Patents

Literature

130results about How to "Guaranteed elongation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

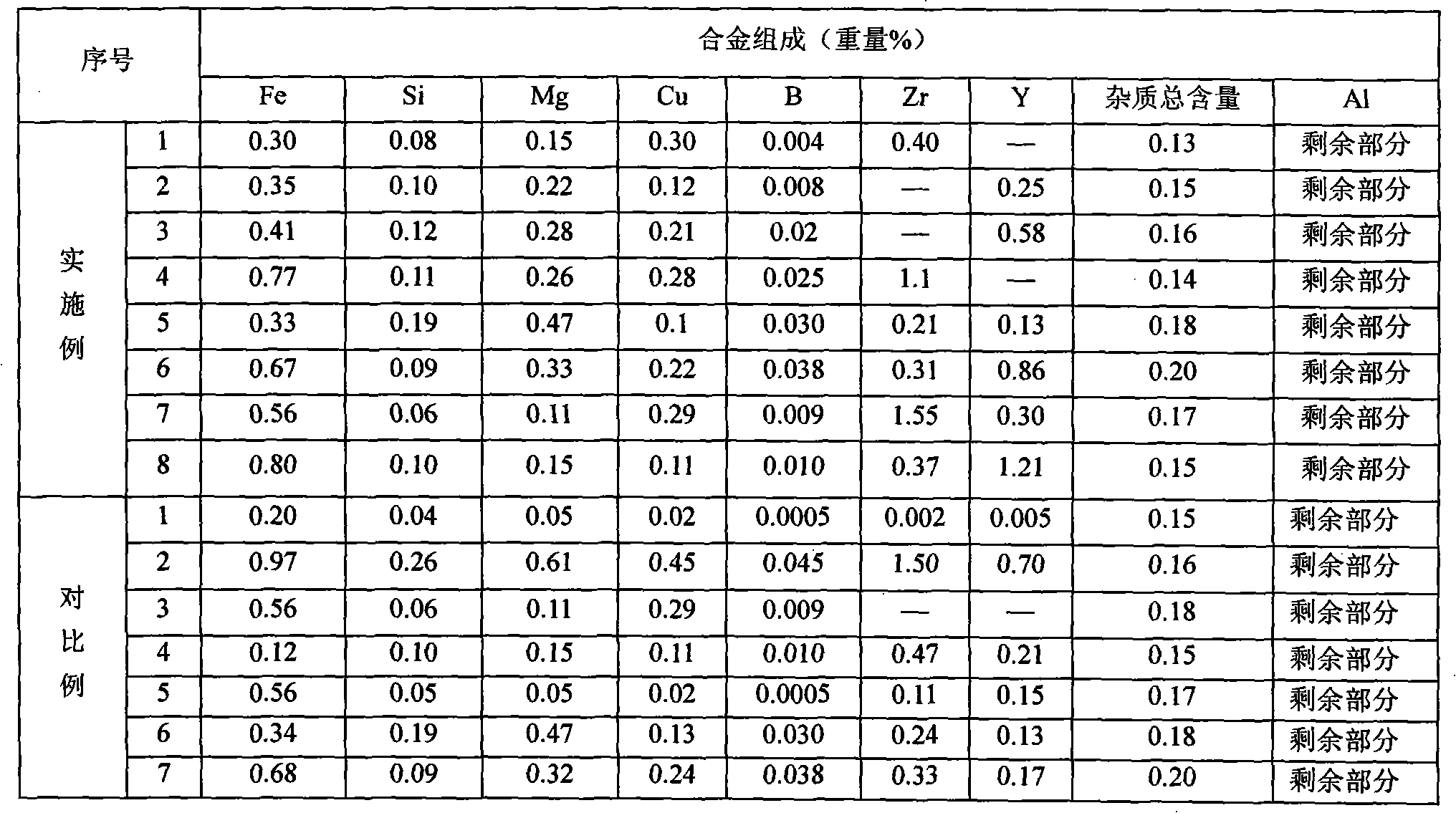

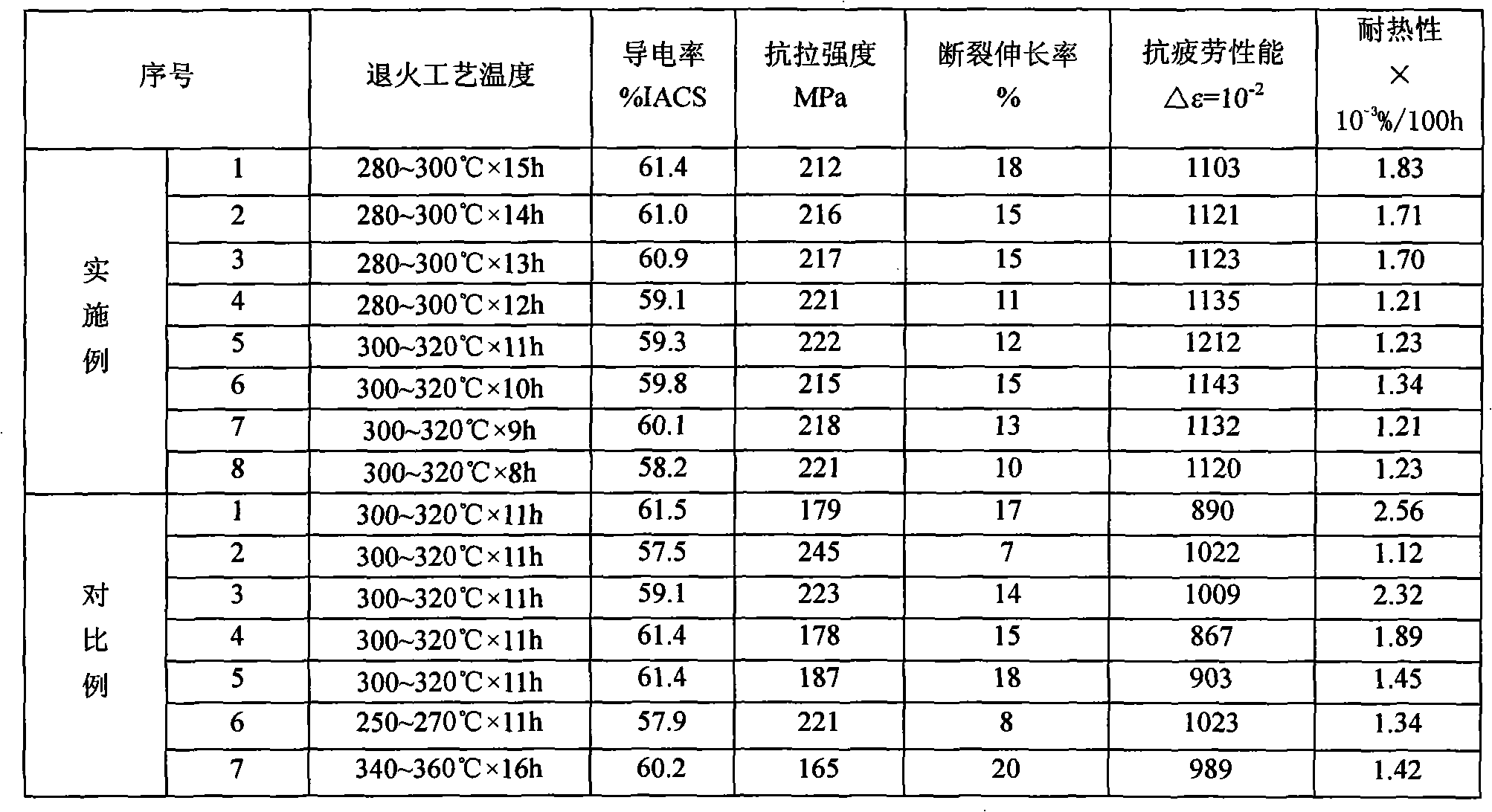

Aluminium alloy conductor for automotive wires and manufacturing method thereof

ActiveCN101923908AHigh tensile strengthImprove corrosion resistanceInsulated cablesMetal/alloy conductorsYttriumMagnesium

The invention discloses an aluminium alloy conductor for automotive wires, which has the advantages of high heat resistance, conductivity, tensile strength, extensibility and fatigue resistance, and a manufacturing method thereof. The alloy contains 0.3 to 0.8 weight percent of iron, 0.05 to 0.20 percent of silicon, 0.1 to 0.5 weight percent of magnesium, 0.1 to 0.3 weight percent of copper, 0.001 to 0.04 weight percent of boron, 0.001 to 0.04 weight percent of zirconium, 0.001 to 0.04 weight percent of yttrium, and the balance of aluminium and inevitable impurities, wherein one or two elements, except the aluminium and the inevitable impurities, account for 0.1 to 2.0 weight percent. The manufacturing method comprises the following steps of: adding the iron, silicon, magnesium, copper, boron, zirconium, yttrium and aluminium into a smelting furnace; smelting, and casting and rolling; performing intermediate annealing treatment; drawing into aluminium alloy filaments with the diameterof 0.5mm; and stranding into wire cores, and performing annealing treatment. The conductor prepared by the method has the tensile strength of 210MPa and above, the elongation at break of over 10 percent, the conductivity of over 58 percent, and excellent heat resistance and flexibility.

Owner:安徽中青欣意铝合金电缆有限公司

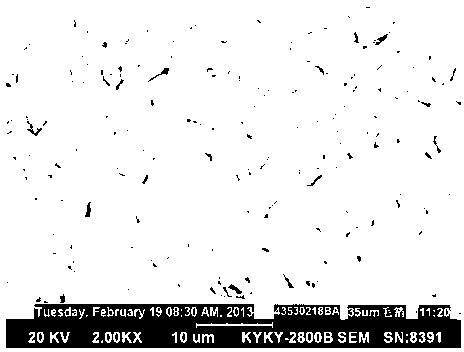

Mixed additive for removing internal stress of electrolytic copper foil and method for producing low-stress copper foil

ActiveCN103173812AThe production process is easy to controlProduct quality is stableCopper foilHydroxyethyl cellulose

The invention relates to a mixed additive for removing internal stress of an electrolytic copper foil and a method for producing a low-stress copper foil and belongs to the technical field of production of a high-precision electrolytic copper foil. The mixed additive for removing internal stress of the electrolytic copper foil comprises gelatin, hydroxyethyl cellulose and liquid additive. The method for producing the low-stress copper foil by using the mixed additive comprises the steps of preparing high-purity cathode copper and sulfuric acid into mixed solution of sulfuric acid and copper sulfate at 60-95 DEG C under the condition of stirring in the presence of air, wherein Cu<2+> is 85-100g / L and H2SO4 is 100-120g / L; adjusting the temperature of electrolyte to 45-60 DEG C and the flow to 50-70m<3> / h; adding 20-50mg / L of Cl<->, adding the mixed additive, with a drum titanium tube which continuously rotates as a cathode and arc titanium as an anode, carrying out copper electrolytic deposition and lastingly stripping to obtain 12-70 microns copper foil under the condition of the direct current of which the current density is 55-70A / dm<2>. The thickness of the copper foil is controlled by adjusting the rotation speed of the cathode; and the obtained copper foil has excellent performances.

Owner:SHANDONG JINBAO ELECTRONICS

Phi 0.03m special titanium filament processing process

InactiveCN101844158AImprove the lubrication effectImprove adhesionDrawing diesFurnace typesTitaniumFriction force

The invention discloses a 0.03m special titanium filament processing process, belonging to the field of metal fine machining. The processing process mainly comprises wire drawing, heat treatment and oxidizing scale treatment; a method for fixing a framework and two ends of a wiredrawing shaft is adopted in two times of wire drawing; by adopting a special lubricating agent, the friction force of the surface of a titanium wire and a calibrating strap part of a wiredrawing film can be reduced; different heat treatment temperatures or annealing points are adopted in two heat treatment processes and the uniform line velocity can be kept; the problems of low tensile strength and poor elongation percentage can be solved; and by adopting a single-line multi-head continuous cleaning method in the treatment process of oxidation scale, the resistance for the titanium wire to pass through a wire release rack, a rinsing tank and leaching pond and to be subjected to drying, taking up and other links can be reduced. The invention has the advantages of simple process and high processing efficiency; the processed titanium wire has high tensile strength and favorable elongation percentage; and the processing of a 0.03mm titanium wire can be realized.

