Patents

Literature

129results about How to "Increase C4 content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

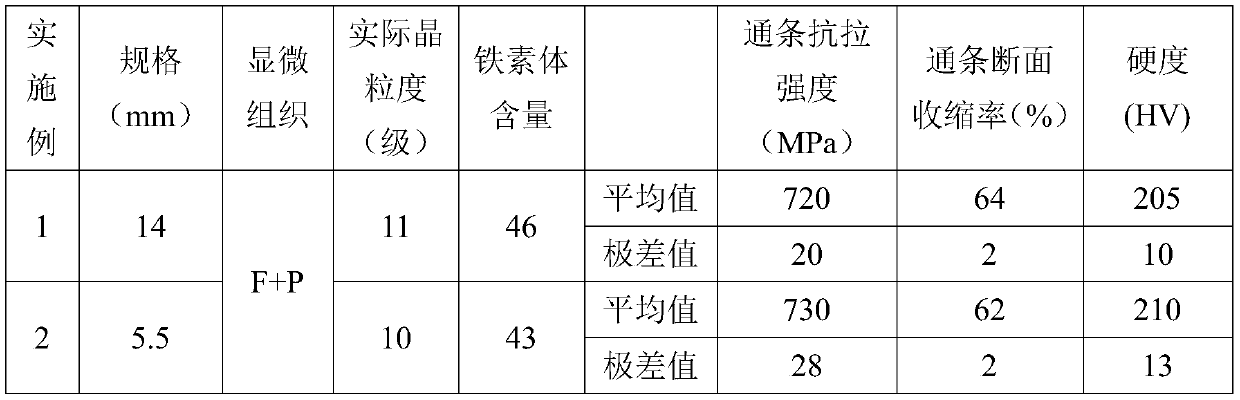

Coil rod for pre-stressed steel strand and production method of coil rod

The invention discloses a coil rod for a pre-stressed steel strand and a production method of the coil rod. The production method comprises the following steps: smelting in a rotary furnace; refining in an LF; continuously casting; heating; carrying out controlled rolling and controlled cooling. In the continuous casting step, a casting blank consists of the following chemical components in percentage by weight:0.78-0.82 percent of C, 0.20-0.25 percent of Si, 0.75-0.80 percent of Mn, 0.20-0.25 percent of Cr, smaller than or equal to 0.012 percent of P, smaller than or equal to 0.010 percent of S and 0.02-0.03 percent of V. The controlled rolling and controlled cooling step comprises steps of rolling, spinning, cooling and collecting and coiling; in the rolling step, the rolling temperature is 1000+ / -15 DEG C; the precision rolling temperature is 920 to 950 DEG C; in the spinning step, the spinning temperature is 860 to 880 DEG C. According to the method, based on optimization and control of the chemical components, by regulating and controlling the steel rolling process, the sorbite rate of the coil rod is increased, the interlamellar spacing of the sorbite is reduced, and generation of poor tissues is avoided, so that the coil rod has the characteristics of high intensity, high plasticity and low pole difference and satisfies the use requirement that the wire is not broken at a high-pulling speed; the pulling speed is increased; the wire breaking rate is reduced; therefore the production efficiency is improved to some degree.

Owner:宣化钢铁集团有限责任公司

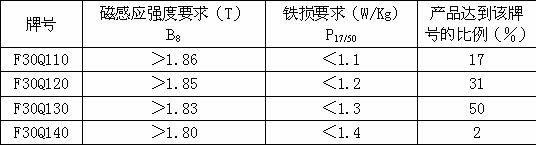

Full production process of low-temperature oriented silicon steel

The invention provides a full production process of a low-temperature oriented silicon steel, relates to the technical field of metallurgy, and aims at solving the technical problems of high slab heating temperature, short service life of a heating furnace, energy waste, low converter smelting designation hit rate of the oriented silicon steel due to narrow range of requirements on C and other chemical element contents, and the like of traditional cold-rolled oriented silicon steel. The full production process of the low-temperature oriented silicon steel comprises the following steps: molteniron pre-treatment, converter treatment, RH (Ruhrstahl-Heraeus) vacuum treatment, slab continuous casting, hot charging and hot delivery, slab heating, hot rolling, primary cold rolling, primary decarbonization and annealing, secondary cold rolling, low-temperature recovery annealing and magnesium oxide coating, high-temperature cover furnace annealing, stretching and insulating layer coating, aswell as slitting, packaging and storing to finally produce the low-temperature oriented silicon steel.

Owner:JIANGYOU FENGWEI NEW MATERIAL +2

Manufacturing method of medium-carbon CrMo steel wire rod free of annealing and drawing

ActiveCN110004376AImprove purityImprove internal qualityTemperature control deviceMetal rolling arrangementsHigh pressure waterHigh pressure

The invention relates to a manufacturing method of a medium-carbon CrMo steel wire rod free of annealing and drawing, and belongs to the field of wire rod production. Raw materials are prepared and smelted according to chemical compositions, and KR hot metal pretreatment, converter smelting, LF and RH refining, steel blank machining, warm supply or heat supply, steel blank heating and cogging, middle blank surface clearing, reheating, high-pressure water descaling, rolling control and temperature control, cooling control and wire rod forming are carried out in sequence. Rolling comprises roughrolling, medium finish rolling and reducing and sizing. In the medium finish rolling process, in the later period, rolled parts are subjected to water cooling to be below phase change temperature, and the compression ratio of the last two passes is set to be larger than or equal to 35%; coils are slowly cooled online; and the roller speed is constant, a heat preservation cover is closed for heatpreservation, and the rolled parts are discharged out of the cover to be subjected to air cooling to room temperature. The wire rod needs no annealing before drawing, large-draft drawing can be directly carried out, the production cost is reduced, and energy saving and environment protection are achieved.

Owner:JIANGYIN XINGCHENG GOLD MATERIALS CO LTD +1

Preparation method of high-carbon hot-continuous-rolling acid-pickling steel strips for hot forming

The invention relates to a preparation method of high-carbon hot-continuous-rolling acid-pickling steel strips for hot forming, belongs to the technical field of preparation of acid-pickling steel strips, and aims at solving the technical problem of providing a low-cost preparation method of high-carbon hot-continuous-rolling acid-pickling steel strips for hot forming. According to the method, C and Mn serve as main elements, and the C content is increased; on the condition that alloy elements such as Nb, Ti, V, B, Mo, La and Cr are not added, on the premise of ensuring steel purity and chemical component uniformity of a cast blank by controlling the smelting procedure, and by means of reasonable rolling control and cooling control technological processes, hot-rolled steel plates which are moderate in strength and high in elongation rate are obtained, the hot-rolled steel plates are subjected to trimming, blanking and heating and then subjected to hot forming and hot treatment, and parts which are moderate in strength and high in ductility and toughness are obtained finally. The steel strips are widely applied to automotive structural parts and can replace part of hot-rolled and cold-rolled continuous annealing steel plates and steel strips which are high in alloy content and product cost and are used for high-strength automobile structures.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Production method of graphitized free-machining steel

The invention relates to a method for producing graphitized free-machining steel from intermediate-carbon manganese-silicon steel, intermediate-carbon manganese-silicon-aluminum steel and the like. The method comprises the following steps: heating casting blanks; maintaining the temperature; cooling to 1050-1150 DEG C; roughly rolling: controlling the reduction percentage of each gate to be 20-40%; cooling to 850-1000 DEG C; carrying out precision rolling according to 4-6 gates; cooling in air; quickly cooling in water to room temperature; heating the precision rolling plate and maintaining the temperature; and cooling in air or cooling in a furnace to room temperature. By controlling the state of C atoms in steel and C content of austenite before tempering based on a process route of low-temperature rolling, relaxation and phase change, quenching and graphitization tempering, the invention converts all C atoms in the steel into graphite in a short time (5h). In the graphitized free-machining steel produced by the method, graphite grains in the organization are small in size and are uniform in distribution.

Owner:武钢集团有限公司

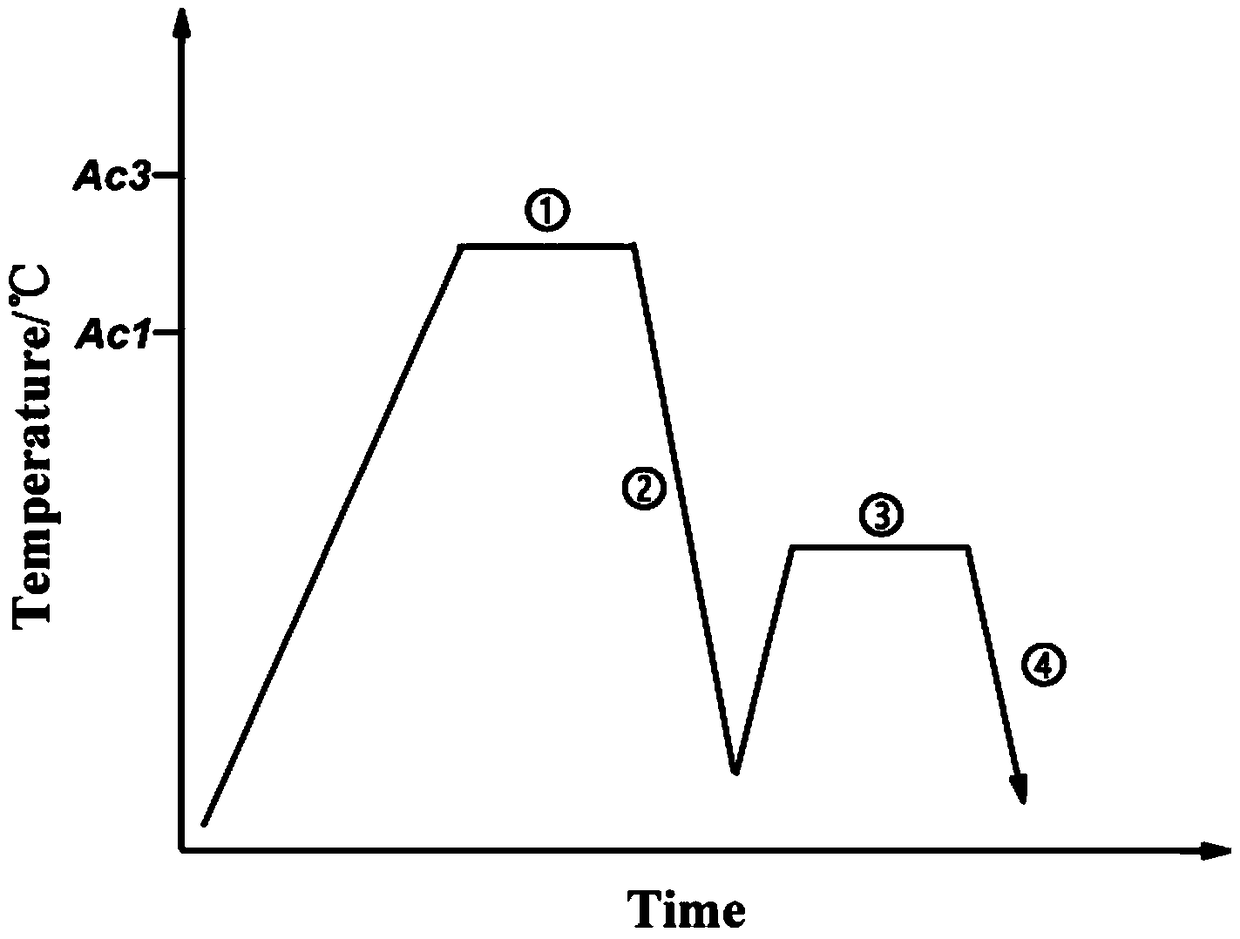

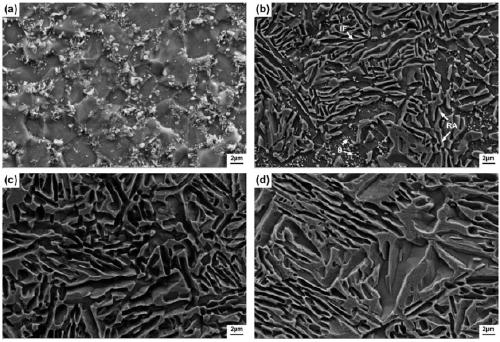

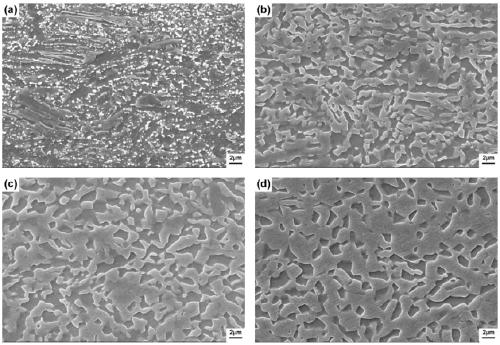

Ultrahigh-strength-toughness medium-manganese phase-change induced plasticity steel and preparation method thereof

The invention discloses an ultrahigh-strength-toughness medium-manganese phase-change induced plasticity steel and a preparation method thereof. The ultrahigh-strength-toughness medium-manganese phase-change induced plasticity steel comprises, by weight, 0.35%-0.36% of C, 4.5%-7.5% of Mn, 3.2% of Al, 0.07% of P, 0.03% of S and the balance Fe. The first preparation process comprises the following steps of smelting, forging and hot rolling, and a two-phase region annealing and low-temperature tempering process; and the second preparation process comprises the following steps of smelting and forging, hot rolling and cold rolling, and a two-phase region annealing and low-temperature tempering process, the stress can be eliminated by the low-temperature tempering process, and the austenite stability is improved. The heating treatment process which is simple and high in feasibility is utilized to obtain the high-toughness advanced steel type, product of strength and elongation can reach 75 GPa%, and the performance requirements of third-generation advanced high-strength steel are met; and meanwhile, according to the preparation method, the content of C (close to 0.4wt.%) is properly increased, and the purposes aim at improving the austenite content at room temperature and ensuring full proceeding of the TRIP effect through element distribution ; and a small amount of Mn and Al elements are added into the components, and other precious alloy elements are not added, so that the production cost is reduced.

