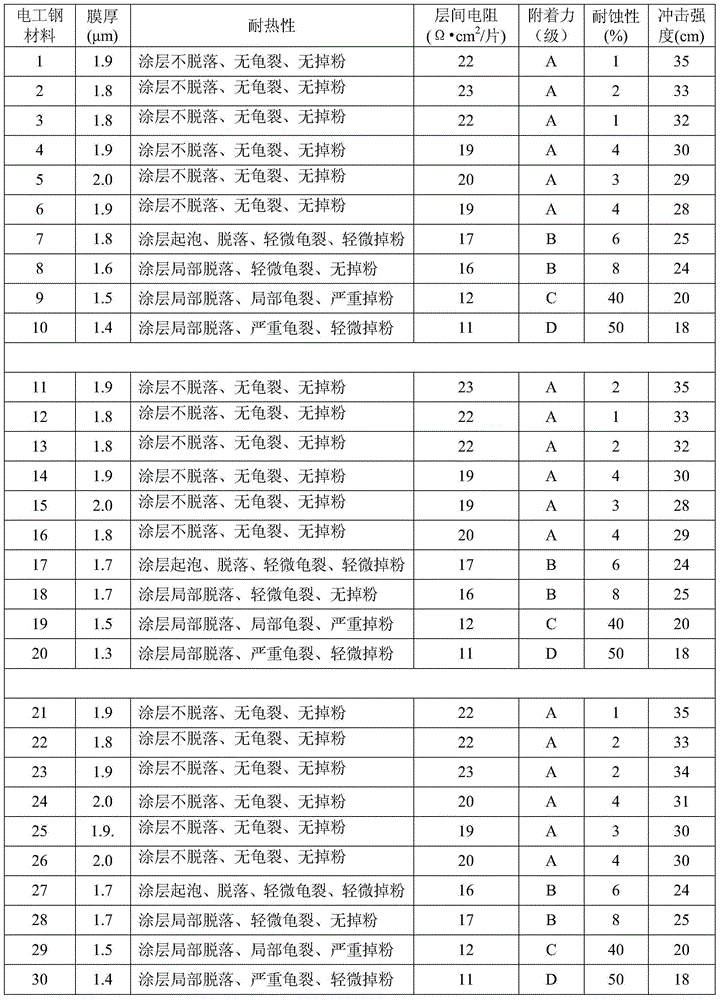

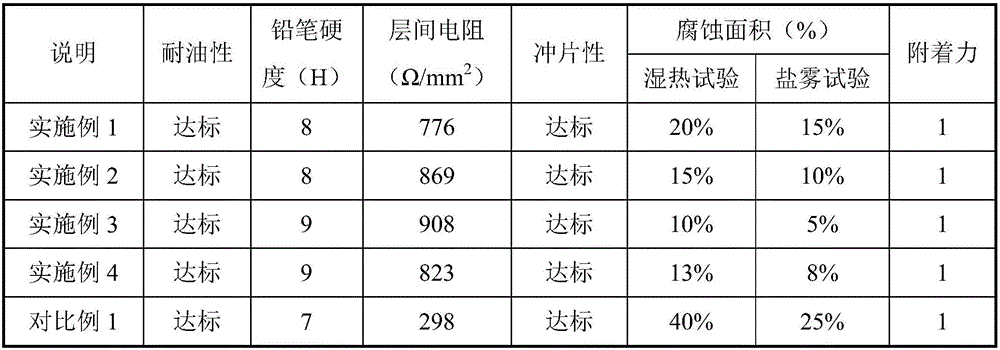

Insulation coating and electrical steel material, and preparation method thereof

ActiveCN103045058AGood heat resistanceLess investment in equipmentLayered productsEpoxy resin coatingsInsulation resistanceChemistry