Owner:SHANGHAI GIORAY METAL MATERIAL

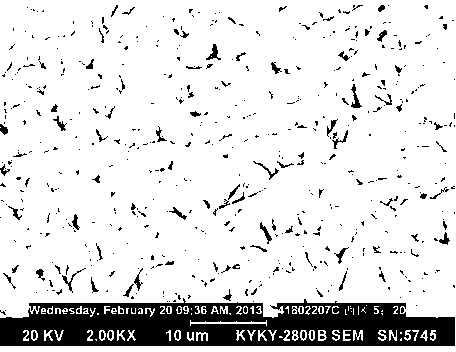

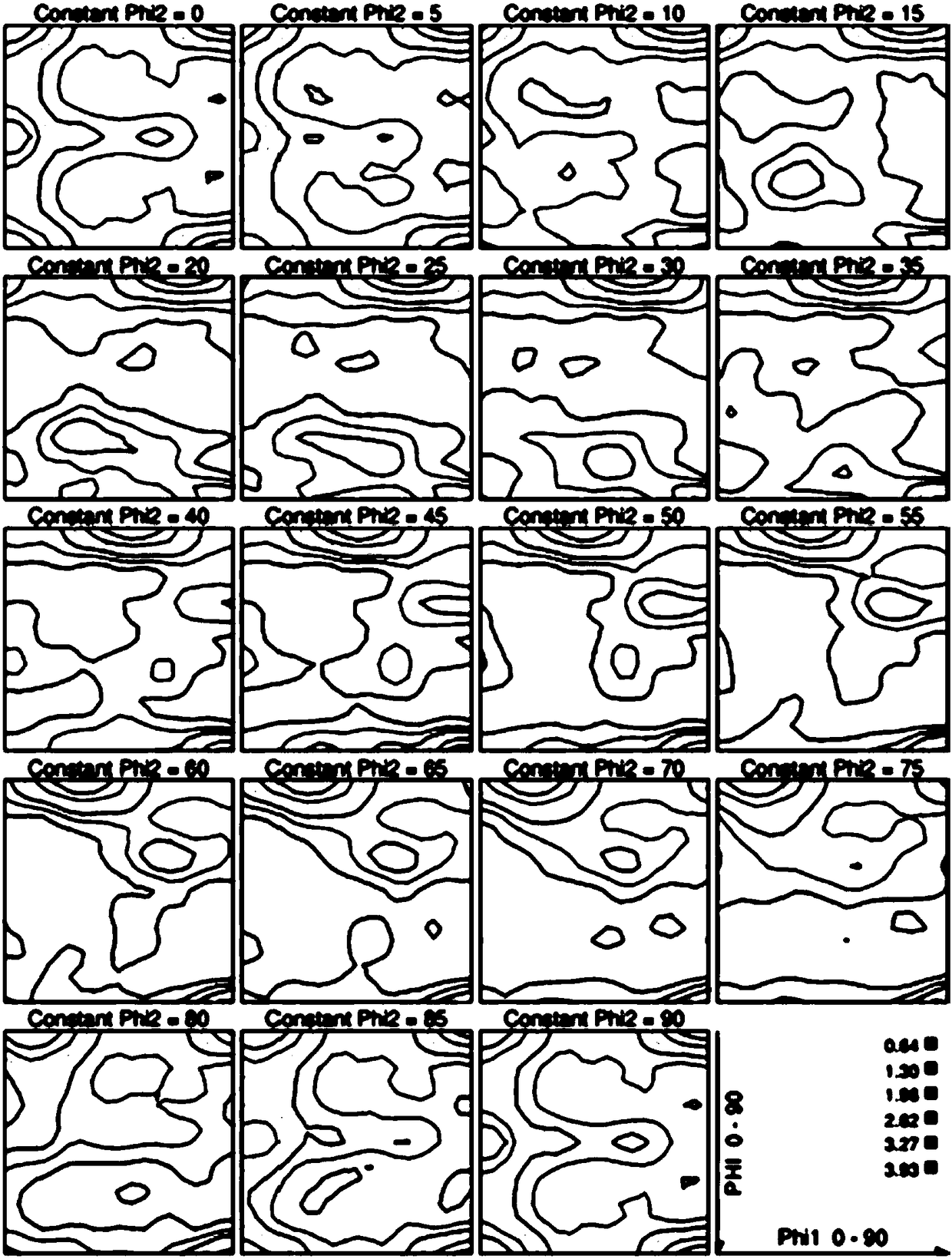

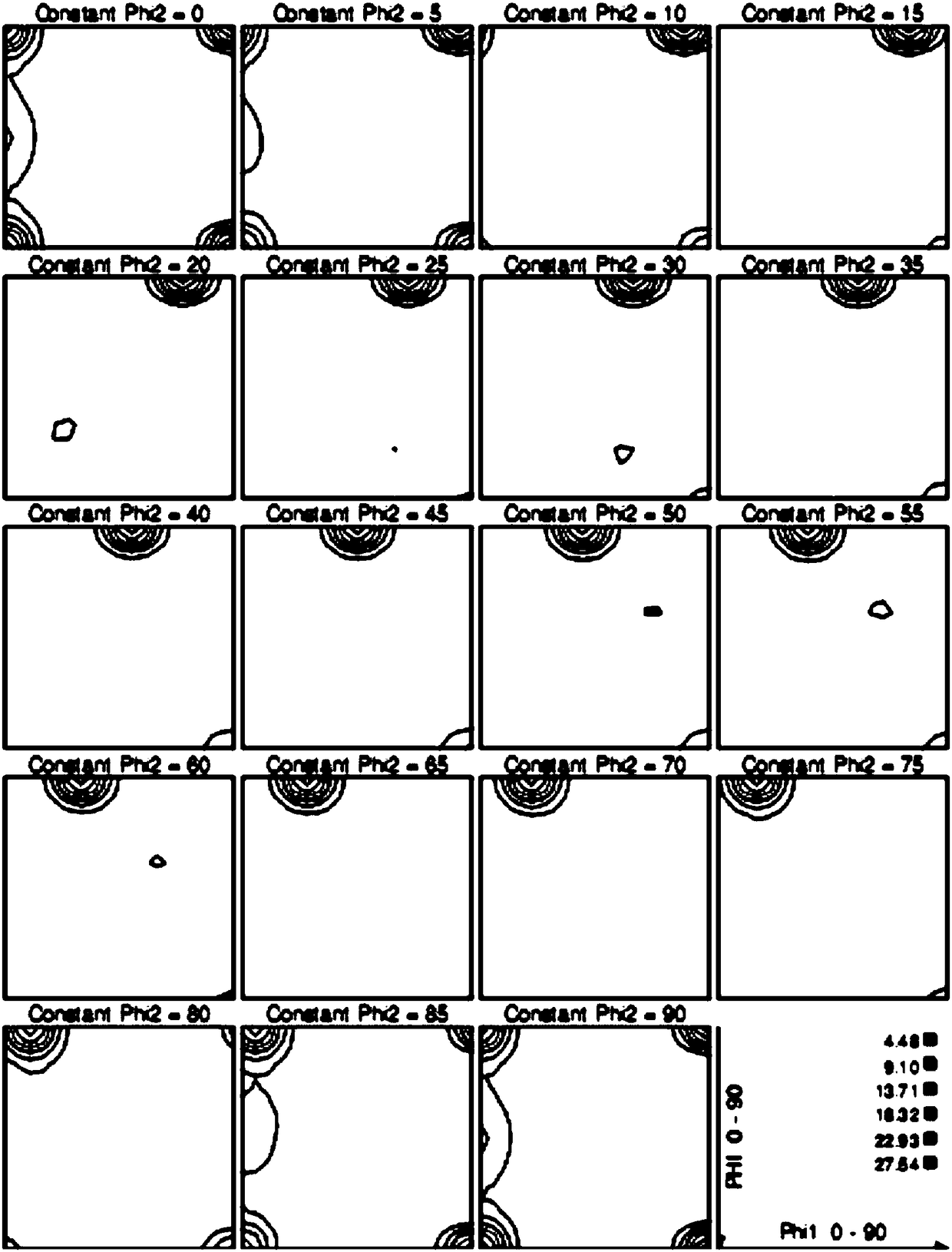

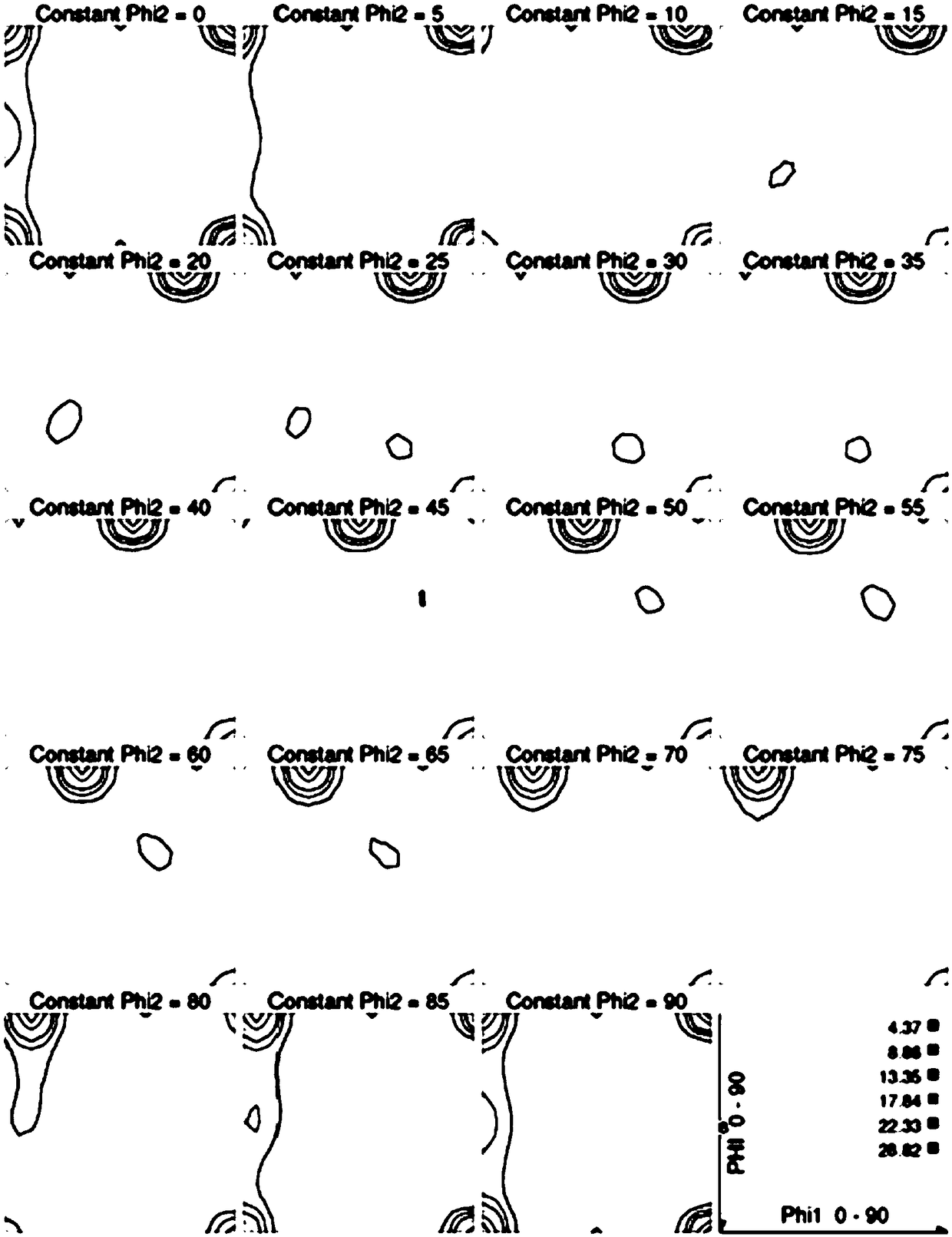

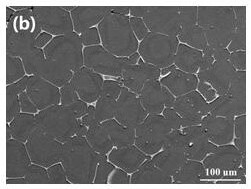

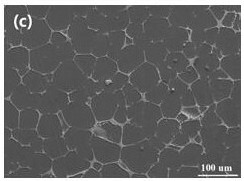

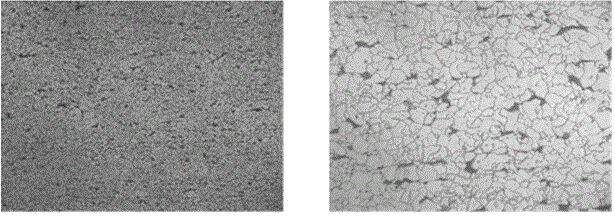

Machining method of fine-grain cubic texture corrosion-fatigue-resistant aluminum alloy plate

The invention relates to a skin material for aviation, in particular to a machining method for preparing corrosion-fatigue-damage-resistant aluminum alloy plates, and belongs to the technical field ofnonferrous metals. The machining method comprises the steps that an aluminum alloy hot rolling material is subjected to solid solution treatment for the first time, then the second time of solid solution treatment is carried out after multi-pass cold rolling with the pass deformation amount being less than or equal to 1.0mm is carried out to achieve the design thickness of the aluminum alloy plate; and in the multi-pass cold rolling process, deep cooling treatment is carried out immediately after each pass of cold rolling, and the temperature of the deep cooling treatment is less than or equal to -100 DEG C. The machining method for preparing the corrosion-fatigue-damage-resistant aluminum alloy plates is reasonable in texture design, the preparation process is simple and controllable, obtained products have good performance, and the machining method for preparing the corrosion-fatigue-damage-resistant aluminum alloy plates is convenient for large-scale industrial application.

Owner:HUNAN UNIV OF SCI & TECH

Aluminum alloy and preparation method thereof

InactiveCN102766789AReasonable control of Sc contentIncreased Sc contentNonferrous metalHigh intensity

The invention relates to the technical field of nonferrous metals, and particularly relates to an aluminum alloy and a preparation method of the aluminum alloy. The aluminum alloy comprises the following components in percentage by weight: 8-10% of Zn, 2.5-3.5% of Mg, 2.3-3.5% of Cu, 0.05-0.25% of Zr, 0.01-0.10% of Sc; in the impurity elements, the content of Si being less than or equal to 0.1%, the content of Fe being less than or equal to 0.15%, each one in other elements being less than 0.05%, the total amount being less than 0.5%, and the balance of Al. With the adoption of the technical scheme, the content of Sc in the alloy is controlled reasonably, the content of Zr is enhanced, so the strength and the coefficient of elongation are ensured, and meanwhile the production cost of the alloy is reduced greatly; the tensile strength of the alloy is more than 750MPa, the yield strength is more than 700MPa, the coefficient of elongation is higher than 10%, so the alloy has excellent overall performance and is suitable for the light components requiring high strength.

Owner:沈阳东铝特材科技有限公司

Production technology of copper-clad steel wire in soft state

ActiveCN102254629AAvoid crackingGuaranteed elongationCommunication cablesManufacturing extensible conductors/cablesElectricityElectrolysis

The invention relates to a production technology of a copper-clad steel wire in a soft state. The production technology successively comprises the following steps: drawing; tempering under high temperature; carrying out electro-deposition pretreatment; carrying out acid electrolysis; washing; carrying out pretreatment of electro-deposition; washing; carrying out electrodeposition thick treatment; washing; carrying out anti-oxidation processing; drying; drawing; washing; carrying out anti-oxidation processing; tempering under high temperature; polishing; carrying out anti-oxidation processing; and spooling to obtain a finished product. An advantage of the production technology of the copper-clad steel wire in the soft state is that an elongation rate of the produced copper-clad steel wire is greater than or equal to 8%, wherein the elongation rate, which is compared with an elongation rate of a copper-clad steel wire produced by a traditional tempering technology, can be enhanced by at least more than one time..

Owner:ZHEJIANG PUJIANG BAICHUAN IND

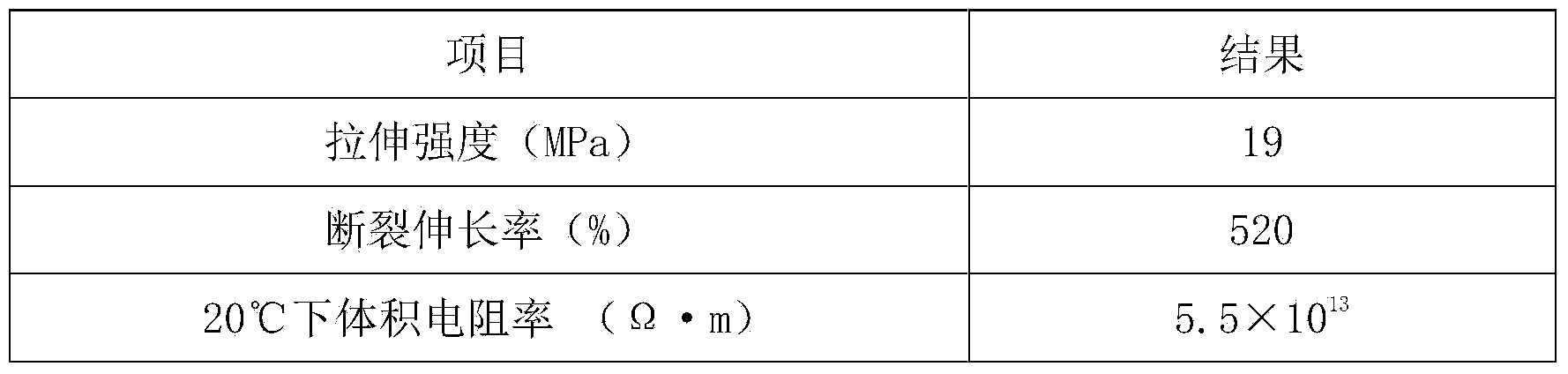

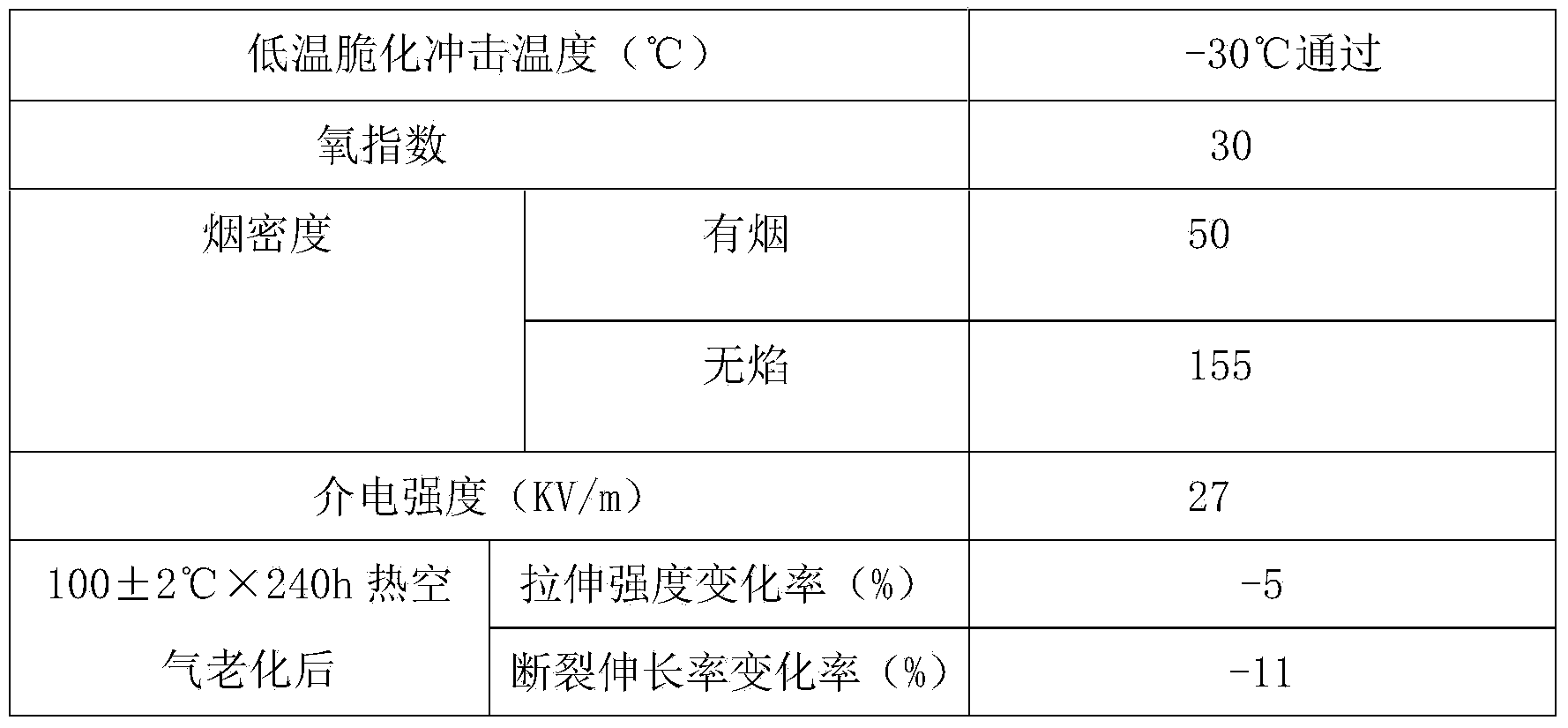

Flexible polyvinyl chloride (PVC) soft cable material

ActiveCN103524942AHigh elongationHigh tensile strengthPlastic/resin/waxes insulatorsInsulated cablesPolyvinyl chlorideStearic acid

The invention provides a flexible polyvinyl chloride (PVC) soft cable material which is prepared from the following component raw materials: by weight, 50-60 parts of PVC resin, 20-40 parts of polyester resin, 10-20 parts of organic silicone resin, 10-15 parts of precipitated white carbon black, 5-10 parts of wollastonite powder, 4-6 parts of dolomite, 4-6 parts of bauxite, 4-6 parts of molybdenum disulfide, 3-5 parts of pentaerythritol, 0.5-1.0 part of triphenyl phosphate, 0.1-0.2 part of antioxidant 1035, 0.1-0.2 part of antioxidant 168, 0.2-0.4 part of ferrocene, 0.1-0.3 part of stearic acid amide, 0.2-0.3 part of zinc stearate, 0.1-0.3 part of calcium stearate, 0.1-0.3 part of barium stearate, 0.1-0.2 part of phenyl methyl silicone oil and 10-15 parts of a modified filler. A plastic high mixing machine is used for mixing the formula components, after plasticizing granulation by use of a plastic extruding machine, the flexible polyvinyl chloride (PVC) soft cable material has excellent elongation and a greatly improved elastic property, and under the condition of ensuring product electrical performances, the elongation and tensile strength of a finished product can be improved.