Owner:SOUTHWEST JIAOTONG UNIV

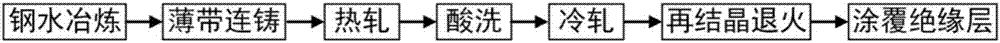

Method for preparing high-magnetic-strength non-oriented silicon steel thin products on basis of thin-strip casting

The invention belongs to the technical field of metallurgy, and particularly relates to a method for preparing high-magnetic-strength non-oriented silicon steel thin products on the basis of thin-strip casting. The method comprises the following steps: (1) smelting molten steel according to set ingredients, wherein the molten steel comprises the following ingredients in percentages by mass: less than or equal to 0.003% of C, 2.0-3.5% of Si, less than or equal to 0.01% of Mn, less than or equal to 0.003% of Al, 0.02-0.06% of P, less than or equal to 0.003% of S, and the balance of Fe and inevitable impurities; (2) carrying out thin-strip casting to obtain a cast strip; (3) carrying out hot rolling under the condition of an inert atmosphere; (4) reeling the cast strip after the cast strip is cooled to the temperature of 650 DEG C, removing iron oxide scale and then carrying out single-stage multi-pass cold rolling; and (5) carrying out continuous annealing on the cold rolled strip, coating the cold rolled strip with an insulating layer and then drying the insulating layer to obtain the high-performance non-oriented silicon steel thin products. The method is based on a thin-strip casting technology, the process is simplified, the production cost is reduced, and the magnetic performance of the non-oriented silicon steel thin finished products is improved.

Owner:NORTHEASTERN UNIV

Low-carbon ferrite soft magnetic stainless steel and production method thereof

The invention relates to low-carbon ferrite soft magnetic stainless steel and a production method thereof. The steel is prepared from, by mass, smaller than or equal to 0.03% of C, 2.5%-3.5% of Si, smaller than or equal to 0.5% of Mn, smaller than 0.03% of P, smaller than 0.03% of S, 13.5%-15.0% of Cr, smaller than or equal to 0.6% of Ni, 0.2%-0.7% of Mo, smaller than or equal to 0.15% of V, smaller than or equal to 0.1% of Ti, smaller than 0.020% of N and the balance Fe and unavoidable impurity elements. The production method comprises the steps of molten iron dephosphorization, AOD furnace smelting, LF furnace refining and continuous casting. The stainless steel has good corrosion resisting performance, the using category of soft magnetic products is greatly widened, and pollution, caused by frequent processing, to the environment is reduced. In the ferrite stainless steel, the C content is further decreased, the content of Si element is increased, the welding performance and soft magnetic performance of materials are improved, and the low-carbon ferrite soft magnetic stainless steel is used for making vehicle ABS controls and solenoid valve components in household appliances.

Owner:XINGTAI IRON & STEEL

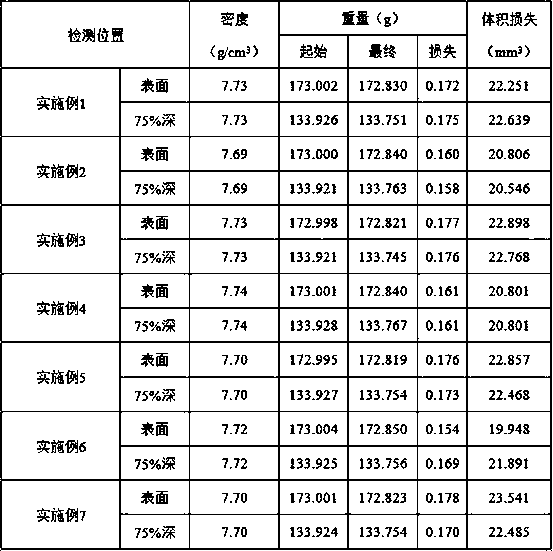

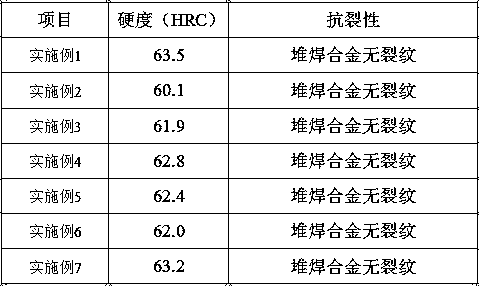

Wear-resistant welding wire and preparation method thereof

InactiveCN108907501AGuarantee the quality of welding wireSave resourcesWelding/cutting media/materialsSoldering mediaNiobiumWear resistant

The invention relates to the technical field of metal welding materials, in particular to a wear-resistant welding wire. The wear-resistant welding wire comprises, by weight, 10.00%-40.00% chromium, 3.00%-8.00% carbon, 0.50%-4.00% manganese, 0.40%-3.50% silicon, 0.10%-2.50% boron, 0.10%-2.00% vanadium, 0.05%-0.50% nickel, 0.20%-1.00% niobium, 0.10%-0.50% molybdenum and the balance iron. Accordingto the wear-resistant welding wire, defects that the traditional welding wire is high in cost and low in wear resistance are overcame; a small amount of vanadium with low cost is added, and the alloying of the wear-resistant welding wire is facilitated; the C content is improved, the wear resistance of the welding wire is improved, and the wear resistance of the surfacing alloy is improved. The invention further provides a preparation method of the wear-resistant welding wire, primary mixing and deep mixing are carried out, the wear resistance of the surfacing alloy is improved, and the service life is prolonged.

Owner:天津沃盾耐磨材料有限公司

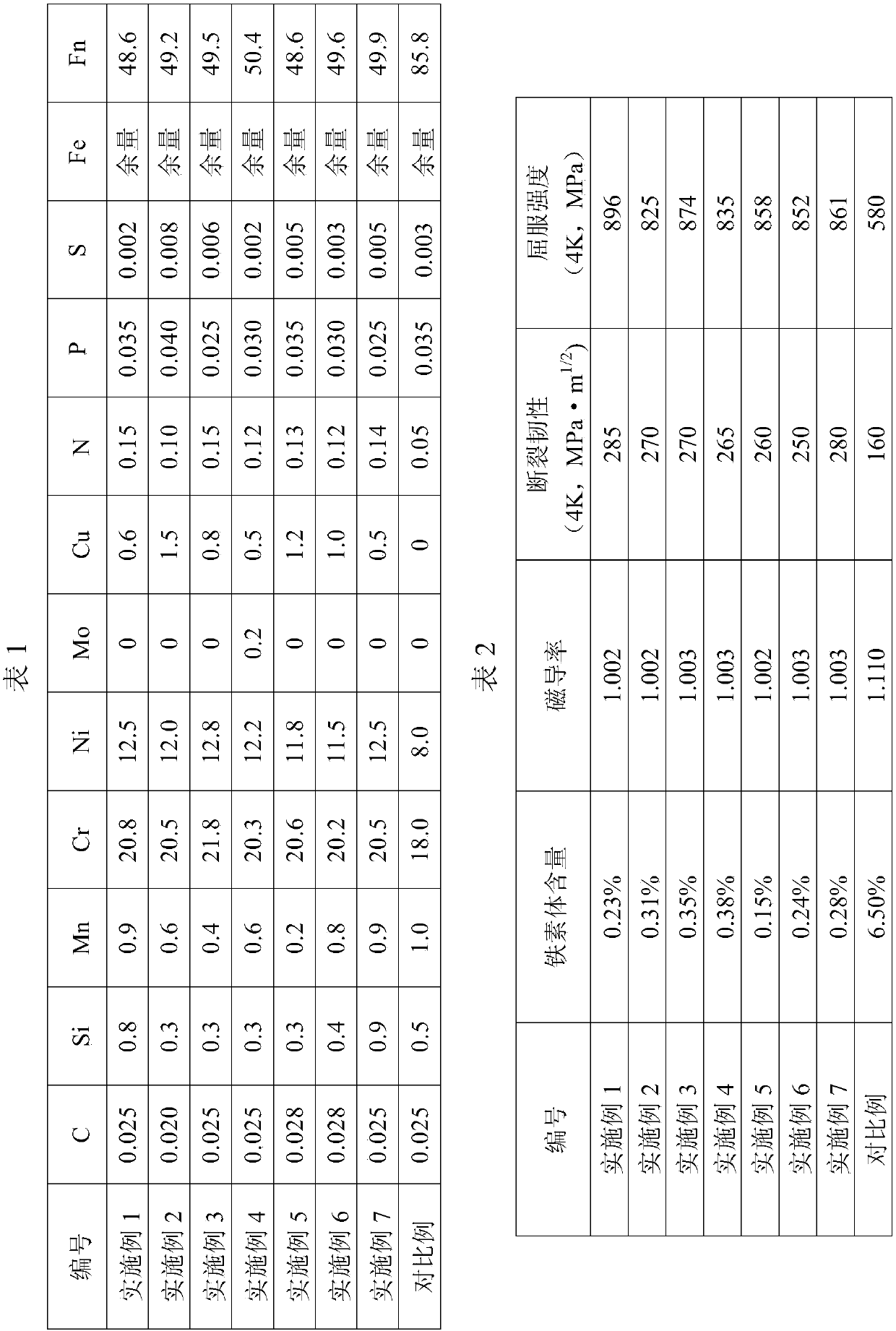

Austenitic stainless steel with excellent ultra-low temperature performance and manufacturing method thereof

ActiveCN109554608AReduced ferrite contentPrevent precipitationChemical compositionUltimate tensile strength

Provided are austenitic stainless steel with excellent ultra-low temperature performance and a manufacturing method thereof. Chemical composition weight percentage of the austenitic stainless steel isC <= 0.03%, Si 0.2 to 1.0%, and Mn 0.2 to 1. 0%, Cr 20.0 to 21.8%, Ni 11.5 to 12.8%, N 0.10 to 0.15%, Cu 0.5 to 1.5%, Mo <= 0.3%, P <= 0.04%, S <= 0.02%, the rest are Fe and inevitable impurities, Fn<51, and Fn=10Cr%+14Si+12Mo%-10Ni%-200N%-250C%-8Cu%-5Mn%. The ferrite content in the structure is < 0.5%. magnetic permeability of the austenitic stainless steel is < 1.01, fracture toughness propertyof 7K is > 200MPa.m1 / 2, and 7K yield strength is > 750MPa. The austenitic stainless steel can be used for nuclear power and superconducting and other industries which have special requirements on ultra-low temperature toughness and ultra-low temperature strength.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Sobering up tea and preparation method

InactiveCN1726797ARegulate immune functionImprove anti-agingTea substituesPlant ingredientsMedicineGLYCYRRHIZA EXTRACT

A sobering-up tea in the form of bag tea, beverage, tablet, infusion, or capsule is proportionally prepared from tea and 12 Chinese-medicinal materials including pueraria flower, gynostemma pentaphyllum, imperate rhizome, liquorice root, etc. Its preparing process is also disclosed.

Owner:郭行贤

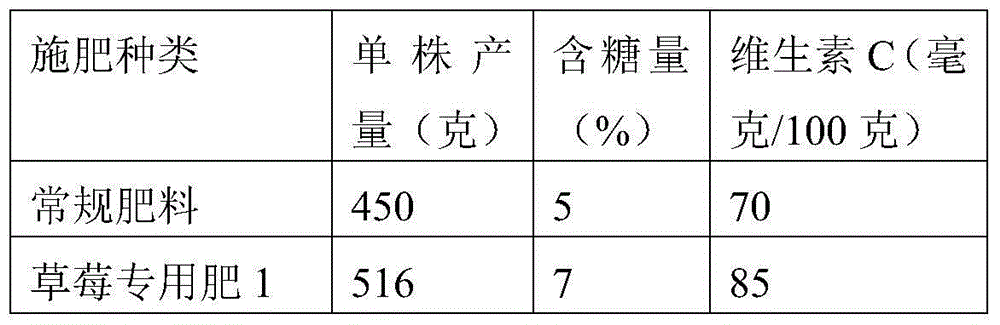

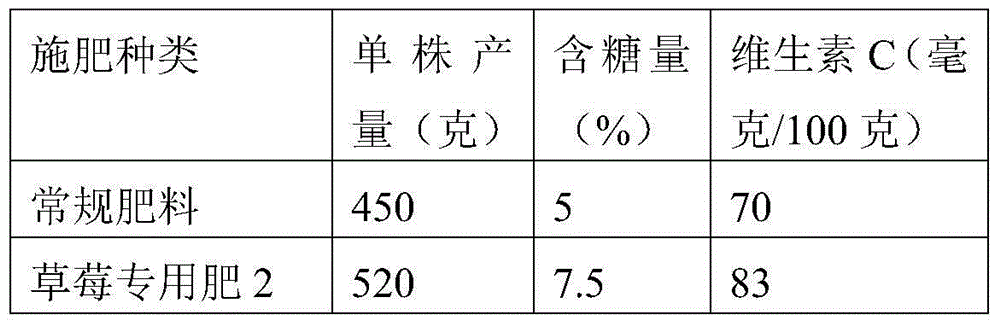

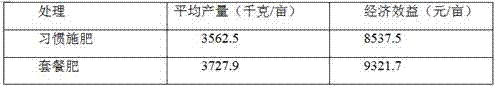

Special fertilizer for strawberries as well as preparation method and fertilizing method of fertilizer

InactiveCN104788164AImprove disease resistancePromote growthFertilising methodsFertilizer mixturesAmmonium Hydrogen CarbonateCopper sulfate

The invention relates to strawberry fertilization technologies and discloses a special fertilizer for strawberries. The fertilizer comprises the following components in parts by weight: 25.4-30.2 parts of urea, 20.1-23.3 parts of ammonium hydrogen carbonate, 11.4-13.6 parts of calcium superphosphate, 20.1-23.9 parts of potassium chloride, 8.5-11.4 parts of calcium nitrate, 0.8-1.0 part of magnesium sulfate, 0.6-0.8 parts of ethylenediamine ferric acetate, 0.38-0.57 parts of zinc oxide, 0.3-0.4 parts of manganese sulfate, 0.15-0.2 parts of copper sulfate, 0.1-0.18 parts of boric acid and 0.05-0.1 parts of ammonium molybdate. Compared with a conventional fertilizer, strawberries produced by using the special fertilizer for the strawberries are higher in yield, better in mouth feel and richer in nourishment.