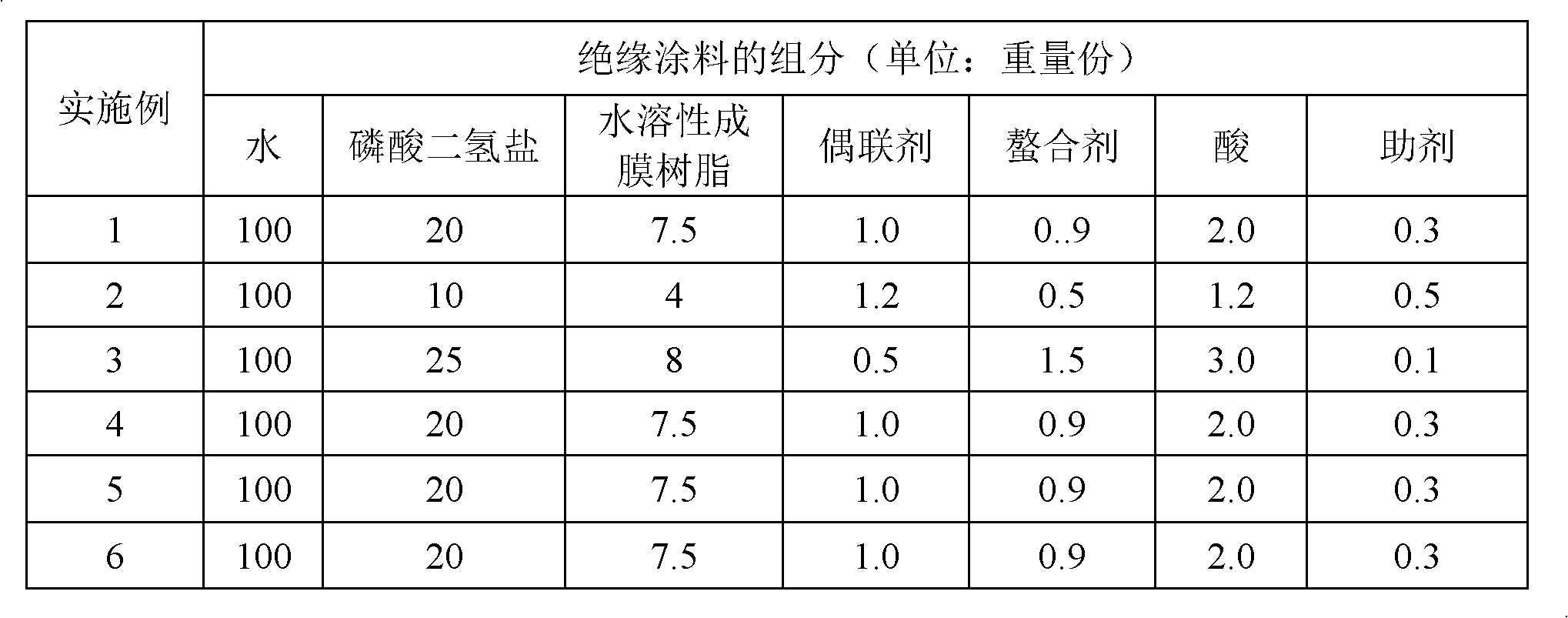

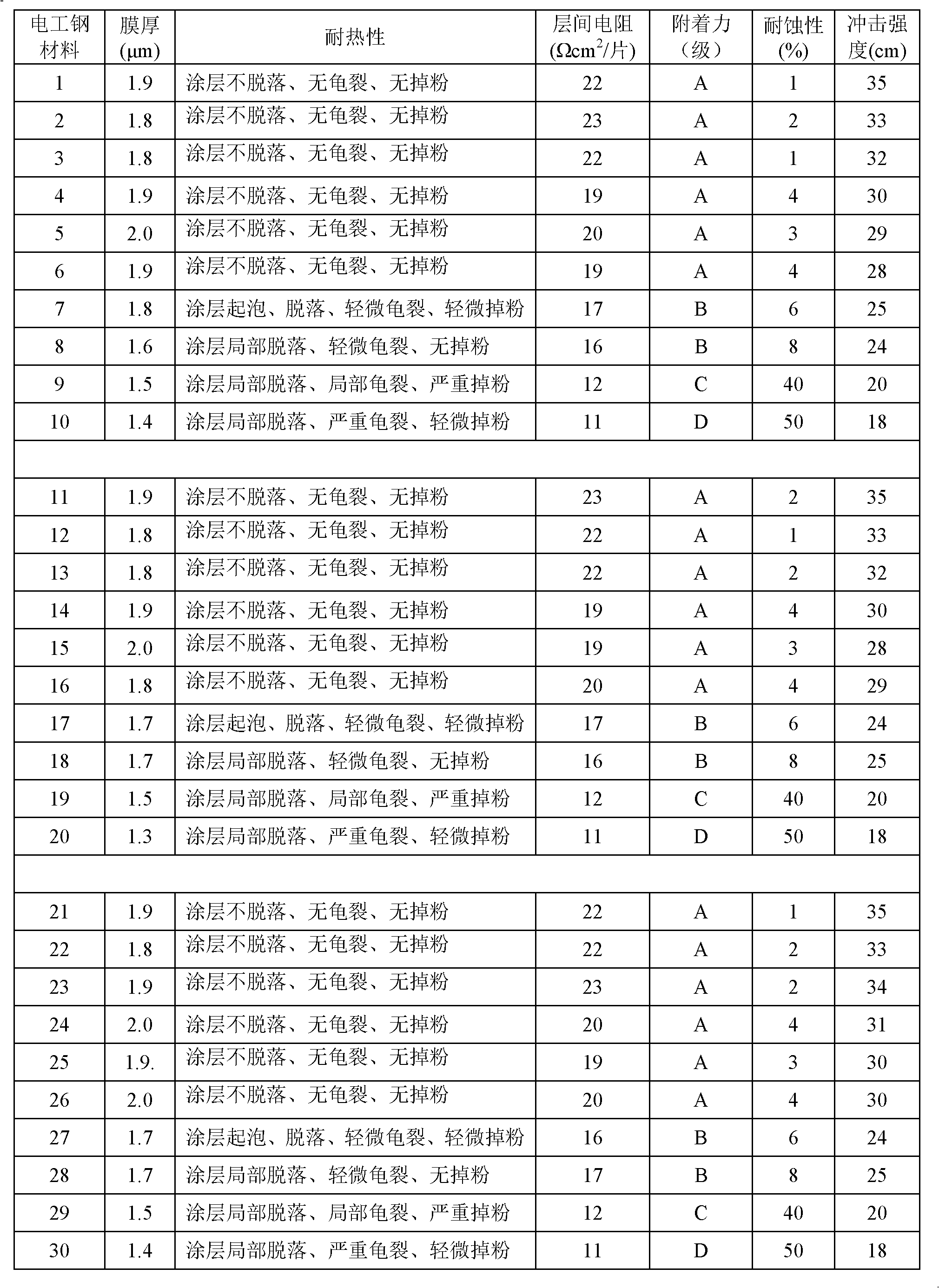

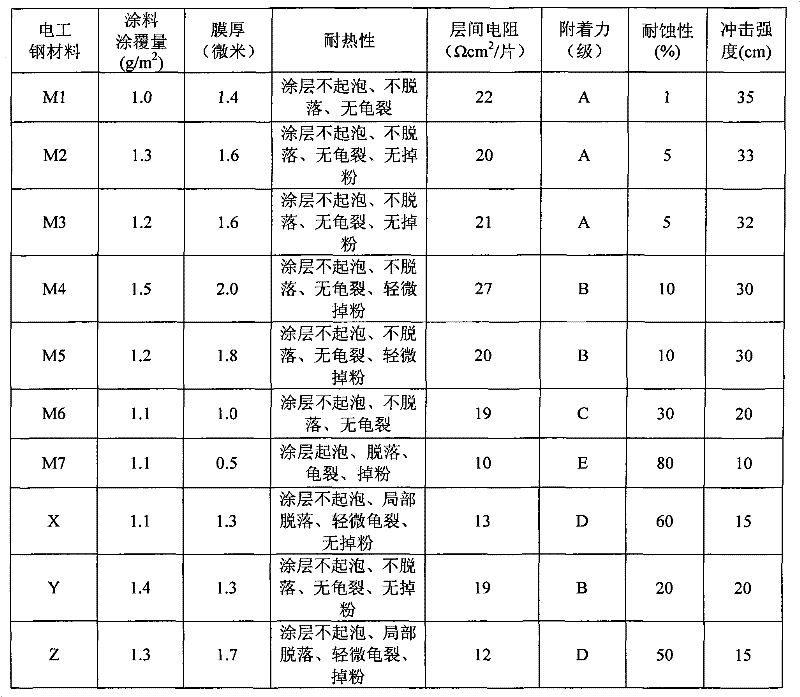

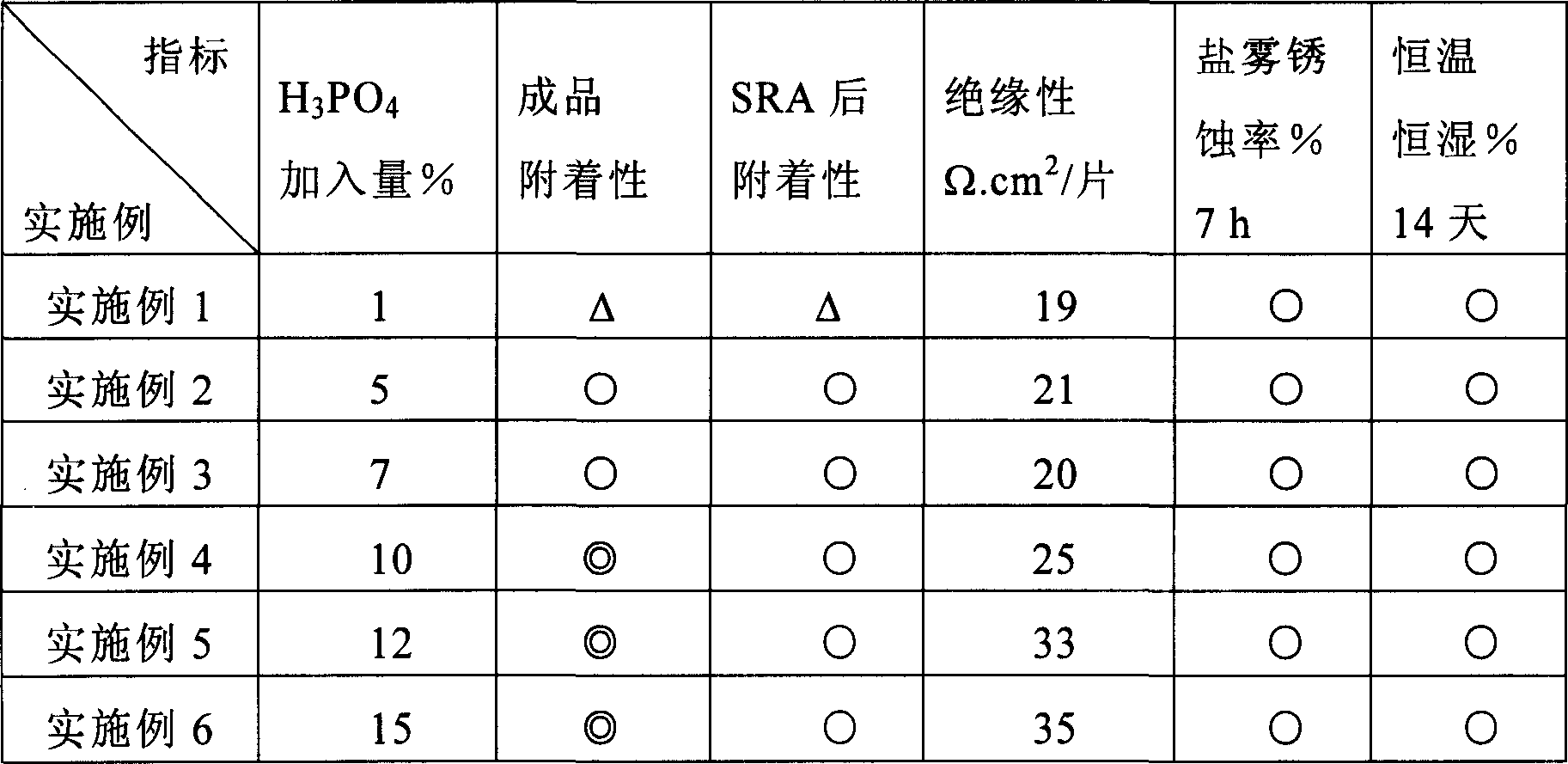

The invention provides an insulation coating which is prepared by uniformly mixing a raw material mixture, wherein the raw material mixture comprises dihydrogen phosphate, water-soluble film-forming resin, a coupling agent, acids and water, and the acids is selected from at least one of phosphoric acid, boric acid, fluotitanic acid, acetic acid, oxalic acid, citric acid, maleic acid, benzoic acid, tannic acid, tartaric acid and phytic acid. The invention further provides an electrical steel material. The invention further provides a preparation method of the electrical steel material. The invention further provides the electrical steel material prepared by the above preparation method. The insulation coating provided by the invention can obtain a coating by curing at a lower temperature, and the cured coating has excellent properties such as heat resistance, insulation resistance, adhesion, corrosion resistance, punching resistance, etc.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Chromium-free insulating coating, electrical sheet material and preparation method thereof

InactiveCN102477235AGood heat resistanceLess investment in equipmentPretreated surfacesEpoxy resin coatingsSolventChromium

The invention provides a chromium-free insulating coating which has better performance after being cured at a lower temperature, an electrical sheet material containing a coating obtained by curing the chromium-free insulating coating and a preparation method thereof. The chromium-free insulating coating is obtained by uniformly mixing a raw material mixture and is characterized in that the raw material mixture comprises a film forming material, dihydric phosphate, an inorganic filler and a solvent. The preparation method of the electrical sheet material comprises the following steps of: adhering the chromium-free insulating coating to an electrical sheet substrate and then curing the chromium-free insulating coating, wherein the curing temperature is not higher than 250 DEG C. The chromium-free insulating coating provided by the invention can be cured at a temperature of 200-250 DEG C, so that the chromium-free insulating coating can be cured by simpler curing equipment, thus the equipment investment is greatly saved, the process flow is easy to further plan and optimize, the equipment utilization rate and the production efficiency of a whole production line are improved, and the energy consumption is greatly reduced.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Cold-rolled non-oriented electrical steel 35WD1900 and production method thereof

ActiveCN109825775AEasy to controlStable productionRoll force/gap control deviceTemperature control deviceElectrical steelSheet steel

The invention discloses a cold-rolled non-oriented electrical steel 35WD1900 and a production method thereof. The cold-rolled non-oriented electrical steel 35WD1900 comprises the following chemical components by weight: <= 0.005% of C, 2.0-2.5% of Si, 0.2-0.4% of Mn, 0.08-0.12% of P, <= 0.008% of S, 0.3-0.5% of Al, 0.004-0.006% of B and the balance of Fe and unavoidable impurities. The productionmethod includes the following steps: (1) a steel plate is subjected to continuous casting to form a continuously-cast billet, which is heated in a heating furnace after being cooled, and then subjected to hot rolling; (2) the hot-rolled billet is subjected to acid pickling, first cold rolling, decarburizing annealing and second cold rolling; and (3) after being subjected to the second cold rolling, the electrical steel is subjected to secondary annealing and coating to obtain the product. The performance of the cold-rolled non-oriented electrical steel 35WD1900 of the invention can meet the requirements of the high-strength non-oriented electrical steel used in the drive motors of new energy automobiles; and the welding performance and the stamping performance are good.

Owner:GUANGDONG ZHONGSHENG ELECTROMAGNETIC TECH CO LTD

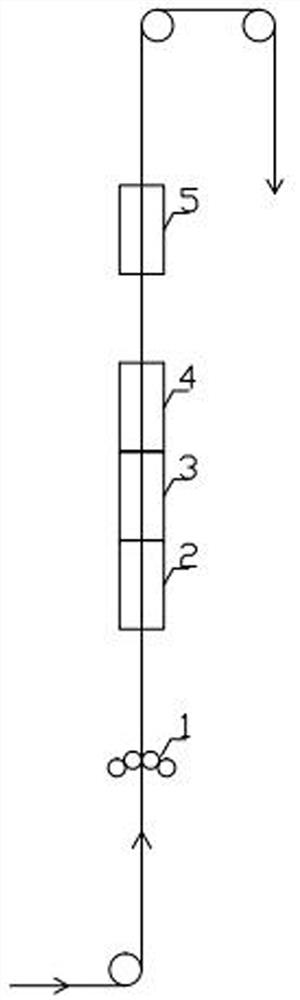

Method for producing non-orientation electric steel plates with insulation coatings

ActiveCN1903498AGood adhesionImprove bindingPretreated surfacesOther manufacturing equipments/toolsSheet steelElectrical steel

A technology for manufacturing the non-orientation electric steel sheet with coated insulating layer includes such steps as rolling, pre-washing, continuous annealing, acid washing, post-washing, coating, drying and winding.