Owner:广东佰佳电线电缆实业有限公司

Method for manufacturing steel thin-wall welding equal-strength components with aluminum or aluminum alloy coatings

ActiveCN111230301APromote homogenizationImprove hardenabilityArc welding apparatusWelding/cutting media/materialsHot stampingMetal alloy

Provided is a method for manufacturing steel thin-wall welding equal-strength components with aluminum or aluminum alloy coatings. A steel plate to be welded comprises a base body and at least one coating on the surface of the base body. Each coating comprises an intermetallic compound alloy layer in contact with the base body and a metal alloy layer on the intermetallic compound alloy layer. Thecoatings do not need to be removed or thinned before welding or in the welding process; by presetting the welding gap and using a carbon manganese steel welding wire, a welding process and protectivegas for welding, after a welding component is subjected to hot stamping treatment, the tensile strength of a weld joint is greater than the tensile strength of a base material, the extension rate of the weld joint is greater than 4%, and the application requirement of the equal-strength welding components in the hot stamping field is met.

Owner:BAOSHAN IRON & STEEL CO LTD

Ethylene propylene rubber material for sealing part of automobile heat dissipation system and production method of ethylene propylene rubber material

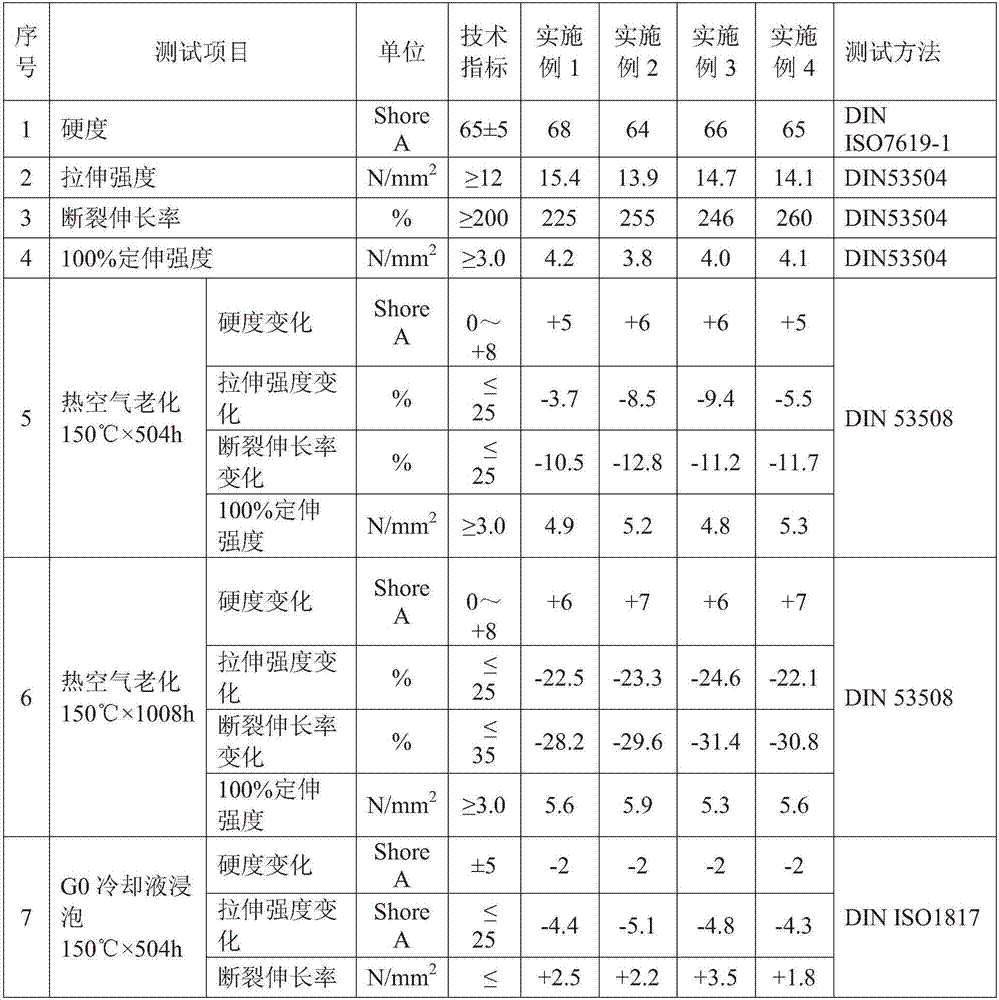

InactiveCN107090133AImprove high temperature resistanceLow temperature resistanceCross-linkRubber material

The invention discloses an ethylene propylene rubber material for a sealing part of an automobile heat dissipation system and a production method of the ethylene propylene rubber material and belongs to the technical field of rubber. The rubber material is prepared from the following components in parts by weight: 100 parts of raw ethylene propylene rubber, 5 parts of zinc oxide, 0.5 to 1.5 parts of stearic acid, 3 to 6 parts of an anti-ageing agent, 20 to 30 parts of fast extruding carbon black N550, 10 to 20 parts of semi-reinforced carbon black N774, 3.5 to 7 parts of a cross-linking auxiliary agent Ricon 153D and 5 to 8.5 parts of a vulcanizing agent Perkadox 14-40B-GR. The rubber material disclosed by the invention has excellent high-temperature-resisting performance and can be used for a long time under the condition that the temperature is -50 DEG C to 150 DEG C; meanwhile, the rubber material has remarkable advantages of low temperature resistance and low-compression permanent deformation.

Owner:南京金三力高分子科技有限公司

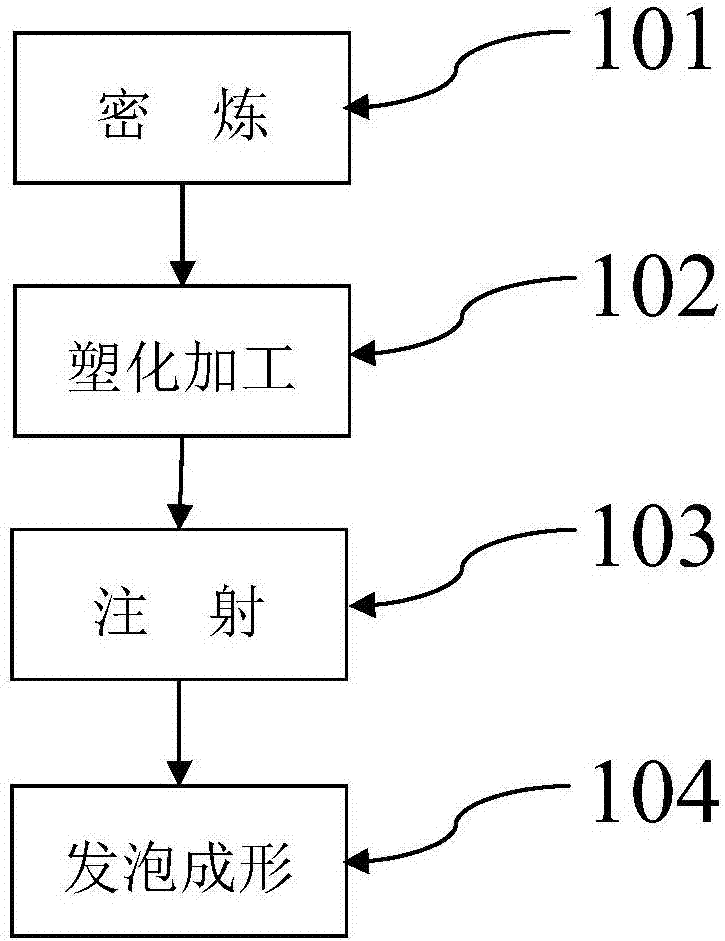

Production formula and preparation method for elastic rotator

The invention discloses a production formula and a preparation method for an elastic rotator, which belong to the technical field of road transportation equipment. The formula comprises the following specific components: 10 to 20 percent of ethylene-octene copolymer (POE), 40 to 60 percent of EVA (ethylene-vinyl acetate copolymer), 10 to 20 percent of ethylene-propylene-diene monomer, 5 to 10 percent of anti-shrinking agent, 1 to 3 percent of filler, 0.6 to 1.6 percent of dispersed lubricant, 1 to 2 percent of zinc oxide, 0.7 to 1.2 percent of cross-linking agent, 1.5 to 2.5 percent of foaming agent, 1.5 to 2.5 percent of flowable agent and 2 to 4 percent of color masterbatch pigment, and the total weight is 100 percent. The POE, the ethylene-propylene-diene monomer and the EVA are mixed and refined, and are added with a variety of additives, so that the three types of materials keep respective properties and complement one another, the elasticity of the prepared elastic rotator is high, moreover, after foaming, the texture is dense, the weight is light, the good anti-aging property of the elastic rotator is ensured, the elastic rotator cannot be easily cracked when receiving impact force, and the service life of the elastic rotator is effectively prolonged.

Owner:江苏恪铭智慧交通科技有限公司

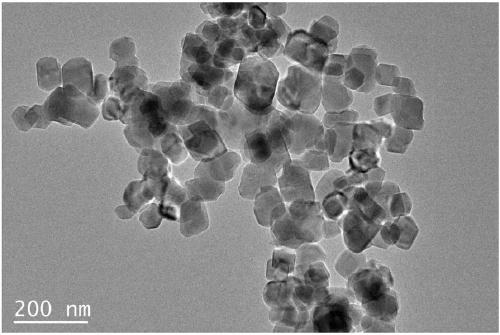

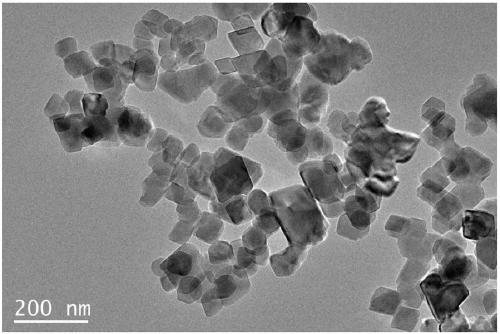

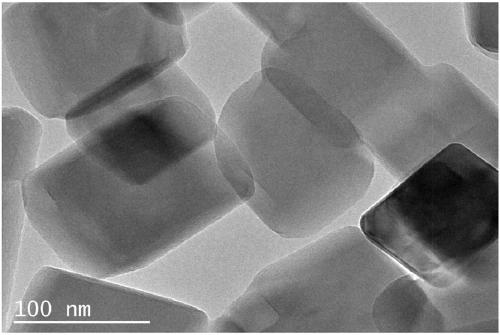

Preparation method of nano calcium carbonate for MS glue

InactiveCN109650431ADetermining performanceThe process steps are the sameCalcium/strontium/barium carbonatesNon-macromolecular adhesive additivesCarbonizationSlurry

The invention discloses a preparation method of nano calcium carbonate for MS glue, which comprises the following steps: removing impurities from calcium hydroxide (Ca (OH) 2) slurry obtained after the digestion reaction of quicklime (CaO) and water (H2O), preserving heat and aging, adding a crystal form control agent, performing primary carbonization synthesis reaction with the washed kiln gas containing carbon dioxide (CO2), adding a post-treatment agent, aging for a certain time, performing secondary carbonization synthesis reaction with the washed kiln gas containing carbon dioxide (CO2) to obtain calcium carbonate (CaCO3) cooked slurry, adding a modifier into the cooked slurry, performing filter pressing dehydration, drying, crushing and grading after the reaction is finished to obtain the nano calcium carbonate for MS glue. The nano calcium carbonate crystal prepared by the method is a standard cube, and the crystal is mono-disperse, and the average particle diameter is only 100-150nm, and the specific surface area is 16-18m <2 > / g, and the nano calcium carbonate crystal is used for MS glue, and the thixotropy is good, and the extrusion property is good, and the storage stability is good, and the surface finish after gluing is good, and the tensile strength is high, and the elongation is high and the bonding property is also good. The preparation method of nano calcium carbonate for MS glue has the advantages of simple and feasible process, low cost, low price and better economic benefit.

Owner:卢氏国嵩莱纳米科技有限公司

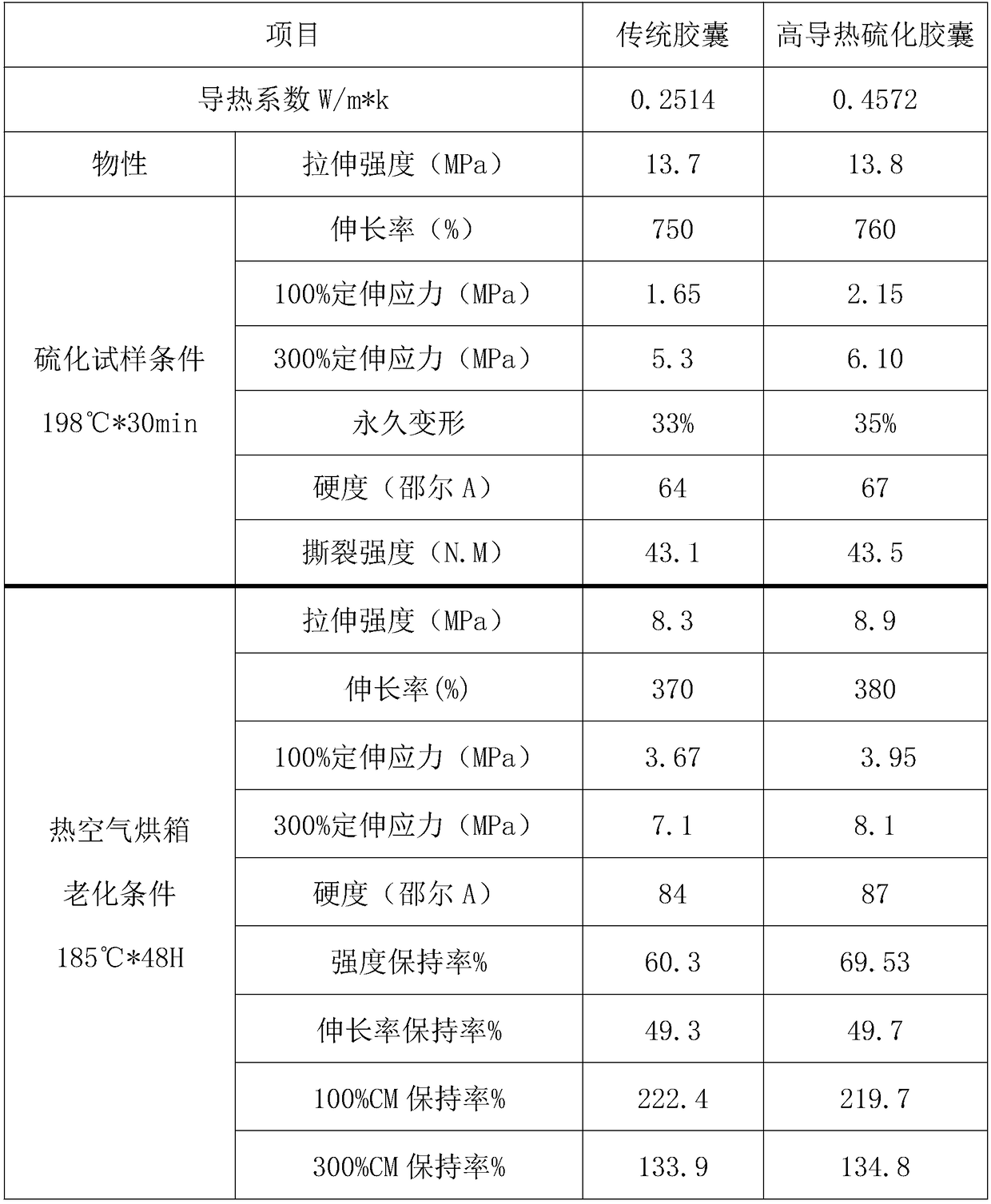

Preparation method of high-heat-conductivity type tire vulcanization capsule

The invention discloses a preparation method of a high-heat-conductivity type tire vulcanization capsule. The preparation method of the high-heat-conductivity type tire vulcanization capsule belongs to the technical field of tires, and comprises the following steps of (1) compounding the components according to the matching ratio: 95 parts of butyl rubber, 4 to 5 parts of chloroprene rubber, 15 to20 parts of N375 carbon black, 35 to 45 parts of acetylene black, 7 to 15 parts of graphene, 7 to 10 parts of alkane oil, 0.5 to 1.5 parts of stearic acid, 5 to 7 parts of zinc oxide, and 8 to 10 parts of resin; (2) primarily mixing; (3) filtering rubber; (4) secondarily mixing; (5) forming; (6) vulcanizing; (7) polishing; and (8) inspecting a finished product. According to the preparation methodof the high-heat-conductivity type tire vulcanization capsule provided by the invention, on the basis of ensuring the stability of various physical and mechanical properties, a heat conductivity coefficient is further improved, so that the aims of saving energy and reducing cost are achieved.