Owner:苏州市新泾村农业基地专业合作社

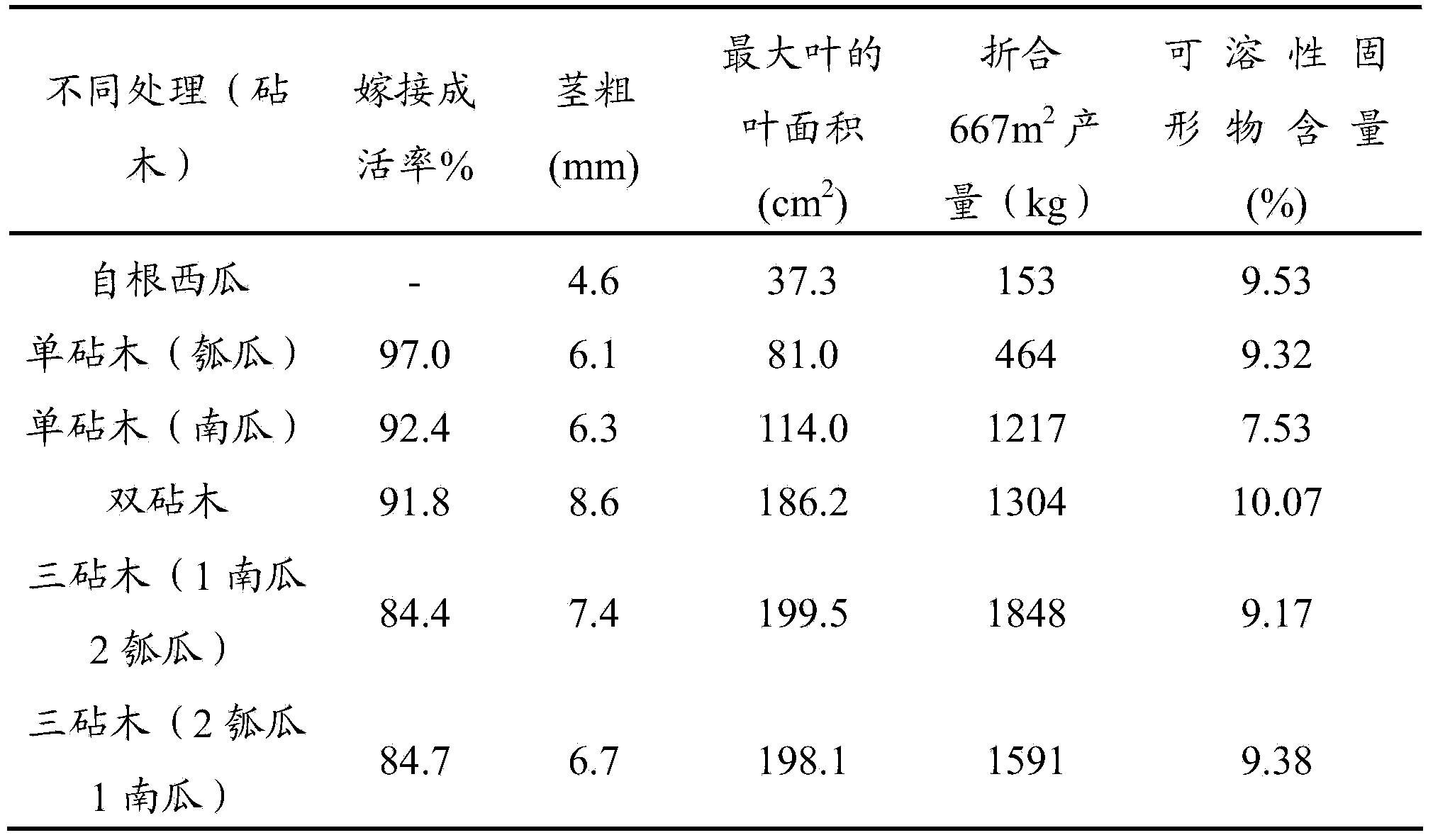

Multi-stock grafting method for watermelon plant

The invention provides a multi-stock grafting method for a watermelon plant. The multi-stock grafting method is characterized by comprising the following steps that a cotyledon with a growing point of both a pumpkin stock and a bottle gourd stock is obliquely cut off to form a tangent plane; the portion below a cotyledon of a watermelon scion is obliquely cut to form two tangent planes; the tangent plane of the pumpkin stock and the tangent plane of the bottle gourd stock are attached to the two tangent planes of the watermelon scion in an alignment mode, and then a grafted seedling is obtained after fixing. According to the multi-stock grafting method for the watermelon plant, one watermelon scion is grafted to two or three stocks combined by the pumpkin stock and the bottle gourd stock at the same time, difference complementarity of different stocks is utilized, multi-stock grafting advantages are achieved, the watermelon plant obtained after grafting is stronger in growth potential, the watermelon quality is ensured, and meanwhile the watermelon output is improved. In addition, the attaching connection method is adopted, one watermelon scion is grafted to two or three stocks at the same time, the operation steps are simple, and the requirement for the technical difficulty level is low.

Owner:SICHUAN AGRI UNIV

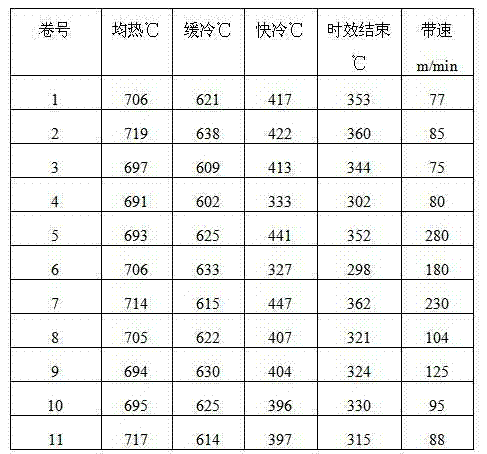

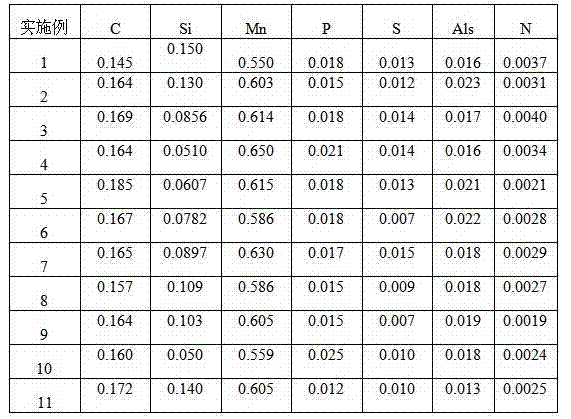

Continuous annealing production method for steel for 280 MPa vehicle structure

InactiveCN102758071AGood toughness matchLow costProcess efficiency improvementChemical compositionSmelting process

The invention relates to a continuous annealing production method for steel for a 280 MPa vehicle structure, belonging to the technical field of the production of metallurgical plates. The technical scheme comprises smelting, hot rolling, cold rolling and continuous annealing processes. The final chemical composition comprises the following components in percentage by mass: 0.145% to 0.185% of C, 0.05% to 0.15% of Si, 0.55% to 0.65% of Mn, less than or equal to 0.025% of P, less than or equal to 0.015% of S, 0.013% to 0.023% of Als, less than or equal to 0.004% of N, and Fe in balancing amount. In the smelting process, the blowing endpoint of a converter requires that: C is less than or equal to 0.10%, P is less than 0.015% and S is less than or equal to 0.035%. According to the continuous annealing production method, no microalloy element is added; the C content is increased by controlling the steel-making process so as to improve the yield strength and reduce the content of Si, Mn and P; the steel-making, hot rolling, cold rolling and continuous annealing processes are improved to produce the steel for the vehicle structure having a yield strength more than 280 MPa and an elongation of more than 30%; the obdurability is matched well; the cost is low; and the mechanical performance index of the finished product is as follows: the yield strength is about 300 MPa, the tensile strength is about 430 MPa, and the elongation is more than or equal to 30%.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

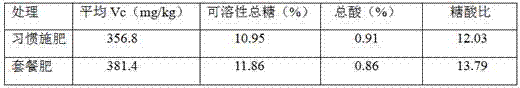

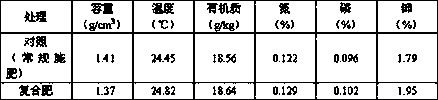

Honey pomelo sustained and controlled release decrement set meal fertilizer and application method thereof

InactiveCN107021863AMeet nutrient needsIncrease productionMagnesium fertilisersFertilising methodsNitro compoundVitamin C

The invention discloses a honey pomelo sustained and controlled release decrement set meal fertilizer which is prepared from a tip-prompting flower-strengthening fertilizer, a fruit-stabilizing fruit-strengthening fertilizer and a harvested fruit preservation fertilizer according to a mass ratio of 91:120:523. The tip-prompting flower-strengthening fertilizer is prepared from a 42% sulfur-containing sustained and controlled release composite fertilizer, a 46% nitro-compound fertilizer and borax according to a mass ratio of 77:22:1; the fruit-stabilizing fruit-strengthening fertilizer is prepared from a 45% sulfur-containing sustained and controlled release composite fertilizer, 46% nitro-compound fertilizer, a 58% water-soluble fertilizer and magnesium sulfate according to a mass ratio of 66.7:16.7:8.3:8.3; the harvested fruit preservation fertilizer is prepared from a 45% sulfur-based compound fertilizer, borax, zinc sulfate, a commercial organic fertilizer and calcium superphosphate according to a mass ratio of 15.3:0.19:0.38:76.48:7.65. The set meal fertilizer can simultaneously provide a sustained and controlled release nitrogen source and a rapid-acting nitrogen source, and meets requirements of honey pomelo for nutriment in different periods; yield of the honey pomelo can be improved, the benefits are increased, fertilizer application times are reduced, and content of vitamin C in the honey pomelo and a sugar-acid ratio are improved.

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI

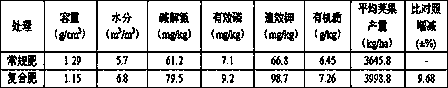

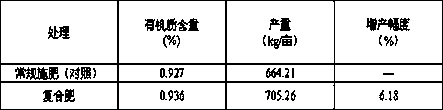

Long-acting soil-improving compound fertilizer and preparation method thereof

PendingCN108911861AAvoid burnsSimple structureAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersMicrobial agentPoultry manure

The invention relates to a long-acting soil-improving compound fertilizer and a preparation method thereof. The long-acting soil-improving compound fertilizer comprises the following raw-material ingredients in parts by weight: 40-60 parts of organic-inorganic composite carbon materials, 20-30 parts of livestock and poultry manure carbide, 0.05-0.1 part of a microbial agent, 5-10 parts of fermented soybean meal, 3-8 parts of fungus dregs, and 10-15 parts of a binding agent. The preparation method of the long-acting soil-improving compound fertilizer comprises the following steps: preparing theorganic-inorganic composite carbon materials and the livestock and poultry manure carbide; and solidifying microorganisms so as to prepare the compound fertilizer. The biochar in the long-acting soil-improving compound fertilizer prepared by the preparation technology and the specific microorganism solidification method has obvious ecological benefits in promoting crop yield increase, improving soil structure and fertilizing soil fertility; moreover, probiotics adopted for the long-acting soil-improving compound fertilize are capable of improving soil structure, enhancing soil fertility and promoting yield increase. The long-acting soil-improving compound fertilizer is ecological, safe and environmentally friendly.

Owner:SHENYANG AGRI UNIV

Fruit vitamin c production method

The invention provides a process for preparing a health food, in particular to a process for food called fruit vitamin C, which can maintain in most degree the vitamin C and other nutriment in fruit and is convenient for carry, preservation and edible. The invention comprises the following steps: peeling and kernel removing the fruit, juice extracting, vacuum condensing the juice in vacuum condensing tank under low temperature, adding various findings, stirring and granulating, drying with micro oven, pelleting, checking, packing and getting the product.