Owner:BAOSHAN IRON & STEEL CO LTD

Annealing method of external layer-oxidized cold-rolled non-oriented electrical steel

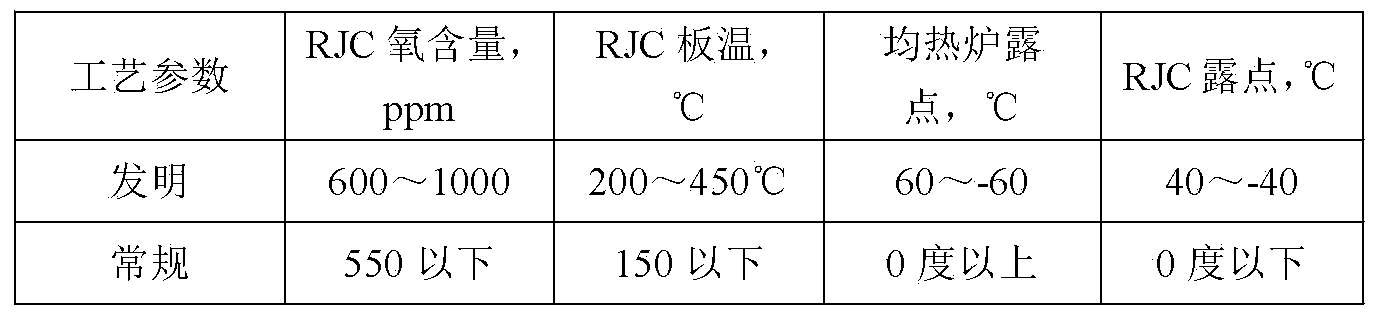

ActiveCN103882193AImprove insulation performanceHigh punchabilitySolid state diffusion coatingSurface oxidationGas cooler

The invention discloses an annealing method of external layer-oxidized cold-rolled non-oriented electrical steel. The circulation in a circulating gas cooler of a continuous annealing furnace is nitrogen circulation, and the oxygen content is 600-1000 ppm; the plate temperature when the steel plate exits the circulating cooler is 200-450 DEG C; the dew point of the circulating cooler is 40 to -40 DEG C; the dew point of a soaking pit furnace is 60 to -60 DEG C. The product with surface oxidation has good insulating properties and punching performance; the insulating layer thickness is decreased to realize the purpose of saving coating solution; the short-flow production of silicon steel with an oxide layer on the surface is realized; and bluing silicon steel can be produced directly.

Owner:ANGANG STEEL CO LTD

Production method of non-oriented electrical steel 50W800 by traditional hot continuous rolling process

The invention discloses a production method of non-oriented electrical steel 50W800 by a traditional hot continuous rolling process. The production method comprises the steps of: 1) pretreatment of molten iron; 2) converter smelting; 3) argon blowing; 4) RH refining; 5) casting; 6) acid washing and cold rolling; 7) degreasing and cleaning, decarbonization and annealing; and 8) coating. The half-process cold-rolled non-oriented electrical steel with a mark of 50W800 and a thickness of 0.50 mm has the product electromagnetic performance of P15 / 50 not more than 5.2 W / kg and the magnetic induction strength of B50 not less than 1.74 T; and compared with the national standard of traditional half-process non-oriented electrical steel, the iron loss is lower by 2.8 W / kg, the magnetic induction strength is higher by 0.04 T, the interlayer resistance is not less than 2100 omega.mm 2 / p to satisfy the national standard and the customer requirements, the Vickers hardness is 80-100 HV10, the repeated bending times are not smaller than 12 times, and the welding performance is excellent.

Owner:SOUTH CHINA UNIV OF TECH

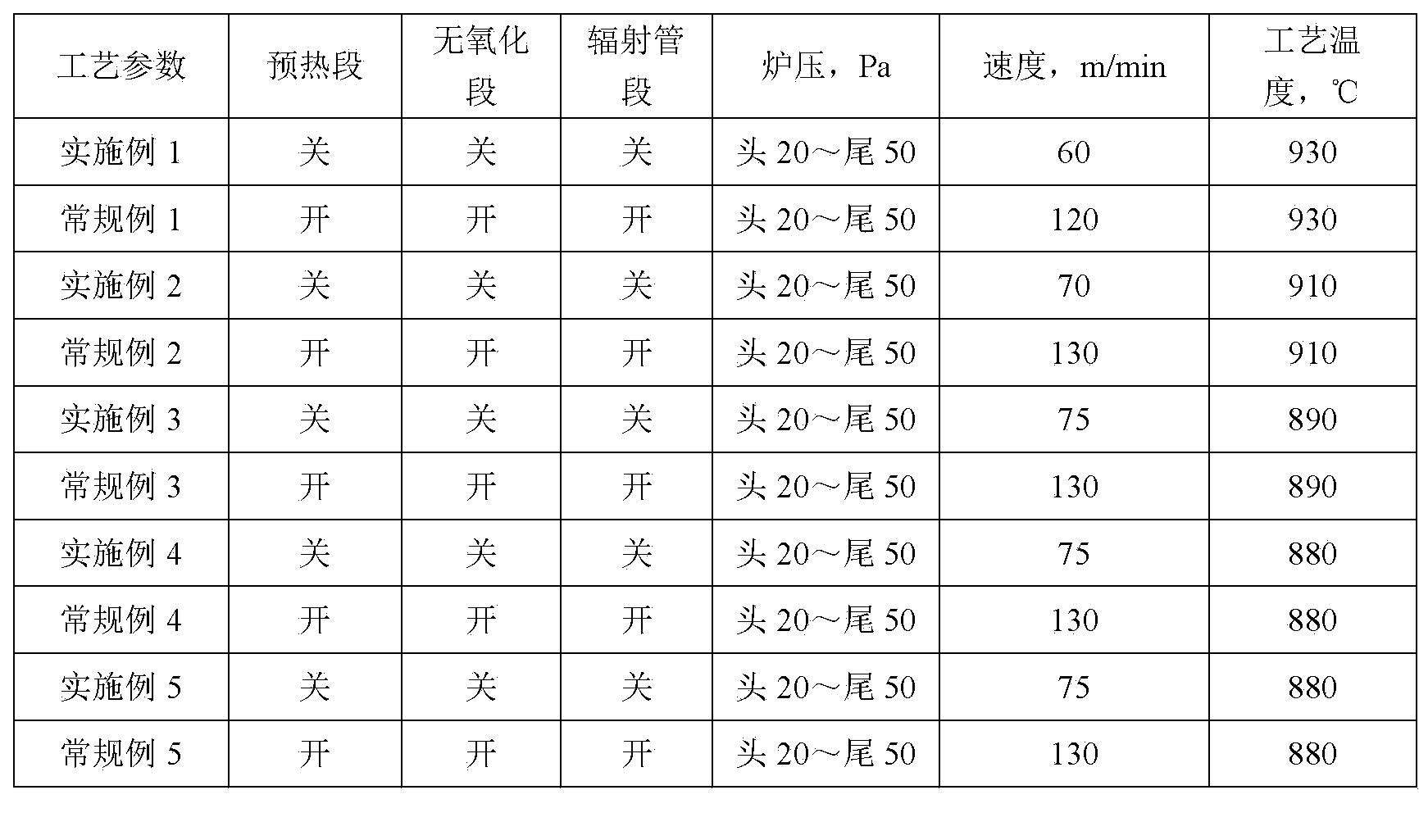

Annealing method for total nitrogen produced cold-rolled non-oriented electrical steel

ActiveCN103882191AGood insulation and punchingSave the use of coating solutionFurnace typesHeat treatment furnacesSteel platesElectrical steel

The invention discloses an annealing method for total nitrogen produced cold-rolled non-oriented electrical steel, and the method is as follows: closing a preheating furnace section, a non-oxidizing heating furnace section and a radiant tube heating furnace section to make the preheating furnace section, the non-oxidizing heating furnace section and the radiant tube heating furnace section in a shutdown state; entering a steel plate into a soaking furnace section, using the soaking furnace section for heating annealing of the steel plate, leading in nitrogen at the temperature of 850-950 DEG C; and controlling the strip steel speed below 120 m / min to enable the steel plate temperature to be 650-850 DEG C. The Furnace pressure is 20-50Pa. The product with an oxidized surface layer has good insulation and punching properties, the use of a coating liquid is saved or not needed, and gas consumption is saved.