Owner:YONGYI RUBBER CO LTD

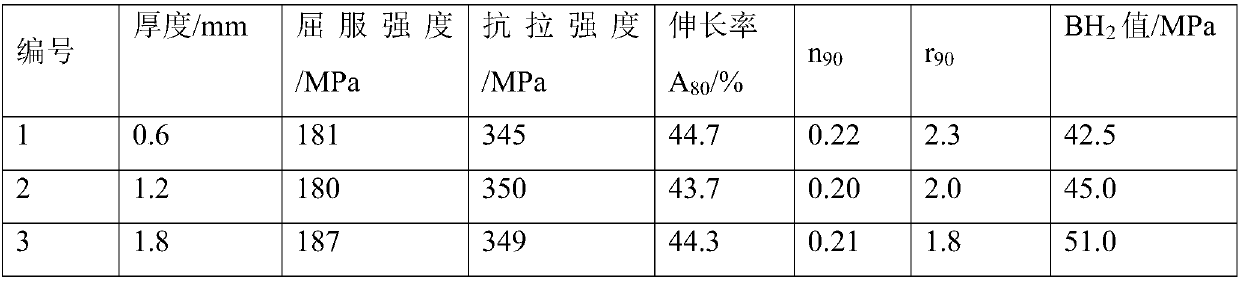

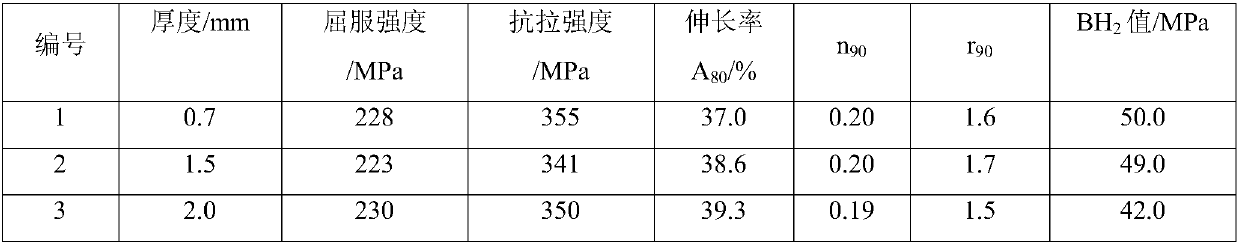

Roasted and hardened hot galvanized steel plate and preparation method thereof

The invention belongs to the technical field of steel plate manufacturing and in particular relates to a hot galvanized steel plate and a preparation method thereof. In order to solve the problems that a hot galvanized steel plate prepared by an existing method is poor in mechanical property and stretching property and the like, the invention provides the hot galvanized steel plate and the preparation method thereof. The hot galvanized steel plate comprises the following chemical components in percentages by weight: less than or equal to 0.0030% of Cm 0.04-0.06% of Si, 0.10-0.20% of Mn, less than or equal to 0.010% of P, less than or equal to 0.008% of S, 0.010-0.020% of Ti, 0.025-0.050% of Als and the balance of Fe and inevitable impurities. The preparation method comprises the followingsteps: carrying out smelting, hot rolling, pickling rolling, hot galvanizing and annealing steps on smelted steel to prepare obtain the hot galvanized steel plate. The yield strength of the hot galvanized steel plate prepared by the invention is 180-240MPa, the tensile strength of the hot galvanized steel plate is 340-360MPa, the ductility is greater than or equal to 34.0%, n90 is greater than orequal to 0.18, r90 is greater than or equal to 1.6, BH is greater than or equal to 30MPa, and the hot galvanized steel plate is excellent in mechanical property and forming property and can meet the using demands of automotive planking users.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

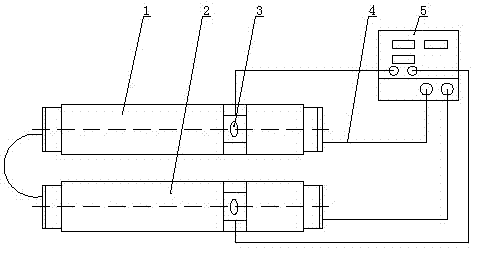

Construction method for prefabricating directly-buried uncompensated centralized heat supply pipeline by electrically preheating

InactiveCN102444750AImprove running stabilityGuaranteed elongationPipe laying and repairElectricityEngineering

The invention relates to a construction method for prefabricating a directly-buried uncompensated centralized heat supply pipeline by electrically preheating. The method comprises the following steps of: (1) grooving, adjusting the coordinate and scale height of the heat supply pipeline, and computing the preheating temperature and the designed elongation of the heat supply pipeline; (2) controlling the sand refilling height at a half to three quarters of the pipeline height H; (3) connecting the same-side end of the heat supply pipeline with preheating equipment through a cable respectively, and short-circuiting the other side of the heat supply pipeline through a cable; (4) arranging temperature sensors on the heat supply pipeline respectively; (5) recording the initial temperature of the heat supply pipeline and the initial position of a measuring point, starting temperature raising, controlling the temperature raising gradient within 1 DEG C per hour, and preserving heat after a preheating temperature is reached; (6) refilling sand into both sides of the heat supply pipeline, tamping, and controlling the preheating temperature within the range of + / -2 DEG C; (7) after the designed elongation is reached, shutting down the preheating equipment; and (8) performing subsequent construction according to the steps (1)-(7). The construction method disclosed by the invention is safe, reliable, easy and practical, is easy for accurately controlling construction equipment, and is consistent with the national policy of energy saving and emission reduction.

Owner:MCC TIANGONG GROUP

Corrosion resistant plastic mould steel and manufacturing method thereof

InactiveCN108060368AImprove corrosion resistanceExpand the scope of applicationCorrosion resistantDuctility

The invention relates to the field of plastic steel, and specifically relates to a corrosion resistant plastic mould steel and a manufacturing method thereof. The plastic mould steel comprises following components in percentage by weight: 0.45 to 0.55% of C, 0.40 to 0.80% of Si, 0.80 to 1.60% of Mn, 0.10 to 0.25% of V, 0.007 to 0.015% of N, 0.005 to 0.050% of Al, not more than 0.035% of S, not more than 0.025% of P, 3.5 to 4.0% of Ni, 8.5 to 10.5% of Cr, 0.25 to 0.45% of Cu, and the balance being Fe and other impurities, which are introduced into the steel during the refining process, whereinCr+Ni=12-14.5%. The original strength, ductility, wear resistant performance, and cutting property of plastic mould steel are guaranteed, at the same time, the corrosion resistant performance of plastic mould steel is greatly improved; after polishing, the roughness is lower than that of products on the market; by controlling the using amounts of copper and molybdenum, the plastic mould steel canbe applied to different fields without influencing the performances of plastic mould steel, and the application range of plastic mould steel is enlarged.

Owner:莫祖勇

Al-Mg-Si-Cu alloy and preparation method thereof

The invention provides an Al-Mg-Si-Cu alloy which is high in strength and elongation. The Al-Mg-Si-Cu alloy comprises, by mass, 0.60-0.80% of Si, 1.05-1.15% of Mg, no more than 0.10% of Fe, 0.10-0.20%of Cu, 0.03-0.09% of Cr, no more than 0.05% of Mn, 0.05-0.12% of Zn, 0.01-0.04% of Ti, and the balance Al. The Al-Mg-Si-Cu alloy which is high in strength and elongation is designed through the reasonable proportion of the alloy components, the tensile strength of the prepared alloy material is 310MPa or over, the elongation is 18% or over, and the alloy material has good machinability such as the flanging performance and the turning performance.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

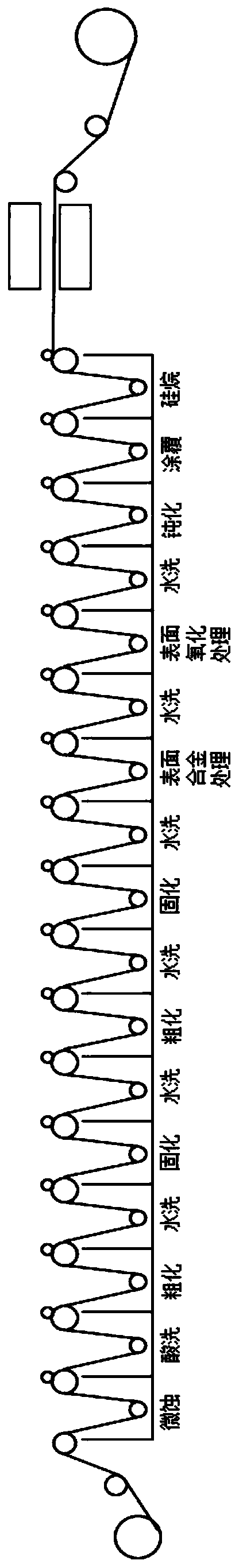

Reversal copper foil production process

InactiveCN111424294AGuaranteed elongationReduce ridgesElectroforming processesPolyester coatingsPtru catalystElectrolysis

The invention relates to a reversal copper foil production process, belonging to the technical field of electrolytic copper foils. The process comprises electrolysis of raw foil and surface treatment,wherein the surface treatment comprises microetching, acid pickling, roughening, washing, curing, washing, roughening, washing, curing, washing, surface alloying treatment, washing, surface anti-oxidation treatment, washing, passivation, applying of an anti-sticking film on a rough surface, silanization treatment, and drying; the applied anti-sticking film comprises the following components according to the weight percentage: 35.5-46 wt% of organochlorosilane, 27.8-33 wt% of organopolysiloxane resin, 12.7-20.1 wt% of aminosilane, 10.2-12.2 wt% of polyester resin, and 2-8.2 wt% of acid carclazyte catalyst; and the applied anti-sticking film has the thickness of 3 micrometers. The production process can reduce the residual copper rate on the surface of a copper foil while ensuring the bonding force between the surface of the copper foil and an etching resist, and ensures the elongation rate of the copper foil.

Owner:惠州联合铜箔电子材料有限公司

Low-rare-earth high-strength wrought magnesium alloy containing neodymium and yttrium and preparation method of low-rare-earth high-strength wrought magnesium alloy

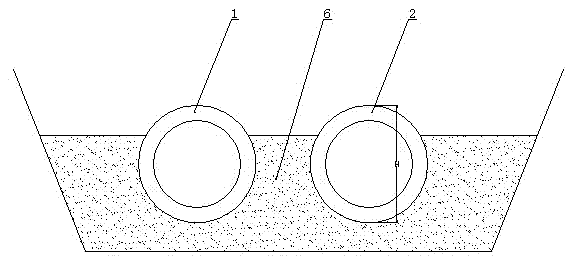

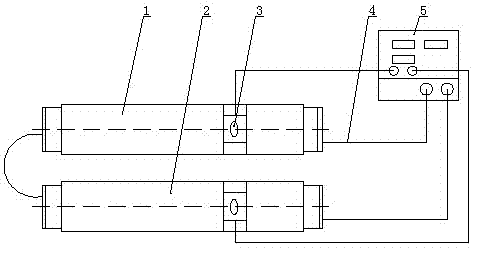

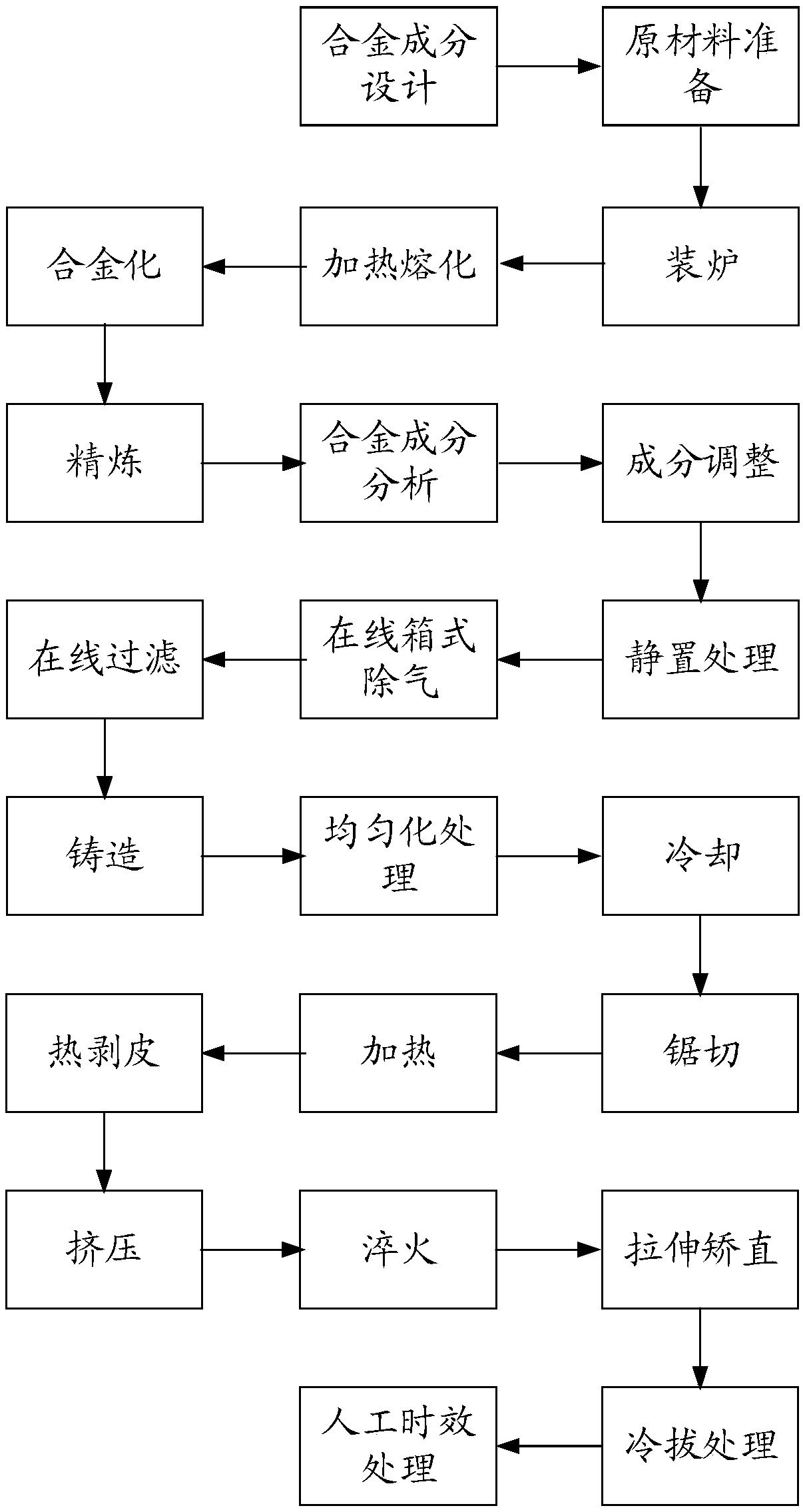

InactiveCN112458349ALow costImprove mechanical propertiesFurnace typesHeat treatment furnacesIngotZinc

The invention provides a high-strength wrought magnesium alloy containing rare earth neodymium and yttrium. The alloy comprises the following components in percentages by mass: 5.50-6.50wt.% of Zn, 0.47-0.80wt.% of Zr, 0.45-0.50wt.% of Nd, 0.72-1.00wt.% of Y, less than 0.10wt.% of inevitable impurities and the balance of Mg. A preparation method comprises the following steps: homogenizing a magnesium alloy ingot containing rare earth neodymium and yttrium, and then performing hot extrusion. Crystal grains are remarkably refined, meanwhile, neodymium, yttrium and elements such as magnesium andzinc in the alloy form second phases, and the second phases are re-crushed and distributed into fine dispersed strengthening phases in the hot extrusion process, so that growth of recrystallized crystal grains in the hot deformation process can be effectively hindered, a matrix is strengthened, and good mechanical properties can be obtained; and after hot extrusion, low-temperature aging treatmentis performed, so that the strength can be further improved, and the tensile strength after aging exceeds 400 MPa and is higher than that of most commercial magnesium alloys at present. The alloy is low in cost, a conventional smelting hot extrusion process is adopted, and the alloy has good operability and practicability and is convenient to popularize and apply.