Owner:邱锦耀

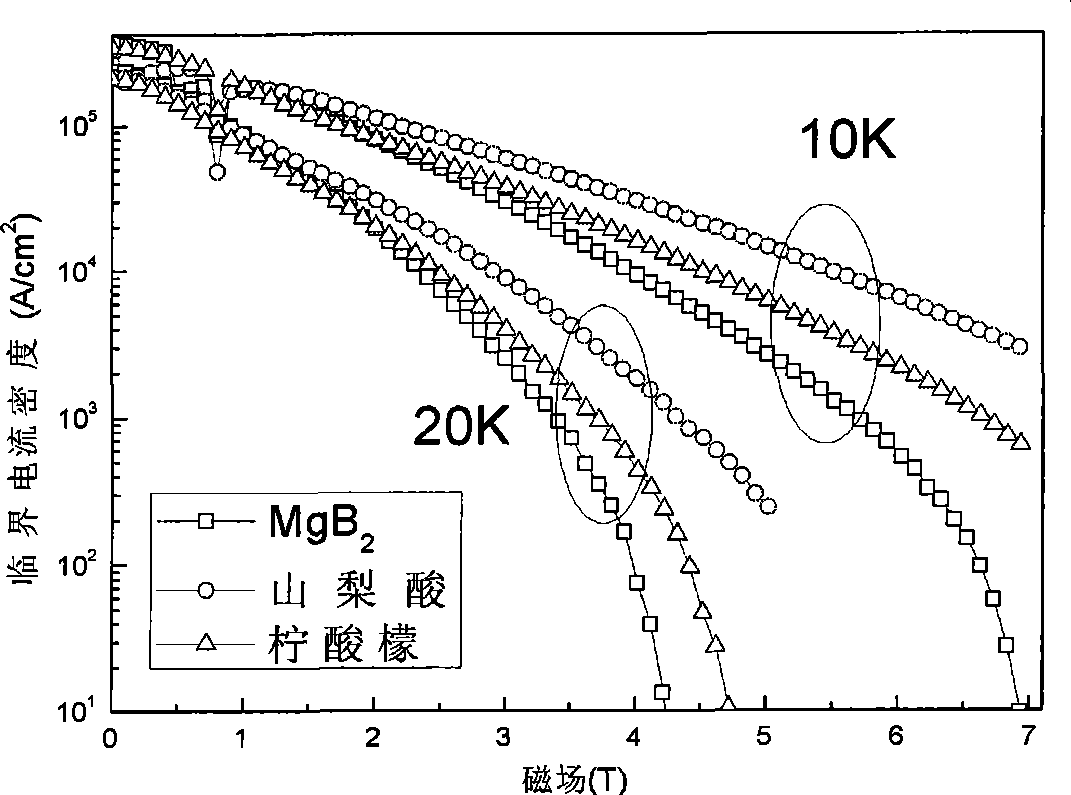

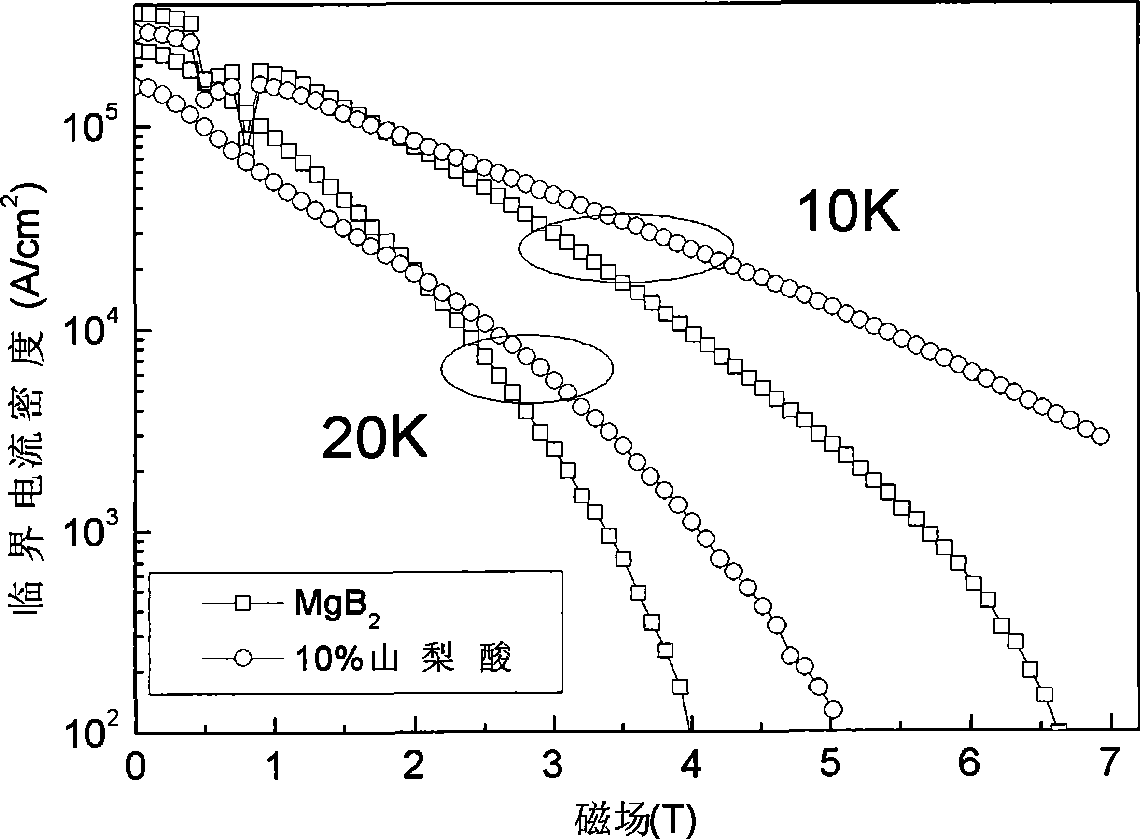

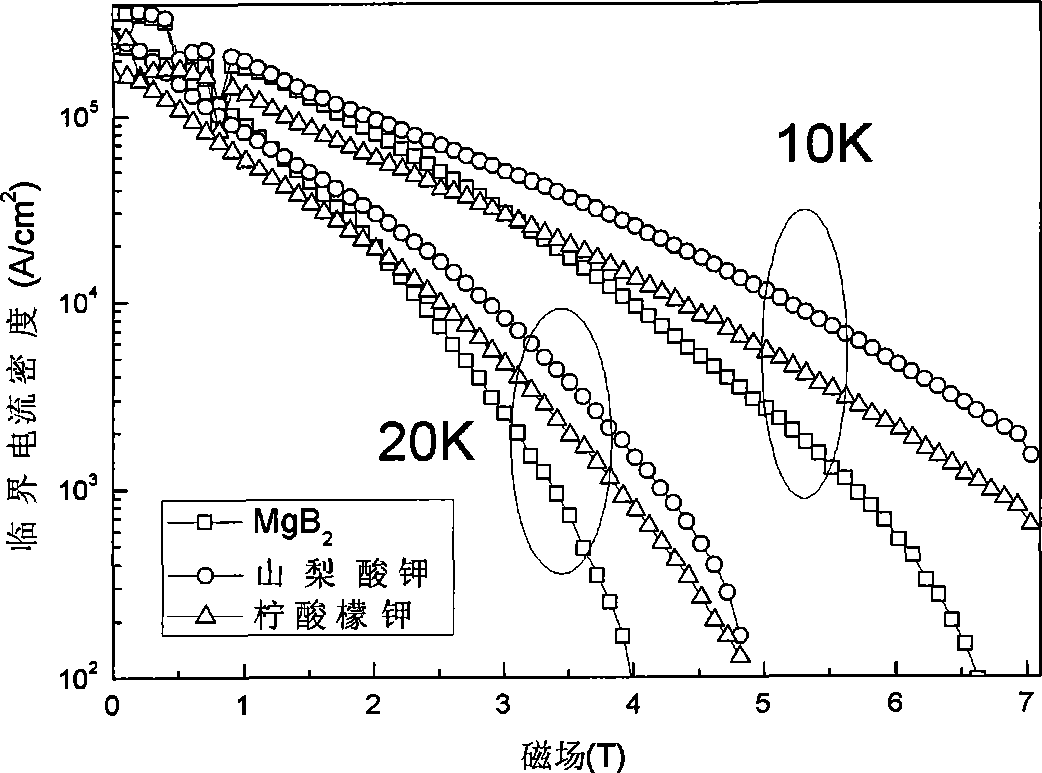

Preparation of magnesium boride doped superconduction material

InactiveCN101462881ALow reaction temperatureShorten the timeSuperconductors/hyperconductorsSuperconductor devicesDopantArgon atmosphere

A preparation method of a magnesium diboride-doped superconducting material comprises the following steps: respectively weighing magnesium powder and boron powder based on a mol ratio of 1:0.7-2.5; weighing a dopant based on the ratio of the total mass of the magnesium powder and the boron powder to the mass of the dopant of 1:0.01-1, wherein, the dopant is one of sorbic acid or sorbate; evenly mixing the magnesium powder, the boron powder and the dopant powder to obtain mixed powder; and sintering the mixed powder under the protection of argon atmosphere at the sintering temperature of 600 DEG C-1200 DEG C, and keeping the temperature for 0.5-12 hours, thus obtaining the superconducting material. The method has the advantages of short preparation time, low reaction temperature, high efficiency and low cost, and is especially suitable for industrialized production. The magnesium diboride superconducting material obtained by the method has obviously increased critical current density especially very high critical current density in a high magnetic field, which is beneficial to the application of the superconducting material to the high magnetic field; and the superconducting material has strong practicability.

Owner:SOUTHWEST JIAOTONG UNIV

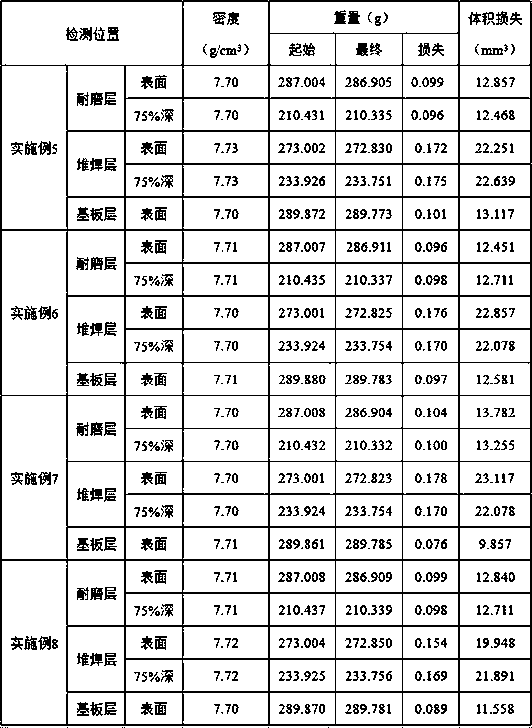

Impact-resistant abrasion-resistant composite steel plate

ActiveCN109082579APromote alloyingImprove wear resistanceWelding/cutting media/materialsSoldering mediaManganeseAlloy composite

The invention relates to the technical field of metal welding materials, in particular to an impact-resistant abrasion-resistant composite steel plate. The impact-resistant abrasion-resistant composite steel plate comprises a base plate layer and an abrasion-resistant layer, wherein the base plate layer is a common steel plate, and the abrasion-resistant layer is a high-strength alloy composite layer. The abrasion-resistant layer comprises, by weight, 25.00%-55.00% of chromium, 3.00%-8.00% of carbon, 0.50%-4.00% of manganese, 0.10%-3.00% of silicon, 0.25%-3.00% of nickel, 0.25%-3.00% of molybdenum, 0.10%-1.50% of vanadium, and the balance iron and inevitable impurities. The impact-resistant abrasion-resistant composite steel plate overcomes the defects that precious metal adding in a traditional abrasion-resistant layer is high and the abrasion resistance is low caused by low C content. By adding a small amount of vanadium with lower cost, the abrasion resistance of the abrasion-resistant layer is improved. According to the impact-resistant abrasion-resistant composite steel plate, the C content is increased within the range of components and proportions, but the abrasion-resistantlayer still has better toughness, so that the composite steel plate has better abrasion-resistant strength and toughness.

Owner:江苏沃盾耐磨新材料有限公司

Oyster peptide buccal tablet and preparation method thereof

PendingCN111227258AFully extractedPromote absorptionFood shapingAnimal proteins working-upBiotechnologyCordyceps militaris

The invention relates to the technical field of health-care products, specifically to an oyster peptide buccal tablet and a preparation method thereof. The oyster peptide buccal tablet comprises the following components in parts by weight: 10-20 parts of oyster peptide, 5-10 parts of cordyceps militaris, 1-5 parts of ginseng, 2-6 parts of rhizoma polygonati, 4-8 parts of sea buckthorn, 3-6 parts of mulberry, 2-6 parts of Chinese yam, 5-10 parts of Chinese wolfberry, 0.5-3 parts of taurine, 2-6 parts of a flavoring agent and 1-3 parts of an adhesive. The oyster peptide buccal tablet provided bythe invention is convenient to be carried and taken, and has more comprehensive effects. The preparation method for the oyster peptide buccal tablet comprises the following steps: pretreatment of auxiliary materials; mixing and granulating; drying and tabletting. According to the preparation method provided by the invention, substances of the oyster peptide buccal tablet can be more easily absorbed by the human body; and preparation is simple.

Owner:中科花鹿农业发展有限公司

Unfired Al2O3-Cr7C3 brick for hot metal ladle wall and preparation method thereof

ActiveCN105272320AReduce manufacturing costSimple preparation processSolid waste disposalBrickFerrochrome

The invention discloses an unfired Al2O3-Cr7C3 brick for a hot metal ladle wall and a preparation method thereof. The unfired Al2O3-Cr7C3 brick comprises aggregate and substrate materials, wherein the aggregate is prepared from, by weight, 55%-60% of ferrochrome slag particles, and the substrate materials are prepared from, by weight, 6%-8% of ferrochrome slag fine powder, 1%-3% of rho-Al2O3 fine powder and 32%-37% of Cr7C3 fine powder. The preparation method comprises the steps that according to the raw materials and the contents thereof, the substrate materials are mixed firstly, and the mixed substrate materials are added to the aggregate to be mixed for 5-8 min; thermosetting phenolic resin accounting for 4%-6% by weight of the raw materials and silica sol accounting for 1%-4% by weight of the raw materials are additionally added, mixing is conducted for 10-15 min, and mechanical pressing is conducted; maintenance is conducted for 10-12 h on the condition that the temperature ranges from 30 DEG C to 35 DEG C, heat preservation is conducted for 12-24 h on the condition that the temperature ranges from 200 DEG C to 220 DEG C, and the unfired Al2O3-Cr7C3 brick for the hot metal ladle wall is prepared. The unfired Al2O3-Cr7C3 brick for the hot metal ladle wall and the preparation method thereof have the advantages of being low in production cost and simple in technology, and the prepared unfired Al2O3-Cr7C3 brick for the hot metal ladle wall is high in density, strong in slag erosion resistance and good in heat-shock stability.