Owner:ANGANG STEEL CO LTD

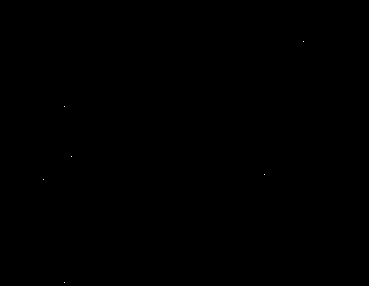

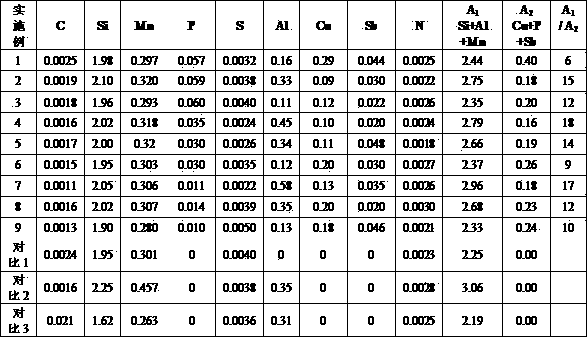

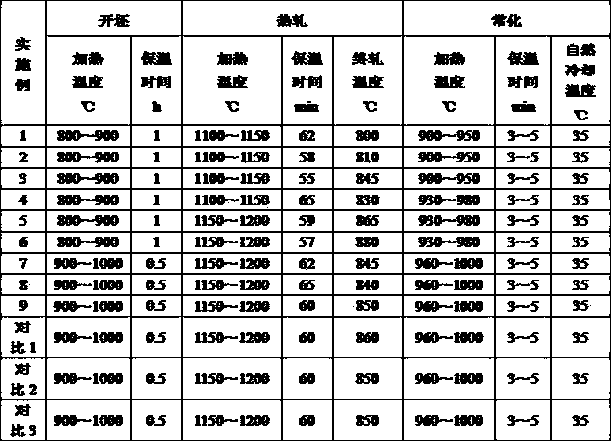

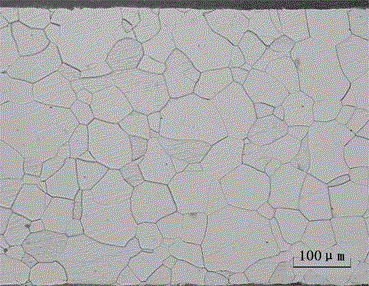

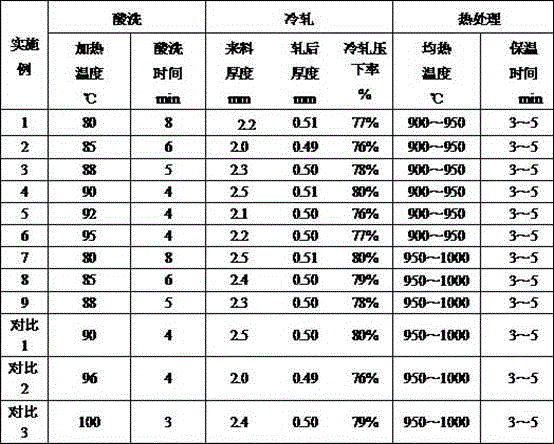

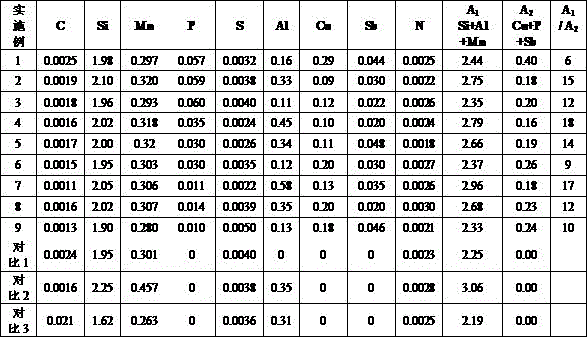

Non-oriented electrical steel for efficient motor and production method

The invention relates to non-oriented electrical steel for an efficient motor. The non-oriented electrical steel for the efficient motor is prepared from the chemical components in percentage by weight: less than or equal to 0.0030% of C, 1.9-2.1% of Si, 0.28-0.32% of Mn, 0.10-0.60% of Al, 0.01-0.06% of P, less than or equal to 0.0050% of S, 0.10-0.30% of Cu, 0.02-0.05% of Sb and less than or equal to 0.0030% of N. The production process comprises the following steps: smelting; cogging; repeatedly forging to obtain square billets; heating; hot-rolling; normalizing; pickling; cold-rolling; and thermally heating. By controlling the total weight of main alloy elements (Si+Al+Mn) and auxiliary elements (Cu+P+Sb), favorable effects of elements in physical metallurgy are fully exerted. By researching the composite effect of elements (Cu+P+Sb) on silicon steel organization structure and magnetism, partial (Si+Al) is replaced by (Cu+P). On the one hand, the inflection time of a normalized plate can be improved and on the other hand, the punching property of a finished plate is improved. The non-oriented electrical steel for the efficient motor excellent in magnetic property and good in punching effect is developed.

Owner:武汉钢铁有限公司

Non-toxic environmentally-friendly oriented electrical steel insulation coating and preparation method thereof

InactiveCN105566970AImprove the problem of moisture absorption and stickinessImprove heat resistanceAnti-corrosive paintsPhosphateMoisture absorption

The present invention provides an oriented electrical steel insulation coating and a preparation method thereof, and the coating is prepared from the following ingredients by mass: 35 to 50 % of a metal dihydric phosphate, 16 to 25 % of zinc molybdate, 4 to 10% of boric acid, 5 to 10% of colloidal silicon dioxide, 2 to 5% of nano oxide powder, 2 to 13% of organic resin, 0.01-0.08% of a nonionic surfactant and the balance of water. The oriented electrical steel insulation coating is free from chromium elements, non-toxic and environmentally-friendly, has good insulating property, adhesion property and blanking property, can ensure the coating uniformity, corrosion resistance, and heat resistance, is low in moisture absorption tendency to tacky, can be saved stably for long term, is simple in preparation method and low in requirements on equipment, and industrialization is easy to realize.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

Insulation coating and electrical steel material, and preparation method thereof

ActiveCN103045058BImprove heat resistanceImprove insulation performanceLayered productsEpoxy resin coatingsBenzoic acidPhosphate

The invention provides an insulation coating which is prepared by uniformly mixing a raw material mixture, wherein the raw material mixture comprises dihydrogen phosphate, water-soluble film-forming resin, a coupling agent, acids and water, and the acids is selected from at least one of phosphoric acid, boric acid, fluotitanic acid, acetic acid, oxalic acid, citric acid, maleic acid, benzoic acid, tannic acid, tartaric acid and phytic acid. The invention further provides an electrical steel material. The invention further provides a preparation method of the electrical steel material. The invention further provides the electrical steel material prepared by the above preparation method. The insulation coating provided by the invention can obtain a coating by curing at a lower temperature, and the cured coating has excellent properties such as heat resistance, insulation resistance, adhesion, corrosion resistance, punching resistance, etc.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for preparing non-hexavalent chromium environment friendly insulating coating material for silicon steel sheet

InactiveCN101381579ASimple production processLow equipment requirementsEpoxy resin coatingsMagnesium orthophosphatePhosphoric acid

The invention relates to a method for preparing a hexavalent chromium-free environment-friendly insulated coating material for a silicon-steel sheet and belongs to the technical field for preparing the insulated coating material for the silicon-steel sheet. A lightweight magnesium-lithium composition and phosphoric acid have reaction to generate magnesium phosphate solution; the acidity of the solution is regulated; and the solution, water-soluble epoxy resin solution and a mixed powder body of nanometer titanium dioxide and nanometer magnesia are mixed and evenly stirred to obtain the hexavalent chromium-free environment-friendly insulated coating material for the silicon-steel sheet. The method has the advantages of availability of raw materials, simple production process, low equipment requirement, low production cost, high production efficiency, no generation of byproducts in the production process, high product yield and easy realization of industrialization; the prepared product has good performance; and a coating layer of the product has good high-temperature resistance and welding and stamping performances, and meets the environment-friendly requirement of the state and European Union.

Owner:EAST CHINA NORMAL UNIVERSITY

Ultraviolet (UV) curing silicon steel insulating coating and preparation method thereof

InactiveCN105860627AReduce energy consumptionTo achieve the goal of green environmental protectionAnti-corrosive paintsUltravioletSolvent

The invention relates to an ultraviolet (UV) curing silicon steel insulating coating and a preparation method thereof. The insulating coating comprises the following raw materials by mass percent: 10-25% of prepolymers, 3-10% of active diluting monomers, 10-28% of pigments and fillers, 1-8% of photoinitiators, 2-10% of additives and the balance of water. The energy loss can be effectively reduced, the curing rate can be increased and the green and environmental protection aims can be achieved by adopting the developed UV curing silicon steel insulating coating, and meanwhile, the formed silicon steel insulating coating also has excellent heat and humidity resistance, solvent resistance, weldability, blanking property, adhesiveness and corrosion resistance, high interlamination resistance, and the like and meets the silicon steel industrial production requirements.

Owner:MAANSHAN IRON & STEEL CO LTD

Chromium-free semi-organic insulating paint for electrical steel and coating method thereof

