Low-iron-loss non-oriented silicon steel suitable for winding type machining and production method of low-iron-loss non-oriented silicon steel

A technology of oriented silicon steel and production method, which is applied in the field of rolling steel production, can solve problems such as difficult to meet the use requirements of electrical steel, unfavorable winding processing, poor magnetic properties, etc., achieve excellent elongation, low manufacturing cost, and ensure the effect of electromagnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

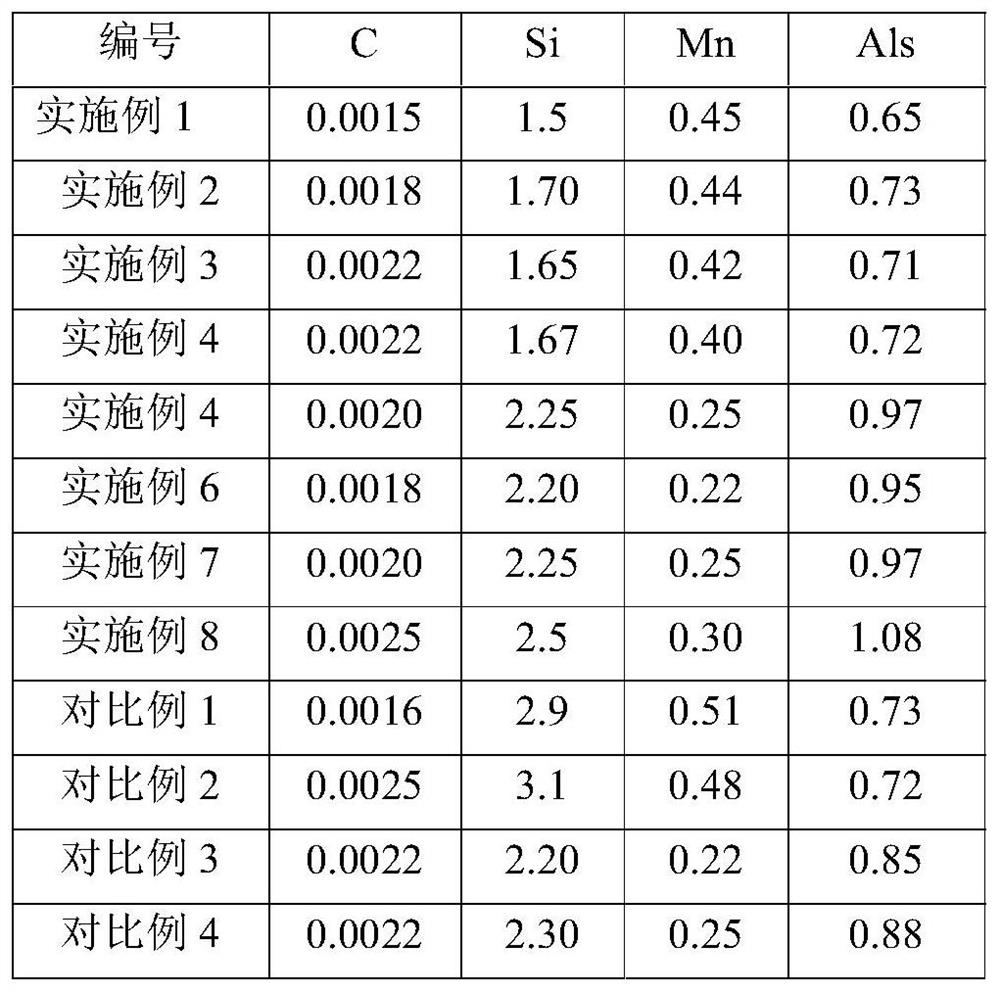

[0055] A low iron loss non-oriented silicon steel suitable for winding processing in this embodiment, the weight percentage range of its components is as follows: figure 1 A list of chemical composition values.

[0056] The test steel with the above content is subjected to molten iron pretreatment, converter smelting, and vacuum treatment, and then continuously casts into a 230mm slab. During the treatment, the ladle top slag is used to reduce the FeO content to less than 5% to ensure that the CaO / Al in the slag 2 o 3 The ratio is controlled at 1.6.

[0057] Enter the furnace at a temperature of 500°C, heat at 1120°C for 230 minutes, and hot-roll it into a hot-rolled coil with a thickness of 2.5mm; after normalizing at 930°C, cold-roll it to a thickness of 0.35mm to roll a hard coil; 2 and 70%N 2 In the mixed gas, and the oxygen content in the furnace is controlled at 16ppm. After annealing at 930°C×45s, the temperature is lowered in the high temperature section for 30s. In...

Embodiment 2

[0059] A low iron loss non-oriented silicon steel suitable for winding processing in this embodiment, the weight percentage range of its components is as follows: figure 1 A list of chemical composition values.

[0060] The test steel with the above content is subjected to molten iron pretreatment, converter smelting, and vacuum treatment, and then continuously casts into a 230mm slab. During the treatment, the ladle top slag is used to reduce the FeO content to less than 5% to ensure that the CaO / Al in the slag 2 o 3 The ratio is controlled at 1.7.

[0061] Enter the furnace at a temperature of 550°C, heat at 1120°C for 210 minutes, and hot-roll it into a hot-rolled coil with a thickness of 2.5mm; after normalizing at 930°C, cold-roll it to a thickness of 0.35mm to roll a hard coil; 2 and 70%N 2 In the mixed gas, and the oxygen content in the furnace is controlled at 16ppm. After annealing at 930°C×45s, the temperature is lowered in the high temperature section for 35s. In...

Embodiment 3

[0063] A low iron loss non-oriented silicon steel suitable for winding processing in this embodiment, the weight percentage range of its components is as follows: figure 1 A list of chemical composition values.

[0064] The test steel with the above content is subjected to molten iron pretreatment, converter smelting, and vacuum treatment, and then continuously casts into a 230mm slab. During the treatment, the ladle top slag is used to reduce the FeO content to less than 5% to ensure that the CaO / Al in the slag 2 o 3 The ratio is controlled at 1.5.

[0065] Enter the furnace at a temperature of 600°C, heat at 1120°C for 230 minutes, and hot-roll it into a hot-rolled coil with a thickness of 2.5mm; after normalizing at 930°C, cold-roll it to a thickness of 0.35mm to roll a hard coil; 2 and 70%N 2 In the mixed gas, and the oxygen content in the furnace is controlled at 16ppm, after annealing at 930°C×45s, the temperature is lowered in the high temperature section for 30s. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com