Owner:锦州集信高温材料有限公司

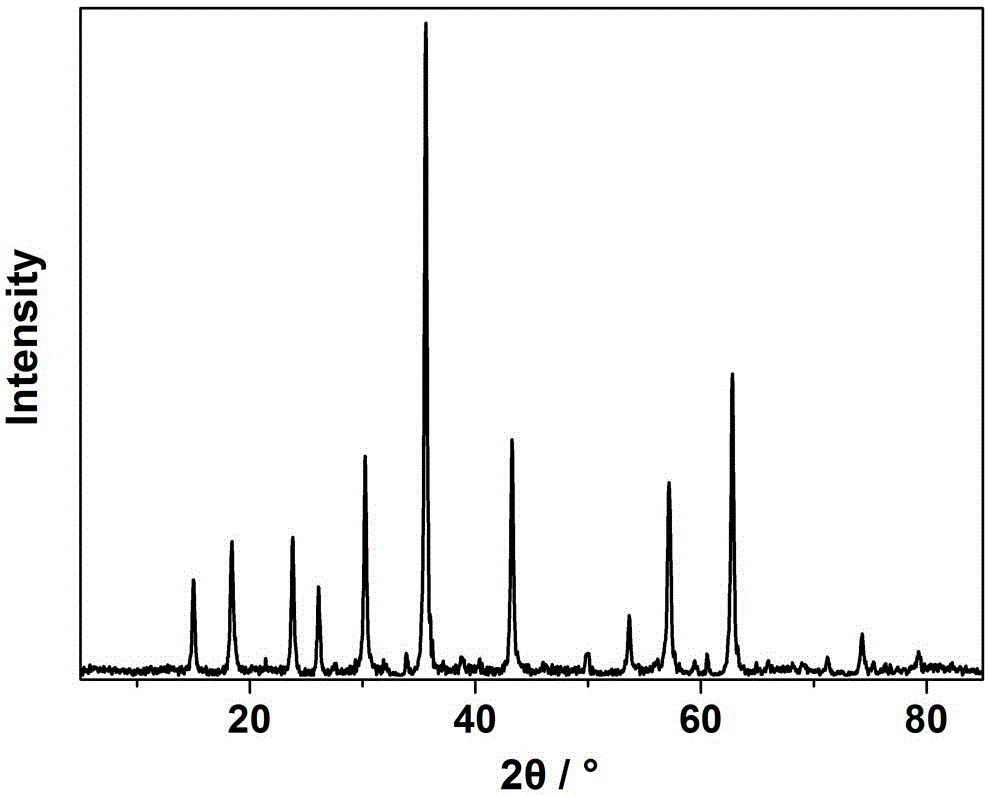

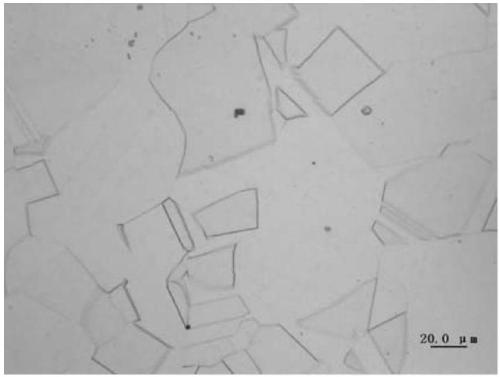

Cf/Hf[x]Zr[1-x]C-SiC composite material and preparation methods thereof

The invention discloses a Cf / Hf[x]Zr[1-x]C-SiC composite material and preparation methods thereof. The composite material comprises a carbon fiber fabricated part, an SiC substrate and an Hf[x]Zr[1-x]C substrate, wherein x is larger than 0 and smaller than 1, and the Hf[x]Zr[1-x]C substrate and the SiC substrate are uniformly filled in the holes of the carbon fiber fabricated part. One preparation method comprises the following steps that (1), a Cf / Hf[x]Zr[1-x]C blank is prepared; (2) the Cf / Hf[x]Zr[1-x]C-SiC composite material is prepared. The other preparation method comprises the following steps that (1), a Cf / Hf[x]Zr[1-x]C blank is prepared; (2) a Cf / Hf[x]Zr[1-x]C-C blank is prepared; (3) the Cf / Hf[x]Zr[1-x]C-SiC composite material is prepared. The Cf / Hf[x]Zr[1-x]C-SiC composite material has the advantages that the material is low in cost, ablative-resistant, excellent in mechanical property and oxidation resistance and the like, and at the same time, the preparation methods are simple, and the contents of the substrates are easy to control.