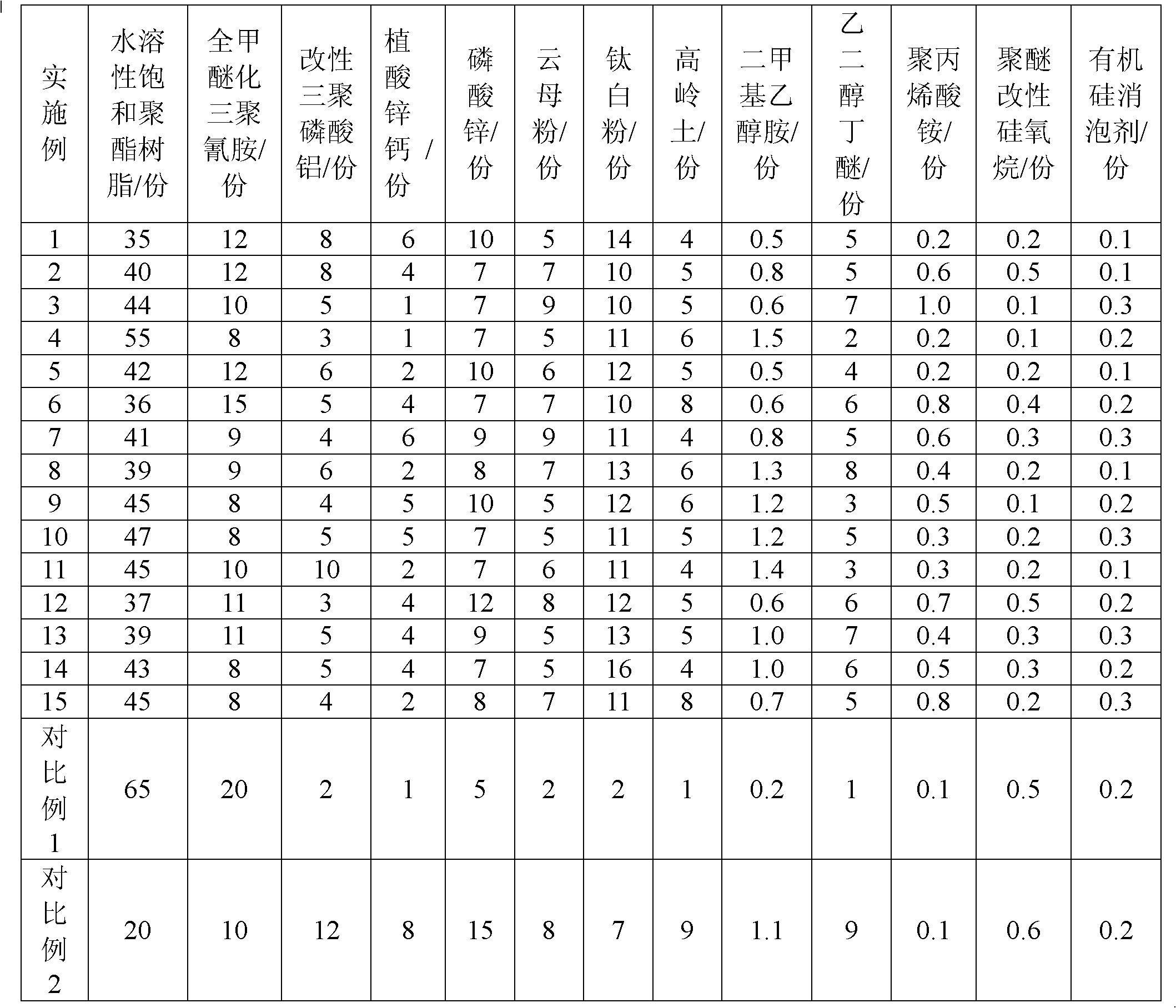

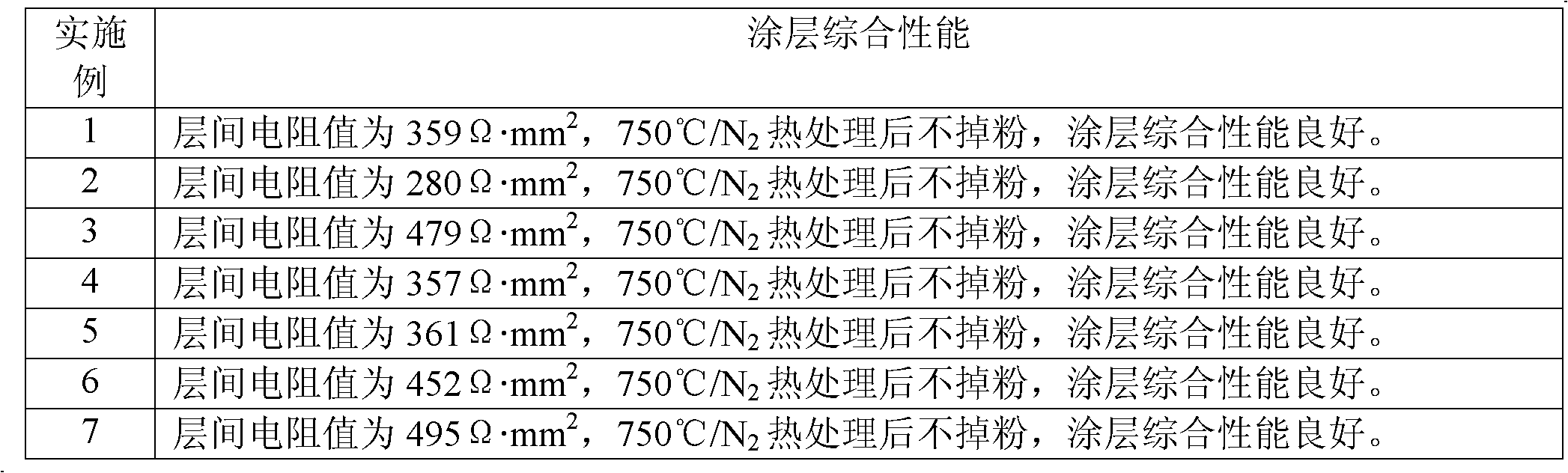

ActiveCN102220073ABeautiful appearanceComplete coatingLiquid surface applicatorsPolyester coatingsWater solubleMelamine resin

The present invention discloses a chromium-free semi-organic insulating paint, which includes the following components: 35-55 parts of water-soluble saturated polyester resin, 8-15 parts of full-methylated melamine resin, 3-10 parts of modified aluminium tripolyphosphate, 1-6 parts of zinc calcium phytate, 7-12 parts of zinc phosphate, 5-9 parts of mica powder, 10-16 parts of titanium dioxide, 4-8 parts of kaolin, 0.5-1.5 parts of dimethylethanolamine, 2-8 parts of ethylene glycol butyl ether, 0.2-1.0 part of ammonium polyacrylate, 0.1-0.5 part of polyether-modified siloxane and 0.1-0.3 part of an organic silicon defoamer. The coating made of the paint disclosed by the invention has the advantages of good insulativity, adhesiveness, heat resistance, stamping capability and weldability, no defects of streak, bubble, color difference and other defects, and long storage life.

Owner:MAANSHAN IRON & STEEL CO LTD

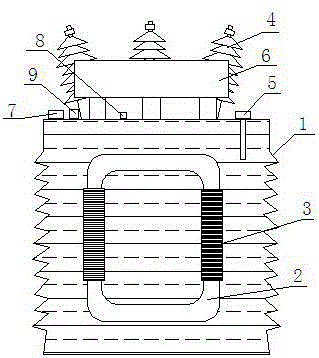

10KV oil-immersed transformer

InactiveCN105225801ALow costEasy maintenanceTransformers/inductances coolingTransformers/inductances coils/windings/connectionsCrystal orientationTransformer oil

The invention provides a 10KV oil-immersed transformer. The 10KV oil-immersed transformer comprises an oil tank, an iron core, windings, insulating sleeves and an oil temperature measuring device. Transformer oil for cooling and insulating the windings is arranged in the oil tank. A high-permeability crystal orientation cold rolling silicon sheet is adopted in the iron core. The iron core is a core-type iron core. The windings are each of a multilayer cylinder type structure. The oil tank is provided with a conservator for storing and replenishing oil for the oil tank. The conservator is a capsule type conservator. The oil temperature measuring device is arranged at the top of the oil tank. The oil tank is provided with a pressure relief valve. The side wall of the oil tank is a corrugated wall. Dust is sprayed to the surface of the oil tank, and a film is painted to the surface of the oil tank so that an outer protective layer can be formed. The 10KV oil-immersed transformer is low in cost, easy to maintain, good in heat dissipation, high in overload capacity and wide in adaptive environment. It is guaranteed that oil does not need to be replaced when the oil-immersed transformer normally runs, the maintenance cost of the transformer is greatly reduced, and meanwhile the service life of the transformer is prolonged.

Owner:STATE GRID CORP OF CHINA +3

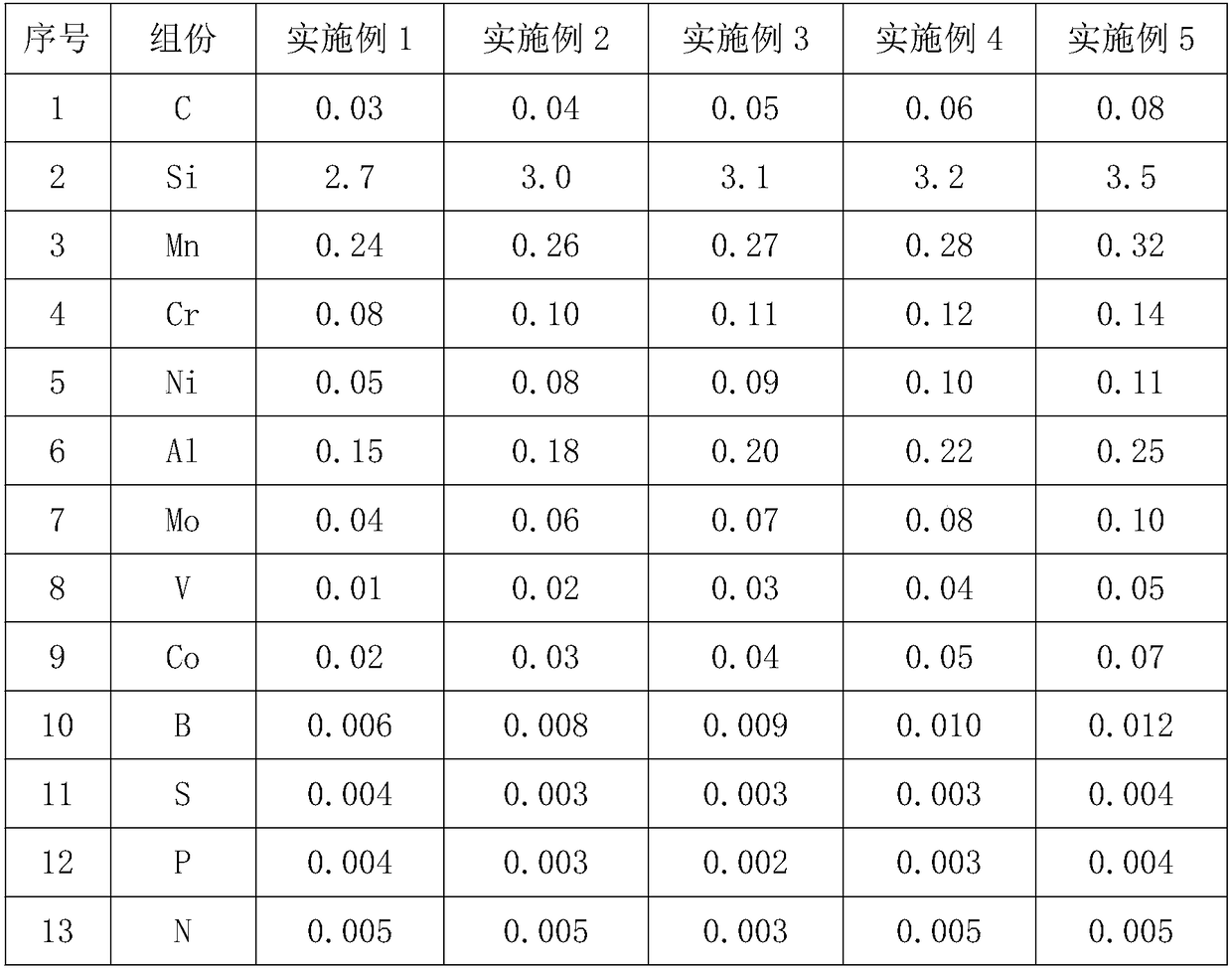

Transformer silicon steel sheet and preparation method thereof

InactiveCN108456829AEasy to manufactureScientific and reasonable process arrangementCoatingsTransformerMechanical property

The invention discloses a transformer silicon steel sheet and a preparation method thereof and relates to the technical field of transformer silicon steel sheet manufacturing. The silicon steel sheetcomprises the following components: C, Si, Mn, Cr, Ni, Al, Mo, V, Co, B, S, P, N and Fe. The preparation method of the transformer silicon steel sheet comprises the following steps: melting industrialraw materials, casting, annealing, performing acid pickling, and performing surface coating, so as to obtain the transformer silicon steel sheet. The transformer silicon steel sheet disclosed by theinvention is excellent in mechanical property, low in iron loss, high in magnetic induction strength, good in insulating property and long in service life.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

A kind of non-oriented electrical steel for high-efficiency motor and its production method

The invention relates to non-oriented electrical steel for an efficient motor. The non-oriented electrical steel for the efficient motor is prepared from the chemical components in percentage by weight: less than or equal to 0.0030% of C, 1.9-2.1% of Si, 0.28-0.32% of Mn, 0.10-0.60% of Al, 0.01-0.06% of P, less than or equal to 0.0050% of S, 0.10-0.30% of Cu, 0.02-0.05% of Sb and less than or equal to 0.0030% of N. The production process comprises the following steps: smelting; cogging; repeatedly forging to obtain square billets; heating; hot-rolling; normalizing; pickling; cold-rolling; and thermally heating. By controlling the total weight of main alloy elements (Si+Al+Mn) and auxiliary elements (Cu+P+Sb), favorable effects of elements in physical metallurgy are fully exerted. By researching the composite effect of elements (Cu+P+Sb) on silicon steel organization structure and magnetism, partial (Si+Al) is replaced by (Cu+P). On the one hand, the inflection time of a normalized plate can be improved and on the other hand, the punching property of a finished plate is improved. The non-oriented electrical steel for the efficient motor excellent in magnetic property and good in punching effect is developed.

