Flexible polyvinyl chloride (PVC) soft cable material

A polyvinyl chloride, flexible cable material technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of reducing the mechanical properties and processing properties of materials, poor compatibility, etc., achieve excellent elongation, enhance elastic properties, improve Effects of elongation and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

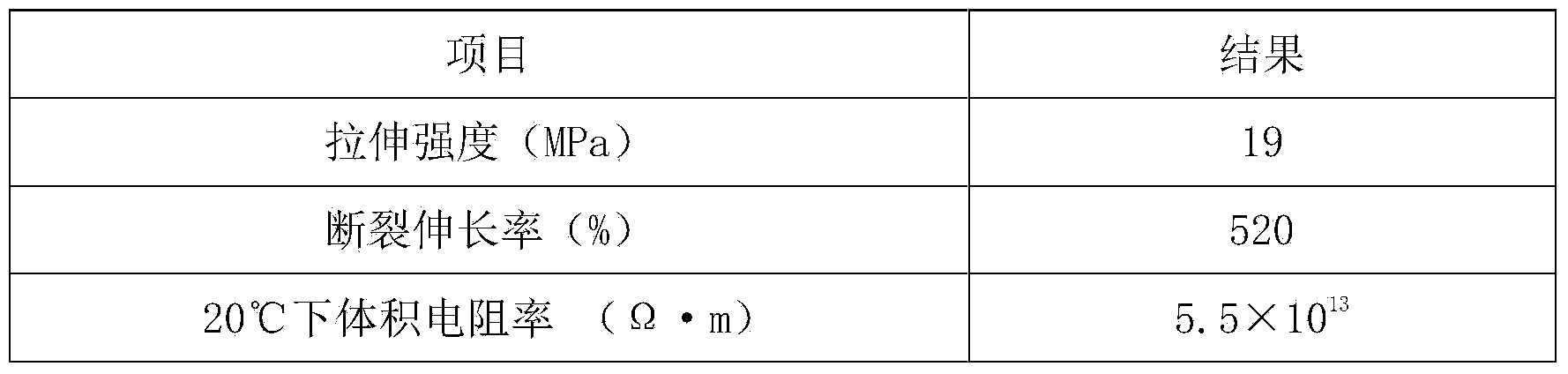

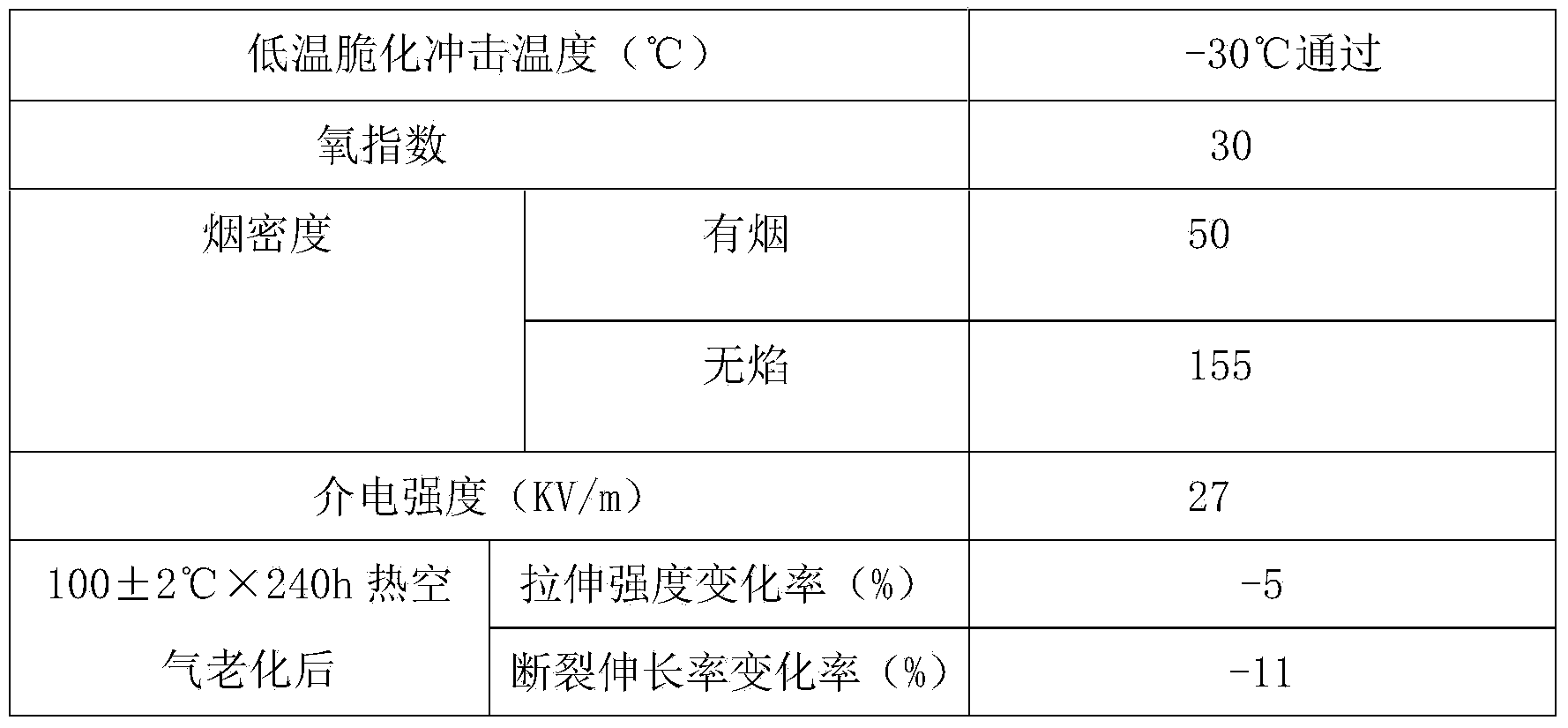

Examples

Embodiment Construction

[0017] A flexible polyvinyl chloride soft cable material, prepared from the following component raw materials in weight (kg):

[0018] PVC resin 58, polyester resin 25, silicone resin 16, precipitated silica 12, wollastonite powder 6, dolomite 5, bauxite 5, molybdenum disulfide 4, pentaerythritol 5, triphenyl phosphite 0.8, Antioxidant 10350.1, antioxidant 1680.2, ferrocene 0.3, stearic acid amide 0.2, zinc stearate 0.3, calcium stearate 0.2, barium stearate 0.3, benzyl silicone oil 0.2, modified filler 13,

[0019] Among them, the modified filler is prepared by the following method: a. Take the following raw materials in parts by weight: kaolin 188, medical stone 32, nano carbon 1-2, ascorbic acid 1, barley oil 1, aluminum nitride powder 2, glucose Zinc acid 3, jade powder 2, polyisobutylene 2, aluminate coupling agent DL-4111, stearic acid 2, antioxidant 10101;

[0020] b. Calcinate kaolin and medical stone at 450-480°C for 5-6h, cool to room temperature, take it out, add 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com