Owner:NAT UNIV OF DEFENSE TECH

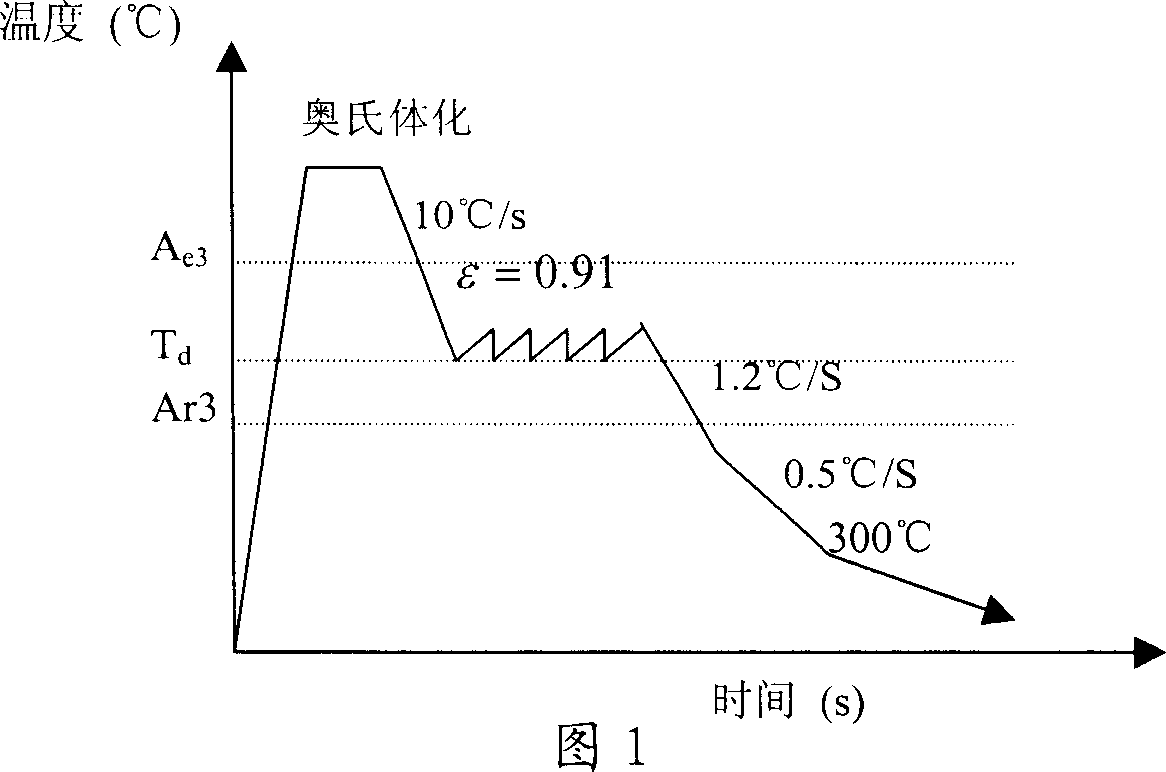

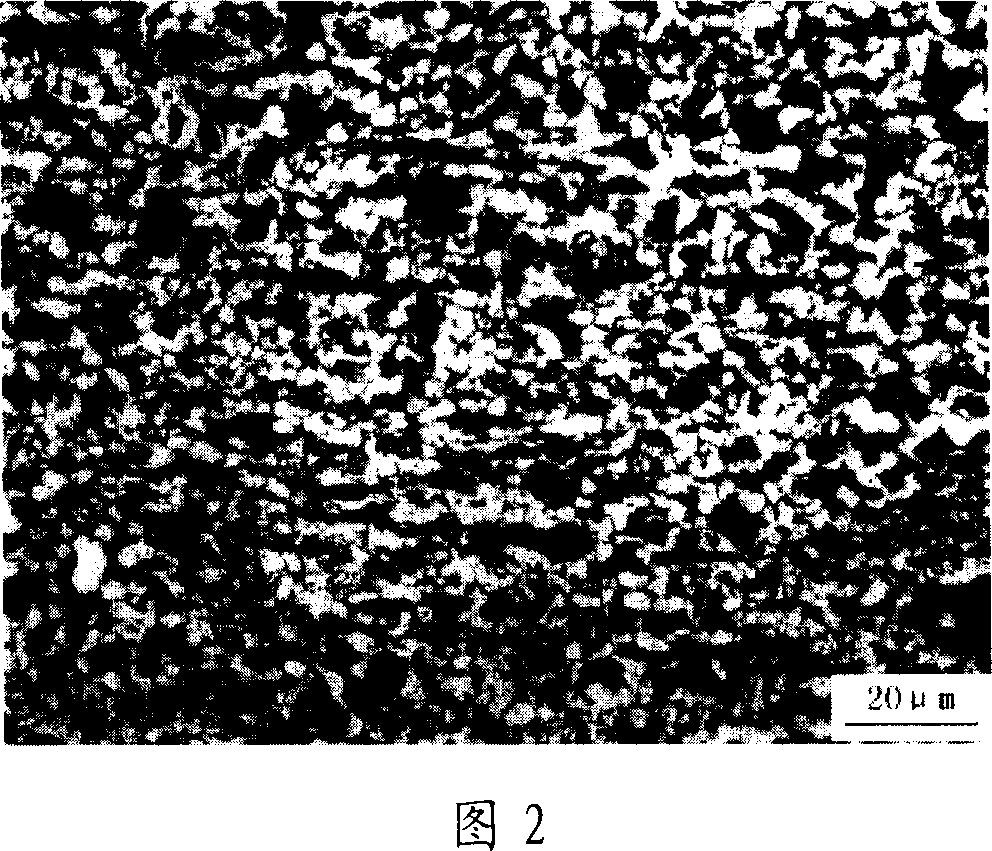

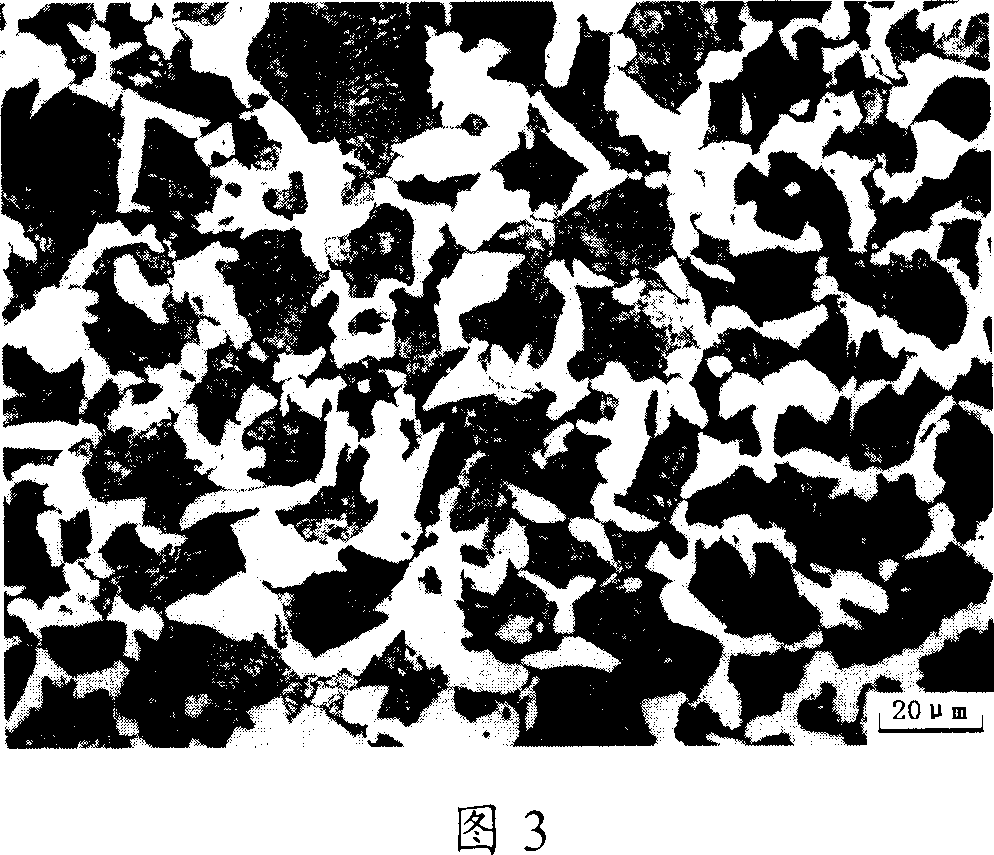

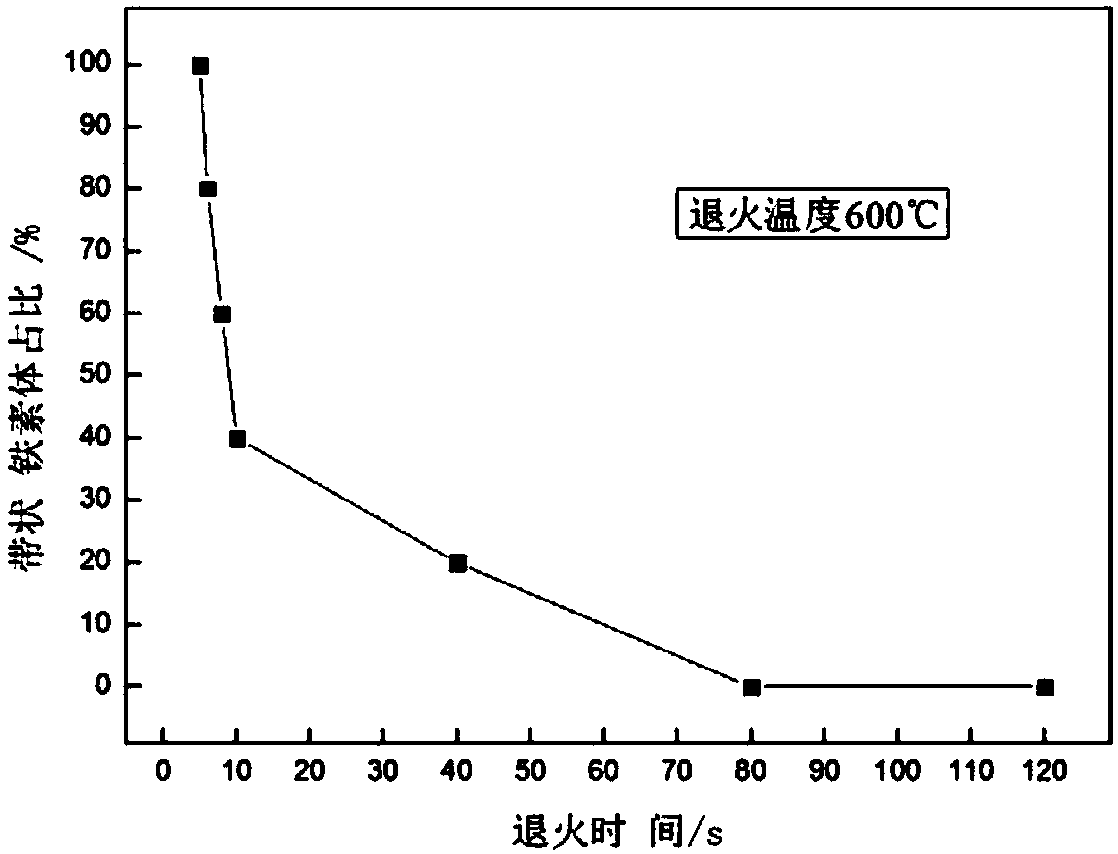

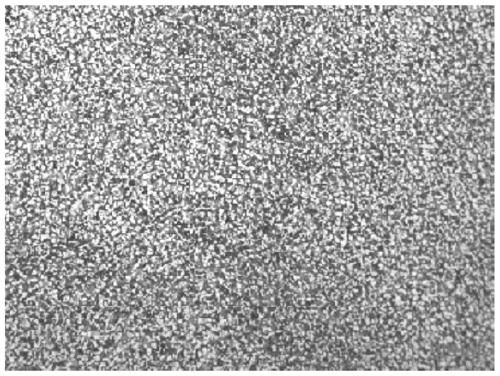

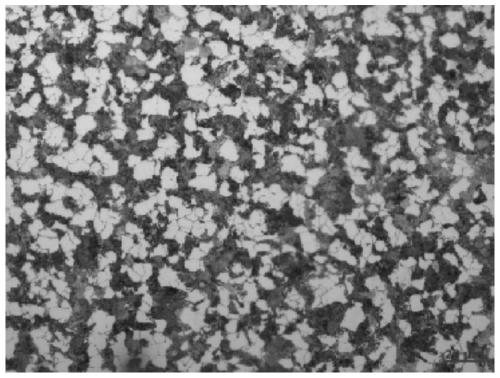

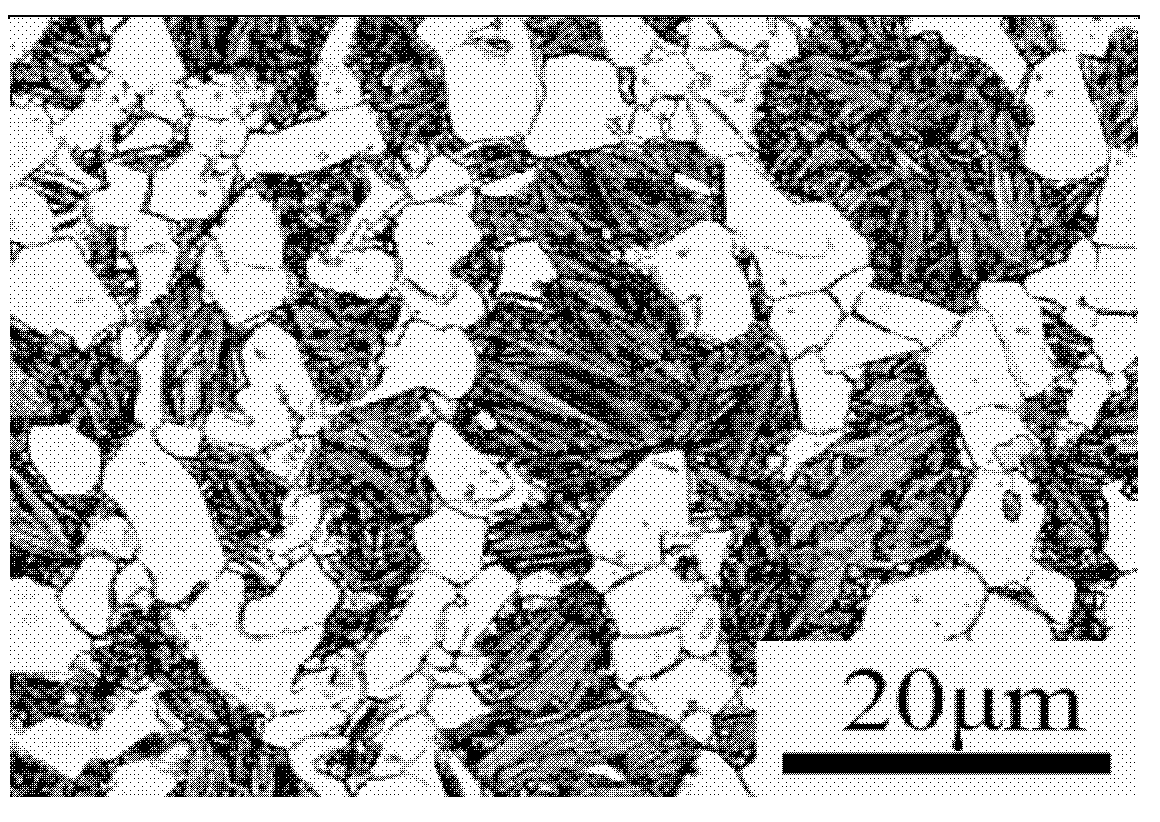

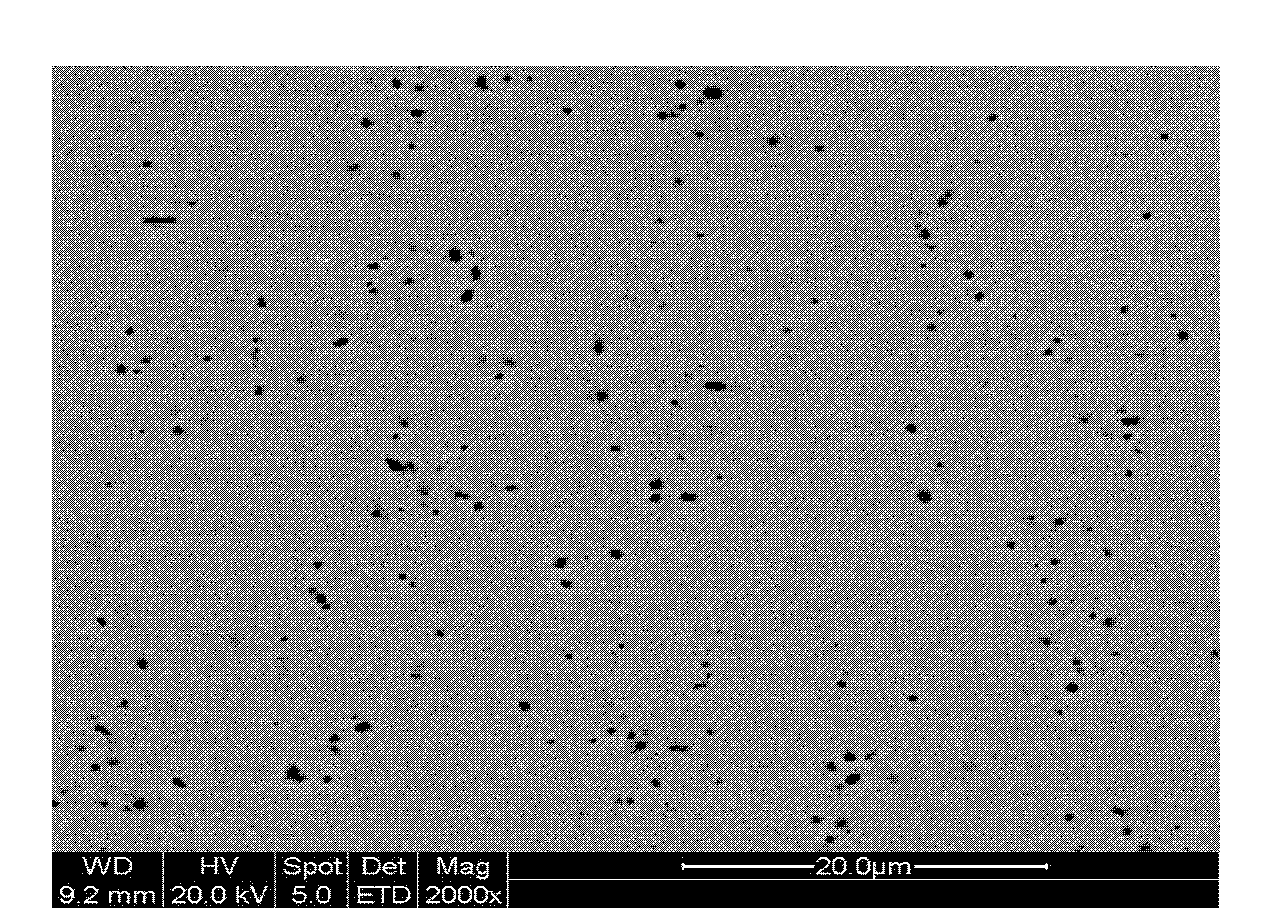

Heat processing method for obtaining fine grain ferrite in medium carbon steel

InactiveCN1944690AImprove toughnessSimple processHeat treatment process controlCarbon steelCrystallite

Owner:CENT IRON & STEEL RES INST

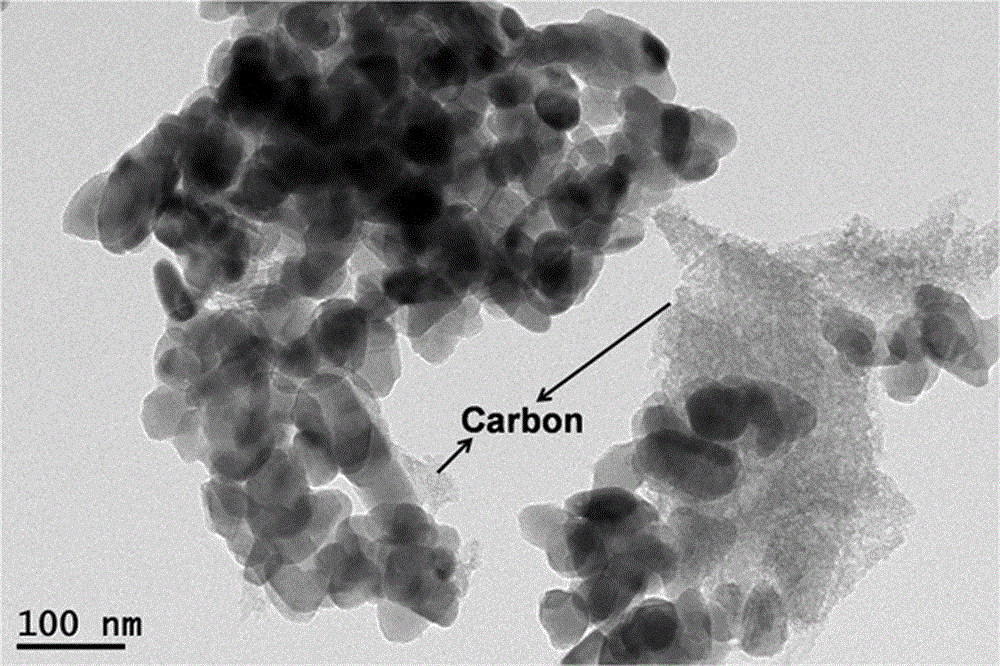

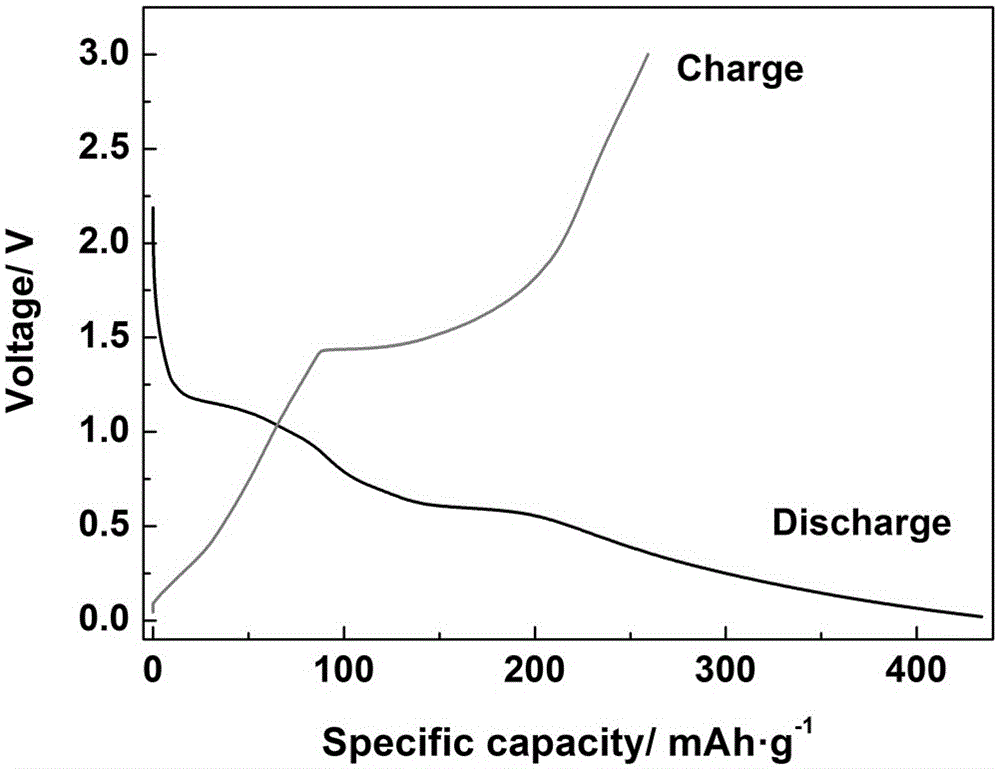

Anode material used for lithium ion battery and preparation method thereof

InactiveCN105024060AImprove electronic conductivityIncrease capacityNegative electrodesMass ratioSodium-ion battery

The invention belongs to the technical field of anode materials used for lithium ion batteries and in particular relates to the anode material Li2ZnTi3O8@C-N used for the lithium ion battery and a preparation method thereof. The anode material is formed by mixed sintering of lithium salt, zinc sources and titanium sources according to a mass ratio of the substances, namely nLi: nZn: nTi=2.0-2.5: 1: 3. The anode material Li2ZnTi3O8@C-N used for the lithium ion battery has high specific discharge capacity; through introducing C and N, the electronic conductivity of the material, the specific discharge capacity, and the multiplying power and the cycling performance of the material can be all improved. In addition, the preparation method has the advantages of simplicity, speediness, low energy consumption, low cost, friendly environment and better application prospect.