Owner:武汉钢铁有限公司

High-strength hot-rolled steel sheet and method for producing the same

ActiveUS20160258032A1Improve stamping effectHigh punchabilityHot-dipping/immersion processesFurnace typesCarbideUltimate tensile strength

A steel slab having a composition containing C: more than 0.07% and 0.2% or less, Si: 2.0% or less, Mn: 1.0% to 3.0%, Al: 0.1% or less, Ti: 0.05% to 0.3%, and V: 0.05% to 0.3% on a mass percent basis is heated to 1100° C. or more and is subjected to rough rolling and finish rolling. In the finish rolling, the total rolling reduction of two final passes is 30% or more, and the finish rolling temperature ranges from (Ar3 transformation temperature) to (Ar3 transformation temperature+120° C.). Cooling is started within 2 seconds after the finish rolling. Coiling is performed at an average cooling rate of 40° C. / s or more at a coiling temperature in the range of 300° C. to 500° C. The resulting high-strength hot-rolled steel sheet has a microstructure in which a bainite phase constitutes more than 90% by volume, the average lath interval of bainite is 0.45 μm or less, and the ratio of Fe-based carbide precipitated in bainite lath to all Fe-based carbide is 10% or more, has a high tensile strength of 900 MPa or more, and has significantly improved punchability in mass production.

Owner:JFE STEEL CORP

High-strength hot-rolled steel sheet and method for producing the same (as amended)

InactiveUS20160068937A1Good punchabilityEasily produceHot-dipping/immersion processesPretreated surfacesMicrostructureTransition temperature

A steel slab having a composition containing C: more than 0.07% and 0.2% or less, Si: 2.0% or less, Mn: 1.0% to 3.0%, Al: 0.1% or less, Ti: 0.05% to 0.3%, and V: 0.05% to 0.3% on a mass percent basis is heated to 1100° C. or more and is subjected to rough rolling and finish rolling. In the finish rolling, the total rolling reduction of two final passes is 30% or more, and the finish rolling temperature ranges from (Ar3 transformation temperature) to (Ar3 transformation temperature+120° C.). Cooling is started within 2 seconds after the finish rolling. Coiling is performed at an average cooling rate of 40° C. / s or more at a coiling temperature in the range of 300° C. to 500° C. The resulting high-strength hot-rolled steel sheet has a microstructure in which a bainite phase constitutes more than 90% by volume, the average lath interval of bainite is 0.45 μm or less, and the ratio of Fe-based carbide precipitated in bainite lath to all Fe-based carbide is 10% or more, has a high tensile strength of 900 MPa or more, and has significantly improved punchability in mass production.