Owner:CHONGQING UNIV

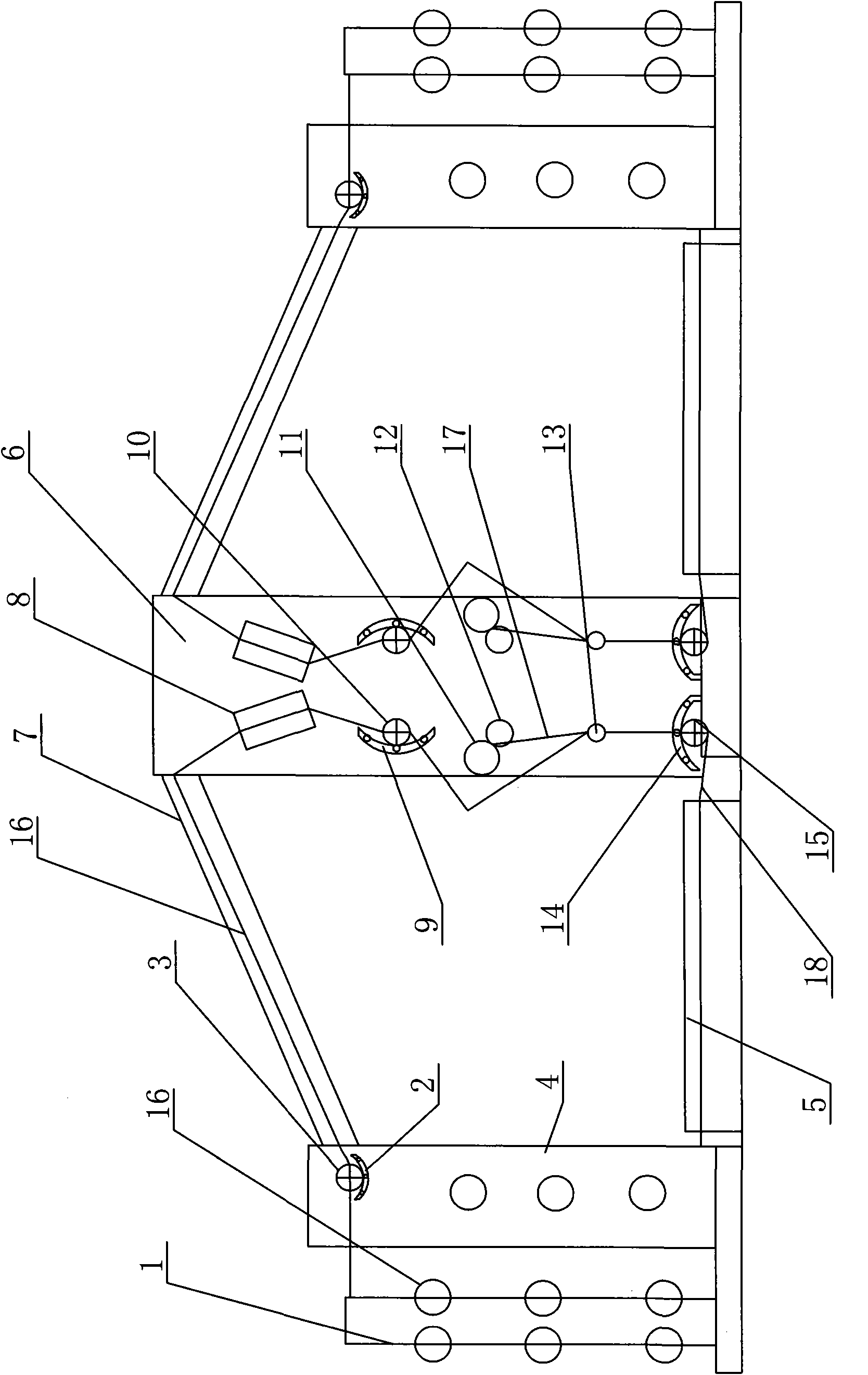

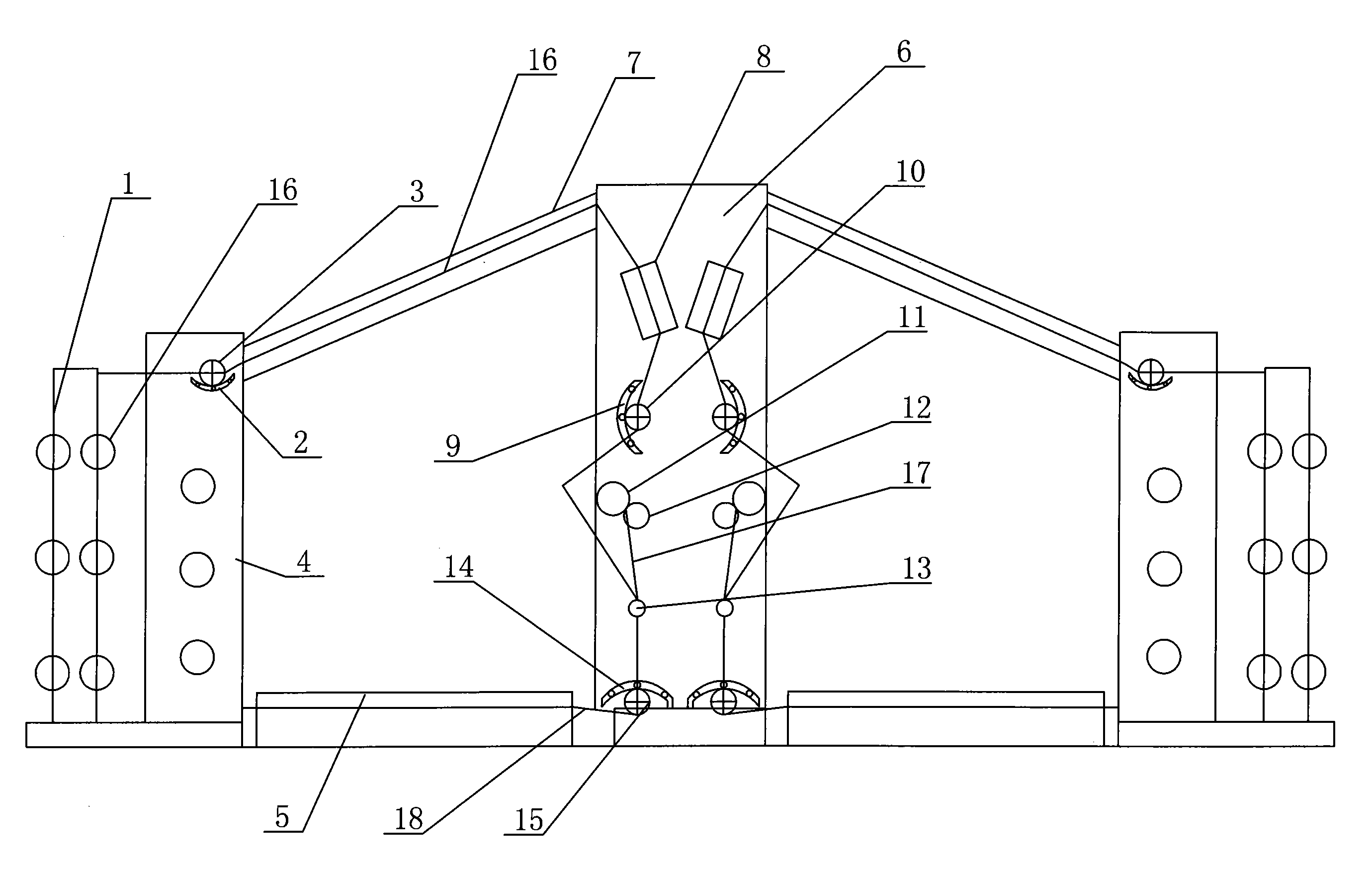

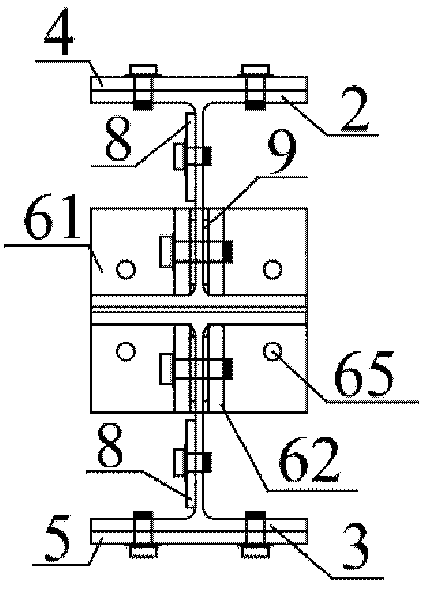

Polyurethane fiber coating device used on elasticizer

InactiveCN101974817AReduce manufacturing costGuaranteed tensionYarnEngineeringMechanical engineering

The invention discloses a polyurethane fiber coating device used on an elasticizer which has low production cost and can directly finish composite coating of fiber filament on the elasticizer. The device comprises a proto-filament frame, a first guide pressing arm, a proto-filament roller, a molding frame, a pedestrian pedal and a stand, wherein the proto-filament roller is matched with the first guide pressing arm; a heating box is arranged on an input part for synthetic fiber filament between the molding frame and the stand; the stand is sequentially provided with a twister, a second guide pressing arm, a first tension roller, a polyurethane fiber drum, a traction roller, a composite filament deformation air spout, a third guide pressing arm and a second tension roller from top to bottom; the first tension roller is matched with the second guide pressing arm; and the second tension roller is matched with the third guide pressing arm.

Owner:JIANGSU SHUNSIDA TEXTILE

Treatment method for brass texture antifatigue aluminum alloy panel

The invention relates to a treatment method for a brass texture antifatigue aluminum alloy panel, which is characterized in that multiple times of warm rolling is performed on an aluminum alloy hot rolling material until reaching the designed thickness of the aluminum alloy panel, and after annealing treatment and solution treatment, short-term artificial aging is performed. According to the invention, a treatment process of multiple times of warm rolling and annealing is adopted; by virtue of warm rolling, grains of the alloy can be effectively refined, the return process of alloy can be promoted, deformation energy storage can be reduced, and recrystallization can be inhibited; and by virtue of primary annealing treatment, annealing temperature and heat insulation time can be controlled, grains cannot grow up, and a deformation texture can be retained, thus obtaining a relatively strong deformation texture. The treatment method is simple in process method and convenient to operate, can effectively improve the composition and the volume fraction of the texture in an aluminum alloy matrix, can effectively prolong the fatigue life of the aluminum alloy on the premise of ensuring that aluminum alloy strength and ductility meet alloy performance requirements, is suitable for industrial application, and provides a feasible technical solution for preparation of aluminum alloy material for aviation and spaceflight.

Owner:湖南润泰新能源科技有限公司

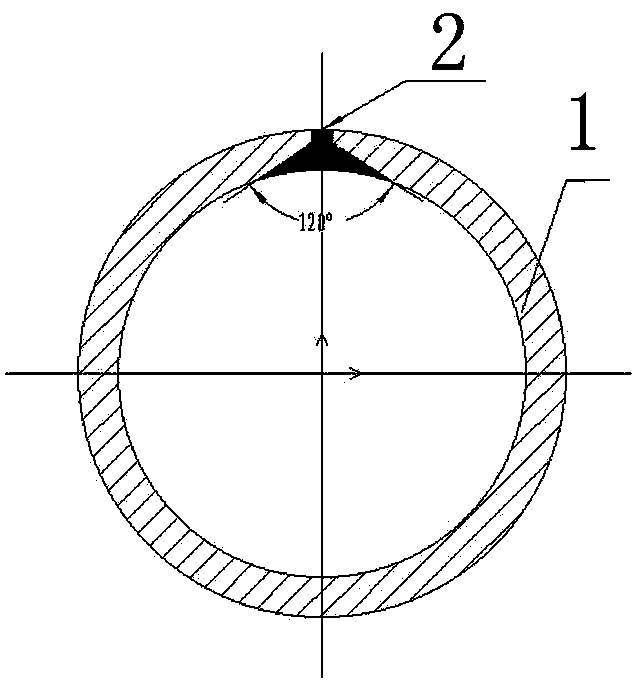

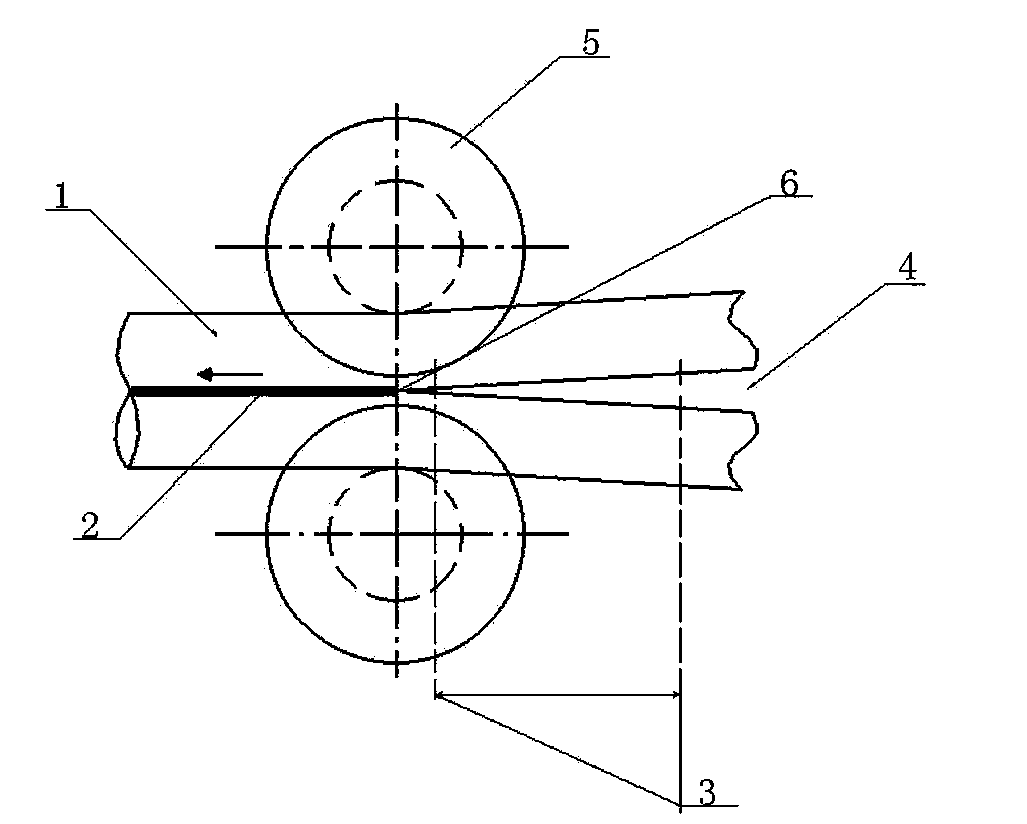

Special steel pipe for CO2 (carbon dioxide) air conditioner compressor casing and processing process of special steel pipe

The invention relates to a special steel pipe for a CO2 (carbon dioxide) air conditioner compressor casing and a processing process of the special steel pipe. The processing method comprises the following process steps that steel coils are sheared into required steel belts according to specifications; the steel belts are subjected to leveling through a leveling machine after entering a machine unit production line, the smoothness is + / -0.30mm, and the two sides of the steel belts are respectively subjected to 60-degree planing and shaping; the welding current is regulated, and the current is controlled to be between 550A and 650A; the welding speed is controlled to be 30meter / minute to 35meter / minute; a heat affecting region is lengthened, and a welding opening angle is enlarged; the steel belts are formed into steel pipes by adopting a multi-roller extruding device; welding seams are formed at the welding points; the steel pipes are naturally cooled through air and are cooled through water after the welding, the steel pipes enter a correcting region, the roundness of the special steel pipes can be ensured, and the appearance dimension requirements are met. The special steel pipe and the processing process have the advantages that the roundness of the welding steel pipe casing and the tightness of the welding seams can be ensured, the welding seams can bear the maximum intensity pressure greater than or equal to 30Mpa, the production process is simple, the productivity can be improved, the manufacturing finished product rate is high, raw materials can be saved, the appearance is smooth and attractive, the quality can be improved, and the cost can also be reduced.

