High-strength tin-plated raw plate and manufacturing method thereof

A manufacturing method and tin-plating technology, applied in the field of steel for packaging, can solve the problems of difficult large-scale stable industrial production and high steelmaking costs, and achieve large-scale stable industrial production, reduce steelmaking costs, and facilitate shape control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0056] Table 1 is the alloy composition of Examples 1-10 of the present invention and Comparative Examples 1-8, Table 2 is the manufacturing process parameters of Examples 1-10 of the present invention and Comparative Examples 1-8, and Table 3 is Examples 1-8 of the present invention 10 and comparative examples 1-8 performance after baking, note: the baking process of the steel plate is 210 ℃ for 30 minutes. The mechanical properties are measured according to the JIS5 standard processing tensile sample, Rp0.2 is the yield strength value based on the stress value of 0.2% residual deformation, A% is the elongation at break, and the measuring gauge length is 50mm.

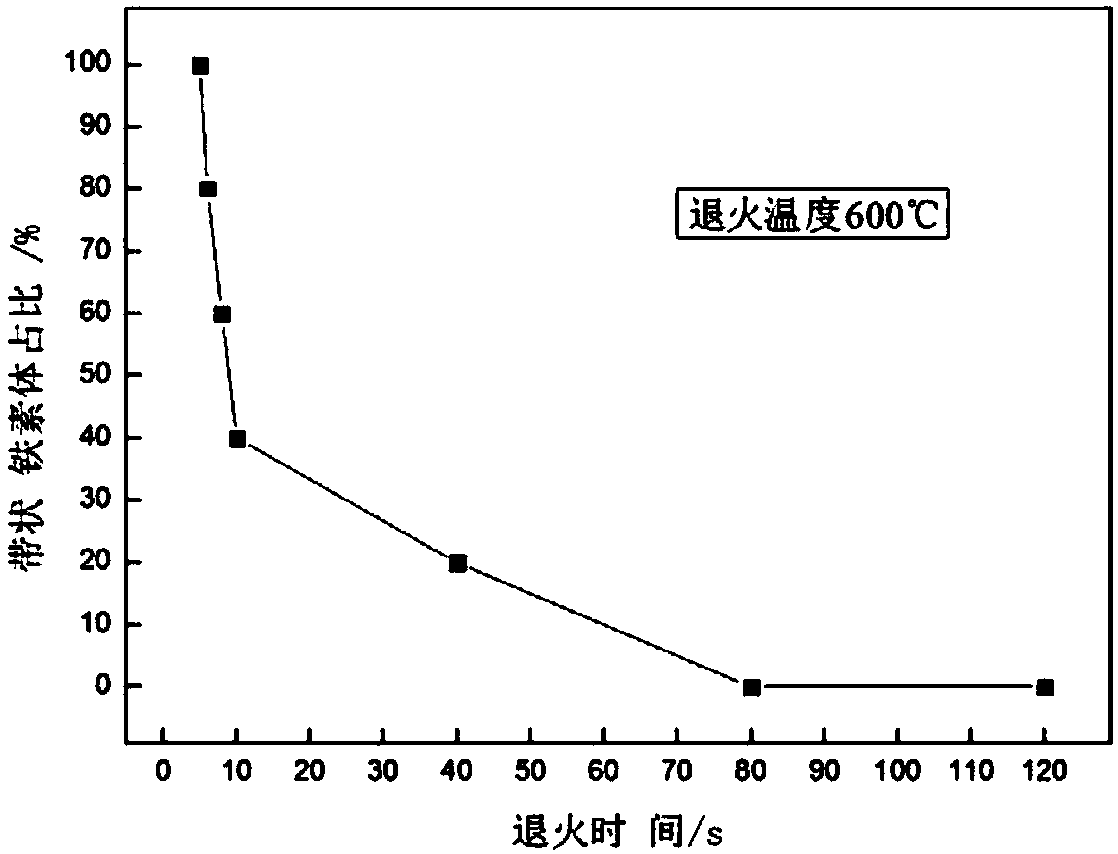

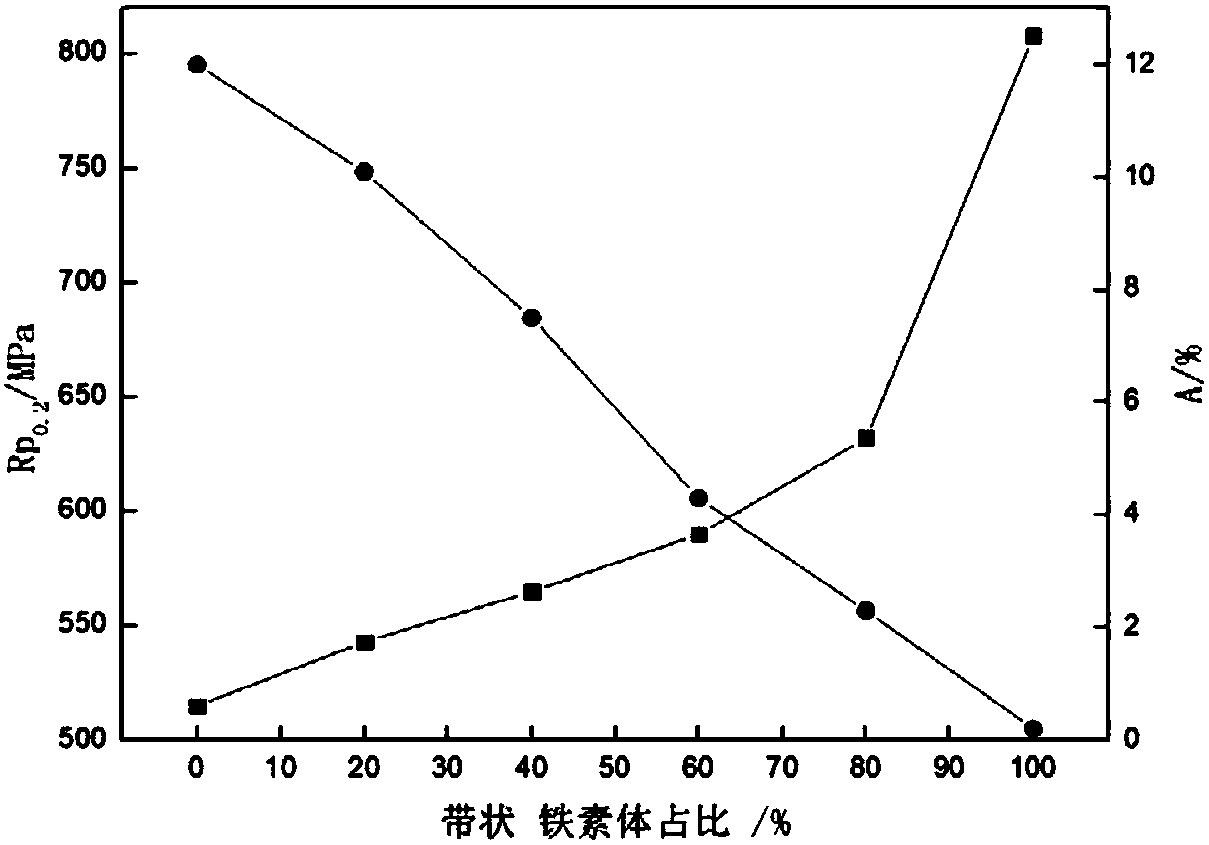

[0057] Depend on figure 1 It can be seen that with the prolongation of the annealing time of the strip steel, the degree of recrystallization of ferrite in the steel of the present invention g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com