Owner:JFE STEEL CORP

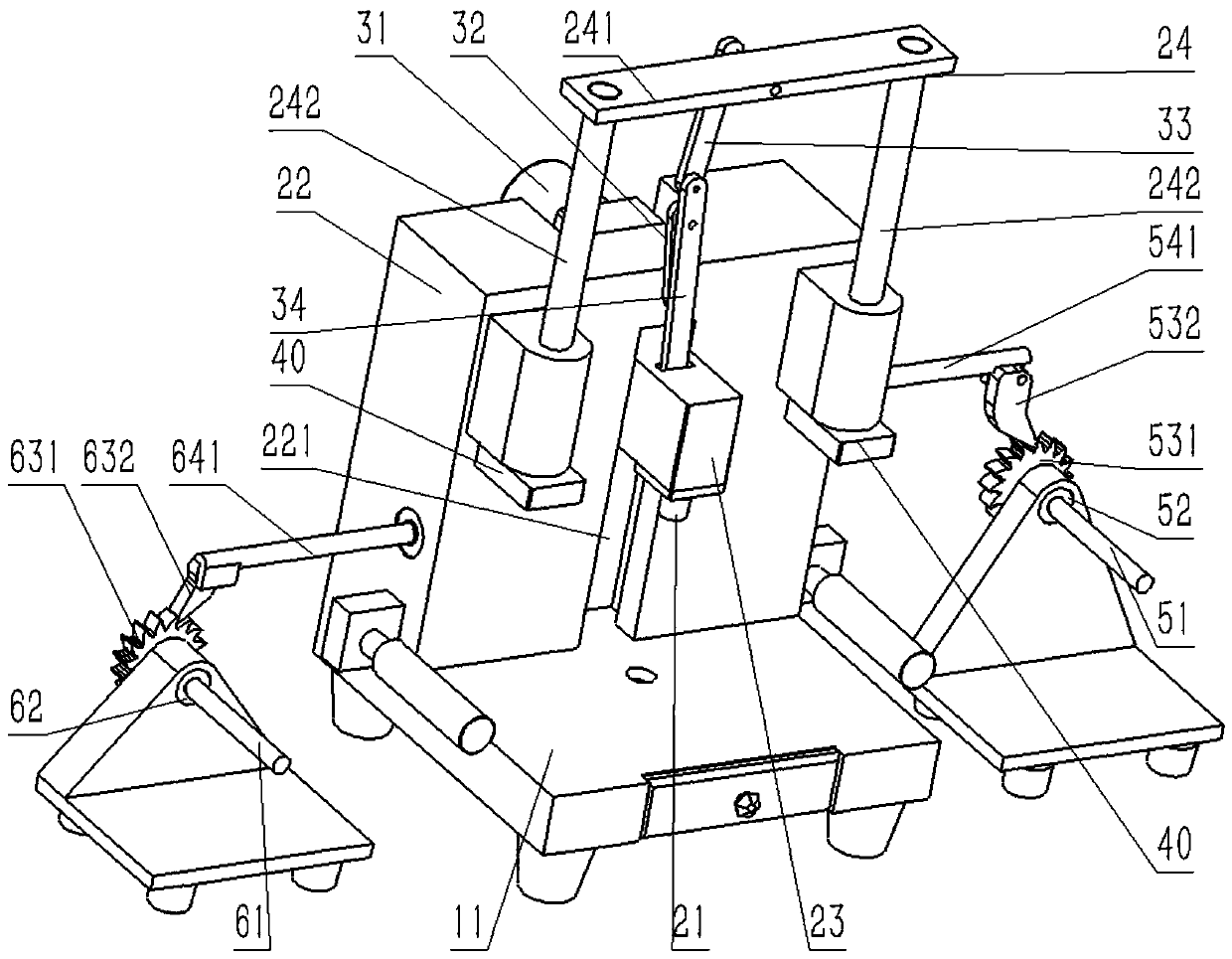

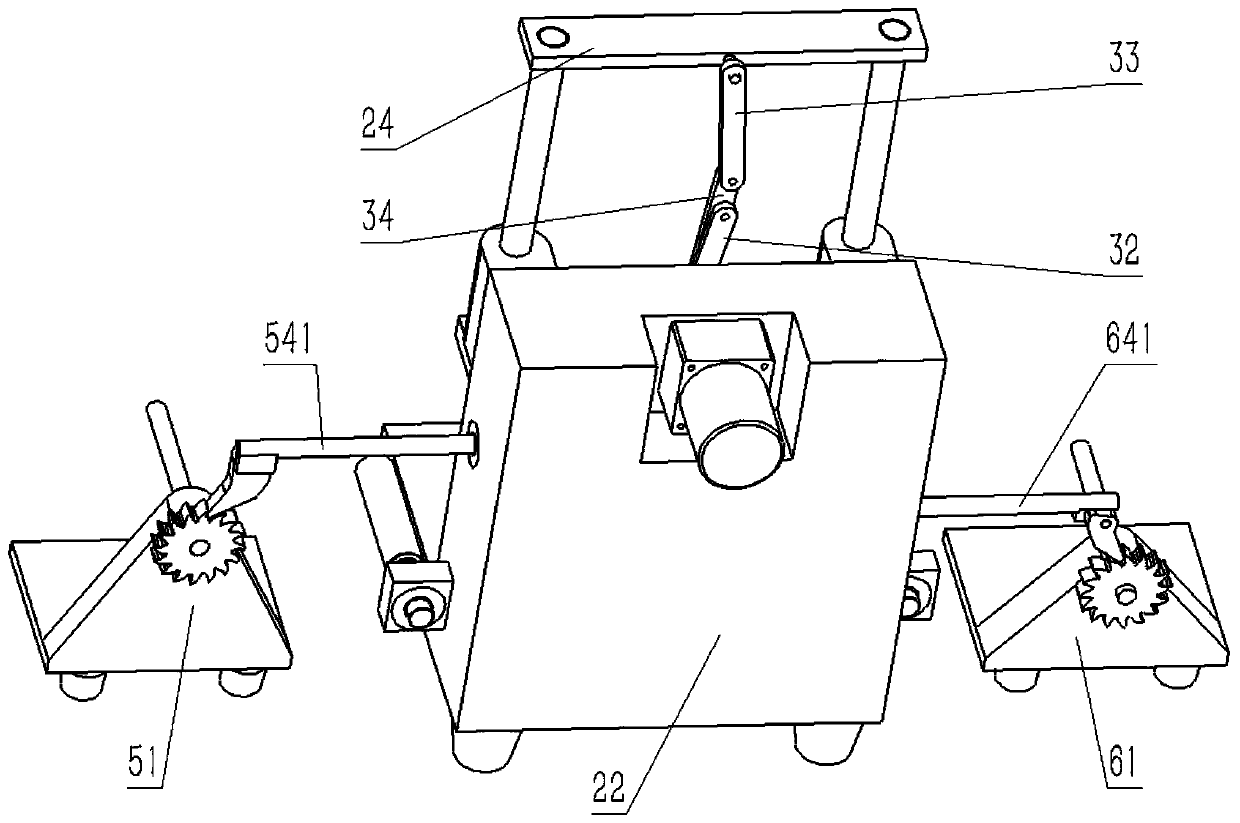

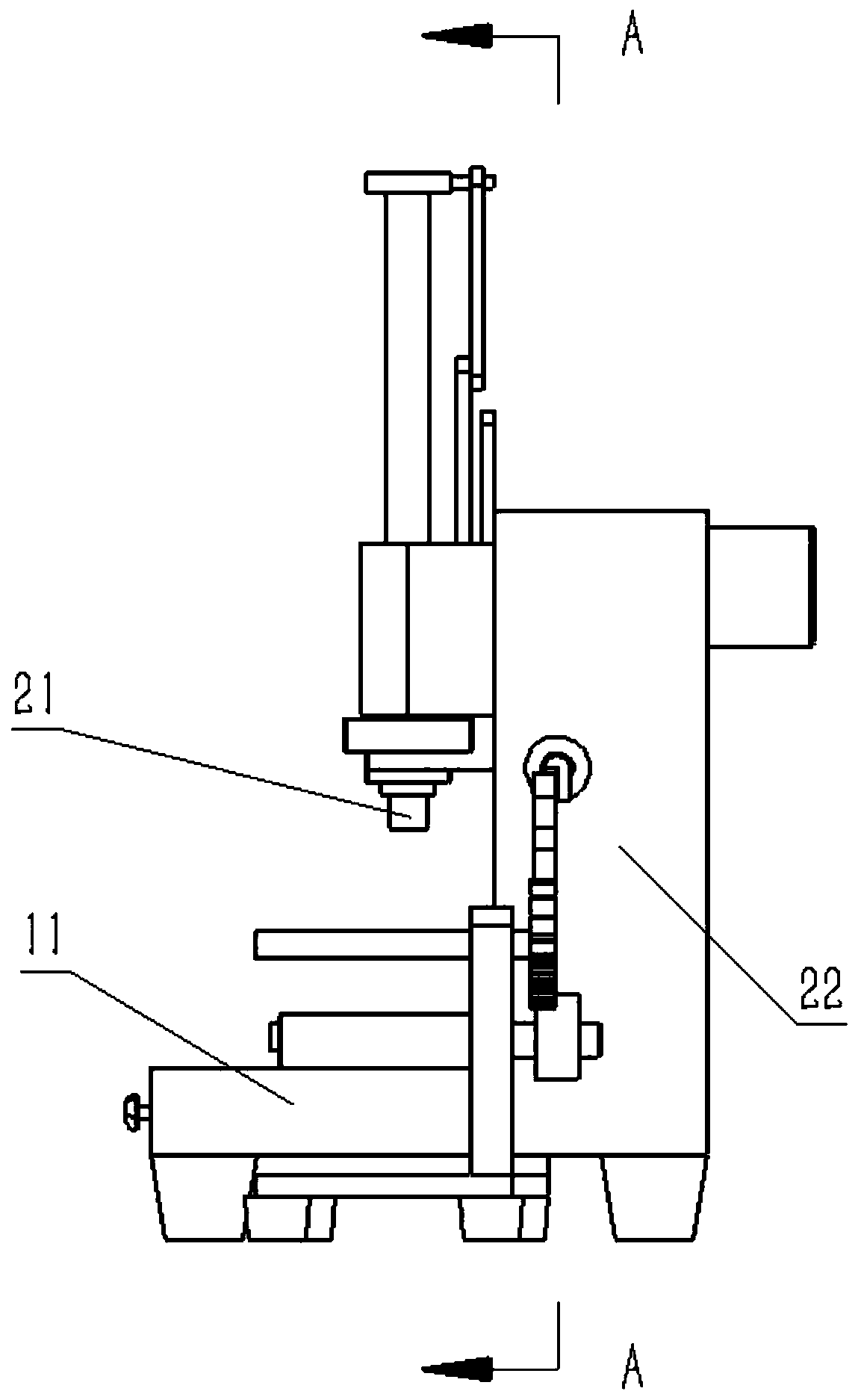

Novel automatic material receiving and discharging sheet punching machine

ActiveCN111129606AReduce power sourcePrinting effect is goodPrimary cell manufactureFinal product manufactureElectric machineryStructural engineering

The invention discloses a novel automatic material receiving and discharging sheet punching machine which comprises a punching base, a punching mechanism, a discharging mechanism, a flattening mechanism and a material receiving mechanism, wherein the material discharging mechanism, the flattening mechanism and the material receiving mechanism are in linkage connection with the punching mechanism.The punching mechanism comprises a punch, a punch vertical lifting guide assembly and a connecting rod type punching driving assembly. The punch vertical lifting guide assembly comprises a punching sheet fixing base, a T-shaped sliding block vertically connected with the punching sheet fixing base in a sliding mode and a lifting frame connected with the punching sheet fixing base in the sliding mode. The connecting rod type punching driving assembly comprises a motor, a rocker, a first connecting rod and a second connecting rod, wherein the first connecting rod and the second connecting rod are mutually hinged; the other end of the rocker is hinged with a non-end part of the second connecting rod; an upper portion of the first connecting rod is hinged to a top of the lifting frame; a lower portion of the second connecting rod is hinged to the T-shaped sliding block; and the motor drives one end of the rocker to do circular motion so as to drive the T-shaped sliding block and the lifting frame to ascend and descend synchronously. According to the machine, the material discharging mechanism, the flattening mechanism and the material receiving mechanism are all in linkage fit withthe sheet punching mechanism, and continuous automatic sheet punching is achieved.