Owner:无锡天龙钢管有限公司

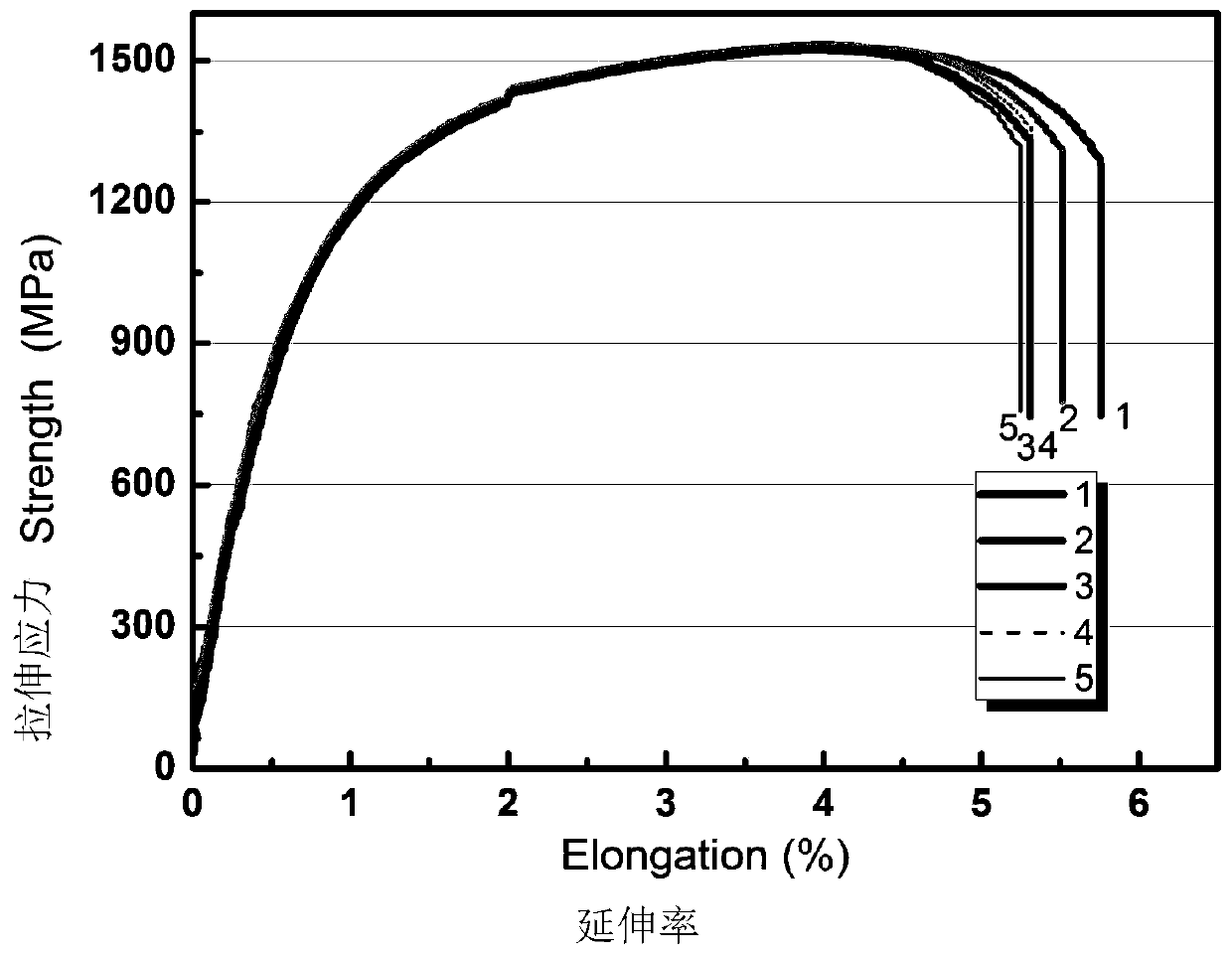

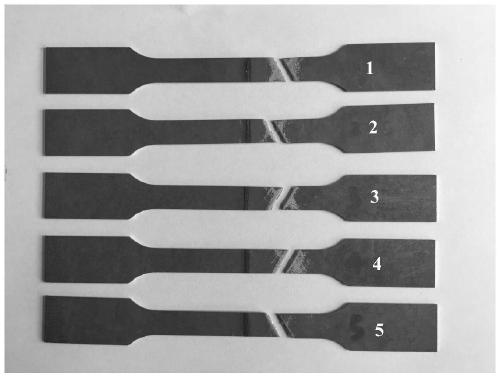

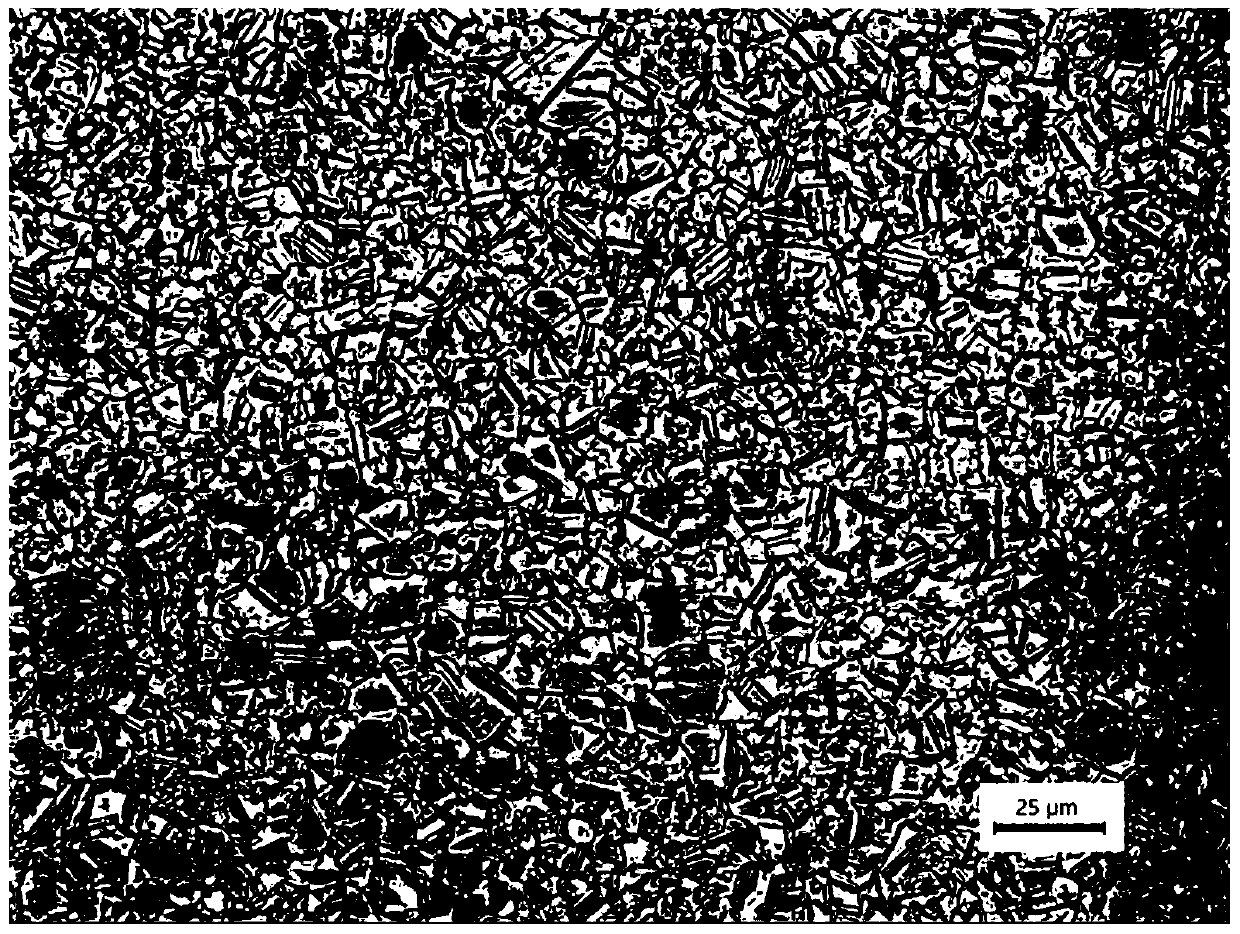

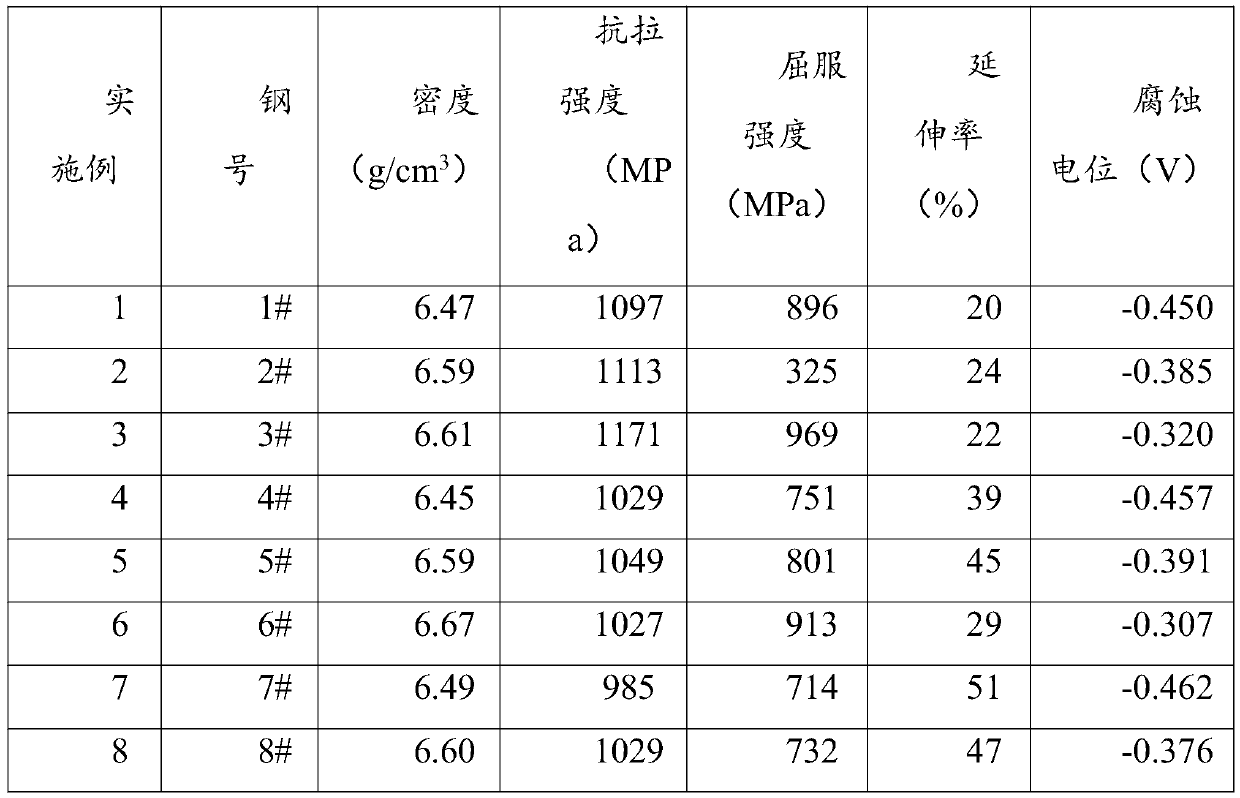

Nb-contained high-strength high-tenacity low-density steel for automobile and preparation method thereof

The invention discloses Nb-contained high-strength high-tenacity low-density steel for an automobile and a preparation method of the Nb-contained high-strength high-tenacity low-density steel for theautomobile, and relates to the field of metal materials. The Nb-contained high-strength high-tenacity low-density steel for the automobile comprise, by mass percentage, 0.9% to 1.1% of C, 9.4% to 9.7%of Al, 26.9% to 28.1% of Mn, 0.08% to 0.50% of Nb, smaller than 0.5% of Si, smaller than 0.004% of S, smaller than 0.003% of P, and the balance Fe and other inevitable impurity elements. According tothe Nb-contained high-strength high-tenacity low-density steel for the automobile, a finely dispersed NbC phase is precipitated by adding the Nb element to traditional Fe-Mn- Al-C low-density steel,the NbC phase and kappa-carbide jointly generate a precipitation strengthening effect, and then the high-strength high-tenacity low-density steel excellent in corrosion resistance is obtained, whereinaccording to the high-strength high-tenacity low-density steel excellent in corrosion resistance, the density is between 6.4 g / cm<3> - 6.7 g / cm<3>, the tensile strength is between 980 MPa and 1200 MPa, and the elongation percentage after fracture is between 20% and 50%, and the corrosion potential is larger than minus 0.462V. The Nb-contained high-strength high-tenacity low-density steel is suitable for automobile steel demands, can achieve lightweight of the automobile and meets the development concept of energy saving and emission reduction.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Aluminum magnesium alloy

InactiveCN101831577AImprove toughness and plasticityImprove the effect of solid solution strengtheningSolid solution strengtheningImpurity

The invention discloses an aluminum magnesium alloy for casting castings with elongation of over 10 percent. The aluminum magnesium alloy comprises the following components in percentage by weight: 3.8 to 4.5 percent of Mg, 0.3 to 0.4 percent of Cu, 0.2 to 0.23 percent of Ti, less than or equal to 0.1 percent of Fe, less than or equal to 0.1 percent of Si and the balance of Al. All properties of the castings meet the requirement by effectively controlling the components of the aluminum magnesium alloy, wherein the control of the adding amount of the Ti is favorable for improving the plasticity and tenacity of the alloy, the reasonable adjustment of the component content of Cu and Mg can ensure that the elongation of the castings is over 10 percent so as to play a good role in solid dissolving strengthening on the alloy, and the strict control of Fe and Si elements belonging to impurities meets the requirement of casting and producing high-end mechanical parts.