Owner:NANYANG NORMAL UNIV

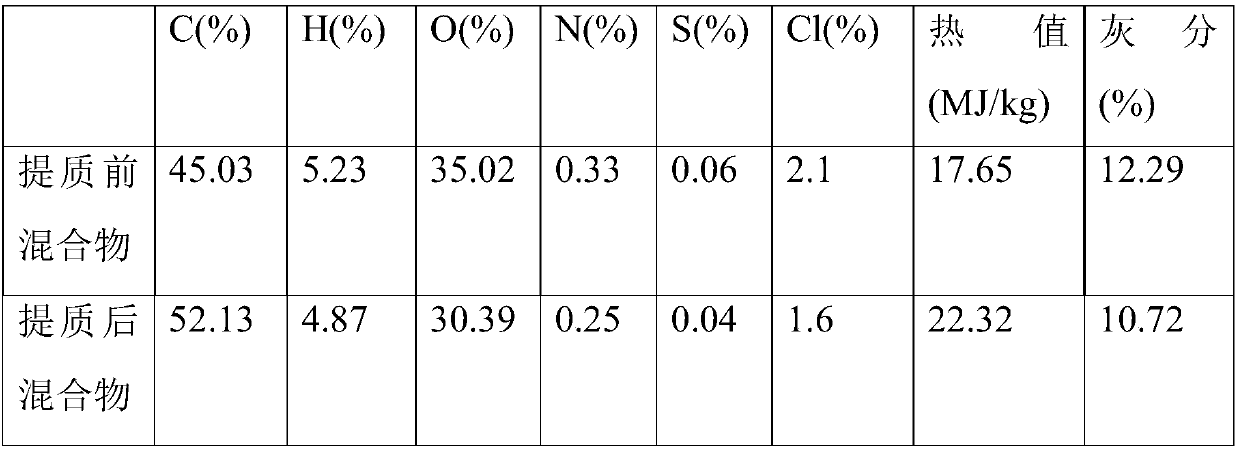

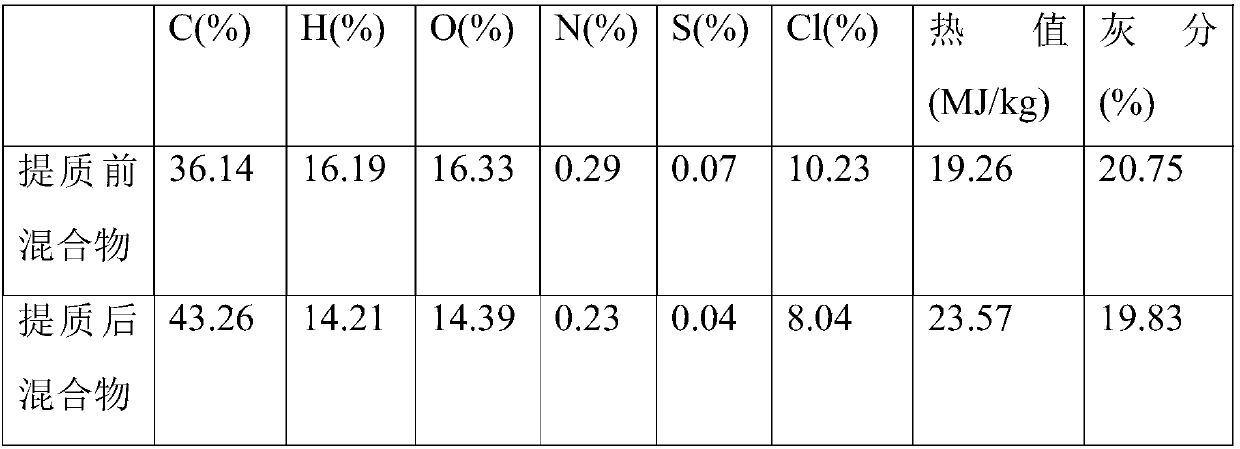

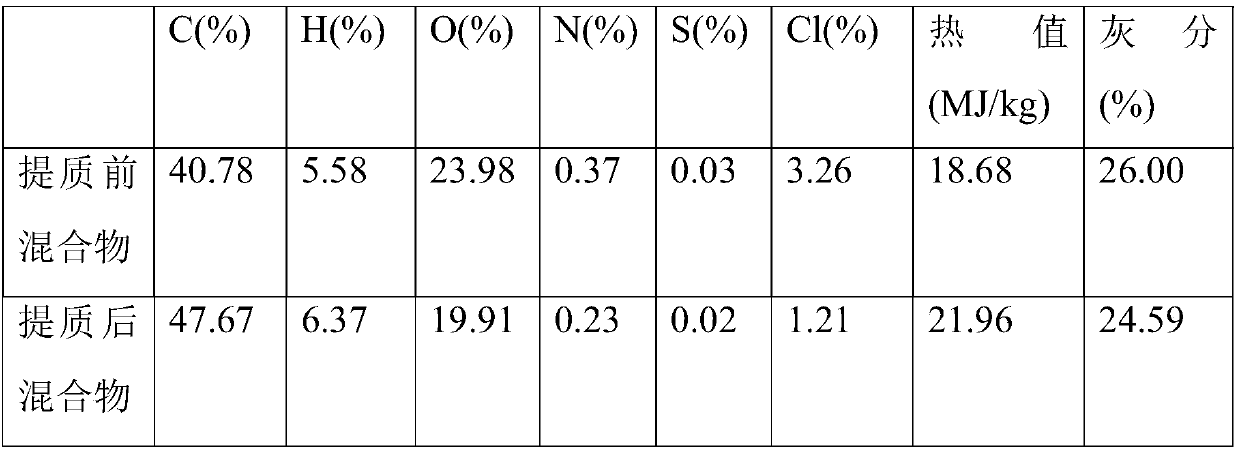

Method for performing multi-level quality-lifting on mixed organic solid waste based on molten salt

ActiveCN109530386AHigh recovery rateEasy to separateSolid waste disposalTransportation and packagingMolten stateImpurity

The invention relates to a method for performing multi-level quality-lifting on mixed organic solid waste based on molten salt. According to the method for performing multi-level quality-lifting on the mixed organic solid waste based on the molten salt, good heat storing and heat transferring properties, lower viscosity, stable chemical properties and a certain catalytic property of the molten salt are used, and the problems that the separation difficulty of the mixed organic solid waste is high, the use value is low and the pollutant concentration is high are solved. The method comprises thesteps of introduction and thorough pouring of the hot molten salt, heating, aeration, modulation of acid and alkali, cooling level by level, precipitation of thermoplastic samples, discharging of themolten salt and elution of residues by the molten salt to remove impurities. The quality-lifting solid product separating effect is good, the recovery rate is high, and the degree of homogenization and the fuel characteristics are improved; and meanwhile, certain effects of removal of N, Cl and S pollutants and de-ashing in the molten salt are realized. The working procedures are relatively simple, the reaction conditions are easy to control, the time is short, the efficiency is high, and effective separation, quality-lifting and pollutant removal of the mixed organic solid waste can be realized.

Owner:HUAZHONG UNIV OF SCI & TECH

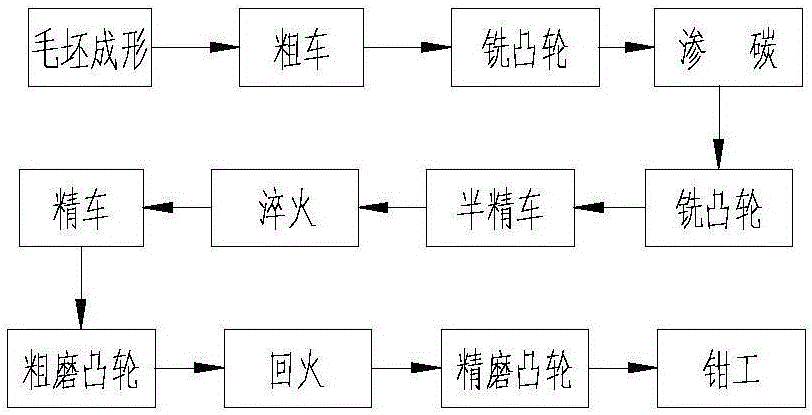

20Cr cam machining process

The invention discloses a 20Cr cam machining process. The cam transmission is an important part in mechanical transmission; and in particular, in manufacturing of some fixtures, workpieces are generally loaded, unloaded and clamped by a cam clamping mode. In the transfer process of a cam structure, the power is generally transferred by dint of a molded surface of the cam, so that the requirement on the molded surface of the cam is higher in the manufacturing process, and the size and the surface roughness are both higher in requirement; in traditional machining, the grinding is generally adopted as the last procedure; but because of special molded surface of the cam, in particular in the lift period of grinding the cam, cracks are liable to generate; and in traditional machining, the crack generation probability is 8%. The 20Cr cam machining process comprises the steps of: blank formation; rough turning; cam profile milling; carburization; semi-finish turning; quenching; finish turning; rough grinding of the cam; tempering; finish grinding of the cam; and clamping.

Owner:CHONGQING BORUN MOLD CO LTD

Quenched and tempered low-yield ratio pipeline steel and preparation method thereof

The invention belongs to the technical field of pipeline steel production and particularly relates to a quenched and tempered low-yield ratio pipeline steel and a preparation method thereof. The quenched and tempered low-yield ratio pipeline steel comprises the following components by weight percentage: 0.04-0.12% of C, 0.10-0.35% of Si, 1.30-1.70% of Mn, less than or equal to 0.02% of P, less than or equal to 0.01% of S, 0.020-0.060% of Nb, 0.010-0.040% of V, 0.040-0.080% of Ti, 0-0.30% of Mo and the balance of iron and unavoidable impurities. The pipeline steel is produced through a quenching and tempering process, the heat treatment heating temperature is controlled between two phase regions and the production process is unique; all performances meet the requirement of the pipeline steel, the yield ratio is less than 0.85 and the drop weight tear shearing area at -15 DEG C is greater than 85%.

Owner:SHANDONG IRON & STEEL CO LTD

High-strength tin-plated raw plate and manufacturing method thereof

The invention discloses a high-strength tin-plated raw plate and a manufacturing method thereof. The tin-plated raw plate comprises the following chemical components in percentage by weight: 0.08%-0.14% of C, 0.2%-0.5% of Mn, 0.03%-0.05% of Al, 0.01%-0.02% of P, 0.006%-0.015% of N and the balance Fe and Fe impurity elements, and the elements need to meet the following relationship simultaneously:50C+10Mn+50P+100N is not less than 8.5% and not greater than 12.75%. According to the manufacturing method disclosed by the invention, a one-step cold rolling process is adopted, an annealing temperature T in a continuous annealing step is controlled to be not less than 550+5*10<4>*(C-0.08%)+5x10<3>*(Mn-0.20%) and not greater than 630+5*10<4>*(C-0.08%), the unit is DEG C, and the tin-plated raw plate with a yield strength of not less than 500MPa and an elongation of not less than 5% after bake-hardening can be manufactured; and the manufacturing method is applicable to produce products with requirements on formability, such as three-piece can bodies, easy-open caps and twist-off caps.

Owner:BAOSHAN IRON & STEEL CO LTD

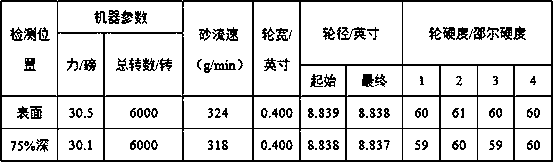

Heat treatment method for high-speed steel for rollers

InactiveCN102766745ASimple production processOptimize heat treatment processProcess efficiency improvementSurface finishChemical composition

The invention discloses a heat treatment method for high-speed steel for rollers. The chemical composition of the high-speed steel consists of the following components in percentage by weight: C: 3.2 to 3.6; W: 1.2 to 1.6; Mo: 5.0 to 7.0; V: 2.0 to 3.0; Cr: 8.0 to 10.0; Al: 0.1 to 0.4; Ni: 2.2 to 2.6; Co: 6.5 to 7.5; Nb: 0.2 to 0.4; Ti: 0.2 to 0.4; Ce: 0.4 to 0.6; Zr: 0.05 to 0.20; Si: less than 0.8; Mn: less than 1.5; S: less than 0.03; P: less than 0.04; and the balance of Fe. After the high-speed steel is cast to form a billet and the billet is roughly machined, the billet is quenched, the quenching process is carried out when a furnace is heated to 1260 DEG C to 1280 DEG C, the temperature is kept for 3 to 5 hours, the billet is then quenched in oil, and is tempered after being quenched, the tempering process is carried out when the furnace is heated to 620 DEG C to 650 DEG C, the temperature is kept for 5 to 7 hours, the furnace is cooled and then heated to 610 DEG C to 630 DEG C again, the temperature is kept for 5 to 7 hours, and after air cooling and tempering, finish machining is carried out, so that a roller, the dimensional precision and surface roughness of which come up to requirements, is obtained.