Owner:HENAN DINGNENG ELECTRONICS TECH

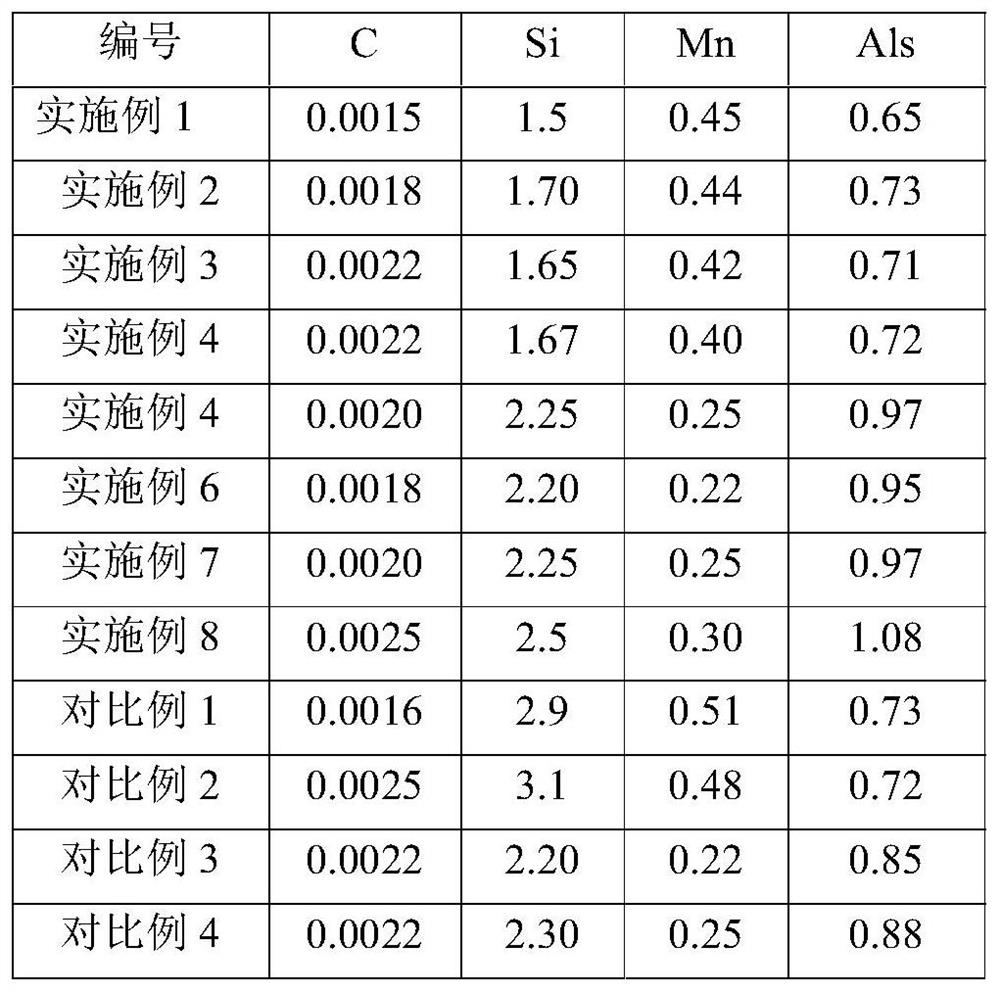

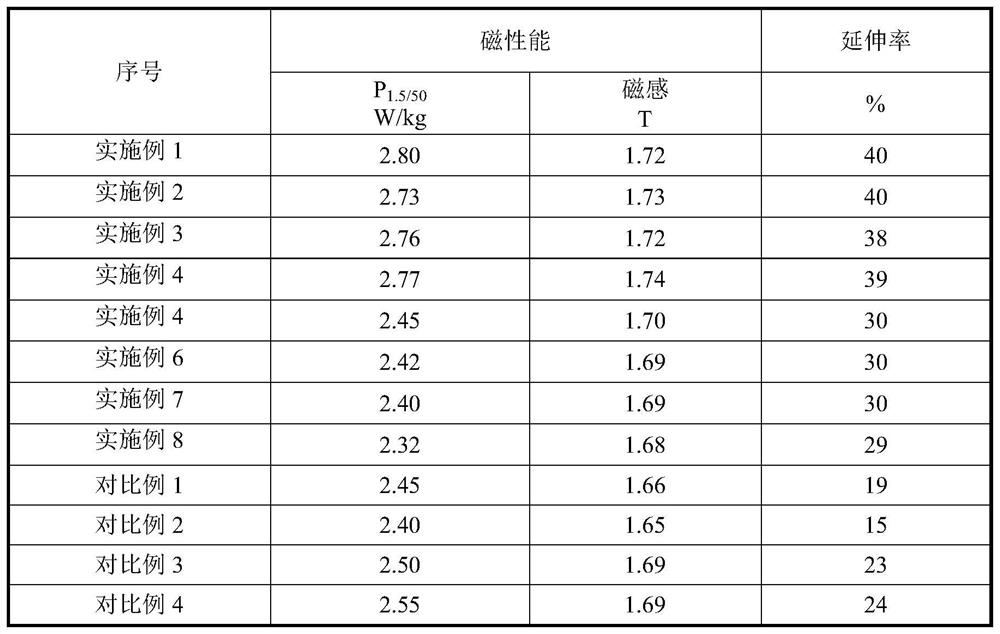

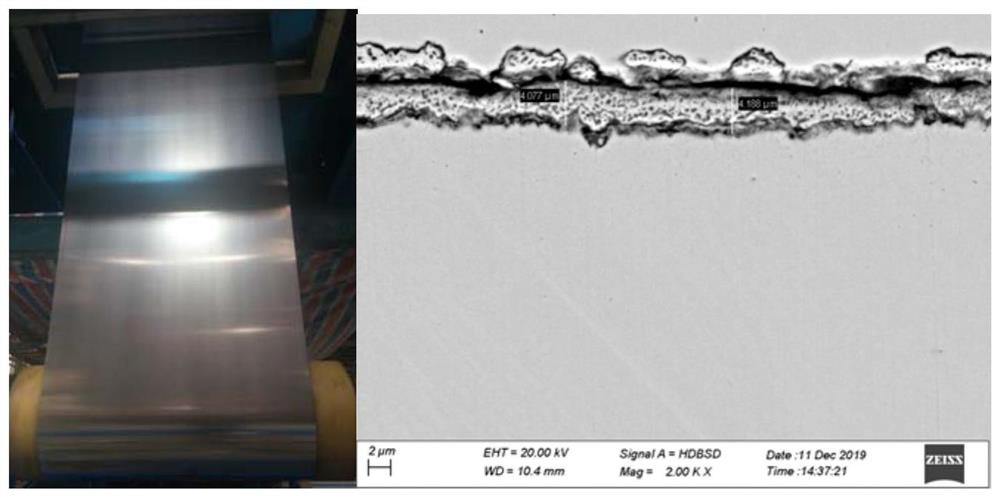

Low-iron-loss non-oriented silicon steel suitable for winding type machining and production method of low-iron-loss non-oriented silicon steel

The invention discloses low-iron-loss non-oriented silicon steel suitable for winding type machining and a production method of the low-iron-loss non-oriented silicon steel, and belongs to the technical field of silicon steel production. The non-oriented silicon steel comprises the following elements in percentage by mass: 1.5 to 2.5 percent of Si, 0.15 to 1.0 percent of Mn, 0.5 to 1.5 percent of Als and the balance of Fe and inevitable impurities. The production process comprises the steps of molten iron pretreatment, converter smelting, vacuum treatment and continuous casting. Heating and hot rolling; normalizing treatment; cold rolling and annealing; preserving heat and cooling; and coating with an insulating layer. The non-oriented silicon steel with excellent electromagnetic performance and elongation can be produced by optimizing the components and proportion of the non-oriented silicon steel in combination with process operation, so that the winding type processing and use requirements of the electrical steel can be effectively met, and the manufacturing process is short in flow and relatively low in cost.

Owner:MAANSHAN IRON & STEEL CO LTD

Organic-inorganic composite chromium-free silicon steel sheet insulating coating

InactiveCN110283508AImprove heat resistanceImprove insulation performanceCoatingsChromium freePhosphate

The invention relates to the technical field of preparation of insulating coatings, and discloses an organic-inorganic composite chromium-free silicon steel sheet insulating coating. The organic-inorganic composite chromium-free silicon steel sheet insulating coating is prepared from the following raw materials in parts by weight: 2-ethyl hexyl phosphate, ammonium tetrathiotungstate, isopropyl tri-isostearoyl titanate, glycerol, silicone acrylic resin, acrylic resin, triethoxyvinylsilane, sodium silicate, silica sol, nano TiO2, a copolymer anti-settling agent and a polyacrylate dispersing agent. The organic-inorganic composite chromium-free silicon steel sheet insulating coating has the advantages that the 2-ethyl hexyl phosphate can serve as a main component of an organic insulating coating layer, compared with a traditional phosphate inorganic coating layer, the 2-ethyl hexyl phosphate has better insulating effect and and better thermal insulation effect, toxic chromic anhydride can be replaced in the ammonium tetrathiotungstate, and therefore, a chromium-free insulating coating layer is prepared, the appearance, the magnetic property and the corrosion resistance of the coating layer are obviously improved, and the silicone acrylic resin and the acrylic resin serve as the organic coating layer.

Owner:嘉兴菱凡贸易有限公司

High-strength steel sheet and production method therefor

ActiveUS20180057907A1High punchabilityImprove crash safetyHot-dipping/immersion processesFurnace typesCrystalliteSheet steel

A high-strength steel sheet having excellent punchability and a tensile strength of at least 780 MPa has a steel structure containing, by area ratio, 70%-90% ferrite phase and 10%-30% martensite phase. The non-recrystallized ferrite content in the ferrite phase is 30%-50% and the ratio of crystal grains having an aspect ratio of 1.0-1.5 in the martensite phase is 40%-100%, by area ratio.

Owner:JFE STEEL CORP

Production method of cold-rolled bright strip steel

The invention discloses a production method of cold-rolled bright strip steel. The production method of the cold-rolled bright strip steel comprises the following steps: (1) batching, (2) smelting, (3) compression molding, (4) annealing treatment, (5) cold-rolling, (6) uncoiling, (7) welding, and (8) cleaning and drying to obtain the cold-rolled bright strip steel. The cold-rolled bright strip steel produced by the invention not only has high dimensional accuracy, bright surface, high magnetic induction, low iron loss, low surface roughness, uniform thickness, high lamination factor and good blanking property, but also has excellent hardness, good stretching resistance, good hot hardness, high hardenability, difficulty in deformation and cracking, high plasticity, toughness and elasticity, high strength of a welded joint and the like, and can replace a thick hot-rolled strip for the same purpose so as to reduce the use amount of steel, and the economic significance is large.

Owner:HUAIBEI YUANLI METAL PROD CO LTD

Manufacturing process of iron core

InactiveCN105679523AReduce size and weightSave raw materialsTransformers/inductances detailsInductances/transformers/magnets manufactureCorrosionTransformer

The invention relates to the field of iron core manufacturing, in particular to a manufacturing process of an iron core. The invention adopts silicon steel after removing impurities, so that the magnetic induction intensity (magnetic induction) is high under a strong magnetic field, which makes the iron core volume of a motor and a transformer smaller than that of the iron core. The weight is reduced and the raw materials are saved; the surface is smooth, flat and uniform, which can improve the filling factor of the iron core; the punching performance is good, which is more important for the manufacture of micro and small motors; Anti-corrosion and improved sheet punching performance; and the present invention has relatively simple manufacturing process and steps, lower requirements for production equipment, and the prepared iron core has a long service cycle, thereby reducing use and production costs.

Owner:ANHUI DEV NONCRYSTAL EQUIP CO LTD

35WD1600 electrical steel for new energy automobile driving motor and production method of 35WD1600 electrical steel

ActiveCN114107640AIncrease magnetic inductionReduce iron lossTemperature control deviceProcess efficiency improvementElectrical steelElectric machine

The invention discloses 35WD1600 electrical steel for a new energy automobile driving motor and a production method of the 35WD1600 electrical steel. Belongs to the technical field of new energy automobile driving motor electrical steel production, mainly solves the technical problem of poor performance of new energy driving motor electrical steel in the prior art, and comprises the following chemical element components in percentage by weight: less than or equal to 0.005% of C, 2.5-2.8% of Si, 0.2-0.4% of Mn, 0.08-0.12% of P, less than or equal to 0.008% of S, 0.20-0.30% of Cu, 0.16-0.25% of Ni, 0.3-0.5% of Al and the balance of Fe and inevitable impurities. The production method comprises the following steps: (1) pretreating molten iron; (2) smelting in a converter; (3) RH refining; (4) continuous casting and rolling; (5) pickling; (6) first cold rolling decarburization annealing; (7) secondary cold rolling decarburization annealing; (8) coating; and (9) sintering and coiling. According to the 35WD1600 electrical steel for the new energy automobile driving motor, the performance meets the national standard and customer requirements of cold-rolled non-oriented electrical steel strips for the new energy automobile driving motor, and the welding performance, the plate shape and the punching performance are good.

Owner:GUANGDONG ZHONGSHENG ELECTROMAGNETIC TECH CO LTD

Vertical drying and curing process for non-oriented silicon steel low-temperature chromium-free environment-friendly insulating coating

ActiveCN112642674ASimple processReasonable workmanshipPretreated surfacesFurnace typesFurnace temperatureHeat resistance

The invention provides a vertical drying and curing process for a non-oriented silicon steel low-temperature chromium-free environment-friendly insulating coating. The process comprises the following steps that after cold-rolled non-oriented silicon steel is annealed in a galvanizing unit, the cold-rolled non-oriented silicon steel is coated with the low-temperature chromium-free environment-friendly insulating coating by using a coating machine, and drying and curing are conducted by using a vertical drying furnace to produce a cold-rolled non-oriented silicon steel product, specifically, the thickness of the low-temperature chromium-free environment-friendly insulating coating is 0.8-1.0 micron; the furnace temperature of each section of the vertical drying furnace is as follows that the furnace temperature of a first heating section is 420-450 DEG C, the furnace temperature of a second heating section is 460-490 DEG C, the furnace temperature of a third heating section is 500-530 DEG C, the outlet plate temperature of the third heating section is 200-240 DEG C, and the outlet plate temperature of a cooling section is 60-65 DEG C; and the heating time of each section of the vertical drying furnace is as follows that the heating time of the first heating section, the second heating section and the third heating section are 3.5-4 seconds correspondingly. By the adoption of the process, it can be guaranteed that a steel belt coating is uniform, the coating of a final product has excellent insulativity, corrosion resistance, adhesiveness, punching performance, weldability and heat resistance, the requirements of downstream procedures are met, the product percent of pass can be further increased, waste products are reduced, and smooth production is guaranteed.

Owner:ANYANG IRON & STEEL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com