Owner:常州华晨铸造有限公司

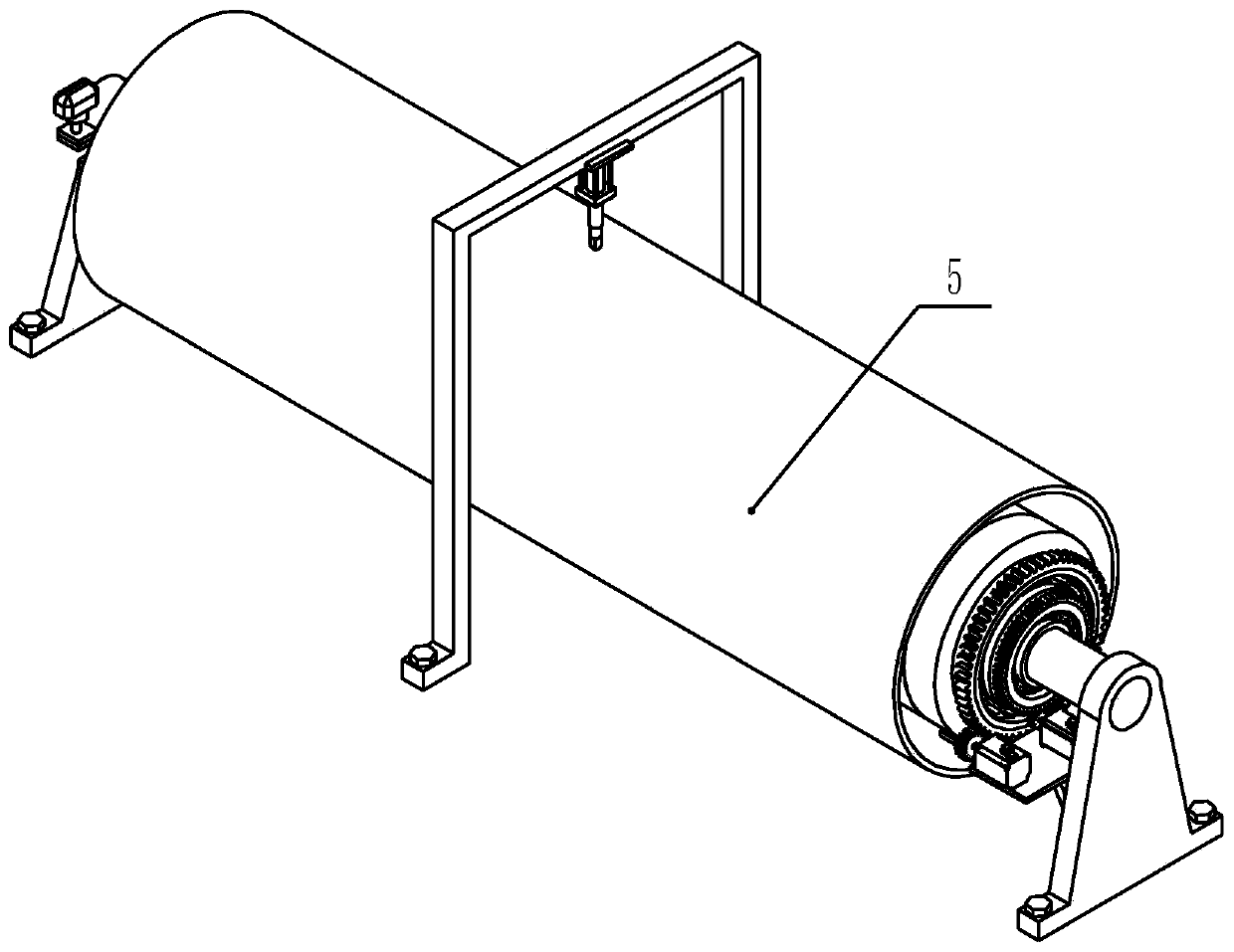

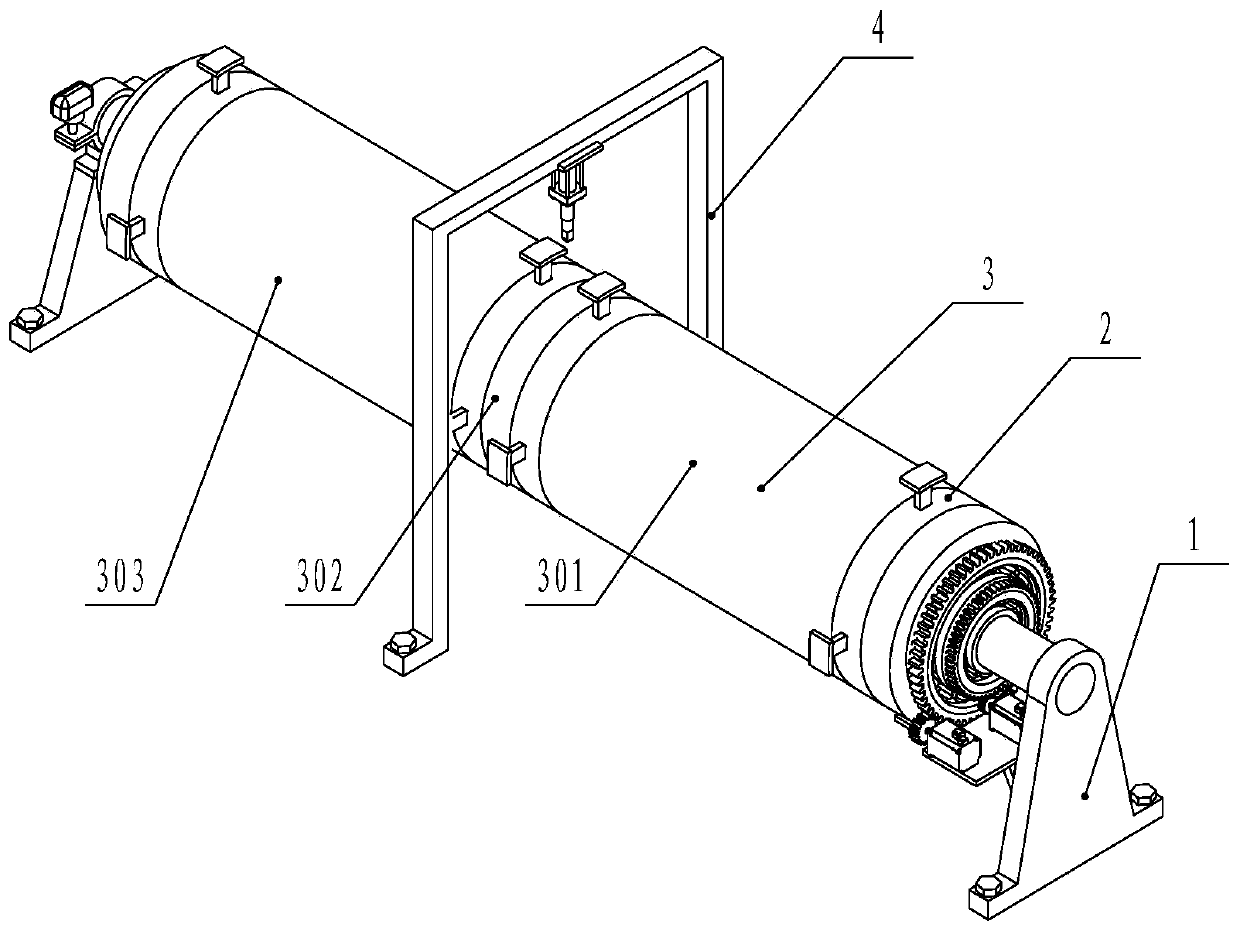

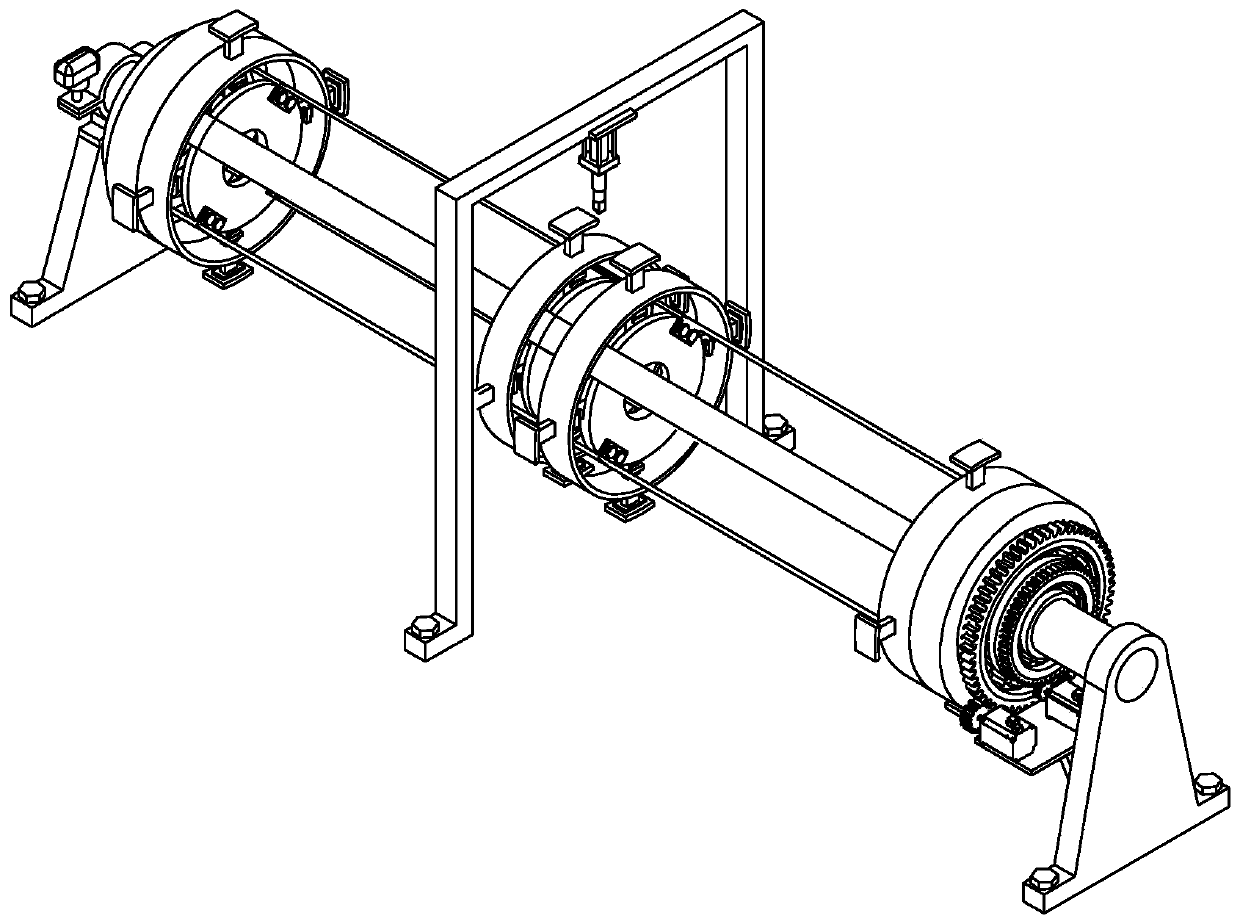

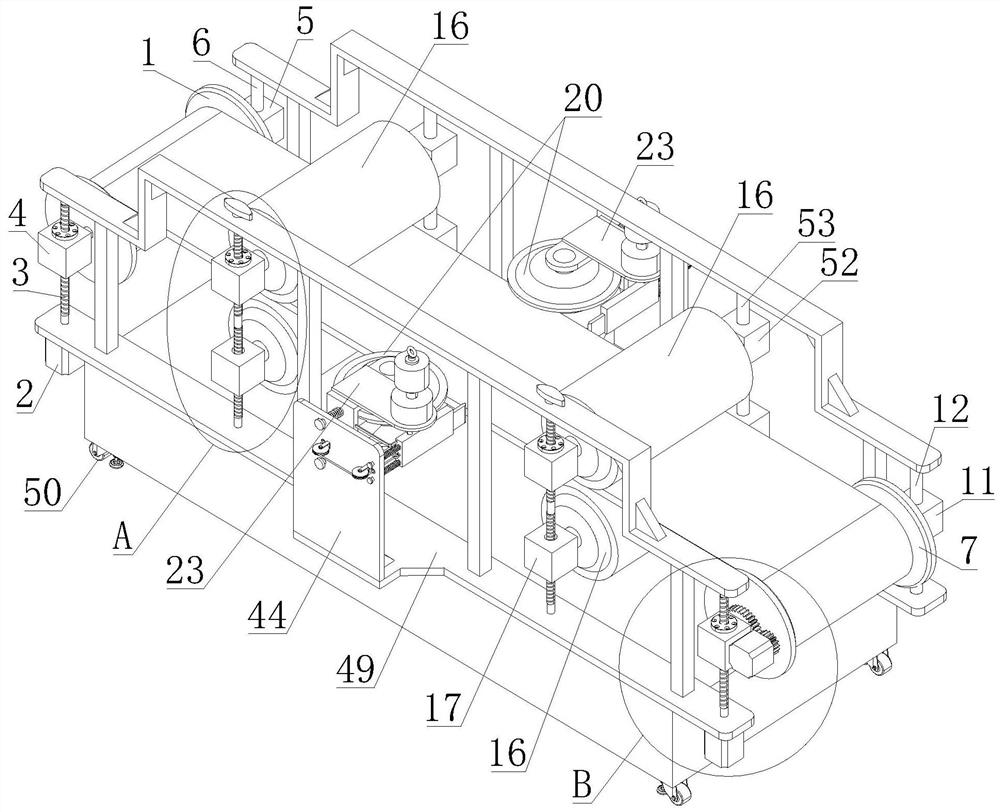

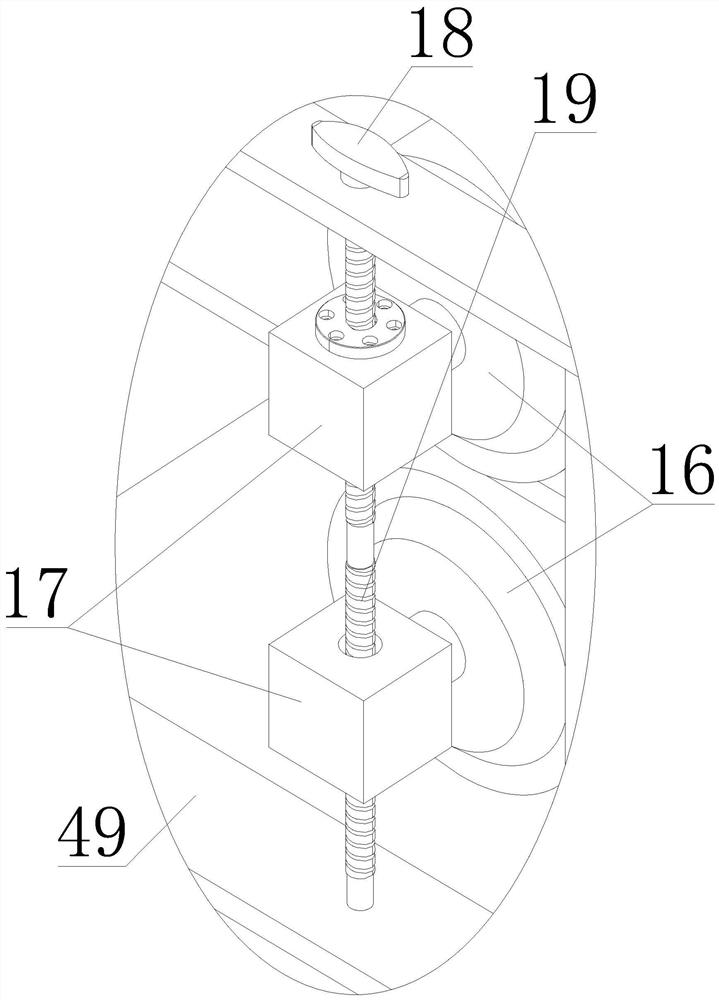

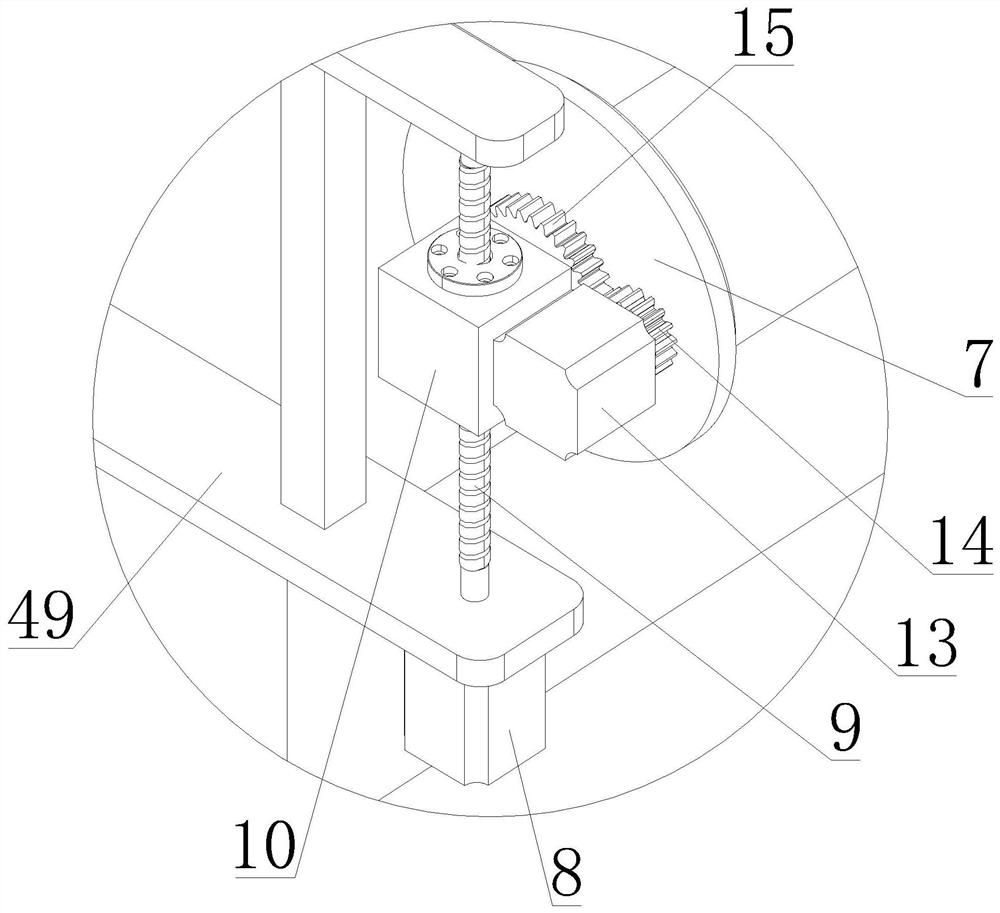

Chuck expansion type metal hard tube rotary cutting machine

InactiveCN110064790AUniform clamping forceAvoid clamping deformationTube shearing machinesShearing machine accessoriesEngineeringGrinding wheel

The invention provides a chuck expansion type metal hard tube rotary cutting machine. The rotary cutting machine comprises a supporting device, a sleeve device, a cutting device and at least four expansion devices, wherein a plurality of expansion devices are sequentially connected and arranged on the same axis through connecting frames, two expansion devices located at two ends are connected withthe supporting device, every two adjacent expansion devices are connected by sleeve pipes of the sleeve device in a sleeving mode, and the cutting device is arranged between two adjacent expansion devices. The expansion devices can expand from the inside of the metal hard tube to achieve the purpose of fixing the metal hard tube, and all lengths of the metal hard tube can be fixed, so that an existing equipment which can only clamp and fix the cut part is replaced, the clamping force is more uniform, and the clamping deformation is prevented; the expansion devices can drive the metal hard tube to rotate together, and then the cutting wall thickness distance can be achieved through feeding movement of a cutting knife, so that the cutting task can be completed, a cutting mode that an existing cutting grinding wheel pieces enter the inner part of the metal hard tube is replaced, and the situation that a cut surface is burned and worn is avoided.

Owner:HEBEI UNIV OF TECH

High-strength tin-plated raw plate and manufacturing method thereof

The invention discloses a high-strength tin-plated raw plate and a manufacturing method thereof. The tin-plated raw plate comprises the following chemical components in percentage by weight: 0.08%-0.14% of C, 0.2%-0.5% of Mn, 0.03%-0.05% of Al, 0.01%-0.02% of P, 0.006%-0.015% of N and the balance Fe and Fe impurity elements, and the elements need to meet the following relationship simultaneously:50C+10Mn+50P+100N is not less than 8.5% and not greater than 12.75%. According to the manufacturing method disclosed by the invention, a one-step cold rolling process is adopted, an annealing temperature T in a continuous annealing step is controlled to be not less than 550+5*10<4>*(C-0.08%)+5x10<3>*(Mn-0.20%) and not greater than 630+5*10<4>*(C-0.08%), the unit is DEG C, and the tin-plated raw plate with a yield strength of not less than 500MPa and an elongation of not less than 5% after bake-hardening can be manufactured; and the manufacturing method is applicable to produce products with requirements on formability, such as three-piece can bodies, easy-open caps and twist-off caps.