Owner:无锡市钻通工程机械有限公司

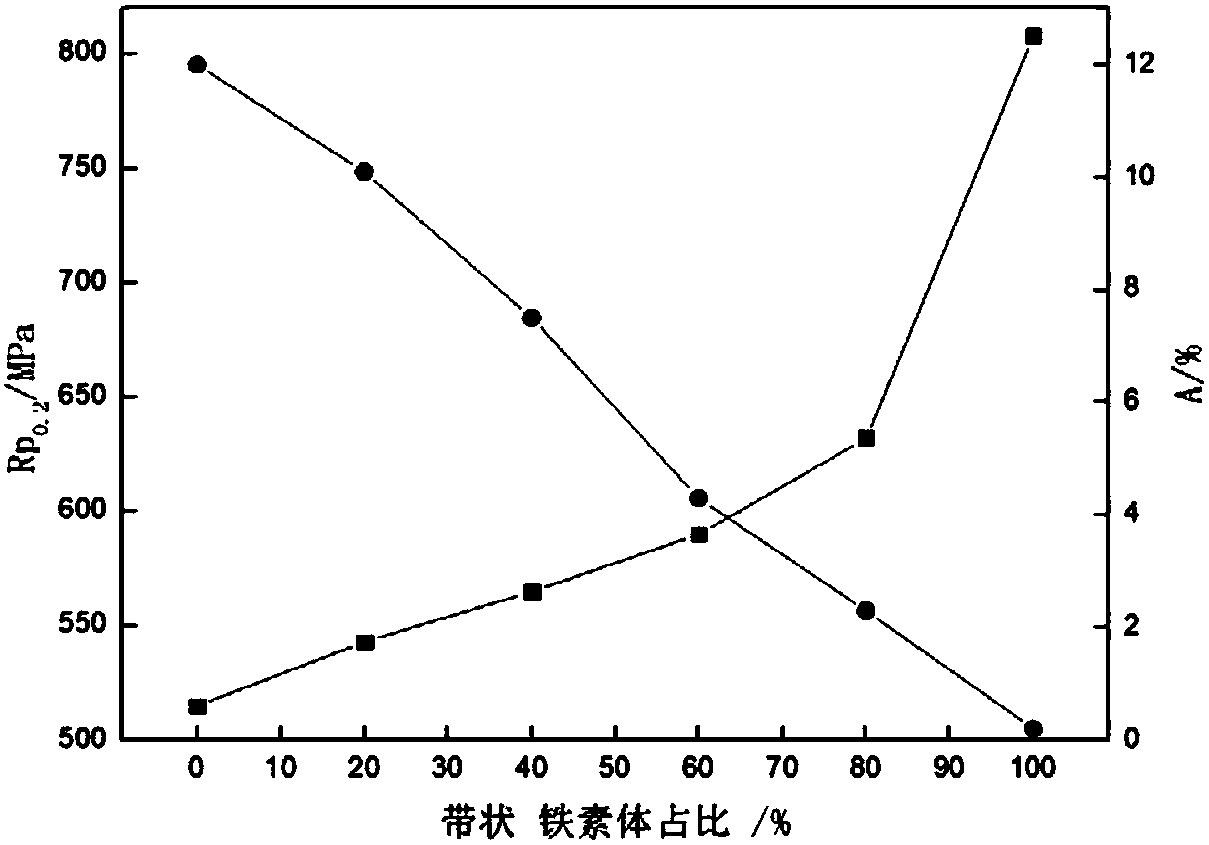

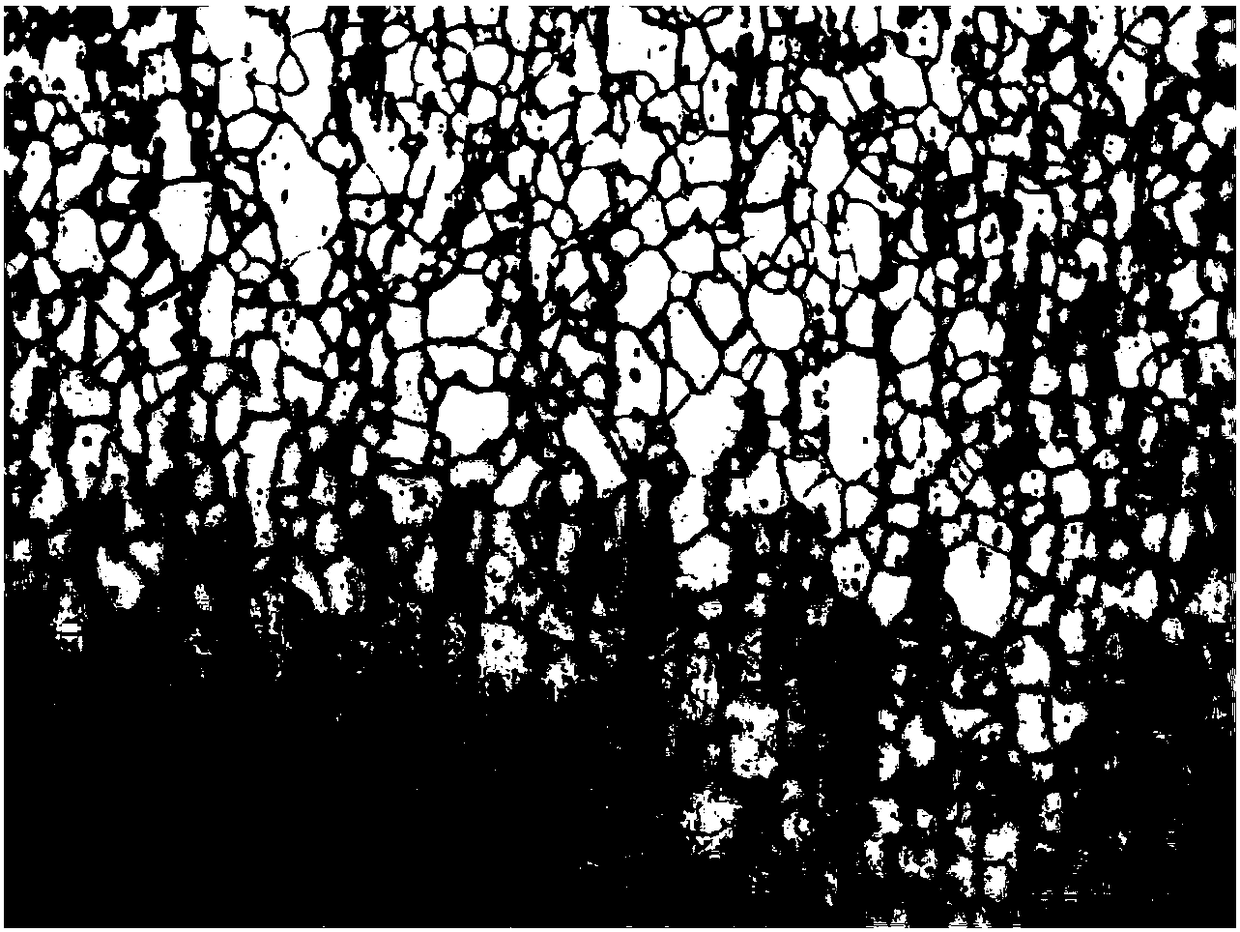

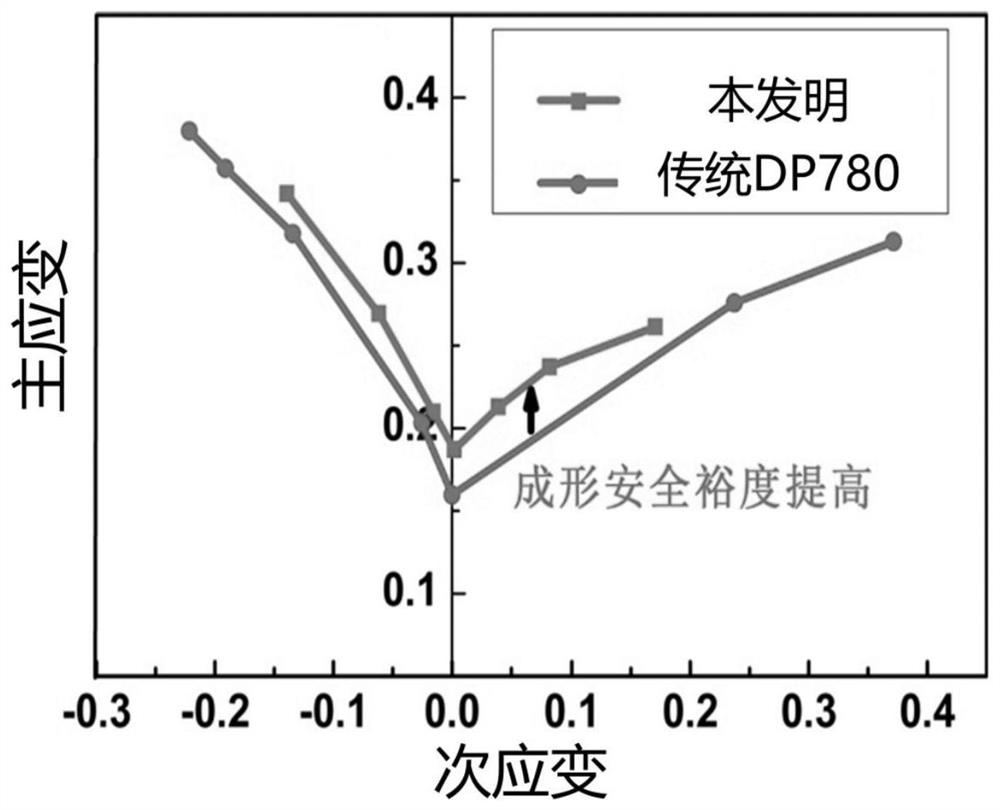

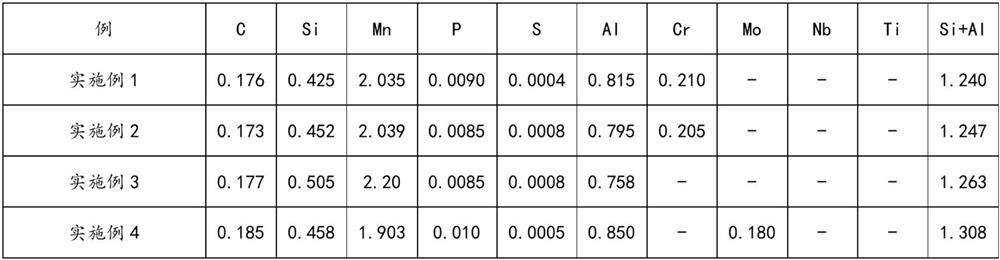

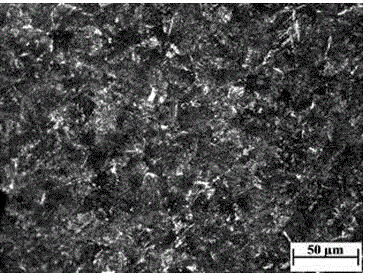

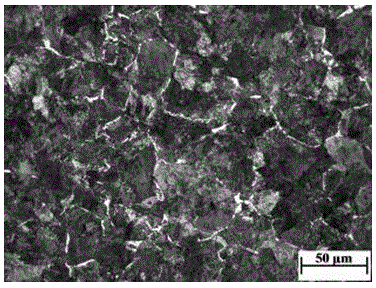

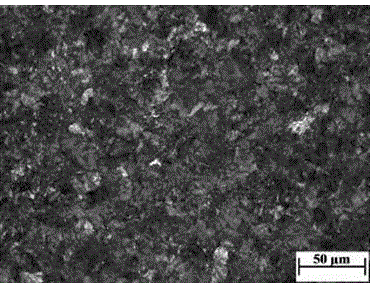

780MPa-grade hot-dip galvanized dual-phase steel with enhanced formability and manufacturing method thereof

ActiveCN111893379AImprove surface qualityIncrease added valueHot-dipping/immersion processesChemical compositionMetallurgy

The invention provides 780MPa-grade hot-dip galvanized dual-phase steel with enhanced formability, and belongs to the field of manufacturing of high-strength steel for automobiles. The 780MPa-grade hot-dip galvanized dual-phase steel with enhanced formability comprises the following chemical components of, in percentage by mass, 0.16%-0.2% of C, 0.35%-0.65% of Si, 1.8%-2.3% of Mn, 0.7%-1.0% of Al,P is less than or equal to 0.01%, S is less than or equal to 0.003%, and the balance Fe and inevitable impurities. Compared with traditional dual-phase steel of the same grade, the dual-phase steel has better forming performance, and the problem that traditional dual-phase steel is difficult to form on a complex stamping structural part is solved. The invention further provides a manufacturing method of the 780 MPa-grade hot-dip galvanized dual-phase steel with the enhanced formability.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

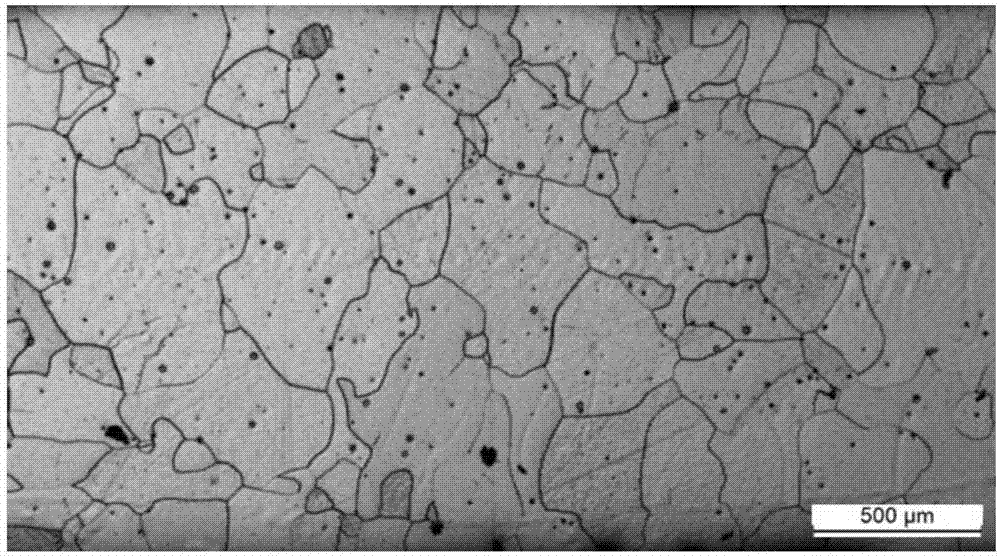

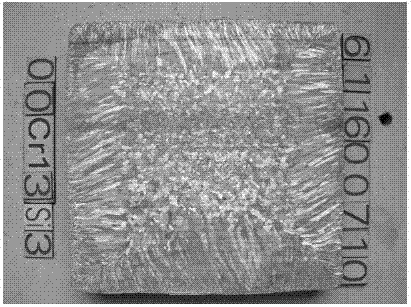

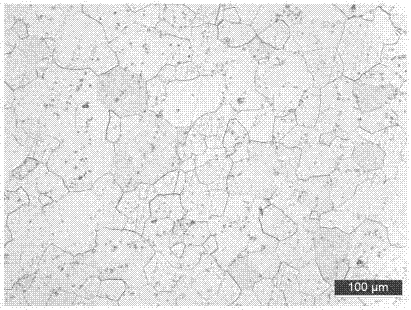

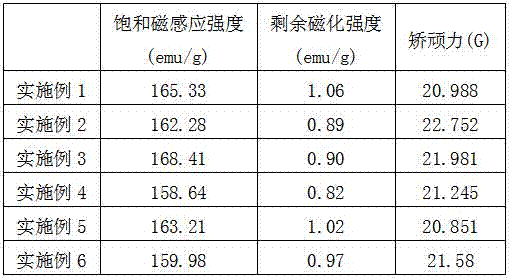

![Cf/Hf[x]Zr[1-x]C-SiC composite material and preparation methods thereof Cf/Hf[x]Zr[1-x]C-SiC composite material and preparation methods thereof](https://images-eureka.patsnap.com/patent_img/d1493a6d-d1c5-4680-925b-9ab2a0619944/HDA0000988282670000011.PNG)

![Cf/Hf[x]Zr[1-x]C-SiC composite material and preparation methods thereof Cf/Hf[x]Zr[1-x]C-SiC composite material and preparation methods thereof](https://images-eureka.patsnap.com/patent_img/d1493a6d-d1c5-4680-925b-9ab2a0619944/HDA0000988282670000012.PNG)

![Cf/Hf[x]Zr[1-x]C-SiC composite material and preparation methods thereof Cf/Hf[x]Zr[1-x]C-SiC composite material and preparation methods thereof](https://images-eureka.patsnap.com/patent_img/d1493a6d-d1c5-4680-925b-9ab2a0619944/HDA0000988282670000021.PNG)