Production method of power cable for solar photovoltaic power generation assembly

A technology for solar photovoltaic and power generation equipment, which is applied in the manufacture of cables/conductors, insulation of conductors/cables, and circuits. The effect of lengthening rate, improving safety performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

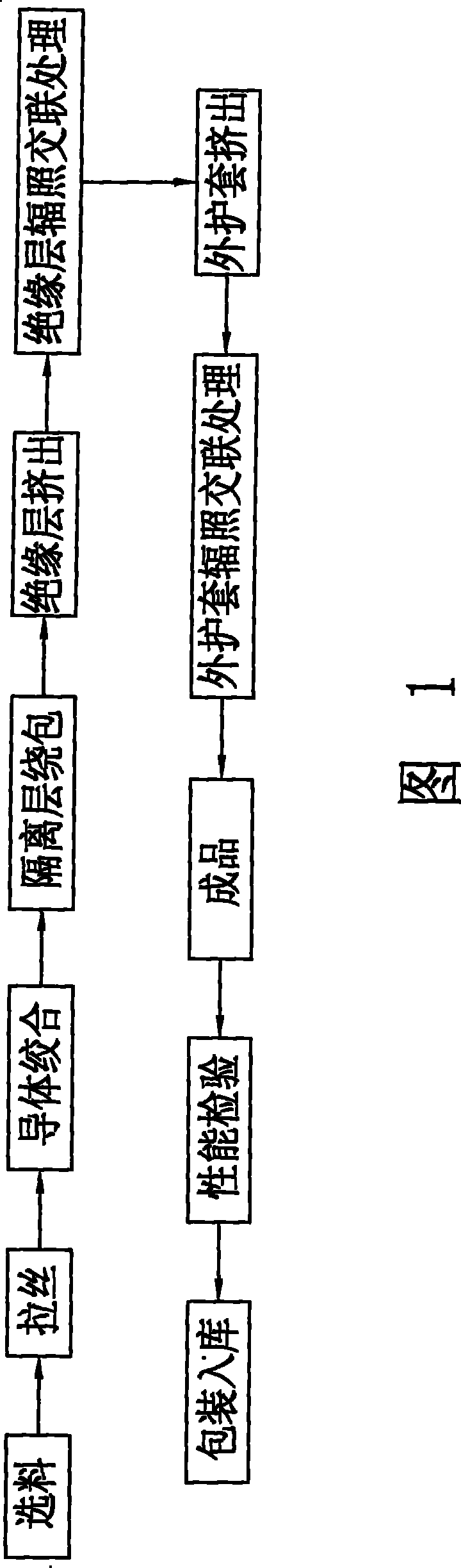

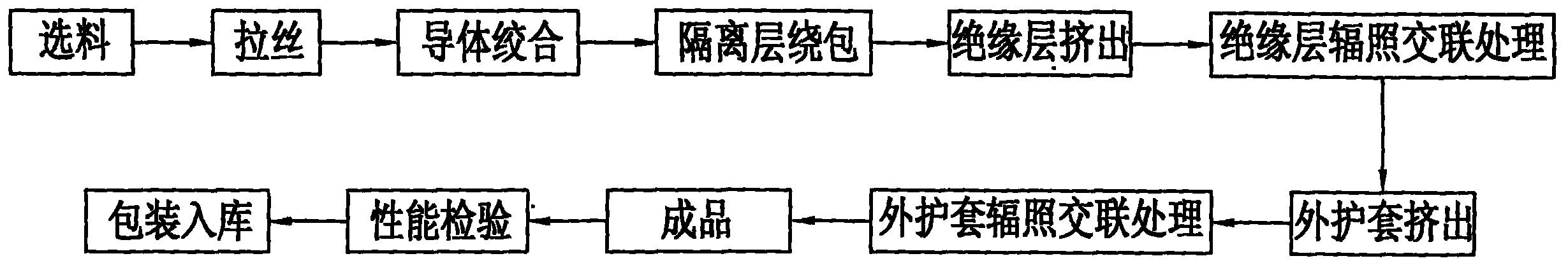

[0030] Referring to the accompanying drawings, the present invention discloses a method for manufacturing a power cable for solar photovoltaic power generation equipment. The manufacturing steps are as follows: material selection-wire drawing-conductor stranding-isolation layer wrapping-insulation layer extrusion-insulation layer irradiation alternating Joint processing - outer sheath extrusion - outer sheath irradiation crosslinking treatment - finished product;

[0031] Extrusion of insulating layer: Extrusion mold is used, and the screw with compression ratio of 1.25:1~2.0:1 is used to extrude low-smoke and halogen-free thermosetting polymer on the insulating layer to form an insulating layer. The processing temperature is controlled at 100-155°C. The actual size of the extrusion die sleeve is 2-3% mm smaller than the actual size of the traditional selection die sleeve;

[0032] Insulation layer radiation cross-linking treatment: radiation cross-linking treatment on the ins...

Embodiment 2

[0040] A method for manufacturing a power cable for solar photovoltaic power generation equipment, the manufacturing steps are as follows: material selection-wire drawing-conductor stranding-isolation layer wrapping-insulation layer extrusion-insulation layer radiation crosslinking treatment-outer sheath extrusion- Radiation cross-linking treatment of the outer sheath - finished product;

[0041] The conductor stranding step refers to stranding the multi-strand copper monofilaments formed after the wire drawing process at a stranding pitch that is 18 to 20 times the diameter of the stranding conductor to form a conductor.

[0042] Extrusion of insulating layer: Extrusion mold is used, and the screw with compression ratio of 1.25:1~2.0:1 is used to extrude low-smoke and halogen-free thermosetting polymer on the insulating layer to form an insulating layer. The processing temperature is controlled at 100-155°C. The actual size of the extrusion die sleeve is 2-3% mm smaller than ...

Embodiment 3

[0047] On the basis of Embodiment 1 or / and 2, the insulation layer wrapping means that the non-hygroscopic tape is evenly wrapped around the conductor made after the conductor stranding step to form an isolation layer, and the wrapping overlap ratio is 20 %, and form the cable core.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com