Owner:BAOSHAN IRON & STEEL CO LTD

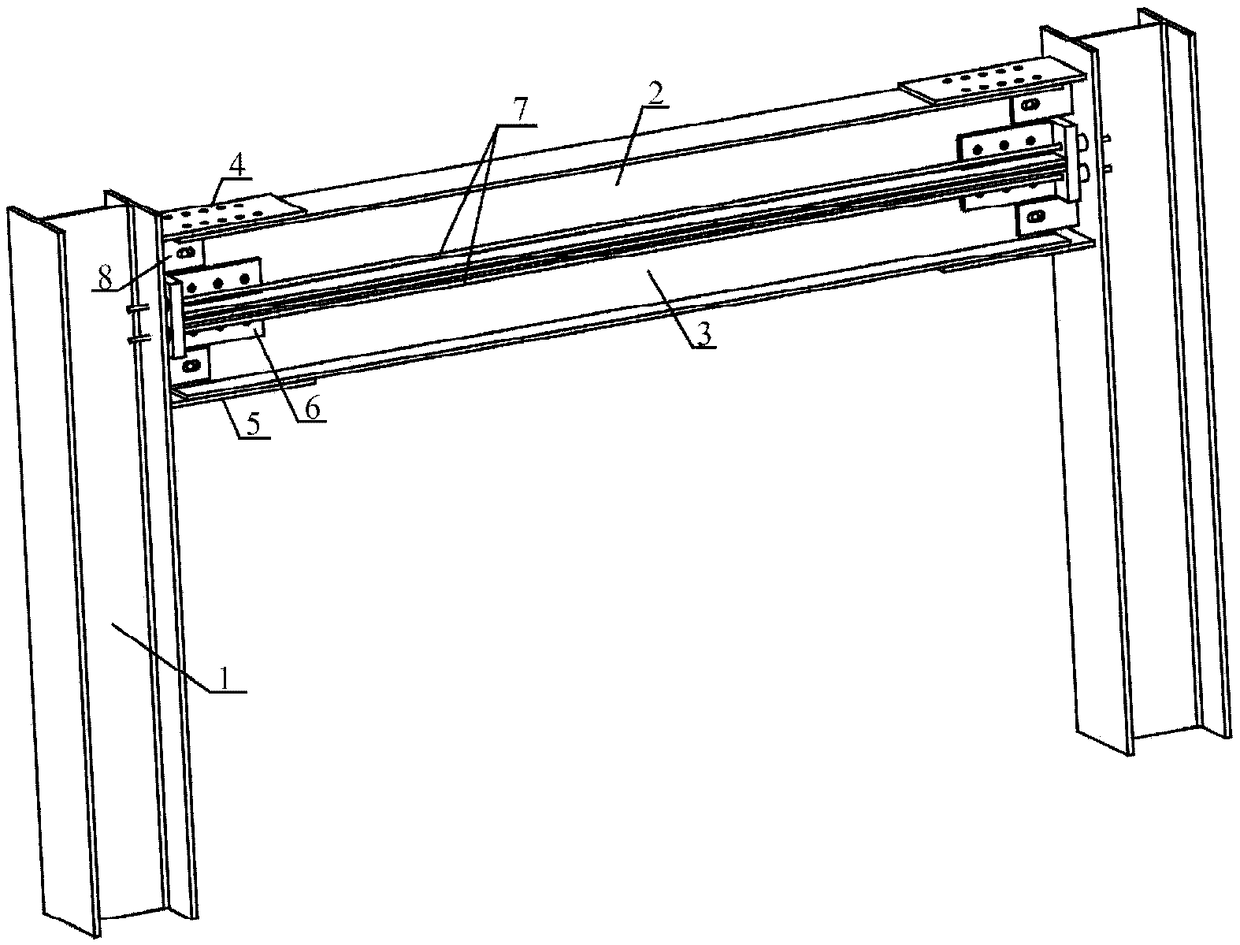

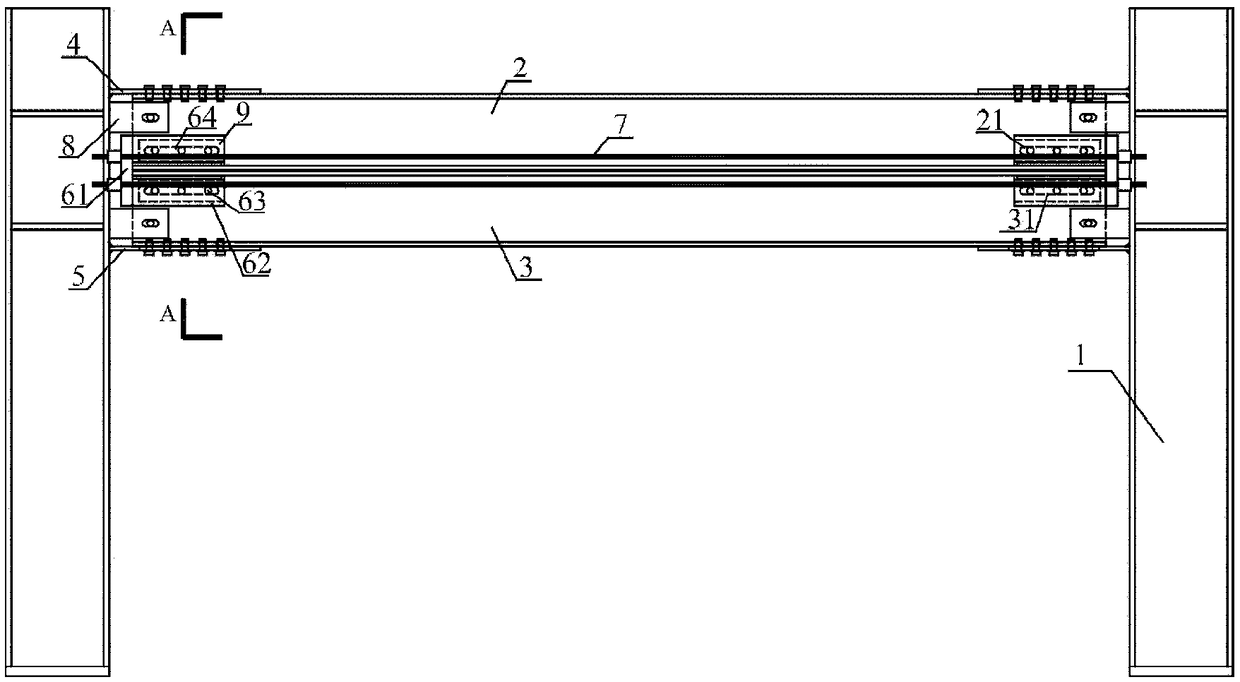

Detection mechanism for amorphous nanocrystalline iron core winding machine

ActiveCN113048866APrevent slippingNot easy to wearOther workshop equipmentMechanical roughness/irregularity measurementsWinding machineMarking out

A detection mechanism for an amorphous nanocrystalline iron core winding machine comprises an unwinding mechanism, two sets of flattening mechanisms, two sets of detection marking mechanisms, a winding mechanism and a rack. The flattening mechanisms are arranged side by side in a transverse direction, the detection marking mechanisms are symmetrically arranged in a longitudinal direction, and the unwinding mechanism, the detection marking mechanisms and the winding mechanism are sequentially arranged in the transverse direction. Each flattening mechanism comprises two flattening rollers arranged side by side in the vertical direction and a distance adjusting mechanism used for adjusting the distance between the two flattening rollers. The detection marking mechanism comprises a roller, a mounting shaft, a moving frame, an ink immersion box, ink absorption cotton, a marking pen point, a first sliding rod, a first elastic piece, a second sliding rod, a second elastic piece, a first connecting ring, a connecting rope, a second connecting ring, a fixing plate, a push rod, a sliding plate, a third elastic piece and an ink supply mechanism used for supplying ink to the ink absorption cotton. According to the invention, the flatness of the edge of an iron core steel strip can be rapidly and effectively detected, and corresponding marking is carried out.

Owner:深圳市普乐华科技有限公司

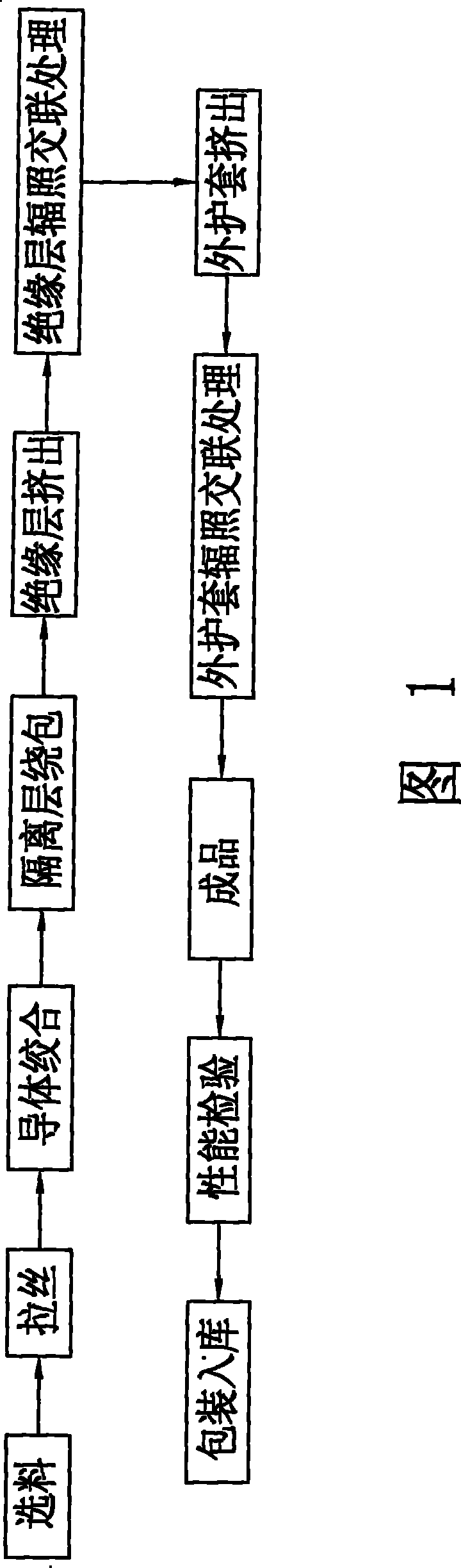

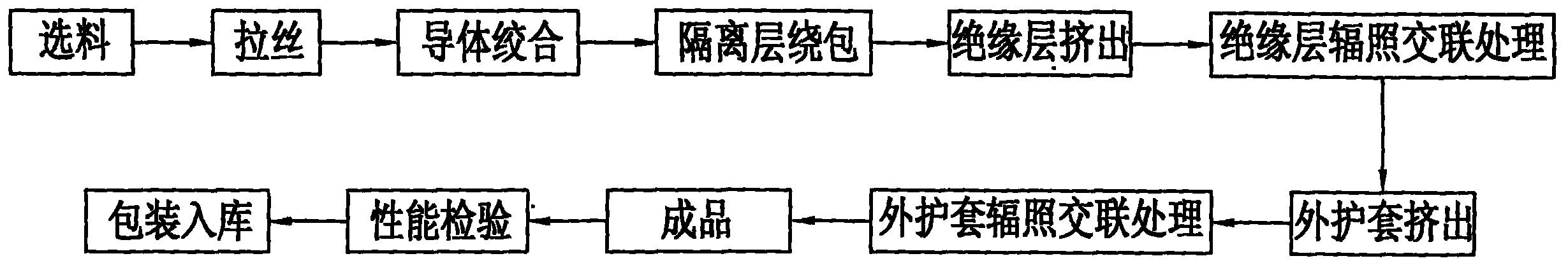

Production method of power cable for solar photovoltaic power generation assembly

ActiveCN101295562BGood weather resistanceHigh mechanical strengthInsulating conductors/cablesCross-linkInsulation layer

The invention discloses a manufacturing method for power cables used for solar energy photovoltaic power-generating equipment. The method is characterized in that the manufacturing process has the following steps: material selection, wire drawing, conductor twisting, isolated-layer wrapping, insulation-layer extrusion, insulation-layer radiation cross-linking processing, jacket extrusion, jacket radiation cross-linking processing and finished-product. The cable manufactured by the method has high weather resistance, high UV radiation resistance and high ozone corrosion resistance. Moreover, the resisted high temperature can reach 120 DEG C. The cable can resist atrocious weathers and mechanical impacts so as to dramatically enhance the safety and service life of the solar energy photovoltaic power-generating equipment.

Owner:SICHUAN MINGXING CABLE

Roasted hardened hot-dip galvanized steel plate with good shape and preparation method thereof

The invention belongs to the technical field of steel plate manufacturing, in particular to a hot-dip galvanized steel plate and a preparation method thereof. In order to solve the problems that the hot-dip galvanized steel plate prepared by an existing method is poor in mechanical property, is not good in extension property and the like, the invention provides the hot-dip galvanized steel plate and the preparation method thereof. The hot-dip galvanized steel plate is prepared from the following chemical components in percentage by weight: 0.04-0.08% of C, 0.01-0.04% of Si, 0.10-0.40% of Mn, less than or equal to 0.020% of P, less than or equal to 0.015% of S, 0.015-0.050% of Als, 0.0010-0.0040% of B and the balance of Fe and inevitable impurities. The preparation method for the hot-dip galvanized steel plate comprises the following steps: performing processes of smelting, hot rolling, acid rolling, hot-dip galvanizing and annealing on smelting molten steel, thereby obtaining the hot-dip galvanized steel plate. The hot-dip galvanized steel plate prepared by the preparation method has yield strength of 220-250 MPa, tensile strength of 320-380 MPa, elongation percentage greater thanor equal to 36.0%, n90 greater than or equal to 0.18, r90 greater than or equal to 1.5, BH greater than or equal to 30 MPa, and excellent mechanical properties and forming properties, and can meet using requirements of an automobile outer panel user.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Floor slab damage avoiding type double-beam self-resetting anti-seismic steel framework

InactiveCN108560709AFast constructionHigh initial stiffnessProtective buildings/sheltersShock proofingFloor slabStructural unit

The invention discloses a floor slab damage avoiding type double-beam self-resetting anti-seismic steel framework which comprises at least one structural unit. Each structural unit comprises two framework columns, an upper I-shaped steel beam and a lower I-shaped steel beam, wherein the upper I-shaped steel beam and the lower I-shaped steel beam are in vertically adjacent arrangement, two ends ofthe upper I-shaped steel beam are connected with the framework columns through upper flange steel plates, two ends of the lower I-shaped steel beam are connected with the framework columns through lower flange steel plates, a gap is reserved between the upper I-shaped steel beam and the lower I-shaped steel beam, two ends of the upper I-shaped steel beam and the lower I-shaped steel beam are connected into a whole through end limiting devices, pre-tensioning rods are anchored between the end limiting devices at two ends, shear connectors are arranged on webs of the upper I-shaped steel beam and the lower I-shaped steel beam, and ends of the shear connectors are welded to the framework columns. The floor slab damage avoiding type double-beam self-resetting anti-seismic steel framework has advantages that self resetting of steel structures in small earthquakes and intermediate earthquakes can be realized, structural damages in severe earthquakes are avoided, floor slab pull cracks are avoided due to a self-resetting mechanism, and accordingly post-earthquake economic loss is effectively reduced.

Owner:SOUTHEAST UNIV

Medium-carbon low-cost L245-L320-grade pipeline steel and manufacturing method thereof

The invention relates to medium-carbon low-cost L245-L320-grade pipeline steel and a manufacturing method thereof. The pipeline steel comprises the following chemical components by mass percent: 0.14 to 0.18% of C, 0.1 to 0.3% of Si, 0.5 to 0.7% of Mn, 0.005% or less of S, 0.015% or less of P and 0.02 to 0.06% of Al, and the balance being iron and unavoidable impurities. The technological process comprises the steps of KR, converter smelting, deoxidation alloying, CAS, LF, VD / RH, continuous casting, 48 hours of casting blank stacking and cooling, casting blank heating, scale removal, rough rolling, finish rolling, ACC, straightening, cooling, flaw detection, and marking and storage. According to the medium-carbon low-cost L245-L320-grade pipeline steel and the manufacturing method thereof, the content of carbon elements is increased, the utilization amounts of V, Ti and Nb are decreased, the alloy cost is effectively reduced, the fineness degree and uniformity of the structure of a product are improved, and the production flexibility of the manufacturing method is high.

Owner:SHANDONG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com